Page 1

Operating Instructions

SPXD

Field Display

BA111O/09/a5/03.05

Page 2

Digital field display

2

Page 3

Digital field display

Digital field display

Operating manual

(Please read before installing the unit)

Unit number:.....................................

Digitaler Feldanzeiger

Betriebsanleitung

(Bitte lesen, bevor Sie das Gerät in Betrieb nehmen)

Gerätenummer:.....................................

Indicador de campo digital

Manual de instrucciones

(Por favor, lea el manual antes de instalar la unidad)

Número de unidad:.....................................

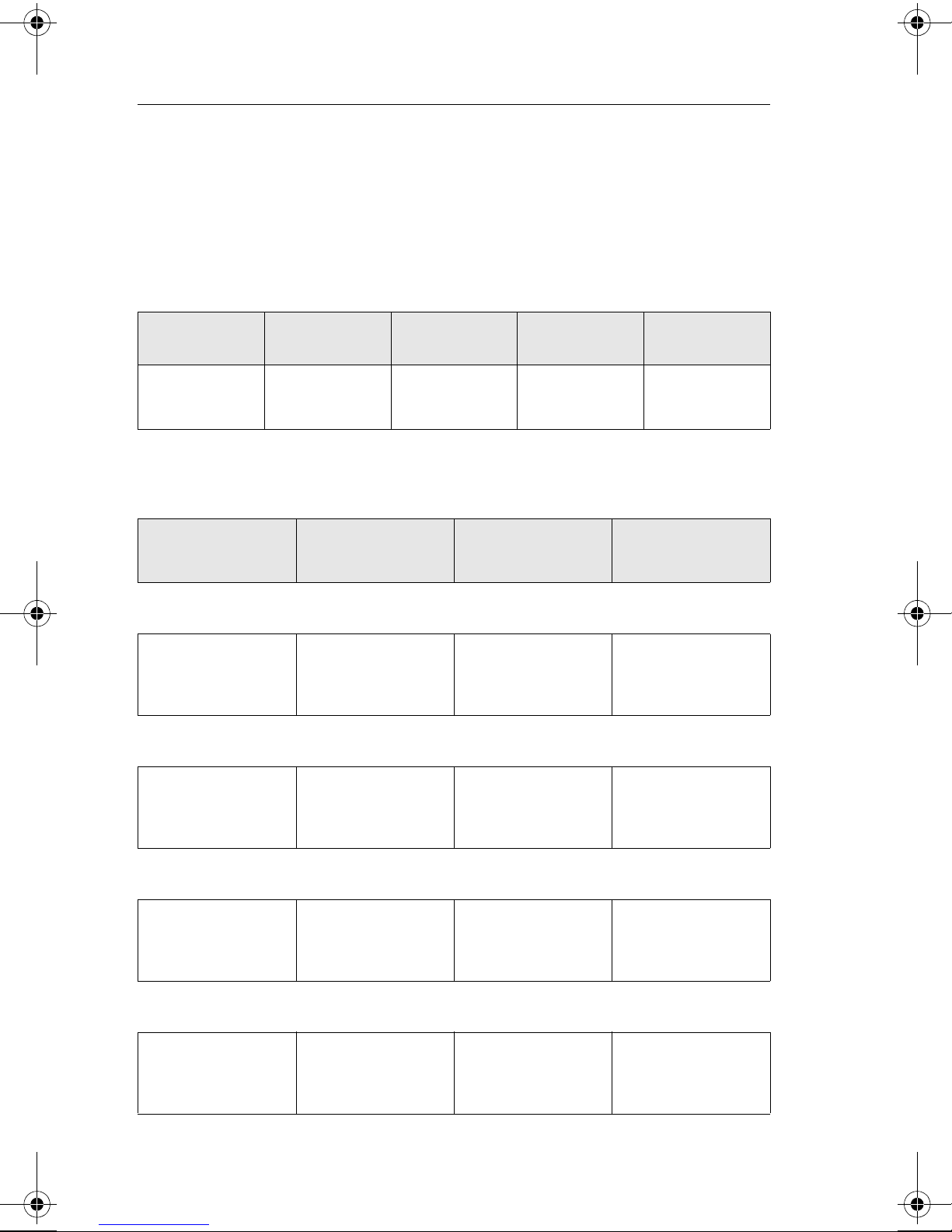

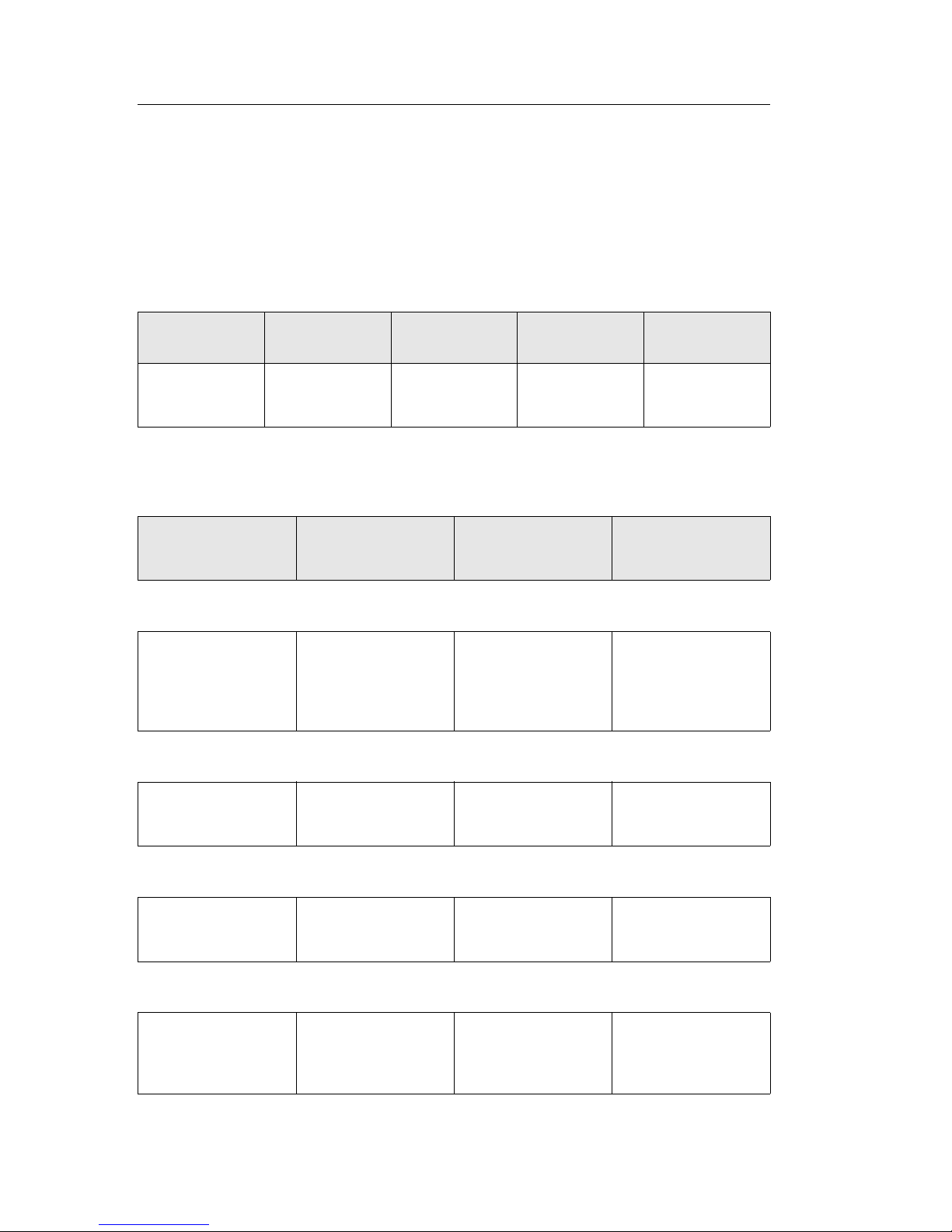

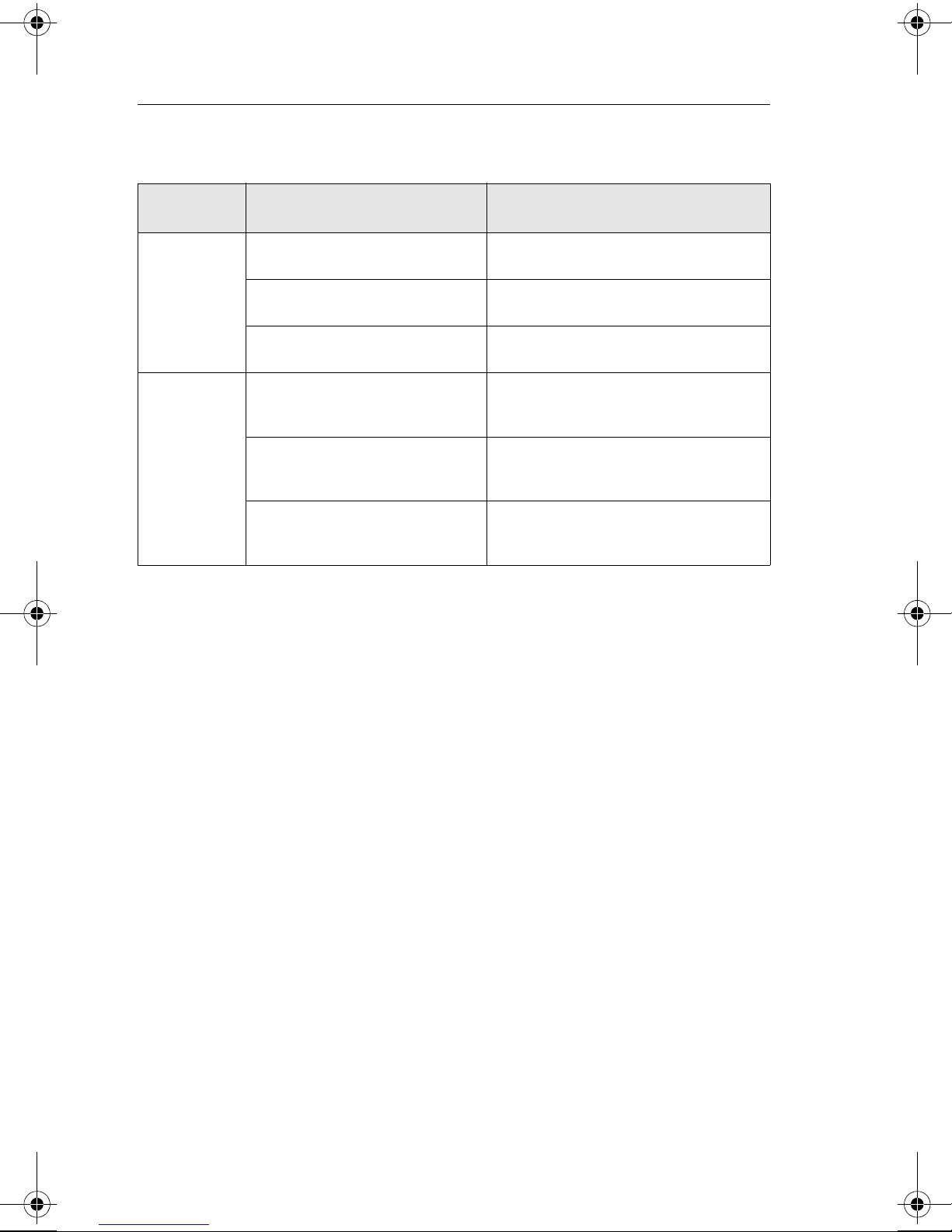

English

English

3 ... 26

19...34

Deutsch

English

27 ... 50

19...34

Español

Español

51 ... 74

19...34

Indicateur de process

Manuel de mise en service

(veuillez entièrement lire le manuel avant la mise en service de l’appareil)

o

appareil:....................................

N

Visualizzatore digitale da campo

Manuale operativo

(Si prega di leggere prima di installare l’unità)

Codice unità:....................................

Français

English

75 ... 98

19...34

Italiano

English

99 ... 122

19...34

3

Page 4

Table of contents Digital field display

Table of contents

1 Safety hints . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Correct use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Installation, commissioning, operation . . . . . . . . . . 6

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Returns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.5 Safety pictograms and symbols . . . . . . . . . . . . . . . . 7

2 Identification. . . . . . . . . . . . . . . . . . . . . 7

2.1 Unit identification . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 What is delivered? . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Operation and system construction . . . 8

3.1 Measurement principle . . . . . . . . . . . . . . . . . . . . . . 8

3.2 System construction . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Mechanical installation . . . . . . . . . . . . . 9

4.1 Installation conditions . . . . . . . . . . . . . . . . . . . . . . 9

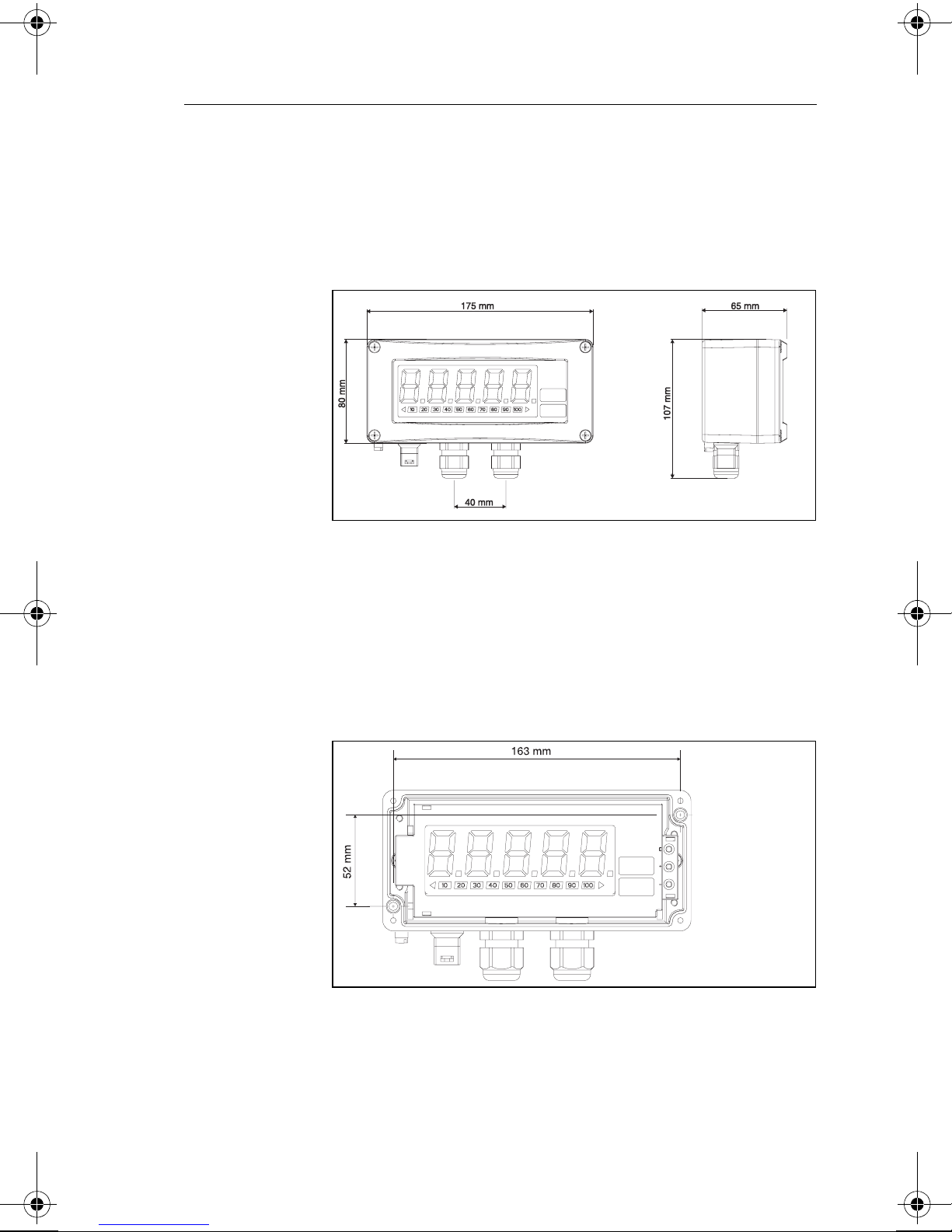

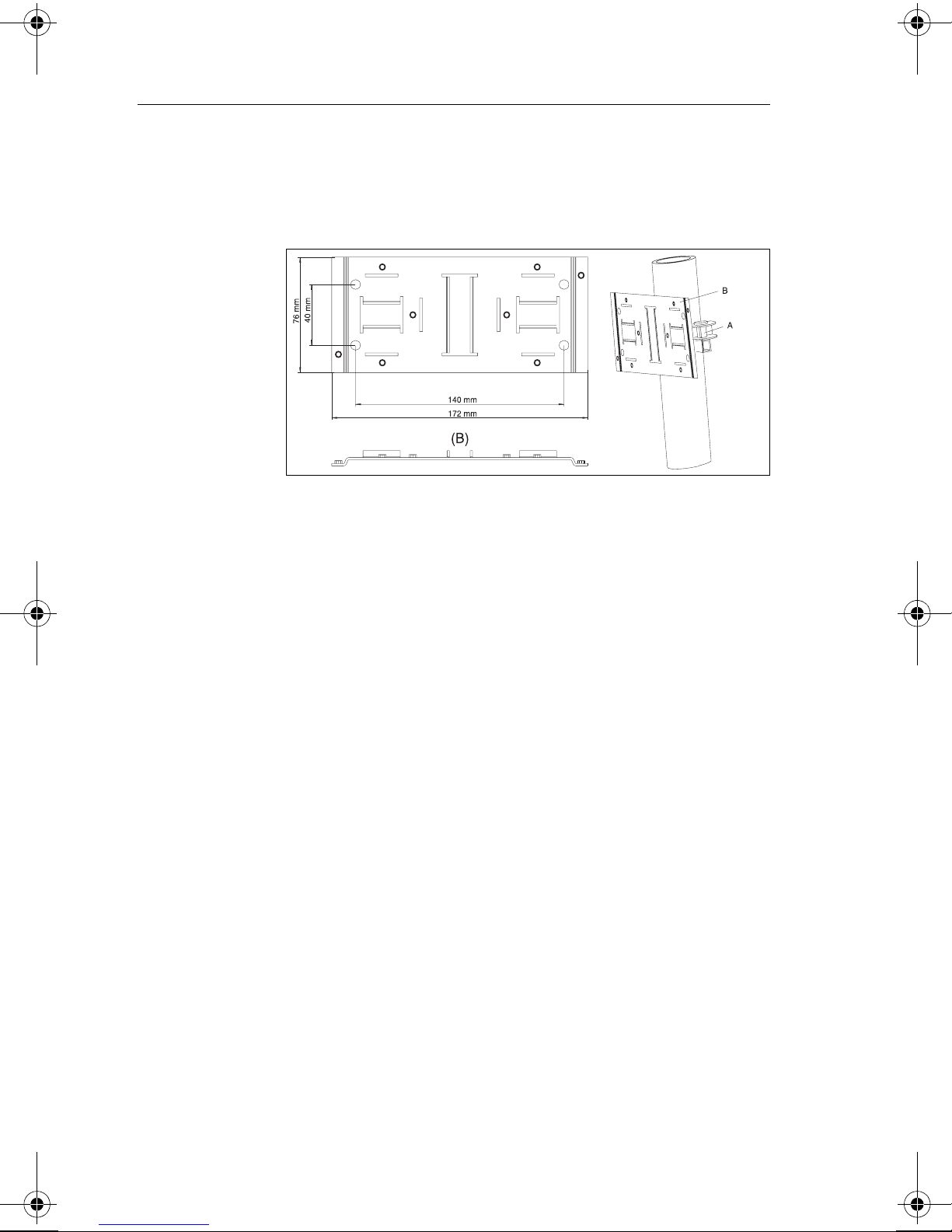

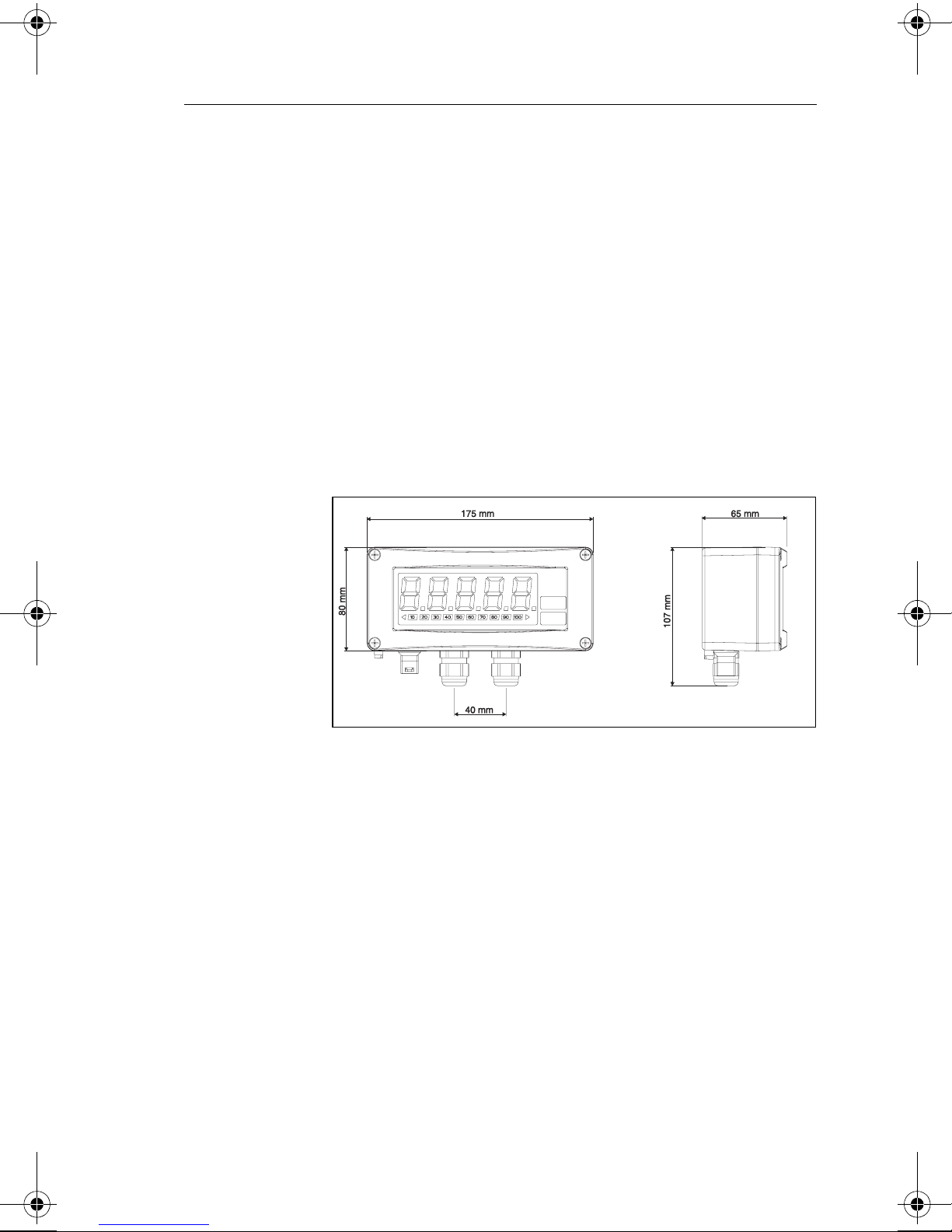

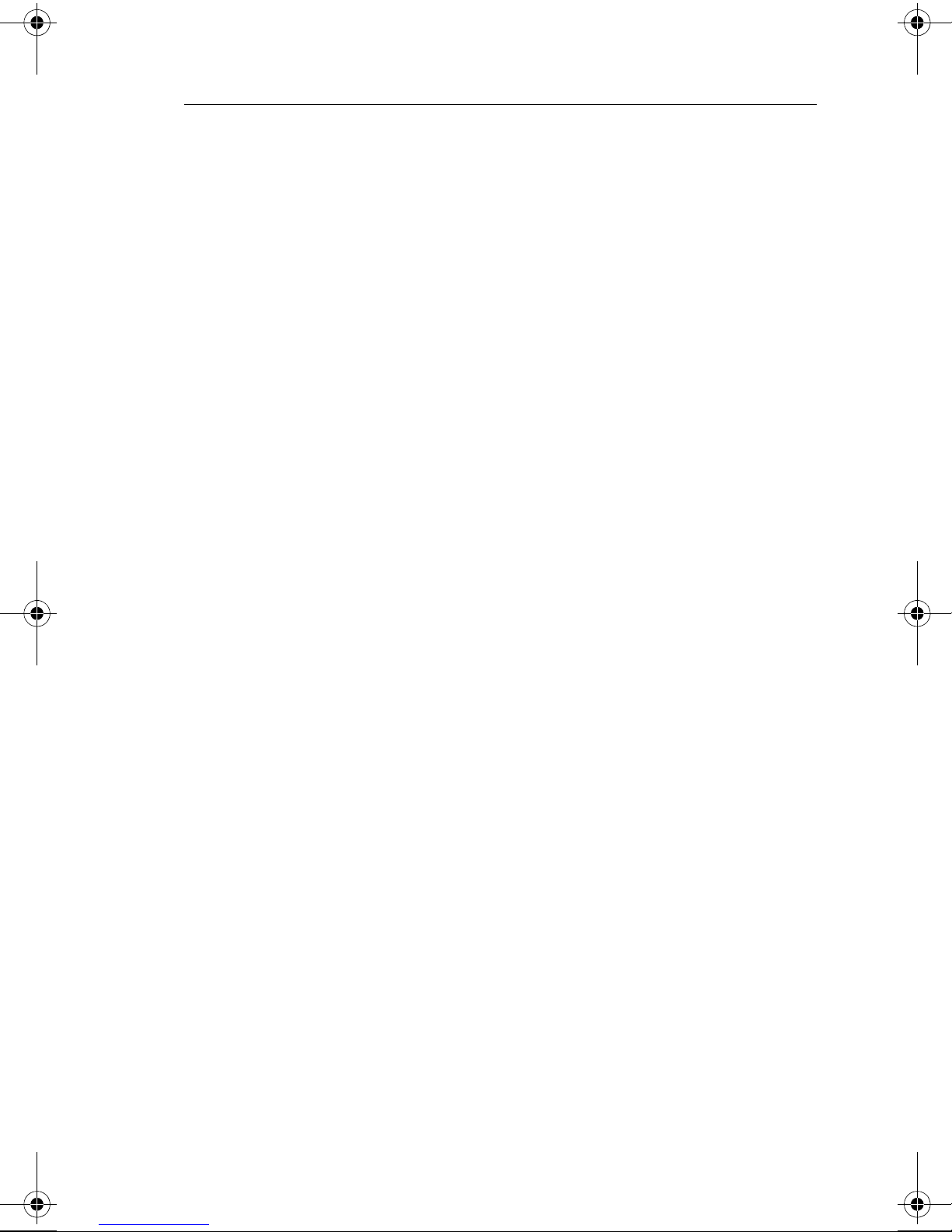

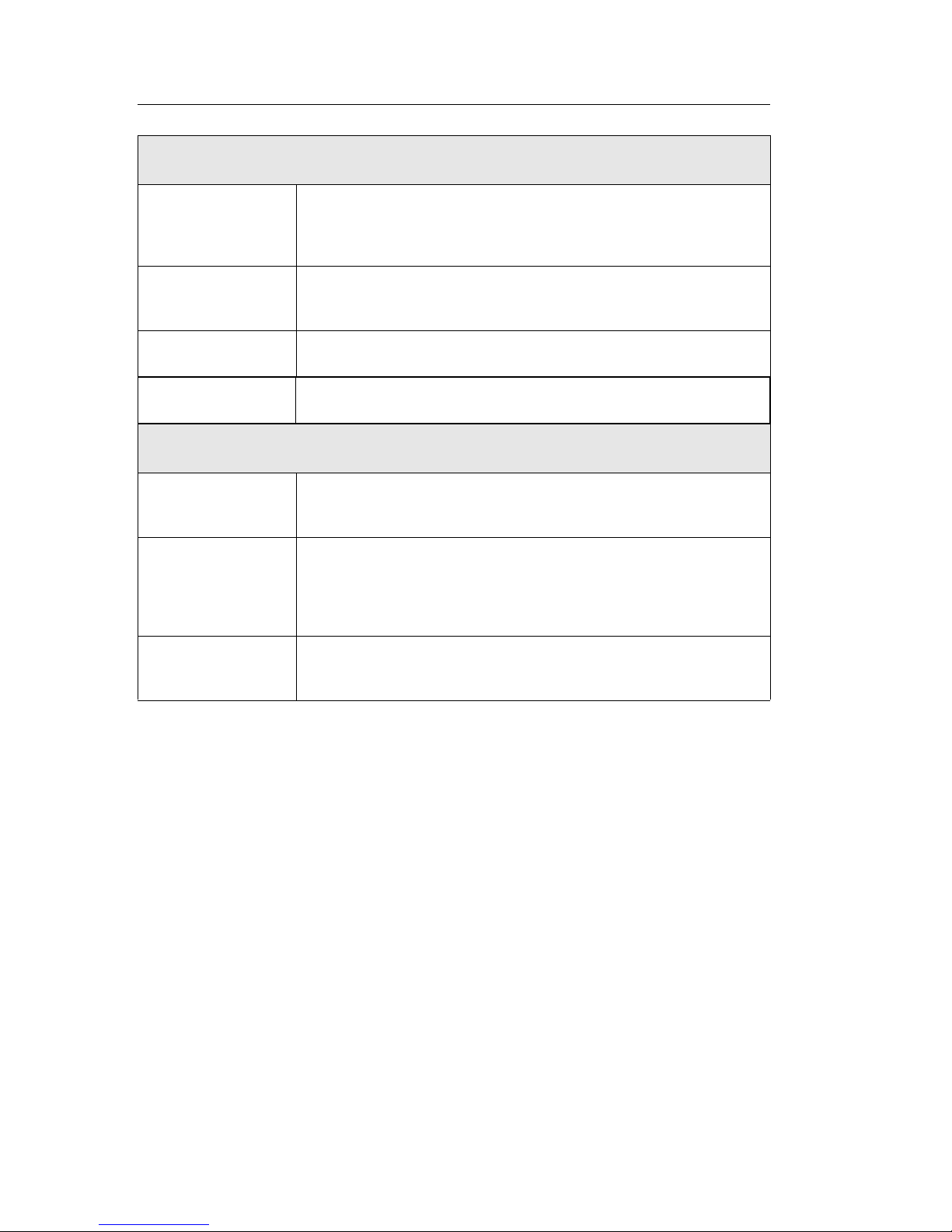

4.1.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

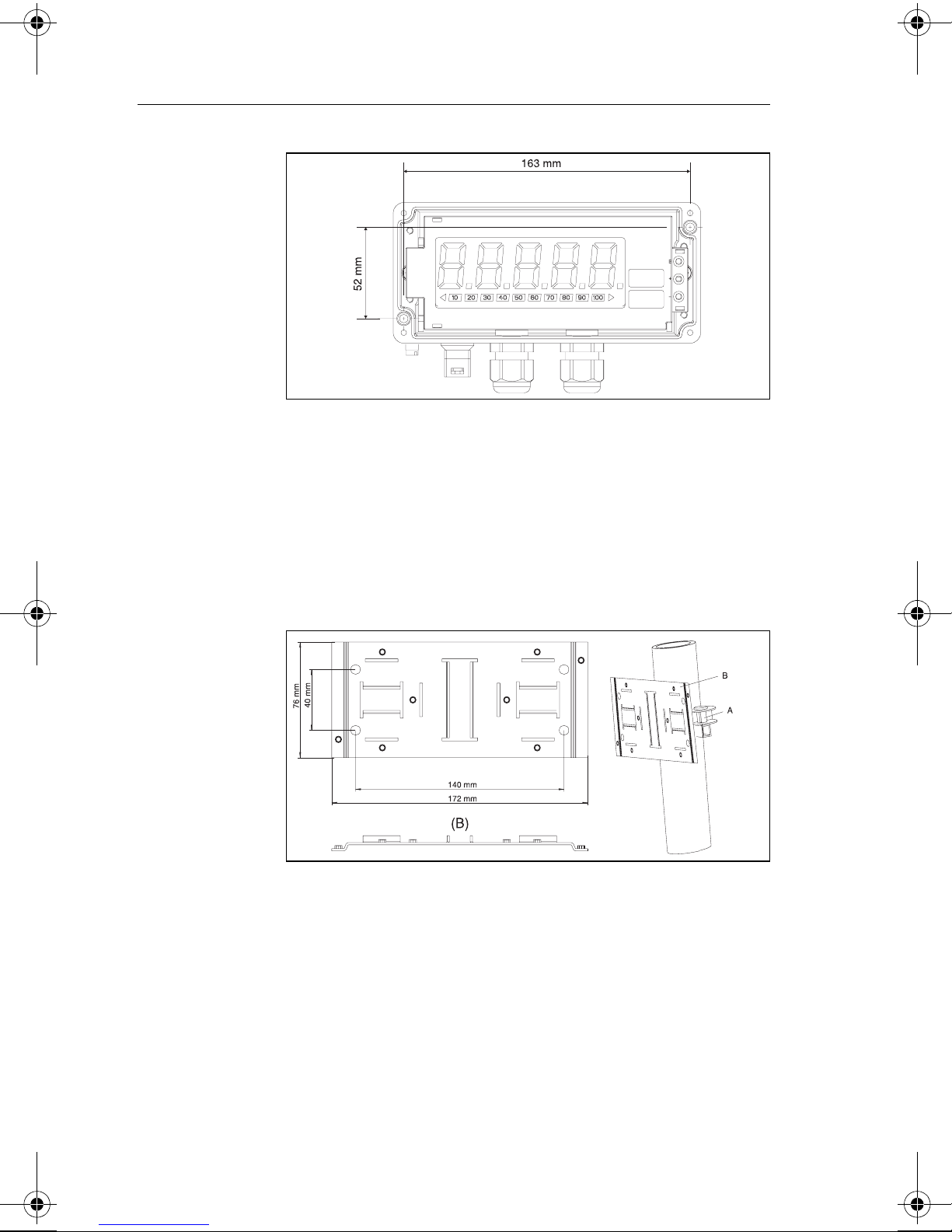

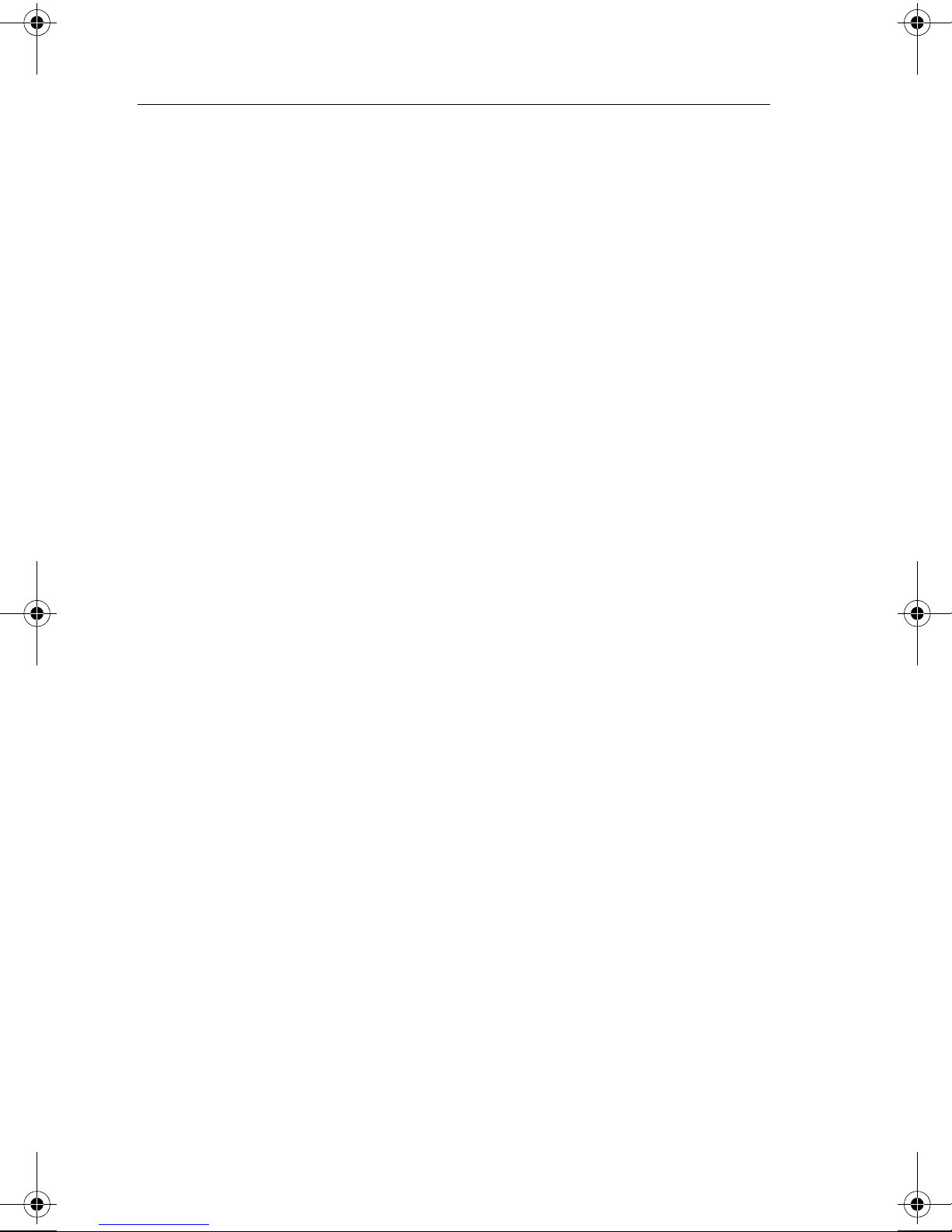

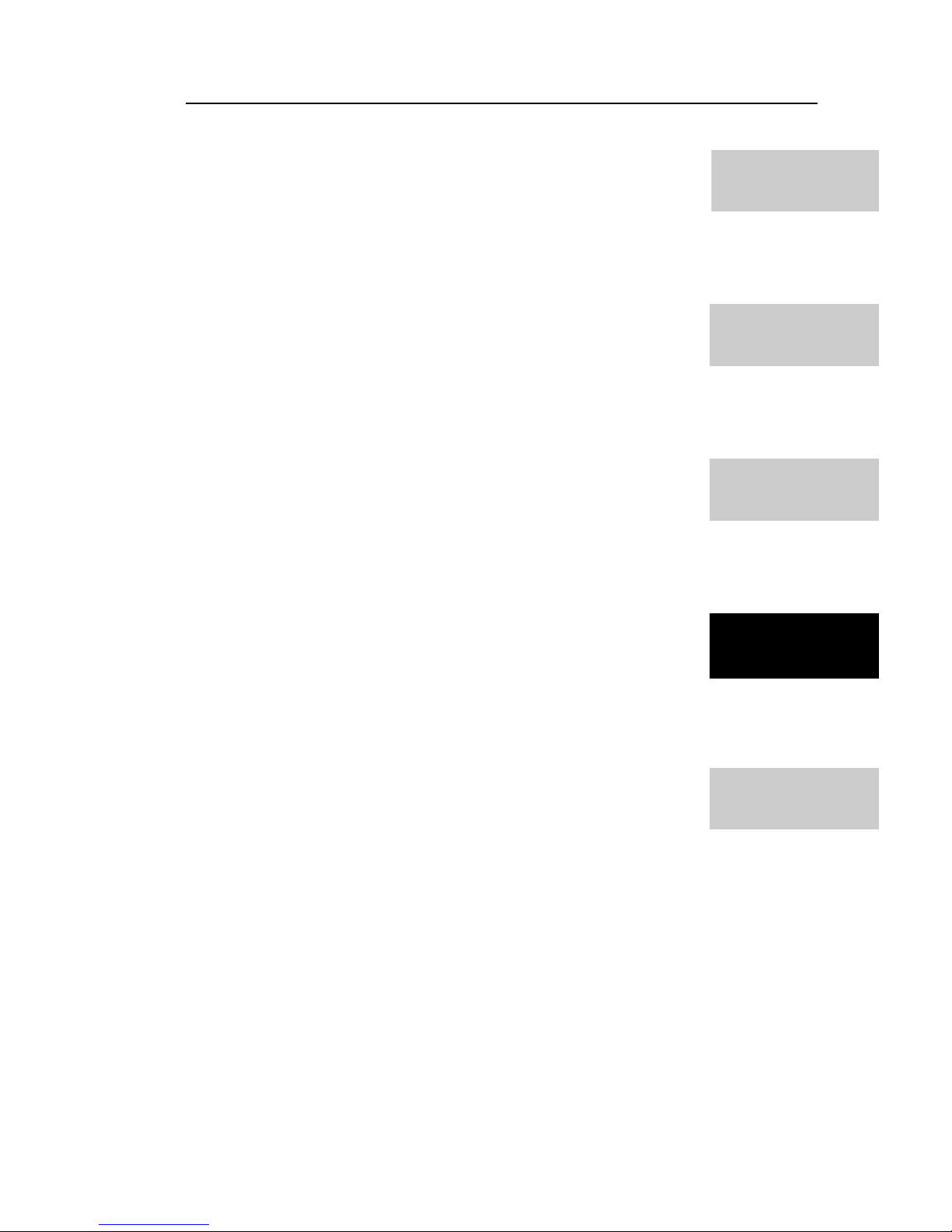

4.2.1 Direct wall mounting . . . . . . . . . . . . . . . . . 9

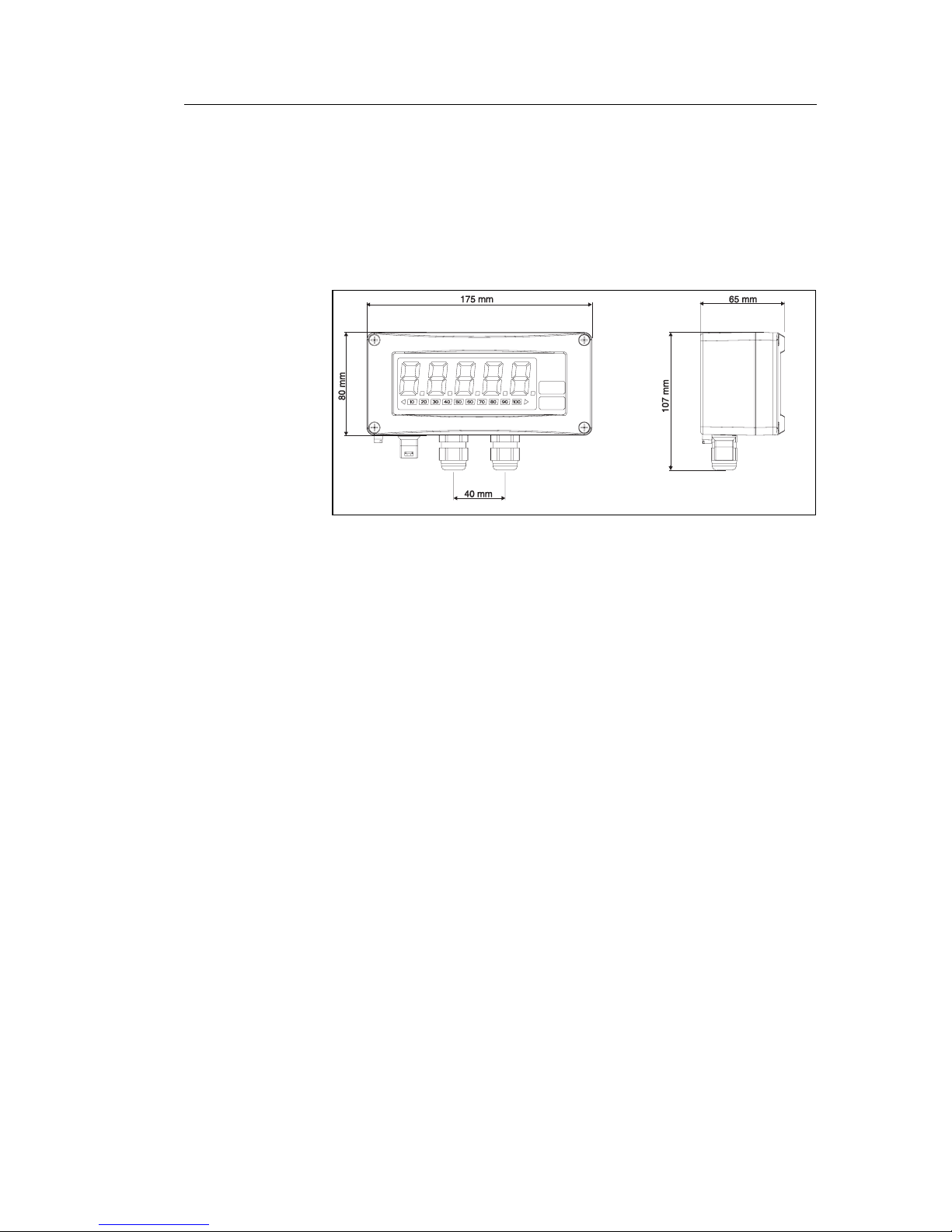

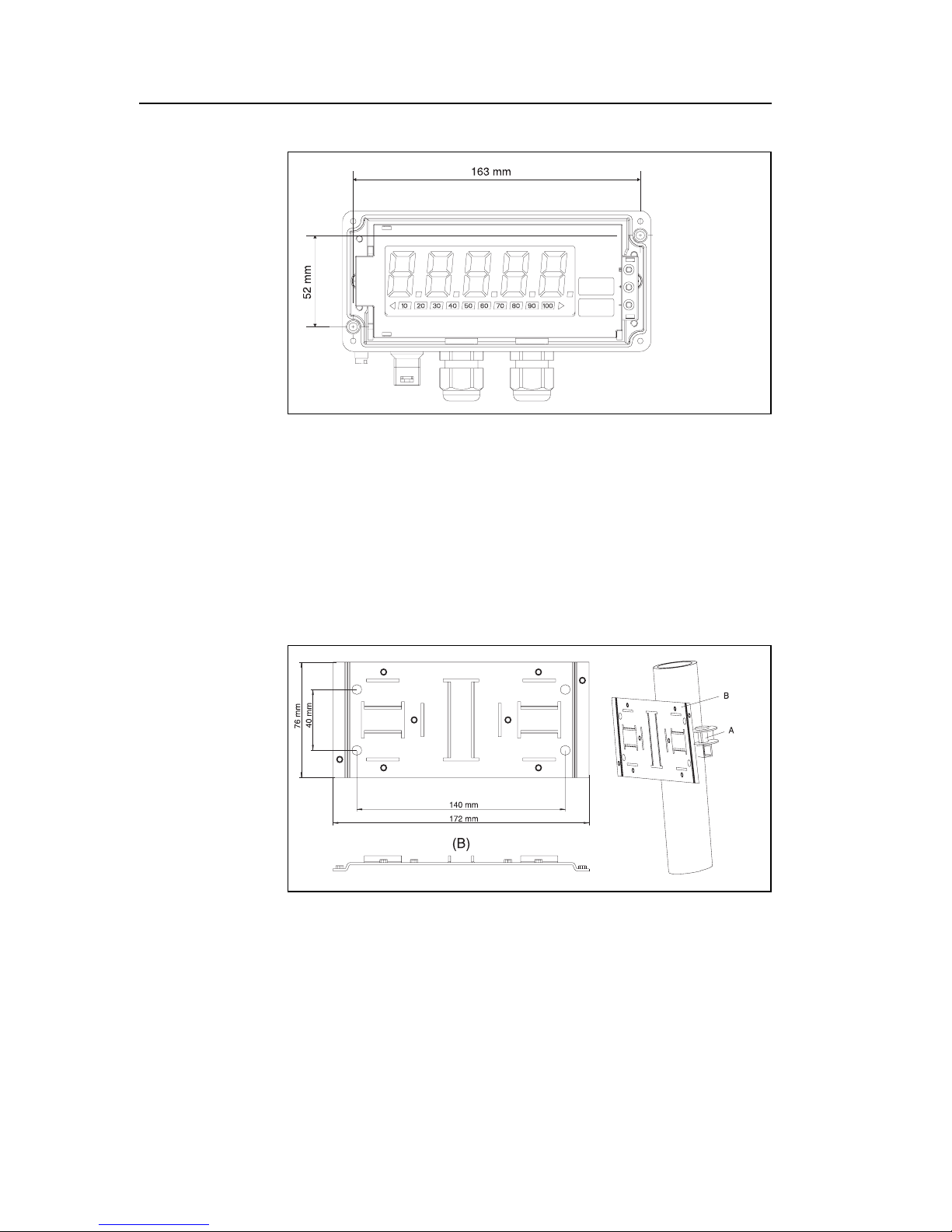

4.2.2 Wall and stand pipe mounting bracket . . . 10

4.2.3 Installation of additional measurement

electronics . . . . . . . . . . . . . . . . . . . . . . . . 10

4.3 Installation control . . . . . . . . . . . . . . . . . . . . . . . . 10

5 Electrical connection. . . . . . . . . . . . . . 11

5.1 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.1.1 Terminal layout . . . . . . . . . . . . . . . . . . . . 11

5.1.2 Electrical connection . . . . . . . . . . . . . . . . 11

5.1.3 Connecting active current source . . . . . . . 12

4

Page 5

Digital field display Table of contents

5.1.4 Connecting a passive current source . . . . . 13

5.2 Connection control . . . . . . . . . . . . . . . . . . . . . . . 13

6 Operation . . . . . . . . . . . . . . . . . . . . . . 13

6.1 Operation overview . . . . . . . . . . . . . . . . . . . . . . . 13

6.2 Display and operating elements . . . . . . . . . . . . . . . 14

6.3 Setting-up using the operating menu . . . . . . . . . . . 15

6.3.1 Operating menu overview . . . . . . . . . . . . 15

6.4 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . 16

7 Commissioning. . . . . . . . . . . . . . . . . . 17

7.1 Installation and function control . . . . . . . . . . . . . . 17

7.2 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8 Maintenance. . . . . . . . . . . . . . . . . . . . 17

9 Accessories. . . . . . . . . . . . . . . . . . . . . 17

10 Fault-finding . . . . . . . . . . . . . . . . . . . . 17

10.1 Fault-finding instructions . . . . . . . . . . . . . . . . . . . 17

10.2 Process fault messages . . . . . . . . . . . . . . . . . . . . . 18

10.3 System messages . . . . . . . . . . . . . . . . . . . . . . . . . 19

10.4 Fault analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

10.5 Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

10.6 Returns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

10.7 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

11 Technical data . . . . . . . . . . . . . . . . . . 20

5

Page 6

1 Safety hints Digital field display

1 Safety hints

1.1 Correct use

The digital field display left the factory in perfect and safe condition.

•

• Safe operation can only be guaranteed if this operating manual has

been correctly followed.

• The manufacturer cannot be held responsible for damage caused by

incorrect use of the instrument.

• The unit must only be used within the specified temperature range.

• Separate Ex documentation for measurement systems within hazar-

dous areas is enclosed. The installation regulations and connection

values must be noted and consequentially followed!

1.2 Installation, commissioning, operation

The unit has been manufactured using state-of-the-art technology and

complies to the relevant regulations as well as EU guidelines. If, however, the unit is misused or not applied correctly, it could become dangerous. Mechanical and electrical installation, commissioning and maintenance must only be carried out by skilled and trained personnel who

have been authorised to do so by the plant operator. The skilled personnel must read this manual and follow the instructions contained in it.

The installer must make sure that the measurement system is connected

following the electrical connection diagrams. Changes and repairs on

the unit must only be done if the manual shows these to be possible.

Always take note of the national electrical safety regulations when opening or repairing electrical units.

1.3 Operational safety

Hazardous area

If the measurement system is to be installed in a hazardous area, the

national regulations must be followed. Make sure that the skilled personnel is suitably trained. All measurement, safety values and regulations must be adhered to.

6

Page 7

Digital field display 2 Identification

Technical advancement

The manufacturer reserves the right to improve and update technical

details without the need for special notification. Information as to the

validity or expansions to this manual can be obtained from the local

sales organisation.

1.4 Returns

If there is any transportation damage, please inform the shipping agent

and the local sales organisation immediately.

1.5 Safety pictograms and symbols

„Note” means activities or sequences that, if done incorrectly, could

!

"

have an indirect influence on the unit’s operation or could release an

unforeseen unit reaction.

„Attention” means activities or sequences that, if done incorrectly,

could lead to personal injury or faulty unit operation.

#

0

.

„Warning” means activities or sequences that, if done incorrectly, could

lead to serious personal injury, a safety risk or total damage of the unit.

Explosion protected, tested units

If this symbol is fitted to the unit legend plate, it can be operated in an

hazardous area.

Safe area (non hazardous areas)

This symbol identifies the non hazardous areas on the drawings contained in this manual. Units mounted in the non hazardous area must also

be certified if connection cables lead to the hazardous area.

2 Identification

2.1 Unit identification

The correct unit?

Please compare the order code on the unit legend plate with that on the

delivery note.

7

Page 8

3 Operation and system construction Digital field display

2.2 What is delivered?

- Field display, model to order.

- Operating manual.

- Accessories as ordered.

2.3 Certification

CE mark, conformity certification

The unit has been manufactured using state-of-the-art technology and

has left the factory in perfect working order. The unit complies with

relevant regulations as well as the IEC 61010 “Safety regulations for

measurement, control and laboratory instrumentation" directives.

This means that the unit described in this operating manual

fulfils the legal requirements laid down in the EU directives. The manufacturer acknowledges successful testing of the unit by adding the CE

mark to it.

3 Operation and system construction

3.1 Measurement principle

The field mounted display is directly connected to a 4 to 20 mA current

circuit. The energy required to power the unit is derived from the current loop. The unit monitors an analogue measured value and shows

this on an easily read LC display. Additionally, the measured value is

also shown in the form of a bargraph.

Increased readability in dark areas is achieved by the addition of a illuminated display.

3.2 System construction

Micro-controller controlled field mounted display with rear illuminated

numeric and analogue LC display. Display update is made every second.

The dynamic internal resistor (load) makes sure that the signal circuit

voltage drop is always < 2.5 V.

8

Page 9

Digital field display 4 Mechanical installation

4 Mechanical installation

4.1 Installation conditions

4.1.1 Dimensions

ƒig. 1: Dimensions

4.2 Installation

The unit is suitable for wall mounting. A combined wall/stand pipe

mounting adaptor can be ordered as an option (see accessories).

4.2.1 Direct wall mounting

ƒig. 2: Direct wall mounting

Follow these instructions when mounting the unit directly to a wall:

• Following the drilling plan, drill and prepare (rawl plugs etc.) the two

mounting holes in the wall.

9

Page 10

4 Mechanical installation Digital field display

• Loosen and remove the unit lid.

• Mount the unit to the wall using the respective screws, bolts.

4.2.2 Wall and stand pipe mounting bracket

(See chapt. 9 "Accessories").

ƒig. 3: Wall and stand pipe mounting bracket

"

Follow these instructions when using the combined wall/stand pipe

mounting bracket:

• For wall mounting follow the drilling plan and drill and prepare the

four holes in the wall (rawl plugs, etc.).

• Install the mounting bracket (B) to the wall or stand pipe using the

materials supplied (A).

• Loosen and remove the unit lid.

• Fix the unit to the bracket using two screws.

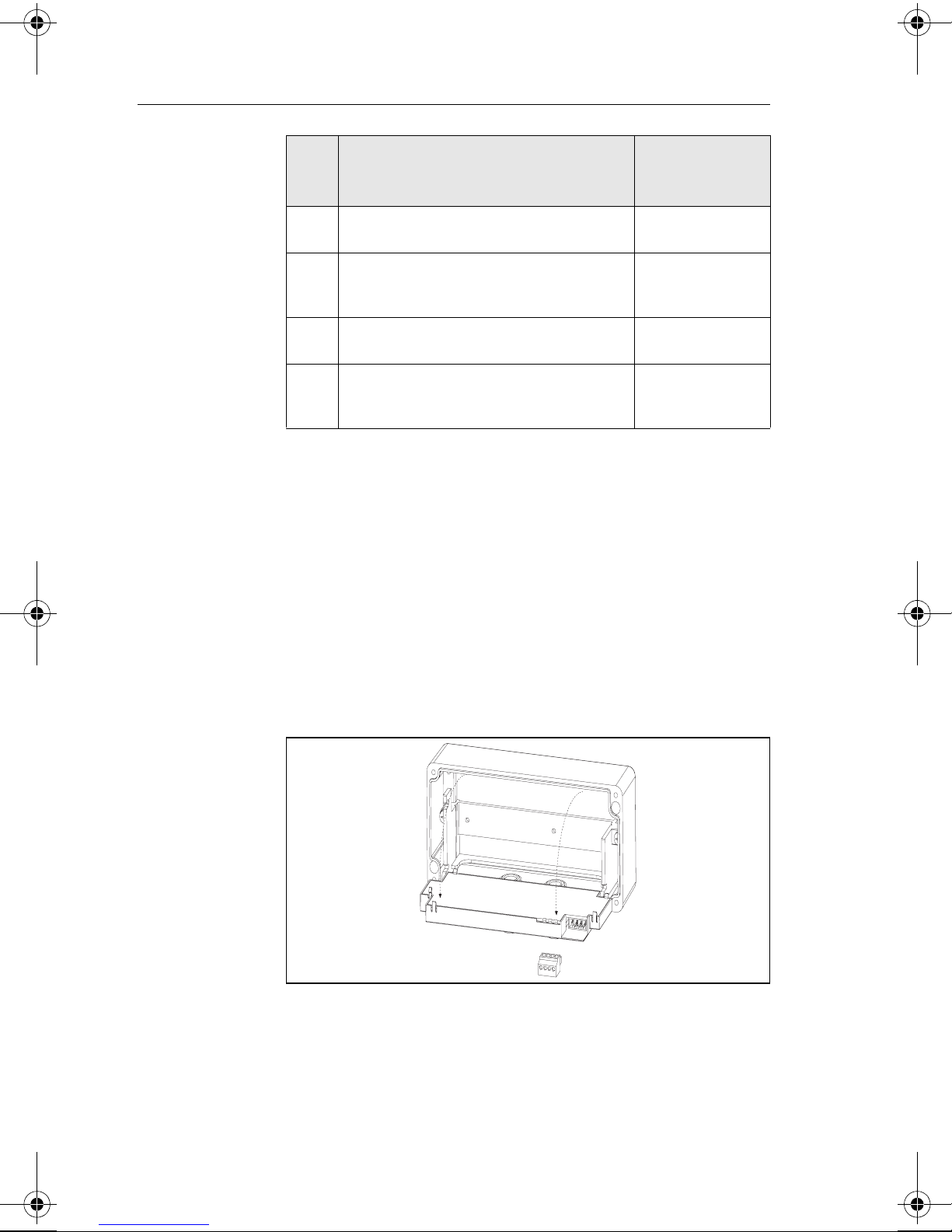

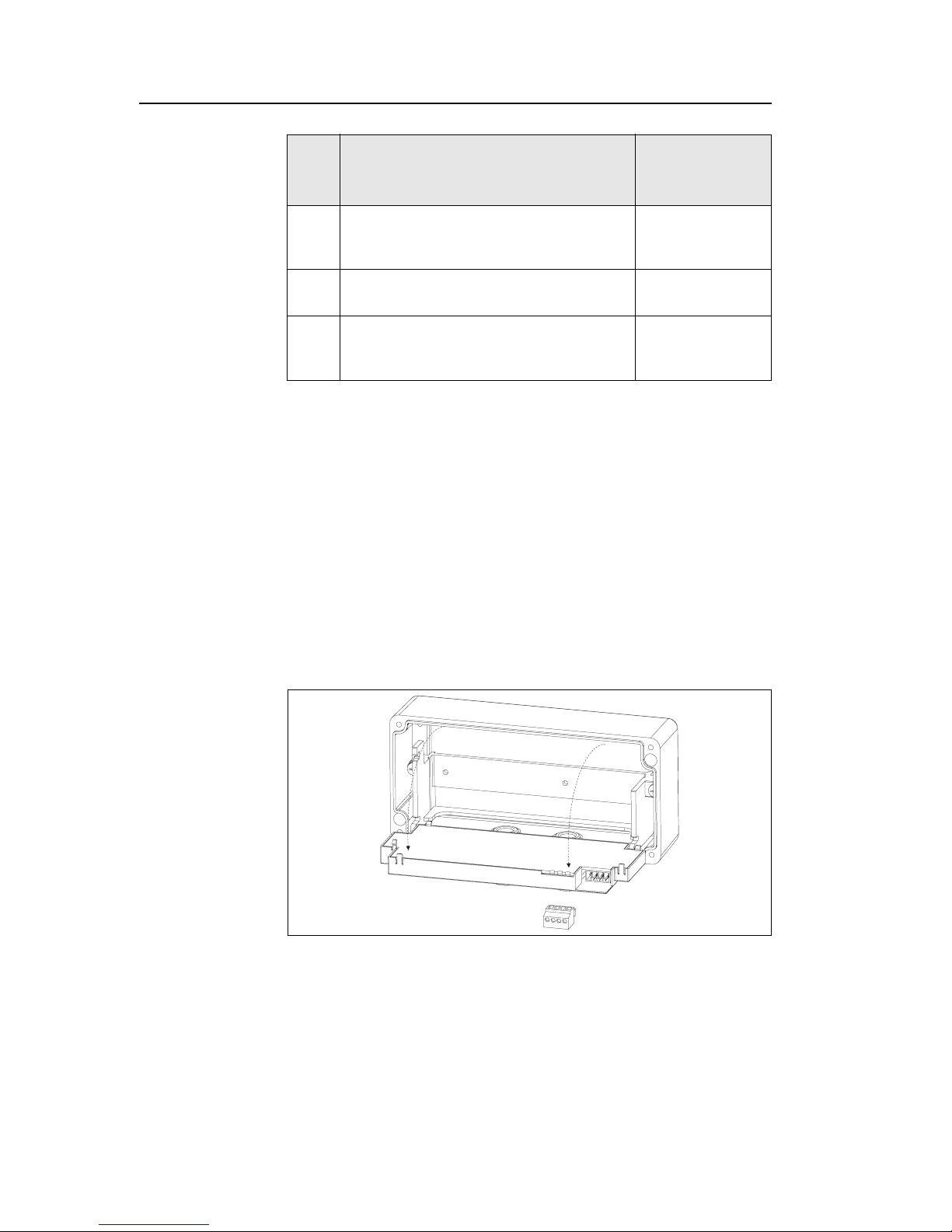

4.2.3 Installation of additional measurement electronics

Behind the hinged electronics there is room in the housing for additional

measurement electronics, e.g. temperature head transmitter.

Attention: Always take note of the manufacturers insatallation and connection instructions of individual manufacturers!

4.3 Installation control

Ingress protection

The unit fulfils all requirements accorcding to IP66 NEMA 4x. In order

to retain this protection class after installation or a service call, the following points must be complied with:

• The housing gaskets must be clean, undamaged and must be placed

in the seal recess in the unit. If this is not the case it should be cleaned, dried or if necessary replaced.

• The housing lid screws and cable glands must be tightened.

10

Page 11

Digital field display 5 Electrical connection

5 Electrical connection

Attention: If connecting the unit in an explosion hazardous area, please

"

take note of the notes and connection diagrams in the Ex-specific documentation in this manual.

5.1 Connections

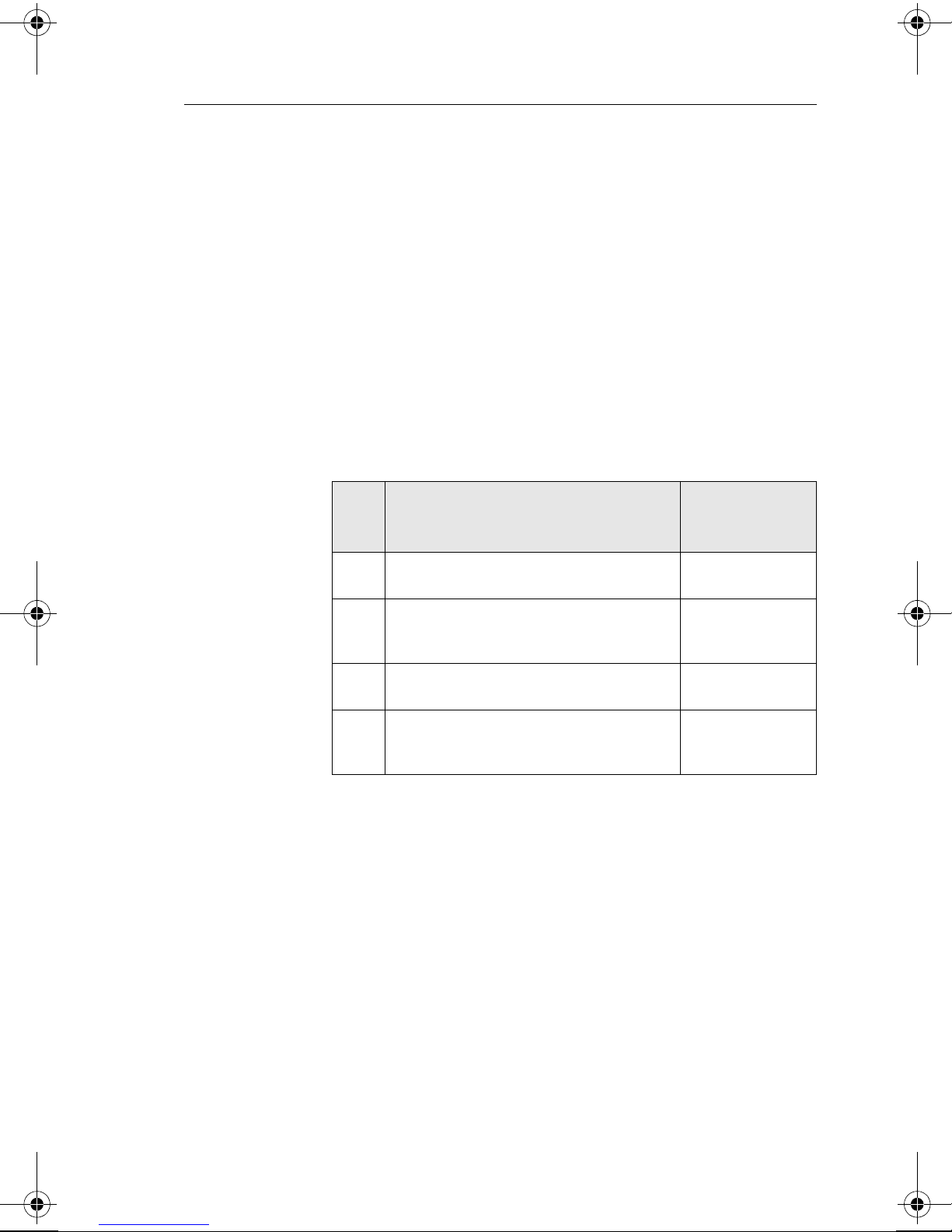

5.1.1 Terminal layout

The terminals for the 4 to 20 mA circuit are found under the housing lid

on the upper right side of the unit. The terminal block is a plug-in version and can be removed from the connection strip when wiring up the

unit.

Terminal layout In and

output

#

1 Measured signal (+) 4 to 20 mA Signal input

2 Terminal for further instrumentation (link

with terminal 4)

3 Measured signal (-) 4 to 20 mA Signal input

4 Terminal for further instrumentation (link

with terminal 2)

5.1.2 Electrical connection

Both the terminal layout and the connection values of the field mounted

display conform to the Ex requirements.

The unit is only meant for use in a 4 to 20 mA current loop circuit.

Potential equilibrium must be guaranteed on the current loop (inside

and outside the hazardous area). In order to achieve this use the earthing (ground) lug on the lower left area of the housing.

The electronic component can be hinged forwards for simple installation

and easy cable laying.

Terminal

Terminal

#

The unit must only be powered by a power supply that operates using

an IEC 61010-1 compliant energy limited circuit, "SELV or Class 2 circuit".

11

Page 12

5 Electrical connection Digital field display

ƒig. 4: Electrical connection

In order to do this follow these instructions:

• Loosen and remove the unit lid.

• Hold the top of the electronics and pull forwards and down, (see

sketch).

#

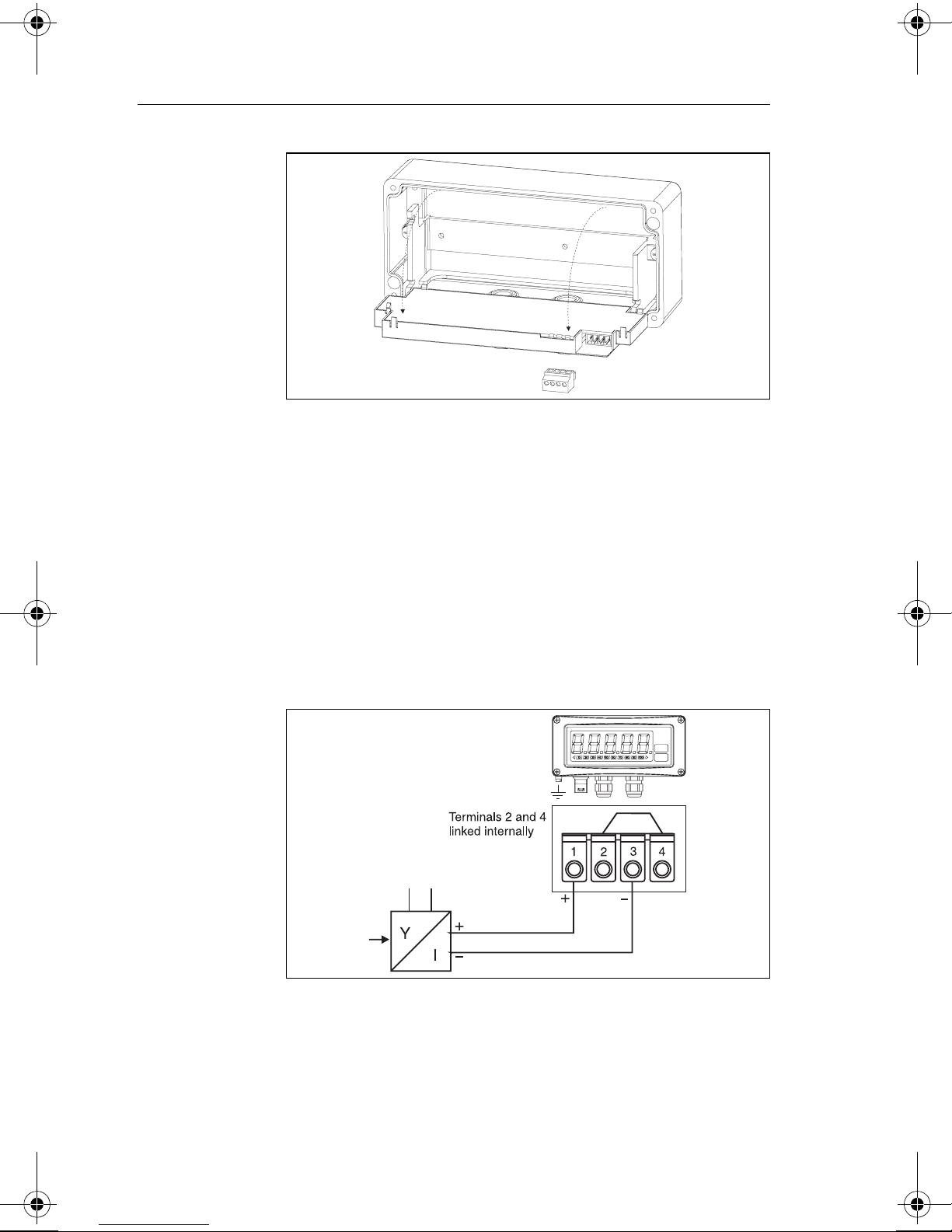

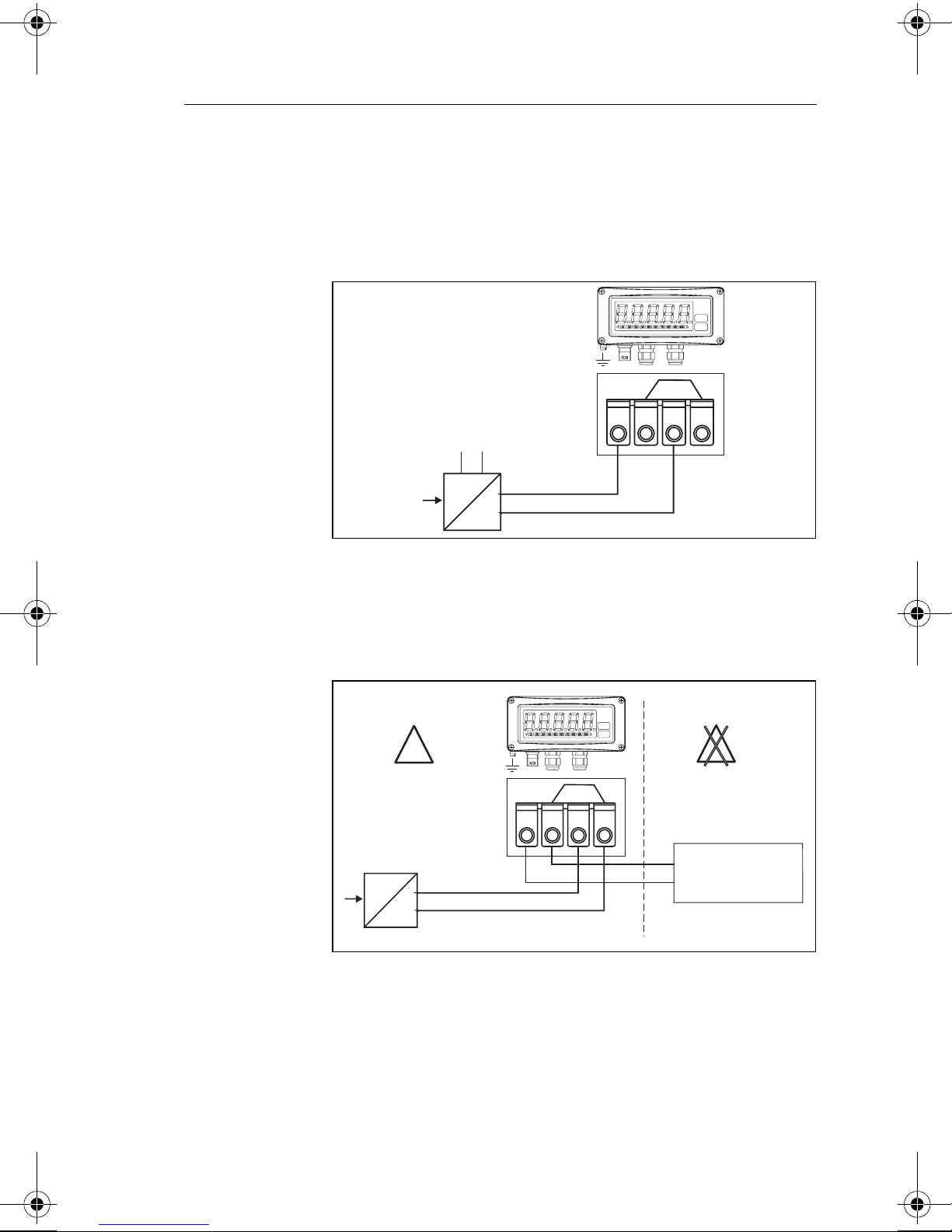

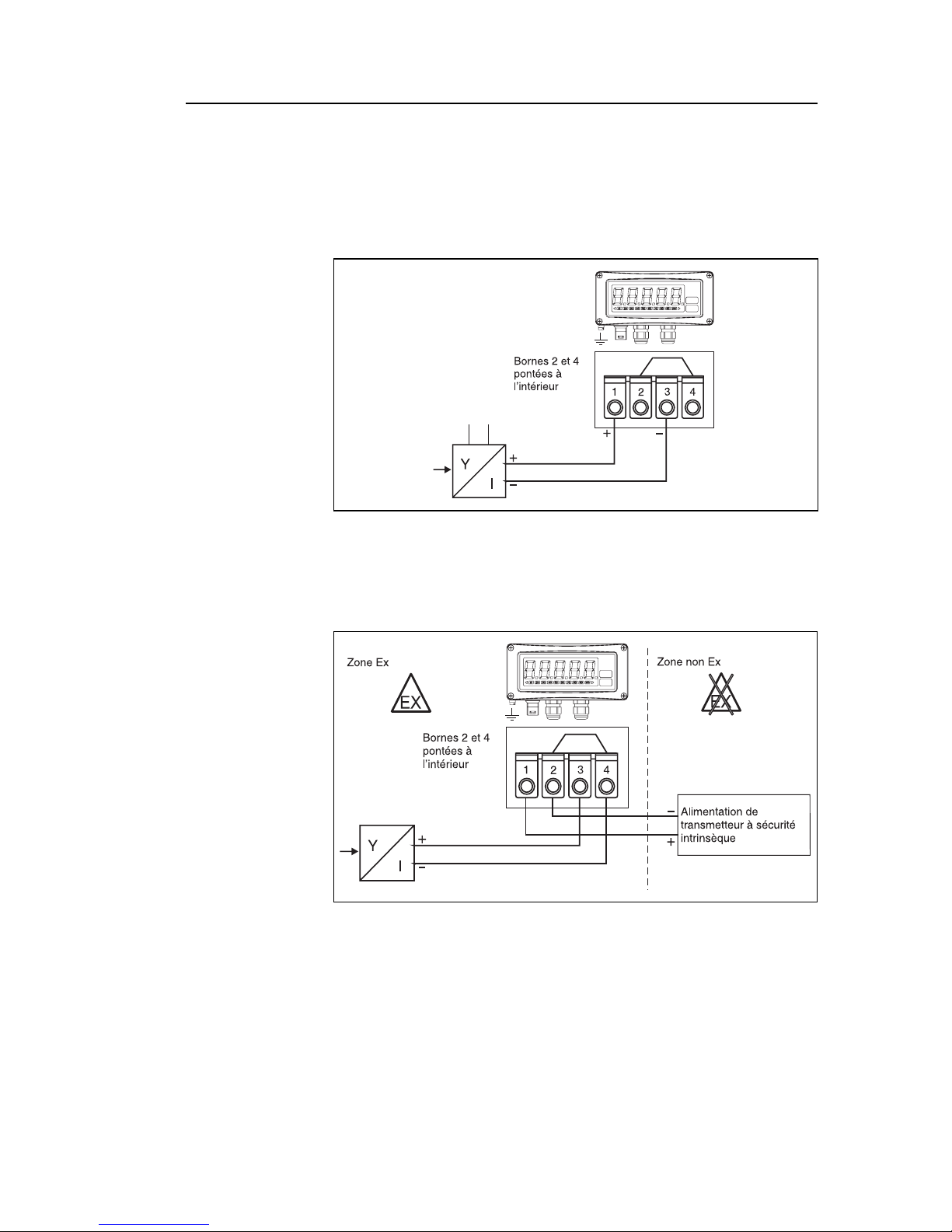

5.1.3 Connecting active current source

E.g. a sensor with its own power supply and active current output:

Note: If a respective barrier is used the unit can be installed directly in

the hazardous area.

ƒig. 5: Connecting active current source

12

Page 13

Digital field display 6 Operation

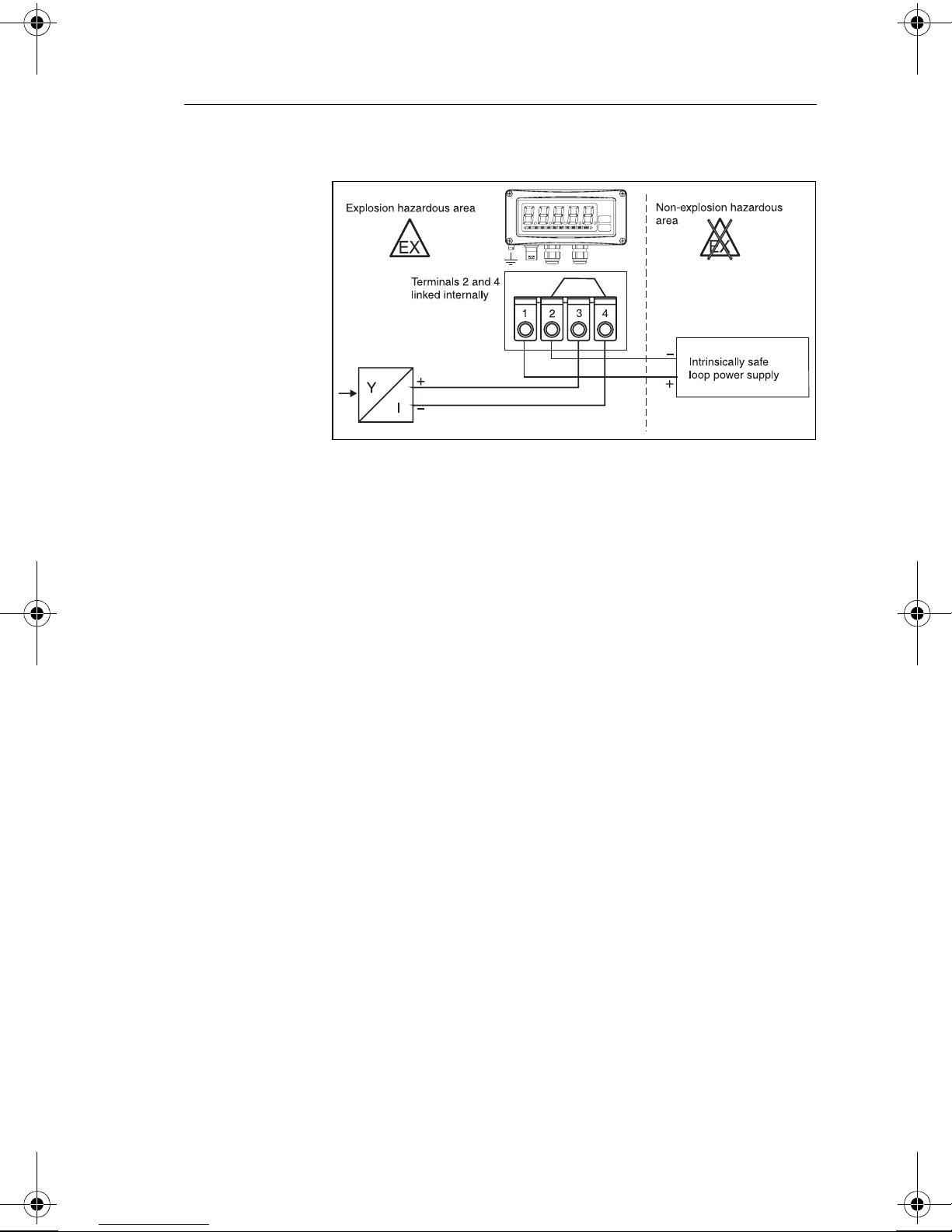

5.1.4 Connecting a passive current source

E.g. 2-wire transmitter with additional loop power supply:

ƒig. 6: Connecting a passive current source

An Ex certified unit can be applied as a front end display in the nonhazardous area. This is not valid the other way round (non-Ex unit in

Ex area)!

#

5.2 Connection control

Before replacing the housing lid please make sure that the electronics

have been returned to the upright position and the lock on the left hand

side has latched in.

6Operation

6.1 Operation overview

The following chapters inform on the commissioning and operation of

the field mounted display. These functions are identical for both the Ex

and non-Ex display versions.

13

Page 14

6 Operation Digital field display

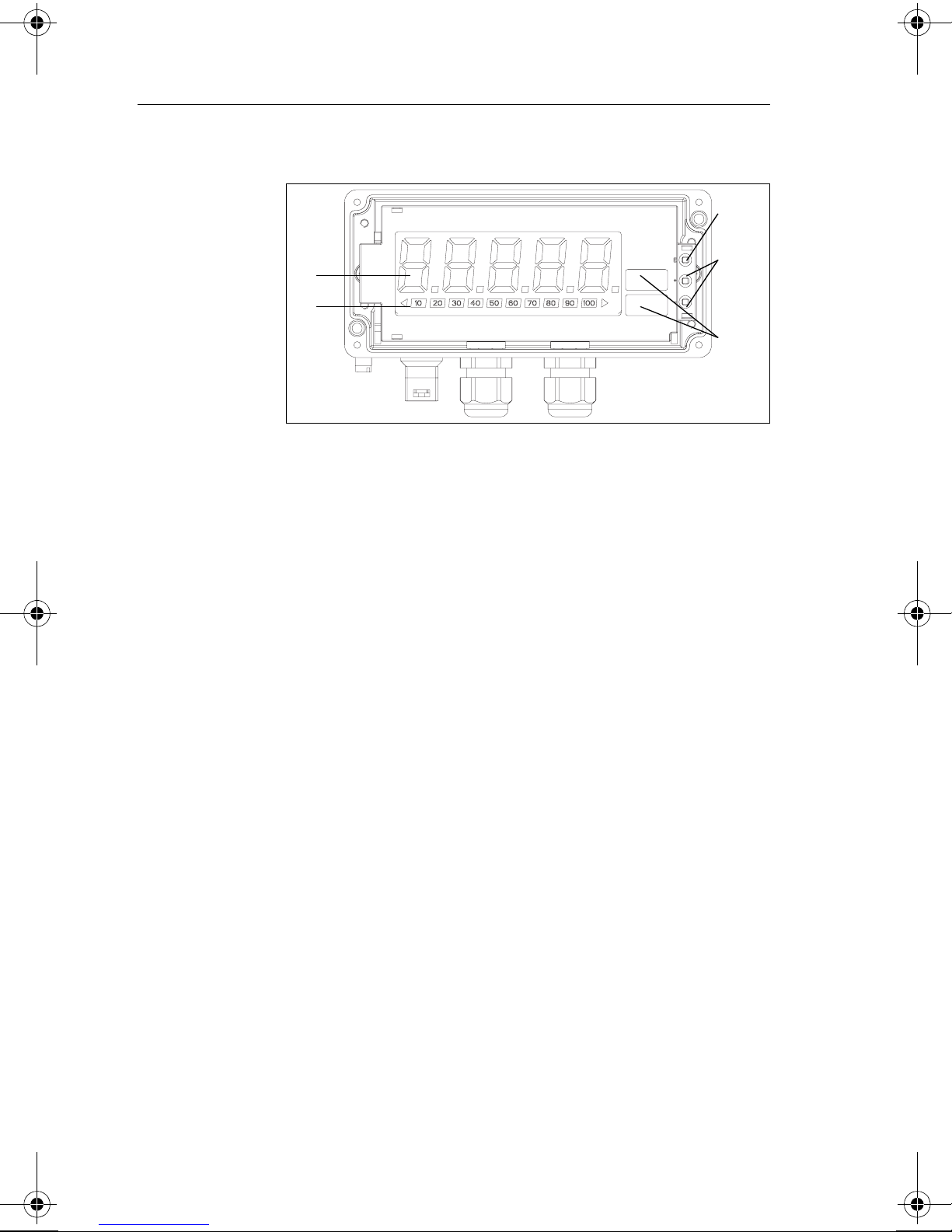

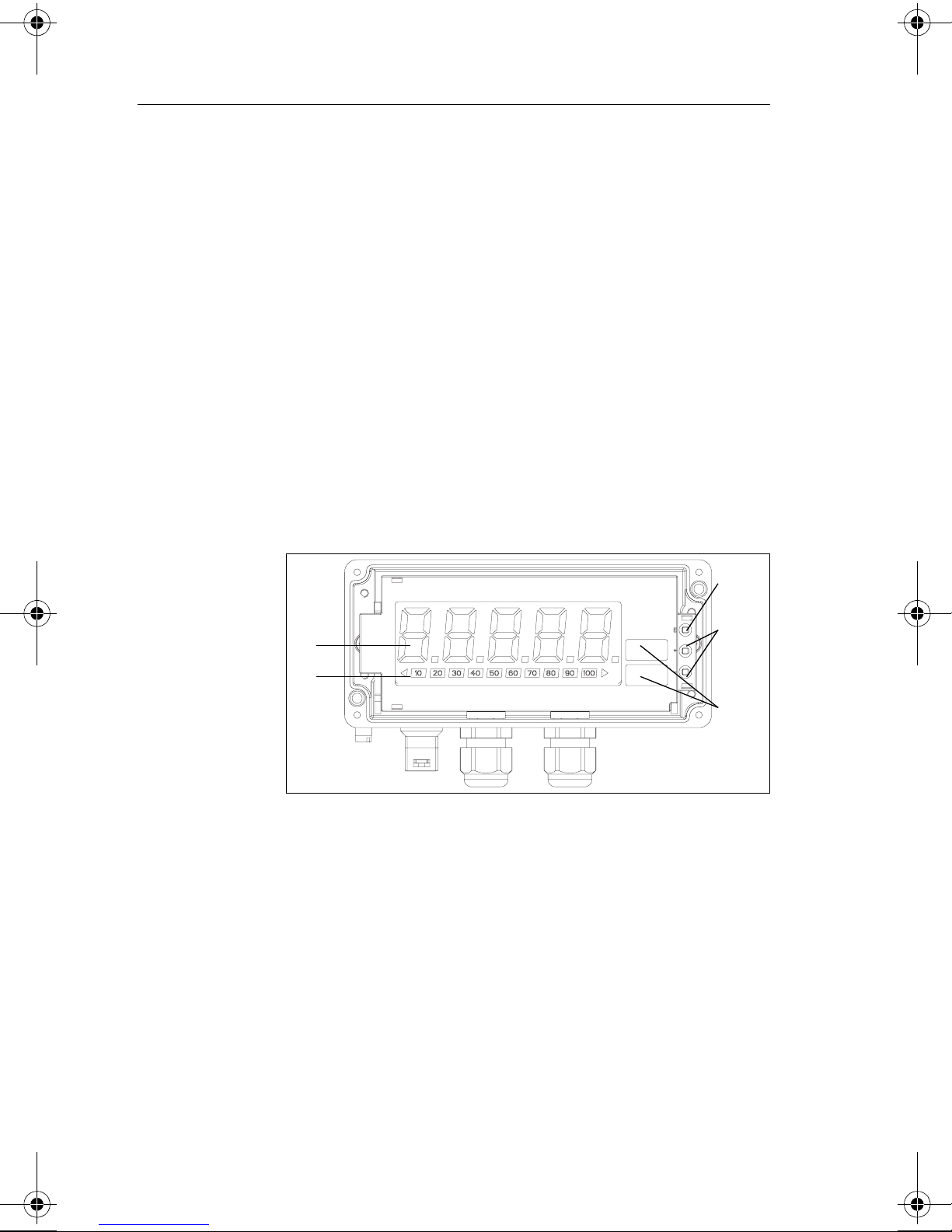

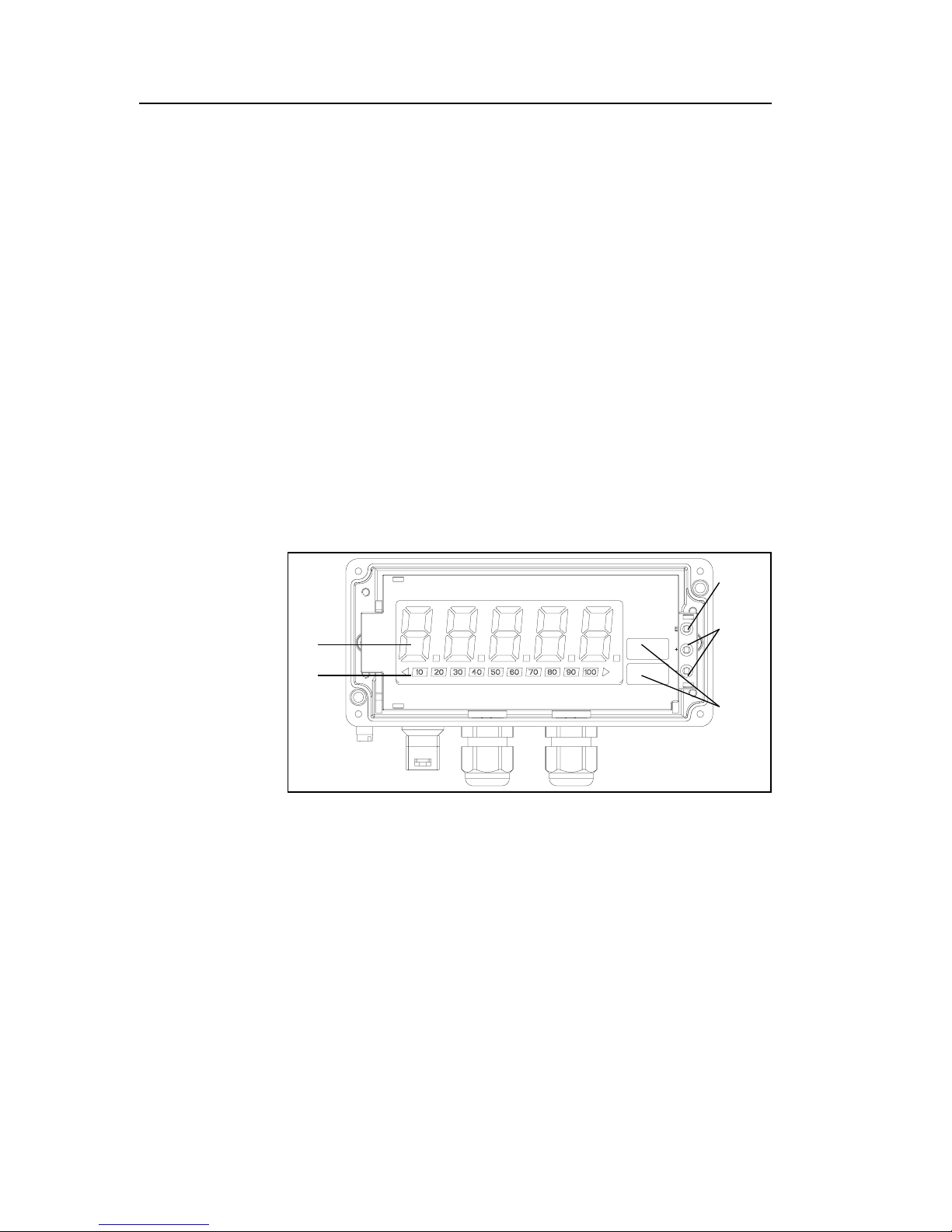

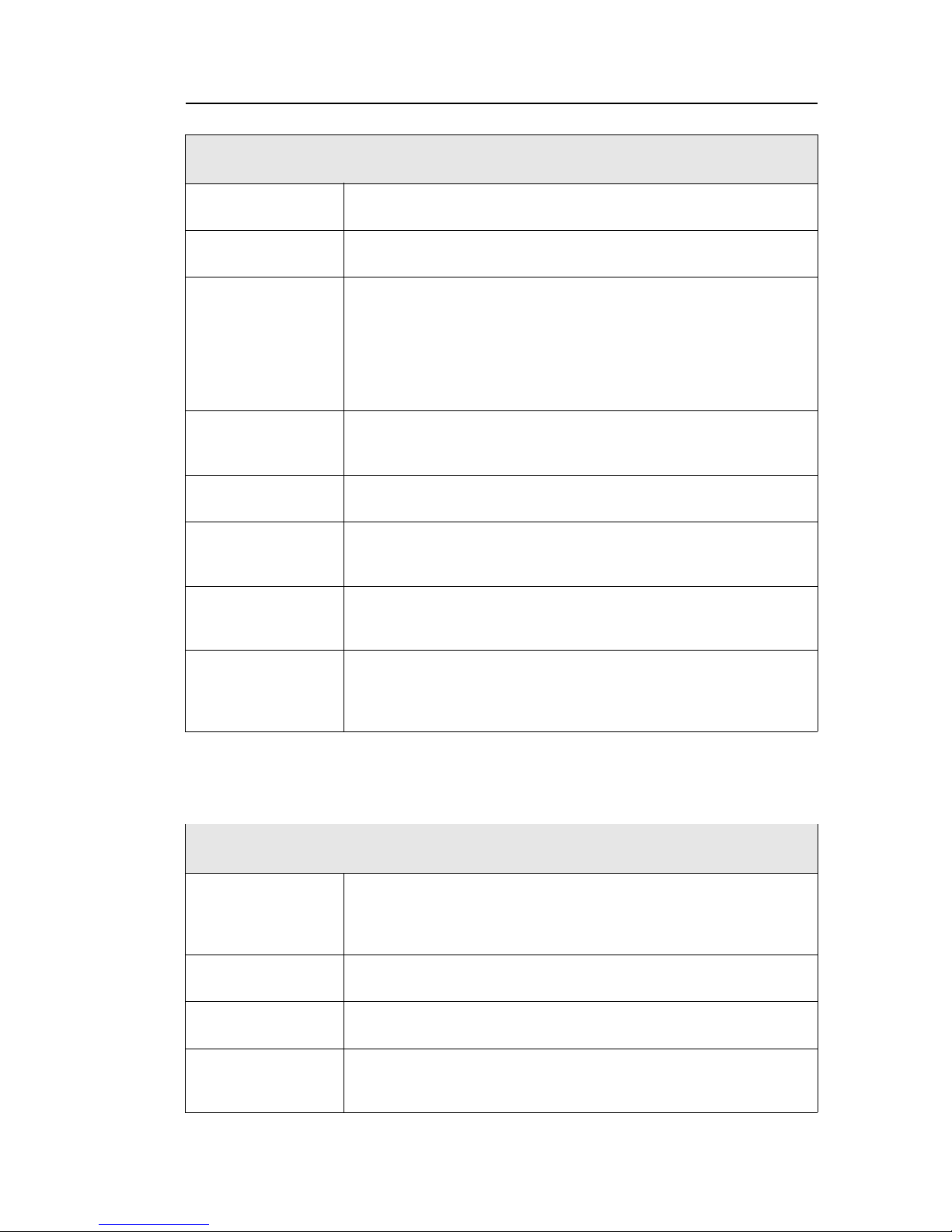

6.2 Display and operating elements

ƒig. 7: Display and operating elements

Measured value:

5 digit, LC display, indicated are:

• Instantaneous numeric measured value (in operation).

• Dialogue setting up text.

Bargraph:

The bargraph displays the scaled measuring range. It indicates the

instantaneous percentage measured value.

Enter push button (E):

Entry into set-up menu.

• Selection of operating function in a function group.

• Saving set-up data.

Selection push buttons (+, -):

• Selection of a function group within the menu.

• Setting up parameters and numbers. (If the push button is conti-

nuously held down then the number change on the display increases).

• The actual loop circuit current is displayed if the +/- push buttons are

held down in operation mode.

Identification fields:

Additional information can be written into the identification fields.

In order to do so, follow these instructions:

• Degrease and clean the fields.

• Write onto the fields using a light and water resistant transparency

pen.

14

Page 15

Digital field display 6 Operation

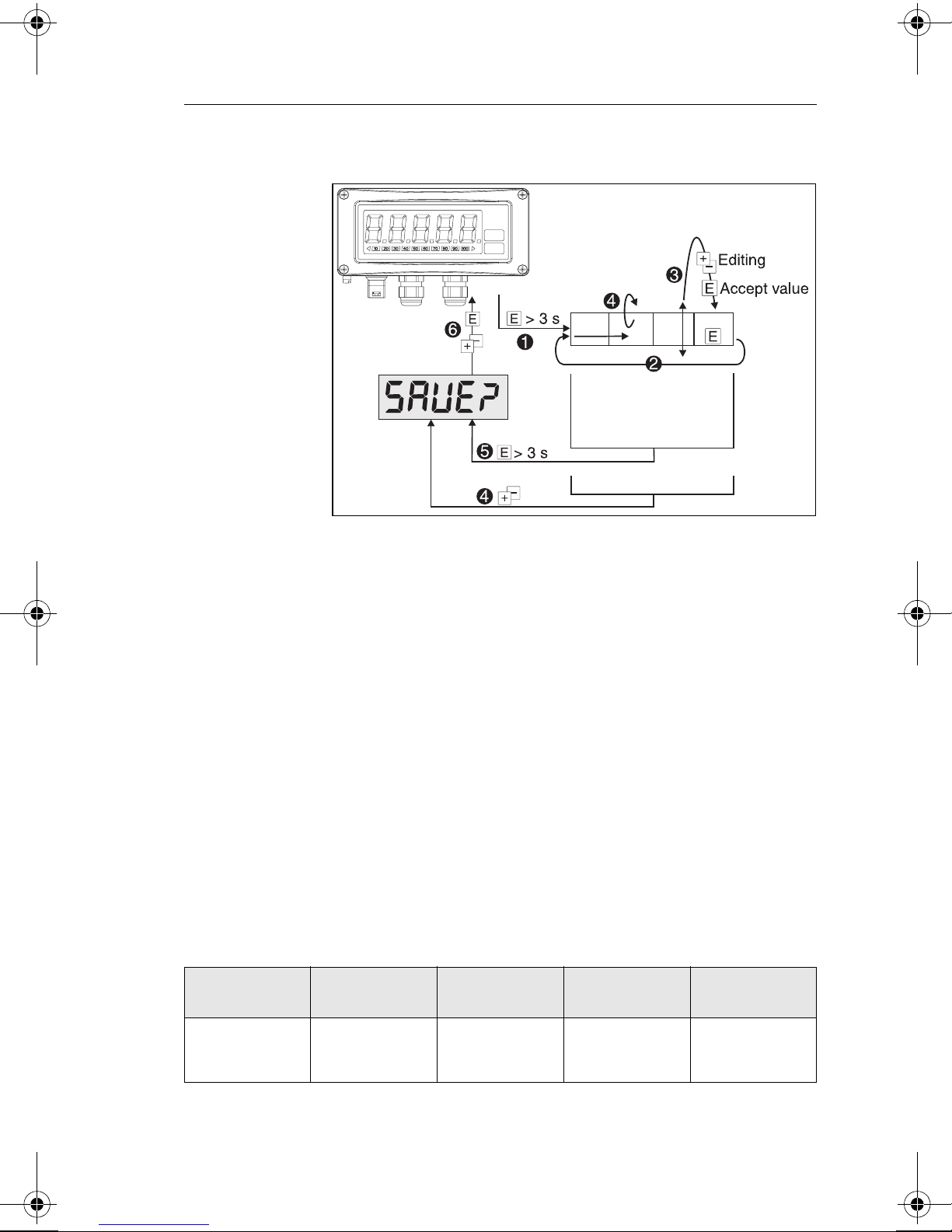

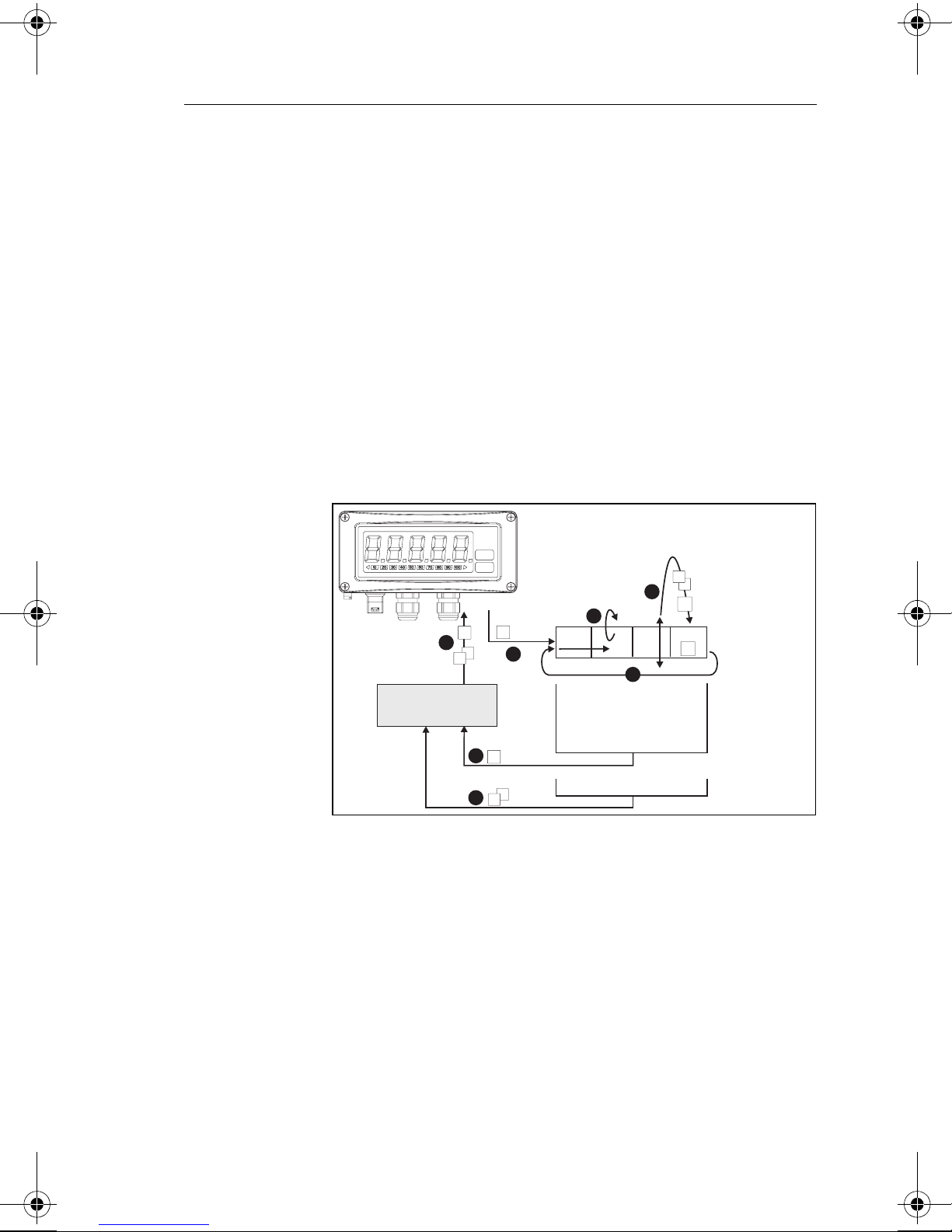

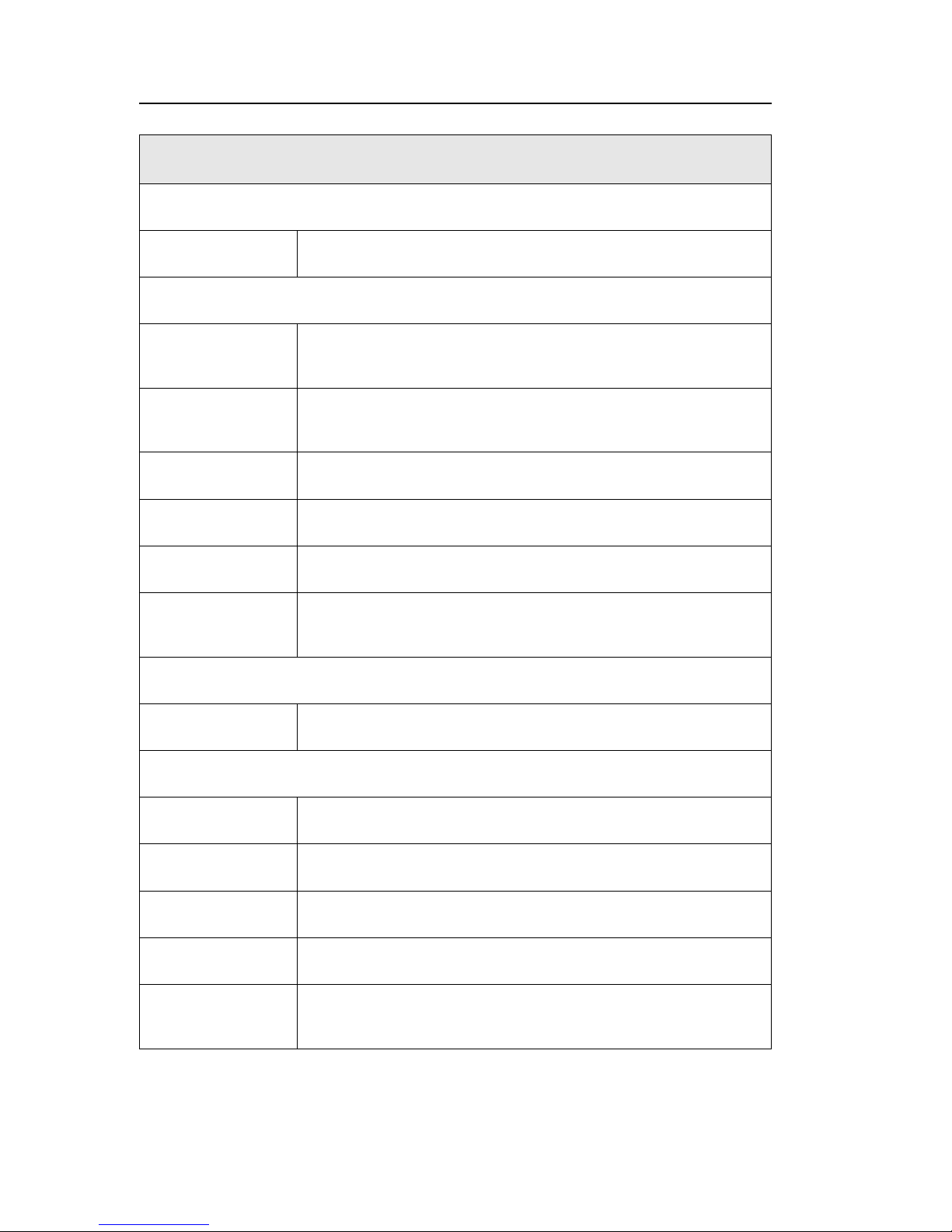

6.3 Setting-up using the operating menu

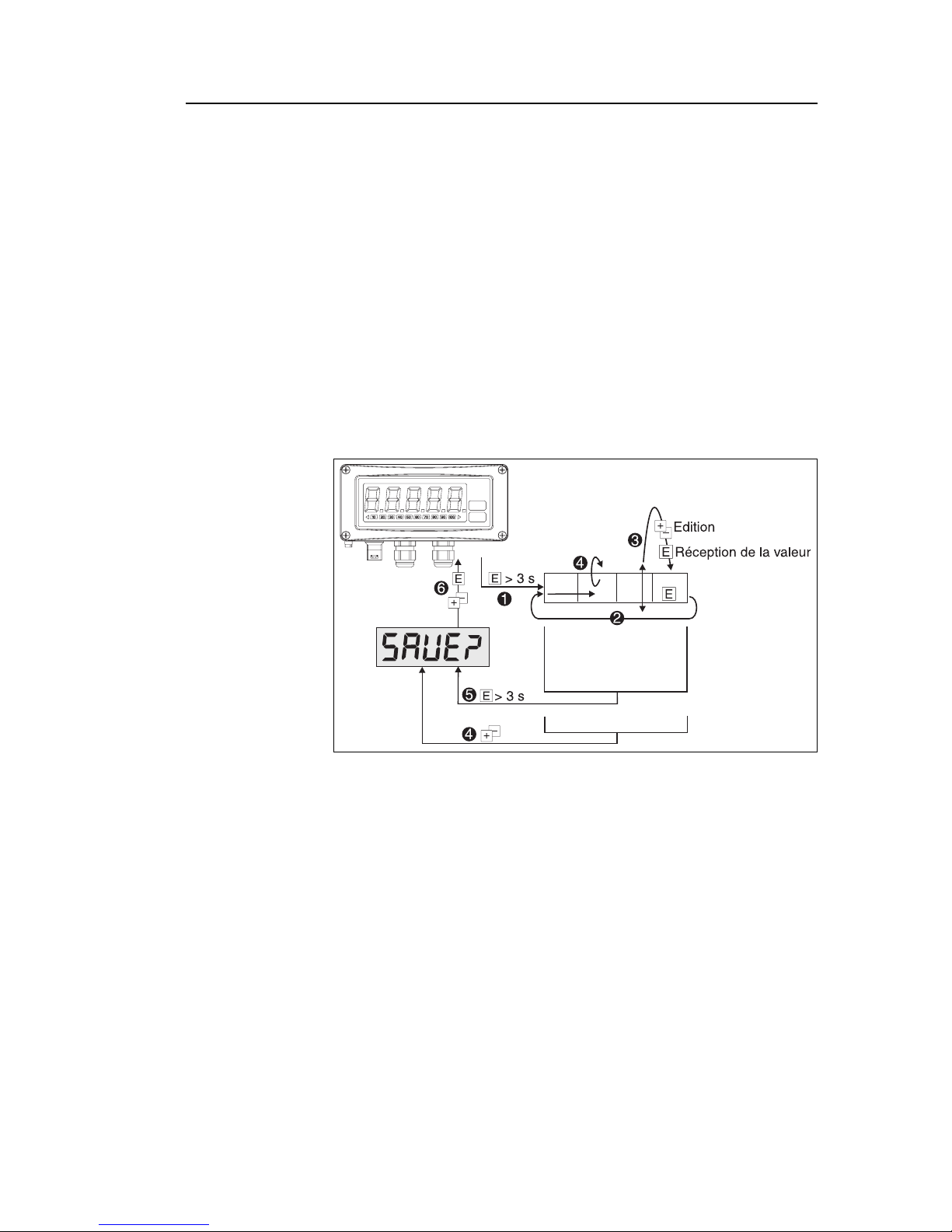

ƒig. 8: Setting up using the operating menu

Enter the operating menu.

Select the operating function required.

Parameter entry in editor mode

(enter/select data using + or - and acknowledge using E).

Return from editor mode or operating function to a function

group. A return to the home position (display mode) can be

made by simultaneous operation of the +/- push buttons a

number of times. Before returning, a question is asked if the

set-up data is to be saved.

Direct return to the home position (display mode). Before

returning, a question is asked if the set-up data is to be

saved.

Question whether the data is to be saved (selection YES/NO

with + or - push button and acknowledge with E).

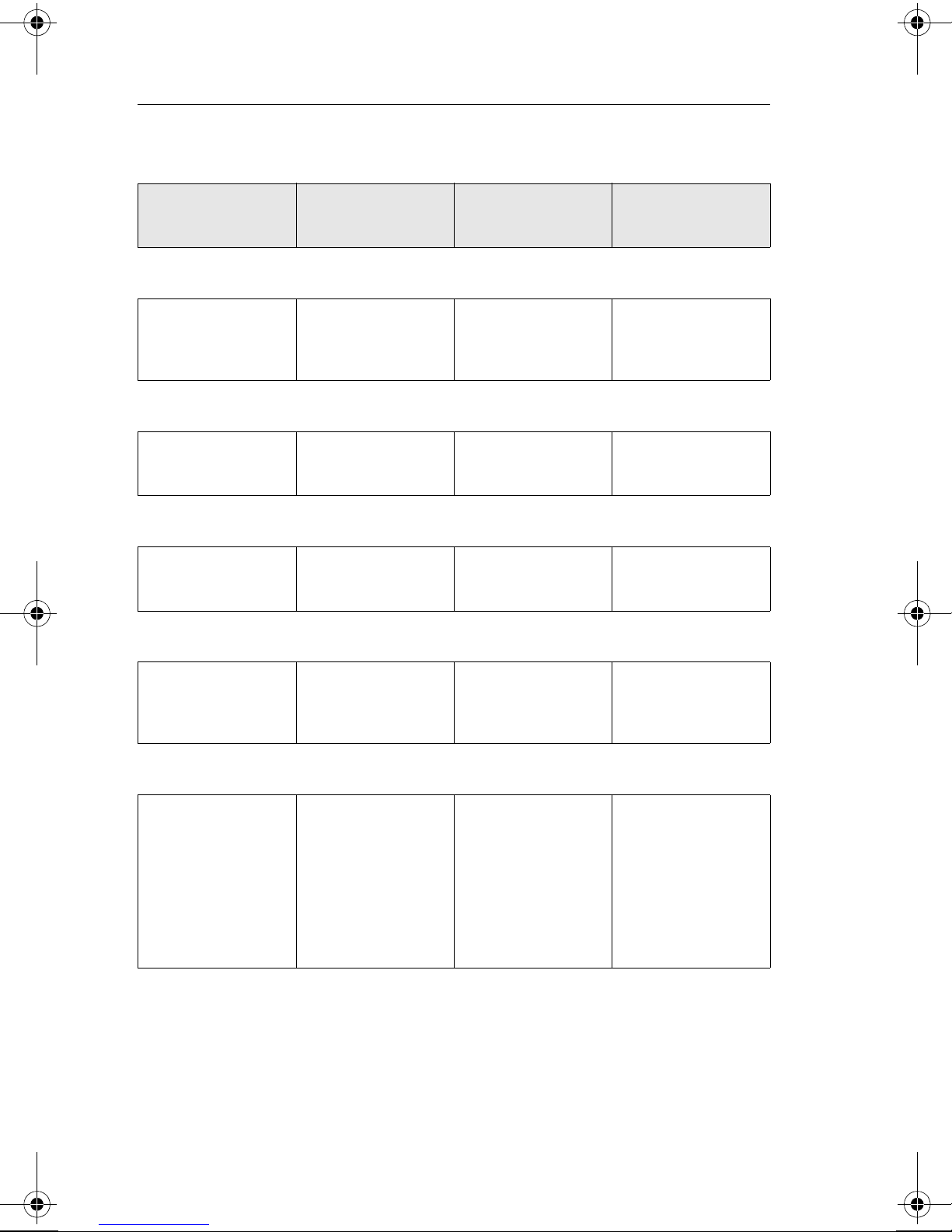

6.3.1 Operating menu overview

% !$ $() $

Decimal point Display value

0%

Display value

100%

Offset User code

15

Page 16

6 Operation Digital field display

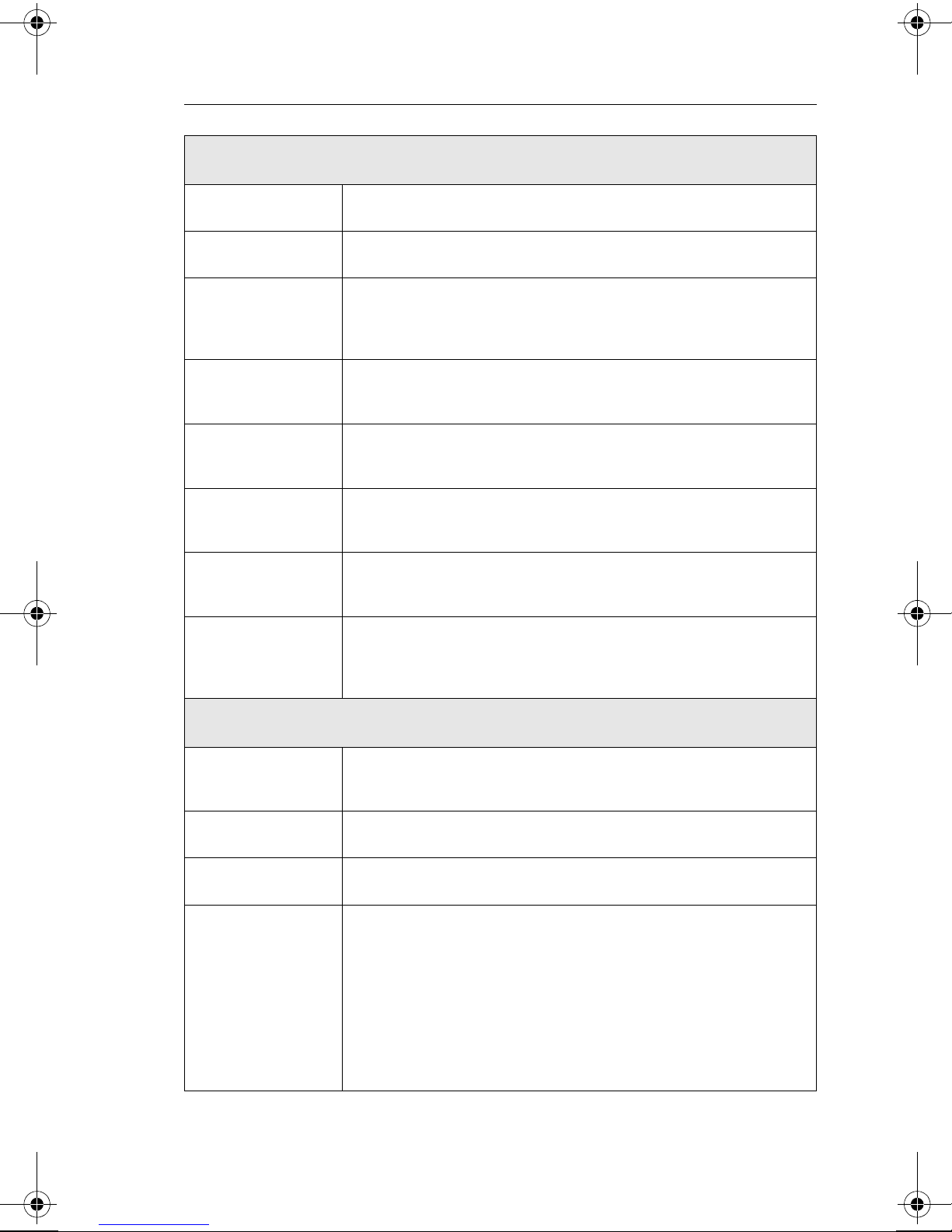

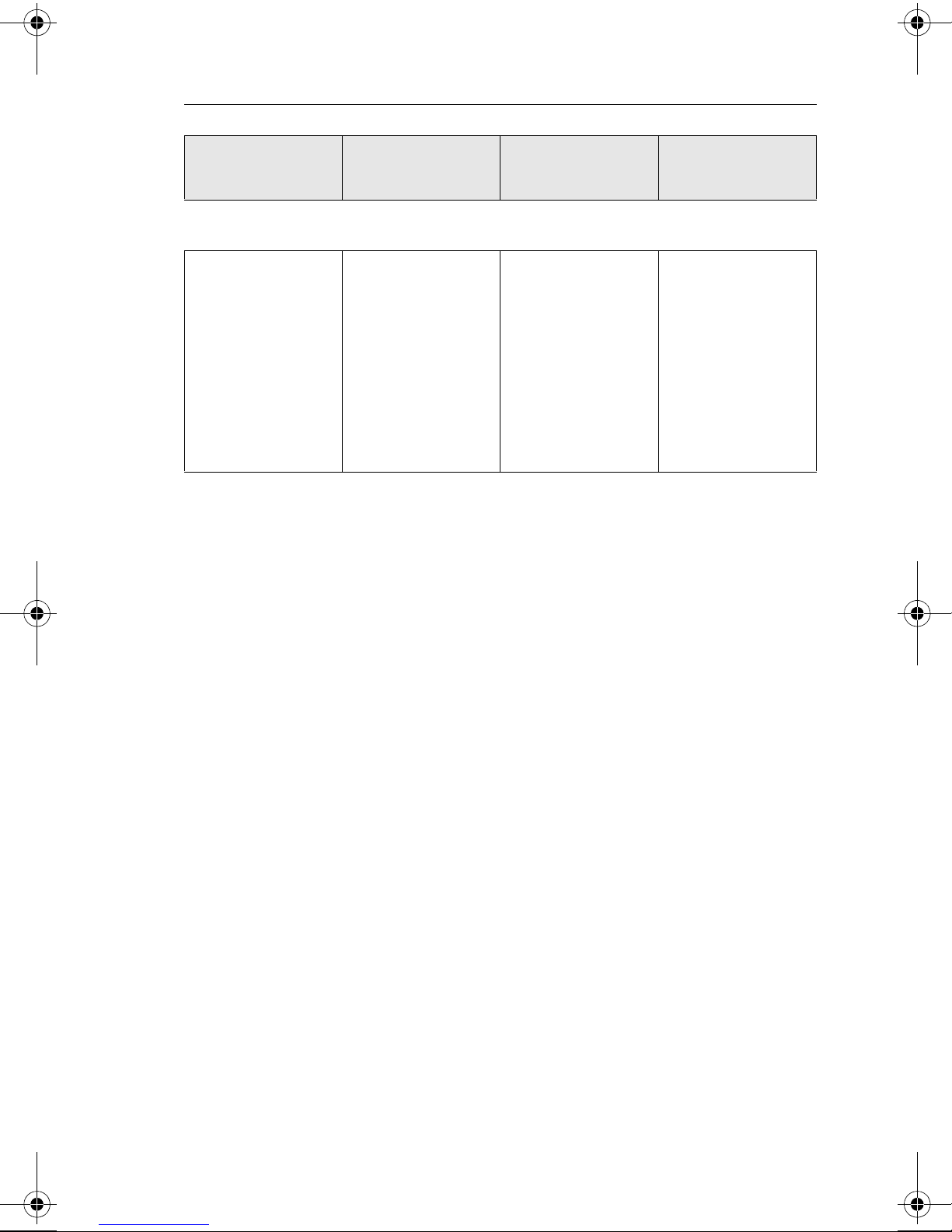

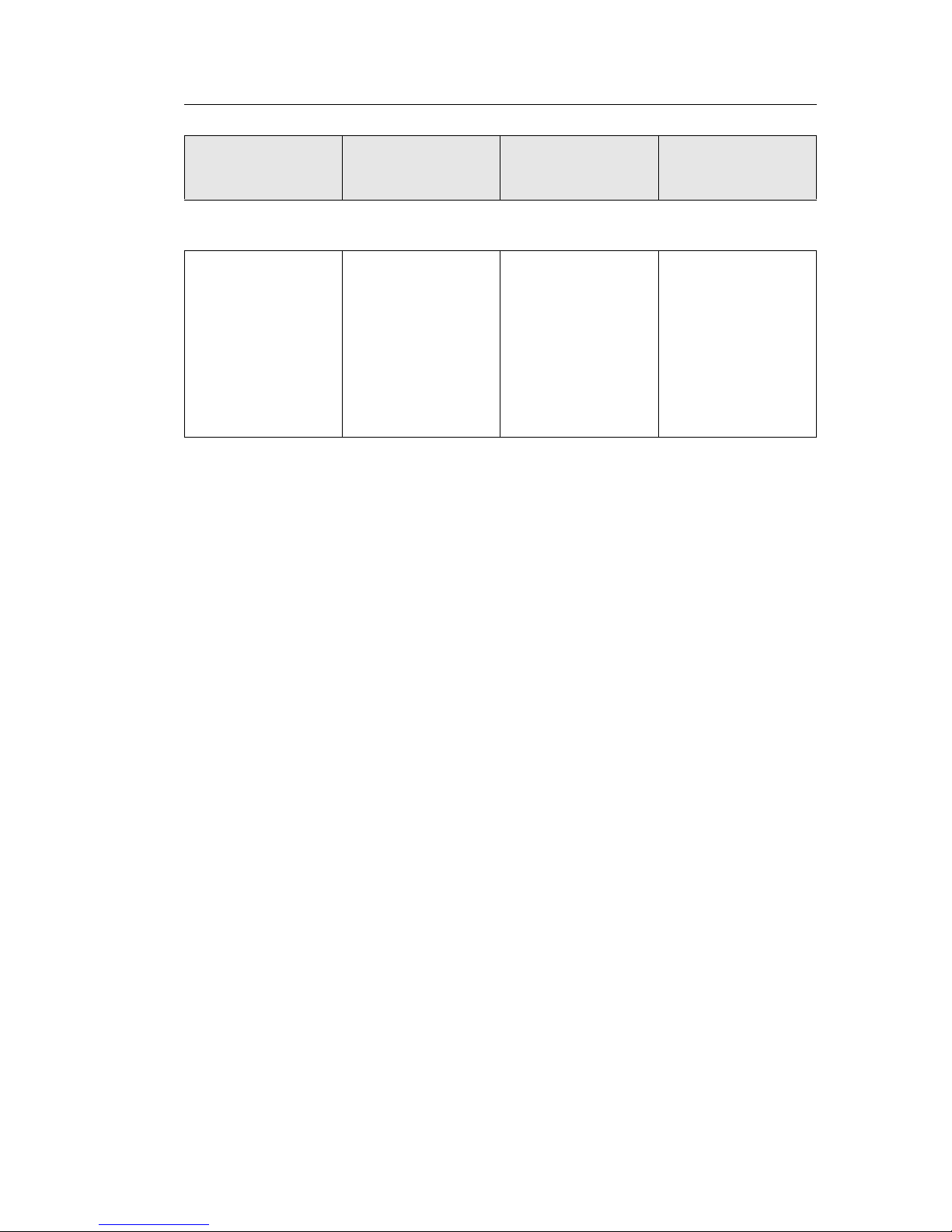

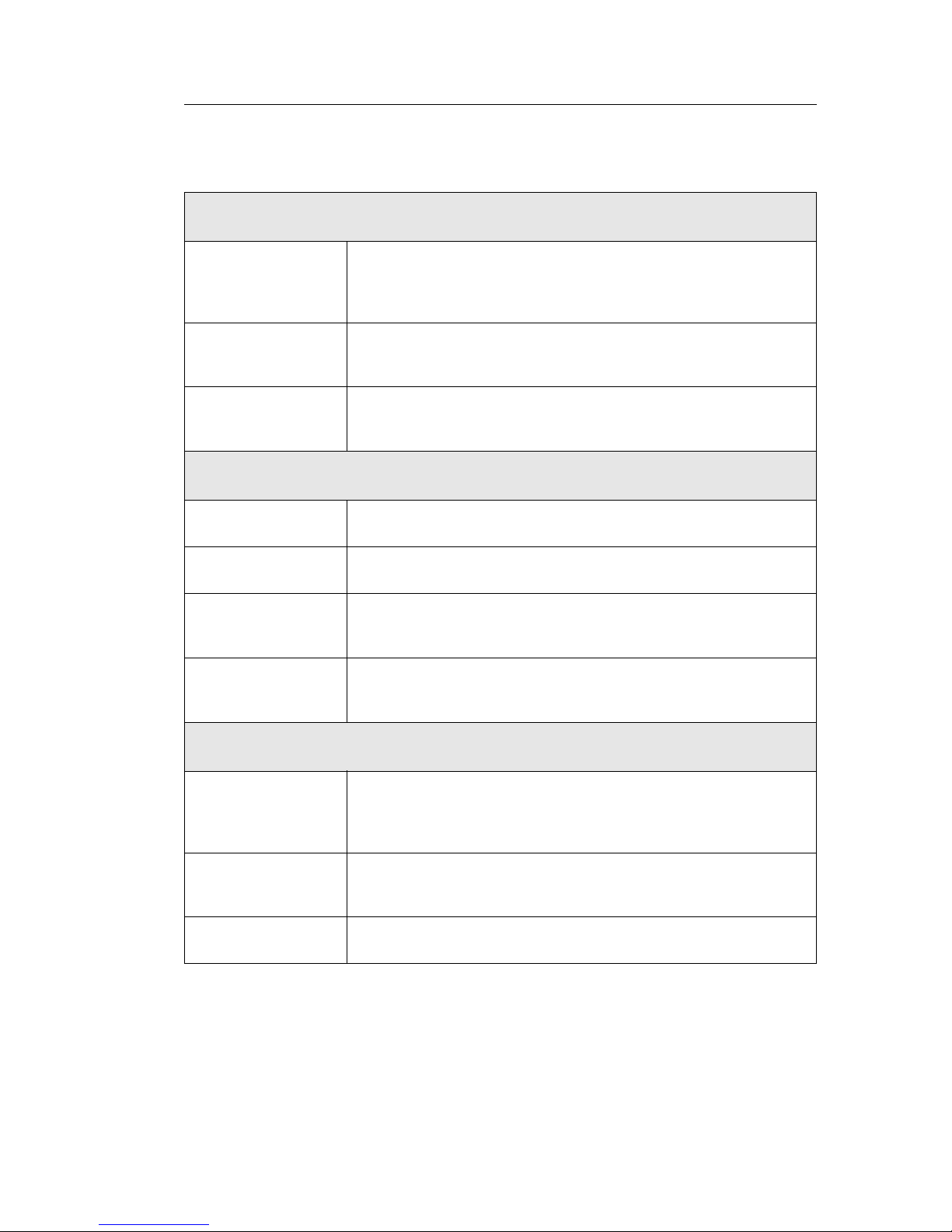

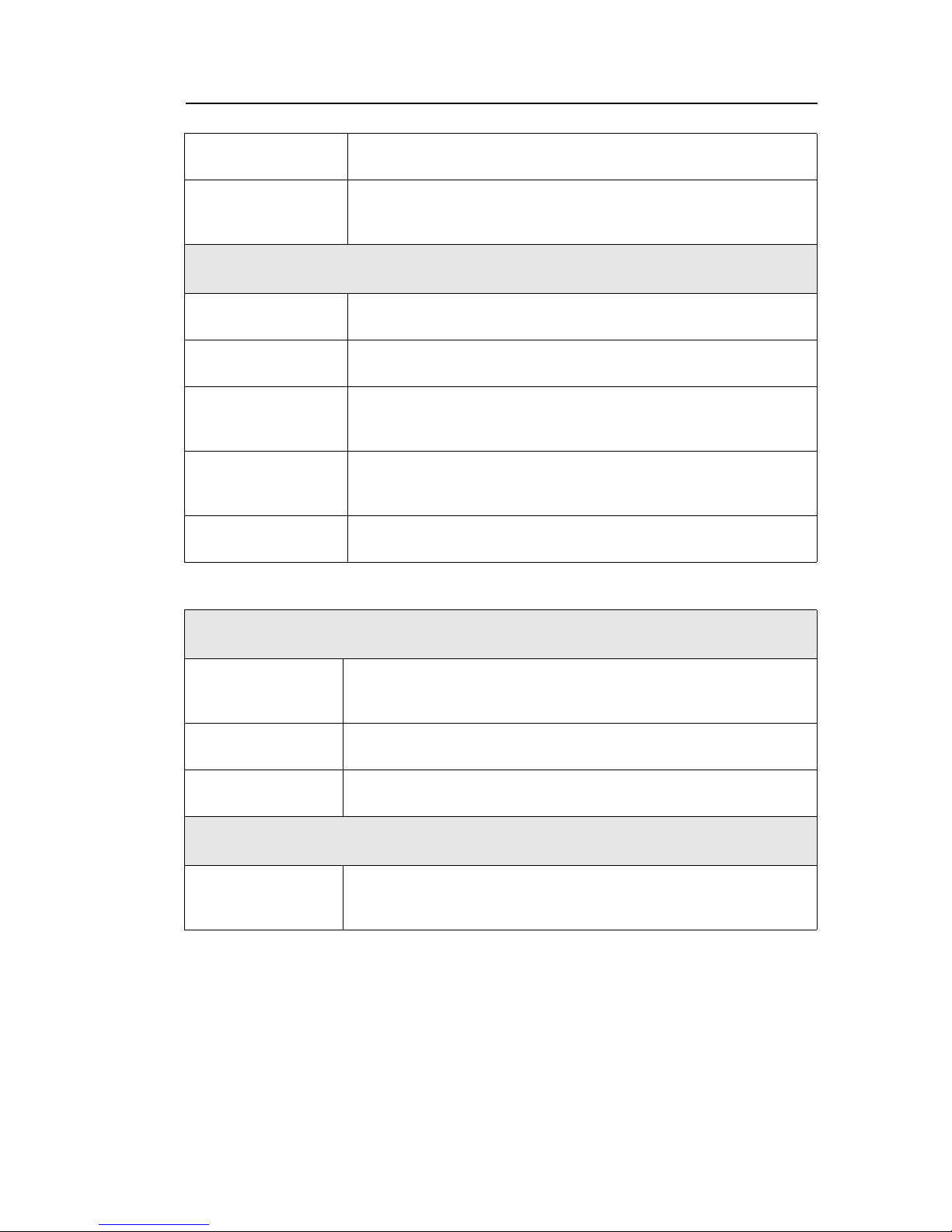

6.4 Parameter overview

Parameter Setting up

selections

Decimal point

Selecting the decimal point of the

numeric display

Display value 0%

Display value of the 4

mA current signal

Display value 100%

Display value of the

20 mA current signal

Offset

%

Selection range:

0 to 4 decimal points

!$

Values:

-19999 to 99999

Values:

-19999 to 99999

$()

Default settings Actual settings

Signal offset for

matching to the measured value display

User code

Freely settable user

code.

A user code that is

already entered can only

be changed if the old

unlock code is

entered.Then the new

code can be set up.

Values:

-19999 to 32767

$

Values:

0000 to 9999

!

There is no active

user code on "0"

16

Page 17

Digital field display 7 Commissioning

7 Commissioning

7.1 Installation and function control

Check all wiring for tightness. In order to guarantee continuous safe

operation, the terminal screws must be tight. The unit is now operational.

7.2 Commissioning

Once installation and wiring is complete, the unit is ready for use.

8 Maintenance

The unit requires no special maintenance or servicing.

"

9 Accessories

Accessories for wall or stand pipe mounting.

For orders (e.g. spare parts) please contact your sales organisation!

When ordering accessories or spare parts, please state the serial number

of the unit!

10 Fault-finding

In order to assist with fault-finding, there follows a list of possible faults,

causes and cures.

10.1 Fault-finding instructions

Warning:

On Ex units fault diagnosis must NOT be made on an open unit. This

would invalidate the ignition protection classification.

17

Page 18

10 Fault-finding Digital field display

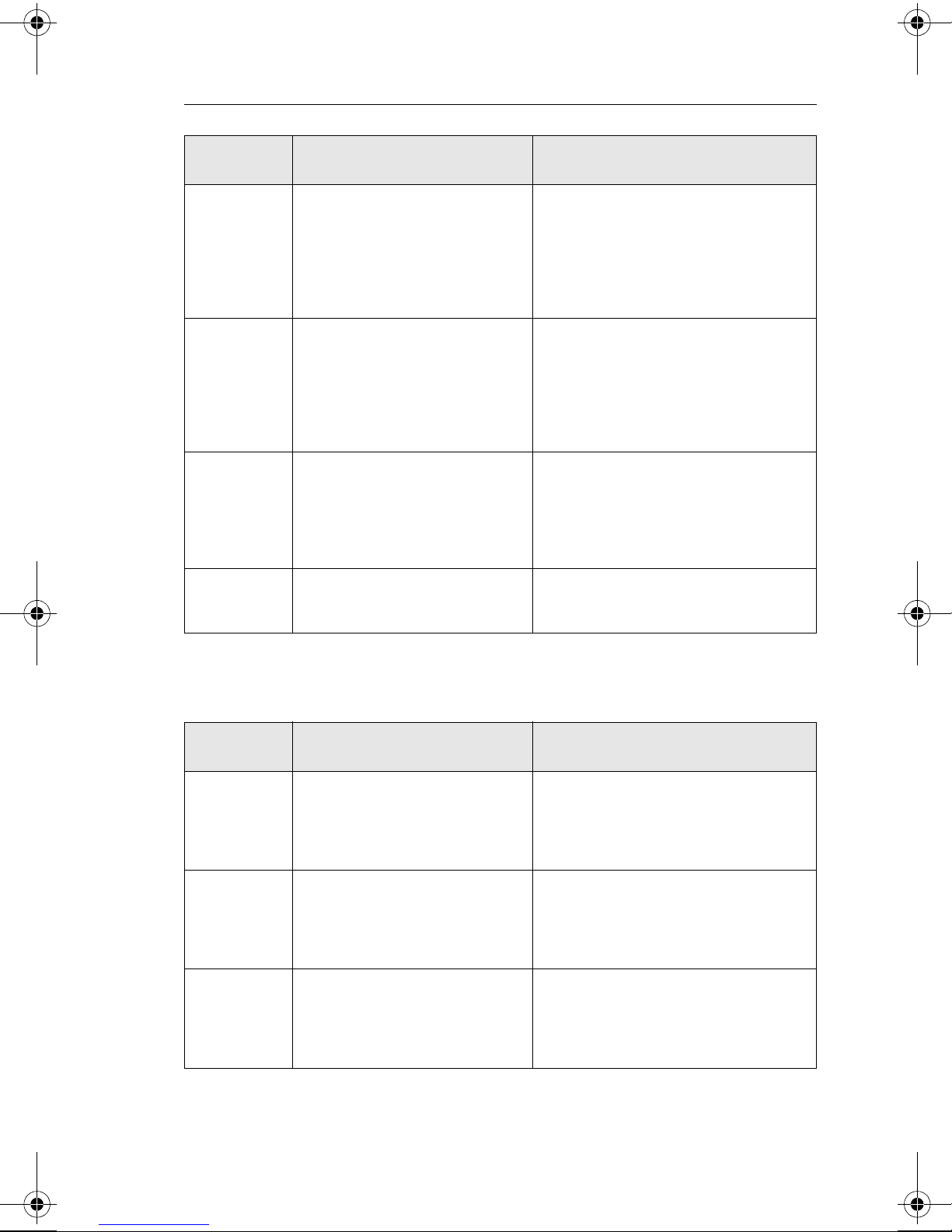

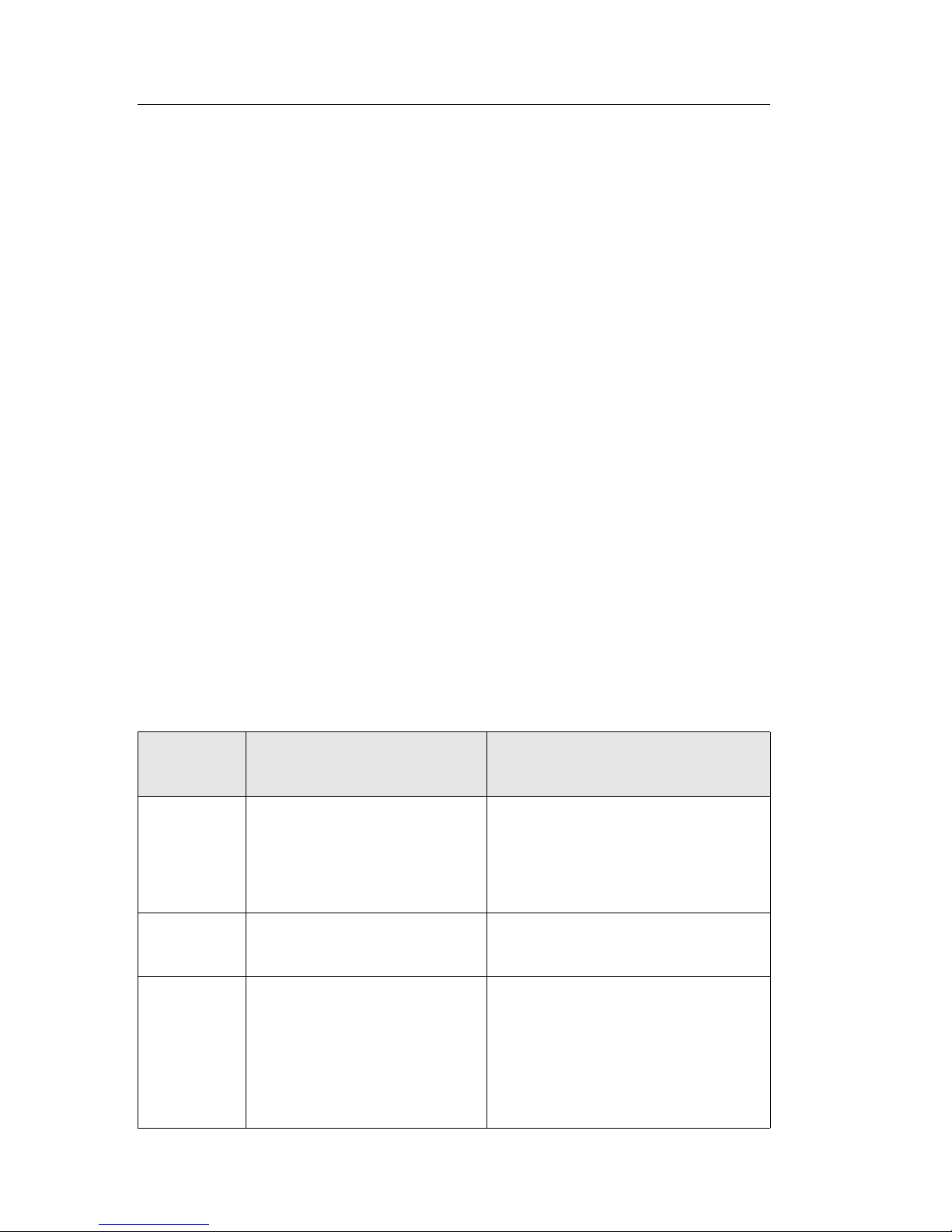

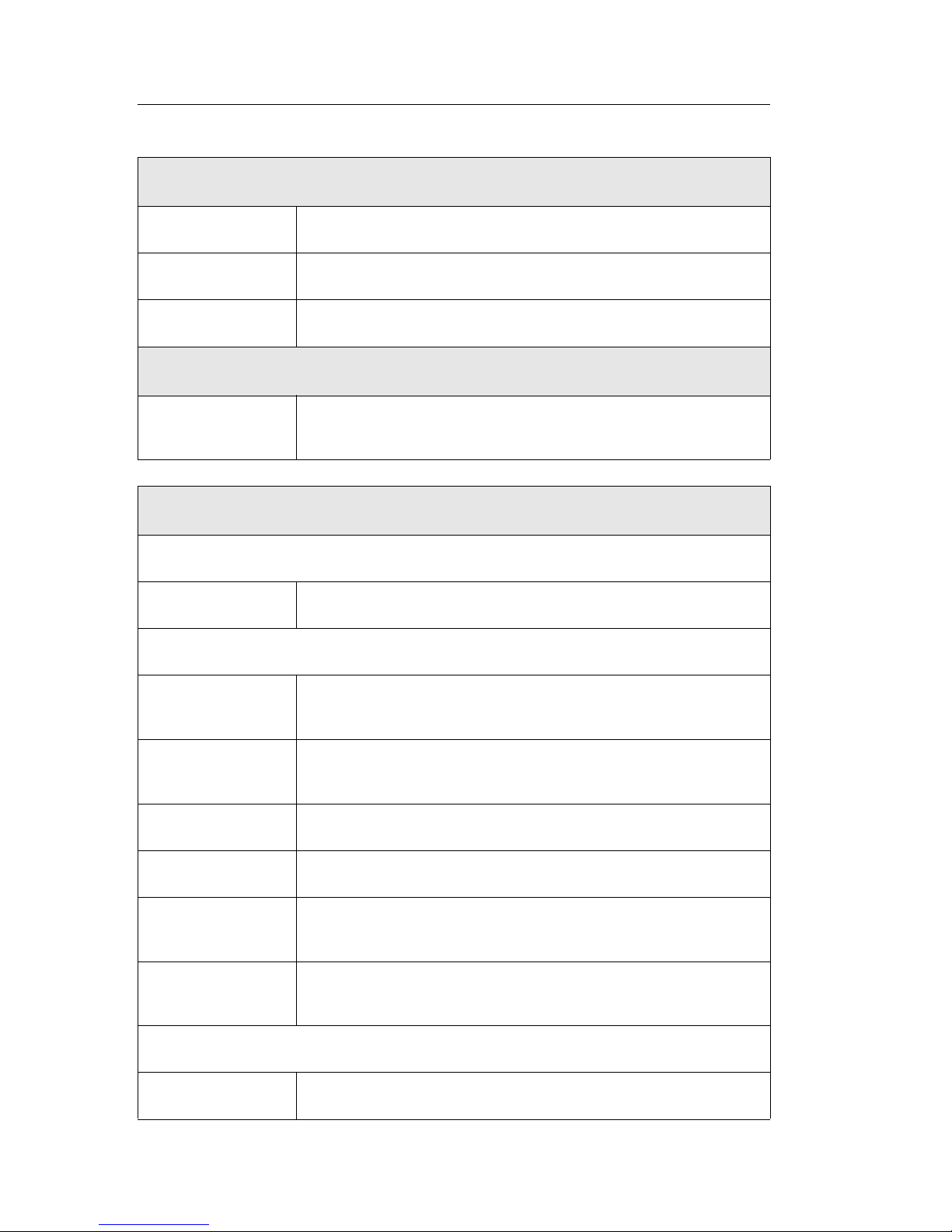

10.2 Process fault messages

Faults that occur during the unit’s self test or during continuous operation are immediately shown on the display. Fault messages that can be

acknowledged are deleted by operating a push button.

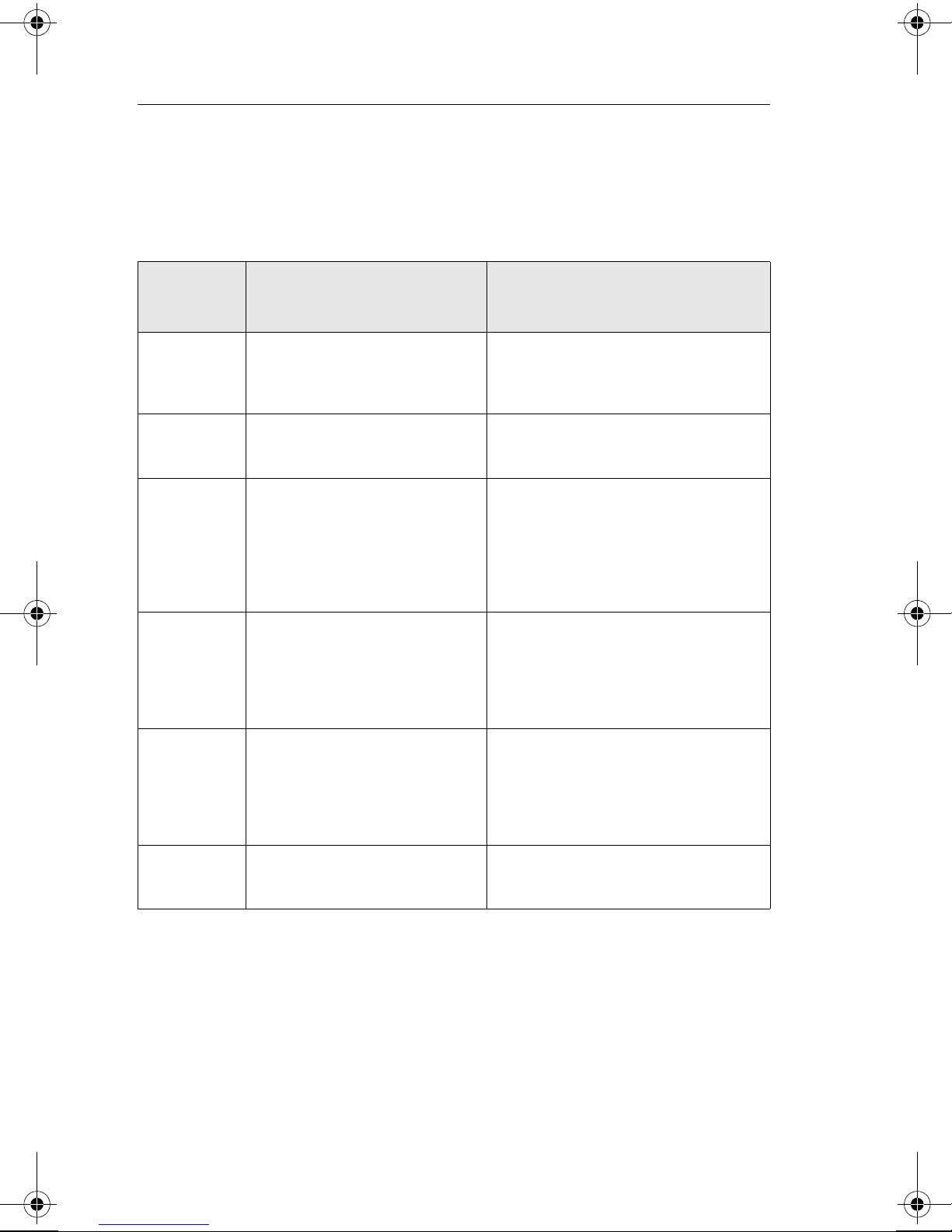

Fault mes-

Cause Cure

sage code

E 090 Loop current too low. To store ope-

rating data a mimimum of 3.6 mA

has to be provided on the input.

E 101 The hardware required to store the

operating parameters is defective.

E 102 Checksum of operating parameters

is invalid or the software version

does not correspond with the operating data. Possible cause is a

power failure during a parameter

save procedure.

E 103 The calibration values for the ana-

logue input are faulty. Possible

cause is a power failure during calibration, an uncalibrated unit or a

defective unit.

Check loop circuit.

Please exchange the unit.

A PRESET is automatically initiated by

operating the "E" push button. This means

that all parameters are returned to the factory default values. Any special customer

specific settings made at the factory are not

taken into consideration!

Please exchange the unit.

E 106 Warning: Due to an installation

fault an incorrect setting up of the

display range/scale was made

(lower and upper values are identical).

E 111 The hardware for saving the opera-

ting parameters is defective.

18

Please correct the values.

Please exchange the unit.

Page 19

Digital field display 10 Fault-finding

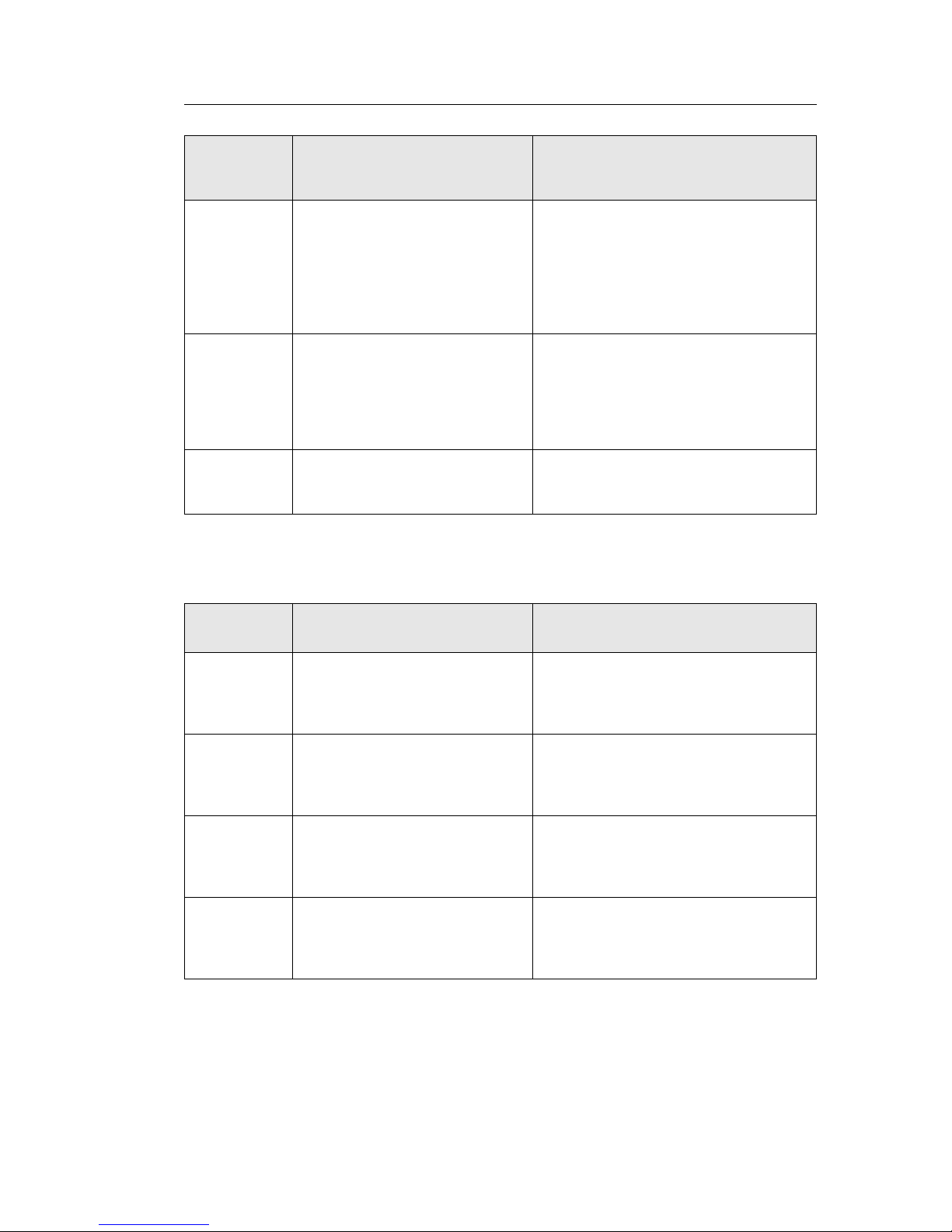

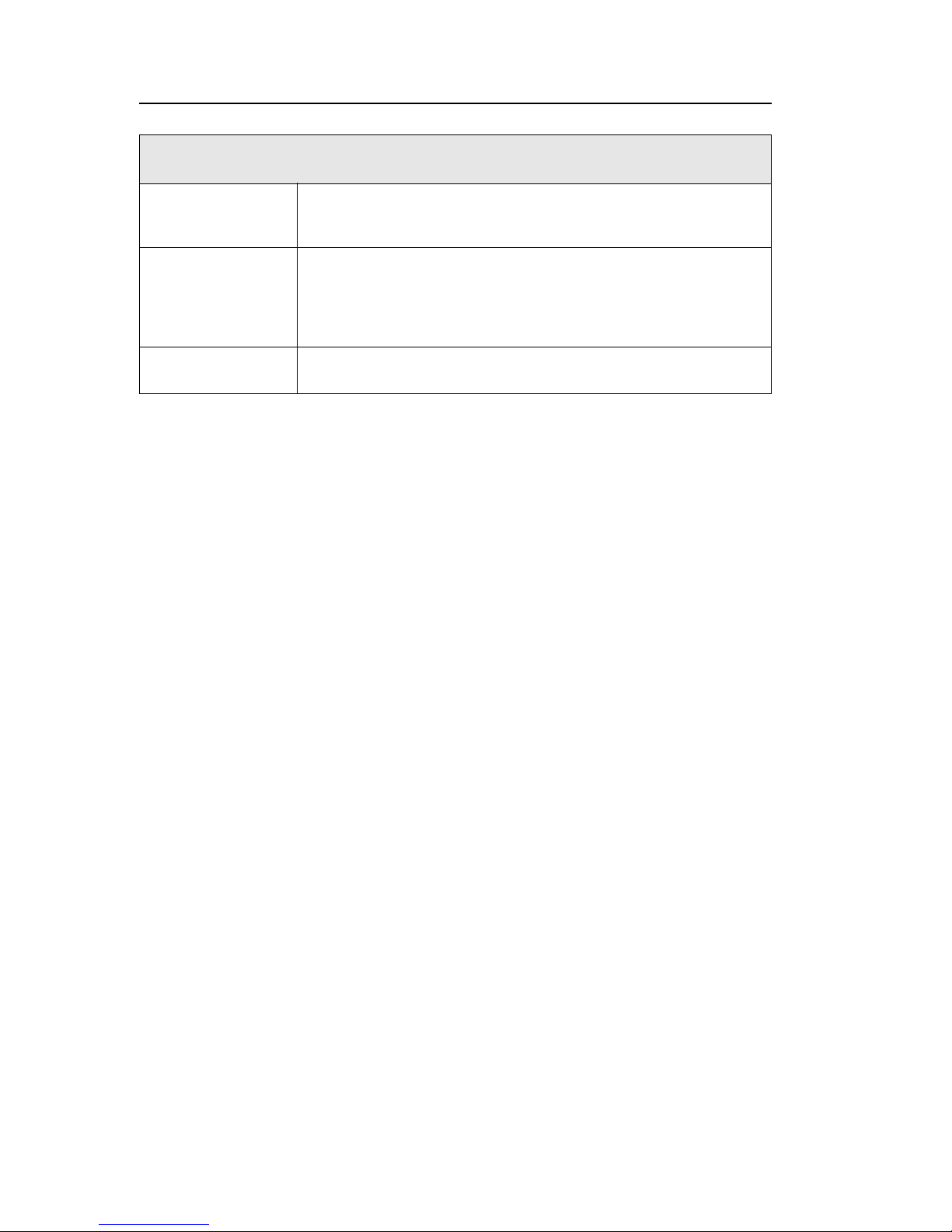

10.3 System messages

Effect Cause Cure

Display

indicates:

#####”

„

Display

indicates:

*****”

„

Display

indicates:

(+”

„

Display

flashes:

(+”

„

Under range. An input signal of <

3.6 mA is connected to unit input.

Over range. An input signal of >

21.0 mA is connected to unit input.

Operating parameters have been

changed. The unit requests a save

command.

The unit is saving changes made to

the operating parameters.

Please check the input signal.

Please check the input signal.

Release save/do not save using the "+/-"

push buttons and acknowledge with "E".

Once the save sequence has been completed the unit returns to displaying the measured values.

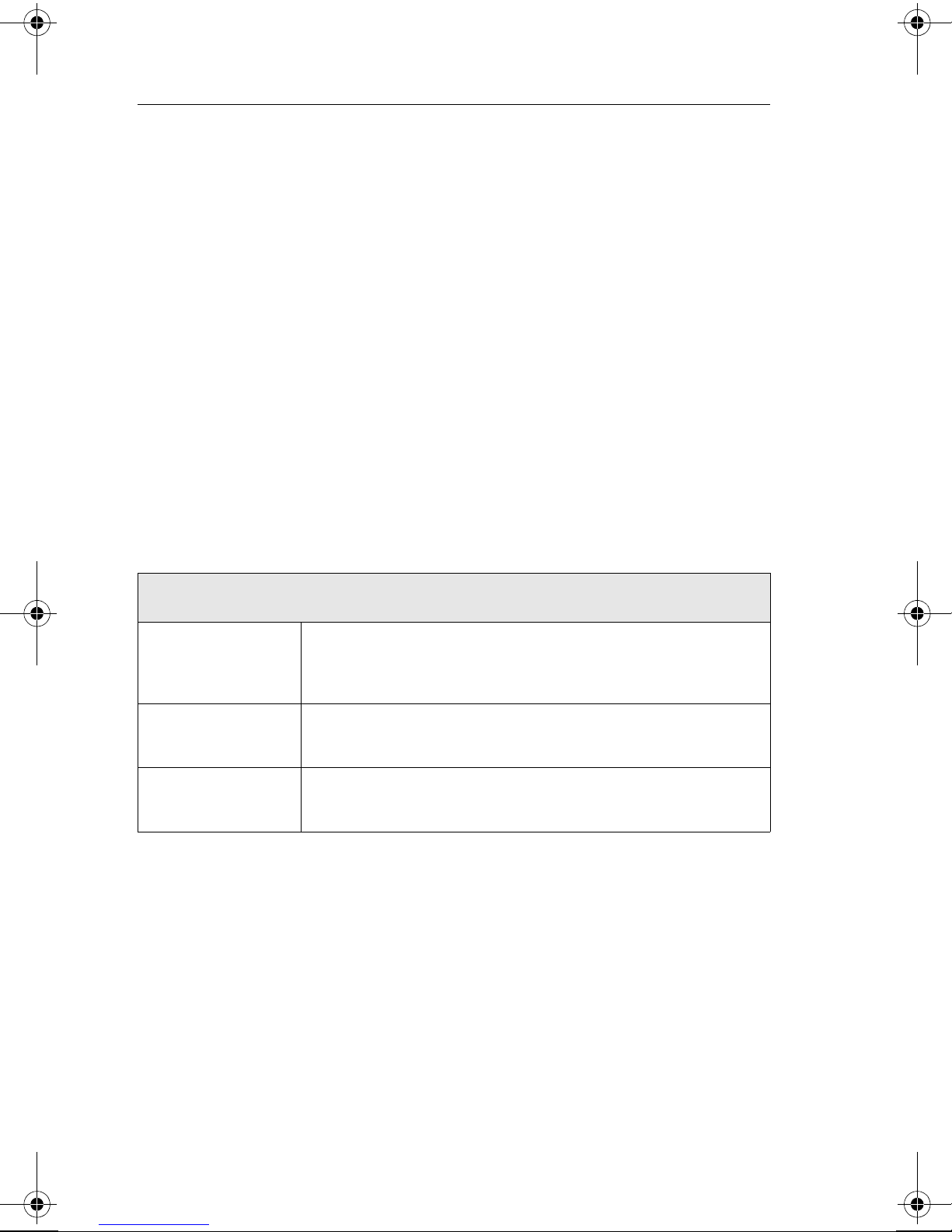

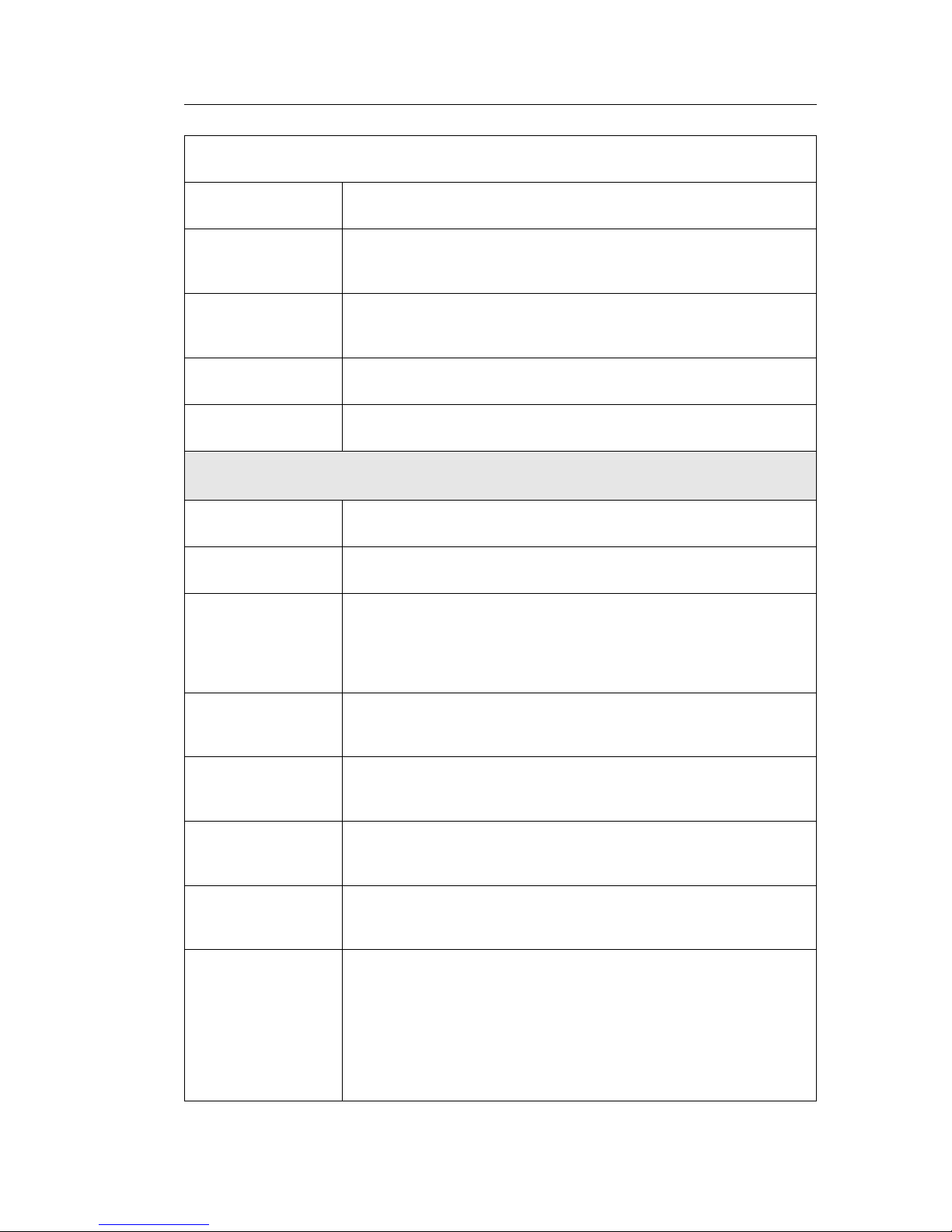

10.4 Fault analysis

Effect Cause Cure

No measured value

display

The 7 segment display shows

an incorrect/inaccurate measured value

There is no circuit connected. Please check the wiring to the unit.

Unit defective. Please exchange the unit.

Display defective. Please exchange the unit.

Measured input incorrectly set up. Change set up in operating menu.

Sensor calibration faulty. Compensate error using the offset.

Offset incorrectly set up. Check offset.

19

Page 20

11 Technical data Digital field display

10.5 Repairs

Due to its construction, the field mounted display cannot be repaired.

10.6 Returns

If the unit is to be returned, always add a fault description as well as the

application and return the unit in its original packaging. If this is not possible, please pack the unit safely.

10.7 Disposal

If the unit is to be disposed of please follow the local disposal regulations

for electronic components.

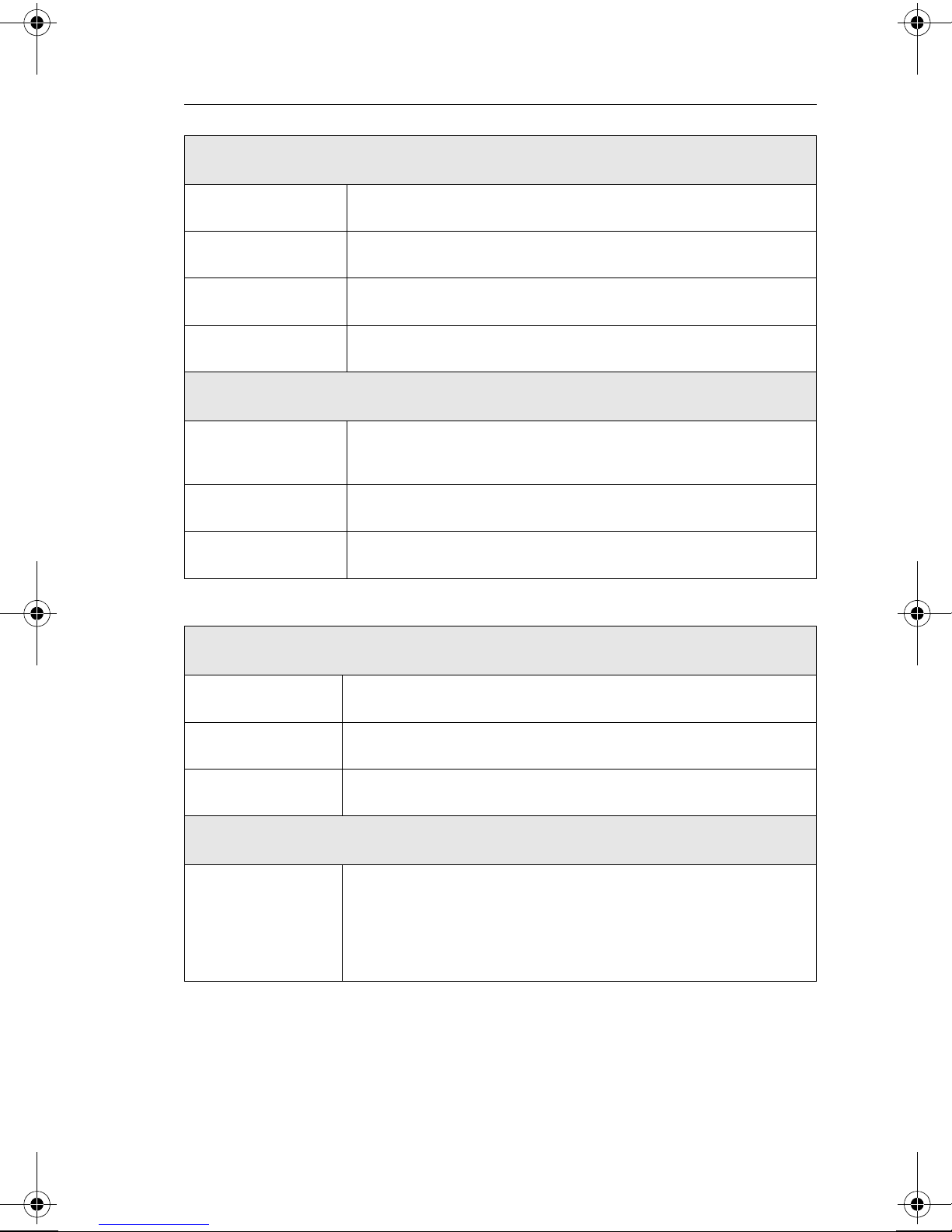

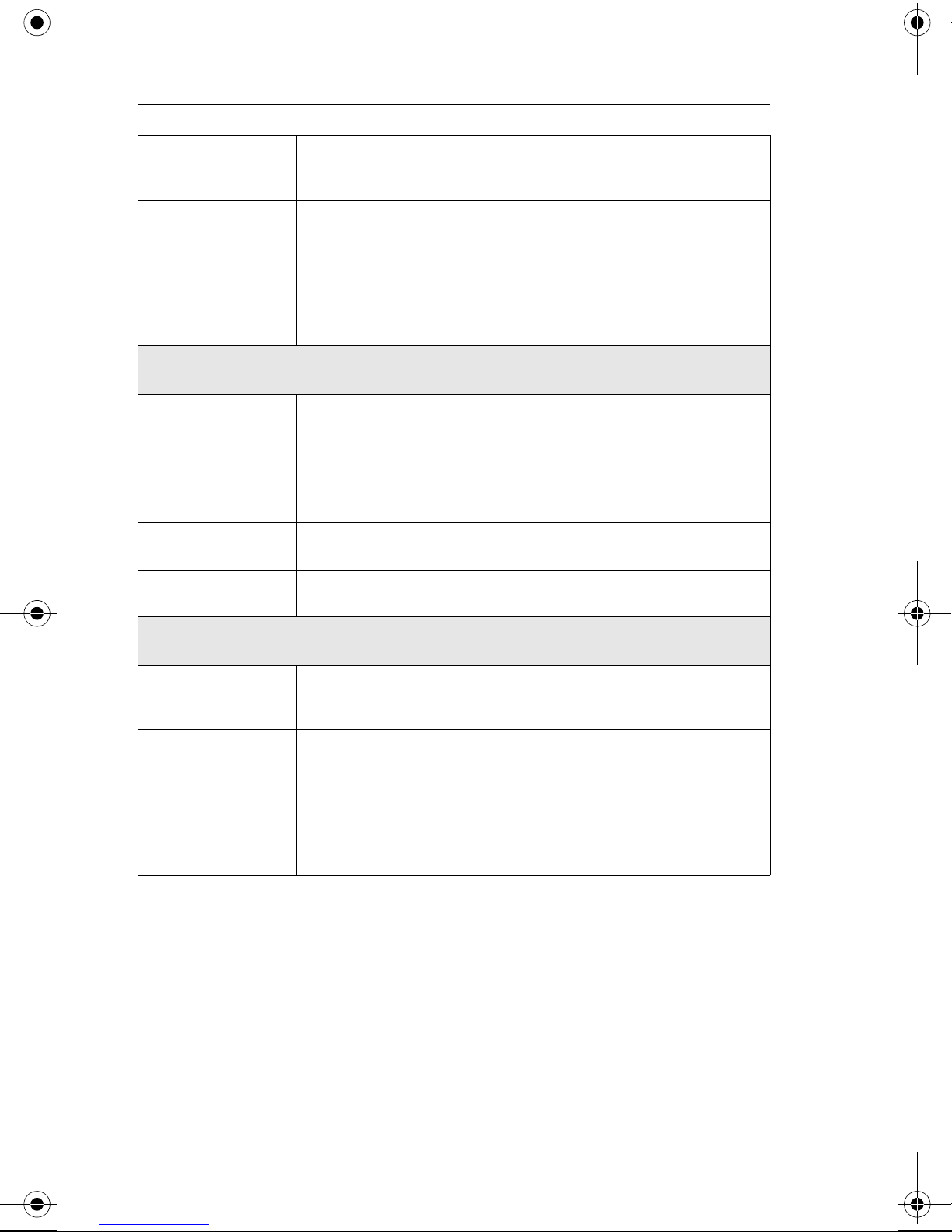

11 Technical data

Operation and system construction

Application area The unit measures an analogue signal and indicates this in the display. The

unit is installed in a 4 to 20 mA current loop circuit and also obtains the

necessary energy supply from that circuit.

Measurement priciple The signal connected to the analogue input is digitalised, analysed and

indicated in the display.

Measurement system Micro-controller controlled field mounted display with illuminated LC

display.

20

Page 21

Digital field display 11 Technical data

Input

Type Current

Measurement range 4 to 20 mA (pole protected)

Max. input current 200 mA (short circuit current)

Volt drop (load) < 2.5 Volt

Output

Output signal The analogue input signal (4 to 20 mA) is not converted. The input signal

is digitalised, analysed and shown in the LC display.

Fault signal No measured value seen in the LC display, no rear illumination.

HART protocol The display allows transmission of the HART

Power supply

Electrical connection See chapter 5

Supply Using the 4 to 20 mA current loop

Volt drop < 2.5 Volt

Accuracy

Current Measurement error < 0.1 % FSD

Temperature drift: 0.01 % / K ambient temperature

®

protocol signal.

21

Page 22

11 Technical data Digital field display

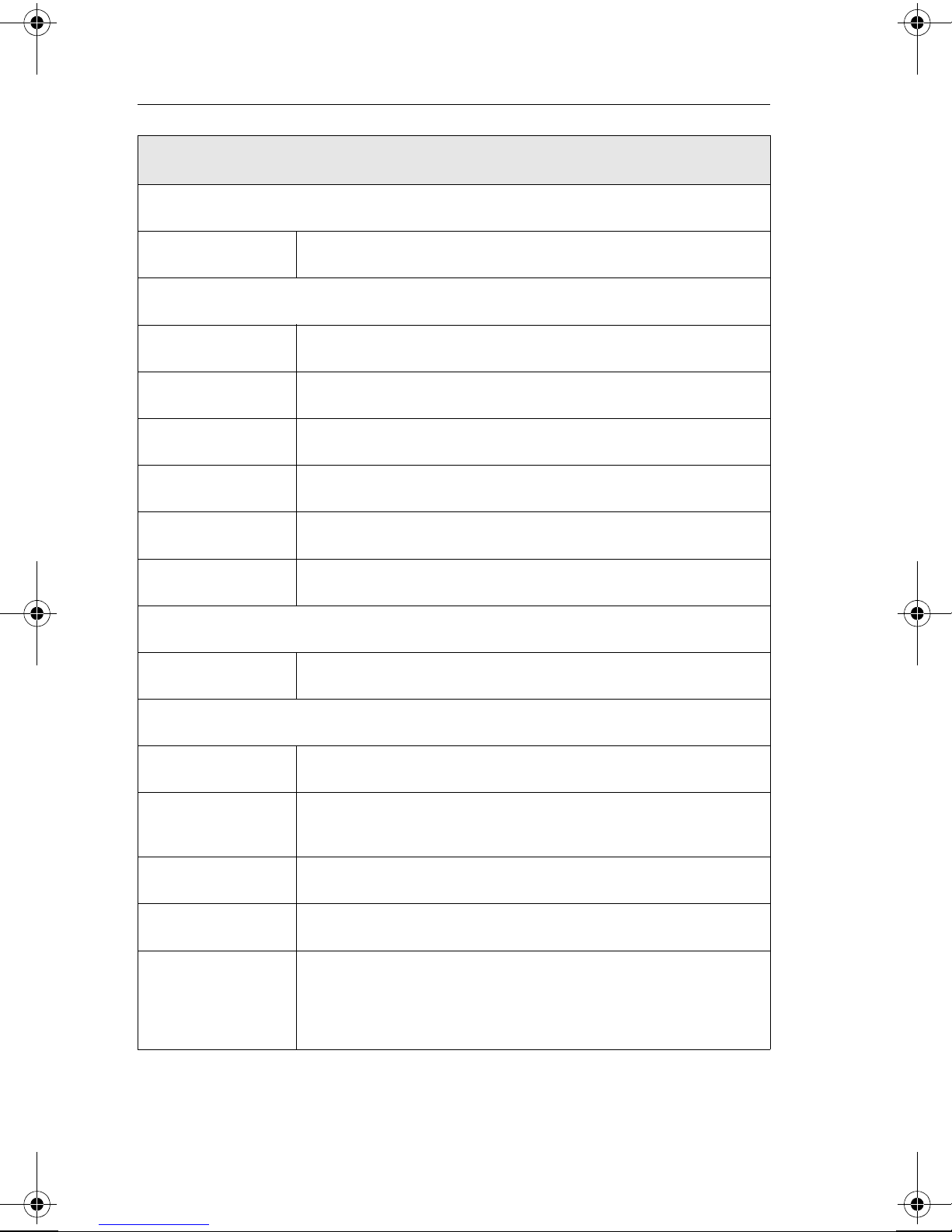

Application conditions

Installation conditions

Installation angle No limitation

Ambient conditions

Ambient temperature -20 °C to +60 °C (for Ex areas see Ex certificate)

Storage temperature -25 °C to +70 °C

Climatic class To IEC 60654-1 Class D1

Ingress protection IP66 / NEMA 4x

Shock resistance 7 Nm housing; 4 Nm glass as per EN 50014

Vibration resistance as per GL-directive VI-part 7: 5 to 500 Hz, 0.7 g, max. 1 octave/minute

EMC immunity

RF protection To EN 55011 Group 1, Class B

Interference safety

ESD To IEC 61000-4-2, 6 kV/8 kV

Electro magnetic

fields

Burst (power supply) To IEC 61000-4-4, 4 kV

Surge To IEC 61000-4-5, 1 kV

Cable high frequency To IEC 61000-4-6, 10 V

To IEC 61000-4-3, 10 V/m

22

Page 23

Digital field display 11 Technical data

Mechanical construction

Dimensions H: 80 mm, W: 175 mm, D: 65 mm

Weight Approx. 800 g

Materials • Housing: Die cast aluminium, epoxy coated with glass insert

• Wall/stand pipe bracket: Stainless steel 1.4301

• Tension strip: Stainless steel 1.4301

Terminals Plug-on screw terminals, Terminal sizing:

1.5 mm² solid core, 1.0 mm² standed with ferrule

Earth (ground)

Terminals

Cable entry 2 x metric M20x1.5 cable entries

Pressure

compensation

Electronic

compartment

Earth (ground) connection on housing exterior:

Terminal range 2.5 mm²

alternative: 2 x NPT 1/2" cable entries

For ventilation and pressure comensation of the electronic compartment a

mainenance free GORE-TEX

There is room for the installation of a further electronic insert e.g. Temperature head transmitter underneath the hinged electronic components. H:

60 mm, W: 140 mm, D: 30 mm

®

membrane is built in

Display and operating level

Display 5 digit LC display, 26 mm character height, rear illuminated, analogue

value display in 10% steps. Indication of over/under range input.

Display range -19999 to +99999

Offset -19999 to +32767

Operation 3 push button operation (-/+/E)

23

Page 24

11 Technical data Digital field display

Certification

CE mark The unit fulfils the legal requirement according to the EU directives 89/

336/EWG.

Ex certification Details regarding the availability of the Ex versions (ATEX, FM, CSA, etc.)

can be obtained from your local sales organisation. All relevant data for

hazardous area protection can be found in Ex documentation, which can

be requested separately.

Marine approval GL Germanische Lloyd / marine approval

24

Page 25

Digital field display Index

Index

A

Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

B

Bargraph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

C

CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8, 24

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

D

Decimal point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Display value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

E

EMC immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Enter push button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Explosion hazardous area . . . . . . . . . . . . . . . . . . . . . . . . . 6

I

Identification fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Ingress protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Installation conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Interference safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

M

Measured value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Measurement range . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Mechanical construction . . . . . . . . . . . . . . . . . . . . . . . . . 23

O

Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

25

Page 26

Index Digital field display

operating level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

P

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

S

Selection push buttons . . . . . . . . . . . . . . . . . . . . . . . . . . 14

sytem construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

T

Technical advancement . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

U

User code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

26

Page 27

Digitaler Feldanzeiger

Digital field display

Operating manual

(Please read before installing the unit)

Unit number:.....................................

Digitaler Feldanzeiger

Betriebsanleitung

(Bitte lesen, bevor Sie das Gerät in Betrieb nehmen)

Gerätenummer:.....................................

Indicador de campo digital

Manual de instrucciones

(Por favor, lea el manual antes de instalar la unidad)

Número de unidad:.....................................

English

English

3 ... 26

19...34

Deutsch

English

27 ... 50

19...34

Español

Español

51 ... 74

19...34

Indicateur de process

Manuel de mise en service

(veuillez entièrement lire le manuel avant la mise en service de l’appareil)

o

appareil:....................................

N

Visualizzatore digitale da campo

Manuale operativo

(Si prega di leggere prima di installare l’unità)

Codice unità:....................................

Français

English

75 ... 98

19...34

Italiano

English

99 ... 122

19...34

27

Page 28

Inhaltsverzeichnis Digitaler Feldanzeiger

Inhaltsverzeichnis

1 Sicherheitshinweise . . . . . . . . . . . . . . 30

1.1 Bestimmungsgemäße Verwendung . . . . . . . . . . . . 30

1.2 Montage, Inbetriebnahme, Bedienung . . . . . . . . . 30

1.3 Betriebssicherheit . . . . . . . . . . . . . . . . . . . . . . . . . 30

1.4 Rücksendung . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

1.5 Sicherheitszeichen und Symbole . . . . . . . . . . . . . . 31

2 Identifizierung . . . . . . . . . . . . . . . . . . . . . . 32

2.1 Gerätebezeichnung . . . . . . . . . . . . . . . . . . . . . . . 32

2.2 Lieferumfang . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.3 Zertifikate und Zulassungen . . . . . . . . . . . . . . . . . 32

3 Arbeitsweise und Systemaufbau . . . . . 32

3.1 Funktionsweise . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.2 Systemaufbau . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4 Montage . . . . . . . . . . . . . . . . . . . . . . . 33

4.1 Einbaubedingungen . . . . . . . . . . . . . . . . . . . . . . . 33

4.1.1 Einbaumaße . . . . . . . . . . . . . . . . . . . . . . . 33

4.2 Einbau . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.2.1 Direkte Wandmontage . . . . . . . . . . . . . . . 34

4.2.2 Wand- und Rohrmontagehalter . . . . . . . . 34

4.2.3 Einbau zusätzlicher Messelektronik . . . . . 35

4.3 Einbaukontrolle . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5 Verdrahtung . . . . . . . . . . . . . . . . . . . . 35

5.1 Verdrahtung auf einen Blick . . . . . . . . . . . . . . . . . 35

5.1.1 Klemmenplan . . . . . . . . . . . . . . . . . . . . . . 35

5.1.2 Elektrischer Anschluss . . . . . . . . . . . . . . . 36

5.1.3 Anschluss aktiver Stromquelle . . . . . . . . . 37

5.1.4 Anschluss passiver Stromquelle . . . . . . . . . 37

28

Page 29

Digitaler Feldanzeiger Inhaltsverzeichnis

5.2 Anschlusskontrolle . . . . . . . . . . . . . . . . . . . . . . . . 38

6 Bedienung . . . . . . . . . . . . . . . . . . . . . 38

6.1 Bedienung auf einen Blick . . . . . . . . . . . . . . . . . . 38

6.2 Anzeige- und Bedienelemente. . . . . . . . . . . . . . . . 38

6.3 Programmieren im Bedienmenü . . . . . . . . . . . . . . 39

6.3.1 Bedienmenü auf einen Blick . . . . . . . . . . . 40

6.4 Beschreibung der Bedienparameter . . . . . . . . . . . . 40

7 Inbetriebnahme . . . . . . . . . . . . . . . . . 41

7.1 Installations- und Funktionskontrolle . . . . . . . . . . 41

7.2 Inbetriebnahme . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8 Wartung . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9 Zubehör . . . . . . . . . . . . . . . . . . . . . . . 42

10 Störungsbehebung . . . . . . . . . . . . . . . 42

10.1 Fehlersuchanleitung . . . . . . . . . . . . . . . . . . . . . . . 42

10.2 Prozessfehlermeldungen . . . . . . . . . . . . . . . . . . . . 42

10.3 Systemmeldungen . . . . . . . . . . . . . . . . . . . . . . . . 43

10.4 Fehleranalyse . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

10.5 Reparatur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

10.6 Rücksendung . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

10.7 Entsorgung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

11 Technische Daten. . . . . . . . . . . . . . . . 45

29

Page 30

1 Sicherheitshinweise Digitaler Feldanzeiger

1 Sicherheitshinweise

1.1 Bestimmungsgemäße Verwendung

Der digitale Feldanzeiger hat das Werk in sicherheitstechnisch ein-

•

wandfreiem Zustand verlassen.

• Ein gefahrloser Betrieb ist nur sichergestellt, wenn die Betriebsanlei-

tung beachtet wird.

• Für Schäden aus unsachgemäßem oder nicht bestimmungsgemäßem

Gebrauch haftet der Hersteller nicht.

• Gerät nur in dem dafür vorgesehenen Temperaturbereich betreiben.

• Messsysteme, die im explosionsgefährdetem Bereich eingesetzt wer-

den, liegt eine separate Ex-Dokumentation bei, die ein fester

Bestandteil dieser Betriebsanleitung ist. Die darin aufgeführten

Installationsvorschriften und Anschlusswerte müssen ebenfalls konsequent beachtet werden!

1.2 Montage, Inbetriebnahme, Bedienung

Das Gerät ist nach dem Stand der Technik betriebssicher gebaut und

berücksichtigt die einschlägigen Vorschriften und EU-Richtlinien.

Wenn es jedoch unsachgemäß oder nicht bestimmungsgemäß eingesetzt wird, können von ihm applikationsbedingte Gefahren ausgehen.

Montage, elektrische Installation, Inbetriebnahme und Wartung des

Gerätes dürfen nur durch ausgebildetes Fachpersonal erfolgen, das vom

Anlagenbetreiber dazu autorisiert wurde. Das Fachpersonal muss diese

Betriebsanleitung unbedingt gelesen und verstanden haben und deren

Anweisungen unbedingt befolgen. Der Installateur hat dafür Sorge zu

tragen, dass das Messsystem gemäß den elektrischen Anschlussplänen

korrekt angeschlossen ist. Veränderungen und Reparaturen am Gerät

dürfen nur vorgenommen werden, wenn dies die Betriebsanleitung ausdrücklich zulässt. Beachten Sie grundsätzlich die in Ihrem Land geltenden Vorschriften bezüglich Öffnen und Reparieren von elektrischen

Geräten.

1.3 Betriebssicherheit

Explosionsgefährdeter Bereich

Bei Einsatz des Messsystems in explosionsgefährdeten Bereichen sind

die entsprechenden nationalen Normen einzuhalten. Stellen Sie sicher,

dass das Fachpersonal ausreichend ausgebildet ist. Die messtechnischen

und sicherheitstechnischen Auflagen an die Messstellen sind einzuhalten.

30

Page 31

Digitaler Feldanzeiger 1 Sicherheitshinweise

Technischer Fortschritt

Der Hersteller behält sich vor, technische Daten ohne spezielle Ankündigung dem entwicklungstechnischen Fortschritt anzupassen. Über die

Aktualität und eventuelle Erweiterungen dieser Betriebsanleitung erhalten Sie bei Ihrer Vertriebsstelle Auskunft.

1.4 Rücksendung

Bei Transportschäden informieren Sie bitte den Spediteur und den Lieferanten.

1.5 Sicherheitszeichen und Symbole

„Hinweis” deutet auf Aktivitäten oder Vorgänge hin, die - wenn sie

!

nicht ordnungsgemäß durchgeführt werden - einen indirekten Einfluss

auf den Betrieb haben, oder eine unvorhergesehene Gerätereaktion auslösen können.

"

#

0

.

„Achtung” deutet auf Aktivitäten oder Vorgänge hin, die - wenn sie

nicht ordnungsgemäß durchgeführt werden - zu Verletzungen von Personen oder zu fehlerhaftem Betrieb führen können.

„Warnung” deutet auf Aktivitäten oder Vorgänge hin, die - wenn sie

nicht ordnungsgemäß durchgeführt werden - zu Personenschäden, zu

einem Sicherheitsrisiko oder zur Zerstörung des Gerätes führen können.

Explosionsgeschützte, baumustergeprüfte Betriebsmittel

Befindet sich dieses Zeichen auf dem Typenschild des Gerätes, kann das

Gerät im explosionsgefährdeten Bereich eingesetzt werden.

Sicherer Bereich (nicht explosionsgefährdeter Bereich)

Dieses Symbol kennzeichnet in den Zeichnungen dieser Bedienungsanleitung den nicht explosionsgefährdeten Bereich. Geräte im nicht explosionsgefährdeten Bereich müssen auch zertifiziert sein, wenn

Anschlussleitungen in den explosionsgefährdeten Bereich führen.

31

Page 32

2 Identifizierung Digitaler Feldanzeiger

2 Identifizierung

2.1 Gerätebezeichnung

Das richtige Gerät?

Vergleichen Sie bitte den Bestellcode auf dem Typenschild (am Gerät)

mit dem auf dem Lieferschein.

2.2 Lieferumfang

- Feldanzeiger, Ausführung nach Bestellung.

- Betriebsanleitung

- Zubehör laut Bestellung

2.3 Zertifikate und Zulassungen

CE-Zeichen, Konformitätserklärung

Das Gerät ist nach dem Stand der Technik betriebsicher gebaut und

geprüft und hat das Werk in sicherheitstechnisch einwandfreiem

Zustand verlassen. Das Gerät berücksichtigt die einschlägigen Normen

und Vorschriften nach IEC 61010 “Sicherheitsbestimmungen für elektrische Mess-, Steuer-, Regel- und Laborgeräte”.

Das in dieser Betriebsanleitung beschriebene Gerät erfüllt somit die

gesetzlichen Anforderungen der EU-Richtlinien. Der Hersteller bestätigt

die erfolgreiche Prüfung des Gerätes mit der Anbringung des CE-Zeichens.

3 Arbeitsweise und Systemaufbau

3.1 Funktionsweise

Der Feldanzeiger wird direkt in den 4 bis 20 mA Messkreis eingeschleift. Die benötigte Energie wird aus der Messschleife entnommen.

Das Gerät erfasst einen analogen Messwert und stellt diesen digital auf

einer deutlich ablesbaren LC-Anzeige dar. Zusätzlich zeigt ein Bargraph

den Messwert grafisch an.

Eine verbesserte Lesbarkeit in dunkler Umgebung ist durch die hinterleuchtete Anzeige gegeben.

32

Page 33

Digitaler Feldanzeiger 4 Montage

3.2 Systemaufbau

Microcontroller gesteuerter Feldanzeiger mit hinterleuchteter numerischer und analoger LC-Anzeige. Die Aktualisierung der Anzeige erfolgt

sekündlich.

Der dynamische Innenwiderstand (Bürde) stellt sicher, dass der Spannungsabfall in der Signalschleife immer <2,5 V ist.

4 Montage

4.1 Einbaubedingungen

4.1.1 Einbaumaße

Abb. 1: Einbaumaße

4.2 Einbau

Das Gerät ist für die direkte Wandmontage geeignet. Optional kann ein

kombinierter Wand-/ Rohrhalter bestellt werden (siehe Zubehör).

33

Page 34

4 Montage Digitaler Feldanzeiger

4.2.1 Direkte Wandmontage

Abb. 2: Direkte Wandmontage

Zur direkten Wandmontage des Gerätes gehen Sie wie folgt vor:

• Die 2 Löcher in der Wand nach Bohrplan bohren

• Gerätedeckel öffnen und herunternehmen

• Gerät an der Wand mit 2 Schrauben anbringen

4.2.2 Wand- und Rohrmontagehalter

(Siehe Kap. 9 Zubehör)

Abb. 3: Wand- und Rohrmontagehalter

Zur Montage des Gerätes auf dem kombinieren Wand- und Rohrmontagehalter gehen Sie bitte wie folgt vor:

• Bei Wandmontage 4 Löcher nach Bohrplan in die Wand bohren

• Den Montagehalter (B) an Wand, bzw. Rohr mit den beiliegenden

Befestigungsmaterial (A) anbringen

• Gerätedeckel öffnen und herunternehmen

• Gerät am Montagehalter mit 2 Schrauben anbringen

34

Page 35

Digitaler Feldanzeiger 5 Verdrahtung

4.2.3 Einbau zusätzlicher Messelektronik

Unter der schwenkbaren Elektronikeinheit steht im Gehäuse Raum für

den Einbau von zusätzlicher Messelektronik, z.B. Temperaturkopftransmitter, zur Verfügung.

Achtung: Beachten Sie die Einbau- und Anschlusshinweise des jeweili-

"

gen Herstellers!

4.3 Einbaukontrolle

Schutzart

Die Geräte erfüllen alle Anforderungen gemäß IP66 NEMA 4x. Um

nach erfolgter Montage oder nach einem Service-Fall diese zu gewährleisten, müssen folgende Punkte zwingend beachtet werden:

• Die Gehäusedichtungen müssen sauber und unbeschädigt in die

Dichtungsnut eingelegt sein. Gegebenenfalls sind die Dichtungen zu

reinigen, zu trocknen oder zu ersetzen.

• Sämtliche Gehäuseschrauben und die Kabeldurchführung müssen

fest angezogen sein.

"

5 Verdrahtung

Achtung: Beachten Sie für den Anschluss von Geräten für den explosionsgefährdeten Bereich die entsprechenden Hinweise und Anschlussbilder in den Ex-spezifischen Zusatzdokumentationen zu dieser

Betriebsanleitung.

5.1 Verdrahtung auf einen Blick

5.1.1 Klemmenplan

Die Anschlussklemmen des 4 bis 20 mA Messstromkreises befinden

sich unter dem Gehäusedeckel an der rechten oberen Seite des Gerätes.

Der Klemmenblock ist steckbar und kann zum Anklemmen der

Anschlussleitungen abgezogen werden.

35

Page 36

5 Verdrahtung Digitaler Feldanzeiger

Klemmenbelegung Ein- und Aus-

gang

1 Messsignal (+) 4 bis 20 mA Signaleingang

#

#

2 Anschlussklemme für weitere Instrumentie-

rung (gebrückt mit 4)

3 Messsignal (-) 4 bis 20 mA Signaleingang

4 Anschlussklemme für weitere Instrumentie-

rung (gebrückt mit 2)

5.1.2 Elektrischer Anschluss

Sowohl die Klemmenbelegung, als auch die Anschlusswerte des Feldanzeigers entsprechen denen der Ex-Ausführung.

Das Gerät ist nur zum Betrieb in einem 4 bis 20 mA Messstromkreis

vorgesehen. Entlang der Stromkreise (innerhalb und ausserhalb des

explosionsgefährdeten Bereichs) muss Potentialausgleich bestehen.

Verwenden Sie hierzu den Erdungsanschluss am Gehäuse links unten.

Zur einfacheren Installation und zum leichten Einführen der Kabel kann

die Elektronikeinheit herausgeklappt werden.

Das Gerät darf nur von einem Netzteil mit energiebegrenztem Stromkreis nach IEC 61010-1 gespeist werden: ’SELV oder Class 2 circuit’.

Stützklemme

Stützklemme

Abb. 4: Aufklappen der Elektronikeinheit

Hierzu gehen Sie bitte wie folgt vor:

• Gerätedeckel öffnen und herunternehmen

• Elektronikeinheit oben anfassen und herausklappen (siehe Skizze)

36

Page 37

Digitaler Feldanzeiger 5 Verdrahtung

5.1.3 Anschluss aktiver Stromquelle

Z.B. Messumformer mit eigener Hilfsenergie und aktivem Stromausgang:

Hinweis: Bei Verwendung einer geeigneten Barriere ist der Anzeiger

#

direkt im explosionsgefährdetem Bereich einsetzbar.

Klemme 2 und 4

intern gebrückt

1

3

2

4

+

Y

+

I

-

-

Abb. 5: Anschluss aktiver Stromquelle

5.1.4 Anschluss passiver Stromquelle

Z.B. 2-Leiter Messumformer mit zusätzlicher Messumformerspeisung:

Explosionsgefährdeter Bereich

EX

Klemme 2 und 4

intern gebrückt

3

1

2

4

Nicht-explosionsgefährdeter

Bereich

EX

-

Y

+

I

-

Eigensichere

+

Messumformerspeisung

Abb. 6: Anschluss passiver Stromquelle

Ein Ex - zugelassenes Gerät kann auch im nicht-explosionsgefährdetem

Bereich eingesetzt werden. Die Umkehrung gilt nicht!

37

Page 38

6 Bedienung Digitaler Feldanzeiger

5.2 Anschlusskontrolle

Bitte beachten Sie, dass vor dem Aufsetzen des Gehäusedeckels die

#

Elektronikeinheit zurückgeklappt, und der Verriegelungsraster auf der

linken Seite eingeschnappt ist.

6 Bedienung

6.1 Bedienung auf einen Blick

In den nachfolgenden Abschnitten finden Sie Hinweise zur Bedienung

und Parametrierung des Feldanzeigers. Diese Funktionen sind bei der

Ex- und Non-Ex Ausführung des Gerätes identisch.

6.2 Anzeige- und Bedienelemente

Abb. 7: Anzeige- und Bedienelemente

Messwert:

5-stellige, LC-Anzeige. Dargestellt werden:

• momentaner numerischer Messwert (im Betrieb).

• Dialogtext für Parametrierung.

Bargraph:

Der Bargraph zeigt den skalierten Messbereich an. Er gibt Auskunft über

den momentanen, prozentualen Messwert.

Eingabetaste (E):

Einstieg in das Programmiermenü.

• Anwählen von Bedienfunktionen innerhalb einer Funktionsgruppe.

• Abspeichern von eingegebenen Daten.

38

Page 39

Digitaler Feldanzeiger 6 Bedienung

Auswahltasten (+, -):

• Anwählen von Funktionsgruppen innerhalb des Menüs.

• Einstellen von Parametern und Zahlenwerten. (Bei dauerndem

Gedrückthalten der Tasten erfolgt eine Zahlenänderung auf der

Anzeige mit zunehmender Geschwindigkeit.)

• Beim Drücken der +/- Taste im Anzeigebetrieb wird der aktuelle

Schleifenstrom in der Anzeige dargestellt.

Beschriftungsfelder:

In die Beschriftungsfelder können zusätzliche Informationen geschrieben werden. Zur Beschriftung des Feldes gehen Sie wie folgt vor:

• Entfetten und reinigen Sie die Felder.

• Beschriften Sie die Felder mit einem lichtbeständigen, wasserfesten

Folienschreiber

6.3 Programmieren im Bedienmenü

+

_

Editieren

3

E

E

E

6

_

+

> 3 s

1

4

2

Wert übernehmen

E

SAVE?

5

E

> 3 s

_

+

4

Abb. 8: Programmieren im Bedienmenü

Einstieg in das Bedienmenü.

Auswahl von Bedienfunktionen.

Eingabe von Parametern im Editormodus

(Daten mit + oder - eingeben/auswählen und mit E überneh men).

Rücksprung aus dem Editormodus bzw. Bedienfunktion in

eine Funktionsgruppe. Beim mehrmaligen gleichzeitigen

Drücken der + /- Tasten gelangt man in die Home Position

(Anzeigebetrieb) zurück. Vorher erfolgt eine Abfrage, ob die

bis dahin eingegebenen Daten gespeichert werden sollen.

39

Page 40

6 Bedienung Digitaler Feldanzeiger

Direkter Sprung zur Home Position (Anzeigebetrieb).

Vorher erfolgt eine Abfrage, ob die bis dahin eingegebenen Daten

gespeichert werden sollen.

Abfrage der Datenspeicherung (Auswahl Ja/Nein mit + oder

- Taste auswählen und mit E bestätigen).

6.3.1 Bedienmenü auf einen Blick

% !$ $() $

Dezimalpunkt Anzeigewert 0% Anzeigewert

100%

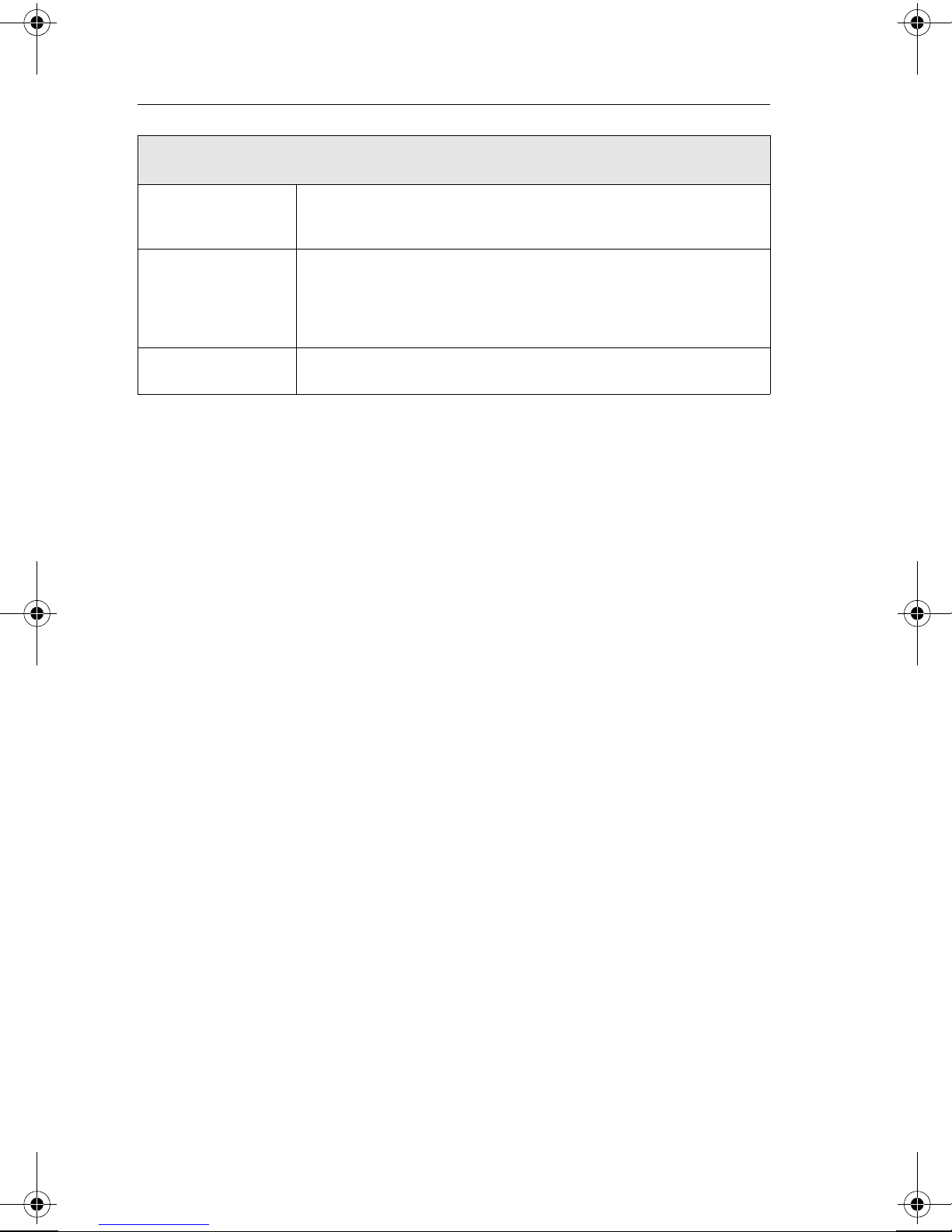

6.4 Beschreibung der Bedienparameter

Parameter Einstellmöglichkei-

ten

Dezimalpunkt

Anwahl der Nachkommastellen der

numerischen Anzeige

Anzeigewert 0%

Anzeigewert zum

Schleifenstrom

4 mA

%

Auswahlbereich:

0 bis 4 Nachkommastellen

!$

Wertebereich:

-19999 bis 99999

Werkseinstellung Aktuelle Einstel-

Offset Benutzercode

lung

Anzeigewert 100%

Anzeigewert zum

Schleifenstrom

20 mA

Offset

Signaloffset zur

Anpassung der Messwertanzeige

40

Wertebereich:

-19999 bis 99999

$()

Wertebereich:

-19999 bis 32767

Page 41

Digitaler Feldanzeiger 7 Inbetriebnahme

Parameter Einstellmöglichkei-

ten

Benutzercode

Frei einstellbarer

Bediencode durch

den Benutzer.

bereits vergebener

Benutzercode kann nur

verändert werden, wenn

der alte Code zur Freischaltung des Geräts eingegeben wird. Danach ist

der neue Code einstellbar.

Ein

$

Wertebereich: 0000

bis 9999

!

Bei “0" ist kein

Benutzercode aktiv

7 Inbetriebnahme

7.1 Installations- und Funktionskontrolle

Werkseinstellung Aktuelle Einstel-

lung

Überprüfen Sie alle angeschlossenen Drähte auf festen Sitz. Um eine

einwandfreie Funktion zu gewährleisten, müssen die Schrauben der

Anschlussklemmen festgedreht sein. Das Gerät ist nun betriebsbereit.

7.2 Inbetriebnahme

Das Gerät ist nach erfolgter Montage und Verdrahtung betriebsbereit.

41

Page 42

8 Wartung Digitaler Feldanzeiger

8 Wartung

Das Gerät erfordert keine speziellen Instandhaltungs- und Wartungsarbeiten.

9 Zubehör

Wand- und Rohrmontagehalter.

Für Bestellungen (z.B. Ersatzteile) kontaktieren Sie bitte Ihren Lieferanten! Geben Sie bei Zubehör- bzw. Ersatzteilbestellungen die Seriennummer des Gerätes an!

10 Störungsbehebung

Um Ihnen eine erste Hilfe zur Störermittlung zu geben, finden Sie nachfolgend eine Übersicht der möglichen Fehlerursachen.

10.1 Fehlersuchanleitung

Warnung:

"

Bei Ex-Geräten kann keine Fehlerdiagnose am offenen Gerät durchgeführt werden, weil dadurch die Zündschutzart aufgehoben wird.

10.2 Prozessfehlermeldungen

Fehler die während des Selbsttests oder im laufenden Betrieb auftreten,

werden sofort im Display dargestellt. Quittierbare Fehlermeldungen

werden nach Tastendruck gelöscht.

Meldung Ursache Behebung

E 090 Schleifenstrom zu klein. Zum spei-

chern der Bediendaten müssen

min. 3,6 mA am Eingang anliegen.

Messschleife überprüfen

E 101 Die Hardware zur Speicherung der

Bedienparameter ist defekt.

42

Bitte tauschen Sie das Gerät aus.

Page 43

Digitaler Feldanzeiger 10 Störungsbehebung

Meldung Ursache Behebung

E 102 Prüfsumme der Bedienparameter

ist ungültig oder die Softwareversion stimmt nicht mit den Bediendaten überein. Mögliche Ursache

ist ein Ausfall der Versorgung während der Parameterspeicherung.

E 103 Die Kalibierwerte des Analogein-

gangs sind fehlerhaft. Mögliche

Ursache ist ein Ausfall der Versorgung während der Kalibrierung, ein

nicht abgeglichenes oder ein defektes Gerät.

E 106 Warnung: Durch einen Program-

mierfehler wurde eine falsche Einstellung des Anzeigebereichs/Skalierung vorgenommen (unterer und

oberer Wert sind gleich).

E 111 Die Hardware zur Speicherung der

Bedienparameter ist defekt.

Durch Quittieren mit der Taste „E” wird

automatisch ein Preset durchgeführt, d.h.

alle Bedienparameter auf Werkseinstellung

gesetzt. Im Werk vorgenommene messstellenspezifische Einstellungen werden

nicht berücksichtigt!

Bitte tauschen Sie das Gerät aus.

Bitte korrigieren Sie die Einstellwerte.

Bitte tauschen Sie das Gerät aus.

10.3 Systemmeldungen

Wirkung Ursache Behebung

In der

Anzeige

steht:

#####”

„

In der

Anzeige

steht:

*****”

„

In der

Anzeige

steht:

(+”

„

Unterbereich. Am Analogeingang

liegt ein Eingangssignal < 3,6 mA

an.

Überbereich. Am Analogeingang

liegt ein Eingangssignal > 21,0 mA

an.

Bedienparameter wurden verändert. Das Gerät fordert die Freigabe

zur Speicherung an.

Überprüfen Sie bitte das Eingangssignal.

Überprüfen Sie bitte das Eingangssignal.

Mit den Tasten „+” / „-” die Freigabe

erteilen/nicht erteilen und mit der Taste

„E” quittieren.

43

Page 44

10 Störungsbehebung Digitaler Feldanzeiger

Wirkung Ursache Behebung

In der

Anzeige

blinkt:

(+”

„

Das Gerät speichert geänderte

Bedienparameter.

Nach Abschluss der Speicherung zeigt das

Gerät wieder den Messwert an.

10.4 Fehleranalyse

Wirkung Ursache Behebung

keine

Messwertanzeige

Die 7-Segmentanzeige zeigt

einen falschen /

ungenauen

Messwert

Kein Messkreis angeschlossen Bitte überprüfen Sie die Verdrahtung zum

Gerät.

Gerät defekt Bitte tauschen Sie das Gerät aus

Anzeige defekt Bitte tauschen Sie das Gerät aus

Messeingang falsch parametriert Parametrierung im Bedienmenü ändern

Sensorabgleich ist fehlerhaft Fehler über den Offset kompensieren

Offset falsch eingestellt Offset überprüfen

44

Page 45

Digitaler Feldanzeiger 11 Technische Daten

10.6 Reparatur

Der Feldanzeiger ist aufgrund seines Aufbaus nicht reparierbar.

10.7 Rücksendung

Bei Rücksendung des Gerätes zur Überprüfung legen Sie bitte eine

Notiz mit der Beschreibung des Fehlers und der Anwendung bei.

Zur

Rücksendung verpacken Sie das Gerät gut geschützt am Besten in der

Originalverpackung.

10.8 Entsorgung

Für eine spätere Entsorgung beachten Sie bitte die örtlichen Vorschriften.

11 Technische Daten

Arbeitsweise und Systemaufbau

Anwendungsbereich Das Gerät erfasst ein analoges Messsignal und stellt dieses in der Anzeige

dar. Das Gerät wird in den 4 bis 20 mA Stromkreis eingeschleift und

bezieht von dort die benötigte Energie.

Messprinzip Das am Analogeingang anliegende Signal wird digitalisiert, bewertet und

in der Anzeige dargestellt.

Messeinrichtung Mikrokontroller gesteuerter Feldanzeiger mit beleuchteter LC- Anzeige.

Eingangskenngrößen

Messgröße Strom

Messbereich 4 bis 20 mA (Verpolungsschutz)

Max. Eingangsstrom 200 mA (Kurzschlussstrom)

Spannungsabfall

(Bürde)

< 2,5 Volt

45

Page 46

11 Technische Daten Digitaler Feldanzeiger

Ausgangskenngrößen

Ausgangssignal Das analoge Eingangssignal (4 bis 20 mA) wird nicht umgeformt. Das Ein-

gangssignal wird digitalisiert, bewertet und in der LC-Anzeige dargestellt.

Ausfallsignal Kein Messwert in der LC-Anzeige sichtbar, keine Hintergrundbeleuch-

tung.

HART-Protokoll Der Anzeiger lässt die Signale des HART® -Protokolls ungehindert passie-

ren.

Hilfsenergie

Elektrische

Anschlüsse

Versorgung über 4 bis 20 mA Stromschleife

Spannungsabfall < 2,5 Volt

siehe Kapitel 5

Messgenauigkeit

Strom Messfehler < 0,1% vom Endwert

Temperaturdrift: 0,01% / K Umgebungstemperatur

Einsatzbedingungen

Einbaubedingungen

Einbaulage keine Einschränkungen

Umgebungsbedingungen

Umgebungstemperatur

Lagerungstemperatur -25 °C bis +70 °C

Klimaklasse nach IEC 60654-1 Klasse D1

46

-20 °C bis +60 °C (für Ex-Bereich siehe Ex-Zusatzdokumentation)

Page 47

Digitaler Feldanzeiger 11 Technische Daten

Schutzart IP66 / NEMA 4x

Stoßfestigkeit 7 Nm Gehäuse; 4 Nm Glas nach EN 50014

Schwingungsfestigkeit

Elektromagnetische Verträglichkeit

Störaussendung Nach EN 55011 Gruppe 1, Klasse B

Störfestigkeit

ESD Nach IEC 61000-4-2, 6 kV/8 kV

Elektromagnetische

Felder

Burst (Versorgung) Nach IEC 61000-4-4, 4 kV

Surge Nach IEC 61000-4-5, 1 kV

Leitungsgeführte

Hochfrequenz

nach GL-Richtlinie VI-Teil 7: 5 bis 500 Hz, 0,7 g, max. 1 Oktave/Minute

Nach IEC 61000-4-3, 10 V/m

Nach IEC 61000-4-6, 10 V

Konstruktiver Aufbau

Bauform, Maße H: 80 mm, B: 175 mm, T: 65 mm

Gewicht ca. 800 g

Werkstoffe • Gehäuse:

Aluminiumdruckguss epoxidbeschichtet mit Glaseinsatz

• Wand-/ Rohrmontagehalter:

1.4301

• Spannband:

1.4301

Anschlussklemmen steckbare Schraubklemme, Klemmbereich 1,5 mm² massiv, 1,0 mm² Litze

mit Aderendhülse

Erdungsanschluss Klemmbereich 2,5 mm

2

47

Page 48

11 Technische Daten Digitaler Feldanzeiger

Kabeleinführung 2 x Kabelverschraubung Metrisch M20x1,5

alternativ: 2 x Verschraubung NPT 1/2"

Druckausgleich Zur Belüftung und zum Druckausgleich des Elektronikraums ist ein war-

tungsfreier GORE-TEX

Elektronikraum Unterhalb der ausklappbaren Elektronikeinheit ist Raum für den Einbau

von z.B. einem Temperaturtransmitter verfügbar.

H: 60 mm, B: 140 mm, T: 30 mm

®

Membran eingebaut.

Anzeige- und Bedienoberfläche

Anzeige 5 stellige LC-Anzeige, Ziffernhöhe 26 mm, hinterleuchtet

Analogwertdarstellung in 10%-Schritten

Marken für Bereichsüber-/ unterschreitung

Anzeigebereich -19999 bis +99999

Offset -19999 bis +32767

Bedienung 3 Knopfbedienung (-/+/E)

Zertifikate und Zulassungen

CE-Zeichen Das Gerät erfüllt die gesetzlichen Anforderungen aus den EU-Richtlinien

89/336/EWG.

Ex-Zulassung Über die aktuell lieferbaren Ex-Ausführungen (ATEX, FM, CSA, usw.)

erhalten Sie bei Ihrer Vertriebsstelle Auskunft. Alle für den Explosionsschutz relevanten Daten finden Sie in separaten Ex-Dokumentationen, die

Sie bei Bedarf anfordern können.

GL-Zulassung GL Germanische Lloyd / Schiffsbauzulassung

48

Page 49

Digitaler Feldanzeiger Stichwortverzeichnis

Stichwortverzeichnis

A

Anzeige . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Anzeigewert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Arbeitsweise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Auswahltasten . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

B

Bargraph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Barriere . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Bedienoberfläche . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Benutzercode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Beschriftungsfelder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Bürde . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

C

CE-Zeichen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

D

Dezimalpunkt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

E

Einbaubedingungen . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Eingabetaste . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Eingangskenngrößen . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Einsatzbedingungen . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Elektromagnetische Verträglichkeit . . . . . . . . . . . . . . . . . 47

Elektronikeinheit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Erdungsanschluss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Explosionsgefährdeter Bereich . . . . . . . . . . . . . . . . . . . . . 30

H

Hilfsenergie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

K

Konformitätserklärung . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Konstruktiver Aufbau . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

49

Page 50

Stichwortverzeichnis Digitaler Feldanzeiger

M

Messbereich . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Messgenauigkeit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Messwert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

O

Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

P

Potentialausgleich . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

S

Schutzart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Störfestigkeit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Systemaufbau . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

T

Technischer Fortschritt . . . . . . . . . . . . . . . . . . . . . . . . . . 31

U

Umgebungsbedingungen . . . . . . . . . . . . . . . . . . . . . . . . . 46

Z

Zertifikate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32, 48

Zulassungen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

50

Page 51

Indicador de campo digital

Digital field display

Operational manual

(Please read before installing the unit)

Unit number:.....................................

Digitaler Feldanzeiger

Betriebsanleitung

(Bitte lesen, bevor Sie das Gerät in Betrieb nehmen)

Gerätenummer:.....................................

Indicador de campo digital

Manual de instrucciones

(Por favor, lea el manual antes de instalar la unidad)

Número de unidad:.....................................

English

Español

3 ... 26

75...??

Deutsch

Español

27 ... 50

19...34

Español

Español

51 ... 74

19...34

Indicateur de process

Manuel de mise en service

(veuillez entièrement lire le manuel avant la mise en service de l’appareil)

o

appareil:....................................

N

Visualizzatore digitale da campo

Manuale operativo

(Si prega di leggere prima di installare l’unità)

Codice unità:....................................

Français

English

75 ... 98

19...34

Italiano

English

99 ... 122

19...34

51

Page 52

Índice de contenidos Indicador de campo digital

Índice de contenidos

1 Notas sobre seguridad . . . . . . . . . . . . . . . 54

1.1 Uso adecuado . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

1.2 Instalación, puesta en marcha y manejo . . . . . . . . 54

1.3 Manejo seguro . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

1.4 Devoluciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

1.5 Pictogramas y símbolos de seguridad . . . . . . . . . . . 55

2 Identificación . . . . . . . . . . . . . . . . . . . 55

2.1 Identificación de la unidad . . . . . . . . . . . . . . . . . . 55

2.2 Material de la entrega . . . . . . . . . . . . . . . . . . . . . . 56

2.3 Certificados . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3 Funcionamiento y montaje

del sistema . . . . . . . . . . . . . . . . . . . . . 56

3.1 Principio de medición . . . . . . . . . . . . . . . . . . . . . . 56

3.2 Diseño del sistema . . . . . . . . . . . . . . . . . . . . . . . . 56

4 Instalación mecánica. . . . . . . . . . . . . . 57

4.1 Condiciones de instalación . . . . . . . . . . . . . . . . . . 57

4.1.1 Dimensiones . . . . . . . . . . . . . . . . . . . . . . . 57

4.2 Instalación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.2.1 Montaje directo en pared. . . . . . . . . . . . . . . 58

4.2.2 Elemento de fijación para montaje

en tubería vertical o pared . . . . . . . . . . . . 58

4.2.3 Instalación de una electrónica

de medición adicional . . . . . . . . . . . . . . . . 59

4.3 Verificación de la instalación . . . . . . . . . . . . . . . . . 59

5 Conexiones eléctricas. . . . . . . . . . . . . 59

5.1 Conexiones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

52

Page 53

Indicador de campo digital Índice de contenidos

5.1.1 Representación esquemática

de los terminales . . . . . . . . . . . . . . . . . . . 59

5.1.2 Conexiones eléctricas . . . . . . . . . . . . . . . . 60

5.1.3 Conexión de una fuente de corriente activa 61

5.1.4 Conexión de una fuente de corriente pasiva 61

5.2 Verificación de las conexiones . . . . . . . . . . . . . . . 62

6 Manejo . . . . . . . . . . . . . . . . . . . . . . . . 62

6.1 Introducción . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.2 Descripción del indicador . . . . . . . . . . . . . . . . . . . 62

6.3 Configuración mediante el menú. . . . . . . . . . . . . . 63

6.3.1 El menú . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.4 Parámetros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7 Puesta en marcha . . . . . . . . . . . . . . . . 65

7.1 Instalación y comprobación de funciones . . . . . . . 65

7.2 Puesta en marcha . . . . . . . . . . . . . . . . . . . . . . . . . 65

8 Mantenimiento. . . . . . . . . . . . . . . . . . 65

9 Accesorios . . . . . . . . . . . . . . . . . . . . . 65

10 Resolución de problemas . . . . . . . . . . 66

10.1 Instrucciones para la resolución de problemas . . . . 66

10.2 Mensajes de fallo de proceso . . . . . . . . . . . . . . . . 66

10.3 Mensajes de sistema . . . . . . . . . . . . . . . . . . . . . . . 67

10.4 Análisis de fallos . . . . . . . . . . . . . . . . . . . . . . . . . . 68

10.5 Reparaciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

10.6 Devoluciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

10.7 Desguace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

11 Datos técnicos . . . . . . . . . . . . . . . . . . 69

Índice . . . . . . . . . . . . . . . . . . . . . . . . . 73

53

Page 54

1 Notas sobre seguridad Indicador de campo digital

1 Notas sobre seguridad

1.1 Uso adecuado

El indicador de campo digital ha salido de fábrica en perfectas condi-

•

ciones de funcionamiento y seguridad.

• Sólo se puede garantizar un funcionamiento seguro si se siguen cor-

rectamente las instrucciones de este manual.

• El fabricante no asume la responsabilidad por daños ocasionados por

un uso incorrecto del instrumento.

• La unidad sólo se puede emplear dentro del rango de temperaturas

especificado.

• Se adjunta documentación Ex adicional para sistemas de medición en

zonas de riesgo. Es importante observar y seguir las normativas de

instalación y los valores de conexión.

1.2 Instalación, puesta en marcha y manejo

La unidad se ha fabricado con la tecnología adecuada y cumple con

todas las normativas relevantes, así como las directivas de la UE. Sin

embargo, puede resultar peligrosa, si no se manipula correctamente.

Sólo personal debidamente preparado y con la autorización del jefe de

planta puede llevar a cabo la instalación mecánica y eléctrica, la puesta

en marcha y el mantenimiento de la unidad. El personal encargado debe

leer este manual y seguir las instrucciones que se especifican en él. Al

instalar el sistema hay que cercionarse de que las conexiones eléctricas

son las indicadas en los diagramas de conexiones. Sólo se pueden efectuar los cambios o las reparaciones en la unidad que el manual indique

como posibles. Obsérvense siempre las normativas nacionales en material de seguridad eléctrica al abrir o reparar los dispositivos eléctricos de

una unidad.

1.3 Manejo seguro

Zona de riesgo

Si el sistema de medición se va a instalar en una zona con riesgo de

explosiones, es necesario seguir las normativas nacionales. Asegúrese de

que el personal encargado está adecuadamente preparado. La instalación debe cumplir con todas las normativas de medición y valores de

seguridad.

54

Page 55

Indicador de campo digital 2 Identificación

Avances técnicos

El fabricante se reserva el derecho de mejorar o actualizar los detalles

técnicos sin necesidad de notificarlo. La oficina de ventas le informará

de la validez o las ampliaciones de este manual.

1.4 Devoluciones

Si se produce cualquier daño durante el transporte, por favor, infórmese

inmediatamente al transportista y a la oficina de ventas local.

1.5 Pictogramas y símbolos de seguridad

La etiqueta "¡Nota!” señala tareas o secuencias de tareas que, si no se

!

"

llevan a cabo correctamente, podrían tener una influencia indirecta en

el funcionamiento de la unidad o incluso provocar una reacción imprevista de la unidad.

La etiqueta "¡Atención!” indica tareas o secuencias de tareas que, si no

se llevan a cabo correctamente, podrían provocar daños personales o un

funcionamiento defectuoso de la unidad.

#

0

.

La etiqueta "¡Precaución!” señala tareas o secuencias de tareas que, si

no se llevan a cabo correctamente, podrían provocar daños personales,

riesgos para la seguridad o un daño irreparable de la unidad.

Certificación de unidad protegida contra explosiones

Si la placa de características incluye este símbolo, el aparato se puede

emplear en zonas con riesgo de explosiones.

Zona segura (sin riesgo de explosiones)

Este símbolo identifica las zonas sin riesgo en los esquemas contenidos

en este manual. Las unidades instaladas en una zona sin riesgo también

deben estar certificadas, si los cables de la unidad alcanzan una zona de

riesgo.

2 Identificación

2.1 Identificación de la unidad

¿Es la unidad correcta?

Por favor, compárese el código de pedido de la placa de características

con el del documento de entrega del pedido.

55

Page 56

3 Funcionamiento y montaje del sistema Indicador de campo digital

2.2 Material de la entrega

- Indicador de campo, modelo según pedido.

- Manual de instrucciones

- Accesorios según pedido.

2.3 Certificados

Mark CE, certificado de conformidad

La unidad se ha fabricado con la tecnología adecuada y ha salido de

fábrica en perfectas condiciones de funcionamiento. La unidad cumple

con todas las normativas relevantes, así como las directivas IEC 61010

"Normas de seguridad relativa a instrumentos de medición, control e

instrumentos de laboratorio".

Por lo tanto, la unidad que se describe en este manual de instrucciones

cumple con todos los requisitos legales establecidos por las directivas de

la UE. El fabricante reconoce con la marca CE que la unidad ha sido

debidamente comprobada.

3 Funcionamiento y montaje del

sistema

3.1 Principio de medición

El indicador de campo se conecta directamente a un circuito de corriente de 4 a 20 mA. La energía requerida para alimentar la unidad se

deriva del circuito de corriente. La unidad registra un valor de medición

analógico y lo presenta en una pantalla de cristal líquido de fácil lectura.

El valor medido se muestra además en forma de gráfico de barras.

La lectura del indicador en lugares oscuros se puede facilitar añadiendo

una pantalla indicadora con luz.

3.2 Diseño del sistema

Un microprocesador controla el indicador numérico analógico de campo

provisto de pantalla de cristal líquido con luz de fondo. El indicador se

actualiza cada segundo.

Un resistencia interna dinámica de carga asegura que la caída de tensión

del circuito jamás sobrepase los 2,5 V.

56

Page 57

Indicador de campo digital 4 Instalación mecánica

4 Instalación mecánica

4.1 Condiciones de instalación

4.1.1 Dimensiones

ƒig. 1: Dimensiones

4.2 Instalación

La unidad permite su instalación en la pared. El usuario también dispone

de una opción de pedido de un adaptador combinado para instalación

en pared o en tubería vertical (véase el apartado "Accesorios").

57

Page 58

4 Instalación mecánica Indicador de campo digital

4.2.1 Montaje directo en pared

ƒig. 2: Montaje directo en pared

Síganse las instrucciones siguientes para instalar la unidad directamente

en la pared:

• Con un taladro, practicar dos agujeros en el lugar de instalación en

pared correspondiente y prepararlos (con tacos de material plástico

para taladros en paredes, etc.).

• Desenroscar y retirar la tapa de la unidad.

• Montar la unidad en la pared con los tornillos y pernos correspon-

dientes.

4.2.2 Elemento de fijación para montaje en tubería vertical o

pared

(-> cap. 9 "Accesorios")

ƒig. 3: Elemento de fijación para montaje en tubería vertical o

pared

Si se emplea el adaptador de fijación combinado para instalación en pared o

en tubería vertical, síganse los pasos siguientes:

• Con un taladro, practicar dos agujeros en el lugar de instalación en

pared correspondiente y prepararlos (con tacos de material plástico

para taladros en paredes, etc.).

• Instalar el adaptador de fijación (B) en la pared o tubería con los mate-

riales suministrados (A).

58

Page 59

Indicador de campo digital 5 Conexiones eléctricas

• Desenroscar y retirar la tapa de la unidad.

• Enroscar la unidad al adaptador de fijación.

"

4.2.3

La electrónica se puede levantar y detrás queda suficiente espacio para

instalar, si se desea, otra electrónicas de medición, por ejemplo, un

transmisor de temperatura.

Atención: Obsérvense siempre las instrucciones de instalación del fabricante y de conexión de cada fabricante individual.

Instalación de una electrónica de medición adicional

4.3 Verificación de la instalación

Grado de protección

La unidad cumple con todos los requisitos que establece el estándar

IP66 NEMA 4x. Para que esta clase de proteción se mantenga una vez

efectuada la instalación o algún servicio de mantenimiento, es necesario

verificar que se satisfagan los siguientes aspectos:

• Las juntas de la caja deben estar limpias y en buen estado y deben

encajar en el hueco pertinente de la unidad. En caso contrario, límpiese y séquese la junta, o sustitúyase, si es necesario.

• Los tornillos que sujetan la tapa de la caja y los prensaestopas para

cable deben estar bien fijados.

"

5 Conexiones eléctricas

Atención: Si la unidad se conecta a una zona con riesgo de explosiones,

ténganse en cuenta las observaciones y los diagramas de conexiones

contenidos en la documentación Ex específica de este manual.

5.1 Conexiones

5.1.1 Representación esquemática de los terminales

Los terminales del circuito de 4 a 20 mA se hallan bajo la tapa de la caja

en la parte superior derecha de la unidad. El bloque de terminales es un

59

Page 60

5 Conexiones eléctricas Indicador de campo digital

módulo independiente y se puede extraer al hacer las conexiones de la

unidad.

Terminal Entrada

y salida

1 Señal de medición (+) 4 a 20 mA Entrada de señal

#

#

2 Instrumentos añadidos (enlaza con el termi-

nal 4)

3 Señal de medición (-) 4 a 20 mA Entrada de señal

4 Instrumentos añadidos (enlaza con el termi-

nal 2)

5.1.2 Conexiones eléctricas

Tanto los terminales como los valores de conexión del indicador de

campo se adecúan a los requerimientos Ex.

La unidad sólo está preparada para funcionar en un circuito de 4 a 20

mA de corriente. Para garantizar el equilibrio de potencial en el circuito

de corriente (dentro y fuera de la zona de riesgo), en la parte inferior

izquierda del cabezal hay una lengüeta para la puesta a tierra.

La electrónica se puede empujar hacia adelante para facilitar su instalación y cableado.

Nota de seguridad: La unidad debe ser accionada solamente por una

fuente de alimentación con un circuito eléctrico de energía limitada

según IEC 61010-1; "SELV o Class 2 circuit".

Terminal

Terminal

ƒig. 4: Conexiones eléctricas

60

Page 61

Indicador de campo digital 5 Conexiones eléctricas

Síganse las instrucciones de conexión siguientes:

• Desenroscar y retirar la tapa de la unidad.

• Agarrar la parte superior de la electrónica y empujarla hacia adelante

y hacia abajo (véase el esquema).

5.1.3 Conexión de una fuente de corriente activa

Ejemplo: un sensor con su fuente de alimentación propia y salida de corriente activa.

Nota: Si se emplea un apantallamiento adecuado, la unidad se puede

!

instalar directamente en la zona de riesgo.

Bornes 2 y 4

puenteados

internamente

3

1

2

4

+

Y

+

I

-

-