Page 1

OPERATING MANUAL

IPX II SeriesIPX II Series

IPX II SeriesIPX II Series

IPX II Series

SmSm

SmSm

Sm

arar

arar

ar

tt

tt

t

Pr Pr

Pr Pr

Pr

ee

ee

e

ss

ss

s

ss

ss

s

urur

urur

ur

e e

e e

e

TT

TT

T

rr

rr

r

anan

anan

an

smittsmitt

smittsmitt

smitt

erer

erer

er

ss

ss

s

ff

ff

f

or High Pror High Pr

or High Pror High Pr

or High Pr

ee

ee

e

ss

ss

s

ss

ss

s

urur

urur

ur

ee

ee

e

ss

ss

s

and High and High

and High and High

and High

TT

TT

T

emperemper

emperemper

emper

atat

atat

at

urur

urur

ur

ee

ee

e

ss

ss

s

P/N 974100

05/05 Rev. F

ECO # 29918

II 1 GII 1 G

II 1 GII 1 G

II 1 G

AA

AA

A

TEX100aTEX100a

TEX100aTEX100a

TEX100a

Page 2

OPERATING MANUAL

Page 3

OPERATING MANUAL

TT

TT

T

ABLEABLE

ABLEABLE

ABLE

OFOF

OFOF

OF

C C

C C

C

ONTENTSONTENTS

ONTENTSONTENTS

ONTENTS

ContentContent

ContentContent

Content

PP

PP

P

agag

agag

ag

ee

ee

e

IconIcon

IconIcon

Icon

1. General 4

2. Notes on safety 6

3. Technical data 8

4. Function 22

5. Transport/delivery 26

6. Assembly 27

7. Commissioning 34

8. Maintenance 66

9. Accessories 68

10. Troubleshooting 69

11. CE-Declaration of conformity 72

12. Ex-Declaration of conformity 73

Page 4

4

GENERAL

1.1.

1.1.

1.

GG

GG

G

ENERALENERAL

ENERALENERAL

ENERAL

1 . 1 Important information .......................................................................................................... 4

1.2 Copyright ............................................................................................................................. 4

1.3 Explanation of icons ............................................................................................................ 5

1.4 Abbreviations....................................................................................................................... 5

1.5 Correct use .......................................................................................................................... 5

1.6 User’s obligations ................................................................................................................. 5

1.11.1

1.11.1

1.1

II

II

I

MPORMPOR

MPORMPOR

MPOR

TT

TT

T

ANTANT

ANTANT

ANT

INFORMAINFORMA

INFORMAINFORMA

INFORMA

TIONTION

TIONTION

TION

This manual applies to the IPX II series only. It must be kept near the equipment in a readily and

immediately accessible location at all times.

The content of this manual must be read, understood and followed in all points by all relevant

people. This applies in particular to the notes on safety. Following the safety instructions will help to

prevent accidents, defects and malfunctions.

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O will not be held liable for any injury, loss or damage resulting from failure to follow the

instructions in this manual.

If malfunctions occur in spite of having followed the operating instructions, please contact the

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O customer service department (see chapter 8, Maintenance).

This applies in particular during the warranty period.

1.21.2

1.21.2

1.2

CC

CC

C

OPYRIGHTOPYRIGHT

OPYRIGHTOPYRIGHT

OPYRIGHT

Copyright law requires that this manual be used for in-house purposes only.

All reproduction, even partially and for in-house purposes, requires the approval of

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O. This

manual may not be forwarded to third parties.

Rosemount and Smart Family are registered trademarks of Rosemount, Inc.

Hart is a registered trademark of Hart Comunication Foundation.

Page 5

5

GENERAL

1.31.3

1.31.3

1.3

EE

EE

E

XPLANAXPLANA

XPLANAXPLANA

XPLANA

TIONTION

TIONTION

TION

OFOF

OFOF

OF

ICIC

ICIC

IC

ONSONS

ONSONS

ONS

The manual uses icons to indicate information pertaining to safety:

Risk of destruction or damage to equipment, machines or installations

General danger to life or limb

Specific danger to life or limb

You MUST do this

The safety instructions are provided again in the individual chapters of the manual.

1.41.4

1.41.4

1.4

AA

AA

A

BBREVIABBREVIA

BBREVIABBREVIA

BBREVIA

TIONSTIONS

TIONSTIONS

TIONS

The following abbreviations are used:

OMOM

OMOM

O M Operating manual

IPXIPX

IPXIPX

IPX Intelligent pressure transmitter

f.s.f.s.

f.s.f.s.

f.s. of full scale

PTPT

PTPT

P T pressure transmitter

1.51.5

1.51.5

1.5

CC

CC

C

ORRECTORRECT

ORRECTORRECT

ORRECT

USEUSE

USEUSE

USE

The IPX II pressure transmitter is specially designed for measuring pressure in explosive atmospheres

(safety class, EEx ia IIC T4, Ta=-20°C to +80°C) as part of a larger overall system. It contains an

integrated signal amplifier. The IPX II can be used in media temperatures up to 350°C. If the pressure

transmitter is used in other applications, the safety and accident prevention regulations specific to

that application must be followed.

When uWhen u

When uWhen u

When u

ss

ss

s

inin

inin

in

g the IPXg the IPX

g the IPXg the IPX

g the IPX

II a II a

II a II a

II a

ss

ss

s

a s a s

a s a s

a s

afaf

afaf

af

etyety

etyety

ety

c c

c c

c

omponentomponent

omponentomponent

omponent

in ac in ac

in ac in ac

in ac

cc

cc

c

oror

oror

or

dd

dd

d

ancanc

ancanc

anc

e we w

e we w

e w

ith the Eith the E

ith the Eith the E

ith the E

CC

CC

C

M M

M M

M

acac

acac

ac

hine Dirhine Dir

hine Dirhine Dir

hine Dir

ectivectiv

ectivectiv

ectiv

e, Annee, Anne

e, Annee, Anne

e, Anne

xx

xx

x

IIc, the equipmentIIc, the equipment

IIc, the equipmentIIc, the equipment

IIc, the equipment

m m

m m

m

anufanuf

anufanuf

anuf

actact

actact

act

urur

urur

ur

er muer mu

er muer mu

er mu

ss

ss

s

tt

tt

t

t t

t t

t

akak

akak

ak

e ane an

e ane an

e an

yy

yy

y

nec nec

nec nec

nec

ee

ee

e

ss

ss

s

ss

ss

s

arar

arar

ar

yy

yy

y

pr pr

pr pr

pr

ecec

ecec

ec

autionaution

autionaution

aution

ss

ss

s

t t

t t

t

o eno en

o eno en

o en

ss

ss

s

urur

urur

ur

e the th

e the th

e th

atat

atat

at

m m

m m

m

alfalf

alfalf

alf

uu

uu

u

nctionnction

nctionnction

nction

ss

ss

s

ofof

ofof

of

the P the P

the P the P

the P

TT

TT

T

cc

cc

c

annotannot

annotannot

annot

c c

c c

c

auau

auau

au

se dse d

se dse d

se d

amam

amam

am

agag

agag

ag

e or injure or injur

e or injure or injur

e or injur

yy

yy

y

..

..

.

The IPX II is also designed for explosion proof areas approved by factory mutual for Class I, Division

1, Groups B, C & D, Class II/III, Division 2, Group E, F & G.

1.61.6

1.61.6

1.6

UU

UU

U

SS

SS

S

ERER

ERER

ER

’’

’’

’

SS

SS

S

OBLIGAOBLIGA

OBLIGAOBLIGA

OBLIGA

TIONSTIONS

TIONSTIONS

TIONS

The operator or owner of the larger overall system, e.g. a machine, is responsible for following the

safety and accident prevention regulations that apply to the specific application.

Page 6

6

SAFETY

2.2.

2.2.

2.

NN

NN

N

OTESOTES

OTESOTES

OTES

ONON

ONON

ON

SAFETYSAFETY

SAFETYSAFETY

SAFETY

The operator or owner of the larger overall system is responsible for following the safety

and accident prevention regulations that apply to the specific application.

TT

TT

T

oo

oo

o

xx

xx

x

icic

icic

ic

h h

h h

h

azaz

azaz

az

arar

arar

ar

d!d!

d!d!

d!

The IPX II contains a small amount of mercury (Hg) as its transmission medium. If the

diaphragm is damaged, mercury may escape.

Never transport or store the IPX II without the protective cap. Remove the cap shortly

before installation.

IfIf

IfIf

If

mer mer

mer mer

mer

cc

cc

c

urur

urur

ur

yy

yy

y

i i

i i

i

ss

ss

s

inh inh

inh inh

inh

alal

alal

al

ed or swed or sw

ed or swed or sw

ed or sw

alal

alal

al

lolo

lolo

lo

ww

ww

w

ed, seeked, seek

ed, seeked, seek

ed, seek

medic medic

medic medic

medic

alal

alal

al

att att

att att

att

ention immediention immedi

ention immediention immedi

ention immedi

atat

atat

at

ely!ely!

ely!ely!

ely!

Mercury is hazardous waste and must be disposed of in accordance with applicable

laws.

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O will accept defective PTs.

If mercury escapes, use airtight packaging!

When planning machinery and using the IPX II, follow the safety and accident

prevention regulations that apply to your application, e.g.:

• EN 60204, Electrical equipment in machines.

• EN 292, Machine safety, general design guidelines.

• DIN 57 100 Part 410, Protection against electric shock.

• EN 50 014:1997, General Requirements

• EN 50 020:1994, Intrinsic safety apparatus

• EN50284:1999, Speical requirements for Group II Category 1G

Mounting and electrical connection of the PT must be done by specialists with EMC training,

following all applicable regulations, and in

pressureless, voltage-free, intrinsically safepressureless, voltage-free, intrinsically safe

pressureless, voltage-free, intrinsically safepressureless, voltage-free, intrinsically safe

pressureless, voltage-free, intrinsically safe

condition with the

machine switched offmachine switched off

machine switched offmachine switched off

machine switched off.

The mThe m

The mThe m

The m

acac

acac

ac

hine muhine mu

hine muhine mu

hine mu

ss

ss

s

tt

tt

t

be sec be sec

be sec be sec

be sec

urur

urur

ur

ed aged ag

ed aged ag

ed ag

ainain

ainain

ain

ss

ss

s

tt

tt

t

bein bein

bein bein

bein

g swg sw

g swg sw

g sw

itit

itit

it

cc

cc

c

hed bhed b

hed bhed b

hed b

acac

acac

ac

kk

kk

k

on! on!

on! on!

on!

Ambient temperature for the electronics housing

mm

mm

m

ax. +80°Cax. +80°C

ax. +80°Cax. +80°C

ax. +80°C (safety class T4 max.).

Higher temperatures can result in damage and malfunction. Do not install the pressure

transmitter in places where this temperature is exceeded.

ExpExp

ExpExp

Exp

lolo

lolo

lo

ss

ss

s

ion hion h

ion hion h

ion h

azaz

azaz

az

arar

arar

ar

d!d!

d!d!

d!

Deviation of the supply voltage from the value given in the technical specifications, or

false polarity, can damage the pressure transmitter and cause malfunctions that can

pose a risk of explosion.

Page 7

7

SAFETY

Operate only with an intrinsically safe, EMC compliant power supply with the following

specifications when employing the pressure 4-20mA output:

Supply voltage max. 30 V DC

Current output max. 125 mA

Power output max. 900 mW

Inductivity max. 0.26 mH

Capacity max. 9.7 nF

Operate only with an intrinsically safe, EMC compliant power supply with the following

specifications when employing the temperature 4-20mA output:

Supply voltage max. 30 V DC

Current output max. 125 mA

Power output max. 900 mW

Inductivity max. 0 mH

Capacity max. 52 nF

For PT that are explosion proof Class I, Division 1, Groups B, C & D, Class II/III, Division

2, Groups E, F and G. Power supply rating is 12-42 Vdc.

ExpExp

ExpExp

Exp

lolo

lolo

lo

ss

ss

s

ion hion h

ion hion h

ion h

azaz

azaz

az

arar

arar

ar

d!d!

d!d!

d!

The pressure transmitter must be connected using a 2x2-core, twisted cable (blue cable

sheath).

Do not lay connecting cables in the direct vicinity of cables carrying higher voltage orDo not lay connecting cables in the direct vicinity of cables carrying higher voltage or

Do not lay connecting cables in the direct vicinity of cables carrying higher voltage orDo not lay connecting cables in the direct vicinity of cables carrying higher voltage or

Do not lay connecting cables in the direct vicinity of cables carrying higher voltage or

used to switch inductive or capacitive loads.used to switch inductive or capacitive loads.

used to switch inductive or capacitive loads.used to switch inductive or capacitive loads.

used to switch inductive or capacitive loads.

Page 8

8

TECHNICAL DATA

3.3.

3.3.

3.

TT

TT

T

EE

EE

E

CHNICALCHNICAL

CHNICALCHNICAL

CHNICAL

D D

D D

D

AA

AA

A

TT

TT

T

AA

AA

A

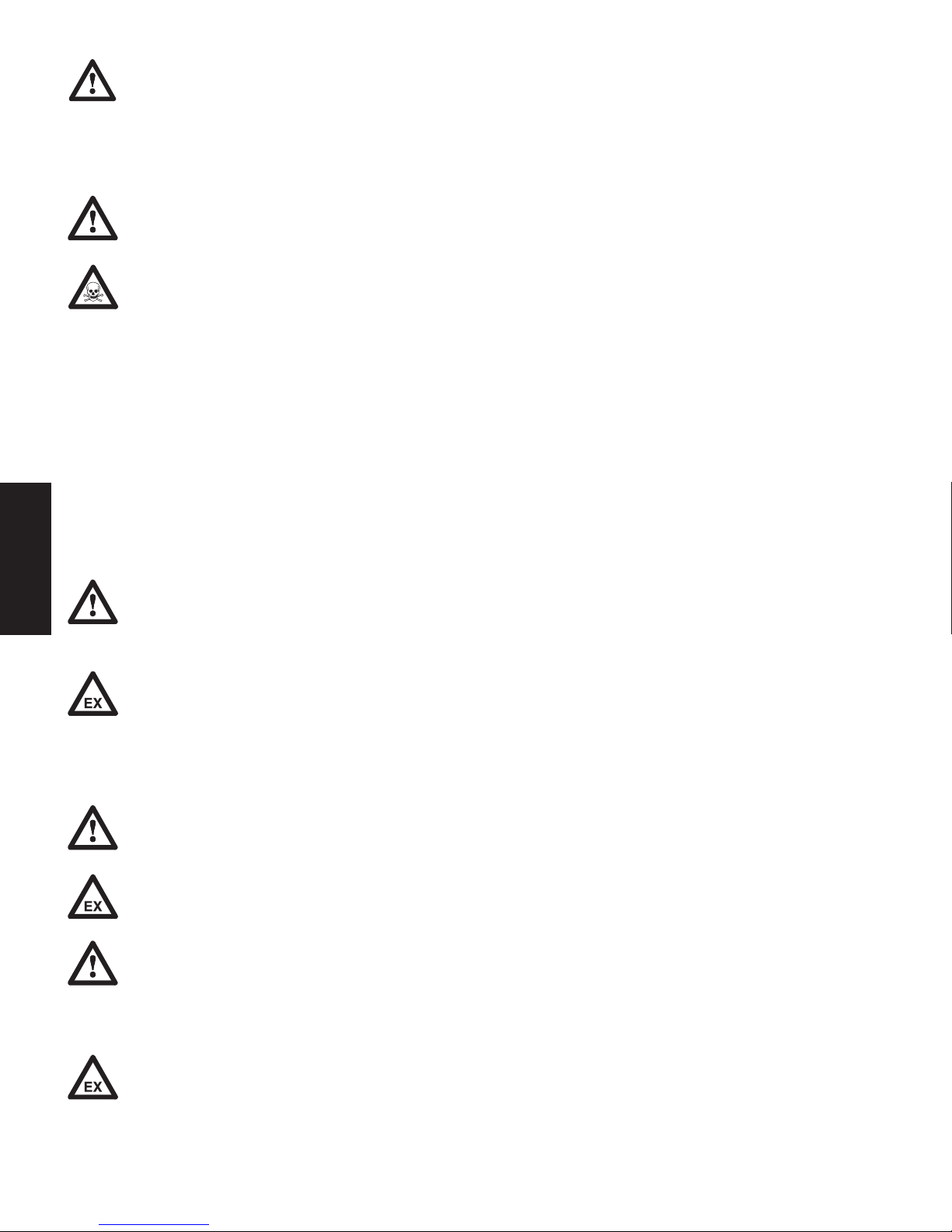

3.1 Ordering guide .................................................................................................................... 8

3.2 Ordering example ................................................................................................................ 9

3.3 Safety related specifications ................................................................................................. 9

3.4 Performance characteristics ................................................................................................. 9

3.4.1 Accuracy ............................................................................................................................. 9

3.4.2 Resolution.......................................................................................................................... 1 0

3.5 Pressure side connection ................................................................................................... 1 1

3.6 Pressure ranges .................................................................................................................. 1 1

3.6.1 Pressure ranges in bar ........................................................................................................ 1 1

3.6.2 Max. Overload .................................................................................................................. 1 1

3.6.3 Burst pressure .................................................................................................................... 1 1

3.6.4 Natural frequency .............................................................................................................. 1 1

3.7 Rigid stem/flexible stem .....................................................................................................11

3.8 Electrical Data ................................................................................................................... 1 1

3.9 Temperature influence ....................................................................................................... 12

3.10 EMC requirements ............................................................................................................. 1 2

3.11 Materials............................................................................................................................ 1 3

3.12 Mounting torque ................................................................................................................ 13

3.13 Environmental Protection ................................................................................................... 13

3.14 Weight ............................................................................................................................... 13

3.15 Dimensions ........................................................................................................................ 1 3

3.13.1

3.13.1

3.1

OO

OO

O

RDERINGRDERING

RDERINGRDERING

RDERING

GUIDEGUIDE

GUIDEGUIDE

GUIDE

The exact meanings of the letter/digit combinations are given in the corresponding sections of

chapter 3.

Page 9

9

TECHNICAL DATA

3.23.2

3.23.2

3.2

EE

EE

E

XAMPLEXAMPLE

XAMPLEXAMPLE

XAMPLE

FORFOR

FORFOR

FOR

ORDERINGORDERING

ORDERINGORDERING

ORDERING

3.33.3

3.33.3

3.3

SS

SS

S

AFETAFET

AFETAFET

AFET

YY

YY

Y

RELARELA

RELARELA

RELA

TEDTED

TEDTED

TED

SS

SS

S

PEPE

PEPE

PE

CIFICACIFICA

CIFICACIFICA

CIFICA

TIONSTIONS

TIONSTIONS

TIONS

ATEX certificate No.: SIRA 02ATEX2244X

EX-Safety class EEx ia IIC T4 (Ta = -20°C to +80°C)

FM approvals Class I, Division 1 Groups B, C & D

Class II / III, Division 2 Groups E, F & G

CC

CC

C

erer

erer

er

tified mtified m

tified mtified m

tified m

axax

axax

ax

imum imum

imum imum

imum

vv

vv

v

aluealue

aluealue

alue

ss

ss

s

f f

f f

f

or EExor EEx

or EExor EEx

or EEx

i i

i i

i

a IICa IIC

a IICa IIC

a IIC

T4T4

T4T4

T4

Associated electrical equipment must satisfy the following conditions:

PrPr

PrPr

Pr

ee

ee

e

ss

ss

s

ss

ss

s

urur

urur

ur

e:e:

e:e:

e:

Supply voltage max. 30 V DC

Current output max. 125 mA

Power output max. 900 mW

Inductivity max. 0.26 mH

Capacity max. 9.7 nF

TT

TT

T

emperemper

emperemper

emper

atat

atat

at

urur

urur

ur

e:e:

e:e:

e:

Supply voltage 30 V DC

Current output max. 125 mA

Power output max. 900 mW

Inductivity max. 0 mH

Capacity max. 52 nF

3.43.4

3.43.4

3.4

PP

PP

P

ERFORMANCERFORMANC

ERFORMANCERFORMANC

ERFORMANC

EE

EE

E

CHARACHARA

CHARACHARA

CHARA

CTERISCTERIS

CTERISCTERIS

CTERIS

TICTIC

TICTIC

TIC

SS

SS

S

xx19xx - xx - x - xx - xx / xx - x - x - x - @xxx - xxxx

3.4.13.4.1

3.4.13.4.1

3.4.1

AA

AA

A

CC

CC

C

CC

CC

C

URAURA

URAURA

URA

CYCY

CYCY

CY

(Linearity and repeatability)

Page 10

10

TECHNICAL DATA

3.4.13.4.1

3.4.13.4.1

3.4.1

AA

AA

A

XX

XX

X

11921192

11921192

1192

XX

XX

X

, ,

, ,

,

XX

XX

X

11941194

11941194

1194

XX

XX

X

±0.15% (20% to 100% f.s.)

±0.25% (0% to 20% f.s.)

(0-3000 psi and above)

±0.25% (20% to 100% f.s.)

±0.50% (0% to 20% f.s.)

(0-1500 psi)

3.4.13.4.1

3.4.13.4.1

3.4.1

BB

BB

B

X1193X, X1193X,

X1193X, X1193X,

X1193X,

XX

XX

X

11951195

11951195

1195

XX

XX

X

±0.15% (20% to 100% f.s.)

±0.25% (0% to 20% f.s.)

(0-1500 psi and above)

±0.25% (20% to 100% f.s.)

±0.50% (0% to 20% f.s.)

(0-750 psi)

3.4.13.4.1

3.4.13.4.1

3.4.1

CC

CC

C

XX

XX

X

21922192

21922192

2192

XX

XX

X

, ,

, ,

,

XX

XX

X

21942194

21942194

2194

XX

XX

X

±0.25% (20% to 100% f.s.)

±0.50% (0% to 20% f.s.)

(0-3000 psi and above)

±0.50% (20% to 100% f.s.)

±1.00% (0% to 20% f.s.)

(0-1500 psi)

3.4.13.4.1

3.4.13.4.1

3.4.1

DD

DD

D

X2193X, X2193X,

X2193X, X2193X,

X2193X,

XX

XX

X

21952195

21952195

2195

XX

XX

X

±0.25% (20% to 100% f.s.)

±0.50% (0% to 20% f.s.)

(0-1500 psi and above)

±0.50% (20% to 100% f.s.)

±1.00% (0% to 20% f.s.)

(0.750 psi and above)

3.4.23.4.2

3.4.23.4.2

3.4.2

RR

RR

R

ESOLUTIONESOLUTION

ESOLUTIONESOLUTION

ESOLUTION

0.035% f.s. or better

Page 11

11

TECHNICAL DATA

3.3.

3.3.

3.

55

55

5

PP

PP

P

RERE

RERE

RE

SS

SS

S

SURESURE

SURESURE

SURE

SIDESIDE

SIDESIDE

SIDE

CC

CC

C

ONNEONNE

ONNEONNE

ONNE

CTIONCTION

CTIONCTION

CTION

2 = 1/2" 20 UNF 2A (xx192x-x . . . )

3 = M18 x 1.5 (xx193x-x . . .)

4 or 5 = flange (xx194x-x . . . ) or (xx195x-x . . . )

3.63.6

3.63.6

3.6

PP

PP

P

RESSURERESSURE

RESSURERESSURE

RESSURE

RANGESRANGES

RANGESRANGES

RANGES

( (

( (

(

XXXX

XXXX

XX

1919

1919

19

XXXX

XXXX

XX

))

))

)

3.6.13.6.1

3.6.13.6.1

3.6.1

PP

PP

P

RESSURERESSURE

RESSURERESSURE

RESSURE

RANGESRANGES

RANGESRANGES

RANGES

ININ

ININ

IN

PSIPSI

PSIPSI

PSI

Model numberModel number

Model numberModel number

Model number

PP

PP

P

ermittermitt

ermittermitt

ermitt

ed pred pr

ed pred pr

ed pr

ee

ee

e

ss

ss

s

ss

ss

s

urur

urur

ur

e re r

e re r

e r

anan

anan

an

gg

gg

g

e in Pe in P

e in Pe in P

e in P

SISI

SISI

SI

xx19xx-xx-x-7.5c-x 0-750

(xx193xx & xx195xx only)(xx193xx & xx195xx only)

(xx193xx & xx195xx only)(xx193xx & xx195xx only)

(xx193xx & xx195xx only)

xx19xx-xx-x-1.5c-xm 0-1500

xx19xx-xx-x-3c-xm 0-3000

xx19xx-xx-x-5c-xm 0-5000

xx19xx-xx-x-7.5c-xm 0-7500

xx19xx-xx-x-10c-xm 0-10000

3.6.23.6.2

3.6.23.6.2

3.6.2

MM

MM

M

AXAX

AXAX

AX

. O. O

. O. O

. O

VERLVERL

VERLVERL

VERL

OO

OO

O

ADAD

ADAD

AD

( (

( (

(

WITHOUTWITHOUT

WITHOUTWITHOUT

WITHOUT

INFLINFL

INFLINFL

INFL

UENCINGUENCING

UENCINGUENCING

UENCING

OPERAOPERA

OPERAOPERA

OPERA

TINGTING

TINGTING

TING

DD

DD

D

AA

AA

A

TT

TT

T

AA

AA

A

))

))

)

xx19xx 1.5 x full scale pressure up to 10,000 psi

3.6.33.6.3

3.6.33.6.3

3.6.3

BB

BB

B

URSTURST

URSTURST

URST

PRESSUREPRESSURE

PRESSUREPRESSURE

PRESSURE

3 x nominal value, max. 30,000 psi

3.6.43.6.4

3.6.43.6.4

3.6.4

NN

NN

N

AA

AA

A

TURALTURAL

TURALTURAL

TURAL

FREFRE

FREFRE

FRE

QUENCYQUENCY

QUENCYQUENCY

QUENCY

50 Hz [-3db]

3.73.7

3.73.7

3.7

RR

RR

R

IGIDIGID

IGIDIGID

IGID

STEMSTEM

STEMSTEM

STEM

//

//

/

FLEXIBLEFLEXIBLE

FLEXIBLEFLEXIBLE

FLEXIBLE

STEMSTEM

STEMSTEM

STEM

( (

( (

(

XXXX

XXXX

XX

1919

1919

19

XXXX

XXXX

XX

-)-)

-)-)

-)

6 = 152 mm standard length for rigid version

6/18 = 152 mm stem length / 457 mm flexible stem

Other lengths on request

3.83.8

3.83.8

3.8

EE

EE

E

LELE

LELE

LE

CTRICALCTRICAL

CTRICALCTRICAL

CTRICAL

DD

DD

D

AA

AA

A

TT

TT

T

AA

AA

A

Configuration 4-arm Wheatstone bridge strain gauge with int. amplifier

Output signal 2-wire 4 - 20 mA, optional 2nd 2-wire 4 - 20 mA

Page 12

12

TECHNICAL DATA

Supply voltage 12-30 VDC for EEx ia IIC T4 12-42 for FM approved explosion proof

models

Power consumption -20 mA

Zero balance (xx192x and xx194x)

0.25% for 3000 psi and above

0.5% for 1500 psi

(xx193x and xx195x)

0.25% for 1500 psi and above

0.5% for 750 psi

3.93.9

3.93.9

3.9

TT

TT

T

EMPERAEMPERA

EMPERAEMPERA

EMPERA

TURETURE

TURETURE

TURE

INFLINFL

INFLINFL

INFL

UENCUENC

UENCUENC

UENC

EE

EE

E

ElEl

ElEl

El

ectrectr

ectrectr

ectr

oniconic

oniconic

onic

ss

ss

s

hou hou

hou hou

hou

ss

ss

s

inin

inin

in

gg

gg

g

Max. housing temperatures

Safety class T4 -20°C to +80°C

Compenstated +25°C to +300°C (option to 350°C) - snout

temperature range +25°C to +80°C - electronics

Zero and sensitivity shift due to temperature change on electronics housing

xx19xx ±0.15% f.s./55°C

DiDi

DiDi

Di

aphraphr

aphraphr

aphr

agm (in cagm (in c

agm (in cagm (in c

agm (in c

ontont

ontont

ont

actact

actact

act

w w

w w

w

ith mediith medi

ith mediith medi

ith medi

a)a)

a)a)

a)

Maximum temperature at the diaphragm

xx19xx 350°C

Zero shift due to temperature change on the diaphragm

xx19xx ±0.01 psi / 100°C

3.103.10

3.103.10

3.10

EMCEMC

EMCEMC

EMC

RERE

RERE

RE

QUIREMENTQUIREMENT

QUIREMENTQUIREMENT

QUIREMENT

SS

SS

S

Conforming to CE in accordance with EMC directive.

Electromagnetic Interference DIN EN 550223 1995

Immunity DIN EN 61000-4-2 1995

Radiated, Radio Freq, etc. DIN EN 61000-4-3 1995 +A1:1998+A2:2000

Pulse Magnetic Field DIN EN 61000-4-9 1993 + A1:2001

Page 13

13

TECHNICAL DATA

Surge Immunity DIN EN 61000-4-5 1995 + A1:2000

Conducted Disturbences DIN EN 61000-4-6 1996 + A1:2000

Power Frequency Magnetic Field DIN EN 61000-4-8 1993 + A1:2001

3.113.11

3.113.11

3.11

MM

MM

M

AA

AA

A

TERIALSTERIALS

TERIALSTERIALS

TERIALS

Diaphragm 15-5PH Mat. No. 1.4545 DyMax™ coated

Stem 17-4PH Mat. No. 517400

3.123.12

3.123.12

3.12

TT

TT

T

ORQUEORQUE

ORQUEORQUE

ORQUE

xx192x xx193x xx194x xx195x

max. 56.5 Nm max. 56.5 Nm max. 5.6 Nm max. 14.1 Nm

(500 inch-lbs.) (500 inch-lbs.) (50 inch-lbs.) (125 inch-lbs.)

min. 11.3 Nm min. 11.3 Nm min. 4.5 Nm min. 11.3 Nm

(100 inch-lbs.) (100 inch-lbs.) (40 inch-lbs.) (100 inch-lbs.)

3.133.13

3.133.13

3.13

EE

EE

E

NVIRONMENTNVIRONMENT

NVIRONMENTNVIRONMENT

NVIRONMENT

ALAL

ALAL

AL

PROPRO

PROPRO

PRO

TETE

TETE

TE

CTIONCTION

CTIONCTION

CTION

TT

TT

T

OO

OO

O

IE IE

IE IE

IE

CC

CC

C

5 5

5 5

5

22

22

2

99

99

9

Electronics housing min. IP66, nema 4x

3.143.14

3.143.14

3.14

WW

WW

W

EIGHTEIGHT

EIGHTEIGHT

EIGHT

5-10 lbs.

3.153.15

3.153.15

3.15

DD

DD

D

IMENSIONSIMENSIONS

IMENSIONSIMENSIONS

IMENSIONS

Page 14

14

TECHNICAL DATA

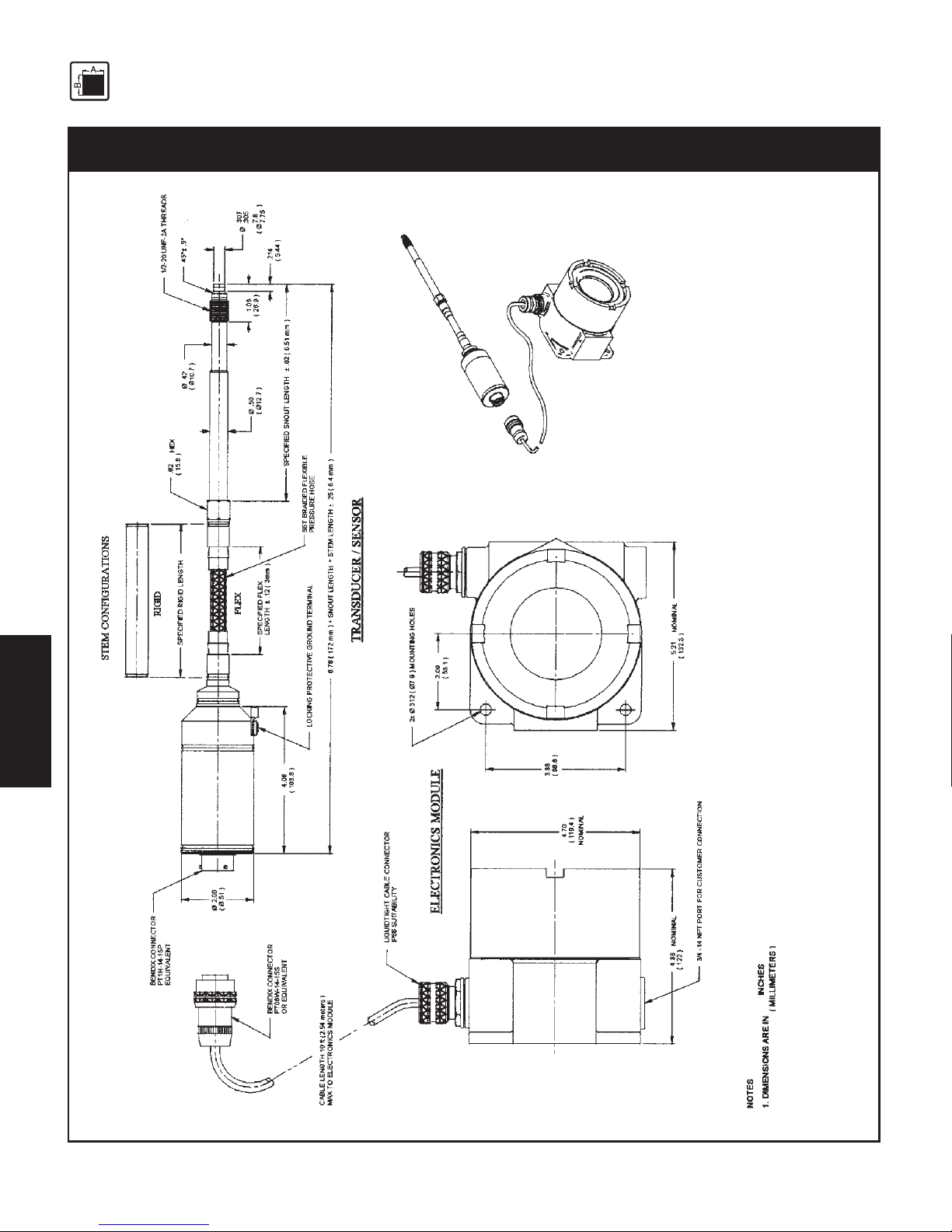

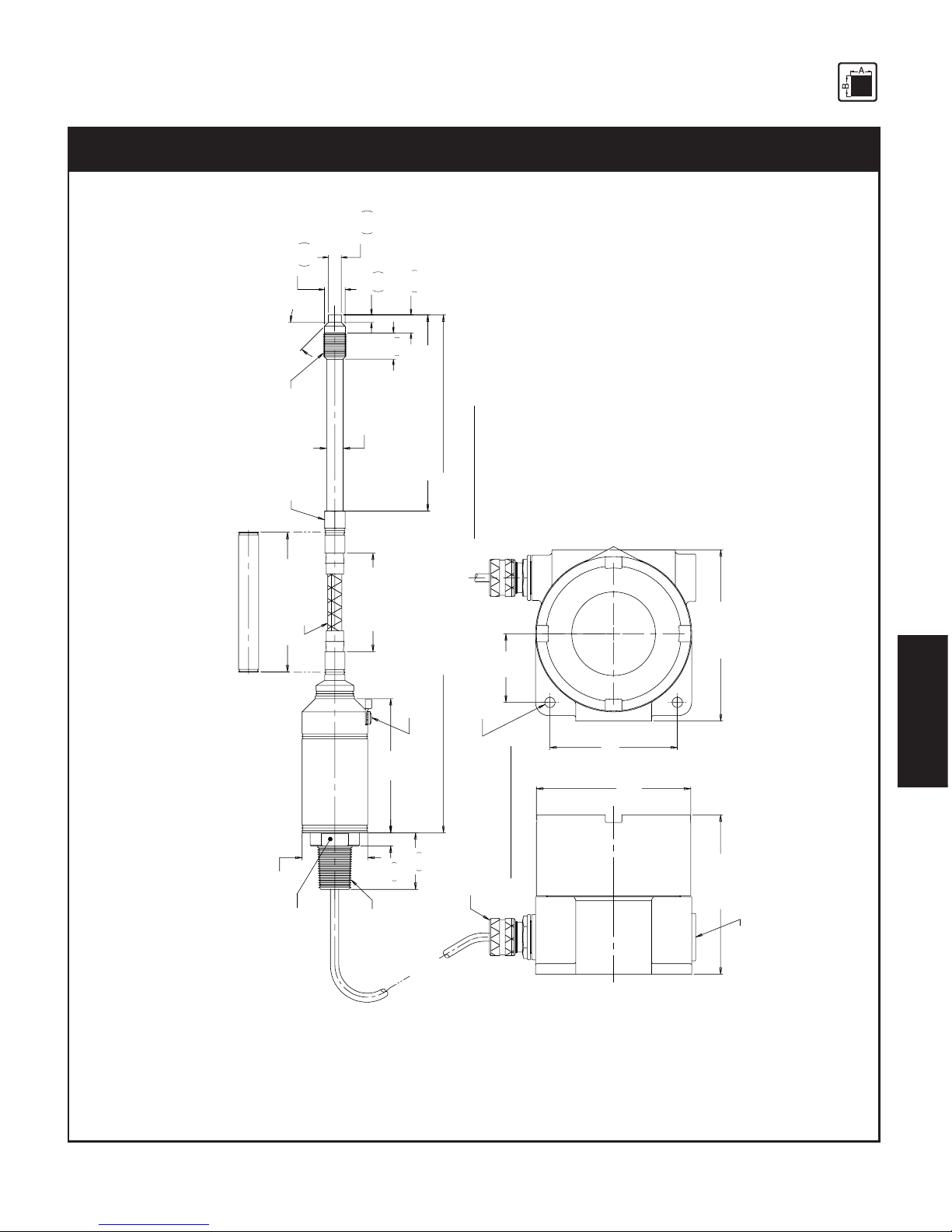

Fig. 3-1Fig. 3-1

Fig. 3-1Fig. 3-1

Fig. 3-1

IPX II Models S1192, S2192, N1192 & N2192IPX II Models S1192, S2192, N1192 & N2192

IPX II Models S1192, S2192, N1192 & N2192IPX II Models S1192, S2192, N1192 & N2192

IPX II Models S1192, S2192, N1192 & N2192

Page 15

15

TECHNICAL DATA

3.88

( 98.6 )

2.09

( 53.1 )

2x

O

.312 (

O

7.9 ) MOUNTIN G HOLES

5.21

( 132.3 )

NOMINAL

4.70

( 119.4 )

4.88

( 122 )

M18X1.5THREAD

45

v

30'

44

v

30'

.80

20.3

.236

.227

5.99

5.77

.550

13.97

.630

.627

16.00

15.93

O

.394

.392

10.01

9.96

O

SNOUT

HEX

.62

( 15.8 )

.50

O

(

O

12.7 )

SST BRAIDED FLEXIBLE

PRESSURE HOSE

BENDIX CONNECTOR

PT1H-14-15P OR EQUIVALENT

LOCKING PROTE CTIVE GROUND TERMINAL

4.08

( 103.6 )

2.00

O

(

O

.51 )

SPECIFIED FLEX

LENGTH

u

.12 (3mm)

TRANSDUCER/SENSOR

FLEX

RIGID

STEM CONFI GURATIONSSTEM CONFI GURATIONS

SPECIFIED RIGID LENGTH

SPECIFIED SNOUT LENG TH

u

.02 ( .51mm )

6.78 ( 172 mm ) + SNOUT LENGTH+ STEM LENGTH

u

.25(6.4mm)

10 ft ( 2.54 meters)

CABLE TO ELECTRONICS MODULE

BENDI X CONNEC TOR

PT06W-14-15S

OR EQUIVALENT

LIQUIDTIGHT CABLE CONNECTOR

IP66 SUITABILITY

NOMINAL

NOMINAL

ELECTRONICSMODULE

3/4 -14 NPT PORT FOR

CUSTOMER CONNECTION

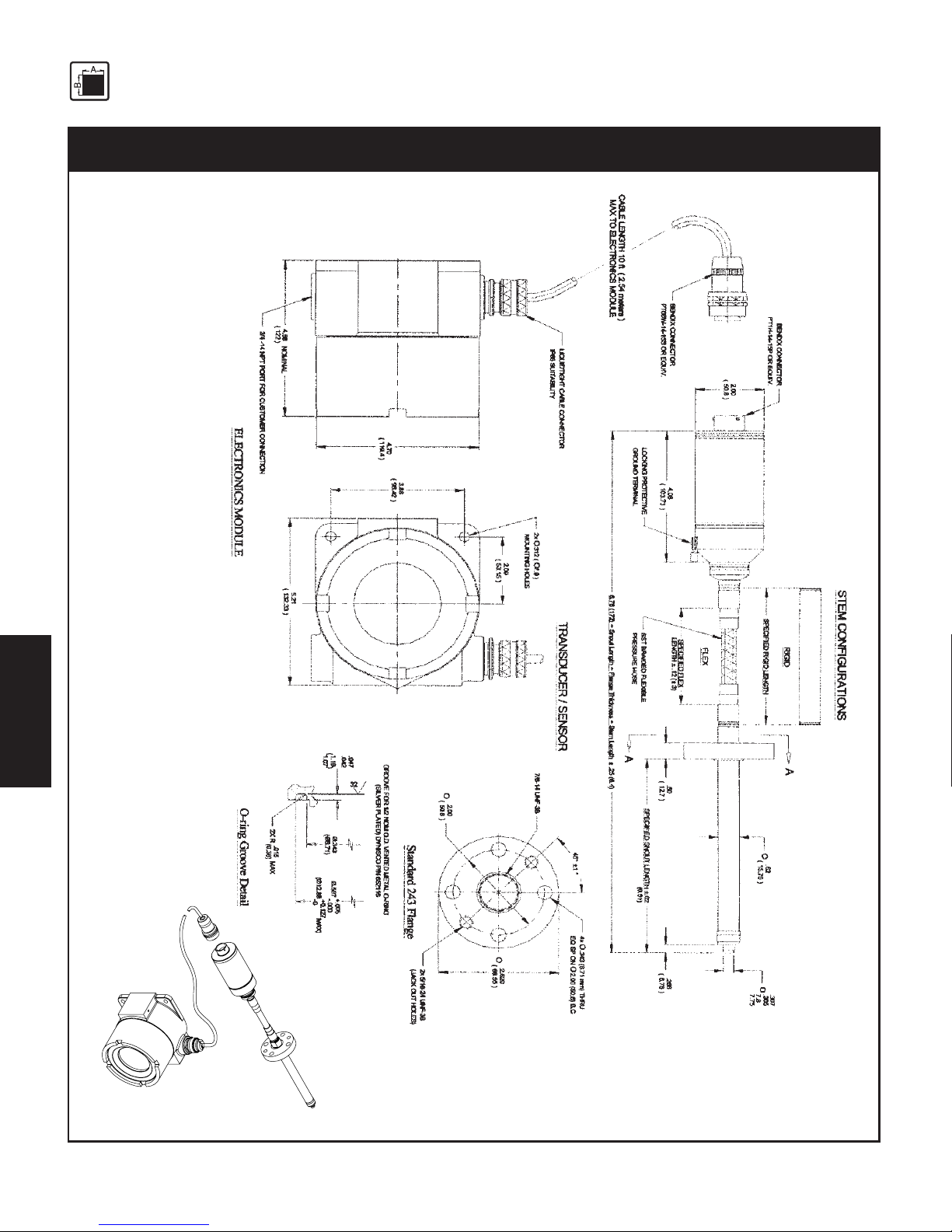

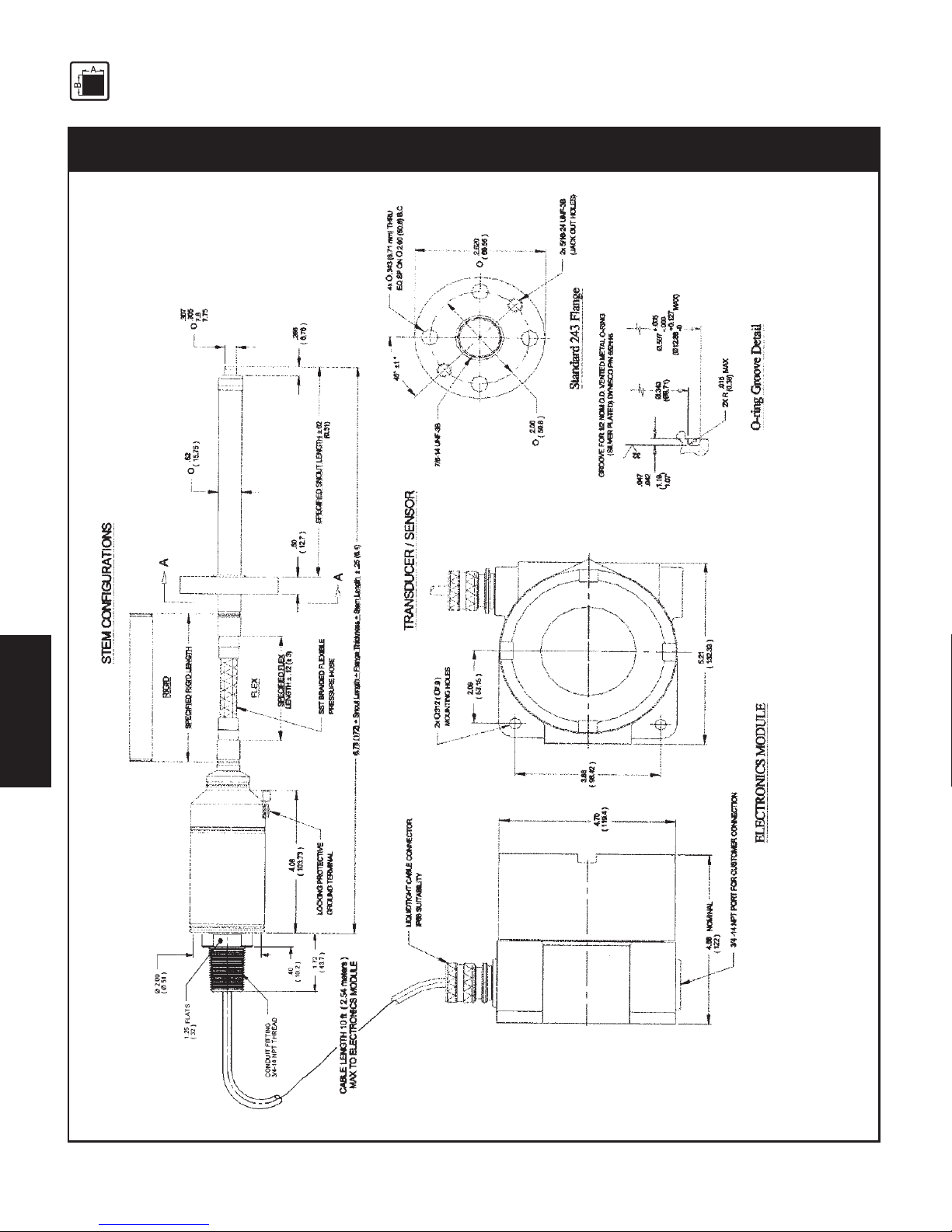

Fig. 3-2Fig. 3-2

Fig. 3-2Fig. 3-2

Fig. 3-2

IPX II Models S1193, S2193, N1193 & N2193IPX II Models S1193, S2193, N1193 & N2193

IPX II Models S1193, S2193, N1193 & N2193IPX II Models S1193, S2193, N1193 & N2193

IPX II Models S1193, S2193, N1193 & N2193

Page 16

16

TECHNICAL DATA

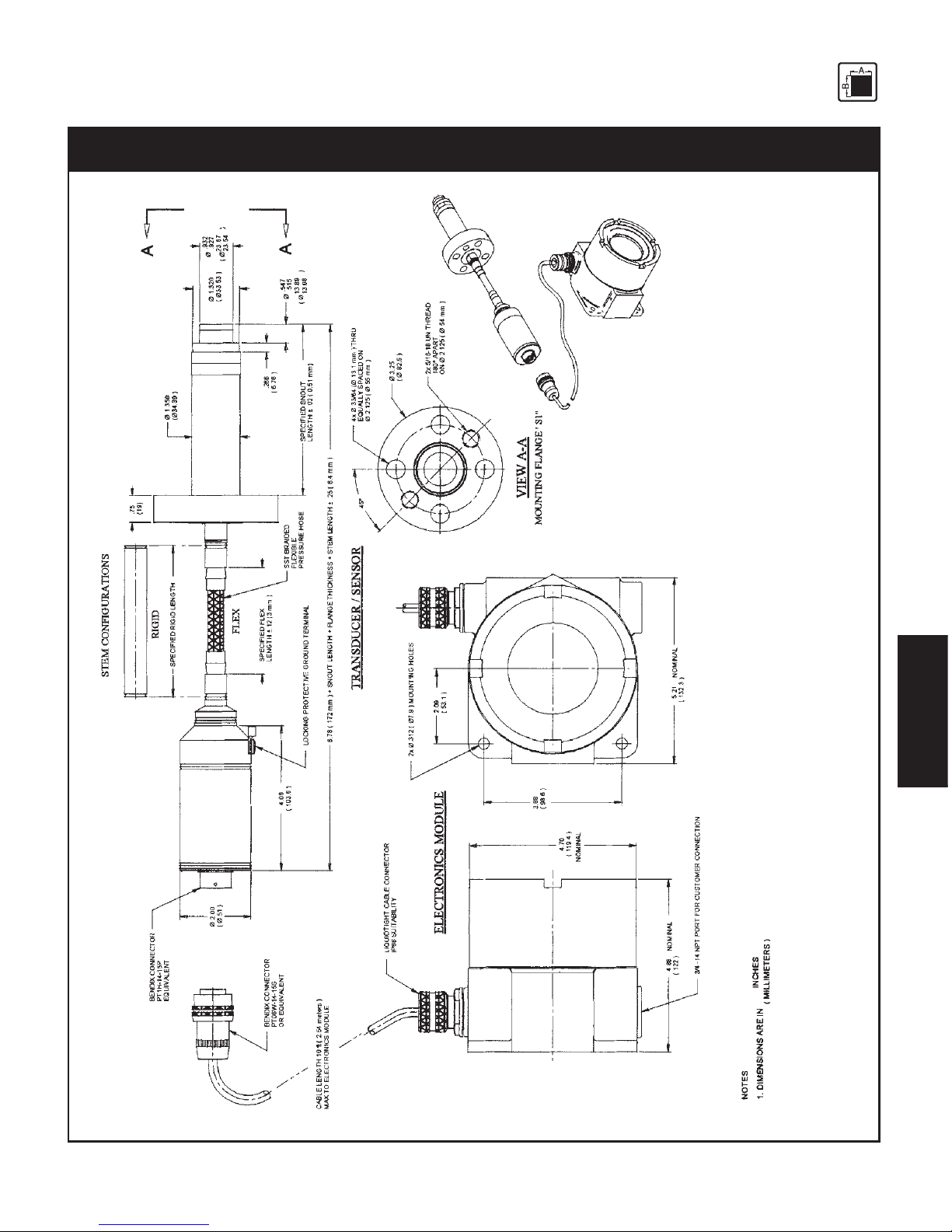

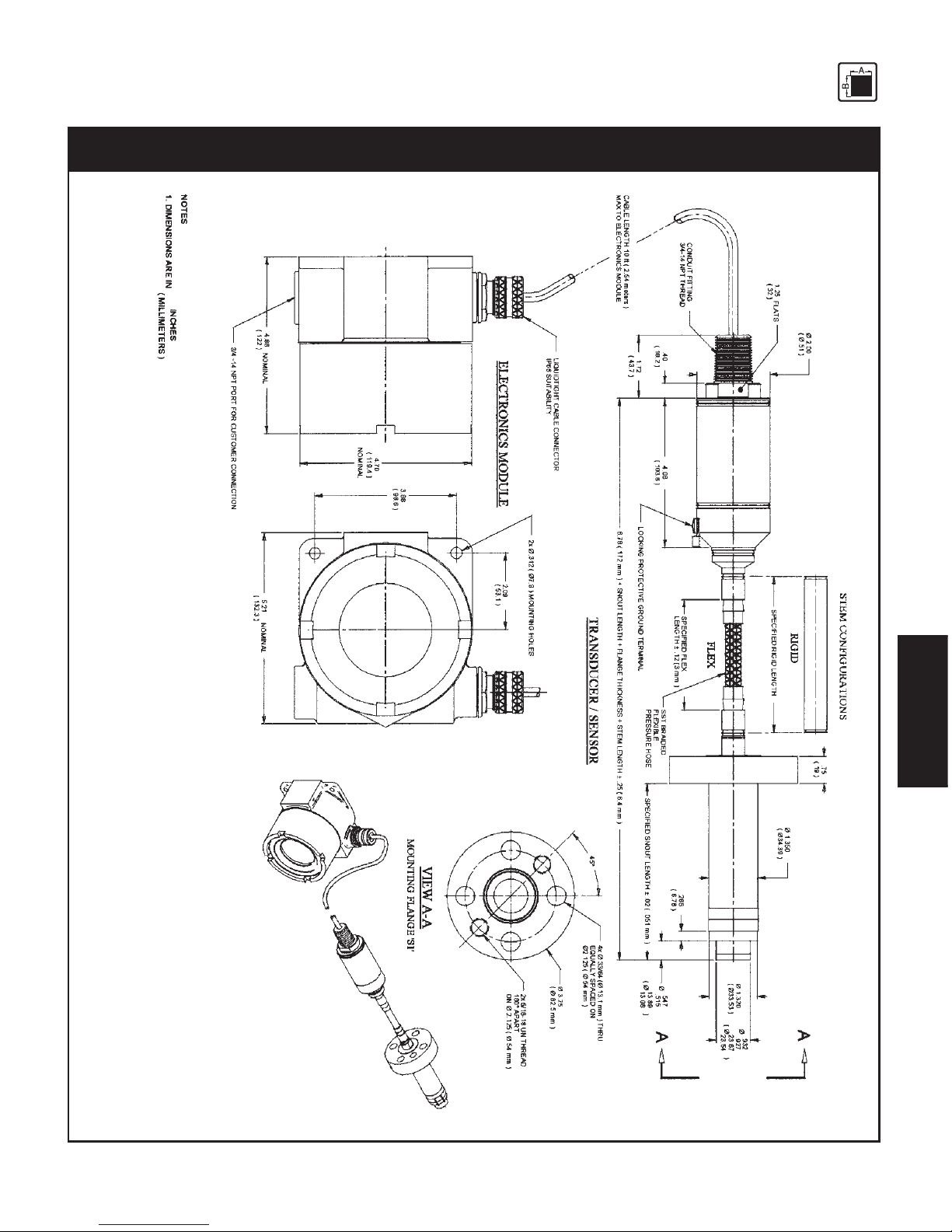

Fig. 3-3Fig. 3-3

Fig. 3-3Fig. 3-3

Fig. 3-3

IPX II Models S1194, S2194, N1194 & N2194IPX II Models S1194, S2194, N1194 & N2194

IPX II Models S1194, S2194, N1194 & N2194IPX II Models S1194, S2194, N1194 & N2194

IPX II Models S1194, S2194, N1194 & N2194

Page 17

17

TECHNICAL DATA

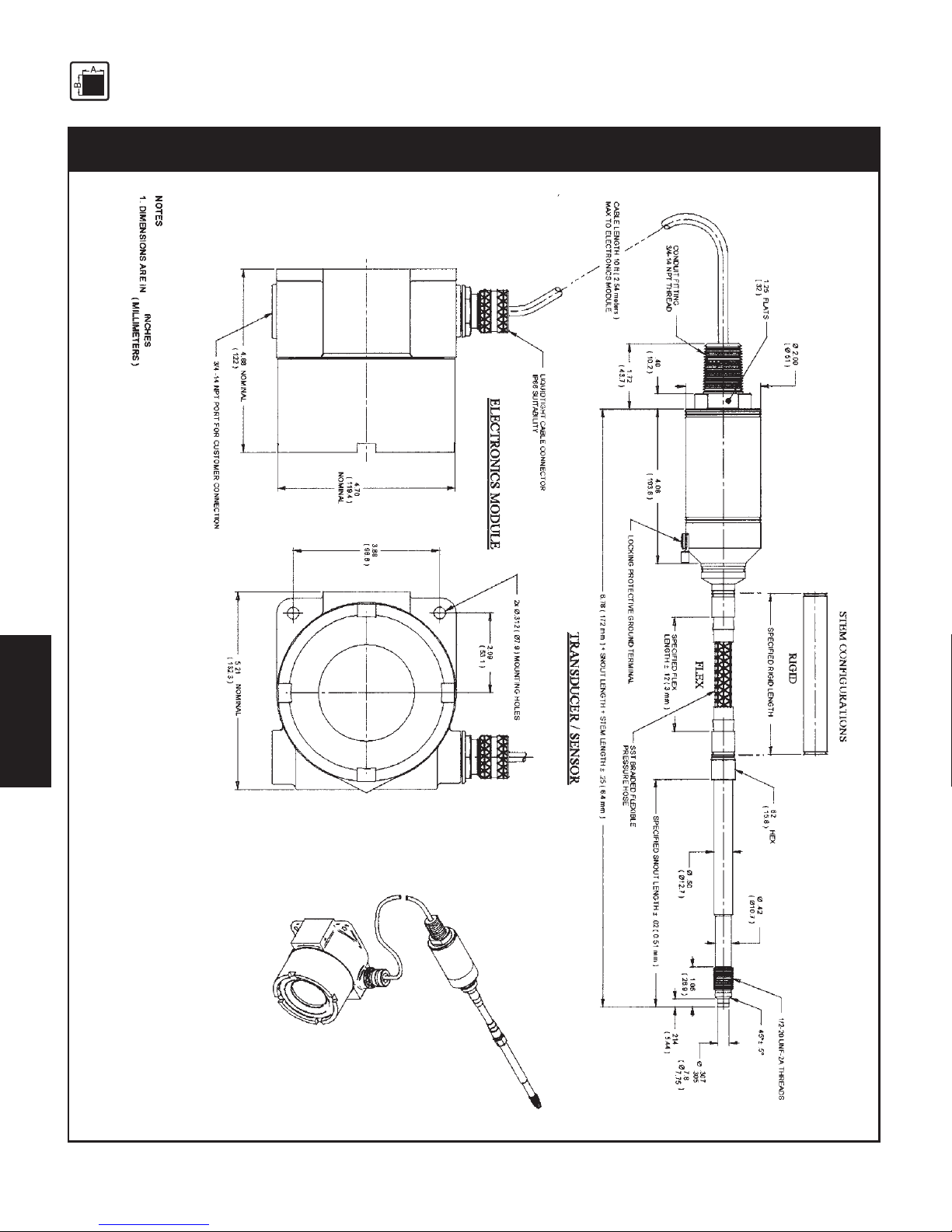

Fig. 3-4Fig. 3-4

Fig. 3-4Fig. 3-4

Fig. 3-4

IPX II Models S1195, S2195, N1195 & N2195IPX II Models S1195, S2195, N1195 & N2195

IPX II Models S1195, S2195, N1195 & N2195IPX II Models S1195, S2195, N1195 & N2195

IPX II Models S1195, S2195, N1195 & N2195

Page 18

18

TECHNICAL DATA

Fig. 3-5Fig. 3-5

Fig. 3-5Fig. 3-5

Fig. 3-5

IPX II Models E1192 & E2192IPX II Models E1192 & E2192

IPX II Models E1192 & E2192IPX II Models E1192 & E2192

IPX II Models E1192 & E2192

Page 19

19

TECHNICAL DATA

M18X1.5THREAD

45

v

30'

44

v

30'

.80

20.3

.236

.227

5.99

5.77

.550

13.97

.630

.627

16.00

15.93

O

.394

.392

10.01

9.96

O

SNOUT

HEX

.62

( 15.8 )

.50

O

(

O

12.7 )

SST BRAIDED FLEXIBLE

PRESSURE HOSE

LOCKING PROTECT IVE GROUND TERMINAL

4.08

( 103.6 )

2.00

O

(

O

.51 )

SPECIFIED FLEX

LENGTH

u

.12 (3mm)

TRANSDUCER/SENSOR

FLEX

RIGID

STEM CONFI GURATIONSSTEM CONF IGURATIONS

SPECIFIED RIGID LENGTH

SPECIFIED SNOUT LENGT H

u

.02 ( .51mm )

6.78 ( 172 mm ) + SNOUT LENGTH+ STEM LENGTH

u

.25(6.4mm)

10 ft ( 2.54 meters )

CABLE TO ELECTRONICS MODULE

FLATS

1.25

(32)

CONDUIT FITTI NG

3/4-14 NPT THREAD

3/4 -14 NPT PORT FOR

CUSTOMER CONNECTION

ELECTRONICSMODULE

NOMINAL

NOMINAL

LIQUIDTIGHT CABLE CONNECTOR

IP66 SUITABILITY

4.88

( 122 )

4.70

( 119.4 )

NOMINAL

5.21

( 132.3 )

2x

O

.312 (

O

7.9 ) MOUNTIN G HOLES

2.09

( 53.1 )

3.88

( 98.6 )

.40

10.2

1.72

43.8

Fig. 3-6Fig. 3-6

Fig. 3-6Fig. 3-6

Fig. 3-6

IPX II Models E1193 & E2193IPX II Models E1193 & E2193

IPX II Models E1193 & E2193IPX II Models E1193 & E2193

IPX II Models E1193 & E2193

Page 20

20

TECHNICAL DATA

Fig. 3-7Fig. 3-7

Fig. 3-7Fig. 3-7

Fig. 3-7

IPX II Models E1194 & E2194IPX II Models E1194 & E2194

IPX II Models E1194 & E2194IPX II Models E1194 & E2194

IPX II Models E1194 & E2194

Page 21

21

TECHNICAL DATA

Fig. 3-Fig. 3-

Fig. 3-Fig. 3-

Fig. 3-

Fig. 3-8Fig. 3-8

Fig. 3-8Fig. 3-8

Fig. 3-8

IPX II Models E1195 & E2195IPX II Models E1195 & E2195

IPX II Models E1195 & E2195IPX II Models E1195 & E2195

IPX II Models E1195 & E2195

Page 22

22

FUNCTION

4.4.

4.4.

4.

FF

FF

F

UNCTIONUNCTION

UNCTIONUNCTION

UNCTION

4.1 Construction ....................................................................................................................... 22

4.2 Description of Functions ...................................................................................................... 22

4.2.1 Theory of Operation ............................................................................................................ 23

4.2.2 Mechanical ......................................................................................................................... 23

4.2.3 Electrical ............................................................................................................................ 24

4.14.1

4.14.1

4.1

CC

CC

C

ONSTRUCTIONONSTRUCTION

ONSTRUCTIONONSTRUCTION

ONSTRUCTION

The PTs of series IPX II are industry standard.

The main advantages are:

• Intrinsically safe EEx ia IIC T4

• temperature compensated

• HART protocol based

• resistance to aggressive media

• insensitivity to electromagnetic radiation (EMC)

• liquid-filled transmission system (mercury)

• pressure measurements in plastic melt up to a temperature of 350°C

4.24.2

4.24.2

4.2

DD

DD

D

ESCRIPTIONESCRIPTION

ESCRIPTIONESCRIPTION

ESCRIPTION

OFOF

OFOF

OF

F F

F F

F

UNCTIONSUNCTIONS

UNCTIONSUNCTIONS

UNCTIONS

The Dynisco IPX II Series of Smart Pressure Transmitters are microprocessor based instruments that

incorporate advanced software techniques and modern sensor design. New, proprietary sensor

processing methods ensure the highest quality and reliability to meet Dynisco’s standards.

The IPX II Series is designed for applications that require high accuracy, even under wide variations

in process temperature. With the capability for up to 6-to-1 span turndown, one pressure range can

be used in several different applications, reducing spare parts inventory. And the IPX II Series’ remote

digital communication utilizing the industry standard HART protocol allows transmitter parameter

changes to be made from safe areas, increasing operator safety.

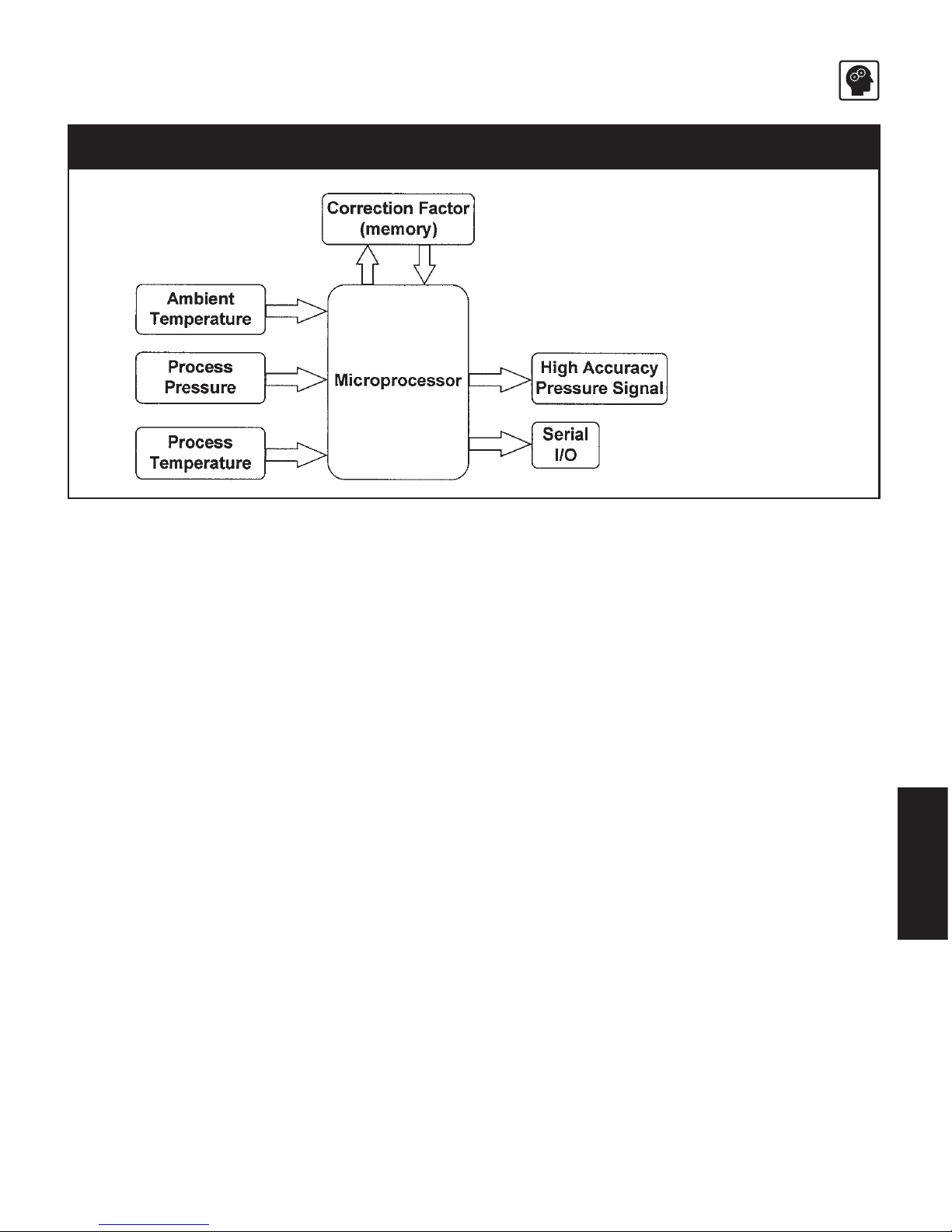

The IPX II Series of Smart Pressure Transmitters are characterized for process temperature effects,

providing an optional linearized stable, temperature reading via 4-20 mA output. Figure 4-1

illustrates the operation of the transmitter in the form of a block diagram. The process temperature

signal is available through the HART protocol. An optional dual LCD will display pressure or

temperature measurements in real-time.

Page 23

23

FUNCTION

Fig. 4-1Fig. 4-1

Fig. 4-1Fig. 4-1

Fig. 4-1

Operation in Block FormOperation in Block Form

Operation in Block FormOperation in Block Form

Operation in Block Form

In addition to the standard analog output, the IPX II Series supports remote digital communications

compatible with the HART Communicator (product of Emerson). The Model 275 can communicate

with IPX II Series transmitters from the control room, at the transmitter site, or from any convenient

junction box or wiring termination point in the measurement loop. The model 275 may be used to

configure the IPX II Series of transmitters or to test the control loop.

4.2.14.2.1

4.2.14.2.1

4.2.1

TT

TT

T

HEHE

HEHE

HE

ORYORY

ORYORY

ORY

OFOF

OFOF

OF

O O

O O

O

PERAPERA

PERAPERA

PERA

TIONTION

TIONTION

TION

The IPX II Smart Pressure Transmitter is a microprocessor-based device capable of measuring process

pressure to within 0.15% of the specified range. It is compensated for temperature effects at the

process end as well as the electronics end by using RTD’s and compensating software customized

for each unit.

The IPX II Series can be broken down into two distinct subsections, mechanical and electrical. The

following describes each in detail.

4.2.24.2.2

4.2.24.2.2

4.2.2

MM

MM

M

EE

EE

E

CHANICALCHANICAL

CHANICALCHANICAL

CHANICAL

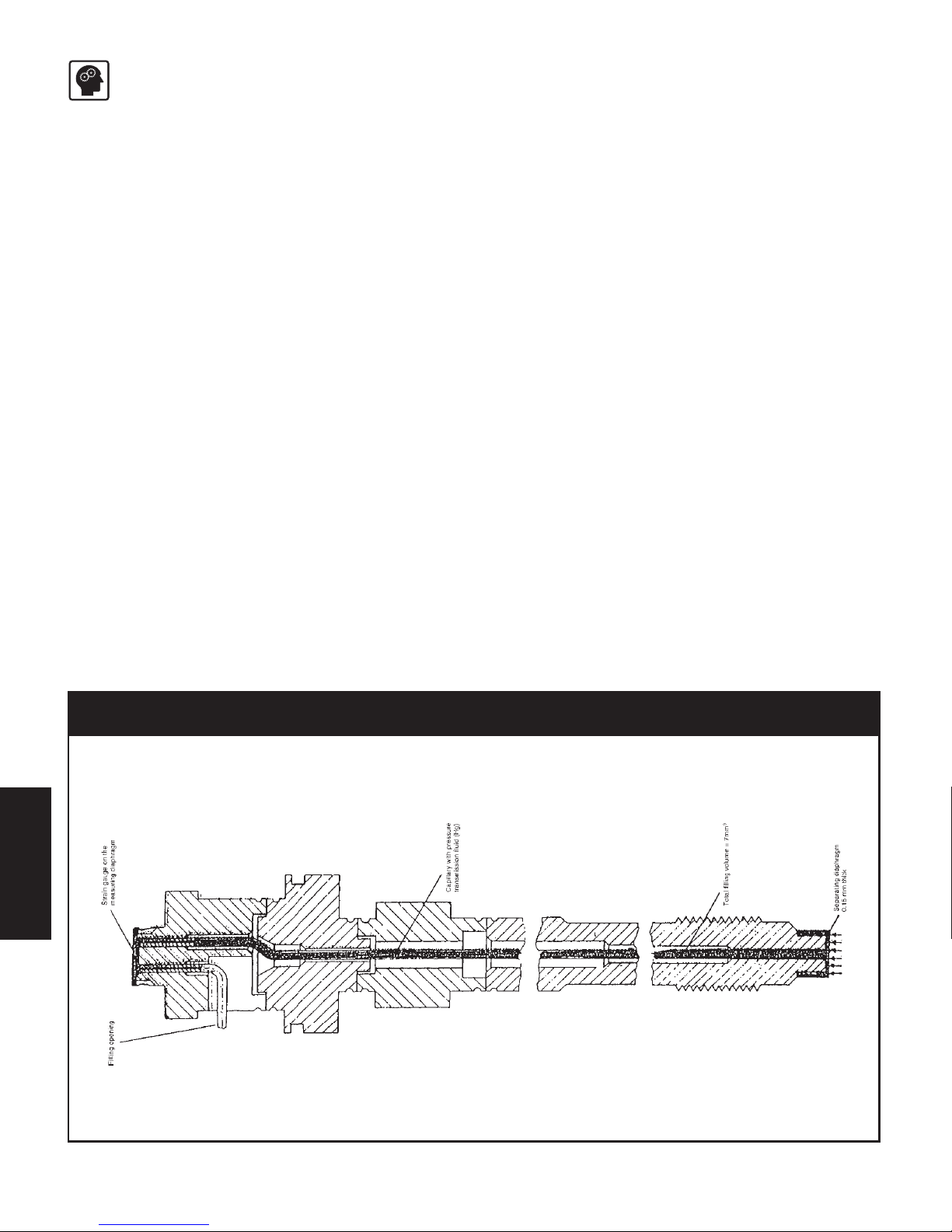

The mechanical system (filled assembly) consists of a lower diaphragm, a filled capillary tube, and

an upper diaphragm with a sputtered thin film strain gage. The filled assembly transmits pressure

from the process to the strain gage diaphragm where it is converted to an electrical signal. The filled

assembly isolates the electronics from the high process temperatures.

The elThe el

The elThe el

The el

ectrectr

ectrectr

ectr

oniconic

oniconic

onic

ss

ss

s

hou hou

hou hou

hou

ss

ss

s

inin

inin

in

g ig i

g ig i

g i

ss

ss

s

mm

mm

m

atat

atat

at

ed wed w

ed wed w

ed w

ith a sith a s

ith a sith a s

ith a s

pecpec

pecpec

pec

ificific

ificific

ific

sen sen

sen sen

sen

sor asor a

sor asor a

sor a

ss

ss

s

sembsemb

sembsemb

semb

lyly

lyly

ly

. Do not. Do not

. Do not. Do not

. Do not

mi mi

mi mi

mi

xx

xx

x

and m and m

and m and m

and m

atat

atat

at

cc

cc

c

h houh hou

h houh hou

h hou

ss

ss

s

inin

inin

in

gg

gg

g

ss

ss

s

and sen and sen

and sen and sen

and sen

sorsor

sorsor

sor

s.s.

s.s.

s.

The lower diaphragm is the surface in contact with the media being measured. This diaphragm can

be made from a choice of materials. The standard material is heat-treated 15-5 stainless steel. This

has average corrosion and abrasion resistance and is similar to 17-4 stainless steel. Other materials are

Page 24

24

FUNCTION

also available including Hastelloy C-276 which has excellent corrosion resistant properties (but is not

good for abrasion). For other materials please consult the factory.

Behind the lower diaphragm is a capillary tube filled to the upper diaphragm. As the process

pressure deflects the lower diaphragm, the fill is displaced through the capillary tube to deflect the

upper diaphragm.

The upper diaphragm has a 5000 ohm thin film strain gage element deposited on it in the

configuration of a Wheatstone Bridge. The deflection of the upper diaphragm causes a change in the

resistance of the strain gage and hence a change in the balance of the bridge. The amount of

imbalance is directly proportional to the applied pressure. This completes the translation of pressure

applied to the lower diaphragm into a usable electrical signal.

4.2.34.2.3

4.2.34.2.3

4.2.3

EE

EE

E

LELE

LELE

LE

CTRICALCTRICAL

CTRICALCTRICAL

CTRICAL

The low level output signal from the bridge is amplified via an instrumentation amp circuit. The

amplified signal then goes to the input of the analog-to-digital (A/D) converter.

Once the microprocessor has the converted voltage input from the A/D converter, the compensation

algorithms are executed. The unit is compensated for any errors introduced by temperature effects on

the gauge, snout electronics, and the nonlinearities of the pressure measurement itself. The corrected

digital signal is sent to a digital-to-analog (D/A) converter which modulates the current of the unit’s

power supply between 4 and 20 milliamps for an output current proportional to the applied

pressure.

Fig. 4-Fig. 4-

Fig. 4-Fig. 4-

Fig. 4-

22

22

2

Functioning Principle of the PT of the IPX II SeriesFunctioning Principle of the PT of the IPX II Series

Functioning Principle of the PT of the IPX II SeriesFunctioning Principle of the PT of the IPX II Series

Functioning Principle of the PT of the IPX II Series

Page 25

25

FUNCTION

Figure 4-3 illustrates typical wiring connections between the HART Communicator and any

compatible device.

Fig. 4-Fig. 4-

Fig. 4-Fig. 4-

Fig. 4-

33

33

3

CC

CC

C

onnectinonnectin

onnectinonnectin

onnectin

g the HARg the HAR

g the HARg the HAR

g the HAR

T CT C

T CT C

T C

ommuommu

ommuommu

ommu

nicnic

nicnic

nic

atat

atat

at

or tor t

or tor t

or t

o the IPXo the IPX

o the IPXo the IPX

o the IPX

II II

II II

II

Explosion can result in death or serious injury. Before connecting the

HART Communicator in an explosive atmosphere, make sure the instruments in the

loop are installed in accordance with intrinsically safe or nonincentive fields wiring

practices. For intrinsically safe and FM wiring connections, see the HART 275

Communication Manual.

Page 26

26

TRANSPORT

5.5.

5.5.

5.

TT

TT

T

RANSRANS

RANSRANS

RANS

PORPOR

PORPOR

POR

TT

TT

T

/ D / D

/ D / D

/ D

ELIVERYELIVERY

ELIVERYELIVERY

ELIVERY

5.1 Transport / packing / transport damage ............................................................................... 26

5.2 Storage .............................................................................................................................. 26

5.3 Scope of delivery ................................................................................................................ 26

TT

TT

T

oo

oo

o

xx

xx

x

icic

icic

ic

h h

h h

h

azaz

azaz

az

arar

arar

ar

d!d!

d!d!

d!

The PT contains a small amount of mercury (Hg) as its transmission medium. If the

diaphragm is damaged, mercury may escape.

Never transport or store the PT without the protective shell bolted in place. Remove the

shell shortly before installation.

IfIf

IfIf

If

mer mer

mer mer

mer

cc

cc

c

urur

urur

ur

yy

yy

y

i i

i i

i

ss

ss

s

inh inh

inh inh

inh

alal

alal

al

ed or swed or sw

ed or swed or sw

ed or sw

alal

alal

al

lolo

lolo

lo

ww

ww

w

ed, seeked, seek

ed, seeked, seek

ed, seek

medic medic

medic medic

medic

alal

alal

al

att att

att att

att

ention immediention immedi

ention immediention immedi

ention immedi

atat

atat

at

elyely

elyely

ely

..

..

.

Mercury is hazardous waste and must be disposed of in accordance with applicable

laws.

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O will accept defective PTs.

If mercury escapes, use airtight packaging!

ESD sensitive component. Electrostatic discharge may damage the PT. Take ESD

precautions.

5.15.1

5.15.1

5.1

TT

TT

T

RANSRANS

RANSRANS

RANS

PORPOR

PORPOR

POR

TT

TT

T

//

//

/

PP

PP

P

AA

AA

A

CKINGCKING

CKINGCKING

CKING

//

//

/

TRANSTRANS

TRANSTRANS

TRANS

PORPOR

PORPOR

POR

TT

TT

T

DD

DD

D

AMAGEAMAGE

AMAGEAMAGE

AMAGE

• Do not let the PT be damaged by other items during transit.

• Use only the original packaging.

• Report transport damage to

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O immediately in writing.

5.25.2

5.25.2

5.2

SS

SS

S

TT

TT

T

ORAGEORAGE

ORAGEORAGE

ORAGE

• Store the PT in original packaging only.

• Protect against dust and moisture.

5.35.3

5.35.3

5.3

SS

SS

S

CC

CC

C

OPEOPE

OPEOPE

OPE

OFOF

OFOF

OF

DELIVERYDELIVERY

DELIVERYDELIVERY

DELIVERY

• PT with diaphragm protection cap

• Fastening clip (transmitter with flexible stem only)

• Calibration sheet

• Operating manual with declaration of conformity

Page 27

27

ASSEMBLY

6.6.

6.6.

6.

AA

AA

A

SS

SS

S

SS

SS

S

EMBLEMBL

EMBLEMBL

EMBL

YY

YY

Y

6.1 Mounting hole ..................................................................................................................... 27

6.2 Checking the mounting hole ................................................................................................ 29

6.3 Mounting the Pressure Transmitter ....................................................................................... 30

6.4 Mounting PTs with flexible stem ............................................................................................ 31

6.5 Mounting PTs with flange.....................................................................................................32

6.6 Electrical connection ........................................................................................................... 32

6.6.1 EMC / CE compliant connection ........................................................................................... 33

6.7 Connection assignments ..................................................................................................... 33

Ambient temperature for the electronics housing max. +80°C (safety class T4 max.).

Higher temperatures can result in damage and malfunction.

Do not install the pressure transmitter in places where this temperature is exceeded.

6.16.1

6.16.1

6.1

MM

MM

M

OUNTINGOUNTING

OUNTINGOUNTING

OUNTING

H H

H H

H

OLEOLE

OLEOLE

OLE

To produce the 1/2-20 UNF mounting hole, use only

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O machining tool kit (DYNISCO

P/N 200925). To produce the M18 x 1.5 moutning hole, use only

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O machining tool kit

(DYNISCO P/N 200105).

• Drill the mounting hole as shown in fig. 6-1, 6-2, 6-3, 6-4.

Fig. 6-1Fig. 6-1

Fig. 6-1Fig. 6-1

Fig. 6-1

Mounting Hole xx192xMounting Hole xx192x

Mounting Hole xx192xMounting Hole xx192x

Mounting Hole xx192x

Page 28

28

ASSEMBLY

Fig. 6-2Fig. 6-2

Fig. 6-2Fig. 6-2

Fig. 6-2

Mounting hole xx193xxMounting hole xx193xx

Mounting hole xx193xxMounting hole xx193xx

Mounting hole xx193xx

Fig. 6-2Fig. 6-2

Fig. 6-2Fig. 6-2

Fig. 6-2

Mounting hole xx194xxMounting hole xx194xx

Mounting hole xx194xxMounting hole xx194xx

Mounting hole xx194xx

M18 X 1.5

a O

.004TA

.401

.399

10.2mm

10.1mm

O

.638

.634

16.2mm

16.1mm

.160

4.1mm

1.000

25.4mm

MIN FULL THD

.242

6.1mm

.787

20mm

O

MIN

Snout Length - .200 MAX

(5.1 mm)

46°

44°

- A -

Page 29

29

ASSEMBLY

Fig. 6-4Fig. 6-4

Fig. 6-4Fig. 6-4

Fig. 6-4

Mounting hole xx195xxMounting hole xx195xx

Mounting hole xx195xxMounting hole xx195xx

Mounting hole xx195xx

When reworking the mounting hole, pay particular attention to the centricity of:

• the hole,

• the thread and

• the sealing surface.

Pressure sealing takes place on the 45° beveled sealing surface or on the front cylindrical section of the

PT with an O-ring (see figures 6-1, 6-2, 6-3, 6-4).

The sealing surface must be:

• correctly machined

• free from marks and rough edges

• free from solidified plastic residue.

6.26.2

6.26.2

6.2

CC

CC

C

HEHE

HEHE

HE

CKINGCKING

CKINGCKING

CKING

THETHE

THETHE

THE

MOUNTINGMOUNTING

MOUNTINGMOUNTING

MOUNTING

HOLEHOLE

HOLEHOLE

HOLE

((

((

(

NONO

NONO

NO

TT

TT

T

FLANGEDFLANGED

FLANGEDFLANGED

FLANGED

MODELSMODELS

MODELSMODELS

MODELS

))

))

)

• Paint the test bolt DYNISCO on the marked area (figure 6-5, item 1) with marking ink up to the thread.

Page 30

30

ASSEMBLY

Fig. 6-5Fig. 6-5

Fig. 6-5Fig. 6-5

Fig. 6-5

TT

TT

T

ee

ee

e

ss

ss

s

tt

tt

t

Bo Bo

Bo Bo

Bo

ltlt

ltlt

lt

w w

w w

w

ith Mith M

ith Mith M

ith M

arkark

arkark

ark

inin

inin

in

g Inkg Ink

g Inkg Ink

g Ink

• Insert the test bolt in the mounting hole.

• Twist it in by hand until the two sealing surfaces make contact.

• Remove and examine the test bolt.

The only acceptable abrasion of marking ink is at the sealing edge (45°), evenly over the entire

circumference.

If the ink has been rubbed off in other places too:

• rework the mounting hole.

6.36.3

6.36.3

6.3

MM

MM

M

OUNTINGOUNTING

OUNTINGOUNTING

OUNTING

THETHE

THETHE

THE

P P

P P

P

RERE

RERE

RE

SS

SS

S

SURESURE

SURESURE

SURE

TT

TT

T

RANSRANS

RANSRANS

RANS

MITMIT

MITMIT

MIT

TERTER

TERTER

TER

Mounting and electrical connection of the PT must be done by specialists with EMC

training, following all applicable regulations, and in

prpr

prpr

pr

ee

ee

e

ss

ss

s

ss

ss

s

urur

urur

ur

elel

elel

el

ee

ee

e

ss

ss

s

s, s,

s, s,

s,

vv

vv

v

oo

oo

o

ltlt

ltlt

lt

agag

agag

ag

e-fre-fr

e-fre-fr

e-fr

ee,ee,

ee,ee,

ee,

intrinintrin

intrinintrin

intrin

ss

ss

s

icic

icic

ic

alal

alal

al

lyly

lyly

ly

s s

s s

s

afaf

afaf

af

ee

ee

e condition with the

mm

mm

m

acac

acac

ac

hine swhine sw

hine swhine sw

hine sw

itit

itit

it

cc

cc

c

hed offhed off

hed offhed off

hed off.

The machine must be secured against being switched back on!The machine must be secured against being switched back on!

The machine must be secured against being switched back on!The machine must be secured against being switched back on!

The machine must be secured against being switched back on!

TT

TT

T

oo

oo

o

xx

xx

x

icic

icic

ic

h h

h h

h

azaz

azaz

az

arar

arar

ar

d!d!

d!d!

d!

The PT contains a small amount of mercury (Hg) as its transmission medium. If the

diaphragm is damaged, mercury may escape.

Never transport or store the PT without the protective cap bolted in place. Remove the cap

shortly before installation.

IfIf

IfIf

If

mer mer

mer mer

mer

cc

cc

c

urur

urur

ur

yy

yy

y

i i

i i

i

ss

ss

s

inh inh

inh inh

inh

alal

alal

al

ed or swed or sw

ed or swed or sw

ed or sw

alal

alal

al

lolo

lolo

lo

ww

ww

w

ed, seeked, seek

ed, seeked, seek

ed, seek

medic medic

medic medic

medic

alal

alal

al

att att

att att

att

ention immediention immedi

ention immediention immedi

ention immedi

atat

atat

at

ely!ely!

ely!ely!

ely!

ESD sensitive component. Electrostatic discharge may damage the PT. Take ESD

precautions.

Before mounting the PT, check the mounting hole carefully. The PT must only be

mounted in holes that satisfy the requirements stipulated in section 6.1. A hole that does

not satisfy these requirements can damage the PT.

Page 31

31

ASSEMBLY

Before mounting the PT, ensure that the mounting hole is free from plastic residue. Remove

plastic residue with the

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O cleaning tool kit. A test bolt is included with this cleaning

set.

To prevent the PT from sticking permanently in the mounting hole, coat the thread section of

the transmitter with high temperature resistant grease or a suitable parting agent.

• Check the mounting hole with the test bolt, and clean with cleaning set if necessary.

• Coat the thread section of the transmitter with high temperature resistant grease or a suitable

parting agent.

Always use a spanner applied to the designated hexagon collar when screwing the PT in

and out. Do not apply the tool to the housing or housing / sensor connection!

Maximum mounting torque 500 inch-pounds. If the mounting torque is too high, the PT

may be damaged or its zero point may shift.

• Screw the PT into the mounting hole and tighten.

6.46.4

6.46.4

6.4

MM

MM

M

OUNTINGOUNTING

OUNTINGOUNTING

OUNTING

P P

P P

P

TT

TT

T

SS

SS

S

WITHWITH

WITHWITH

WITH

F F

F F

F

LEXIBLELEXIBLE

LEXIBLELEXIBLE

LEXIBLE

SS

SS

S

TEMTEM

TEMTEM

TEM

Mounting a PT with a flexible stem to the pressure sensor is done analogously to the procedure in

6.3.

Avoid kinking or crushing the flexible stem.

Minimum bending radius

•

1” (25 mm)1” (25 mm)

1” (25 mm)1” (25 mm)

1” (25 mm) for protected capillary

The connector must be easily accessible (on connector versions).

• Mount the electronics housing of the PT with the fastening clip. See mounting example in figure

6-6.

• Additionally secure the flexible stem between the electronics housing with a standard cable clip.

Page 32

32

ASSEMBLY

Fig. 6-6Fig. 6-6

Fig. 6-6Fig. 6-6

Fig. 6-6

Mounting Example for Sensor Portion of IPX II with Flexible StemMounting Example for Sensor Portion of IPX II with Flexible Stem

Mounting Example for Sensor Portion of IPX II with Flexible StemMounting Example for Sensor Portion of IPX II with Flexible Stem

Mounting Example for Sensor Portion of IPX II with Flexible Stem

6.56.5

6.56.5

6.5

II

II

I

NSNS

NSNS

NS

TT

TT

T

ALLINGALLING

ALLINGALLING

ALLING

THETHE

THETHE

THE

F F

F F

F

LANGEDLANGED

LANGEDLANGED

LANGED

P P

P P

P

RERE

RERE

RE

SS

SS

S

SURESURE

SURESURE

SURE

TT

TT

T

RANSRANS

RANSRANS

RANS

MITMIT

MITMIT

MIT

TERTER

TERTER

TER

Installation of the pressure transmitter with flexible connection to the pressure transducer is

analogous to the procedure described under 6.3, except mounting torque is different. See

specification section for details.

6.66.6

6.66.6

6.6

EE

EE

E

LELE

LELE

LE

CTRICALCTRICAL

CTRICALCTRICAL

CTRICAL

C C

C C

C

ONNEONNE

ONNEONNE

ONNE

CTIONCTION

CTIONCTION

CTION

Mounting and electrical connection of the PT must be done by specialists with EMC

training, following all applicable regulations, and in

prpr

prpr

pr

ee

ee

e

ss

ss

s

ss

ss

s

urur

urur

ur

elel

elel

el

ee

ee

e

ss

ss

s

s, s,

s, s,

s,

vv

vv

v

oo

oo

o

ltlt

ltlt

lt

agag

agag

ag

e-fre-fr

e-fre-fr

e-fr

ee,ee,

ee,ee,

ee,

intrinintrin

intrinintrin

intrin

ss

ss

s

icic

icic

ic

alal

alal

al

lyly

lyly

ly

s s

s s

s

afaf

afaf

af

ee

ee

e condition with the

mm

mm

m

acac

acac

ac

hine swhine sw

hine swhine sw

hine sw

itit

itit

it

cc

cc

c

hed offhed off

hed offhed off

hed off.

The mThe m

The mThe m

The m

acac

acac

ac

hine muhine mu

hine muhine mu

hine mu

ss

ss

s

tt

tt

t

be sec be sec

be sec be sec

be sec

urur

urur

ur

ed aged ag

ed aged ag

ed ag

ainain

ainain

ain

ss

ss

s

tt

tt

t

bein bein

bein bein

bein

g swg sw

g swg sw

g sw

itit

itit

it

cc

cc

c

hed bhed b

hed bhed b

hed b

acac

acac

ac

kk

kk

k

on! on!

on! on!

on!

ExpExp

ExpExp

Exp

lolo

lolo

lo

ss

ss

s

ion hion h

ion hion h

ion h

azaz

azaz

az

arar

arar

ar

d!d!

d!d!

d!

The pressure transmitter must be connected using a 2x2-core, twisted cable (blue cable

sheath).

Do not lay connecting cables in the direct vicinity of cables carrying higher voltage or

used to switch inductive or capacitive loads.

Operate only with an intrinsically safe, EMC compliant power supply with the following

specifications when employing the pressure 4-20 mA output:

Page 33

33

ASSEMBLY

Supply voltage max. 30 V DC

Current output max. 125 mA

Power output max. 900 mW

Inductivity max. 0.26 mH

Capacity max. 9.7 nF

Operate only with an intrinsically safe, EMC compliant power supply with the following

specifications when employing the temperature 4-20 mA output:

Supply voltage max. 30 V DC

Current output max. 125 mA

Power output max. 900 mW

Inductivity max. 0 mH

Capacity max. 52 nF

ESD sensitive component. Electrostatic discharge may damage the PT. Take ESD

precautions.

The electrical connection must comply with EMC requirements.

If the electrical connection is not made as described in chapter 6.6.1, or if cables /

cable connectors / cable glands other than those stipulated by

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O are used,

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O cannot guarantee that EMC requirements will be satisfied.

6.6.16.6.1

6.6.16.6.1

6.6.1

EMC / CE CEMC / CE C

EMC / CE CEMC / CE C

EMC / CE C

OMPLIANTOMPLIANT

OMPLIANTOMPLIANT

OMPLIANT

C C

C C

C

ONNECTIONONNECTION

ONNECTIONONNECTION

ONNECTION

• Earth the machine section with the screw-in trunnion / mounting hole for the PT in accordance

with regulations. The PT must be connected to earth via the screw-in trunnion / mounting hole.

• Connect the shield of the connecting cable on both sides, making sure it conducts with full and

continuous contact.

• When introducing the connecting cable into an EMC compliant switch cabinet, for example,

connect the shield correctely (cable gland, conducting, full contact, continuous) to the

conductive housing or route it via built-in cable connector that is also connected to the

conductive housing.

• Connect unused cable cores or free cable ends correctely to the cable shield on both sides.

6.76.7

6.76.7

6.7

CC

CC

C

ONNEONNE

ONNEONNE

ONNE

CTIONCTION

CTIONCTION

CTION

A A

A A

A

SS

SS

S

SIGNMENTSIGNMENT

SIGNMENTSIGNMENT

SIGNMENT

SS

SS

S

Page 34

34

COMMISSIONING

77

77

7

..

..

.

CC

CC

C

OMMISSIONINGOMMISSIONING

OMMISSIONINGOMMISSIONING

OMMISSIONING

7.1 Installation and mounting ..................................................................................................... 35

7.1.1a Hazardous area installations ................................................................................................ 35

7.1.1b Intrinsically safe installations ................................................................................................ 35

7.1.1c Temperature Environment..................................................................................................... 37

7.1.1d Electrical Guidelines ............................................................................................................. 37

7.1.2 Power supply ....................................................................................................................... 37

7.1.2a Non-intrinsically safe power supply ....................................................................................... 37

7.1.2b Intrinsically safe power supply .............................................................................................. 37

7.1.3 Mounting the transmitter ......................................................................................................37

7.1.3a Gaskets for mounting xxx195x transmitter ............................................................................. 37

7.1.4 Installation of electronics .................................................................................................... 38

7.1.4a Process Electronics Housing ................................................................................................ 38

7.1.4b Mounting the process electronics housing ............................................................................ 39

7.1.4c Conduit mounting ................................................................................................................ 39

7.1.5 Electrical installation ........................................................................................................... 39

7.1.5a Temperature output.............................................................................................................. 41

7.1.5b 4-20 mA transmitter output cable .......................................................................................... 41

7.1.5c Output terminals/cable ....................................................................................................... 42

7.1.5d Case ground ....................................................................................................................... 42

7.2 Configuration using the display ............................................................................................ 43

7.2.1 Optional analog operating mode w/display .......................................................................... 43

7.2.2 Configuring the IPX II ........................................................................................................... 44

7.2.2a Operate mode .................................................................................................................... 44

7.2.2b Entering operate mode ......................................................................................................... 45

7.2.2c Select display status ........................................................................................................... 46

7.2.2d Sensor units ....................................................................................................................... 46

7.2.2e Sensor temperature units .................................................................................................... 48

7.2.2f Sensor position adjust ......................................................................................................... 49

7.2.2g Change zero ........................................................................................................................ 50

7.2.2h Changing full scale output .................................................................................................... 52

7.2.2i Line frequency filter ............................................................................................................. 54

7.2.2j Select transmitter fail safe .................................................................................................... 55

7.2.2k Trim 4mA .............................................................................................................................. 56

7.2.2l Trim 20mA ............................................................................................................................ 57

7.2.2m Sensor zero trim ................................................................................................................... 58

7.2.2n Sensor full scale trim ............................................................................................................ 59

7.2.2o Reset sensor trim ................................................................................................................ 60

7.2.2p Offset .................................................................................................................................. 61

7.2.2q Select language .................................................................................................................. 62

7.2.2r Return to operate mode ....................................................................................................... 63

7.2.3 IPX II display flow chart for configuring using the display ....................................................... 64

Page 35

35

COMMISSIONING

77

77

7

.1.1

.1.1

.1

II

II

I

NSNS

NSNS

NS

TT

TT

T

ALLAALLA

ALLAALLA

ALLA

TIONTION

TIONTION

TION

ANDAND

ANDAND

AND

M M

M M

M

OUNTINGOUNTING

OUNTINGOUNTING

OUNTING

Please read the entire manual prior to installation and use.

• Do not remove protective cap until ready to install.

• Prior to initial installation, verify correct machining of mounting hole.

• When reinstalling, make sure mounting hole is clear of frozen plastic.

• Transducer should be removed when at operating temperature (no pressure in system).

7.1.17.1.1

7.1.17.1.1

7.1.1

AA

AA

A

HH

HH

H

AZARDOUSAZARDOUS

AZARDOUSAZARDOUS

AZARDOUS

A A

A A

A

REAREA

REAREA

REA

I I

I I

I

NSNS

NSNS

NS

TT

TT

T

ALLAALLA

ALLAALLA

ALLA

TIONSTIONS

TIONSTIONS

TIONS

Dynisco’s IPX II Series of Smart Pressure Transmitters are designed with circuitry suitable for

operation in a Class I , Division 1, Groups B, C & D, Class I/II, Division 2, Groups E, F & G

hazardous area. An explosion-proof electronics housing is standard on all IPX II Series models. The

specific approvals carried by individual transmitters are marked on the label. Refer to the product

data sheet for the most current information on these approvals.

7.1.17.1.1

7.1.17.1.1

7.1.1

BB

BB

B

II

II

I

NTRINSICALLNTRINSICALL

NTRINSICALLNTRINSICALL

NTRINSICALL

YY

YY

Y

SS

SS

S

AFEAFE

AFEAFE

AFE

I I

I I

I

NSNS

NSNS

NS

TT

TT

T

ALLAALLA

ALLAALLA

ALLA

TIONSTIONS

TIONSTIONS

TIONS

Dynisco’s IPX II Series of Smart Pressure Transmitters are designed with circuitry suitable for

operation in Intrinsically safe environments, with an approval code of EEx ia IIC T4.

The customer is required to install an approved galvanic barrier with entity parameters from DrawingThe customer is required to install an approved galvanic barrier with entity parameters from Drawing

The customer is required to install an approved galvanic barrier with entity parameters from DrawingThe customer is required to install an approved galvanic barrier with entity parameters from Drawing

The customer is required to install an approved galvanic barrier with entity parameters from Drawing

000092.000092.

000092.000092.

000092.

The specific approvals carried by individual transmitters are marked on the label. Refer to the product

data sheet for the most current information on these approvals.

Each sensor cable supplied with a cap plug (Dynisco P/N 598091) to protect the Bendix

connector from environmental conditions. Do not remove cap plug until you are ready to

connect to the sensor assembly.

Page 36

36

COMMISSIONING

3. ANY POSITIVE POLARITY SHUNT ZENER DIODE BARRIER APPROVED BY THE APPLICABLE AGENCY

USED IN THE APPLICABLE GROUPS:

FMRC & CSA - GROUPS B, C & D

CENELEC - GROUPS IIB +H2, IIB & IIA

WITH THE FOLLOWING OUTPUT PARAMETERS:

Voc orVtlessthanorequal to 30VDC