Page 1

CLUTCH KIT

INSTALLATION GUIDE

2016-2018 Polaris General 1000

PARTS LIST

3 CLUTCH ARMS

1 PRIMARY SPRING SILVER

1 SECONDARY SPRING PURPLE

1 HELIX

PLEASE READ ALL DIRECTIONS BEFORE STARTING INSTALLATION

2191 MENDENHALL DRIVE, NORTH LAS VEGAS, NV 89081

800-992-4993 WWW.DYNOJET.COM

19-DCK3

6 MAGNETS (3/16”)

27 MAGNETS (3/8”)

1 WASHER

Page 2

CLUTCH KIT ADJUSTMENT

SETTINGS

INTENDED USE ELEVATION MAGNET POSITION TOTAL WEIGHT PRIMARY SPRING SECONDARY SPRING

Trail Std Tire

Trail 30” Tire

Paddle Tire / Heavy load

RECOMMENDED SETTINGS FOR HIGH ELEVATION

Subtract 1 Magnet (from each arm starting from toe side)

Subtract 2 Magnets (from each arm starting from toe side)

Subtract 3 Magnets (from each arm starting from toe side)

Subtract 4 Magnets (from each arm starting from toe side)

0-2500 ft 1-3-3-2-0 68 gr SILVER PURPLE

0-2500 ft 1-3-3-1-0 66 gr SILVER PURPLE

0-2500 ft 1-3-3-0-0 65 gr SILVER PURPLE

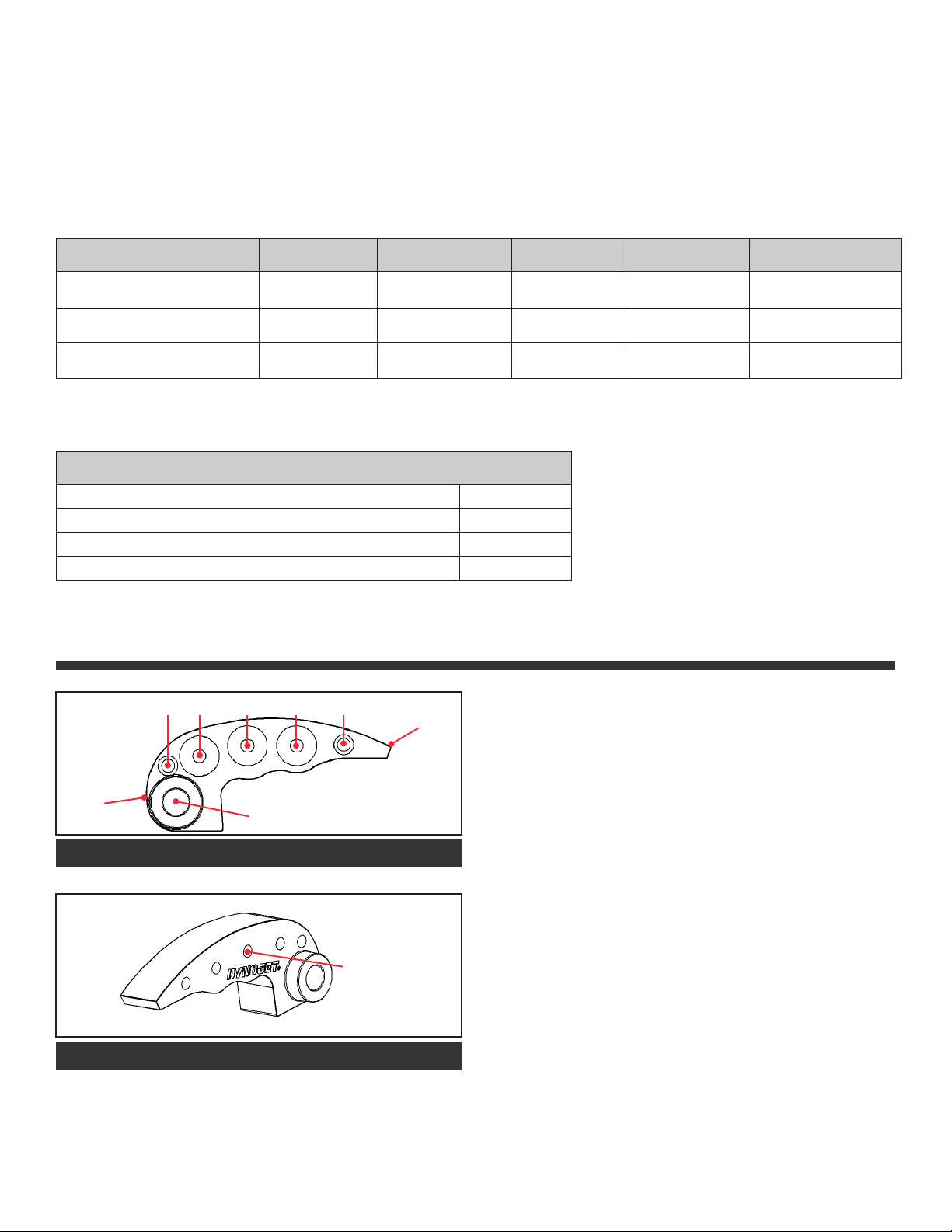

CLUTCH ARM ADJUSTMENT

MAGNET POS 1 2 3 4 5

TOE

3000 ft

6000 ft

7500 ft

9000 ft

LOAD MAGNETS PER THE TABLE ABOVE. MAKE SURE EACH

CLUTCH ARM IS LOADED WITH THE SAME AMOUNT OF

WEIGHT.

MORE WEIGHT NEAR HEEL INCREASES ACCEL

•

MORE WEIGHT AT TOE DECRESASES RPM

HEEL

PIVOT

LOAD MAGNETS STARTING AT HEEL - POS #1

USE A SMALL

ALLEN KEY OR

SIMILAR TO PUSH

THE MAGNETS

OUT FROM THIS

SIDE

TO REMOVE MAGNETS

19-DCK3 CLUTCH KIT 16-18 POLARIS GENERAL 1000

•

1 MAGNET CHANGE WILL ALTER RPM

•

APPROXIMATELY 150RPM

OUR SETTINGS ARE A GENERAL BASELINE. MANY THINGS

CAN EFFECT CLUTCH SETUP:

TIRE BRAND & SIZE

•

STATE OF CLUTCH WEAR

•

DRIVEBELT CONDITION

•

ENGINE POWER OUTPUT

•

ENVIRONMENT CONDITIONS

•

Page 3

INSTALLATION INSTRUCTIONS

IT IS RECOMMENED TO HAVE AN AUTHORIZED POLARIS

TECHNICIAN INSTALL THE CLUTCH KIT AS SPECIAL TOOLS

ARE NEEDED TO COMPLETE THE INSTALLATION.

Removing the left hand side rear shock gives better access

to the clutch housing and parts but is not necessary for

installation. Remove all the 8mm head bolts for the plastic,

clutch housing. Remove clutch housing. Mark the direction

of the drivebelt. Remove the drivebelt. Using the Polaris

clutch puller part #2872085 remove the primary clutch. It

is recommended to grease the threads of the clutch puller

before usage. Remove the 6 bolts for the primary spring

cover. Remove the bolts evenly as there is a significant

amount of spring pressure.

Install the supplied plastic washer to the inside of the stock

spider plate.

Replace the stock spring with the Dynojet spring. When reassembling make sure to align the tab on the Dynojet spring

with the notch in the sheave. Also align the “X” marks on

the spider plate and sheave. Install the Dynojet helix. The

orientaion of the helix is not important. Apply blue loctite

and torque the retaining bolts to 48 in-lb (5 Nm).

Reinstall the primary clutch on the output shaft. Torque the

retaining bolt to 96 ft-lb (130 Nm). Reinstall the secondary

clutch onto the output shaft. Torque the retaining bolt to

38 ft-lb (52 Nm) Reinstall the drivebelt.

Remove the clutch arms using 3/8” socket and 1/8” allen key. Install the Dynojet clutch arms with the proper

amount of weight. Refer to chart on page 2. Replace the

stock spring with the Dynojet SILVER spring and reinstall

the spring cover. Tighten the 6mm bolts evenly to 9 ft-lb (12

Nm).

Remove the secondary

clutch. Use a 15mm socket

to remove the retaining bolt

and slide the secondary

clutch off the input shaft.

Remove the 4 torx head

bolts. The helix is under extreme spring pressure. Use

a clutch compression tool.

TUNING NOTES

For best performance your RPM when checked at 50mph

should be 8400rpm. This should be checked on a surface

that offers good traction and tested with normal load in the

vehicle. Adjustments to overall weight of each clutch arm

may be necessary to achieve this RPM target.

If you were to test on the street and then ride in the sand

or mud it is not uncommon to see a loss of 300-400rpm if

using paddle tires.

Our settings are based on using a PVCX tune in the ECM for

optimal performance.

TOOLS NEEDED FOR INSTALLATION

PULLER (2872085)

•

21MM SOCKET

•

15MM SOCKET

•

T27 TORX

•

3/8” SOCKET

•

1/8” ALLEN KEY

•

INSTALLATION GUIDE

Page 4

PUSH THE LIMIT.

WWW.DYNOJET.COM

© 2018 DYNOJET RESEARCH ALL RIGHTS RESERVED

Loading...

Loading...