Page 1

Model 1440

Microprocessor-based

Temperature Controller

Installation and Operation Manual

P/N 974073

06/02 Rev. C

ECO # 27007

Page 2

2

CONTENTS

Quick Start Instructions ....................................................................................................................3

1. Introduction ...............................................................................................................................6

2. Specifications ............................................................................................................................ 6

3. Front Panel Description ............................................................................................................10

4. Alarms ..................................................................................................................................... 12

5. Mounting .................................................................................................................................13

6. Wiring Guidelines ................................................................................................................... 15

7. Instrument Configuration .........................................................................................................21

8. Operating Instructions ............................................................................................................. 35

9. Error Codes ..............................................................................................................................51

10. Repair ......................................................................................................................................53

11. Warranty ................................................................................................................................. 53

Page 3

1440 Microprocessor-based Temperature Controller 3

MODEL 1440-2-3 QUICK START INSTRUCTIONS

1. MOUNTING

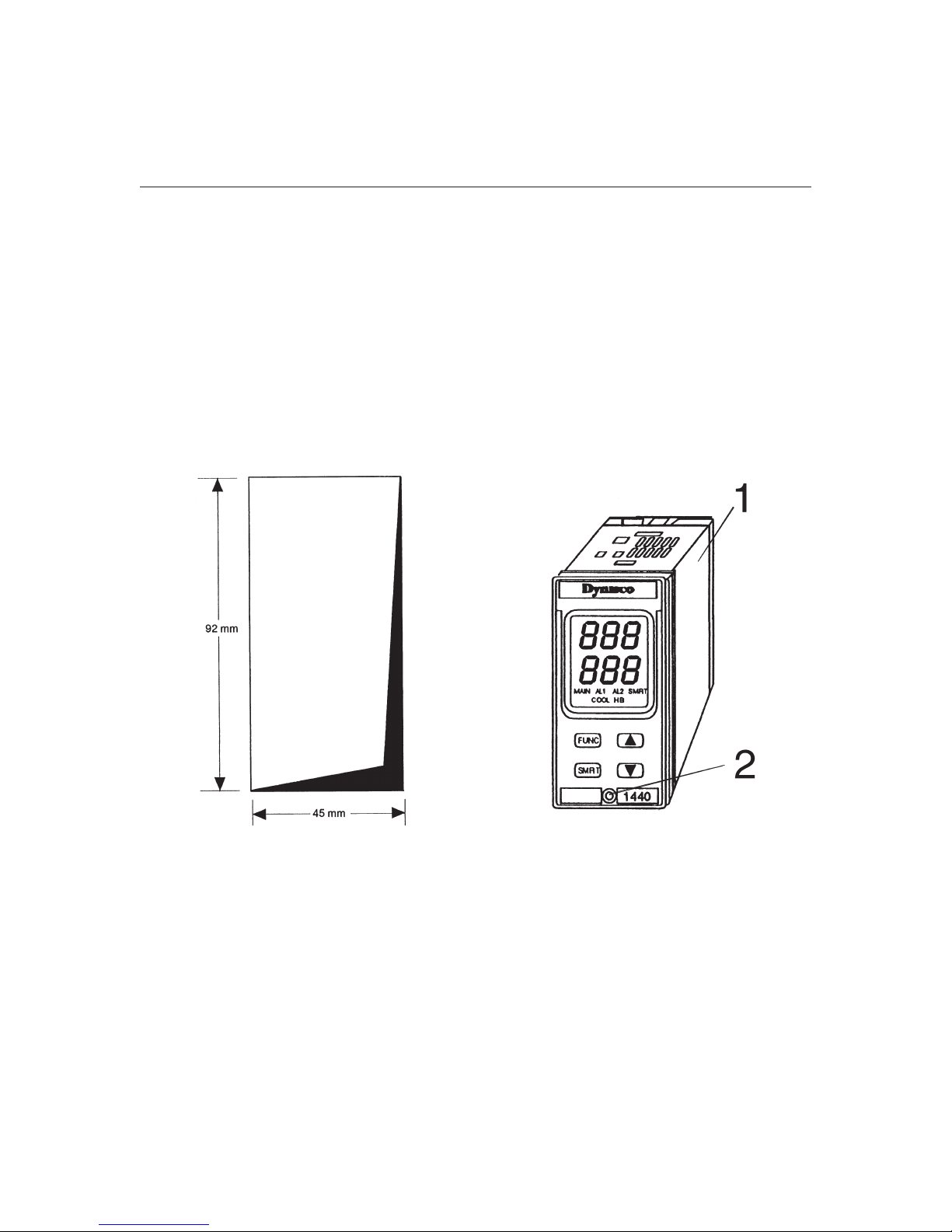

• Prepare panel cutout to dimensions shown below.

• Remove instrument from case by turning captive safety screw (2) counter clockwise.

• Grasp the bezel and slide the instrument out of its case (1).

• Slide the supplied rubber gasket over the case.

• Slide the instrument case (1) into the panel cutout.

• Slide the panel mounting bracket over the instrument case.

• Tighten two screws on panel mounting bracket until case is securely mounted in panel cutout.

• Slide the instrument back into the case and tighten safety screw.

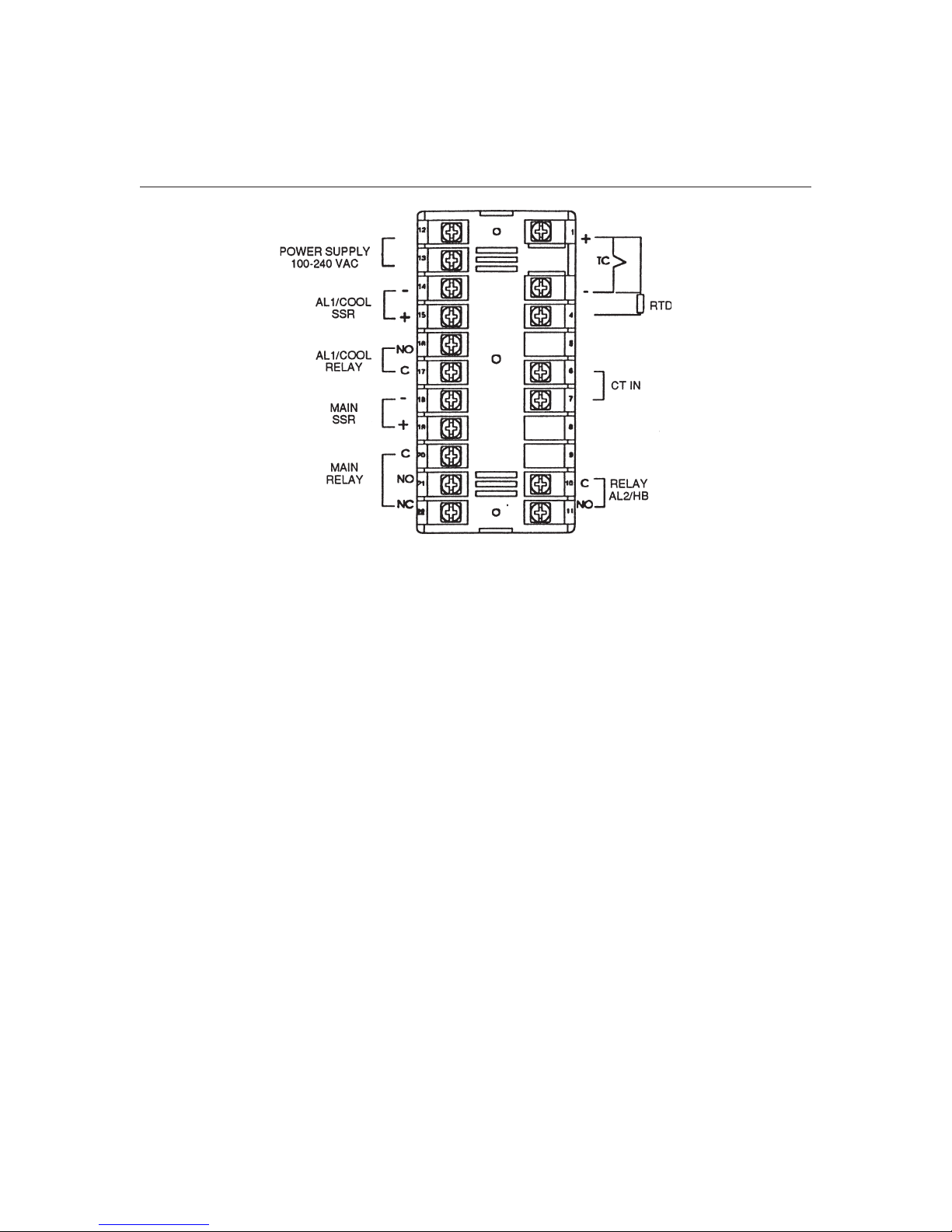

2. WIRING

• Connect an appropriate length of either thermocouple extension wire (e.g.Type J), OR 3 wire

RTD leads to the appropriate terminals as shown below.

• Connect Outputs for Heat/Cool. Note that Outputs are jumper selectable for Relay/SSR output.

Refer to Figure 15, Page 22 for jumper location.

• If a current transformer option is to be used for Heater Breakdown Alarm, connect to

appropriate terminals.

• Connect power to the appropriate terminals as shown below.

Page 4

4

3. INSTRUMENT CONFIGURATION

• Remove instrument from case by loosening safety screw, grab bezel and slide out of case.

• Refer to Figure 15, Page 22, for jumper selection of Relay/SSR selection and AL1 Cool relay NO/

NC selection. Default factory settings are Main/Relay, AL1 Cool/Relay Normally open.

• Locate jumper V2 in Figure 14, page 21 and place in the open position.

• Slide instrument back in case and apply power. Display will now show CnF.

• Press the FUNC button until P1 is displayed.

• Refer to Parameter List on page 23. Using the UP arrow, select appropriate P1 code for Input

type and standard range.

• Press the FUNC button until next parameter is displayed.

• Repeat for each parameter to be changed.

• When configuration is complete, remove instrument from case, place jumper V2 in the closed

position, return instrument into case and secure with safety screw.

• Apply power to instrument, Upper display will show process temperature, lower display will

show setpoint.

• Using UP and DOWN arrows, temperature setpoint can be adjusted.

• Refer to Manual page 36 in for Control Parameters if PID tuning is required.

• Instrument is now ready for use.

NOTE: The preceding Quick Start instructions are the basic settings required to install, wire, and

get the controller operating. It is assumed that the operator is familiar with PID temperature

controllers. Please refer to the complete installation and operation manual for additional

functions and instructions.

Page 5

1440 Microprocessor-based Temperature Controller 5

INDEX

How to: See Section Page

Wire the 1440 6 15

Configuration

Configuration 7 21

Calibration

General Guidelines for Calibration 8.7 43

Calibration Procedure 8.9 45

Operation

Operating Instructions 8 35

Alarms

Main Alarms 4.1 12

Heater Breakdown Alarms 8.5 43

Control Parameters

Control Parameters 8.1 36

Default Control Parameters 8.2 40

Security

Set Safety Lock 3 31

Error Codes

Error Codes 9 51

Instrument Repair

Repair the Instrument 10 53

Get Technical Assistance 10 53

Page 6

6

1. INTRODUCTION

The Model 1440 is a highly flexible, field or laboratory reconfigurable controller. This product’s

design has been implemented with up-to-date technology and accurate engineering. The following

is a summary of the features of the Model 1440:

• 1/8 DIN size (48 x 96 mm)

• IP 54 font protection

• SMART function for automatic self-tuning

• Measurement of the heater current consumption

• Heater breakdown alarm

• TC or RTD input with programmable range

• Programmable transfer ramp between the set points

• Programmable output maximum rate of change

• Output power limiter with programmable time duration

• Two independent alarms programmable as process, band or deviation alarms

• Control outputs: relay or solid state relay (SSR) drive programmable as heating or heating and

cooling controls

• Output power-off

• Direct access to the set point modification

• Switching power supply (for 100 to 240 VAC sources)

2. SPECIFICATIONS

2.1 GENERAL

Case: PC/ABS, black; self-extinguishing, level V-0, per UL94

Front panel: IP 54 protection

Installation: Panel mounting by means of tie rods; instrument removable from

case with a screwdriver

Rear terminal block: Screw terminals; terminal identification labels, connection

diagrams and rear safety cover

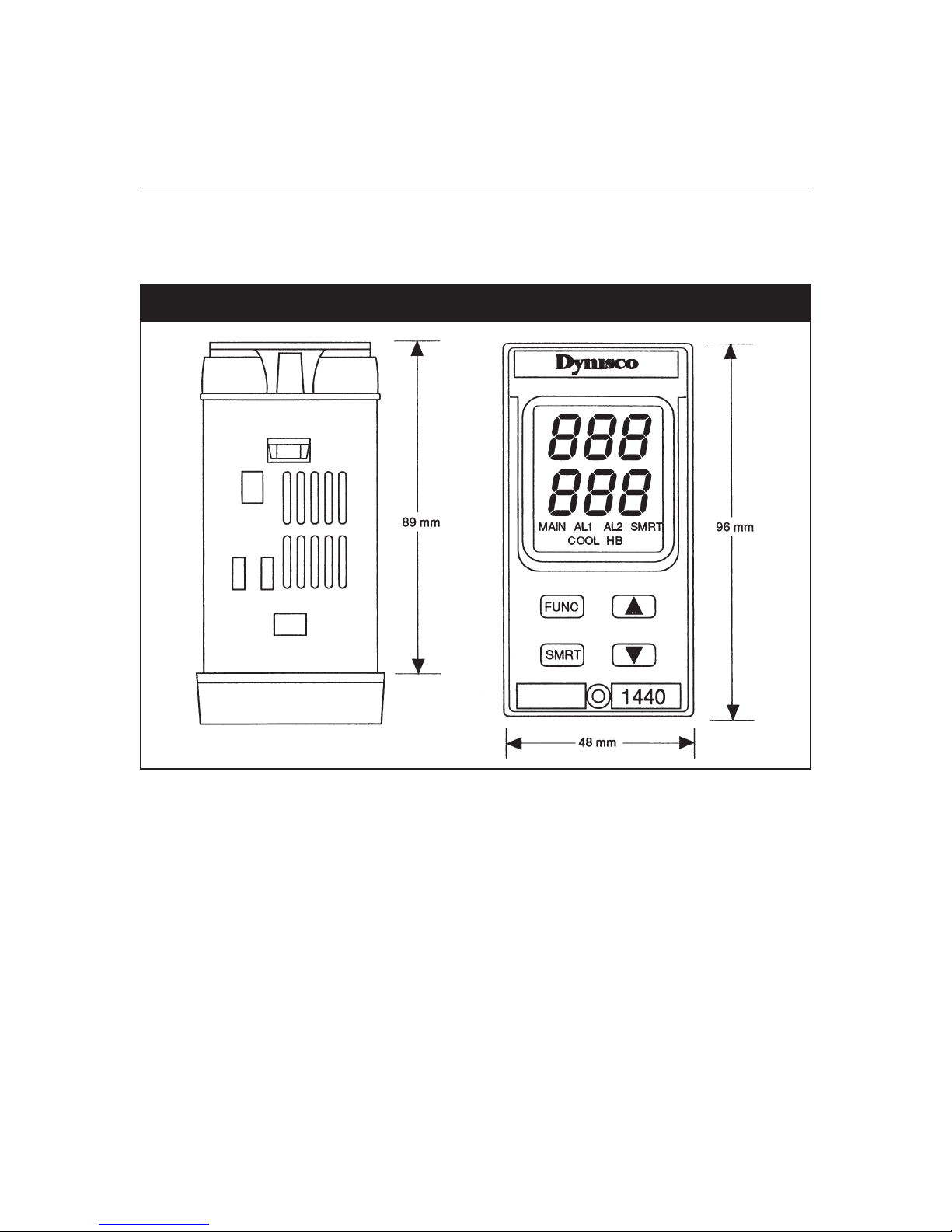

Dimensions: 48 mm wide x 96 mm high x 89 mm deep

(DIN 43700)

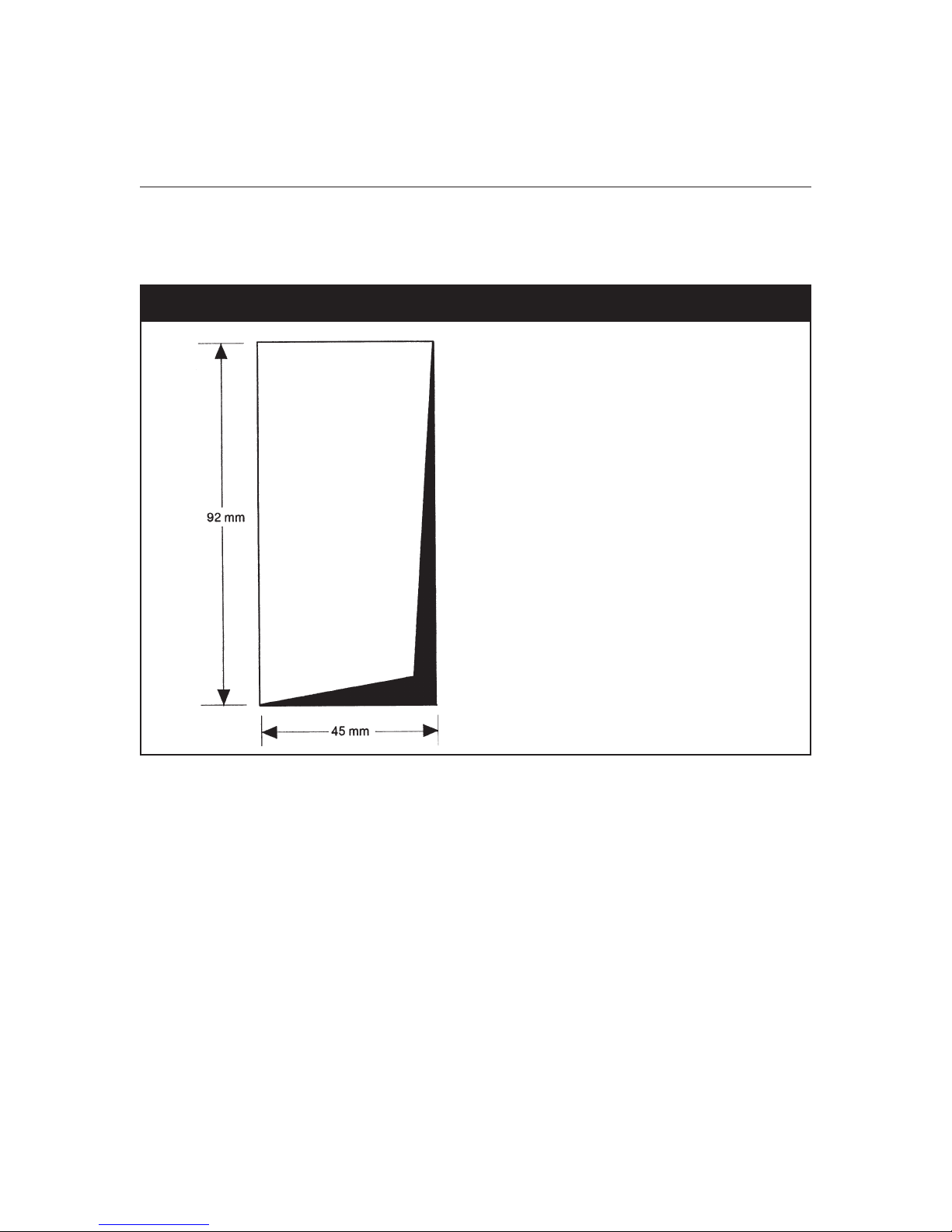

Cutout: 45 x 92 mm

Weight: 600 g maximum

Page 7

1440 Microprocessor-based Temperature Controller 7

Upper display: 3 green LED digits, 7 segments with decimal point

10 mm high

Lower display: 3 orange LED digits, 7 segments with decimal point

10 mm high

Front indication: red LEDs for alarms and instrument status indication

Power supply: 100 to 240 VAC power source, 50/60 Hz

Power Supply Variations: -15 to +10%

Power consumption: 6 VA maximum

Insulation resistance: >100 MΩ for 500 VDC (IEC 348)

Insulation voltage: 1500 V according to IEC 348

Conversion: Dual slope integration with autozero

Resolution 30,000 counts

Sampling time: 500 msec.

Accuracy (@25°C amb. temp.) +0.2% of the input span or +1°C

Common mode rejection ratio: 120 dB

Normal mode rejection ratio: 60 dB

Noise rejection: According to IEC 801-4 level 3

Temperature drift: <200 ppm/°C (Rj excluded); <400 ppm/°C for RTD input with -

19.9/99.9°C ranges

Operating temperature: 0 to +50°C

Storage temperature: -30 to +70°C

Humidity: 20 to 85% RH non-condensing

Protections: 1) WATCH DOG circuit for automatic restart

2) Internal switch for protection against tampering of configuration

and calibration parameters

Page 8

8

2.2 INPUTS

Thermocouple

Type: L,J,K,N programmable by front pushbuttons

Line resistance: 100Ω max, with error <+0.1% of the input span

Temperature units: °C of °F programmable

Reference junction: Automatic compensation of the ambient temperature from 0 to

+50°C

Burn-out: Up or down scale selectable

Calibration: According to IEC 584-1 and DIN 43710-1977 (TC type L)

Standard Ranges Table

TC Type Measuring Ranges

L 0 to +800°C 0 to +999°F

J 0 to +800°C 0 to +999°F

K 0 to +999°C 0 to +999°F

N 0 to +999°C 0 to +999°F

RTD (Resistance Temperature Detector)

Type: Pt 100-3-wire connection

Current 135 mA

Line resistance: Automatic compensation up to 20Ω/wire with <+0.1% error of the

input span for range -19.9 at 99.9°C; no measurable error for the

other ranges

Engineering units: °C or °F programmable

Burn-out: Up scale

Calibration: According to DIN 43760

Page 9

1440 Microprocessor-based Temperature Controller 9

Standard Ranges Table

RTD Type Measuring Ranges

RTD Pt 100 -199 to +500°C -199 to +999°F

RTD Pt 100 -19.9 to +99.9°C -21.6 to +217°F

Current Transformer Input (optional)

The 1440 controller is capable of measuring heater band current with the addition of a small remote

transformer.

Ranges: 25A and 100A

Indication: Use P/N 820754 for 25A range; use P/N 820755 for 100 A range

2.3 CONTROL ACTIONS

Control action: PID or SMART

Proportional band: 0.1 to 99.9% of the input span

When setting Pb = 0: Hysteresis

(for ON/OFF control action): 0.1 to 10.0% of the input span

Integration time: 10 seconds to 20 minutes; resolution 10 seconds; setting a value

greater than 20 minutes will disable the integration action

Differential time: <10 minutes

Heating cycle time: 1 to 200 seconds

Cooling cycle time: 1 to 200 seconds

Relative cooling gain: 0.20 to 1.00 seconds

NOTE: The Pb, ti, tc and parameters may be limited when the SMART function is enabled.

Overlapping/dead band: -20 to 50%

Rate of rise for set point variations: 1 to 100 units/minute

Page 10

10

2.4 OUTPUTS

Output 1 - Heating

Relay output with SPDT contact; contact rating 3 A/250 VAC with resistive load.

Logic voltages for SSR drive

Logic status 1: 24 V +20% @1 mA; 14 V + 20% @20 mA

Logic status 0: <0.5 V

Option output: Direct/reverse programmable

The selection between relay or SSR is made by internal jumper.

Output 2 - Cooling or Alarm 1

Relay output with SPST contact; contact rating 1.5 A/250 VAC with resistive load. Select the NC or

NO contacts by internal jumper.

Logic voltages for SSR drive:

Logic status 1: 24 V ±20% @1 mA; 14 V ±20% mA

Logic status 0: <0.5V

The selection between relay or SSR is made by internal jumper.

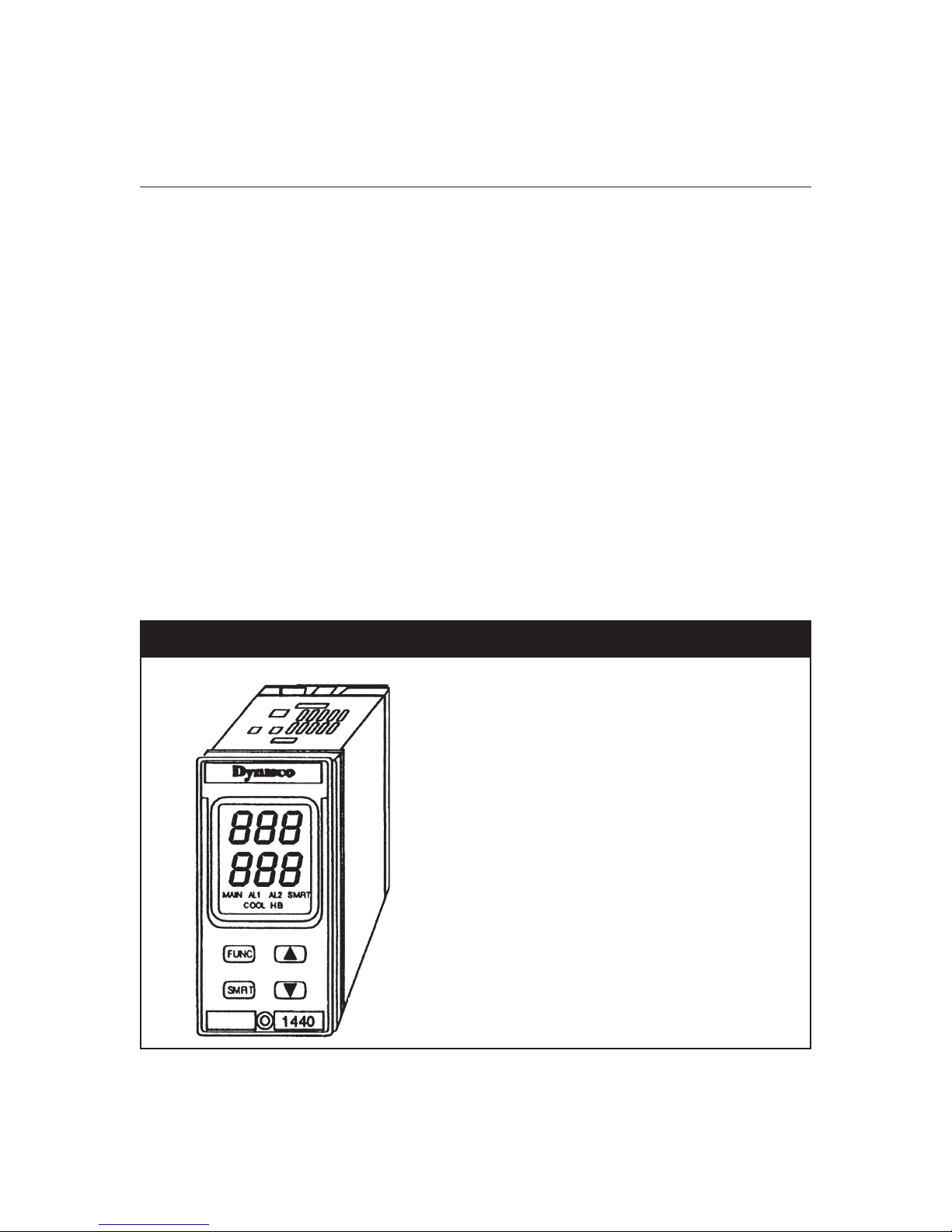

3. FRONT PANEL DESCRIPTION

Figure 1 illustrates the front panel of the Model 1440.

Fig. 1 1440 Temperature Controller Front Panel

Page 11

1440 Microprocessor-based Temperature Controller 11

3.1 INDICATOR DESCRIPTION

MAIN

Indicator

Indicator lit Main output is

AL1/COOL

Indicator

Indicator lit Cooling output is On or Alarm 1

AL2/HB

Indicator

Indicator lit Alarm 2 is in alarm condition

Indicator flashing Heater breakdown is in alarm condition

SMRT

Indicator

Indicator flashing First step of the SMART function is running

Indicator lit Second step of the SMART function is running

OFF

OFF

OFF

OFF

Main output is

OFF

On

Cooling output is

Alarm 2 and heater breakdown

SMART function is disabled

OFF

or Alarm 1

is not

in alarm condition

is in

alarm condition

are not

in alarm condition

3.2 DISPLAY DESCRIPTION

Upper Display

The upper display continuously shows the process variable in amperes. During the programming

procedure, this display shows the numerical value of the selected parameters or functions.

Lower Display

The lower display continuously shows the current set point value. Pressing the ▲ pushbutton for less

than 1.5 seconds causes the heater consumption in amperes to be shown. Pressing the ▲

pushbutton again causes the set point value to be re-shown. During configuration, calibration, and

parameter setup, the lower display will show the code of the selected parameter.

Page 12

12

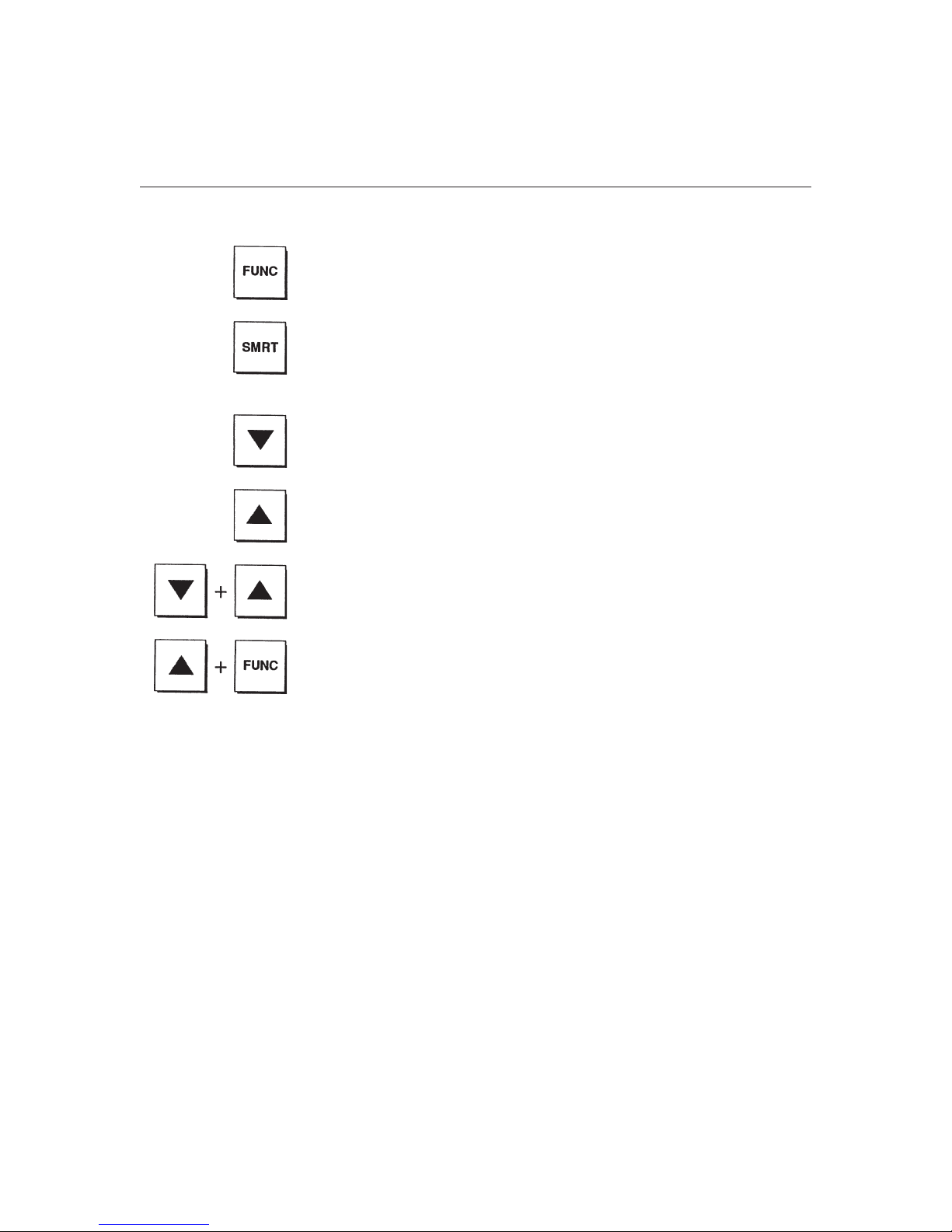

3.3 KEYBOARD DESCRIPTION

Selects the parameters. Pressing the FUNC pushbutton causes the

parameters to be shown sequentially on the upper and lower displays.

Simultaneously, the value of the previous parameter will be stored.

In operating mode, the SMRT pushbutton enables or disables the SMART

function. In configuration and calibration mode it is used to scroll the

configuration and calibration parameters backwards without storing the

modified value.

Decreases the parameter value. When the instrument is in operating mode,

it allows direct access to the set point modification.

Increases the parameter value. When the instrument is in operating mode,

it allows the display of the heater consumption or direct access to the set

point modification.

Loads the default control parameters.

Turns the control output

OFF

or On.

4. ALARMS

4.1 MAIN ALARMS

Two independent alarms are available, each of which can be configured in one of three modes, as

follows:

• Process alarm

• Band alarm

• Deviation high or deviation low

Action: Direct or Reverse Action

Threshold resolution: 1 digit

Alarm hysteresis: Programmable between 0.1% and 10.0% of the input span

Alarm indication: Two LEDs (Al1, Al2) lit for alarm ON

Alarm 1: See Outputs, page 18

Alarm 2: Relay output with SPST contact;

contract rating 2 A/250 VAC with resistive load

Page 13

1440 Microprocessor-based Temperature Controller 13

4.2 HEATER BREAKDOWN ALARM

This function uses a measurement (in amperes) of the main load consumption along with a user-set

alarm threshold to indicate either a partial or complete heater malfunction. This alarm output is

linked to Alarm 2 with a logical OR.

NOTE: This is supplied with the current transformer input option.

Threshold resolution: 1 digit

Alarm hysteresis: 1 digit

Alarm indication: LED Al2/HB flashes when alarm is On

Alarm output: See Alarm 2

5. MOUNTING

Select a mounting location where there is minimum vibration and the ambient temperature range is

between 0 and 50°C. The instrument can be mounted in a panel up to 15 mm thick with a

rectangular cutout of 45 x 92 mm. To mount the Model 1440, insert the instrument through the

panel cutout. While holding the instrument against the panel, slide bracket over case and tighten the

screws until the instrument is held tightly against the panel (see figure 2).

Fig. 2 Mounting the Model 1440

Page 14

14

5.1 OUTLINE DIMENSIONS

Figure 3 shows the outline dimensions of the Model 1440.

Fig. 3 Outline Dimensions

Page 15

1440 Microprocessor-based Temperature Controller 15

5.2 CUTOUT DIMENSIONS

Figure 4 shows the panel cutout dimensions of the Model 1440.

Fig. 4 Cutout Dimensions

5.3 VERTICAL PACKING

The minimum distance between cutouts is 20 mm.

Horizontal Packing for More Instruments in a Single Cutout

The total dimension of the cutout is the addition of the front dimensions minus 3 mm. The horizontal

dimension of the cutout equals (n x 48) - 3 mm, where n is the number if instruments to be packed

(maximum 10 instruments).

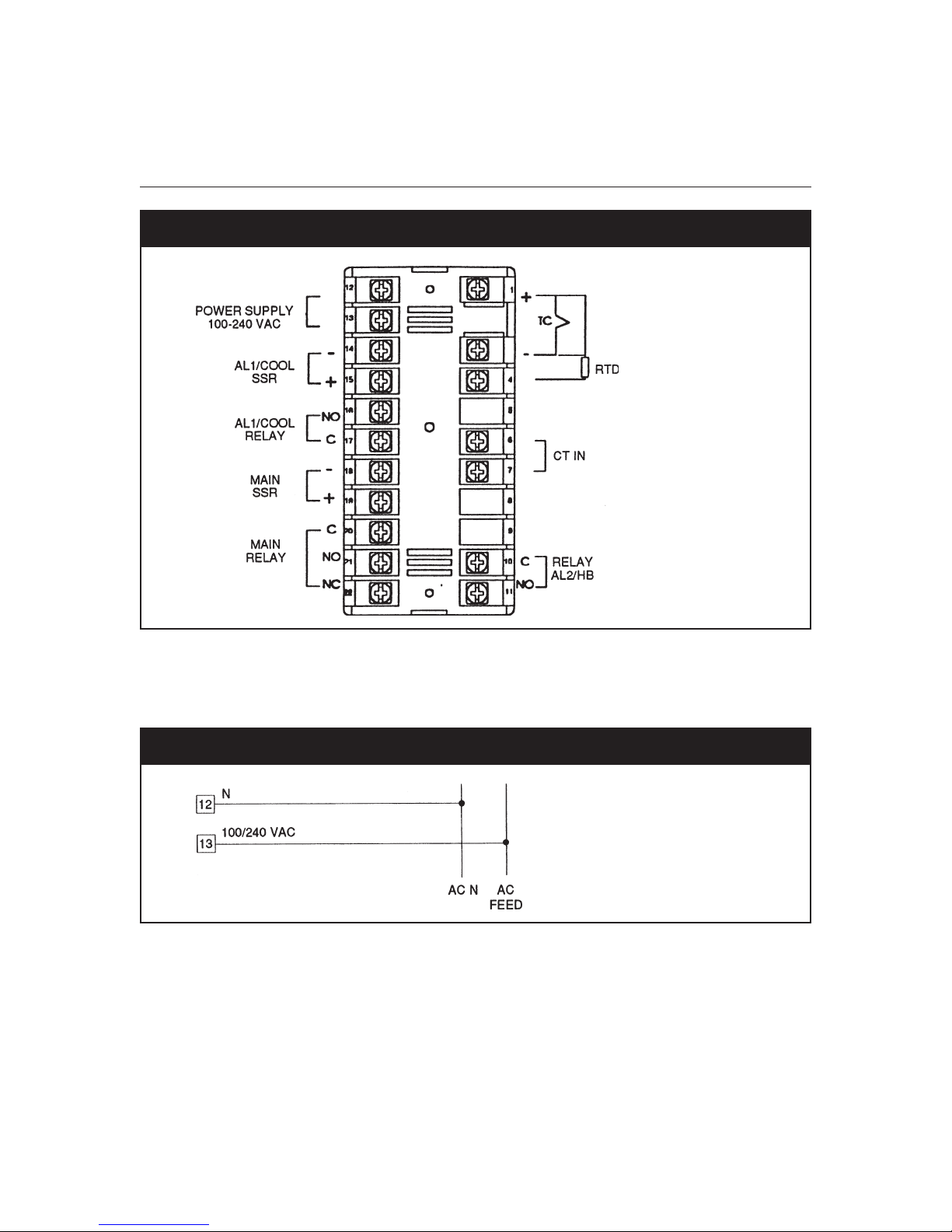

6. WIRING GUIDELINES

Connections should be made with the instrument housing installed in its proper location. Figure 5

illustrates the rear terminal block of the Model 1440.

Page 16

16

Fig. 5 Rear Terminal Block

6.1 POWER LINE AND EARTH WIRING

Figure 6 illustrates the power line wiring for the Model 1440.

Fig. 6 Power Line Wiring

6.2 INPUTS

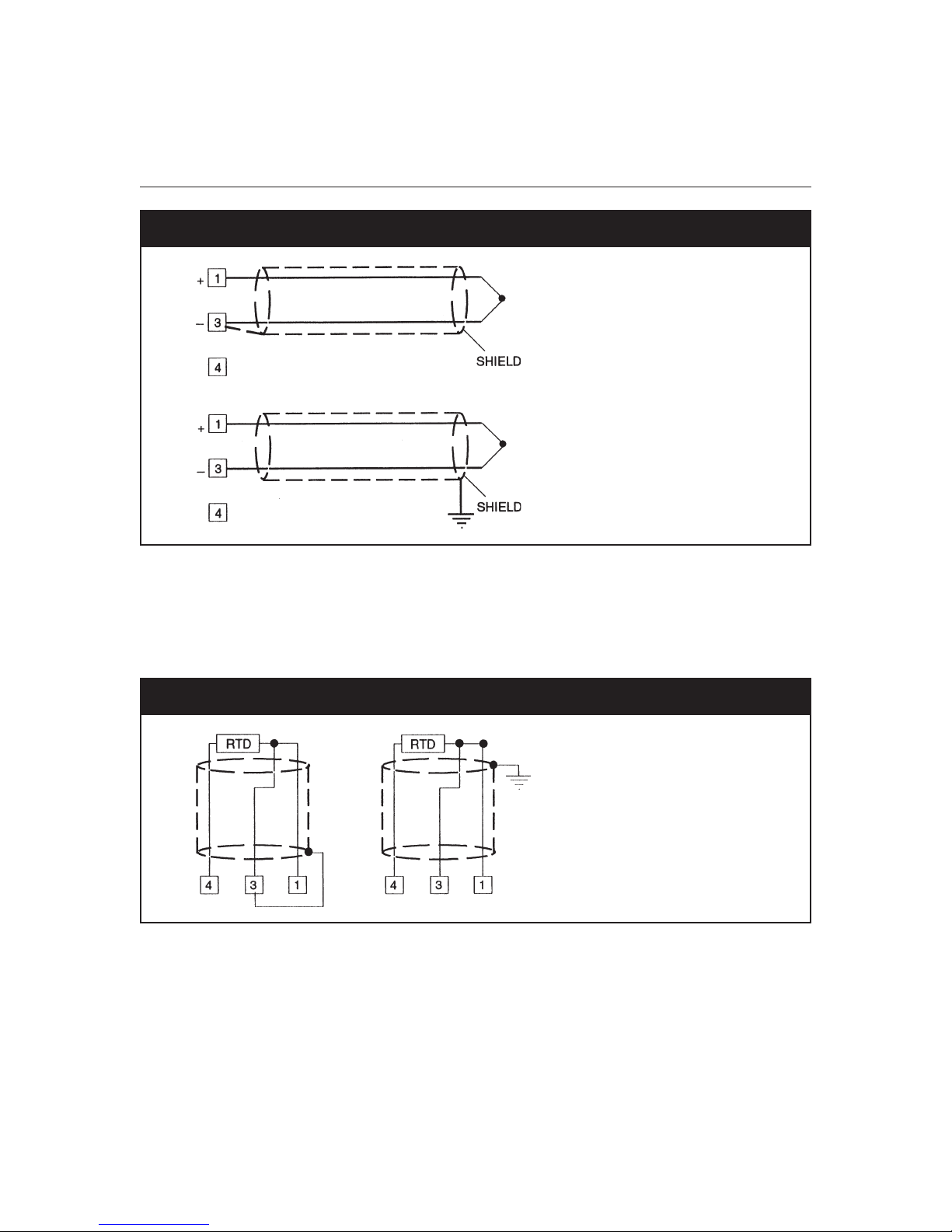

Figure 7 illustrates the thermocouple input wiring for the Model 1440.

Page 17

1440 Microprocessor-based Temperature Controller 17

Fig. 7 Thermocouple Input Wiring

NOTE: DO NOT run input wires together with power cables. For TC wiring, use proper

compensating cable, preferable shielded. If shielded cable is used, it should be grounded at

one point only.

Figure 8 illustrates the RTD input wiring for the Model 1440.

Fig. 8 RTD Input Wiring

NOTE: DO NOT run RTD wires together with power cables. If shielded cable is used, it should be

grounded at one point only. Use copper wires of appropriate size (see Product

Specifications). The resistance of the three wires must be the same

Any external components (e.g., zener barriers) connected between sensor and input terminals may

cause errors in measurement due to excessive and/or unbalanced line resistance or possible leakage

currents.

Page 18

18

Figure 9 illustrates the current transformer input wiring for the Model 1440.

Fig. 9 Current Transformer Input Wiring

6.3 OUTPUTS

Relay Outputs

Figure 10 illustrates the relay output wirings for the Model 1440

Fig. 10 Relay Output Wirings

The relay output is not protected with a snubber network.

Page 19

1440 Microprocessor-based Temperature Controller 19

Relay Output Contact Rating (Resistive Load)

1 3 A/250 VAC

2 1.5 A/250 VAC

3 2 A/250 VAC

Inductive Loads

NOTE: The following recommendations should be followed to avoid serious problems, which may

occur when using relay outputs for driving inductive loads.

When switching inductive loads, high voltage transients may occur. These transients may introduce

disturbances, which can affect the performance of the Model 1440 through the internal contact.

Whenever an inductive load is switched by instrument contacts, an external network should be

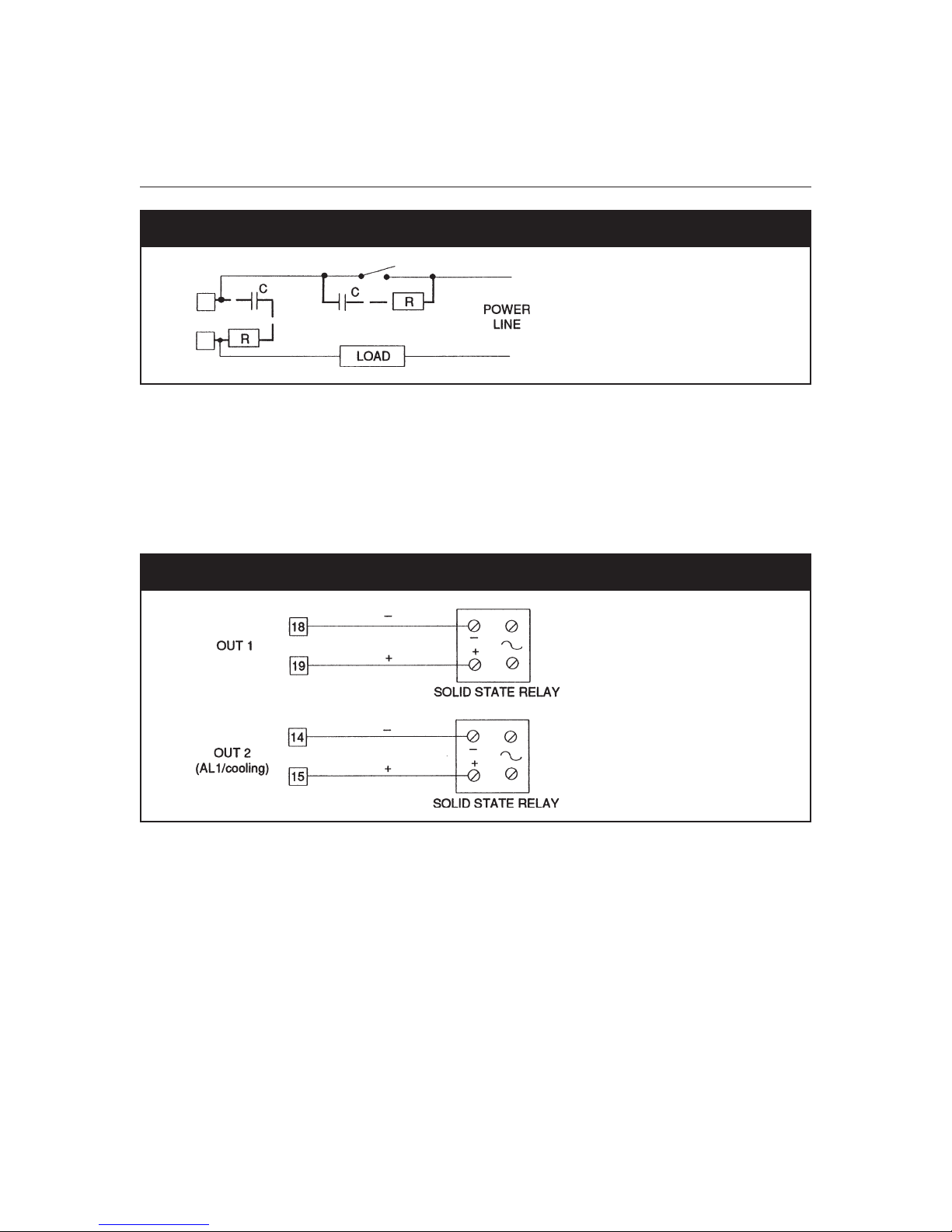

connected across the terminals as near as possible to the terminals (see Figure 11).

Fig. 11 External Protection for an Inductive Load

The values of capacitor [C] and resistor [R] are shown in the following table.

Load Current C (µF) R (Ω) Resistance Power (Ω) Resist. And Capac. Voltage

<40 mA 0.047 100 1/2 260

<150 mA 0.1 22 2 260

<0.5A 0.33 47 2 260

<1A 0.47 47 2 260

The same problem may occur when a switch is used in series with the internal contact, as shown in

Figure 12.

Page 20

20

Fig. 12 External Switch in Series with Internal Contacts

In this case, it is recommended that an additional RC network be installed across the external

contact as shown in Figure 12. The cable involved in relay output wiring must be as far away as

possible from input and communication cables.

6.4 VOLTAGE OUTPUTS FOR SSR DRIVE

Figure 13 illustrates the SSR drive output wiring for the Model 1440.

Fig. 13 SSR Drive Output Wiring

The voltage outputs for the SSR drive are time proportional outputs. Logic voltages for SSR drive:

Logic status 1: 24V ±20% @1 mA; 14 V ±20% @ 20 mA

Logic status 0: <0.5V

NOTE: These outputs are not isolated. Isolation between instrument outputs and power supply must

be ensured by the external solid-state relay. The relay output and SSR output are mutually

exclusive. To activate the SSR output, first deactivate the relay by setting dipswitches J304

and J305 as shown in Figure 15.

Page 21

1440 Microprocessor-based Temperature Controller 21

7. INSTRUMENT CONFIGURATION

7.1 PRELIMINARY

Before actual operation of the Model 1440 controller, an initial configuration of the unit is required.

Proceed as follows:

1. Remove the unit from its enclosure by removing the front panel captive screw and pulling the

unit from the case.

2. Locate the internal dipswitch, V2 (Figure 14), and set the switch to the open condition.

3. Re-install the controller into its case and follow the Configuration Procedure.

Fig. 14 Internal Dip Switch Location

In the process of configuring or reconfiguring the Model 1440, the jumper shown in Figure 15 may

have to be accessed.

Page 22

22

Fig. 15 Jumper Locations

7.2 CONFIGURATION PROCEDURE

Once the internal dip switch has been set as described in Figure 14, proceed as follows:

1. Switch the instrument On. The upper display should show

NOTE: If

2. Press the FUNC pushbutton to start the configuration procedure.

3. The lower display will show the parameter code (e.g., P1 - P2) and the upper display will show

4. To modify this value press ▲ or ▼ to obtain the desired setting.

5. When the upper display shows the new setting, press the FUNC pushbutton to store the value

CAL

is indicated in the display, press the ▲ pushbutton to return to the configuration

mode.

the previously stored value.

and go to the next parameter. (The values are stored only when the FUNC pushbutton is

depressed.)

CnF

.

Page 23

1440 Microprocessor-based Temperature Controller 23

The SMRT pushbutton can be used to scroll backwards through the configuration parameters

without affecting the previously modified value.

7.3 BASIC CONFIGURATION

The following is a list of the basic configuration parameters. Some of these parameters may be

skipped, depending on the previous setting.

P1 - Input type and standard range

0 = TC type L Range 0/+800°C

1 = TC type J Range 0/+800°C

2 = TC type K Range 0/+999°C

3 = TC type N Range 0/+999°C

4 = RTD type Pt100 Range -199/+500°C

5 = RTD type Pt100 Range -19.9/+99.9°C

8 = TC type L Range 0/+999°F

9 = TC type J Range 0/+999°F

10 = TC type K Range 0/+999°F

11 = TC type N Range 0/+999°F

12 = RTD type Pt100 Range -199/+999°F

P2 - Initial scale value

Not available when P1=5. The initial and full scale values are used by the PID algorithm to calculate

the input span.

P3 - Full scale value

Not available when P1=5. The initial and full scale values are used by the PID algorithm to calculate

the input span. The minimum input span (P3 - P2) is:

300°C or 600°F for TC input

100°C or 200°F for RTD input

P4 - Output configuration

H

= Heating only

HC

= Heating/cooling

P5 - Heating output type

rEL

= Relay

SSr

= SSR

Page 24

24

The setting P5 =

The setting P5 =

P6 - Cooling element

Available only when P4 = HC.

Air

= air

OIL

= Oil

H2O

= Water

The setting P6 =

The setting P6 =

The setting P6 =

0.4.

P7 - Alarm 1

Available only when P4 = H.

0

= Not provided

1

= Process Alarm

2

= Band alarm

3

= Deviation alarm

rEL

forces the cycle time parameter to 20 seconds.

SSr

forces the cycle time parameter to 2 seconds.

Air

forces the cooling cycle time to 10 seconds and the relative cooling gain to 1.

OIL

forces the cooling cycle time to 4 seconds and the relative cooling gain to 0.8.

H2O

forces the cooling cycle time to 2 seconds and the relative cooling gain to

Pages 24 through 28 graphically represent the relay actions for the process band and deviation

settings.

High alarm.

Direct Action.

Page 25

1440 Microprocessor-based Temperature Controller 25

Low alarm.

Direct action.

Band alarm with neutral zone off with respect to the set point.

Direct Action.

Threshold is expressed as Deviation.

(Measure - Set point = Deviation)

Page 26

26

Band alarm with neutral zone on with respect to the set point.

Direct action.

Threshold is expressed as Deviation.

(Measure - Set Point = Deviation)

Page 27

1440 Microprocessor-based Temperature Controller 27

High deviation alarm.

Direct Action

Threshold is expressed as Deviation.

(Measure - Set Point = Deviation)

Page 28

28

Low deviation alarm.

Direct Action.

Threshold is expressed as Deviation.

(Measure - Set Point = Deviation)

Reverse Action (P21 = r) works only on the relay status:

DIRECT ACTION

(P21 = d)

REVERSE ACTION

(P21 = r)

Indicator Relay Status

On

OFF

On

OFF

ENERGIZED

DE-ENERGIZED

DE-ENERGIZED (fail safe alarm)

ENERGIZED

Page 29

1440 Microprocessor-based Temperature Controller 29

P8 - Alarm 1 operating mode

Available only when P7 is different from 0 and P4 = H.

H

= High alarm (external for band alarm)

L

= Low alarm (internal for band alarm)

P9 - Alarm 1 standby

Available only when P7 is different from 0 and P4 = H.

OFF

= Standby disabled

On

= Standby enabled

This function allows the alarms to be put in standby condition at the instrument start up or to impose

a standby condition on the band alarms or deviation alarms after a set point modification.

In both situations, the instrument disables the alarm indication until the process variable is reached

for the first time, under the following conditions:

• For the process alarm and start up, only the process variable must reach the alarm threshold.

• For the band alarm, the process variable must reach the alarm band (or the new alarm band

generated by the new set point).

• For the deviation alarm, the process variable must reach the deviation area (or the new

deviation area generated by the new set point).

P10 - Alarm 2

0

= Not provided

1

= Process alarm

2

= Band alarm

3

= Deviation alarm

The relay output of Alarm 2 is also used as a relay output by the heater breakdown function (OR

condition).

P11 - Alarm 2 operating mode

Available only when P10 is different from 0.

H

= High alarm (external for band alarm)

L

= Low alarm (internal for band alarm)

For other details, see Alarm 1 examples.

Page 30

30

P12 - Alarm 2 standby

Available only when P10 is different from 0.

OFF

= Standby disabled

On

= Standby enabled

P13 - Type of offset applied on the measured value

When P13 = 0, the offset (P14) is constant over the entire range. When P13 is different from 0, P13

shows the application point of the offset value set by parameter P14. When P14 is set to 0, there is

no offset.

P14 - Offset value

When P13 = 0, P14 is programmable in engineering units from -20% to +20% of the input range.

= no offset. When P13 is different from 0, P14 is programmable from -20% to +20% of the value of

P13. Refer to Figure 16.

0

Fig. 16 Offset Values

P15 - Threshold of the Soft Start Function

Threshold value, in amperes, for the automatic start of the output power limiting Soft Start function.

At instrument start up, if the measured value is lower than the threshold value, the Soft Start function

will be enabled; otherwise it will be disabled. The instrument will not take into account this

parameter when the

is always enabled.

P16 - Current measurement

LOL

parameter (see Control Parameters) is set to infinity and the power limiting

OFF

= Current measurement disabled

= The current measurement will be made during the On period (logic status 1 for SSR or

relay energized for relay output)

= The current measurement will be made during the

relay de-energized for relay output.

OFF

period (logic status 0 for SSR or

Page 31

1440 Microprocessor-based Temperature Controller 31

P17 - Current transformer range

Available only if P16 is different from

10

= 10A

25

= 25A

50

= 50A

100

= 100A

P18 - Safety lock

0 = Safety lock disabled (all the parameters can be modified)

1 = Safety lock always enabled (only parameter SP may be modified)

2 to 499 = Parameter SP is always modifiable and this code is the safety key used to access the

other operating parameters’ modification

500 to 999 = Parameters SP, A1 and A1 are always modifiable and this code is the safety key used

to access the other operating parameters’ modification

When the standard configuration procedure is completed, the instrument shows on both displays. If

no other settings are required, press the FUNC pushbutton. The instrument returns to the beginning

of the configuration procedure. This ends the basic configuration procedure. If a complete

configuration is desired, press the ▲ or ▼ pushbutton and set the 217 code on the upper display.

NOTE: Setting the 217 code must be performed in order to perform an Advanced Configuration.

OFF

.

7.4 ADVANCED CONFIGURATION

Press the FUNC pushbutton. The instrument will go to the advanced configuration procedure and it

will show the following additional parameters:

P19 - Main output action (see Figure 17 on next page)

Available only when P4 = H.

r

= Reverse (heating)

d

= Direct (cooling)

When P4 = HC, this parameter is forced to r.

Page 32

32

Fig. 17 Actions of the Alarm Relays

P21 - Action of the Alarm 1 relay (see Figure 17)

This parameter is available only if P7 is different from 0 and P4 = H.

r

= Reverse (relay de-energized in alarm condition)

d

= Direct (relay energized in alarm condition)

P22 - Action of the Alarm 2 relay (see Figure 17)

This parameter is available only if P10 is different from 0 and P16 is different from

r

= Reverse (relay de-energized in alarm condition)

d

= Direct (relay energized in alarm condition)

P23 - Automatic modification of relative cooling gain

OFF

= The SMART function will not modify the relative cooling gain parameter

On

= The SMART function will modify the relative cooling gain parameter

P24 - Output maximum rate of change

This parameter allows the maximum rate of change of the power output to be set. P24 is

programmable from 1 to 10% of the control output. If set over 10%, the instrument blanks the upper

display and the output variations have no limit.

OFF

.

Page 33

1440 Microprocessor-based Temperature Controller 33

P25 - Protect parameter visualization

This parameter is available only if P18 is different from 0.

OFF

= All the protected parameters cannot be displayed

On

= The parameter values can be displayed

P26 - SMART enabled/disabled

0

= The SMART function is always disabled (manual PID adjustment)

1

= The SMART function enabling/disabling

2

= The SMART function enabling/disabling is protected by the safety key

P27 - Maximum value of the proportional band set by the SMART function

is not

protected by the safety key

This parameter may be programmed over the range of the P28 or P29 value to

P28 - Minimum value of the proportional band set by the SMART function in heating control only

This parameter may be programmed from 1.0% to the P27 value

P29 - Minimum value of the proportional band set by the SMART function in heating/cooling only

This parameter may be programmed from 1.5% to the P27 value.

The advanced configuration procedure is now complete and the instrument should show

upper display.

99.9

.

CnF

on the

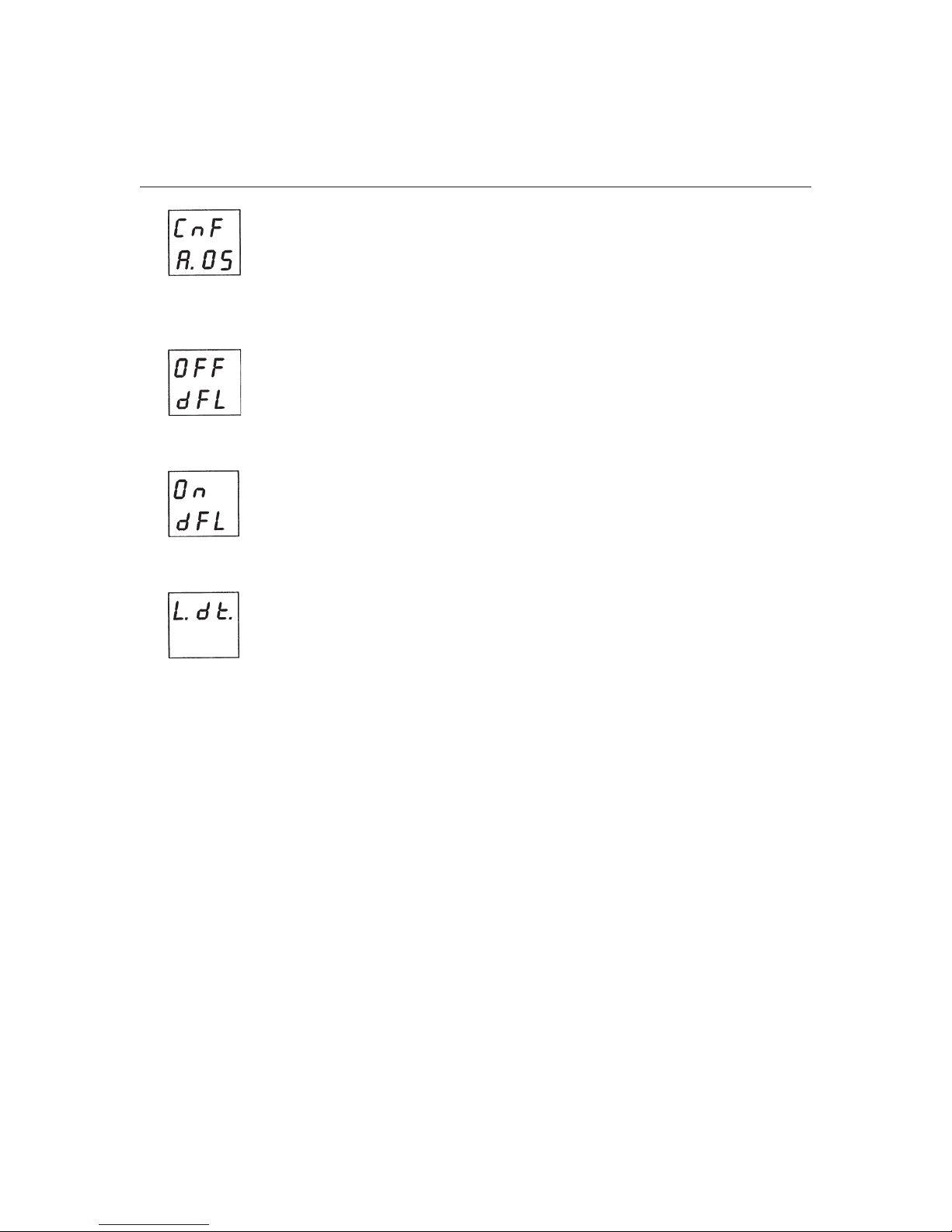

7.5 DEFAULT CONFIGURATION PARAMETERS

The configuration parameters can be loaded with predetermined default values. These data are the

typical values loaded in the instrument prior to shipment from the factory. To load the default values,

proceed as follows:

1. The internal dip switch, V2, (see figure 14) should be open.

2. The upper display will show:

3. Press the ▼ pushbutton; the lower display will show the firmware version:

Page 34

34

4. While maintaining pressure on the ▼ pushbutton, press the ▲ pushbutton. The display will

show:

5. Press the ▲ pushbutton again; the display will show:

6. Press the FUNC pushbutton; the display will show:

Appearance of the previous display means that the loading procedure has been initiated. After about

3 seconds the loading procedure is terminated and the instrument reverts to the display shown in

step 2 (above).

Page 35

1440 Microprocessor-based Temperature Controller 35

The following are the default parameters loaded during the above procedure:

Parameter Value Default Value

P1

P2

P3

P4

P5

P6

P7

P8

P9

P10

P11

P12

P13

P14

P15

P16

P17

P18

P19

P21

P22

P23

P24

P25

P26

P27

P28

P29

1

0

400

H

rEL

Air

1

H

OFF

0

H

OFF

0

0

0

OFF

10

0

r

d

d

OFF

10

On

2

30.0

1.0

1.5

J-type thermocouple with °C indication

0°C

400°C

Heating

Relay

Air

Process alarm

High alarm

Standby disabled

Not provided

High alarm

Standby disabled

Constant offset

No offset

Soft Start threshold

Current measurement disabled

10A

Safety lock disabled

Main output with Reverse Action

Direct Action of the alarm 1 relay

Direct Action of the Alarm 2 relay

Relative cooling gain will not be modified by the SMART function

Power output rate of change is 10% per second

All the parameters are displayed

SMART function enabling/disabling is protected by the safety key

30%

1.0%

1.5%

8. OPERATING INSTRUCTIONS

NOTE: To operate this unit as a controller, the internal dip switch, V2, located on the input card

(see figure 14) must be closed.

Page 36

36

It is assumed at this point that the Model 1440 has been correctly configured as detailed in

Instrument Configuration. In most applications as a controller, the Model 1440 will operate in the

normal display mode, where the upper display shows the measured variable and the lower display

shows the set point. If selected by the ▲ pushbutton, the lower display will show the heater current

amperes.

By pressing the FUNC pushbutton it is possible to scroll through all the parameters; their

abbreviated names will be shown on the lower display while their value is shown on the upper

display. To modify a parameter, first select the desired parameter with the FUNC pushbutton, then

set the new value with the ▲ or ▼ pushbuttons. Press the FUNC pushbutton to record the new

value and proceed to the next parameter.

The access time for parameter scrolling is limited to 10 seconds. Therefore, if no pushbutton is

pressed within this time, the instrument will automatically revert to the normal display mode.

The instrument does not always display all parameters. It selects the parameter in accordance with

the following:

• Instrument configuration in general (see Instrument Configuration)

• Parameter P25 in particular (see Configuration Procedure)

• The setting of the proportional band (see Control Parameters)

8.1 CONTROL PARAMETERS

The following is a list of all the available control parameters. Note that some parameters may not be

visualized according to the specific instrument configuration.

SP

- Set Point

Lower display:

Upper display: Set point value

Range: From parameter rL value to parameter rH value

nnn

- Safety Lock

Lower display:

Upper display:

To enable the safety lock, set a value different from P18 (see Parameters List) and press the FUNC

pushbutton. To disable the safety lock, set a value equal to P18 and then press the FUNC

pushbutton.

SP

nnn

On

(safety lock is enabled)

OFF

(safety lock is disabled)

Page 37

1440 Microprocessor-based Temperature Controller 37

A1, A2

- AlarmsThreshold

These parameters are present only if the relative alarm is configures.

Lower display:

Upper display: Alarm threshold value

Process alarm range: From P2 to P3 value

Band alarm range: 0 to 500 (F/C

Deviation alarm range: -199 to 500(F/C

h1, h2

- Alarms Hysteresis

Lower display:

Upper display: Value of alarm 1 or Alarm 2 hysteresis

Range: 0.1% (minimum 1 digit) to 10.0% of the

The instrument will use a hysteresis equal to the band alarm by setting a band alarm out of band

indication and an alarm hysteresis larger than the band alarm (minus 1 digit).

Pb

- Proportional band

Lower display:

Upper display: Value of proportional bank

Range: 1.0 to 99.9% of span for heating output;

When parameter Pb is set to 0, the control action becomes ON/OFF and parameters

OLP, Olh

and

tOL

A1, A2

h1, h2

input span (P3 - P2)

Pb

1.5 to 99.9% of span for heating/cooling output

t, td, C, C2, rC,

are skipped.

HS

- Hysteresis

This parameter is present if parameter Pb is equal to 0.

Lower display:

Upper display: Hysteresis for ON/OFF control action

Range: 0.1 to 10.0% of input span (P3 - P2)

ti

- Integral time

This parameter is present only if parameter Pb is different from 0.

Lower display:

Upper display: Integral time defined in minutes and seconds

Range: 1 minute and 20 seconds to 20 minutes; above the upper value, the display

HS

ti

Page 38

38

blanks out and the integral action is disabled.

Resolution: 10 seconds

td

- Differential time

This parameter is present only if parameter Pb is different from 0.

Lower display:

Upper display: Cycle time value for output 1

Range: 1 to 200 seconds

C2

- Output 1 (cooling) cycle time

This parameter is present only if P4 = HC and parameter Pb is different from 0.

Lower display:

Upper display: Cycle time value for output 2

Range: 1 to 200 seconds

rC

- Relative output 2 (cooling gain)

This parameter is present only if P4 = HC and parameter Pb is different from 0.

Lower display:

Upper display: Gain in proportional cooling band

Range: 0.20 to 1.00

C

C2

rC

Fig. 18 Gain in the Proportional Cooling Band

OLP

- Overlap/dead band between heating and cooling outputs

This parameter is present only if P4 = HC and parameter Pb is different from 0.

Page 39

1440 Microprocessor-based Temperature Controller 39

Lower display:

Upper display: A positive value means overlap between heating and cooling outputs;

Range: -20 to 50% of the proportional band

See Figure 19 on the next page.

OLP

A negative value means dead band between the two outputs

Fig. 19 Overlap/Dead Band Between Heating and Cooling Outputs

rL

- Set point low limit

Lower display:

Upper display: Value of set point low limit

Range: From the initial scale value (P2) to rH value

rH

- Set point high limit

Lower display:

Upper display: Value of set point high limit

Range: From rL value to the full scale value (P3)

rP

- Rate of change for set point variations

Lower display:

Upper display: Value of the rate of change imposed to set point variations

Range: 1 to 100 units per minute; above the maximum value, the display blanks so

rL

rH

rP

that the transfer is a step transfer

Page 40

40

OLH

- Control limit high limiter

This parameter is present only if parameter Pb is different from 0.

Lower display:

Upper display: Value of control output maximum limit

Range: 0 to 100% for heating output: -100 to 100% for heating/cooling output

t0L

- Time for Soft Start enabling

t0L

is a programmable time where the output level is limited to the value of parameter

time counts begin at instrument start up if the measured variable is less than the threshold value

programmed (parameter P15). This parameter is present only if parameter Pb is different from 0.

Lower display:

Upper display: Value of control output limiter time duration

Range: 1 to 100 minutes; above 100 minutes, the upper display blanks out and the

NOTE: Parameter

up.

Hdb

- Threshold for the heater breakdown function

This parameter is present only if parameter P16 is different from

Lower display:

Upper display: Value in amperes of the heater breakdown threshold

Range: Within the current transformer input span

OLH

0LH

. These

t0L

limiter will be enabled.

t0L

may always be modified but the new value will be active only at the next start

OFF

.

Hdb

8.2 DEFAULT CONTROL PARAMETERS

The control parameters can be loaded with predetermined default values. These data are the typical

values loaded in the instrument prior to shipment from the factory. To load the default values,

proceed as follows:

1. Close the internal dip switch (V2, Figure 14).

2. Disable the SMART function. The upper display will show the process variable while the lower

display will show the set point value or the current measurement.

3. Hold down the ▼ pushbutton and press the ▲ pushbutton; the display will show:

Page 41

1440 Microprocessor-based Temperature Controller 41

4. Within 10 seconds press the ▲ or ▼ pushbutton; the display will show:

5. Press the FUNC pushbutton; the display will show:

This means that the loading procedure has been initiated. After about 3 seconds, the loading

procedure is terminated and the instrument reverts to normal display mode.

The following is a list of the default parameters loaded during the above procedure.

Parameter Default Value

SP

Minimum range-value

nnn OFF

A1, A2

h1, h2

Pb

h5

ti

td

C

C2

rC

DLP

rL

rH

rP

OLH

tOL

Hbd

Minimum range-value for process alarms; 0 for deviation or band alarms

0.1%

4.0%

0.5%

04.0 (4 minutes)

1.00 (1 minute)

20 seconds for relay output; 2 seconds for SSR output

10 seconds if P6=

1.00 if P6=

0

Initial scale value

Full scale value

Blank display (step transfer)

100%

Blank display

50% of the full scale value

Air

Air

; 0.80 if P6=

; 4 seconds if P6=

OIL

; 0.40 if P6=

OIL

; 2 seconds if P6=

H20

H20

Page 42

42

8.3 SMART ALGORITHM

The SMART algorithm is a new self-tuning function of the instrument. It is used by the instrument to

automatically calculate and set the proportional band, the reset time, the derivative time and the

relative cooling gain values. The SMART algorithm can always be operative; in this case it will adapt

the control parameters continuously in order to perform the best control action.

To start the SMART function, depress the SMRT pushbutton when the instrument is in normal

display mode. The SMRT indicator will go blank or light according to the special function that is

being performed. When it is desired to use a fixed set of control parameters, press the SMRT

pushbutton again; the SMRT indicator will turn off.

During SMART function operation, the relative cooling gain (if present) is limited to the following

ranges:

Cooling Element Range

Air 0.85 to 1.00

Water 0.80 to 0.90

Oil 0.30 to 0.60

The SMART function uses a derivative action equal to 1/4 of the integral action.

The limits of the proportional band set by the SMART function are programmed by parameters P27,

P28 and P29.

8.4 OUTPUT POWER

This feature allows the Model 1440 control to be temporarily turned

output, depress the ▲ pushbutton, and while keeping it depressed press the function button. Keep

them depressed for more than 3 seconds. The upper display will show the measured value while the

lower display will show

When it is desired to return to the normal display mode, depress the ▲ pushbutton, and while

keeping it depressed, press the FUNC pushbutton. Keep them depressed for more than 3 seconds.

The instrument then goes automatically to the normal display mode.

NOTE: If the output is turned

algorithm (the SMRT indicator is flashing), the

instrument comes back to normal display mode, the

If the output is turned

algorithm (the SMRT indicator is lit), the

instrument comes back to the normal display mode, the

OFF

OFF

.

OFF

OFF

while the

while the

SMART

SMART

SMART

OFF

. To turn

function is performing the first part of the

SMART

function is performing the adaptive part of the

function will be aborted. When the

SMART

function will be stopped. When the

function will be disabled.

SMART

function will be activated.

OFF

the control

Page 43

1440 Microprocessor-based Temperature Controller 43

8.5 HEATER BREAKDOWN ALARM (OPTION)

This alarm allows continuous monitoring of the main load consumption and generation of an alarm

condition when the main load consumption is outside (either lower or higher than) the programmed

threshold. See parameter

pushbutton when the instrument is in normal display mode. The upper display will show the

measured value while the lower display will show the main load consumption (in amperes) followed

by the engineering units (A). To return to the normal display mode, press the ▲ pushbutton. When

an alarm condition is detected, the AL2/HB indicator will be flashing and the relay of the output 3

(Alarm 2 or heater breakdown alarm) will be activated.

Hbd

. To display the main load consumption, momentarily press the ▲

8.6 DIRECT ACCESS TO THE SET POINT MODIFICATION

The instrument allows modification of the set point value without the use of the FUNC pushbutton.

When a rapid set point modification is required, proceed as follows:

1. Press and hold the ▲ or ▼ pushbutton for more than 5 seconds; the set point value, shown on

the lower display will start to change.

2. Using the ▲ and ▼ pushbuttons, set the desired value.

3. When the desired value is reached, do not depress any pushbutton for more than 3 seconds; the

new set point will become operative after 3 seconds from the last pushbutton depression.

If during this procedure, it is desired to return to the previous set point value, press the FUNC

pushbutton; the instrument returns automatically to the normal display mode without storing the

new set point.

8.7 GENERAL GUIDELINES FOR CALIBRATION

CAUTION: The Model 1440 is calibrated at the factory. Calibrating in the field is not normally

required. If calibration is required, return the unit to the factory for calibration or adhere to these

calibration steps using only the equipment designated.

For a good calibration, observe these precautions:

• The instrument under calibration should be mounted in its case in order to keep the internal

temperature constant.

• The ambient temperature should be stable. Avoid any drift (e.g., due to air conditioning).

• The relative humidity should not exceed 70%.

• Minimum warm-up time must be 20 minutes.

• Operate in a noise-free environment, if possible.

• During calibration, connect one input at a time to the rear terminal block.

For this calibration procedure it is necessary to use calibrators with the following accuracy and

Page 44

44

resolution:

Accuracy

• TC input: +0.005%; output +0.001%; range: +5 mV

• RTD input: ±0.02%; ±0.0025 Ω/decade

• Cold junction compensation: better than 0.1°C

• Current transformer input: 0.1 mA AC RMS

Resolution

• TC input: 1 mV

• RTD input: 10 mΩ

• Cold junction compensation: better than 0.1°C

• Current transformer input: 0.1 mA AC RMS

8.8 INTERNAL DIP SWITCH LOCATION

To start the calibration procedure, the internal dipswitch, V2, must be open as shown in Figure 20.

Fig. 20 Internal Dip Switch Location

Page 45

1440 Microprocessor-based Temperature Controller 45

8.9 CALIBRATION PROCEDURE

8.9.1 FOREWORD

Calibration parameters are logically divided into groups of two parameters each:

Initial and final scale value. After each group, the calibration check is called for, but it also possible

to proceed without making a new calibration.

When only a calibration check is required, press the FUNC pushbutton twice when

on the display. The instrument will go directly to the specific group check. The lower display will

show the parameter code while the upper display will show On or

pushbuttons to select between On and

To go to the next parameter without modifying the calibration, press the FUNC pushbutton when

the display is showing

To set the parameter for calibration, press the FUNC pushbutton when the display shows On.

NOTE: By pressing the SMRT pushbutton, it is possible to go back to the previous parameter

without storing the new calibration.

OFF

.

OFF

.

OFF

. Use the ▲ and ▼

OFF

is shown

8.9.2 CALIBRATION CODES

The Model 1440 is originally calibrated by means of calibrators with high accuracy and resolution

(see General Guidelines for Calibration). The following is a complete list of calibration codes:

Code Parameter

tL

tH

t

rj

rj.

PL

PH

P.

AL

AH

A.

TC input initial scale value (0 mV)

TC input full scale value (50 mV)

TC input check

Cold junction compensation

Cold junction compensation check

RTD input initial scale value (0 Ω)

RTD input full-scale value (300 Ω)

RTD input check

Current transformer input initial scale value (0 mA AC)

Current transformer input full-scale value (50 mA AC)

Current transformer input check

8.9.3 HOW TO PROCEED

1. Switch the instrument On. The upper display will show

CnF

.

Page 46

46

2. Press the ▲ pushbutton. The upper display will show

3. Press the FUNC pushbutton to show the first calibration code on the lower display. Depress the

FUNC pushbutton until the desired calibration code is reached.

tL

- TC input initial scale value

1. Provide connections between the RTD/thermocouple calibrator and the instrument under test as

shown in Figure 21.

2. The upper display will show

3. Set calibrator to 0.000 mV. Press the ▲ pushbutton; the display will change to

4. After a few seconds, start the calibration by pressing the FUNC pushbutton.

The display blanks out to indicate that it is performing the calibration routine. At the end of this

calibration routine, the instrument will go to the next parameter.

OFF

, while tL will appear on the lower display.

CAL

.

On

.

Fig. 21 Connections from a Calibrator to an Instrument Under Test

tH

- TC input full scale value

1. Set the calibrator to 50.000 mV (see Figure 21).

2. Press the ▲ pushbutton; the upper display will show

3. After a few seconds, start calibration by pressing the FUNC pushbutton.

The display blanks out to indicate that it performing the calibration routine. At the end of the

calibration routine, the instrument will go to the next parameter.

t.

- TC input check

The display will show t. followed by a number showing the measured value in counts.

On

.

Page 47

1440 Microprocessor-based Temperature Controller 47

The calibration is correct if the indication is

1. Check the zero calibration by setting the calibrator to 0.000 mV. The readout must be

± 10 counts.

2. Check linearity at half scale by setting the proper value on the calibrator. The readout must be

t.15 000

3. Press the FUNC pushbutton.

rJ

- Cold junction compensation

NOTE: Make sure that parameters tL and tH are correctly calibrated before rJ calibration.

1. Measure the temperature close to terminals 1 and 3 using an appropriate measuring device (see

figure 22).

2. Wait a few minutes to allow temperature stabilization of the entire system (compensation cable,

sensor, calibrator and instrument).

3. Using the ▲ or ▼ pushbuttons, set a value equal to the temperature as measured in tenths of °C.

4. After a few seconds, start calibration by pressing FUNC pushbutton.

The display blanks out to indicate that it performing the calibration routine. At the end of this

calibration routine, the instrument will go to the next parameter.

± 10 counts.

OFF

t. 30 000

and rJ will appear on the displays.

± 10 counts.

t. 0 0 000

Fig. 22 Measuring the Temperature Close to Terminals 1 and 3

rJ

- Cold junction compensation check

The display will show

Make sure that the display readout is equal to the value read on the thermocouple. Press the FUNC

pushbutton, the instrument will go to the next parameter.

PL

- RTD input initial scale value

1. Connect a resistor box as shown in Figure 23.

rJ

. And the temperature in tenths of °C, measured by the

CJ

compensator.

Page 48

48

2. Set 0.00 Ω on the resistor box.

3. Press the ▲ pushbutton. The instrument will show

4. After a few seconds, start calibration by pressing the FUNC pushbutton.

The display blanks out to indicate that it is performing the calibration routine. At the end of this

calibration routine, the instrument will go to the next parameter.

On

and PL.

Fig. 23 Connections to a Resistor Box

PH

- RTD input full scale value

1. Set the resistor box to 300.00 Ω (see Figure 23).

2. Press the ▲ pushbutton. The displays will show

On

and PH.

3. Wait a few seconds, then press the FUNC pushbutton.

The display will go blank to indicate that it is performing the calibration routine. At the end of this

calibration routine, the instrument will go to the next parameter.

P.

- RTD input check

1. The display will show P. followed by a number showing the measured value in counts. Set the

resistor box to 300.00 Ω (see Figure 23). The calibration is correct if the indication is

±10 counts.

2. Check the zero calibration by setting 0.00 Ω on the resistor box; the display should show

000

±10 counts.

3. Check linearity.

The ratio between input signal and counts for RTD input is not linear. The correct ratio is shown in

the following table:

P. 30 000

Pt.00

Page 49

1440 Microprocessor-based Temperature Controller 49

Resistor Box Ω Display Counts

00 ±10 counts

100 10153 ±10 counts

200 20151 ±10 counts

300 30000 ±10 counts

5. Press the FUNC pushbutton to proceed to the next parameter.

AL

- Current transformer input initial scale value

1. Connect the instrument to a 0-5- mA AC source as shown in Figure 24.

Fig. 24 Connections from a Calibrator to an Instrument Under Test

2. The display will show AL and

3. Set 0.00 mA on the mA AC generator.

4. Depress the ▲ pushbutton until the display changes to

5. After a few seconds, start calibration by pressing the FUNC pushbutton.

The display will go blank to indicate that it is performing the calibration routine. At the end of this

calibration routine, the instrument will go to the next parameter.

AH

- Current transformer input full scale value

1. The display shows AH and

2. Set 50.00 mA RMS on the mA AC generator.

3. Press the ▲ pushbutton until the display changes to

4. After a few seconds, start calibration by pressing the FUNC pushbutton.

OFF

OFF

.

.

On

.

On

.

Page 50

50

The display will go blank to indicate that it is performing the calibration routine. At the end of this

calibration routine, the instrument will go to the next parameter.

A.

- Current transformer input check

1. The display should show A.. followed by a number of counts. The calibration is correct if the

indication is

2. Check the zero calibration by setting 0.00 mA on the mA AC generator; the readout should be

A. 0 000

A. 1000

±10 counts.

± 10 counts.

3. Check linearity at half scale by setting 25.00 mA on the calibrator. The readout must be

10 counts.

4. Press the FUNC pushbutton.

The calibration procedure is now complete.

If it desired to go to the configuration procedure, press the ▲ pushbutton. The upper display will

show

CnF

and the instrument will be in configuration mode. If the previous configuration is correct,

switch the instrument

Instructions.

OFF

and set the V2 switch according to the Preliminary Operating

A. 500

8.10 OUT OF RANGE INDICATIONS

The instrument shows Under Range and Over Range conditions with the following messages on the

upper display:

Burn-out conditions will be shown as Over Range.

±

For TC input it is possible to select an Under Range indication. See Open Input Circuit for more

information.

NOTE: When an Over Range or an Under Range condition is detected, the instrument operates as

if in the presence of the maximum or the minimum measurable value, respectively.

To eliminate the Out of Range condition, proceed as follows:

1. Check the input signal source and the connecting line.

Page 51

1440 Microprocessor-based Temperature Controller 51

2. Make sure that the input signal is in accordance with instrument configuration. Otherwise,

modify the input configuration (see Instrument Configuration).

3. If no errors are detected, send the instrument back to the supplier for examination.

8.11 OPEN INPUT CIRCUIT

The Model 1440 is able to identify an open circuit for TC and RTD inputs. The open input circuit

condition for RTD input is shown by an Over Range indication.

For TC input, it is possible to select an Over Range indication (standard) by setting CH2 closed and

SH2 open; otherwise it is possible to select the Under Range indication by setting CH2 open and

SH2 closed. Both solder pads are located on the solder side of the CPU board (Figure 25).

Fig. 25 CH2 and SH2 Locations

9. ERROR CODES

Diagnostics are made at instrument start up and during the normal mode of operation. If a fault

condition (error) is detected, the lower display will show the message

Err

while the upper display

Page 52

52

shows the relative error code. Some errors reset the instrument; if the error persists, send the

instrument back to the supplier.

The following is a list of possible errors, their causes, instrument output conditions and possible

remedies, in numerical order.

Err 100

- EEPROM memory writing error.

After 2 seconds the instrument restarts automatically.

Send the instrument back to the supplier.

Err 150

- General hardware error on the CPU card.

Send the instrument back to the supplier.

Err 200

- Protect register memory error.

The instrument repeats this check every 2 seconds.

Set the V2 switch in open condition.

Switch on the instrument.

Set the V2 switch in closed condition; this error must be deleted.

If this error persists, send the instrument back to the supplier.

From

Err 201 to Err 229

- Wrong configuration parameter value.

The two less significant digits show the number of the wrong configuration parameter.

Return to the configuration procedure and check the values.

Err 301

- RTD calibration error.

Return to the calibration procedure and check the PL and PH calibrations.

Err 305

- Thermocouple input calibration error.

Return to the calibration procedure and check the tl and th calibrations.

Err 307

- Reference junction calibration error.

Return to the calibration procedure and check the rJ calibration.

Err 310

- Current transformer input calibration error.

Return to the calibration procedure and check the AL and AH calibrations.

Err 400

- One or more control parameters are Out of Range with respect to the allow values.

This error may appear at instrument start up.

Press the ▲ and ▼ pushbuttons momentarily and load all the default parameters.

Reset the parameter settings.

Err 500

- Autozero error.

The instrument measures an internal autozero value too negative or too positive.

The instrument makes this check every 30 seconds.

If this error persists, send the instrument back to the supplier.

Page 53

1440 Microprocessor-based Temperature Controller 53

Err 502

The instrument cannot make the cold junction compensation.

This error may appear during the operative mode.

Check the ambient temperature and, if necessary, recalibrate the unit.

If this error persists, send the instrument back to the supplier.

Err 510

This error may appear during the calibration procedure.

Check the input value and, if necessary, recalibrate the unit.

If this error persists, send the instrument back to the supplier.

- Cold junction measurement errors.

- Wrong measured value during the calibration procedure.

10. REPAIR

Questions concerning warranty, repair cost, delivery, and requests for a RA# should be directed to

the Dynisco Repair Department, 508-541-9400 or email: repair@dynisco.com. Please call for a

return authorization number (RA#) before returning any product. Damaged products should be

returned to:

DYNISCO INSTRUMENTS

Attn: RA # _______________

38 Forge Parkway

Franklin, MA 02038

For technical assistance please call 800-221-2201 or 508-541-9400 or fax 508-541-9436.

11. WARRANTY

This Dynisco product is warranted under terms and conditions set forth in the Dynisco Web Pages.

Go to www.dynisco.com and click on “Warranty” at the bottom of any page for complete details.

Page 54

NOTES:

Page 55

WARRANTY REGISTRATION CARD

MODEL NUMBER ______________________________________________________________

SERIAL NUMBER _______________________________________________________________

DATE PURCHASED _____________________________________________________________

PURCHASED FROM ____________________________________________________________

NAME _________________________________________________________________________

COMPANY ____________________________________________________________________

DIVISION______________________________________________________________________

STREET ________________________________________________________________________

CITY _____________________________ STATE _____________ ZIP __________________

COUNTRY _____________________________________________________________________

TELEPHONE _____________________________ FAX________________________________

My application is _______________________________________________________________

Is this your first purchase from Dynisco? YES __________ NO __________

How did you first hear of Dynisco? ADVERTISING________ REP __________

PREVIOUS USE ___________ COLLEAGUE _____________ DIRECTORY______________

I need further product information on ______________________________________________

I need application help on ________________________________________________________

Please send complete catalog _____________________________________________________

Tel.: 508-541-9400 Fax: 508-541-9436 E-mail: www.dynisco.com

PLEASE FOLD AND STAPLE OR TAPE

Page 56

DYNISCO INSTRUMENTS

38 FORGE PARKWAY

FRANKLIN, MA 02038

ATTN: MARKETING DEPT.

Place

Stamp

Here

Loading...

Loading...