Page 1

Page 2

©1999-2002 Dynojet Research, Inc. All Rights Reserved.

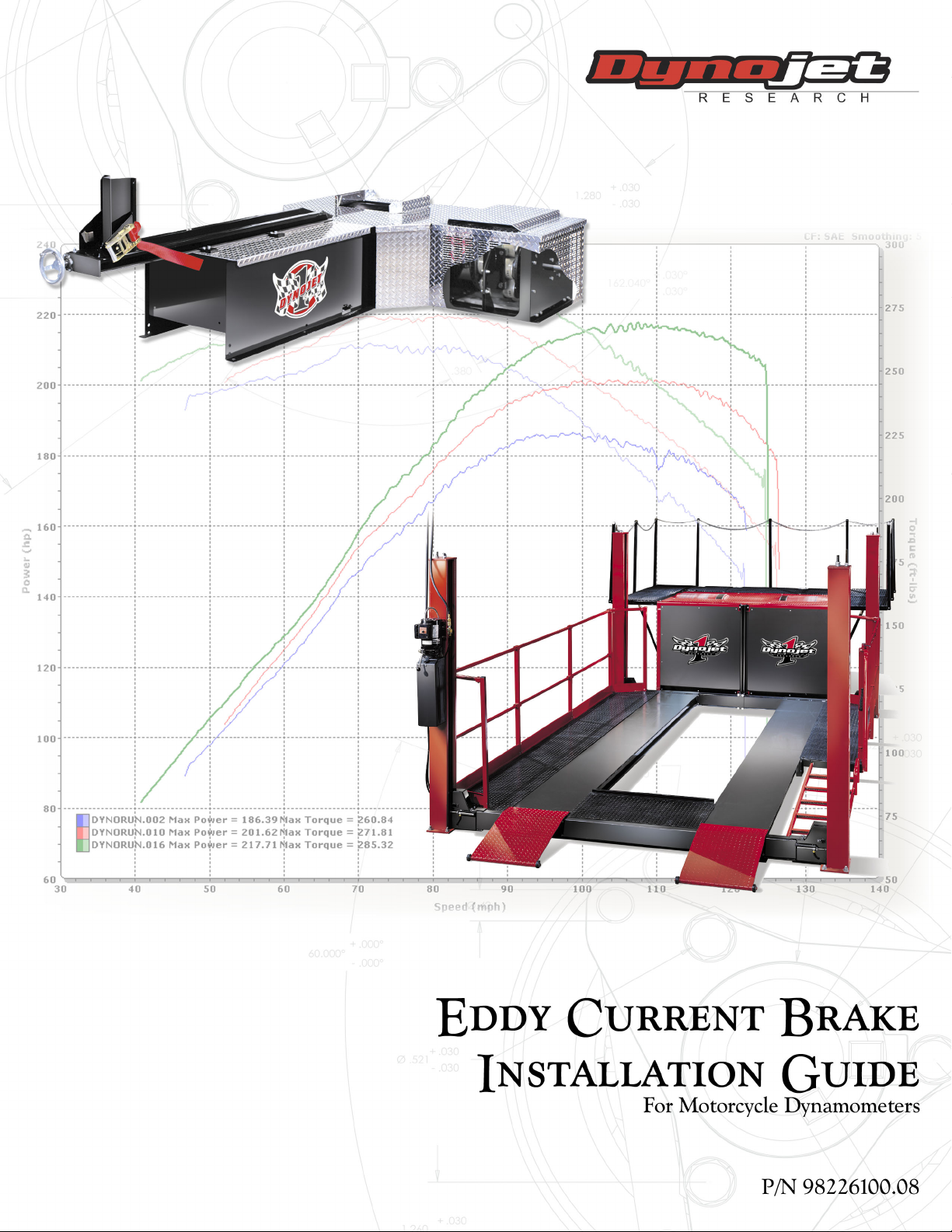

Eddy Current Brake Installation Guide For Motorcycle Dynamometers.

This manual is copyrighted by Dynojet Research, Inc., hereafter referred to as Dynojet,

and all rights are reserved. This manual is furnished under license and may only be used

or copied in accordance with the terms of such license. This manual is furnished for

informational use only, is subject to change without notice, and should not be construed

as a commitment by Dynojet. Dynojet assumes no responsibility or liability for any error

or inaccuracies that may appear in this manual. Except as permitted by such license, no

part of this manual may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, recording, or otherwise, without the prior

written permission of Dynojet.

The Dynojet logo is a trademark of Dynojet Research, Inc.

Any trademarks, trade names, service marks, or service names owned or registered by any

other company and used in this guide are the property of their respective companies.

Dynojet Research, Inc., 2191 Mendenhall Drive, North Las Vegas, Nevada 89031, USA.

Printed in USA.

Part Number: 98226100 Version 8 (03/02)

Page 3

T

ABLE OF

C

ONTENTS

List of Figures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Chapter 1 Eddy Current Brake Installation

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Unpacking the Eddy Current Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Removing the Dyno Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Air Brake and Manual Brake Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Removing the Air Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Removing the Manual Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Removing the Brake Caliper Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Eddy Current Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Adjusting the Brake for Right Side Installations . . . . . . . . . . . . . . . . . . . . . .1-9

Installing the Connecting Arms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Installing the Dyno Shaft Coupler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

Connecting the Eddy Current Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Aligning the Eddy Current Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

Coupling the Eddy Current Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Securing the Eddy Current Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

Theta Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Adjusting the Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

Drilling the Mounting Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Installing the Theta Controller—Left Side . . . . . . . . . . . . . . . . . . . . . . . . .1-20

Installing the Theta Controller—Right Side . . . . . . . . . . . . . . . . . . . . . . .1-22

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Replacing the Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-24

Changing the Input Power Cable Plug . . . . . . . . . . . . . . . . . . . . . . . . . . .1-26

Verifying the Eddy Current Brake Wiring Configuration . . . . . . . . . . . . . .1-26

Hood Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-27

Assembling the Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-27

Installing the Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-28

Eddy Current Brake Installation Guide

i

Page 4

TABLE OF CONTENTS

Appendix A Red Head Anchor Installation

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Contact Information for ITW Ramset/Red Head . . . . . . . . . . . . . . . . . . . . .A-1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Appendix B High Inertia Drum—Older Dyno Installation

Connecting the Eddy Current Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Appendix C Theta Controller—Internal Fuse

Replacing the Internal Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

Appendix D Mounting Templates

ii

Eddy Current Brake Installation Guide

Page 5

L

IST OF

Figure 1-1: Remove the Brake Cover and Hood Keepers . . . . . . . . . . . . . .1-3

Figure 1-2: Remove the Eddy Current Brake from the Crate . . . . . . . . . . .1-4

Figure 1-3: Remove the Hood. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Figure 1-4: Remove the Air Brake Solenoid Wires . . . . . . . . . . . . . . . . . . . . 1-5

Figure 1-5: Remove the Brake Wires from the Breakout Board . . . . . . . . .1-5

Figure 1-6: Air Brake—Remove the Springs. . . . . . . . . . . . . . . . . . . . . . . . .1-6

Figure 1-7: Air Brake—Remove the Master Cylinder. . . . . . . . . . . . . . . . . .1-6

Figure 1-8: Air Brake—Remove the Air Cylinder . . . . . . . . . . . . . . . . . . . . .1-7

Figure 1-9: Remove the Manual Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Figure 1-10: Remove the Brake Caliper Assembly. . . . . . . . . . . . . . . . . . . .1-8

Figure 1-11: Right Side Installation Set-up . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Figure 1-12: Remove the Connecting Arm Bolts. . . . . . . . . . . . . . . . . . . . .1-9

F

IGURES

Figure 1-13: Install the Connecting Arms . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Figure 1-14: Replace the Coupler Set Screws . . . . . . . . . . . . . . . . . . . . . .1-11

Figure 1-15: Install the Dyno Shaft Coupler . . . . . . . . . . . . . . . . . . . . . . .1-11

Figure 1-16: Remove the Connecting Bolts from the Dyno. . . . . . . . . . .1-12

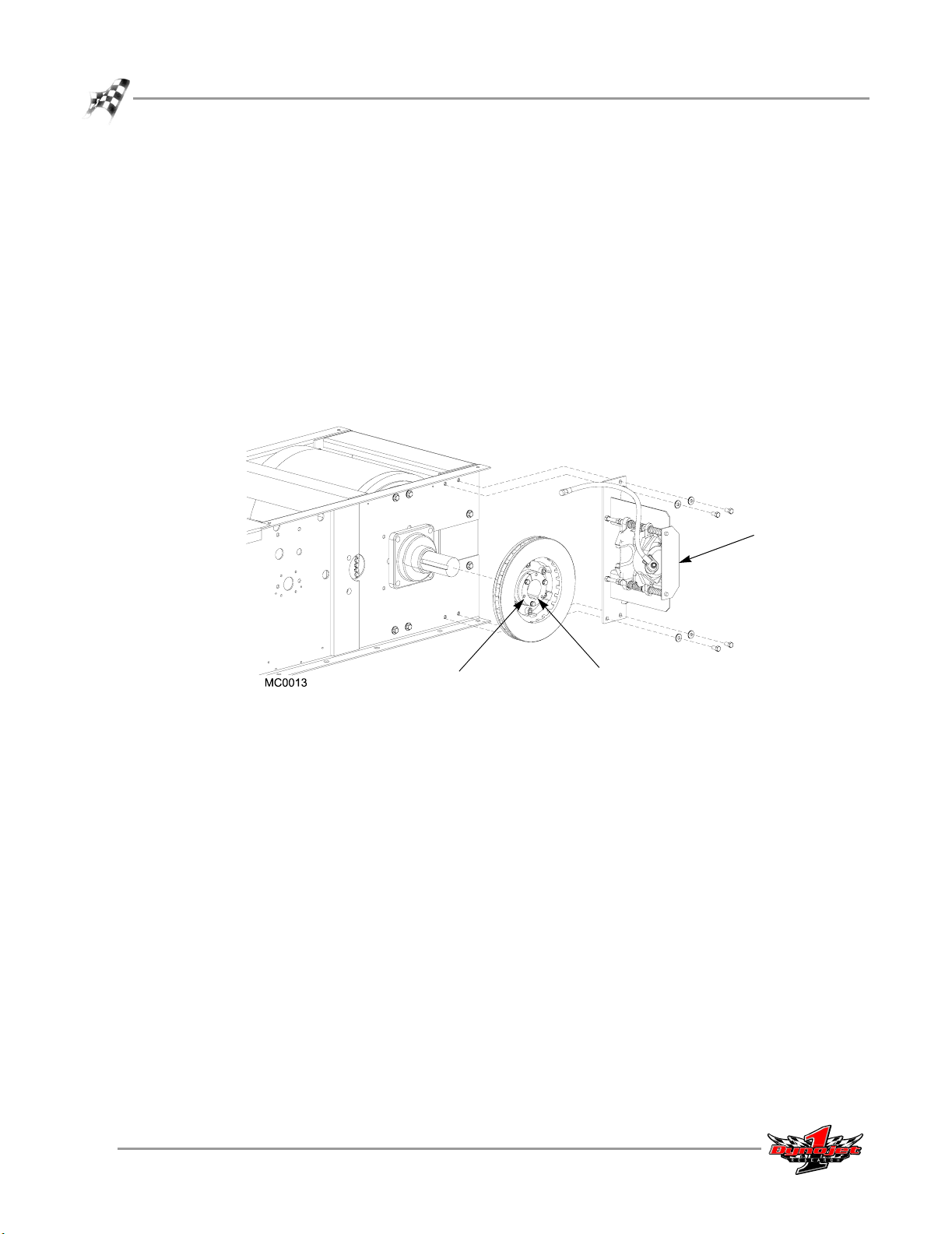

Figure 1-17: Connect the Eddy Current Brake . . . . . . . . . . . . . . . . . . . . .1-12

Figure 1-18: Align the Eddy Current Brake . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Figure 1-19: Secure the Couplers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

Figure 1-20: Secure the Brake to the Ground . . . . . . . . . . . . . . . . . . . . . .1-14

Figure 1-21: Theta Controller—Metal Plug . . . . . . . . . . . . . . . . . . . . . . . .1-15

Figure 1-22: Theta Controller—North America 120 VAC

Dip Switch Settings

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Eddy Current Brake Installation Guide

iii

Page 6

LIST OF FIGURES

Figure 1-23: Theta Controller—Europe and Australia 240 VAC

Figure 1-24: Theta Controller—Drill Mounting Holes on Left Side . . . . . 1-18

Figure 1-25: Theta Controller—Drill Mounting Holes on Right Side. . . . 1-19

Figure 1-26: Theta Controller—Install on Left Side. . . . . . . . . . . . . . . . . .1-20

Figure 1-27: Theta Controller—Routing the Cables on Left Side . . . . . .1-21

Figure 1-28: Theta Controller—Install on Right Side . . . . . . . . . . . . . . . .1-22

Figure 1-29: Theta Controller—Routing the Cables on Right Side . . . . . 1-22

Figure 1-30: Theta Controller—Remove the Breakout Board Cover . . . .1-23

Figure 1-31: Theta Controller—Breakout Board Wiring and

Figure 1-32: Theta Controller—Replace the Fuse . . . . . . . . . . . . . . . . . . .1-24

Figure 1-33: Theta Controller—Determine the Type . . . . . . . . . . . . . . . .1-25

Dip Switch Settings

Jumper Settings

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Figure 1-34: Theta Controller—Input Power Cable Plug . . . . . . . . . . . . . 1-26

Figure 1-35: Theta Controller —Eddy Current Brake Wiring . . . . . . . . . .1-26

Figure 1-36: Dyno Hood Side Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-27

Figure 1-37: Secure Eddy Current Brake Cover to Dyno Hood . . . . . . . . 1-27

Figure 1-38: Install the New Dyno Hood . . . . . . . . . . . . . . . . . . . . . . . . . .1-28

Figure 1-39: Secure the Hood Clamps and Brake Cover . . . . . . . . . . . . .1-28

Figure A-1: Red Head Anchor—Drill the Hole . . . . . . . . . . . . . . . . . . . . . . .A-2

Figure A-2: Red Head Anchor—Insert the Anchor. . . . . . . . . . . . . . . . . . . .A-2

Figure A-3: Red Head Anchor—Drive the Anchor Flush . . . . . . . . . . . . . . .A-3

Figure A-4: Red Head Anchor—Expand the Anchor . . . . . . . . . . . . . . . . . .A-3

Figure B-1: High Inertia Drum—Measure the Axle . . . . . . . . . . . . . . . . . . .B-1

Figure B-2: High Inertia Drum—Remove Nuts and Washers . . . . . . . . . . .B-2

Figure B-3: High Inertia Drum—Connect Brake . . . . . . . . . . . . . . . . . . . . .B-2

Figure C-1: Theta Controller—Replace Internal Fuse . . . . . . . . . . . . . . . . .C-1

iv

Eddy Current Brake Installation Guide

Page 7

E

DDY

C

URRENT

C HAPTER

B

RAKE INSTALLATION

1

This document provides instructions for installing the Eddy Current Brake (retarder)

optional hardware to Dynojet’s Model 150 and 200 Motorcycle Dynamometers. To

ensure safety and accuracy in the procedures, perform the procedures as they are

described.

Document Part Number: 98226100

Versio n 8

Last Updated: 03-29-02

CONVENTIONS

The conventions used in this manual are designed to protect both the user and the

equipment.

example of convention description

The Caution icon indicates a potential hazard to the

dynamometer equipment. Follow all procedures

exactly as they are described and use care when

performing all procedures.

The Warning icon indicates potential harm to the

person performing a procedure and/or the

dynamometer equipment.

TECHNICAL SUPPORT

For assistance, please contact Dynojet Technical Support at 1-800-992-3525, or write

to Dynojet at 2191 Mendenhall Drive, North Las Vegas, NV 89031.

Visit us on the World Wide Web at www.dynojet.com where Dynojet provides state of

the art technical support, on-line shopping, 3D visualizations, and press releases

about our latest product line.

Eddy Current Brake Installation Guide

1-1

Page 8

CHAPTER 1

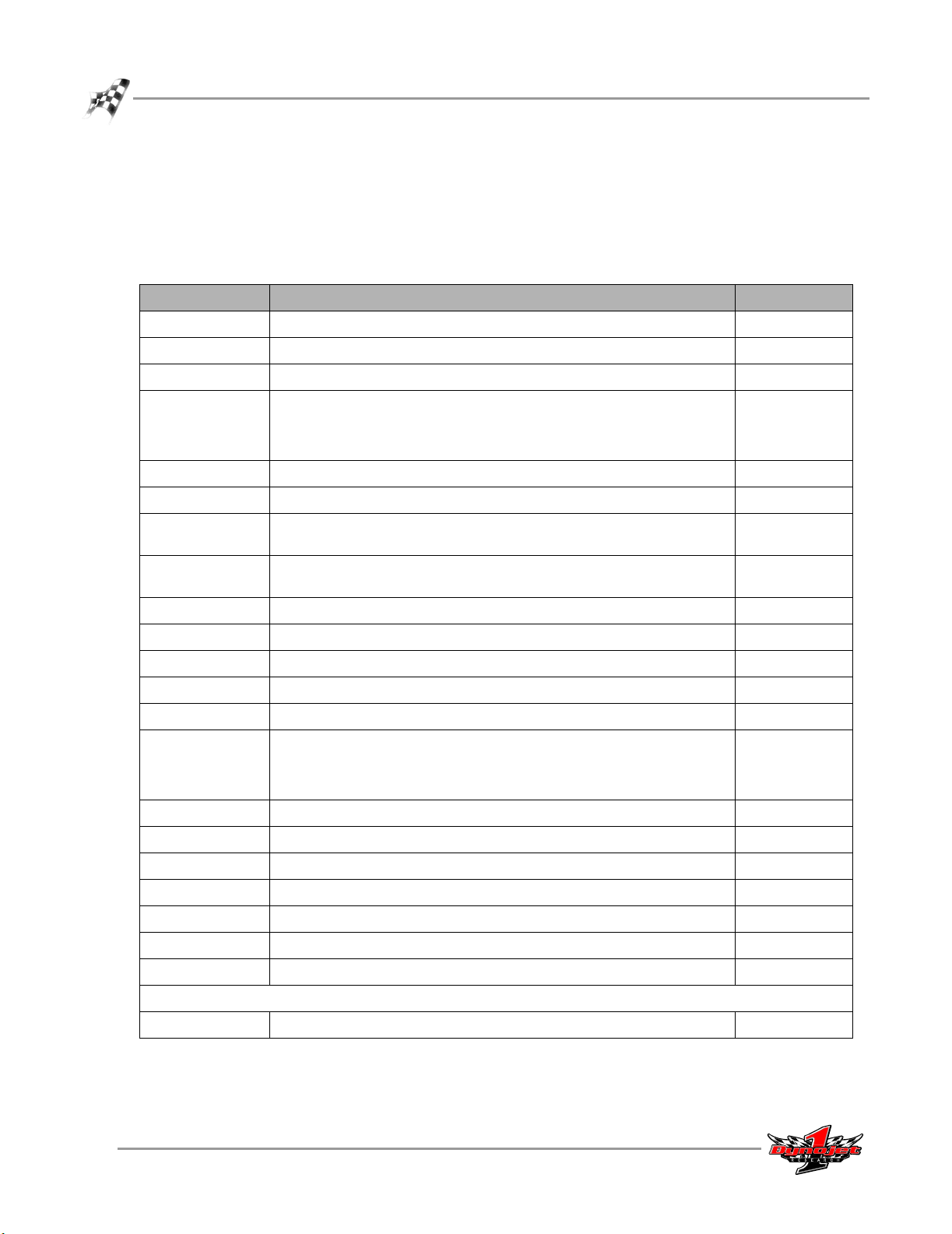

Parts List

PARTS LIST

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The following table lists all of the parts included in the Eddy Current Brake

Installation kit. Check your kit against the parts listed to make sure you have received

all of the parts. If any part is missing, contact Dynojet Technical Support.

part number description quantity

197104130 4" Zip Tie 4

25111310 Clamp, Retarder Hood 2

61229101 Hood Assembly, M/C Retarder 1

62992001

Or

62992002

29250001 Mod-Key, 1/2 x 7/16 x 2" 1

29250002 Key, 3/8 x 3/8 x 2" (installed) 1

Retarder-Generic

Or

Retarder-Generic, European

1

32431332 Male Coupler, mounted on eddy current brake

32431333 Female Coupler Assembly with four set screws

36488101 Nut, 3/8-16, Hex, W/Tlok 5

36581270 Bolt, 3/8-16 x 3/4", W/Tlok 28

36581670 Bolt, 3/8-16 x 1", W/Tlok (for right side installation) 4

43312200 Grommet, 1-5/8OD x 1-3/8ID (one is installed) 2

61329105 Connecting Rod Sub-Assembly 2

66411002

Or

66411003

66952004 Power Cable, M/C Retarder Sub-Assembly 1

DC100-104 Pendant and Cable 1

DM150-002-007 5/16" Flat Washer 8

DM150-033 Rubber Grommet 1

(with male coupler hub, P/N 32431330, installed)

(with female coupler hub, P/N 32431331, installed)

Theta-2 Controller-120V

Or

Theta-2 Controller-240V

Red Head Anchor Kit 1

Theta Controller Mounting Hole Drill Template For Left Side Mounting 1

Theta Controller Mounting Hole Drill Template For Right Side Mounting 1

1

1

1

The following part number should be used when replacing all of the coupler pieces:

78122002 Coupler Kit

1-2

Eddy Current Brake Installation Guide

Page 9

EDDY CURRENT BRAKE INSTALLATION

PREPARATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This section describes how to unpack the eddy current brake and remove the hood

from your dyno.

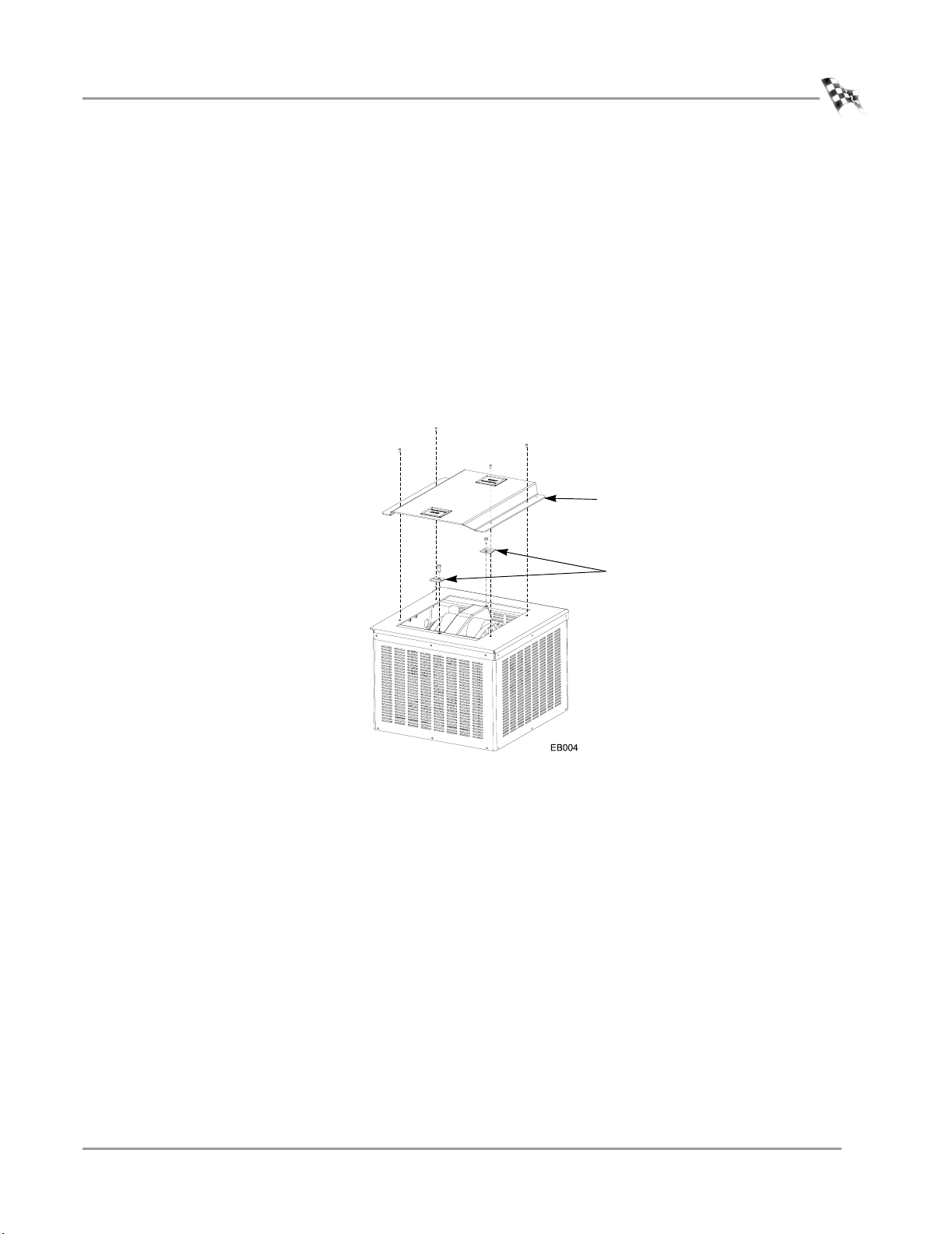

UNPACKING THE EDDY CURRENT BRAKE

1 Remove the top and sides of the crate.

2 If you ordered a hood upgrade, remove the new hood from the crate.

3 Remove the four bolts securing the eddy current brake cover and set aside.

4 Remove the two bolts securing the hood clamps to the brake and set aside.

5 Remove the hardware box from the crate and verify the hardware box contents.

Refer to the parts list on page 1-2.

brake cover

Preparation

hood clamps

Figure 1-1: Remove the Brake Cover and Hood Keepers

Vers ion 8 Eddy Current Brake Installation Guide

1-3

Page 10

CHAPTER 1

Preparation

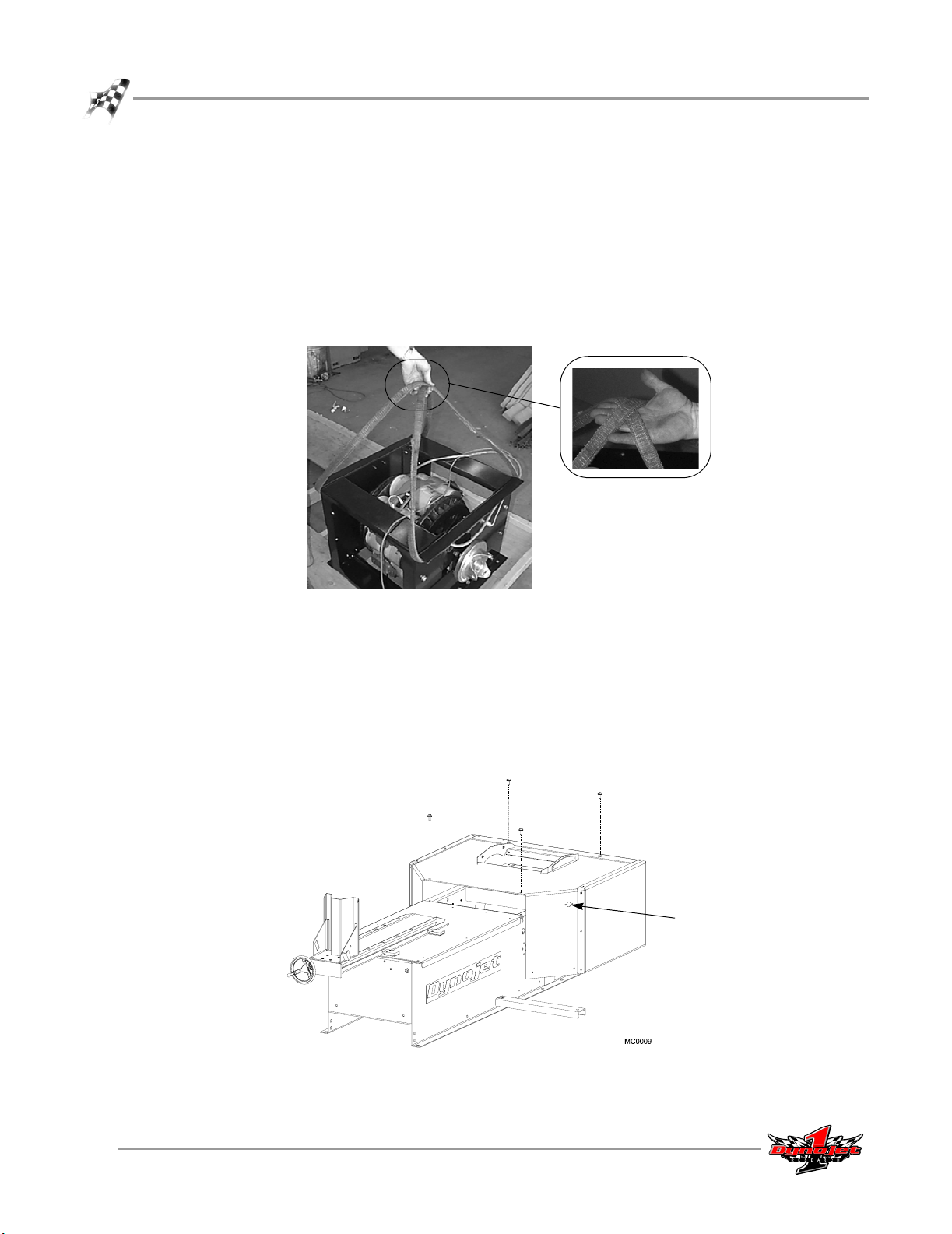

6 Remove the eddy current brake from the crate.

Note: Dynojet recommends using a continuous nylon loop style strap to lift the

eddy current brake from the crate.

6a Remove the bolts securing the eddy current brake to the crate.

6b Place the nylon loop strap around the top of the brake frame making sure it

crosses as shown in Figure 1-2.

6c Using the nylon loop strap, remove the eddy current brake from the crate

and place it near the dyno.

Figure 1-2: Remove the Eddy Current Brake from the Crate

REMOVING THE DYNO HOOD

1 Remove the four bolts securing the hood to the dyno and set aside. Prop up the

hood.

2 If present, disconnect the wires to the key switch.

3 Remove the hood from the dyno and set aside.

4 Disconnect all battery wires.

key switch

1-4

Eddy Current Brake Installation Guide

Figure 1-3: Remove the Hood

Page 11

EDDY CURRENT BRAKE INSTALLATION

Air Brake and Manual Brake Removal

AIR BRAKE AND MANUAL BRAKE REMOVAL

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This section describes how to remove both the air brake and the manual brake, the

brake caliper assembly, and the rotor.

If you are mounting the eddy current brake on the right side of your dyno, you do not

need to remove the air or manual brake.

Note: Safety requirements of your local country may require that both brakes are

installed. Be sure to follow the safety requirements specific to your country.

REMOVING THE AIR BRAKE

1 Disconnect all air lines from the dyno.

2 Disconnect the brake electrical wires.

• Model 150 dynos: Disconnect the brake wires from the electrical block

mounted on the center of the dyno frame. Refer to the DynoWare EX+

Upgrade manual for more information.

air brake

solenoid wires

loosen screws

Figure 1-4: Remove the Air Brake Solenoid Wires

• Upgraded Model 150/Model 200 dynos: Disconnect the brake wires from

the Breakout board located on the side of the dyno.

brake wires

Figure 1-5: Remove the Brake Wires from the Breakout Board

Vers ion 8 Eddy Current Brake Installation Guide

1-5

Page 12

CHAPTER 1

Air Brake and Manual Brake Removal

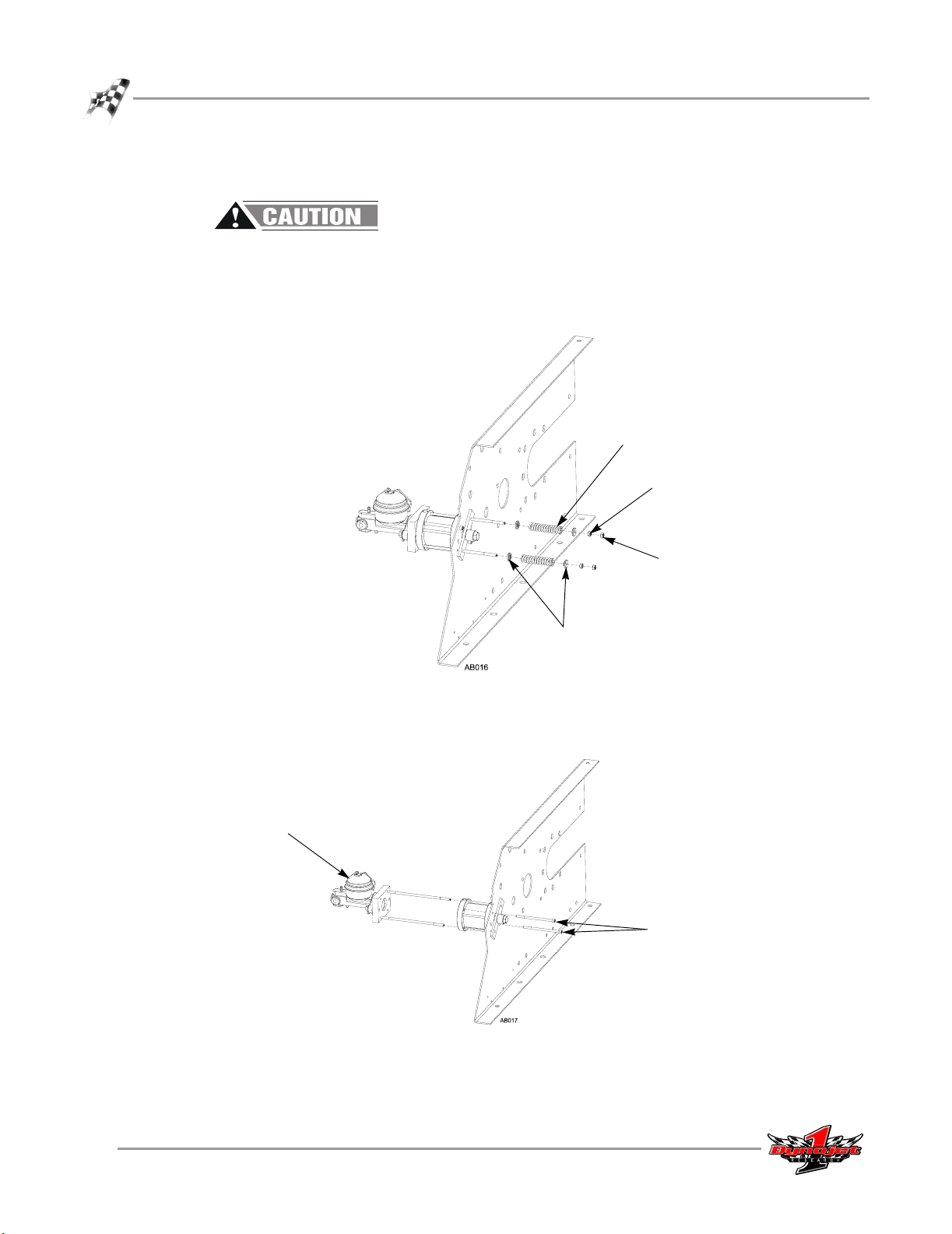

3 Remove the jam nuts, adjuster nuts, retainers, and springs.

The springs are compressed. Use caution when removing the springs.

4 Disconnect the brake line from the master cylinder to the caliper.

Note: Make sure you have disconnected all air lines and released the tension in

the springs before disconnecting the brake line.

cut away view of dyno

side panel

spring

adjuster nut

jam nut

retainer

Figure 1-6: Air Brake—Remove the Springs

5 Remove the two bolts securing the master cylinder to the air cylinder using a

3/16-inch allen wrench. Remove the master cylinder.

master cylinder

bolts

1-6

Eddy Current Brake Installation Guide

Figure 1-7: Air Brake—Remove the Master Cylinder

Page 13

EDDY CURRENT BRAKE INSTALLATION

Air Brake and Manual Brake Removal

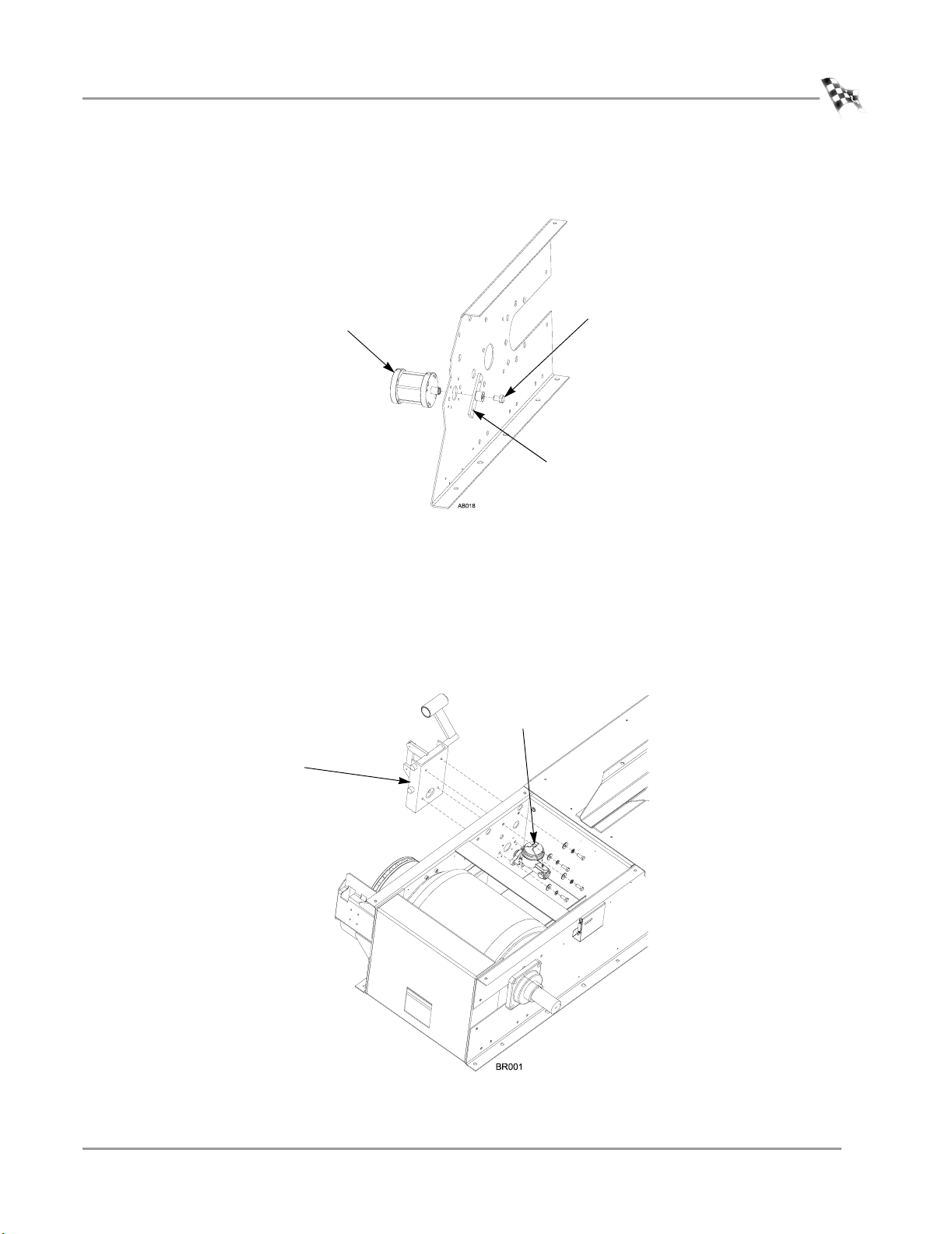

6 Remove the bolt securing the spring bolt mounting plate.

7 Remove the mounting plate and the air cylinder from the dyno frame.

air cylinder

Figure 1-8: Air Brake—Remove the Air Cylinder

REMOVING THE MANUAL BRAKE

1 Disconnect the brake line from the master cylinder to the caliper.

2 Remove the four bolts, lock washers, and flat washers that secure the master

cylinder and foot pedal.

The bolts run from the inside, through the master cylinder, and into the foot

pedal mounting plate.

foot pedal

bolt

mounting plate

master cylinder

Figure 1-9: Remove the Manual Brake

Vers ion 8 Eddy Current Brake Installation Guide

1-7

Page 14

CHAPTER 1

Air Brake and Manual Brake Removal

REMOVING THE BRAKE CALIPER ASSEMBLY

1 Remove the four bolts and washers that secure the caliper assembly.

2 Loosen the brake pads and remove the assembly.

Note: Do not put the bolts back into the dyno frame. The holes will be used to

mount the eddy current brake to the dyno.

3 Loosen the set screw above the keyway in the drum axle using a 3/16-inch allen

wrench.

4 Remove the three 5/16-inch bolts in the lock collar and insert these bolts in the

three threaded holes in the lock collar. Tighten the bolts until the collar comes

loose.

5 Slide the rotor and lock collar off the drum axle and remove the key.

caliper assembly

lock collar

Figure 1-10: Remove the Brake Caliper Assembly

key way

1-8

Eddy Current Brake Installation Guide

Page 15

EDDY CURRENT BRAKE INSTALLATION

EDDY CURRENT BRAKE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The eddy current brake can be installed on either the left or right side of the dyno. Be

sure to check the dyno drum axle for damage or rust and carefully file any marks flush

with the axle.

ADJUSTING THE BRAKE FOR RIGHT SIDE INSTALLATIONS

Make the following adjustments to the eddy current brake only if the brake will be

mounted on the right side of the dyno.

1 Move the coupler and key to the other side of the brake.

2 Move the sensor temperature cable and power cable to the other side of the

brake.

Eddy Current Brake

power cable

temp sensor cable

Figure 1-11: Right Side Installation Set-up

INSTALLING THE CONNECTING ARMS

Attach the upper and lower connecting arms on the corresponding side of the eddy

current brake. The connecting arms are identical and interchangeable.

1 Remove the eight 3/8-inch bolts and washers from the side of the eddy current

brake.

Figure 1-12: Remove the Connecting Arm Bolts

coupler

remove

Vers ion 8 Eddy Current Brake Installation Guide

1-9

Page 16

CHAPTER 1

Eddy Current Brake

2 Loosely attach one of the connecting arms to the bottom of the eddy current

3 Loosely attach the remaining connecting arm to the top of the eddy current brake

brake using four 3/8-inch bolts and four 3/8-inch washers.

using four 3/8-inch bolts and four 3/8-inch washers.

Note: All eight bolts need to remain loose in order to align the brake.

connecting arm

bolt (only one visible

from this view

washer

Figure 1-13: Install the Connecting Arms

1-10

Eddy Current Brake Installation Guide

Page 17

INSTALLING THE DYNO SHAFT COUPLER

1 Replace the existing set screw in the key way of each coupler with the thread-lock

set screws provided.

Note: Replace the dyno shaft coupler set screw before installing the coupler on

the shaft.

set screw

EDDY CURRENT BRAKE INSTALLATION

Eddy Current Brake

key way

eddy current brake coupler

Figure 1-14: Replace the Coupler Set Screws

2 Insert the key into the keyway.

3 Slide the coupler over the key on the axle.

Note: Do not tighten the set screw in the coupler.

key way

set screw

dyno shaft coupler

coupler

key way

Figure 1-15: Install the Dyno Shaft Coupler

Vers ion 8 Eddy Current Brake Installation Guide

1-11

Page 18

CHAPTER 1

Eddy Current Brake

CONNECTING THE EDDY CURRENT BRAKE

The following instructions and figures show the eddy current brake mounting to the

left side of the dyno; however, the instructions are the same for both left and right

side installations.

Use the following instructions to install the eddy current brake to both the standard

and high inertia drums. If you have a high inertia drum, refer to Appendix B for

installation details.

1 If not already removed, remove the bolts and washers from the dyno frame as

shown in Figure 1-16.

remove

do not remove

remove

Figure 1-16: Remove the Connecting Bolts from the Dyno

2 Place the eddy current brake next to the dyno.

3 Line up the connecting arms with the dyno and loosely attach the arms to the

dyno using four 3/8-inch bolts and 3/8-inch washers for each arm. These bolts

need to remain loose in order to align the brake

Note: If you have an older dyno with no threaded insert, you will also need to use

3/8-inch nuts with threadlock on the inside of the dyno side panel.

1-12

Eddy Current Brake Installation Guide

Figure 1-17: Connect the Eddy Current Brake

Page 19

ALIGNING THE EDDY CURRENT BRAKE

Eddy current brake and coupler alignment is very important. You must follow

these instructions very carefully to ensure proper alignment and function.

Dynojet will not warranty any coupler that is damaged due to improper

installation.

1 Place a straight edge with a notch across the apex of the drum with the notch

across the eddy current brake.

2 Using the straight edge as a guide, measure the distance to the collars on the axle

shaft of the eddy current brake (not the black bearing lock collars).

3 Place shims between the floor and the eddy current brake or dyno until the

collars are 7 19/32-inch (19.288 cm), +/- 1/16-inch (1.58 mm), down from the top

of the drum on the dyno.

4 Torque all the bolts securing the connecting arms to the dyno and to the eddy

current brake to 33 ft. lb. (45 N-m). Verify the height and make sure nothing has

moved.

EDDY CURRENT BRAKE INSTALLATION

Eddy Current Brake

straight edge

with notch

7 19/32 inches

(19.288 cm)

eddy current

brake

collars on axle shaft

Figure 1-18: Align the Eddy Current Brake

connecting arms

drum

Vers ion 8 Eddy Current Brake Installation Guide

1-13

Page 20

CHAPTER 1

Eddy Current Brake

COUPLING THE EDDY CURRENT BRAKE

Coupler alignment is very important. You must follow these directions very

carefully to ensure proper alignment and function. Dynojet will not warranty

any coupler that is damaged due to improper installation.

1 Slide the dyno coupler over the eddy current brake coupler so the three holes in

each of the couplers line up.

2 Secure the couplers together using three 3/8-inch bolts and tighten to 33-37 ft. lb.

(45-50 N-m).

3 Verify the key has not moved laterally.

4 Tighten the set screws in the couplers to 24 ft. lb. (29-33 N-m).

set screws

bolts

Figure 1-19: Secure the Couplers

SECURING THE EDDY CURRENT BRAKE

Note: Dynojet recommends you anchor the dyno to the floor in your dyno room

as well.

1 Install the Red Head Anchors. Refer to Appendix A for Red Head Anchor

installation instructions.

2 Secure the eddy current brake to the ground.

1-14

Eddy Current Brake Installation Guide

Figure 1-20: Secure the Brake to the Ground

Page 21

EDDY CURRENT BRAKE INSTALLATION

THETA CONTROLLER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This section describes how to install the Theta Controller, make power adjustments,

and replace the fuses.

ADJUSTING THE POWER

Newer Theta Controllers are capable of operating at either 60 Hz or 50Hz and are able

to compensate for a lower AC line voltage allowing improved performance under

varying AC power conditions. Each Theta Controller is designed for either the 240

VAC or the 120 VAC range and are not interchangeable. Each eddy current brake is

wired for either 240 VAC or 120 VAC operation and must match the specific Theta

Controller for the desired line voltage.

To determine whether a Theta Controller is capable of power adjustments, look for a

metal plug on the bottom of the Theta Controller. Refer to Figure 1-21. If this metal

plug is not present, the Theta Controller is not capable of power line frequency

selection. Continue with the installation instructions.

Hazardous voltage. To avoid risk of electrical shock, disconnect the power cord

to the Theta Controller. Do not remove the cover. No user serviceable parts

inside.

Theta Controller

The two dip switches are the only adjustments that can be altered. Be sure not

to damage any other parts on the circuit board. Do not attempt any other

adjustments.

Dynojet recommends you set the dip switches at the time of installation.

1 Remove the metal plug from the bottom of the Theta Controller.

2 Use a small screwdriver to set the dip switches for the desired line voltage.

Refer to “120 VAC Theta Controller (P/N 66411002)” on page 1-16 and “240 VAC

Theta Controller (P/N 66411003)” on page 1-17 for more information on dip

switch settings.

3 Replace the metal plug.

metal plug

Figure 1-21: Theta Controller—Metal Plug

Vers ion 8 Eddy Current Brake Installation Guide

1-15

Page 22

CHAPTER 1

Theta Controller

120 VAC THETA CONTROLLER (P/N 66411002)

The 120 VAC Theta Controller is designed for operation in North America and Japan

and is identified by a single external fuse holder. This controller is nominally

calibrated for 115 to 120 VAC line voltage; in Japan, the nominal line voltage is 100

VAC and the dip switch on the Theta Controller can be set to compensate for the

reduced line voltage while still providing the full output current of 20 amps.

Note: This controller cannot be converted to operate on 240 VAC line voltage.

Power Line Frequency Adjustment—The Theta Controller is shipped with the dip

switch set for 60 Hz. For all of North America, this switch should be set to the 60 Hz

position. In Japan, there may be either 50 Hz or 60 Hz power line frequency;

determine the correct line frequency and set the switch accordingly.

Power Line Voltage Adjustment—The Theta Controller is shipped with the dip

switch set for normal (NORM) line voltage. In the NORM position, the controller is

calibrated for a nominal 115 to 120 VAC line voltage. For all of North America, this

switch should be set to the NORM position. In Japan, the nominal line voltage is rated

for 100 VAC and the dip switch should be set to the LO position.

In some cases in North America, it may be necessary to set the dip switch to the LO

position when the AC line voltage is consistently around or below 110 VAC and

combined with reduced brake performance.

• Measure the AC line voltage with all normal AC loads running in the shop (lights,

heater, etc.).

• If the line voltage is reduced to or below 110 VAC and remains at these levels, move

the switch to the LO position. This will boost the output current with the lower AC

power voltages.

Note: Be sure to review and comply with the model 250 motorcycle dyno

installation requirements before setting the dip switch to the LO position. The

Theta Controller should be on its own dedicated AC power circuit.

Note: If the AC power voltage returns above the 115 VAC range while the dip

switch is set to LO, overheating and damage to the eddy current brake or fuse

failure may result. Review the LO/NORM dip switch position setting and re-

measure your incoming AC line voltage.

1-16

Eddy Current Brake Installation Guide

Figure 1-22: Theta Controller—North America 120 VAC Dip Switch Settings

Page 23

EDDY CURRENT BRAKE INSTALLATION

Theta Controller

240 VAC THETA CONTROLLER (P/N 66411003)

The 240 VAC Theta Controller is identified by the two external fuse holders. The 240

VAC Theta Controller is calibrated for a nominal 230 to 240 VAC line voltage; in

certain countries, line voltages of 210 to 220 VAC may be encountered and the dip

switch can be set to provide full output current of 10 amps even with the reduced line

voltage.

Note: This controller cannot be converted to operate on 120 VAC line voltage.

Power Line Frequency Adjustment—The Theta Controller is shipped with the dip

switch set for 50 Hz. Determine the correct line frequency and set the switch

accordingly.

Power Line Voltage Adjustment—The Theta Controller is shipped with the dip

switch set for normal (NORM) line voltage. In the NORM position, the controller is

calibrated for a nominal 235 to 240 VAC line voltage.

In some cases in Europe, it may be necessary to set the dip switch to the LO position

when the AC line voltage is consistently around or below 225 VAC and combined with

reduced brake performance.

• Measure the AC line voltage with all normal AC loads running in the shop (lights,

heater, etc.).

• If the line voltage is reduced to or below 225 VAC and remains at these levels, move

the switch to the LO position. This will boost the output current with the lower AC

power voltages.

Note: Be sure to review and comply with the model 250 motorcycle dyno

installation requirements before setting the dip switch to the LO position. The

Theta Controller should be on its own dedicated AC power circuit.

Note: If the AC power voltage returns above the 230 VAC range while the dip

switch is set to LO, overheating and damage to the eddy current brake or fuse

failure may result. Review the LO/NORM dip switch position setting and re-

measure your incoming AC line voltage.

Figure 1-23: Theta Controller—Europe and Australia 240 VAC Dip Switch Settings

Vers ion 8 Eddy Current Brake Installation Guide

1-17

Page 24

CHAPTER 1

Theta Controller

DRILLING THE MOUNTING HOLES

Depending on the age of your dyno, you may need to drill the holes needed to mount

the Theta Controller. If your dyno already has the required holes, skip these steps and

continue with the installation.

LEFT SIDE INSTALLATION

1 Locate the template for left side installations included with the control box.

This template can also be found in Appendix D.

2 Locate the large hole on the left side of the dyno. This hole should have four

smaller holes around it.

3 Place the template on the dyno. Line the template up using the large hole and the

four smaller holes around it.

4 Mark and drill the four mounting holes to 3/16-inch (5 mm).

Note: Make sure no metal chips come in contact with the electrical components.

large hole

template

Figure 1-24: Theta Controller—Drill Mounting Holes on Left Side

1-18

Eddy Current Brake Installation Guide

Page 25

RIGHT SIDE INSTALLATION

1 Locate the template for right side installations included with the control box.

This template can also be found in Appendix D.

2 Place the template on the dyno. Line the template up using the existing hole and

the bottom lip of the dyno frame.

3 Mark and drill the three mounting holes to 3/16-inch (5 mm).

Note: Make sure no metal chips come in contact with the electrical components.

Breakout board

template

EDDY CURRENT BRAKE INSTALLATION

Theta Controller

existing hole

Figure 1-25: Theta Controller—Drill Mounting Holes on Right Side

Vers ion 8 Eddy Current Brake Installation Guide

1-19

Page 26

CHAPTER 1

Theta Controller

INSTALLING THE THETA CONTROLLER—LEFT SIDE

The Theta Controller is mounted on the left side of the dyno regardless of which side

the eddy current brake is on. The only exception is when the air brake is mounted on

the left side and the eddy current brake is mounted on the right side. Refer to

“Installing the Theta Controller—Right Side” on page 1-22 for more information.

Be sure to set the dip switch power settings before installation.

1 Attach the input power cable to the Theta Controller as shown in Figure 1-27.

2 Place the large rubber grommet over the plug on the eddy current brake power

cable.

3 Route the brake power cable through the dyno as shown in Figure 1-27 and attach

the cable to the Theta Controller. Secure the rubber grommet in the hole.

4 Secure the Theta Controller to the dyno using four No. 8 screws and lock

washers.

1-20

Eddy Current Brake Installation Guide

Figure 1-26: Theta Controller—Install on Left Side

Page 27

EDDY CURRENT BRAKE INSTALLATION

Theta Controller

5 Route the input power cable under and out the front of the dyno.

6 Insert the smaller rubber grommet as shown in Figure 1-27.

7 Route the temperature sensor cable from the eddy current brake through the

dyno to the Breakout board.

8 Route the control cable from the Theta Controller to the Breakout board.

brake power

cable

large

grommet

control cable

Figure 1-27: Theta Controller—Routing the Cables on Left Side

small

grommet

Breakout board

temp sensor

cable

input power

cable

Vers ion 8 Eddy Current Brake Installation Guide

1-21

Page 28

CHAPTER 1

Theta Controller

INSTALLING THE THETA CONTROLLER—RIGHT SIDE

1 Install the Theta Controller using four No. 8 screws and washers. The screws will

mount from the inside of the dyno.

Figure 1-28: Theta Controller—Install on Right Side

2 Attach the input power cable to the Theta Controller and route the input power

cable along the side of the dyno.

3 Attach the eddy current brake cable to the Theta Controller.

Note: Make sure the brake power cable is clear of the coupler.

4 Attach the temperature sensor cable from the eddy current brake to the Breakout

board.

5 Attach the control cable from the Theta Controller to the Breakout board.

temp sensor cable

Breakout board

brake power

cable

Figure 1-29: Theta Controller—Routing the Cables on Right Side

control cable

input power cable

1-22

Eddy Current Brake Installation Guide

Page 29

WIRING

EDDY CURRENT BRAKE INSTALLATION

Theta Controller

1 Remove the four screws securing the Breakout board and cover. Set the cover

aside.

Breakout board

and cover

Figure 1-30: Theta Controller—Remove the Breakout Board Cover

2 Attach the temperature cable to the Breakout board. The temperature cable has

five wires which connect to the wiring block labeled TEMP.

• Green wire connects to G1 • White wire connects to W1

• Black wire connects to B1 • Red wire connects to R1

• Ground (shield) wire connects to S1

3 Attach the control cable to the Breakout board. The control cable has five wires

which connect to the wiring block labeled LOAD CONTROL.

• Black wire connects to V- • Red wire connects to V+

• White wire connects to O+ • Green wire connects to O-

• Ground (shield) wire connects to SH

4 Verify jumpers J1 and J2 are set either for the eddy current brake only or for the

eddy current and air brake as shown in Figure 1-31.

5 Replace the Breakout board cover using the four screws removed earlier.

load control

eddy current brake only

jumper settings

jumpers

J1 and J2

temp

eddy current and air

brake jumper settings

Figure 1-31: Theta Controller—Breakout Board Wiring and Jumper Settings

Vers ion 8 Eddy Current Brake Installation Guide

1-23

Page 30

CHAPTER 1

Theta Controller

REPLACING THE FUSE

Older Theta Controllers have an internal fuse. Refer to Appendix C for more

information on replacing an internal fuse.

Hazardous voltage. To avoid risk of electrical shock, disconnect the power cord

to the Theta Controller before replacing the fuse. Do not remove the cover. No

user serviceable parts inside.

1 Remove the Theta Controller from the dyno. Refer to Figure 1-26 or Figure 1-28.

2 Gently push the fuse holder slightly inward and rotate counterclockwise to

remove.

3 Replace the fuse. Refer to the table on page 1-25 for fuse replacement types.

For continued protection against risk of fire, replace only with a fuse of the

same type and having the same electrical rating.

1-24

Eddy Current Brake Installation Guide

Figure 1-32: Theta Controller—Replace the Fuse

Page 31

EDDY CURRENT BRAKE INSTALLATION

Theta Controller

To determine whether you have a 120 volt or 240 volt Theta Controller, look at

the serial number/fuse(s) on the Theta Controller. If the serial number begins

with an “E”, and the control box has dual fuses, then it is a 240 volt unit; if the

serial number does not begin with an “E” and the control box has a single fuse,

then it is a 120 volt unit.

120 volt, single fuse

North America

Theta Controller replacement fuse

240 volt Buss P/N BAF-15, 15A Fuse

120 volt Buss P/N BAF-25, 25A Fuse

Note: Changing the fuse rating to the higher or lower specification does not allow

you to use the Theta Controller with an eddy current brake that was wired for

120 volt or 240 volt originally. Refer to “Verifying the Eddy Current Brake Wiring

Configuration” on page 1-26.

Note: If the eddy current brake has been rewired to a different voltage, you will

need a different Theta Controller. The original Theta Controller will not work.

Figure 1-33: Theta Controller—Determine the Type

Little Fuse, KLK 15

Fast Blow, Dynojet P/N 54211201

Little Fuse, KLK 25

Fast Blow, Dynojet P/N 54202501

240 volt, dual fuses

Europe/Australia

Vers ion 8 Eddy Current Brake Installation Guide

1-25

Page 32

CHAPTER 1

Theta Controller

CHANGING THE INPUT POWER CABLE PLUG

If the input power cable is not provided with a power plug, you must install the

correct power plug for your country. The input power cable plug must connect to a

properly grounded outlet and be easily accessible so that it may be disconnected. Do

not wire the input power cable directly into the power panel. Refer to Figure 1-34 for

individual wire descriptions.

Note: The eddy current brake is set up to run on 120 volts/20 amps/60 Hz for

North America and 240 volts/10 amps/50 Hz for Europe/Australia.

Note: The voltage source and power plug must be capable of handling a

minimum of 20 amps for North America and 10 amps for Europe/Australia.

neutral—clear or white

insulation wire

hot—black insulation wire

ground—bare or

green wire

Figure 1-34: Theta Controller—Input Power Cable Plug

VERIFYING THE EDDY CURRENT BRAKE WIRING CONFIGURATION

Refer to Figure 1-35 to determine whether the eddy current brake is currently wired

for 120 or 240 volt operation.

120 volt wiring, North America

Figure 1-35: Theta Controller —Eddy Current Brake Wiring

240 volt wiring, Europe/Australia

1-26

Eddy Current Brake Installation Guide

Page 33

EDDY CURRENT BRAKE INSTALLATION

HOOD UPGRADE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Use the following instructions to assemble and install the hood upgrade or to attach

the eddy current brake cover to your existing hood.

ASSEMBLING THE HOOD

1 Verify that the dyno hood side panel is on the correct side for your eddy current

brake. You may have to remove the side panel and move it to the opposite side for

your particular installation.

dyno hood set up for left side

installation

Hood Upgrade

Figure 1-36: Dyno Hood Side Panel

2 Place the eddy current brake cover in position next to the dyno hood.

Note: Place the front and rear flanges of the eddy current brake cover on the

inside of the dyno hood. Place the top flange of the eddy current brake cover on

top of the dyno hood.

3 Secure the eddy current brake cover to the dyno hood using the six 1/4-inch

button head screws and locking nuts.

eddy current brake cover flange on

dyno hood

eddy current brake cover flange on the

inside of the dyno hood

Figure 1-37: Secure Eddy Current Brake Cover to Dyno Hood

top of the dyno hood

eddy current

brake cover

Vers ion 8 Eddy Current Brake Installation Guide

1-27

Page 34

CHAPTER 1

Hood Upgrade

INSTALLING THE HOOD

1 Verify the bolts and the set screws on the couplers are tight.

2Connect the battery.

3 Carefully place the hood on the dyno leaving it propped up. Secure the key

switch, if present.

4 Lower and secure the hood using the four bolts removed earlier.

Verify the hood is not pinching or contacting any cables or wires.

Figure 1-38: Install the New Dyno Hood

5 Secure the hood clamps to the brake using the two bolts you removed earlier.

6 Secure the brake cover using the four bolts you removed earlier.

Never operate the dyno with this cover removed.

7 Plug the input power cable into a wall outlet.

brake cover

hood clamps

Figure 1-39: Secure the Hood Clamps and Brake Cover

1-28

Eddy Current Brake Installation Guide

Page 35

R

ED

H

EAD

A PPENDIX

A

A

NCHOR INSTALLATION

This appendix contains instructions for installing the Red Head Multi-Set™II Anchors.

The anchors will be used to secure the dyno to concrete. To ensure safety and

accuracy in the procedures, perform the procedures as they are described. Be sure to

read and understand the warnings included in this appendix.

WARNINGS

Always wear safety glasses and other necessary protective devices or apparel

when installing or working with anchors.

ITW Ramset/Red Head Multi-Set II Anchors are designed to operate properly

only when installed with ITW Ramset/Red Head brand Setting Tools.

The use of a 24 to 40 ounce hammer is recommended for expanding Multi-Set II

anchors.

The use of carbide drill bits manufactured with ANSI B94. 12-77 drill bit diameter

requirements is recommended for installation of this anchor.

Not recommended for use in lightweight masonry material such as block or brick.

Use of core drills is not recommended to drill holes for use with this anchor.

Not recommended for use in new concrete which has not had sufficient time to cure.

Anchor spacing and edge distance requirements (anchor installation locations) are

the responsibility of the engineer of record.

CONTACT INFORMATION FOR ITW RAMSET/RED HEAD

Contact ITW Ramset/Red Head at 1-630-350-0370, or 1300 North Michael Drive,

Wood Dale, IL 60191.

Eddy Current Brake Installation Guide

A-1

Page 36

APPENDIXA

Installation

INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Use the table below to determine the catalog number, drill bit size, minimum hole

depth, and setting tool catalog number.

catalog number drill bit size minimum hole depth

Carbon Steel

RM-38/RL-38 (9.5 mm)

Use the following instructions to install the Red Head anchors.

1 Drill the hole in the concrete the same outside diameter as the anchor being used

to any depth exceeding minimum embedment.

1/2-inch 1 5/8-inch (41.2 mm) RT-138

setting tool

catalog number

Figure A-1: Red Head Anchor—Drill the Hole

2 Insert the anchor.

anchor

Figure A-2: Red Head Anchor—Insert the Anchor

A-2

Eddy Current Brake Installation Guide

Page 37

RED HEAD ANCHOR INSTALLATION

Installation

3 Using a hammer, drive the anchor flush with the surface of the concrete, or below

the surface if the hole depth exceeds minimum embedment.

Figure A-3: Red Head Anchor—Drive the Anchor Flush

4 Using a hammer, expand the anchor with the setting tool. The anchor is properly

expanded when the shoulder of the setting tool is flush with the top of the

anchor.

Note: Use only Ramset/Red Head setting tools to insure proper installtion.

setting tool

Figure A-4: Red Head Anchor—Expand the Anchor

Vers ion 8 Eddy Current Brake Installation Guide

A-3

Page 38

Page 39

A PPENDIX

B

H

IGH INERTIA

D

Older high inertia dynos may not have threaded mounting holes for the eddy current

brake. You will need to use nuts to secure the brake to the dyno. This appendix

contains instructions for mounting the eddy current brake to the older high inertia

dyno.

D

RUM

—O

LDER

YNO INSTALLATION

CONNECTING THE EDDY CURRENT BRAKE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Verify the axle length.

1a Measure the axle from the bearing on the starter side to the end of the axle.

1b If the measurement is more than four inches, mark four inches on the axle

and cut the axle.

Figure B-1: High Inertia Drum—Measure the Axle

Eddy Current Brake Installation Guide

B-1

Page 40

APPENDIXB

2 If not already removed, remove the four bolts in the dyno frame from the

positions shown in Figure B-2.

3 Remove the four nuts and washers from the positions shown in Figure B-2 leaving

the bolts in place.

remove nuts

and washers

remove nuts

and washers

Figure B-2: High Inertia Drum—Remove Nuts and Washers

4 Slip the connecting arms over the four existing bolts on the dyno frame and

loosely attach the arms using the four washers and nuts removed earlier. These

nuts need to remain loose in order to align the brake

5 Loosely attach the connecting arms using the four 3/8-inch bolts and 3/8-inch

washers removed earlier. These bolts need to remain loose in order to align the

brake

6 Continue with “Aligning the Eddy Current Brake” on page 1-13.

remove bolts

do not remove

remove bolts

B-2

Eddy Current Brake Installation Guide

Figure B-3: High Inertia Drum—Connect Brake

Page 41

T

HETA

C

ONTROLLER

—I

A PPENDIX

NTERNAL

F

C

USE

Older Theta Controllers have the fuse located inside the theta control box. This

appendix contains instructions to replace the internal fuse.

REPLACING THE INTERNAL FUSE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hazardous voltage. To avoid risk of electrical shock, disconnect the power cord

to the Theta Controller before replacing the fuse.

1 Remove the six screws that secure the cover to the base of the Theta Controller.

There are two screws on top and two on each side of the cover.

2 Remove the theta control cover and set it aside.

3 Remove the blown fuse and replace it. Refer to the table below for fuse

replacement types.

4 Replace the theta control cover.

Figure C-1: Theta Controller—Replace Internal Fuse

Eddy Current Brake Installation Guide

C-1

Page 42

APPENDIXC

For continued protection against risk of fire, replace only with a fuse of the

same type and having the same electrical rating.

To determine whether you have a 120 volt or 240 volt early style Theta Controller,

look at the serial number on the Theta Controller. If it begins with an “E”, then it

is a 240 volt unit; if it does not begin with an “E”, then it is a 120 volt unit.

Theta Controller replacement fuse

240 volt Buss P/N FNQ-15, 15A TIme Delayed Fuse

120 volt Buss P/N FNQ-25, 25A Time Delayed Fuse

Note: Changing the fuse rating to the higher or lower specification does not allow

you to use the Theta Controller with an eddy current brake that was wired for

120 volt or 240 volt originally. Refer to “Verifying the Eddy Current Brake Wiring

Configuration” on page 1-26.

Note: If the eddy current brake has been rewired to a different voltage, you will

need a different Theta Controller. The original Theta Controller will not work.

C-2

Eddy Current Brake Installation Guide

Page 43

M

OUNTING

A PPENDIX

D

T

EMPLATES

Depending on the age of your dyno, you may need to drill the holes needed to mount

the Theta Controller. This appendix contains the templates needed to locate and

place the mounting holes for both left and right side installations.

This appendix contains the following templates:

• Theta Controller Mounting Hole Drill Template For Left Side Mounting

• Theta Controller Mounting Hole Drill Template For Right Side Mounting

Eddy Current Brake Installation Guide

D-1

Page 44

THETA CONTROLLER MOUNTING HOLE DRILL

TEMPLATE FOR LEFT SIDE MOUNTING

EXISTING HOLES

P:\Templates\ Left Theta template 12/13/01

UP

(102mm)

4.00IN

(222mm)

8.75IN

DRILL 3/16" (5mm)

4 PLACES

Page 45

THETA CONTROLLER MOUNTING HOLE DRILL

DRILL 3/16" (5MM) HOLES

IN THREE LOCATIONS

TEMPLATE FOR RIGHT SIDE MOUNTING

EXISTING HOLE

P:\Templates\ right theta template 12/13/01

Loading...

Loading...