Page 1

ATC770 Microprocessor-Based

Pressure/Process Controller

Installation and Operation Manual

P/N 974086

12/04 Rev. G

ECO # 29250

Page 2

2

CONTENTS

Quick Start Instructions ................................................................................................................... 3

1. Introduction.............................................................................................................................. 8

2. Specifications ........................................................................................................................... 8

3. Unpacking.............................................................................................................................. 17

4. Mounting and Wiring ............................................................................................................. 18

5. Start Up Procedures................................................................................................................ 24

6. Configuration ......................................................................................................................... 31

7. Operation............................................................................................................................... 45

8. Instrument Calibration ............................................................................................................ 53

9. Error Codes............................................................................................................................. 57

10. Normative References............................................................................................................. 60

11. Parameter Group Menus ......................................................................................................... 61

12. PID Controller Definitions ...................................................................................................... 82

13. Repair..................................................................................................................................... 83

14. Warranty ................................................................................................................................ 83

Page 3

ATC770 Microprocessor-Based Pressure/Process Controller 3

MODEL ATC770-0-2-3 QUICK START INSTRUCTIONS

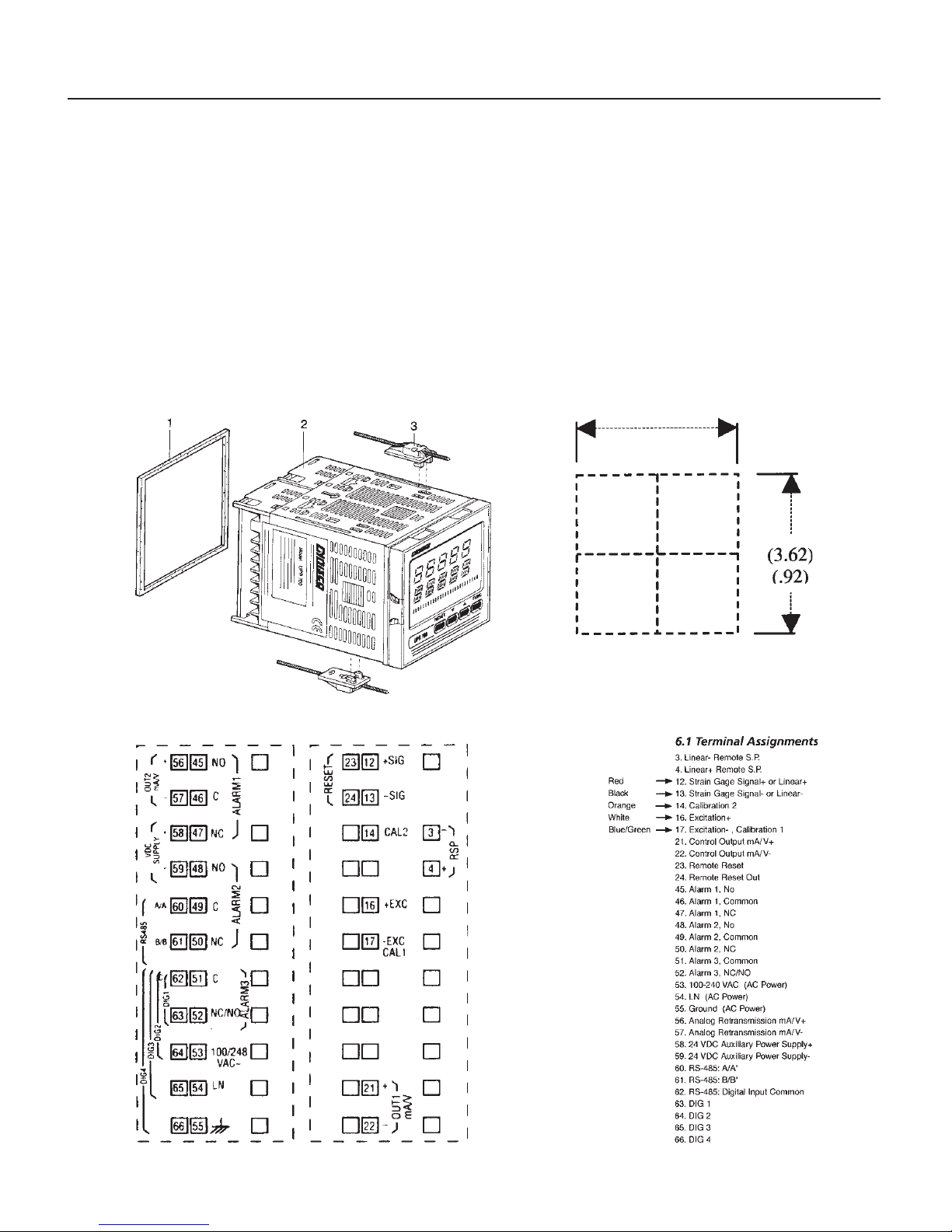

1. MOUNTING

• Prepare panel cutout to dimensions shown below.

• Remove instrument from case by spreading locking tabs.

•Grasp the bezel and slide the instrument out of its case.

• Slide the rubber gasket over the case.

• Slide the instrument case into the cutout.

• Attach the panel mounting hardware tightening the threaded rod for a secure fit.

• Slide the instrument back into the case until an audible click is heard as each tab engages.

Page 4

4

2. WIRING

• Connect the wires from transducer cable as shown in the terminal diagram.

• Connect final control device.

• Connect alarm(s) if applicable. Note that alarm defaults are High, Reverse Acting for alarms 2 &

3 - alarm 1 is low inhibited.

• Connect power to the appropriate terminals as shown.

3. SCALING

• Apply power to the instrument; Upper display will give a reading near zero.

•Lower display will read the manual output %.

• Press FUNC key until the Upper display reads NONE and lower display reads GROUP.

• If your transducer is not a 10,000-psi model, select Group 3 using the Up arro w, enter with

function key.

•Lower display reads PI.FSV (Full Scale Value), and the upper display reads 10,000. NOTE: If

your transducer is a 10,000-psi model skip next two steps. Scroll to GROUP and select 2.

• Using the Down arrow key set the appropriate Full Scale Value for your transducer.

• Enter using the FUNC key to scroll until GROUP legend appears again.

• Using Up arrow key, select GROUP 2. Enter with FUNC key.

•Follow instructions for Calibration and Operation in Step 4 of Quick Start

4. CALIBRATION AND OPERATION

•Lower display reads ZERO.C and upper display reads OFF. Be sure transducer is at operation

temperature and that no pressure is applied.

• Change upper display to ON by using the Up arrow key. Enter with the FUNC key. After a few

seconds, the lower display will show SPAN.C and upper display will show OFF.

• Change upper display to ON using Up arrow key. Enter with the FUNC key. In a few seconds

lower display shows SMART and upper display shows OFF. Calibration is complete.

• Using the FUNC key, scroll to the GROUP display. Enter 1 with the Up arrow, and enter with

the FUNC key. Instrument shows 0 on upper display and SP on lower display.

• Set Process Setpoint. Press Function twice.

• Set Alarm 1,2,3 thresholds (if applicable).

• Press FUNC twice. Lower display will read GROUP, and upper display will read none.

• Press FUNC key. Upper display will read 0 +/- 10 process pressure, lower display will read 0.

This is control output %.

• Be sure process is at operating temperature.

• Utilizing up and down keys, manipulate the output % until the upper display is reading at

approximately the setpoint.

• Press FUNC key until lower display reads GROUP. Select group 2.

• Press function key three times. Lower display reads SMART and upper display reads OFF.

• Using up arrow key, turn SMART function to on. Enter with FUNC key.

•SMART LED will flash and a countdown will begin as the controller arrives at initial P&I(D)

parameters.

Page 5

ATC770 Microprocessor-Based Pressure/Process Controller 5

• Return to GROUP none and observe that the value in the upper display is the actual setpoint

you wish to control.

•When the SMART LED has stopped flashing, press and hold the A/M key for at least 5 seconds.

The manual LED will extinguish, and you will be automatic control mode.

• Again, return to GROUP 2 and select SMART. Turn the function on with the up arrow, and enter

with the FUNC. This will activate the Adaptive Tune algorithm, and will maintain the correct

P&I(D) parameters for the process. It will remain on until manually turned off. It will also come

on anytime the ATC770 is the automatic control mode.

• Return to Group none, and observe the process. The setpoint may be adjusted in GROUP 1

while the controller is in automatic mode.

•Operator may alternately display Output %, Set Point, Deviation, Peak Value, or RPM by

pressing the up arrow key.

The preceding Quick Start instructions are the basic settings required to install, wire, and get the

controller operating. Please refer to the complete installation and operation manual for additional

functions. Questions on your transducer will be addressed in the manual included with your

transducer.

Page 6

6

INDEX

How to: See Section: Page

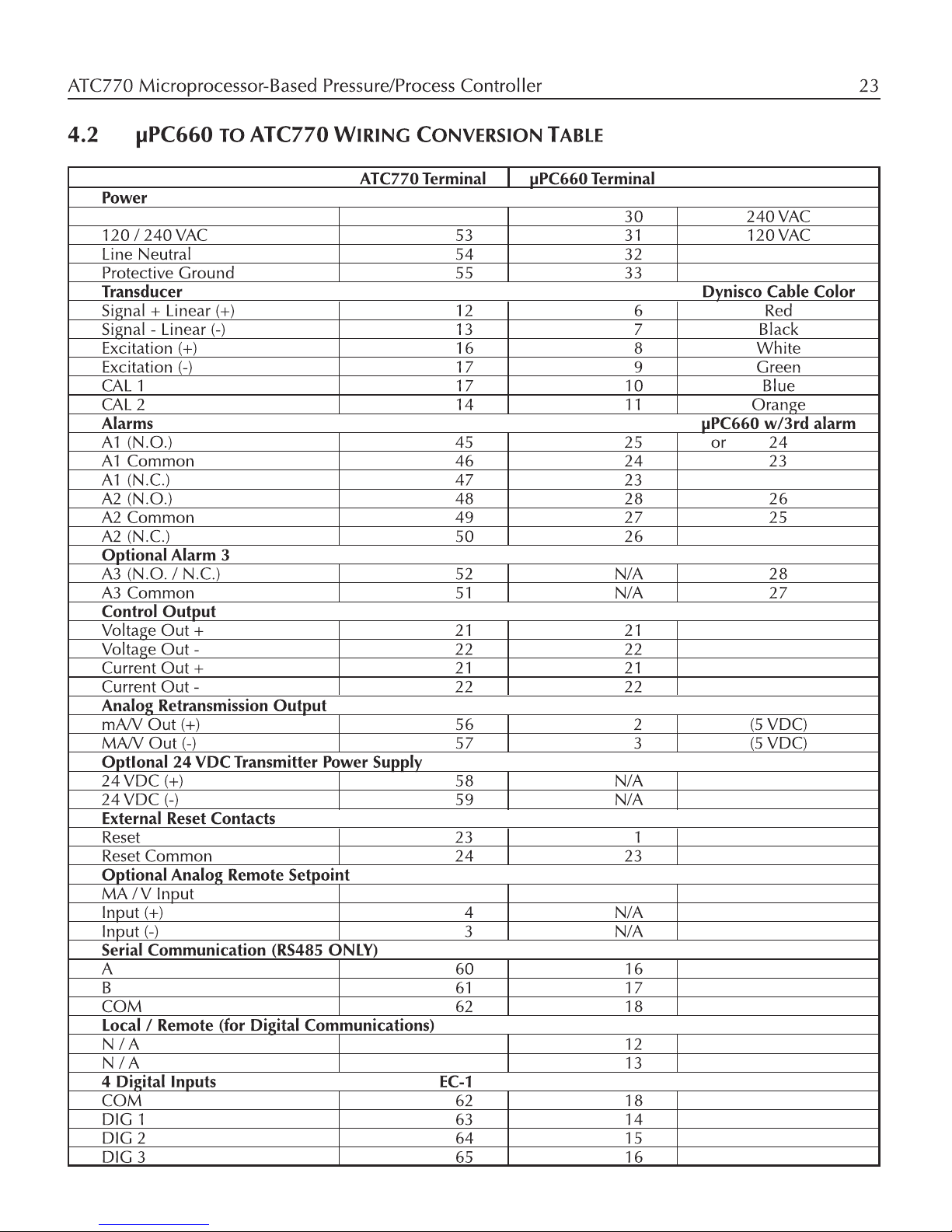

Wire the ATC770 4.1, 4.2 22, 23

Primary Input

Set the Primary Input Type 6.1.1, 6.1.3 31, 34

Set the Shunt Calibration 6.1.2 33

Set the Primary Input Full Scale Value 6.1.4 35

Set the Primary Input Failsafe Mode 6.1.7 36

Calibration of Primary Input

Calibrate the Primary Input to the instrument 7.1 45

With Internal Shunt 7.1.1, 7.1.2 46

With External Shunt 7.1.3 46

With Linear Input 7.1.5 47

Alarms

Set which Input the Alarms will Monitor 6.2.1 37

Set the Alarm Type (high, low, etc.) 6.2.2 37

Set the Reset Mode for Alarms 6.2.5 38

Set the Failsafe Mode for Alarms 6.2.6 38

Set the Alarm Value 6.2.7 39

Setting Control Ouput

Set the Control Output Voltage or Current 6.4.1 41

Set the Control Output Direct/Reverse 6.4.2 43

Retransmission Output

Set the Retransmission Output Voltage or Current 6.3 39

SMART Tuning of Control Output

Set the Process Set Point 7.2.1 48

Engage SMART Tuning 7.2.2 48

Engage Adaptive Tuning (In Manual Mode) 7.3.2 49

Engage Adaptive Tuning (In Automatic Mode) 7.3.4 50

Security

Set the Security Codes 6.5 44

Error Codes

Interpreting the Error Codes and Troubleshooting 9.0 57

Page 7

ATC770 Microprocessor-Based Pressure/Process Controller 7

Instrument Maintenance and Repair

Instrument Maintenance 9.3 59

Repair the Instrument 13 83

Get T ec hnical Assistance 13 83

Page 8

8

1. INTRODUCTION

The ATC770 Pressure/Process Controller is a microprocessor-based instrument, with the capability of

controlling an extruder or other process using an advanced proprietary SMART self-tuning

algorithm. The input is user configurable to be 350⏲ Strain Gage, high-level voltage or high level

current. The voltage or current inputs are compatible with many process transmitter combinations.

Input and output groups are selected via internal jumpers, with the appropriate range selected via

the keypad. Thus the need to make numerous selections within the instrument is minimized. In

addition to this flexibility, 24 VDC transmitter power supply is a standard feature of the ATC770.

Three fully programmable alarms and an analog retransmission output are also included as part of

the standard ATC770 package.

Five groups of configuration parameters are available from the keyboard, and are protected by three

levels of user definable software locks. (A sixth group of read-only parameters can also be viewed)

In the programming mode the lower display will show the parameter being displayed, and the upper

display will show its value. In the operating mode, the upper display will show the process variable,

and the lower display offers the choice of displaying setpoint, deviation from setpoint, output %,

RPM or peak. In addition, a red LED bargraph presents an analog representation of the main input,

as well as indication of the alarm setpoints.

WARNING NOTE: The user should be aware that if this equipment is used in a manner not

consistent with the specifications and instructions in this manual, the protection provided by the

equipment might be impaired.

1.1 PRODUCT CODES

Model Second Input Options Power

Code Description Code Description Code Voltage

0 Not Present 2 Auxiliary Power supply 3 100-240 VAC

ATC770 & retransmission output (switching)

1 Analog, remote 3 RS-485 and 4 digital inputs 5 24 VAC/VDC

setpoint (switching)

2. SPECIFICATIONS

2.0 MECHANICAL SPECIFICATIONS

Case: Polycarbonate Black color Self-extinguishing degree VO according to UL 94

Front Panel: Designed and tested for IP65 and NEMA 4X for indoor location

Installation: Panel mounting

Page 9

ATC770 Microprocessor-Based Pressure/Process Controller 9

Rear T erminal Block: 34 screw terminals with rear safety cover

2.1 MAIN POWER SUPPLY & ENVIRONMENTAL SPECIFICATION

Main Power Supply: From 100 to 240 VAC (-15% to 10%), 50/60 Hz switching. Option: 24 V AC/DC

(-10% to 10%)

Power Consumption: Max 22 VA at 50 Hz; Max 27 VA at 60 Hz

Insulation Resistance: 100 Mohm @500 VDC

Dielectric Strength: 1500 V rms for 1 min, 1800 V for 1 sec (according to EN6 1010-1)

Ambient T emperature: From 0 to 50°C

Storage T emperatur e: From -20 to 70°C

Humidity: Max 85% RH non-condensing

Watchdog: Hw/Sw is provided for automatic restart

Protection: Two internal dip switches for factory calibration and security codes protection

Agency Appro vals: UL File # 193253, cUL pending

Self-Certification: CE

Electromagnetic Compatibility and Safety Requirements: The instrument is marked CE. Therefore, it

conforms to council directives 89/336/EEC (reference harmonized standard EN50081-2 and

EN50082-2) and to council directives 73/23/EEC and 93/68/ EEC (reference harmonized standard

EN61010-1).

Installation Category: II

2.2 DISPLAY SPECIFICATION

Display: LED technology, custom type.

Upper Digits: Red color, 5 numeric digits, 7 segments with decimal point 13.2 mm high.

Lower Digits: Green color, 5 alphanumeric digits (British flag), 14 segments with decimal points,

12.7 mm high.

Bar Graph: Red color, 35 segment with 3% resolution. Displays continuous bar graph to indicate the

measured variable of the main input (0-100% full scale). Alarm set point values displayed. Last

Page 10

10

segment blinks for pressure greater than full scale value.

Indicators:

9 red LED’s annunciator for:

A1 Lit when alarm 1 is in Alarm State

A2 Lit when alarm 2 is in Alarm State

A3 Lit when alarm 3 is in Alarm State

SMRT Flashing when the first step of SMART algorithm is activated

Lit when the second step of SMART algorithm is activated

MAN Lit when device is in manual mode

RSP Lit when Remote Set Point is selected

REM Lit when device is controlled by serial link.

The LED’s:

0 25 50 75

and

100 %

are always on to improve the bar-graph indication.

5 green LED annunciators for:

SP Lit when lower display shows the Set Point

DEV Lit when lower display shows the deviation (Measured Variable minus Set Point

OUT% Lit when lower display shows the Output Value (absolute value with 0.1% resolution)

RPM Lit when lower display shows the Output Value scaled to RPM

PEAK Lit when lower display shows the peak value

2.3 MAIN INPUT SPECIFICATION

Main Input: Selectable between strain gage and linear by jumper and configuration.

Strain Gage Input: 350 Ohm, 2-4 mV/V. Excitation 10 VDC ±7%. 6 wire connection.

Linear Input: Selectable between 0-5 VDC, 0-10 VDC, 0-20 mA, 4-20 mA.

Input Signal: -25/125% of full scale (approximately -10 / 50mV).

Shunt Calibration: With or without shunt resistor (value programmable from 40.0 to 100.0%).

Zero Balance: ±25% of full scale (approximately ± 10 mV).

Auxiliary Power Supply: 24 VDC / 1.5W ± 2% power supply for two or four wire transmitter.

Input Impedance:

<10 Ohm for linear current input

>165 Kohm for linear voltage input

Input Protection: Open circuit detection for strain gage (on signal and excitation wires) and 4-20

mA inputs; it is not available for 0-5 VDC, 0-10 VDC and 0-20 mA. Up or down scale keyboard

programmable.

Page 11

ATC770 Microprocessor-Based Pressure/Process Controller 11

Sampling time: 50 ms typical.

Display Update Time: 400 ms.

Engineering Units: Peel-off labels.

Calibration Mode: Field calibrations (zero and span) are applicable for both strain gage and linear

input. Moreover it is possible to delete the field calibration done by the end user and to restore

original factory calibration values.

Input Resolution: 4000 Counts

Full scale value Resolution

10 / 4000 1 digit

4002 / 8000 2 digits

8005 / 20000 5 digits

20010 / 40000 10 digits

40020 / 80000 20 digits

80050 / 99950 50 digits

Decimal Point: Settable in any position of the display.

2.4 REMOTE SET POINT INPUT SPECIFICATION

Remote Set Point Input: Selectable between the ranges 0-10 VDC, 0-20 mA, or 4-20 mA by jumper

and instrument configuration.

Input Protection: open circuit for 4-20 mA input (excluded for 0-10 VDC and 0-20 mA inputs). Up

or down scale keyboard programmable.

NOTE: This input is not isolated from the main input. A double or reinforced insulation between

instrument output and power supply must be guaranteed by the external device.

Input Impedance:

<10 Ohm for linear current input

>165 Kohm

Sampling T ime: 1000 ms.

Display update: At each sample.

Input Resolution with Linear Input: 4000 counts.

Low/High Scale Values: Set from 0 to pressure input full scale value with the same resolution and

decimal point position as Pressure unit.

Page 12

12

2.5 PRESSURE & REMOTE SET POINT INPUTS COMMON SPECIFICATION

Common Mode Rejection Ratio: 120 dB @50/60 Hz

Normal Mode Rejection Ratio: 60 dB @ 50/60 Hz

Reference Accurac y: ± 0.2% of full scale value ± 1 digit @ 25 ± 10°C and nominal power voltage.

Operative accuracy - temperature drift:

<300 ppm/°C of full span for current, voltage and strain gage input

2.6 DIGITAL INPUT SPECIFICATION

Digital Input: One input from contact closure (voltage free). It may be keyboard programmable for

the following functions:

• alarm reset

• peak reset

• alarm and peak reset

NOTE: This input is not isolated from main input. A double or reinforced insulation between

instrument output and power supply must be guaranteed by the external device.

Opto-isolated Digital Input: Four optional digital inputs are provided for control purposes. The

interface circuit is opto-isolated with respect to the CPU and analog inputs.

DIG1: This contact acts as an automatic / manual switch, if it is enabled by the proper parameter

(closed means manual mode, open means automatic mode).

DIG2: Control output value increase.

DIG3: Control output value decrease.

These three contacts are used to increase / decrease the output value with a linear, not exponential,

rate of change (about 20 seconds for a full scale variation from 0 to 100%).

NOTE: Use for manual mode only. Not used for set point adjust.

DIG4: This contact is used to switch the controller from automatic to manual mode setting to zero

the control output. When this logic input is closed the transfer from manual to automatic mode by

the front panel is inhibited while the user may modify the control output. To return to automatic

mode the logic input should be de-activated.

2.7 ALARMS SPECIFICATION

Page 13

ATC770 Microprocessor-Based Pressure/Process Controller 13

Alarm Outputs: 3 standard alarms (AL1, AL2 and AL3).

AL1 and AL2 Contacts: 1 SPDT 2 A max @ 240 VAC resistive load.

AL3 Contacts: 1 SPST solder jumper selectable NO/NC 2 A max @ 240 VAC resistive load.

Contact Protection: Varistor for spike protection.

Alarm T ype: Each alarm is keyboard programmable for:

• Process / Deviation / Band

• High / Low / Low inhibited on start up

•Auto / Manual reset

Alarm Mask: The alarm mask may be restored using the keyboard parameter

(AL.MSK)

. Moreover

the alarm mask of deviation and band alarms is restored at set point change and during set point

ramp.

Excitation T ype: Keyboard configurable for each alarm: relay coil energized in no alarm condition

(failsafe) or relay coil energized in alarm condition (non-failsafe). The default condition is failsafe.

Threshold: From 0 to 110% Full Scale (the threshold may be limited due to the selected full scale

value).

Hysteresis: Keyboard programmable for each alarm; from 0.1% to 10.0% of span or 1 Least

Significant Digit (whichever is greater) for each alarm.

Alarm Filter: Selectable from the following values: OFF, 0.4 s, 1 s, 2 5. 3 s. 4 s, 5 s.

Alarm Update Time: At every input conversion.

2.8 OPTIONAL SERIAL COMMUNICATION INTERFACE SPECIFICATION

Serial Interface: RS-485 type. Opto-isolated.

Protocol T ype: Modbus/Jbus (RTU mode).

Type of Parameters: Run-time and configuration are available by serial link.

Device Address: From 1 to 255

NOTE: The physical interface can only support up to 31 devices for each segment. Use multiple

segments for more than 31 devices.

Baud Rate: 600 up to 19200 baud.

Page 14

14

Format: 1 start bit, 8 bits with or without parity, 1 stop bit

Parity: Even/Odd.

2.9 CONTROL OUTPUT SPECIFICATION

Control Output: Opto-isolated from CPU input and output circuits.

Type of Analog Output: Jumper and keyboard selectable between:

•+ 0/10 VDC min. load 5 K⏲

•- 10/+10 VDC mm. load 5 K⏲

•+ 0 / 5 VDC mm. load 5 K⏲

•+ 0/20 mA max. load 500⏲

•- 4/20 mA max. load 500⏲

Resolution: 0.1% in manual mode, 0.03% in automatic mode.

Scaling: The output control value may be displayed in two modes:

• from 0.0 to 100.0% (0.1% resolution)

• from a low to a high limit selection from - 10000 to 10000

2.10 RETRANSMISSION OUTPUT SPECIFICATION

Retransmission Output: Opto-isolated from CPU input and output circuits.

Type of Analog Output: Jumper and keyboard selectable between:

•+ 0/10 VDC min. load 5 K⏲, with under / overrange capability from -2.5 to 12.5 V.

• ± 10 VDC min. load 5 K⏲, with under / overrange capability from -12.25 to 12.5 V.

•+ 0/5 VDC min. load 5 K⏲, with under / overrange capability from -1.25 to 6.25 V.

•+ 0/20 mA max. load 500⏲, with under / overrange capability from 0 to 24 mA (max. load 400

Ohm over 20 mA).

•+ 4/20 mA max. load 500⏲, with under / overrange capability from 0 to 24 mA (max. load 400

Ohm over 20 mA).

Resolution: 0.1% of output mode

Scaling: The retransmission low and high limits are selectable from 0 to full scale input value. The

two scaling values may be freely selectable within the above range. This allows for a direct or

reverse output type.

Output Filter: Selectable from the following values: OFF, 0.4 s, 1 s, 2 5. 3 s. 4 s, 5 s.

Page 15

ATC770 Microprocessor-Based Pressure/Process Controller 15

2.11 CONTROL AND RETRANSMISSION OUTPUTS COMMON SPECIFICATION

Reference Accurac y: ±0.1% of output span @ 25 ± 10°C and nominal line voltage.

Linearity Error: <0.1% of output span.

Output Noise: <0.1% of output span.

2.12 CONTROL ALGORITHM SPECIFICATION

Control Type: PID plus Integral Preload plus Anti-Reset Windup

Output Value Indication: Selectable between the following Modes:

• Range 0 / 100.0%

• Selectable with two calibrated values for RPM indication

• In automatic mode either mode is available

• In manual mode, a parameter is provided to select the first or second method of indication.

SMART Algorithm: The SMART procedure is activated by setting the SMART Parameter to ON. In

manual mode the controller will start the TUNE algorithm (SMRT led flashes), while in automatic

mode it will enable the ADAPTIVE function (SMRT led lights steady).

The SMART can select two types of procedures:

1. The TUNE algorithm

2. The Adapti ve algorithm

1. TUNE ALGORITHM

To implement the TUNE algorithm, set the instrument in manual mode and the select SMART ON.

SMART will switch to OFF after the PID parameters (PB, TI, TD) are calculated (during this

procedure the LED will be flashing). The basic concepts of the auto-tuning system are based on the

open loop step response, for this reason the TUNE function may be activated only in the manual

mode.

The equivalent mathematical model of the process is characterized by three parameters: the gain,

the time constant and the equivalent time delay. The power output of the controller is changed by a

small step value. Then, the controller stores the process variable response. From the transient

response, the controller estimates the three basic process parameters by means of the area’s method.

It applies these parameters, and re-runs the step process. When this is done, it calculates the final

PID parameters.

The step response is a convenient way to characterize this type of process dynamics because its

model is based on the alteration of the behavior of the process and very accurately determining the

Page 16

16

response. It is capable of estimating the process parameters with high precision.

2. ADAPTIVE ALGORITHM

In order to implement the adaptive algorithm, the instrument should be in automatic mode. Then

change SMART to ON. In this case the ON will be remembered by the instrument even if the

instrument was switched off.

In order to deactivate the adapti ve processes, return the SMART parameter to OFF.

The ADAPTIVE is an on-line algorithm that “observes” the measured value and looks for oscillation

due to a variation of the load or the set point. When a significant pattern is “recognized,” the

decision procedure starts to recalculate the PID parameters of the controller. While the ADAPTIVE

procedure is enabled the PID parameters can only be monitored.

AUTOMATIC STAND-BY: This function avoids overshoot due to temporary process interruptions (PV

goes to zero).

In cases where the main input goes to zero, the controller output quickly reaches the saturation for

integral factor effect; when the process restarts, the controlled output will have an excessive and

dangerous overshoot, (i.e. it will start at full speed).

When the Automatic Stand-By function is activ ated, the algorithm monitors the controller input and

output: when the input value goes lower than a threshold (specified by the Automatic Stand-By

Pressure Low Limit parameter). When this happens, and the output value reaches the saturation

condition and the control output saves the last value stored when the process was stable.

This freezing of the output of the controller will last for the time specified by the Automatic Stand-By

Recover y Time parameter. If the input does not recover within the specified time, the output value is

forced to zero. If the controller input recovers within the specified time, the algorithm waits for two

and one half times the integral value; after this time has elapsed, the controller will come back

automatically to normal running condition to the output level calculated when the process was

stable.

2.13 CONTROL AND RETRANSMISSION OUTPUTS COMMON SPECIFICATION

The ATC770 Pressure/Process controller has four digital inputs that can switch between Manual and

Automatic control (DIG1), increase (DIG2) or decrease (DIG3) the control output value and switch

from Automatic to Manual while setting the control output to zero (DIG4).

Digital Input 1 (DIG1) is available at all times. It acts as an Auto/Manual Switch. In the closed

position the Manual mode is accessed. In the open position the Automatic mode is

accessed.

Digital Input 2 (DIG2) is available only when the Group 1 function

A/M

is changed from

LoCAL

to

Page 17

ATC770 Microprocessor-Based Pressure/Process Controller 17

CnCt

. It will increase the set point in a linear fashion (about 20 seconds from 0 to

100% output).

Digital Input 3 (DIG3) is available only when the Group 1 function

A/M

is changed from

LoCAL

to

CnCt

. It will decrease the set point in a linear fashion (about 20 seconds from

100% to 0 output).

Digital Input 4 (DIG4) is available at all times. It switches the controller from Automatic to Manual

and sets the control output to zero. It also inhibits keyboard control of switching

from Automatic to Manual, but allows keyboard increase of the output value.

NOTE: A dry contact switch or relay must be fitted between terminal 62 (Common) and terminal 63

(Digital Input 1 Remote AUTO/MAN) to enable the use of Digital Input 2 (DIG2) and Digital

Input 3 (DIG3) (Control output value increase and decrease).

3.0 UNPACKING

Upon receipt, examine the package for shipping damage. Notify the carrier immediately in the event

of any evidence of damage, and retain the shipping materials for their inspection. The package

should contain the instrument, two panel mounting brackets, a sheet of peel-off labels with a variety

of engineering units and an

Installation and Operation Manual

.

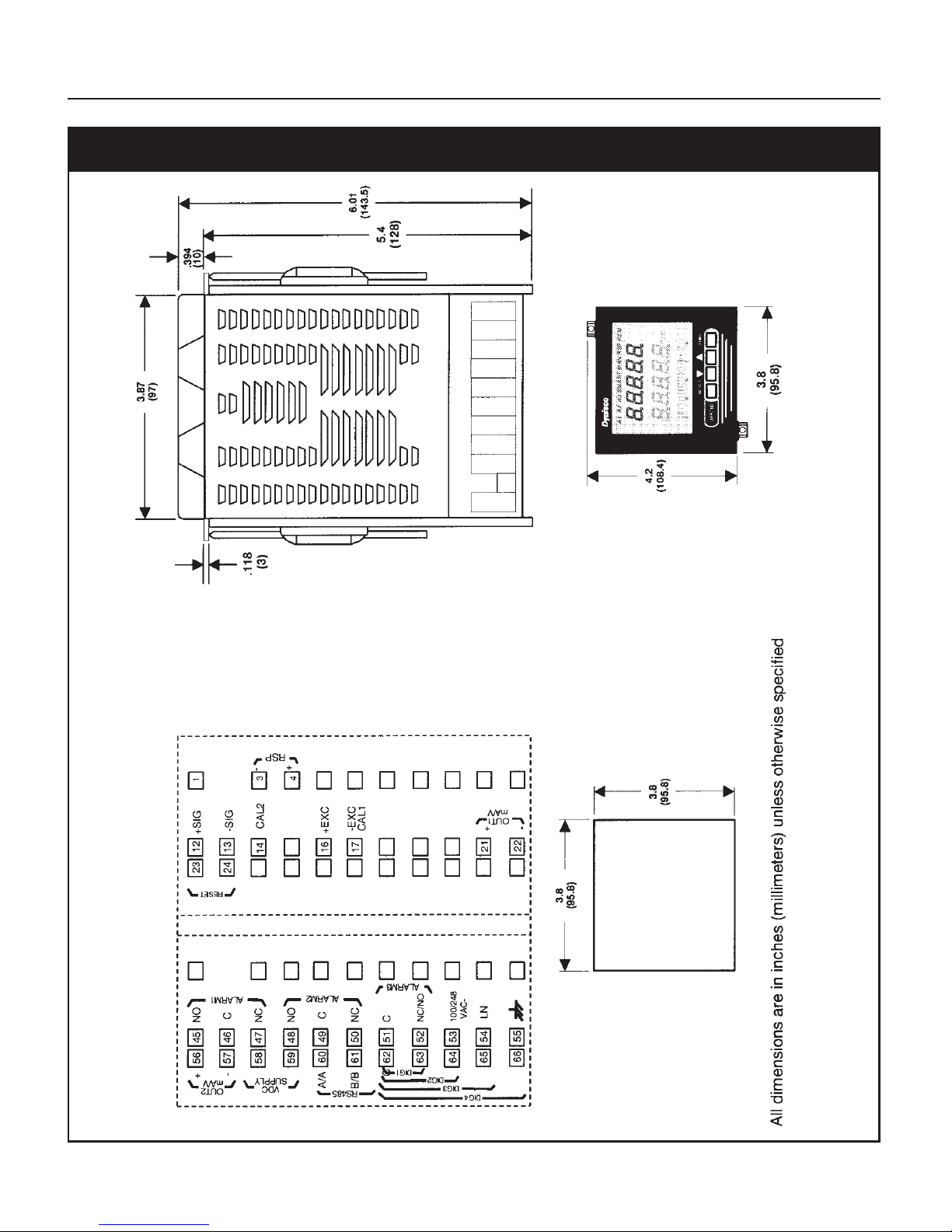

3.1 DIMENSIONAL INFORMATION

Dimensions: 3.78" X 3.78" X 6.01" overall (96mm X 96mm X 143.5mm)

Cutout: 3.62" X 3.62" (92mm X 92mm)

Depth behind panel: 5.04" (128mm)

Weight: 1.43 lbs. (650g)

Page 18

18

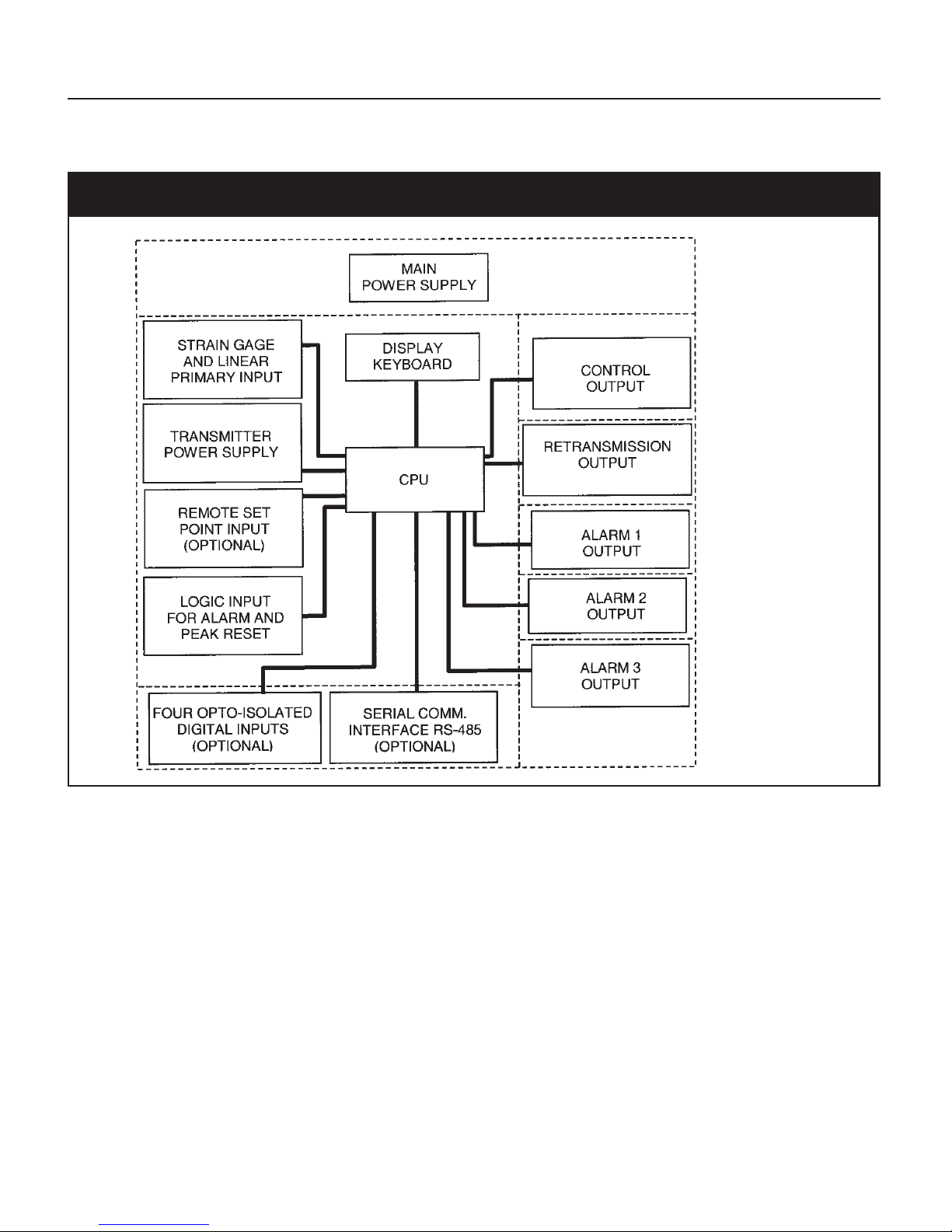

3.2 ATC770 BLOCK DIAGRAM

Fig. 1 ATC770 Electronics Layout Block Diagram

NOTE: Dashed Line represents insulation boundary.

4. MOUNTING AND WIRING

Please refer to Figure 2 for cutout dimensions and clearance requirements. Locate the two mounting

brackets packed with the instrument and have them available.

1. Remove instrument from case. To accomplish this, spread the two locking tabs located on either

side of the case . The instrument will move forward past the locked position. Grasp the bezel

and slide the instrument from the case. Depending on the options chosen, you may find that

one or two boards appear to be loosely mounted. This patent-pending design allows the

instrument to be removed from the case without having to overcome the friction of all terminals

on all boards at one time. Initially the CPU board and alarm board will be released, followed by

the I/O and digital communication boards.

Page 19

ATC770 Microprocessor-Based Pressure/Process Controller 19

Fig. 2 ATC770 Outline Drawing

Page 20

20

2. Slide the instrument case into the cutout, being sure that it is right-side-up (terminal 1 at the

top). Attach the panel mounting hardware at diagonally opposite sides of the top and bottom of

the case, tightening the threaded rod until the case is secure against the panel.

3. Carefully slide the instrument back into its case, until the locking tabs have engaged. An audible

click will be heard as each tab engages.

4. Refer to the model number to determine the hardware and options included as part of your unit.

Please refer to Section 4.1 for the terminal assignments. Terminals are accessed by opening the

terminal covers from the side with the “OPEN” legend.

NOTE 1:

The ATC770 is equipped with screw terminals, and no connectors are necessary when wiring the

unit

NOTE 2:

When wiring the alarms, wire to the Common and NO (normally open) terminals to maintain a failsafe configuration. Remember to configure the software for failsafe operation.

Fail-safe denotes a situation where the alarms relay coils are activated in a no-alarm situation. As the

relay coil is energized, terminals that are normally open are closed and can cause completion of a

circuit when used as an interlock. Should the alarm threshold be exceeded, OR should power be

lost to the instrument the contacts will open, and the circuit will be broken. If the alarm is a latching

alarm, it will require an external reset signal to be activated again.

If the alarm is used to provide a contact to an alarm device (light, buzzer, etc.), when the threshold

is exceeded, wiring should be to the Common and NC (normally closed) terminals. Activation of the

relay coil will cause the contacts to open in a non-alarm situation, and on alarm, or if power is

interrupted to the instrument. If the alarm is a latching alarm, it will require an external reset signal

to be activated again.

NOTE 3: Relay outputs

The contact rating of all outputs is equal to 2A/240 VAC on resistive load.

•To avoid electrical shock, connect power line at the end of the wiring procedure.

•For power connections use No 16 AWG or larger wires rated for at least 75°C.

• Use copper conductors only.

NOTE 4: Power line

Before connecting the instrument to the power line, make sure that the line voltage corresponds to

the description on the identification label.

•To avoid electrical shock, connect power line at the end of the wiring procedure.

•For supply connections use No. 16 AWG or larger wires rated for at least 75°C

• Use copper conductors only

Page 21

ATC770 Microprocessor-Based Pressure/Process Controller 21

• Don’t run input wires together with power cables

•For 24 V DC the polarity need not be observed.

The power supply input is fuse protected by a sub miniature fuse rated T, 1A, 250V.

When the fuse is damaged, it is advisable to verify the power supply circuit. It may be necessary to

send back the instrument to Dynisco for service.

The safety requirements for Permanently Connected Equipment say:

•a switch or circuit-breaker shall be included In the building installation;

• it shall be in close proximity to the equipment and within easy reach of the operator

• it shall be marked as the disconnecting device for the equipment

NOTE 5:

A single switch or circuit breaker can drive more than one Instrument.

•When a neutral line is present, please connect it to terminal 54.

• Protective conductor terminals shall be connected to earth.

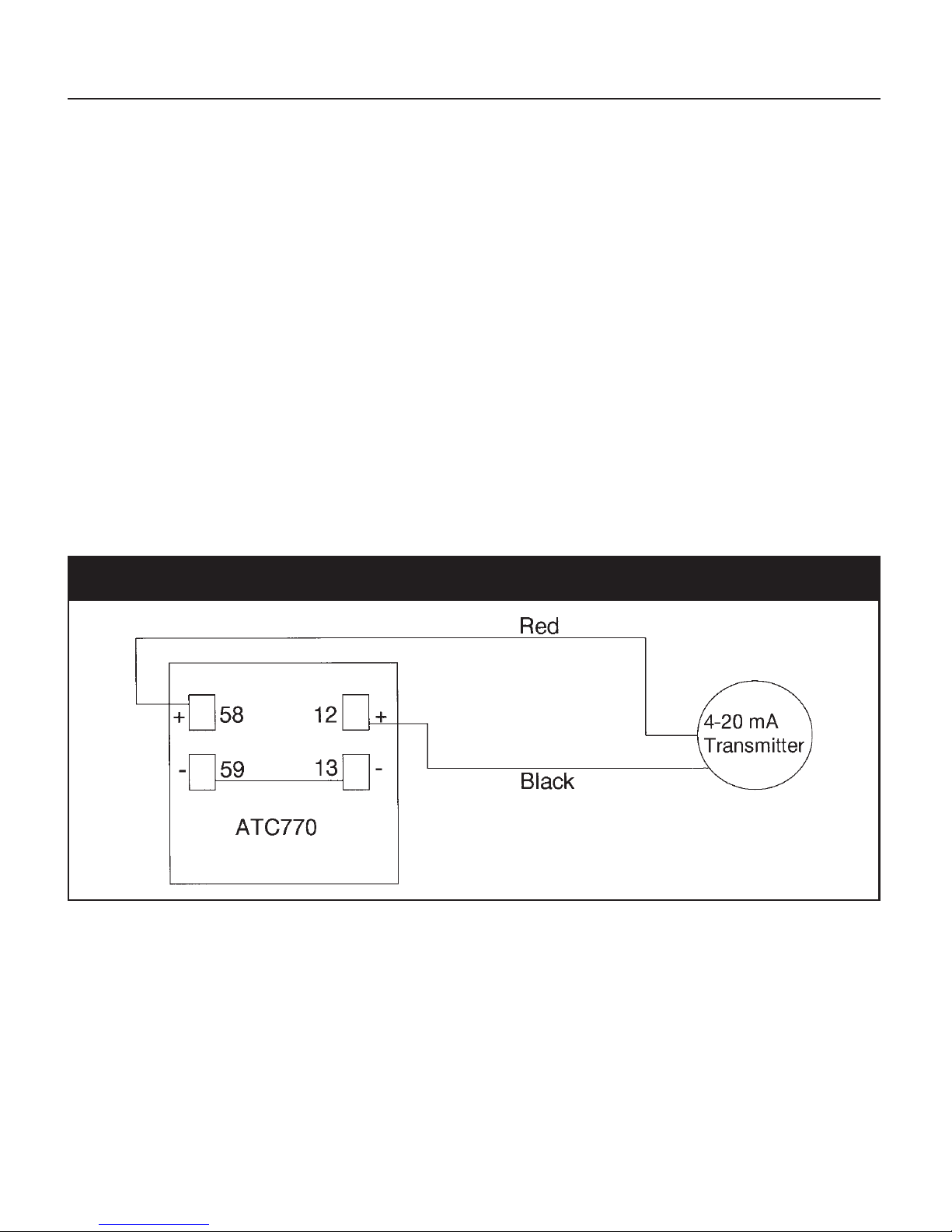

Fig. 3 ATC770 Wiring - 4-20 mA Transmitter Internal 24 VDC Power Supply

Page 22

22

4.1 TERMINAL ASSIGNMENTS

3. Linear - Remote Setpoint Input

4. Linear +

12. Strain Gage Signal + or Linear +

13. Strain Gage Signal - or Linear -

14. Calibration 2 Primary Input

16. Excitation +

17. Excitation -, Calibration 1

21. Main Output mA/V +

22. Main Output mA/V -

23. Remote Reset

24. Remote Reset

45. Alarm 1. NO

46. Alarm 1, Common

47. Alarm 1. NC

48. Alarm 2, NO

49. Alarm 2. Common

50. Alarm 2, NC

51. Alarm 3, Common OPTIONAL

52. Alarm 3. NC/NO

53. 100-240 VAC OR 24 VAC OR 24 VDC (Polarity need not be observed)

54. Line Neutral Line Neutral 24 VDC

55. Protective Ground Protective Ground

56. Retransmission Output, mA/V +

57. Retransmission Output. mA/V -

OPTIONAL

58. 24 VDC Auxiliary Power Supply +

59. 24 VDC Auxiliary Power Supply -

60. RS-485: A/A’

61. RS-485: B/B’ OPTIONAL

62. RS-485: DIG In Common

63. DIG 1

64. DIG 2

OPTIONAL

65. DIG 3

66. DIG 4

Page 23

Page 24

24

5. START-UP PROCEDURE

5.1 CONFIGURATION

The ATC770 is shipped with the hardware jumpers set for the following:

1. Main Input (Pressure) - Strain Gage

2. Main Output - V oltage

3. Secondary Output - Voltage

In addition, the DIP switches controlling the software security lock codes are in the “OFF” positions.

Please ensure that the correct jumper settings for the input(s) and output(s) used in your particular

application are selected. It is necessary only to select the category (e.g. Voltage or Current). The

specific range will be chosen in the software menu.

On special order the ATC770 can be powered from a 24 VAC or VDC supply (not to be confused

with the on-board 24 volt power supply used to power transmitters). If operating with a 24-volt

power supply, connect to terminals 53 and 54 as normal.

5.2 PARAMETERS

The ATC770 parameters are grouped in five sections guarded by three security levels. The more

common parameters are in the first groups, with the higher Group numbers for those parameters an

operator would not normally modify. Each group can be reset to its default value by two keystrokes.

This also resets the parameters of any lower numbered group to default. If GROUP 5 is set to default,

the entire instrument is reset to its default parameters. If a unit does not have a particular option, its

parameters will not appear. For example, an instrument that does not have RS-485 communications

will skip those parameters related to communications. Likewise, if a particular function is turned off,

its other parameters will not appear. For example, if Alarm 2 link

(A2.lNK)

is turned to

OFF

in Group

3, the hysteresis, reset, filter, type, and threshold functions will not appear on screen. Nor will the

alarm appear on the bar graph display.

5.2.1 GETTING READY

Apply power to the cabinet and allow the system to stabilize for about 30 minutes. When the

instrument is turned on, it will go through a self-test during which the front panel will illuminate.

The instrument will then be in the normal display mode showing the value of the main input on the

upper display, usually near zero, and the Output % on the lower display, usually 0.0%. In the event

that no input device is connected, or if the transducer is amplified, the upper display will show

OPEn

, and the bar graph display will be at 100% with the last segment flashing. Turn the power to

the instrument off and connect an input device to the appropriate terminals. Upon turning the

instrument back on, the displays should have a numeric value, close to zero pressure on the

pressure display. Depressing FUNC will go automatically into the GROUP 1 parameters.

Page 25

ATC770 Microprocessor-Based Pressure/Process Controller 25

Successively pressing FUNC will scroll through all the parameters of GROUP 1. The last two

parameters of each group allow the default parameters to be restored, and returns to

GROUP

. If

nonE

is chosen in the group access function, the instrument will return to normal operating mode

after pressing of the FUNC key.

5.2.2 KEYBOARD DESCRIPTION

The keyboard is composed of four push buttons, covered by a silicone protective operator, labeled

▼, ▲, FUNC and A/M.

These keys must be pressed and released to move about in the configure screens. Do not press and

hold a key unless told to do so; simply press the key and release it to advance to the next screen.

The arrow keys ▼ or ▲ may be held down to advance rapidly through the values.

The ▼ is called the “Down Arrow Key”, and is used to decrement or modify the parameter value. In

manual mode it is used to decrement the output value. When pressed for more than 3 seconds in

automatic mode, it used to access and decrease the set point parameter

The ▲ is called the “Up Arrow Key”, and is used to increment or modify the parameter value. In

manual mode it is used to increment the output value. When pressed for more than 3 seconds in

automatic mode, it is used to access and decrease the set point parameter. When pressed for less

than 3 seconds in automatic mode, it used to switch the lower display from set point value,

deviation value, output value (%), output value (RPM) and peak value if enabled.

The FUNC (“function”) key is used to access the parameter to view and acts as an “Enter key” when

a value has been modified.

The A/M key is used to switch the controller from automatic to manual mode (and back again)

when depressed for more than 1 second. When monitoring / modifying control parameters, it is used

to return to the normal display mode without storing the parameter changes.

Pressing ▼ and FUNC together may be used to reset the stored peak value and to reset the alarms.

This function is disabled when the device is controlled by serial link.

Pressing ▼ and A/M together, or the ▲ and A/M may be used to jump to maximum or minimum

parameter values when the instrument is in function mode.

Pressing ▲ and ▼ together, or FUNC and A/M together, may be used on power-up when the

instrument detects a parameter error; the upper display shows

Err

and the lower display shows the

parameter name.

If the wrong parameter is a run-time parameter (i.e. from SP to

RO.TYP

), pressing the ▲ and ▼ push-

buttons will have the instrument load the default parameters for all groups of parameters.

NOTE: All of the actions explained above that require two or more keystrokes must follow the

button pushing sequence exactly.

Page 26

26

5.2.3 OPERATING MODE DESCRIPTION

The FUNC key is used to access the parameters organized in five groups. Use the FUNC

pushbutton to access the Group 1 parameters; the last entry (showing

Group

and

nonE

) is intended

to access the other groups of parameters, or pressing FUNC again returns to the normal display

mode. Each group has its own family of parameters, loosely grouped around the decreasing need to

change the parameters. Each group (except Group 9) also has the ability to load its own default

parameters and the default values of the lower number groups.

To reset a specific group (and lower numbered groups) to the default factory settings, press the

FUNC key until

nonE

and

GROUP

show on the display. Press the ▲ key until the appropriate group

number appears in the upper display. Press the FUNC key to enter the appropriate group. Press the

FUNC key until

DEFLT

shows on the lower display and

OFF

shows on the upper display. Press the

▼ or ▲ key until

ON #

(where # is the Group number). Press the FUNC key to load the factory

parameters for that group (and lower numbered groups; for example selecting Group 5 resets groups

1, 2, 3, 4 and 5).

5.3 SETTING THE INSTRUMENT’S BASIC CONFIGURATION

The example below shows those parameters by group, which will permit an ATC770 to control a

motor. A modification of any other of the default parameters is not needed. Please note in the Value

column, the final values used in your process for future set-up use.

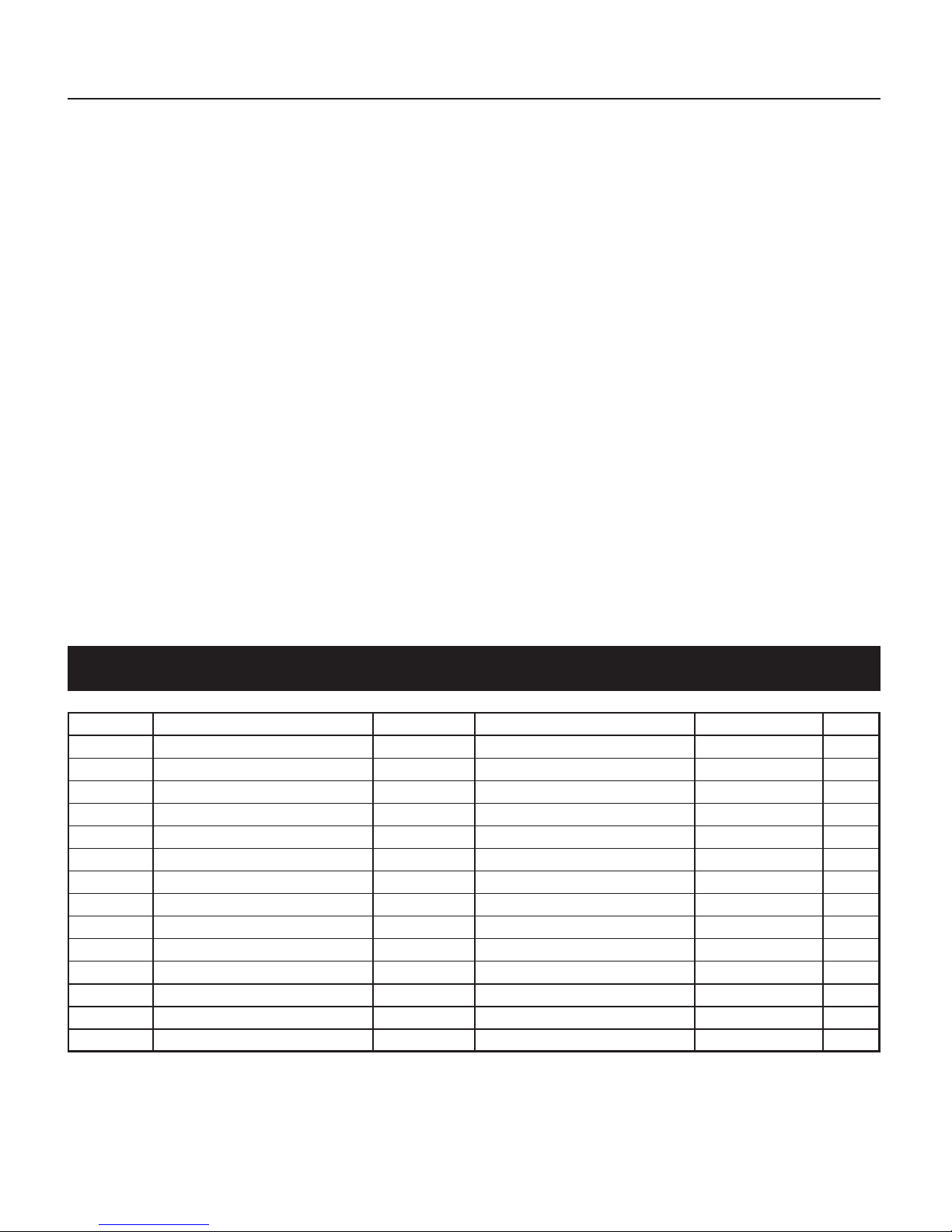

Fig. 4 Basic Parameter Table

Group # Function Mnemonic Choices Default Value

Group 5 Primary Input Selection PI.TYP Str, 0-20, 4-20, 0-5, 0-10 Str

Group 5 Control Output Selection CO.TYP 0-20, 4-20, 0-5 0-10, -10-10 0-10

Group 4 Shunt Calibration SHUNT OFF,On On

Group 4 Shunt Value SHNT% 40.0 TO 100.0% 80.0%

Group 4 Line Frequency LINE.F 50, 60 50

Group 3 Input Full Scale Value PI.FSV 10 TO 99.950 10000

Group 3 Input Low Scale Value PI.LSV ±25% OF FSV 0

Group 3 Input Decimal Point Position PI.DP None, 1,2,3,4 places None

Group 3 Secondary Input T/C Type Sl.TC tc J, tc CA, tc L, tc n tc J

Group 2 Zero Calibration ZERO.C OFF, On, CLEAr OFF

Group 2 Span Calibration SPAN.C OFF, On, CLEAr OFF

Group 2 Type of Automatic Tuning AT.TYP PID, PI PI

Group 2 Self-Tuning SMART OFF, On On

Group 1 Setpoint SP SP.LO to SP.HI SP.LO

5.3.1 SETTING THE SHUNT CALIBRATION:

For transducers and transmitters with a shunt calibration function (internal or external), the various

Page 27

ATC770 Microprocessor-Based Pressure/Process Controller 27

values must be set and the shunt capability enabled. The Shunt Calibration value is a percentage of

the full scale transducer range. If the Shunt Value is supplied as a pressure, it must be converted to

percent.

To enter the Shunt Calibration value, the shunt should first be enabled by pressing the FUNC key

until

nonE

and

GROUP

show on the display. Press the ▲ key until 4 shows in the upper display.

Press the FUNC key until the lower displa y shows

SHUNT

. Press the ▼ or ▲ key until the upper

display shows the ON. Press the FUNC key to set the value and move to the next parameter, Shunt

%

(SHNT.%)

. Press the ▼ or ▲ key until the upper display shows the appropriate percentage for the

shunt value (normally 80%). Once the percentage value is set, press the FUNC key to set the value

and press the A/M key to go back to the active display.

5.3.2 SETTING THE LOGIC INPUT CONFIGURATION (IF SUPPLIED):

If the unit does not have the logic input option, skip to Section 5.3.4.

NOTE: Alarm and peak reset is only available when A/M in Group 1 is set to Local.

The Logic Input can be off, can be set to function as an alarm reset, a peak reset, or it can reset both.

To verify this parameter or to change it, press the FUNC key until

nonE

and

GROUP

show on the

display. Press the ▲ key until 4 shows in the upper display. Press the FUNC key until the lower

display shows

LI.TYP

. Press the ▼ or ▲ key until the upper display shows the correct selection:

OFF

,

AL

- alarms reset, P - Peak reset or

AL-P

). Press the FUNC key to set the value and move to the next

parameter, or press the A/M key to go back to the active display.

5.3.3 SETTING THE LOGIC INPUT STATUS (IF SUPPLIED)

The Logic Input Status can be set to Open or Closed as the active state. To verify this parameter or to

change it, press the FUNC key until

nonE

and

GROUP

show on the display. Press the ▲ key until

4

shows in the upper display. Press the FUNC key until the lower display shows

LI.STS

. Press the ▼ or

▲ key until the upper display shows the correct selection:

CLOSE

, or

OPEn

. Press the FUNC key to

set the value and move to the next parameter, or press the A/M key to go back to the active display.

5.3.4 SETTING THE STATUS OF AUTO/MANUAL SELECTION (IF SUPPLIED)

If the unit does not have the Digital Input option, skip to Section 5.3.5.

NOTE: Remote Auto/Manual is only available when Auto/Manual in Group 1 is set to CNCT.

The ATC770 Pressure/Process controller has four digital inputs that can switch between Manual and

Automatic control (DIG 1), increase (DIG2) or decrease (DIG3) the control output value and switch

from Automatic to Manual setting the control output to zero (DIG4). The Auto/Manual Selection

parameter determines the status of the communication protocol. Select

LoCAL

to use the front push

buttons or RS-485 to control switching from manual to automatic, or Select

CnCt

to use external

means to control switching from manual to automatic.

Page 28

28

NOTE: A dry contact switch or relay must be fitted between terminal 62 (Common) and terminal 63

(Digital Input 1 Remote AUTO/MAN (DIG1)) to enable the use of Digital Input 2 (DIG2) and

3 (DIG3) (Control output value increase and decrease).

To verify this parameter or to c hange it, press the FUNC key until the lower display shows

A/M

.

Press the ▼ or ▲ key until the upper display shows the correct value (

LoCAL

or

CnCt

). Press the

FUNC key to set the value and move to the next parameter, or press the A/M key to go back to the

active display .

5.3.5 SETTING PEAK DETECTION

The Peak Detection can be either set to OFF, the default value of HIGH, or to LOW. To verify or

change this parameter, press the FUNC key until

nonE

and

GROUP

show on the display. Press the

▲ key until 4 shows in the upper display. Press the FUNC key until the lower display shows

PEAK

.

Press the ▼ or ▲ key until the display shows the correct value (

OFF, HI

, or LO). Press the FUNC key

to set the value and move to the next parameter, or press the A/M key to go back to the active

display.

5.3.6 SETTING THE LINE FREQUENCY

The Line Frequency default value is 50 Hz. To verify this parameter or to change to 60 Hz, press the

FUNC key until

nonE

and

GROUP

show on the display. Press the ▲ key until 4 shows in the upper

display. Press the FUNC key until the lower display shows

LINE.F

. Press the ▼ or ▲ key until the

upper display shows the correct frequency. Press the FUNC key to set the value. Press the FUNC

key to set the value and move to the next parameter, or press the A/M key to go back to the active

display.

5.3.7 SETTING THE DISPLAY FILTER

Filtering is an electrical method of averaging the displayed values over a period of time to arrive at a

more legible display. Filtering helps to eliminate short duration transients and spikes that may cause

false or spurious readings.

To change or view the Display and Controller input Filter, press the FUNC key until

nonE

and

GROUP

show on the display. Press the ▲ key until 2 shows in the upper display. Press the FUNC

key until the lower display changes to

AT.FL

. Using the ▼ or ▲ keys, select the amount of filtering

desired, from none

(OFF)

to five seconds. When finished, press the FUNC key to lock in the value

and advance to the next parameter, or press the A/M key to go back to the active display.

5.4 SETTING THE REMOTE SET POINT INPUT (OPTIONAL)

The Remote Set Point allows the user to control the setpoint from a remote voltage or current source

(0-10 VDC, 0-20 mA or 4-20 mA sources), and to select either the keyboard or the remote power

source as control device.

Page 29

ATC770 Microprocessor-Based Pressure/Process Controller 29

5.4.1 SETTING THE REMOTE SET POINT INPUT VOLTAGE OR CURRENT

To change or view the Remote Set Point selection parameter, press the FUNC key until

nonE

and

GROUP

show on the display. Press the ▲ key until 5 shows in the upper display. Press the FUNC

key until the lower display changes to

RI.TYP

. Using the ▼ or ▲ keys, select the voltage or current

input desired: (0-10 VDC, 0-20 mA or 4-20 mA sources or

OFF

). When finished, press the FUNC

key to lock in the value. To select the jumper setting necessary, see Figure 5 below:

Fig. 5 ATC770 Board Location

Page 30

30

Fig. 6 Remote Set Point Jumper Location, Board E

Page 31

ATC770 Microprocessor-Based Pressure/Process Controller 31

5.4.2 SETTING THE REMOTE SET POINT INPUT FAILSAFE MODE

The Remote Set Point Failsafe parameter sets the value of the control signal in the event of a failure

of the Remote Set Point signal. The Default value is

Low

.

To change or view the Remote Set Point Failsafe Mode, press the FUNC key until

nonE

and

GROUP

show on the display. Press the ▲ key until 4 shows in the upper display. Press the FUNC key until

the lower display changes to

RI.IFS

. Using the ▲ or ▼ keys, select the desired setting: LO or HI.

When finished, press the FUNC key to lock in the value.

5.4.3 SETTING THE REMOTE SET POINT LIMITS

The Remote Set Point can be limited to a specific output both on the low and the high side. Either

value can be set to the Primary Input Full Scale Value.

To set the Remote Set Point Low parameter, press the FUNC key until

nonE

and

GROUP

show on

the display. Press the ▲ key until 3 shows in the upper display. Press the FUNC key until the lower

display shows

SP.LO

. Using the ▲ or ▼ keys, select the desired value from the default 0 to the

Primary Input Full Scale Value

(PI.FSV)

. When finished, press the FUNC key to lock in the value and

advance to the next variable, the Remote Set Point High parameter

SP.HI

.

To set the Remote Set Point High parameter, press the ▲ or ▼ keys, select the desired value from the

default

PI.SFV

to the value selected in

SP.LO

. When finished, press the FUNC key to lock in the

value and advance to the next parameter, or press the A/M key to go back to the active display.

5.4.4 SETTING THE LOCAL REMOTE SET POINT SELECTION

Either the Remote Set Point or local control can be used to start the process. To select the start mode,

press the FUNC key until

nonE

and

GROUP

show on the display. Press the ▲ key until 2 shows in

the upper display. Press the FUNC key until the lower display shows

LR.SP

. Using the ▲ or ▼ keys,

select the desired value from the default

LOC

(local) to

rEn

(remote). When finished, press the

FUNC key to lock in the value. Press the A/M key to go back to the active display. The selection of

LR.SP

is stored in nonvolatile memory, and this selection will be saved even if the instrument has

been totally shut down. On start-up, the

LR.SP

status will be restored as set.

6. CONFIGURATION

6.1 PRIMARY INPUT SETUP

6.1.1 SETTING THE PRIMARY INPUT TYPE FOR A STRAIN GAGE TRANSDUCER

If you have an amplified transducer, or other amplified input, skip to Section 6.1.2, otherwise, if

using a

Dynisco

transducer, the model number of the transducer will designate its own electrical

output. For example, in plastic melt applications, the PT462E-5M-6/18 or TPT432A-10M-6/18 have

Page 32

32

a strain gage (0-3.33 mV/V full scale) signal output. Amplified units have a number where the strain

gage units have a letter (E or A). The PT4624-5M-6/18 has a 4-20 mA signal output; the PT4625-5M6/18 has a 0-5 VDC signal output, while PT4626-5M-6/18 has a 0-10 VDC signal output. In

Industrial applications, amplified units have a middle or end number of 4, 5, or 6. The S840-000-1C

has a 4-20 mA signal output; the PT150-7.5M has a 0-5 VDC signal output, while PT276-5M has a

0-10 VDC signal output.

The ATC770’s default setting is strain gage input. To verify that the input is set for strain gage, press

the FUNC key until

nonE

and

GROUP

show on the display. Press the ▲ key until 5 shows in the

upper display. Press the FUNC key and the upper display should show

Str

while the lower display

shows

PI.TYP

. If not, press the ▲ or ▼ key until the upper displa y changes to

Str

(for strain gage).

Press the FUNC key to set the value. Press the A/M key to return to the active display. Remember to

change the jumper settings to correspond to the proper input as shown in Figure 7 for board location

and Figure 8 for amplified input jumpers.

Fig. 7 ATC770 Board Location

Page 33

ATC770 Microprocessor-Based Pressure/Process Controller 33

Fig. 8 Input/Output Jumper Location

6.1.2 SETTING THE SHUNT CALIBRATION FOR STRAIN GAGE TRANSDUCERS

AND

AMPLIFIED TRANSMITTERS

The Dynisco strain gage transducers and amplified transmitters (if so equipped) have an internal

shunt to allow the ATC770 to set the internal scaling for correct display. To Access the Shunt

Calibration parameter, press the FUNC key until

nonE

and

GROUP

show on the display. Press the

▲ key until 4 shows in the upper display. Press the FUNC key and the upper display will show

OFF

while the lower displa y shows

SHUNT

. Press the ▲ or ▼ key until the upper display changes to the

ON

. Press the FUNC key to set the value and move to the next Shunt par ameter.

The upper display will show

80.0

while the lower display shows

SHNT%

. In most cases, the

Page 34

34

Dynisco transducers have an 80% shunt value so no changes need be made. However, some

transducers and strain gages have shunt values that may range from 40% to 100%. If so, press the ▲

or ▼ key until the upper display changes to the correct values. Press the FUNC key to set the value.

Press the A/M key to go back to the active display.

6.1.3 SETTING THE PRIMARY INPUT TYPE FOR AN AMPLIFIED TRANSMITTER

If using a voltage or current output transducer, the model number of the transducer will designate its

own electrical output. For example, a PT4624-7.5M-6/18 or an S840-000-10M has an amplified

signal output. In plastic melt applications, amplified units have a number where the strain gage units

have a letter (E or A). The PT4624-7.5M-6/18 has a 4-20 mA signal output; the PT4625-7.5M-6/18

has a 0-5 VDC signal output, while PT4626-7.5M-6/18 has a 0-10 VDC signal output. In Industrial

applications, amplified units have a middle or end number of 4, 5, or 6. The S840-000-1C has a 420 mA signal output; the PT150-7.5M has a 0-5 VDC signal output, while PT276-5M has a 0-10

VDC signal output.

If you have a strain gauge transducer, load cell, or other Wheatstone bridge device, see Section

6.1.1.

The Instrument’s default setting is strain gage input. To select another input for a transmitter or to use

another process instrument, such as humidity sensors, position sensors, etc., press the FUNC key

until

nonE

and

GROUP

show on the display. Press the ▲ key until 5 shows in the upper display.

Press the FUNC key and the lower display will show

PI.TYP

. Press the ▲ or ▼ key until the upper

display changes to the correct value (

0-20

for 0-20 mA linear input,

4-20

for 4-20 mA current loop

input,

0-5

for 0-5 VDC linear input, and

0-10

for 0-10 VDC linear input). Press the FUNC key to set

the value. Press the A/M key to go back to the active display.

Remember to change the jumper settings to correspond to the proper input as shown in Figure 7 for

board location and Figure 9 for amplified input jumpers.

Page 35

ATC770 Microprocessor-Based Pressure/Process Controller 35

Fig. 9 Input Selection J84 for Amplified Input

6.1.4 SETTING THE PRIMARY INPUT FULL-SCALE VALUE

The model number of the transducer or transmitter will designate the full-scale pressure capability.

For example, model number TPT432A-5M-6/18 indicates that the full-scale pressure is 5,000 (5M),

while the PT150-5C indicates that the full-scale pressure is 500 (5C). Since the default value in the

instrument is 10,000 full scale, the input full scale value must be changed to 5,000 (or 500). Note

that there are no units here, it can be psi, bar, mPa, kg/cm2 or any engineering unit; the magnitude

is all that is important.

To set the full-scale value, press the FUNC key until

nonE

and

GROUP

show on the display. Press

the ▲ key until 3 shows in the upper display. Press the FUNC key and the upper display will show

10000

while the lower display shows

PI.FSV

. Hold the ▲ or ▼ key until the upper display changes

to

5000

(or whatever the full-scale value of the primary input may be). Press the FUNC key to set

the value. Check that the next display reads 0 in the upper display and

PI.LSV

in the lower display; if

not, set to zero with the arrow keys and press FUNC to lock in the value. Finally, press the A/M key

to go back to the active display. Similarly, if the full-scale pressure is 350 Bar (3.5CB), set

PI.FSV

to

350.

Page 36

36

6.1.5 SETTING THE PRIMARY INPUT LOW-SCALE VALUE

For applications where a low scale value is non-zero, the Instrument can provide a low scale value

of ±25% of the full scale value.

To set the low-scale value, press the FUNC key until

nonE

and

GROUP

show on the display. Press

the ▲ key until 3 shows in the upper display. Press the FUNC key and the upper display will show a

value while the lo wer display shows

PI.FSV

. Press the FUNC key and the upper display will sho w

0

while the lower displa y shows

PI.LSV

. Hold the ▼ or ▲ key until the upper displa y changes to

whatever the low-scale value of the primary input may be. Press the FUNC key to set the value.

Finally, press the A/M key to go back to the active display.

6.1.6 SETTING THE PRIMARY INPUT DECIMAL PLACE

To set the decimal place, press the FUNC key until

nonE

and

GROUP

show on the display. Press the

▲ key until 3 shows in the upper displa y. Press the FUNC key until the lower display shows

PI.DP

.

Press the ▼ or ▲ key until the upper display shows the correct decimal place location. For example,

a 350 Bar unit may show 350.0 for decimal place setting. Press the FUNC key to set the value.

Finally, press the A/M key to go back to the active display.

6.1.7 SETTING THE PRIMARY INPUT FAILSAFE MODE

The Primary Input Failsafe Mode is nothing more than a safety mechanism that tells the instrument

what to do in the event of a loss of the primary signal. If the system is set up to shut down the

process in a high alarm condition, the Primary Input Failsafe parameter can set the value of the

primary input to full scale if it looses the primary signal. If the system is set up to shut down the

process in a low alarm condition, the Primary Input Failsafe parameter may set the value of the

primary input to low scale if it looses the primary signal. The default Primary Input Failsafe Mode is

to set the value to full scale high.

To set the Primary Input Failsafe Mode, press the FUNC key until

nonE

and

GROUP

show on the

display. Press the ▲ key until 4 shows in the upper display. Press the FUNC key until the lower

display shows

PI.IFS

. Press the ▼ or ▲ key until the upper display shows the correct mode, either

HI

or Lo. Press the FUNC key to set the value. Finally, press the A/M key to go back to the active

display.

6.2 SETTING THE ALARMS

All Alarms supplied with the Instrument can be linked to the actual pressure value, a pre-selected

band about that pressure value, deviation from setpoint, or turned off. The alarms are capable of

being set as High Level Alarms or Low Level Alarms, and may operate in either

Failsafe

or

Direct

condition.

Failsafe

means that in the event of power failure to the Instrument, the Alarm will activate. Use this

feature on a shutdown alarm. Please note that in a proper operating condition in Failsafe mode, the

Page 37

ATC770 Microprocessor-Based Pressure/Process Controller 37

Normally Closed Contact are held OPEN, while the Normally Open contacts are held CLOSED. On

power failure, they are released.

On start-up, a Low Alarm may cause the unit to go into an undesired alarm condition prior to

reaching running conditions. This Alarm can be masked so that the Low Alarm will be deactivated

until it has gone above the alarm value for the first time. It will then operate as a normal low alarm.

The default values for Alarm 1 are: an inhibited low alarm set at 5% of full scale, linked to the

primary process input, 0.4 second filtering, 1% hysteresis, automatic reset and failsafe mode. Each

alarm may be set to 110% of full scale.

The default values for Alarm 2 are: high alarm at 60% of full scale, linked to the primary process

input, 0.4 second filtering, 1% hysteresis, automatic reset, and failsafe mode.

The default values for Alarm 3 are: high alarm at 80% of full scale, linked to the primary process

input, 0.4 second filtering, 1% hysteresis, automatic reset, and failsafe mode.

Set the Alarm parameters before setting the alarm value. If the alarm parameters have already been

set, set the alarm values as described in Section 6.2.7.

6.2.1 SETTING WHAT THE ALARM WILL MONITOR (ALARM INPUT CHANNEL LINK)

The Alarm 1 Input Channel Link defaults to the primary process input. To check or change this value

press the FUNC key until

nonE

and

GROUP

show on the display. Press the ▲ key until 3 shows in

the upper display. Press the FUNC key until

A1.LNK

shows in the lower display. Select the choice

desired by pressing the ▼ or ▲ keys. The choices are:

OFF

, (disabled), a process alarm (on achieving

a specific pressure)

Proc

, a band alarm around a specific pressure range

bAnd

, or a deviation alarm

from a specific pressure

dEu

. Press the FUNC key to lock in the value and advance to the next

parameter. Similarly, you may configure Alarm 2

(A2.LNK)

and Alarm 3

(A3.LNK)

.

6.2.2 SETTING ALARM TYPE

A high alarm will activate when a set point is exceeded. A low alarm will activate whenever the

value falls below a set point (including startup). An inhibited low alarm must exceed the low alarm

set point before it is enabled. Then it will work like a low alarm. This is ideal on startup.

The default alarm type for Alarm 1 is high. To check or change this value press the FUNC key until

nonE

and

GROUP

show on the display. Press the ▲ key until 3 shows in the upper display. Press the

FUNC key until

A1.TYP

shows in the lower display. Using the ▼ or ▲ keys, select HI for high level

alarm, LO for low level alarm or

Inhib

for a low level alarm with mask at start-up. Press the FUNC

key to lock in the value and advance to the next parameter. If finished, press A/M to return to the

operating screen. Similarly, you may configure Alarm 2

(A2.TYP)

and Alarm 3

(A3.TYP)

.

Page 38

38

6.2.3 SETTING THE FILTERING FOR ALARMS

Filtering is an electrical method of averaging the input values over a period of time to arrive at a

smoother curve. This helps to eliminate short duration transients and spikes which can cause alarms,

but which may cause false or spurious readings.

The Alarm filter default is 0.4 seconds of filtering. To change this value, press the FUNC key until

nonE

and

GROUP

show on the display. Press the ▲ key until 2 shows in the upper display. Press the

FUNC key until the lower display c hanges to

A1.FL

. Using the ▼ or ▲ keys, select the amount of

filtering desired, from none

(OFF)

to five seconds. When finished, press the FUNC key to lock in the

value and advance to the next parameter. If finished, press A/M to return to the operating screen.

Similarly, you may configure Alarm 2

(A2.FL)

and Alarm 3

(A3.FL)

.

6.2.4 SETTING THE HYSTERESIS FOR ALARM

Hysteresis is used to describe the amount that the reading must drop below the alarm point (in a

high alarm) or must rise above the alarm point (in a low alarm) to clear the alarm condition. This

helps to eliminate short duration alarms when operating near the alarm condition. To change or

view this value, press the FUNC key until

nonE

and

GROUP

show on the display. Press the ▲ key

until 4 shows in the upper display. Press the FUNC key until the lower display changes to

A1.HYS

.

The values for hysteresis can range from .1% to 10.0%. Press the ▼ or ▲ keys until the upper

display changes to the desired value. Press the FUNC key to lock in the value and advance to the

next parameter, or press A/M to return to the operating screen. Similarly, you may configure Alarm

2

(A2.HYS)

and Alarm 3

(A3.HYS)

.

6.2.5 SETTING THE RESET MODE FOR ALARMS

The Alarm Reset Mode determines if the alarm resets itself once the alarm condition is been

corrected, or whether the operator must press a button to reset the alarm. The Alarm Reset Mode

default is automatic reset once the alarm has cleared. To change or view this value, press the FUNC

key until

nonE

and

GROUP

show on the display. Press the ▲ key until 4 shows in the upper display.

Press the FUNC key until the lower display c hanges to

A1.RES

. The value for reset mode is either

Auto

for automatic reset, or

LAtCH

for manual reset. Press the ▼ or ▲ keys until the upper display

changes to the desired value.

Press the FUNC key to lock in the value and advance to the next parameter, or press A/M to return

to the operating screen. Similarly, you may configure Alarm 2

(A2.RES)

and Alarm 3

(A3.RES)

.

6.2.6 SETTING THE FAILSAFE MODE FOR ALARMS

The Alarm Failsafe Mode determines how the alarms react in the event of a power failure to the

ATC770. In the failsafe mode, the alarms will activate in the event of power loss. In non-failsafe

mode they cannot activate on power loss. The Alarm Failsafe default is failsafe mode. To change this

value, press the FUNC key until

nonE

and

GROUP

show on the display. Press the ▲ key until

4

shows in the upper display. Press the FUNC key until the lower display changes to

A1.FSM

. The

Page 39

ATC770 Microprocessor-Based Pressure/Process Controller 39

options for failsafe mode are either FS for failsafe mode, or

nFS

for non-failsafe mode. Press the ▼ or

▲ keys until the upper display changes to the desired value. Press the FUNC key to lock in the

value and advance to the next parameter. Similarly, you may configure Alarm 2

(A2.FSM)

and Alarm

3

(A3.FSM)

.

Carefully consider the Alarm wiring: For failsafe operation the alarm contacts must be wired

differently to have operation as expected. The ATC770 energizes the contact relay during failsafe

operation. This means the NO contact will be held CLOSED during normal operation. In the event

of an alarm or the loss of power to the ATC770, the relay will be de-energized and will then open.

The same holds true for a NC contact. It will be held OPEN during normal operation. In the event of

an alarm condition or the loss of power to the ATC770, the relay will be de-energized and will then

close. In non-failsafe operation the reverse is true, in that a NO acts as a NO and a NC acts as an

NC.

6.2.7 SETTING THE ALARMS VALUE

The Alarm 1Threshold Values, is the value beyond which the Alarm will activate (i.e. the threshold).

Alarm 1 is set in the same engineering units that the Full Scale Value uses. To change or view this

value when in the operating screen, press the FUNC key, when in the main screen, and the lower

display will c hange to

AL1

with the threshold value in the upper display . Press the ▼ or ▲ keys until

the upper display changes to the desired value. Press the FUNC key to lock in the value and

advance to the next parameter, or press A/M to return to the operating screen. Similarly, you may

configure Alarm 2

(AL2)

and Alarm 3

(AL3)

.

6.2.8 SETTING THE ALARMS MASK RESET TYPE

The Alarm 1 Mask Reset may only be used on alarms configured as inhibited low alarms on startup.

It prevents the alarm from activating (masks the alarm) until the value of the primary input exceeds

the alarm value. To change or view this value when in the operating screen, press the FUNC key

until the lower display changes to

AL.MSK

with

OFF

in the upper display. Press the ▼ or ▲ keys

until the upper display changes to

rESEt

. Press the FUNC key to lock in the value and advance to

the next parameter, or press A/M to return to the operating screen. You may similarly configure

Alarm 2 or 3.

6.3 RETRANSMISSION OUTPUT SETUP

This ATC770 has a retransmission output which can send a signal to a recorder or some other device

that can accept a voltage or current signal.

6.3.1 SELECTION THE RETRANSMISSION OUTPUT

The Retransmission Output Type sets the output to specific voltages or currents. The available

outputs are 0-20 mA, 4-20 mA, 0-10 VDC, -10 to +10 VDC, and 0-5 VDC. To change or view this

value, press the FUNC key until

nonE

and

GROUP

show on the display. Press the ▲ key until

5

shows in the upper display. Press the FUNC key until the lower display changes to

RO.TYP

, and the

Page 40

40

upper display shows the selected type. Press the ▼ or ▲ keys until the upper display changes to the

desired value. Then press the FUNC key to lock in the value. Press A/M to return to the operating

screen.

Next, select the jumper setting necessary. See Figure 10 below:

Fig. 10 Input/Output Jumper Location

Page 41

ATC770 Microprocessor-Based Pressure/Process Controller 41

6.3.2 SETTING THE RETRANSMISSION OUTPUT RANGE

To change or view the Retransmission Output Range Low, press the FUNC key until

nonE

and

GROUP

show on the display. Press the ▲ key until 3 shows in the upper display. Press the FUNC

key until the lower display changes to

RO.LO

. Press the ▼ or ▲ keys until the upper display

changes to the desired value. The value may be anything from 0 to the primary input full scale value,

PI.FSV

. This can act as a scale expander; i.e. if the system has a 10,000 psi transducer but usually

runs from 3,000 to 6,500, the

RO.LO

can be set to 2,500 so that the output at 2,500 psi is 0. Once

the desired value is set, press the FUNC key to lock in the value and advance to the next parameter

the Retransmission Output Range High

RO.HI

.

6.3.3 SETTING THE RETRANSMISSION OUTPUT RANGE HIGH

If

RO.HI

does not appear from the previous step, press the FUNC key until

nonE

and

GROUP

show

on the display. Press the ▲ key until 3 shows in the upper display. Press the FUNC key until the

lower display changes to

RO.HI

.

Once

RO.HI

appears, press the ▼ or ▲ keys until the upper display changes to the desired value.

The value may be anything from 0 to the primary input full scale value,

PI.FSV

. This can act as a

scale expander; i.e. if the system has a 10,000 psi transducer but usually runs from 3,000 to 6,500,

the

RO.HI

can be set to 7,500 so that the output at 7,500 psi is full scale voltage or current. Once

the desired value is set, press the FUNC key to lock in the value and advance to the next parameter,

or press A/M to return to the operating screen.

6.3.4 SETTING THE RETRANSMISSION OUTPUT FILTER

Filtering is an electrical method of averaging the output values over a period of time to arrive at a

smoother curve. This helps to eliminate short duration transients and spikes that may cause false or

spurious readings.

To change or view the Retransmission Output Filter, press the FUNC key until

nonE

and

GROUP

show on the display. Press the ▲ key until 2 shows in the upper display. Press the FUNC key until

the lower display changes to

RO.FL

. Using the ▼ or ▲ keys, select the amount of filtering desired,

from none

(OFF)

to five seconds. When finished, press the FUNC key to lock in the value. Press

A/M to return to the operating screen.

6.4 SETTING THE CONTROL OUTPUT

The control output is opto-isolated from the CPU input and output circuits. The types of Control

Outputs available are jumper and keyboard selectable between various voltages and currents.

6.4.1 SETTING THE CONTROL OUTPUT VOLTAGE OR CURRENT

The control output can have a 0-5 VDC, a 0-10 VDC, a -10 to +10 VDC, a 4-20 mA or a 0-20 mA

output. The range of output is selected from the keyboard, but the type of output must be selected by

Page 42

42

using jumpers. To select the voltage or amperage range, press the FUNC key until

nonE

and

GROUP

show on the display. Press the ▲ key until 5 shows in the upper display. Press the FUNC

key until the lower display sho ws

CO.TYP

. Using the ▼ or ▲ keys, select the desired value:

0-5

(VDC),

0-20

(mA),

4-20

(mA),

0-10

(VDC), or

-10.10

(VDC). When finished, press the FUNC key to

lock in the value and A/M to return to the main screen.

Next, select the jumper setting necessary. See Figure 11 below:

Fig. 11 Input/Output Jumper Location

Page 43

ATC770 Microprocessor-Based Pressure/Process Controller 43

6.4.2 MAKING THE CONTROL OUTPUT DIRECT/REVERSE SELECTION

The input signal can cause the control output to either increase or decrease with an increasing or

decreasing input signal. The table below shows the value of Direct/Reverse Control Output selection

(CO.D/R)

. The first digit shows the relationship between the input signal and the displayed output

value

(OUT%)

. The last digit shows the relationship between the displayed output signal and the

output value voltage or current.

Value Input Signal Displayed Output Control Output

r d

0-100 (increase) 100-0 (decrease) 100-0 (decrease)

r r

0-100 (increase) 100-0 (decrease) 0-100 (increase)

d d

0-100 (increase) 0-100 (increase) 0-100 (increase)

d r

0-100 (increase) 0-100 (increase) 100-0 (decrease)

The default value is

r d

(Reverse-Direct), or decreasing the Displayed and Control outputs with

increasing signal.

6.4.3 SETTING THE CONTROL OUTPUT LIMIT

The Control Output Signal can be limited to a specific percentage value to prevent downstream

problems. To set the Control Output Limiter parameter

(CO.MAX)

, press the FUNC key until

nonE

and

GROUP

show on the display. Press the ▲ key until 4 shows in the upper display. Press the

FUNC key until the lower display shows

CO.MAX

. Using the ▼ or ▲ keys, select the desired value

from 10.0 to 100.0%. When finished, press the FUNC key to lock in the value and A/M to return to

the main screen.

6.4.4 SETTING THE CONTROL OUTPUT MANUAL MORE INDICATION