DYNEX MAS17502LS, MAS17502LL, MAS17502LE, MAS17502LD, MAS17502LB Datasheet

...

MA17502

1/30

BLOCK DIAGRAM

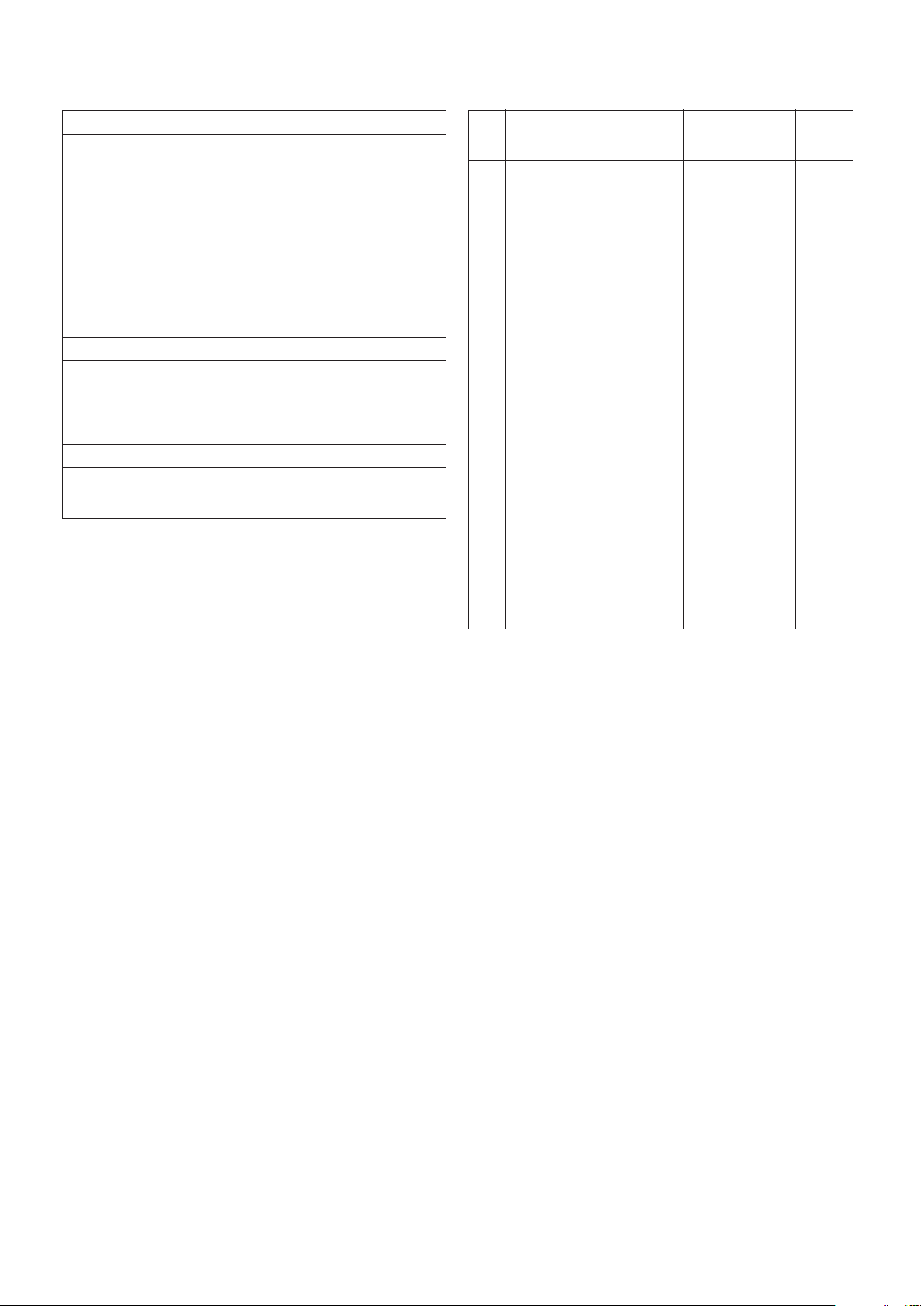

The MA17502 Control Unit is a component of the MAS281

chip set. Other chips in the set include the MA17501 Execution

Unit and the MA17503 Interrupt Unit. Also available is the

peripheral MA31751 Memory Management Unit/Block

Protection Unit. In conjunction these chips implement the full

MIL-STD-1750A Instruction Set Architecture.

The MA17502 consisting of a microsequencer, a microcode

storage ROM, and an instruction mapping ROM - controls all

chip set operations. Table 1 provides brief signal definitions.

The MA17502 is offered in several speed and screening

grades, and in dual in-line, flatpack or leadless chip carrier

packaging. Screening options are described in this document.

For availability of speed grades, please contact Dynex

Semiconductor.

FEATURES

■ MIL-STD-1750A Instruction Set Architecture

■ Full Performance Over Military Temperature Range

■ 12-Bit Microsequencer

- Instruction Prefetch

- Pipelined Operation

- Subroutine Capability

■ On-Chip ROM

- 2K x 40-Bit Microcode Store

- 512 x 8-Bit Instruction Map

■ MAS281 Integrated Built-In Self Test

■ TTL Compatible System Interface

■ Low Power CMOS/SOS Technology

1.0 SYSTEM CONSIDERATIONS

The MA17502 Control Unit (CU) is a component of the

Dynex Semiconductor MAS281 chip set. The other chips in the

set are the MA17501 Execution Unit (EU) and the MA17503

lnterrupt Unit (lU). Also available is the peripheral MA31751

Memory Management Unit/Block Protection Unit (MMU(BPU)).

The Control Unit, in conjunction with these chips, implements

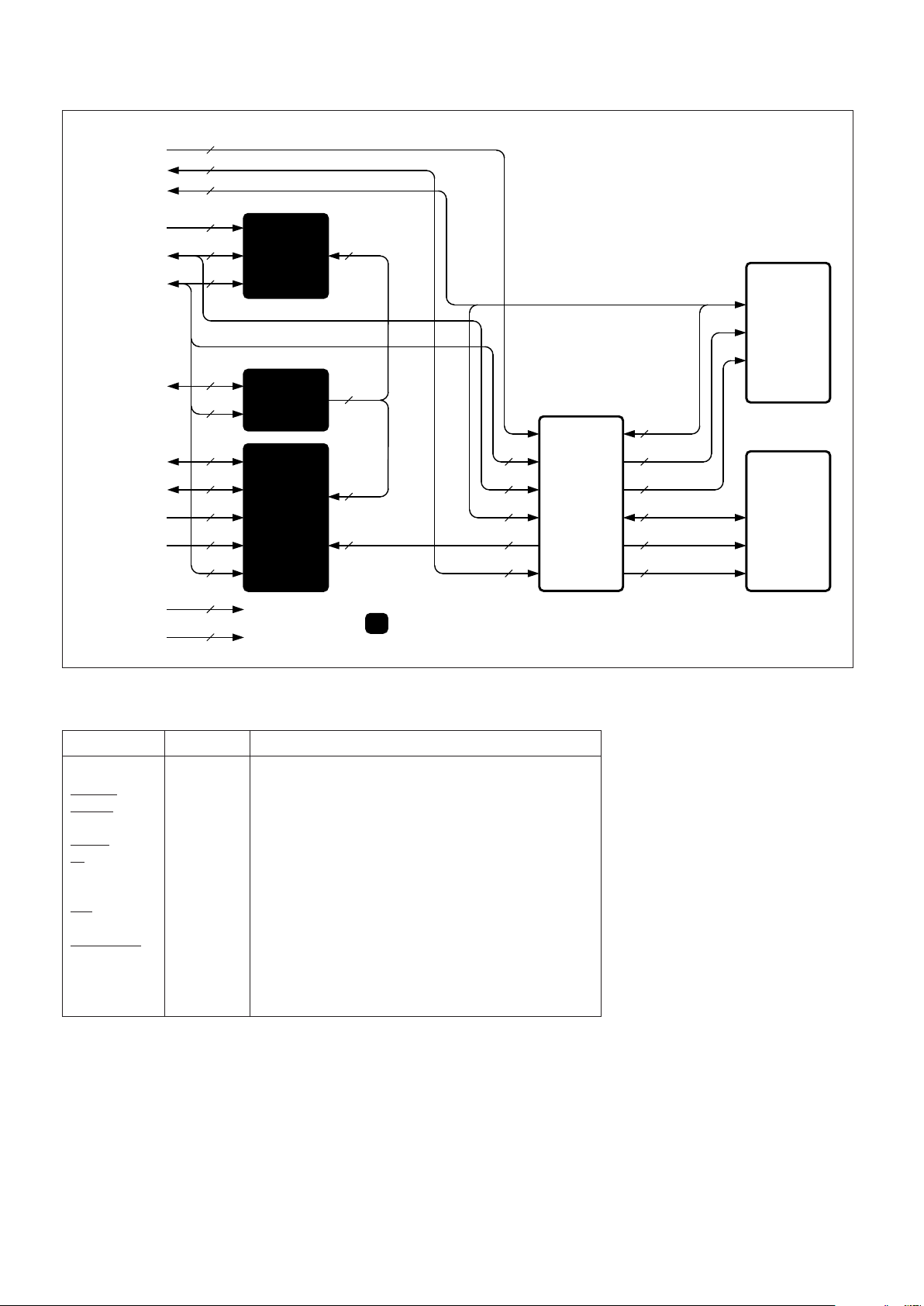

the full MIL-STD-1750A lnstruction Set Architecture. Figure 1

depicts the relationship between the chip set components.

The CU provides the microprogram storage and

sequencing resources for the chip set. The EU provides the

MAS281’s system synchronizing and arithmetic/logic

computational resources. The lU provides interrupt and fault

handling resources, DMA interface control signals, and the

three MIL-STD-1750A timers. The MMU/BPU may be

configured to provide 1M-word memory management (MMU)

and/or 1K-word memory block write protection (BPU) functions.

MA17502

Radiation Hard MIL-STD-1750A Control Unit

Replaces June 1999 version, DS3565-4.0 DS3565-5.0 January 2000

MA17502

2/30

Figure 1: MAS281 Chip Set With Optional MA17504 and Support RAMs

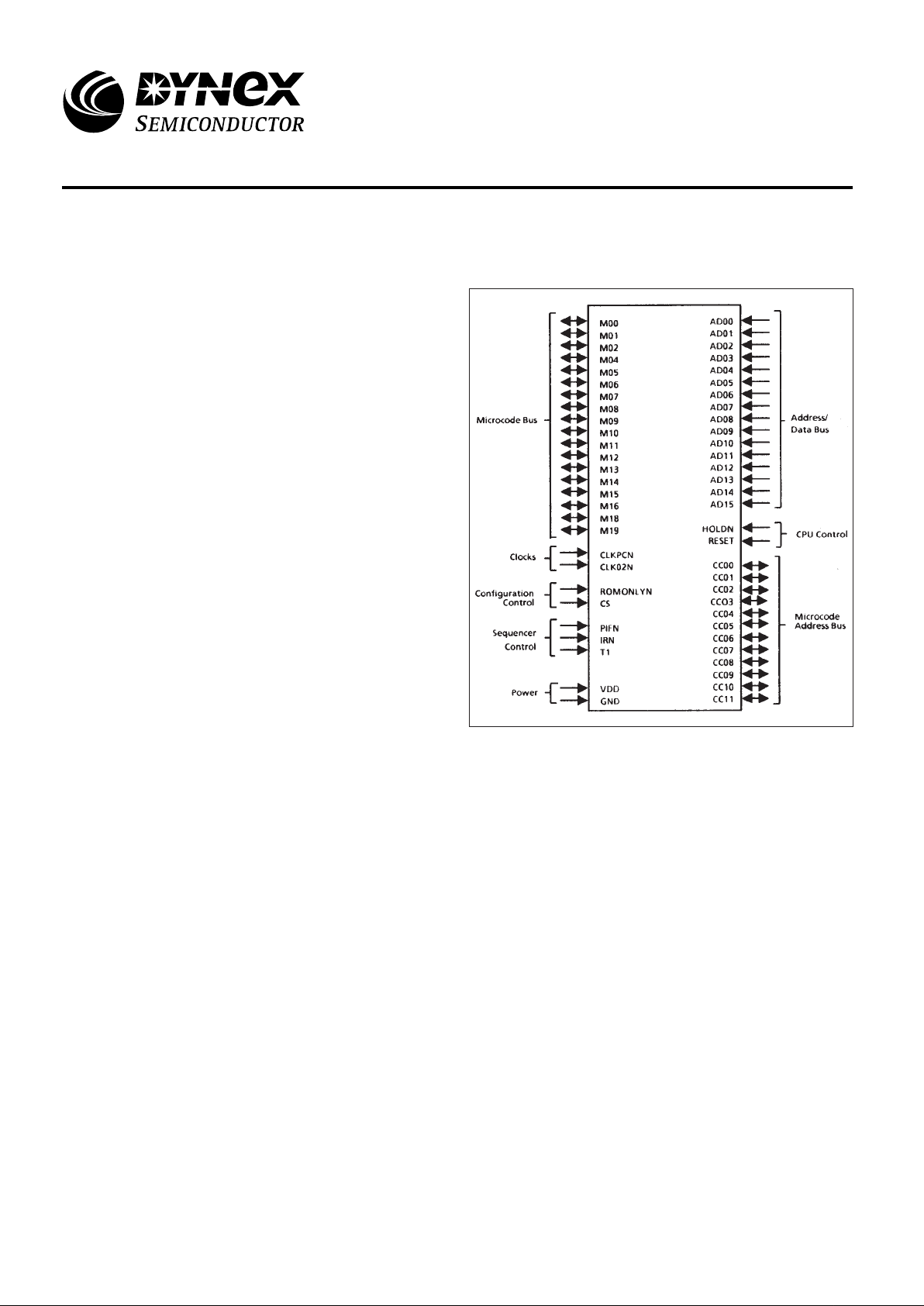

Signature l/O Definition

AD00 - AD15 I External 16-Bit Address/Data Bus

CC00 - CC11 I/O 12-Bit Microcode Address Bus

CLKPC I Precharge Clock

CLK02 I Phase 2 Clock

CS I Chip Select

HOLD I Hold Request Suspends lnternal Processor Functions

IR I Interrupt Request

M00 - M19 I/O/Z 20-Bit Microcode Bus

NC - No Connection

PIF I Privileged lnstruction Fault

RESET I Rest Indicates Device Initialization

ROMONLY I Indicates if Control Unit to be Used as ROM Only

T1 I Branch or Jump Control

VDD Power (External), 5 Volts

GND Ground

Table 1: Signal Definitions

MA17501

Execution

Unit

MA17502

Control

Unit

MA17503

Interrupt

Unit

MA31751

Block

Protection

& Memory

Management

Unit

Protection

RAM

128 x 16

Page

RAM

512 x 13

Address

7

Control

1

Data

16

Address

9

Control

1

Data

13

4

3

8

7

16

3

3

20

20

M Bus

16

4

4

7

9

10

1

16

1

16

10

1

8

4

8

Status

Control

Physical Page

Address

Clock

Control

Address/Data

Bus

Control

Control

Faults

Interrupts

Timer

Controls

Power

Reset

MAS281 Chip Set

MA17502

3/30

As shown in Figure 1, the MAS281 is the minimum

processor configuration consisting of an Execution Unit, a

Control Unit, and an Interrupt Unit. This configuration is

capable of accessing a 64K-word address space. Addition of

an MMU configured MA31751 allows access to a 1M-word

address space. This can also be configured as a BPU to

provide hardware support for 1K-word memory block write

protection.

The CU, as with all components of the MAS281 chip set, is

fabricated with CMOS/SOS process technology. Input and

output buffers associated with signals external to the MAS281

are TTL compatible.

Detailed descriptions of the CU’s companion chips are

provided in separate data sheets. Additional discussions on

chip set system considerations, interconnection details, and the

Digital Avionics lnstruction Set (DAlS) mix benchmarking

analysis are provided in separate applications notes.

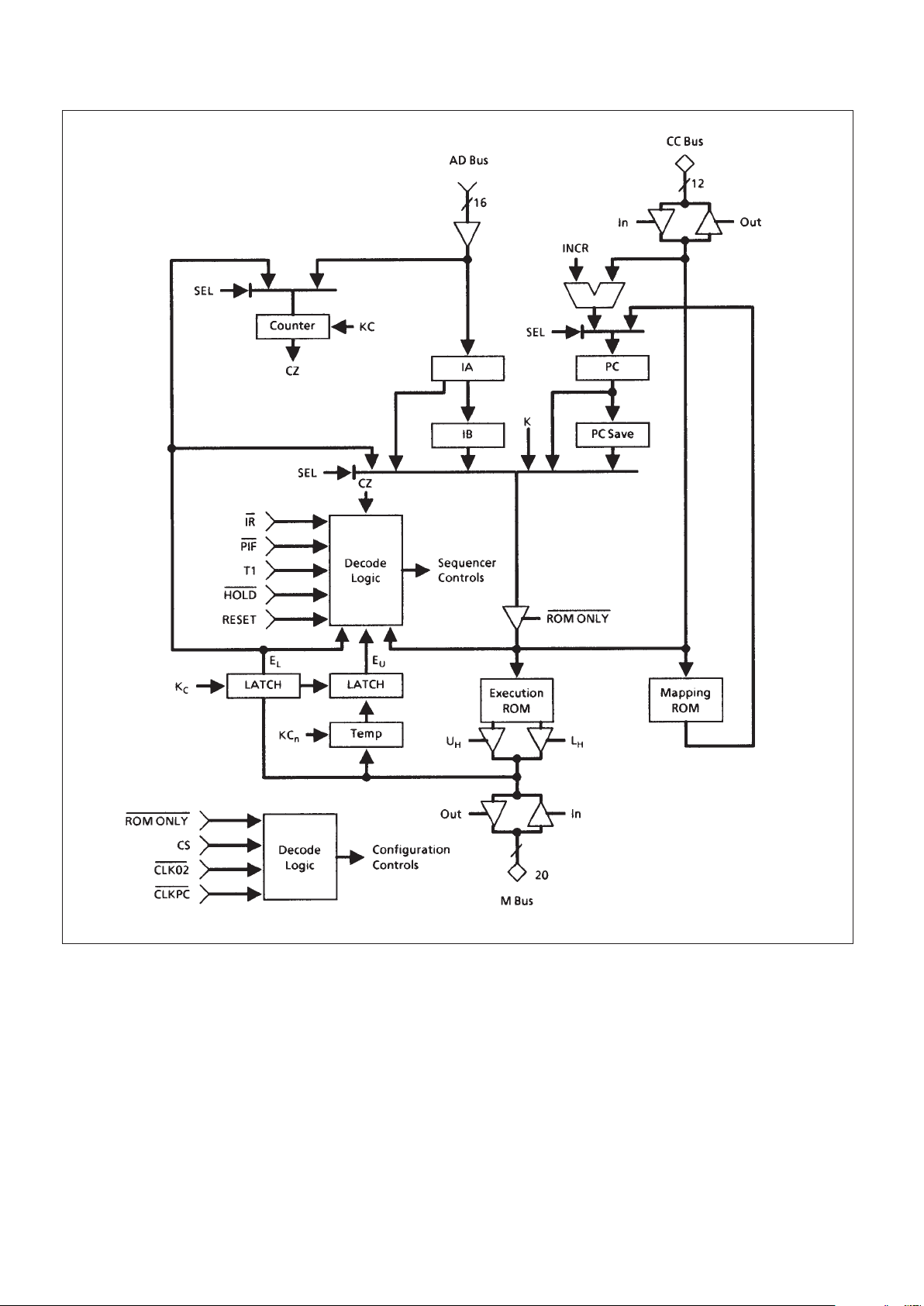

2.0 ARCHITECTURE

The Control Unit consists of a microsequencer, an

instruction mapping ROM, a microcode storage ROM, and

various buses. Details of these components are shown in

Figure 2 and are discussed below:

2.1 MICROSEQUENCER

The CU microsequencer is a 12-bit wide microcode address

generator. Major features of the microsequencer include a

microprogram counter (PC), a microprogram counter save

register (PC Save), microcode address increment logic,

instruction pipeline registers IA and IB, an iteration of loop

counter, a next microcode address source multiplexer, and

various pipelining latches. These features are represented in

Figure 2.

The 12-bit microcode address width allows the

microsequencer to access up to 4096 words of microcode. The

MIL-STD-1750A instructions are implemented as sequences of

microinstructions stored within the lower 2048 locations of this

address space. The address for each microinstruction in a

sequence is provided by the next microcode address source

multiplexer. This multiplexer, under control of the CU control

logic, select from one of six next address sources. Sequential,

direct jump, conditional jump, and subroutine address

generation modes are supported.

Sequential addressing is accomplished by providing a path

from the output of the next microcode address multiplexer to an

incrementer and back to the PC register input. Direct jumps are

supported by routing a portion of the microinstruction to one of

the next microcode address source multiplexer inputs.

Conditional jumps are determined in the ALU of the Execution

Unit which communicates the decision to the CU via the T1

signal. The T1 signal enables a portion of the microcode word

to create the new address. Subroutine jumps are accomplished

by loading the contents of the incremented PC register into the

PC Save register and then performing a direct jump. Upon

completion of the subroutine, the contents of the PC Save

register are used as the next microcode address.

A new microinstruction sequence begins when an opcode

residing in the lA or IB register is selected by the next

microcode address source multiplexer and used as an address

to simultaneously access both the CU’s Instruction Mapping

ROM and the Microcode Storage ROM. The instruction

Mapping ROM access provides a pointer which is then used to

update the microprogram counter (PC); the Microcode Storage

ROM access provides the first microinstruction of the

sequence. Remaining microinstructions in a sequence are

accessed through the use of the four address generation

modes discussed above.

Iterative microprogram operations are achieved through the

use of the loop counter. The loop counter may be selectively

loaded from either the AD bus or directly from microcode. This

counter tracks the number of iterations remaining and, when

appropriate, issues a completion signal (CZ). When an iterative

operation is called for, the loop counter is loaded and the CU

control logic repeats a particular microinstruction sequence,

using the four address generation modes discussed above,

until the CZ signal is received.

2.2 INSTRUCTION MAPPING ROM

The CU instruction mapping ROM provides 512 8-bit words

of microcode instruction vector storage. The address space of

this ROM is mapped into a portion of the microcode storage

ROM’s address space. Hence, both ROMs are accessed

whenever the microcode address falls within this range. The

eight bits from the instruction mapping ROM serve as-the lower

eight bits of a 12-bit microcode address; the upper four bits are

a hardwired constant. The 12-bit microcode address formed

from the 4-bit constant and the mapping ROM’s eight bits are

loaded into the PC register of the microsequencer and serve as

a means to access nonsequential microcode addresses within

the address space allocated to both the instruction mapping

and microcode storage ROMs.

2.3 MICROCODE ROM

The CU microcode ROM provides 2K (2048) 40-bit words of

storage capacity. All of the microcode required to implement

the full MIL-STD-1750A lnstruction Set Architecture (lSA) fits in

one such ROM.

2.4 BUSES

A 16-bit multiplexed Address/Data (AD) bus provides a

communications path between the CU, the other components

of the MAS281 chip set, the MA31751 MMU/BPU, and any

other devices mapped into the chip set’s address space. The

CU receives MIL-STD-1750A instructions, accessed from

system memory, over this bus and loads them into its

instruction pipeline registers.

A 20-bit multiplexed Microcode (M) bus provides a pathway

between the CU chip and the microcode decode logic on all

other chips which are under CU microcode control. The 40-bit

wide microinstructions from the CU’s microcode ROM are

multiplexed on chip as two 20-bit words and presented on the

interchip M bus during alternate phases of CLK02N. Microcode

bits 39 through 20 are placed on the M bus during the CLK02N

low phase and bits 19 through 0 during the high phase of

CLK02N. The M bus is bidirectional to permit microcode

memory expansion.

A 12-bit microcode address (CC) bus is used to route

microcode addresses from the next microcode address source

multiplexer to the microcode and instruction mapping ROMs as

shown in Figure 2.

MA17502

4/30

3.0 INTERFACE SIGNALS

All signal definitions are shown in Table 1. In addition, each

of these functions is provided with Electrostatic Discharge

(ESD) protection diodes. All unused inputs must be held to their

inactive state via a connection to VDD or GND.

Throughout this data sheet, active low signals are denoted

by either a bar over the signal name or by following the name

with an “N” suffix. e.g. HOLDN. Referenced signals that are not

found on the MA17502 are preceded by the originating chip’s

functional acronym in parentheses, e.g. (IU)DMAKN.

A description of each pin function, grouped according to

functional interface, follows. The function acronym is presented

first, followed by its definition, its type, and its detailed

description. Function type is either input, output, high

impedance (Hi-Z), or a combination thereof. Timing

characteristics of each of the functions described are provided

in Section 6.0.

3.1 POWER INTERFACE

The power interface consists of a single 5V VDD connection

and two common GND connections.

3.2 CLOCKS

The clock interface, discussed below, is the means by

which the synchronous, microcoded operation of the MAS281

is driven.

3.2.1 Precharge Clock (CLKPCN)

Input. The MA17501 Execution Unit (EU), generates the

CLKPCN signal for the Control Unit. The Control Unit uses this

signal for most of its internal sequencing. During the low phase

of CLKPCN, the internal M Bus is precharged to the high state

to accelerate its response.

The normal CLKPCN period is defined by five OSC cycles

(two cycles low and three cycles high). When a microcode

branch is indicated by the EU, the low state of CLKPCN is

extended to three OSC cycles. During execution of Interrupt

Unit decoded XlO and microcode commands, the high state of

CLKPCN is extended to four OSC cycles. Also, during external

bus cycles, RDYN may be used to cause the EU to prolong the

high state of CLKPCN to greater than three OSC cycles; this

allows the MAS281 chip set to interface with slower external

memory or input/output devices.

During DMA ((IU)DMAKN is low) or Hold ((EU)HLDAKN is

low), CLKPCN will remain low until the CPU takes control

again.

3.2.2 Phase 2 Clock (CLK02N)

Input. The MA17501 generates the CLK02N signal for the

Control Unit. The CU then uses this signal, in conjunction with

CLKPCN, to control the distribution of microcode on the M Bus.

CLK02N is used to multiplex the 40-bit microcode instruction

into two 20-bit words (µW1 and µW2). The high-to-low edge of

CLK02N switches µW1 (bits 39 through 20) off the M Bus while

switching µW2 (bits 19 through 0) onto the M Bus.

The normal CLK02N period is defined by five OSC cycles

(one cycle low, three cycles high, one cycle low). When a

microcode branch is indicated by the EU, the high state of

CLK02N is extended to four cycles. During execution of

Interrupt Unit decoded XIO and microcode commands, the

trailing low state of CLK02N is extended to two OSC cycles.

Also, during external bus cycles, RDYN may be used to cause

the EU to prolong the CLK02N trailing low state to greater than

one OSC cycle; this allows the MAS281 chip set to interface

with slower external memory or inpuVoutput devices.

During DMA ((IU)DMAKN is low) or Hold ((EU)HLDAKN is

low), CLKPCN will remain low until the CPU takes control

again.

3.3 BUSES

The following is a discussion of the communication buses

connecting the three-chip set. The AD Bus and M Bus are

mainly operand transfer buses, while the CC Bus is strictly for

providing microcode addresses to auxiliary CUs.

3.3.1 Address/Data Bus (AD Bus)

Input. These signals comprise the multiplexed address and

data bus. During external bus operations, the AD bus

accommodates the transfer of instructions, from memory and

l/O ports, to the MA17502. During internal bus operations, the

AD bus provides additional data to the Control Unit from the

Execution Unit. AD00 is the most significant bit position and

AD15 is the least significant bit position of both the 16-bit data

and 16-bit address. A high on this bus corresponds to a logic 1

and a low corresponds to a logic 0. lnformation on the AD Bus is

clocked into the CU by the high-to-low transition of CLKPCN.

3.3.2 Microcode Bus (M Bus)

Input/Output/Hi-z. The M Bus is the 20-bit multiplexed

microcode bus. The 40-bit microcode instruction is multiplexed

onto the M Bus as two 20-bit words (µW1 and µW2). The first

half of the microcode word, µW1 (bits 39 through 20), is

assured valid on the high-to-low transition of CLK02N and µW2

(bits 19 through 0) is assured valid on the high-to-low transition

of CLKPCN. M00 corresponds to microcode bit 0 (µW1) or 20

(µW2) while M19 corresponds to microcode bit 19 (µW1) or 39

(µW2). A high level indicates a logic 1 and a low level indicates

a logic 0. A high level on CS allows the Control Unit to distribute

microcode over this bus, a low level places the bus in the high

impedance state.

During DMA or Hold states, CLKPCN is held low, thus

holding the internal M bus in the precharged state. Precharging

the internal M Bus forces the 20 bits of the external M Bus low.

3.3.3 Microcode Address Bus (CC Bus)

Input/Output/Hi-Z. The CC bus is provided for future

expansion and is left unconnected.

3.4 SEQUENCER CONTROL

The following is a discussion of the microsequencer control

input signals. These signals support chip set functions that

require microcode branching based on the results of operations

performed in the Execution or Interrupt Units.

3.4.1 Interrupt Request (IRN)

Input. A low on this input directs the CU to service pending

interrupt requests latched by the Interrupt Unit (IU). Upon

completion of the currently executing MIL-STD-1750A

instruction, the CU checks the IRN input. If IRN is low, then the

CU sequencer will branch to the microcoded interrupt service

routine; else the next MIL-STD-1750A instruction is mapped to

its microcode routine. The microcoded interrupt service routine

MA17502

5/30

Figure 2: MA17502 Control Unit Architecture

MA17502

6/30

stores the processor state, retrieves the highest priority

pending interrupt’s service routine processor state, and vectors

software execution to the user’s interrupt service routine. IRN

originates in the IU.

3.4.2 Privileged Instruction Fault (PIFN)

A low on this signal causes the CU to enable control of the

DMA interface (located in the Interrupt Unit), abort the currently

executing MIL-STD-1750A instruction and check the IRN input

for a pending level 1 interrupt caused by the IU latching a

memory protect (MPROEN), memory address (EXADEN), or

Bus Time-out fault. PIFN originates in the IU.

3.4.3 Branch or Jump Control (T1)

Input. A high on this input directs the CU microcode address

sequencer to branch execution to a nonsequential microcode

address. This signal is under the control of the Execution Unit’s

ALU and its level is dependent on the outcome of the presently

executing microcode instruction, e.g. conditional branch. T1

originates in the EU.

3.5 CONFIGURATION CONTROL

The following inputs are provided for control of multiple CU

systems. They allow for expansion of the microcode store to 4K

40-bit words.

3.5.1 ROM-Only (ROMONLYN)

Input. This signal is provided for future microcode

expansion and must be pulled up to VDD.

3.5.2 Chip Select (CS)

Input. A high on this signal enables the CU to drive the 20bit external M Bus. This signal is provided for future microcode

expansion and must be pulled up to VDD.

3.6 CPU CONTROL

Grouped under this heading are signals that have CPUwide control of normal operation. Each of these has the ability

to “freeze” the processor.

3.6.1 Hold Request (HOLDN)

Input. A low on this input will suspend internal processor

functions at the end of the currently executing MlL-STD1750A

instruction. When this signal becomes active, the CU

completes the currently executing MIL-STD-1750A instruction,

then branches to the Hold microcode routine and enters the

Hold state. The CU will resume normal operation by refilling the

instruction pipeline registers (IA and IB) upon release of

HOLDN.

3.6.2 System Reset (RESET)

Input. A high on this input for a duration of at least one

CLKPCN period will reset the MAS281 chip set by forcing the

Control Unit to microcode address zero. The high-to-low

transition of this input will cause the CU to begin executing the

MAS281 initialisation sequence starting with the first instruction

in microcode. Built-in Test (BIT) is performed as part of the

initialisation sequence. At the conclusion of initialisation and

successful execution of BIT, the MAS281 will be initialised as

shown in Table 3.

4.0 OPERATING MODES

The following discussions detail the MAS281 chip set

operating modes from the perspective of the Control Unit.

MAS281 operating modes involving the MA17502 include: (1)

Initialisation, (2) lnstruction Execution, (3) Interrupt Servicing,

(4) DMA Support, and (5) HOLD Support.

4.1 INITIALISATION

The MA17502 sequences the MAS281 chip set through the

microcoded initialisation routine in response to a high pulse on

the RESET input. This routine clears the chip set registers,

disables and masks interrupts’ reads the configuration register,

resets the output discrete register (if applicable), initialises the

MMU and BPU (if applicable), performs Built-in Test (BIT),

raises the StartUp ROM Enable discrete, clears and starts

timers A and B, resets the Trigger-Go counter, and loads the

instruction pipeline. The initialisation sequence is contained in

the first 33 locations of microcode ROM (an additional 14

locations contain the optional MMU and BPU initialisation

code). Because the initialisation sequence clears the Execution

Unit’s lnstruction Counter and Status Word (also the address

and processor state copies stored in the MMU(BPU), if

applicable), program execution begins with the instruction

located at address zero (page zero). Table 2 provides a

detailed breakdown of the initialisation sequence and Table 3

summarises the resulting initialised state.

BIT occupies 332 words of microcode storage ROM, and

consists of five subroutines that exercise the internal circuitry of

the MAS281, as outlined in Table 4. BIT begins by pulling the

Normal Power-UP ((IU)NPU) output low; this is the first time

after power-up that the state of NPU is guaranteed. If all five

BIT subroutines execute successfully, NPU is raised high.

If any part of BIT fails, an error code identifying the failed

subroutine is loaded into the Interrupt Unit Fault Register (via

the AD Bus), BlT is aborted, and NPU is left in the low state.

Table 4 defines the coding of the BIT results. (NPU is raised

high through microcode control of the lU in conjunction with the

(EU)lNTREN signal. The BIT error codes are loaded in the lU

Fault Register via the AD Bus under microcode control of the lU

in conjunction with the (EU)lNTREN signal.)

ln the event of such a failure, the resulting chip set reset

state is dependent on where in BIT the error occurred and may

not be the same as that shown in Table 3. A BIT failure

indication in the fault register sets the level 1 pending interrupt.

Since initialisation disables and masks interrupts, the IRN input

will remain high; thus the interrupt will not be serviced

immediately.

The last action performed by the initialisation routine is to

load the instruction pipeline. lnstruction fetches start at memory

location zero (page zero) from the Start-Up ROM (if

implemented). Whether BlT passes or not, the processor will

begin instruction execution at this point.

Note: To complete initialisation and pass BIT, interrupt and

fault inputs must be high for the duration of the initialisation

routine. Also, the Timers A and B must be clocked for BIT

success.

MA17502

7/30

Label Cycle

MAIN B1 1. Enable Control of DMAE Output signal

P2.B1 3. Clear MAS281 Execution Unit Status Word (SW)

Clear Interrupt Mask (MK) (Internal l/O command, SKM, 2000H)

B1 4. Clear Pending lnterrupt Register (Pl) and Fault Register (FT) (lnternal l/O Command, CLlR, 2001H)

Clear Instruction Counter (IC)

P5.B1 6. Disable Interrupts (Internal l/O Command, DSBL, 2003H)

P7.B1 8. Clear MMU Status Word (lnternal l/O Command, WSW, 200EH) (Note 1)

P9.B1 10. Disable DMA Access (Internal l/O Command, DMAD, 4007H)

P 11. B1 12. Read Configuration Register (Internal l/O Command, RCW, 8400H, CONFWN Drops low per Figure

25, Section 5.0)

P 13. P 14. B2 15. - (If Output Discrete Register Present, then Continue; Else, Skip to 18)

P (16). I/O (17). Clear Output Discrete Register (External l/O Command)

B2 19. - (If BPU present, then Branch to BPU; else, continue)

P 20. B2 21. - (If MMU present, then Branch to MMU; Else, Continue)

P 22. - (Setup Temporary Register to indicate No MMU Present)

B2 23. - (Branch to MAS281 BIT)

P 24. B1 25. Enable Start-Up ROM (Internal l/O Command, ESUR, 4004H; SURE Raises High per Figure 25,

Section 5.0)

P 26. B1 27. Clear and Start Timer A (Internal l/O Command, OTA, 400AH)

B1 28. Reset the Trigger-Go timer (Internal l/O Command, GO, 400BH)

P 29. B1 30. Clear and Start Tlmer B (Internal l/O Command, OTB, 400EH)

B2 31. - (Branch to Load Instruction Pipeline Routine)

M 32. Load data-ln register (Dl) and instruction Register A (IA) from [IC], Increment IC

M 33. Load Data-ln Register (Dl) and lnstruction Register a (lA) from [lC] ([lA] Moves to lB), lncrement lC

Map Instruction Register B (IB) into Microcode Routine

BPU P (1). -

P (2). - (Set Loop to Clear Memory Protect RAM)

I/O (3). Clear a Location in MPRAM (Internal l/O Command, LMP, 50XXH), Increment Address; Do 128 Times

(4). - (Branch Back to 20.)

MMU P (1). -

P (2). P (3). - (Setup Loop to Load Instruction Page Registers (IPR) and Operand Page Registers (OPR) wlth

Sequential Values of 0 to 255)

P (4). P (5). I/O (6). Load a Location in the IPR with the value of the Locatron Address (Internal l/O Command, WIPR,

51XYH)

I/O (7). Load a Location in the OPR Increment Loaded Value with the Value of the Location Address (Internal

I/O Command, WOPR, 52XYH)

P (8). - (Increment IPR Address)

P (9). - (Increment OPR Address - Repeat Loop [4. - 9.] 256 Times)

B2 (10). - (Setup Temporary Register to Indicate MMU Present; Branch back to 23)

Notes: 1. This operation Is performed whether or not an MMU is present.

2. “-” indicates internal CPU operation.

3. Sequence numbers in “( )” are performed only under the stated conditions.

4. Each step enumerated above represents a single machine (SYNC) cycle of the type shown in the “Cycle” column.

“P” indicates a 5 OSC cycle, 60% duty cycle, machine cycle.

“I/O” and “M” indicate a 5 OSC cycle, 50% duty cycle, machine cycle.

“B1” indicates a 6 OSC cycle 50% duty cycle machine cycle.

“B2” indicates a 6 OSC cycle 66% duty cycle machlne cycle.

Table 2: MAS281 Initialisation Sequence

MA17502

8/30

MAS281

Instruction Counter (IC) Zeroed

Status Word (EU and MMU) (SW) Zeroed

Fault (FT) Zeroed

Pending Interrupt (Pl) Zeroed

Mask (MK) Zeroed

General Register File (RO R15) Zeroed

Interrupts Disabled

DMA Access Disabled

TimerA Reset and Started

Timer B Reset and Started

Trigger-Go Timer Reset and Started

MMU

Page Registers Group Zero Enabled

AL, W, E, Fields Zeroed

PPA Field Logical to Physical

Map

BPU

Write Protect Zeroed

Global Memory Protect Enabled

BIT Test BIT Fail Codes Cycles

Coverage (FT

13, 14,15

)

Microcode Sequencer

1 IB Register Control 100 221

Barrel Shifter

Byte Operations and

Flags

Temporary Registers

(T0 - T7)

2 Microcode Flags 101 166

Multiply

Divide

Interrupt Unit

3 MK, Pl, FT 111 214

Enable/Disable

Interrupts

Status Word Control

4 User Flags 110 154

General Registers

(R0 - R15)

5 Timer A 111 763

Timer B

BIT Pass/Fail - 26

Overhead

Note: BIT pass is indicated by all zeros in FT bits 13, 14 and 15

Table 3: Initialisation State

Table 4: Built In Test (BIT) Summary

driven low during execution of this instruction). Interrupt, DMA,

and Hold support are explained in more detail in following

sections.

4.3 DIRECT MEMORY ACCESS

Direct Memory Access (DMA) is controlled by the Execution

Unit (EU) in concert with the Interrupt Unit DMA interface. The

CU supports DMA by suspending processor control upon

completion of the current machine cycle. If DMA is enabled

((UI)DMAE signal, high) a DMA request ((IU)DMARN input,

low) to the MAS281 causes the lU to acknowledge with

DMAKN, low. When the EU receives the DMAKN (DMA

Acknowledge) signal from the lU, the CU clocks are suspended

(CLKPCN, low; CLK02N, high) halting the MAS281’s

microcode sequencing. Microinstruction execution remains

suspended until DMARN is removed. When DMARN is

removed, microcode execution resumes where DMARN had

interrupted it.

4.4 INTERRUPT HANDLING

Interrupts are handled by the interrupt Unit (IU) and

communicated to the CU via the lRN input. The CU checks the

status of the lRN (lnterrupt Request) signal after the completion

of each MlL-STD-1750A microcode instruction sequence. lf the

lRN signal is low, the CU initiates interrupt handling, otherwise

the CU processes a new instruction.

4.2 INSTRUCTION EXECUTION

The MIL-STD-1750A microcoded instruction subroutines

are stored in 1255 locations of microcode storage ROM. The

Control Unit receives instructions from memory, via the AD

Bus, through the instruction pipeline registers lA and IB. When

the previous instruction or special process (Interrupts or Hold)

has been completed, the new instruction residing in register IB

is selected by the next microcode address source multiplexer.

A 4-bit hardwired constant, appended by the instruction

opcode, is then used as the first address of a microcode

sequence which distributes the required control to execute the

instruction. The microsequencer generates the remaining

microcode addresses necessary to complete the sequence as

described in Section 2.0 of this data sheet entitled,

“Architecture”.

Upon completion of the current instruction, the CU will

accept the next instruction in the program unless an interrupt,

DMA, or Hold request is received. The interrupt and Hold

request share a common branch point in microcode. If an

interrupt and Hold request are both pending at the conclusion of

the MIL-STD-1750A instruction microcode routine, the Hold

request has priority and is serviced first. Upon release of the

Hold state, the first instruction will execute even if the interrupt

is still pending; when this instruction is complete the interrupt

will be serviced (assuming the HOLDN input has not been

MA17502

9/30

IU interrupt handling is controlled by the CU through three

microcode bits - M04, M05, and M06. Upon receipt of the IRN

signal and after completion of the currently executing

instruction, the CU branches to a microcoded interrupt handling

routine. The microprogram sequence supplies microcoded

control to the lU for reading the highest priority pending

interrupt vector code, which also clears this pending interrupt.

Due to the similarity of interrupt and hold request handling

by the CU, if a Hold and interrupt request are pending at the

end of an instruction sequence the Hold has priority and will be

serviced.

4.5 HOLD SUPPORT

The CU accepts a Hold request in much the same way as

an interrupt request. After the completion of each MlL-STD1750A microcode instruction sequence, the CU checks the

status of the HOLDN signal. If the HOLDN signal is low, a

microcoded sequence suspends further internal processing

functions; otherwise, the CU processes a new instruction or

services interrupt requests (Hold requests have priority over

interrupt requests).

The Control Unit responds to an active HOLDN signal, upon

completion of the currently executing instruction, but branching

to a microprogrammed sequence of instructions that suspends

all internal operations. This sequence of microinstructions

allows the processor to resume instruction execution at the

point HOLDN was accepted when the CU regains control of the

processor. The MAS281 remains in the Hold state until HOLDN

is pulled high (if the Hold state was reached through the

hardware interface, HOLDN) or HOLDN is pulsed low (if the

Hold state was reached through software, BPT instruction).

HOLDN should be synchronised to AS falling.

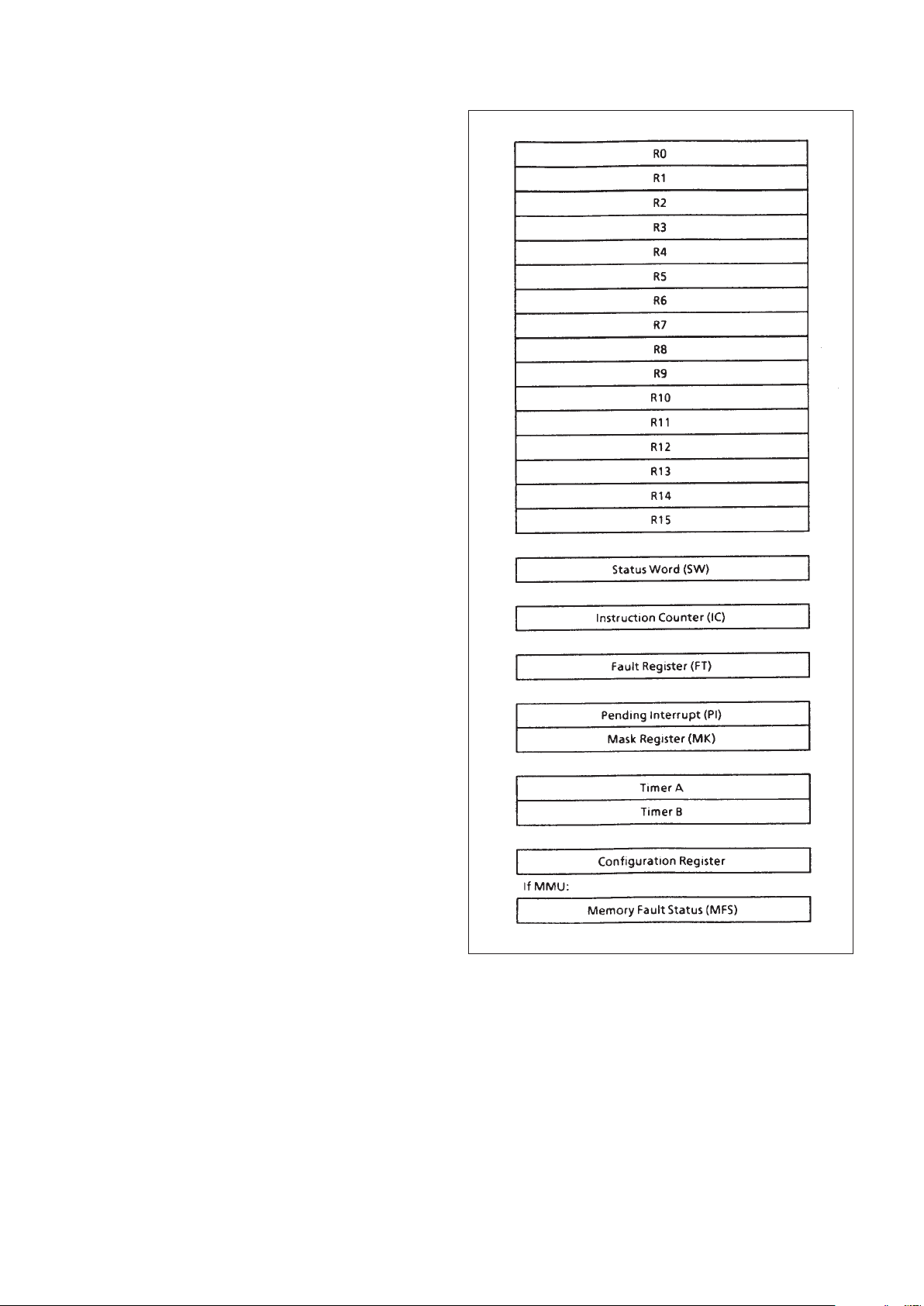

5.0 SOFTWARE CONSIDERATIONS

The MAS281 chip set implements the full MlL-STD-1750A

instruction set. Table 6a gives a brief listing of this instruction

set and provides performance data for each instruction. Table

6b provides a summary of the l/O commands implemented in

MAS281 and MA31751 MMU/BPU hardware. A complete

description of this instruction set is provided in MIL-STD-1705A

(Notice 1). The register set available to the software

programmer is depicted in Figure 3. A discussion of data types,

addressing modes, and benchmarking considerations fol lows.

5.1 DATA TYPES

The MAS281 chip set supports 16-bit fixed-point single

precision, 32-bit fixed-point double-precision, 32-bit floatingpoint, and 48-bit extended-precision floatingpoint data types.

Figure 4 depicts the formats of these data types.

All numerical data is represented in two’s complement form.

Floating-point numbers are represented by a fractional two’s

complement mantissa with an 8-bit two’s complement

exponent. The MAS281 expects all floating point operands to

be normalised. If they are not normalised, the results from an

instruction are not defined.

Figure 3: Register Set Model

Loading...

Loading...