Page 1

OPERATING MANUAL

PT46XDN SeriesPT46XDN Series

PT46XDN SeriesPT46XDN Series

PT46XDN Series

DD

DD

D

evev

evev

ev

icic

icic

ic

eNeteNet

eNeteNet

eNet

M M

M M

M

eltelt

eltelt

elt

Pr Pr

Pr Pr

Pr

ee

ee

e

ss

ss

s

ss

ss

s

urur

urur

ur

e e

e e

e

TT

TT

T

rr

rr

r

anan

anan

an

smittsmitt

smittsmitt

smitt

erer

erer

er

ss

ss

s

P/N 974131

05/05 Rev. B

ECO # 29918

Page 2

OPERATING MANUAL

TT

TT

T

ABLEABLE

ABLEABLE

ABLE

OFOF

OFOF

OF

C C

C C

C

ONTENTSONTENTS

ONTENTSONTENTS

ONTENTS

ContentContent

ContentContent

Content

PagePage

PagePage

Page

IconIcon

IconIcon

Icon

1. General 3

2. Notes on Safety 9

3. Technical Data 10

4. Transport/Delivery 18

5. Installation 19

6. Configuration 23

7. DeviceNet Object Model 25

8. Maintenance 31

9. Accessories 33

10. Troubleshooting 34

11. CE-Declaration of Conformity 36

12. ODVA Cerficate of Conformity 37

13. Appendices 39

Page 3

3

GENERAL

1.1.

1.1.

1.

GG

GG

G

ENERALENERAL

ENERALENERAL

ENERAL

1.1 Important Information ............................................................................................................ 3

1.2 Copyright .............................................................................................................................. 3

1.3 Explanation of Icons .............................................................................................................. 3

1.4 Abbreviations ........................................................................................................................ 4

1.5 Overview .............................................................................................................................. 4

1.6 Transmitter Principle of Operation .......................................................................................... 4

1.7 DeviceNet Features ................................................................................................................ 5

1.7.1 Indicators ............................................................................................................................. 6

1.7.2 I/O Messaging ...................................................................................................................... 6

1.7.3 Interpreting the Output ...........................................................................................................7

1.7.4 Explicit Messaging ................................................................................................................ 8

1.11.1

1.11.1

1.1

II

II

I

MPORMPOR

MPORMPOR

MPOR

TT

TT

T

ANTANT

ANTANT

ANT

INFORMAINFORMA

INFORMAINFORMA

INFORMA

TIONTION

TIONTION

TION

This manual applies to the PT46XDN Series only. It must be kept near the equipment in a readily and

immediately accessible location at all times. The content of this manual must be read, understood and

followed in its entirety. This applies in particular to the notes on safety. Following the safety

instructions will help to prevent accidents, defects and malfunctions.

Models covered by this manual include the PT460DN, PT462DN and the TPT463DN.

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O will not be held liable for any injury, loss or damage resulting from failure to follow the

instructions in this manual.

If the product malfunctions, in spite of having followed the operating instructions, please contact the

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O customer service department (See the back of the manual for contact information). This

applies in particular during the warranty period.

1.21.2

1.21.2

1.2

CC

CC

C

OPYRIGHTOPYRIGHT

OPYRIGHTOPYRIGHT

OPYRIGHT

Copyright law requires that this manual be used for intended purposes only.

It is strictly forbidden to allow reproduction of any kind “in whole or in part” to persons outside of

Dynisco, without approval from Dynisco.

1.1.

1.1.

1.

33

33

3

EE

EE

E

XPLANAXPLANA

XPLANAXPLANA

XPLANA

TIONTION

TIONTION

TION

OFOF

OFOF

OF

ICIC

ICIC

IC

ONSONS

ONSONS

ONS

The manual uses icons to indicate information pertaining to safety:

Risk of destruction or damage to equipment, machines or installations

Page 4

4

GENERAL

General danger to life or limb

Specific danger to life or limb

You MUST do this

The safety instructions are provided again in the individual chapters of the manual.

1.41.4

1.41.4

1.4

AA

AA

A

BBREVIABBREVIA

BBREVIABBREVIA

BBREVIA

TIONSTIONS

TIONSTIONS

TIONS

The following abbreviations are used:

OM Operating Manual

PT Pressure Transmitter

f.s. of full scale

BFSL Best Fit Straight Line

1.1.

1.1.

1.

55

55

5

OO

OO

O

VERVIEWVERVIEW

VERVIEWVERVIEW

VERVIEW

The Dynisco PT46xDN is a full-featured, smart digital melt pressure transmitter, combining the reliability of

this industry-standard Dynisco pressure transducer with the added flexibility of DeviceNet digital

communications. The pressure sensing technology is the same as other Dynisco products, proven in such

rugged applications such as Polymer Melt Processing applications. The rugged construction is ideal for

harsh industrial environments.

The PT46xDN is easily integrated into any digital control system with a DeviceNet scanner. Continuous

pressure data is available in real-time at a minimum digital resolution of 0.01% of full scale (14 bits).

Monitoring and configuration of the PT46xDN is accomplished via the DeviceNet network using commerciallyavailable DeviceNet programming software.

The PT46xDN effectively combines the features of a melt pressure transducer, power regulator, alarm

monitor, and DeviceNet digital signal conditioner into a single, cost-effective package. Wiring the PT46xDN

transmitter is simple and fast by virtue of a standard DeviceNet 5 pin Micro-connector. The PT46xDN is

powered directly by the DeviceNet bus eliminating the need for a separate power supply. Multiple DeviceNet

Pressure Transmitters can be added to a network using a single DeviceNet Master scanner, making this

approach very attractive when an application calls for multiple pressure transmitters.

1.61.6

1.61.6

1.6

TT

TT

T

RANSRANS

RANSRANS

RANS

MITMIT

MITMIT

MIT

TERTER

TERTER

TER

P P

P P

P

RINCIPLERINCIPLE

RINCIPLERINCIPLE

RINCIPLE

OFOF

OFOF

OF

O O

O O

O

PERAPERA

PERAPERA

PERA

TIONTION

TIONTION

TION

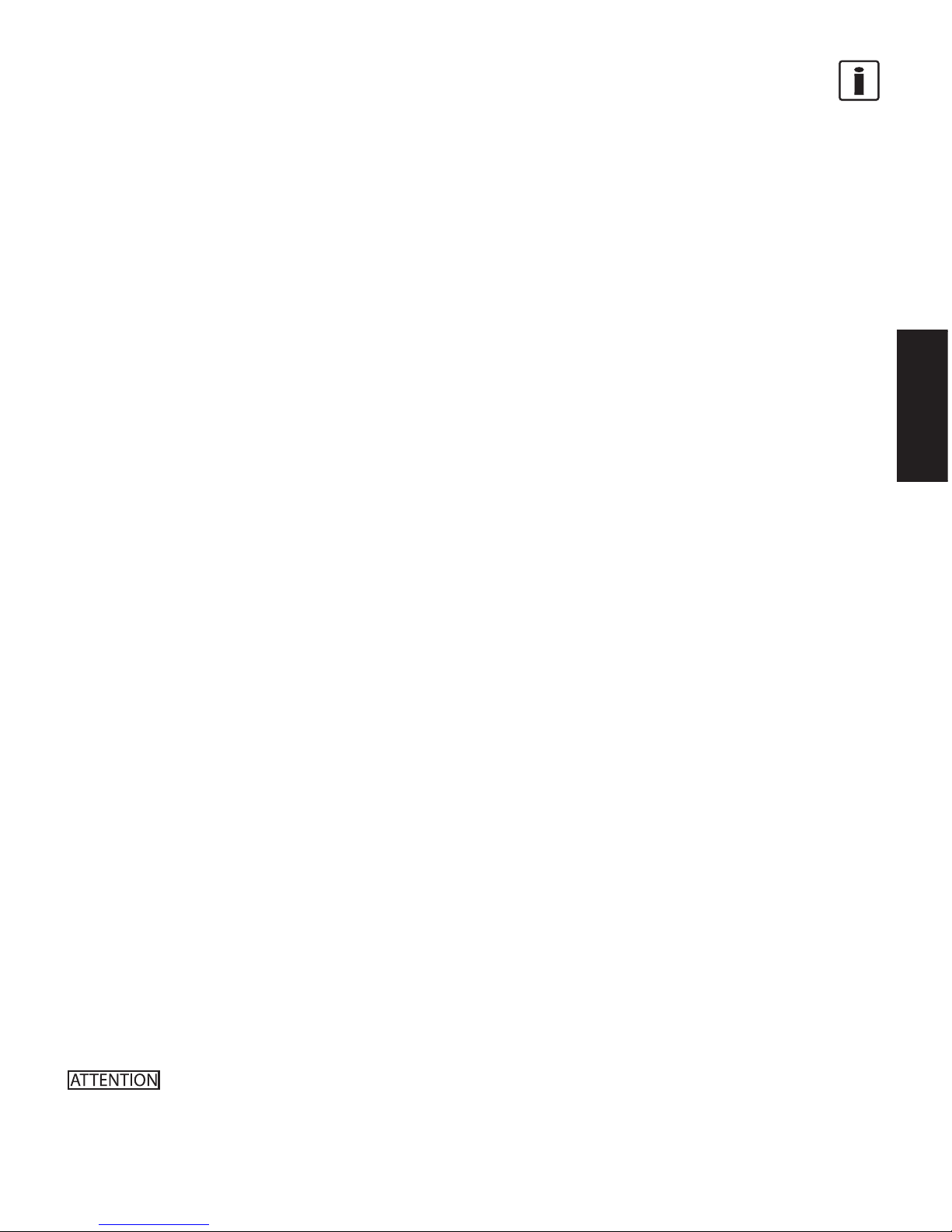

The mechanical system (filled assembly) consists of a lower diaphragm, a filled capillary tube, and an

upper diaphragm with a strain gage. The filled assembly transmits pressure from the process to the strain

gage diaphragm where it is converted to a digital signal. The filled assembly isolates the electronics from

Page 5

5

GENERAL

the high process temperatures.

The lower diaphragm is the surface in contact with the media being measured. This diaphragm can be

made from a choice of materials. The standard material is heat-treated 15-5 stainless steel with DyMaxTM

coating. This has average corrosion and excellent abrasion resistance and is similar to 17-4 stainless

steel. Other materials are also available such as Hastelloy C-276 which has excellent corrosion resistant

properties (but is not good for abrasion). For other materials please consult the factory.

Behind the lower diaphragm is a capillary tube filled to the upper diaphragm. As the process pressure

deflects the lower diaphragm, the fill is displaced through the capillary tube to deflect the upper

diaphragm.

The upper diaphragm has a strain gage element in the configuration of a Wheatstone Bridge. The

deflection of the upper diaphragm causes a change in the resistance of the strain gage and hence a

change in the balance of the bridge. The amount of imbalance is directly proportional to the applied

pressure. This completes the translation of pressure applied to the lower diaphragm into a usable

electrical signal.

Fig. 1-1Fig. 1-1

Fig. 1-1Fig. 1-1

Fig. 1-1

Functioning Principle of the Dynisco Filled AssemblyFunctioning Principle of the Dynisco Filled Assembly

Functioning Principle of the Dynisco Filled AssemblyFunctioning Principle of the Dynisco Filled Assembly

Functioning Principle of the Dynisco Filled Assembly

The low level output signal from the bridge is amplified via an instrumentation amp circuit. The amplified

signal then goes to the input of the analog-to-digital (A/D) converter.

1.1.

1.1.

1.

77

77

7

DD

DD

D

EVICEVIC

EVICEVIC

EVIC

EE

EE

E

NN

NN

N

ETET

ETET

ET

F F

F F

F

EAEA

EAEA

EA

TURETURE

TURETURE

TURE

SS

SS

S

The PT4xxDN utilizes the DeviceNet Predefined Master Slave Connection Set operating as a Group 2 Only

Server. The PT4xxDN supports baud rates of 125K, 250k, and 500k. The node address can be set to any

address between 0 and 63. The default baud rate and node address are 125k and 63, respectively.

Pressure, alarm, and status data are available via polled I/O messages. Alarm, Warning and Scaling

parameters are configured using Explicit messages.

Filling opening

Strain gage

on the

measuring

diaphragm

Capillary with pressure

transmission fluid (Hg)

Total filling

volume = 7mm

3

Separating

diaphragm

0.15mm thick

Base of electronics housing

Page 6

6

GENERAL

1.1.

1.1.

1.

77

77

7

.1.1

.1.1

.1

II

II

I

NDICANDICA

NDICANDICA

NDICA

TT

TT

T

ORSORS

ORSORS

ORS

The PT46xDN utilizes 2 bi-color status indicators (i.e. LED’s) to report Network and Module/Device

status.

1.1.

1.1.

1.

77

77

7

.1.1

.1.1

.1

AA

AA

A

NN

NN

N

ETET

ETET

ET

WW

WW

W

ORKORK

ORKORK

ORK

SS

SS

S

TT

TT

T

AA

AA

A

TUSTUS

TUSTUS

TUS

I I

I I

I

NDICANDICA

NDICANDICA

NDICA

TT

TT

T

OROR

OROR

OR

(“A”) (“A”)

(“A”) (“A”)

(“A”)

OO

OO

O

ff:ff:

ff:ff:

ff: Transmitter is not on-line. Duplicate MAC ID check has not been completed.

GrGr

GrGr

Gr

een:een:

een:een:

een: Transmitter is on-line and is allocated to a Master.

FlFl

FlFl

Fl

aa

aa

a

shinshin

shinshin

shin

g Grg Gr

g Grg Gr

g Gr

een:een:

een:een:

een: Transmitter is on-line and has passed Duplicate MAC ID check, but is not allocated to a

Master.

Red: Red:

Red: Red:

Red: Communications Failure. Check for Duplicate MAC ID or incompatible baud rate.

Flashing Red:Flashing Red:

Flashing Red:Flashing Red:

Flashing Red: Connection timed-out.

1.1.

1.1.

1.

77

77

7

.1.1

.1.1

.1

BB

BB

B

DD

DD

D

EVICEVIC

EVICEVIC

EVIC

EE

EE

E

SS

SS

S

TT

TT

T

AA

AA

A

TUSTUS

TUSTUS

TUS

I I

I I

I

NDICANDICA

NDICANDICA

NDICA

TT

TT

T

OROR

OROR

OR

(“B”) (“B”)

(“B”) (“B”)

(“B”)

OffOff

OffOff

Off: Power is off.

GrGr

GrGr

Gr

eeneen

eeneen

een: Transmitter is operating in a normal condition.

FlFl

FlFl

Fl

aa

aa

a

shinshin

shinshin

shin

g Grg Gr

g Grg Gr

g Gr

eeneen

eeneen

een: Transmitter requires baud or address configuration.

RedRed

RedRed

Red: Open Gage or electronics fault condition. If possible, check the I/O status message for fault

condition.

1.1.

1.1.

1.

77

77

7

.2.2

.2.2

.2

I/O MI/O M

I/O MI/O M

I/O M

ESSAGINGESSAGING

ESSAGINGESSAGING

ESSAGING

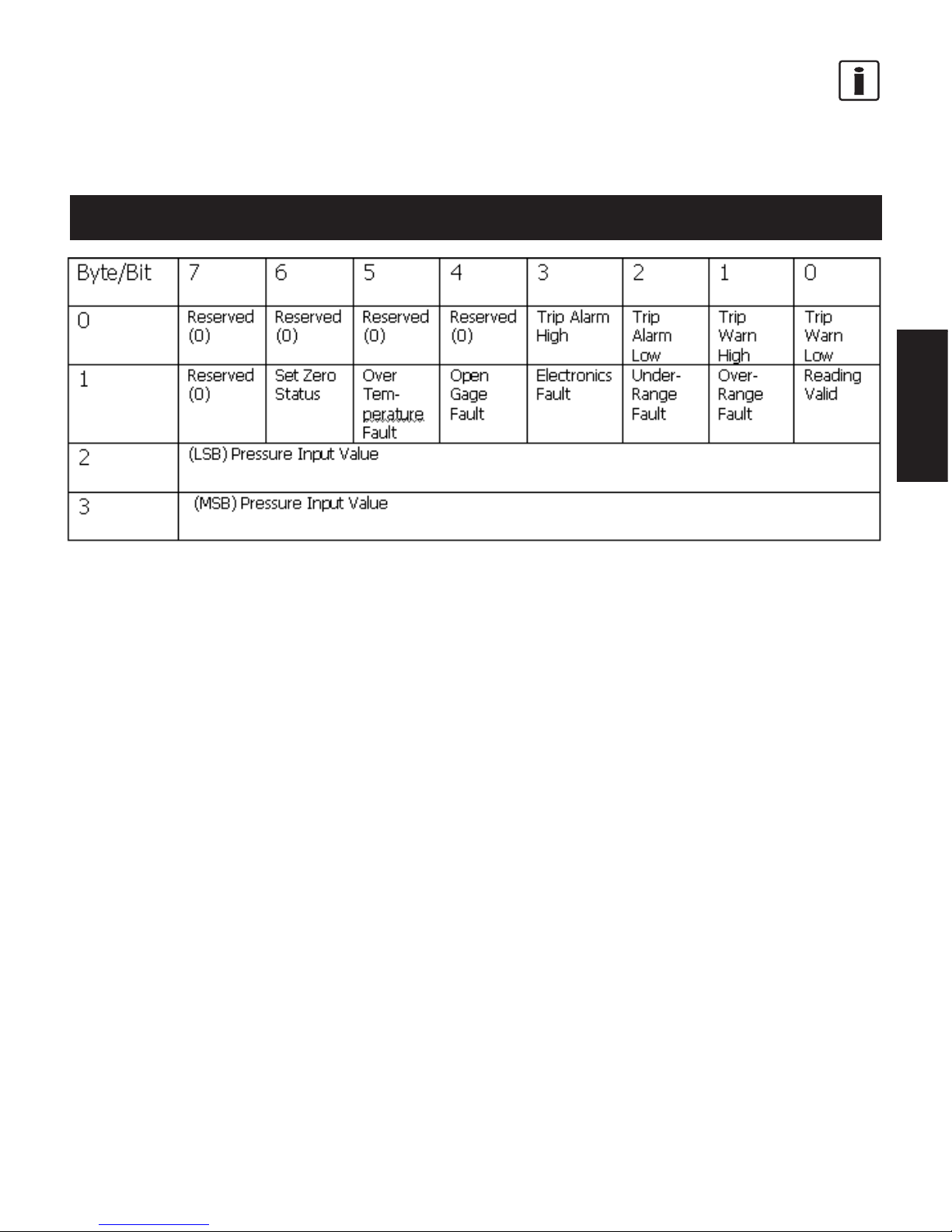

The PT46xDN Transmitter supports Polled I/O Messaging to read “real-time” data. It does not support

Cyclic I/O, Change of State (COS), or Bit-Strobe connections. The control system Master must be configured

first 8-bit word (Byte 0) of the I/O Message Response as shown in Table 1. Note that the most significant

4 bits of the first byte are reserved for future use. The next 8-bit word (Byte 1) supplies transmitter status

information, e.g. reading valid, electronics fault, etc. Further information on alarm and status bits is

available in Section 7.4. The remaining 2 8-bit words (Bytes 2 & 3) represent the Pressure Value (PV).

"B" Module Status

"A" Network Status

Page 7

7

GENERAL

Refer to Section 1.7.3 for additional information in interpreting the pressure data reported in the I/O

message.

Fig. 1-1Fig. 1-1

Fig. 1-1Fig. 1-1

Fig. 1-1

DeviceNet Message Format for I/O MessagingDeviceNet Message Format for I/O Messaging

DeviceNet Message Format for I/O MessagingDeviceNet Message Format for I/O Messaging

DeviceNet Message Format for I/O Messaging

1.1.

1.1.

1.

77

77

7

..

..

.

33

33

3

II

II

I

NTERPRETINGNTERPRETING

NTERPRETINGNTERPRETING

NTERPRETING

THETHE

THETHE

THE

O O

O O

O

UTPUTUTPUT

UTPUTUTPUT

UTPUT

When reading the PV, it is important to understand how the value is scaled by the Engineering Units

parameter and the Unity Gain Reference (UGR) parameter.

The PV can be scaled to a variety of engineering units, e.g. counts, psi, bar, etc., by setting the Data Units

parameter to the appropriate value as listed in Attribute #02 of Section 7.4.

When reporting the PV in any engineering unit other than counts, a decimal scale factor called the Unity

Gain Reference (UGR) is used to convert PV to “real world” pressure. By employing the UGR, the I/O data

is presented in a more efficient integer format rather than a floating point. The UGR is factory-set and

cannot be changed.

To compute the actual pressure, the control system must simply divide the PV by the UGR (

Pressure = PV /

UGR

).

ExEx

ExEx

Ex

ampamp

ampamp

amp

ll

ll

l

e (e (

e (e (

e (

500-p500-p

500-p500-p

500-p

ss

ss

s

i Pi P

i Pi P

i P

T4T4

T4T4

T4

60DN 60DN

60DN 60DN

60DN

TT

TT

T

rr

rr

r

anan

anan

an

smittsmitt

smittsmitt

smitt

er):er):

er):er):

er):

A DeviceNet Master reads the PV via an I/O message and the UGR and Data Units via an explicitA DeviceNet Master reads the PV via an I/O message and the UGR and Data Units via an explicit

A DeviceNet Master reads the PV via an I/O message and the UGR and Data Units via an explicitA DeviceNet Master reads the PV via an I/O message and the UGR and Data Units via an explicit

A DeviceNet Master reads the PV via an I/O message and the UGR and Data Units via an explicit

message as follows:message as follows:

message as follows:message as follows:

message as follows:

PV = 3852PV = 3852

PV = 3852PV = 3852

PV = 3852

UGR = 10UGR = 10

UGR = 10UGR = 10

UGR = 10

Data Units = 4864 (PSI)Data Units = 4864 (PSI)

Data Units = 4864 (PSI)Data Units = 4864 (PSI)

Data Units = 4864 (PSI)

Page 8

8

GENERAL

The control system must compute the actual pressure as follows:The control system must compute the actual pressure as follows:

The control system must compute the actual pressure as follows:The control system must compute the actual pressure as follows:

The control system must compute the actual pressure as follows:

Pressure = 3852/10 = 385.2 psi.Pressure = 3852/10 = 385.2 psi.

Pressure = 3852/10 = 385.2 psi.Pressure = 3852/10 = 385.2 psi.

Pressure = 3852/10 = 385.2 psi.

1.1.

1.1.

1.

77

77

7

.4.4

.4.4

.4

EE

EE

E

XPLICITXPLICIT

XPLICITXPLICIT

XPLICIT

M M

M M

M

ESSAGINGESSAGING

ESSAGINGESSAGING

ESSAGING

The PT46xDN Transmitter supports explicit messaging for setup and configuration. Any DeviceNet

master that supports explicit messaging can be used in conjunction with the EDS file supplied with the

PT46xDN to configure it. Refer to Section 6.4 for a description of configurable parameters.

Page 9

9

SAFETY

2.2.

2.2.

2.

NN

NN

N

OTESOTES

OTESOTES

OTES

ONON

ONON

ON

SAFETYSAFETY

SAFETYSAFETY

SAFETY

The operator or owner of the larger overall system is responsible for following the safety

and accident prevention regulations that apply to the specific application.

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O will not be held liable for any injury, loss or damage resulting from failure to

follow the instructions in this manual.

TT

TT

T

oo

oo

o

xx

xx

x

icic

icic

ic

Haz Haz

Haz Haz

Haz

arar

arar

ar

d!d!

d!d!

d!

The PT46XDN may contain a very small amount of mercury (Hg) 0.00322 in³ typically with a

6/18 configuration, as its transmission medium. If the diaphragm is damaged, mercury

mayescape. Never transport or store the PT46XDN without the protective cap. Remove the

cap shortly before installation.

If mercury is inhaled or swallowed, seek medical attention immediately!If mercury is inhaled or swallowed, seek medical attention immediately!

If mercury is inhaled or swallowed, seek medical attention immediately!If mercury is inhaled or swallowed, seek medical attention immediately!

If mercury is inhaled or swallowed, seek medical attention immediately!

Mercury is hazardous waste and must be disposed of in accordance with applicable laws.

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O will accept defective PT’s. If mercury escapes, use airtight packaging!

TT

TT

T

emperemper

emperemper

emper

atat

atat

at

urur

urur

ur

ee

ee

e

The PT46XDN series of pressure transmitters can be used in media temperatures up to 400°C. If the

pressure transmitter is used in other applications, the safety and accident prevention regulations

specific to that application must be followed. Maximum ambient temperature for the electronics

housing is +85°C (185°F).

Higher temperature can result in damage and malfunction. Do not install the pressure transmitter in

places where this temperature is exceeded.

Page 10

10

TECHNICAL DATA

X PT46 X DN-X-X-X/XX-XXXX

Optional Temperature Sensor

0.5% Combined Error

Snout/Capillary Configuration Descriptor

DeviceNet Output

Optional Process Connections

Pressure Range

Rigid Snout (Stem)

Rigid or Flexible Capillary

Option Code

3.3.

3.3.

3.

TT

TT

T

EE

EE

E

CHNICALCHNICAL

CHNICALCHNICAL

CHNICAL

D D

D D

D

AA

AA

A

TT

TT

T

AA

AA

A

3.1 Ordering Guide for PT46XDN ................................................................................................. 10

3.2 Ordering Example ................................................................................................................ 10

3.3 Ordering Information ............................................................................................................ 10

3.4 Configuration and Temperature Option .................................................................................. 11

3.5 Process Connections ............................................................................................................ 11

3.6 Pressure Range - Full Scale................................................................................................... 12

3.7 Rigid Stem & Rigid or Flexible Capillary .................................................................................. 12

3.8 Option Codes ....................................................................................................................... 12

3.9 Output ................................................................................................................................. 12

3.10 DeviceNet Conformance .......................................................................................................13

3.11 Digital Resolution .................................................................................................................13

3.12 DeviceNet Specifications ...................................................................................................... 13

3.13 Engineering Units.................................................................................................................14

3.14 Sensor Diagnostics .............................................................................................................. 14

3.15 Performance Characteristics ................................................................................................. 14

3.15.1 Combined Error (Accuracy) .................................................................................................... 14

3.15.2 Repeatability ....................................................................................................................... 14

3.15.3 Max. Pressure (without Influencing Operating Data) .............................................................. 15

3.15.4 Burst Pressure ..................................................................................................................... 15

3.15.5 Humidity .............................................................................................................................. 15

3.16 Electrical Termination ........................................................................................................... 15

3.17 Temperature Influence ......................................................................................................... 15

3.18 Materials ............................................................................................................................. 15

3.19 Torque ................................................................................................................................. 16

3.20 Weight ................................................................................................................................16

3.21 Dimensions.......................................................................................................................... 16

3.13.1

3.13.1

3.1

OO

OO

O

RDERINGRDERING

RDERINGRDERING

RDERING

G G

G G

G

UIDEUIDE

UIDEUIDE

UIDE

FORFOR

FORFOR

FOR

PT46XDN PT46XDN

PT46XDN PT46XDN

PT46XDN

The exact meanings of the letter/digit combinations are given in the corresponding sections of

Chapter 3.

Page 11

11

TECHNICAL DATA

3.23.2

3.23.2

3.2

OO

OO

O

RDERINGRDERING

RDERINGRDERING

RDERING

E E

E E

E

XAMPLESXAMPLES

XAMPLESXAMPLES

XAMPLES

T PT46 3 DN-M18-5M-6/18-B628

Optional J Type Thermocouple

0.5% Combined Error

Thermocouple Version

DeviceNet Output

M18 Process Connections

5000 psi

6” Rigid Snout (Stem)

18” Flexible Capillary

NaK Filled

3.3.

3.3.

3.

33

33

3

OO

OO

O

RDERINGRDERING

RDERINGRDERING

RDERING

I I

I I

I

NFORMANFORMA

NFORMANFORMA

NFORMA

TIONTION

TIONTION

TION

XPT46XDN-X-X-X/XX-XXXX

3.43.4

3.43.4

3.4

CC

CC

C

ONFIGURAONFIGURA

ONFIGURAONFIGURA

ONFIGURA

TIONTION

TIONTION

TION

ANDAND

ANDAND

AND

TT

TT

T

EMPERAEMPERA

EMPERAEMPERA

EMPERA

TURETURE

TURETURE

TURE

O O

O O

O

PP

PP

P

TIONTION

TIONTION

TION

XX

XX

XPT46

XX

XX

XDN-X-X-X/XX-XXXX

Blank, 0 = No Temperature Sensor, Rigid Snout with No Capillary

Blank, 2 = No Temperature Sensor, Rigid Snout with Capillary

T, 3 = Temperature Sensor, Rigid Snout with Capillary

3.3.

3.3.

3.

55

55

5

PP

PP

P

ROCESSROCESS

ROCESSROCESS

ROCESS

C C

C C

C

ONNECTIONSONNECTIONS

ONNECTIONSONNECTIONS

ONNECTIONS

XPT46XDN-

XX

XX

X-X-X/XX-XXXX

Blank = 1/2-20 UNF

M18 = M18 x 1.5 Thread

Other process connections are available. Please consult factory

Page 12

12

TECHNICAL DATA

3.63.6

3.63.6

3.6

PP

PP

P

RESSURERESSURE

RESSURERESSURE

RESSURE

R R

R R

R

ANGEANGE

ANGEANGE

ANGE

- F - F

- F - F

- F

ULLULL

ULLULL

ULL

S S

S S

S

CALECALE

CALECALE

CALE

XPT46XDN-X-

XX

XX

X-X/XX-XXXX

psipsi

psipsi

psi

OrderOrder

OrderOrder

Order

BarBar

BarBar

Bar

OrderOrder

OrderOrder

Order

CodeCode

CodeCode

Code

CodeCode

CodeCode

Code

250 2.5C 17.5 17.5B (M18 only)

500 5C 35 35B

750 7.5C 50 50B

1000 1M 70 70B

1500 1.5M 100 1CB

3000 3M 200 2CB

5000 5M 350 3.5CB

7500 7.5M 500 5CB

10000 10M 700 7CB

15000 15M 1000 1MB

20000 20M 1400 1.4MB

30000 30M 2000 2MB

Other ranges and pressure configurations are available, please consult factory.

3.3.

3.3.

3.

77

77

7

RR

RR

R

IGIDIGID

IGIDIGID

IGID

STEMSTEM

STEMSTEM

STEM

& R & R

& R & R

& R

IGIDIGID

IGIDIGID

IGID

OROR

OROR

OR

C C

C C

C

APILLARYAPILLARY

APILLARYAPILLARY

APILLARY

XPT46XDN-X-X-

X/XXX/XX

X/XXX/XX

X/XX-XXXX

6 = 6” Rigid Stem/0” Flexible Capillary

6/18 = 6” Rigid Stem/18” Flexible Capillary

6/30 = 6” Rigid Stem/30” Flexible Capillary

12/18 = 12” Rigid Stem/18” Flexible Capillary

12/30 = 12” Rigid Stem/30” Flexible Capillary

Other lengths and configurations are available, please consult factory.

3.83.8

3.83.8

3.8

OO

OO

O

PTIONPTION

PTIONPTION

PTION

C C

C C

C

ODESODES

ODESODES

ODES

XPT46XDN-X-X-X/XX-

XXXXXXXX

XXXXXXXX

XXXX

Please consult factory for list of approved options.

3.3.

3.3.

3.

99

99

9

OO

OO

O

UTPUTUTPUT

UTPUTUTPUT

UTPUT

DeviceNet

Page 13

13

TECHNICAL DATA

3.103.10

3.103.10

3.10

DD

DD

D

EVICEEVICE

EVICEEVICE

EVICE

NN

NN

N

ETET

ETET

ET

C C

C C

C

ONFORMANCEONFORMANCE

ONFORMANCEONFORMANCE

ONFORMANCE

Conformance-Tested by ODVA Independent Test Lab (CIP protocol test, EDS test, physical layer test &

system interpretability test).

3.113.11

3.113.11

3.11

DD

DD

D

IGITIGIT

IGITIGIT

IGIT

ALAL

ALAL

AL

R R

R R

R

EE

EE

E

SOLSOL

SOLSOL

SOL

UTIONUTION

UTIONUTION

UTION

Pressure Operating 14 bits minimum (±0.01% FS or 16 ppm) typically ,

Range Resolution full scale = ~20,000 counts

3.123.12

3.123.12

3.12

DD

DD

D

EVICEVIC

EVICEVIC

EVIC

EE

EE

E

NN

NN

N

ETET

ETET

ET

SS

SS

S

PEPE

PEPE

PE

CIFICACIFICA

CIFICACIFICA

CIFICA

TIONSTIONS

TIONSTIONS

TIONS

Digital Communication Protocol DeviceNet Version 2.0, ~Errata 5

ODVA Vendor ID 852 (Dynisco Instruments)

Device Profile Generic Device 00

hex

(Refer to 1C

hex

Vacuum/

Pressure Gauge Device in DN spec. Vol. 2, 3-26 as a

guideline)

Network Power Consumption Maximum 30 mA @ 24 Vdc

Connector Style Sealed 5-pin Micro (IEC-60947-5-2)

Isolated Physical Later Non-isolated per DN spec 9-2

LED Support 2 bi-color LED’s (module and network status per

Device Net spec 8-2.)

MAC ID Setting Software selectable only. Default id = 63.

Communication Rate Setting Software selectable

Communication Rates Supported 125k (default), 250k and 500k bits/sec

Predefined Master/Slave Group only 2 server (Slave)

Connection Set

Message Types Supported Polled/Explicit

Dynamic Connections Supported (UCMM) No

Fragmented Explicit Messaging Implemented Yes

Page 14

14

TECHNICAL DATA

Alarm Setpoints 2 High and 2 Low user-setable alarm points.

Configured and transmitted via DeviceNet protocol.

Include user-defined hysteresis band.

3.133.13

3.133.13

3.13

EE

EE

E

NGINEERINGNGINEERING

NGINEERINGNGINEERING

NGINEERING

U U

U U

U

NITSNITS

NITSNITS

NITS

Counts Analog to Digital Counts o to 20000 typical

PSI pounds-force per square inch 14.503774*bar

BAR bar (Full Scale Bar)/(Full Scale Counts)*Counts

kgf/cm

2

kilogram-force per square centimeter 1.0197162*bar

MPa MegaPascal 0.1*bar

% Full Scale Percent full scale 0 to 100

3.143.14

3.143.14

3.14

SS

SS

S

ENSORENSOR

ENSORENSOR

ENSOR

D D

D D

D

IAGNOSTICSIAGNOSTICS

IAGNOSTICSIAGNOSTICS

IAGNOSTICS

Overrange Notification Yes

CPU Watchdog Error Yes

EEPROM Failure Yes

Open Gauge Detection Yes

Electronics Temperature Detection Yes

3.153.15

3.153.15

3.15

PP

PP

P

ERFORMANCEERFORMANCE

ERFORMANCEERFORMANCE

ERFORMANCE

CHARACTERISTICSCHARACTERISTICS

CHARACTERISTICSCHARACTERISTICS

CHARACTERISTICS

3.15.13.15.1

3.15.13.15.1

3.15.1

CC

CC

C

OMBINEDOMBINED

OMBINEDOMBINED

OMBINED

E E

E E

E

RRORRROR

RRORRROR

RROR

(A (A

(A (A

(A

CC

CC

C

CC

CC

C

URAURA

URAURA

URA

CYCY

CYCY

CY

))

))

)

Combined error is also known as accuracy which includes linearity, hysteresis and repeatability, and is

determined by BFSL (Best Fit Straight Line).

±0.5% of full scale

±0.75% of full scale for transmitters with ranges of 1000 psi and less with lengths greater than 36”.

3.15.23.15.2

3.15.23.15.2

3.15.2

RR

RR

R

EPEAEPEA

EPEAEPEA

EPEA

TT

TT

T

ABILITABILIT

ABILITABILIT

ABILIT

YY

YY

Y

±0.20% of full scale

Page 15

15

TECHNICAL DATA

3.15.3.15.

3.15.3.15.

3.15.

33

33

3

MM

MM

M

AXAX

AXAX

AX

. P. P

. P. P

. P

RERE

RERE

RE

SS

SS

S

SURESURE

SURESURE

SURE

( (

( (

(

WITHOUTWITHOUT

WITHOUTWITHOUT

WITHOUT

INFLINFL

INFLINFL

INFL

UENCINGUENCING

UENCINGUENCING

UENCING

OPERAOPERA

OPERAOPERA

OPERA

TINGTING

TINGTING

TING

DD

DD

D

AA

AA

A

TT

TT

T

AA

AA

A

))

))

)

2 x full scale pressure or 35,000 psi, which ever is less.

3.15.43.15.4

3.15.43.15.4

3.15.4

BB

BB

B

URSTURST

URSTURST

URST

PRESSUREPRESSURE

PRESSUREPRESSURE

PRESSURE

6 x nominal value, max. 45,000 psi

3.15.3.15.

3.15.3.15.

3.15.

55

55

5

HH

HH

H

UMIDITYUMIDITY

UMIDITYUMIDITY

UMIDITY

0 - 90% relative humidity (non-condensing)

3.163.16

3.163.16

3.16

EE

EE

E

LELE

LELE

LE

CTRICALCTRICAL

CTRICALCTRICAL

CTRICAL

TT

TT

T

ERMINAERMINA

ERMINAERMINA

ERMINA

TIONTION

TIONTION

TION

DeviceNet Micro (5 pin)

3.173.17

3.173.17

3.17

TT

TT

T

EMPERAEMPERA

EMPERAEMPERA

EMPERA

TURETURE

TURETURE

TURE

INFLINFL

INFLINFL

INFL

UENCUENC

UENCUENC

UENC

EE

EE

E

EE

EE

E

LECTRONICSLECTRONICS

LECTRONICSLECTRONICS

LECTRONICS

H H

H H

H

OUSINGOUSING

OUSINGOUSING

OUSING

Housing Temperature Range -20°C to +85°C (-5°F to +185°F)

Zero shift due to temperature change on electronics housing

PT46XDN 0.01% full scale/°F max. (0.02% f.s./°C max.)

Diaphragm (in contact with media) span shift due to temperature change on electronics housing.

PT46XDN 0.01% full scale /°F max.(0.02% f.s./°C max.)

Zero shift due to temperature change on the diaphragm.

PT46XDN 15 psi/100°F typical (27 psi/100°C)

3.183.18

3.183.18

3.18

MM

MM

M

AA

AA

A

TERIALSTERIALS

TERIALSTERIALS

TERIALS

Standard Diaphragm 15-5PH Mat. No. 1.4545 Various proprietary coatings

Standard Stem(Snout) 17-4PH Mat. No. 517400

Please note other diaphragm and stem materials may be substituted.

Page 16

16

TECHNICAL DATA

3.193.19

3.193.19

3.19

TT

TT

T

ORQUEORQUE

ORQUEORQUE

ORQUE

FORFOR

FORFOR

FOR

1/2-20 UNF P 1/2-20 UNF P

1/2-20 UNF P 1/2-20 UNF P

1/2-20 UNF P

ROCESSROCESS

ROCESSROCESS

ROCESS

C C

C C

C

ONNECTIONONNECTION

ONNECTIONONNECTION

ONNECTION

PT46XDN

max. 56.5 Nm

(500 inch-lbs.)

min. 11.3 Nm

(100 inch-lbs.)

3.203.20

3.203.20

3.20

WW

WW

W

EIGHTEIGHT

EIGHTEIGHT

EIGHT

The weight varies depending on product configuration. Average weight range is 1 to 5 pounds.

3.213.21

3.213.21

3.21

DD

DD

D

IMENSIONSIMENSIONS

IMENSIONSIMENSIONS

IMENSIONS

Page 17

17

TECHNICAL DATA

Fig. 3-1Fig. 3-1

Fig. 3-1Fig. 3-1

Fig. 3-1

PT46XDNPT46XDN

PT46XDNPT46XDN

PT46XDN

1

23

4

5

CONNECTOR PINOUT

PIN FUNCTION WIRE

1 DRAIN BA RE

2V+RED

3V-BLACK

4CAN_HWHITE

5CAN_LBLUE

(114.3mm)

1/2-20 UNF-2A

5/8 HEX

.44

11.2mm

1.06

26.8mm

.50

12.7mm

O

45° 30'

44° 30'

.307

.305

7.8mm

7.75mm

O

.414

.412

10.52mm

10.46mm

O

.214

5.44mm

RIGID SNOUT LENGTH

u

.06 (1.5mm)

.55

14mm

REF

3.75

95.25mm

4.50 + RIGID SNOUT LENGTH

u

.25 (6.35mm)

DIAGNOSTIC LED (2)

M12 MICRO

5 PIN CONNECTOR

1.50

38.1mm

O

DIAGNOSTIC LED (2)

M12 MICRO

5 PIN CONNECTOR

6.88 + FLEX LENGTH + RIGID SNOUT LENG TH

u

.25 (6.35mm)

(174.8mm)

3.750

95.3mm

.55

14mm

REF

1.50

38.1mm

SST ARMORED CABLE

.414

.412

10.52mm

10.46mm

O

.307

.305

7.8mm

7.75mm

O

45° 30'

44° 30'

.214

5.43mm

RIGID SNOUT LEN GTH

u

.06 (1.5mm)

.50

12.7mm

O

FLEX LENGTH

u

.12 (3.1mm)

.69

17.5mm

O

5/8 HEX

.42

10.7mm

O

1.25

31.8mm

1.06

27mm

1/2-20 UNF-2A

.44

11.1mm

DIAGNOSTIC LED (2)

3.75

95.3mm

.55

14mm

REF

1.50

38.1mm

Ø.307

.305

(7.8mm)

( 7.75mm)

.414

.412

10.5mm

10.5mm

O

SST ARMORED CABLE

SST ARMORED CABLE

T/C FLEX LENGTH

u

.12 (3.1mm)

+

-

+

-

2-PRONG

STANDARD

FEMALE CONN

STANDARD

MALE CONN

THERMOCOUPLE

CABLE CLAMP

45° 30'

44° 30'

.214

5.44mm

RIGID SNOUT LENGTH

u

.06 (1.5mm)

.42

10.7mm

O

1.06

26.8mm

.44

11.23mm

1/2-20 UNF-2A

.50

12.7mm

O

SET SCREW

1.25

31.8mm

O

7/8 HEX

UNIT FLEX LENGTH

u

.12 (3.1mm )

.69

17.5mm

O

M12 MICRO

5 PIN CONNECTOR

6.90 + UNIT FLEX LENGTH + RIGID SNOUT LENGTH

u

.25 (6.35mm)

(175.3mm)

Page 18

18

TRANSPORT

4.4.

4.4.

4.

TT

TT

T

RANSPORTRANSPORT

RANSPORTRANSPORT

RANSPORT

/D/D

/D/D

/D

ELIVERYELIVERY

ELIVERYELIVERY

ELIVERY

4.1 Transport/Packing/Transport Damage ...................................................................................18

4.2 Storage ............................................................................................................................... 18

4.3 Scope of Delivery ................................................................................................................. 18

TT

TT

T

oo

oo

o

xx

xx

x

icic

icic

ic

h h

h h

h

azaz

azaz

az

arar

arar

ar

d!d!

d!d!

d!

The PT contains a small amount of mercury (Hg) as its transmission medium. If the

diaphragm is damaged, mercury may escape.

Never transport or store the PT without the protective shell bolted in place. Remove the shell

shortly before installation.

If mercury is inhaled or swallowed, seek medical attention immediately.If mercury is inhaled or swallowed, seek medical attention immediately.

If mercury is inhaled or swallowed, seek medical attention immediately.If mercury is inhaled or swallowed, seek medical attention immediately.

If mercury is inhaled or swallowed, seek medical attention immediately.

Mercury is hazardous waste and must be disposed of in accordance with applicable laws.

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O will accept defective PTs.

If mercury escapes, use airtight packaging!

4.14.1

4.14.1

4.1

TT

TT

T

RANSRANS

RANSRANS

RANS

PORPOR

PORPOR

POR

TT

TT

T

//

//

/

PP

PP

P

AA

AA

A

CKINGCKING

CKINGCKING

CKING

//

//

/

TRANSTRANS

TRANSTRANS

TRANS

PORPOR

PORPOR

POR

TT

TT

T

DD

DD

D

AMAGEAMAGE

AMAGEAMAGE

AMAGE

• Do not let the PT be damaged by other items during transit.

• Use only the original packaging.

• Report transport damage to

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O immediately in writing.

4.24.2

4.24.2

4.2

SS

SS

S

TORAGETORAGE

TORAGETORAGE

TORAGE

• Store the PT in original packaging only.

• Protect against dust and moisture.

4.4.

4.4.

4.

33

33

3

SS

SS

S

CC

CC

C

OPEOPE

OPEOPE

OPE

OFOF

OFOF

OF

D D

D D

D

ELIVERYELIVERY

ELIVERYELIVERY

ELIVERY

• PT with diaphragm protection cap

• Fastening clip (transmitter with flexible stem only)

• Calibration sheet

• Operating manual with declaration of conformity

Page 19

19

I

NSTALLATION

5.5.

5.5.

5.

II

II

I

NSNS

NSNS

NS

TT

TT

T

ALLAALLA

ALLAALLA

ALLA

TIONTION

TIONTION

TION

5.1 General Mounting Information .............................................................................................. 19

5.2 Mounting Hole Torque ......................................................................................................... 20

5.3 Mounting Hole Dimensions .................................................................................................. 20

5.4 Mounting the Pressure Transmitter ........................................................................................21

5.5 DeviceNet Wiring ................................................................................................................ 22

5.6 DeviceNet Connector Wiring ................................................................................................ 22

5.15.1

5.15.1

5.1

GG

GG

G

ENERALENERAL

ENERALENERAL

ENERAL

M M

M M

M

OUNTINGOUNTING

OUNTINGOUNTING

OUNTING

I I

I I

I

NFORMANFORMA

NFORMANFORMA

NFORMA

TIONTION

TIONTION

TION

Do not remove the protective cap on the PT until ready to install.

Before mounting the PT, check mounting hole carefully. The PT must only be mounted in holes that

satisfy the requirements below. A hole that does not satisfy these requirements can damage the

Transmitter.

Insure the mounting hole is clear of any frozen polymer or debris and is machined to the proper

dimensions.

For threaded PT transmitters coat the threads with a high temperature anti-seize grease or a suitable

parting agent, this will help prevent the PT snout from sticking permanently in the mounting hole.

Install unit into the process connection. (Do NOT torque transmitter into the hole at this time!) Allow time

for the transmitter snout temperature to equalize to the process temperature. This will help eliminate

thread galling and ease removal later. There should be NO pressure applied at this time.

Always use a torque wrench applied to the designated hexagon collar or mounting bolts while screwing

the transmitter in and out. Do not apply the tool to the housing or housing/sensor connection.

After temperatures have equalized, apply proper torque as described in Section 3.20 of the Manual and

tighten transmitter into mounting hole.

After the correct torque has been applied units with flexible capillary require the electronics to be

mounted away from the process heat using mounting hardware, P/N 200941.

Make sure that the medium is in molten condition during transmitter removal. Removing the transmitter

while the medium is in solidified condition can damage the sensor diaphragm.

When removing the PT, carefully clean the diaphragm of the transmitter with a soft cloth while the

medium is still malleable.

Page 20

20

INSTALLATION

Always remove the PT prior to cleaning the machine with abrasives or steel wire brushes. Also, do not

clean the PT with hard objects, such as a screwdriver, a wire brush, etc. this will possibly damage the

transmitter.

Before reinstalling the PT, ensure that the mounting hole is free from hardened plastic. A mounting hole

cleaning tool kit is available to aid in removing of the material. (Dynisco Part Number 200100 for ½-20,

200101 for M18 and 200102 for M10 ports.) A gauge plug to check the hole is included in this kit.

The most common causes of transducer damage are: installation in improperly machined or plugged

mounting holes and cold starts. The tip of the transducer consists of a stainless steel diaphragm that

must be protected from severe abrasives, dents and scores.

Burn Hazard!Burn Hazard!

Burn Hazard!Burn Hazard!

Burn Hazard!

The PT must be removed with the melt in the molten condition. The PT can be very hot

when removed. WEAR PROTECTIVE GLOVES!

Careful attention should be paid to correctly machine the mounting port. Failure to use the

recommended mounting port may result in erroneous pressure measurement, difficult transducer

removal, premature sensor failure, process fluid leaks, and personnel hazard. In applications involving

high temperature operation and/or repeated thermal cycling a good high quality anti-seize compound

should be applied to the threaded surfaces.

5.25.2

5.25.2

5.2

MM

MM

M

OUNTINGOUNTING

OUNTINGOUNTING

OUNTING

H H

H H

H

OLEOLE

OLEOLE

OLE

T T

T T

T

ORQUEORQUE

ORQUEORQUE

ORQUE

PT46XDN

max. 56.5 Nm

(500 inch-lbs.)

min. 11.3 Nm

(100 inch-lbs.)

5.5.

5.5.

5.

33

33

3

MM

MM

M

OUNTINGOUNTING

OUNTINGOUNTING

OUNTING

H H

H H

H

OLEOLE

OLEOLE

OLE

D D

D D

D

IMENSIONSIMENSIONS

IMENSIONSIMENSIONS

IMENSIONS

Drill the mounting hole as shown in Fig. 5-1.

Please consult factory for other mounting configurations.

Page 21

21

I

NSTALLATION

5.45.4

5.45.4

5.4

MM

MM

M

OUNTINGOUNTING

OUNTINGOUNTING

OUNTING

THETHE

THETHE

THE

P P

P P

P

RESSURERESSURE

RESSURERESSURE

RESSURE

T T

T T

T

RANSMITTERRANSMITTER

RANSMITTERRANSMITTER

RANSMITTER

Dynisco offers a set of mounting hole-machining tools with all the necessary drills, taps, and reamers

for the Dynisco standard ½-20UNF-2A and M18 and M10 mounting holes used in high temperature and

plastics processing applications (Dynisco Part Numbers 200925, 200105 and 901949 respectively).

Detailed instructions are sent with the machining kits. Copies of the instructions are available from

Dynisco upon request.

When machining the hole pay careful attention to the concentricity between the threads and the 0.312/

0.314 diameter. Since the pressure seal is on the 45° seating surface, this surface should be examined

for good finish, free from burrs, etc.

It is general good practice to check the mounting hole before installing the transducer. One procedure

is to coat a gauge plug (Dynisco Part Number 200908 for the 1/2 –20 standard port, 435901 for the

short tip 1/2 –20 version, 200960 for the M18), with Dykem machine bluing on surfaces below the

thread. Insert the gauge plug into the mounting hole and rotate until surface binding is encountered.

Remove and inspect. Bluing should only be scraped off of the 45° sealing chamfer. If bluing has been

removed from other surfaces, the mounting hole has not been machined properly.

Fig. 5-1Fig. 5-1

Fig. 5-1Fig. 5-1

Fig. 5-1

PT46XDN (1/2-20 UNF) Mounting Hole PT46XDN (1/2-20 UNF) Mounting Hole

PT46XDN (1/2-20 UNF) Mounting Hole PT46XDN (1/2-20 UNF) Mounting Hole

PT46XDN (1/2-20 UNF) Mounting Hole

Page 22

22

INSTALLATION

5.5.

5.5.

5.

55

55

5

DD

DD

D

EVICEEVICE

EVICEEVICE

EVICE

NN

NN

N

ETET

ETET

ET

W W

W W

W

IRINGIRING

IRINGIRING

IRING

The PT46XDN can be readily connected to the DeviceNet bus using the optional connector and cable

assembly or a customer-supplied connector and cable. It is important to adhere to proper DeviceNet wiring

practices. The DeviceNet Technical Overview available from the Open DeviceNet Vendors Association

(www.odva.org) provides additional information on DeviceNet physical layer topologies including cable

types, trunk and drop lengths, and terminating resistors.

It is recommended that all wiring be validated using a media checker to identify potential media problems,

e.g. shorts, opens, excessive cable length, and crossed connections.

5.65.6

5.65.6

5.6

DD

DD

D

EVICEEVICE

EVICEEVICE

EVICE

NN

NN

N

ETET

ETET

ET

C C

C C

C

ONNECTORONNECTOR

ONNECTORONNECTOR

ONNECTOR

W W

W W

W

IRINGIRING

IRINGIRING

IRING

The DeviceNet Pressure Transmitter uses the standard DeviceNet Micro DIN 5-pin connector. The

connections are as follows:

Cable Leads To Connector Pin

Black -V 3

Blue CAN-L 5

Bare Drain 1

White CAN-H 4

Red +V 2

CONNECTOR PINOUT

1

2

3

4

5

Page 23

23

CONFIGURATION

6.6.

6.6.

6.

CC

CC

C

ONFIGURAONFIGURA

ONFIGURAONFIGURA

ONFIGURA

TIONTION

TIONTION

TION

6.1 Initializing DeviceNet Communications ................................................................................. 23

6.2 Setting the Node Address and Baud Rate ............................................................................. 23

6.3 Electronic Data Sheet File (EDS) ........................................................................................... 23

6.4 Parameter Configuration ..................................................................................................... 24

6.16.1

6.16.1

6.1

II

II

I

NITIALIZINGNITIALIZING

NITIALIZINGNITIALIZING

NITIALIZING

D D

D D

D

EVICEVIC

EVICEVIC

EVIC

EE

EE

E

NN

NN

N

ETET

ETET

ET

C C

C C

C

OMMUNICAOMMUNICA

OMMUNICAOMMUNICA

OMMUNICA

TIONSTIONS

TIONSTIONS

TIONS

When the transmitter is connected to the DeviceNet bus, it will perform an initialization sequence to

establish communications with the Master.

1. Initially, the Device Status LED will flash red one time, and then will change to a steady green.

At this point the Transmitter has passed its internal health check.

2. Simultaneously, the Network Status LED will flash green one time, then after a few seconds

will continue to flash green.

3. At this point, the duplicate MAC ID check is complete, and the transmitter is waiting to be

allocated to a Master.

4. If the Network status LED stays solid red, remove the connector and then reconnect. If the

LED is still solid red, continue to section 6.2 Setting the Node Address and Baud Rate

6.26.2

6.26.2

6.2

SS

SS

S

ETET

ETET

ET

TINGTING

TINGTING

TING

THETHE

THETHE

THE

N N

N N

N

ODEODE

ODEODE

ODE

A A

A A

A

DDREDDRE

DDREDDRE

DDRE

SS

SS

S

SS

SS

S

ANDAND

ANDAND

AND

B B

B B

B

AA

AA

A

UDUD

UDUD

UD

R R

R R

R

AA

AA

A

TETE

TETE

TE

The Node Address and Baud Rate are set via explicit messaging by means of any commercially-available

DeviceNet configuration tool.

1. The default node address is

63,63,

63,63,

63, and the default baud rate is

125K125K

125K125K

125K.

2. If the node address is changed, the DeviceNet Pressure Transmitter will reinitialize prior to assuming

the new node address.

3. If the baud rate is changed, it is necessary to disconnect the transmitter from the network. The

transmitter will assume the new baud rate once it is reconnected to the network and it has

reinitialized.

66

66

6

..

..

.

33

33

3

EE

EE

E

LELE

LELE

LE

CTRONICCTRONIC

CTRONICCTRONIC

CTRONIC

D D

D D

D

AA

AA

A

TT

TT

T

AA

AA

A

SS

SS

S

HEETHEET

HEETHEET

HEET

F F

F F

F

ILEILE

ILEILE

ILE

(ED (ED

(ED (ED

(ED

S)S)

S)S)

S)

The EDS or Electronic Data Sheet file for the Dynisco DeviceNet Pressure Transducer is named PT46XDN.EDS

and is available online at www.dynisco.com. The EDS file is used to automate the DeviceNet network

configuration process by precisely defining vendor-specific and required device parameter information.

Page 24

24

CONFIGURATION

The EDS file describes a device’s configurable parameters, including its legal and default values and the

public interfaces to those parameters. Software configuration tools utilize the EDS files to configure a

DeviceNet network.

6.46.4

6.46.4

6.4

PP

PP

P

ARAMETERARAMETER

ARAMETERARAMETER

ARAMETER

C C

C C

C

ONFIGURAONFIGURA

ONFIGURAONFIGURA

ONFIGURA

TIONTION

TIONTION

TION

After the baud rate and node address have been established, the device parameters are ready to be

configured. The following configurable parameters are available (see Section 7.4 for more information):

1. Data Units (Attribute #02 / Default is “counts”)

The Pressure Value (PV) can be scaled to a variety of engineering units by configuring the Data units

to digital counts, PSI, bar, kg/cm^2, MPa or % full scale.

2. Alarm and Warn Status Enable (Attribute #06 and #07 / Default is “disabled”)

The respective parameters must be set (i.e. enabled) if the master will use the alarm or warning bits in

the I/O message.

3. Alarm Trip Point High and Low (Attribute #13 and #14)

These values (and the Hysteresis) define under what conditions the Alarm High and Low status bits are

set in the I/O message.

4. Alarm Trip Point Hysteresis (Attribute #15)

This value (and the Alarm Trip Point High and Low values) define under what conditions the Alarm High

and Low status bits are set in the I/O message.

5. Warning Trip Point High and Low (Attribute #17 and #18)

These values (and the Hysteresis) define under what conditions the Warn High and Low status bits are

set in the I/O message.

6. Warning Trip Point Hysteresis (Attribute #19)

This value (and the Warn Trip Point High and Low values) define under what conditions the Warn High

and Low status bits are set in the I/O message.

7. Set Zero Service (for zeroing effects of temperatures and mounting position)

Execute this service to zero the PV output. Refer to Section 7.3 for more information.

Page 25

25

CONFIGURATION

77

77

7

..

..

.

DD

DD

D

EVICEEVICE

EVICEEVICE

EVICE

NN

NN

N

ETET

ETET

ET

O O

O O

O

BJECTBJECT

BJECTBJECT

BJECT

M M

M M

M

ODELODEL

ODELODEL

ODEL

7.1 Object Model ....................................................................................................................... 25

7.2 Dynisco Pressure Sensor Object ............................................................................................ 25

7.3 Set Zero Service ................................................................................................................... 25

7.4 DeviceNet Class Attributes .................................................................................................... 25

77

77

7

.1.1

.1.1

.1

OO

OO

O

BJECTBJECT

BJECTBJECT

BJECT

M M

M M

M

ODELODEL

ODELODEL

ODEL

Objects Present in the DeviceNet Pressure Transmitter

ObjectObject

ObjectObject

Object

Optional/RequiredOptional/Required

Optional/RequiredOptional/Required

Optional/Required

# of Instances# of Instances

# of Instances# of Instances

# of Instances

Identity (1) Required 1 Message

Router (2) Required 1

DeviceNet (3) Required 1

Assembly (4) Required 1

Connection (5) Required 3

Parameter (15) Required 1

Pressure (100) Required 22

77

77

7

.2.2

.2.2

.2

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O

P P

P P

P

RERE

RERE

RE

SS

SS

S

SURESURE

SURESURE

SURE

SS

SS

S

ENSORENSOR

ENSORENSOR

ENSOR

O O

O O

O

BJEBJE

BJEBJE

BJE

CTCT

CTCT

CT

This class covers the entire Pressure Sensor and acts as an interface to the PLC.

Class ID: 100

77

77

7

..

..

.

33

33

3

SS

SS

S

ETET

ETET

ET

Z Z

Z Z

Z

EROERO

EROERO

ERO

S S

S S

S

ERVICEERVICE

ERVICEERVICE

ERVICE

There is one manufacturer-specific service to start “SetZero” functionality. The service acts as a “tare”

function by offsetting the current pressure value by the pressure value at the time the service is

invoked. This is typically used to eliminate a zero shift which may occur at elevated temperature. The

service code is 100

dec

(64

hex

). There are no parameters associated with this service.

77

77

7

.4.4

.4.4

.4

DD

DD

D

EVICEEVICE

EVICEEVICE

EVICE

NN

NN

N

ETET

ETET

ET

C C

C C

C

LASSLASS

LASSLASS

LASS

A A

A A

A

TTRIBUTESTTRIBUTES

TTRIBUTESTTRIBUTES

TTRIBUTES

The Table below shows the mapping of the DeviceNet Class Attributes.

The DeviceNet Class is always 100

dec

(64

hex

), and the Instance is always 01

.

Page 26

26

CONFIGURATION

AttributeAttribute

AttributeAttribute

Attribute

AccessAccess

AccessAccess

Access

DescriptionDescription

DescriptionDescription

Description

DatDat

DatDat

Dat

a a

a a

a

TT

TT

T

ypeype

ypeype

ype

VV

VV

V

aluealue

aluealue

alue

ID ID

ID ID

ID

RuleRule

RuleRule

Rule

(Decimal)(Decimal)

(Decimal)(Decimal)

(Decimal)

01 Get Data Type – Constant UINT C7

hex

always returns Hex C7

02 Get/Set Data Unit/Engineering UINT Hex (Decimal)

Units 4097

dec

(1001

hex

) = counts

4864

dec

(1300

hex

) = psi

4871

dec

(1307

hex

) = bar

2048

dec

(0800

hex

) = kg/cm

2

2049

dec

(0801

hex

) = MPa

4103

dec

(1007

hex

) = % FS

03 Get Device Status BIT 0=clear; 1 =set

ReadingValid: Bit 0: Reading Valid

1 = PV (Attr. 04) is valid,

0 = PV is invalid.

OverRangeFault: Bit 1:OverRangeFault

PV > OverRangeValue

UnderRangeFault: Bit 2: UnderRangeFault

PV < UnderRangeValue

EEPROM/CPUFault: Bit 3: EEPROM/CPU Fault

EEPROM or WatchDog Timer failure

OpenGageFault: Bit 4: OpenGaugeFault

Failure of strain gage bridge

OverTemperatureFault: Bit 5: OverTemperatureFault

Electronics Temp. exceeds factory limit

SetZeroStatus: Bit 6: SetZeroStatus

1 = Set zero in progress

0 = Set zero not in progress

Bits 0-7 are also available Bit 7: Reserved (0)

via Bytes #1 & #2 of the I/O

message (see section 1.7.3)

Page 27

27

CONFIGURATION

AttributeAttribute

AttributeAttribute

Attribute

AccessAccess

AccessAccess

Access

DescriptionDescription

DescriptionDescription

Description

DatDat

DatDat

Dat

a a

a a

a

TT

TT

T

ypeype

ypeype

ype

VV

VV

V

aluealue

aluealue

alue

ID ID

ID ID

ID

RuleRule

RuleRule

Rule

(Decimal)(Decimal)

(Decimal)(Decimal)

(Decimal)

04 Get PressureValue (PV) UINT

PV is in Engineering

Units as defined by

Attribute # 2. PV is

affected by Set Zero

Service (see Section 7.3).

When interpreting the

PV, be sure to account

for the UnityGainRef

(see Attr #12).

05 Get Alarm/Warn Status BYTE 0=cleared, 1=set

TripWarnLow is set when Bit 0: TripWarnLow

PV <= WarnTripPointLow

TripWarnHigh is set when Bit 1: TripWarnHigh

PV >= WarnTripPointHigh

TripAlarmLow is set when Bit 2: TripAlarmLow

PV <= AlarmTripPointLow

TripAlarmHigh is set when Bit 3: TripAlarmHigh

PV >= AlarmTripPointHigh

Note: AlarmEnable or Warning Bit 4 to 7: Reserved

Enable Attributes must be set

to enable the Alarm/Warn status bits.

06 Get/Set AlarmEnable BIT 0 = Disable (default)

1 = Enable

07 Get/Set WarnEnable BIT 0 = Disable (default)

1 = Enable

08 Get SensorFullScaleValue UINT Maximum allowable value FFFF

hex

09 Get Offset A INT Factory use only

10 Get Offset B INT Factory use only

Page 28

28

CONFIGURATION

AttributeAttribute

AttributeAttribute

Attribute

AccessAccess

AccessAccess

Access

DescriptionDescription

DescriptionDescription

Description

DatDat

DatDat

Dat

a a

a a

a

TT

TT

T

ypeype

ypeype

ype

VV

VV

V

aluealue

aluealue

alue

ID ID

ID ID

ID

RuleRule

RuleRule

Rule

(Decimal)(Decimal)

(Decimal)(Decimal)

(Decimal)

11 Get Gain UINT Factory use only

12 Get Unity Gain Reference UINT

(UGR) Decimal scale

factor used to convert

PV to “real world”

pressure. Pressure =

PV / UGR. Note that the

UGR is fixed for each

transducer range.

13 Get AlarmTripPointHigh UINT Valid Range:

(ATPH) If AlarmEnable

is set and PV >= ATPH, (WTPH - Alarm Hysteresis)

TripAlarmHigh is set <= ATPH <= Overrange

(see Attr 05).

TripAlarmHigh is cleared

once PV <= ATPH –

AlarmHysteresis

(see Attr 15)

14 Get/Set AlarmTripPointLow UINT Valid Range:

(ATPL) If AlarmEnable

is set and PV <= ATPL, Underrange <= ATPL <=

TripAlarmLow is set (WTPL - AlarmHysteresis)

(see Attr 05).

TripAlarmLow is cleared

once PV >= ATPL +

AlarmHysteresis (see Attr 15).

15 Get/Set AlarmHysteresis UINT Valid Range:

The amount by which

PV must recover to clear AlarmHysteresis <=

either TripAlarmHigh or (ATPH - WTPH) or

TripAlarmLow. (WTPL - ATPL)

16 Get/Set AlarmSettlingTime UINT Units are in milliseconds

The time that the PV

must exceed the trip point

before TripAlarmHigh or

TripAlarmLow is set.

Page 29

29

CONFIGURATION

AttributeAttribute

AttributeAttribute

Attribute

AccessAccess

AccessAccess

Access

DescriptionDescription

DescriptionDescription

Description

DatDat

DatDat

Dat

a a

a a

a

TT

TT

T

ypeype

ypeype

ype

VV

VV

V

aluealue

aluealue

alue

ID ID

ID ID

ID

RuleRule

RuleRule

Rule

(Decimal)(Decimal)

(Decimal)(Decimal)

(Decimal)

17 Get/Set WarnTripPointHigh UINT Valid Range:

(WTPH) If WarnEnable

is set and PV >= WTPH, (WTPL + WarmHysteresis) <=

TripWarnHigh is set WTPH <=

(see Attr. 05) (ATPH - AlarmHysteresis)

TripWarnHigh is cleared

once PV <= WTPH –

WarnHysteresis (see Attr 19).

18 Get/Set WarnTripPointLow UINT Valid Range:

(WTPL)If AlarmEnable is

set and PV <= WTPL, (ATPL + AlarmHysteresis) <=

TripWarnLow is set WTPH <= WarnHysteresis

(see Attr. 05)TripWarnLow

is cleared once PV >= WTPL

+ WarnHysteresis (see Attr 19).

19 Get/Set WarnHysteresis UINT Valid Range:

The amount by which

PV must recover to clear WarnHysteresis <=

either T ripW arnHigh (WTPH - WTPL)

or TripWarnLow.

20 Get/Set WarnSettlingTime UINT Units are in milliseconds

The time that the PV

must exceed the trip

point before T ripW arnHigh

or T ripW arnLow is set.

21 Get OverRange UINT

If PV > OverRange,

then OverRangeF ault

is set (see Attr. 03).

22 Get UnderRange UINT

If PV < UnderRange,

then UnderRangeF ault

is set (see Attr. 03).

25 Set Execute Rezero SINT

When set tol, unit

is rezeroed

Page 30

30

MAINTENANCE

8.8.

8.8.

8.

MM

MM

M

AINTENANCEAINTENANCE

AINTENANCEAINTENANCE

AINTENANCE

8.1 Maintenance ...................................................................................................................... 30

8.2 Thermocouple/RTD Replacement ......................................................................................... 30

8.3 Repair/Disposal ................................................................................................................... 31

8.4 Warranty ............................................................................................................................ 32

8.18.1

8.18.1

8.1

MM

MM

M

AINTENANCEAINTENANCE

AINTENANCEAINTENANCE

AINTENANCE

Burn hazard!Burn hazard!

Burn hazard!Burn hazard!

Burn hazard!

The PT must be removed with the melt in molten condition. The PT can be very hot when

removed.

Wear protective gloves!Wear protective gloves!

Wear protective gloves!Wear protective gloves!

Wear protective gloves!

Installation and Removal Instructions

• DO NOT REMOVE PROTECTIVE CAP UNTIL READY TO INSTALL.

• PRIOR TO INITIAL INSTALLATION, VERIFY CORRECT MACHINING OF MOUNTING HOLE.

• WHEN REINSTALLING, MAKE SURE MOUNTING HOLE IS CLEAR OF DEBRIS OR HARDENED

PLASTIC.

• THE MEDIUM MUST BE IN MOLTEN CONDITION DURING TRANSDUCER REMOVAL.

(Removing the transducer with the medium in a solidified condition can damage the

sensor diaphragm.)

• ALWAYS REMOVE THE PT BEFORE CLEANING THE MACHINE WITH ABRASIVES OR STEEL

WIRE BRUSHES, ETC.

• DO NOT CLEAN THE “SCREWED-IN” SECTION OF THE PT WITH HARD OBJECTS – THIS

WILL DAMAGE THE PT.

• ALWAYS USE A TORQUE WRENCH APPLIED TO THE DESIGNATED HEXAGONAL COLLAR

WHEN SCREWING THE PT IN AND OUT. DO NOT APPLY THE TOOL TO THE HOUSING OR

HOUSING/ SENSOR CONNECTION.

• ELECTROSTATIC DISCHARGE MAY DAMAGE THE PT – TAKE ESD PRECAUTIONS.

8.28.2

8.28.2

8.2

TT

TT

T

HERMOCHERMOC

HERMOCHERMOC

HERMOC

OUPLEOUPLE

OUPLEOUPLE

OUPLE

/R/R

/R/R

/R

TT

TT

T

D RD R

D RD R

D R

EPLAEPLA

EPLAEPLA

EPLA

CC

CC

C

EMENTEMENT

EMENTEMENT

EMENT

1. To remove, loosen setscrew on side of snout.

2. Without twisting, pull the thermocouple probe or RTD stem carefully out of snout.

3. To install, align slot on probe stem with pressure capillary tube and press into snout carefully

until top of probe shoulders against snout.

4. Lock in place with setscrew.

Page 31

31

MAINTENANCE

Fig. 7-1Fig. 7-1

Fig. 7-1Fig. 7-1

Fig. 7-1

ThermocoupleThermocouple

ThermocoupleThermocouple

Thermocouple

88

88

8

..

..

.

33

33

3

RR

RR

R

EPEP

EPEP

EP

AIRAIR

AIRAIR

AIR

//

//

/

DISDIS

DISDIS

DIS

POPO

POPO

PO

SS

SS

S

ALAL

ALAL

AL

TT

TT

T

oo

oo

o

xx

xx

x

icic

icic

ic

h h

h h

h

azaz

azaz

az

arar

arar

ar

d!d!

d!d!

d!

The PT contains a small amount of mercury (Hg) as its transmission medium. If the

diaphragm is damaged, mercury may escape.

Never transport or store the PT without the protective cap bolted in place. Remove the cap

shortly before installation.

If mercury is inhaled or swallowed, seek medical attention immediately!If mercury is inhaled or swallowed, seek medical attention immediately!

If mercury is inhaled or swallowed, seek medical attention immediately!If mercury is inhaled or swallowed, seek medical attention immediately!

If mercury is inhaled or swallowed, seek medical attention immediately!

Mercury is hazardous waste and must be disposed of in accordance with applicable laws.

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O will accept defective PTs.

If mercury escapes, use airtight packaging!

Page 32

32

MAINTENANCE

Please send defective PT units back to your DYNISCO representative. For DYNISCO addresses, see the

back cover of the operating manual.

8.48.4

8.48.4

8.4

WW

WW

W

ARRANTYARRANTY

ARRANTYARRANTY

ARRANTY

Dynisco Pressure transmitters will provide excellent service and superior performance if proper care is

taken during handling, installation, and use. This DYNISCO product is warranted under terms and

conditions set forth in the DYNISCO web pages. Go to www.dynisco.com and click “warranty” at the

bottom of any page for complete details.

Page 33

33

ACCESSORIES

9.9.

9.9.

9.

AA

AA

A

CC

CC

C

CC

CC

C

EE

EE

E

SS

SS

S

SORIESORIE

SORIESORIE

SORIE

SS

SS

S

• Machining tool kit 1/2”-20UNF-2A P/N 200295

• Cleaning tool kit 1/2”-20UNF-2A P/N 200100

Page 34

34

TROUBLESHOOTING

10.10.

10.10.

10.

TT

TT

T

ROUBLESHOOTINGROUBLESHOOTING

ROUBLESHOOTINGROUBLESHOOTING

ROUBLESHOOTING

SymptomSymptom

SymptomSymptom

Symptom

Corrective ActionsCorrective Actions

Corrective ActionsCorrective Actions

Corrective Actions

Output Not at Zero 1) Preform Set Zero Service

Output is Negative at Zero Pressure 1) Process temperature has cooled down since last Set

Zero. Wait for process to fully heat up to operating

temperature.

2) Transducer has lost its fill due to diaphragm damage or

rupture.

Large Zero Shift when screwing 1) Check mounting hole for frozen polymer.

in to mounting hole 2) Check transdcuer tip for damage

3) Check mounting hole for concentricity by using gauge

plug in transducer cleaning tool kit (p/n 200100) to check

for side loading of the transducer tip. Dykem bluing should

only be rubbed off at the 45° sealing surface and threads.

Rework hole to proper specifications.

4) Check mounting torque is within specifications.

No response to changes in 1) Check Port/Piping for blockage or solidified polymer

applied pressure 2) Check Transducer tip for diaphragm damage, rupture or

missing

3) Check Flexible Capillary for visible damage like

pinched, Crushed, over-extended armor on the capillary

Output not linear 1) Check for dented diaphragm

2) Check for frozen polymer on tip

Erroneous Pressure Reading 1) Check Data Units/Engineering units for correct setting

2) Was Transmitter zeroed at process operating

temperature with no pressure applied

3) Check mounting hole for proper depth dimension.

Transmitter tip may be recessed too far from polymer flow

and pressure sensing may be deadened from polymer

buildup in from of tip

4) Check mounting hole for concentricity by using Gauge

Plug in transducer cleaning tool kit (P/N 200100) to check

for side loading of transducer tip. Dykem bluing should

only be rubbed off at the 45° sealing surface and threads

5) Remove and check Transmitter tip for damage. Tip

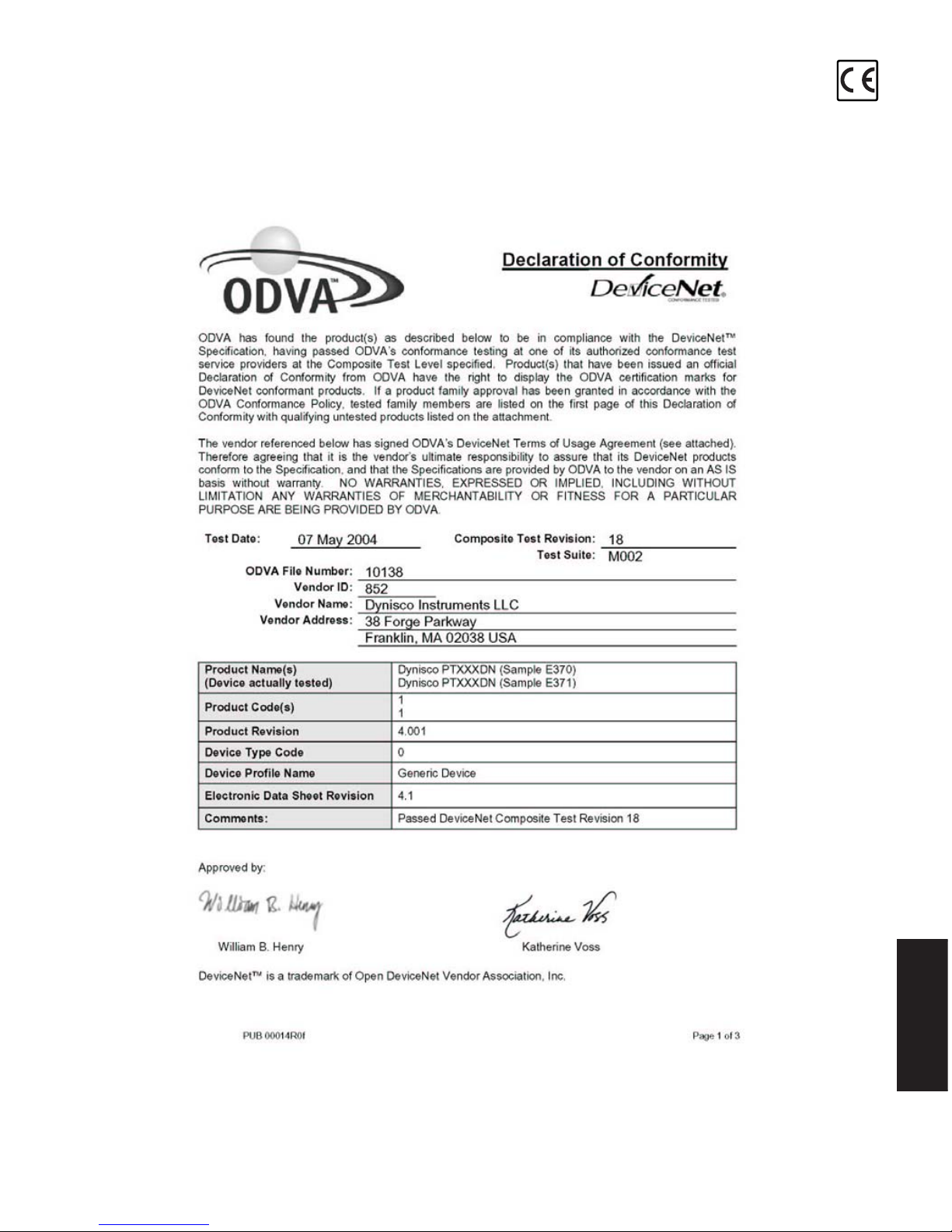

face should be free of dents or tears in the diaphragm