Page 1

MODEL SC170MODEL SC170

MODEL SC170

MODEL SC170MODEL SC170

TWO-WIRE “SMART”TWO-WIRE “SMART”

TWO-WIRE “SMART”

TWO-WIRE “SMART”TWO-WIRE “SMART”

SIGNAL CONDITIONERSIGNAL CONDITIONER

SIGNAL CONDITIONER

SIGNAL CONDITIONERSIGNAL CONDITIONER

INSTALLATION AND OPERATION MANUALINSTALLATION AND OPERATION MANUAL

INSTALLATION AND OPERATION MANUAL

INSTALLATION AND OPERATION MANUALINSTALLATION AND OPERATION MANUAL

Page 2

Contents

PREFACE 1

1.0 INTRODUCTION ............................................ 1

2.0 UNPACKING AND INSTALLATION ............. 2

2.1 Unpacking .............................................. 2

2.2 Mechanical Installation ............................ 3

2.2.1 Weather Proof Housing ......................... 3

2.2.2 Thermowell Mounting ............................ 3

2.2.3 Pipe Mounting ........................................ 5

2.2.4 Surface Mounting .................................. 6

2.3 Electrical Installation ............................... 6

2.3.1 Output Terminals ................................... 7

2.3.2 Case Ground .......................................... 7

2.3.3 Input Terminals ...................................... 8

3.0 SIGNAL CONDITIONER OPERATION .......... 9

3.1 In a Hurry? ............................................. 9

3.1.1 Factory Configuration ............................ 10

3.1.2 Analog Operating Mode ......................... 10

3.1.3 Operation With a Display ...................... 11

4.0 CONFIGURATION USING

THE TWO-LINE DISPLAY............................... 12

4.1 Entering the Display Mode ..................... 12

4.2 Display Mode Operation ........................ 13

4.3 Select Sensor Input................................. 14

4.4 Change Zero .......................................... 15

4.5 Change Full Scale.................................... 17

4.6 Select Fail Safe Reporting ....................... 17

4.7 Transmitter Fail Safe .............................. 17

4.8 Trim 4.0mA ........................................... 18

4.9 Trim 20.mA ........................................... 19

5.0 ACCESSORIES & INFORMATION .................. 21

6.0 SPECIFICATIONS ............................................ 22

Page 3

DYNISCO SC170 Manual

1.0 INTRODUCTION

The SC170 is a programmable, two-wire, isolated signal conditioner

that accommodates DC milliamperes, DC millivolts, DC volts,

Potentiometer (slidewire), two and three wire resistance as inputs.

This instrument is exceptionally versatile and can be used when any

one or all of the following requirements exist:

• Signal isolation

• Conversion of signal types (e.g., Millivolt input to 4 to 20mA

output)

• User-tailored noise filter to eliminate noise without damping

• Local digital display in engineering units

• Bar graph display indicating percent of span

• Local configuration without external calibration sources

• NIST traceable calibration warranted for 24 months.

The SC170 achieves its performance through the use of digital signal

processing and microcontroller technologies. Many of the features,

such as the automatic self diagnostics and the exceptional temperature

stability, are transparent to the user.

It is simple to setup and operate the SC170 signal conditioner. It can

be set up, with a smart local display, the LD-2, and a two-key

keyboard, the KB-2. These accessories facilitate local configuration

and ranging of the signal conditioner. In operation, the local LCD

display indicates the measured signal and units of measurement to six

digit resolution, an analog percent of range indication and also

provides a seven-character alphanumeric label or message indication.

The SC170 signal conditioner does not have any potentiometers or

switches to set, and there are no user-serviceable components inside

the enclosure. It has a two-year NIST traceable calibration warranty.

Opening the enclosure will void the manufacturer’s warranty.

This manual is divided into several main sections. Section One,

INTRODUCTION, describes briefly the signal conditioner and the

organization of this manual. Section Two, UNPACKING AND

INSTALLATION, contains much useful information for the first time

installer. Section Three, SIGNAL CONDITIONER OPERATION,

contains analog mode of operation. Section Four, CONFIGURATION,

THE DISPLAY MODE, explains display mode. Section Five,

APPLICATIONS INFORMATION, contains additional applications

information. Section Six, SPECIFICATIONS, deals with the signal

conditioner specification.

11

1

11

11

1

11

Page 4

DYNISCO SC170 Manual

2.0 UNPACKING AND

INSTALLATION

2.1 UNPACKING

Remove the Packing List to check off the actual equipment received.

If you have any questions on your shipment, please call DYNISCO

INSTRUMENTS Customer Service Department at (508) 541-9400.

Upon receipt of shipment, inspect the container for any signs of

damage in transit. Especially take note of any evidence of rough

handling. Report any apparent damage immediately to the shipping

agent.

NOTE: The carrier will not honor any claims unless all shipping

material is saved for their examination. After examining and

removing the contents, save the packing material and carton in the

event reshipment is necessary.

22

2

22

22

2

22

Page 5

DYNISCO SC170 Manual

2.2 MECHANICAL INSTALLATION

2.2.1 Weather Proof Housing

Optional weather-proof and explosion-proof housings are available.

The XP-HDC2-L accommodates a signal conditioner when the display

option is not required. The XP-HDGC2-L, with its glass window,

may be used when the display option is desired. These housings have

appropriate mounting plates in the bottom to attach the SC170 in any

of four orientations 90° apart. In addition special captive 6-32

machine screws are installed on the signal conditioner to facilitate

installation and removal. These captive screws are installed only if the

signal conditioner and housing are ordered at the same time. Figure

2-1 indicates the dimensions of these housings.

Fig. 2-1 Optional Weather Proof Housing

2.2.2 Conduit Mounting

The weather-proof housing has two 1/2” female NPT conduit entries.

These can be used to mount the housing directly onto the 1/2” male

NPT ends of conduits. Alternatively, a 1/2” union coupling can be

placed between the weatherproof housing and the wiring from the

signal source.

33

3

33

33

3

33

Page 6

Fig. 2-2 XP-HDGC2-L

Fig. 2-3 XP-HDC2-L

DYNISCO SC170 Manual

44

4

44

44

4

44

Fig. 2-4 Din-Rail Kit

Page 7

DYNISCO SC170 Manual

2.2.3 Pipe Mounting

A stainless steel bracket, the PB-2, is available for mounting the

weatherproof housing onto any 2" pipe in any of four operations.

The housing is attached to the bracket as shown in Figure 2-5.

Fig. 2-5

Fig. 2-6 Pipe Mounting Bracket with XP-HDC2-L

55

5

55

55

5

55

Page 8

DYNISCO SC170 Manual

2.2.4 Surface Mounting

The weatherproof housings, type XP-HDC2-L and the XP-HDGC2L,

have two mounting ears allowing them to be attached to any flat

surface by means of two bolts. If the additional weather resistance is

not required, the SC170 can be mounted directly on a flat surface by

the two mounting ears found on these units. In applications requiring

several signal conditioners, these can be mounted on the plate

normally found inside of NEMA-4 rated rectangular metal enclosures.

2.3 ELECTRICAL INSTALLATION

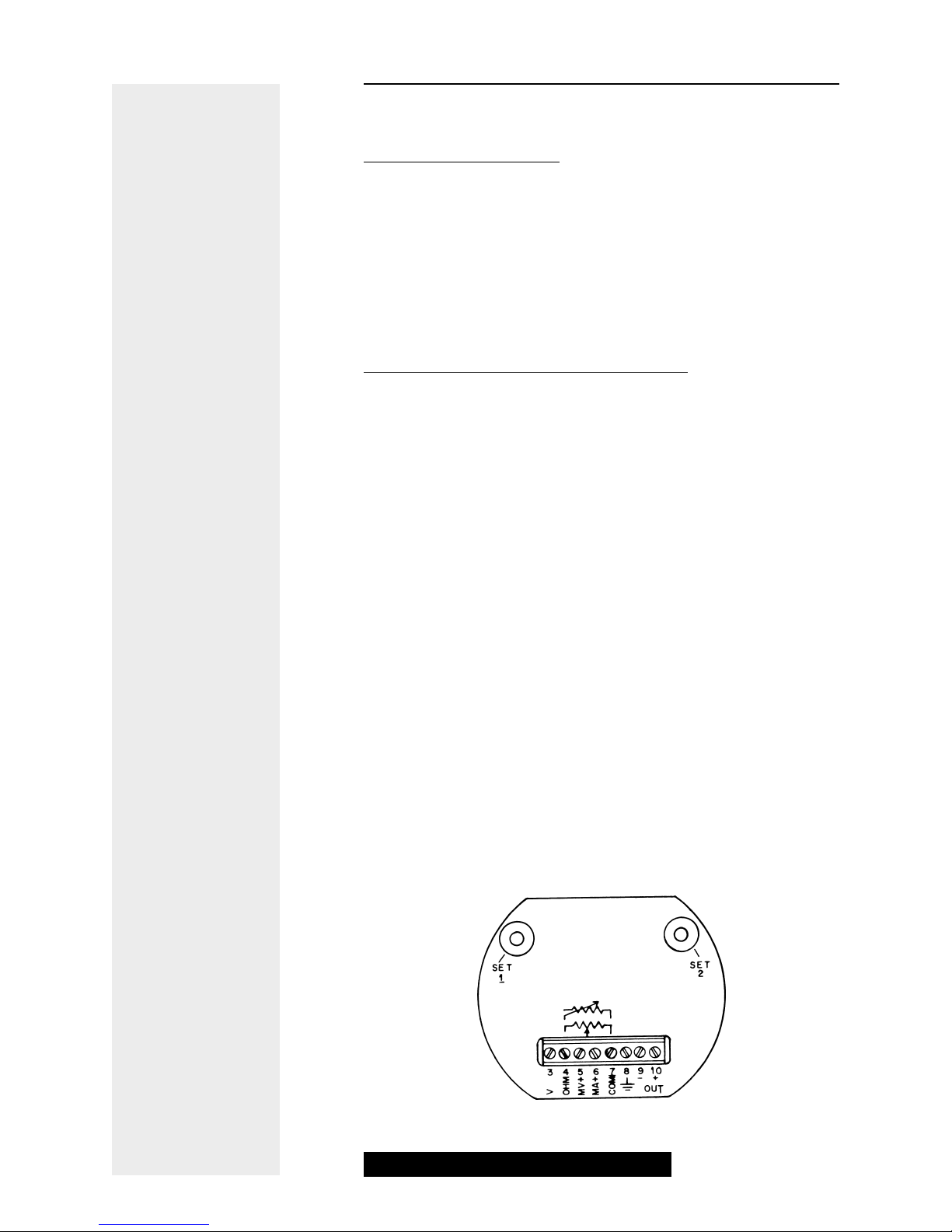

The SC170 has two groups of terminals.

Terminals 1 and 2 also serve as the mounting screw locations for the

LCD display. These terminals, designated as SET 1 and SET 2, in

conjunction with terminal 7 as common, are used for setup,

configuration and trim purposes. The SET 1 and the SET 2 terminals

are marked as such and are located near the upper left and upper

right areas of the signal conditioner cover. There is a slanted line

pointing directly from the word SET 1 towards the corresponding

terminal inside of a round black insulating area. The SET 2 terminal

can be found similarly on the right-hand side of the signal conditioner.

Terminals labeled 3, 4, 5, 6, and 7 are used in various connections to

accommodate the different input signals. Terminal 8 is used to ground

the enclosure.

Terminals 9 and 10 are the 4 to 20mA output terminals. These are

normally connected to the corresponding polarity terminals of the

power supply of the current loop. Refer to Figure 2-7 for the

terminal connections arrangement.

66

6

66

66

6

66

Fig. 2-7 Terminal Connections

Page 9

DYNISCO SC170 Manual

2.3.1 Output Terminals

The output terminals 9 and 10 are connected to a power supply

having a nominal 24 Volt DC voltage and capable of supplying 100mA

for the SC170. In the analog mode, these signal conditioners require a

maximum of 23mA. The + OUT and - OUT terminals of the power

supply. The maximum series resistance in the circuit (including wiring

lead resistance) can be calculated using the formula:

Rs = ————————

The following chart gives maximum series resistance:

Max. Series Resistance Rs Supply Voltage Vs

2.3.2 Case Ground

Terminal 8 provides a connection to the metal enclosure of the signal

conditioner. For safety, optimum performance and EMI immunity the

case of the instrument should be connected to a good local earth

ground. When using grounded sensors that are connected to the

local electrical ground, then the signal conditioner case should be

connected to that same ground point.

Vs - 12

0.023

1300 ohms 42.0 Volts

520 ohms 24.0 Volts

417 ohms 21.6 Volts

250 ohms 18.0 Volts

0 ohms 12.0 Volts

77

7

77

77

7

77

Page 10

DYNISCO SC170 Manual

2.3.3 Input Terminals

2.3.3.1 DC Milliampere Input

Apply signal to 6(+) and 7(-).

–

+

Fig. 2-8 Typical Connection for Milliampere Input

2.3.3.2 DC Millivolt Input

Apply signal to 5(+) and 7(-).

Fig. 2-9 Typical Connection for Millivolt Input

2.3.3.3 DC Volt Input

Apply signal to 3(+) and 7(-).

88

8

88

88

8

88

Fig. 2-10 Typical Connection for Voltage Input

Page 11

DYNISCO SC170 Manual

2.3.3.4 Potentiometer

Connect high side to 4, center wiper to 5 and low side to 7.

Fig. 2-11 Typical Connectionfor Slideware/Resistance

2.3.3.5 Three wire Ohms

Connect high side of the resistor to 4, one wire from the low side to

5, and the second wire from the low side to 7.

Fig. 2-12 Typical Connection for Slidewire/Resistance

2.3.3.6 Two wire Rheostat (Ohms)

Connect high side to 4 and low side to 7.

3.0 SIGNAL CONDITIONER

OPERATION

3.1 IN A HURRY?

When in a hurry, this short set of instructions and references will help

get the signal conditioner running.

99

9

99

99

9

99

Page 12

DYNISCO SC170 Manual

3.1.1 Factory Configuration

Milliampere mode, Analog Output

4.00mA Input = 4.00mA Output

20.00mA Input = 20.00mA Output

Sensor Fail-safe = 21.00mA

On special request the factory will set the signal conditioner to any

desired configuration. Special configurations are identified on a tag

attached to the unit.

3.1.2 Analog Operating Mode

If the unit was ordered with the standard factory configuration, the

input required is a 4 to 20mA current loop. The packing slip should

indicate if the unit was set up to any other customer requested special

configuration. If there is a need to change the configuration of the

signal conditioner, or to re-range it, refer to the procedures described

in SECTION 4.

1010

10

1010

1010

10

1010

NOTE: Even when “In a Hurry”, the use of an appropriate power

supply is important. A 24V DC supply having a current handling

capacity of at least 0.1A is commonly used. Do not use a power

supply whose output voltage drops to 20 volts or below when a

0.1 ampere load is connected to it. Always use a DC (direct

current) supply, or suitable size battery. Never connect the signal

conditioner directly to 115VAC.

With the power supply off, connect the + side of the power supply to

the +OUT terminal of the signal conditioner. Connect the - side of the

power supply through an optional 250 ohm resistor to the -OUT (9)

terminal of the signal conditioner. Connect the input terminals 6 and

7 in series with the current loop to be measured. Terminal 6 should

be more positive than 7.

Current Input High (+MA) (6)

Current Input Low (-COM) (7)

To connect other sensors to the input refer to Section 2.3.32 for the

proper sensor connections.

The output can be monitored by connecting a milliammeter in series

with either of the two output terminals, or by connecting a high

impedance voltmeter across the optional 250 ohm resistor. Now

turn on the power supply. In about 5 seconds the SC170 loop current

will settle to its normal value in the range of 4 to 20mA. In this

configuration the SC170 is a loop-powered isolator. The output

current will duplicate the current applied to the input terminals.

Page 13

DYNISCO SC170 Manual

3.1.3 Analog Operating Mode With Display

If the signal conditioner was ordered with the display option, it will

have a small local LCD display module plugged in and attached to the

top of the unit. The display option can be ordered already installed

on the SC170 signal conditioner. Having the display option as part of

the signal conditioner does not affect its operation in the analog mode

and the description of the previous section applies.

However, the display option does provide some very useful local

indication of the measured temperature and other diagnostic

functions. The Figure 3.1 below indicates the arrangement of the

display screen and some of the symbols that are available.

Fig. 3-1 Appearance of the Local Displays (LD-2)

In operation, the top row displays the measured variable and a minus

sign if applicable. The number of decimal places displayed changes to

be appropriate for the input selected.

The mid portion is an analog bar graph display showing the % of range

based on the ZERO and FULL SCALE setting of the signal conditioner.

When power is applied the leftmost segment of the bar graph, the 0%

and the 100% become energized. If the input signal is below what the

ZERO is set to, then the left arrow is energized. If the input signal is

above the FULL SCALE setting, then the right arrow becomes

energized.

The bottom portion of the LCD is capable of displaying alphanumeric

messages. In normal operation this row shows a label, which is factory

set to display SC170. Seven characters are available. The user may

order a desired label in place of SC170.

1111

11

1111

1111

11

1111

Page 14

DYNISCO SC170 Manual

In the event of certain signal conditioner failure modes, the indication

changes to

S FAULT

In the event of certain signal conditioner failure modes the indication

changes to

X FAULT

This LCD display takes full advantage of the precision of these signal

conditioners. The digital display of measurement does not include the

small D/A error otherwise present in the analog output. It provides

highly accurate local indication of the measurement, local fault

diagnostics, and signal conditioner identification. The LCD continues

to display the measured variable even if it is beyond the zero and span

limits set for the analog output. The value of this display as a set-up,

calibration and reconfiguration tool may even be greater, as will be

seen in later chapters.

4.0 CONFIGURATION USING THE

TWO-LINE DISPLAY

To configure a transmitter using the DISPLAY MODE, LD-2

local LCD display and the KB-2 two key keyboard are required. The

transmitter can also be purchased with these options already installed.

These inexpensive options make the reconfiguration, or re-ranging of

the transmitter very simple and easy to follow. Without the use of a

calibrator, or any other tools, the transmitter can be set up for a

different sensor, or the new range limits can be set much like one

would set the time on a digital watch.

In the event that the KB-2 or LD-2 keyboard and display are not

purchased at the same time as the transmitter, follow carefully the

field installation instructions supplied with the display to avoid damage

to the transmitter or the display.

4.1 ENTERING THE DISPLAY MODE

To start the DISPLAY MODE, first connect the transmitter to

an appropriate DC power supply. Typically a 24VDC supply is

connected with the + side to signal conditioner terminal (10) and side to terminal (9). A series resistor in the loop is optional, but not

required. A sensor may be connected to the transmitter’s input

terminals, but this is not required for setting up the transmitter.

DISPLAY MODE,

DISPLAY MODE,

1212

12

1212

1212

12

1212

Page 15

DYNISCO SC170 Manual

Once the transmitter is powered up, it comes on in the normal

operating mode that it was previously set to. The standard factory

set-up puts the transmitter in the analog operating mode. With the

standard factory set-up and no sensor connected, the LD-2 display will

give the following indication:

< 0% 100%>

S FAULT

The transmitter is indicating SENSOR FAULT, since no sensor is

connected, and the analog output is indicating greater than 100%,

loop current at 21.00mA, which is the standard over range condition.

Please note that if you plug the display in to the transmitter while the

transmitter is powered up, you may not start the menu sequence at

the beginning. You should power down the transmitter without

disconnecting the display or simply wait about two minutes for the

transmitter to reset itself.

Press the key marked NEXT. The display starts to alternate

asking if the user wishes to enter the DISPLAY MODE,

DISPLAY MODE ?

Display Mode

The answer would be yes, therefore, press the Enter key. This will

allow you to configure the transmitter using the DISPLAY MODE. A

flow chart summarizing the operation of the DISPLAY MODE appears

at the end of this manual.

SENSOR FAULT,

NEXT.

DISPLAY MODE,

Note that when more than seven characters are required to describe

a function, the display keeps sequencing through two or more screens.

In this manual, the sequencing of the display is indicated by placing the

two or more parts of the message adjacently. With some functions,

the LD-2 display indicates a numeric value and unit of measurement

on the top line of the display in addition to the message on the lower

display line.

4.2 DISPLAY MODE OPERATION

The DISPLAY MODE will allow the user to do the following:

DISPLAY MODE

• Select a Sensor Input

• Change the 4mA Lower Range Value (CHANGE ZERO)

1313

13

1313

1313

13

1313

Page 16

DYNISCO SC170 Manual

• Change the 20mA Full Scale Value (CHANGE FULL SCALE)

• Change the Sensor Fail Safe detection (SELECT SENSOR

FAIL SAFE)

• Change the Transmitter Fail-Safe detection (SELECT XMITTER

FAIL SAFE )

• Trim the 4.0mA output current (TRIM 4 MA)

• Trim the 20.0mA output current (TRIM 20 MA)

Each of these functions is presented in sequence on the LCD display.

If the indicated function need not be performed, press NEXT,

and the next function is displayed on the screen. To perform any

function, press the ENTER key. This will cause additional

screens to be displayed which enable you to perform the function.

These are described in detail below and summarized on the LD-2

flowsheet found in the rear of this booklet.

4.3 SELECT A SENSOR INPUT

ENTER

NEXT,

SELECT INPUT

The SELECT INPUT is the first function in the sequence. The

display will read as follows to indicate this position on the menu:

SELECT INPUT ?

If the sensor does not require changing, then press NEXT and

skip to Section 4.4 of this manual; otherwise press ENTER.

After pressing the ENTER key, the display will change to:

MAMPS

Indicating that the transmitter is set to a milliampere input. If this is

the desired sensor, then press ENTER, otherwise press

NEXT repeatedly to sequence through the available sensors.

NEXT

Each time NEXT is pressed, the next available sensor selection

is displayed.

MVOLTS

NEXT

ENTER

ENTER.

(Millivolts)

NEXT

ENTER.

1414

14

1414

1414

14

1414

Press the NEXT key to go the next sensor

VOLTS

RHEOST

NEXT

(Volts)

(Rheostat, or 2 wire ohms)

Page 17

DYNISCO SC170 Manual

OHMS 3W

SLIDEW

One can stop at any one of the input type selections and pressing of

the ENTER key changes the signal conditioner mode to that

ENTER

input type. If no input change is desired, then without sequencing

through the various inputs options, but just pressing the ENTER

key will allow one to confirm the input selection and leave it

unchanged. We will assume that the input is left as MAMPS.

After pressing ENTER, the display returns to:

SELECT INPUT ?

Press next to go to the next menu option.

4.4 CHANGE ZERO

The display will then alternate between the following screens to

indicate that one may now change the zero, or 4mA output point.

4.00

CHANGE

(three wire ohms)

(Slidewire or Potentiometer)

ENTER

MAMPS.

ENTER,

4.00

ZERO ?

The numeric value seen on the upper portion of the screen is the

current ZERO value of the transmitter. One can now change this

ZERO, or LOWER RANGE VALUE, (LRV), totally independent of the

FULL SCALE, or UPPER RANGE VALUE, (URV), without the use of

any calibrators or external sensor inputs. To change the ZERO, press

ENTER. The display changes to

ENTER.

04.000

PLUS ?

indicating that the existing zero is set to “plus” 004.00. The question

mark (?) indicates a question asking if this value is to remain positive

(PLUS ?). By repeatedly pressing the NEXT key the display will

alternate

-04.000

MINUS ?

After deciding whether the zero value, LRV, is to remain positive

(PLUS), press the ENTER key. In this example assume it is to

remain positive. The display changes to

04.000

PLUS ?

ENTER

NEXT

1515

15

1515

1515

15

1515

Page 18

DYNISCO SC170 Manual

4000.00

TENS ?

and the leftmost digit position will start blinking (shown here in italics)

asking if the tens position needs to be changed. To change the

thousands position, start pressing the NEXT key and the

leftmost digit will increment through 1 2 3 4 5 6 7 8 9 0. Stop

pressing the NEXT key at any of the numerals desired, then

press ENTER to accept the selection. If the numeral selected

before pressing ENTER was 0, then the display would change to

400.00

ONES ?

and the second digit from the left will start blinking (shown here in

italics) asking if the hundreds position needs to be changed. As

before, to change the number in this digit position repeatedly press

the NEXT key until the desired numeral is reached. Then press

ENTER to go to the next lower significant digit position. Each

time the NEXT key cycles through the ten choices for that digit

position and the ENTER key enters the selected number. The

digit position being changed is the one that is blinking. The legend on

the display will change successively to

ENTER

NEXT

ENTER

NEXT

ENTER

NEXT

ENTER

NEXT

040.00

TENS ?

004.00

ONES ?

000.40

TENTHS ?

00.040

HUNDTH ?

After the hundreth’s digit position has also been changed to the desired

value, the next pressing of the ENTER key returns the transmitter

to the alternating display of CHANGE ZERO. Since changing of

the zero has just been completed, press the NEXT key to

proceed to the next menu selection, CHANGE FULL SCALE.

ENTER

CHANGE ZERO.

NEXT

CHANGE FULL SCALE.

1616

16

1616

1616

16

1616

Page 19

DYNISCO SC170 Manual

4.5 CHANGE FULL SCALE

200.00

CHANGE

To change the full scale value press ENTER. The procedure for

selecting Plus or Minus is identical to that described for changing the

ZERO. Similarly, the procedure for changing each of the digit

ZERO.

positions is identical to that described for changing the ZERO.

Once the steps of changing the FULL SCALE have been

completed and the ENTER key is pressed at the end of the

procedure, the display returns to CHANGE FULL SCALE.

Press NEXT for the next function SELECT SENSOR

FAIL SAFE DE

FAIL SAFE.

When the desired fail-safe condition is displayed, pressing the

ENTER

ENTER key will change to the new setting and the screen returns

to the SELECT SENSOR FAIL SAFE display. Pressing the

NEXT key will bring up the TRANSMITTER FAIL

selection screen.

4.6 SELECT FAIL-SAFE

NEXT

SELECT SENSOR FAIL SAFE

NEXT

200.00

FULL

ENTER

200.00

SCALE ?

ENTER.

ZERO.

FULL SCALE

CHANGE FULL SCALE.

SELECT SENSOR

XMITTER FAIL SAFE

SELECT FAIL SAFE

Fail-safe allows the transmitter to change the 4-20mA loop to indicate

a failure condition. This failure may be a sensor failure or a

transmitter. In any event, the user may select to drive the loop to

22.0mA, corresponding to the “HI” selection; to 3.6mA,

corresponding to the “LO” selection or to turn the function “OFF”

LOW

HIGH

OFF

4.7 TRANSMITTER FAIL SAFE

Using a similar procedure as above (4.6) the signal conditioner fail safe

condition can be changed to High, Off or Low. When a selection is

completed and the screen is back to the main menu item: press the

next key to bring up the next selection.

NEXT

1717

17

1717

1717

17

1717

Page 20

DYNISCO SC170 Manual

4.8 TRIM 4.0MA

TRIM 4 MA ?

This allows trimming of the 4.00mA output current.

NOTE: This function is only for the purpose of adjusting the

4.00mA limit of the transmitter loop current to be exactly 4.00mA

according to the plant’s local standard. This is NOT for the purpose

of ranging the transmitter!

If trimming the 4.00mA limit is still desired then press ENTER.

The transmitter will now output a milliamp current equal to its

internally set 4mA. This 4 mA value should be read on an external

meter and compared to a local standard. It is advisable to use a very

good voltmeter to make these comparisons. It is very possible that

the transmitter will be more accurate than a great many voltmeters.

In this case, trimming will make the transmitter less accurate rather

than more accurate!

Once trimming the 4.00mA value has been selected, the display will

alternate as follows:

RAISE MA OUT ?

By pressing the NEXT key the display then alternates as

LOWER MA OUT ?

When it is decided whether to raise or lower the output current, then

press ENTER and the display changes to one of the following

depending on whether the raise or lower function has been selected.

ENTER

NEXT

ENTER.

1818

18

1818

1818

18

1818

NEXT = + NEXT = -

Now every time the NEXT key is pressed, the display blinks,

and the 4.0mA output limit decreases (-), or increases (+). The

decrease or increase is in approximately 2.0 microampere increments.

NOTE: The 4.0mA limit is factory calibrated to a precision standard.

Do not arbitrarily trim the output unless a qualified and accurate local

standard is available to measure the adjusted 4.0mA output! Also

note that the 4.0mA limit should not be trimmed by more than about

⫾50uA, or transmitter operation may be impaired.

NEXT

Page 21

DYNISCO SC170 Manual

Once the desired trim is reached, pressing ENTER will return

to one of the corresponding TRIM 4MA screen. At this point

one may still go back and do further trimming of the 4.0mA limit

by pressing the ENTER key, or pressing the Next key changes

to the next function.

4.9 TRIM 20.MA

TRIM 20 MA ?

Trimming of the 20.0mA current limit is done in exactly the same

manner as was described for trimming the 4.0mA point. Similarly the

same precautions apply. After completing the trim 20.0mA pressing

the Next key brings up the menu option.

RETURN TO OPERATE MODE ?

If all of the set-up and re-ranging operations have been satisfactorily

completed, then pressing ENTER will return the transmitter to

the normal operate mode. Pressing the NEXT key at this point

will return the display to the first screen in the sequence, SELECT

INPUT.

INPUT.

ENTER

TRIM 4mA

ENTER

ENTER

NEXT

SELECT

Note again, that whenever the transmitter is in the display set-up

mode, if no activation of the keyboard occurs for approximately

2-1/2 minutes, the transmitter returns to the operate mode. One

can also return to the operate mode at any point in the DISPLAY

MODE by removing power from the transmitter for about 30

MODE

seconds, then reapplying power.

DISPLAY

1919

19

1919

1919

19

1919

Page 22

DYNISCO SC170 Manual

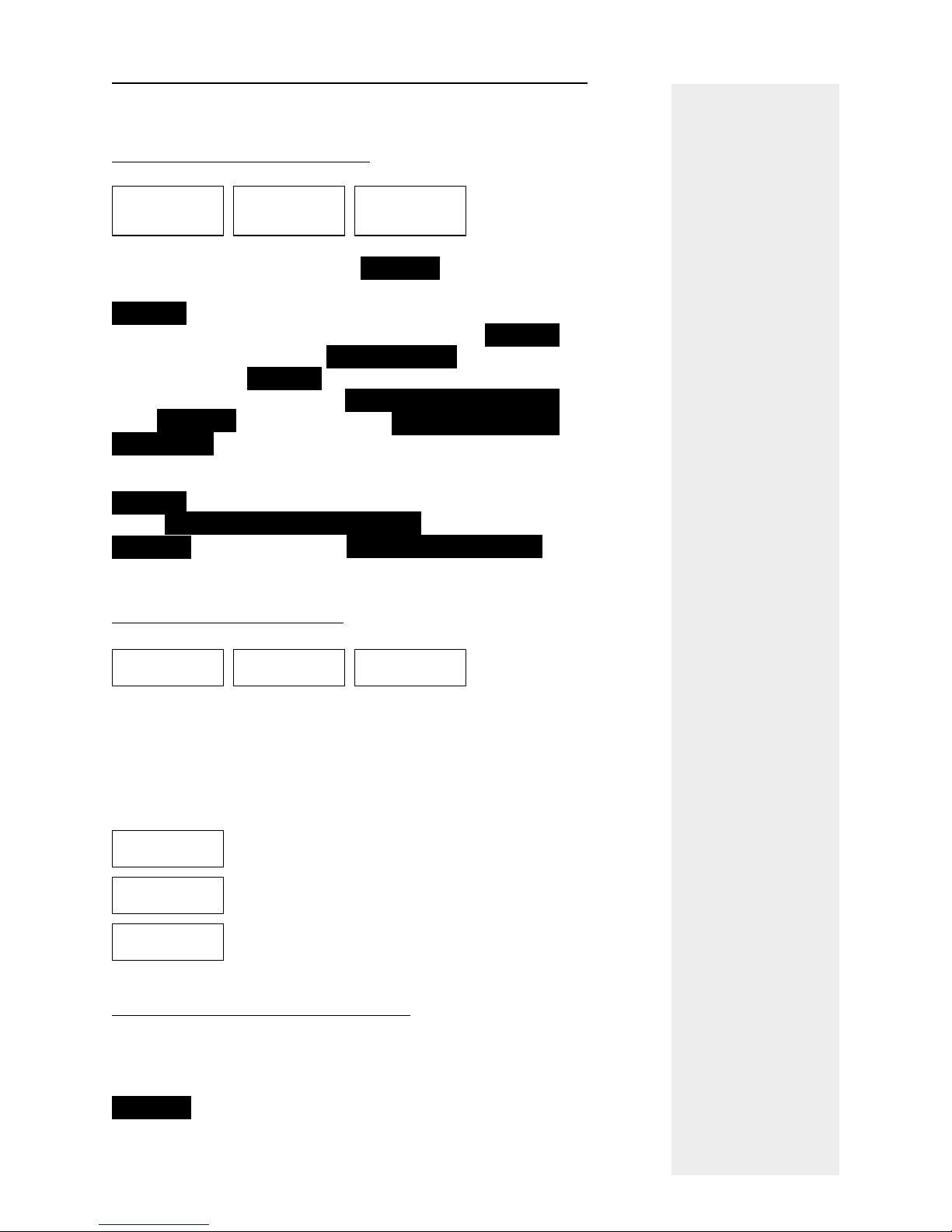

SC170 Programmable Signal Conditioner

DISPLAY Mode Configuration Setup Flowchart

ENTER

from

KEYPAD

Setup

2020

20

2020

2020

20

2020

Fig. 4-1 Dynisco SC170 Configuration Flowchart

LD-2 / KB-2

Page 23

DYNISCO SC170 Manual

5.0 ACCESSORIES & INFORMATION

Other accessories available from Dynisco are:

LD-2 Local Display

XP-HDC2-L Explosion/Weather proof Housing

(No Display Option)

XP-HDGC2-L Explosion/Weather proof Housing with

mounting lugs and glass window

PB-2 Pipe mount bracket (for 2" pipe)

PS-2412 Power Supply, 24/28 VDC, 1.2/0.8A

PS-2405 Power supply, 24 VDC, 0.5A

Fig. 5-1 Mechanical Dimensions

2121

21

2121

2121

21

2121

Page 24

DYNISCO SC170 Manual

6.0 SPECIFICATIONS

INPUT TYPE & RANGE:

DC Milliamp -5.0 to +60.0 mA

DC Millivolt -15.0 to +160 mV

DC Volt -0.5 to +10.0 V

Potentiometer, 3 wire 0.0 to 10.0 Kohm

Resistance, 2or 3 wire 0.0 to 10.0 Kohm

INPUT RESISTANCE:

DC Milliamp 2.75 Ohms

DC Millivolt >10M Ohms

DC Volt 1.0M Ohms

ISOLATION: 850 VDC or peak AC

LINEARIZATION:

Square, square root, log, and in to +/- 0.05% of input. Custom

linearization user programmable at 21 points. Two selected functions

and custom linearization can operate on the input signal.

OUTPUT: Analog, Two wire 4 to 20mA

MINIMUM OUTPUT RANGE: None

OUTPUT RANGING ADJUSTMENTS:

Analog Zero: 100% of sensor range, non-interlacing

Analog full scale: Normal or reverse acting

OUTPUT RESOLUTION:

Analog, 2.1 uA:

ACCURACY:

Includes repeatability, hysteresis, load and ambient temperature effect

and uncertainty of factory NIST traceable calibration equipment.

Enhanced accuracy calibrations available from the factory.

OUTPUT ACCURACY:

+/- 0.04% of the millivolt or ohm equivalent reading, or the

accuracy from the table below, whichever is greater.

Input type Accuracy

Milliamp +/-0.005mA

Millivolt +/-0.008mV

Volt +/-0.003V

Resistance +/-0.12ohm

2222

22

2222

2222

22

2222

TRANSMITTER REPEATABILITY:

One half of accuracy.

Page 25

DYNISCO SC170 Manual

REFERENCE CONDITION ACCURACY:

One half of the accuracy specified above. The transmitter is then

referenced to the prevailing conditions and transmitter accuracy at this

reference condition will include repeatability, linearity, and hysteresis

effects.

DYNAMIC RESPONSE:

Turn On Time: Less than 5 seconds after power up

Ambient Temperature Gradient: Automatic compensation to

20°C/Hour Change

Update Time: 0.15 second digital, 1.0 seconds

Response to Step Input: 0.25 Seconds, Typical

OPERATING TEMPERATURE RANGE:

-40°F to +167°F (-40°C to +75°C) Electronics

-4°F to +158°F (-20°C to +70°C) Display

STORAGE TEMPERATURE RANGE:

-58°F to +185°F (-50°C to +85°C)

AMBIENT TEMPERATURE STABILITY:

Self-correcting over the operating temperature range.

LONG TERM STABILITY:

Less than 0.05% of reading plus ±3.6A per year.

AUTOMATIC DIAGNOSTICS:

Every 3 seconds the SC170 signal conditioner performs self-checks for

zero, span, each open resistance lead, signal over the range condition

and signal conditioner malfunction.

FAILSAFE:

User settable 21mA, 3.9mA, or OFF

INTERCHANGEABILITY:

All units interchangeable without field calibration.

EMI/RFI IMMUNITY:

Less than 0.5% of reading (SAMA PMC 33.1c test method) 20KHz to

1000MHz, 10 V/meter.

COMMON MODE REJECTION:

120dB

REVERSE POLARITY PROTECTION:

42 VDC applied with either polarity

2323

23

2323

2323

23

2323

Page 26

DYNISCO SC170 Manual

POWER AND LOAD:

Supply voltage (no load resistance); 12 to 42VDC;

Supply voltage (with load resistance);

Vsupply=(12)+(Rload in Kohm) x (23mA)

Supply Voltage Effect: < +/-0.005% of Span per Volt

WEIGHT:

12 oz.

STANDARD CONFIGURATION:

Factory configured as a loop isolator for 4.0mA, to 20mA input.

Configurations can be user performed. Special configurations are

available to suit your requirements. See Price List.

OPTIONS:

LD-2 Local Displays.

PACKAGING:

The SC170 is packaged in rugged, nickel-plated aluminum enclosure

suitable for mounting on a flat surface. The metal enclosure is totally

sealed against moisture and provides excellent immunity to the effects

of electromagnetic interference (EMI/EFI). For hazardous

environments, the SC170 will fit within an available explosion proof

housing.

2424

24

2424

2424

24

2424

Page 27

DYNISCO SC170 Manual

NOTES

2525

25

2525

2525

25

2525

Page 28

NOTES

DYNISCO SC170 Manual

2626

26

2626

2626

26

2626

Page 29

DYNISCO SC170 Manual

SC Manual PN-974088

6/00 REV. A

DCN #22033

DYNISCO INSTRUMENTS

38 Forge Parkway

Franklin, MA 02038

Tel.: 508-541-9400

Fax: 508-541-9436

Loading...

Loading...