Page 1

Page 2

©2003-2005 Dynojet Research, Inc. All Rights Reserved.

High Pressure Blower Installation Guide for Model 200i/250i and 200/250 Motorcycle

Dynamometers.

This manual is copyrighted by Dynojet Research, Inc., hereafter referred to as Dynojet,

and all rights are reserved. This manual is furnished under license and may only be used

or copied in accordance with the terms of such license. This manual is furnished for

informational use only, is subject to change without notice, and should not be construed

as a commitment by Dynojet. Dynojet assumes no responsibility or liability for any error

or inaccuracies that may appear in this manual. Except as permitted by such license, no

part of this manual may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, recording, or otherwise, without the prior

written permission of Dynojet.

The Dynojet logo is a trademark of Dynojet Research, Inc.

Any trademarks, trade names, service marks, or service names owned or registered by any

other company and used in this guide are the property of their respective companies.

Dynojet Research, Inc., 2191 Mendenhall Drive, North Las Vegas, Nevada 89031, USA.

Printed in USA.

Part Number: 98220105 Version 3 (04/2005)

Page 3

T

ABLE OF

C

ONTENTS

High Pressure Blower Installation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Conventions Used In This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Installing the Blower Arm Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Installing the High Pressure Blower Assemblies . . . . . . . . . . . . . . . . . . . . . .1-5

Power Hookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Stand Alone Blower Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Installing the Blower and Base Assemblies . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Installing the Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Power Hookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Appendix A Model 200/250 Blower Installation

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Modifying the Tire Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Installing the Extension Arm Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Installing the High Pressure Blower Assemblies . . . . . . . . . . . . . . . . . . . . . .A-4

Power Hookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-5

Modifying the Extension Arm Assembly (For Power Carriage Only) . . . . . .A-6

High Pressure Blower Installation Guide

i

Page 4

Page 5

H

IGH

P

RESSURE

B

LOWER INSTALLATION

This document provides instructions for installing the high pressure blower

assemblies to the model 200i/250i motorcycle dynamometer (dyno). Appendix A

includes instructions for installing the high pressure blower assemblies to the model

200/250 dyno. To ensure safety and accuracy in the procedures, perform the

procedures as they are described.

Document Part Number: 98220105

Version 3

Last Updated: 04-11-05

High Pressure Blower Installation Guide

1

Page 6

HIGH PRESSURE BLOWER

Introduction

INTRODUCTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The high pressure blower supplies air to cool the bike’s engine. This section will walk

you through the blower installation procedures on the model 200i and 250i

motorcycle dynos.

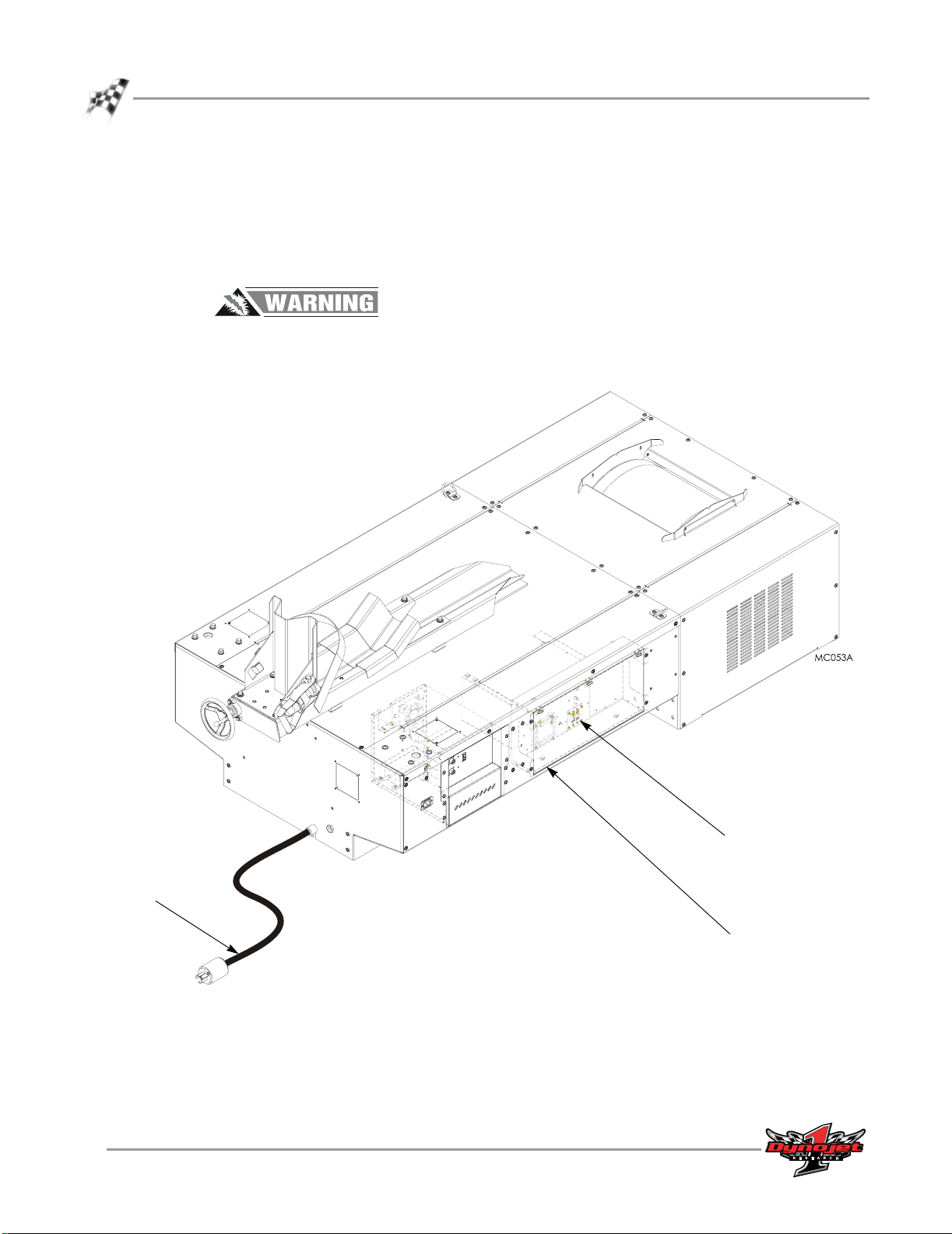

To prevent possible injury, place the breaker inside the power distribution

enclosure to the off position and unplug the dyno. Refer to Figure 1 for breaker

location.

power cord

2

High Pressure Blower Installation Guide

breaker

power distribution enclosure

Figure 1: Model 200i/250i Breaker Location

Page 7

CONVENTIONS USED IN THIS MANUAL

The conventions used in this manual are designed to protect both the user and the

equipment.

example of convention description

The Caution icon indicates a potential hazard to the

dynamometer equipment. Follow all procedures

exactly as they are described and use care when

performing all procedures.

The Warning icon indicates potential harm to the

person performing a procedure and/or the

dynamometer equipment.

TECHNICAL SUPPORT

For assistance, please contact Dynojet Technical Support at 1-800-992-3525, or write

to Dynojet at 2191 Mendenhall Drive, North Las Vegas, NV 89031.

Visit us on the World Wide Web at www.dynojet.com where Dynojet provides state of

the art technical support, on-line shopping, 3D visualizations, and press releases

about our latest product line.

INSTALLATION GUIDE

Introduction

PARTS LIST

The following table lists all of the parts included in the High Pressure Blower

Installation kit (P/N 76722003). Check your kit against the parts listed to make sure

you have received all of the parts. If any part is missing, contact Dynojet Technical

Support.

part number description quantity

61328101 High Pressure Blower 2

63413004 Lower Blower Arm Assembly (longer arm and pin) 2

63413001 Upper Blower Arm Assembly 2

26215521 Washer, 1.87 x 1.25 ID x .25 Thick (Poly Washer) 2

35712992 Clamp Lever, 3/8-16 x 1.5” 2

Version 3 High Pressure Blower Installation Guide

3

Page 8

HIGH PRESSURE BLOWER

Installation

INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

If you have a monitor tray, the support arm must be installed before the blower arm

assemblies. Refer to the Model 200i/250i Motorcycle Dynamometer Installation Guide

for more information.

INSTALLING THE BLOWER ARM ASSEMBLIES

Repeat the following steps for each blower arm assembly.

1 Place a 1/4-inch thick poly washer around the pin on the blower arm assembly.

2 Insert the pin on the blower arm assembly into the dyno.

3 Secure the clamp lever to the dyno.

blower arm

assembly

clamp lever

lower arm has longer

arm and pin

1/4-inch thick

poly washer

blower arm

assembly

clamp lever

4

High Pressure Blower Installation Guide

Figure 2: Install the Blower Arm Assemblies

Page 9

INSTALLING THE HIGH PRESSURE BLOWER ASSEMBLIES

Repeat the following steps for each blower assembly.

Note: Make sure the motor on each blower is facing out (away from the dyno)

and that the intake is facing in.

1 Place a 1/8” thick poly washer around the pin on the blower assembly.

2 Insert the pin on the blower assembly into the blower arm.

blower assembly

intake facing in

1/8-inch thick

poly washer

INSTALLATION GUIDE

Installation

blower arm

motor facing out

Figure 3: Install the Blower Assemblies

Version 3 High Pressure Blower Installation Guide

5

Page 10

HIGH PRESSURE BLOWER

Installation

POWER HOOKUP

Each blower has its own power cord and will plug directly into the dyno chassis.

1 Plug the power cord from the blower into the power source located on the dyno

chassis.

2 Activate the blower using the switch on the blower motor. The blowers are

independent of one another; each blower can be turned on and off individually.

Risk of injury. Eye protection required. Be aware of debris from blowers. Be

sure the blowers are free and clear of any obstruction. The blowers can run at

any time once the cord is plugged into a power source.

power cord

from blower

Figure 4: Power Hookup

plug into

dyno chassis

power cord

from blower

6

High Pressure Blower Installation Guide

Page 11

INSTALLATION GUIDE

Stand Alone Blower Base

STAND ALONE BLOWER BASE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The stand alone blower base was designed for use with pit dynos and automotive

dynos allowing you to direct air flow where you need it. The stand alone base will also

accommodate the older style fans.

PARTS LIST

The following table lists all of the parts included in the Stand Alone High Pressure

Blower Base kit (P/N 71329002). Check your kit against the parts listed to make sure

you have received all of the parts. If any part is missing, contact Dynojet Technical

Support.

part number description quantity

61328101 High Pressure Blower Assembly 2

61329001 Stand Alone Handle Assembly 2

61329111 Stand Alone Extension Assembly 2

61329600 Stand Alone Base Assembly 2

35712991 Clamp Lever, 3/8-16 x 3/4” 2

26215520 Washer, 1.87 x 1.25 ID x .12 Thick 2

INSTALLING THE BLOWER AND BASE ASSEMBLIES

Repeat the following steps for each blower and base assembly.

1 Secure the handle to the blower, if not already installed.

1a Remove the two 5/16-inch bolts from the blower.

1b Secure the handle to the blower using the 5/16-inch bolts you just removed.

2 Insert the pin on the blower assembly into the stand alone base.

3Tighten the clamp lever.

blower assembly

base

handle

bolt

clamp lever

Figure 5: Secure Blower to Base

Version 3 High Pressure Blower Installation Guide

7

Page 12

HIGH PRESSURE BLOWER

Stand Alone Blower Base

INSTALLING THE EXTENSION

The extension provides an extra twelve inches of height allowing you to precisely

direct air flow where you need it. Repeat the following steps for each blower and base

assembly.

1 Insert the pin on the extension assembly into the stand alone base. Tighten the

clamp lever.

2 Place a poly washer around the pin on the blower assembly.

3 Insert the pin on the blower assembly into the extension. Tighten the clamp lever.

blower assembly

washer

clamp lever

base

POWER HOOKUP

Each blower has its own power cord and will plug directly into a power source

located in your dyno room. Each blower must be plugged into a separate circuit.

• 17A at 120VAC each 50/60Hz

1 Plug the power cord from the blower into a power source located in your dyno

room.

Note: Each blower must be plugged into a separate circuit. When using the

blowers in conjunction with an eddy current brake (retarder), make sure the

retarder is plugged into a separate circuit than either of the blowers.

2 Activate the blower using the switch on the blower motor. The blowers are

independent of one another; each blower can be turned on and off individually.

extension

clamp lever

Figure 6: Installing the Extension

Risk of injury. Eye protection required. Be aware of debris from blowers. Be

sure the blowers are free and clear of any obstruction. The blowers can run at

any time once the cord is plugged into a power source.

8

High Pressure Blower Installation Guide

Page 13

M

ODEL

200/250 B

LOWER INSTALLATION

A PPENDIX

A

This appendix provides instructions for installing the high pressure blower assemblies

to the model 200/250 motorcycle dynamometer (dyno). To ensure safety and

accuracy in the procedures, perform the procedures as they are described.

This section will walk you through the blower installation procedures and adjusting

the extension arm assembly when a power carriage is installed.

PARTS LIST

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The following table lists all of the parts included in the High Pressure Blower Retrofit

Installation kit (P/N 77020002). Check your kit against the parts listed to make sure

you have received all of the parts. If any part is missing, contact Dynojet Technical

Support.

part number description quantity

61328101 High Pressure Blower Assembly 2

63413002 Mounting Bracket and Extension Arm Assembly 1

26215520 Washer, 1.87 x 1.25 ID x .12 Thick (Poly Washer) 2

36582477 Bolt, 3/8"-16 x 1.5", Hex 4

36488100 Nut, 3/8"-16, Nylock 4

36932100 Washer, 3/8", Splitlock, Stl 4

High Pressure Blower Installation Guide

A-1

Page 14

APPENDIXA

Installation

INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The high pressure blower supplies air to cool the bike’s engine.

The blower extension arm assembly comes ready to mount to the tire carriage on the

dyno. However, if you have a power carriage installed on your dyno, you will need to

make adjustments to the extension arm assembly before mounting the assembly to

the dyno. Refer to “Modifying the Extension Arm Assembly (For Power Carriage

Only)” on page A-6.

To prevent possible injury, disconnect the battery before performing any dyno

maintenance or installing any optional accessory.

MODIFYING THE TIRE STOP

Older dynos may not have the four holes on the tire stop needed to mount the

extension arm assembly; you will need to modify the tire stop before continuing with

the blower installation instructions. Refer to Figure A-1 for hole size and placement.

A-2

High Pressure Blower Installation Guide

Figure A-1: Modify the Tire Stop

Page 15

INSTALLING THE EXTENSION ARM ASSEMBLY

The blower extension arm assembly comes ready to mount to the tire stop on the

dyno.

Note: If you have a power carriage installed on your dyno, you will need to make

adjustments to the extension arm assembly before mounting the assembly to the

dyno. Refer to “Modifying the Extension Arm Assembly (For Power Carriage

Only)” on page A-6.

1 Remove the two screws securing the extension arm assembly to the crate and

remove the assembly.

remove screws

MODEL 200/250 BLOWER INSTALLATION

Installation

clip zip tie securing poly washer

before installing blower

Figure A-2: Remove the Extension Arm Assembly from the Crate

2 Secure the main bracket on the extension arm assembly to the tire stop using four

3/8-16 x 1.5-inch bolts and four 3/8-inch washers.

Note: If you modified the tire stop, you will also need to use four 3/8-inch nylock

nuts.

bolt

washer

main bracket

tire stop

Figure A-3: Secure the Extension Arm Assembly to the Tire Stop

Version 3 High Pressure Blower Installation Guide

A-3

Page 16

APPENDIXA

Installation

INSTALLING THE HIGH PRESSURE BLOWER ASSEMBLIES

Repeat the following steps for each blower assembly.

Note: Your blowers may be different than the blowers shown in the following

figures. Installation procedures are the same.

1 Place a poly washer between the pin and the extension arm.

Note: The poly washer is secured to the extension arm with a zip tie. Clip the zip

tie before installing the blower assembly. Refer to Figure A-2.

2 Insert the pin on the blower assembly into the extension arm.

3 If not already installed, secure the hand knobs to the extension arm and to the

blower base.

Note: Your hand knobs may be different than the hand knobs shown in the

following figures.

blower assembly

poly washer

extension arm

hand knob

Figure A-4: Install the Blower Assemblies

A-4

High Pressure Blower Installation Guide

Page 17

POWER HOOKUP

Each blower has its own power cord and will plug directly into a power source

located in your dyno room. Each blower must be plugged into a separate circuit.

• 17A at 120VAC each 50/60Hz

1 Plug the power cord from the blower into a power source located in your dyno

room.

Note: Each blower must be plugged into a separate circuit. When using the

blowers in conjunction with an eddy current brake (retarder), make sure the

retarder is plugged into a separate circuit than either of the blowers.

2 Activate the blower using the switch on the blower motor. The blowers are

independent of one another; each blower can be turned on and off individually.

Risk of injury. Eye protection required. Be aware of debris from blowers. Be

sure the blowers are free and clear of any obstruction. The blowers can run at

any time once the cord is plugged into a power source.

MODEL 200/250 BLOWER INSTALLATION

Installation

Version 3 High Pressure Blower Installation Guide

A-5

Page 18

APPENDIXA

Installation

MODIFYING THE EXTENSION ARM ASSEMBLY (FOR POWER CARRIAGE ONLY)

When the blower assemblies are used with a power carriage, the following

modifications must be made to the extension arm assembly before mounting the

extension arm assembly to the dyno.

Note: These modifications should be made only when a power carriage is

installed.

1 Remove the four hand knobs from the extension arms.

2 Remove arm A, including the poly washer, and set aside.

3 Remove the bolt, lock washer, fl at washer, and spacer securing arm B to the main

bracket, including the poly washer, and set aside.

Note: Arm B is the only arm with a threaded pin.

hand knob

arm A

bolt

lock washer

flat washer

spacer

poly washer

hand knob

arm A

poly washer

arm B

Figure A-5: Modify the Extension Arm Assembly—Removing the Arms

threaded pin

arm B

hand knob

hand knob

A-6

High Pressure Blower Installation Guide

Page 19

hand knob

MODEL 200/250 BLOWER INSTALLATION

Installation

4 Flip arm A over, place the poly washer on the pin, and insert into the main

bracket from the top.

5 Flip arm B over, place the poly washer on the pin, and insert into arm A from the

bottom. Secure Arm B using the bolts, washers, and spacers removed earlier.

Note: Arm B is the only arm with a threaded pin.

6 Replace the four hand knobs removed earlier.

7 Continue with “Installing the Extension Arm Assembly” on page A-3, “Insta lling

the High Pressure Blower Assemblies” on page A-4, and “Power Hookup” on page

A-5 to complete the blower installation.

hand knob

arm A

threaded pin

hand knob

arm B

main bracket

arm A

hand knob

Figure A-6: Modify the Extension Arm Assembly—New Arm Configuration

arm B

Version 3 High Pressure Blower Installation Guide

A-7

Page 20

Loading...

Loading...