Page 1

DYNISCO UPR800 Series Instruction Manual

Page | 1

UPR800 Series

Process Indicator

1/4 DIN Panel Display of Pressure and Temperature

P/N: 974144

REV: 04/10

ECO #: 36299

Page 2

DYNISCO UPR800 Series Instruction Manual

Page | 2

Table Of Contents

QUICK START INSTRUCTION .................................................................................................................. 5

Mounting ........................... ...................... ......................... ...................... ......................... ....................... 5

Wiring .................................................................................................................................................... 6

Scaling ........................... ................. ................... ................. ................ .................... ................. .............. 6

Calibration and Operation ....................................................................................................................... 6

1.0 INTRODUCTION ................................................................................................................................. 7

2.0 SPECIFICATIONS ............................................................................................................................... 8

2.1 Mechanical Specifications ................................................................................................................ 8

2.2 Main Power Supply & Environmental Specification .......................................................................... 8

2.3 Display Specifications ...................................................................................................................... 9

2.4 Primary Input ................................................................................................................................. 10

2.5 Secondary Input (optional) ............................................................................................................. 11

2.6 Primary & Secondary Analog Inputs Common ............................................................................... 13

2.7 Digital Input Specification .............................................................................................................. 13

2.8 Alarms ........................................................................................................................................... 13

2.9 Optional Serial Communication Interface Specification .................................................................. 14

2.10 Main Analog Output Specification ................................................................................................ 14

2.11 Second Analog Output Specification ............................................................................................ 15

2.12 Primary & Secondary Analog Outputs Common Specification ...................................................... 15

3.0 UNPACKING ..................................................................................................................................... 17

4.0 DIMENSIONAL INFORMATION ........................................................................................................ 18

5.0 HARDWARE ..................................................................................................................................... 19

6.0 MOUNTING AND WIRING ................................................................................................................ 20

6.1 Terminal Assignments ................................................................................................................... 22

6.2 UPR700 to UPR800 Wiring Conversion Table ............................................................................... 23

7.0 START-UP PROCEDURE ................................................................................................................. 28

7.1 Getting Ready: .............................................................................................................................. 28

7.2 Configuring the UPR800: ............................................................................................................... 28

7.3 Keyboard Description: ................................................................................................................... 29

7.4 Operating Mode Description: ......................................................................................................... 29

8.0 CONFIGURATION ............................................................................................................................ 31

8.1 Parameters ................................................................................................................................... 31

8.2 Parameter Configuration Procedures ............................................................................................. 31

8.2.1 Setting the Logic Input Configuration (if supplied) ....................................................................... 32

8.2.2 Setting the Logic Input Status (if supplied) .................................................................................. 32

8.2.3 Setting Peak Detection ............................................................................................................... 32

8.2.4 Setting the Line Frequency ......................................................................................................... 32

8.2.5 Setting the Display Filter ............................................................................................................. 33

8.3 Primary Input Setup ....................................................................................................................... 34

8.3.1 Setting the Primary Input Type for a Strain Gage Transducer ...................................................... 34

8.3.2 Setting the Shunt Calibration for Strain Gage Transducers and Amplified units ........................... 34

8.3.3 Setting the Primary Input Type for an Amplified Transmitter ........................................................ 34

8.3.4 Setting the Primary Input Full-Scale Value .................................................................................. 35

8.3.5 Setting the Primary Input Low-Scale Value ................................................................................. 35

8.3.6 Setting the Primary Input Decimal Place ..................................................................................... 36

8.3.7 Setting the Primary Input Failsafe Mode ..................................................................................... 36

8.4 Secondary Input Setup .................................................................................................................. 36

8.4.1 Setting the Secondary Input Type ............................................................................................... 36

8.4.2 Setting the Secondary Input Scale and Decimal Point ................................................................. 36

Page 3

DYNISCO UPR800 Series Instruction Manual

Page | 3

8.4.3 Setting the Thermocouple Type and Units: ................................................................................. 37

8.4.4 Setting the Secondary Input Failsafe Mode ................................................................................. 37

8.5 Setting the Alarms: ......................................................................................................................... 38

8.5.1 Setting Channel Alarm to Monitor (Alarm Input Channel Link): .................................................... 38

8.5.2 Setting Alarm Type: .................................................................................................................... 38

8.5.3 Setting the Filtering for Alarm 1: .................................................................................................. 39

8.5.4 Setting the Hysteresis for Alarm: ................................................................................................. 39

8.5.5 Setting the Reset Mode for Alarms: ............................................................................................ 39

8.5.6 Setting the Failsafe Mode for Alarms: ......................................................................................... 40

8.5.7 Setting the Alarms Value (Alarms Threshold): ............................................................................. 40

8.5.8 Setting the Alarms Mask Reset Type: ......................................................................................... 40

8.6 Main Analog Output Setup ............................................................................................................. 40

8.6.1 Setting the Main Analog Output Type .......................................................................................... 41

8.6.2 Setting the Main Analog Output Link ........................................................................................... 41

8.6.3 Setting the Main Analog Output Range Low ................................................................................ 41

8.6.4 Setting the Main Analog Output Range High ............................................................................... 41

8.6.5 Setting the Main Analog Output Filter .......................................................................................... 41

6.5 Setting the Security Codes: ........................................................................................................... 42

8.7.1 Setting the Security Codes for Level A ........................................................................................ 42

8.7.2 Setting the Security Codes for Level B ........................................................................................ 42

8.7.3 Setting the Security Codes for Level C ........................................................................................ 43

8.7 Configure Differential Pressure ...................................................................................................... 43

8.8 Configure by Remote PC (Configuration Port Interface or CPI) ...................................................... 48

9.0 OPERATION ..................................................................................................................................... 50

9.1 Primary Input Calibration ............................................................................................................... 50

9.1.1 Calibration of Pressure Transducers Equipped with an Internal Shunt Resistor ........................... 50

9.1.2 Calibration of Amplified Pressure Transmitters with an Internal Shunt Resistor ........................... 50

9.1.3 Calibration of Pressure Transducers with External Shunt Resistors ............................................. 50

9.1.4 Calibration of Analog Inputs Using a Pressure Calibration Source ............................................... 51

9.1.5 Calibration of the UPR800 to Calibrated Linear Analog Input ...................................................... 51

9.2 Instrument Calibration ................................................................................................................... 52

9.2.2 General Calibration Procedure .................................................................................................... 52

9.3 RS-485 (Optional) ......................................................................................................................... 55

9.3.1 Serial Communication Interface Address .................................................................................... 55

9.3.2 Protocol Type ............................................................................................................................. 56

9.3.3 Communication Type ................................................................................................................... 56

9.3.4 Communication Baud Rate ......................................................................................................... 56

10.0 ERROR CODES .............................................................................................................................. 57

10.1 Error Codes and Troubleshooting ................................................................................................ 57

10.2 “OPEN” Error Code and Troubleshooting ..................................................................................... 58

10.3 Instrument Maintenance .............................................................................................................. 58

11.0 NORMATIVE REFERENCES .......................................................................................................... 60

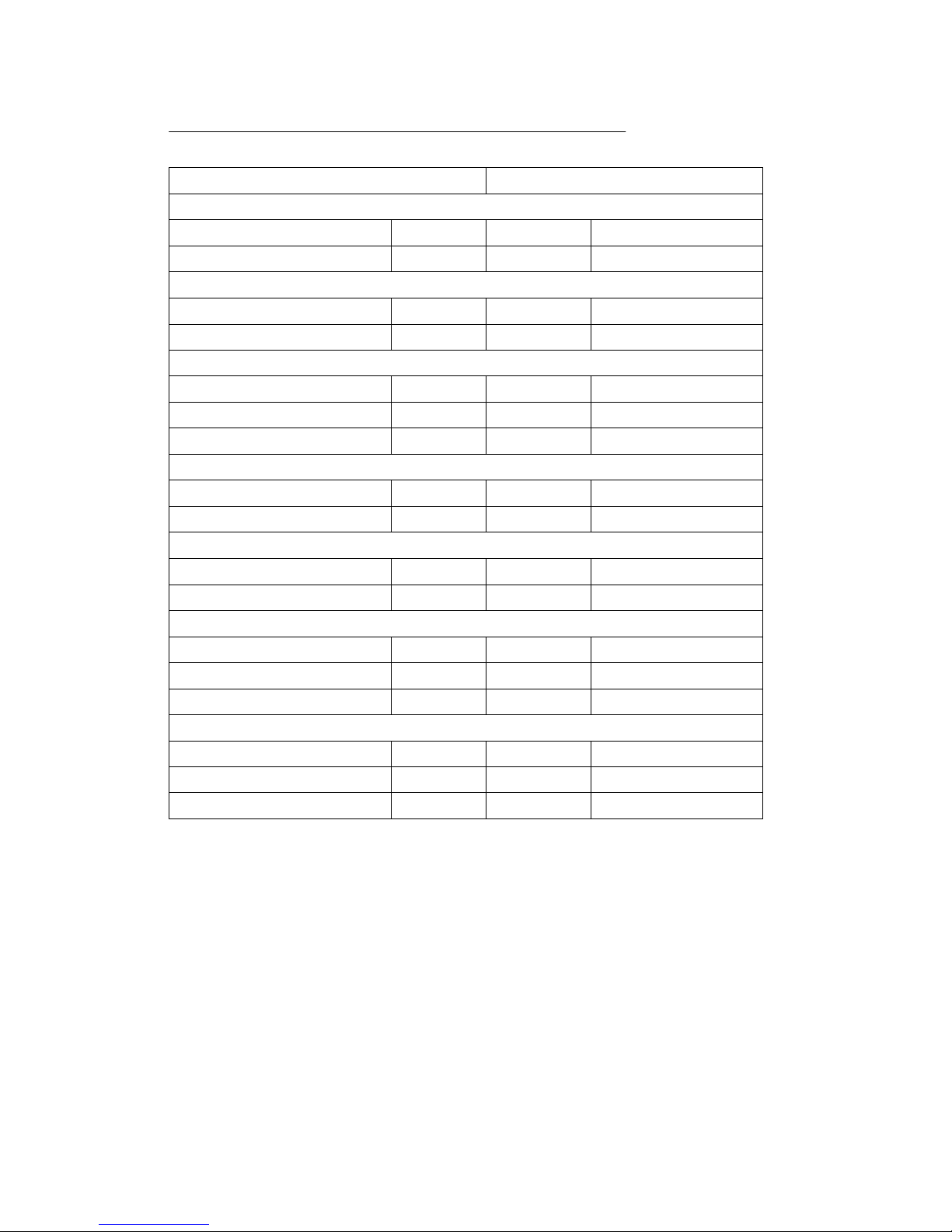

12.1 Group 1 Parameters .................................................................................................................... 63

12.2 Group 2 Parameters .................................................................................................................... 65

12.3 Group 3 Parameters .................................................................................................................... 67

12.4 Group 4 Parameters .................................................................................................................... 71

12.5 Group 5 Parameters .................................................................................................................... 75

12.6 Group 6 Parameters .................................................................................................................... 76

13.0 WARRANTY AND SERVICE: ........................................................................................................... 78

Page 4

DYNISCO UPR800 Series Instruction Manual

Page | 4

Page 5

DYNISCO UPR800 Series Instruction Manual

Page | 5

QUICK START INSTRUCTION

Mounting

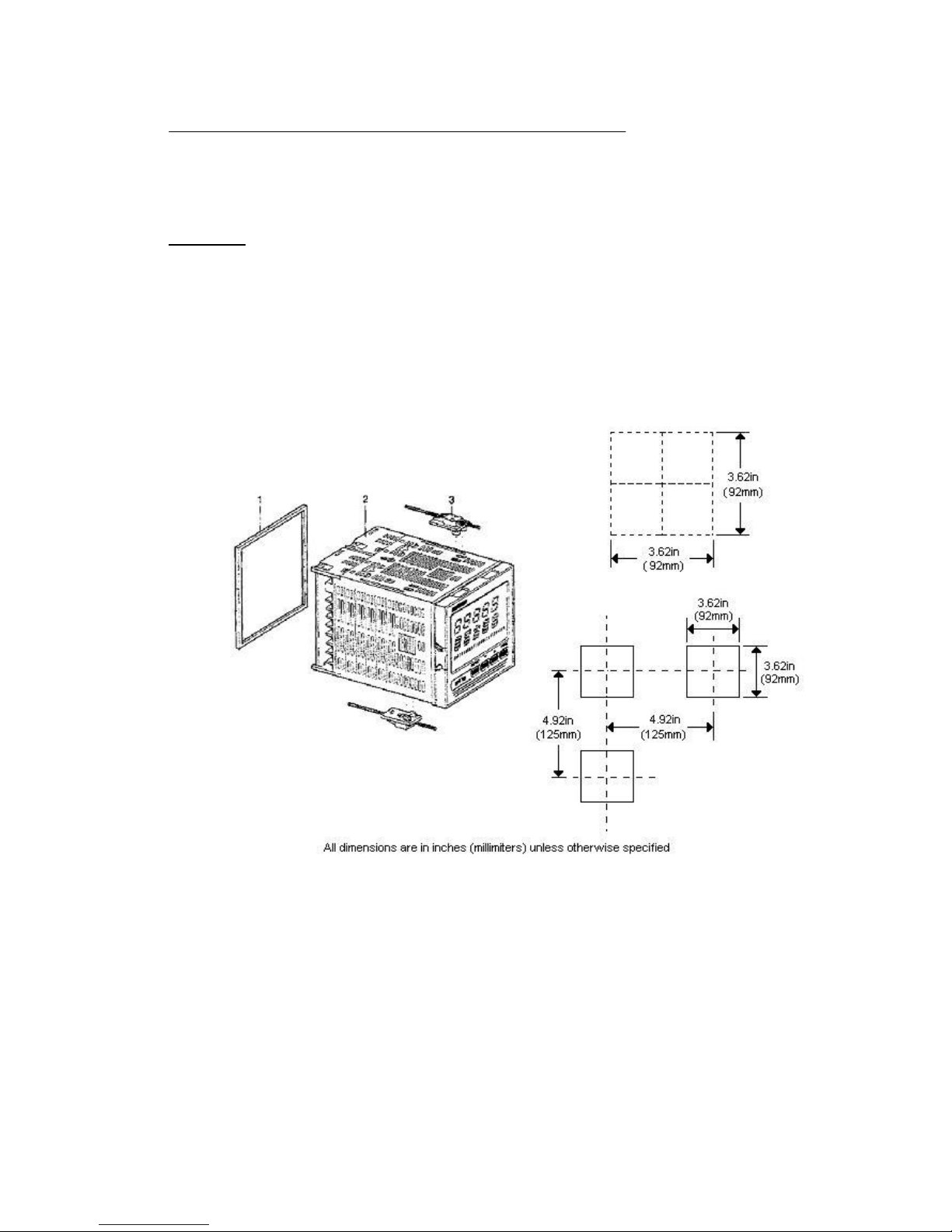

• Prepare panel cutout to dimensions shown below.

• If more instruments are mounted in the same panel near together, maintain

the distances between one instrument to another like as in the figure.

• Slide the rubber gasket (1) over the case.

• Slide the instrument case into the cutout.

• Attach the panel mounting hardware tightening the threaded rod (3) for a

secure fit and with a screwdriver, turn the screws with a torque between 0.3

and 0.4 Nm.

Page 6

DYNISCO UPR800 Series Instruction Manual

Page | 6

Wiring

• Connect the wires from transducer cable as shown in the terminal diagram,

turn the screws with a torque between 1.0 and 1.2 Nm.

• Connect an appropriate length of thermocouple extension wire (Type J) to the

connector.

• Connect the thermocouple to the appropriate terminals (remember that red is

negative).

• Connect alarm(s) if applicable. Note that alarm defaults are High, Reverse

Acting.

• Connect power to the appropriate terminals as shown.

Scaling

• Apply power to the instrument; Upper display will give a reading near zero.

Lower display will read the actual temperature.

• Press FUNC key until the Upper display reads NONE.

Lower display reads GROUP.

• If your transducer is not a 10,000-psi model, select Group 3 using the Up

arrow, enter with function key.

• Lower display reads PI.FSV (Full Scale Value), and the upper display reads

10,000. Note: If your transducer is a 10,000 psi model skip next two steps.

Scroll to GROUP.

• Using the Down arrow key set the appropriate Full Scale Value for your

transducer.

• Enter using the FUNC key to scroll until GROUP legend appears again.

• Using Up arrow key, select GROUP 2.

Calibration and Operation

• Lower display reads ZERO.C and upper display reads OFF. Be sure

transducer is at operation temperature and that no pressure is

applied.

• Change upper display to ON by using the Up arrow key. Enter with

the FUNC key. After a few seconds, the lower display will show

SPAN.C and upper display will show OFF.

• Change upper display to ON using Up arrow key. Enter with the

FUNC key. In a few seconds lower display shows DSP.FL and

upper display shows 0.4. Calibration is complete.

• Using the FUNC key, scroll to the GROUP display. Enter 1 with the

Up arrow, and enter with the FUNC key. Instrument shows 0 (±10)

on upper display and temperature on lower display. System is ready

for use.

References to Profibus features and instructions should be ignored. Profibus is being

considered for a future line expansion and has been accommodated in the current design.

Page 7

DYNISCO UPR800 Series Instruction Manual

Page | 7

1.0 INTRODUCTION

The UPR800 Pressure/Process Indicator is a microprocessor-based instrument, with the

capability of monitoring one or two process variables simultaneously. The primary input is

user configurable to be 350K Strain Gage, high-level voltage or high level current. If the

second input option is chosen, it is configurable by the user as any of four thermocouples,

PT-100 RTD, high-level voltage or high level current. They are compatible with many

process transmitters and can be scaled by the user to give an appropriate range in

engineering units. The UPR800, in its dual input version, can provide simultaneous

readout of common process variable pairs such as Pressure and Temperature,

Temperature and Humidity, etc., when used with the appropriate sensor / transmitter

combinations. Pressure value input and retransmission output groups are selected

though the keypad. Thus the need to make numerous selections within the instrument is

minimized. The UPR800 is provided with two alarms and an analog retransmission

output any of which can be assigned to the primary or secondary input. A second analog

retransmission output is available as an option, as is a 24Vdc power supply for two and

four wire process transmitters. A third alarm is also available as an option.

Five groups of configuration parameters are available from the keyboard, and are

protected by three levels of user definable software locks. The displays can be single-line

(primary input only; lower display blanked), dual line with primary input in the upper

display and high or low peak in the lower display, or dual display of primary input in the upper display and secondary input in the lower display. In the last mode, the lower display

can alternate between the secondary input and the primary input peak value via

keystroke. In addition, a red LED bar graph presents an analog representation of the

primary input, as well as indication of the alarm set points.

References to Profibus features and instructions should be ignored. Profibus is being

considered for a future line expansion and has been accommodated in the current design.

WARNING NOTE: The user should be aware that if this equipment is used in a

manner not consistent with the specifications and instructions in this manual, the

protection provided by the equipment might be impaired.

Product (Model) Codes

Model

Input

Options

Power

Code Descriptio

n

Code Description

Code Voltage

0 Not Present 0 No Option 3 100-240 Vac (switching)

UPR800-

1 T/C, RTD, mV,

mA/V

2 24 Vdc transmitter power

supply and 2

nd

analog

retransmission.

5 24 Vac/Vdc (switching)

3 24 Vdc transmitter power

supply and 2nd analog

retransmission & RS-485

Instruments with the suffix - A3 after the model number have the optional third alarm.

Page 8

DYNISCO UPR800 Series Instruction Manual

Page | 8

2.0 SPECIFICATIONS

2.1 Mechanical Specifications

Case: Polycarbonate Black color Self-extinguishing degree VO according to UL 94

Front Panel: Designed and verified for IP65 and NEMA 4X for indoor location

Installation: Panel mounting

Rear Terminal Block: 43 screw terminals with rear safety cover

2.2 Main Power Supply & Environmental Specification

Main Power Supply: From 100 to 240Vac (-15% to 10%), 50/60 Hz switching. Option:

24Vac/dc

Power supply variation: From -15% to 10% (for 100 to 240Vac). From 14 to 32 Vdc or

from 14 to 30 Vac (for optional 24Vac/dc).

Power Consumption: 15VA, max.

Insulation Resistance: 100 MN @500Vdc

Dielectric Strength: 1500V rms for 1 min, 1800V for 1 sec

Ambient Temperature: From 0 to 50°C

Storage Temperature: From -20 to 70°C

Humidity: Max 85% RH non-condensing

Watchdog: Hw/Sw is provided for automatic restart

Agency Approvals: UL File # 193253

Self-Certification: CE

Electromagnetic Compatibility and Safety Requirements: The instrument is CE

Marked. It is compliant with the European Directive 2004/108/CE according to Product

Standard EN 61326-1.

Emission limit: class A – group 1 ISM for equipment suitable for use in all

establishments other then domestic and those directly connected to a

low voltage power supply network which supplies buildings used for

domestic purposes.

Immunity:

Page 9

DYNISCO UPR800 Series Instruction Manual

Page | 9

• Electrostatic discharge (according to EN 61000-4-2):

contact discharge = 4kV; air discharge = 8kV

• Radio-frequency electrical magnetic (according to EN 61000-4-3):

EM field (amplit. mod.) = 10 V/m (80 MHz to 1 GHz);

3V/m (1,4 GHz to 2 GHz);

1 V/m (2 GHz to 2,7 GHz)

• Electrical fast transient/burst (according to EN 61000-4-4):

AC Power = 2kV;

I/O Signal/Control = 2kV (5/50 ns, 5 kHz);

I/O Signal/Control connected directly to mains supply = 2kV (5/50 ns,

5 kHz)

• Surge (according to EN 61000-4-5):

AC power = 1kV (Line to Line) / 2kV (Line to GND);

I/O Signal/Control (analog inputs excluded) = 1kV (Line to Line) / 2kV

(Line to GND)

• Radio frequency common mode (according to EN 61000-4-6):

AC Power = 3 V (150kHz to 80 MHz);

I/O Signal/Control = 3 V (150kHz to 80 MHz)

• Voltage dips/short interruptions (according to EN 61000-4-11):

0% during 1 cycle; 40% during 12 cycles; 70% during 30 cycles

This equipment is intended for use in an industrial location. There may be potential

difficulties ensuring electromagnetic compatibility in other environmental due to conducted

as well as radiated disturbances.

Safety Requirements:

The instrument is compliant with the European Directive 2006/95/CE according to

Reference Standard EN 61010-1 for installation category I and pollution degree 2

Installation category CAT I: Voltage transients on any power connected to the

instrument must not exceed 1.5kV.

Pollution degree 2: Conductive pollution must be excluded from the

cabinet in which the instrument is mounted.

2.3 Display Specifications

Display: LED technology, custom type.

Upper Digits: Red color, 5 numeric digits, 7 segments with decimal point 13.2mm high.

Lower Digits: Green color, 5 alphanumeric digits (British flag), 14 segments with decimal

points. 11.3mm high.

Bar Graph: Red color, 35 segment with 3% resolution. Displays continuous bar graph to

indicate the measured variable of the primary input (0-100% full scale). Alarm set point

values displayed. Last segment blinks for pressure greater than full scale value.

Page 10

DYNISCO UPR800 Series Instruction Manual

Page | 10

Indicators (Beacons):

Red

LED’s annunciations:

• A1: Lit when alarm 1 is in alarm state

• A2: Lit when alarm 2 is in alarm state

• A3: Lit when alarm 3 is in alarm state

• REM: Lit when device is controlled by serial link

• 0-25-50-75-100-%: These six LEDs are always on to improve the bar graph

indication.

• Kg/cm

2

, PSI, Bar, MPa: Engineering unit for the pressure input. These four

beacons are located within the display window, between the numeric digits and the

alarm beacons.

Green

LED’s annunciations:

• PEAK: Lit when lower display shows the peak value

• TEMP: Lit when lower display shows the temperature input value

2.4 Primary Input

Primary Input: Selectable between strain gage and linear by software configuration.

Strain Gage Input: From 340 to 5000K, 1-4mV/V. Excitation 10V ±7%. 5 wire

connection.

Input Signal: -25/125% of full scale (approximately –10 / 50mV).

Shunt Calibration: With or without shunt resistor (value programmable from 40.0 to

100.0%).

Zero Balance: ±25% of full scale (approximately ± 10mV).

Linear Input: Selectable between 0-5Vdc, 0-10Vdc, 0-20mA, 4-20mA.

Auxiliary Power supply: 24Vdc / 1.5W ± 2% power supply for two or four wire

transmitter.

Input Impedance:

<10K for linear current input

>165KK for linear voltage input

Input Protection: Open circuit detection for strain gage (on signal and excitation wires)

and 4-20mA inputs; it is not available for 0-5Vdc, 0-10Vdc and 0-20mA. Up or down scale

keyboard programmable.

Sampling Time: 50mS typical.

Display Update Time: Selectable: 50, 100, 250 or 400mS.

Page 11

DYNISCO UPR800 Series Instruction Manual

Page | 11

Engineering Units: Dedicated beacons within the display window.

Calibration mode: Field calibrations (zero and span) are applicable for both strain gage

and linear input. Moreover it is possible to delete the field calibration done by the end user

and to restore original factory calibration values.

Input resolution: 4000 counts.

Full scale value Resolution

10/4000 1 count

4002/8000 2 counts

8005/20000 5 counts

20010/40000 10 counts

40020/80000 20 counts

80050/99950 50 counts

Decimal Point Settable in any position of the display.

2.5 Secondary Input (optional)

Temperature Input: Selectable between linear, thermocouple or RTD input by software

configuration.

Function: Selectable between: temperature (in case of linear, thermocouple, RTD the

input); second sensor for the measurement of a differential pressure (in case of strain

gage or linear input)

Linear Input: Selectable between 0-5Vdc, 0-10Vdc, 0-20mA, and 4-20mA

Page 12

DYNISCO UPR800 Series Instruction Manual

Page | 12

Sensor Type and Range:

Thermocouple J -200/+800°C -328/+1472°F

Thermocouple K -200/+1200°C -328/+2192°F

Thermocouple L -200/+800°C -328/+1472°F

Thermocouple N 0/1300°C 32/+2372°F

Thermocouple T -200/+400°C -328/+752°F

Thermocouple E -200/+600°C -328/+1112°F

RTD Pt100 -200/+600°C -328/+1112°F

RTD Pt500 -200/+600°C -328/+1112°F

Input Protection: Open circuit detection for strain gage (on signal and excitation wires),

thermocouple, RTD and 4-20mA inputs; not available for 0-10Vdc, 0-5Vdc and 0-20mA

inputs. Up or down scale keyboard.

Input Impedance:

>1MK for thermocouple input.

<10K for linear current input

>165KK for linear voltage input

T/C Lead Length: 100K max.

Reference Junction Compensation: from -20 to 60°C.

RTD measure system: 3 wire.

RTD Lead Length Compensation: Up to 20K/wire for the Pt100 and Pt500.

Sampling Time: Temperature input is selectable among 100, 200, 500 or 1000mS;

differential pressure is 50 mS, typical.

Display Update: At each sample.

Input Resolution with Linear Input: 4000 counts.

Low/High Scale Values: From -1000 to 3000, linear inputs only. Secondary differential

pressure is selectable, but with the same resolution and decimal point position of the

primary pressure input.

Decimal point: Settable in any position.

NOTE: These secondary inputs are not isolated from the primary input. A double or

reinforced insulation between instrument output and power supply must be guaranteed by

the external device.

Page 13

DYNISCO UPR800 Series Instruction Manual

Page | 13

2.6 Primary & Secondary Analog Inputs Common

Common Mode Rejection Ratio: >120dB @50/60Hz

Normal Mode Rejection Ratio: >60dB @ 50/60Hz

Strain gage input: From 340 to 5000K, 1-4 mV/V. Excitation 10V +/- 7%. 5 wires

connection.

Input signal: -25/125% of full scale (approximately -10/50mV).

Shunt calibration: With or without shunt resistor (value programmable from 40.0 to

100.0%), the same setting will be used for both inputs (main and secondary) when the

differential pressure measurement is selected.

Zero balance: +/- 25% of full scale (approximately +/- 10mV).

Reference accuracy: +/- 0.1% FSV +/-1 digit @ 25 +/- 1°C and nominal power supply

voltage.

Operative accuracy: temperature drift:

• < 200 ppm/K of full span (RJ excluded) for TC input.

• < 300 ppm/K of full span for current, voltage and strain gage input.

• < 400 ppm/K of full span for RTD input.

• < 0.1K/K for reference junction.

Zero and span calibration: If differential input used, there is no relation between the

calibration of the two single sensors; each input is provided with its own zero and span

calibration parameters.

Wiring caution: The analog input lines cannot exceed the 30 meter length or leave the

building.

2.7 Digital Input Specification

Digital input: One input from contact closure (voltage free). It may be keyboard

programmable for the following functions:

• Alarm reset

• Peak reset

• Alarm and peak reset

NOTE: This input is not isolated from primary input. A double or reinforced insulation

between instrument output and power supply must be guaranteed by the external device.

2.8 Alarms

Alarm Outputs: 2 standard alarms (AL1 and AL2). 1 optional alarm (AL3).

Page 14

DYNISCO UPR800 Series Instruction Manual

Page | 14

AL1 and AL2 Contacts: 1 SPDT 2A max 0 240Vac resistive load.

AL3 Contacts: 1 SPST selectable NO/NC 2A max @ 240Vac resistive load.

Contact Protection: Varistor for spike protection.

Alarm Type: Each alarm is keyboard programmable for:

• Primary/Secondary input

• High/Low/Low inhibited on start up

• Auto/Manual reset

Excitation Type: Keyboard configurable for each alarm: relay coil energized in no alarm

condition (failsafe) or relay coil energized in alarm condition (non-failsafe).

Threshold: From 0 to 110% Full Scale (the threshold may be limited due to the selected

full scale value).

Hysteresis: Keyboard programmable for each alarm; from 0.1% to 10.0% of span or 1

LSD (whichever is greater) for each alarm.

Filter: Selectable from the following values for each alarm:

OFF, 0.4S, 1S, 2.5S, 3S, 4S, 5S.

Alarm Update Time: At every input conversion.

2.9 Optional Serial Communication Interface Specification

Serial Interface: RS-485 type. Opto-isolated.

Protocol Type: Modbus/Jbus (RTU mode).

Type of Parameters: Run-time and configuration are available by serial link.

Device Address: From 1 to 255

NOTE: The physical interface can only support up to 31 devices for each

segment. Use multiple segments for more than 31 devices.

Baud Rate: 600 up to 19200 baud.

Format: 1 start bit, 8 bits with/without parity. 1 stop bit

Parity: Even/Odd.

2.10 Main Analog Output Specification

Main Analog Output: Opto-isolated from CPU input and output circuits.

Page 15

DYNISCO UPR800 Series Instruction Manual

Page | 15

Type of Output Function: Keyboard selectable as

• Primary input retransmission

• Secondary input retransmission

Type of Analog Output: Keyboard selectable between:

• +0/10Vdc min. load 5 KN, with under/over range capability from -2.5 to 12.5V

• -10/+10Vdc mm. load 5KN, with under/overrange capability from -12.5 to 12.5V

• +0/5Vdc mm. load 5KN, with under/overrange capability from -1.25 to 6.25V

• +0/20mA max. load 500N, with under/over range capability from -5 to 25mA

(max. load 400N over 20mA).

• +4/20mA max. load 500N, with under / over range capability from 0 to 24mA

(max. load 400N over 20mA).

2.11 Second Analog Output Specification

Second Analog Output: Opto-isolated from CPU input and output circuits.

Type of Output Function: Keyboard selectable for:

• Primary input retransmission

• Secondary input retransmission

Type of Analog Output: Keyboard selectable between:

• +0/10Vdc min. load 5KN, with under/over range capability from -2.5 to 12.5V

• +0/5Vdc min. load 5 KN, with under/over range capability from -1.25 to 6.25V

• +0/20mA max. load 500N, with under/over range capability from 0 to 24mA

(max. load 400N over 20mA).

• +4/20mA max. load 500N, with under/over range capability from 0 to 24mA

(max. load 400N over 20mA).

2.12 Primary & Secondary Analog Outputs Common Specification

Resolution: 0.1% of output span.

Reference Accuracy: ±0.1% of output span @ 25 ± 1°C and nominal line voltage.

Linearity Error: <0.1% of output span.

Output Noise: <0.1% of output span.

Scaling: The retransmission low and high limits are selectable from 0 to primary input

full-scale value (when the retransmitted variable is primary input) or from low to high

secondary limits (when the retransmitted variable is the secondary input). The two scaling

values may be freely selectable within the above range. This allows having a direct or

reverse output type.

Output Filter: Selectable: OFF, 0.4S, 1S, 2S, 3S, 4S, 5S

Page 16

DYNISCO UPR800 Series Instruction Manual

Page | 16

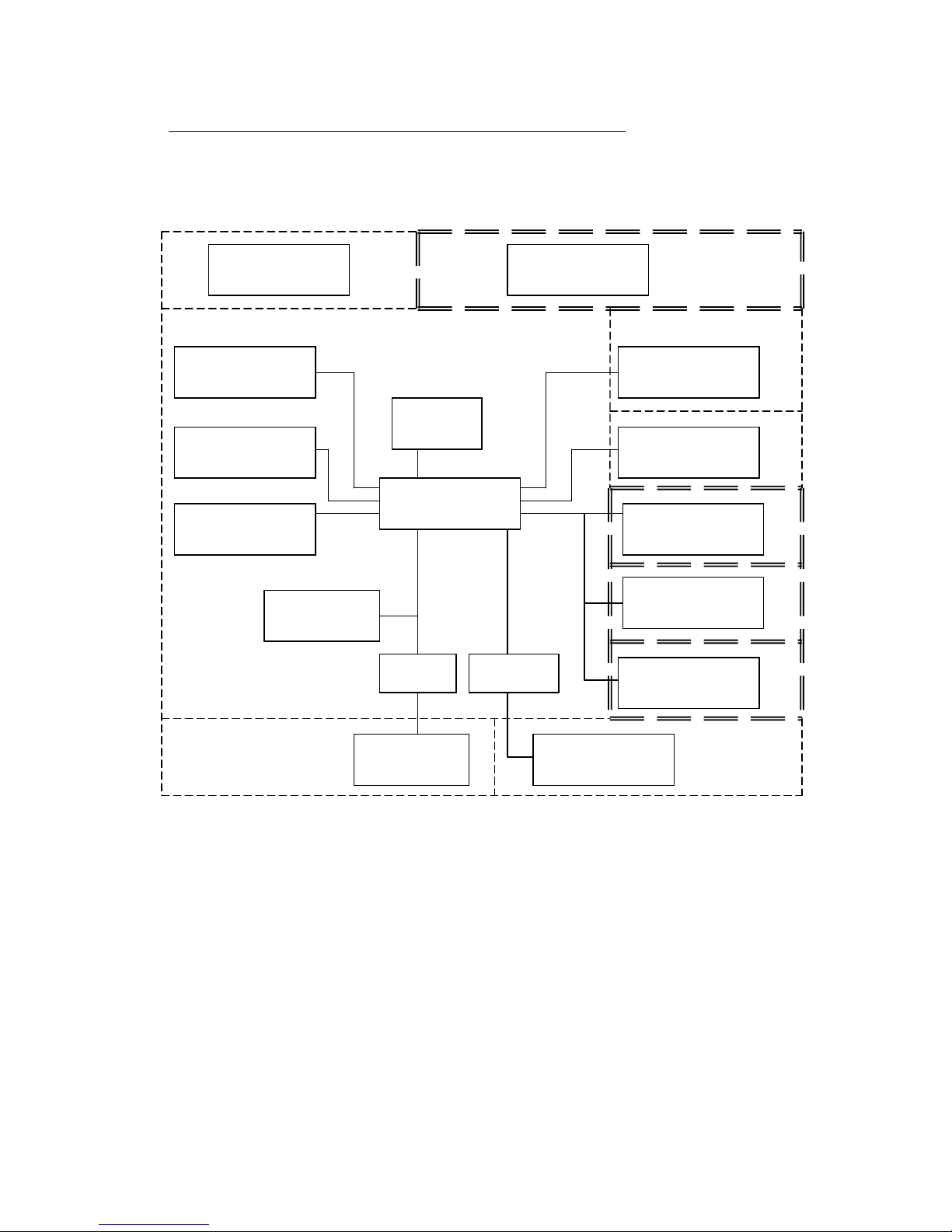

NOTE: Dashed Line represents insulation boundary.

Double Dashed Line represents reinforced insulation boundary.

AUXILIARY

POWER SUPPLY

MAIN

POWER SUPPLY

MAIN

ANALOG

OUTPUT

SECONDARY

ANALOG

OUTPUT

ALARM 1

OUTPUT

CPI

Configuration Port

Interface

ALARM 3

OUTPUT

(option)

MAIN

ANALOG INPUT

Strain gage and Linear

DISPLAY

KEYBOARD

CPU

RS485

INTER FACE

PROFIBUS

DP

INTERFACE (NA)

SECONDARY

ANALOG INPUT

Tc, RTD and Linear

RESET

Logic Input

MODBUS

RTU

PROFIBUS

DP Module (NA)

ALARM 2

OUTPUT

Page 17

DYNISCO UPR800 Series Instruction Manual

Page | 17

3.0 UNPACKING

Upon receipt, examine package for shipping damage. Notify the carrier immediately in the

event of any evidence of damage, and retain shipping materials for their inspection.

This package should contain the instrument and two panel mounting brackets.

Page 18

DYNISCO UPR800 Series Instruction Manual

Page | 18

4.0 DIMENSIONAL INFORMATION

Dimensions: 3.78” X 3.78” X 6.01” overall (96mm X 96mm X 143.5mm)

Cutout: 3.62” X 3.62” (92mm X 92mm)

Depth behind panel: 5.04” (128mm)

Weight: 1.43 lbs. (650g)

Page 19

DYNISCO UPR800 Series Instruction Manual

Page | 19

5.0 HARDWARE

The UPR800 is shipped configured for the following:

• Primary Input (Pressure) - Strain Gage

• Optional Secondary Input - Thermocouple

• Main Output - Voltage

• Optional Secondary Output – Voltage

• Security lock is OFF

Please refer to the drawings in the appropriate sections to determine the configuration for

input(s) and output(s) used in your particular application. It is necessary only to select the

category (e.g. Voltage or Current). The specific range will be chosen in the software

menu.

Page 20

DYNISCO UPR800 Series Instruction Manual

Page | 20

6.0 MOUNTING AND WIRING

Please refer to figures for cutout dimensions and clearance requirements. Locate the two

mounting brackets packed with the instrument and have them available.

1. Slide the instrument case into the cutout, being sure that it is right-side-up (terminal 1

at the top). Attach the panel mounting hardware at diagonally opposite sides of the top

and bottom of the case, tightening the threaded rod until the case is secure against

the panel.

2. Refer to the model number of the instrument to determine the hardware and options

included as part of your unit. Please refer to Section 6.1 for the terminal assignments.

Terminals are accessed by opening the terminal covers from the side with the “OPEN”

legend.

NOTE 1: The UPR800 is equipped with screw terminals, and no connectors are

necessary when wiring the unit

NOTE 2: When wiring the alarms, wire to the Common and NO (normally open) terminals

to maintain a fail-safe configuration.

Fail-safe denotes a situation where the alarms relay coils are activated in a no-alarm

situation. As the relay coil is energized, terminals that are normally open are closed and

can cause completion of a circuit when used as an interlock. Should the alarm threshold

be exceeded, OR should power be lost to the instrument the contacts will open, and the

circuit will be broken. If the alarm is a latching alarm, it will require an external reset signal

to be activated again.

If the alarm is used to provide a contact to an alarm device (light, horn buzzer, etc., when

the threshold is exceeded, wiring should be to the Common and NC (normally closed)

terminals. Activation of the relay coil will cause the contacts to open in a non-alarm

situation, and to close if the threshold is exceeded, or power is interrupted to the

instrument. If the alarm is a latching alarm, it will require an external reset signal to be

activated again.

NOTE 3: Relay Outputs

The contact rating of all outputs is equal to 2A/240 Vac on resistive load.

• To avoid electrical shock, connect power line at the end of the wiring procedure.

• For power connections use No 16AWG or larger wires rated for at least 75°C.

• Use copper conductors only.

NOTE 4: Power Line

Before connecting the instrument to the power line, make sure that the line voltage

corresponds to the description on the identification label.

Page 21

DYNISCO UPR800 Series Instruction Manual

Page | 21

• To avoid electrical shock, connect power line at the end of the wiring procedure.

• For supply connections use No. 16AWG or larger wires rated for at least 75°C.

• Use copper conductors only.

• Don’t run input wires together with power cables.

• When a neutral line is present, please connect it to terminal 54.

• For 24Vdc the polarity need not be observed.

The power supply input is fuse protected by a sub miniature fuse rated T, 250V, 1A (2A

for the optional 24Vac/dc).

When the fuse is damaged, it is advisable to verify the power supply circuit. It is

necessary to send back the instrument to Dynisco for service.

The safety requirements for Permanently Connected Equipment say:

• A switch or circuit-breaker shall be included In the building installation;

• It shall be in close proximity to the equipment and within easy reach of the operator

• It shall be marked as the disconnecting device for the equipment.

• A single switch or circuit breaker can drive more than one Instrument

• Protective conductor terminals shall be connected to earth.

Page 22

DYNISCO UPR800 Series Instruction Manual

Page | 22

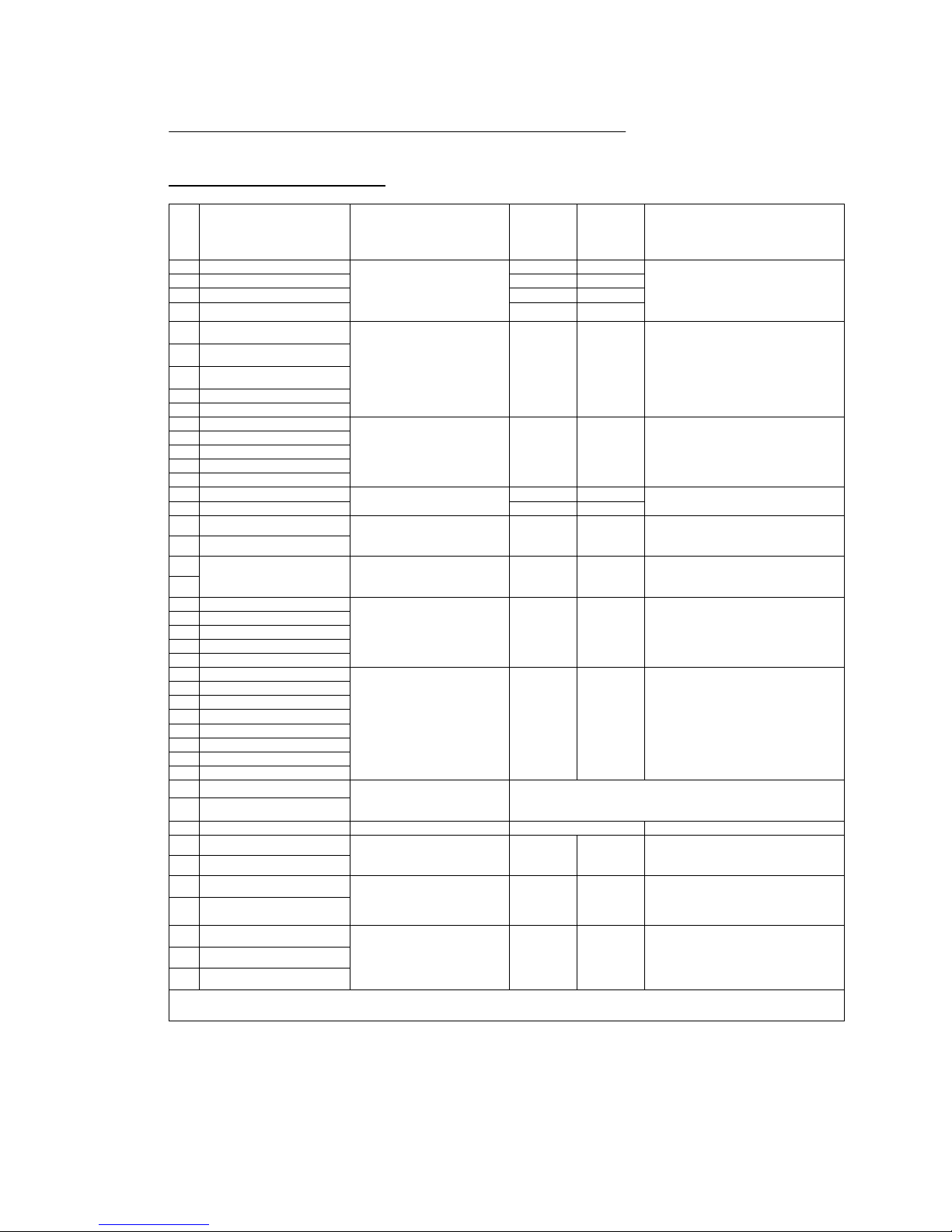

6.1 Terminal Assignments

Terminal

Terminal

Assignment Description

Function

category / class

Voltage

Rating,

V

Current

Rating,

A

Load type and Rating

1 RTD, T/C +

Secondary Inputs

CAT I

2 Vdc 0.001 Adc

3 RTD, T/C -, mA/V -

4 mA +, RTD compensation 0.020 Adc

5 V + 10 Vdc

6 SIG +

Secondary Input Strain

Gage

CAT I

From 340N to 5000N,

Excitation 10Vdc ±7% (between

EXC + and EXC -)

7 SIG -

8 CAL2

10 EXC +

11 EXC - , CAL1

12 SIG +

Main Input Strain Gage

CAT I

From 340N to 5000N,

Excitation 10Vdc ±7% (between

EXC + and EXC -)

13 SIG -

14 CAL2

16 EXC +

17 EXC - , CAL1, mA -, V -

18 mA +

Main Linear Inputs

CAT I

0.020 Adc

19 V + 10 Vdc

21 OUT1 mA/V +

Main Analog

Retransmission

Class 2

±12.5 Vdc min load 5KN.

-5/+25 mA max load 500N

(max. load 400K over 20 mA).

22 OUT1 mA/V -

23

RESET

Remote Reset of Alarm

and/or peak

Class 2

Dry Contact switch

(voltage free)

24

29 SHIELD

Standard ProfiBus

Communication

Class 2

30 5VP

31 B/B’

32 A/A’

33 DGND

45 ALARM1 N.O.

Relay contacts used to

identify an event (alarm)

condition

240 Vac, 2A , resistive

46 ALARM1 C

47 ALARM1 N.C

48 ALARM2 N.O.

49 ALARM2 C

50 ALARM2 N.C.

51 ALARM3 C

52 ALARM3 N.C./N.O.

53

Line ~ or +

Main Power Supply

(according to the Product Code)

100 – 240Vac

27VA maximum

or

24Vdc, 12W maximum

24Vac, 18VA maximum

Class 2

54

Neutral

~ or -

55 Earth (Ground)

56 OUT2 mA/V +

Secondary Analog

Retransmission

Class 2

±12.5Vdc min load 5KN.

-5/+25 mA max load 500N

(max. load 400K over 20 mA).

57 OUT2 mA/V -

58 Vdc SUPPLY +

Auxiliary Power Supply

Class 2

24 Vdc

0.063 Adc

(1.5W)

59 Vdc SUPPLY -

60 A/A’

Serial Communication

RS485

Class 2

61 B/B’

62 C

Note:

The instrument is not suitable for use with equipment for measurement within measurement categories II, III and IV.

Page 23

DYNISCO UPR800 Series Instruction Manual

Page | 23

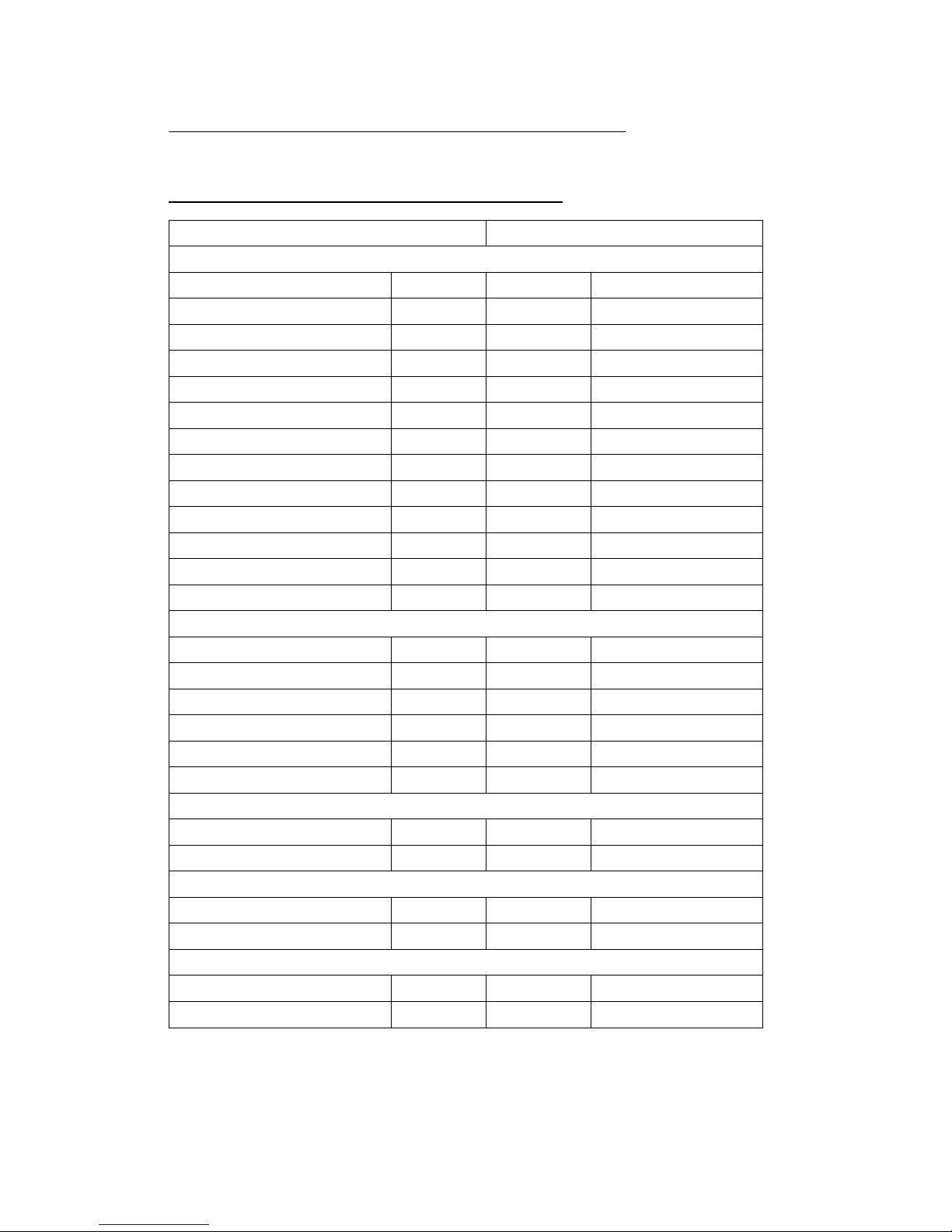

6.2 UPR700 to UPR800 Wiring Conversion Table

UPR800 Terminal UPR700 Terminal

Power

100 - 240Vac or 24Vac/dc 53 53

Line Neutral 54 54

Earth (Ground) 55 55

Transducer Dynisco Cable Color

Signal (+) 12 12 Red

Signal (-) 13 13 Black

Excitation (+) 16 16 White

Excitation (-) 17 17 Green

CAL 1 17 17 Blue

CAL 2 14 14 Orange

mA (+) 18 12

V (+) 19 12

mA/V (-) 17 13

Alarms

A1 (N.O.) 45 45

A1 Common 46 46

A1 (N.C.) 47 47

A2 (N.O.) 48 48

A2 Common 49 49

A2 (N.C.) 50 50

Alarm 3 (optional)

A3 (N.O. / N.C.) 52 52

A3 Common 51 51

Analog Output

mA/V Out (+) 21 21

mA/V Out (-) 22 22

2nd Analog Output (optional)

mA/V Out (+) 56 56

mA/V Out (-) 57 57

Page 24

DYNISCO UPR800 Series Instruction Manual

Page | 24

UPR800 Terminal UPR700 Terminal

24 VDC Transmitter Power Supply (optional)

24 Vdc (+) 58 58

24 Vdc (-) 59 59

External Reset Contacts

Reset 23 23

Reset Common 24 24

Second Analog Input (optional)

Thermocouple Input

TC (+) 1 1

TC (-) 3 3

mA Input

lnput (+) 4 4

lnput (-) 3 3

V Input

lnput (+) 5 4

lnput (-) 3 3

RTD Input 3-wire

Red 1 1

Black 3 3

Black 4 4

Serial Communications (RS485 only)- (optional)

A 60 60

B 61 61

COM 62 62

Page 25

DYNISCO UPR800 Series Instruction Manual

Page | 25

Page 26

DYNISCO UPR800 Series Instruction Manual

Page | 26

Page 27

DYNISCO UPR800 Series Instruction Manual

Page | 27

Page 28

DYNISCO UPR800 Series Instruction Manual

Page | 28

7.0 START-UP PROCEDURE

In general, the UPR800 Pressure/Process Indicator is a microprocessor-based

instrument, with the capability of monitoring one or two process variables simultaneously.

The primary input is configured to accept a 350N Strain Gage, but can be changed to

accept high level voltage or current. The primary input full-scale value can be as low as

10, and as high as 99,950 units. The secondary input, if supplied, will accept a “J” type

thermocouple, but can be changed to most thermocouples or RTD’s, or to a high-level

voltage or current. The secondary input full-scale value can be as low as -1,000 and as

high as 3,000 units.

The standard UPR800 has 2 SPDT dry contact closure alarms, with an optional third

alarm. In addition, it has one or two scalable analog retransmission outputs, or RS-485

communications.

Alarm 1 is configured as a High Alarm at 40% of the full-scale transducer value, with 0.4

second filtering, 1.0% hysteresis, Auto reset, failsafe mode, and it is linked to the primary

input.

Alarm 2 is configured as a High Alarm at 60% of the full-scale value, with 0.4 second

filtering, 1.0% hysteresis, Auto reset, failsafe mode, and is also linked to the primary

input,

Alarm 3, if supplied, is configured as a High Alarm at 80% of the full-scale value, with 0.4

second filtering, 1.0% hysteresis, Auto reset, failsafe mode, and it is disabled (not linked

to any input),

These terms will be described in the ALARMS section.

7.1 Getting Ready:

1. Slide the case into the panel cutout. MAKE SURE TERMINAL 1 IS AT THE TOP!

Attach the panel mounting hardware at diagonally opposite sides of the top and

bottom of the case, tightening the threaded rod until the case is secure against the

panel.

2. Attach the primary and secondary devices, (if supplied) and wire according to the

terminal assignments.

7.2 Configuring the UPR800:

Apply power to the cabinet. The upper display will show a reading near zero, and the

lower display will show the current temperature or PEAK if the unit does not have

secondary input. It may display OPEN if there is no transducer connected, or if the

transducer is amplified.

Page 29

DYNISCO UPR800 Series Instruction Manual

Page | 29

The keys on the UPR800 must be pressed and released to move about in the configure

screens. Do not press and hold a key unless told to do so; simply press the key and

release it to advance to the next screen. The arrow keys u or t may be held down to

advance rapidly through the values.

7.3 Keyboard Description:

The keyboard is composed of four push buttons, covered by a silicone protective

operator, labeled u, t, FUNC and RESET.

The u is called the “Down Arrow Key”, and is used to increment and decrement the

parameter value.

The t is called the “Up Arrow Key”, and is used to increment and decrement the

parameter value. It also may be used to switch the lower display from the secondary

input (if available) to the peak value (if enabled) and back again. At power up, the lower

display shows the secondary input value (if present) or it shows the peak value. If there is

no secondary input and the peak value is disabled, the lower display is blank.

The FUNC (“function”) key is used to access the parameter to view, modify, and enter the

“Operating Mode Switching” procedure (when pressed for more than 7 seconds).

The RESET key is used to reset the stored peak value and to reset the alarms when held

for 1 second, (once the alarm condition has cleared beyond the hysteresis value). This

function is disabled when the device is controlled by the serial link. In addition, when

checking or changing parameters, it is used to return to the normal display mode without

storing the parameter change.

Pressing t then RESET together, or u then, may be used to jump to maximum or

minimum parameter values when the instrument is in function mode.

At power up, if the instrument detects a parameter error, the upper display shows ERR #,

(where # is the error number), and the lower display will show the parameter name. If the

wrong parameter is a run-time parameter (i.e. AL 1 to SO.TYP) pressing the t then u

together will cause the instrument to load the default values for all parameters.

If the wrong parameter is a calibration or code parameter, pressing the FUNC then

RESET keys together, enables the instrument to access the run-time parameters. This

function is intended only to restore a misplaced parameter’s value; however, the

performance of the instrument is not guaranteed. The user is advised to check the stated

parameter.

NOTE: All the actions explained above that require two or more pushbuttons, must follow

the pushbutton sequence exactly.

7.4 Operating Mode Description:

The FUNC key is used to access the parameters organized in five groups. Use the

FUNC pushbutton to access the Group 1 parameters; the last entry (showing Group and

Page 30

DYNISCO UPR800 Series Instruction Manual

Page | 30

None is intended to access the other groups of parameters, or pressing FUNC again

returns to the normal display mode. Each group has its own family of parameters, loosely

grouped around the decreasing need to change the parameters. Each group also has the

ability to load its own default parameters and the default values of the lower number

groups.

Page 31

DYNISCO UPR800 Series Instruction Manual

Page | 31

8.0 CONFIGURATION

8.1 Parameters

The UPR800 parameters are grouped in five sections guarded by three security levels.

The more common parameters are in the first groups, with the higher Group numbers for

those parameters an operator would not normally modify. Each group can be reset to its

default value by two keystrokes. This also resets the parameters of any lower numbered

group to default. If GROUP 5 is set to default, the entire instrument is reset to its default

parameters. If a unit does not have a particular option, its parameters will not appear.

For example, an instrument that does not have RS-485 communications will skip those

parameters related to communications. Likewise, if a particular function is turned off, its

other parameters will not appear. For example, if Alarm 2 is turned to OFF in Group 3, the

hysteresis, reset, filter, type, and threshold functions will not appear on screen. Nor will

the alarm appear on the bar graph display.

When the instrument is turned on, it will go through a self-test during which the front panel

will illuminate. The instrument will then be in the normal display mode showing the value

of the main input on the upper display, and the value of the secondary input on the lower

display (if so equipped). If there is no secondary input, the lower display will show the

maximum peak value of the main input. In the event that no input device is connected,

both displays will show OPEn. If no secondary input is present, the lower display will

show OPEn indicating that the unit failed to full scale, the bar graph display will be at

100% with the last segment flashing. Turn the power to the instrument off and connect an

input device to the appropriate terminals, and connect a thermocouple or appropriate

signal source to the secondary input terminals (if supplied). Upon turning the instrument

back on, the displays should have a numeric value, close to zero pressure on the

pressure display, and near room temperature on the thermocouple display. Depressing

FUNC will go automatically into the GROUP 1 parameters.

Successively pressing FUNC will scroll through all the parameters of GROUP 1. The last

two parameters of each group allow the default parameters to be restored, and returns to

GROUP. If nonE is chosen in the group access function, the instrument will return to

normal operating mode after pressing of the FUNC key.

When in GROUP 1, if no keyboard activity is detected for approximately 10 seconds, the

instrument will automatically return to the normal display mode.

8.2 Parameter Configuration Procedures

The parameters in the five groups are extensive, and not all parameters need to be

addressed. While they are fully explained in the following section, it would be well to

review them prior to configuring the instrument in your application. It is entirely possible

that only a minimum number of parameters need to be adjusted to have your process

operating satisfactorily. Please note that at any time, the default parameters may be

reset to the factory settings. Each parameter group can be reset at any time, (which also

resets the levels with numbers higher than the selected group). To set a default level,

press the FUNC key until DEFLT shows on the lower display and OFF shows on the

Page 32

DYNISCO UPR800 Series Instruction Manual

Page | 32

upper display. Press the u or t key until ON 1 shows in the upper display. Press the

FUNC key to load all of the factory parameters for groups 1, 2, 3, 4, and 5.

To reset a specific group (and higher numbered groups) to the default factory settings,

press the FUNC key until nonE and GROUP show on the display. Press the t key until

the appropriate group number appears in the upper display. . Press the FUNC key to

enter the appropriate group. Press the FUNC key until DEFLT shows on the lower

display and OFF shows on the upper display. Press the u or t key until ON # (where #

is the Group number). Press the FUNC key to load the factory parameters for that groups

(and higher numbered groups).

8.2.1 Setting the Logic Input Configuration (if supplied)

If the unit does not have the logic input option, skip to Section 8.3.3.

The Logic Input can be off, can be set to function as an alarm reset, a peak reset, or it

can reset both. To verify this parameter or to change it, press the FUNC key until nonE

and GROUP show on the display. Press the t key until 4 shows in the upper display.

Press the FUNC key until the lower display shows LI.TYP. Press the u or t key until

the upper display shows the correct selection: OFF, AL - alarms reset, P - Peak reset or

AL-P, Alarm & Peak reset), CAL.0, Remote Zero Cal, ALL, AL+P+CAL.0). Press the

FUNC key to set the value and move to the next parameter, or press the RESET key to

go back to the active display.

8.2.2 Setting the Logic Input Status (if supplied)

The Logic Input Status can be off, can be set to function as an alarm reset, a peak reset,

or it can reset both. To verify this parameter or to change it, press the FUNC key until

nonE and GROUP show on the display. Press the t key until 4 shows in the upper

display. Press the FUNC key until the lower display shows LI.STS. Press the u or t

key until the upper display shows the correct selection: CLOSE, or OPEn.

Press the FUNC key to set the value and move to the next parameter, or press the

RESET key to go back to the active display.

8.2.3 Setting Peak Detection

The Peak Detection can be either set to OFF, the default value of HIGH, or to LOW. To

verify this parameter or to change it, press the FUNC key until nonE and GROUP show

on the display. Press the t key until 4 shows in the upper display. Press the FUNC key

until the lower display shows PEAK. Press the u or t key until the upper display shows

the correct value (OFF, HI, or LO). Press the FUNC key to set the value and move to the

next parameter, or press the RESET key to go back to the active display.

8.2.4 Setting the Line Frequency

The Line Frequency default value is Auto. To verify this parameter or to change to 50 Hz,

press the FUNC key until nonE and GROUP show on the display. Press the t key until

4 shows in the upper display. Press the FUNC key until the lower display shows LINE.F.

Press the u or t key until the upper display shows the correct frequency. Press the

FUNC key to set the value. Press the FUNC key to set the value and move to the next

Page 33

DYNISCO UPR800 Series Instruction Manual

Page | 33

parameter, or press the RESET key to go back to the active display. When set to Auto,

Group 4 Parameter LINE.R displays the detected Line Frequency.

8.2.5 Setting the Display Filter

Filtering is an electrical method of averaging the displayed values over a period of time to

arrive at a more legible display. Filtering helps to eliminate short duration transients and

spikes that may cause false or spurious readings.

To change or view the Main Analog Output Filter, press the FUNC key until nonE and

GROUP show on the display. Press the t key until 2 shows in the upper display. Press

the FUNC key until the lower display changes to DSP.FL. Using the u or t keys, select

the amount of filtering desired, from none (OFF) to five seconds. When finished, press

the FUNC key to lock in the value and advance to the next parameter.

GROUP #

FUNCTION

MNEMONIC

CHOICES

DEFAULT

Group 5 Primary Input PI.TYP Str, 0-20, 4-20, 0-5, Str

Selection 0-10

Group 5 Secondary Input SI.TYP OFF, tc, rtd, 0-20

Selection 4-20, 0-10, str Tc

Group 4 Shunt Calibration SHUNT OFF, On On

Group 4 Shunt Value SHNT% 40.0 TO 100.0% 80.0%

Group 3 Input Full Scale

Value

PI.FSV 10 TO 99950 10000

Group 3 Input Low Scale

Value

PI.LSV ± 25% OF SFV 0

OF FS V

Group 3 Input Decimal PI.DP None, 1,2,3,4 None

Point Position places

Group 3 Secondary Input Sl.TC tc J, tc CA, tc L, tc n tc J

T/C Type

Group 3

Alarm I Input

AI.LNK

OFF, Prl.ln, Sec.ln Prl.ln

Channel Link

Group 3

Alarm I T

ype

AI.TYP

HI, LO, lnhib HI

Group 3

Alarm 2 Input

A2.LNK

OFF, Prl.ln, Sec.ln PrLIn

Channel Link

Group 3

Alarm 2 Type

ALTYP

HI, 10, lnhib HI

Group 2 Zero Calibration ZERO.C OFF, On, CLEAr OFF

Group 2 Span Calibration SPAN.C OFF, On, CLEAr OFF

Group 1

Alarm I Threshold

AL1

TO 110%of span 40% of range of related

input

Group 1

Alarm 2 Threshold

AL2

TO 110% of span 60% of range of related

input

In this example, these are functions necessary to allow operation of a pressure/temperature indicator with

two high alarms.

Page 34

DYNISCO UPR800 Series Instruction Manual

Page | 34

8.3 Primary Input Setup

8.3.1 Setting the Primary Input Type for a Strain Gage Transducer

If using a Dynisco transducer, the model number of the transducer will designate its own

electrical output. For example, in plastic melt applications, the PT462E-5M-6/18 or

TPT432A-10M-6/18 have a strain gage (0-3.33 mV/V dc full scale) signal output.

Amplified units have a number where the strain gage units have a letter (E or A). The

PT4624-5M-6/18 has a 4-20mA signal output; the PT4625-5M-6/18 has a 0-5 Vdc signal

output, while PT4626-5M-6/18 has a 0-10Vdc signal output. In Industrial applications,

amplified units have a middle or end number of 4, 5, or 6. The S840-000-1C has a 420mA signal output; the PT150-7.5M has a 0-5Vdc signal output, while PT276-5M has a

0-10Vdc signal output.

If you have an amplified transducer, or other amplified input, skip this section.

The UPR800’s default setting is strain gage input. To verify that the input is set for strain

gage, press the FUNC key until nonE and GROUP show on the display. Press the t

key until 5 shows in the upper display. Press the FUNC key and the upper display should

show Str while the lower display shows PI.TYP. If not, press the u or t key until the

upper display changes to Str (for strain gage). Press the FUNC key to set the value. The

upper display changes to tc with SI.TYP on the lower display. Press the RESET key to

return to the active display.

8.3.2 Setting the Shunt Calibration for Strain Gage Transducers and Amplified

units

The Dynisco strain gage transducers and amplified transmitters (if so equipped) have an

internal shunt to allow the UPR800 to set the span full scale value automatically. To

Access the Shunt Calibration parameter, press the FUNC key until nonE and GROUP

show on the display. Press the t key until 4 shows in the upper display. Press the

FUNC key and the upper display will show OFF while the lower display shows SHUNT.

Press the u or t key until the upper display changes to the ON. Press the FUNC key to

set the value and move to the next Shunt parameter.

The upper display will show 80.0 while the lower display shows SHNT%. In most cases,

the Dynisco transducers have an 80% shunt value so no changes need be made.

However, some transducers and strain gages have shunt values that may range from 40100%. If so, press the u or t key until the upper display changes to the correct values.

Press the FUNC key to set the value. Press the RESET key to go back to the active

display.

8.3.3 Setting the Primary Input Type for an Amplified Transmitter

If using a voltage or current output transducer, the model number of the transducer will

designate its own electrical output. For example, a PT4624-7.5M-6/18 or an S840-00010M has an amplified signal output. In plastic melt applications, amplified units have a

number where the strain gage units have a letter (E or A). The PT4624-7.5M-6/18 has a

4-20mA signal output; the PT4625-7.5M-6/18 has a 0-5Vdc signal output, while PT4626-

7.5M-6/18 has a 0-10Vdc signal output. In Industrial applications, amplified units have a

Page 35

DYNISCO UPR800 Series Instruction Manual

Page | 35

middle or end number of 4, 5, or 6. The PT140 has a 4-20mA signal output; the PT150-

7.5M has a 0-5Vdc signal output, while PT276-5M has a 0-10Vdc signal output. NOTE: If

using 0-10V transmitter, do not connect RCal leads to terminals 14 & 17.

If you have a strain gauge transducer, load cell, or other mV/V device, see other section.

The Instrument’s default setting is strain gage input. To select another input for a

transmitter or to use another process instrument, such as humidity sensors, position

sensors, etc., press the FUNC key until nonE and GROUP show on the display. Press

the t key until 5 shows in the upper display. Press the FUNC key and the upper display

will show Str while the lower display shows PI.TYP. Press the u or t key until the upper

display changes to the correct value (0-20 for 0-20 mA linear input, 4-20 for 4-20 mA

current loop input, 0-5 for 0-5Vdc linear input, and 0-10 for 0-10Vdc linear input. Press

the FUNC key to set the value. Press the RESET key to go back to the active display.

Remember to change software configuration to correspond to the proper input.

8.3.4 Setting the Primary Input Full-Scale Value

The model number of the transducer or transmitter will designate the full-scale pressure

capability. For example, model number TPT432A-5M-6/18 indicates that the full-scale

pressure is 5,000 (5M), while the PT150-5C indicates that the full-scale pressure is 500

(5C). Since the default value in the instrument is 10,000 full scale, the input full-scale

value must be changed to 5,000 (or 500). Note that there are no units here, it can be psi,

bar, mPa, kg/cm

2

or any engineering unit; the magnitude is all that is important. To set

the full-scale value, press the FUNC key until nonE and GROUP show on the display.

Press the t key until 3 shows in the upper display. Press the FUNC key and the upper

display will show 10000 while the lower display shows PI.FSV. Hold the u or t key until

the upper display changes to 5000 (or whatever the full-scale value of the primary input

may be). Press the FUNC key to set the value. Check that the next display reads 0 in

the upper display and PI.LSV in the lower display; if not, set to zero with the arrow keys

and press FUNC to lock in the value. Finally, press the RESET key to go back to the

active display. Similarly, if the full-scale pressure is 350 Bar (3.5CB), set PI.FSV to 350.

8.3.5 Setting the Primary Input Low-Scale Value

For applications where a low scale value is non-zero, the Instrument can provide a low

scale value of ±25% of the full scale value.

To set the low-scale value, press the FUNC key until nonE and GROUP show on the

display. Press the t key until 3 shows in the upper display. Press the FUNC key and

the upper display will show a value while the lower display shows PI.SFV. Press the

FUNC key and the upper display will show 0 while the lower display shows PI.LFV. Hold

the u or t key until the upper display changes to whatever the low-scale value of the

primary input may be. Press the FUNC key to set the value. Finally, press the RESET

key to go back to the active display.

Page 36

DYNISCO UPR800 Series Instruction Manual

Page | 36

8.3.6 Setting the Primary Input Decimal Place

To set the decimal place, press the FUNC key until nonE and GROUP show on the

display. Press the t key until 3 shows in the upper display. Press the FUNC key until

the lower display shows PI.DP. Press the u or t key until the upper display shows the

correct decimal place location. Press the FUNC key to set the value. Finally, press the

RESET key to go back to the active display.

8.3.7 Setting the Primary Input Failsafe Mode

The Primary Input Failsafe Mode is nothing more than a safety mechanism that tells the

instrument what to do in the event of a loss of the primary signal. If the system is set up

to shut down the process in a high alarm condition, the Primary Input Failsafe parameter

sets the value of the primary input to full scale if it loses the primary signal. If the system

is set up to shut down the process in a low alarm condition, the Primary Input Failsafe

parameter sets the value of the primary input to low scale if it loses the primary signal.

The default Primary Input Failsafe Mode is to set the value to full scale high.

To set the Primary Input Failsafe Mode, press the FUNC key until nonE and GROUP

show on the display. Press the t key until 4 shows in the upper display. Press the

FUNC key until the lower display shows PI.IFS. Press the u or t key until the upper

display shows the correct mode, either HI or Lo. Press the FUNC key to set the value.

Finally, press the RESET key to go back to the active display.

8.4 Secondary Input Setup

Skip this section if there is no secondary input or if this is a new installation and the

secondary input is for a “J” type thermocouple expressed in degrees Fahrenheit (°F).

8.4.1 Setting the Secondary Input Type

The Secondary Input measured values will show in the lower display. The Instrument’s

default secondary input setting is for a “J” type thermocouple. To select another type of

input, press the FUNC key until nonE and GROUP show on the display. Press the t key

until 5 shows in the upper display. Press the FUNC key twice and the upper display will

show tr while the lower display shows SI.TYP. Press the u or t key until the upper

display changes to the correct value (rtd for Platinum RTD, 0-20 for 0-20 mA linear input,

4-20 for 4-20mA current loop input, 0-10 for 0-10Vdc linear input, and OFF if the input is

to be disabled. Press the FUNC key to set the value. Finally, press the RESET key to go

back to the active display.

Remember to change software configuration to correspond to the proper input.

8.4.2 Setting the Secondary Input Scale and Decimal Point

Skip to “Setting the Thermocouple Type and Units” if the secondary input is for an RTD or

a thermocouple.

If the Instrument’s secondary input is set as a voltage or current, the Range Values need

to be set. Press the FUNC key until nonE and GROUP show on the display. Press the

t key until 3 shows in the upper display. Press the FUNC key and the upper display will

show the full scale value while the lower display shows SI.FSV. Press the FUNC key until

Page 37

DYNISCO UPR800 Series Instruction Manual

Page | 37

the lower display changes to SI.LO. Using the u or t keys, enter the zero value for the

input. For example if the input from a device is 500-3,000 units, it is 500 units at zero, so

enter 500. Press the FUNC key to set the value. The lower display will change to SI.HI.

Using the u or t keys, enter the high (full-scale) value for the input. For example if the

input from a device is 500-3,000 units, it is 3,000 units at full scale, so enter 3000. Press

the FUNC key to set the value. The lower display will change to SI.DP, the decimal point

position for the secondary input. Using the u or t keys, select the position for the

decimal point for this input and press FUNC to lock in the value. Finally, press the

RESET key to go back to the active display.

8.4.3 Setting the Thermocouple Type and Units:

If the secondary input is from a thermocouple, set the thermocouple type and temperature

units, by pressing the FUNC key until nonE and GROUP show on the display. Press the

t key until 3 shows in the upper display. Press the FUNC key until the lower display

shows SI.TC. Press the u or t key until the upper display changes to the correct value

(tc j for type “J”, tc CA for type “K”, tc L for type “L”, and tc n for a type “N”

thermocouple). Press the FUNC key to set the value. The upper display changes to

FAHr (for Fahrenheit) while the lower display shows SI.C/F. Press the u or t key to

change to Celsius CEL or if desired.

These inputs are factory pre-calibrated for the following ranges, and require no further

calibration.

ThermocoupleType J -200 to 800°C -328 to 1472°F

Type K (CA) -200 to 1200°C -328 to 2192°F

Type L -200 to 800°C -328 to 1472°F

Type N 0 to 1300°C 32 to 2372°F

Type T -200 to 400°C -328 to 752°F

Type E -200 to 600°C -328 to 1112°F

RTD Pt100 -200 to 600°C -328 to 1112°F

Pt500 -200 to 600°C -328 to 1112°F

8.4.4 Setting the Secondary Input Failsafe Mode

The Secondary Input Failsafe Mode is a safety mechanism that tells the instrument what

to do in the event of a loss of the Secondary signal. In the event of a Secondary input

signal loss, the Secondary Input Failsafe parameter sets the value of the primary input to

full scale (in the default mode).

To set the Primary Input Failsafe Mode, press the FUNC key until nonE and GROUP

show on the display. Press the t key until 4 shows in the upper display. Press the

FUNC key until the lower display shows SI.IFS. Press the u or t key until the upper

Page 38

DYNISCO UPR800 Series Instruction Manual

Page | 38

display shows the correct mode, either HI or Lo. Press the FUNC key to set the value.

Finally, press the RESET key to go back to the active display.

8.5 Setting the Alarms:

All Alarms supplied with the Instrument can be linked to either the Primary Input or the

Secondary Input (if available), and are capable of being set as High Level Alarms or Low

Level Alarms, and may operate in either Failsafe or Direct condition.

Failsafe means that in the event of power failure to the Instrument, the Alarm will activate.

Use this feature on a shutdown alarm. Please note that in a proper operating condition in

Failsafe mode, the Normally Closed Contact are held OPEN, while the Normally Open

contacts are held CLOSED. On power failure, they are released.

On start-up, a Low Alarm may cause the unit to go into an undesired alarm condition prior

to reaching running conditions. This Alarm can be masked so that the Low Alarm will be

deactivated until it has gone above the alarm value for the first time. It will then operate

as a normal low alarm.

The default values for Alarm 1 are: high alarm at 40% of full scale, linked to the primary

input, 0.4 second filtering, 1% hysteresis, automatic reset, and failsafe mode. Each alarm

may be set to 110% of full scale.

The default values for Alarm 2 are: high alarm at 60% of full scale, linked to the primary

input, 0.4 second filtering, 1% hysteresis, automatic reset, and failsafe mode.

The default values for Alarm 3, if supplied, are: high alarm at 80% of full scale, disabled

(not linked to any input), 0.4 second filtering, 1% hysteresis, automatic reset, and failsafe

mode.

Set the Alarm parameters before setting the alarm value. If the alarm parameters have

already been set, set the alarm values as described in section 8.6.7.

8.5.1 Setting Channel Alarm to Monitor (Alarm Input Channel Link):

The Alarm 1 Input Channel Link defaults to the primary input. To check or change this

value press the FUNC key until nonE and GROUP show on the display. Press the t key

until 3 shows in the upper display. Press the FUNC key until A1.LNK shows in the lower

display. Select the choice desired by pressing the u or t keys. The choices are: OFF,

(disabled), linked to the primary input Prl.In, or linked to the secondary input Sec.In.

Note: if you do not have a secondary input, Sec.In will not appear as a choice. Press the

FUNC key to lock in the value and advance to the next parameter. Similarly, you may

configure Alarm 2 (A2.LNK) and if supplied, Alarm 3 (A3.LNK).

8.5.2 Setting Alarm Type:

A high alarm will activate when a set point is exceeded. A low alarm will activate

whenever the value falls below a set point (including startup). An inhibited low alarm

must exceed the low alarm set point before it is enabled. Then it will work like a low

alarm. This is ideal on startup.

Page 39

DYNISCO UPR800 Series Instruction Manual

Page | 39

The default alarm type for Alarm 1 is high. To check or change this value press the

FUNC key until nonE and GROUP show on the display. Press the t key until 3 shows in

the upper display. Press the FUNC key until A1.TYP shows in the lower display. Using

the u or t keys, select HI for high level alarm, LO for low level alarm or Inhib for a low

level alarm with mask at start-up. Press the FUNC key to lock in the value and advance

to the next parameter. If finished, press RESET to return to the operating screen.

Similarly, you may configure Alarm 2 (A2.TYP) and if supplied, Alarm 3 (A3.TYP).

8.5.3 Setting the Filtering for Alarm 1:

Filtering is an electrical method of averaging the input values over a period of time to

arrive at a smoother curve. This helps to eliminate short duration transients and spikes

which can cause alarms, but which may cause false or spurious readings.

The Alarm filter default is 0.4 seconds of filtering. To change this value, press the FUNC

key until nonE and GROUP show on the display. Press the t key until 2 shows in the

upper display. Press the FUNC key until the lower display changes to A1.FL. Using the

u or t keys, select the amount of filtering desired, from none (OFF) to five seconds.

When finished, press the FUNC key to lock in the value and advance to the next

parameter. If finished, press RESET to return to the operating screen. Similarly, you may

configure Alarm 2 (A2.FL) and if supplied, Alarm 3 (A3.FL).

8.5.4 Setting the Hysteresis for Alarm:

Hysteresis is used to describe the amount that the reading must drop below the alarm

point (in a high alarm) or must rise above the alarm point (in a low alarm) to clear the

alarm condition. This helps to eliminate short duration alarms when operating near the

alarm condition. To change or view this value, press the FUNC key until nonE and

GROUP show on the display. Press the t key until 4 shows in the upper display. Press

the FUNC key until the lower display changes to A1.HYS. The values for hysteresis can

range from 0.1% to 10.0%. Press the u or t keys until the upper display changes to the

desired value. Press the FUNC key to lock in the value and advance to the next

parameter, or press RESET to return to the operating screen. Similarly, you may

configure Alarm 2 (A2.HYS) and if supplied, Alarm 3 (A3.HYS).

8.5.5 Setting the Reset Mode for Alarms:

The Alarm Reset Mode determines if the alarm resets itself once the alarm condition is

been corrected, or whether the operator must press a button to reset the alarm. The

Alarm Reset Mode default is automatic reset once the alarm has cleared. To change or

view this value, press the FUNC key until nonE and GROUP show on the display. Press