Page 1

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-1-

SPX Product Family

Smart Industrial Pressure Transmitters

Intrinsically safe and Explosion-proof

pressure transmitters with integrated amplifier

for use in hazardous environments

Operating Manual

www.dynisco.com

Page 2

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-2-

ATTENTION

ATTENTION

DYNISCO SPX QUICK START CARD

This Quick Start Setup guide can be used by experienced instrumentation technicians to configure the

Transmitter using the Zero and Span actuators or via the optional HART Communications. For more

detailed information please consult the complete manual before operating. The Quick Start procedure

with HART is designed for users already familiar with the use of the HART Communicator and loop

powered instrumentation.

QUICK START USING PUSH BUTTONS

1. Insure the process connection is clear of any debris and is machined to the proper dimensions.

nstall unit into the process connection. (Do NOT torque transmitter into the hole at this time!)

I

Allow time for the transmitter temperature to equalize to the process temperature. This w

h

elp eliminate thread galling and ease removal later. There should be NO pressure applied at

this time.

ill

2. Connect power to the transmitter. For conduit output configurations, Red wire is Sig+/Exc +,

Black wire is Sig-/Exc-, Green wire is Ground. For a 6 pin connector version, Pin A is Sig+/Exc+

and pin B is Sig-/Exc-. Insure proper loop supply voltage is applied to transmitter.

3. After temperatures have equalized, tighten transmitter.

4. Perform Zero Function

• D

o not remove seal screws when the circuit is live in a hazardous area

• Remove zero pushbutton seal screw

• Using a 2mm or smaller Allen key, depress the pushbutton for a ½ second

• Release pushbutton for a ½ second

• Depress the pushbutton again for a ½ second and release

5. Verify loop output is zero (4 mA).

6. Replace the Seal Screw.

• Seal screws must remain in place to retain Explosion Proof

certification

www.dynisco.com

Page 3

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-3-

QUICK START UTILIZING HART COMMUNICATOR

ollow Steps 1 through 3 from Quick Start Using Push Buttons.

1. F

2. Connect Communicator to the loop. If unsure on how to do this, refer to “Connecting the HART

Handheld Communicator” (Figure 6-1).

3. Power on HART Communicator. See HART Command tree on the following page for reference.

4. From the Main Menu:

a. Enter Tag (Quick Key 1, 3, 1)

b. Set Pressure Units (Quick Key 1, 3, 2), if required

c. Set URV (Quick Key 1, 3, 3, 2) if output turndown (rescaling), is required

d. Perform Zero Trim (Quick Key 1, 2, 5, 1, 3, 1)

5. Verify loop output is zero (4mA).

6. Remove HART Communicator from loop.

www.dynisco.com

Page 4

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-4-

1 Device Setup 1 Proc ess 1 PV Pres 1

Alrms & Wrnings EEPROM Fai lure

Variabl es 2 Pv % rnge Gage Fail ure

3 PV AO 2 Max. Press ure Watchdog Error

4 TV Snout temp Pushbutton Stuck

5 TV % rnge 3 Max. Ele ctronics Low Voltage

6 TV A O Tempe rature Outside URV LRV

7 SV Elect temp 4 Max. Snout Temp Current S IM ON

2 Diag/Se rvice 1 Device S tatus 1 Pressure 1 Rer ange 1 Enter values 1 PV LRV

2 Apply values 2 PV URV

2 Self Test 2 Temperatu re 2 Trim analog 3 PV USL

output 1 Zero trim 4 PV LSL

3 Master reset 3 Recall Fact. Trim 3 Se nsor trim 2 Lower Sensor Tri m

2 PV Pres 3 Upper Sen sor Trim

4 Loop test psi 4 Rcal

bar 1 Rcal Set

5 Calibration kg/S qcm

% 1 Temperatu re 1 Temp Ove rride Disable

6 Restore MPa Overri de Enable

Factory De faults KPa 2 Trim analog 2 Tem p Overrid e

Output Value

3 Basi c Set up 1 T ag 1 PV LRV

2 PV URV 1 PV Pres

2 PV Unit 3 TV LR V 2 PV % rgne

4 TV UR V 3 P V AP 1 PV LRV

3 Range valu es 5 PV LSL 4 TV Snout temp 2 PV URV

6 PV USL 5 TV % r nge 3 PV USL

3 TV Snout 4 Dev ice 7 TV LSL 6 TV AO 4 P V LSL

Temp Information 8 TV USL 7 SV Elect temp

5 PV Damp

1 Date 1 Enter values

4 Detailed 1 Signal condition 2 Des criptor 2 Apply values

Setup 3 Message

2 Output condition psi

1 Process v ariable s bar

3 Field Device Inf. kg/Sqcm

2 Rer ange %

MPa

5 Review 1 Mode l 3 PV Unit KPa

2 Manufacturer

3 Dev id 4 PV Rnge unit psi

4 Distrib utor bar

4 PV LRV 1 PV LRV 5 Poll addr 5 PV Min span kg/Sqcm

2 PV URV 6 Num req preams %

7 PV Unit 6 PV Damp MPa

5 PV URV 1 P V LRV 8 PV USL KPa

2 PV URV 9 PV L SL 7 SV C

PV Min span 1 PV Pres

PV Damp 1 Proce ss variabl es 2 PV % rgn e

PV % rn ge 3 PV A P

PV Xfer fnctn 2 Analog output 4 TV Sno ut temp

PV Rnge unit 5 TV % rn ge

PV URV 3 HART output 6 TV A O 1 Enter values 1 PV LRV

PV LRV 7 SV Elect temp 2 PV URV

Lower Tri m Point V … Hi 2 Apply value s 3 PV USL

Upper Trim Point V… 1 PV AO Lo 4 PV LSL

TV C 2 TV A O Hold last out value

TV US L 3 PV AO Alrm typ

TV LSL 4 Loop test 1 Pressure 1 Rerang e 1 Zero tri m

TV % rn ge 5 Calibration 2 Lower Sensor

TV Rnge unit 2 Te mperature 2 Trim AO Trim

TV UR V 1 Poll addr 3 Upper Sensor

TV LRV 2 Num req preams 3 Recall Fact. Trim 3 Sensor t rim Trim

Write protect 3 Burst mode

Tag 4 Burst option Off 4 Rcal 1 Rcal Set

Descrip tor 1 Tag On

Message 2 Date Disable No t used 1 Tem p 1 Te mp Disable

Date 3 Descript or Enable None Overri de Override Enable

Unive rsal rev 4 Message Std Unknown 2 Trim AO

Fld dev rev 5 Mo de l Zero trim Spcl 2 Tem p

Softw are rev 6 Local Pushbuttons Overri de Val

Hardware re v 7 Revision #'s 1 Univers al rev PV

8 Final asmbly num 2 Fld dev rev % ran ge/current

9 Dev id 3 Softw are rev Proce ss vars/crnt

enu Tree

M

OTE: Above is the Menu Tree for the latest Device Descriptor. For units with software revision < 100

N

refer to Appendix 2 for appropriate Menu Tree.

www.dynisco.com

Page 5

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-5-

Table of Contents

1 GENERAL …………………………………………………………………………….6

2 NOTES ON SAFETY ...................................................................... 11

3 TECHNICAL DATA ........................................................................ 16

4

5

6

7

8

9

10

11

12

13

TRANSPORT/DELIVERY ............................................................. 20

INSTALLATION .......................................................................... 21

COMMISSIONING ..................................................................... 23

MAINTENANCE ......................................................................... 35

TROUBLESHOOTING ................................................................. 36

APPROVALS/CERTIFICATES ....................................................... 37

APPENDIX 1 - DEFAULT VALUES ............................................... 41

APPENDIX 2 – Menu Tree (Software Revision < 100) ............... 52

DRAWINGS…………… .................................................................. 53

DYNISCO CONTACT INFORMATION .......................................... 56

www.dynisco.com

Page 6

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-6-

1 GENERAL

1.1 IMPORTANT INFORMATION

This manual applies to the SPX industrial pressure product family only (SPX228/SPX538). The SPX melt

pressure family is covered in a separate manual. This manual must be kept near the equipment in a

readily and immediately accessible location at all times. The content of this manual must be read,

understood and followed in its entirety. This applies in particular to the notes on safety. Following the

safety instructions will help to prevent accidents, defects and malfunctions.

DYNISCO will not be held liable for any injury, loss or damage resulting from failure to follow the

instructions in this manual.

If the product malfunctions, in spite of having followed the operating instructions, please contact

customer service from our website:

www.dynisco.com/contact

1.2 COPYRIGHT

Copyright law requires that this manual be used for intended purposes only.

It is strictly forbidden to allow reproduction of any kind “in whole or in part” to persons outside of

Dynisco, without approval from Dynisco.

HART is a registered trademark of HART Communication Foundation.

www.dynisco.com

Page 7

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-7-

ATTENTION

1.3 EXPLANATION OF ICONS

The manual uses icons to indicate information pertaining to safety:

Risk of destruction or damage to equipment, machines or installations

General danger to life or limb

Specific danger to life or limb

Related to ATEX/Intrinsic Safety requirements

Related to Factory Mutual Approval requirements

Related to Safety Integrity and Performance Level Applications

The safety instructions are provided again in the individual sections of the manual.

www.dynisco.com

Page 8

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-8-

1.4 ABBREVIATIONS

The following abbreviations are used:

BSL Best Straight Line

DD Device Descriptor

EEPROM Electrically Erasable Programmable Read Only Memory

FS Full Scale

HART Highway Addressable Remote Transducer

LRV Lower Range Value

PT Pressure Transmitter

PV Primary Variable (Pressure)

SV Secondary Variable (Electronics Temperature)

URV Upper Range Value

Watchdog An internal monitor for the electronics

1.5 NAMING CONVENTION

SPX S

PX Industrial Smart Pressure Transmitters (228 & 538 Series)

www.dynisco.com

Page 9

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

-9-

providing a window into the process

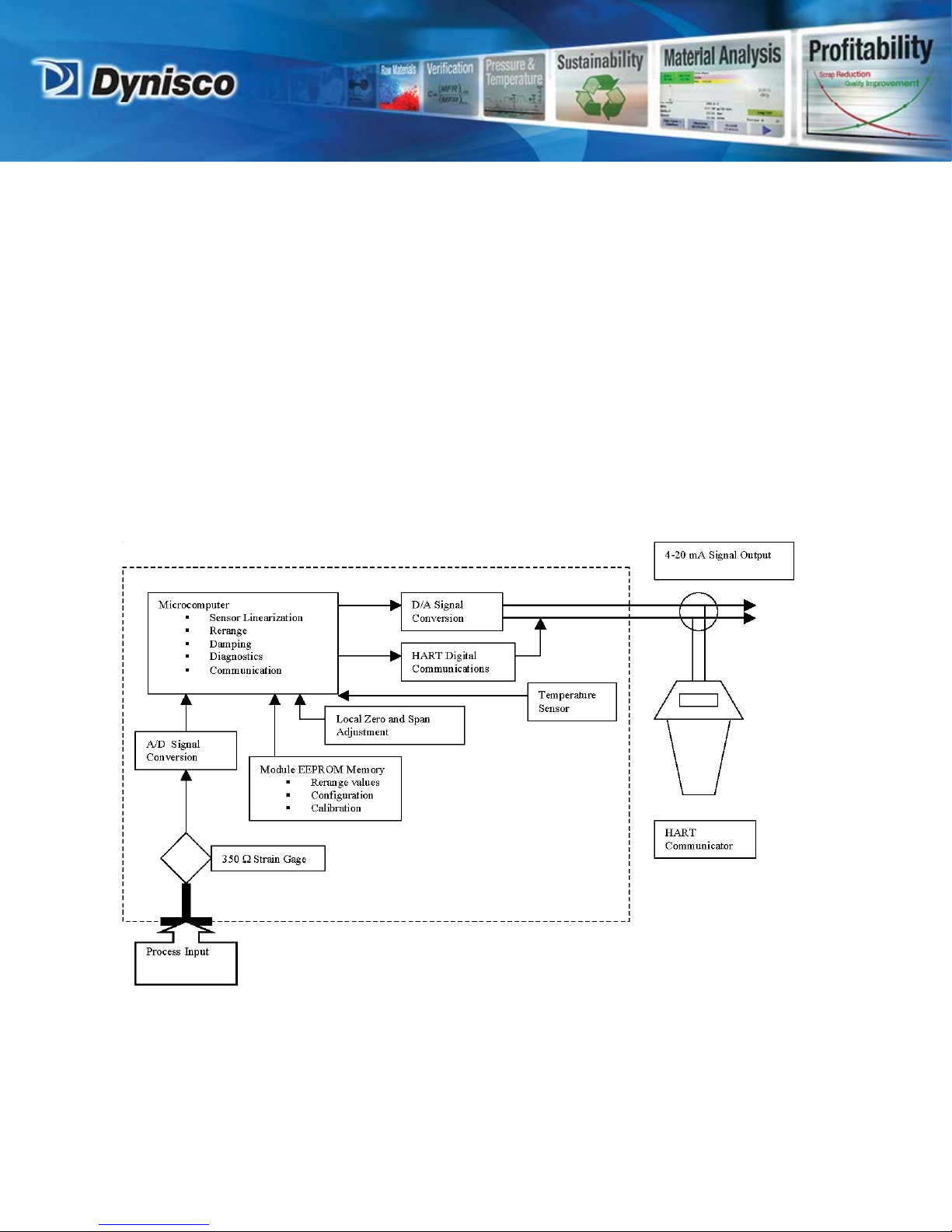

1.6 TRANSMITTER PRINCIPLES OF OPERATION

The mechanical system consists of a gaged diaphragm. One side of the diaphragm is in direct contact

with the fluid media (gas or liquid) while a strain gage element in the configuration of a Wheatstone

bridge is bonded to the backside.

The deflection of the diaphragm causes a change in the resistance of the strain gage and hence a change

in the balance of the bridge. The amount of imbalance is directly proportional to the applied pressure.

This completes the translation of pressure applied to the diaphragm into a usable electrical signal.

The low level output signal from the bridge is amplified via an instrumentation amp circuit. The

amplified signal then goes to the input of the analog-to-digital (A/D) converter.

Once the microprocessor has the converted voltage input from the A/D converter, the digital signal is

sent to a digital-to-analog (D/A) converter which modulates the current of the unit’s power supply

between 4 and 20 mA for an output current proportional to the applied pressure.

Figure 1-1 Block Diagram of Operation

www.dynisco.com

Page 10

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-10-

1.7 CORRECT USE

When using an SPX as a safety component in accordance with the EC Machine Directive, Annex IIc, the

equipment manufacturer must take any necessary precautions to ensure that malfunction of the PT

cannot cause damage or injury.

For explosive gas the installation of the device must be in accordance with European installation

guidelines EN 60079-14 for explosive gas atmospheres. Over voltage protection shall be implemented as

mentioned in EN 60079-14.

When planning machinery and using one of the units from the SPX Family, follow the safety and accident

prevention regulations that apply to your application, such as:

• EN 60204, Electrical equipment in machines

• EN 12100, Machine safety, general design guidelines

• DIN 57 100 Part 410, Protection against electric shock

• EN 60079-0

• EN 60079-11 Intrinsically Safe Apparatus

• EN 60079-25 Special Requirements for Group II Category 1G

1.8 USER’S OBLIGATIONS

The operator or owner of the larger overall system, e.g. a machine, is responsible for following the

safety and accident prevention regulations that apply to the specific application.

www.dynisco.com

Page 11

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-11-

2 NOTES ON SAFETY

he operator or owner of the larger overall system is responsible for following the safety and accident

T

prevention regulations that apply to the specific application.

DYNISCO will not be held liable for any injury, loss or damage resulting from failure to follow the

instructions in this manual.

Warnings

The SPX is an ESD sensitive component. Electrostatic discharge may damage the SPX. Take ESD

precautions.

Electrical shock can result in death or serious injury. Avoid contact with the leads and terminals. High

voltage that may be present on leads can cause electrical shock.

Mounting and electrical connection of the PT must be done by specialists with EMC training, following

all applicable regulations, and in pressure-less, voltage-free, intrinsically safe condition with the

machine switched off. The machine must be secured against being switched back on!

EMC/CE Compliant Connection

Earth the machine section with the process connections for the SPX in accordance with regulations. The

SPX must be connected to earth via the process connection.

Connect the shield of the connecting cable on both sides, making sure it conducts with full and

continuous contact.

When introducing the connecting cable into an EMC compliant switch cabinet, for example, connect the

shield correctly (cable gland, conducting, full contact, and continuous) to the conductive housing or

route it via a built-in cable connector that is also connected to the conductive housing. Connect unused

cable cores or free cable ends correctly to the cable shield on both sides.

www.dynisco.com

Page 12

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-12-

Temperature

The SPX can be used in me

dia temperatures up to +85°C (based on configuration). If the pressure

transmitter is used in other applications, the safety and accident prevention regulations specific to that

application must be followed. Ambient temperature for the electronics housing is +85°C maximum in

areas that are not classified as hazardous.

Higher temperatures can result in damage and malfunction. Do not install the pressure transmitter in

places where these temperatures are exceeded.

Use in Hazardous Classified Areas

Se

veral configurations of the SPX are designed and approved for use in hazardous classified areas. Units

intended for installation in these areas must bear the applicable approval agency label.

The SPX is specially designed for measuring pressure in explosive gas atmospheres for Zone 0 under

safety class II 1 G Ex ia IIC T6/T4 (T6, Ta = -20 to + 50°C; T4, Ta = -20 to + 85°C). The SPX is also approved

for hazardous gas area Zone 1 under safety class II 2 G Ex ia IIC T6/T4 (T6, Ta = -20 to + 60°C; T4, Ta = -20

to + 85°C).

The maximum T

(medium temperature) for temperature class T6 is +60°C and for T4 is +85°C. The

med

medium temperature for the SPX is defined as the temperature of the pressure transmission fluid below

the measuring diaphragm (See Figure 1-1). This temperature can be verified by measuring the surface

temperature at the base of the electronics housing.

For category 1 (Zone 0) installations, care must be taken to avoid the danger of ignition due to

electrostatic discharges (ESD). The chance for static build up on the cable surface during normal

conditions of use, maintenance and cleaning must be eliminated. Install the cable in an appropriate

conduit or use some other cable reliable installation technique to avoid static electricity at the cable

surface.

The free length of the cable must be below 5 cm. If metallic conduits are used they need to be

g

rounded. If nonmetallic conduits are used they need to be antistatic (< 1G Ohm/cm

2

).

The housing shall be connected reliably to the local equipotential bonding system.

Those variants that include the material aluminum shall be installed in such a way that sparking as a

sult of impact or friction between aluminum and steel is excluded. Impact or friction between

re

aluminum and stainless steel is allowed if the existence of rust particles can be excluded.

For application as Category-1-E

conductive coating (R

surface < 10

quipment the connecting cable shall be equipped with a suitable

9

Ω) to avoid possible electrostatic charge.

After installation before operating the device the user must check that the complete

installation and wiring is intrinsically safe. Care must be taken that the power source is a

certified apparatus.

www.dynisco.com

Page 13

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-13-

Deviation of the supply voltage from the value given in the technical specifications, or reverse polarity,

can damage the pressure transmitter and cause malfunctions that can pose a risk of explosion. Operate

only with an intrinsically safe, EMC compliant power supply with the following specifications when

employing the pressure 4-20 mA output:

Supply Voltage max. Uo = 30 V

DC Current Output max. Io = 100 mA

Power max. Po = 0.750 W

The specified values of Lo and Co for the power supply need to be greater than Ci + Ccable and Li +

Lcable.

Internal Inductance Li < 40 µH

Internal Capacitance Ci < 4.5 nF

If the transmitter is installed in hazardous areas, only passive devices like switches or resistors may be

connected between the RCAL+ and RCAL- signals. Connection of any active electronic circuits or voltage

or current sources is not allowed.

Certain configurations of the SPX are also designed for use in hazardous areas as Explosion-proof and

Dust Ignition-proof by Factory Mutual for Class I, Division 1, Groups A, B, C & D, and Class II, III, Division

1, Groups E, F & G.

For SPX units that are explosion-proof approved for Class I, Division 1, Groups A, B, C & D the power

supply rating is 13-30 Vdc.

Additional Comments:

1) Do not remove the transmitter push-button seal screws in explosive environments when the circuit

is live.

2) Transmitter push-button seal screws must be fully engaged to meet Explosion-proof requirements.

3) Before connecting a HART handheld communicator in an explosive atmosphere, make sure the

instruments in the loop are installed in accordance with intrinsically safe or non-incendive field wiring

practices.

www.dynisco.com

Page 14

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-14-

2.1 SAFETY integrity and performance level applications

User’s obligations

The operator or owner of the larger overall system, e.g. a machine, is responsible for following the

safety and accident prevention regulations that apply to the specific application.

Intended Use

See Certificate in section 9.4

Safety Function

See Certificate in section 9.4

For units with the optional monitoring channel (Guardian Series, Option Code = GCxxx):

Under normal operating conditions the relay contacts are closed. In the event that a failure is detected

the relay contacts open. Detectable failures include:

1) Loss of Power

2) Open Gage

3) Input over a predefined (customer selectable at time of order) threshold

The Guardian Series transducer has been designed to provide a protective measure. This has been done

by the avoidance and control of systematic and random failures.

This product will:

Measure the pressure and provide a safety relay output. Since this is being used to perform a protective

measure, this sensor should only be used for monitoring the pressure and not controlling the process.

Best practices declare that safety and control must be independent from each other.

The Guardian Series transducer detects many hardware failures including an open or short in the

measuring gage and if there is an overpressure condition. If any of these failures occur, the output relay

will open. It is the user’s responsibility to connect this relay to the system in such a way that when this

relay opens, it brings the system to a safe state.

www.dynisco.com

Page 15

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-15-

This fault state is not latched. It is up to the user to latch this error if desired.

Recommended practices

This Guardian Series transducer must be installed in such a way that the opening of the

output relay will bring the system to a safe state. In this safe state the instrument that is

monitoring the pressure should be left operational.

This error indication is not latched. If it is necessary to latch the error until it is manually

reset, this is the user’s responsibility.

At startup and on a periodic basis the safety system should be tested to ensure proper

operation. This will require applying a pressure to the Guardian Series transducer that is

over the safe level but less than the maximum pressure. Verify that the protective measure

is initiated to take the machine to a safe operating condition.

Use of qualified personnel

The product may only be assembled, installed, configured, commissioned, operated and

maintained by persons with proven skills. Persons with proven skills are suitably

experienced to operate devices, systems, plant and machinery in accordance with the

general standards and guidelines for safety technology.

It is the user’s responsibility only to employ personnel who:

• Are familiar with the basic regulations concerning health and safety and accident prevention

• Have read and understood the safety guidelines given in this description

• Have a good knowledge of the generic and specialist s ta nd a rds applicable to the specific application

Connecting Safety Relay

Relay specs: Maximum switching voltage: 200Vdc; Maximum switching current: 0.5A

Device pinout

www.dynisco.com

Page 16

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-16-

XXX

Accuracy

Pressure Reference

Hazardous Area Classification

Process Connections

Electrical Connections

Wiring Connections

Pressure

Option Code

Communications

Pressure Range

Model

X

X X

X

XX X

X XX

X

XXXX

228

+/- 0.25%

Gage Pressure (PSI)

Non-Approved

1/8-27 NPTF Internal

PT02A-10-6P Connector

Standard Wiring

PSI

Option Code

4-20mA HART Comms

5000

228

1

N G

A

AA 0

P

21

B

XXXX

3 TECHNICAL DATA

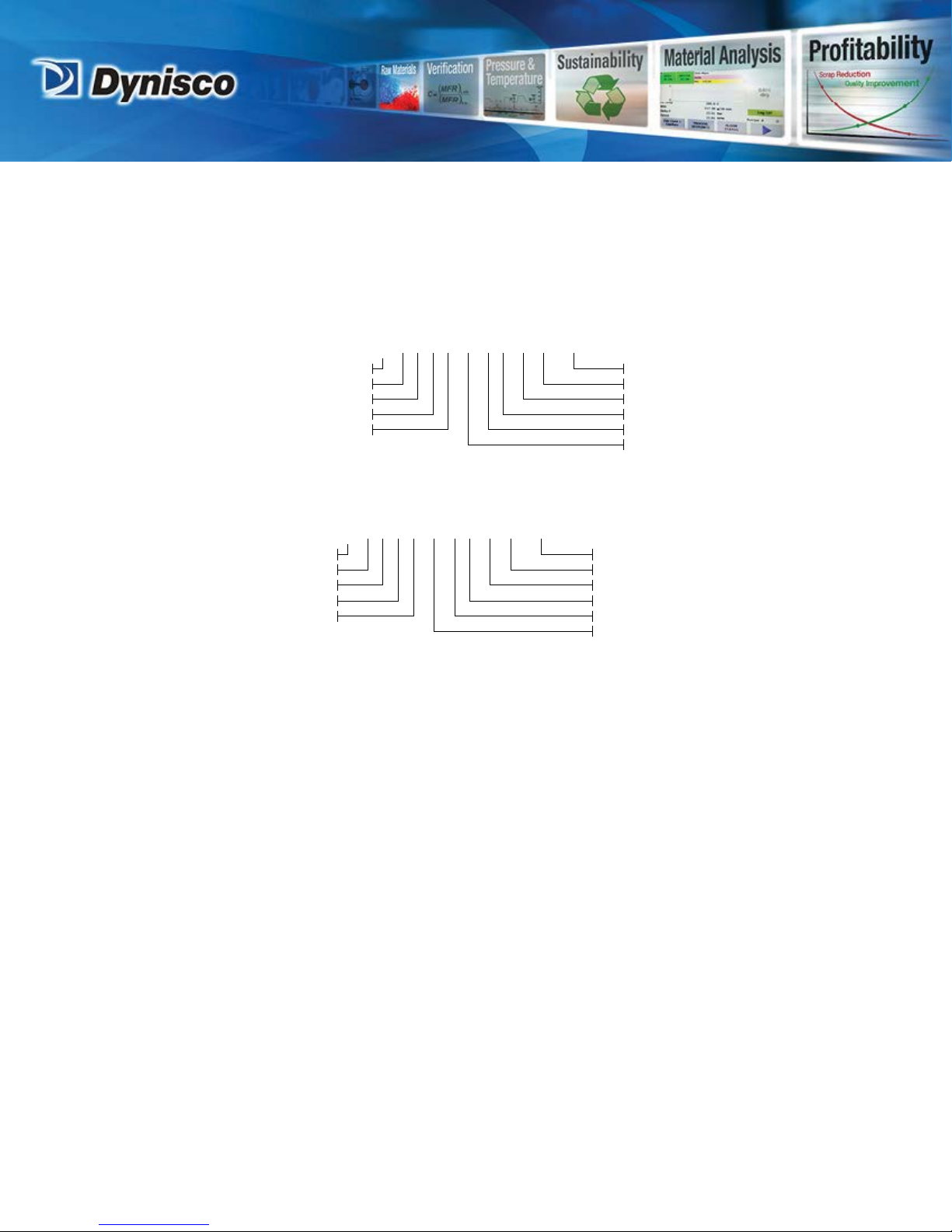

3.1 MODEL CODE BREAKDOWN

e exact meanings of the letter/digit combinations are given in the corresponding sections of this

Th

Chapter.

.2 ORDERING EXAMPLE

3

ote(s):

N

1) Review section 3.4 Performance Characteristics for accuracy definition and details.

2) Review “Notes on Safety” (Chapter 2) before installation in Hazardous locations.

3) Certain models are not available in some configurations.

4) For other process connections please consult factory.

5) Other approved ranges may exist, please consult factory.

6) Transmitters are available with certain approved option codes. Please consult factory for list of

approved options.

3.3 SAFETY SPECIFICATIONS

Please see “Notes on Safety” (Chapter 2.)

www.dynisco.com

Page 17

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-17-

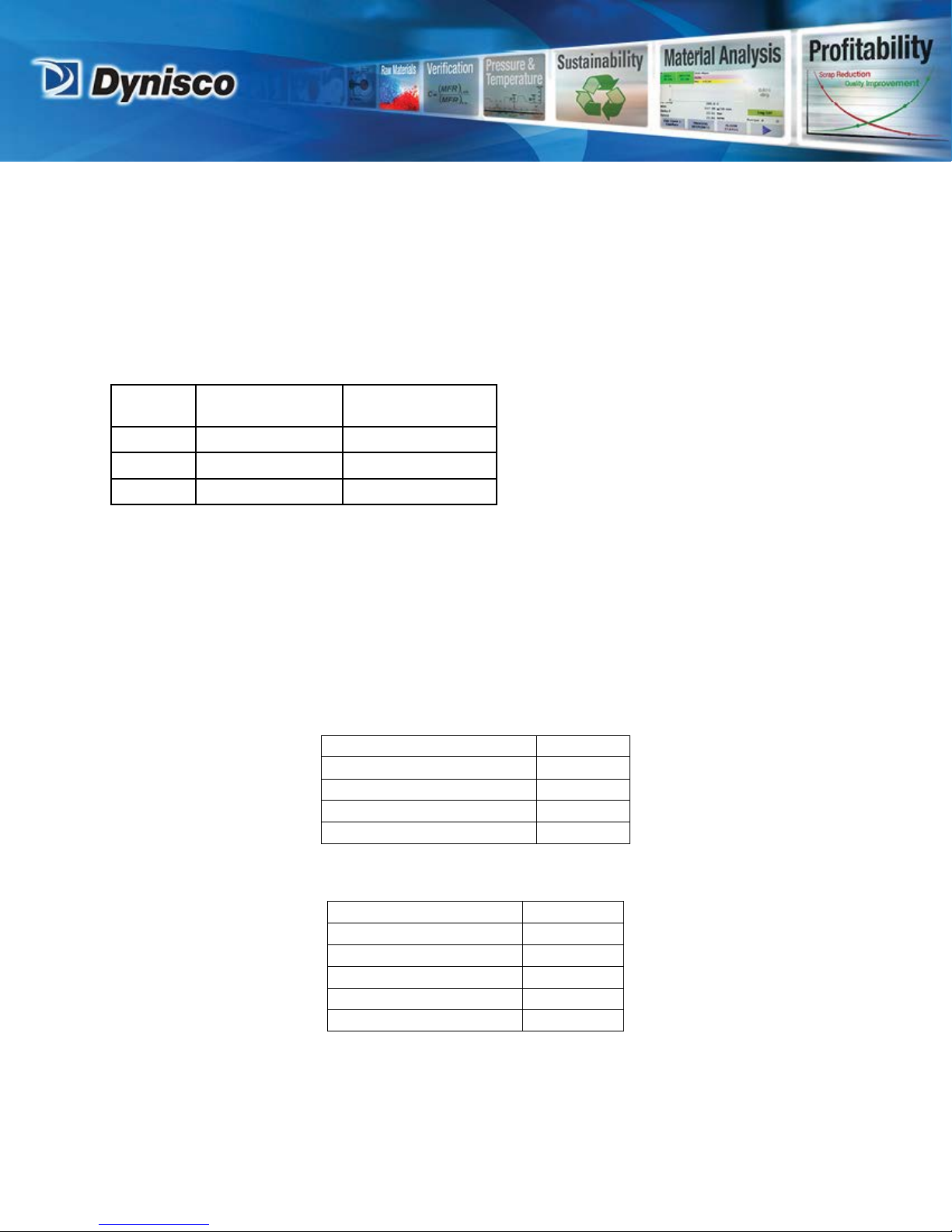

Model

Range

Accuracy (% of

FS)

2280

15 – 72,500 PSI

+/- 0.50

2281

15 – 72,500 PSI

+/- 0.25

2282

5 – 10,000 PSI

+/- 0.15

Model

Pressure

5-25 psi, w/ overload stop

10 x range

50-750 psi, w/ overload stop

5 x range

250 – 30,000 psi

1.5 x range

Greater than 30,000 psi

1.2 x range

Model

Pressure

250 psi

10 x range

500-3,000 psi

5 x range

5,000 – 10,000 psi

3 x range

15,000 – 30,000 psi

2.5 x range

40,000 – 60,000 psi

1.5 x range

3.4 PERFORMANCE CHARACTERISTICS

3.4.1 ACCURACY

Accuracy is defined as combined error expressed as a percentage of full scale (% F.S.) output based

on the following standard configurations/conditions:

1) Best Straight Line % F.S. as per ISA-37.3

2) +20°C ambient electronics

*Consult factory for non-standard configurations.

.4.2 RESOLUTION

3

±0.035% full scale @ 50% F.S. (average resolution)

3.4.3 REPEATABILITY

± 0.10% of full scale

3.4.4 OVERLOAD PRESSURE (MAX PRESSURE WITHOUT INVALIDATING SPECIFIED ACCURACY)

3.4.5 BURST PRESSURE

3.4.6 FREQUENCY RESONSE

20 Hz [-3db]

www.dynisco.com

Page 18

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-18-

3.4.7 RESPONSE TIME

50 mS

3.5 ELECTRICAL DATA

Configuration 4-arm Wheatstone bridge strain gauge with internal amplifier

Output Signal 2-wire 4 - 20 mA

Saturation Levels 3.8 mA and 20.5 mA

Fail Safe Levels 3.6 mA for Low Level

Current Consumption < 25 mA

Supply Voltage 13 - 30 VDC for PTB ATEX IS and FM XP approved models

>21mA for High Level

13 - 32 VDC for non-approved models

Note: Transmitter incorporates overvoltage protection and reverse

polarity protection and will not operate if inputs are reversed.

Sense Resistor Load Line

250 ohms minimum for HART communication

3.6 TEMPERATURE INFLUENCE

ELECTRONICS HOUSING

Operating Temperature Range -29°C to +85°C

Compensated Temperature Range -17°C to +65°C

www.dynisco.com

Page 19

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-19-

Zero Shift due to temperature change on electronics housing

0.01% FS/°F max. (0.02% FS/°C max.)

Span shift due to temperature change on electronics housing

0.01% FS/°F max. (0.02% FS/°C max.)

PROCESS CONNECTION

Zero shift due to temperature change on the diaphragm

0.01% FS/°F max. (0.02% FS/°C max.)

Span shift due to temperature change on diaphragm

0.02% FS/°F max. (0.04% FS/°C max.)

3.7 EMC REQUIREMENTS

The SPX Conforms to CE in accordance with EMC directive. See Declaration of Conformity for more

details.

3.8 MATERIALS

Standard Diaphragm 15-5PH Mat. No. 1.4545

Standard Wetted Parts 17-4PH Mat No. 517400

Please note other diaphragm and stem materials may be substituted.

3.9 ENVIRONMENTAL PROTECTION TO ANSI/IEC-60529 & ANSI/NEMA-250

SPX with sealed conduit to IP67, NEMA 4X

3.10 WEIGHT

The weight varies depending on product configuration. Average weight range is 1 to 3 pounds.

3.11 DIMENSIONS

The dimensions vary based on product configurations. Contact Dynisco if product dimensions are

required.

www.dynisco.com

Page 20

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

-20-

ATTENTION

providing a window into the process

4 TRANSPORT/DELIVERY

The SPX is an ESD sensitive component. Electrostatic discharge may damage the SPX. Take ESD

precautions.

4.1 TRANSPORT/PACKING/TRANSPORT DAMAGE

• Do not let the SPX be damaged by other items during transit

• Use only the original packaging

• Report transport damage to DYNISCO immediately in writing

4.2 STORAGE

• Store the SPX in original packaging only

• Protect against dust and moisture

4.3 SCOPE OF DELIVERY

• SPX with diaphragm protection cap

• Calibration sheet

• Operating manual with declaration of conformity

www.dynisco.com

Page 21

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

-21-

providing a window into the process

5 INSTALLATION

NOTES: Follow all Notes on Safety in Section 2 during installation.

5.1 GENERAL MOUNTING INFORMATION

Do not remove the protective cap on the SPX until ready to install.

Before mounting the SPX, check the process connection carefully. The SPX must only be mounted in

process connections that satisfy the requirements below. A process connection that does not satisfy

these requirements can damage the transmitter.

Insure the process connection is clear of any debris and is machined to the proper dimensions. In

applications involving high temperature operation and/or repeated thermal cycling a good high quality

anti-seize compound should be applied to the threaded surfaces.

Install unit into the process connection (Do NOT torque transmitter into the hole at this time!). Allow

time for the transmitter snout temperature to equalize to the process temperature. This will help

eliminate thread galling and ease removal later. There should be NO pressure applied at this time.

Always use a torque wrench applied to the designated wrench flats while screwing the transmitter in

and out. Do not apply the tool to the housing or housing/sensor connection.

After temperatures have equalized tighten transmitter into process connection.

When removing the SPX, carefully clean the diaphragm of the transmitter with a soft cloth while the

medium is still malleable.

Always remove the SPX prior to cleaning the machine with abrasives or steel wire brushes. Also, do not

clean the SPX with hard objects, such as a screwdriver, a wire brush, etc. This will possibly damage the

transmitter.

Burn Hazard! The SPX can be very hot when removed. WEAR PROTECTIVE GLOVES!

Careful attention should be paid to correctly machine the mounting port. Failure to use

the recommended mounting port may result in erroneous pressure measurement, difficult transducer

removal, premature sensor failure, process fluid leaks, and personnel hazard.

5.2 ELECTRICAL CONNECTION

Connect power to the transmitter. For conduit output configuration, Red wire is Sig+/Exc +, Black wire is

Sig-/Exc-, Green wire is Ground. For a 6 pin connector version, Pin A is Sig+/Exc+ and pin B is Sig-/Exc-.

Insure proper loop supply voltage is applied to transmitter.

www.dynisco.com

Page 22

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-22-

Connection Type

Terminal

Description

Conduit-Lead

Wire Color

PWR+/SIG+

Red

A

PWR-/SIG-

Black

B

CASE

Green

-

RCAL+

Orange

F

RCAL-

Blue

E

ATTENTION

he SPX is an ESD sensitive component. Electrostatic discharge may damage the PT. Take ESD

T

precautions.

Mounting and electrical connection of the SPX must be done by specialists with EMC

training, following all applicable regulations, and in pressure less, voltage-free,

intrinsically safe condition with the machine switched off.

he machine must be secured against being switched back on!

T

5.3 CONNECTION ASSIGNMENTS

The device must be connected to a certified power supply. Each unit will include a primary 4-20mA

output. The unit may also have one of the options listed in the table below. See section 2.1

details of units with GCxxx option code.

for wiring

Signal

6-Pin

Primary 4-20mA

Optional RCAL

If the transmitter is installed in hazardous areas, only passive devices like switches or resistors may be

connected between the RCAL+ and RCAL- signals. Connection of any active electronic circuits or

voltage or current source is not allowed.

www.dynisco.com

Page 23

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-23-

6 COMMISSIONING

ere are two ways of commissioning the SPX transmitters. This can be done by utilizing the ZERO and

Th

SPAN actuators or by HART Communications via a communicator connected to the pressure loop.

If the SPX is equipped with the optional HART Communications, it is not necessary to access the

zero/span actuators on the sensor.

If the transmitter is not equipped with HART then the zero/span actuators must be utilized. However,

Sections 6.3 through 6.8 and 6.11 may be skipped.

6.1 WHY A TRANSMITTER MUST BE REZEROED

The transmitter output must be nulled at zero pressure after installation when the machine has

stabilized at operating temperature. This is easy to understand why when considering the mechanical

properties of the sensor.

Depending on the orientation of the sensor, the weight of the diaphragm will have an effect on the

sensing diaphragm. The weight of the diaphragm will either increase or decrease deflection of the

diaphragm, creating a shift in the strain gage output that can appear as a positive or negative pressure.

There are some other effects that may affect the zero as well, such as torque, side loading, etc. For

more information contact Dynisco.

www.dynisco.com

Page 24

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

-24-

ATTENTION

ATTENTION

providing a window into the process

All of these effects can be compensated for by setting the transmitter zero after the machine has

stabilized at operating temperature.

6.2 UTILIZING THE ZERO AND SPAN ACTUATORS

When the transmitter output needs to be corrected due to mounting location and temperature shift the

zero actuator can be used (if a HART Communicator is not available.) Please wait until the process has

been brought to operating temperature before zeroing. The zero procedure is only recommended after

the process temperature has stabilized and the SPX electronics housing has been permanently installed.

When the actuator is depressed in a certain sequence, the output will be corrected to reflect 4 mA. This

is done by the transmitter electronics automatically by adjusting the LRV and URV settings

simultaneously to the offset required to obtain 4 mA. Normally a Zero calibration is all that is required

after installation since the Transmitter span has been calibrated at the factory. In the event the Full

Scale output is not correct when checked against a calibrated pressure source or dead weight tester, the

transmitter span can be adjusted via the Span actuator. This is performed by applying a known

calibrated full scale pressure to the transmitter and depressing the Span actuator in a certain sequence.

When complete, the transmitter electronics will have adjusted the URV to correct to output to equal 20

mA.

The span actuator should never be used to set the URV without zeroing the PT with the zero actuator

first.

If for some reason the calibration is incorrect and the user wishes to revert back to the Factory

Calibration, a procedure can be performed to revert the calibration back to factory state. Refer to

“Resetting to Factory Default Settings” in this Chapter.

6.2.1 ZERO AND SPAN PROCEDURE

1. Connect Power Supply to SPX signal leads with 250 Ohm load and milliamp meter in series with

loop.

2. If commissioning on the bench with a dead weight tester or calibrated pressure source, ensure

pressure connection is free of leaks.

3. Apply power to the SPX transmitter and observe loop current with zero pressure applied. It

should be 4 mA. If other than 4 mA proceed to step 4.

4. Perform Zero Function.

i. Do not remove seal screw when the circuit is live in a hazardous area.

ii. Remove zero pushbutton seal screw.

iii. Using a 2mm or smaller Allen key, depress the pushbutton for a ½ second.

iv. Release pushbutton for a ½ second.

v. Depress the pushbutton again for a ½ second and release.

www.dynisco.com

Page 25

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

-25-

ATTENTION

ATTENTION

ATTENTION

providing a window into the process

The available pressure is now adopted as the new lower range value.

Steps past this point are not part of a normal bench setup and should only be performed by qualified

individuals, as the SPX is highly stable and has been factory calibrated with highly accurate pressure

generators. This function should only be performed on such equipment.

5. Apply Full Scale pressure and verify output is 20 mA. If output is other than 20 mA, perform

Local Span adjustment:

i. Do not remove seal screw when the circuit is live in a hazardous area.

ii. Remove span pushbutton seal screw.

iii. Using a 2mm or smaller Allen key, depress the pushbutton for a ½ second.

iv. Release pushbutton for a ½ second.

v. Depress the pushbutton again for a ½ second and release.

The available pressure is now adopted as the new upper range value.

6.3 UTILIZING THE HART COMMUNICATIONS

The zero procedure is only recommended after the process temperature has stabilized and the SPX

electronics housing has been permanently installed. When the zero trim function is selected (HART

Quick key 1,2,5,1,3,1) the output will be corrected to reflect zero pressure. This is done by the

transmitter electronics automatically by adjusting digital PV to zero and analog output will be 4 mA.

Normally a Zero Trim is all that is required after installation since the Transmitter span has been

calibrated at the factory

In the event the Full Scale output is not correct when checked against a calibrated pressure source or

dead weight tester, the Transmitter span can be adjusted by performing the Sensor Trim function. This is

performed by first applying Zero Pressure and selecting Lower Sensor Trim (HART Quick Key 1, 2, 5, 1, 3,

2) and following the prompts on the HART Communicator. When complete, apply a known calibrated

full scale pressure to the Transmitter and selecting Upper Sensor Trim (HART Quick Key 1, 2, 5, 1, 3, 3)

and follow the prompts on the HART Communicator. When complete, the transmitter electronics will

have adjusted the digital PV to correct to full scale output.

Never perform upper sensor trim without performing lower sensor trim first.

www.dynisco.com

Page 26

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

-26-

ATTENTION

providing a window into the process

6.3.2 CONNECTING THE HART HANDHELD COMMUNICATOR

In hazardous areas, refer to the handheld communicator instruction manual for instructions for HART

Communicator to function properly.

A minimum of 250 Ohms resistance must be present in the loop.

The HART Communicator does not measure loop current directly.

The HART Communicator can interface with the SPX anywhere along the 4 - 20 mA cable as shown in the

following figure.

Figure 6-1 HART Communicator Interface

6.3.3 PROCEDURE

1. Connect Power Supply and HART Communicator per the above diagram.

2. If commissioning on the bench with a dead weight tester or calibrated pressure source, insure

pressure connection is free of leaks.

www.dynisco.com

Page 27

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

-27-

ATTENTION

providing a window into the process

3. Apply power to the SPX transmitter and turn on the HART Communicator by pressing the

ON/OFF key. The LCD display should show [SPX-T or SPX depending on model] in the upper left

corner. If this is not present, consult the Troubleshooting section of this manual.

4. Set PV Units (Fast Key 1,3,2) to appropriate pressure unit. (e.g. psi, Bar, kgf/cm2, MPa)

5. Set Tag (Fast Key 1,3,1).

6. If transmitter output needs to be re-ranged, set the appropriate LRV (Fast Key 4,1) and URV

(Fast Key 4,2)

• Note: URV cannot be turned down below the PV Minimum span (Fast Key 1,4,1,5)

7. Set Lower Trim (Fast Key 1,2,5,1,3,1)

8. Verify SPX transmitter output. Zero pressure output should read 4 mA.

Steps past this point are not part of a normal bench setup and should only be performed by qualified

individuals, as the SPX is highly stable and has been factory calibrated with highly accurate pressure

generators. This function should only be performed on such equipment.

9. Next, using calibrated pressure source, apply pressure equal to value set in URV in step 6.

Output should equal 20 mA. If output does not equal 20 mA proceed to step 10.

10. To calibrate full scale output, first apply pressure equal to full scale pressure of unit. Next

perform Upper Sensor Trim (Fast Key 1,2,5,1,3,2). Output should now equal full scale pressure.

11. If Transmitter Output Damping is required, set PV Damping (Fast Key 1,3,5) to the appropriate

value.

12. Press the left arrow key until the HART Communicator is off-line then turn the power off.

The SPX pressure transmitter is now ready to be installed in the process.

6.4 SPX ANALOG OUTPUT

The SPX has a 4-20 mA output proportional to pressure for normal operating conditions. However,

unlike a traditional sensor, the SPX performs self-diagnostic routines continually during operation. If a

special condition is detected, the transmitter drives its analog output outside the normal saturation

values to indicate that investigation is necessary (this condition is called fail-safe mode alarm). The

conditions detected by the self-diagnostic routines (and the corresponding effect on the analog output)

are listed later in this section.

When a special condition is detected, the SPX goes into fail-safe mode and the transmitter output goes

high, by default. However, using a HART communicator, the transmitter can also be configured to drive

its output low or to freeze the output where it was just before the fail-safe was detected. The actual

analog output levels are indicated below.

A low alarm (3.6 mA) is possible but not recommended because HART communications are not

guaranteed until the cause of the alarm is removed.

Using the HART communicator, the specific condition that triggered the fail-safe mode alarm can be

read for diagnostic purposes (see Status in the HART menu tree).

www.dynisco.com

Page 28

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-28-

n a fail-safe condition the PV is not affected and can still be read using the handheld HART

I

communicator. For process related fail-safe conditions, the transmitter will remain in the alarm state

until the source of error disappears. If certain electronics errors are detected, the fail-safe condition will

latch until a reset is performed by either cycling the power or through a software command.

NAMUR Compliant Saturation and Alarm Values

4 - 20 mA Saturation 4 - 20 mA Alarm

ow 3.8 mA 3.6 mA

L

High 20.5 mA >21 mA

You can alter the actual transmitter mA output values by performing an analog output trim using the

HART Communicator.

When a transmitter is in an alarm condition, the analog output displayed by the handheld indicates the

alarm value of the analog output – NOT the value the transmitter would have, if the sensor had not

detected the failure.

Special Conditions and the Corresponding Analog Output

Condition Alarm Value (fail safe)

EEPROM failure detected Set to configured fail safe mode

Cold start Set to fail safe mode low

Pressure above upper limit Unchanged

Pressure below lower limit Unchanged

Electronics temp above upper limit Unchanged

Electronics temp above lower limit Unchanged

Strain gage open detected Set to configured fail safe mode

Analog output saturated Unchanged

Watchdog error detected Unchanged

Zero/Span Actuator stuck Set to configured fail safe mode

Low voltage detected Unchanged

Outside URV or LRV Unchanged

Rcal simulation on Unchanged

6.5 ALARM & SATURATION VALUES BURST MODE

No special requirements are defined for the burst mode.

6.6 ALARM & SATURATION VALUES IN MULTIDROP MODE

If the device is in multidrop mode, the NAMUR levels are no longer achievable. Instead the fail safe

condition is indicated by the field device status and the additional diagnostics.

www.dynisco.com

Page 29

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

-29-

ATTENTION

providing a window into the process

6.7 SPX TRANSMITTER FUNCTIONS VIA HART

Zero Trim (1,2,5,1,3,1)

Digital Correction to zero which affects the digital output. This differs from Lower

Sensor Trim in that zero trim is ONLY performed at zero pressure.

Lower Sensor Trim (1,2,5,1,3,2)

Digital Correction to zero which affects the digital output. This differs from Zero Trim in that Lower

Sensor Trim can be performed at pressures above zero.

Note: This must be performed before Upper Sensor Trim. Only perform this function with a known

calibrated pressure source.

Upper Sensor Trim (1,2,5,1,3,3)

Digital correction to Full Scale which affect digital output.

Note: Lower Sensor Trim must be performed before Upper Sensor Trim. Only perform this function with

a known calibrated pressure source.

Digital to Analog trim (1,2,5,1,2)

This is used to match the digital representation of the analog output with its actual analog loop current.

Note: This should only be performed with a known Calibrated Current (mA) meter.

Reranging

The SPX allows for the 4 mA and 20 mA points (LRV and URV respectively) to be adjusted so that output

resolution can be improved. A Re-range or “Turndown” ratio of 6:1 is possible. Accuracy specifications

remain dependent upon the Full Sensor Range without any turndown applied. Three methods of Reranging the SPX Transmitter are outlined below.

Note: If pressure applied to the transmitter is not in the range of the 6:1 turndown ratio, the transmitter

will reject the Span attempt. This will be indicated by the output not adjusting to 20 mA after a few

attempts using the Span Actuator.

Reranging via Zero/Span Actuators

When HART Communication is not used, LRV and URV values are entered by applying zero pressure to

the SPX-T and “Rezeroing” by:

i. Do not remove seal screw when the circuit is live in a hazardous area.

ii. Remove zero pushbutton seal screw.

iii. Using a 2mm or smaller Allen key, depress the pushbutton for a ½ second.

iv. Release pushbutton for a ½ second.

v. Depress the pushbutton again for a ½ second and release.

The LRV and URV have now been adjusted to zero the device without affecting the span.

After Rezeroing, it is possible to set the span by adjusting the URV with the span actuator. The span

actuator should never be used to adjust the URV without using the zero actuator to set the LRV first.

www.dynisco.com

Page 30

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

-30-

ATTENTION

providing a window into the process

URV or Full Scale Turndown is performed by applying any pressure, within the 6:1 ratio of the

transmitter that you want to be the 20 mA point. When the pressure is held steady:

i. Do not remove seal screw when the circuit is live in a hazardous area.

ii. Remove span pushbutton seal screw.

iii. Using a 2mm or smaller Allen key, depress the pushbutton for a ½ second.

iv. Release pushbutton for a ½ second.

v. Depress the pushbutton again for a ½ second and release.

The SPX has now adjusted the URV 20 mA point to match the pressure applied.

6.8 RERANGING VIA HART

Rerange LRV (4)

This is the pressure at which the transmitter will output 4 mA as entered directly by the user. Changing

the LRV affects the transmitter span so the is range is limited by the minimum span value found in Fast

Key (1,4,1,5)

Rerange URV (5)

This is the pressure at which the transmitter will output 20 mA as entered directly by the user. This

range is limited by the minimum span value found in Fast Key (1,4,1,5)

Rerange LRV By Applying Pressure (1,2,5,1,1,1,1)

This is done by applying a known pressure and initiating the procedure so that the transmitter adopts

the pressure as the 4 mA point.

Note: This should only be performed with a Calibrated Pressure Source.

Rerange URV By Applying Pressure (1,2,5,1,1,1,2)

This is done by applying a known pressure and initiating the procedure so that the transmitter adopts

the pressure as the 20 mA point.

Note: This should only be performed with a Calibrated Pressure Source.

Recall Factory Trim (1,2,5,3)

This is used to restore the Zero, Lower, and Upper Trim to the Values as set from the Factory.

R-Cal Set % (1,2,5,1,4,1)

This is used on versions with a Rcal. By activating R-Cal, the output will be set to the percentage of span

set by this function. Default is 80%. Setting Rcal to 0%, disables the Rcal function.

Damping (1,3,5)

The damping time constant affects the speed with which the primary output signal reacts to changes in

pressure as shown in the figure on the following page. Damping is off by default but values between 0

and 30 seconds can be set using the handheld communicator. The damping value must be entered in

integers. If non-integers are entered, the system rounds to the next integer.

www.dynisco.com

Page 31

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

-31-

providing a window into the process

Local Actuator Disable (1,4,3,6)

Local zero and span actuators can be disabled using the HART handheld communicator function

“Local Push-buttons.” When turned off, the software Lock Out prevents changes to transmitter range

points via the local zero and span actuators. With local Push-buttons disabled, changes to configuration

are still possible via HART.

Status (1,2,1,2)

Reads Device Status from SPX.

PV Unit (1,3,2)

The pressure unit defines the unit of measure that the pressure-specific parameters are transmitted in.

The SPX can be configured in the engineering units of psi, Bar, MPa, and kgf/cm² or as a percentage of

Full Scale (FS). After selecting a new pressure unit, all entries for pressure are recalculated to the new

unit, using the following conversion rules:

1 psi = 0.068947 Bar = 0.0068947 MPa = 0.070309 kgf/cm²

Tag (1,3,1)

An inventory “Tag” identification number may be stored in transmitter memory (8 characters

maximum). Software tag is a single question mark by default.

Descriptor (1,3,4,2)

A 16 character text can be entered for further description of transmitter e.g. location, function, position,

etc.

Message (1,3,4,3)

A 20 character message can be set and displayed on the HART Communicator.

SV Electronics Temperature (1,1,7)

Temperature measured on the Electronics Assembly is used for reference and factory diagnostics only.

Poll Address (1,4,3,3,3)

Use in Multidrop mode allows more than one transmitter (up to 15) on a single loop. If this value is

other than zero, the transmitter is in Multidrop mode. An example of Multidrop mode would be a

www.dynisco.com

Page 32

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-32-

ATTENTION

group of HART devices wired in parallel on a single powered loop and each device being assigned a

unique Poll address (1-15). The HART communicator would prompt for the individual address of the

transmitter to communicate with and would only poll that specific device. All others would remain

unchanged. Note: Analog output is set to 4mA when in multi-drop mode.

Burst Mode (1,4,2,3,1)

When the SPX-T is used in Burst Mode, the transmitter outputs one-way digital communications from

the transmitter to the Host. Communication rate is faster since the transmitter does not have to be

polled to send data. Information transmitted in Burst Mode includes Pressure Variable, Analog Output

value, Pressure in % of range. Access to other information can still be obtained through normal HART

Comms.

6.9 RESETTING TO FACTORY DEFAULT SETTINGS

The factory settings for the sensor (including zero and span) can be restored if they are changed

inadvertently using the Zero/Span Actuators or the HART communicator. The list of parameters

restored is shown below.

Make sure Control System is in Manual mode. Temporary loss of Loop Output during

Electronics Re-boot may occur.

To reset the sensor using the actuators, use the following procedure:

i. Do not remove seal screw when the circuit is live in a hazardous area.

ii. Remove zero and span pushbutton seal screws.

iii. Using a 2mm or smaller Allen key, depress the pushbuttons for a ½ second.

iv. Release pushbuttons for a ½ second.

v. Depress the pushbuttons again for a ½ second and release.

At this point, the LRV and URV will be set to factory defaults.

www.dynisco.com

Page 33

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

-33-

providing a window into the process

6.10 DEFINITION OF “RESTORE FACTORY DEFAULTS”

1. Restore LRV and URV to their values at shipment.

2. Restore the Pressure Unit (psi, Bar, etc.) to its value at shipment.

3. Set the Analog Output Alarm Level to its value at shipment.

4. Remove all Pressure Damping.

5. Clear all Sensor and Analog Output Trim values.

6. Clear Burst Mode.

7. Restore the Address to Zero.

8. Restore the Rcal option to its value at shipment (enable or disable the Rcal option).

9. Set actuators to the settings they were when shipped from DYNISCO.

6.11 HART COMMUNICATOR FAST KEY SEQUENCES

Below defines the HART Communicator Fast Key sequences. Fast Keys are a means of supplying a

shortcut to navigate through the menu tree.

www.dynisco.com

Page 34

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-34-

Function

Fast Key Sequence

Read PV Pressure

2

Read % of Full Scale

1,1,2

Read Analog Output (PV)

1,1,3

Read SV Electronics Temperature

1,1,7

Read Peak Pressure Value

1,2,1,2

Read Peak Electronic Temp Value (SV)

1,2,1,3

Read Sensor Diagnostic Status

1,2,1,1

Read PV Minimum Span

1,4,1,5

Perform Sensor Self-Test

1,2,2

Perform Sensor Master Reset

1,2,3

Perform Loop Test

1,2,4

Perform D/A Trim (PV)

1,2,5,1,2

Perform Zero Trim

1,2,1,3,1

Perform Lower Sensor Trim

1,2,5,1,3,2

Perform Upper Sensor Trim

1,2,5,1,3,3

Recall Factory Trim

1,2,5,3

Set Rcal %

1,2,5,1,4,1

Set Tag

1,3,1

Set PV Unit

1,3,2

Set Lower Range Value (LRV) (PV)

1,3,3,1

Set Upper Range Value (URV) (PV)

1,3,3,2

Display Lower Set Limit (LSL) (PV)

1,3,3,5

Display Upper Set Limit (USL) (PV)

1,3,3,6

Set Date

1,3,4,1

Set Descriptor

1,3,4,2

Set Message

1,3,4,3

Set PV Damping

1,3,5

Set SV Temperature Unit

1,4,1,7

Set PV Analog Output Alarm Type

1,4,2,2,3

Set Poll Address

1,4,2,3,1

Set # of Request Preambles

1,4,2,3,2

Set Burst Mode

1,4,2,3,3

Set Burst Option

1,4,2,3,4

Read Analog Output (TV)

1,1,6

Read Peak Temp Value (TV)

1,2,3,4

Perform D/A Trim (TV)

1,2,5,2,2

Set Lower Range Value (LRV) (TV)

1,3,3,3

Set Upper Range Value (URV) (TV)

1,3,3,4

Temperature Override

1,2,5,2,1,1

Temperature Override Value

1,2,5,2,1,2

HART Communicator Fast Key sequences

www.dynisco.com

Page 35

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

-35-

Symptom

Corrective Actions

Milliamp Reading is Zero

1) Check if Power Polarity is Reversed

2) Verify Voltage Across Transmitter Pins

providing a window into the process

7 MAINTENANCE

7.1 MAINTENANCE

Mounting and electrical connection of the SPX must be done by specialists with EMC training, following

all applicable regulations, and in pressureless, voltage-free, intrinsically safe condition with the

machine switched off.

The machine must be secured against being switched back on!

Burn Hazard! The SPX can be very hot when removed. WEAR PROTECTIVE GLOVES!

Installation and Removal Instructions

• DO NOT REMOVE PROTECTIVE CAP UNTIL READY TO INSTALL.

• PRIOR TO INITIAL INSTALLATION, VERIFY CORRECT MACHINING OF MOUNTING HOLE.

• WHEN REINSTALLING, MAKE SURE THE PROCESS CONNECTION IS CLEAR OF DEBRIS.

• ALWAYS REMOVE THE SPX BEFORE CLEANING THE MACHINE WITH ABRASIVES OR STEEL WIRE

BRUSHES, ETC.

• DO NOT CLEAN THE “SCREWED-IN” SECTION OF THE SPX WITH HARD OBJECTS – THIS WILL

DAMAGE THE SPX.

• ALWAYS USE A TORQUE WRENCH APPLIED TO THE DESIGNATED WRENCH FLATS. DO NOT

APPLY THE TOOL TO THE HOUSING OR HOUSING/ SENSOR CONNECTION.

• ELECTROSTATIC DISCHARGE MAY DAMAGE THE SPX – TAKE ESD PRECAUTIONS.

7.2 REPAIR/DISPOSAL

For SPX repair and disposal please contact customer service from our website:

www.dynisco.com/contact

7.3 WARRANTY

The SPX Series Dynisco Pressure transmitters will provide excellent service and superior performance if

proper care is taken during handling, installation, and use. This DYNISCO product is warranted under

terms and conditions set forth in the DYNISCO web pages. Go to www.dynisco.com

"warranty" link under the “Post-Sales Support” tab at the top of the web page for complete details.

8 TROUBLESHOOTING

and click on the

www.dynisco.com

Page 36

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-36-

Large Zero Shift when Screwing In

1) Check Hole with Gage Plug and Rework Hole as Required

2) Check Mounting Torque

Primary Milliamp Reading is Low or

1) Check Pressure Variable Reading for Saturation

4) Perform 4 - 20 mA Output Trim with HART Communicator

No Response to Changes in Applied

1) Check Test Equipment

4) Check if in multi-drop mode

Pressure Variable Reading is Low or

1) Check Test Equipment

3) Perform Full Sensor Trim

Pressure Variable Reading is Erratic

1) Check Port/Pipe for Blockage or Solidified Plastic

3) Check for EMI

Transmitter Not Communicating with

HART Communicator

1) Check Power Supply Voltage at Transmitter

5) Confirm HART communicator is connected to primary

(Pressure) output 4-20mA

HART Communicator missing SPX

Features Described in Manual

From the Communicator’s Main Menu, Access the On-Line

Arrange for DD Upgrade

Primary output =3.6mA or > 21mA

4) Unit is in fail safe, consult fail safe section

High

Pressure

High

2) Check if Output in Alarm Condition

3)Verify 4 and 20 mA Range Points or Simply Reset

2) Check Port/Pipe for Blockage or Solidified Plastic

3)Check if Output in Alarm Condition

2) Check Port/Pipe for Blockage or Solidified Plastic

2) Check Damping

2) Check Load Resistance (250 Ohm minimum)

3)Check Communicator Connection Across Power Supply

4)Check if Unit is Addressed Properly

Menu. The Name SPX Should be Displayed on the Top Line of

the LCD. If the Name is not Present, Contact Dynisco to

www.dynisco.com

Page 37

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-37-

9 APPROVALS/CERTIFICATES

9.1 CE DECLARATION OF CONFORMITY .................................................................................... 388

9.2 EC-TYPE EXAMINATION CERTIFICATE ................................................................................. 400

9.3 EX FM CERTIFICATE OF COMPLIANCE ................................................................................. 445

9.4 SAFETY INTEGRITY AND PERFORMANCE LEVEL APPLICATION …………………………………………409

Note additional approvals available; please consult factory.

www.dynisco.com

Page 38

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-38-

9.1 CE DECLARATION OF CONFORMITY

www.dynisco.com

Page 39

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-39-

www.dynisco.com

Page 40

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-40-

9.2 EC-TYPE EXAMINATION CERTIFICATE

www.dynisco.com

Page 41

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-41-

www.dynisco.com

Page 42

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

-42-

providing a window into the process

www.dynisco.com

Page 43

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

-43-

providing a window into the process

www.dynisco.com

Page 44

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

-44-

providing a window into the process

9.3 EX FM CERTIFICATE OF COMPLIANCE

www.dynisco.com

Page 45

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

-45-

providing a window into the process

www.dynisco.com

Page 46

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

-46-

providing a window into the process

www.dynisco.com

Page 47

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-47-

www.dynisco.com

Page 48

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-48-

www.dynisco.com

Page 49

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-49-

9.4 Safety Integrity and Performance Level Applications

www.dynisco.com

Page 50

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

providing a window into the process

-50-

www.dynisco.com

Page 51

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

-51-

Variable

Default Value

Access

Options

Analog Output Alarm Flag

Low

RW

High

Hold Last

Burst Command Enable

Off

RW Burst Option Variable

PV

RW

Date of Last Factory Calibration

Date of Calibration

RO

User Selectable Date

Date of Calibration

RW Manufacturer Identification Code

0 x 72

RO Dev ID (Device Identifier)

Unique number set by Factory

RO Final Assembly Number

<BLANK>

RW

Local Push-button Enable

Enable

RW

Enabled

Disabled

Factory Default LRV

0

RO Lower Sensor Limit

-0.04 * full scale of SPX-T

RO Message Text

HTTP://WWW.DYNISCO.COM/

RW PV Minimum Span Value

Factory Default PV_URV divided by 5

RO Number of Request Preambles

5

RW PV Damping Constant Value

0 Seconds

RW

0-30

PV Lower Range Value

0

RW

0-30

PV Engineering Unit Code

Per Customer Order

RW

0 x 06 – PSI

0 x ED – MPa

PV Upper Range Value

Full scale (same as on label)

RW PV Transfer Function Code

Linear

RO Rcal Calibration Percentage

80%

RW

20 - 100%

Field Device Serial Number

As Set at Factory

RO Tag ? RW Transmit Address

0

RW

0 - 15

Factory Default URV

Per Customer Order

RO Upper Sensor Limit

1.5 * full scale of SPX

RO

providing a window into the process

APPENDIX 1 - DEFAULT VALUES

Low

www.dynisco.com

0 x 07 – Bar

0 x 0A – kg/cm²

0 x 39 – % of FS

Page 52

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

-52-

providing a window into the process

11 APPENDIX 2 – Menu Tree (Software Revision < 100)

for software revision < 100

www.dynisco.com

Menu Tree

Page 53

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

-53-

providing a window into the process

www.dynisco.com

Page 54

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

-54-

providing a window into the process

www.dynisco.com

Page 55

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

-55-

providing a window into the process

www.dynisco.com

Page 56

P/N: 974153 | Rev: 072016 | ECO: 46503

From lab to production,

-56-

providing a window into the process

12 DYNISCO CONTACT INFORMATION

Please visit our website for up to date contact information:

www.dynisco.com/contact

www.dynisco.com

Loading...

Loading...