Page 1

OPERATING MANUAL

240 and 290 Series240 and 290 Series

240 and 290 Series240 and 290 Series

240 and 290 Series

MM

MM

M

eltelt

eltelt

elt

Pr Pr

Pr Pr

Pr

ee

ee

e

ss

ss

s

ss

ss

s

urur

urur

ur

e e

e e

e

TT

TT

T

rr

rr

r

anan

anan

an

smittsmitt

smittsmitt

smitt

erer

erer

er

ss

ss

s

Intrinsically safe and explosion proofIntrinsically safe and explosion proof

Intrinsically safe and explosion proofIntrinsically safe and explosion proof

Intrinsically safe and explosion proof

pressure transmitters with integratedpressure transmitters with integrated

pressure transmitters with integratedpressure transmitters with integrated

pressure transmitters with integrated

amplifier for use in hazardous environmentsamplifier for use in hazardous environments

amplifier for use in hazardous environmentsamplifier for use in hazardous environments

amplifier for use in hazardous environments

P/N 974080

05/05 Rev. F

ECO # 29918

II 1G II 1G

II 1G II 1G

II 1G

AA

AA

A

TEXTEX

TEXTEX

TEX

100a 100a

100a 100a

100a

Page 2

OPERATING MANUAL

TT

TT

T

ABLEABLE

ABLEABLE

ABLE

OFOF

OFOF

OF

C C

C C

C

ONTENTSONTENTS

ONTENTSONTENTS

ONTENTS

ContentContent

ContentContent

Content

PP

PP

P

agag

agag

ag

ee

ee

e

IconIcon

IconIcon

Icon

1. General 3

2. Notes on safety 5

3. Technical data 7

4. Function 22

5. Transport/delivery 23

6. Assembly 24

7. Commissioning 35

8. Maintenance 39

9. Accessories 42

10. Troubleshooting 43

11. CE-Declaration of conformity 44

12. Ex-Declaration of conformity 45

Page 3

3

GENERAL

1.1.

1.1.

1.

GG

GG

G

ENERALENERAL

ENERALENERAL

ENERAL

1.1 Important information .......................................................................................................... 3

1.2 Copyright ............................................................................................................................. 3

1.3 Explanation of icons ............................................................................................................ 4

1.4 Abbreviations ...................................................................................................................... 4

1.5 Correct use .......................................................................................................................... 4

1.6 User’s obligations ................................................................................................................ 4

1.11.1

1.11.1

1.1

II

II

I

MPORMPOR

MPORMPOR

MPOR

TT

TT

T

ANTANT

ANTANT

ANT

INFORMAINFORMA

INFORMAINFORMA

INFORMA

TIONTION

TIONTION

TION

This manual applies to the 240 and 290 series only. It must be kept near the equipment in a readily

and immediately accessible location at all times.

The content of this manual must be read, understood and followed in its entirety. This applies in

particular to the notes on safety. Following the safety instructions will help to prevent accidents, defects

and malfunctions.

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O will not be held liable for any injury, loss or damage resulting from failure to follow the

instructions in this manual.

If the product malfunctions, in spite of having followed the operating instructions, please contact the

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O customer service department (see the back of the manual for contact information).

1.21.2

1.21.2

1.2

CC

CC

C

OPYRIGHTOPYRIGHT

OPYRIGHTOPYRIGHT

OPYRIGHT

Copyright law requires that this manual be used for in-house purposes only.

All reproduction, even partially and for in-house purposes, requires the approval of

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O. This

manual may not be forwarded to third parties.

Page 4

4

GENERAL

1.1.

1.1.

1.

33

33

3

EE

EE

E

XPLANAXPLANA

XPLANAXPLANA

XPLANA

TIONTION

TIONTION

TION

OFOF

OFOF

OF

ICIC

ICIC

IC

ONSONS

ONSONS

ONS

The manual uses icons to indicate information pertaining to safety:

Risk of destruction or damage to equipment, machines or installations

General danger to life or limb

Specific danger to life or limb

You MUST do this

The safety instructions are provided again in the individual chapters of the manual.

1.41.4

1.41.4

1.4

AA

AA

A

BBREVIABBREVIA

BBREVIABBREVIA

BBREVIA

TIONSTIONS

TIONSTIONS

TIONS

The following abbreviations are used:

OMOM

OMOM

O M Operating manual

f.s.f.s.

f.s.f.s.

f.s. of full scale

PTPT

PTPT

P T pressure transmitter

1.51.5

1.51.5

1.5

CC

CC

C

ORRECTORRECT

ORRECTORRECT

ORRECT

USEUSE

USEUSE

USE

The 240 and 290 series of pressure transmitters is specially designed for measuring pressure in explosive

atmospheres (safety class, EEx ia IIC T4, Ta=-20°C to +80°C) as part of a larger overall system. It

contains an integrated signal amplifier. The 240 and 290 series of pressure transmitters can be used in

media temperatures up to 400°C. If the pressure transmitter is used in other applications, the safety and

accident prevention regulations specific to that application must be followed.

When using the PT as a safety component in accordance with the EC Machine Directive,When using the PT as a safety component in accordance with the EC Machine Directive,

When using the PT as a safety component in accordance with the EC Machine Directive,When using the PT as a safety component in accordance with the EC Machine Directive,

When using the PT as a safety component in accordance with the EC Machine Directive,

Annex IIc, the equipment manufacturer must take any necessary precautions to ensure thatAnnex IIc, the equipment manufacturer must take any necessary precautions to ensure that

Annex IIc, the equipment manufacturer must take any necessary precautions to ensure thatAnnex IIc, the equipment manufacturer must take any necessary precautions to ensure that

Annex IIc, the equipment manufacturer must take any necessary precautions to ensure that

mm

mm

m

alfalf

alfalf

alf

uu

uu

u

nctionnction

nctionnction

nction

ss

ss

s

of of

of of

of

the P the P

the P the P

the P

TT

TT

T

cc

cc

c

annotannot

annotannot

annot

c c

c c

c

auau

auau

au

se dse d

se dse d

se d

amam

amam

am

agag

agag

ag

e or injure or injur

e or injure or injur

e or injur

yy

yy

y

..

..

.

The 240 and 290 series of pressure transmitters are also designed for explosion proof areas approved

by factory mutual for Class I, Division 1, Groups A, B, C & D. Explosion proof models are also

approved for intrinsic safety by factory mutual for Class I, Division 1, Groups A, B, C, & D.

1.61.6

1.61.6

1.6

UU

UU

U

SS

SS

S

ERER

ERER

ER

’’

’’

’

SS

SS

S

OBLIGAOBLIGA

OBLIGAOBLIGA

OBLIGA

TIONSTIONS

TIONSTIONS

TIONS

The operator or owner of the larger overall system, e.g. a machine, is responsible for following the

safety and accident prevention regulations that apply to the specific application.

Page 5

5

SAFETY

2.2.

2.2.

2.

NN

NN

N

OTESOTES

OTESOTES

OTES

ONON

ONON

ON

SAFETYSAFETY

SAFETYSAFETY

SAFETY

The operator or owner of the larger overall system is responsible for following the safety

and accident prevention regulations that apply to the specific application.

TT

TT

T

oo

oo

o

xx

xx

x

icic

icic

ic

h h

h h

h

azaz

azaz

az

arar

arar

ar

d!d!

d!d!

d!

The PT contains a small amount of mercury (Hg) as its transmission medium. If the

diaphragm is damaged, mercury may escape.

Never transport or store the PT without the protective cap. Remove the cap shortly

before installation.

IfIf

IfIf

If

mer mer

mer mer

mer

cc

cc

c

urur

urur

ur

yy

yy

y

i i

i i

i

ss

ss

s

inh inh

inh inh

inh

alal

alal

al

ed or swed or sw

ed or swed or sw

ed or sw

alal

alal

al

lolo

lolo

lo

ww

ww

w

ed, seeked, seek

ed, seeked, seek

ed, seek

medic medic

medic medic

medic

alal

alal

al

att att

att att

att

ention immediention immedi

ention immediention immedi

ention immedi

atat

atat

at

ely!ely!

ely!ely!

ely!

Mercury is hazardous waste and must be disposed of in accordance with applicable

laws.

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O will accept defective PTs.

If mercury escapes, use airtight packaging!

When planning machinery and using the PT, follow the safety and accident prevention

regulations that apply to your application, e.g.:

• EN 60204, Electrical equipment in machines.

• EN 292, Machine safety, general design guidelines.

• DIN 57 100 Part 410, Protection against electric shock.

• EN 50 014:1997, General Requirements

• EN 50 020:1994, Intrinsically safe apparatus

• EN50284:1999, Special requirements fro Group II Category 1G

Mounting and electrical connection of the PT must be done by specialists with EMC training,

following all applicable regulations, and in

pressureless, voltage-free, intrinsically safepressureless, voltage-free, intrinsically safe

pressureless, voltage-free, intrinsically safepressureless, voltage-free, intrinsically safe

pressureless, voltage-free, intrinsically safe

condition with the

machine switched offmachine switched off

machine switched offmachine switched off

machine switched off.

The mThe m

The mThe m

The m

acac

acac

ac

hine muhine mu

hine muhine mu

hine mu

ss

ss

s

tt

tt

t

be sec be sec

be sec be sec

be sec

urur

urur

ur

ed aged ag

ed aged ag

ed ag

ainain

ainain

ain

ss

ss

s

tt

tt

t

bein bein

bein bein

bein

g swg sw

g swg sw

g sw

itit

itit

it

cc

cc

c

hed bhed b

hed bhed b

hed b

acac

acac

ac

kk

kk

k

on! on!

on! on!

on!

Ambient temperature for the electronics housing

mm

mm

m

ax. +80°Cax. +80°C

ax. +80°Cax. +80°C

ax. +80°C (safety class T4 max.).

Higher temperatures can result in damage and malfunction. Do not install the pressure

transmitter in places where this temperature is exceeded.

ExpExp

ExpExp

Exp

lolo

lolo

lo

ss

ss

s

ion hion h

ion hion h

ion h

azaz

azaz

az

arar

arar

ar

d!d!

d!d!

d!

Deviation of the supply voltage from the value given in the technical specifications, or

false polarity, can damage the pressure transmitter and cause malfunctions that can

pose a risk of explosion.

Page 6

6

SAFETY

Operate only with an intrinsically safe, EMC compliant power supply with the following

specifications when employing the pressure 4-20mA output:

Supply voltage max.40 V DC

Current output max. 100 mA

Inductivity max. 0

Capacity max. 0.017 µF

For PT’s that are explosion proof Class I, Division 1, Groups A, B, C & D, the power

supply rating is 16-40 Vdc.

Do not lay connecting cables in the direct vicinity of cables carrying higher voltage or

used to switch inductive or capacitive loads.

Page 7

7

TECHNICAL DATA

3.3.

3.3.

3.

TT

TT

T

EE

EE

E

CHNICALCHNICAL

CHNICALCHNICAL

CHNICAL

D D

D D

D

AA

AA

A

TT

TT

T

AA

AA

A

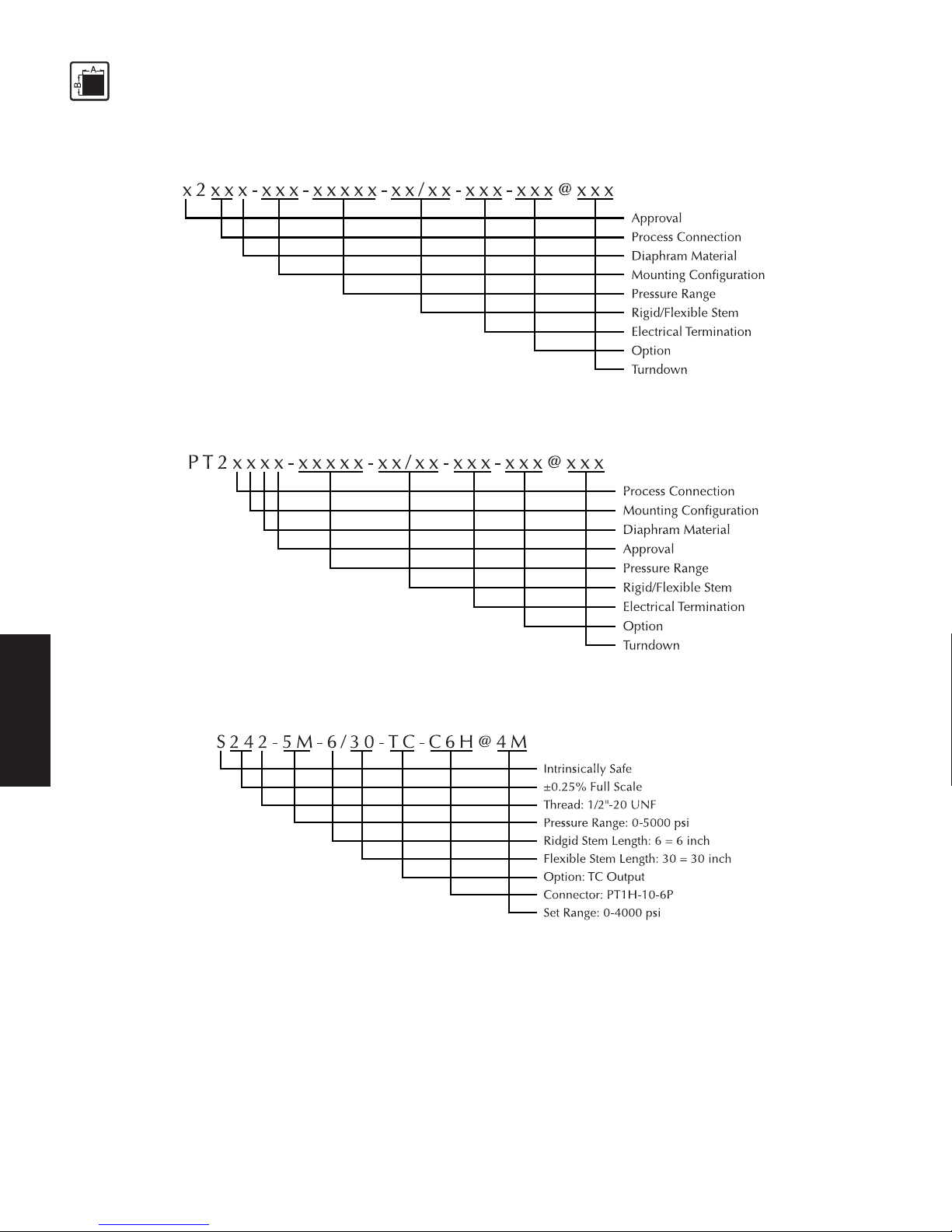

3.1 Ordering guides ................................................................................................................... 7

3.1.1 Ordering guide for x242 and x243 ....................................................................................... 8

3.1.2 Ordering guide for PT241x, PT244x, PT290x, PT291x, and PT292x ..................................... 8

3.2 Ordering example ............................................................................................................... 8

3.3 Safety related specifications ................................................................................................8

3.4 Performance characteristics ................................................................................................. 9

3.4.1 Accuracy ............................................................................................................................. 9

3.4.2 Resolution .......................................................................................................................... 10

3.4.3 Repeatabilty ...................................................................................................................... 10

3.5 Pressure side connection .................................................................................................... 10

3.6 Pressure ranges .................................................................................................................. 10

3.6.1 Pressure ranges in bar ........................................................................................................ 10

3.6.2 Max. Overload .................................................................................................................. 1 1

3.6.3 Burst pressure ..................................................................................................................... 1 1

3.6.4 Natural frequency .............................................................................................................. 1 1

3.7 Rigid stem/flexible stem .................................................................................................... 11

3.7.1 x242x, x243x ..................................................................................................................... 1 1

3.7.2 PT241xx............................................................................................................................. 12

3.7.3 PT244xx ............................................................................................................................. 1 2

3.7.4 PT290x, PT291x, PT292x ................................................................................................... 1 2

3.8 Electrical Data .................................................................................................................. 1 2

3.9 Temperature influence ....................................................................................................... 12

3.10 EMC requirements ............................................................................................................. 1 3

3.11 Materials ........................................................................................................................... 13

3.12 Mounting torque ................................................................................................................ 13

3.13 Environmental Protection .................................................................................................. 1 4

3.14 Weight............................................................................................................................... 14

3.15 Dimensions ........................................................................................................................ 14

3.13.1

3.13.1

3.1

OO

OO

O

RDERINGRDERING

RDERINGRDERING

RDERING

GUIDESGUIDES

GUIDESGUIDES

GUIDES

The exact meanings of the letter/digit combinations are given in the corresponding sections of

chapter 3.

Page 8

8

TECHNICAL DATA

3.1.13.1.1

3.1.13.1.1

3.1.1

OO

OO

O

RDERINGRDERING

RDERINGRDERING

RDERING

GUIDEGUIDE

GUIDEGUIDE

GUIDE

FORFOR

FORFOR

FOR

XX

XX

X

22

22

2

42 42

42 42

42

ANDAND

ANDAND

AND

XX

XX

X

22

22

2

44

44

4

33

33

3

3.1.23.1.2

3.1.23.1.2

3.1.2

OO

OO

O

RDERINGRDERING

RDERINGRDERING

RDERING

GUIDEGUIDE

GUIDEGUIDE

GUIDE

FORFOR

FORFOR

FOR

PT241 PT241

PT241 PT241

PT241

XX

XX

X

, PT244, PT244

, PT244, PT244

, PT244

XX

XX

X

, PT290, PT290

, PT290, PT290

, PT290

XX

XX

X

, PT291, PT291

, PT291, PT291

, PT291

XX

XX

X

, ,

, ,

,

ANDAND

ANDAND

AND

PT292 PT292

PT292 PT292

PT292

XX

XX

X

3.23.2

3.23.2

3.2

OO

OO

O

RDERINGRDERING

RDERINGRDERING

RDERING

E E

E E

E

XAMPLEXAMPLE

XAMPLEXAMPLE

XAMPLE

3.33.3

3.33.3

3.3

SS

SS

S

AFETAFET

AFETAFET

AFET

YY

YY

Y

RELARELA

RELARELA

RELA

TEDTED

TEDTED

TED

SS

SS

S

PEPE

PEPE

PE

CIFICACIFICA

CIFICACIFICA

CIFICA

TIONSTIONS

TIONSTIONS

TIONS

ATEX certificate No.: SIRA 03ATEX2422

EX-Safety class EEx ia IIC T4 (Ta = -20°C to +80°C)

FM approvals Class I, Division 1 Groups A, B, C & D

CC

CC

C

erer

erer

er

tified mtified m

tified mtified m

tified m

axax

axax

ax

imum imum

imum imum

imum

vv

vv

v

aluealue

aluealue

alue

ss

ss

s

f f

f f

f

or EExor EEx

or EExor EEx

or EEx

i i

i i

i

a IICa IIC

a IICa IIC

a IIC

T4T4

T4T4

T4

Page 9

9

TECHNICAL DATA

Associated electrical equipment must satisfy the following conditions:

Supply voltage max. 40 V DC

Current output max. 100 mA

Inductivity max. 0

Capacity max. 0.017 µF

3.43.4

3.43.4

3.4

PP

PP

P

ERFORMANCERFORMANC

ERFORMANCERFORMANC

ERFORMANC

EE

EE

E

CHARACHARA

CHARACHARA

CHARA

CTERISCTERIS

CTERISCTERIS

CTERIS

TICTIC

TICTIC

TIC

SS

SS

S

x2xxx - xxx - xxxxx - xx / xx - xxx - xxx@xxx

3.4.13.4.1

3.4.13.4.1

3.4.1

AA

AA

A

CC

CC

C

CC

CC

C

URAURA

URAURA

URA

CYCY

CYCY

CY

(Linearity, hysterisis and repeatability)

3.4.13.4.1

3.4.13.4.1

3.4.1

AA

AA

A

XX

XX

X

242, 242,

242, 242,

242,

XX

XX

X

243243

243243

243

±0.25% of full scale

(0-1500 psi and above)

±0.50% of full scale

(0-1000 psi and below)

3.4.13.4.1

3.4.13.4.1

3.4.1

BB

BB

B

PT241PT241

PT241PT241

PT241

XX

XX

X

±0.50% of full scale

(0-1500 psi and above)

±1.0 of full scale

(10-1000 psi and below)

3.4.13.4.1

3.4.13.4.1

3.4.1

CC

CC

C

PT244PT244

PT244PT244

PT244

XX

XX

X

±0.25% of full scale

(0-500 psi and above)

±0.50% of full scale

(0-250 psi)

3.4.13.4.1

3.4.13.4.1

3.4.1

DD

DD

D

PT290PT290

PT290PT290

PT290

XX

XX

X

, PT291, PT291

, PT291, PT291

, PT291

XX

XX

X

, PT292, PT292

, PT292, PT292

, PT292

XX

XX

X

±0.50% of full scale

Page 10

10

TECHNICAL DATA

3.4.23.4.2

3.4.23.4.2

3.4.2

RR

RR

R

ESOLUTIONESOLUTION

ESOLUTIONESOLUTION

ESOLUTION

Infinite

3.4.33.4.3

3.4.33.4.3

3.4.3

RR

RR

R

EPEAEPEA

EPEAEPEA

EPEA

TT

TT

T

ABILITABILIT

ABILITABILIT

ABILIT

YY

YY

Y

±0.10% of full scale

3.53.5

3.53.5

3.5

PP

PP

P

RESSURERESSURE

RESSURERESSURE

RESSURE

SIDESIDE

SIDESIDE

SIDE

CONNECTIONCONNECTION

CONNECTIONCONNECTION

CONNECTION

2 = 1/2" 20 UNF 2A (x24

22

22

2x . . . )

1, 3, 4, 90, 91 or 92 = flange (PT24

11

11

1xx-x), (x24

33

33

3x-x), (PT24

44

44

4xx-x), (PT2

9090

9090

90xx-x), (PT2

9191

9191

91xx-x), or

(PT2

9292

9292

92xx-x)

3.63.6

3.63.6

3.6

PP

PP

P

RESSURERESSURE

RESSURERESSURE

RESSURE

RANGESRANGES

RANGESRANGES

RANGES

3.6.13.6.1

3.6.13.6.1

3.6.1

PP

PP

P

RESSURERESSURE

RESSURERESSURE

RESSURE

RANGESRANGES

RANGESRANGES

RANGES

ININ

ININ

IN

PSIPSI

PSIPSI

PSI

3.6.13.6.1

3.6.13.6.1

3.6.1

AA

AA

A

Model numberModel number

Model numberModel number

Model number

PP

PP

P

ermittermitt

ermittermitt

ermitt

ed pred pr

ed pred pr

ed pr

ee

ee

e

ss

ss

s

ss

ss

s

urur

urur

ur

e re r

e re r

e r

anan

anan

an

gg

gg

g

e in Pe in P

e in Pe in P

e in P

SISI

SISI

SI

x24xx-2.5C-x/xx 0-250

x24xx-5C-x/xx 0-500

x24xx-7.5C-x/xx 0-750

x24xx-1M-x/xx 0-1,000

x24xx-1.5M-x/xx 0-1,500

x24xx-3M-x/xx 0-3,000

x24xx-5M-x/xx 0-5,000

x24xx-7.5M-x/xx 0-7,500

x24xx-10M-x/xx 0-10,000

x24xx-15M-x/xx 0-15,000

x24xx-20M-x/xx 0-20,000

x24xx-30M-x/xx 0-30,000

3.6.13.6.1

3.6.13.6.1

3.6.1

BB

BB

B

Model numberModel number

Model numberModel number

Model number

PP

PP

P

ermittermitt

ermittermitt

ermitt

ed pred pr

ed pred pr

ed pr

ee

ee

e

ss

ss

s

ss

ss

s

urur

urur

ur

e re r

e re r

e r

anan

anan

an

gg

gg

g

e in Pe in P

e in Pe in P

e in P

SISI

SISI

SI

PT24xx-2.5C-x/xx 0-250

PT24xx-5C-x/xx 0-500

PT24xx-7.5C-x/xx 0-750

PT24xx-1M-x/xx 0-1,000

PT24xx-1.5M-x/xx 0-1,500

PT24xx-3M-x/xx 0-3,000

Page 11

11

TECHNICAL DATA

PT24xx-5M-x/xx 0-5,000

PT24xx-7.5M-x/xx 0-7,500

3.6.13.6.1

3.6.13.6.1

3.6.1

CC

CC

C

Model numberModel number

Model numberModel number

Model number

PP

PP

P

ermittermitt

ermittermitt

ermitt

ed pred pr

ed pred pr

ed pr

ee

ee

e

ss

ss

s

ss

ss

s

urur

urur

ur

e re r

e re r

e r

anan

anan

an

gg

gg

g

e in Pe in P

e in Pe in P

e in P

SISI

SISI

SI

PT29xx-25-x/xx 0-25

PT29xx-50-x/xx 0-50

PT29xx-1C-x/xx 0-100

PT29xx-2.5C-x/xx 0-250

PT29xx-5C-x/xx 0-500

PT29xx-7.5C-x/xx 0-750

PT29xx-1M-x/xx 0-1,000

PT29xx-1.5M-x/xx 0-1,500

PT29xx-3M-x/xx 0-3,000

PT29xx-5M-x/xx 0-5,000

PT29xx-7.5M-x/xx 0-7,500

PT29xx-10M-x/xx 0-10,000

3.6.23.6.2

3.6.23.6.2

3.6.2

MM

MM

M

AXAX

AXAX

AX

. O. O

. O. O

. O

VERLVERL

VERLVERL

VERL

OO

OO

O

ADAD

ADAD

AD

( (

( (

(

WITHOUTWITHOUT

WITHOUTWITHOUT

WITHOUT

INFLINFL

INFLINFL

INFL

UENCINGUENCING

UENCINGUENCING

UENCING

OPERAOPERA

OPERAOPERA

OPERA

TINGTING

TINGTING

TING

DD

DD

D

AA

AA

A

TT

TT

T

AA

AA

A

))

))

)

x24xx 2 x full scale pressure or 35,000 psi, whichever is less.

PT29x 2 x full scale pressure or 15,000 psi, whichever is less.

PT24x 2 x full scale pressure

3.6.33.6.3

3.6.33.6.3

3.6.3

BB

BB

B

URSTURST

URSTURST

URST

PRESSUREPRESSURE

PRESSUREPRESSURE

PRESSURE

6 x nominal value, max. 45,000 psi

3.6.43.6.4

3.6.43.6.4

3.6.4

NN

NN

N

AA

AA

A

TURALTURAL

TURALTURAL

TURAL

FREFRE

FREFRE

FRE

QUENCYQUENCY

QUENCYQUENCY

QUENCY

50 Hz [-3db]

3.73.7

3.73.7

3.7

RR

RR

R

IGIDIGID

IGIDIGID

IGID

STEMSTEM

STEMSTEM

STEM

//

//

/

FLEXIBLEFLEXIBLE

FLEXIBLEFLEXIBLE

FLEXIBLE

STEMSTEM

STEMSTEM

STEM

3.7.13.7.1

3.7.13.7.1

3.7.1

XX

XX

X

242242

242242

242

XX

XX

X

, ,

, ,

,

XX

XX

X

243243

243243

243

XX

XX

X

6 = 152 mm standard length for rigid version

6/18 = 152 mm stem length / 457 mm flexible stem

Other lengths available

Page 12

12

TECHNICAL DATA

3.3.

3.3.

3.

77

77

7

.2.2

.2.2

.2

PT241PT241

PT241PT241

PT241

XXXX

XXXX

XX

2.031/18 = 2.031” stem length / 18” flexible stem

3.7.33.7.3

3.7.33.7.3

3.7.3

PT244PT244

PT244PT244

PT244

XXXX

XXXX

XX

2.406/18 - 2.406” stem length / 18” flexible stem

Other lengths available

3.7.43.7.4

3.7.43.7.4

3.7.4

PT290PT290

PT290PT290

PT290

XX

XX

X

, PT291, PT291

, PT291, PT291

, PT291

XX

XX

X

, PT292, PT292

, PT292, PT292

, PT292

XX

XX

X

5/30 = 5” stem length / 30” flexible stem

Other lengths available

3.83.8

3.83.8

3.8

EE

EE

E

LELE

LELE

LE

CTRICALCTRICAL

CTRICALCTRICAL

CTRICAL

DD

DD

D

AA

AA

A

TT

TT

T

AA

AA

A

Configuration 4-arm Wheatstone bridge strain gauge with int. amplifier

Output signal 2-wire 4 - 20 mA

Supply voltage 16-40 VDC for EEx ia IIC T4 and FM approved explosion proof models

Power consumption ≤20 mA

Zero balance (x24x and PT24x)

adjusment range -40% to +10% > 500 psi

-80% to +20% < 500 psi

(PT29x)

-40% to +10% > 100 psi

-80% to +20% < 100 psi

3.93.9

3.93.9

3.9

TT

TT

T

EMPERAEMPERA

EMPERAEMPERA

EMPERA

TURETURE

TURETURE

TURE

INFLINFL

INFLINFL

INFL

UENCUENC

UENCUENC

UENC

EE

EE

E

Electronics housingElectronics housing

Electronics housingElectronics housing

Electronics housing

Max. housing temperatures

Safety class T4 -20°C to +80°C

Compenstated -18°C to +65°C

temperature range

240 Series

Page 13

13

TECHNICAL DATA

Compenstated -18°C to +60°C

temperature range

PT29x Series

Zero shift due to temperature change on electronics housing

x24x, PT24x, PT29x 0.01% full scale/°F maximum (0.02% f.s./°C maximum)

Diaphragm (in contact with media)Diaphragm (in contact with media)

Diaphragm (in contact with media)Diaphragm (in contact with media)

Diaphragm (in contact with media)

Maximum temperature at the diaphragm

x2xxxx 400°C (750°F)

Zero shift due to temperature change on the diaphragm

x2xxxx 15 psi/100°F typical (27 psi/100°C)

PT29x, PT24x 1 psi/100°F typical (from 75°F to 450°F)

2 psi/100°F typical (from 450°F to 600°F)

0.07 bar/38°C typical (from 24°C to 232°C)

0.14 bar/38°C typical (from 233°C to 315°C)

3.103.10

3.103.10

3.10

EMC EMC

EMC EMC

EMC

REQUIREMENTSREQUIREMENTS

REQUIREMENTSREQUIREMENTS

REQUIREMENTS

Conforming to CE in accordance with EMC directive.

Electromagnetic Interference DIN EN 550223 1995

Immunity DIN EN 61000-4-2 1995

Radiated, Radio Freq, etc. DIN EN 61000-4-3 1995 +A1:1998+A2:2000

Pulse Magnetic Field DIN EN 61000-4-9 1993 + A1:2001

Surge Immunity DIN EN 61000-4-5 1995 + A1:2000

Conducted Disturbences DIN EN 61000-4-6 1996 + A1:2000

Power Frequency Magnetic Field DIN EN 61000-4-8 1993 + A1:2001

3.113.11

3.113.11

3.11

MM

MM

M

AA

AA

A

TERIALSTERIALS

TERIALSTERIALS

TERIALS

Diaphragm 15-5PH Mat. No. 1.4545 DyMax™ coated

Stem 17-4PH Mat. No. 517400

3.123.12

3.123.12

3.12

TT

TT

T

ORQUEORQUE

ORQUEORQUE

ORQUE

x242x x243x PT292 PT24x, PT290 and PT291

max. 56.5 Nm max. 5.6 Nm max. 14.1 Nm max. 14.1 Nm

(500 inch-lbs.) (50 inch-lbs.) (125 inch-lbs.) (125 inch-lbs.)

min. 11.3 Nm min. 4.5 Nm min. 11.3 Nm min. 11.3 Nm

(100 inch-lbs.) (40 inch-lbs.) (100 inch-lbs.) (100 inch-lbs.)

Page 14

14

TECHNICAL DATA

3.133.13

3.133.13

3.13

EE

EE

E

NVIRONMENTNVIRONMENT

NVIRONMENTNVIRONMENT

NVIRONMENT

ALAL

ALAL

AL

PROPRO

PROPRO

PRO

TETE

TETE

TE

CTIONCTION

CTIONCTION

CTION

TT

TT

T

OO

OO

O

IE IE

IE IE

IE

CC

CC

C

5 5

5 5

5

22

22

2

99

99

9

PT housing with conduit 1P66 nema 4x

PT02A-10-6P 1P55 nema 4x (Using Dynisco P/N 711600)

PT02H-10-6P 1P66 nema 4x (Using Dynisco P/N 711610)

PT1H-10-6P 1P66 nema 4x (Using Dynisco P/N 711610)

3.143.14

3.143.14

3.14

WW

WW

W

EIGHTEIGHT

EIGHTEIGHT

EIGHT

1-5 lbs.

3.153.15

3.153.15

3.15

DD

DD

D

IMENSIONSIMENSIONS

IMENSIONSIMENSIONS

IMENSIONS

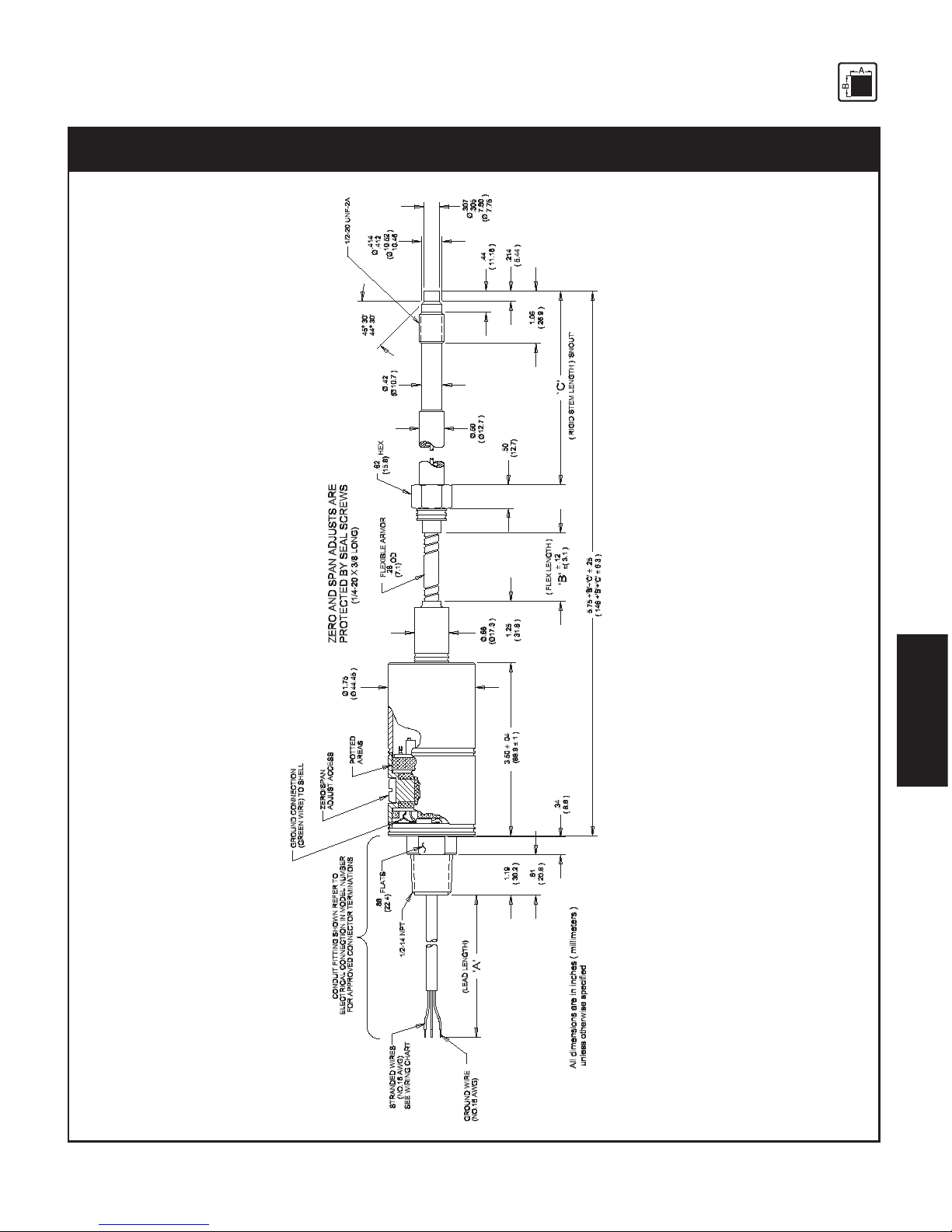

Page 15

15

TECHNICAL DATA

Fig. 3-1Fig. 3-1

Fig. 3-1Fig. 3-1

Fig. 3-1

x242 Modelsx242 Models

x242 Modelsx242 Models

x242 Models

Page 16

16

TECHNICAL DATA

Fig. 3-2Fig. 3-2

Fig. 3-2Fig. 3-2

Fig. 3-2

x243 Modelsx243 Models

x243 Modelsx243 Models

x243 Models

Page 17

17

TECHNICAL DATA

Fig. 3-3Fig. 3-3

Fig. 3-3Fig. 3-3

Fig. 3-3

PT241 ModelsPT241 Models

PT241 ModelsPT241 Models

PT241 Models

Page 18

18

TECHNICAL DATA

Fig. 3-4Fig. 3-4

Fig. 3-4Fig. 3-4

Fig. 3-4

PT244x ModelsPT244x Models

PT244x ModelsPT244x Models

PT244x Models

Page 19

19

TECHNICAL DATA

Fig. 3-5Fig. 3-5

Fig. 3-5Fig. 3-5

Fig. 3-5

PT290 ModelsPT290 Models

PT290 ModelsPT290 Models

PT290 Models

Page 20

20

TECHNICAL DATA

Fig. 3-6Fig. 3-6

Fig. 3-6Fig. 3-6

Fig. 3-6

PT291x ModelsPT291x Models

PT291x ModelsPT291x Models

PT291x Models

Page 21

21

TECHNICAL DATA

Fig. 3-7Fig. 3-7

Fig. 3-7Fig. 3-7

Fig. 3-7

PT292x ModelsPT292x Models

PT292x ModelsPT292x Models

PT292x Models

Page 22

22

FUNCTION

4.4.

4.4.

4.

FF

FF

F

UNCTIONUNCTION

UNCTIONUNCTION

UNCTION

4.1 Construction ...................................................................................................................... 22

4.2 Description of Functions .................................................................................................... 22

4.14.1

4.14.1

4.1

CC

CC

C

ONSTRUCTIONONSTRUCTION

ONSTRUCTIONONSTRUCTION

ONSTRUCTION

The PTs of series 240’s and 290’s are industry standard.

The main advantages are:

• Intrinsically safe EEx ia IIC T4

• thermal stability

• resistance to aggressive media

• insensitivity to electromagnetic radiation (EMC)

• liquid-filled transmission system (mercury)

• pressure measurements in plastic melt up to a temperature of 400°C

4.24.2

4.24.2

4.2

DD

DD

D

ESCRIPTIONESCRIPTION

ESCRIPTIONESCRIPTION

ESCRIPTION

OFOF

OFOF

OF

F F

F F

F

UNCTIONSUNCTIONS

UNCTIONSUNCTIONS

UNCTIONS

Through a closed, liquid-filled pressure transmission system, the PT furnishes an electrical signal

that is proportional to the pressure of the melt.

The pressure applied by the medium is forwarded to the measuring diaphragm and the mercury in

the capillary. The deflection of the measuring diaphragm changes the resistance of the strain gauge

bonded to the measuring diaphragm. The strain gauge is a Wheatstone bridge.

Depending on the model, the integrated amplifier generates and electrical signal (mA or Volts)

proportional to the pressure.

Fig. 4-1Fig. 4-1

Fig. 4-1Fig. 4-1

Fig. 4-1

Functioning Principle of the PT of the X242 SeriesFunctioning Principle of the PT of the X242 Series

Functioning Principle of the PT of the X242 SeriesFunctioning Principle of the PT of the X242 Series

Functioning Principle of the PT of the X242 Series

Page 23

23

TRANSPORT

5.5.

5.5.

5.

TT

TT

T

RANSRANS

RANSRANS

RANS

PORPOR

PORPOR

POR

TT

TT

T

/ D / D

/ D / D

/ D

ELIVERYELIVERY

ELIVERYELIVERY

ELIVERY

5.1 Transport / packing / transport damage .............................................................................. 23

5.2 Storage .............................................................................................................................. 23

5.3 Scope of delivery .............................................................................................................. 23

TT

TT

T

oo

oo

o

xx

xx

x

icic

icic

ic

h h

h h

h

azaz

azaz

az

arar

arar

ar

d!d!

d!d!

d!

The PT contains a small amount of mercury (Hg) as its transmission medium. If the

diaphragm is damaged, mercury may escape.

Never transport or store the PT without the protective shell bolted in place. Remove the

shell shortly before installation.

IfIf

IfIf

If

mer mer

mer mer

mer

cc

cc

c

urur

urur

ur

yy

yy

y

i i

i i

i

ss

ss

s

inh inh

inh inh

inh

alal

alal

al

ed or swed or sw

ed or swed or sw

ed or sw

alal

alal

al

lolo

lolo

lo

ww

ww

w

ed, seeked, seek

ed, seeked, seek

ed, seek

medic medic

medic medic

medic

alal

alal

al

att att

att att

att

ention immediention immedi

ention immediention immedi

ention immedi

atat

atat

at

elyely

elyely

ely

..

..

.

Mercury is hazardous waste and must be disposed of in accordance with applicable

laws.

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O will accept defective PTs.

If mercury escapes, use airtight packaging!

ESD sensitive component. Electrostatic discharge may damage the PT. Take ESD

precautions.

5.15.1

5.15.1

5.1

TT

TT

T

RANSRANS

RANSRANS

RANS

PORPOR

PORPOR

POR

TT

TT

T

//

//

/

PP

PP

P

AA

AA

A

CKINGCKING

CKINGCKING

CKING

//

//

/

TRANSTRANS

TRANSTRANS

TRANS

PORPOR

PORPOR

POR

TT

TT

T

DD

DD

D

AMAGEAMAGE

AMAGEAMAGE

AMAGE

• Do not let the PT be damaged by other items during transit.

• Use only the original packaging.

• Report transport damage to

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O immediately in writing.

5.25.2

5.25.2

5.2

SS

SS

S

TT

TT

T

ORAGEORAGE

ORAGEORAGE

ORAGE

• Store the PT in original packaging only.

• Protect against dust and moisture.

5.35.3

5.35.3

5.3

SS

SS

S

CC

CC

C

OPEOPE

OPEOPE

OPE

OFOF

OFOF

OF

DELIVERYDELIVERY

DELIVERYDELIVERY

DELIVERY

• PT with diaphragm protection cap

• Fastening clip (transmitter with flexible stem only)

• Calibration sheet

• Operating manual with declaration of conformity

Page 24

24

ASSEMBLY

6.6.

6.6.

6.

AA

AA

A

SS

SS

S

SS

SS

S

EMBLEMBL

EMBLEMBL

EMBL

YY

YY

Y

6.1 Mounting hole ................................................................................................................... 24

6.2 Checking the mounting hole ............................................................................................. 27

6.3 Mounting the Pressure Transmitter ..................................................................................... 28

6.4 Mounting PTs with flexible stem ....................................................................................... 29

6.5 Mounting PTs with flange .................................................................................................. 30

6.6 Electrical connection ........................................................................................................ 30

6.6.1 EMC / CE compliant connection ...................................................................................... 3 1

6.7 Connection assignments .................................................................................................... 3 1

6.8 Flange configurations ........................................................................................................31

Ambient temperature for the electronics housing max. +80°C (safety class T4 max.).

Higher temperatures can result in damage and malfunction.

Do not install the pressure transmitter in places where this temperature is exceeded.

6.16.1

6.16.1

6.1

MM

MM

M

OUNTINGOUNTING

OUNTINGOUNTING

OUNTING

H H

H H

H

OLEOLE

OLEOLE

OLE

To produce the mounting hole, use only

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O machining tool kit (DYNISCO P/N

200925).

• Drill the mounting hole as shown in fig. 6-1, 6-2, 6-3, 6-4, 6-5, 6-6.

Fig. 6-1Fig. 6-1

Fig. 6-1Fig. 6-1

Fig. 6-1

Mounting Hole x242Mounting Hole x242

Mounting Hole x242Mounting Hole x242

Mounting Hole x242

Page 25

25

ASSEMBLY

Fig. 6-2Fig. 6-2

Fig. 6-2Fig. 6-2

Fig. 6-2

Mounting hole x243Mounting hole x243

Mounting hole x243Mounting hole x243

Mounting hole x243

Fig. 6-3Fig. 6-3

Fig. 6-3Fig. 6-3

Fig. 6-3

Mounting hole PT241xMounting hole PT241x

Mounting hole PT241xMounting hole PT241x

Mounting hole PT241x

Page 26

26

ASSEMBLY

Fig. 6-4Fig. 6-4

Fig. 6-4Fig. 6-4

Fig. 6-4

Mounting hole PT244xMounting hole PT244x

Mounting hole PT244xMounting hole PT244x

Mounting hole PT244x

Fig. 6-5Fig. 6-5

Fig. 6-5Fig. 6-5

Fig. 6-5

Mounting hole PT290 & PT291Mounting hole PT290 & PT291

Mounting hole PT290 & PT291Mounting hole PT290 & PT291

Mounting hole PT290 & PT291

Page 27

27

ASSEMBLY

Fig. 6-6Fig. 6-6

Fig. 6-6Fig. 6-6

Fig. 6-6

Mounting hole PT292Mounting hole PT292

Mounting hole PT292Mounting hole PT292

Mounting hole PT292

When reworking the mounting hole, pay particular attention to the centricity of:

• the hole,

• the thread, if present, and

• the sealing surface.

Pressure sealing takes place on the 45° beveled sealing surface and on the front cylindrical section

of the PT (see figures 6-1, 6-2, 6-3, 6-4, 6-5, 6-6).

The sealing surface must be:

• correctly machined

• free from marks and rough edges

• free from solidified plastic residue.

6.26.2

6.26.2

6.2

CC

CC

C

HEHE

HEHE

HE

CKINGCKING

CKINGCKING

CKING

THETHE

THETHE

THE

MOUNTINGMOUNTING

MOUNTINGMOUNTING

MOUNTING

HOLEHOLE

HOLEHOLE

HOLE

((

((

(

NONO

NONO

NO

TT

TT

T

FLANGEDFLANGED

FLANGEDFLANGED

FLANGED

MODELSMODELS

MODELSMODELS

MODELS

))

))

)

• Paint the test bolt DYNISCO on the marked area (figure 6-7, item 1) with marking ink up to the

thread.

Page 28

28

ASSEMBLY

Fig. 6-7Fig. 6-7

Fig. 6-7Fig. 6-7

Fig. 6-7

TT

TT

T

ee

ee

e

ss

ss

s

tt

tt

t

Bo Bo

Bo Bo

Bo

ltlt

ltlt

lt

w w

w w

w

ith Mith M

ith Mith M

ith M

arkark

arkark

ark

inin

inin

in

g Inkg Ink

g Inkg Ink

g Ink

• Insert the test bolt in the mounting hole.

• Twist it in by hand until the two sealing surfaces make contact.

• Remove and examine the test bolt.

The only acceptable abrasion of marking ink is at the sealing edge (45°), evenly over the entire

circumference.

If the ink has been rubbed off in other places too:

• rework the mounting hole.

6.36.3

6.36.3

6.3

MM

MM

M

OUNTINGOUNTING

OUNTINGOUNTING

OUNTING

THETHE

THETHE

THE

P P

P P

P

RERE

RERE

RE

SS

SS

S

SURESURE

SURESURE

SURE

TT

TT

T

RANSRANS

RANSRANS

RANS

MITMIT

MITMIT

MIT

TERTER

TERTER

TER

Mounting and electrical connection of the PT must be done by specialists with EMC

training, following all applicable regulations, and in

prpr

prpr

pr

ee

ee

e

ss

ss

s

ss

ss

s

urur

urur

ur

elel

elel

el

ee

ee

e

ss

ss

s

s, s,

s, s,

s,

vv

vv

v

oo

oo

o

ltlt

ltlt

lt

agag

agag

ag

e-fre-fr

e-fre-fr

e-fr

ee,ee,

ee,ee,

ee,

intrinintrin

intrinintrin

intrin

ss

ss

s

icic

icic

ic

alal

alal

al

lyly

lyly

ly

s s

s s

s

afaf

afaf

af

ee

ee

e condition with the

mm

mm

m

acac

acac

ac

hine swhine sw

hine swhine sw

hine sw

itit

itit

it

cc

cc

c

hed offhed off

hed offhed off

hed off.

The mThe m

The mThe m

The m

acac

acac

ac

hine muhine mu

hine muhine mu

hine mu

ss

ss

s

tt

tt

t

be sec be sec

be sec be sec

be sec

urur

urur

ur

ed aged ag

ed aged ag

ed ag

ainain

ainain

ain

ss

ss

s

tt

tt

t

bein bein

bein bein

bein

g swg sw

g swg sw

g sw

itit

itit

it

cc

cc

c

hed bhed b

hed bhed b

hed b

acac

acac

ac

kk

kk

k

on! on!

on! on!

on!

TT

TT

T

oo

oo

o

xx

xx

x

icic

icic

ic

h h

h h

h

azaz

azaz

az

arar

arar

ar

d!d!

d!d!

d!

The PT contains a small amount of mercury (Hg) as its transmission medium. If the

diaphragm is damaged, mercury may escape.

Never transport or store the PT without the protective cap bolted in place. Remove the

cap shortly before installation.

IfIf

IfIf

If

mer mer

mer mer

mer

cc

cc

c

urur

urur

ur

yy

yy

y

i i

i i

i

ss

ss

s

inh inh

inh inh

inh

alal

alal

al

ed or swed or sw

ed or swed or sw

ed or sw

alal

alal

al

lolo

lolo

lo

ww

ww

w

ed, seeked, seek

ed, seeked, seek

ed, seek

medic medic

medic medic

medic

alal

alal

al

att att

att att

att

ention immediention immedi

ention immediention immedi

ention immedi

atat

atat

at

ely!ely!

ely!ely!

ely!

ESD sensitive component. Electrostatic discharge may damage the PT. Take ESD

precautions.

Before mounting the PT, check the mounting hole carefully. The PT must only be

mounted in holes that satisfy the requirements stipulated in chapter 6.1. A hole that

does not satisfy these requirements can damage the PT.

Before mounting the PT, ensure that the mounting hole is free from plastic residue.

Page 29

29

ASSEMBLY

Remove plastic residue with the

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O cleaning tool kit. A test bolt is included

with this cleaning set.

To prevent the PT from sticking permanently in the mounting hole, coat the thread

section of the transmitter with high temperature resistant grease or a suitable parting

agent.

• Check the mounting hole with the test bolt, and clean with cleaning set if necessary.

• Coat the thread section of the transmitter with high temperature resistant grease or a suitable

parting agent.

Always use a torque wrench applied to the designated hexagon collar when screwing

the PT in and out. Do not apply the tool to the housing or housing / sensor connection!

Maximum mounting torque 500 inch-pounds for 1/2-20 UNF transmitters. If the

mounting torque is too high, the PT may be damaged or its zero point may shift.

• Screw the PT into the mounting hole and tighten.

6.46.4

6.46.4

6.4

MM

MM

M

OUNTINGOUNTING

OUNTINGOUNTING

OUNTING

P P

P P

P

TT

TT

T

SS

SS

S

WITHWITH

WITHWITH

WITH

F F

F F

F

LEXIBLELEXIBLE

LEXIBLELEXIBLE

LEXIBLE

SS

SS

S

TEMTEM

TEMTEM

TEM

Mounting a PT with a flexible stem to the pressure sensor is done analogously to the procedure in

6.3.

Avoid kinking or crushing the flexible stem.

Minimum bending radius

•

1” (25 mm)1” (25 mm)

1” (25 mm)1” (25 mm)

1” (25 mm) for protected capillary

The connector must be easily accessible (on connector versions).

• Mount the electronics housing of the PT with the fastening clip. See mounting example in figure

6-8.

• Additionally secure the flexible stem between the electronics housing with a standard cable

clip.

Page 30

30

ASSEMBLY

Fig. 6-8Fig. 6-8

Fig. 6-8Fig. 6-8

Fig. 6-8

MouMou

MouMou

Mou

ntinntin

ntinntin

ntin

g Exg Ex

g Exg Ex

g Ex

ampamp

ampamp

amp

ll

ll

l

e fe f

e fe f

e f

or Pror Pr

or Pror Pr

or Pr

ee

ee

e

ss

ss

s

ss

ss

s

urur

urur

ur

e e

e e

e

TT

TT

T

rr

rr

r

anan

anan

an

smittsmitt

smittsmitt

smitt

er wer w

er wer w

er w

ith Flith Fl

ith Flith Fl

ith Fl

ee

ee

e

xx

xx

x

ibib

ibib

ib

ll

ll

l

e e

e e

e

StSt

StSt

St

emem

emem

em

6.56.5

6.56.5

6.5

II

II

I

NSNS

NSNS

NS

TT

TT

T

ALLINGALLING

ALLINGALLING

ALLING

THETHE

THETHE

THE

F F

F F

F

LANGEDLANGED

LANGEDLANGED

LANGED

P P

P P

P

RERE

RERE

RE

SS

SS

S

SURESURE

SURESURE

SURE

TT

TT

T

RANSRANS

RANSRANS

RANS

MITMIT

MITMIT

MIT

TERTER

TERTER

TER

Installation of the flange mounted pressure transmitter is analogous to the procedure described

under 6.3, except mounting torque is designed for the mounting bolts and varies depending on

specific transmitter. See specification section 3.12 for details.

6.66.6

6.66.6

6.6

EE

EE

E

LELE

LELE

LE

CTRICALCTRICAL

CTRICALCTRICAL

CTRICAL

C C

C C

C

ONNEONNE

ONNEONNE

ONNE

CTIONCTION

CTIONCTION

CTION

Mounting and electrical connection of the PT must be done by specialists with EMC

training, following all applicable regulations, and in

prpr

prpr

pr

ee

ee

e

ss

ss

s

ss

ss

s

urur

urur

ur

elel

elel

el

ee

ee

e

ss

ss

s

s, s,

s, s,

s,

vv

vv

v

oo

oo

o

ltlt

ltlt

lt

agag

agag

ag

e-fre-fr

e-fre-fr

e-fr

ee,ee,

ee,ee,

ee,

intrinintrin

intrinintrin

intrin

ss

ss

s

icic

icic

ic

alal

alal

al

lyly

lyly

ly

s s

s s

s

afaf

afaf

af

ee

ee

e condition with the

mm

mm

m

acac

acac

ac

hine swhine sw

hine swhine sw

hine sw

itit

itit

it

cc

cc

c

hed offhed off

hed offhed off

hed off.

The machine must be secured against being switched back on!The machine must be secured against being switched back on!

The machine must be secured against being switched back on!The machine must be secured against being switched back on!

The machine must be secured against being switched back on!

Do not lay connecting cables in the direct vicinity of cables carrying higher voltage or

used to switch inductive or capacitive loads.

Operate only with an intrinsically safe, EMC compliant power supply with the

following specifications when employing the pressure 4-20 mA output:

Supply voltage max. 40 V DC

Current output max. 100 mA

Inductivity max. 0

Capacity max. 0.017 µF

Page 31

31

ASSEMBLY

ESD sensitive component. Electrostatic discharge may damage the PT. Take ESD

precautions.

The electrical connection must comply with EMC requirements.

If the electrical connection is not made as described in chapter 6.6.1, or if cables /

cable connectors / cable glands other than those stipulated by

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O are used,

DD

DD

D

YNISCYNISC

YNISCYNISC

YNISC

OO

OO

O cannot guarantee that EMC requirements will be satisfied.

6.6.16.6.1

6.6.16.6.1

6.6.1

EMC / CE CEMC / CE C

EMC / CE CEMC / CE C

EMC / CE C

OMPLIANTOMPLIANT

OMPLIANTOMPLIANT

OMPLIANT

C C

C C

C

ONNECTIONONNECTION

ONNECTIONONNECTION

ONNECTION

• Earth the machine section with the screw-in trunnion / mounting hole for the PT in accordance

with regulations. The PT must be connected to earth via the screw-in trunnion / mounting hole.

• Connect the shield of the connecting cable on both sides, making sure it conducts with full and

continuous contact.

• When introducing the connecting cable into an EMC compliant switch cabinet, for example,

connect the shield correctely (cable gland, conducting, full contact, continuous) to the

conductive housing or route it via built-in cable connector that is also connected to the

conductive housing.

• Connect unused cable cores or free cable ends correctely to the cable shield on both sides.

6.76.7

6.76.7

6.7

CC

CC

C

ONNEONNE

ONNEONNE

ONNE

CTIONCTION

CTIONCTION

CTION

A A

A A

A

SS

SS

S

SIGNMENTSIGNMENT

SIGNMENTSIGNMENT

SIGNMENT

SS

SS

S

Conduit / LeadsConduit / Leads

Conduit / LeadsConduit / Leads

Conduit / Leads

Red + Signal/Power

Black - Signal/Power

Green Ground

ConnectorConnector

ConnectorConnector

Connector

A + Signal/Power

B - Signal/Power

Transmitter incorporates over-voltage protection and reverse polarity protection and will not operate

if inputs are reversed.

6.86.8

6.86.8

6.8

FF

FF

F

LANGELANGE

LANGELANGE

LANGE

C C

C C

C

ONFIGURAONFIGURA

ONFIGURAONFIGURA

ONFIGURA

TIONSTIONS

TIONSTIONS

TIONS

Page 32

32

ASSEMBLY

REV

ECO

BY APP DATE

28746 KEMT R

Certification Drawing,

Flange Configurations

243, 2243

000053

06/02/97

WBM

LEB 10/07/04

SCALE:

1

1

SHEET OF

NONE

000053

TITLE

DRAWN

CHECKED

APPROVED

FINISH

DATE

DATE

DATE

MATERIAL

DO NOT SCALE DRAWING

ITEM

PART NO.

DESCRIPTION QTY

MODEL NO.

TOLERANCES UNLESSO THERWISESPECI FIED;

SIZE DWG. NO. REV

>

0.5 DIA

-.003

+.008

+.005

-.002

4. ANGLES ±0.5 °

3 PLACE DECIMAL ±.005

1. 2 PLACEDECIMAL ±.01

2. FRACTIONS ± 1/32

5. FILLETS R .005 MAX

6. EDGES R.005 OR CHAMFER MAX

7. PART TO BE FREE OF BURRS

8. ALL DIMENSIONS ARE IN INCHES.

<

3. DRILLS 0.5 DIA

12/9/96

C

DRG

V

EXCEPT AS MAY BE OTHERWISE PROVIDED BY

CONTRACT, THESE DRAWINGS AND SPECIFICATIONS

ARE THE PROPERTY OFDYNISCO, ARE ISSUED IN

STRICT CONFIDENCE, AND SHALL NOT BE

REPRODUCED ORCOPIED, OR USED AS THE BASIS

FOR THE MANUFACTURE OR SALEOF APPARATUS

WITHOUT PERMISSION.

FORGEPARKWAY, FRANKLIN,MA

29371 DRGU

HWM 12/01/04

29792 DRGV

HWM

4/27/05

45° ± 1°

Ø'C'4HOLES

EQUALLY SPACED

(ONØ'B')

Ø

'B'

Ø

'A'

Ø

'B'

Ø

Ø

'A'

(2JACK-OUTHOLES)

5/16-24 UNF-3B

7/8-14 UNF-3B

45° ± 1°

Ø'C'4HOLES

EQUALLY SPACED

(ONØ'B')

'D'

DIM 'A'

DIM 'B'

(2JACK-OUTHOLES)

5/16-24 UNF-3B

DIM 'A'

FIG 2

FIG 1

FIG 3

5/16-24 UNF-3B

22.5° ± 1°

Ø'C'8HOLES

EQUALLY SPACED

(ONØ'B')

DIM 'B'

DIM 'A'

Ø

'D'

Ø

'A'

(2JACK-OUTHOLES)

C

O

N

T

R

O

L

L

E

D

P

R

O

D

U

C

T

A

L

L

C

H

A

N

G

E

S

M

U

S

T

B

E

A

P

P

R

O

V

E

D

B

Y

A

P

P

R

O

V

A

L

S

C

O

-

O

R

D

I

N

A

T

O

R

B

E

F

O

R

E

E

X

E

C

U

T

I

O

N

MODEL TPT243

243863

N/A

.50

(12.7)

N/A

.375

(9.5)

2.00

(50.8)

RAISED FACE,

300 LB, 2 in

40

F15

2.62

(66.6)

N/A

FLAT FACE,

TPT FLANGE

25

EXCEPT T HREAD

=1-12UNF-3B

39

38

37

36

35

34

33

32

31

30

29

28

27

2243

CODE

26

DESCRIPTION

FIG

243

CODE

FLANGEMOUNTING CONFIGURATIONS

STANDARD

FLANGE

(66.6)

2.62

1

(50.8)

2.00

(8.71)

.343

N/A

Ø'A'

Ø'B'

Ø'C'

Ø'D'

F14

F13

F12

F11

F8

F7

F1

F2F3F4F5F6

F9

F10

(19)

.750

(92)

3.62

(127)

5.00

(165.1)

6.50

(22.35)

.88 .06

(1.52)

243869

3

RAISED FACE

1500 LB, 1in

2

(149.4)

5.88

4.00

(101.6)

1.00

(25.4)

2.00

(50.8)

1.37

(34.8)

.25

(6.35)

243867

2.00

(50.8)

.62

(15.7)

RAISED FACE

150 LB, 1in

2

(108)

4.25

3.12

(79.2)

.56

(14.2)

.06

(1.52)

243866

RING T YPE JOINT

2500 LB, 1in, TPT

2

(158.8)

6.25

4.25

(108.0)

1.00

(25.4)

2.25

(57.2)

243703

RAISED FACE

150 LB, .5in

1

(88.9)

3.50

(60.5)

2.38

.62

(15.7)

243824

1.38

(35.1)

.44

(11.2)

.06

(1.52)

1500 LB, 1in

RAISE D FACE

2

(149.4)

5.88

(101.6)

4.00

(25.4)

1.00

243806

(50.8)

2.00

(34.8)

1.37

(6.35)

.25

FLAT FACE

(66.6)

2.62

1

(50.8)

2.00

(9.5)

.375

N/A

(12.7)

.50

N/A

1500 LB, 1in

RAISE D FACE

2

2

243652

(149.4)

5.88

(101.6)

4.00

(25.4)

1.00

243659

(50.8)

2.00

(34.8)

1.37

(6.35)

.25

600 LB, 1/2in

RAISE D FACE

(15.9)

.625

(35)

1.38

(66.6)

2.62

(95.3)

3.75

(20.6)

.81 .25

243831

2

150 LB, 2in

RAISE D FACE

(19)

.750

(92)

3.62

(120.6)

4.75

(152.4)

6.00

(19)

.75

.06

243680

3

600 LB, 2in

RAISE D FACE

(19)

.750

(92)

3.62

(127)

5.00

(165.1)

6.50

(31.8)

1.25 . 25

243683

TPT STANDARD

1

2.62

(66.6)

2.00

(50.8)

.343

(8.71)

483607

N/A

.50

(12.7)

N/A

STANDARD

IPX184 FLANGE

RAISED FACE

1500 LB, 1in

4

2

2.50

(63.5)

(149.4)

5.88

4.00

(101.6)

1.876

(47.6)

1.00

(25.4)

.344

(8.73)

2.00

(50.8)

N/A

1.37

(34.8)

.500

(12.7)

.25

(6.35)

N/A

(6.35)

(1.52)

(6.35)

183649

243858

DIM 'A'

DIM 'B'

PART& DWG

(12.7)

.50

N/A

183802

NUMBER

N/A

N/A

NOTES

WELDED

NO SET SCREW

5/16-18 JACKOUT

HOLES

M12 JACKOUT

HOLES

WELDED

NO SET SCREW

WELDED

NO SET SCREW

RING JOINT

FACING DIM ONDW G

N/A

.031

(.79)

.140

3.56

DIM 'A'

.973

.971

O

O

'A'

O

'C' THRU

cO

.500

`

.344

4 HOLES EQ SPACED

90

v

APART ON

O

'B'

7/8-14 UNF-3B

45°

O

'B'

5/16-24 UNF-3BTAP, THRU

2PLACESON

O

'B'

X45

vu

5

v

FIG 4

3

1. ALL DIMENSIONS ARE IN IN

(mm).

2. UNLESS NOTED OTHERWISE, FLANGE SECURED TO SNOUT

VIA SET SCREW.

3. UPDATE 242945 & 242946 WITH ANY CHANGES OR ADDITIONS

TO MODEL CODING O R DESCRIPTIONS.

NOTES:

41F16

SET SCREW

N/A

4.88

(124)

3.50

(88.9)

(19)

.75

2.00

(50.8)

.25

(6.35)

243807

(25.4 1.5)

1.00 .06

±

±

RAISED FACE,

ANSI, 600 LB, 1 in

N/AF17

3.75

(95.3)

2.62

(66.6)

.63

(16)

1.38

(35.1)

.625

(15.9)

.63

(16)

SET SCREW

243671

42

RAISED FACE,

(NON-STANDARD)

Fig. 6-9Fig. 6-9

Fig. 6-9Fig. 6-9

Fig. 6-9

x243 Flange Configurationsx243 Flange Configurations

x243 Flange Configurationsx243 Flange Configurations

x243 Flange Configurations

Page 33

33

ASSEMBLY

1

SEENOTE1.

07/23/97

AA

000057

000057

NONE

B

>0.5DIA.

+.005

+.008

4. ANGLES

±

0.5

TOLERANCES UNLESSOTHERWISE SPECIFIED;

1. 2 PLACEDECIMAL

±

.01

3 PLACEDECIMAL

±

.005

5. FILLETS .005R MAX

6. EDGES.005 ROR CHAMFER MAX

7. PART TOBE FREEOF BURRS

8. ALL DIMENSIONSARE ININCHES.

3. DRILLS <0.5 DIA.

-.002

-.003

2. FRACTIONS

±

1/32

MODEL NO.

DO NOT SCALE DRAW ING

MATERIAL

DRAWN

CHECKED

APPROVED

FINISH

DATE

DATE

DATE

SCALE

SHEET OF

REV DCN BY APP DATE

ITEM PART NO DESCRIPTION QTY

SIZE DWG. NO. REV

TITLE

FLANGES, TYPE 'S'

10/09/97

SFP

Instruments

FORGE PARKWAY,F RANKLIN,MA

EXCEPT AS MAY BE OTHERWISE PROVIDED BY

CONTRACT, THESE DRAWINGS AND SPECIFICATIONS

ARE THE PROPERTY OFDYNISCO, ARE I SSUED IN

STRICT CO NFIDENCE, AND S HALL NOT BE

REPRODUCED OR COPIED, OR USED AS THE BASIS

FOR THE MANUFACTURE OR SALE OFAPPARATUS

WITHOUT PERMISSION.

Y 29630 DRG

1

R

SFP

KEM

10/09/97

HWM

2/31/05

29712 DRGAA

HWM

3/10/05

CONTROLLED PRODUCT

ALL CHANGES MUST BE APPROVED BY

APPROVALS CO-ORDINATOR

BEFORE EXECUTION

ITEM MATERIAL OUTER DIAMETER BOLT CIRCLE BOLT CIRCLE THRU HOL E JACK-OUT THICKNESS PART

P/N P/N ∅

"A"

∅

"B"

∅

"C"

∅

"D"

THREAD DIM 'T' REV

S1 48 291625 175325 3.250 2.125 2.125 33/64 5/ 16-18 0.75 A

S2 49 291682 175325 3.220 2.250 2.250 17/32 1/2-13 1.00 A

S3 50 291685 175325 3.250 2.250 2.250 17/32 5/ 16-18 0.75 A

S4 51 291620 175350 3.500 3.000 2.500 17/32 5/ 16-18 1.00 B

S5 52 199654 REFE R TO SEPERA TE DRAW ING FOR DIMENSIONS A ND MATERIAL

S6 53 195639

S7 54 291762 175350 3.500 2.500 2.500 9/16 M12 x 1. 75 0.75 A

S8 55 185603 175350 3.500 2.500 2.500 9/16 5/16-18 0.75 B

S9 56 291606 175350 3.500 2.500 2.500 17/32 1/2-13 1.00 A

S10 57 291696 175325 3.250 2.125 2.520 33/ 64 5/16-18 1.00 A

S11 58 291772

S12 59 199650

S13 60 195632

S14 61 291853 175350 3.500 2.500 2.500 17/ 32 1/2 -13 0. 75 A

S15 62 291858

S16 63 195645

S17 64 195665

S18 65 195648

S19 66 195677

S20 67 291861 17-4, H1075 7.010 4. 882 4.882 28mm M12 X 1.75 1.34 A

S21 68 291860 17-4, H1075 4.490 2. 756 2.756 20mm M12 X 1.75 1.18 A

PER DRA WING 195677, 1" 600 LB, RF, 304 SST ANS I FLANGE, W ELDED

291

CODE

2291

CODE

REFER TO SEPE RATE DRAWING FOR DIMENSIONS AND MA TERIAL

PER DRA WING 195639, 2" 600 LB RF 304 SS TA NSI FLANGE, SECURED BY S ET-SCREW

PER DRA WING 195648, 1" 2500 LB RF ANSI, SECURED BY S ET-SCREW

PER DRA WING 195645, 2" 600 LB RF 316 SS TA NSI FLANGE, WE LDED, NO SET-SCREW HOLE

REFER TO SEPE RATE DRAWING FOR DIMENSIONS AND MA TERIAL

PER DRA WING 195632, 1-1/2 300 LB RF 316 SS TF LANGE, w/ 1/ 2-20 JACKOUT HOLES,W ELDED, NO S ET-SCREW

PER DRA WING 291858, 2" 300 LB RF 304 SS TA NSI FLANGE, SECURED BY S ET-SCREW

PER DRA WING 195665, 1-1/2" 2500 LB RF ANS I, WELDED, NO SE TS CREW HOLE

4

3

"T"

Ø'A'

1.506

1.502

O

Ø.201 THRU (NO. 7 DRILL)

ONE W ALL ONLY

1/4-20 UNC-2B .53 -.56

45vu5v

45° ± 5°, 2PL

TO THD ROOT

11/2-16UN-2B

.140

4x Ø 'D' DRIL L THRU

EQUALLY SPACED ON A

Ø 'C' BOLT CIRCLE

2x 'JACKOUT ' T HREAD

EQUALLY SPACED ON A

Ø 'B' BOLT CI RCLE

45vu5v

`

5

5. UPDATE 242945 & 242946 WITH ANY CHANGES OR ADDITIONS

TO MODEL CODING OR DESCRIPTIONS.

NOTES:

1. MATERIAL: UNLESS OTHERWISE SPECIFIED,17-4 PH SST,

COND H1075. RAW MATERIAL P/N PER ABOVE TABLE.

2. ALL THREADS ARE UN-2B, UNLESS OTHERWISE SPECIFIED.

3. S5 IS A 150 LB - 2 1/2" RAISED FACE ANSI FLANGE, SEE

STANDARD ASME B16.5 FOR DIMENSIONS.

4. S11 IS A 600 LB - 2" RAISED FACE ANSI FLANGE, SEE

STANDARD ASME B16.5 FOR DIMENSIONS.

.190

AA

Fig. 6-10Fig. 6-10

Fig. 6-10Fig. 6-10

Fig. 6-10

PP

PP

P

T2T2

T2T2

T2

9x9x

9x9x

9x

“S” “S”

“S” “S”

“S”

TT

TT

T

ype Flype Fl

ype Flype Fl

ype Fl

anan

anan

an

gg

gg

g

ee

ee

e

ss

ss

s

Page 34

34

ASSEMBLY

+.005

- .002

63

06/30/97

KEM

000058

REV ECO BY APP DATE

28746

N

SCALE

SHEET OF

TITLE

DRAWN

CHECKED

APPROVED

FINISH

DATE

DATE

DATE

MATERIAL

DO NOT SCALE DRAWING

ITEM

PART NO.

DESCRIPTION QTY

MODEL NO.

TOLERANCES UNLESS OTHERWISE SPECIFIED;

SIZE DWG. NO. REV

B

NONE 1 1

000058

N

>

0.5 DIA

- .003

+.008

4. ANGLES ± 0.5°

3 PLACE DECIMAL ± .005

1. 2 PLACE DECIMAL ± .01

2. FRACTIONS ± 1/32

5. FILLETS R .005 MAX

6. EDGES R .005 OR CHAMFER MAX

7. PART TO BE FREE OF BURRS

8. ALL DIMENSIONS ARE IN INCHES.

<

3. DRILLS 0.5 DIA

SPLIT FLANGES

TYPE 'T'

10/09/97

SFP

10/09/97

SFP

LEB 10/07/04KEM

R

EXCEPT AS MAY BE OTHERWISE PROVIDED BY

CONTRACT, THESE DRAWINGS AN D SPECIFICATIONS

ARE THE PROPERTY O FDYNISCO, ARE ISSUED IN

STRICT CONFIDENCE, AND SHALL NOT BE

REPRODUCED OR COPIED, OR USED AS THE BASIS

FOR THE MANUFACTURE OR SALE OFAPPARATUS

WITHOUT PERMISSION.

FORGE PARKWAY,FRANKLIN, MA

1

(2) JACK-OUT HOLES

EQUALLY SPACED ON

O

'B'

4x

O

'D' (DRILL) THRU

EQUALLY SPACED ON

O

'C'

45

vu

5

v

DIM 'G'

O

DIM 'L'

DIM 'E'

DIM 'A'

O

O

'F'

DIM 'T'

DIM 'S'

PART

"ORDERE D"

DIM 'A'

DIM 'T' BOLT CIRCLE BOLT CIRCLE THRU HOLE DIM 'E' DIM 'F' DIM 'G' DIM 'L' DIM 'S ' JACKO UT

REV SNOUT LENGTH (DIA) THICKNESS 'B' DIA 'C' DIA 'D' DIA (DIA) (DIA) OVERA LL LENGTH THREA D

T1 70 291623

G

4.847

3.500

1.00

2.500 2. 500 17/32

4.050 5.050 0. 31

1/2-13

T2 71 291614

G

5.047

3.500

1.00

2.500 2. 500 17/32

4.250 5.250 0. 31

1/2-13

T3 72 291618

G

4.847

3.250

0.75

2.125 2. 125 33/64

4.050

0.906

4.800 0. 31

5/16-18

T4 73 291601

G

4.547

3.500

1.00

2.500 2. 500 17/32

3.750 1 . 365 4.750 0. 31

1/2-13

T5 74 291600

G

2.047

3.250

0.75

2.125 2. 125 33/64

1.250

(29/32)

2.000 N/A

5/16-18

T6 75 291610

G

5.847

3.250

0.75

2.125 2. 125 33/64

5.050

drill

5.800 N/A

5/16-18

T7 76 291616

G

4.847

3.500

1.00

2.500 2. 500 17/32

4.050 5.050 0. 31

1/2-13

T8 77 291429

G

2.00

3.250

0.75

2.125 2. 125 33/64

1.220 1 . 310 1.970 N/A

5/16-18

T9 78 291924

C4.000

1.00

3.000 3. 000 11/16

9.000 1 . 375

1.000

10.000 0.50

1/2-13

T10 79 291851

A

5.94

3.500

1.00

2.500 2. 500 17/32

5.140 1 . 365

0.906

6.140 0. 31

1/2-13

290

CODE

ITEM

P/N

2290

CODE

2

A

L

L

C

H

A

N

G

E

S

M

U

S

T

B

E

A

P

P

R

O

V

E

D

B

Y

A

P

P

R

OVA

L

S

C

O

-

O

R

D

I

N

A

T

O

R

B

E

F

OR

E

E

X

E

C

U

T

I

O

N

C

O

N

T

R

O

L

L

E

D

P

R

O

D

U

C

T

2. UPDATE 242945 & 242946 WITH ANY CHANGES OR ADDITIONS

TO MODEL CODING OR DESCRIPTIONS.

1. MATERIAL: 17-4 SST, CONDITION 1075.

NOTES:

Fig. 6-11Fig. 6-11

Fig. 6-11Fig. 6-11

Fig. 6-11

PP

PP

P

T2T2

T2T2

T2

9x9x

9x9x

9x

“T” “T”

“T” “T”

“T”

SS

SS

S

pp

pp

p

li li

li li

li

StylStyl

StylStyl

Styl

e Fle Fl

e Fle Fl

e Fl

anan

anan

an

gg

gg

g

ee

ee

e

ss

ss

s

Page 35

35

COMMISSIONING

7.7.

7.7.

7.

CC

CC

C

OMMISSIONINGOMMISSIONING

OMMISSIONINGOMMISSIONING

OMMISSIONING

7.1 Supply voltage ................................................................................................................... 35

7.2 Calibration ......................................................................................................................... 35

7.3 Zero adjustment ................................................................................................................. 36

7.4 Operation .......................................................................................................................... 36

7.5 Hazardous area electrical configuration ............................................................................ 36

7.17.1

7.17.1

7.1

SS

SS

S

UPPLUPPL

UPPLUPPL

UPPL

YY

YY

Y

VV

VV

V

OLOL

OLOL

OL

TT

TT

T

AGEAGE

AGEAGE

AGE

Please read the entire manual prior to installation and use.

Explosion hazard!Explosion hazard!

Explosion hazard!Explosion hazard!

Explosion hazard!

Deviation of the supply voltage from the value given in the technical specifications, or

false polarity, can damage the pressure transmitter and cause malfunctions that can

pose a risk of explosion.

7.27.2