Page 1

Studio Series

Installation Manual

S4-LCRMT S4-LCR65W

Page 2

Welcome to the custom install Studio Series and thank you for choosing a

Dynaudio Custom Install product.

The S4-LCRMT and S4-LCR65W are modular in-wall speakers designed for left,

centre and right channel applications in multi-channel audio systems.

The S4-LCR Series offers very high quality audio performance while at the same

time providing multiple conguration options and incorporating numerous features

designed to ease installation.

Important safety instructions

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water

6. Clean only with dry cloth.

7. Do not block any ventilation openings. Install in accordance with the

manufacturer’s instructions.

8. Do not install near any heat sources such as radiators, heat registers,

stoves, or other apparatus that produce heat.

9. Only use attachments / accessories specied by the manufacturer.

10. Refer all servicing to qualied service personnel.

Environmental note

This product complies with international directives, including but not

limited to the Restriction of Hazardous Substances (RoHS) in electrical

and electronic equipment, the Registration, Evaluation, Authorisation and

restriction of Chemicals (REACH) and the disposal of Waste Electrical and

Electronic Equipment (WEEE). Consult your local waste disposal authority

for guidance on how properly to recycle or dispose of this product.

Disposal

Disposal of used electrical and electronic equipment (applicable in

European countries with separate collection systems for this equipment).

This symbol on the product or its packaging indicates that the product

may not be treated as household waste. Instead it must be handed

over to the applicable collection point for the recycling of electrical

and electronic equipment. By ensuring this product is disposed of

correctly, you will help prevent potential negative consequences for

the environment and human health. The recycling of materials helps to

conserve natural resources. For more detailed information on recycling

this product, please contact your local authority, community waste

disposal of, or the shop where you purchased the product.

Dynaudio custom install limited warranty

Dynaudio warrants its custom install products to be free from defects in

materials and workmanship under conditions of normal use and service

for a lifetime period from the date of original purchase. For this warranty

to apply, the unit must be installed and used according to its written

instructions.

The obligation under this warranty shall be limited to the replacement, repair or

refund of any such defective device within the warranty period, provided that:

1. inspection by Dynaudio indicates the validity of the claim;

2. the defect is not the result of damage, misuse, lightning, power

surges, negligence, improper operation (installation) or failure to follow

instructions contained in the manual or written instructions provided by

Dynaudio after the original purchase;

3. the product has not been altered in any way or repaired by others and

that factory sealed units are unopened (a service charge plus parts and

labour will be applied to units defaced or physically damaged);

4. the dealer from whom the Dynaudio products were purchased was

authorized to sell such products at the time of the original purchase;

5. the service provider for, including but not limited, installation or repair of

the product, was authorized in writing by Dynaudio;

6. the original, dated Bill of Sale is presented whenever service is required

during the warranty period;

7. freight charges for the return of products to Dynaudio are prepaid;

8. all units ‘out of warranty’ are subject to a service charge. The service

charge will cover minor repairs (major repairs will be subject to

additional charges for parts and labour).

This warranty is in lieu of and excludes all other warranties, expressed or

implied. Neither this warranty nor any other warranty, express or implied,

including implied warranties of merchantability and tness, shall extend

beyond the warranty period.

Dynaudio shall not be liable for damages to any other equipment or

other items at the site of use, or any other damages whether incidental,

consequential or otherwise. Dynaudio shall not be liable for any anticipated

prots, any incidental or consequential damages, loss of time or other

losses incurred by the purchaser in connection with the purchase, operation

or use of the product.

The information this document contains is subject to change without

notice. In the event that there are differences between this warranty and

the provisions of any advertisements, documentation, product brochures or

packaging cartons, the terms of this warranty shall prevail.

Page 3

1. Introduction

This manual describes the installation of S4-LCR Series modules

within drywall/plasterboard walls. It begins by listing the carton

contents and continues information specic to installing in-wall

speakers.

If this is your rst time working with Dynaudio Studio Series

custom install speakers, or if you have not done so for a while, we

recommend that you read the appropriate sections of this manual

before you begin.

Note: Visit dynaudio.com for the latest Studio Series news and

information.

The S4-LCR Series is designed to provide very high quality left,

centre, and right channel audio in custom installations where

speakers are required to be tted ush in walls. The S4-LCR Series

not only benets from four decades of Dynaudio speaker expertise

but has been designed through its modular format to offer enhanced

versatility in terms of both practical installation and acoustic

performance.

• S4-LCR Series modules are uniquely simple to install. Once a

wall cut-out is created, no tools are required and installation

can be completed by one person without assistance. Every

element of the S4-LCR Series installation procedure, from

unpacking the speakers to painting and tting the magnetic

grilles is simplied and streamlined by design.

• S4-LCR Series speakers employ numerous Dynaudio

technologies, borrowed from the company’s studio monitors

and high-end hi- speakers, to bring genuinely high

performance audio to custom installations: unique bass/

mid drivers with large diameter aluminium voice coils and

nite element optimised, low-distortion magnet systems,

proprietary MSP (Magnesium Silicate Polymer) diaphragms,

and precision coated soft dome tweeters with powerful

neodymium magnets are just a few examples among many.

• The S4-LCR Series comprises two modules:

the S4-LCRMT mid/tweeter module and the S4-LCR65W

twin driver bass module. A single S4-LCRMT module can be

used with one or, for higher volume level applications, two

S4-LCR65W modules.

• Each S4-LCR Series module is supplied with a pair of

Installation Frame Flanges. With frame anges tted, modules

can be installed individually and spaced apart. With one

or both frame anges removed, multiple modules can be

consolidated and installed in a common wall cut-out.

• S4-LCRMT modules are intended to be installed only in

portrait orientation, however S4-LCRMT speaker units can be

rotated within their installation frames in order that the frames

match the orientation of adjacent S4-LCR65W modules.

• S4-LCR65W modules can be installed in either landscape or

portrait format. In either case, multiple modules can be either

consolidated for installation in a common wall cut-out, or

installed in individual wall cut-outs.

Grilles are not supplied with S4-LCR Series modules but can be

supplied as accessories in a range of lengths to suit installation

congurations. S4-LCR grilles attach magnetically and fully paintable.

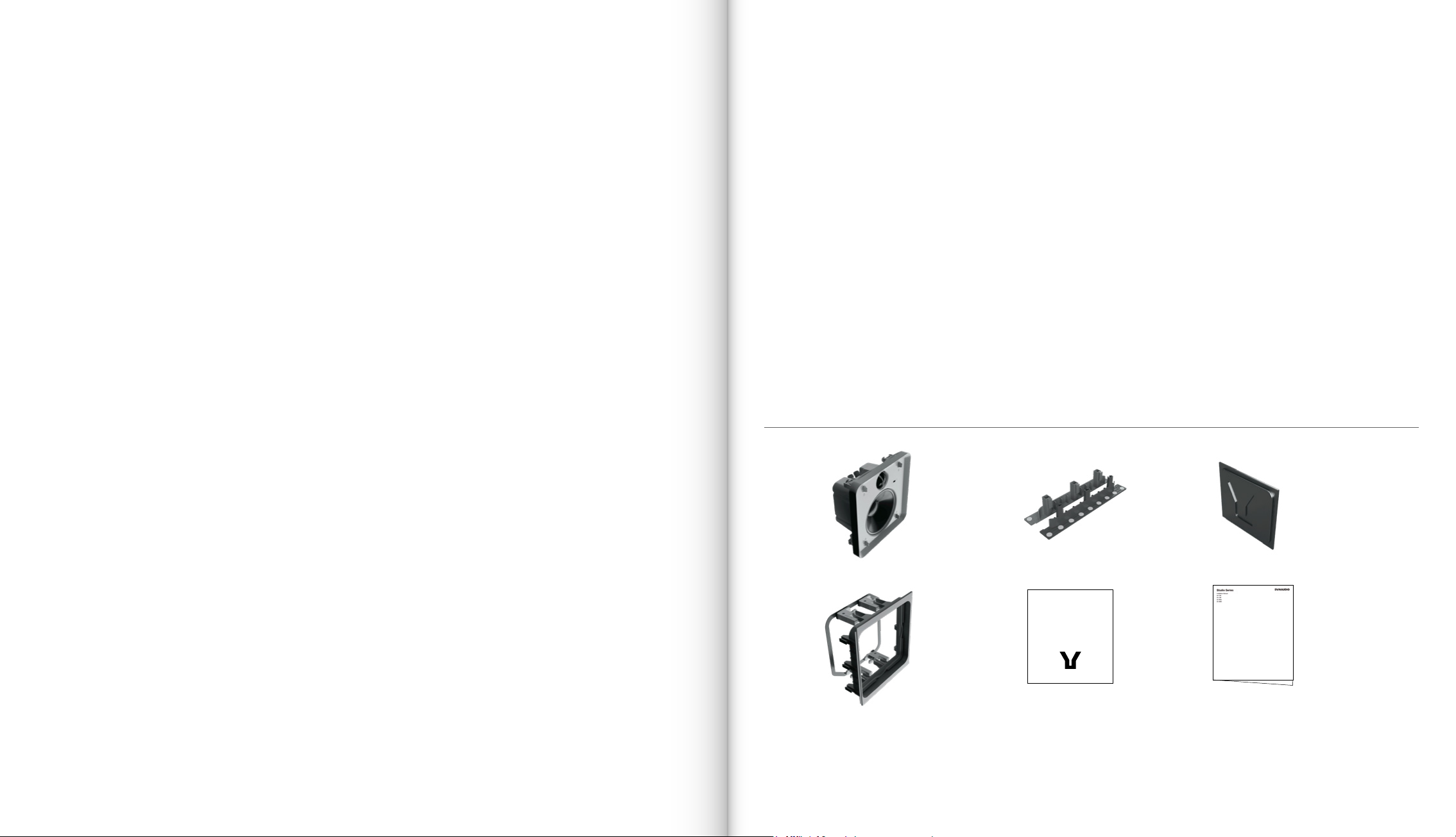

1.1 Carton Contents

The carton contents for all S4-LCR Series modules are essentially the

same. Items only differ in terms of format and dimension. Within each

carton can be found:

1 x Speaker Module

1 x Installation Frame

2 x Frame Flange

1 x Cut-out Template

1 x Paint Mask

1 x Document pack

A typical carton contents is illustrated in Diagram 1.

S4-LCR Series modules comprise a Speaker Unit and Installation

Frame. The Installation Frame is inserted into the wall cut-out and

securely xed in place using auto-locking clamps. The Speaker Unit

is then connected to the speaker cables before being inserted into

the Installation Frame to be held in place by a latch system. The grille

is then tted, secured by magnets integrated within the Installation

Frame.

• S4-LCRMT sensitivity can be adjusted via a rear mounted

switch to match either one or two S4-LCR65W modules. The

electrical crossover between S4-LCRMT and S4-LCR65W

modules can be accomplished passively, using either the

standard internal passive lters, or actively using external

active lter components. Switches and bypass jumpers

located on the rear of the speaker units engage or bypass the

internal passive bass module low pass and mid/tweeter high

pass lters.

Diagram 1

Speaker Unit Frame Flange (pair)

Installation Frame

Cut-out Template

190mm (7.5”)

x 195mm (7.7”)

S4-LCRMT

Paint Mask

Document Pack

Page 4

2. Preparation

Before commencing any S4-LCR Series installation you must be

sure that the wall positions chosen are free of obstructions such as

pipe work, ducting or wiring that might interfere with the installation.

Stud-nding, pipe detecting and wire detecting tools can help map

the wall construction and identify any potential obstructions.

2.1 S4-LCR Series Module Selection

The modular format of the S4-LCR Series enables a variety of

arrangements of mid/tweeter (S4-LCRMT) and bass modules (S4LCR65W) to be installed to suit different front channel requirements.

The S4-LCR Series modular format also enables in-wall front

channel speakers to be installed around the constraints that

may result from dry-wall stud spacing. Three typical installation

examples are illustrated below.

Left and right speakers can be created from an S4-LCRMT module

combines with either one, or in larger listening spaces, twin S4LCR65W modules. Centre channel speakers always require a single

S4-LCRMT and twin S4-LCR65W modules.

2.2 S4-LCR Series Installation Examples

Installation Example A:

• Left, centre and right speakers installed with 42” TV in a dry

wall with simple 400mm (16”) stud spacing.

• Each Left and Right speakers comprises one S4-LCRMT

and one S4-LCR65W consolidated in a common wall cutout. S4-LCRMT upper frame ange and S4-LCR65W lower

frame ange tted.

• Centre speaker comprises one S4-LCRMT and two S4LCR65W mounted in separate wall cut-outs. All frame

anges tted.

Installation Example B:

• Left, centre and right speakers installed with 42” TV in a

dry wall with modied 400mm (16”) stud spacing. Stud

arrangement congured to create centre speaker aperture.

• Each Left and Right speakers comprises one S4-LCRMT

and one S4-LCR65W consolidated in a common wall cutout. S4-LCRMT upper frame ange and S4-LCR65W lower

frame ange tted.

• Centre speaker comprises one S4-LCRMT and two S4LCR65W consolidated in a common wall cut-out.

Installation Example C:

Left, centre and right speakers installed with 65” TV in a dry wall

with simple 400mm (16”) stud spacing.

• Each left and Right speaker comprises one S4-LCRMT and

two S4-LCR65W consolidated in a common wall cut-out.

S4-LCR65W lower and upper frame anges tted.

• Centre speaker comprises one S4-LCRMT and two S4LCR65W mounted in separate wall cut-outs. All frame

anges tted.

S4-LCR65W left and right frame anges tted.

Page 5

2.3 S4-LCR Series Cut-out and Clearance Dimensions

Diagram 2

The S4-LCRMT and S4-LCR65W modules require specic wall cut-out

dimensions but have common mounting depth space and drywall (plasterboard)

thickness constraints. These dimensions are illustrated in Diagram 2 and listed

in the table. Diagram 2 also illustrates an S4-LCR module with Frame Flanges

tted and removed, and an S4-LCRMT and S4-LCR65W module consolidated.

Diagram 2

2A. S4-LCR Series wall cut-out dimensions

190mm

(71⁄2 in)

Single S4-LCRMT

module.

213mm

3

⁄8in)

(8

190mm

(71⁄2 in)

Single S4-LCR65W

module.

373mm

11

(14

⁄16in)

Single S4-LCRMT

module consolidated

with single S4-

LCR65W module.

190mm

(71⁄2 in)

563mm

(223⁄16in)

190mm

(71⁄2 in)

Single S4-LCRMT

module consolidated

with twin S4-

LCR65W modules.

2B. S4-LCR Series minimum clear depth and dry-wall thickness

90.25mm

(31⁄2in)

X

2C. S4-LCRMT Installation Frame with and without Frame Flanges

914mm

(36in)

2D. S4-LCRMT and S4-LCR65W Installation Frames consolidated with Frame Flanges

Note: All wall cut-outs are shown in portrait orientation for

left/right channel use with upper/lower frame anges. For

centre channel use, with left/right frame anges, the wall

cut-out must be rotated 90° (landscape format).

Module Cut-out Size Min Clear Depth Drywall (Plasterboard) thickness

S4-LCRMT 190 x 213mm 90.25mm X = 32mm max / 8mm min

(71⁄2 x 83⁄8 in) (31⁄2in) (11⁄4in max / 05⁄16in min)

S4-LCR65W 190 x 373mm 90.25mm X = 32mm max / 8mm min

1

(7

⁄2 x 1411⁄16 in) (31⁄2in) (11⁄4in max / 05⁄16in min)

S4-LCRMT 190 x 563mm 90.25mm X = 32mm max / 8mm min

1

+ 1 x S4LCR65W (7

⁄2in x 223⁄16 in) (31⁄2in) (11⁄4in max / 05⁄16in min)

S4-LCRMT 190 x 914mm 90.25mm X = 32mm max / 8mm min

1

+ 2 x S4LCR65W (7

⁄2in x 36 in) (31⁄2in) (11⁄4in max / 05⁄16in min)

2.4 Back Boxes

In-wall speakers are often installed with back boxes in order

to reduce sound transmission into adjacent rooms or to satisfy

any local statutory building regulations. S4-LCRMT modules

however incorporate an integrated back box so none is needed on

installation.

S4-LCR65W modules do not incorporate a back box and if back

boxes are to be used they must be installed within the walls and

ceilings before the drywall (plasterboard) is afxed to the studs.

Alternatively, the existing drywall (plasterboard) around each

speaker installation position may be removed to enable a back

box to be installed. The drywall (plasterboard) should be reinstated

following back box installation.

Dynaudio does not supply back boxes suitable for S4-LCR65W

modules however, back boxes from alternative manufacturers may

be used, or back boxes may be constructed on site. In either case,

3

each S4-LCR65W module requires a 30 Litre (1.1ft

) minimum back

box volume in order to reach its full audio performance potential.

Check with local building regulations for re

safety. In some areas it is required to have a re-

rated back box as a re safety barrier. Ensure that

the surrounding materials meet the ammability

Class 5VA. A re rated metal back box must have a

minimum uncoated thickness of 1.35mm.

Page 6

3. Speaker Positions

S4-LCR Series modules are designed specically for front

and centre channel applications in multi-channel audio visual

installations. Position guidelines and diagrams are covered in the

following paragraphs and illustrated in the Diagram 3.

The left and right speakers should be located either side of the

screen. The centre channel speaker should be located centrally

above or below the screen, ideally less than 0.25 m (10 in) away.

In the case of acoustically transparent screens the centre channel

speaker should be located centrally behind the screen.

Note: The nature of the installation of custom install speakers

means that it is sometimes impractical to locate them in acoustically

optimal positions. Compromise is often more likely to be necessary

in multi-channel installations where positions have to be found for

multiple speakers. In these circumstances it is preferable to favour

the position of the front and centre channel speakers over that of

the surround channel speakers.

4. Connections and Mode Settings

S4-LCR Series systems can be connected in either passive or

active mode. Diagram 4 illustrates passive and active connection of

systems comprising both one and two S4-LCR65W modules.

4.1 Passive Mode

• In passive mode, the S4-LCRMT and S4-LCR65W modules

employed for each channel are connected in parallel to a

single power amplier channel.

• The two mode selection jumpers on the crossover PCB

of each S4-LCR65W module should be located in the J1

position. The mode selection jumpers can be accessed by

lifting the crossover assembly from the back of the S4LCR65W module. This is achieved by removing the four

screws identied in Diagram 4.

Note: S4-LCR65W modules are initially supplied with their jumpers

in the J1 position. Jumper position should however always be

conrmed visually before S4-LCR65W modules are installed.

Diagram 3

Left

<0.25m

(<10in)

Centre

Right

• The mode selection switch on the rear of the S4-LCRMT

module should be switched to “1W” if one S4-LCR65W is

used (per S4-LCRMT) and switched to “2W” if two are used.

Ensure that the mode selection switch position is correct

before use.

Diagram 4

4A. S4-LCRMT and single S4-LCR65W connection in passive mode.

Crossover assembly screws

+

–

Connect to amplier

–

+

IMPORTANT Ensure that the mode selection

switch position is correct. Damage may result if

the switch position is incorrect.

Jumpers in J1 position

Switch in 1W position

Page 7

Diagram 4 Diagram 4

4B. S4-LCRMT and twin S4-LCR65W connection in passive mode.

Crossover assembly screws

+

–

Switch in 2W positionJumpers in J1 position

4.2 Active Mode

• In active mode, each S4-LCRMT and single or multiple S4LCR65W module employed for each channel is connected

separately to a power amplier channel.

• The mode selection switches on the rear of each S4LCR65W module or modules should be switched to “BYP”

(bypass). Ensure that the mode selection switch

position is correct before use.

• The two mode selection jumpers on the crossover PCB

of each S4-LCR65W module should be located in the J2

position. The mode selection jumpers can be accessed

by lifting the crossover PCB module from the back of the

S4-LCR65W module. This is achieved by removing the four

screws identied in Diagram 4.

• The power amplier channel driving each S4-LCRMT and

S4-LCR65W modules must be driven via active lters. The

recommended lter characteristics are tabulated below.

Connect to amplier

–

+

Crossover assembly screws.

–

+

IMPORTANT

Ensure that the mode

selection switch

position is correct.

Damage may result if

the switch position is

incorrect.

Filter S4-LCR65W S4-LCRMT

Type Low pass High pass

Frequency 300 Hz 500 Hz

Slope 12db/octave 12db/octave

Q 0.71 1.0

Gain 0 dB (see note) 0 dB

Note: Where a S4-LCRMT module is used with a single S4LCR65W module ,the S4-LCR65W gain should be reduced by

-6dB.

Jumpers in J1 position

4C. S4-LCRMT and single S4-LCR65W connection in active mode.

Crossover assembly screws

Connect to bass

+

amplier

–

Jumpers in J2 position

4D. S4-LCRMT and twin S4-LCR65W connection in active mode.

Crossover assembly screws

Switch in BYP position

Connect to bass

amplier

+

–

Jumpers in J2 position

Switch in BYP position

Connect to mid/tweeter

amplier

–

+

IMPORTANT

Ensure that the mode selection switch

position is correct. Damage may result

if the switch position is incorrect.

Connect to mid/tweeter

amplier

–

Crossover

assembly screws

+

–

+

IMPORTANT

Ensure that the mode

selection switch

position is correct.

Damage may result if

the switch position is

incorrect.

Jumpers in J2 position

Connect to bass

amplier

+

–

Page 8

5. Speaker Installation

To install S4-LCR Series modules, proceed as described in the

following paragraphs and Diagram 6:

Note: Diagram 6 illustrates the installation of a S4-LCRMT module.

S4-LCR65W and multiple module installation is carried out in the

same manner.

• Having selected the installation positions and checked for

the presence of studs (joists), pipe work, ducts or cables,

mark cut-lines on the wall using the supplied template or

templates. Check that the dimensions of the cut-line are

correct.

The speaker cable can now be connected to the Speaker

4

Unit. Strip 15mm insulation from the cable (if necessary),

twist the wire strands and insert the stripped ends into the

speaker spring terminals. Ensure that the positive conductor

is connected to the red speaker terminal and the negative

conductor is connected to the black speaker terminal.

With the Speaker Unit connected to the speaker cable it

5

can be inserted into the Installation Frame. Turn the locking

tabs on the front surface of the Speaker Unit fully clockwise

(aligned with the lock icons) and insert it in the Installation

Frame. Push gently around each locking tab until a click

is heard. The Speaker Unit will then be secured in the

Installation Frame.

Diagram 6

1

2

Note: In order to reduce the possibility of audible wall vibration

it may be prudent to apply a bead of adhesive mastic between

the wall studs and the drywall (plasterboard) in the vicinity of wall

speakers.

Use an appropriate tool to cut along the cut-line to create a

1

cut-out in the wall. Trial t the Installation Frame or frames in

the cut-out to check clearances.

With the cut-out checked, the Installation Frame or frames

2

can be installed. If frame anges are required these should

be tted at this stage. If the installation comprises multiple

S4-LCR modules, all installation frames should be tted at

the same time.

To install an Installation Frame, insert the frame into the wall

3

cut-out and while holding it against the wall with one hand.

Use your other hand to turn four yellow securing clamps

outwards and slide them down securely against the inner

surface of the drywall (plasterboard).

Note: If speaker cables are not already installed it should be done

at this stage. It is possible that access will be required through the

opposite side of the wall to route the cables. Use low resistance

speaker cable with clear polarity marking on its insulation. Low

resistance is especially important if the length of cable from

amplier to speaker exceeds 5m. Your local Dynaudio retailer or

distributor will be able to offer advice on speaker cable selection if

required.

• Pull the speaker cable through the appropriate Installation

Frame and wall cut-out. The length of free cable should be

sufcient to allow the Speaker Unit to be held in one hand

while connecting the cable to the speaker terminals with the

other hand.

Note: Take care that the cable is positioned in such a way that it will

not get trapped as the Speaker Unit is secured into the Installation

Frame and is not touching the Speaker Unit in such a manner that it

is likely to result in audible vibrations.

Note: To remove a Speaker Unit from the Installation Frame turn

the locking tabs 90° counter-clockwise. Take care to support the

speaker as the locking tabs are turned.

Note: The high frequency tonal balance of S4-LCRMT modules

can be adjusted to suit different installation environments. A

tweeter level switch located on the Speaker Unit front panel

offers +2dB and -1dB options. The level adjustment operates

from approximately 3kHz upwards. The +2 dB option may be

appropriate if, for example, carpets, soft furnishings and curtains

dominate in the listening environment. The -1dB option may

be more suited to an environment where hard oors and glass

predominate.

• With speaker units connected and secured into in

installation frames, installation is completed by tting grilles.

Grilles are secured magnetically and require no more than

placing into position.

Note: If the wall is to be painted following speaker installation, the

supplied paint mask must be used to protect the speaker hardware

from paint ingress. Speaker grilles should not be tted during wall

painting. They should be painted separately.

Diagram 6 illustrates the in-wall speaker installation procedure.

3

5

4

+

–

Switch to adjust tweeter

level

Push to click.

Four locations.

Rotate clockwise to lock.

Rotate counter-clockwise to release.

Page 9

Specications

S4-LCR Series

Data S4-LCRMT S4-LCR65W

Type Two-way in-wall mid/tweeter module Twin-driver in-wall bass module

Drivers

Frequency response 250 Hz - 20 kHz ±3 dB 35 Hz - 3 kHz ±3 dB

Impedance

Sensitivity 89±3 dB (250-20 KHz) 86±3 dB (40-250 Hz)

Rated power* 50 W 50 W

Long term power* 150 W 200 W

Tweeter level options +3 dB/0/-3 dB N/A

Dimensions (including anges) 235x 213mm

Depth

Cut-out dimensions

Grille material Painted steel Painted steel

Grille attachment Magnetic Magnetic

Grille nish Paintable Paintable

Certications CE CE

Environmental RoHS RoHS

Tweeter: 25mm (1in)

Bass/mid: 100mm (4 in)

8 Ω nominal

5 Ω minimum

1

9

⁄4 x 83⁄8in

90 mm

1

⁄2 in

3

190x 213mm

1

⁄2 x 83⁄8 in

7

2 x 165 mm (6

4 Ω nominal

3.2 Ω minimum

395x 213mm

151⁄2 x 83⁄8in

90 mm

31⁄2 in

190 x 373 mm

71⁄2 x 1411⁄16 in

1

⁄2in)

* Power handling according to IEC268. Rated power is continuous power for 100 hours.

Grille

dimensions

System 1 x S4-LCRMT 1 x S4-LCR65W

Dimensions

264 x 230 mm

103⁄8 x 9 in

424 x 230 mm

1611⁄16 x 9 in

Dynaudio A/S, 8660 Skanderborg, Denmark

EN - Item No. 307001017205 Rev J

1 x S4-LCRMT

1 x S4-LCR65W

614 x 230 mm

243⁄16 x 9 in

www.dynaudio.com

1 x S4-LCRMT

2 x S4-LCR65W

985 x 230 mm

383⁄4 x 9 in

Custom

1319 x 230 mm

5115⁄16 x 9 in

Loading...

Loading...