Page 1

CDT-20

Introducing:

The world’s first

high-throughput

real-time

particle counter

for stents.

Coating Durability Tester

Page 2

Discover what you’ve not been seeing with your stents

CDT-20: The most powerful coating durability tester in the world

Introducing the patented1 CDT-20 Coating Durability Tester from Dynatek Labs. Inc., the world’s first

and only high-throughput stent tester offering durability testing and real-time particle counts from

coated and bare metal stents. Capable of testing 20 coated or bare stents of similar sizes2 for durability

simultaneously, the CDT-20 is a powerful workhorse that can drive your stent from the lab to regulatory

approval in record time. An optional isolation valve system allows you to hot-swap samples in minutes.

Deployment phase data can be obtained using an optional Tuohy-Borst fitting for stent delivery. Data

from your tests are encrypted for security and logged into TDMS files that can be accessed by Excel,

DIAdem and Matlab programs.

High-throughput testing speeds you to

regulatory approval

The CDT-20 features Dynatek’s Hyper Drive linear motor to produce

an adjustable bellows compression which allows for physiological

to accelerated loading conditions for up to 20 stent samples

simultaneously. Unrivaled flexibility allows you to test straight, curved

or bifurcated tube configurations under precisely controlled test

parameters, while tube deflection is monitored by a laser micrometer3.

The CDT-20 is available in two configurations: benchtop or with an

integrated mounting stand.

Particle counts track shedding behavior of

stents

Particle shedding by coated and bare metal stents is a regulatory

concern, but it doesn’t need to be yours – with the CDT-20. With

cutting-edge patented technology, the CDT-20 features 20 customdesigned laser particle counters that detect, in real time, the number

and size of particles greater than 5 microns4 shed by each individual

stent during pulsatile durability testing. Once these particles are

detected, they are categorized into between 2-6 configurable size

ranges or virtual ‘bins.’

Real time counts offer powerful insight into

potential disease state formation

Instead of a single count of all shed particles after a test run is

completed, the CDT-20 allows you to count particles as they are being

shed. As particles pass through the particle counter, they are detected

and logged by particle size and quantity. Real time counts let you

visualize when and how much your stent is shedding particles at every

stage of testing, helping you understand your stent’s potential for

promoting a pathological condition in vivo.

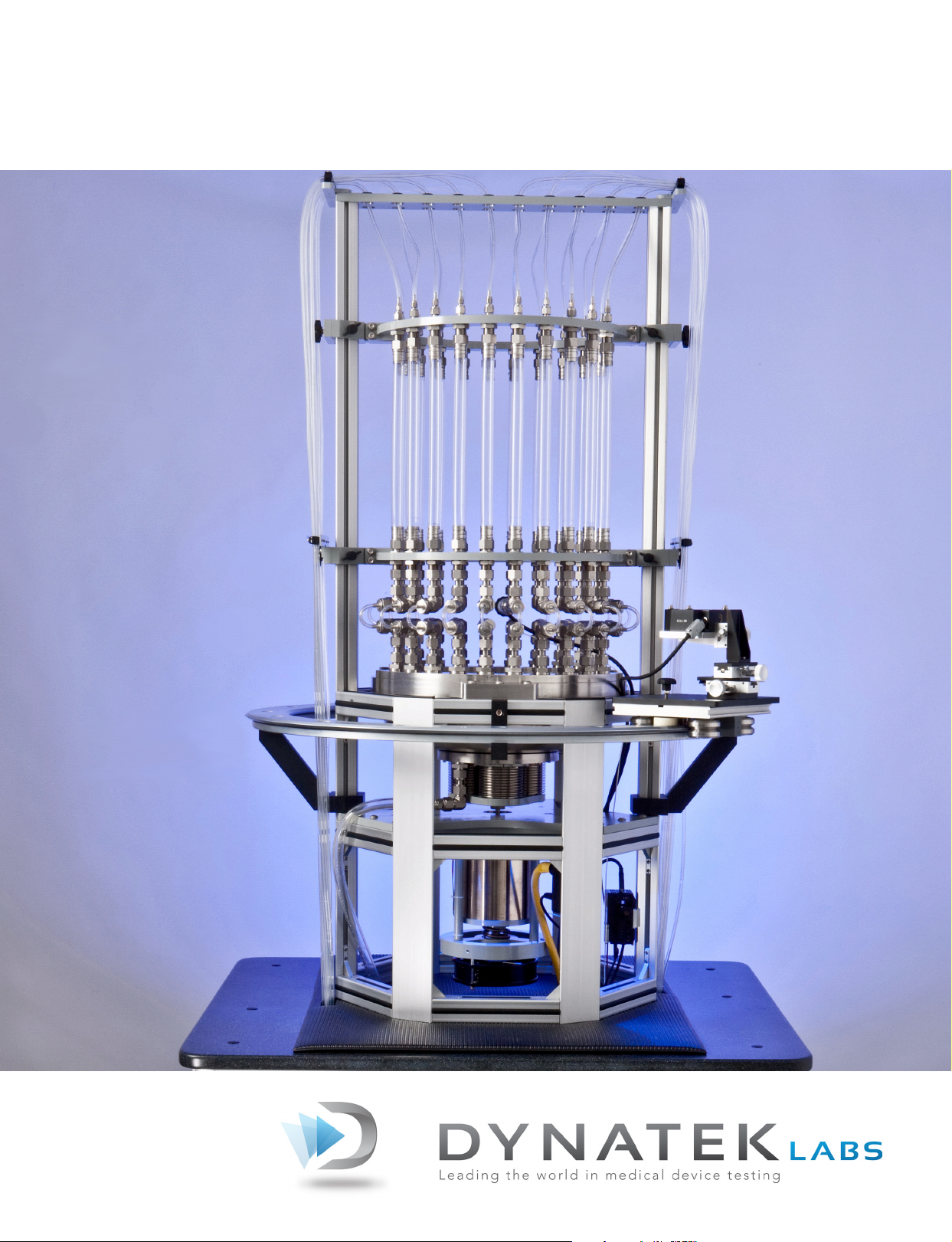

Dynatek’s CDT-20 benchtop Coating Durability Tester

Real time particle counts on the CDT-20

“…the CDT-20 takes us beyond compliance

to true patient safety by allowing us to

address standards passed or being drafted

by the ASTM and AAMI/ISO committees that

focus on the release of particulates from

stents…”

Page 3

Designed to take your product beyond regulatory compliance to real patient safety

Particle characterization drives stent

design

An optional filtration system for the CDT-20 is available, featuring

a separate filter for each stent sample. The particles shed by

each stent are captured by individual downstream filters, allowing

you to chemically characterize them. Chemical characterization

of particles sheds light on potential toxicity and provides vital

information that affects coating and stent design.

“…if you’re not counting particles in real time,

you’re not getting the full picture…”

25 micron particle on a 10 micron filter membrane

Deflection monitoring that exceeds

current regulatory standards

Real time high-speed photography showing two points on stent

being tracked

“You guys are always easy to contact and

provide the best customer support ever; truly

appreciate it!”

Easy to use walk-up operation

It has never been simpler to get advanced technology into your

stent testing lab. The unrivaled technology offered by the CDT-20

is matched by its easy-to-use walk-up operation. Everything in the

CDT-20 has been designed to flatten the learning curve of its users,

ensuring that your path to reliable, consistent results is short and

smooth.

Count on us for world-class support

The CDT-20 can monitor the tube deflection of up to 20 stents

serially with a laser micrometer that actively measures the realtime outer diameter of the selected mock artery as it undergoes

deflection. For the most accurate picture of stent deflection,

however, we recommend the optional high-speed camera. The

high-speed camera tracks two digital points on the stent and the

relative distance between the markings will change as the mock

vessel hosting the stent expands and contracts, providing critical

stent deflection data. With the CDT-20, you will be compliant with

the requirement of upcoming regulations that mandate observation

of actual stent deflection.

With Dynatek, your investment in cutting-edge technology comes

complete with peace of mind. Our comprehensive support services

for instruments are designed to ensure continuous uptime of your

testing platform. When you choose the CDT-20, you receive the

high-quality service that Dynatek has been known to deliver for

decades.

Page 4

Dynatek’s CDT-20 Coating Durability Tester Specications

Description Specification

Number of test samples 20

Tube configuration Straight, curved or bifurcated

Tube length (straight) Adjustable to ≤220 mm

Tube inner diameter ≈1 mm to ≤15 mm

Typical distention 0.3% to 18% of tube ID

Testing fluid PBS or distilled water

Fluid temperature Ambient to ≤45º

Flow rate 100 mL/min per sample

Test parameters Stent deflection, tube deflection, pressure, temperature, frequency

Automatic test control method Tube distention

Pressure transducer 0-10 psig

Laser micrometer Solid-state laser diode (780 nm, 3 mW)

Number of particle counters 20

Particle size range 5-1,000 microns

Max. particle concentration 15,000 p/mL @ 10 microns

Particle bin range 2-6 bins

System fluid filter 0.2 micron

Particle capture filters 20 (optional)

Particle capture filter size 1 micron (optional, customizable)

Controller Universal Controller, featuring the NI™ Single-Board RIO platform

Software Invitroflow software package, with intuitive user

interface to monitor and control the CDT-20

Capacitance tank 1.6 gal

5

6

7

Configuration Dimensions Weight Power

Integrated system 38”W x 40”D x 94”H 745 lbs 120 VAC 12 A

Bench-top system 60”W X 72”D X 53”H 600 lbs 120 VAC 12 A

1

US Patent # 7,621,192 B2

2

E.g., coronary or neuro or carotid stent sizes

3

Standards require stent observation to verify pulsatile deflection

4

Customizable to your requirements up to 1,000 microns

5

Depending on sample compliance

6

With optional larger heater

7

Based on use of appropriate standards

CDT-20™ Coating Durability Tester

and Invitroflow™ are trademarks of

Dynatek Labs.

To receive a customized proposal,

contact us today at:

Dynatek Labs

105 East 4th Street

Galena, MO 65656

800.325.8252

1.417.357.6155

www.dynateklabs.com

Loading...

Loading...