Dynatest

1295 PAVEMENT FRICTION TESTER

OPERATION MANUAL

Version 1.07

®

Dynatest 1295 Version 1.07 i Sep 2017

Dynatest North America, Inc.

11415 Old Roswell Road Suite 100

Alpharetta, Georgia USA

PHONE: +1 678-781-1799

FAX: +1 678-823-9952

E-mail: MI@dynatest.com

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

Section 1 Introduction

1.1 Introduction .....................................................................................1

1.2 Model 1295 System Description .......................................................1

1.3 Principles of Operation .....................................................................1

1.4 Daily Start-up Procedures ................................................................3

1.5 Model 1295 Electrical Systems Components ....................................4

1.5.1 Control Console ................................................................4, 5, 6

1.5.2 Portable Computer ............................................................7

1.5.3 Embedded Data Acquisition System .................................7

1.5.4 Operator Pendant Push Button Control .............................7

1.5.5 Printer ................................................................................7

1.5.6 Vehicle Speed Display Meter .............................................7

1.6 Tow Vehicle Rear Bed Components .................................................8

1.6.1 250/300 Gallon Baffled Water Tank ...................................9

1.6.2 12 Volt DC Battery ............................................................9

1.6.3 750 Watt Power Inverter ....................................................9

1.6.4 Inverter Bracket..................................................................9

1.6.5 12 Volt DC Air Compressor ................................................9

1.6.6 Air Preparation Unit ...........................................................9

1.6.7 External Retractable AC Power Cord .................................9

1.6.8 Four-Way AC Outlet Box ....................................................9

1.7 Tow Vehicle Underside .....................................................................10

1.7.1 Positive Displacement Water Pump ...................................10

1.7.2 Water Tank Dump Valve ...................................................10

1.8 Tow Vehicle Rear Bumper ...............................................................11

1.8.1 Continuously Adjustable Ball Hitch .....................................11

1.8.2 Water Hose Quick Disconnect ...........................................11

1.8.3 Signal Cable ......................................................................12

1.8.4 Power Cable ................................................................ .....12

1.8.5 Air Hose Quick Disconnect ................................................12

1.9 Two Wheel Trailer Components .......................................................13

1.9.1 Single/Dual Model 1270 Two-Axis Force Transducer(s) .....14

1.9.2 Digital Encoders ................................................................14

1.9.3 Laminar Flow Water Nozzle(s) ...........................................14

1.9.4 Power Disc Brakes .............................................................14

1.9.5 Brake Actuator Units ..........................................................14

1.9.6 Test Brake Pressure Regulator ..........................................14

1.9.7 Electric Lift Jacks ...............................................................15

1.9.8 Electric Lift Jack Raise/Lower Switch .................................15

1.9.9 Rear Trailer LED Lights ......................................................15

1.9.10 Air Shocks ..........................................................................15

Section 2 Calibration

2.1 Calibration menu ..............................................................................16

2.2 Force Transducer Calibration ...........................................................17

2.2.1 How to perform the Daily Force Transducer(s) Calibration ....17

Dynatest 1295 Version 1.07 ii Sep 2017

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

Section 2 2.2.2 Editing the Transducer Platform Calibration Values ...............18

2.2.3 The Two types of Force transducer(s) Calibrations ................18

2.2.4 Understanding How Friction is Calculated .............................18

2.2.5 How often Should the Force Transducer(s) be Calibrated .....19

2.2.6 Description of All Force calibration Fields ..............................19

2.2.6.1 View .........................................................................19

2.2.6.1.1 Un-calibrated ..........................................19

2.2.6.1.2 Calibrated ...............................................19

2.2.6.2 Calibrated Values ....................................................19

2.2.6.2.1 Traction Calibration .................................19

2.2.6.2.2 Load Calibration ................................ ......19

2.2.6.2.3 Trailer Weight..........................................19

2.2.6.2.4 Traction Gain ..........................................20

2.2.6.2.5 Load Gain ...............................................20

2.2.6.2.6 Traction Offset ........................................20

2.2.6.2.7 Load Offset .............................................20

2.2.6.3 Calibration Resistors ................................................20

2.2.6.4 Calibration Status ....................................................20

2.2.6.5 Calibrate Button .......................................................20

2.3 Distance and Velocity Calibration .....................................................21

2.3.1 How to Perform Automatic Distance and Speed Calibration 21

2.3.2 How to Manually Enter a Distance & Speed Calibration Value 22

2.3.3 How Often Should the Distance & Speed be Calibrated .........22

2.3.4 What Happens if the Distance & Speed Values are Incorrect .22

2.3.5 How Does Distance and Speed Calibration Function .............22

2.3.6 Description of the Distance Calibration Fields ........................23

2.3.6.1 Distance Calibration Length ......................................23

2.3.6.2 Right Wheel Encoder Calibration Value ....................23

2.3.6.3 Left Wheel Encoder Calibration Value ......................23

2.3.6.4 Vehicle Encoder Calibration Value ...........................23

2.3.6.5 Calibration Status Box ..............................................23

2.3.6.6 Calibration Button .....................................................24

2.3.6.7 Distance Traveled .....................................................24

2.3.6.8 Left Encoder Count ...................................................24

2.3.6.9 Right Encoder Count ................................................24

2.3.6.10 Vehicle Encoder Count .............................................24

2.3.6.11 Left Calibration Value ...............................................24

2.3.6.12 Right Calibration Value ............................................. 24

2.3.6.13 Vehicle Calibration Value ..........................................24

2.3.6.14 Last Calibration Value ...............................................24

2.3.6.15 Left Timer Count .......................................................24

2.3.6.16 Right Timer Count .....................................................25

2.3.6.17 Vehicle Timer ............................................................25

2.3.6.18 Left Wheel Speed .....................................................25

2.3.6.19 Right Wheel Speed ...................................................25

2.3.6.20 Vehicle Speed ..........................................................25

Dynatest 1295 Version 1.07 iii Sep 2017

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

Section 2 2.4 Temperature Sensor Calibration .......................................................26

2.4.1 Temperature Sensor Calibration ..........................................26

2.4.1.1 Air Temperature ................................................26

2.4.1.1.1 Gain .............................................26

2.4.1.1.2 Offset ...........................................27

2.4.1.2 Surface Temperature .........................................27

2.4.1.2.1 Gain .............................................27

2.4.1.2.2 Offset ...........................................27

2.4.1.3 Tire Temperature ...............................................27

2.4.1.3.1 Gain .............................................27

2.4.1.3.2 Offset ...........................................27

2.5 Flow and Level Sensor Calibration ....................................................28

2.5.1 Flow Meter and Sensor Calibration ......................................28

2.5.1.1 Flow Meter 1 ......................................................28

2.5.1.1.1 Gain .............................................28

2.5.1.1.2 Offset ...........................................28

2.5.1.2 Flow Meter 2 ......................................................28

2.5.1.2.1 Gain ............................................. 28

2.5.1.2.2 Offset ...........................................29

2.5.1.3 Water Tank Sensor ............................................29

2.5.1.3.1 Gain .............................................29

2.5.1.3.2 Offset ...........................................29

2.6.1 How to Use the Meter and DAC Calibration ...................................30

2.6.2 Meter DAC Field Descriptions .............................................31

2.6.2.1 DAC 1 – Speed DVM ........................................31

2.5.2.1.1 Gain .............................................31

2.5.2.1.2 Offset ...........................................31

2.6.2.2 DAC 2 – Left Load DVM ...................................31

2.5.2.2.1 Gain .............................................31

2.5.2.2.2 Offset ...........................................31

2.6.2.3 DAC 3 – Right Load DVM .................................31

2.5.2.3.1 Gain .............................................31

2.5.2.3.2 Offset ...........................................31

Section 3 Setup

3.1 Initial Setup of the Tow Vehicle and Trailer .......................................32

3.2 Initial Setup of the Computer For Testing .........................................33

3.3 General Software Organization ........................................................34

3.4 Software Setup Process Outline .......................................................36

Dynatest 1295 Version 1.07 iv Sep 2017

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

Section 4 Operation

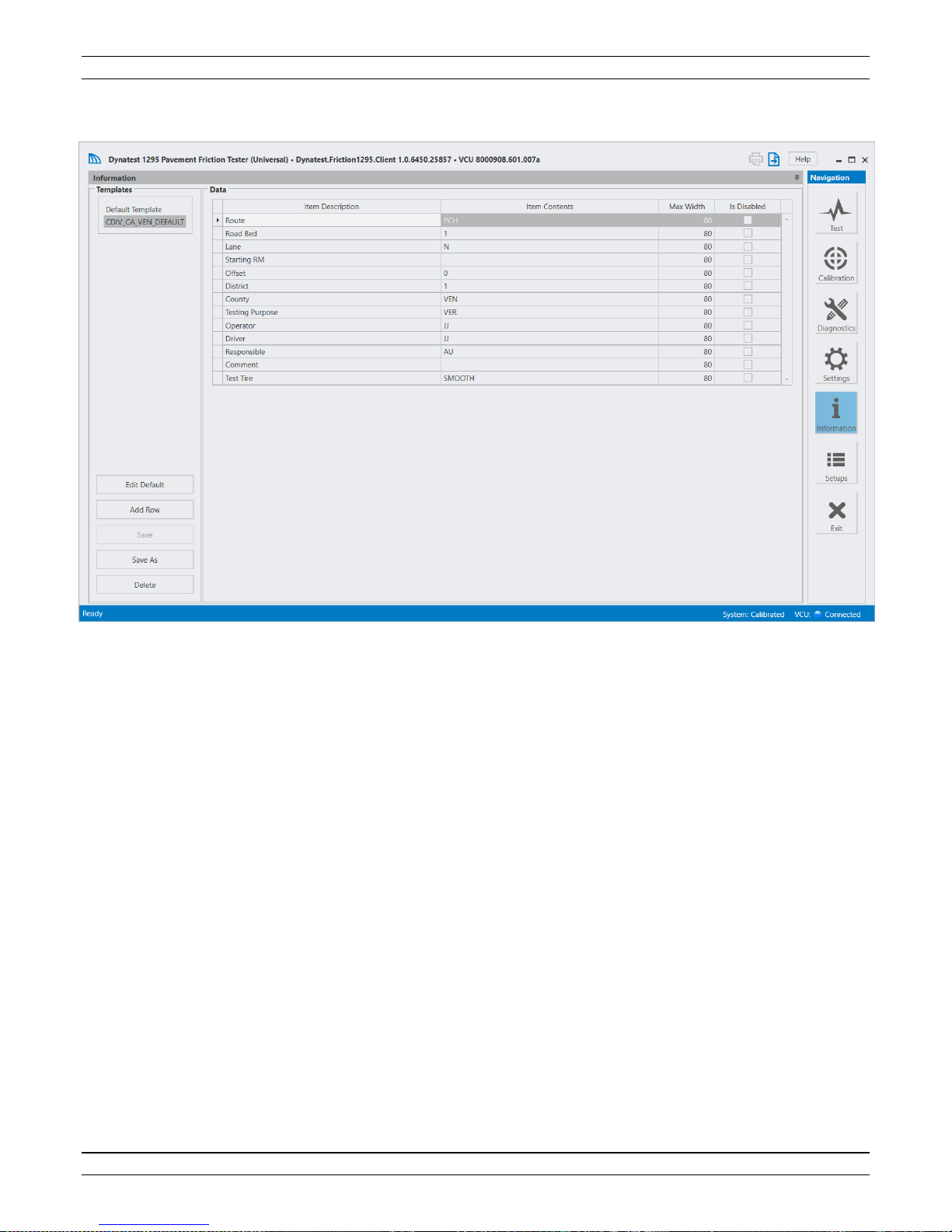

4.1 Test Information Menu ......................................................................37

4.1.1 Editing Information .................................................................38

4.1.2 Loading Default .....................................................................38

4.1.3 Recalling a Template .............................................................38

4.2 Settings ............................................................................................39

4.2.1 Control Parameter Overview .................................................40

4.2.1.1 Test Type........................................................................40

4.2.1.1.1 Standard ...........................................................40

4.2.1.1.2 Chirp .................................................................40

4.2.1.1.3 Target Speed ....................................................40

4.2.1.1.4 Speed Range ....................................................40

4.2.1.1.5 Test Suspension Speed ....................................40

4.2.1.2 Test Cycle Sequence ......................................................40

4.2.1.2.1 Manual ..............................................................41

4.2.1.2.2 Auto ..................................................................41

4.2.1.3 Test Wheel Sequence ....................................................41

4.2.1.3.1 Left ....................................................................41

4.2.1.3.2 Right..................................................................41

4.2.1.3.3 Alternate (L-R) ...................................................41

4.2.1.3.4 Alternate (R-L) ....................................................41

4.2.1.4 Test Start .......................................................................42

4.2.1.4.1 Start Test by Pendant at DMI Start ....................42

4.2.1.4.2 Start Test by Pendant after DMI ........................42

4.2.1.4.3 Start Test on Distance From DMI ......................42

4.2.1.4.4 Auto Test Start Distance....................................42

4.2.1.5 Test Stop .......................................................................42

4.2.1.5.1 Pendant .............................................................42

4.2.1.5.2 Distance ............................................................42

4.2.1.6 Test Time Parameters ...................................................43

4.2.1.6.1 Time parameter 1 ..............................................43

4.2.1.6.2 Time Parameter 2..............................................43

4.2.1.6.3 Time Parameter 3..............................................43

4.2.1.6.4 Time Parameter 4..............................................43

4.2.1.6.5 Time Parameter 5..............................................43

4.2.1.7 DMI – Distance Measuring Instrument ...........................43

4.2.1.7.1 DMI (Units) .........................................43

4.2.1.7.2 DMI Starting Distance .........................43

4.2.1.7.3 Count UP or Down ..............................43

4.2.1.8 Miscellaneous ...............................................................

4.2.1.8.1 System Units..............................................................44

4.2.1.8.1.1 US/English .....................................................44

4.2.1.8.1.2 Metric .............................................................44

4.2.1.9 Test Watering ................................................................44

4.2.1.9.1 Wet ...................................................................44

4.2.1.9.2 Dry ....................................................................44

4.2.1.9.3 Pre-wet ..............................................................44

Dynatest 1295 Version 1.07 v Sep 2017

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

Section 4

4.2.1.10 Data Average Filter ..............................................44

4.2.1.11 Display Settings…………………………………….45

4.2.1.11.1 Speed ...............................................45

4.2.1.11.2 DMI ...................................................45

4.2.1.11.3 SN ....................................................45

4.2.1.11.4 SN Display Value ..............................45

4.2.1.12 Cycle Options ......................................................45

4.2.1.12.1 Water Control Options ......................45

4.2.1.12.2 Nozzle control Options ...................... 45

4.2.1.12.3 Air Compressor Options ...................45

4.2.1.13 GPS Settings .......................................................45

4.2.1.13.1 GPS Bearing ....................................45

4.2.1.13.2 GPS Coordinate display ...................46

4.2.1.14 ROW Camera Settings ........................................46

4.2.1.14.1 Mounted upside down .......................46

4.2.1.14.2 Image Inspector ................................46

4.2.1.14.3 Image Inspector Duration..................46

4.2.1.15 Vehicle Dashboard Display Settings ....................46

4.3.1 Trend Graph Description ....................................................47

4.3.2.1 Trend Chart Field Definitions ..........................................48

4.3.2.1 SN Interval – Friction Trend Chart .......................48

4.3.2.1.1 SN Average .......................................48

4.3.2.1.2 SN Max .............................................48

4.3.2.1.3 SN Min ..............................................48

4.3.2.1.4 Y-Scale Min .......................................48

4.3.2.1.5 Y-Scale Max ......................................48

4.3.2.1.6 X-Scale .............................................48

Dynatest 1295 Version 1.07 vi Sep 2017

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

Section 4 4.3.2.2 SN Interval – Traction Force Trend Chart .............49

4.3.2.2.1 Traction Average ...............................49

4.3.2.2.2 Traction Max .....................................49

4.3.2.2.3 Traction Min ......................................49

4.3.2.2.4 Y-Scale Min .......................................49

4.3.2.2.5 Y-Scale Max ......................................49

4.3.2.2.6 X-Scale .............................................49

4.3.2.2.7 Auto Y-Scale .....................................49

4.3.2.2.8 Manual Y-Scale ..................................49

4.3.2.3 SN Interval – Load Force Trend Chart ................49

4.3.2.3.1 Load Force Average ..........................49

4.3.2.3.2 Load Force Max ................................50

4.3.2.3.3 Load Force Min .................................50

4.3.2.3.4 Y-Scale Min .......................................50

4.3.2.3.5 Y-Scale Max .......................................50

4.3.2.3.6 X-Scale .............................................50

4.3.2.3.7 Auto Y-Scale .....................................50

4.3.2.3.8 Manual Y-Scale .................................50

4.3.2.4 SN Interval – Speed Trend Chart ........................50

4.3.2.4.1 Vehicle Speed Average .....................50

4.3.2.4.2 Vehicle Speed Max ...........................50

4.3.2.4.3 Vehicle Speed Min ............................50

4.3.2.4.4 Y-Scale Min .......................................50

4.3.2.4.5 Y-Scale Max .......................................50

4.3.2.4.6 X-Scale .............................................51

4.3.2.4.7 Auto Y-Scale .....................................51

4.3.2.4.8 Manual Y-Scale .................................51

4.3.2.5 SN Interval – Flow Trend Chart ...........................51

4.3.2.5.1 Flow Average ....................................51

4.3.2.5.2 Flow Max ...........................................51

4.3.2.5.3 Flow Speed Min .................................51

4.3.2.5.4 Y-Scale Min .......................................51

4.3.2.5.5 Y-Scale Max .......................................51

4.3.2.5.6 X-Scale .............................................51

4.3.2.5.7 Auto Y-Scale .....................................51

4.3.2.5.8 Manual Y-Scale .................................51

4.3.2.6 SN Interval – Standard Deviation Trend Chart ....52

4.3.2.6.1 Friction SN Standard Deviation .........52

4.3.2.6.2 Traction Force Standard Deviation ....52

4.3.2.6.3 Load Force Standard Deviation .........52

4.3.2.6.4 Vehicle Speed Standard Deviation ....52

4.3.2.6.5 Flow Rate Standard Deviation ...........52

4.3.2.6.6 Y-Scale Min ......................................52

4.3.2.6.7 Y-Scale Max .......................................52

4.3.2.6.8 X-Scale .............................................52

4.3.2.6.9 Auto Y-Scale .....................................52

Dynatest 1295 Version 1.07 vii Sep 2017

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

Section 4 4.3.2.6.10 Manual Y-Scale ...................................52

4.3.2.7 Locking Interval – Friction Trend Chart ...............53

4.3.2.7.1 SN at Peak ........................................53

4.3.2.7.2 SN Max .............................................53

4.3.2.7.3 SN Min ..............................................53

4.3.2.7.4 Y-Scale Min .......................................53

4.3.2.7.5 Y-Scale Max .......................................53

4.3.2.7.6 X-Scale .............................................53

4.3.2.7.7 Auto Y-Scale .....................................53

4.3.2.7.8 Manual Y-Scale .................................53

4.3.2.8 Locking Interval – Traction Trend Chart ..............53

4.3.2.8.1 Traction at Peak ................................53

4.3.2.8.2 Traction Max .....................................53

4.3.2.8.3 Traction Min ......................................53

4.3.2.8.4 Y-Scale Min .......................................54

4.3.2.8.5 Y-Scale Max .......................................54

4.3.2.8.6 X-Scale .............................................54

4.3.2.8.7 Auto Y-Scale .....................................54

4.3.2.8.8 Manual Y-Scale .................................54

4.3.2.9 Locking Interval – Load Trend Chart ...................54

4.3.2.9.1 Load Force Average ..........................54

4.3.2.9.2 Load Force Max ................................54

4.3.2.9.3 Load Force Min .................................54

4.3.2.9.4 Load Force @ Peak ..........................54

4.3.2.9.5 Y-Scale Min ........................................54

4.3.2.9.6 Y-Scale Max .......................................54

4.3.2.9.7 X-Scale .............................................55

4.3.2.9.8 Auto Y-Scale .....................................55

4.3.2.9.9 Manual Y-Scale .................................55

4.3.2.10 Locking Interval – Speed Trend Chart ................55

4.3.2.10.1 Vehicle Speed Average ....................55

4.3.2.10.2 Vehicle Speed Max .........................55

4.3.2.10.3 Vehicle Speed Min ..........................55

4.3.2.10.4 Vehicle Speed @ Peak ....................55

4.3.2.10.5 Wheel Speed @ Peak .....................55

4.3.2.10.6 Y-Scale Min .....................................55

4.3.2.10.7 Y-Scale Max .....................................55

4.3.2.10.8 X-Scale ............................................55

4.3.2.10.9 Auto Y-Scale ...................................56

4.3.2.10.10 Manual Y-Scale .............................56

4.3.2.11 Locking Interval – Flow Rate Trend Chart ...........56

4.3.2.11.1 Flow Rate Average ...........................56

4.3.2.11.2 Flow Rate Max ................................56

4.3.2.11.3 Flow Rate Min .................................56

4.3.2.11.4 Flow Rate Peak ...............................56

Dynatest 1295 Version 1.07 viii Sep 2017

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

Section 4 4.3.2.11.5 Y-Scale Min ................................ 56

4.3.2.11.6 Y-Scale Max .....................................56

4.3.2.11.7 X-Scale ...........................................56

4.3.2.11.8 Auto Y-Scale ...................................56

4.3.2.11.9 Manual Y-Scale ...............................56

4.3.2.12 Locking Interval – Misc. Trend Chart ...................57

4.3.12.1 % Slip at Peak .....................................57

4.3.12.2 Time to Peak .......................................57

4.3.12.3 Time to Lockup ....................................57

4.3.12.4 Y-Scale Min ........................................57

4.3.12.5 Y-Scale Max ........................................57

4.3.12.6 X-Scale ..............................................57

4.3.12.7 Auto Y-Scale ......................................57

4.3.12.8 Manual Y-Scale ..................................57

4.4 Installed hardware field descriptions ..................................58

4.4.2 Force Transducers ..................................................59

4.4.2.1 Left Wheel ...........................................59

4.4.2.2 Right Wheel .........................................59

4.4.3 Water Equipment and Sensors ...............................59

4.4.3.1 Flow Meters .........................................................59

4.4.3.2 Water Pumps .......................................................59

4.4.3.3 Water Tanks ........................................................59

4.4.4.1 DMI Distance Measuring Instrument ....................59

4.2.4.4.1 Left Wheel ........................................59

4.2.4.4.2 Right Wheel ......................................59

4.2.4.4.3 Vehicle .............................................59

4.4.5 Test Start/Stop Devices

4.4.5.1 Pendant ...............................................60

4.4.5.2 Photocell .............................................60

4.4.6 Temperature Sensors

4.4.6.1 Air Temperature Sensor ......................60

4.4.6.2 Surface Temperature Sensor...............60

4.4.6.3 Left Tire Temperature Sensor..............60

4.4.6.4 Right Tire Temperature Sensor ...........60

4.4.6.5 TankTemperature Sensor ....................60

4.4.7 Additional Equipment

4.4.7.1 Printer .................................................60

4.4.7.2 GPS ....................................................61

4.4.7.3 Right of Way Camera ..........................61

4.4.7.4 Vehicle Dash Display ..........................61

4.4.7.5 Inclinometer .........................................61

4.4.7.6 Accelerometer .....................................61

4.4.7.7 Texture Sensor ....................................61

Dynatest 1295 Version 1.07 ix Sep 2017

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

Section 4 4.5 Storage and Printing Field Descriptions ............................................62

4.5.1 Data Storage ...........................................................62

4.5.2 File Name ..............................................................62

4.5.3 File Directory ...........................................................63

4.5.4 Test Set Number .....................................................63

4.5.5 Default File Setting……………………………………63

4.5.6 Output Files ............................................................63

4.6 Miscellaneous .................................................................................63

4.6.1 Test Printing ............................................................63

4.6.2 Print Disk Files ........................................................64

4.7 F Key Events ......................................................................................65

4.8 SN Correction ....................................................................................66

4.9 Diagnostics ........................................................................................67

4.9.1 Encoders and Timers ..........................................................67

4.9.1.1 dt meters and measurement theory ....................67

4.9.1.2 Speed Meters ....................................................68

4.9.1.3 Encoder Count Meters .......................................68

4.10.1 Analog I/O ........................................................................70

4.10.2 Analog Hardware Overview.................................70

4.10.3 Trace Select ........................................................71

4.11.1 Digital I/O ..........................................................................72

4.11.2 Digital Inputs:Port1,Port2,Port3 ...........................72

4.11.3 Digital Outputs:Port1,Port2 .................................73

4.12 Testing ...........................................................................................75

4.12.1 Test Screen Layout ...........................................................75

4.12.2.1 SN Average .....................................................76

4.12.2.2 SN Max ................................ ............................76

4.12.2.3 SN Min .............................................................76

4.12.2.4 SN Standard Deviation .....................................76

4.12.2.5 Traction Average ..............................................76

4.12.2.6 Traction Max ....................................................76

4.12.2.7 Traction Min .....................................................76

4.12.2.8 Traction Standard Deviation .............................77

4.12.2.9 Load Average...................................................77

4.12.2.10 Load Max .........................................................77

4.12.2.11 Load Min ..........................................................77

4.12.2.12 Load Standard Deviation ..................................77

4.12.2.13 Speed Average ................................................77

4.12.2.14 Flow Average ...................................................77

4.12.2.15 Peak SN (PSN) ................................................77

4.12.2.16 Time To Peak (TTP).........................................77

Dynatest 1295 Version 1.07 x Sep 2017

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

Section 4

4.12.2.17 % Slip ..............................................................77

4.12.2.18 Time To Lockup (TTL) ......................................77

4.13 Setups……………………………………………………………………..78

Section 5 Troubleshooting

5.1 Troubleshooting ................................................................................79

5.2 Troubleshooting the Software ...........................................................79

5.2.1 Rebooting the 1295 Operating Software ............................81

5.2.2 Troubleshooting the 1295 Electronics ................................81

Section 6 Maintenance

6.1 Preventative Maintenance ................................................................82

6.2 Service Schedule (Tow Vehicle) .......................................................82

6.3 Service Schedule (Trailer) ................................................................83

6.3.1 Replacing the Trailer Wheel Bearings ................................86

6.3.2 Measure Wheel Bearing Endplay .......................................86

6.3.3 Brake Bleeding Procedure (Trailer) ....................................87

6.3.4 Verifying/Adjusting Trailer Brake Pressures .......................87

6.3.4.1 Safety Brakes ......................................................88

6.3.4.2 Left Or Right Wheel Lockup Brakes .....................88

6.3.4.2.1 Safety Brakes ....................................88

6.3.4.2.2 Test Brake(s) .....................................89

6.3.5 Aligning the Water Pump Gearbox with the Drive Shaft .....90

6.3.6 Adjusting the Water Pump Belts (Tow Vehicle) .................90

6.3.7 Adjusting the Electric Clutch (Water Pump) .......................91

Dynatest 1295 Version 1.07 xi Sep 2017

SECTION 1 INTRODUCTION

1.1 INTRODUCTION

This manual contains the descriptive information, operation, setup, and service instructions for the 1295

Computer Controlled Pavement Friction Tester manufactured by Dynatest. (Figure 1-1)

The purpose of this manual is to provide the instructions necessary to insure the proper operation and

maintenance of the 1295. Adherence to the instructions will insure satisfactory operation.

1.2 1295 SYSTEM DESCRIPTION

The 1295 Pavement Friction Tester has been developed to perform dry or self-wetted locked wheel

(skid) and peak incipient (slip) friction testing for paved surfaces (see Figure 1-1). The 1295 is designed

to operate at speeds between 20 to 70 MPH (30 to 110 km/hr) while computing the dynamic skid

number FN(t).

The computerized 1295 consists of a fully instrumented tow vehicle and two wheel trailer which uses

one or two M1270 two-axis force transducer(s) mounted on the axle assembly. All electronic

instrumentation is solid state, including a Portable laptop computer and a printer. Windows software

provided with the system allows the operator perform friction testing, enter test information, configure

test settings, calibrate the system and perform system diagnostics .

The on-board computer calculates the dynamic skid number FN(t) from the two-axis force transducer

in real time, and displays the friction and speed traces on the laptop test screen. Test headers, skid

numbers, as well as curves and peak incipient friction, if desired, can be printed or stored on a laptop

hard drive/ SSD. Additional software capabilities include automatic system calibration, full system

diagnostics, and adjustable test cycle timing (within ASTM E274 specifications).

1.3 PRINCIPLES OF OPERATION

Friction testing on pavement is accomplished by using one of two recognized methods. These methods

are the Continuous Peak Friction Test and the Locked Wheel Friction Test. The 1295 Pavement

Friction Tester utilizes the Locked Wheel Friction Test method.

First, the operator selects whether the test is to be dry or wet. Next, the two wheel trailer is brought up

to test speed prior to reaching the test site. The brake on the right or left test wheel is applied until it is

locked. The wheel must achieve lock-up within the pre-programmed limit, while the test vehicle is

held at a constant speed (+/- 1 MPH). Tire braking traction force, vehicle speed, and all other desired

parameters are recorded when the brake is first applied during the test cycle. Those parameters continue

to be recorded until the test tire is unlocked. Peak and locked wheel sliding forces are calculated by

the computer for each specific test run. The test results are displayed both graphically and numerically

on the laptop, and are stored on hard disk drive.

Dynatest 1295 Version 1.07 1 Sep 2017

SECTION 1 INTRODUCTION

Figure 1-1. Model 1295 Pavement Friction Tester

Dynatest 1295 Version 1.07 2 Sep 2017

SECTION 1 INTRODUCTION

1.4 DAILY START-UP PROCEDURES

1. Some mechanical checks are required to maintain the accuracy of the test vehicle and trailer. It is

recommended that the tow vehicle tire pressure be checked daily to avoid excessive wear on the

tires. The tire manufacturer’s tire pressure recommendations are listed on the tire. The tires

should be inflated to the maximum pressure listed due to extreme weight conditions.

2. Check the trailer tires daily. Prior to each series of tests, warm up the tires by traveling for at least

5 miles (10 km) at normal traffic speeds. Replace the tire if it has been worn beyond the wear

line(s). Set the E501 and E524 test tire inflation pressure at 24 0.5 psi (165 3 kPa) at ambient

temperature just before the 5 mile (10 km) warm-up. (See ASTM E 274).

3. A daily check of the air shocks should be done to verify the proper amount of air pressure is

maintained in them. 50 psi (345 kPa) of air is needed to maintain level and to provide a stable

ride.

4. Proper maintenance of the tow vehicle (as described in the owner's manual) DOES NOT eliminate

the need for daily fluid level checks, belt inspections, etc.

5. A daily visual inspection of the trailer and under the cover should consist of the areas where fluid

leaks may occur. This includes such areas as the brake caliper area on both spindles, the hose

connections, and also in the area of the master cylinder. Detection of leaks may occur early with

the observation of areas with excessive moisture, and/or areas where dirt begins to collect.

6. The water tank, can be filled to its capacity. Verify first that the drain valve is closed. An internal

overflow tube will allow the tank to fill to capacity without flowing over the tank fill tube.

7. If the pneumatic lines are disconnected from the trailer, the tow vehicle pneumatic storage tanks

will maintain their pressure. If the pneumatic lines are NOT disconnected from the trailer, the

system will deplete itself of air pressure. This is due to the design of the valves on the trailer to

continuously exhaust. If the system becomes depleted, the tow vehicle compressor may be used

to recharge the pneumatic system, or the system may be recharged by an external compressor

source.

8. Inspect the trailer jacks to see that they are fully retracted. Inspect the trailer attaching points to

see that the trailer is properly coupled to the tow vehicle, and that the safety chain, water, air, and

electrical connectors are properly connected.

9. It is necessary to calibrate of the DYNATEST 1295 system each time power has been turned off.,

Perform calibration on a level surface, with the tow vehicle in park, and your foot off the brake.

All power must be on (AC and DC). Allow the system to warm-up 15 minutes prior to

calibration. To perform system calibration, refer to Initial Setup.

10. When traveling to and from test sites it is recommended that the DC power and compressor power

be ON to allow the test trailer's service brakes to assist in stopping.

Dynatest 1295 Version 1.07 3 Sep 2017

SECTION 1 INTRODUCTION

1.5 1295 ELECTRICAL SYSTEM COMPONENTS

All electric power for the 1295 is provided by a single 135 amp. alternator driven off the tow vehicle's

engine. The following information is designed to familiarize the operator with the 1295's electrical

system components located inside the tow vehicle's cab.

1.5.1 CONTROL CONSOLE

This console is located between the driver and the passenger seats inside the tow vehicle's cab (see

Figure 1-3). Located on the top of the console are a series of electronic rocker switches and status

lights. The console layout is shown below in figure 1-2.

Figure 1-2. Console Layout

Dynatest 1295 Version 1.07 4 Sep 2017

SECTION 1 INTRODUCTION

1.5.1 CONTROL CONSOLE

AC Power On/Off Switch

Turns power ON and OFF for the 1295's power inverter supplies 120 Volt AC power for the portable

PC and printer.

DC Power On/Off Switch

Turns 12 Volt DC battery power ON and OFF for the 1295's solid state logic, meters, and switching

functions within the main console. This 12 Volt DC battery is located in the rear bed of the tow

vehicle.

Compressor On/Off Switch

Turns 12 Volt DC power ON and OFF to the pressure switch which energizes the air compressor in

the rear bed of the tow vehicle. The compressor is responsible for operating the 1295's air system,

which raises and lowers the Laminar flow water nozzle(s), and controls the air over hydraulic brakes

on the two wheel trailer.

Flasher On/Off Switch

Turns the the alternating flashers on top of the two wheel trailer.

Emergency Stop Button

For immediately terminating the Automatic Test cycle in case of an emergency. Press the button one

(1) time to end the Automatic Test cycle, and release the test brakes. Pressing the emergency button

will abort the pavement friction test in progress.

Operator Pendant Jack

For plugging in the operator hand pendant. The hand pendant is responsible for STARTING the test

cycle. The operator programs the computer to automatically stop the test cycle. This hand pendant is

also used to start and stop the distance calibration of the digital encoders on the two wheel trailer, and

to START and STOP the distance testing.

Compressor Status Light

Indicates when the air compressor in the rear bed of the tow vehicle is pumping air into the air system

on the two wheel trailer. The compressor is automatically controlled by a pressure switch to maintain

approximately 80 PSI (552 kPa). The compressor will not operate during a test run.

Dynatest 1295 Version 1.07 5 Sep 2017

SECTION 1 INTRODUCTION

IMPORTANT

Processor Ready Status Light

Indicates that the embedded data acquisition computer is running and is ready for Ethernet

communication to the laptop. The laptop should NOT be turned on until the Status light blinks. Once

blinking the light indicates that the communications for the software are ready for use.

If the compressor light comes on during a test, that indicates there is

inadequate pressure to conduct the test, and a test fault may occur.

Figure 1-3. Laptop PC and Control Console

Dynatest 1295 Version 1.07 6 Sep 2017

SECTION 1 INTRODUCTION

1.5.2. LAPTOP COMPUTER

The current model 15 inch laptop computer is equipped at minimum with:

Intel Core I7processor @ 2.70 GHz or better

Minimum 8 GB Random Access Memory (RAM).

Ethernet communication ports.

Minimum of a 500 Gb hard disk drive or SSD

The computer operating system is Windows 7 or 10 that includes option to down grade to

Windows 7.

The 1295 Windows software is used for friction testing and data analysis

1.5.3 EMBEDDED DATA ACQUISITION SYSTEM

The data acquisition system is equipped with::

16 channel, 16 bit Analog to Digital Converter

4 channel, 12 bit Digital to Analog Converter.

Optically Isolated Digital I/O.

Ethernet Communication Port.

Serial Communication Ports

1.5.4. OPERATOR PENDANT PUSH BUTTON CONTROL

This control allows the operator to start the automatic test cycle without taking their eyes off the road.

The control can easily be held in one hand during the entire testing procedure.

1.5.5. PRINTER

The printer is supplied for printing hardcopy test results and report printouts.

1.5.6. VEHICLE SPEED DISPLAY

This dashboard mounted meter allows the operator to view the accurate vehicle test speed. The meter

is connected to the system's computer. The right or left test wheel, whichever is not locked during

friction testing, supplies the digital speed and distance pulses to the computer.

Dynatest 1295 Version 1.07 7 Sep 2017

SECTION 1 INTRODUCTION

1.6 TOW VEHICLE REAR BED COMPONENTS

The following information is designed to help the operator identify the electrical and mechanical

components located in the rear bed of the tow vehicle (see Figure 1-4).

Figure 1-4. Tow Vehicle Rear Bed Components

Dynatest 1295 Version 1.07 8 Sep 2017

SECTION 1 INTRODUCTION

1.6.1 250/300 GALLON BAFFLED WATER TANK

This corrosion resistant water tank has interior baffling to minimize the effects of water motion, and a

vent to ensure continuous water flow. At the bottom of the tank is a serviceable water filter to ensure

the self-watering system does not plug. The tank is filled through the screw-on cap located on top of

the tank. Optional larger tank systems available.

1.6.2 12 VOLT DC BATTERY

Operates the 1295's 12 Volt DC electronics. This battery is isolated from the tow vehicle's 12 Volt DC

battery during shut-down.

1.6.3 POWER INVERTER

Supplies 120 Volt AC power to the monitor, computer, printer, and electronic power supplies.

1.6.4 INVERTER BRACKET

This bracket supports the power inverter. Mounted on the outside of the bracket are several relays; one

relay starts the power inverter, and another to starts the air compressor.

1.6.5 12 VOLT DC AIR COMPRESSOR

This compressor is responsible for operating the air system on the two wheel trailer. This air system

raises and lowers the Laminar flow water nozzles and supplies air to the air over hydraulic brakes on

the two wheel trailer.

1.6.6 AIR PREPARATION UNIT

This unit is mounted on the water tank and includes the air filter, dryer, pressure switch, and pressure

gauge for the air system. The drying agent used in the dryer is desiccant. Its condition can be

determined by the color code on the side of its container. New desiccant is blue and turns pink when it

needs to be replaced.

1.6.7 EXTERNAL RETRACTABLE AC POWER CORD

This power cord supplies external 120 Volt AC power to the power inverter for operating the computer

and printer on AC power and for charging the rear battery.

1.6.8 FOUR-WAY AC OUTLET BOX

This AC outlet box allows the operator to plug in the power inverter, used for external AC power-up

of the computer and printer.

Dynatest 1295 Version 1.07 9 Sep 2017

SECTION 1 INTRODUCTION

1.7 TOW VEHICLE UNDERSIDE

Underneath the cab of the tow vehicle are several components for the self-watering system.

1.7.1 POSITIVE DISPLACEMENT WATER PUMP

There is one (1) pump mounted on a steel bracket directly underneath the tow vehicle's cab. The pump

is gear belt driven off the drive shaft and idler assembly by means of a 12 Volt DC electric clutch and

gearbox assembly. This gearbox and idler assembly, along with the gear belt pulleys, provides the

necessary gear reduction to drive the pump at the proper speed for the desired water flow.

1.7.2 WATER TANK DUMP VALVE

This valve is located directly underneath the driver’s door on the tow vehicle's cab. The valve allows

the operator to quickly dump water from the baffled water tank in the rear bed of the tow vehicle.

NOTE

Underneath the tow vehicle are two (2) nine (9) gallon (40 liter) air storage tanks,

for the pneumatic system.

Dynatest 1295 Version 1.07 10 Sep 2017

SECTION 1 INTRODUCTION

Air Connection

P/N 002318

Water Connection

P/N 002323

Adjustable Hitch

P/N 016420

Trailer Signal

Connector

P/N 001715

Trailer Power

Connector

P/N 001714

Safety Chains

Trailer Jack

P/N 002631

1.8 TOW VEHICLE REAR BUMPER

The following information is designed to familiarize the operator with the various connections between

the tow vehicle and the two wheel trailer (see Figure 1-5).

Figure 1-5. Tow Vehicle Rear Bumper

1.8.1 CONTINUOUSLY ADJUSTABLE BALL HITCH

This feature allows the operator to vertically raise and lower the ball hitch which levels the tongue on

the two wheel trailer. Leveling the two wheel trailer is required in order to properly align the two-axis

force transducer(s) with the test pavement.

1.8.2 WATER HOSE QUICK DISCONNECT

This feature allows the operator to quickly disconnect the 1.5 inch (3.5mm) diameter water hose(s), for

the 1295's self-watering system, from the tow vehicle.

Dynatest 1295 Version 1.07 11 Sep 2017

SECTION 1 INTRODUCTION

Air Connection

P/N 002318

Water Connection

P/N 002323

Adjustable Hitch

P/N 016420

Trailer Signal

Connector

P/N 001715

Trailer Power

Connector

P/N 001714

Safety Chains

Trailer Jack

P/N 002631

1.8.3 SIGNAL CABLE

This cable connects the two-axis force transducer(s) on the two wheel trailer with the tow vehicle's

electronics. An environmental connector on the rear bumper of the tow vehicle is provided for this

connection.

1.8.4 POWER CABLE

This cable allows the 12 Volt DC power from the tow vehicle to be transferred to the 12 Volt DC

electronics on the two wheel trailer. An environmental connector on the bumper of the tow vehicle is

provided for this connection.

1.8.5 AIR HOSE QUICK DISCONNECT

This connector allows the operator to quickly disconnect the 1/4 inch (6 mm) diameter air line, for the

two wheel trailer's air system, from the tow vehicle.

Figure 1-6. Tow Vehicle / Trailer Hookup Illustration.

Dynatest 1295 Version 1.07 12 Sep 2017

SECTION 1 INTRODUCTION

Air Connection

P/N 002318

Water Connection

P/N 002323

Adjustable Hitch

P/N 016420

Trailer Signal

Connector

P/N 001715

Trailer Power

Connector

P/N 001714

Safety Chains

Trailer Jack

P/N 002631

1.9 TWO WHEEL TRAILER COMPONENTS

This information is designed to familiarize the operator with the various mechanical and electrical

components on the two wheel trailer. The trailer is constructed of 2 x 4 inch (50 x100 mm) rectangular

box sectional steel tubing with a 2 inch (50 mm) ball coupler. The suspension uses a parallelogram

trailing arm design with upper and lower control arms mounted on each side of the trailer. Coil springs,

air adjustable shock absorbers, and an anti-sway bar are used in the trailer's suspension.

Figure 1-7. Two Wheel Trailer and Components

Dynatest 1295 Version 1.07 13 Sep 2017

SECTION 1 INTRODUCTION

1.9.1 SINGLE/DUAL M1270 TWO-AXIS FORCE TRANSDUCER(S)

Depending upon customers specifications, one (1) or two (2) force transducers are mounted next to the

test wheels. These transducers provide the dynamic vertical load and horizontal tractive force

measurements and their outputs are fed into the computer to provide the Dynamic Friction Number

FN(t) in real time.

1.9.2 DIGITAL ENCODERS

There are two (2) encoders on the 1295. They are mounted on the axle assembly by both test tires.

These encoders provide accurate distance and tow vehicle velocity pulses, as well as instantaneous

locked wheel velocities.

1.9.3 LAMINAR FLOW WATER NOZZLE(S)

Depending upon customer specifications, one (1) or two (2) 7 inch (178 mm) water nozzles are mounted

directly in front of the trailer's test wheel(s), and are controlled by the computer. During testing, the

right or left nozzle, whichever the operator has selected, will provide a uniform .020 inch flow of water

on the pavement at any speed during self-wetted testing. When the operator selects self-wetted testing

in the Auto Cycle Setup menu, the Laminar flow nozzle selected will remain in the down position

throughout testing.

NOTE

The Laminar Flow Nozzle will retract upward when the 1295 is NOT in

the TEST MODE or the 1295 system is in reverse. This feature is

provided to prevent damage to the nozzle(s).

1.9.4 POWER DISC BRAKES

Located on both trailer wheels, these hydraulic brakes are capable of providing lock-up for the left or

right test wheel. Safety brakes are applied on the trailer when the tow vehicle's brakes are applied.

1.9.5 BRAKE ACTUATOR UNITS

Located on the panel directly behind the electrical enclosure (underneath the front trailer cover), these

two (2) units consist of a truck style brake chamber mounted to an automobile brake master cylinder.

One brake actuator unit per test wheel is connected to a disc brake caliper. The braking system is air

over hydraulic. Valves located directly below the master cylinder apply the brakes. Brakes can be

applied by depressing the tow vehicle brakes and also by computer control.

1.9.6 TEST BRAKE PRESSURE REGULATOR

An adjustable air pressure control is provided to adjust the desired brake line pressure for wheel lockup. To increase brake line pressure, screw the adjustment knob IN, to decrease pressure, screw the

adjustment knob OUT.

NOTE

Brake Line Pressure On The hydraulic pressure gauge must be adjusted

to 1000 psi (6895 kPa) of hydraulic pressure 55 to 60 psi (345 kPa to 415

kPa) air pressure on test brake regulator gauge).

Dynatest 1295 Version 1.07 14 Sep 2017

SECTION 1 INTRODUCTION

1.9.7 ELECTRIC LIFT JACKS

These two (2) jacks operate off the 12 Volt DC battery located in the rear bed of the tow vehicle.

Located on either side of the two wheel trailer, these jacks lift the trailer off the ground during test tire

changeover. Manual handles are also provided in case of power jack failure.

1.9.8 ELECTRIC LIFT JACK RAISE/LOWER SWITCH

This switch is mounted on an electrical cabinet underneath the two wheel trailer's cover. There are

three (3) positions to this switch:

UP = Raise

MIDDLE = Locked

DOWN = Lower

1.9.9 REAR TRAILER LED LIGHTS

The rear of the trailer is fitted with dual (2) tail, brake, and turn signal lights. Four (4) red alternately

flashing safety lights are mounted on the trailer for use during testing. They are turned ON by the

Flashers On Switch on the Main Console.

1.9.10. AIR SHOCKS

The axle is suspended on air shocks. For proper operation the shocks should be inflated to 50 PSI (344

kPa). This will also be necessary to keep the trailer level.

Dynatest 1295 Version 1.07 15 Sep 2017

SECTION 2 CALIBRATION

2.1 CALIBRATION MENU

Locate the CALIBRATION menu button on the main menu screen.

1. Press the ‘Calibration’ button with the mouse to enter the CALIBRATION section of the program.

Figure 2-1: Main Menu Screen

2. There are five (5) calibration pages which are listed below.

To access any of the calibration pages press the calibration tab of interest with the mouse

1 Force Transducer

2 Distance and Velocity

3 Temperature

4 Flow and Level

5 Meters and DAC

Dynatest 1295 Version 1.07 16 Sep 2017

SECTION 2 CALIBRATION

2.2 FORCE TRANSDUCER Calibration

Figure 2-2: Force Transducer Calibration Screen (dual transducer system shown)

2.2.1 How to perform the Daily Force Transducer(s) Calibration

1. Verify that the trailer is level by putting a level on the trailer tongue

2. Verify that the traction, load and trailer weight platform calibration values are correct

3. Press the ‘Calibrate’ button with the mouse

4. Wait for the computer to calculate the gain and offset trim values.

5. View the corrected calibration force values by selecting the view / calibrated selection. The traction and

load offset meters should read close to zero.

Dynatest 1295 Version 1.07 17 Sep 2017

SECTION 2 CALIBRATION

2.2.2 Editing the Transducer Platform Calibration Values

To change the force transducer platform calibration values it is necessary to press the ‘Edit’ button with the

mouse. The calibration values are saved by pressing ‘Save’ button with the mouse .

NOTE: Dynatest has supplied the customer with a copy of the master platform calibration values

for the two-axis force transducer(s) when the 1295 was shipped.

2.2.3 The Two Types of Force Transducer(s) Calibration

To fully understand the calibration process it is important to understand the different types and aspects of how a

friction measurement system is calibrated. There are two different types of force transducer calibration.

Calibration Type I

The first type of calibration is called a daily ‘trim calibration’ it is performed before each test session.

This is the calibration process described in the above calibration section. This calibration usually takes about five

minutes to perform and dos not require any special equipment. Each time the system is turned on this ‘trim

calibration’ must be performed.

Calibration Type II

The second type of calibration is called a ‘platform’ calibration. This is a long term calibration that is usually

performed at an annual or semi-annual interval. This calibration is used to determine the traction, load and trailer

weight calibration values that are used in the ‘trim calibration’ described in ‘Calibration Type I’ above. This

calibration is performed in about one hour. This calibration requires an air bearing platform, a floor mounted air

bearing platform anchor, an air compressor source, and air bearing electronic signal conditioning hardware.

2.2.4 Understanding How Friction is Calculated

The measurement system requires an accurate force calibration to produce accurate friction measurements.

The force transducer is used to measure the applied force in the traction and load axis. The trailer must be level to

achieve an accurate calibration. The calibration process involves taking force transducer measurements with the

system computer

Friction (F) is calculated as mu = traction / load Skid Number (SN) is calculated as SN = mu x 100

Meters are used to display the transducer forces in pounds or kilograms. The meters are positioned in a left and

right force transducer grouping. If the system has a left force transducer the left meter grouping will be visible

If the system has a right force transducer the right meter grouping will also be visible

The traction force meter displays the traction force. (horizontal axis)

The traction force offset meter displays the traction offset force. (horizontal axis)

The load force meter displays the load force (vertical axis)

The load force offset meter displays the load offset force (vertical axis)

Dynatest 1295 Version 1.07 18 Sep 2017

SECTION 2 CALIBRATION

2.2.5 How Often Should the Force Transducer(s) be Calibrated?

A ‘Platform’ Calibration should generally be performed on an annual or semi-annual basis. It should also be

performed whenever a force transducer is removed for any reason from the trailer system.

The daily calibration must be performed each time the operator starts up the 1295 friction testing software. You

cannot perform a friction test unless the operator has performed a daily calibration.

2.2.6 Description of All Force Calibration Fields

2.2.6.1 View

The view selections let the operator view calibrated or un-calibrated transducer force values

2.2.6.1.1 Uncalibrated

This selection allows the force meters to display un-calibrated force values

2.2.6.1.2 Calibrated

This selection allows the force meters to display calibrated force values

2.2.6.2 Calibration Values

The calibration values are entered into this section. This section also displays the computer generated

calibration gain and offset numbers.

2.2.6.2.1 Traction Calibration

The traction calibration value is the force that is electronically applied to the force

transducer by inserting a resistive shunt across the traction resistive bridge

circuit. The resistive shunt is automatically connected by the computer system.

The traction calibration value is shown on the traction force meter.

2.2.6.2.2 Load Calibration

The load calibration value is the force that is electronically applied to the force

transducer by inserting a resistive shunt across the load resistive bridge

circuit. The resistive shunt is automatically connected by the computer system.

The load calibration value is shown on the load force meter.

2.2.6.2.3 Trailer Weight

The trailer weight calibration value is the actual weight of the trailer in pounds or

kilograms. The trailer weight value is also shown on the load force meter.

Dynatest 1295 Version 1.07 19 Sep 2017

SECTION 2 CALIBRATION

2.2.6.2.4 Traction Gain

The traction gain number is a computer generated value that is calculated from

the automated system calibration. The traction gain number has units of

pounds / volt or kilograms / volt

2.2.6.2.5 Load Gain

The load gain number is a computer generated value that is calculated from the

automated system calibration. The load gain number has units of pounds / volt

or kilograms / volt

2.2.6.2.6 Traction Offset

The traction offset number is a computer generated value that is calculated from

the automated system calibration. The traction offset number has units of

pounds or kilograms

2.2.6.2.7 Load Offset

The load offset number is a computer generated value that is calculated from the

automated system calibration. The load offset number has units of pounds or

kilograms

2.2.6.3 Calibration Resistors

The calibration resistors can be manually turned on and off for diagnostic purposes

by pressing the ‘Resistor On or Off’ with the mouse. When the calibration

resistors are turned on the ‘Calibrate’ indicator will turn red.

2.2.6.4 Calibration Status

This display line is used to guide the operator through the force transducer calibration

process. Follow the instructions given on this line to perform the calibration.

2.2.6.5 Calibrate Button

The system can be calibrated by pressing the calibration button. Follow the instructions in

the upper right instruction box. The ‘Calibrate’ button can be selected by the

mouse. The computer will automatically calibrate the system calibration values.

The calibration time and date are recorded after each calibration is performed and is saved

in the data storage header information.

NOTE: It is very important that the proper traction gain, load gain and trailer weight

calibration values have entered into the system. If these calibration values are

not correct the system calibration will be in error.

Dynatest 1295 Version 1.07 20 Sep 2017

SECTION 2 CALIBRATION

2.3 DISTANCE AND VELOCITY

Figure 2-3: Distance and Velocity calibration

2.3.1 How to Perform an Automatic Distance and Speed Calibration

1) Press the ‘Calibrate’ button with mouse . This will initialize the calibration.

2) While moving at a steady speed, press the operator pendant at the test section starting location.

3) Drive the vehicle in a straight line and press the operator pendant when reaching the test section stop

location. (The vehicle must be moving at all times during the calibration, do not stop )

Note: The system will now calculate the distance and velocity calibration value.

4) Press the ‘Save’ button with the mouse.

Dynatest 1295 Version 1.07 21 Sep 2017

SECTION 2 CALIBRATION

2.3.2 How to Manually Enter a Distance and Speed Calibration Value

1) Press the ‘Edit’ button with mouse.

2) Enter the calibration value into the appropriate encoder box.

3) Press the ‘Save’ button with the mouse.

2.3.3 How Often Should the Distance and Speed be Calibrated?

1) If an encoder has been repaired or replaced or removed for service

2) If new tires have been installed on the trailer or vehicle

3) If you notice that your speed differs from your vehicle speedometer by more than 3 mph (5 kph)

4) If you have accidentally modified your calibration value and are not sure what the original value should be.

5) Before and after any critical project where data accuracy is critical. It is strongly recommended that a

distance and speed calibration be performed before and after performance related testing is performed to

bracket the test data as proof that the distance and speed related measurements are accurate and documented.

2.3.4 What Happens if the Distance and Speed Calibration Values are Incorrect?

1) The DMI reading will not be correct. If the test is setup for auto testing based on distance the start of the

test will not correspond with the correct DMI mark

2) The vehicle measured speed will not be correct. Friction values vary with test speed. If your speed is not

correct, your friction values will not represent true values for the specified test speed.

2.3.5 How Does Distance and Speed Calibration Function ?

The system uses a device called an ‘Encoder” to generate pulses when the vehicle tire rotates. Encoders are

mounted on each trailer wheel axle and in some systems also on the test vehicle. A digital pulse train is generated

as the encoder is turned.

___ ___ ___

The digital trace looks like this __| |__| |___| |___

To calibrate the encoder it is necessary to count the number of encoder pulses over a known distance interval.

Then a unit distance value can be calculated for a single encoder pulse.

Distance Per Encoder Pulse = Total Distance Traveled / Encoder Pulses Counted

The Distance Per Encoder Pulse value measured in Inches or Millimeters is call the “Distance and Speed

calibration Factor”

When the operator pendant is pressed at the start of the measured distance test section the computer then begins to

count the pulses. When the operator pendant is pressed at the end of the measured test section the computer stops

counting the pulses.

Dynatest 1295 Version 1.07 22 Sep 2017

SECTION 2 CALIBRATION

2.3.6 Description of the Distance Calibration Fields

To manually enter the calibration values, it is necessary to press the ‘Edit’ button with the mouse. The selections

can be saved by pressing ‘Save’ with the mouse.

If the distance scale factor is not known then a distance calibration must be performed.

After completion of the distance calibration, this field will be automatically updated with

the new distance scale factor after the ‘Save’ button is pressed by the mouse.

2.3.6.1 Distance Cal Length

This is the known distance length that the distance calibration test will be conducted over. This known

distance must be accurately measured. The distance calibration accuracy is only as good as the accuracy

of this measured distance.

This value is entered in Feet if English Measurement Units are used.

This value is entered in Meters if Metric Measurement Units are used.

Note 1: Short distance calibration site lengths are not as accurate as longer calibration site lengths. A

minimum of 1000 feet (304.8 meters) should be used

Note 2: The distance calibration should generally be conducted at the vehicle speed the skid testing is

to be performed at, to minimize the effects of tire growth.

2.3.6.2 Right Wheel Encoder Calibration Value

This is the calibrated distance value for the right wheel encoder. The calibration value has units of in

inches or millimeters per encoder pulse.

2.3.6.3 Left Wheel Encoder Calibration Value

This is the calibrated distance value for the left wheel encoder. The calibration value has units of in inches

or millimeters per encoder pulse.

2.3.6.4 Vehicle Encoder Calibration Value

This is the calibrated distance value for the vehicle encoder. The calibration value has units of in inches or

millimeters per encoder pulse.

2.3.6.5 Calibration Status Box

This display line is used to guide the operator through the distance calibration process. Follow the

instructions given on this line to perform the distance calibration.

Dynatest 1295 Version 1.07 23 Sep 2017

SECTION 2 CALIBRATION

2.3.6.6 Calibration Button

This button is used to start and/or stop the distance calibration if the button selection is active for the start

or stop method. The calibration ‘Calibrate’ button can be actuated by the mouse. Follow the instructions

in the calibration status box

2.3.6.7 Distance Traveled

The distance travel during the calibration test is displayed in this field. The distance units are feet or

meters.

2.3.6.8 Left Encoder Count

This field displays the number of encoder pulses counted for the left encoder.

2.3.6.9 Right Encoder Count

This field displays the number of encoder pulses counted for the right encoder.

2.3.6.10 Vehicle Encoder Count

This field displays the number of encoder pulses counted for the vehicle encoder.

2.3.6.11 Left Calibration Value

This field displays the new encoder calibration value for the left encoder.

2.3.6.12 Right Calibration Value

This field displays the new encoder calibration value for the right encoder.

2.3.6.13 Vehicle Calibration Value

This field displays the new encoder calibration value for the vehicle encoder.

2.3.6.14 Last Calibration – Stored in data file header

Time - Recorded Time of Last Calibration

Date - Recorded Date of Last Calibration

2.3.6.15 Left Timer Count

This field displays the measured time value used for generating the timing parameters for the calculation

of the left wheel speed or vehicle speed. The time value is measure for the duration of each encoder pulse.

Dynatest 1295 Version 1.07 24 Sep 2017

SECTION 2 CALIBRATION

2.3.6.16 Right Timer Count

This field displays the measured time value used for generating the timing parameters for

the calculation of right wheel speed or vehicle speed. The time value is measure for the

duration of each encoder pulse.

2.3.6.17 Vehicle Timer Count

This field displays the measured time value used for generating the timing parameters for the calculation

of vehicle speed. The time value is measure for the duration of each encoder pulse. This is used for

systems that have dual force transducers.

2.3.6.18 Left Wheel Speed

This field displays the calculated wheel speed. The left wheel speed units are miles per hour or kilometers

per hour.

2.3.6.19 Right Wheel Speed

This field displays the calculated wheel speed. The right wheel speed units are miles per hour or

kilometers per hour.

2.3.6.20 Vehicle Speed

This field displays the calculated wheel speed. The vehicle speed units are miles per hour or kilometers

per hour.

Dynatest 1295 Version 1.07 25 Sep 2017

SECTION 2 CALIBRATION

2.4 TEMPERATURE SENSOR CALIBRATION

Figure 2-4: Temperature calibration

2.4.1 Temperature Sensor Calibration

This calibration page is for entering calibration values for temperature sensors. To enter the calibration values it is

necessary to press the ‘Edit’ button by using the mouse. To save the calibration values press the ‘Save’ button by

using the mouse.

2.4.1.1 Air Temperature

The air temperature sensor values are displayed in voltage and Fahrenheit or Celsius degree units.

2.4.1.1.1 Gain

The air temperature gain calibration value has units of (Fahrenheit degree/volt)

(Celsius degree/volt)

Dynatest 1295 Version 1.07 26 Sep 2017

SECTION 2 CALIBRATION

2.4.1.1.2 Offset

The air temperature offset calibration value has units of (Fahrenheit degrees) or

(Celsius degrees)

2.4.1.2 Surface Temperature

The surface temperature sensor values are displayed in voltage and Fahrenheit or Celsius degree units.

2.4.1.2.1 Gain

The surface temperature gain calibration value has units of (Fahrenheit degree/volt) or

(Celsius degree/volt)

2.4.1.2.2 Offset

The surface temperature offset calibration value has units of (Fahrenheit degrees) or

(Celsius degrees)

2.4.1.3 Tire Temperature

The tire temperature sensor values are displayed in voltage and Fahrenheit or Celsius degree units.

2.4.1.3.1 Gain

The tire temperature gain calibration value has units of Fahrenheit degree/volt) or

(Celsius degree/volt)

2.4.1.3.2 Offset

The tire temperature offset calibration value has units of (Fahrenheit degrees) or (Celsius degrees)

Dynatest 1295 Version 1.07 27 Sep 2017

SECTION 2 CALIBRATION

2.5 FLOW SENSOR CALIBRATION

This calibration page is for entering calibration values for flow meters and water tank sensors. To enter the

calibration values it is necessary to press the ‘Edit’ button by using the mouse. To save the calibration values

press the ‘Save’ button by using the mouse.

2.5.1.1. Flow Meter 1

The flow meter 1 values are displayed in voltage and flow rate units of gallons per minute

or liters per minute. The flow meter calibration values are described below.

2.5.1.1.1 Gain

The flow rate gain calibration value has units of (gpm/volt) or (lpm/volt)

2.5.1.1.2 Offset

The flow rate offset calibration value has units of (gpm) or (lpm)

2.5.1.2 Flow Meter 2

The flow meter 2 values are displayed in voltage and flow rate units of gallons per minute

or liters per minute. The flow meter calibration values are described below.

2.5.1.2.1 Gain

Dynatest 1295 Version 1.07 28 Sep 2017

SECTION 2 CALIBRATION

The flow rate gain calibration value has units of (gpm/volt) or (lpm/volt)

2.5.1.2.2 Offset

The flow rate offset calibration value has units of (gpm) or (lpm)

2.5.1.3 Water Tank Sensor

The water tank sensor values are displayed in voltage and units of gallons

or liters. The water tank sensor calibration values are described below.

2.5.1.3.1 Gain

The volume gain calibration value has units of (gallons/volt) or (liters/volt)

2.5.1.3.2 Offset

The water tank sensor offset calibration value has units of (gallons) or (liters)

Dynatest 1295 Version 1.07 29 Sep 2017

SECTION 2 CALIBRATION

2.6 METER AND DAC CALIBRATION

Figure 2-5: Meter Calibration

2.6.1 How to Use the Meter and Digital to Analog Converter (DAC) Calibration Screen

The meter and DAC calibration page is used for calibrating the force and speed display meters.

The computer uses a digital to analog converters to drive the dash mounted speed meter and the transducer force

readout meters located in the bed of the vehicle. The computer needs to know how to convert speed units of

miles per hour or kilometers per hour into analog voltage values to drive the speed meter. The computer also

needs to know how to convert force values in pounds or kilograms into analog voltage values to drive the force

meters. The values entered into the DAC gain fields provide the computer with the proper conversion numbers.

Different meters will require different gain conversion values. Some meters will require a voltage offset or ‘null’

value which can be entered into the ‘Offset’ fields for each meter. To change values it is necessary to press the

‘Edit’ button by using the mouse. The entered calibration values are saved by pressing the ‘Save’ button by using

the mouse.

Dynatest 1295 Version 1.07 30 Sep 2017

SECTION 2 CALIBRATION

2.6.2 Meter DAC Fields Descriptions.

2.6.2.1 DAC 1 – Speed DVM

The speed DAC controls the speed display meter.

2.6.2.1.1 Gain

The speed DAC gain calibration value has units of (mph/volt) or (kph/volt)

2.6.2.1.2 Offset

The speed DAC offset calibration value has units of (mph/volt) or (kph/volt)

2.6.2.2 DAC 2 – Left Load DVM

The left load DAC controls the trailer load display meter.

2.6.2.2.1 Gain

The left load DAC gain calibration value has units of (lbs/volt) or (kgs/volt)

2.5.2.2.2 Offset

The left load DAC offset calibration value has units of (lbs/volt) or (kgs/volt)

2.6.2.3 DAC 3 – Right Load DVM

The Right load DAC controls the trailer load display meter.

2.6.2.3.1 Gain

The right load DAC gain calibration value has units of (lbs/volt) or (kgs/volt)

2.6.2.3.2 Offset

The right load DAC offset calibration value has units of (lbs/volt) or (kgs/volt)

Dynatest 1295 Version 1.07 31 Sep 2017

SECTION 3 SETUP

3.1 INITIAL SETUP OF THE TOW VEHICLE AND TRAILER

The following information is designed to familiarize the operator with the initial setup procedures on

the 1295 before a test run.

1. Position the tow vehicle and two wheel trailer on a level section of pavement.

2. Fill the 250/300 gallon water tank on the tow vehicle until it is approximately half full of water.

The water level can be viewed on the monitor in the TEST menu screen.

3. Make sure the tongue of the trailer is parallel to the pavement. A carpenters level placed on top of

the two wheel trailer's tongue will verify the trailer is parallel with the pavement. If the tongue is

not parallel with the pavement:

4. Use a 3/4 inch box end wrench to loosen the four (4) lock nuts on the continuously adjustable ball

hitch.

5. Loosen the four (4) 1/2 inch Allen head cap screws which lock the continuously adjustable ball

hitch in position.

6. Use a 3/4 inch socket to slip over the main screw on the continuously adjustable ball hitch. Adjust

the ball up or down in order to level the two wheel trailer's tongue.

7. Once the trailer's tongue is level, tighten the four (4) 1/2 inch Allen head cap screws until they are

secure.

8. Use the 3/4 inch box end wrench to re-tighten the four (4) lock nuts until they are secure. The two

wheel trailer is level and ready for testing.

9. Check the ball hitch connection on the two wheel trailer to verify it is secure.

10. Check all the connections between the tow vehicle and the two wheel trailer to make sure they are

the same

11. Verify that both electric lift jacks on the two wheel trailer have been raised.

12. You can now finish filling the water tank. Replace the fill cap and hand tighten.

13. Start the engine on the tow vehicle to run the charging system. This charging system is

responsible for charging both the tow vehicle's 12 Volt DC battery and the system's 12 Volt DC

battery independently.

NOTE

An external retractable power cord and AC power outlets are provided in the

rear bed of the tow vehicle for indoor operation.

14. Energize the system by turning the DC Power switch ON, the AC Power switch ON, and the