Page 1

Motorcycle

Dynamometer

Installation Guide

Dynojet Research, Inc.

200 Arden Drive

Belgrade, MT 59714

999

2191 Mendenhall Drive

North Las Vegas, NV 89031

©1993-2002 Dynojet Research, Inc. All Rights Reserved. 020329SD

P/N 98220100

Version 3

Page 2

Copyright

This manual is copyrighted by Dynojet Research, Inc., hereafter referred to as

Dynojet, and all rights are reserved. This manual is furnished under license and

may only be used or copied in accordance with the terms of such license. This

manual is furnished for informational use only, is subject to change without

notice, and should not be construed as a commitment by Dynojet. Dynojet

assumes no responsibility or liability for any error or inaccuracies that may appear

in this manual.

Trademarks

The Dynojet logo is a trademark of Dynojet Research, Inc.

Any trademarks, trade names, service marks, or service names owned or

registered by any other company and used in this guide are the property of their

respective companies.

© 2002 Dynojet Research, Inc.

Page 3

T

ABLE OF

C

ONTENTS

List of Figures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Chapter 1 Dyno Installation and Setup

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Uncrate the Dyno . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Tire Carriage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Pickup Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Dyno Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Ramp Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

Electrical Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

Chapter 2 Hardware Installation

Dynoware EX+ Hardware Stack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Chapter 3 Optional Accessories

Optional Accessories Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Air Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Dual Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Extended Carriage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Mechanical Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

Monitor Arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-34

Power Carriage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index-i

Motorcycle Dynamometer Installation Guide

i

Page 4

TABLE OF CONTENTS

ii

Motorcycle Dynamometer Installation Guide

Page 5

L

IST OF

Figure 1-1: Custom Dyno Room . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Figure 1-2: Remove the Ramp Supports and Face . . . . . . . . . . . . . . . . . . . . .1-5

Figure 1-3: Remove the Tire Carriage from the Crate . . . . . . . . . . . . . . . . . .1-5

Figure 1-4: Remove the Ramp Bracket from the Crate . . . . . . . . . . . . . . . . .1-6

Figure 1-5: Hardware Box Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Figure 1-6: Remove the Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Figure 1-7: Loop Strap Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Figure 1-8: Remove the Metal Outrigger from the Crate . . . . . . . . . . . . . . . 1-8

Figure 1-9: Secure the Metal Outrigger to the Dyno . . . . . . . . . . . . . . . . . . . 1-8

Figure 1-10: Tire Carriage—Loosen the Clamps and Nut Block . . . . . . . . . . 1-9

Figure 1-11: Tire Carriage—Secure the Hand Crank . . . . . . . . . . . . . . . . . . .1-9

Figure 1-12: Tire Carriage—Install the Screw Support Bracket . . . . . . . . . . 1-10

F

IGURES

Figure 1-13: Attach the Pickup Card to the Bracket . . . . . . . . . . . . . . . . . . .1-11

Figure 1-14: Align the Pickup Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Figure 1-15: Install the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Figure 1-16: Secure the Hood to the Dyno. . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Figure 1-17: Ramp Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Figure 1-18: Electrical Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

Figure 2-1: Dynoware EX+ Hardware Stack . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Figure 2-2: RPM Module

Figure 2-3: Dynamometer Input/Output Module . . . . . . . . . . . . . . . . . . . . .2-4

Figure 2-4: CPU Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Figure 2-5: Connecting the Dynoware EX+ Cables . . . . . . . . . . . . . . . . . . . .2-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Motorcycle Dynamometer Installation Guide

iii

Page 6

LIST OF FIGURES

Figure 3-6: Remove and Replace the Hood. . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Figure 3-7: Connect Your Shop Air Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Figure 3-8: Install the Rotor/Taper Lock Assembly . . . . . . . . . . . . . . . . . . . . .3-6

Figure 3-9: Check for Run Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Figure 3-10: Caliper Assembly Mounting Bolts. . . . . . . . . . . . . . . . . . . . . . . .3-7

Figure 3-11: Secure the Caliper Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-12: Adjust the Brake Pad Space. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Figure 3-13: Install the Air Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Figure 3-14: Install the Master Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Figure 3-15: Install the Metal Brake Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Figure 3-16: Install the Spring Bolt Assembly . . . . . . . . . . . . . . . . . . . . . . . .3-10

Figure 3-17: Secure the Air Hose to the Regulator . . . . . . . . . . . . . . . . . . . .3-11

Figure 3-18: Install the Bulk Head Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Figure 3-19: Wire Set Up 1—Terminal Strip Wiring . . . . . . . . . . . . . . . . . . .3-13

Figure 3-20: Wire Set Up 1—Breakout Board Wiring . . . . . . . . . . . . . . . . . . 3-13

Figure 3-21: Wire Set Up 2—Terminal Strip Wiring . . . . . . . . . . . . . . . . . . .3-14

Figure 3-22: Wire Set Up 2—Breakout Board Wiring and

Jumper Settings

Figure 3-23: Air Brake Assembly Schematic . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Figure 3-24: Modify the Tire Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Figure 3-25: Remove the Extension Arm Assembly from the Crate . . . . . . 3-19

Figure 3-26: Secure the Extension Arm Assembly to the Tire Stop. . . . . . .3-19

Figure 3-27: Install the Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Figure 3-28: Install the Outlet Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Figure 3-29: Modify the Extension Arm Assembly—

Removing the Arms

Figure 3-30: Modify the Extension Arm Assembly—

New Arm Configuration

Figure 3-31: Remove the Carriage Screw Support Bracket . . . . . . . . . . . . . 3-25

Figure 3-32: Remove the Tire Carriage, Nut Block, and Clamps. . . . . . . . .3-25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Figure 3-33: Remove the Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

Figure 3-34: Install the Extended Carriage Support Bracket . . . . . . . . . . . . 3-26

iv

Motorcycle Dynamometer Installation Guide

Page 7

LIST OF FIGURES

Figure 3-35: Install the Nut Block and Front Clamp. . . . . . . . . . . . . . . . . . .3-27

Figure 3-36: Install the Screw Support Bracket. . . . . . . . . . . . . . . . . . . . . . . 3-28

Figure 3-37: Install the Rotor/Taper Lock Assembly . . . . . . . . . . . . . . . . . . .3-30

Figure 3-38: Check for Run Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-30

Figure 3-39: Caliper Assembly Mounting Bolts. . . . . . . . . . . . . . . . . . . . . . .3-31

Figure 3-40: Secure the Caliper Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

Figure 3-41: Adjust the Brake Pad Space. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Figure 3-42: Install the Master Cylinder and Foot Pedal . . . . . . . . . . . . . . . 3-32

Figure 3-43: Install the Metal Brake Line . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

Figure 3-44: Install the Monitor Arm Bracket . . . . . . . . . . . . . . . . . . . . . . . .3-35

Figure 3-45: Install the Arms and Tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-36

Figure 3-46: Remove the Hand Crank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-37

Figure 3-47: Remove the Flange Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . .3-38

Figure 3-48: Remove the Aluminum Cover. . . . . . . . . . . . . . . . . . . . . . . . . .3-38

Figure 3-49: Install the Motor Mount Assembly . . . . . . . . . . . . . . . . . . . . . . 3-39

Figure 3-50: Power Carriage Secured to Dyno . . . . . . . . . . . . . . . . . . . . . . . 3-40

Vers ion 3 Motorcycle Dynamometer Installation Guide

v

Page 8

LIST OF FIGURES

vi

Motorcycle Dynamometer Installation Guide

Page 9

D

YNO INSTALLATION AND

C HAPTER

1

S

ETUP

This document provides instructions for installing the Dynojet Motorcycle

Dynamometer (dyno). To ensure safety and accuracy in the procedures, perform the

procedures as they are described.

Document Part Number: 98220100

Versio n 3

Last Updated: 03-29-02

This chapter is divided into the following categories:

•Introduction, page 1-2

• Uncrate the Dyno, page 1-5

• Tire Carriage, page 1-9

• Pickup Card, page 1-11

• Battery, page 1-12

• Dyno Hood, page 1-13

• Ramp Assembly, page 1-14

• Electrical Diagram, page 1-15

Motorcycle Dynamometer Installation Guide

1-1

Page 10

CHAPTER 1

Introduction

INTRODUCTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thank you for purchasing the Dynojet Motorcycle Dynamometer. Before installing

your dynamometer (dyno), please take a moment to review the items you will need to

provide for your dyno.

YOUR DYNO ROOM

This section is not meant to imply that a dyno room is essential to repeatable results

on a Dynojet dynamometer. However, a dyno room with an engine cooling intake fan,

exhaust extraction, and noise reduction capabilities can add a new dimension to your

shop.

A proper dyno room design will help to ensure repeatable, accurate runs. A good

dyno room should do the following:

• minimize noise

• provide a controlled environment for testing

• provide a view window for customers

• be designed with safety in mind

Cooling Fan—After building your dyno room, you will need to supply a cooling fan.

The cooling fan supplies air to cool the bike’s engine while supplying fresh oxygen for

you and your bike to breathe. It is a common misconception that you cannot tune a

bike without a large fan simulating exact road conditions; however, a good cooling

fan is the only requirement for consistent diagnostics and tuning.

Exhaust Extraction—An exhaust fan is needed to remove exhaust gasses, especially

carbon monoxide, from the dyno room. Carbon monoxide is extremely harmful to

people if not removed from the room and will affect engine power when mixed with

fresh air.

Equalizer Box—If the air coming into the dyno room is greater than the air leaving

the dyno room, the room will become pressurized. A pressurized dyno room will

make measured power misleading. To compensate, you need an equalizer box. The

equalizer box is a baffled (to reduce noise) vent to the outside of your dyno room.

The size of the equalizer box is dependent on the size of your dyno room and the size

of your fans.

1-2

Motorcycle Dynamometer Installation Guide

Page 11

DYNO INSTALLATION AND SETUP

Introduction

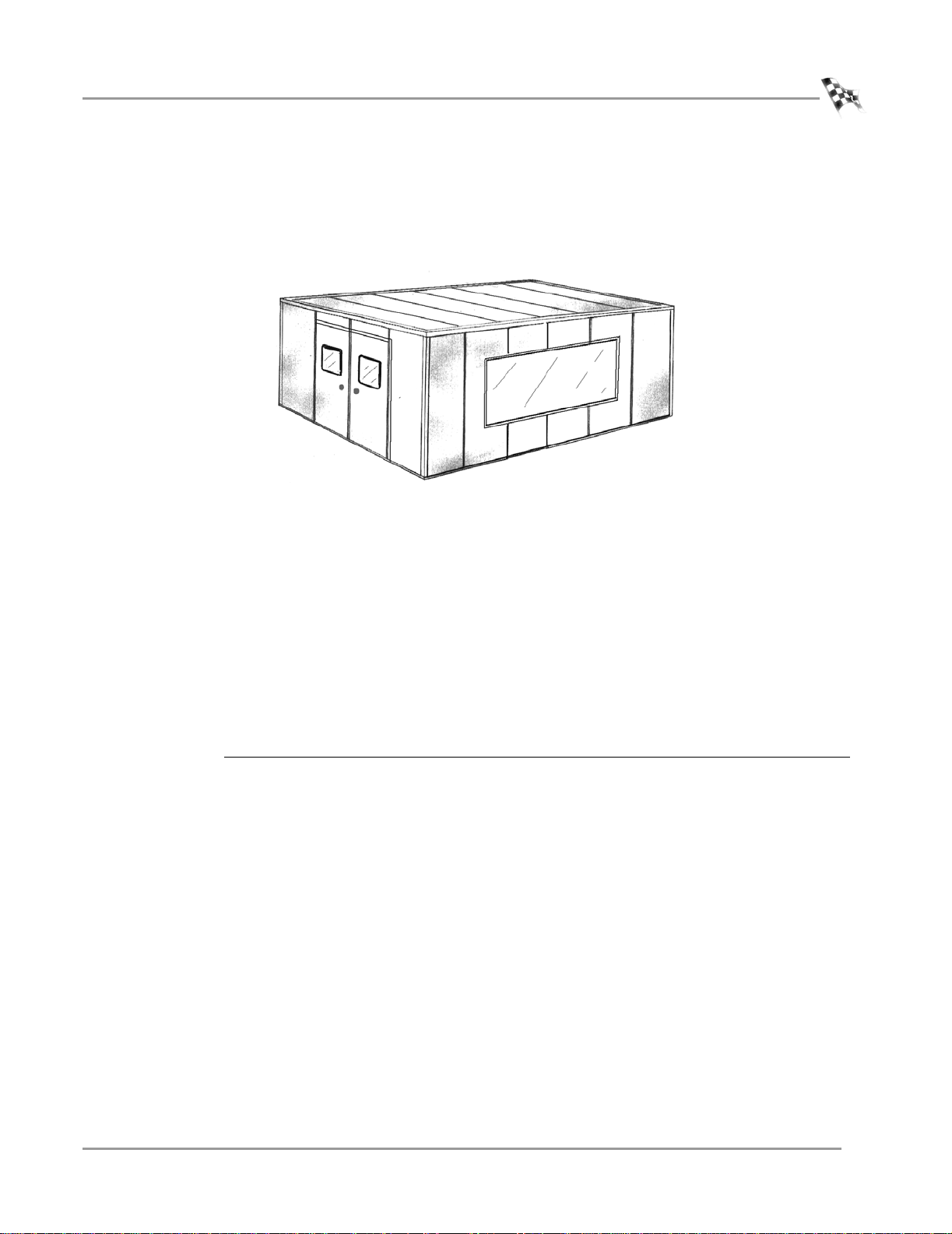

Industrial Noise Control, Inc.—Industrial Noise Control, Inc. offers a zinc-coated

steel room custom built to your specifications. This room meets all dyno room

requirements. For more information on building a dyno room, read the DynoSource

newsletter Volume 1, No. 7 (published by Dynojet) included in your information

pack. The dyno room must be clean, dry, at a minimum of 32 degrees Fahrenheit (0

degrees Celsius), and have some system of exhaust extraction.

Figure 1-1: Custom Dyno Room

12 Volt Battery—A motorcycle starting system is included with your Dynojet

Dynamometer. You will need an automotive battery to use this feature. The dyno is

designed to carry a group 24 deep cycle series battery with a minimum of 600 cold

cranking amps.

Motorcycle Tie-Down Straps—Dynojet recommends using motorcycle tie-down

straps for securing the bike on the dyno. You will need to provide the tie-down straps.

Computer System—You will need to provide a computer system to run the WinPEP

software.

system requirements recommended hardware and software

• Pentium P5-100 processor • Pentium P5-133 or greater processor

• Microsoft® Windows® 9x • 28.8 K modem or better

• 800 MB hard drive • 1.2 gigabyte hard drive or better

• 16 MB of available RAM • 16 MB of available RAM (32 MB for Windows 98)

• 800x600 (SVGA) monitor • 1024x768 (SVGA) monitor

• 16k color video • 16k color video or better

• 8x CD-ROM Drive • 8x CD-ROM Drive

• 8 MB of available hard-disk space is required to install WinPEP

Vers ion 3 Motorcycle Dynamometer Installation Guide

1-3

Page 12

CHAPTER 1

Introduction

CONVENTIONS USED IN THIS MANUAL

The conventions used in this manual are designed to protect both the user and the

equipment.

Example of Convention Description

TECHNICAL SUPPORT

For assistance, please contact Dynojet Technical Support at 1-800-992-3525, or write

to Dynojet at 2191 Mendenhall Drive, North Las Vegas, NV 89031.

Visit us on the World Wide Web at www.dynojet.com where Dynojet provides state of

the art technical support, on-line shopping, 3D visualizations, and press releases

about our latest product line.

The Caution icon indicates a potential hazard to the

dynamometer equipment. Follow all procedures

exactly as they are described and use care when

performing all procedures.

The Warning icon indicates potential harm to the

person performing a procedure and/or the

dynamometer equipment.

1-4

Motorcycle Dynamometer Installation Guide

Page 13

DYNO INSTALLATION AND SETUP

UNCRATE THE DYNO

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

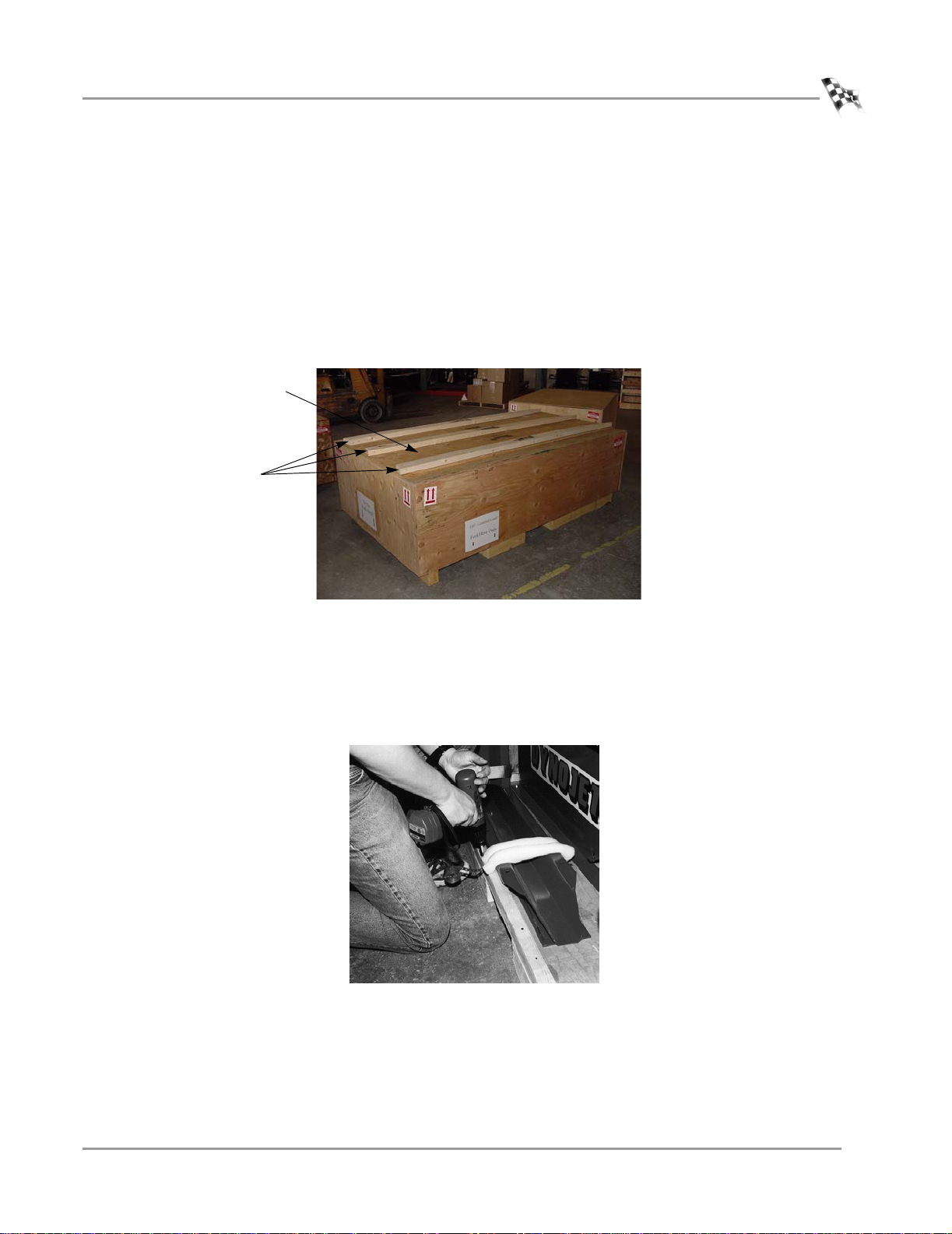

Use the following steps to uncrate your dyno. You will need to provide equipment

capable of lifting a minimum of 1600 lb. (725 kg.) to move the crated dyno into

position in your dyno room.

1 Move the crated dyno to a clear area near your dyno room.

2 Remove the three ramp supports and the ramp face. If you ordered your dyno

without a ramp, skip to step 3.

Refer to “Ramp Assembly” on page 1-14 for ramp assembly instructions,

ramp face

ramp supports

Uncrate the Dyno

Figure 1-2: Remove the Ramp Supports and Face

3 Remove the top and sides of the crate.

3a Use a pry bar, or large flat screwdriver, and a hammer to loosen and remove

the top of the crate.

3b Remove the crate braces and sides.

4 Remove the tire carriage. The tire carriage is fastened to the bottom of the crate.

Figure 1-3: Remove the Tire Carriage from the Crate

Vers ion 3 Motorcycle Dynamometer Installation Guide

1-5

Page 14

CHAPTER 1

Uncrate the Dyno

5 Remove the ramp bracket. The ramp bracket is attached to the bottom of the

crate.

Figure 1-4: Remove the Ramp Bracket from the Crate

6 Remove the hardware box containing two outrigger bolts and lock washers, the

tire carriage screw handle, and the screw support bracket. Refer to Figure 1-5.

If you ordered a ramp, the hardware box will also contain six carriage bolts, six

flat washers, six lock washers, and six nuts to be used in the ramp installation.

Refer to “Ramp Assembly” on page 1-14 for ramp assembly instructions,

1-6

Motorcycle Dynamometer Installation Guide

Figure 1-5: Hardware Box Contents

Page 15

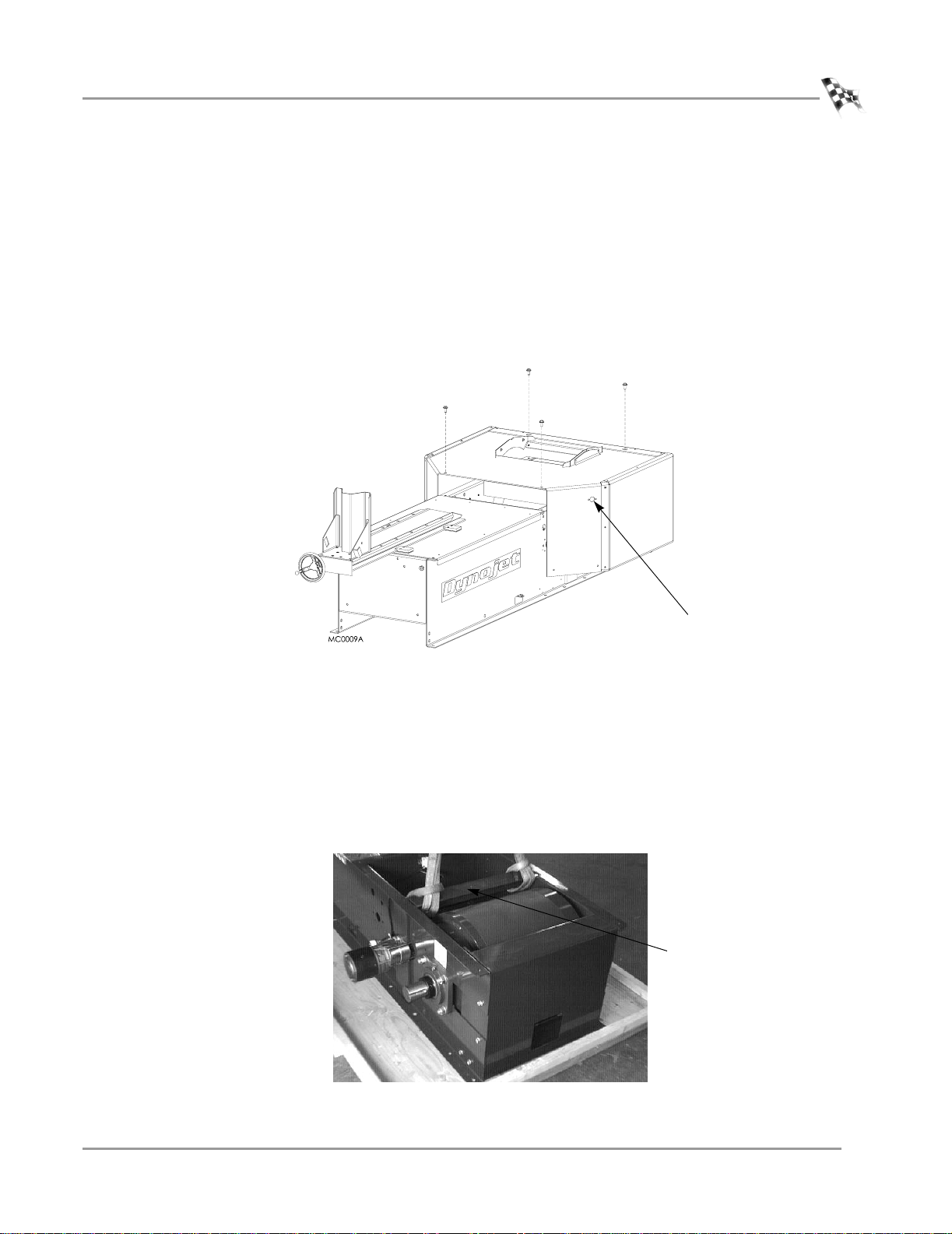

REMOVING THE DYNO FROM THE CRATE

You will need to provide equipment capable of lifting a minimum of 1600 lb.

(725 kg.) to lift the dyno off the crate and into position in your dyno room. You will

also need a pair of straps capable of supporting 1600 lb. (725 kg.) to attach to the

dyno. Dynojet recommends using single loop style straps.

1 Remove the four bolts securing the hood to the dyno and set aside. Prop up the

hood.

2 If present, disconnect the wires to the key switch.

3 Remove the hood from the dyno and set aside.

DYNO INSTALLATION AND SETUP

Uncrate the Dyno

key switch

Figure 1-6: Remove the Hood

4 Remove the four screws securing the dyno to the crate base using a 9/16-inch

socket, open or box end wrench.

5 Wrap the single loop straps around the dyno support frame just in front of the

drum.

6 Position the straps as far to the outside of the support frame as possible. Refer to

Figure 1-7 for exact placement.

Note: Exact placement of the loop straps is important. Any other placement could

damage the dyno.

support frame

in front of drum

Figure 1-7: Loop Strap Placement

Vers ion 3 Motorcycle Dynamometer Installation Guide

1-7

Page 16

CHAPTER 1

Uncrate the Dyno

7 Lift the dyno off the crate and move into position in your dyno room.

8 Remove the metal outrigger attached to the bottom of the crate.

metal outrigger

Figure 1-8: Remove the Metal Outrigger from the Crate

9 Attach the metal outrigger to the dyno. The outrigger is used when strapping the

bike to the dyno.

9a Slide the outrigger through the rectangular hold in the dyno frame.

9b Secure the outrigger to the dyno using two 3/8-inch bolts and lockwashers.

bolt

lock washer

metal outrigger

Figure 1-9: Secure the Metal Outrigger to the Dyno

1-8

Motorcycle Dynamometer Installation Guide

Page 17

DYNO INSTALLATION AND SETUP

TIRE CARRIAGE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

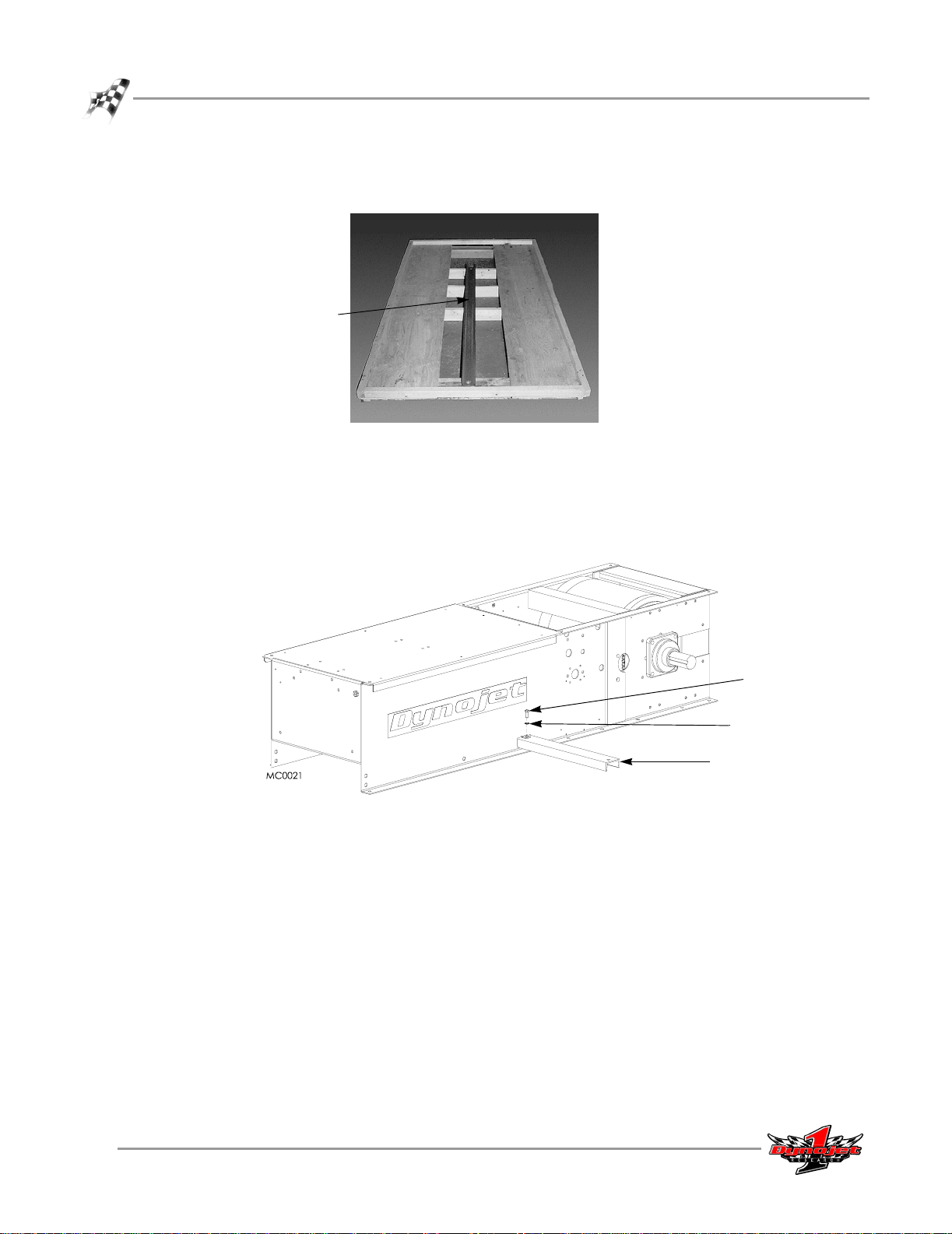

The tire carriage is fastened to the bottom of the crate next to the dyno. Refer to

step 4 on page 1-5 for instructions on removing the tire carriage from the crate.

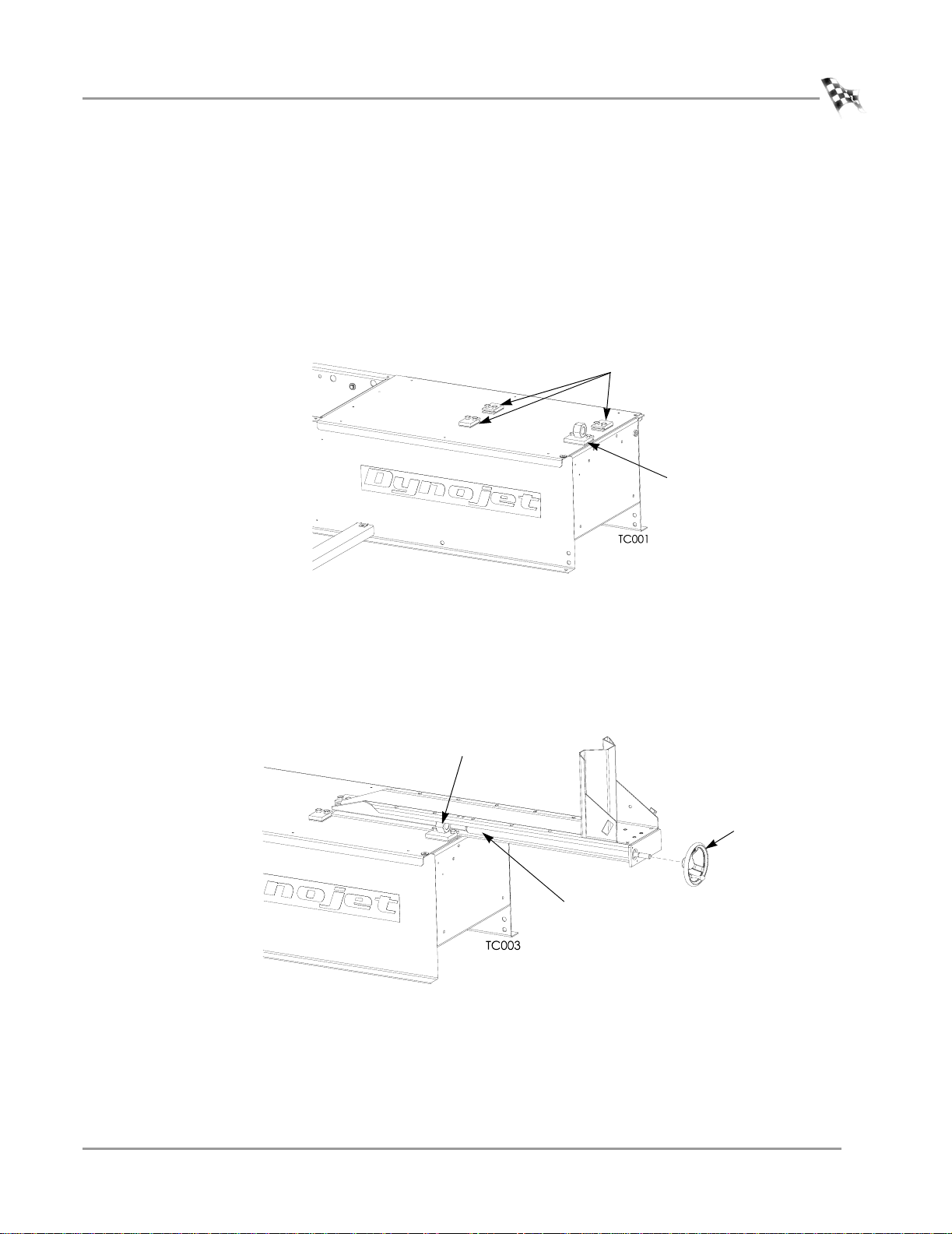

INSTALLING THE TIRE CARRIAGE

1 Loosen the bolts securing the three carriage clamps and nut block to the top of

the dyno using a 1/2-inch socket, open or box end wrench.

Tire Carriage

carriage clamps

nut block

Figure 1-10: Tire Carriage—Loosen the Clamps and Nut Block

2 Slide the carriage under the carriage clamps and the nut block until the carriage

screw is touching the nut block as shown in Figure 1-11.

3 Slide the hand crank onto the end of the carriage screw.

4 Secure the hand crank to the screw shaft by tightening the set screw using a

5/32-inch allen wrench.

nut block

hand crank

carriage screw

Figure 1-11: Tire Carriage—Secure the Hand Crank

Vers ion 3 Motorcycle Dynamometer Installation Guide

1-9

Page 18

CHAPTER 1

Tire Carriage

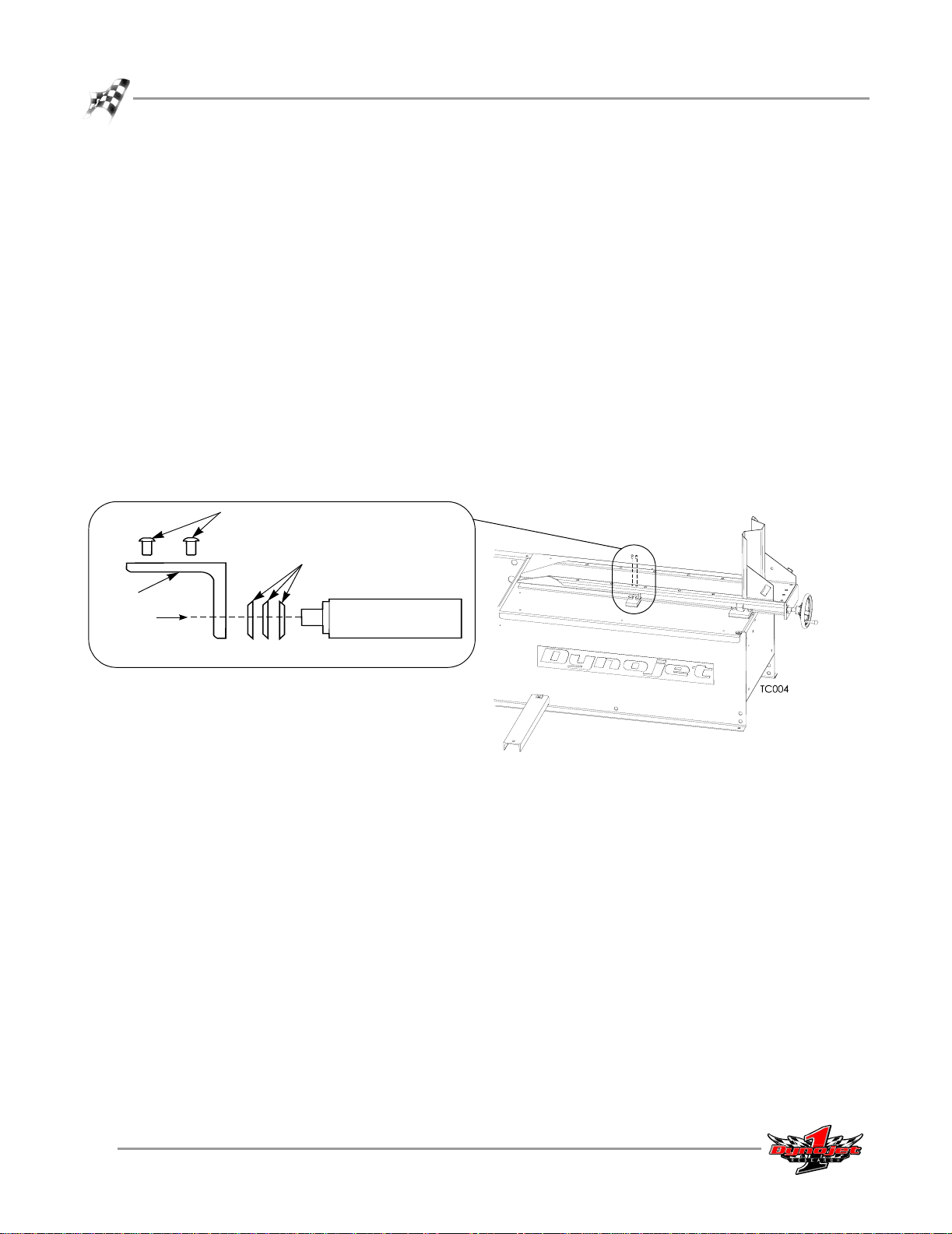

5 Using the hand crank, screw the carriage through the nut block.

6 Install the screw support bracket.

6a Place the belleville washers over the end of the carriage screw. It is

important the belleville washers are installed in the configuration shown in

Figure 1-12.

6b Place the screw support bracket in front of the carriage screw. The two

threaded holes in the bracket should face the two matching holes in the

carriage. Loosely install the two 1/4 x 1/2-inch button-head screws.

6c Before tightening the screws, apply some pressure to the bracket to

compress the belleville washers. The handle should still turn freely, but the

turning force should now be around five to six pounds.

To adjust the force needed to turn the crank handle, adjust the compression

of the belleville washers.

6d Using a 5/32-inch allen wrench, tighten the two button-head screws.

7 Tighten the clamp and nut block bolts with a 1/2-inch wrench.

screws

support

bracket

belleville washers

carriage screw

Figure 1-12: Tire Carriage—Install the Screw Support Bracket

1-10

Motorcycle Dynamometer Installation Guide

Page 19

DYNO INSTALLATION AND SETUP

PICKUP CARD

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The pickup card is an electronic circuit board that accurately senses each drum

revolution.

INSTALLING THE PICKUP CARD

1 Locate the pickup card bracket on the right side of the dyno just ahead of the

drum.

2 Install the new pickup card in the notch on the new bracket using two

No. 8 screws and lock washers. Do not tighten, the card must be aligned first

Make sure the side of the card with the optical pickup faces the back of the dyno.

Refer to Figure 1-14.

pickup card

bracket

pickup card

Pickup Card

Figure 1-13: Attach the Pickup Card to the Bracket

3 Align the optical pickup card with the tab on the dyno drum axle. Once aligned,

tighten the screws to secure the pickup card in place.

The optical pickup is very delicate. Be careful not to damage the optical pickup

during alignment.

tab on dyno

optical pickup

Figure 1-14: Align the Pickup Card

Vers ion 3 Motorcycle Dynamometer Installation Guide

1-11

Page 20

CHAPTER 1

Battery

BATTERY

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A bike starting system is included with your Dynojet Dynamometer. You will need to

provide an automotive battery to use this system. The dyno is designed to carry a

group 24 series battery with a minimum of 600 cold cranking amps.

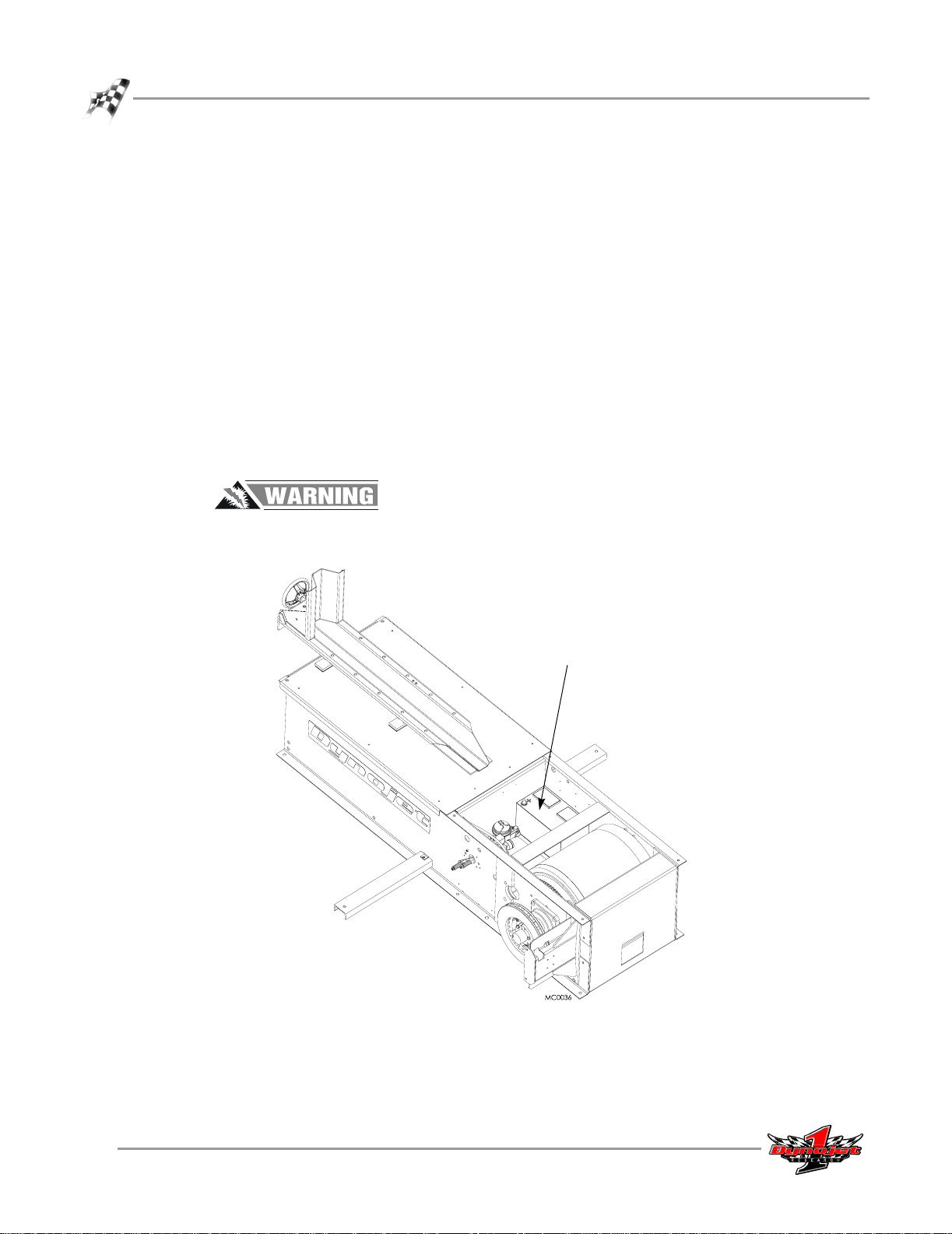

INSTALLING THE BATTERY

1 Locate the red battery cable on the inside of the dyno.

2 Place the battery in the battery carrier on the inside of the dyno so the red cable

can reach the positive (+) post on the battery and the black battery cable can

reach the negative (-) post.

3 Secure the red battery cable to the positive (+) battery post.

4 Secure the black battery cable to the negative (-) battery post.

5 Press the starter button to verify that the starter turns the drum correctly.

To prevent possible injury, disconnect the battery before performing any dyno

maintenance or installing any optional accessories.

battery with positive side

towards the front of the dyno

Figure 1-15: Install the Battery

1-12

Motorcycle Dynamometer Installation Guide

Page 21

DYNO INSTALLATION AND SETUP

DYNO HOOD

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

There is a door safety switch included with the European dynos only. European dyno

owners will need to install this switch before reinstalling the hood. Installation

instructions are included with the switch.

INSTALLING THE HOOD

1 Make a final inspection of your dyno and verify that all connections are tight.

2 If you have not already done so, connect the battery.

3 Carefully place the hood on the dyno leaving it propped up.

4 Secure the wires to the key switch.

Note: You must have the wires connected and the key installed to operate the

dyno. The orientation of the wires on the key switch is not important.

5 Lower and secure the hood using the four bolts you removed earlier.

Never operate the dyno with this cover removed.

Dyno Hood

key switch

Figure 1-16: Secure the Hood to the Dyno

Vers ion 3 Motorcycle Dynamometer Installation Guide

1-13

Page 22

CHAPTER 1

Ramp Assembly

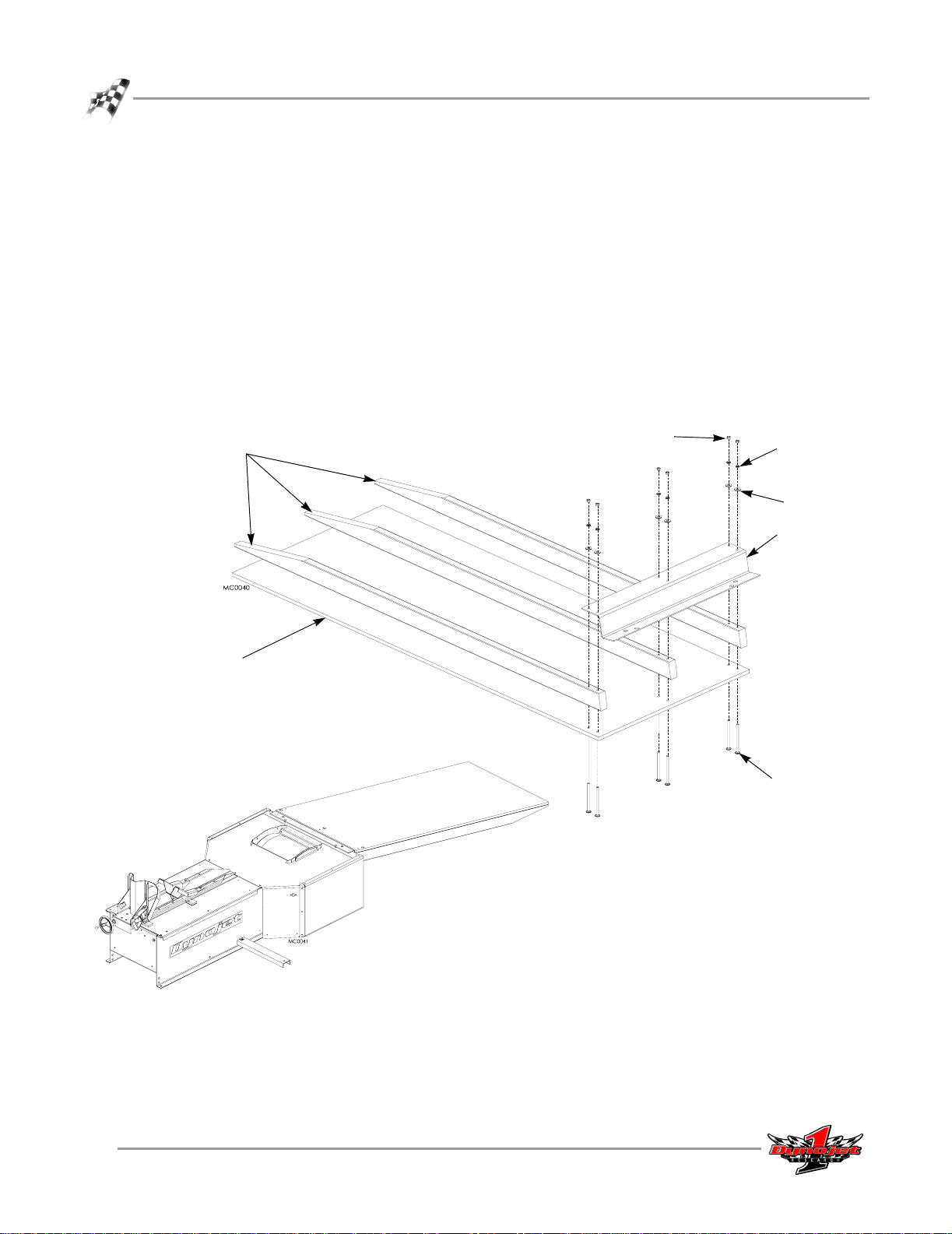

RAMP ASSEMBLY

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The ramp is assembled by bolting the ramp face, the ramp supports, and the ramp

bracket together.

Note: You will need to supply additional wood screws or nails to secure the ramp

supports to the ramp face.

1 Using the ramp bracket as a template, mark and drill six holes in the ramp face

using a 3/8-inch bit.

2 Secure the ramp face, supports, and bracket using six six-inch carriage bolts, six

flat washers, six lock washers, and six nuts.

3 Make sure the supports are aligned properly with the ramp face and secure the

supports to the ramp face using wood screws or nails.

nut

ramp support

lock washer

flat washer

ramp bracket

ramp face

carriage bolt

Figure 1-17: Ramp Assembly

1-14

Motorcycle Dynamometer Installation Guide

Page 23

ELECTRICAL DIAGRAM

DYNO INSTALLATION AND SETUP

Electrical Diagram

Figure 1-18: Electrical Diagram

Vers ion 3 Motorcycle Dynamometer Installation Guide

1-15

Page 24

CHAPTER 1

Electrical Diagram

1-16

Motorcycle Dynamometer Installation Guide

Page 25

C HAPTER

2

H

ARDWARE INSTALLATION

This chapter contains the hardware installation specifications for the DynoWare EX+

modules.

This chapter is divided into the following categories:

• Dynoware EX+ Hardware Stack, page 2-2

• Atmospheric Sensing Module, page 2-2

•RPM Module, page 2-3

• Dynamometer Input/Output Module, page 2-4

• CPU Module, page 2-5

• Connecting the DynoWare EX+ Cables, page 2-6

Motorcycle Dynamometer Installation Guide

2-1

Page 26

CHAPTER 2

Dynoware EX+ Hardware Stack

DYNOWARE EX+ HARDWARE STACK

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The standard dynamometer electronics package (hardware stack) is comprised of four

interconnected modules: Atmospheric Sensing Module, RPM Module, Dynamometer

Input/Output Module, and the CPU Module.

system expansion

connector

atmospheric

sensing module

RPM module

dynamometer

input/output module

CPU module

Figure 2-1: Dynoware EX+ Hardware Stack

ATMOSPHERIC SENSING MODULE

The atmospheric sensing module measures absolute pressure, air temperature, and

relative humidity. These measurements are used by WinPEP to correct power and

torque measurements to standard atmospheric conditions according to a DIN, SAE, or

other formula.

LED Indicator Description

The green LED glows when the atmospheric sensing

module is receiving power.

The flashing amber LED indicates the module processor

is operating properly.

2-2

Motorcycle Dynamometer Installation Guide

Page 27

RPM MODULE

The RPM module receives and processes signals from up to two inductive pickups for

measurement of engine RPM. Each input has an automatic gain circuit to compensate

for a wide variance of ignition systems.

LED Indicator Description

HARDWARE INSTALLATION

Dynoware EX+ Hardware Stack

Figure 2-2: RPM Module

The green LED glows when the RPM module is receiving

power.

The amber LED flashes when an RPM signal is detected.

A steady flash rate, proportional to engine RPM, indicates

a good RPM signal.

These connectors are the inputs for both primary and

secondary inductive pickup clips. Either input may be

used with a primary inductive pickup or a secondary

inductive pickup on a single ended coil. Both inputs can

be used for a wasted spark ignition.

Vers ion 3 Motorcycle Dynamometer Installation Guide

2-3

Page 28

CHAPTER 2

Dynoware EX+ Hardware Stack

DYNAMOMETER INPUT/OUTPUT MODULE

The dynamometer input/output module sends and receives data from the

dynamometer and the hand-held pendant. The module also contains a buzzer and

light which are activated when either the vehicle or the dynamometer speed limit is

approached.

Figure 2-3: Dynamometer Input/Output Module

LED Indicator Description

The green LED glows when the dynamometer

input/output module is receiving power.

The amber LED flashes proportionally to dynamometer

drum RPM.

This 25-pin connector attaches to the shielded cable from

the dynamometer.

This 9-pin connector attaches to the hand held pendant

which houses the button used to start/stop acquiring

data. The pendant may also contain a brake switch.

2-4

Motorcycle Dynamometer Installation Guide

Page 29

CPU MODULE

The CPU module contains a 32-bit processor which acquires data from the expansion

modules and communicates to the main computer running the WinPEP software. The

processor queries the expansion modules to determine their identity and capabilities.

LED Indicator Description

HARDWARE INSTALLATION

Dynoware EX+ Hardware Stack

Figure 2-4: CPU Module

The green LED glows when the CPU module is receiving

power.

The blue LED is lighted when data from the modules is

being acquired and saved.

One of these connectors is used to communicate to the

main computer. The 9-pin connector (left) attaches to

the PC’s RS-232 serial communications port. The 8-pin

modular connector (right) provides communications

according to the RS-422/485 specification.

This connector provides a synchronization signal to a

third party data acquisition system.

This connector provides 12 volt DC power to a third

party data acquisition system.

This connector accepts 12 volt DC power from a power

supply or battery. The adjacent LED glows bright green

when power is properly connected.

When this switch is on, power is supplied to all

connected modules.

Vers ion 3 Motorcycle Dynamometer Installation Guide

2-5

Page 30

CHAPTER 2

Dynoware EX+ Hardware Stack

CONNECTING THE DYNOWARE EX+ CABLES

Attach the following cables using the cables that came in the DynoWare package. Refer

to Figure 2-5 for cable placement locations.

• Attach the 9-pin shielded serial cable to the RS-232 socket on the CPU module and

a free COM (serial communications) port on the PC. A 9-pin to 25-pin adapter may

be required at the PC.

• Attach the 25-pin shielded cable from the dynamometer to the Dynamometer

Input/Output module.

• Attach the 9-pin connector from the hand-held pendant to the Dynamometer

Input/Output module.

• Attach the 3-pin plug from the power supply to the CPU module with the flat side

facing down.

Note: The DynoWare EX+ hardware stack must be mounted in your shop so as to

be easily seen while making dyno runs.

primary inductive

pickup socket

25-pin socket

9-pin, RS-232 socket

9-pin, hand help

pendant

3-pin power plug

Figure 2-5: Connecting the Dynoware EX+ Cables

2-6

Motorcycle Dynamometer Installation Guide

Page 31

O

PTIONAL

C HAPTER

A

CCESSORIES

3

This chapter discusses the various optional accessories that are available for the

Dynojet Dynamometer (dyno). For more information about these accessories, please

contact Dynojet’s Product Specialist’s at 1-800-992-3525 for pricing and availability.

This chapter is divided into the following categories:

• Optional Accessories Overview, page 3-2

• Removing and Replacing the Hood, page 3-3

•Air Brake, page 3-4

• Dual Fan, page 3-17

• Extended Carriage, page 3-24

• Mechanical Brake, page 3-29

• Monitor Arm, page 3-34

• Power Carriage, page 3-37

Motorcycle Dynamometer Installation Guide

3-1

Page 32

CHAPTER 3

Optional Accessories Overview

OPTIONAL ACCESSORIES OVERVIEW

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Depending on your current configuration, there are various optional accessories that

can be added to your Dynojet Dynamometer to meet your individual needs. All of

these options can be added from the factory at the time of original dyno purchase, or

purchased separately and added at any time thereafter. A brief description of these

accessories follows.

Installation instructions for some of these options can be found in this chapter.

Complete installation instruction manuals may also be found by browsing the

Manuals folder on your WinPEP installation CD.Visit the Dynojet web site for more

information about dynamometer accessories and ordering information.

Air or Mechanical Brake—The air brake is an electro-pneumatic braking system

while the mechanical brake is a foot actuated hydraulic brake. Both brakes can be

utilized to quickly slow the drum after a run is complete. This is especially useful for

two-stroke applications when engine compression cannot be used to slow the drum.

Both brakes can greatly speed up the testing process. Refer to “Air Brake” on page 3-4

or “Mechanical Brake” on page 3-29 for installation instructions.

Dual Fan—The dual fan supplies air to cool the bike’s engine. Refer to “Dual Fan” on

page 3-17 for installation instructions.

Eddy Current Brake— The eddy current brake is perfect for engine break-in,

durability testing, and fuel injection mapping. Refer to your WinPEP CD for

installation instructions.

Extended Carriage—The extended carriage option increases the maximum wheel

base (measured from the front of the front wheel to the center of the rear wheel) from

84 inches to 102 inches for testing raked cruisers and drag bikes. Refer to “Extended

Carriage” on page 3-24 for installation instructions.

Fat Boy Adapter—The Fat Boy adapter is necessary when strapping a HarleyDavidson Fat Boy, or any other bike with a solid front wheel, to the carriage of the

dyno. Adapter includes a second ratchet, ratchet strap, double-hook strap, and

necessary fastening hardware. Refer to your WinPEP CD for installation instructions.

High Inertia Drum—The high inertia drum is suggested when testing bikes that

produce more than 250 horsepower at the rear wheel. The extra inertia built into this

special drum adjusts the run time to be equivalent to that of a standard drum with an

average-power motorcycle.

Mobile Base—The mobile base is essential for shops that require maximum flexibility

and mobility. The mobile base allows the dyno to be relocated in a matter of minutes.

Refer to your WinPEP CD for installation instructions.

Monitor Arm—This articulated arm and platform supports the monitor, keyboard,

and mouse in a convenient position for operation while seated on the motorcycle.

Refer to “Monitor Arm” on page 3-34 for installation instructions.

3-2

Motorcycle Dynamometer Installation Guide

Page 33

OPTIONAL ACCESSORIES

Optional Accessories Overview

Power Carriage—The power carriage replaces the standard hand crank with an

electrically powered tire carriage allowing you to easily adjust for various wheel base

distances with the press of a button. This option is ideal for dynos that are recessed

where the hand crank is difficult to access. The power carriage will also reduce the

time spent making adjustments for various length motorcycles. Refer to “Power

Carriage” on page 3-37 for installation instructions.

RPM Pickup—The secondary RPM pickup attaches to a spark plug wire to acquire an

RPM signal for the hardware stack.

Trailer Package—The trailer package is a simple and attractive way to make your

dyno portable. Each bolt-on kit includes independent suspension, tires, fenders, tow

hitch, lights, and a license plate bracket. The trailer package is not available for model

250 dynos. Refer to the WinPEP CD for installation instructions.

REMOVING AND REPLACING THE HOOD

Many of the procedures and instructions in this chapter require you to remove and

replace the hood. Refer to the following steps for removing and replacing the hood.

1 Remove the hood.

1a Remove the four bolts securing the hood to the dyno and set aside. Prop up

the hood.

1b If present, disconnect the wires to the key switch.

1c Remove the hood from the dyno and set aside.

1d Disconnect all battery wires.

2Replace the hood.

2a Connect the battery.

2b Carefully place the hood on the dyno, leaving it propped up.

2c Secure the wires to the key switch, if present.

2d Lower and secure the hood using the four bolts removed earlier.

key switch

Figure 3-6: Remove and Replace the Hood

Vers ion 3 Motorcycle Dynamometer Installation Guide

3-3

Page 34

CHAPTER 3

Air Brake

AIR BRAKE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The air brake is an electro-pneumatic braking system and includes a two button

pendent. The air brake can be utilized to quickly slow the drum after a run is

complete. This is especially useful for two-stroke applications when engine

compression cannot be used to slow the drum. The air brake can also greatly speed

up the testing process.

When upgrading from a mechanical brake, you will no longer use the sample button;

you will need to use the new two button pendant (P/N DC100-104). The new pendant

attaches to the same nine-pin terminal on your hardware stack.

If you purchased your dyno with an air brake assembly, the air brake will already be

installed. You will need to provide an air hose nipple to connect your shop air supply

(80 psi constant line pressure) to the dynamometer. Once air pressure is connected,

the air brake is ready to use.

connect shop air supply

Figure 3-7: Connect Your Shop Air Supply

To prevent possible injury, disconnect the battery before performing any dyno

maintenance or installing any optional accessory.

3-4

Motorcycle Dynamometer Installation Guide

Page 35

OPTIONAL ACCESSORIES

PARTS LIST

The following table lists all of the parts included in the Air Brake (P/N 102-201)

Installation kit. Check your kit against the parts listed to make sure you have received

all of the parts. If any part is missing, contact Dynojet Technical Support.

part number description quantity

197104130 Zip Tie, 4” 6

22103080 Rod, Air Brake Spring 2

22923000 Spring Guide (retainer ring) 4

36390640 Bolt, 1/2-20 x 3/4, Hex 1

43310600 Grommet, 7/16” ID x 3/4” OD 1

61322300 Spring Bolt Mounting Plate 1

63990001 Caliper Assembly 1

63990002 Rotor/Taper Lock Assembly with Hub and Key 1

63990004 Air Cylinder Assembly 1

BR102-033 Grommet, 1”OD, 3/8ID, 3/4H, 1/8G 1

Air Brake

BR102-038-5 Air Hose Push Lock Fitting 1

BR102-038-6 Air Hose Bulk Head Fitting 1

BR102-038-7 Air Hose, 55” .05 55.00 inches

BR102-041 Master Cylinder 1

BR102-045 Brake Hose (installed) 1

None Copper Washers (installed) 2

BR102-046 Brake Line 1

BR102-047 Banjo Bolt (installed) 1

BR102-055 Springs, Purple (for Spring Bolt Assembly) 2

BR102-061 Bolts, 1/4 x 4 1/2”, Socket Head 2

DC100-104 Pendant and Cable 1

DE100-134 Screw, 8 x 1/2”, Self Tapping 2

DM150-035 1/2” Cable Clamp, Nylon 2

DM150-009-005 Nut, 1/4”, Adjuster (for Spring Bolt Assembly) 4

Vers ion 3 Motorcycle Dynamometer Installation Guide

3-5

Page 36

CHAPTER 3

Air Brake

INSTALLING THE ROTOR/TAPER LOCK ASSEMBLY

When upgrading from a manual brake, the rotor/taper lock assembly and caliper

assembly will already be installed. Proceed to “Installing the Air Cylinder and Master

Cylinder Assembly” on page 3-8.

1 Insert the key into the slot on the shaft.

2 Slide the rotor/taper lock assembly on to the shaft.

key

shaft

rotor/taper lock

assembly

Figure 3-8: Install the Rotor/Taper Lock Assembly

3 Attach the dial indicator to the side of the dyno. Spin the drum and check for run

out; the tolerances are +/- .005".

4 Tighten the taper lock bolts. While tightening, adjust the bolts to keep the run out

within tolerances. Torque the taper lock bolts to 15 ft. lb.

dial indicator

taper lock bolts

(two visible here)

Figure 3-9: Check for Run Out

3-6

Motorcycle Dynamometer Installation Guide

Page 37

INSTALLING THE CALIPER ASSEMBLY

1 Tighten the two bolts shown in Figure 3-39.

2 Remove the four bolts and washers in the top and bottom right corners (as shown

in Figure 3-10) and set aside. These bolts will be used to mount the caliper

assembly in step 3.

OPTIONAL ACCESSORIES

Air Brake

remove bolts and use to

mount caliper assembly

tighten

remove bolts and use to

mount caliper assembly

Figure 3-10: Caliper Assembly Mounting Bolts

3 Secure the caliper assembly with the four bolts and washers removed in step 2.

caliper assembly

Figure 3-11: Secure the Caliper Assembly

Vers ion 3 Motorcycle Dynamometer Installation Guide

3-7

Page 38

CHAPTER 3

Air Brake

4 Adjust the space between the brake pad and the rotor making sure the rotor is

able to spin free of contact.

Loosen the jam nut and use the adjuster nut to move the brake pads in or out.

jam nut

Figure 3-12: Adjust the Brake Pad Space

adjuster nut

INSTALLING THE AIR CYLINDER AND MASTER CYLINDER ASSEMBLY

1 With the air cylinder on the inside of the dyno frame and the mounting plate on

the outside, secure the air cylinder with the 1/2-20 x 3/4-inch bolt.

cut away view of

dyno side panel

air cylinder

3-8

Motorcycle Dynamometer Installation Guide

bolt

mounting plate

Figure 3-13: Install the Air Cylinder

Page 39

OPTIONAL ACCESSORIES

Air Brake

2 Slide the master cylinder assembly through the holes in the air cylinder and

through the dyno frame.

3 Secure the master cylinder to the air cylinder with two 1/4 x 4 1/2-inch socket

head mounting bolts using a 3/16-inch allen wrench.

cut away view of dyno

side panel

master cylinder

bolts

air cylinder

Figure 3-14: Install the Master Cylinder

4 Run the metal brake line from the master cylinder to the caliper brake hose.

4a Insert a rubber grommet into the hole shown in Figure 3-15.

4b Run the brake line from the master cylinder through the grommet and over

to the caliper assembly.

4c Secure the brake line to the master cylinder and to the caliper brake hose.

4d Secure the brake line to the outside of the dyno frame using two nylon

loops and two 8 x 1/2-inch self tapping screws.

grommet

master

cylinder

grommet

metal brake line

nylon loops

secure metal brake line

to caliper brake hose

brake

hose

metal brake line

Figure 3-15: Install the Metal Brake Line

Vers ion 3 Motorcycle Dynamometer Installation Guide

3-9

Page 40

CHAPTER 3

Air Brake

INSTALLING THE SPRING BOLT ASSEMBLY

1 Push the mounting plate flush with the dyno cabinet.

2 Install the rear retainer, spring, front retainer, and adjuster nut. Be sure the

hardware is in this order.

Note: You may need to compress the spring to get the adjuster nut on.

The distance from the front retainer to the dyno cabinet should be 3.25 inches.

Final adjustments will be made later.

If the distance is less that 3.25 inches, us a flat blade screwdriver to unscrew the

spring rod until the proper distance is achieved.

3 Turn the adjuster nut to tighten the spring until there is enough room on the

spring rod for the jam nut.

4 While holding the adjuster nut from turning, tighten the jam nut against the

adjuster nut.

cut away view of dyno

side panel

hold adjuster nut

tighten jam nut

against adjuster nut

dyno cabinet

front retainer

mounting plate

front retainer

adjuster nut

3-10

Motorcycle Dynamometer Installation Guide

spring rod

jam nut

spring

rear retainer

Figure 3-16: Install the Spring Bolt Assembly

Page 41

INSTALLING THE AIR HOSE

1 Install the 1-inch grommet into the hole shown in Figure 3-17.

2 Wrap the push lock fitting with thread tape. Refer to Figure 3-18.

3 Insert the five foot section of air hose through the hole. Leave enough air hose

exposed and attach it to the regulator.

attach air hose to

regulator

OPTIONAL ACCESSORIES

Air Brake

run air hose

inside dyno

grommet

Figure 3-17: Secure the Air Hose to the Regulator

Vers ion 3 Motorcycle Dynamometer Installation Guide

3-11

Page 42

CHAPTER 3

Air Brake

4 Lift the front of the dyno high enough to access the cut out on the bottom side of

the dyno.

The dyno is heavy. Use suitable methods to lift and support the dyno while

working through these steps.

5 Reach into the access hole in the bottom of the dyno and find the air hose.

6 Place the nut and washer from the bulk head fitting onto the air hose.

7 Insert the air hose through the hole in the front dyno panel and thread the bulk

head fitting onto the push lock fitting.

8 Insert the bulk head fitting into the hole. While holding the bulk head fitting from

the outside, tighten the nut from the inside.

Note: You will need to supply the couplers/fittings to attach to the bulk head

fitting. Using a quick coupler at the end is convenient if you need that air source

for other activities in the shop.

air hose

(inside dyno)

cut away view of

front dyno panel

bulk head fitting

(outside dyno)

push lock fitting

bulk head fitting

nut

washer

push lock fitting

with thread tape

install complete

Figure 3-18: Install the Bulk Head Fitting

3-12

Motorcycle Dynamometer Installation Guide

Page 43

WIRING THE AIR VALVE ASSEMBLY

The wires that attach to the air valve assembly can be attached in two different places

depending on your dyno’s set up. Wire Set Up 1 is generally for older dynos while

Wire Set Up 2 is for newer dynos.

WIRE SET UP 1

This wire set up is used in older dynos that have an exposed (not in a black box)

terminal strip with only eight terminals. If your terminal strip is in a box and has

sixteen terminals, refer to Wire Set Up 2 on page 14.

1 Attach the air hose to the coupler and adjust the regulator to 80 psi.

2 Run the two black wires from the air valve to the top two terminals on the left

side, refer to Figure 3-19.

3 Wire the two black extension leads to the top two terminals on the right side.

OPTIONAL ACCESSORIES

Air Brake

black leads from

the air valve

Figure 3-19: Wire Set Up 1—Terminal Strip Wiring

4 Remove the four screws securing the Breakout board and cover. Set the screws

and cover aside.

5 Attach the extension leads to the Breakout board. Orientation of the wires is not

important.

6 Replace the Breakout board cover using the four screws removed earlier.

two black terminal

strip wires

extension leads to

the Breakout board

Breakout board

and cover

Figure 3-20: Wire Set Up 1—Breakout Board Wiring

Vers ion 3 Motorcycle Dynamometer Installation Guide

3-13

Page 44

CHAPTER 3

Air Brake

WIRE SET UP 2

This wire set up is used in newer dynos where the terminal strip is housed in a black

box and has sixteen terminals. If your terminal strip is not in a box and has only eight

terminals, refer to Wire Set Up 1 on page 13.

1 Attach the air hose to the coupler and adjust the regulator to 80 psi.

2 Remove the cover from the black box.

3 Run the wires from the air valve through the hole on the side of the black box.

4 Attach the air valve wires to the terminal strip as shown in Figure 3-21. The black

and yellow leads for the Breakout board have been pre wired to the terminal strip

at Dynojet.

hole

air valve wire

Figure 3-21: Wire Set Up 2—Terminal Strip Wiring

5 Secure the cover to the black box.

6 Remove the four screws securing the Breakout board and cover. Set the screws

and cover aside.

7 Attach the black and yellow leads from the terminal strip to the Breakout board.

Orientation of the wires is not important.

8 Verify the jumper settings on the Breakout board.

9 Replace the Breakout board cover using the four screws removed earlier.

yellow

black

air valve wire

black and yellow leads

to breakout board

Breakout board

and cover

Figure 3-22: Wire Set Up 2—Breakout Board Wiring and Jumper Settings

3-14

Motorcycle Dynamometer Installation Guide

Page 45

FINAL ADJUSTMENTS AND TESTS

1 Verify the dyno is set up properly, the hardware stack is powered up and

operational, and the air supply is connected properly.

2 Verify the brake is off; the red light on the pendant should be off.

3 Fill the master cylinder with DOT 5 brake fluid.

4 Open the bleeder valve on the caliper assembly and use the red brake button on

the pendant to activate the brake. You should see fluid and air being purged from

the bleeder valve. Repeat this procedure until the system is completely bled.

5 If you find you are not getting sufficient brake performance, adjust the spring rod

nuts to increase the spring pressure.

5a Loosen the jam nut.

5b Place the jam nut flush with the end of the spring rod and insert a

screwdriver into the slot on the end of the spring rod.

5c Tighten the adjuster nut until the springs begin to overcome the force of the

air pushing against them.

5d Once the adjuster nut is in place, snug the jam nut up to the adjuster nut.

5e Test the brake several more times to verify the brake pads return far enough

to clear the rotor.

6 Use the red brake button on the pendant to activate and deactivate the brake.

Listen for air leaks and double check all connections.

7 Adjust the clearance between the pads and the rotor by loosening the jam nut and

turning the adjuster nut on the caliper assembly. There should be equal space on

both sides of the rotor. Refer to Figure 3-41 for more information on the caliper

assembly jam and adjuster nuts.

Note: Cycle the brake to verify the brake pads release far enough and do not

touch the rotor. If the pads touch the rotor during a run, the information

provided by the dyno will be inaccurate.

8 Replace the hood. Refer to “Removing and Replacing the Hood” on page 3-3.

OPTIONAL ACCESSORIES

Air Brake

Vers ion 3 Motorcycle Dynamometer Installation Guide

3-15

Page 46

CHAPTER 3

Air Brake

AIR BRAKE ASSEMBLY SCHEMATIC

3-16

Motorcycle Dynamometer Installation Guide

Figure 3-23: Air Brake Assembly Schematic

Page 47

OPTIONAL ACCESSORIES

DUAL FAN

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The dual fan supplies air to cool the bike’s engine. This section will walk you through

the fan installation procedures and adjusting the extension arm assembly when a

power carriage is installed.

The fan extension arm assembly comes ready to mount to the tire carriage on the

dyno. However, if you have a power carriage installed on your dynamometer, you will

need to make adjustments to the extension arm assembly before mounting the

assembly to the dyno. Refer to “Modifying the Extension Arm Assembly (For Power

Carriage Only)” on page 3-22.

To prevent possible injury, disconnect the battery before performing any dyno

maintenance or installing any optional accessory.

PARTS LIST

The following table lists all of the parts included in the Dual Fan Installation kit.

Check your kit against the parts listed to make sure you have received all of the parts.

If any part is missing, contact Dynojet Technical Support.

Dual Fan

part number description quantity

76722001

Or

76722002

63413002 Dual Fan Mounting Bracket and Extension Arm Assembly 1

26215520 Washer, 1.87 x 1.25 IDx .12Thk (Poly Washer) 2

36582477 Bolt, 3/8"-16 x 1-1/2", Hex 4

36488100 Nut, 3/8"-16, Nylock 4

36932100 Washer, 3/8", Splitlock, Stl 4

DE100-311 &

21629100

Dual Fan Assembly (complete assembly)

Or

Dual Fan Assembly-220V (complete assembly)

Outlet Box and Mounting Bracket 1

1

Vers ion 3 Motorcycle Dynamometer Installation Guide

3-17

Page 48

CHAPTER 3

Dual Fan

MODIFYING THE TIRE STOP

Older dynos may not have the four holes on the tire stop needed to mount the

extension arm assembly; you will need to modify the tire stop before continuing with

the fan installation instructions. Refer to Figure 3-24 for hole size and placement.

3-18

Motorcycle Dynamometer Installation Guide

Figure 3-24: Modify the Tire Stop

Page 49

INSTALLING THE EXTENSION ARM ASSEMBLY

The fan extension arm assembly comes ready to mount to the tire stop on the dyno.

Note: If you have a power carriage installed on your dyno, you will need to make

adjustments to the extension arm assembly before mounting the assembly to the

dyno. Refer to “Modifying the Extension Arm Assembly (For Power Carriage

Only)” on page 3-22.

1 Remove the two screws securing the extension arm assembly to the crate and

remove the assembly.

remove screws

OPTIONAL ACCESSORIES

Dual Fan

clip zip tie securing poly

washer before installing fan

Figure 3-25: Remove the Extension Arm Assembly from the Crate

2 Secure the main bracket on the extension arm assembly to the tire stop using four

3/8-16 x 1-1/2-inch bolts and four 3/8-inch washers.

Note: If you modified the tire stop, you will also need to use four 3/8-inch nylock

nuts.

bolt

washer

main bracket

tire stop

Figure 3-26: Secure the Extension Arm Assembly to the Tire Stop

Vers ion 3 Motorcycle Dynamometer Installation Guide

3-19

Page 50

CHAPTER 3

Dual Fan

INSTALLING THE FAN ASSEMBLIES

Repeat the following steps for each fan assembly.

1 Place a poly washer between the stud and the extension arm.

Note: The poly washer is secured to the extension arm with a zip tie. Clip the zip

tie before installing the fan assembly. Refer to Figure 3-25.

2 Insert the stud on the fan assembly into the extension arm.

3 If not already installed, secure the hand knobs to the extension arm and to the fan

base.

Note: Your hand knobs may be different than the hand knobs shown in the

following figures.

fan assembly

poly washer

extension arm

hand knob

Figure 3-27: Install the Fan Assembly

3-20

Motorcycle Dynamometer Installation Guide

Page 51

INSTALLING THE OUTLET BOX

The outlet box mounts to the main bracket on the extension arm assembly. Install the

outlet box the same way for dynos with or without a power carriage installed.

1 Remove the two button-head screws from the front of the main bracket.

2 Secure the outlet box bracket to the main bracket using the two button-head

screws you just removed.

Note: Extra button-head screws are included in the hardware bag if needed.

3 Plug the power cord into a 120 volt (North America) or 240 volt (Europe and

Australia) power source.

Note: When using the dual fan assembly in conjunction with an eddy current

brake (retarder), make sure the dual fan assembly is plugged into a separate

circuit than the retarder.

The current draw at 120 volts is 17 amps and at 240 volts is 8 1/2 amps.

4 Activate the fans by flipping the toggle switch on the motors. The fans are

independent of one another; each fan can be turned on and off individually.

Note: Be sure the fans are free and clear of any obstruction. The fans can run at

any time once the cord is plugged into a power source.

OPTIONAL ACCESSORIES

Dual Fan

outlet box and

bracket

screw

Figure 3-28: Install the Outlet Box

Vers ion 3 Motorcycle Dynamometer Installation Guide

3-21

Page 52

CHAPTER 3

Dual Fan

MODIFYING THE EXTENSION ARM ASSEMBLY (FOR POWER CARRIAGE ONLY)

When the fan assembly is used with a power carriage, the following modifications

must be made to the extension arm assembly before mounting the extension arm

assembly to the dyno.

Note: These modifications should be made only when a power carriage is

installed.

1 Remove the four hand knobs from the extension arms.

2 Remove arm A, including the poly washer, and set aside.

3 Remove the bolt, lock washer, flat washer, and spacer securing arm B to the main

bracket, including the poly washer, and set aside.

Note: Arm B is the only arm with a threaded stud.

hand knob

arm A

bolt

lock washer

flat washer

spacer

poly washer

hand knob

arm A

poly washer

arm B

Figure 3-29: Modify the Extension Arm Assembly—Removing the Arms

threaded stud

arm B

hand knob

hand knob

3-22

Motorcycle Dynamometer Installation Guide

Page 53

hand knob

OPTIONAL ACCESSORIES

Dual Fan

4 Flip arm A over, place the poly washer on the stud, and insert into the main

bracket from the top.

5 Flip arm B over, place the poly washer on the stud, and insert into arm A from the

bottom. Secure Arm B using the bolts, washers, and spacers removed earlier.

Note: Arm B is the only arm with a threaded stud.

6 Replace the four hand knobs removed earlier.

7 Continue with “Installing the Extension Arm Assembly” on page 3-19, “Installing

the Fan Assemblies” on page 3-20, and “Installing the Outlet Box” on page 3-21 to

complete the fan installation.

hand knob

arm A

threaded stud

hand knob

arm B

main bracket

arm A

hand knob

Figure 3-30: Modify the Extension Arm Assembly—New Arm Configuration

arm B

Vers ion 3 Motorcycle Dynamometer Installation Guide

3-23

Page 54

CHAPTER 3

Extended Carriage

EXTENDED CARRIAGE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The extended carriage option increases the maximum wheel base (measured from the

front of the front wheel to the center of the rear wheel) from 84 inches to 102 inches

for testing raked cruisers and drag bikes.

To prevent possible injury, disconnect the battery before performing any dyno

maintenance or installing any optional accessory.

PARTS LIST

The following table lists all of the parts included in the Extended Carriage Installation

kit. Check your kit against the parts listed to make sure you have received all of the

parts. If any part is missing, contact Dynojet Technical Support.

part number description quantity

36488100 Nut, 3/8"-16, Nylock 6

36560834 Screw, 1/4-20 x 1/2", Button-head 2

DM150-002-008 Nut, 5/16" 4

DM150-011-002 Washer, 3/8", Flat 12

DM150-015-001 Nut Block 1

DM150-016-007 Carriage Screw Support Bracket 1

DM150-019-012 Bolt, 3/8 x 1", Hex 6

EXT100-206 Extended Carriage Support Bracket 1

EXT100-206

DM150-014-002 Small Leveling Shim 1

DM150-015-002 Large Leveling Shim 1

DM150-002-003 Bolt, 5/16 x 1 1/2" 4

DM150-002-004 Washer, 5/16", Lock 4

Carriage and Tire Stop 1

DM150-019

3-24

Motorcycle Dynamometer Installation Guide

Page 55

REMOVING THE TIRE CARRIAGE

1 Using a 5/32-inch allen wrench, remove the two button-head screws securing the

carriage screw support bracket and remove the bracket.

carriage screw support bracket

Figure 3-31: Remove the Carriage Screw Support Bracket

2 Unscrew the carriage until it is free from the nut block. Slide the carriage off the

dyno.

3 Using a 1/2-inch wrench, remove the bolts (discard bolts) and washers securing

the nut block and front clamp to the dyno cover and set aside.

4 Using a 1/2-inch wrench, remove the bolts and washers securing the two rear

clamps to the dyno cover and set aside.

nut block

slide carriage

off dyno

rear clamps

OPTIONAL ACCESSORIES

Extended Carriage

nut block

front clamp

carriage screw

Figure 3-32: Remove the Tire Carriage, Nut Block, and Clamps

Vers ion 3 Motorcycle Dynamometer Installation Guide

3-25

Page 56

CHAPTER 3

Extended Carriage

INSTALLING THE EXTENDED CARRIAGE SUPPORT BRACKET

1 Remove the eight screws securing the top cover to the dyno and set aside.

Remove the cover and set aside.

Removing the cover will make installing the extended carriage support bracket

less difficult.

cover

Figure 3-33: Remove the Top Cover

2 Loosely attach the extended carriage support bracket to the front of the dyno

using six 3/8 x 1-inch bolts, twelve 3/8-inch flat washers, and six 3/8-inch nylock

nuts. Be sure the bolts are installed from the inside of the dyno.

Figure 4 shows a cut away view of the extended carriage support bracket, dyno

frame, and three of the six mounting bolts.

extended carriage

support bracket

Figure 3-34: Install the Extended Carriage Support Bracket

3-26

Motorcycle Dynamometer Installation Guide

Page 57

OPTIONAL ACCESSORIES

Extended Carriage

3 Using a straight edge, line the top of the support bracket with the top of the dyno

chassis.

4 Tighten all six mounting bolts to 30 ft. lb.

5 Install the top cover on the dyno using the eight screws removed earlier. Refer to

Figure 3-33.

6 Install the two rear clamps to the dyno cover using the bolts and washers

removed earlier. Refer to Figure 3-32.

7 Using the original shim and the large shim included with the kit, loosely attach

the nut block to the front of the extended carriage support bracket using two

5/16 x 1 1/2-inch bolts, the flat washers you removed earlier, two 5/16-inch lock

washers, and two 5/16-inch nuts.

8 Using the original shim and the small shim included with the kit, loosely attach

the front clamp to the front of the extended carriage support bracket using two

5/16 x 1 1/2-inch bolts, the flat washers you removed earlier, two 5/16-inch lock

washers, and two 5/16-inch nuts.

nut block

front clamp

Figure 3-35: Install the Nut Block and Front Clamp

Vers ion 3 Motorcycle Dynamometer Installation Guide

3-27

Page 58

CHAPTER 3

Extended Carriage

INSTALLING THE EXTENDED CARRIAGE

1 Slide the extended carriage through the nut block and clamps until the carriage

screw contacts the nut block. Be sure the slide plate is under the rear carriage

clamps.

2 Screw the carriage through the nut block.

3 Install the screw support bracket.

3a Place the belleville washers over the end of the carriage screw. It is

important the belleville washers are installed in the configuration shown in

Figure 3-36.

3b Place the screw support bracket in front of the carriage screw. The two

threaded holes in the bracket should face the two matching holes in the

carriage. Loosely install the two 1/4 x 1/2-inch button-head screws.

3c Before tightening the screws, apply some pressure to the bracket to

compress the belleville washers. The handle should still turn freely, but the

turning force should now be around five to six pounds.

To adjust the force needed to turn the crank handle, adjust the compression

of the belleville washers.

3d Using a 5/32-inch allen wrench, tighten the two button-head screws.

4 Tighten the bolts in the nut block and the three carriage clamps.

screws

belleville washers

support

bracket

carriage screw

Figure 3-36: Install the Screw Support Bracket

3-28

Motorcycle Dynamometer Installation Guide

Page 59

OPTIONAL ACCESSORIES

MECHANICAL BRAKE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The mechanical or manual brake is a foot actuated hydraulic brake. The mechanical

brake can be utilized to quickly slow the drum after a run is complete. This is

especially useful for two-stroke applications when engine compression cannot be

used to slow the drum. The brake can also greatly speed up the testing process.

The following installation instructions are for the model 200 dyno; however, the

mechanical brake may be installed on model 100 and 150 dynos with proper

modification. Contact Dynojet Technical Support for more information about model

100 and 150 dyno modifications

To prevent possible injury, disconnect the battery before performing any dyno

maintenance or installing any optional accessory.

PARTS LIST

The following table lists all of the parts included in the Mechanical Brake Installation

kit. Check your kit against the parts listed to make sure you have received all of the

parts. If any part is missing, contact Dynojet Technical Support.

Mechanical Brake

part number description quantity

63990001 Caliper Assembly 1

63990002 Rotor with Hub, Taper Lock, and Key 1

BR102-009 Mechanical Brake Pedal Assembly 1

BR102-029 Brake Spring Plug 1

— Rubber Boot 1

BR102-033 Grommet 1" OD, 3/8" ID 1

BR102-041 Master Cylinder 1

BR102-046 Brake Line 1

DE100-134 Screw, #8 x 1/2”, Self Tapping 2

DM150-035 1/2" Cable Clamp, Nylon 2

DM150-011-002 Washer, 3/8" Flat 4

DM150-011-003 Washer, 3/8" Lock 4

DM150-011-006 Bolt, 3/8 x 1 1/4", Hex 2

DM150-019-012 Bolt, 3/8 x 1", Hex 2

Vers ion 3 Motorcycle Dynamometer Installation Guide

3-29

Page 60

CHAPTER 3

Mechanical Brake

INSTALLING THE ROTOR/TAPER LOCK ASSEMBLY

1 Remove the hood. Refer to “Removing and Replacing the Hood” on page 3-3.

2 Insert the key into the slot on the shaft.

3 Slide the rotor/taper lock assembly on to the shaft.

key

shaft

rotor/taper lock

assembly

Figure 3-37: Install the Rotor/Taper Lock Assembly

4 Attach the dial indicator to the side of the dyno. Spin the drum and check for run

out; the tolerances are +/- .005".

5 Tighten the taper lock bolts. While tightening, adjust the bolts to keep the run out

within tolerances. Torque the taper lock bolts to 15 ft. lb.

dial indicator

taper lock bolts

(two visible here)

Figure 3-38: Check for Run Out

3-30

Motorcycle Dynamometer Installation Guide

Page 61

INSTALLING THE CALIPER ASSEMBLY

1 Tighten the two bolts shown in Figure 3-39.

2 Remove the four bolts and washers in the top and bottom right corners (as shown

in Figure 3-39) and set aside. These bolts will be used to mount the caliper

assembly in step 3.

OPTIONAL ACCESSORIES

Mechanical Brake

remove bolts and use to

mount caliper assembly

tighten

remove bolts and use to

mount caliper assembly

Figure 3-39: Caliper Assembly Mounting Bolts

3 Secure the caliper assembly with the four bolts and washers removed in step 2.

caliper assembly

Figure 3-40: Secure the Caliper Assembly

Vers ion 3 Motorcycle Dynamometer Installation Guide

3-31

Page 62

CHAPTER 3

Mechanical Brake

4 Adjust the space between the brake pad and the rotor making sure the rotor is

able to spin free of contact.

Loosen the jam nut and use the adjuster nut to move the brake pads in or out.

jam nut

Figure 3-41: Adjust the Brake Pad Space

adjuster nut

INSTALLING THE MASTER CYLINDER AND FOOT PEDAL

1 Position the master cylinder to the inside of the dyno frame and slip the rubber

boot on from the outside. The rubber boot slips over the piston sleeve on the

master cylinder.

2 Mount the foot pedal to the outside of the dyno frame. The bolts should run from

the inside, through the master cylinder, and into the threaded foot pedal

mounting plate.

Note: Use the two 3/8 x 1-inch bolts on the top and the two 3/8 x 1 1/4-inch bolts

on the bottom. All bolts get a lock washer and flat washer.

3-32

Motorcycle Dynamometer Installation Guide

foot pedal

master cylinder

3/8 x 3/4-inch

bolts for top

3/8 x 1 1/4-inch

bolts for bottom

Figure 3-42: Install the Master Cylinder and Foot Pedal

Page 63

master cylinder

grommet

OPTIONAL ACCESSORIES

Mechanical Brake

3 Remove the plunger from the pedal brake assembly. Slip the plunger into the

rubber boot and then reattach it to the pedal brake arm.

4 Run the metal brake line from the master cylinder to the caliper brake hose.

4a Insert a rubber grommet into the hole shown in Figure 3-43.

4b Run the brake line from the master cylinder through the grommet and over

to the caliper assembly.

4c Secure the brake line to the master cylinder and to the caliper brake hose.

4d Secure the brake line to the outside of the dyno frame using two nylon

loops and two 8 x 1/2-inch self tapping screws.

grommet

metal brake line

nylon loops

secure to caliper

brake

hose

metal brake line

plunger

Figure 3-43: Install the Metal Brake Line

5 Fill the master cylinder with DOT 5 brake fluid.

6 Open the bleeder valve on the caliper assembly and cycle the brake to expel air.

You should see fluid and air being purged from the bleeder valve. Repeat this

procedure until the system is completely bled.

7 Adjust the clearance between the pads and the rotor by loosening the jam nut and

turning the adjuster nut. There should be equal space on both sides of the rotor.

Refer to Figure 3-41 for more information on the jam and adjuster nuts.

8 Replace the hood. Refer to “Removing and Replacing the Hood” on page 3-3.

Vers ion 3 Motorcycle Dynamometer Installation Guide

3-33

Page 64

CHAPTER 3

Monitor Arm

MONITOR ARM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This articulated arm and platform supports the monitor, keyboard, and mouse in a

convenient position for operation while seated on the motorcycle. The arm can be

mounted on either side of the dynamometer.

PARTS LIST

The following table lists all of the parts included in the Monitor Stand Installation kit.

Check your kit against the parts listed to make sure you have received all of the parts.

If any part is missing, contact Dynojet Technical Support.

Part Number Description Quantity

21229300 Monitor Arm Tray 1

32391064 Bushing, 1" x 2", 10 Gauge, Stl 3

35521420 Plastic Cap, 1-3/4" x 1/2", Black 4

36701100 Nut, 1/2-13, Hex 2

36801253 Screw, 1/2-13 x 1-1/2", Sh-Cap 2

36932100 Washer, 3/8", Splitlock, Stl 1

36942100 Washer, 1/2", Splitlock, Stl 2

36943100 Washer, 1/2", Flat, Stl 4

61329100 Monitor Arm 2

61329102 Monitor Arm Base 1

61329103 Monitor Arm Upright 1

DM150-011-002 Washer, 3/8" Flat 1

DM150-011-006 Bolt, 3/8-16 x 1 1/4", Hex 1

3-34

Motorcycle Dynamometer Installation Guide

Page 65

INSTALLING THE MONITOR ARM BRACKET

1 Drill a 1/2-inch hole through the aluminum deck plate as shown in Figure 3-44.

Use the existing hole under the deck plate as a guide.

2 Fasten the top of the monitor arm bracket to the dyno using a 3/8-inch bolt,

3/8-inch lock washer, and 3/8-inch flat washer.

Note: Do not tighten.

3 Secure the bottom of the bracket to the dyno using two 1/2-inch bolts,

four 1/2-inch washers, two 1/2-inch lock washers, and two 1/2-inch nuts.

4 Fully tighten all three bracket bolts.

3/8-inch bolt

drill hole

OPTIONAL ACCESSORIES

Monitor Arm

monitor arm bracket

1/2-inch bolt

Figure 3-44: Install the Monitor Arm Bracket

Vers ion 3 Motorcycle Dynamometer Installation Guide

3-35

Page 66

CHAPTER 3

Monitor Arm

INSTALLING THE ARMS AND TRAY

1 Place a bushing on the pin of the first arm and insert the arm into the upright.

Both arms are identical and interchangeable.

2 Place a bushing on the pin of the second arm and insert the arm into the first arm.

3 Place a bushing on the pin of the tray and insert the tray into the second arm.

4 Insert a plastic cap in both ends of each arm.

5 Check for clearance between the monitor arm and motorcycle, walls, ceiling, etc.

Note: Dynojet does not recommend placing the computer CPU on the

monitor/keyboard tray since vibration can cause damage to the computer.

tray

bushing

plastic cap

second arm

first arm

upright

3-36

Motorcycle Dynamometer Installation Guide

Figure 3-45: Install the Arms and Tray

Page 67

OPTIONAL ACCESSORIES

POWER CARRIAGE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The power carriage replaces the standard hand crank with an electrically powered tire

carriage allowing you to easily adjust for various wheel base distances with the press

of a button. This option is ideal for dynos that are recessed where the hand crank is

difficult to access. The power carriage will also reduce the time spent making

adjustments for various length motorcycles.

Power Carriage

The power carriage motor is preset to be installed with the carriage screwed in

all the way. Do not run the motor prior to installing it on your dyno.

To prevent possible injury, disconnect the battery before performing any dyno

maintenance or installing any optional accessory.

PARTS LIST

The following table lists all of the parts included in the Power Carriage Installation kit.

Check your kit against the parts listed to make sure you have received all of the parts.

If any part is missing, contact Dynojet Technical Support.

part number description quantity