Page 1

Dynisco Polymer Test Systems

LMI 4000

Series

Melt

Indexer

Manual

Version 4.1

Manual Part Number: M0704 www.dynisco.com

Original Language Version

38 Forge Parkway

Franklin, MA 02038

Phone +1 508 541 9400

Fax +1 508 541 6206

Page 2

Notice

This manual contains descriptions, drawings and specifications for a Dynisco Polymer Test

Systems Product. Equipment or products made prior to or subsequent to the publication

date of this manual may have parts, features, options or configurations that are not covered

in this manual. Specifications contained herein are subject to change by Dynisco Polymer

Test Systems without prior notice. Dynisco Polymer Test Systems is not responsible for

errors or omissions that may be contained herein or for incidental or consequential damages

in connection with the furnishing or use of this information. The information contained in

this manual is the property of Dynisco Polymer Test Systems, unless otherwise stated.

Comments or suggestions for possible improvement to the manual are appreciated and may

be sent to the following location:

38 Forge Parkway

Franklin, MA 02038

Phone +1 508 541 9400

Fax +1 508 541 6206

www.dynisco.com

Page 3

Contents

Introduction 1

Getting Started 6

Safety 10

Series 4000 Melt Indexer Operation Manual Contents i

About DYNISCO POLYMER TEST SYSTEMS Inc. ................................................................................... 1

How to Use this Manual.................................................................................................................................. 1

Typographic Conventions ............................................................................................................................... 2

How to Contact Dynisco Polymer Test Systems Inc....................................................................................... 2

Model Descriptions ......................................................................................................................................... 2

On Overview of MI ......................................................................................................................................... 3

ASTM Melt Index Tests.................................................................................................................................. 3

Method A .......................................................................................................................................... 3

Method A/B ...................................................................................................................................... 3

Method B .......................................................................................................................................... 3

Series 4000 Product Offerings: ....................................................................................................................... 3

Introduction....................................................................................................................................... 3

Model 4001 ....................................................................................................................................... 4

Model 4002 ....................................................................................................................................... 4

Model 4003 ....................................................................................................................................... 4

Model 4004 ....................................................................................................................................... 4

Method B Encoder Option ................................................................................................................ 4

Pneumatic Lift................................................................................................................................... 5

Mini-Lift ........................................................................................................................................... 5

Intrinsic Viscosity Option ................................................................................................................. 5

Unpacking the Indexer .................................................................................................................................... 6

Bench Requirements and Placement ................................................................................................. 6

Level the Melt Indexer ...................................................................................................................... 6

Pneumatic lift setup........................................................................................................................... 7

Installing the Digital Encoder ........................................................................................................... 7

RTD Connection ............................................................................................................................... 9

Power Cord ....................................................................................................................................... 9

Printer Connection ............................................................................................................................ 9

Computer Connection ....................................................................................................................... 9

Options:............................................................................................................................................. 9

Use gloves, it's HOT! .................................................................................................................................... 10

Electrical Hazard ........................................................................................................................................... 10

Calibration Thermometers use Mercury........................................................................................................ 10

Pinch Points................................................................................................................................................... 11

Fumes from Materials ................................................................................................................................... 11

Pre-Run Check List ....................................................................................................................................... 11

Page 4

Series 4000: A Guided Tour 12

Four Options from the main menu screen. .................................................................................................... 12

Overview......................................................................................................................................... 12

Setup ............................................................................................................................................... 12

Edit.................................................................................................................................................. 12

Run.................................................................................................................................................. 12

System............................................................................................................................................. 12

Navigating the Keypad.................................................................................................................................. 13

Introduction..................................................................................................................................... 13

The Keypad ..................................................................................................................................... 13

Keypad Definitions ......................................................................................................................... 14

Configuring the Instrument 15

Series 4000 Melt Indexer Operation Manual Contents ii

Intro: The SYS (SYSTEM) Mode................................................................................................................. 15

Selecting CALIB (Calibration) in the SYS Mode ......................................................................................... 16

CALIB:Digital Flag Home.............................................................................................................. 16

CALIB:RTD Electronics................................................................................................................. 16

CALIB:RTD Sensor........................................................................................................................ 16

CALIB:Optical Flag........................................................................................................................ 16

CALIB:Intrinsic Viscosity Offset ................................................................................................... 16

Selecting TEST in the SYS Mode ................................................................................................................. 17

TEST:RTD Display ........................................................................................................................ 17

TEST:Digital Encoder .................................................................................................................... 17

TEST:Printer ................................................................................................................................... 17

TEST:Display Brightness ............................................................................................................... 17

The SETUP mode ......................................................................................................................................... 17

Introduction..................................................................................................................................... 17

REJECTION ................................................................................................................................... 17

AVERAGE ..................................................................................................................................... 17

MFR / MVR .................................................................................................................................... 17

B FLAG .......................................................................................................................................... 17

VISCOSITY.................................................................................................................................... 17

PRINTER ........................................................................................................................................ 17

FORM FEED .................................................................................................................................. 17

COMM PORT................................................................................................................................. 18

MINI LIFT ...................................................................................................................................... 18

PNEU LIFT..................................................................................................................................... 18

LOCKOUT ..................................................................................................................................... 18

DATE and TIME ............................................................................................................................ 18

MACHINE ID................................................................................................................................. 18

LANGUAGE .................................................................................................................................. 18

ORIFICE DIA ................................................................................................................................. 18

ORIFICE LEN ................................................................................................................................ 18

Programming ................................................................................................................................................. 18

Introduction..................................................................................................................................... 18

Create (New) ................................................................................................................................... 18

Recall (Old)..................................................................................................................................... 18

Save Program .................................................................................................................................. 18

While EDITING ............................................................................................................................. 18

Method A Run Parameters .............................................................................................................. 19

Method A/B Run Parameters .......................................................................................................... 19

Method B Run Parameters .............................................................................................................. 19

RATIO (Flow Ratio) Run parameters .............................................................................................. 20

Page 5

Run a Program............................................................................................................................................... 20

Method "A" Run 21

Programming a Method A ............................................................................................................................. 21

Loading the Sample....................................................................................................................................... 23

User Tips: ...................................................................................................................................................... 25

General Description ........................................................................................................................ 21

Calculations: Method A .................................................................................................................. 21

Power-Up ........................................................................................................................................ 21

Introduction..................................................................................................................................... 21

Machine Setup ................................................................................................................................ 22

Loading the Barrel .......................................................................................................................... 23

Bubbles ........................................................................................................................................... 23

RUN ................................................................................................................................................ 23

Making the Cut ............................................................................................................................... 24

Weigh the Sample ........................................................................................................................... 24

Cleaning Up .................................................................................................................................... 25

User Tip #1 ..................................................................................................................................... 25

User Tip #2 ..................................................................................................................................... 25

Always leave the barrel clean. ........................................................................................................ 26

Cleaning Up a really Big Mess ....................................................................................................... 26

Method "A/B" Run 27

Programming Method A/B ............................................................................................................................ 27

The Actual Run ............................................................................................................................................. 29

General Description ........................................................................................................................ 27

Calculations : Method A/B ............................................................................................................. 27

Introduction..................................................................................................................................... 28

Machine Setup ................................................................................................................................ 28

How to do it: Step by Step .............................................................................................................. 29

Instrument Prep ............................................................................................................................... 29

Loading the Barrel .......................................................................................................................... 29

Inserting the Timing Flag................................................................................................................ 30

Making the Cut ............................................................................................................................... 31

Cleaning Up .................................................................................................................................... 31

Your data......................................................................................................................................... 31

Method "B" Run 32

Programming Method B ................................................................................................................................ 33

The Actual Run ............................................................................................................................................. 35

General Description ........................................................................................................................ 32

Calculations: Method B .................................................................................................................. 32

Method B Flags Setup..................................................................................................................... 33

Choosing a Timing Flag.................................................................................................................. 34

How to do it: Step by Step .............................................................................................................. 35

Instrument Prep ............................................................................................................................... 35

Loading the Barrel .......................................................................................................................... 35

Timing Flag and Starting the Run ................................................................................................... 36

Cleaning Up .................................................................................................................................... 37

“Flow Ratio” Runs 39

Series 4000 Melt Indexer Operation Manual Contents iii

Flow Rate Ratio test and the Pneumatic Lift Option..................................................................................... 39

Page 6

What is it? ....................................................................................................................................... 39

Why do it?....................................................................................................................................... 39

Flow Rate Ratio - How to Do It ...................................................................................................... 39

“Intrinsic Viscosity” Runs with PET 41

Calculating PET I.V. from the Melt Indexer ................................................................................................. 41

What is it? ....................................................................................................................................... 41

Why do it?....................................................................................................................................... 42

How to do it .................................................................................................................................... 42

Charge Weight 44

The Amount of Sample ................................................................................................................................. 44

A-Standard Operating Procedure 46

Introduction:.................................................................................................................................... 46

Instrument Preparation .................................................................................................................... 46

Conducting the Test ........................................................................................................................ 47

Clean Up ......................................................................................................................................... 47

Your data......................................................................................................................................... 47

Out of Control Action List 48

Actions ............................................................................................................................................ 48

Generic Run Check List .................................................................................................................. 48

Model 4004 and Computer Control 49

Introduction ................................................................................................................................................... 49

The Digital Encoder: Use and Calibration 50

Programming for use with the Digital Encoder............................................................................................. 52

Encoder Homing and Maintenance ............................................................................................................... 53

Introduction..................................................................................................................................... 50

Method B Encoder Option .............................................................................................................. 50

Encoder Advantages ....................................................................................................................... 50

Why use it? ..................................................................................................................................... 51

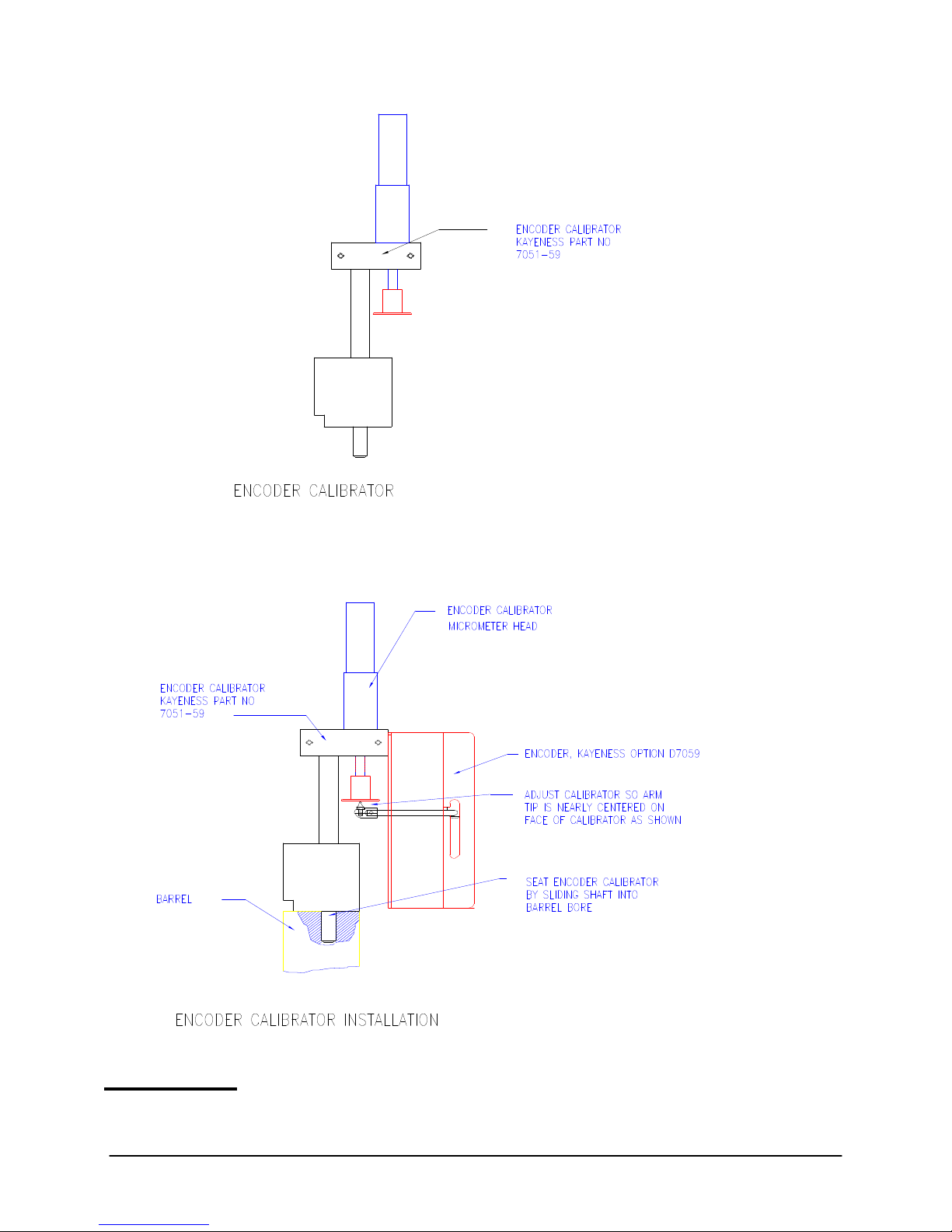

Digital Encoder Installation ............................................................................................................ 51

Method B: Setup ............................................................................................................................. 52

Enable the Digital Encoder ............................................................................................................. 52

Auto Flag ON/OFF ......................................................................................................................... 52

Flag Calculation MANUAL or AUTO? ......................................................................................... 53

AUTO flag selected ........................................................................................................................ 53

So you picked MANUAL ............................................................................................................... 53

Digital Flag Home........................................................................................................................... 53

Testing and Maintenance ................................................................................................................ 53

Complete Digital Encoder Calibration ............................................................................................ 54

Referenced Spec D1238-95 ............................................................................................................ 54

Pneumatic Lift Options 59

Series 4000 Melt Indexer Operation Manual Contents iv

Pneumatic Lift ............................................................................................................................................... 59

Introduction..................................................................................................................................... 59

Activation and Operation ................................................................................................................ 59

Page 7

Mini-Lift........................................................................................................................................................ 59

Introduction..................................................................................................................................... 59

Activation and Operation ................................................................................................................ 59

Instrument Calibration 60

RTD Electronics ............................................................................................................................................ 60

RTD Sensor ................................................................................................................................................... 60

Calibration Steps: ............................................................................................................................ 60

SINGLE .......................................................................................................................................... 60

DOUBLE ........................................................................................................................................ 61

Optical Flag ................................................................................................................................................... 61

Calibration Steps: ............................................................................................................................ 61

Digital Encoder Calibration .......................................................................................................................... 62

Calibration:Digital Flag Home........................................................................................................ 62

Intrinsic Viscosity ......................................................................................................................................... 62

Offset .............................................................................................................................................. 62

Instrument Maintenance and Troubleshooting 63

Maintenance .................................................................................................................................................. 63

Daily................................................................................................................................................ 63

Weekly ............................................................................................................................................ 63

Monthly or Long Term ................................................................................................................... 63

Barrel Diameter............................................................................................................................... 64

Support Vendors ............................................................................................................................. 64

Conversion Factors ......................................................................................................................... 65

Troubleshooting ............................................................................................................................................ 65

Flow Rates are Changing ................................................................................................................ 65

Temperature is Unstable ................................................................................................................. 66

Mercury Separation in Thermometer .............................................................................................. 66

Reuniting Mercury Thermometers .................................................................................................. 66

Pneumatic Lift Troubleshooting ..................................................................................................... 67

Pneumatic Lift maintenance............................................................................................................ 67

Questions and Answers 69

Typical Problems ............................................................................................................................ 69

Typical Questions ........................................................................................................................... 70

Glossary of Terms 73

Series 4000 Melt Indexer Operation Manual Contents v

Digital Flag, Digital Encoder........................................................................ 73

Firmware....................................................................................................... 73

Flow rate ....................................................................................................... 73

Flow Rate Ratio ............................................................................................ 73

Intrinsic Viscosity ......................................................................................... 73

Melt Flow Indexer ........................................................................................ 73

Method A ...................................................................................................... 73

Method A/B .................................................................................................. 73

Method B ...................................................................................................... 73

MVI .............................................................................................................. 73

Optical Flag or Optical Eye Sensor .............................................................. 73

Pneumatic Lift .............................................................................................. 73

RTD .............................................................................................................. 73

Timing Flag .................................................................................................. 73

Page 8

Setting-Up USB Communications 74

Set-Up with Daisy Software ........................................................................ 74

Set-Up with MI Works Software.................................................................. 77

Index 81

Series 4000 Melt Indexer Operation Manual Contents vi

Page 9

Introduction

About Dynisco Polymer Test

Dynisco Polymer Test is a manufacturer of laboratory test equipment supplying

capillary rheometers, melt indexers, a variety of impact testers, coefficient of

friction testers, contact angle testers, film tensile testers and other small test

devices. Through its innovative work with electronics and mechanical design,

Dynisco Polymer Test Systems has carved a niche in the market place by

providing the highest performance per cost ratio in the business.

The company was founded in the late '60's in Honey Brook P.A., and is built on

two principles: quality workmanship and outstanding service. Dynisco Polymer

Test Systems' mission has grown to meeting the physical testing needs of the

plastics, food, and rubber industries by providing high quality equipment and

services at low cost. The company was purchased in 1988 by Dynisco, and is

now a wholly owned subsidiary of Dynisco Inc. Dynisco, an ISO 9002 qualified

supplier, is the world’s largest manufacturer of pressure transducers and is

located in Franklin, MA.

How to Use this Manual

This manual describes the setup procedure and basic operation of the Dynisco

Polymer Test Systems Series 4000 class indexers. With the accompanying

MIWORKS or Daisy software manual (if software was purchased) it provides

the complete description of resources at your command. It is not necessary to

read this manual in its entirety. However, even experienced rheologists and

technicians can benefit from the SAFETY tips and cleaning suggestions learned

over many years of operating these instruments in our applications laboratory.

The Getting Started Chapter explains the details of setting up the instrument and

preparing it for use. Please take a few minutes to review the safety precautions

that should be taken when operating Dynisco Polymer Test Systems Melt Index

Series 4000 Melt Indexer Operation Manual Introduction 1

equipment.

Page 10

Typographic Conventions

Italics: Rheological items that have defining equations presented in the manual

are shown in italics. If you come across an italicized item that is unclear you

can be sure it has a mathematical definition previously defined in the manual.

Bold Italics: These are parameters that are set from the front panel on the

indexer (i.e. Melt Time, Mtd A Time etc.). These parameters are entered into

the indexer's control programs via the indexer key pad.

BOLD ALL CAPITALS: This indicates an actual key found on the indexer

key pad. Example: Press the RESET button to return to main screen. Underlined

Items: Underlined items' head paragraphs or sections that pertain to the

particular item or model underlined. If you do not have or are not interested in

the underlined item skip the section that follows it. Underlining is also used

to emphasize safety issues.

How to Contact Dynisco Polymer

Test Inc.

Before calling Dynisco Polymer Test be sure you have gone through the

"Answers to common questions" section of the manual. To help us handle your

questions as quickly as possible, have the following items ready before you call:

Machine name and model number

Machine serial number (on back panel)

Current version of firmware (Power up unit to see)

Computer system make and model

Current version of software (if applicable)

Call Dynisco Polymer Test directly at (508) 541-9400 and ask for technical

support. Should you wish to comment or query in writing, address to:

Dynisco Polymer Test Inc. : Customer Service

38 Forge Parkway

Franklin, MA 02038

You can also reach us through the internet at: www.Dynisco.com.

Model Descriptions

The DYNISCO POLYMER TEST SYSTEMS Series 4000 Melt Flow Indexer

incorporates the latest in micro-electronic technology. It is designed to make

melt flow rate testing faster, more accurate and flexible, and generate more

rheological information. The heart of the system is a 32 bit microprocessor

developed by DYNISCO POLYMER TEST SYSTEMS. It controls

temperature, responds to keyboard commands and implements testing programs.

Series 4000 Melt Indexer Operation Manual Introduction 2

System capabilities:

Communications with computers

Direct output to printer

Stores test conditions in program memory

Shows instantaneous flow rate read-out

Battery backed-up date & test conditions

Page 11

Download to MS-DOS compatible systems

Methods A, B, or A/B conversion and flow rate ratio

Automated purge or weight lowering

Control temperature within 0.1C.

Automatic check of RTD sensor probe and over temperature alarm.

On Overview of MI

A flow rate test is a measure of a polymer's mass flow rate (grams extruded in

10 minutes) using a particular orifice under specified conditions of temperature

and load. Machines that determine flow rate are generally called Melt Indexers.

Test methods by ISO, DIN, ASTM and others specify heat chamber and piston

tip diameter such that the shear stress on the polymer is the same in all machines

for a given load. In addition, material specification guidelines (by ISO, DIN,

ASTM, GM etc) may exist which give further constraints on how a particular

type of material may be run.

The tests we are interested in performing are those described by ASTM D1238

and ISO 1133. This manual in no way supersedes either of these documents.

The precision and accuracy of the test has been determined by ASTM method

D1238 and can be found at the end of this manual. Contributing to both

precision and accuracy are operator variances such as; packing technique,

cleaning, cutting, weighing etc. With moisture sensitive polymers, dryness can

also play a major role, and time can be a factor with thermally unstable

polymers, so procedures must be identical. Dynisco Polymer Test Systems has

found that charging a consistent mass of material into the barrel (0.1 grams) is

the most critical factor in getting precise data.

ASTM Melt Index Tests

Two basic methods have been developed for running flow rate tests under D1238, Methods A and B. Method A is simply the collection of extrudate over

time, while Method B is the measurement of time for the flow of a fixed volume

Method A

Method A/B

Method B

Series 4000 Melt Indexer Operation Manual Introduction 3

Introduction

of polymer.

Method A -- the test is completely manual and is sometimes called the "cut-nweigh" method.

Method A/B -- this employs the electronic eye or digital encoder. In order to

run a method B test, an A/B run MUST be run first to determine the polymer's

melt density

Method B can be conducted only after an A/B experiment is conducted. This is

a "no-cuts" test that is the most convenient for busy laboratories.

Series 4000 Product Offerings:

The Series 4000 of melt indexers are actually 2 pieces of equipment in one.

First, the instrument houses the hardware needed to conduct the measurement

itself -- the heaters, temperature sensors, die/orifice assembly, and so on.

Page 12

Second, the instrument has a 32 bit micro-processor incorporated into its base

to control the aforementioned hardware, but also to make calculations of the

Melt Index, Viscosity, and in some cases (Model 4003, 4004) calculate

rheological data about the sample as well.

Method B Encoder Option

Model 4001

Model 4002

Model 4003

Model 4004

Series 4000 Melt Indexer Operation Manual Introduction 4

This is the entry level machine. It will conduct method A tests only and cannot

be upgraded to higher models. The 4001 has a 5 program memory.

This model performs Method A, Method B and flow rate ratio testing.

Temperature and flow rate are displayed on the instrument front panel. It has a

20 program memory. The unit can be upgraded to higher models.

This model contains additional program capacity and can retain up to 60 test

programs. In addition, it communicates with printers and can provide a series of

more advanced technical information such as shear rate, shear stress and

viscosity. Statistics on flow rate and viscosity can be averaged over replicated

tests.

The 4004 is the most sophisticated of the Dynisco Polymer Test's models ever

available. It has all of the capabilities of the 4001, 4002 and 4003, and will

communicate with other computers, and can be multiplexed (8 machines to one

PC). With the addition of the encoder option, 10 complete test programs (set

ups) can be stored.

The Digital Encoder option replaces the optical flag and sensor with highly

accurate digital flags and sensors. You can perform experiments using from one

digital flag up to fifteen digital flags. The Dynisco Polymer Test Encoder for

Method B tests employs a 1016 count optical encoder, coupled to high accuracy

gears, to measure the piston travel. The optical encoder has dual outputs,

enabling the signal to be processed in quadrature, yielding a resolution of 0.015

mm. The linear distance of the piston is transferred to rotary displacement via a

precisely calibrated arm. The tip of this arm employs a hardened & ground tip

for extra long life. Accuracy over the ASTM measurement range of 0.25" and

1.00" is +/-0.4%. The optical encoder, while being very accurate, also enables

the test length signal to be processed and varied digitally. Thus, any test length

up to 1"(ASTM) or 30 mm (ISO) may be selected. Up to 15 MFR results per

barrel filling can be obtained. The unit is securely fastened to the rear of the Melt

Indexer, and the arm latches down to facilitate cleaning of the unit after the test is

completed.

Encoder Advantages

Completely Automatic Flag Length Selection on Single MFR Tests

Up to 15 MFR readings per Barrel Filling

Any test length ("Flag") up to 30 mm

User Defined test length & test spacing for single or multiple tests

Automatic Test Length & Test Spacing for multiple tests

Page 13

Pneumatic Lift

Intrinsic Viscosity Option

Mini-Lift

The pneumatic lift accessory is a key piece of hardware if the flow ratio test

needs to be conducted. The Flow Ratio test provides users with insight into a

material’s thinning ability. This test involves obtaining two flow rates at two

different stress levels, of generally a 10:1 ratio. First, the lower mass weight is

added to the piston. Next the higher mass weight is added to the piston. The

high mass weight can be 21 Kilograms. The pneumatic lift automatically raises

and lowers the weight safely.

This is a small Pneumatic Lift assembly that supports the piston rod itself. It is

useful for high-flow materials and can be used in conjunction with a melt plug.

This is a firmware upgrade to the computer housed in the Series 4003 and 4004

melt indexers only. It enables a calculation of IV values, based on the correlation

between melt-index and the "wet-chemistry" technique for determining the

Intrinsic Viscosity of a polymer. The IV is used to determine the molecular

weight of a poly mer. This is described in greater detail in the Dynisco Polymer

Test applications brief, "Correlating Melt Rheology of PET to Solution Intrinsic

Viscosity" by J. Reilly and P. Limbach.

Series 4000 Melt Indexer Operation Manual Introduction 5

Page 14

Bench Requirements and Placement

Level the Melt Indexer

Series 4000 Melt Indexer Operation Manual Getting Started 6

Getting Started

Unpacking the Indexer

The DYNISCO POLYMER TEST'S Melt Flow Indexer comes in a heavy duty,

double-walled cardboard container. First, open the main box and remove the

instrument. Several boxes will also arrive by UPS; check that all boxes are

received. They are coded 1 of 5 or 3 of 5, indicating the total number is five. It

is recommended that the shipping carton be saved a few days until you are

certain the machine works as expected.

Typical laboratory benches are too high for efficient use of the indexers.

Cleaning can be difficult and requires awkward hand positions and forces that

could lead to carpal tunnel syndrome or back discomfort. We strongly suggest a

bench height of 29 inches (desk top height) for an average height operator.

Place the front of the indexer flush with the edge of the table. This will prevent

the operator from having to bend forward excessively when cleaning the barrel

and allow easier access to the back of the machine. As a minimum, the lab

bench should easily be able to support the indexer and operator (total approx.

300 lbs.). DYNISCO POLYMER TEST recommends placing from left to

right, if purchased, the melt indexer; printer; computer. Test shake the melt

indexer for stability. The bench top should also be able to withstand hot dies

and tools being dropped on them. Carpet protection is necessary near the

indexer since a hot die dropped on the carpet will quickly burn spots in it.

Adequate ventilation will also be required to remove potentially harmful fumes

from samples being tested. Consult the Material Safety Data Sheets (MSDS) on

the products to be tested and your material supplier to assess the magnitude of

your ventilation needs. You may wish to consider these ventilation needs when

positioning the instrument in the laboratory.

Most of the machine comes pre-assembled to your door, however, cer tain parts

are prone to breakage if they were placed in their normal operating position

during shipping. These items will need to be installed before safe operation of

the machine is possible. Other issues important to getting accurate data must

also be addressed before valid testing can begin.

Using the small round bubble level, supplied, level the melt indexer. Place the

level on top of the COLD barrel and using the adjustable screw feet, bring the

machine into level. Tighten the locking nuts to keep the feet in level position

Test shake the melt indexer for stability. Some companies bolt the machines

Page 15

directly to their benches. Be sure to remove the level before turning on the

machine. The level will be damaged if it gets hot.

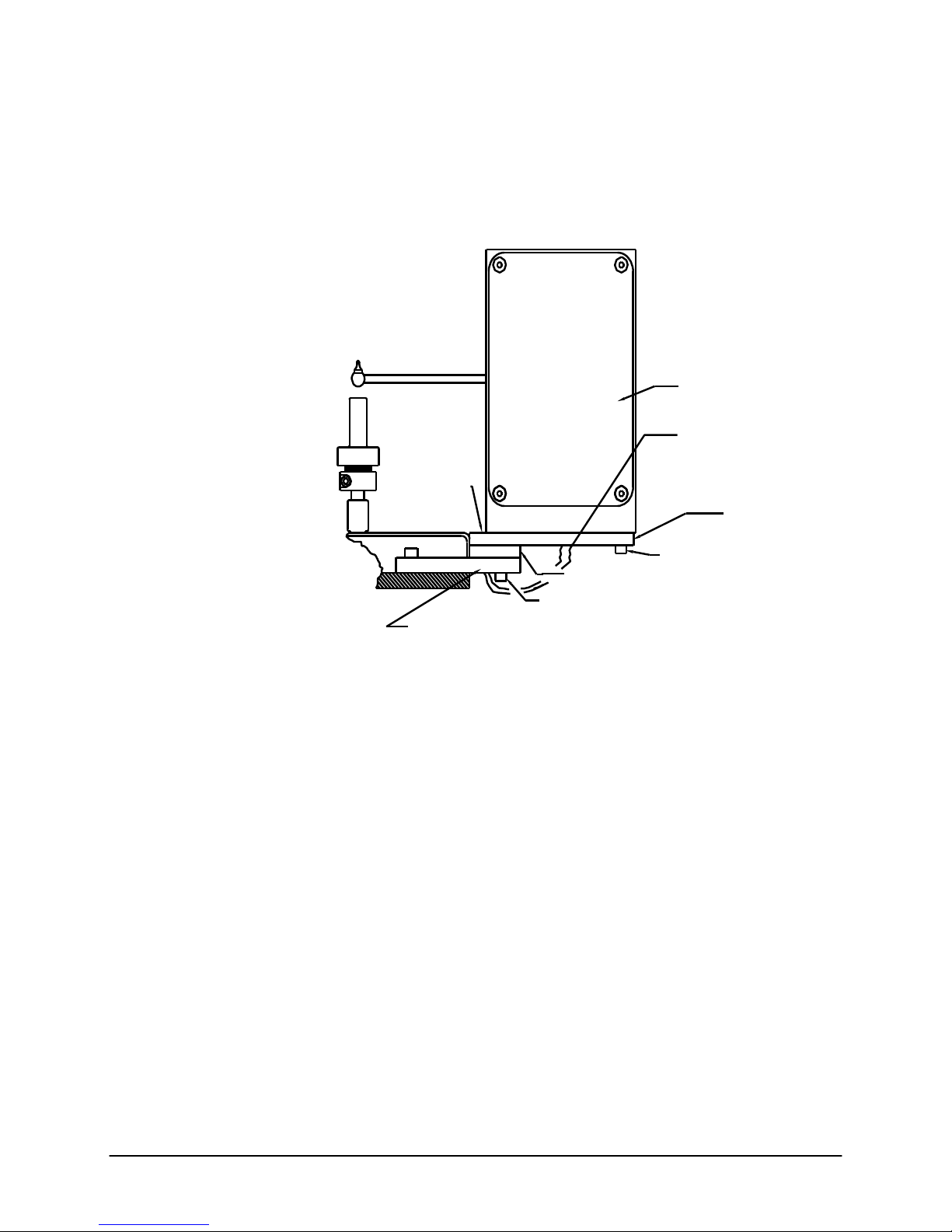

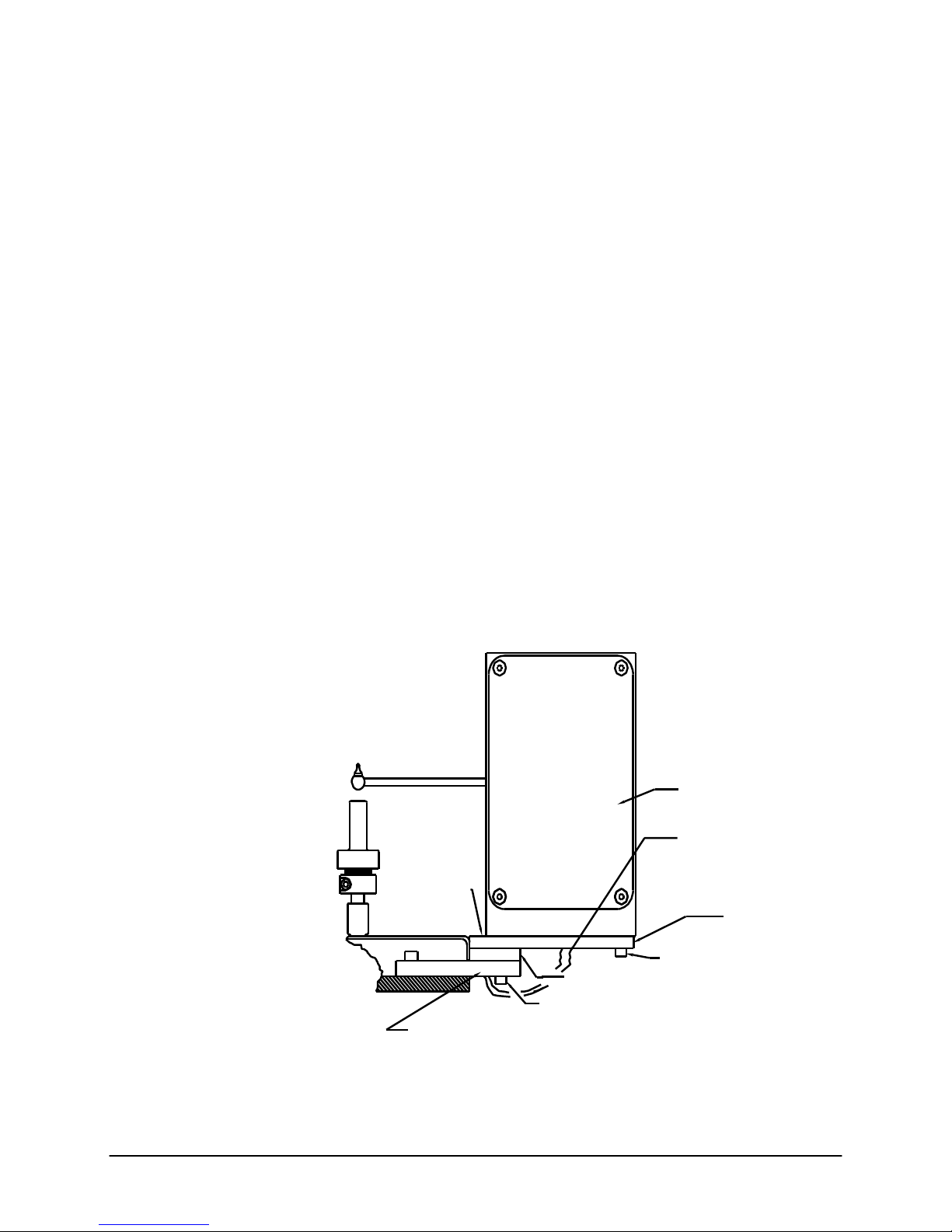

Pneumatic lift setup

*** Be sure to enable the following features in the SETUP Mode ***

(Please refer to drawing below)

a.) Find the safety spike

shipped in the down position. Remove the spike from the post and mount it into

the aluminum weight bucket

bottom of the weight bucket. Tighten set screw

b.) Loosen the guide block set screws

the guide post

block. Tighten the guide block set screws

c.) Connect a length of tubing (supplied) to the main solenoid valve

Push the tubing into the brass fitting and pull it to seal. Attach shop air supply

(60 psi) to the other end of the tubing. Be sure to incorporate a water trap in the

air line.

(2)

up until the bottom snap ring touches the bottom of the guide

(1)

taped to the guide post

(3)

as shown. The spike should be flush with the

(5)

with a 3/32” hex wrench and slide

(5)

.

(2)

. The guide post is

(4)

with a 1/8” hex wrench.

(6)

.

d.)

(8)

is the low voltage solenoid switch which controls the UP and DOWN

functions via signals from the Indexer. The main solenoid valve

pressure to the appropriate cylinder for UP and DOWN movement. Switch

Installing the Digital Encoder

Series 4000 Melt Indexer Operation Manual Getting Started 7

is an extra safety “lock” feature that will lock the lift in place if closed.

The following parts should be in the encoder upgrade kit or included with the

encoder based melt indexer: (if ordered)

Two 1.25" long #8-32 Socket Head Cap Screws (SHCS)

Two 5/8" long #8-32 Socket Head Cap Screws

Two 5/8" long #8-32 Reduced Head Socket Cap Screws

Six #8 Lock Washers & Four #8 Washers

One Encoder Housing

One Long Plate, Plate #1

(6)

directs air

(7)

Page 16

One Small Plate, Plate #2

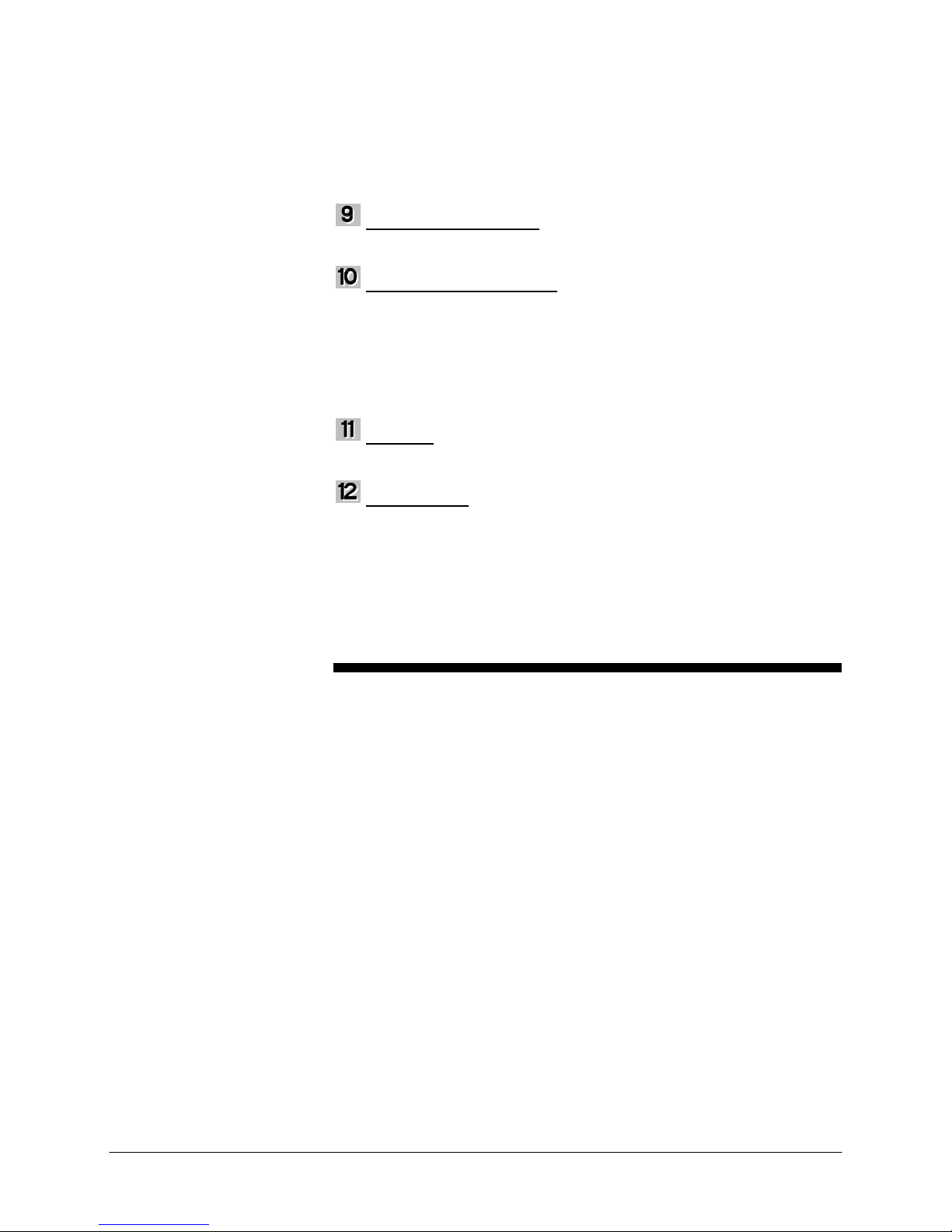

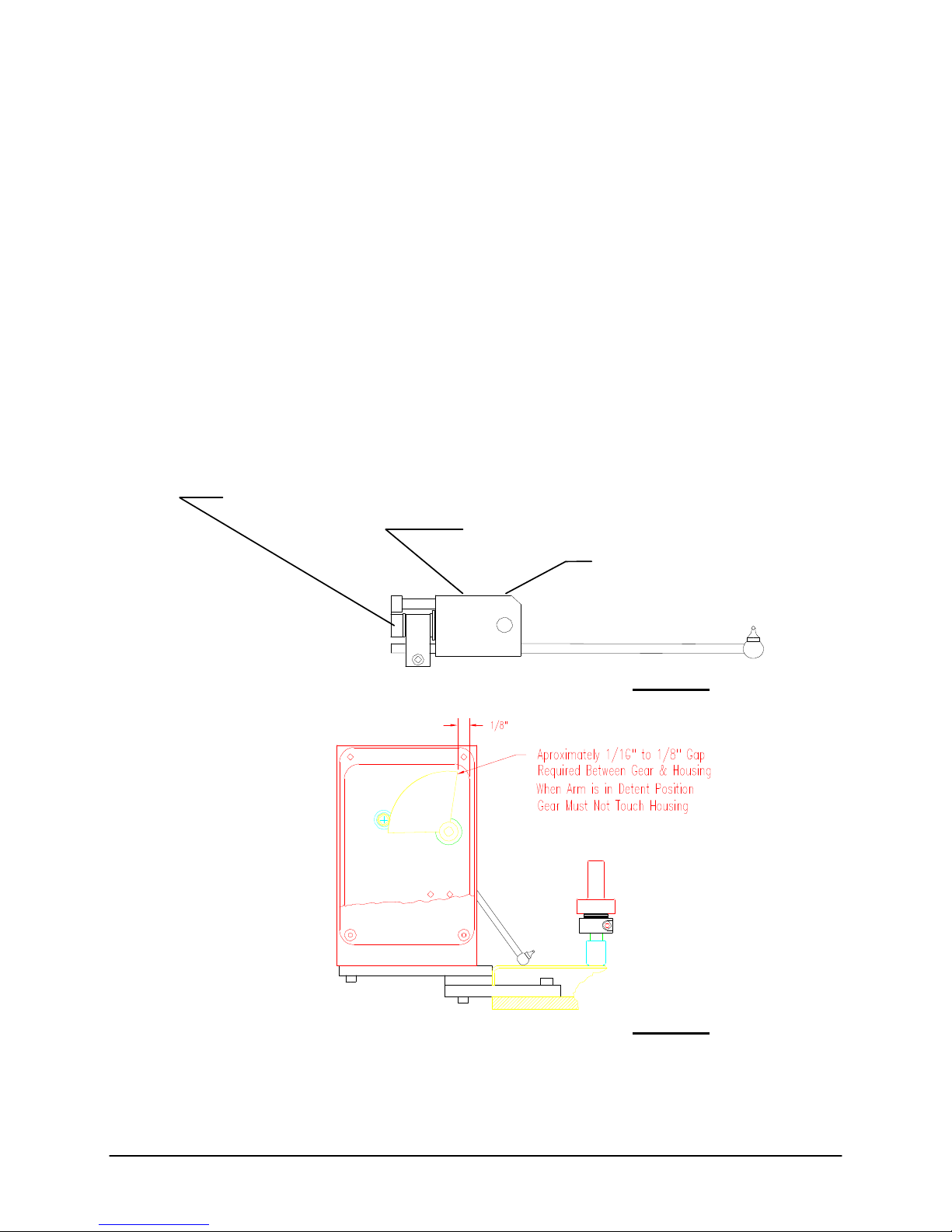

Installation Steps (See Figure 1);

1. Using two 5/8 " Reduced Head Socket Cap Screws & two #8 Lock Washers,

attach plates #1 & #2 to plate #3 (plate #3 is already attached to the MI).

Tighten the screws.

Two Reduced Head

#8-32 x 5/8" Long

Socket Cap Screws &

Two Lock Washers

Plate #2

Figure #1

Plate #3 (Already Mounted to MI)

Two #8-32 x 1.25" SHCS

Two Washers & Lock Washers

Encoder Housing

Phone Jack Cable

Plate #1

Two #8-32 x 5/8" SHCS

Two Washers & Lock Wash

2. Attach the Encoder Housing to the long plate (plate #1) using two 1.25" long

SHCS, two 5/8" long SHCS, 4 washers & 4 lock washers (washers first then

lock washers, i.e. lock washers under screw head).

Note for Pneumatic Lift Users: With the encoder arm in the down position,

lower the pneumatic lift. Move the arm up and down to check for clearance

with the pneumatic lift bucket. Clearance may be increased a small amount by

rotating the encoder housing before tightening the screws. If no clearance

exists and the arm hits the pneumatic lift bucket, contact Dynisco Polymer Test

before proceeding.

Tighten the screws

3. Plug the phone jack cable into the encoder housing.

4. Move the encoder arm into the down position.

5. Turn the power on.

6. Enable the Encoder by pressing the SETUP key. Browse the options until

you reach B FLAG and press EDIT. Press —› Quick Key so that ENCODR is

over the SELECT Quick Key. SELECT ENCODER and press ENTER to

accept. Press ESC to back out to the main menu.

Series 4000 Melt Indexer Operation Manual Getting Started 8

Page 17

7. Press the SYS key and select TEST. Browse the menu and select Digital

Encoder Test. The display shows current position and should change when the

arm is moved. Press QUIT ending the procedure. ESC out to main menu.

8. See section entitled for detailed instructions on the variety of uses and

RTD Connection

Printer Connection

Computer Connection

Power Cord

Series 4000 Melt Indexer Operation Manual Getting Started 9

Options:

programming available with the encoder option.

The RTD, or thermocouple, is buried inside the instrument's barrel. The RTD

and associated temperature control electronics are calibrated against NIST

traceable temperature probes at Dynisco Polymer Test Systems. To achieve

accuracy required by ASTM D1238 the RTD and electronics control should be

kept together. Changing a RTD requires a complete temperature re-calibration.

Please consult the factory when required to replace the RTD.

Connect the power cord to the melt indexer. There may be a number of standard

power cords supplied; the heaviest is used for the melt indexer. The factory

suggests using a noise filtering outlet strip to connect the instrument and

associated components to the power source.

Connect the printer (if you have one) to the melt indexer. A cable is provided

with two distinctly different ends; one connects to the printer and the other to

the melt indexer. The connections are on the back sides of both machines. Be

sure the printer is OFF when connecting the indexer.

The data processing system (4004 models only) consists of a PC and the

MIWORKS software package . If your melt indexer is so configured, you will

find the proper cable included with the equipment. The cable will connect to

COM 1 on the computer side and to the smaller connector on the back of the

indexer. Set COMM PORT to PC under the SYSTEM key on the indexer.

Refer to the MIWORKS software manual for more details.

If system purchased after February, 2012, the system will only have a USB

connection. Please see “Setting-Up USB Connections” section of this manual.

The Series 4000 melt indexer has various options to make conducting specific

measurements easier, or make running multiple samples faster and more

convenient. As previously described, the Melt Indexer maybe shipped with a

Digital Encoder, a Pneumatic Lift System or a Mini-Lift system. The

installation of these options is described in the appropriate Appendix of this

manual.

Page 18

Safety

Use gloves, it's HOT!

To prevent burns, gloves and a long sleeve shirt (or lab coat) are essential. Dies

and piston rods are extremely hot and are designed to quickly transfer heat to

the sample being tested. Unfortunately this means they will transfer heat very

quickly to you as well. Even brief contact with a hot item can cause a burn. The

indexer barrel housing can also get fairly hot, however, at barrel temperatures

lower than 350 C these will not cause burns if touched for a brief period.

Consider where dies may fall. If they are dropped on Nylon carpeting or similar

materials they can quickly form holes. Protective mats may be needed.

DYNISCO POLYMER TEST recommends keeping a hot piston rod in the

chamber; this precludes someone picking it up inadvertently. Be sure to hold

the piston by the top insulator.

Electrical Hazard

Your Dynisco Polymer Test indexer contains high voltage inside the steel

housing. DO NOT remove the housing unless you are instructed to do so by a

DYNISCO POLYMER TEST representative or are experienced with high

voltage devices. Be sure the outlet used to power the indexer is properly

grounded.

Calibration Thermometers use

Mercury

To calibrate the temperature on the indexer, a thermometer containing about 8

grams of mercury is used. Every lab with mercury thermometers or equipment

containing mercury must be prepared for breakage. Note that mercury exposed

to air "evaporates" at room temperature, producing an invisible, tasteless,

odorless and dangerous vapor. Thermometers have been used for decades in

laboratory equipment and when used properly provide an accurate and effective

means of calibration. Keep the thermometer in a safe place where it will not be

crushed or otherwise broken. When using the thermometer be careful not to

drop or bend the glass. Place a hot thermometer onto cotton patches to cool .

Never put a hot thermometer in contact with cold metal or cold solvent because

the thermal shock can crack or shatter the glass. Mercury is extremely toxic and

should be handled accordingly.

A material safety data sheet (MSDS) for mercury (Hg) can be found in the

appendix. Observe local, state and federal hazardous waste disposal laws when

disposing of any broken thermometers. If packaged in a sealed plastic container

Series 4000 Melt Indexer Operation Manual Safety 10

and labeled with the following symbol:

Page 19

Broken thermometers and their spilled mercury can be sent back to the

manufacturer. UPS will accept these packages provided they are labeled and the

material is in a secure container. See Princo support vendor for address

information.

Pinch Points

Do not place weights in precarious positions where they can be bumped and fall

to the floor. For large weights (over 10 kg) the pneumatic lift system is

recommended. In using a pneumatic lift system for weights up to 21,600 gram,

the safety pin (spike) that goes through the weights must be used. When the

machine is in operation the lift system moves the weight downward quickly

creating an area where anything lying beneath could be crushed. Press the UP

and DN keys only when the areas above and below the weight are clear.

Fumes from Materials

Plan for the unexpected when it comes to materials giving off hazardous vapors.

Many polymers (PVC, PVF etc.) are well known for giving off hazardous fumes

at elevated temperatures. An exhaust system that removes fumes from both the

die exit and near the top of the barrel is strongly recommended. Consideration

should also be given to additives that may degrade or decompose at elevated test

temperatures.

Pre-Run Check List

The following points should be addressed before running the instrument for the

first time:

120V power outlet properly grounded? (230 V Europe/Asia)

Indexer level and on a sturdy bench?

Protective oil wiped out of barrel?

Exhaust hood or snorkel working?

Arm protection, long sleeves or lab coat

Operator using high temp gloves?

Series 4000 Melt Indexer Operation Manual Safety 11

Operator using safety glasses?

Page 20

Series 4000:

A Guided Tour

Overview

Setup

Edit

Series 4000 Melt Indexer Operation Manual Series 4000: 12

Run

System

Four Options from the main menu

screen.

The Series 4000 Melt Indexer has been designed for ease of use. The VFD

display prompts the user for input necessary to program, configure and run the

instrument. From the main menu screen, the user has the choice of four

instrument routines. The user may:

Configure the Instrument (by pressing the SETUP Key)

Edit a Program (by pressing the EDIT Smartkey)

Run a Program (by Pressing the RUN Smartkey)

Enter Calibration and Test Routines (by pressing the SYS key)

It is important that the instrument first be properly configured. This involves

pressing the SETUP key and checking instrument options and units for

particular parameters

Melt Index experiments (particularly method A tests) rely on the instrument to

reach the proper temperature and (in method B and A/B tests) collect

information on the travel of the plunger. The user is first expected to input the

appropriate parameters for the experiment and subsequent calculations in the

EDIT routine. After this is accomplished, the user may RUN the program.

The melt index unit relies on the operator to properly program the unit, load the

sample, start the experiment, wait the appropriate length of time, and (in method

A tests) collect the sample to weigh. All tests require that the instrument be

properly cleaned between runs

Many calibrations can be performed in the SYS, CALIBRATE mode. Although

the unit is not expected to change calibration values over years, it is always wise

Page 21

to check the previous values. Maintenance should typically be performed on our

instruments every 6 months. Your lab procedures may be different.

Each of these instrument routines is covered in greater detail in the following

sections. Before the user attempts to work with the instrument, it is important to

become familiar with the keyboard itself and the keystrokes necessary to

perform particular functions.

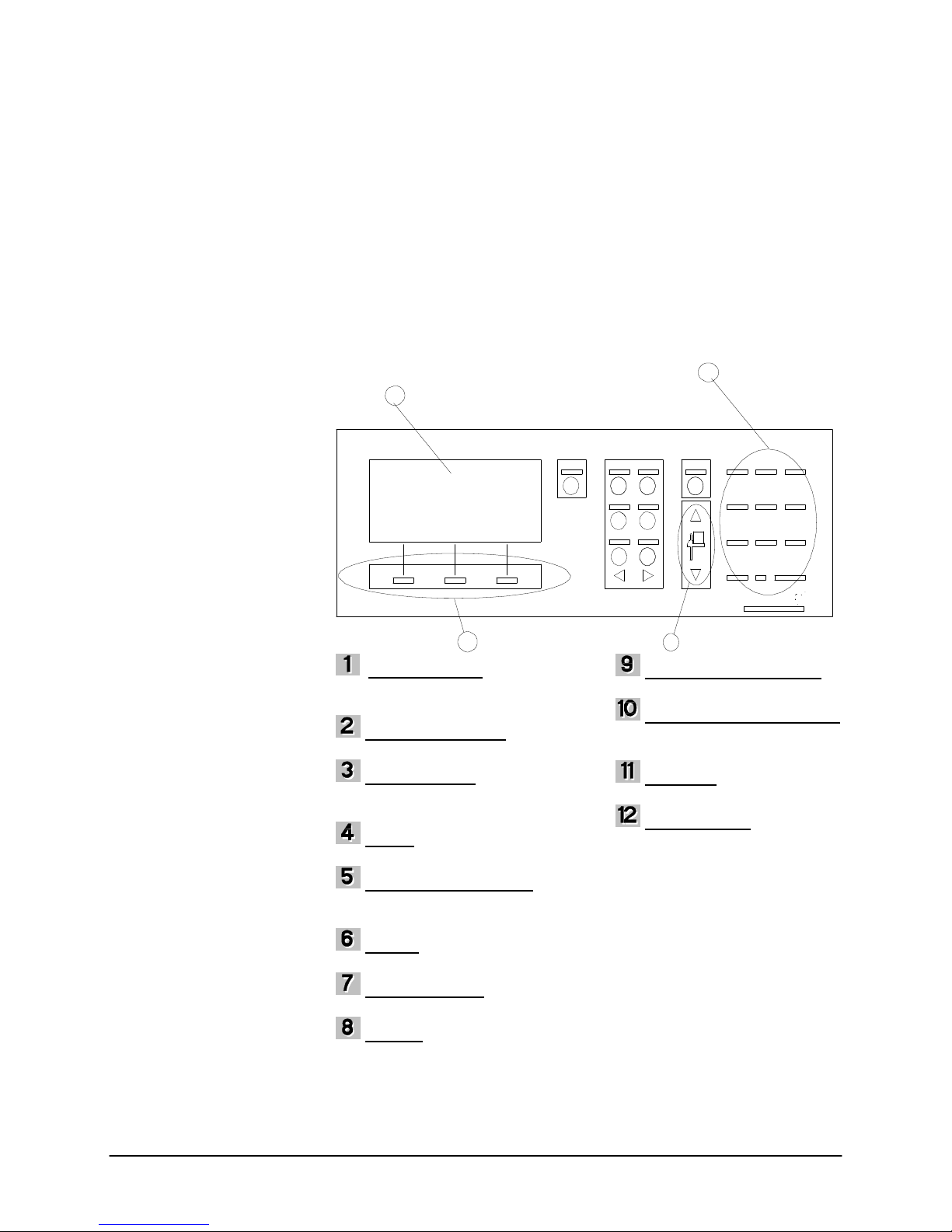

Navigating the Keypad

Introduction

Series 4000 Melt Indexer Operation Manual Series 4000: 13

The Keypad

The keypad provides all of the means necessary for programming the Dynisco

Polymer Test Melt Indexer (Unless it is connected to a PC.) Other functions that

can be performed on the keypad include calibration, instrument tests, parameter

setups and pneumatic lift controls.

10

11

12

ESC (ESCAPE) - Backs out

one level from any mode. Quits a

test totally

PROG (PROGRAM) - Browse

and select a preprogrammed program

SYS (SYSTEM) - Enter self

calibration modes or hardware

diagnostic modes for testing unit.

SHIFT - Toggle between

numerical and alpha-numerical input

ID (IDENTIFICATION) -

Enter operator and sample

identifications

SETUP - Change system

parameters

LIFT UP/DOWN - Raise and

lower pneumatic lift(s) if equipped

CLEAR - Clears present value

in editing modes

ESC PROG SY S

1 2 3 4

ID SETUP

6

CLEAR BACkSP

98

Destructive backspace

Allows for numerical and alpha

numerical character input.

display

used for browsing, selecting and

entering values and parameters

SHIFT ABC 7 DEF 8 GHI 9

JKL MNO4 5 PQR 6

kg STU VWX1 2 YZ 3

*-# 0 .

ENTER

7

BACKSP (BACKSPACE) -

NUMERAL/ALPHA INPUT -

DISPLAY - 4 X 20 instrument

SMART KEYS - Main Keys

Page 22

Keypad Definitions

ESC (ESCAPE)

The ESC key can be used in any screen. During an EDIT function, ESC backs

out one level. During a sample run, ESC aborts the test.

PROG (PROGRAM)

Pressing the PROG key lets the user browse through a list of preprogrammed

test parameters. From this mode the user can browse through a list of programs

by using the UP or DOWN SMART KEY button and then select the desired

program by pressing the ACTIVE SMART KEY button.

SYS (SYSTEM)

In this mode the user can choose to calibrate, test or quit by selecting the

appropriate CALIB, TEST or QUIT SMART KEY, respectively.

*** Depending on what instrument model you have, prompts may vary ***

CALIB- Select either Digital Flag, RTD Electronics, RTD Sensor, Optical

Flag or IV Offset calibrations by toggling prompt with UP or DOWN QUICK

KEYS and using SELECT to start the calibrations. Please reference

Configuring the Instrument sections (Page ) or Appendix # for more

detailed operations of calibrations.

TEST- Select either RTD Display, Digital Encoder, Printer or Display

Brightness tests by toggling prompts with the UP or DOWN SMART KEYS

and using SELECT to start the test. Please reference Configuring the

Series 4000 Melt Indexer Operation Manual Series 4000: 14

Instrument sections (Page ) for more detailed operations of tests.

SHIFT

The shift key is used when inputting numeric and alphanumeric characters in the

sample, operator or program identification screens. Pressing SHIFT, then the

appropriate numeric/alpha key enters the alpha input mode. This mode provides a

selection of alpha characters above the SMART KEYS that correspond to the

numeric/alpha key pressed. When in the alpha mode it is not necessary to press

the SHIFT key to select alpha input every time. Just press the appropriate

numeric key to select different alpha characters. Press SHIFT to re-enter the

numeric input mode.

ID (IDENTIFICATION)

Define your operator and sample identifications for each program by pressing

the ID keypad. Toggle between operator and sample by pressing the right

SMART KEY . Press the ENTER SMART KEY to enter a new identification for

the desired parameter.

SETUP

Setup provides a series of system settings pertaining to your test. After pressing

SETUP, scroll through the list of settings using the UP or DOWN SMART

KEYS . Select the EDIT SMART KEY to change the parameter accordingly.

Please reference Configuring the Instrument Section for a detailed description

of each parameter

LIFT UP/DOWN

If your instrument is equipped with the Pneumatic lift option, these keys will

manually operate them.

CLEAR

Page 23

The CLEAR key will clear any active value displayed in the EDIT PROGRAM

mode (EDIT SMART KEY then EDIT SMART KEY again) or any text entry.

The clear key will also clear the PROGRAM number in the VIEW PROGRAM

mode (EDIT SMART KEY) where a new program number can be entered.

BACKSP (BACKSPACE)

The BACKSP key performs a destructive backspace function in text editing

screens.

NUMERAL/ALPHA INPUT

Using combinations of the SHIFT key and the NUMERAL/ALPHA INPUT

keys, either numbers or letters can be entered in the SAMPLE, OPERATOR and

PROGRAM identification modes. Pressing SHIFT then the appropriate

numeric/alpha key enters the alpha input mode. This mode provides a selection of

alpha characters above the SMART KEYS that correspond to the numeric/alpha

key pressed. Press SHIFT to re-enter the numeric input mode.

A space can be entered by pressing the 3, YZ keypad.

DISPLAY

Your instrument uses a 4 line vacuum fluorescent display, VFD, to display

information. Brightness can be adjusted in the SYSTEM TEST mode.

SMART KEYS

Dynisco Polymer Test provided three keypads below the VFD, to allow for

quick navigation of the machine interface. The functions of these keys change

depending on the mode of operation. Each SMART KEY is clearly and

concisely labeled to assist you in programming your instrument.

Configuring the

Instrument

Series 4000 Melt Indexer Operation Manual Configuring the Instrument 15

Intro: The SYS (SYSTEM) Mode

Many functions can be performed on the instrument using its operator interface.

Hardware calibrations, tests and option configurations will be discussed in this

section.

The system mode lets the user perform calibrations or hardware tests. The

system mode is entered by pressing the SYS keypad. For complete information

on the keypad and its function's reference Navigating the Keypad Sections in

the manual. Once you have entered the CALIBRATE and TEST Select mode

you can select between calibrate and test.

Page 24

Selecting CALIB (Calibration) in the

SYS Mode

CALIB:Digital Flag Home

CALIB:RTD Electronics

CALIB:RTD Sensor

CALIB:Optical Flag

CALIB:Intrinsic Viscosity Offset

Series 4000 Melt Indexer Operation Manual Configuring the Instrument 16

The Digital Encoder is calibrated at Dynisco Polymer Test prior to shipment.

Because the arm is locked into place, calibration is rarely required.

The instrument does allow you to reset the home position of the encoder.

If calibration needs to be checked due to suspected encoder damage, then

contact Dynisco Polymer Test for assistance and the necessary tool kit.

Please reference the section entitled “Instrument Calibration”

for further details on actual calibrations.

The RTD electronics are calibrated at Dynisco Polymer Test prior to shipment.

Please do not reconfigure this option.

Please reference the section entitled “Instrument Calibration”

for further details on actual calibrations.

Calibration of the RTD Sensors requires one or two thermometers or equivalent.

The RTD sensor is calibrated at Dynisco Polymer Test prior to shipment.

There should be no need to re calibrate the RTD sensor.

Please reference the section entitled “Instrument Calibration”

for further details on actual calibrations.

The instrument allows for the adjustment of the Optical Flag sensitivity. This

determines how sensitive the Optical Flag LED Receiver is in either of two

states, blocked or open. Sensitivity directly affects the measured length of the

tape flag.

The Optical Sensor is calibrated at Dynisco Polymer Test prior to shipment.

There should be no need to re-calibrate the Optical sensor. For this procedure

you must have the Flag Calibration Unit (Factory Part # D2044).

Please reference the section entitled “Instrument

Calibration” for further details on actual calibrations.

The IV offset is the difference between the computed IV and the experimentally

obtained IV. If option available, enter the difference here for correlation during

IV runs. See the I.V. section.

Please reference the section entitled “Instrument Calibration”

for further details on actual calibrations.

Page 25

Selecting TEST in the SYS Mode

TEST:RTD Display

TEST:Digital Encoder

TEST:Printer

TEST:Display Brightness

Introduction

REJECTION

Series 4000 Melt Indexer Operation Manual Configuring the Instrument 17

AVERAGE

MFR / MVR

B FLAG

VISCOSI

TY

PRINTE

R

FORM FEED

Press SELECT to view actual temperature reading accurate to 1/100 of a degree

Celsius. Dynisco Polymer Test technical support may have you do this under

certain conditions. RTD Display Test may also come in handy when

equilibrating RTD’s and thermometers.

Displays the current digital encoder arm position. Readings for home position

should be 105.00 mm, +/- 1.5 mm.

Your model must support printer output to perform this test. A test pattern

output will be produced on the connected printer. Press STOP to end printer

output.

The operator can control the VFD brightness level. Select a percentage of

default brightness.

The SETUP mode

This software routine is used to set user preferences for data collection. This

routine also turns off instrument options such as the digital encoder or pneumatic

lift. Please scroll through the settings prior to commissioning the instrument and

make a note of the values particular to your instrument. If for some reason the

settings are changed or erased they can be easily re-entered from this menu. By

pressing the SETUP key the following series of inputs are requested of the user.

Press the ENTER SMART Key to input the appropriate value. After entry is

complete, press the ESC key to save modified information.

After pressing SETUP, scroll through the list of settings using the UP or

DOWN SMART KEYS . Select the EDIT SMART KEY to change the parameter

accordingly. Please reference Configuring the Instrument Section for a

detailed description of each parameter. Note the order the items appear can vary.

[1..5, OFF] ] Exclude data points that are more than the operator entered

number of standard deviations from the mean. Exclude these points from all

statistical calculations. Points are not deleted but marked on the printouts with

asterisks. The rejection option is used for systems configured with a printer.

Data points are printed but not included in statistics.

[AUTO, OFF, ON] ON: average is computed for one or more data collection

runs. Generates statistics for printout. AUTO: compute the average of a single

data collection run without operator interaction at the end of the run.

[MFR or MVR] The operator can choose the calculated result. The choices are

Melt Flow Index or Melt Volume Index respectively.

[ENCODR or FLAG] Enable either the Digital Encoder or the Optical Flag

devices, respectively.

[POISE, PA-S, REYN] Select units of viscosity for displayed results.

[MINI, OFF, EPSON, IBM, LASER] Select output device. Mini printer, No

device, Epson compatible, HP Laser Jet compatible, respectively. (Only 4002

models will have the mini-printer option)

[OFF or ON] Perform a Form Feed (A page is sent out of the printer) after the

run data is printed.

Page 26

COMM PORT

MINI LIFT

PNEU LIFT

LOCKOUT

DATE and TIME

MACHINE ID

LANGUAGE

ORIFICE DIA

ORIFICE LEN

Introduction

Create (New)

Recall (Old)

Save Program

While EDITING

[ PC, OFF, DIAG] Open up communications port for computer output, no

output or diagnostics mode, respectively.

[OFF or ON] Enable the mini lift to function during material runs when

installed.

[OFF or ON] Enable pneumatic lift to function during material runs, when

installed.

[OFF or ON] Enable password protection. When ON users can not edit test or

system parameters only run tests. The default password is 1234, if the

LOCKOUT is enabled this number must be put in to turn the LOCKOUT off.

The NUMBER item allows a new password number to be entered.

Set the appropriate date and time here. Follow prompts.

[##] Assign a unique machine number to the instrument. If using MIWORKS

be sure this is set to one if you have only a single machine or to the Porter box

port number for multiple machines. This allows you to tell what machine your

sample was run on when you have more than one machine.

[CUSTOM, ENGLISH, FRENCH, ITALIAN, SPANISH, GERMAN] Switch

between desired languages.

[XXX] Store standard orifice diameter, 2.096 mm. Used in calculations.

[X.XXX] Store standard orifice radius, 8.000 mm. Used in calculations Scroll

through this menu and make appropriate changes. Press ESC twice and any

changes that have been made will be implemented.

Programming

This section is intended for a quick reference of method parameters. Please refer

to the appropriate sections in the manual for more specific information about a

particular method.

Before a measurement can be made, the RUN PARAMETERS must be

entered. These parameters dictate how the experiment will be performed. Many

of these parameters are set by particular ASTM test procedures. The SERIES

4000 software has many of these values pre-loaded into memory.

Press the EDIT SMART Key to start the EDIT mode. Enter the new program

number into the upper left hand corner of the display and press ENTER.

Proceed to EDIT.

Press the PROG button and enter the program number in the upper left hand

corner of the display or BROWSE with the Smart Keys. Press ACTIVE to use

the selected program number.

From the EDIT mode, ESC out until prompted to SAVE PROGRAM. Select

SAVE to save. In order to receive the SAVE PROGRAM prompt, a value

must be changed while in the editing mode.

Browse the suggested values appearing on the 3rd line of the Edit Screen with

the

SMART Key (Browse Key). Select the desired value with the

Series 4000 Melt Indexer Operation Manual Configuring the Instrument 18

Page 27

SELECT SMART Key. Accept the value with the ENTER SMART Key. The

user always has the option to enter values manually via the numeric keypad.

Below is a listing of the run parameters that are required for each test method.

Method A Run Parameters

METHOD = [A, B, A/B or RATIO] SELECT and ENTER Method A.

SET POINT = [Temp. Celsius] Dependent on the material, ASTM

requirements. Enter or Select value using browse key .

MELT TIME: [Time, Seconds] ASTM D1238 equilibration time for most

materials. Enter or Select value using browse key .

CUT TIME =[Time, Seconds] This is the sample collection time, the length of

time an extrudate sample is squeezed out. Enter or Select value using browse

key. Dependent on Flow Rate characteristics.

NO OF CUTS =[Number] Dependent on material - up to 5 cuts allowed

LOAD =[Weight, Grams]. Mass of weight plus piston assembly, ASTM

requirements

QC LIMITS [On or Off] Allows QC limiting of data to be used

QC Limits High [Number] Highest MFR limit saved

QC Limits Low [Number] Lowest MFR limit saved

PROGRAM ID [Characters] Name of program up to 14 characters long

METHOD = [A, B, A/B or RATIO] SELECT and ENTER Method A/B.

SET POINT = [Temp., Celsius] Dependent on the material, ASTM

Method A/B Run Parameters

requirements. Enter or Select value using browse key .

MELT TIME: [Time, Seconds] ASTM D1238 equilibration time for most

materials. Enter or Select value using browse key .

CUT TIME =[Time, Seconds] This is the sample collection time, the length of

time an extrudate sample is squeezed out. Enter or Select value using browse

key . Dependent on Flow Rate characteristics.

FLG LENGTH =[Length, millimeters] Flag length in millimeters. Dependent

on Melt Flow Rate. Digital Encoder equipped instruments will be asked further

questions. Reference Digital Encoder Section in manual.

LOAD =[Weight, Grams] Mass of weight plus piston assembly, ASTM

requirements

PROGRAM ID [Characters] Name of program up to 14 characters long

METHOD = [A, B, A/B or RATIO] SELECT and ENTER Method B.

Method B Run Parameters