Dynatech BBM, YBM Additional Maintenance And Repair Instructions

BBM & YBM INSTRUCTIONS [May 2004]

Additional Maintenance

and Repair Instructions

BBM / YBM

Mini Masonry Saw

Issue 1

May 2004

NEVER ATTEMPT ANY OF THE INSTRUCTIONS WITH POWER CONNECTED TO SAW!

BBM & YBM INSTRUCTIONS [May 2004]

DISCONNECT ALL POWER TO THE SAW!

NEVER ATTEMPT ANY OF THE INSTRUCTIONS WITH POWER CONNECTED TO SAW!

Removing the Motor

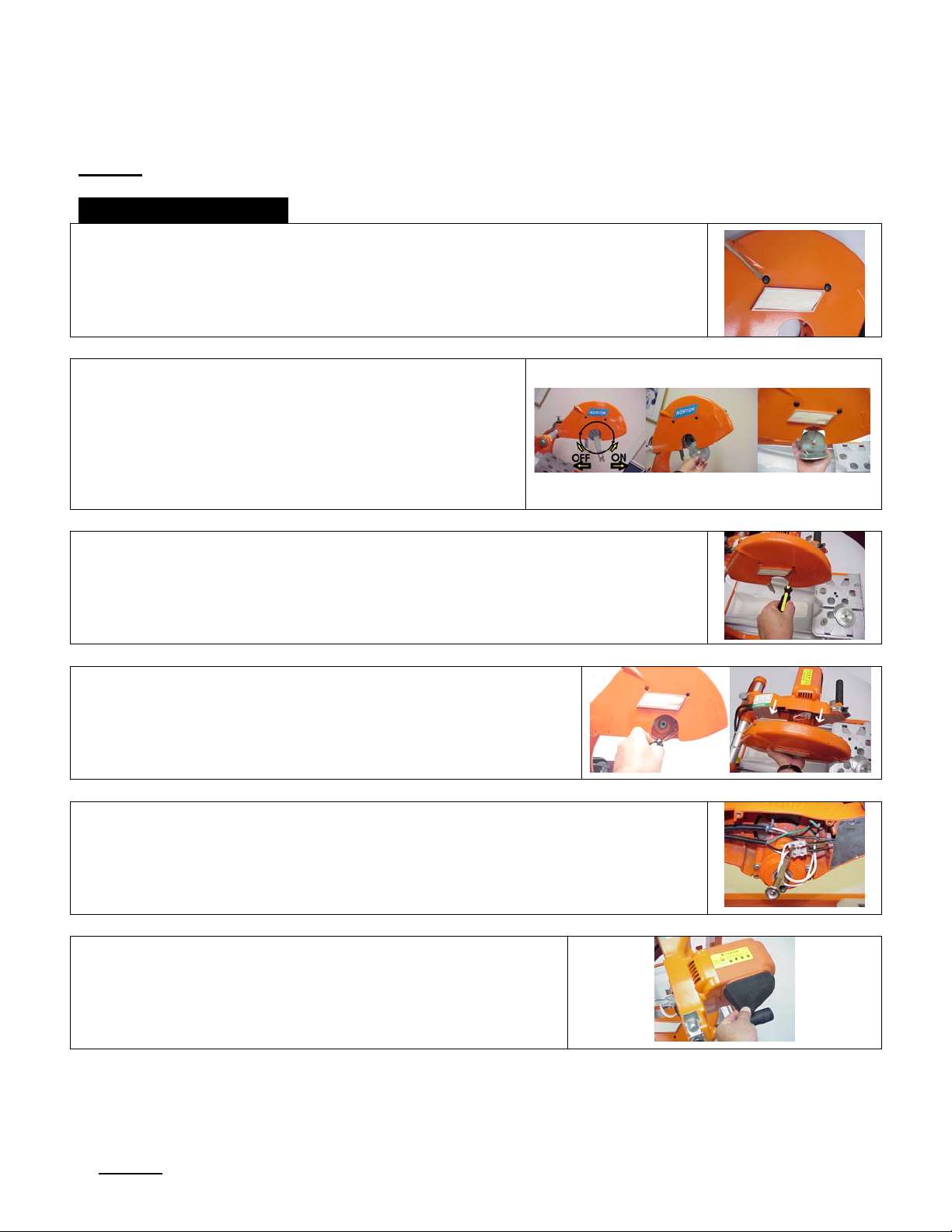

1. Remove the two plastic plugs in the blade guard to expose

the two blade guard mounting screws located under the

blade guard.

2. Using a 17mm wrench, turn the blade shaft

screw clockwise and take the screw and

washer out of the end of the shaft. With the

blade shaft screw and washer removed, pull

both blade flanges outward and off the end of

the blade shaft.

3. Insert a Phillips head screw driver into the blade guard screw

access holes and remove the two screws holding the blade guard

on the cutting head casting.

4. From under the blade guard, remove the two screws

located at the bottom of the blade shaft housing

casting and pull the blade guard outward and off the

blade shaft casting housing.

5. Using a narrow tip slot screw driver remove the two white motor

wires in the terminal block.

6. Remove the air filter.

NEVER ATTEMPT ANY OF THE INSTRUCTIONS WITH POWER CONNECTED TO SAW!

BBM & YBM INSTRUCTIONS [May 2004]

Removing the Motor [Continued]

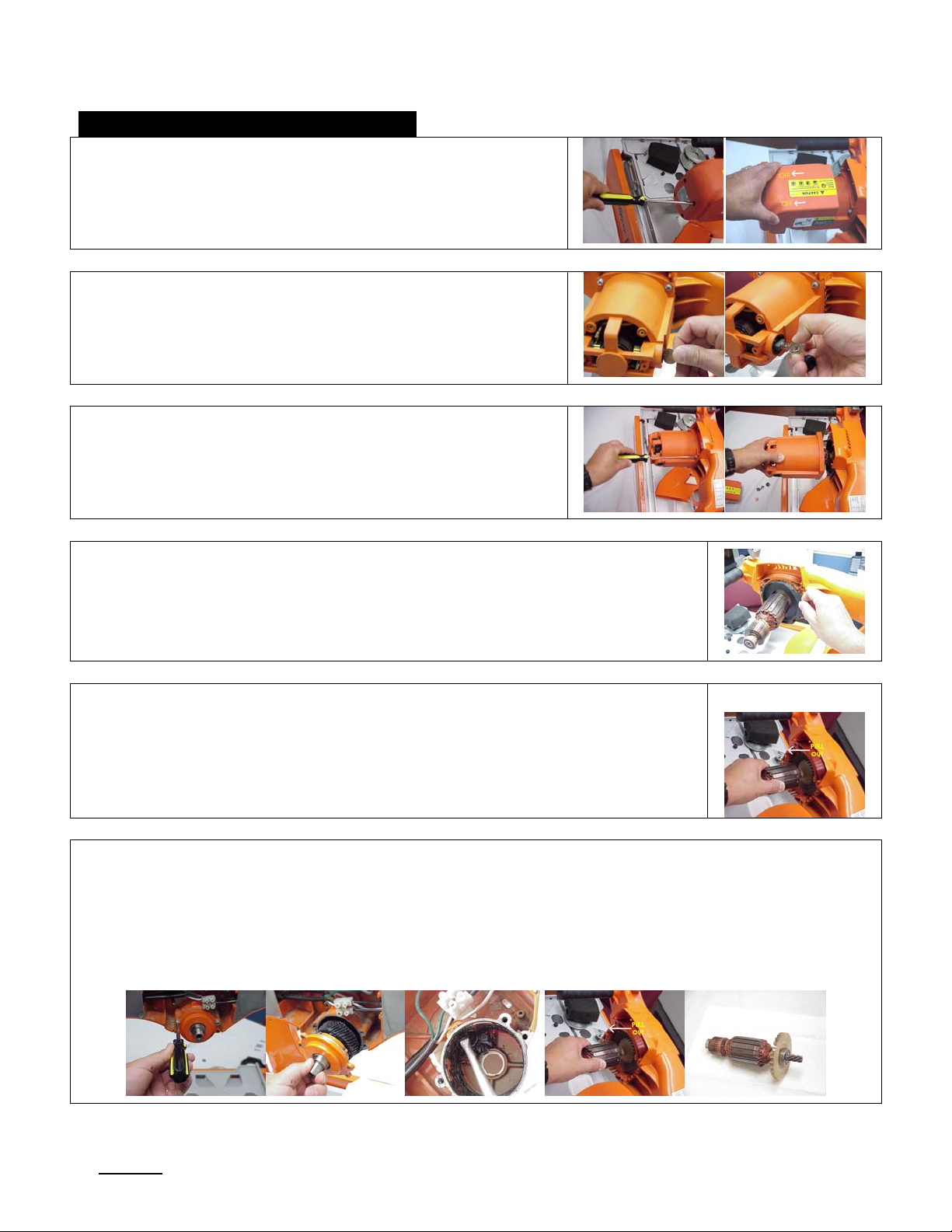

7. Using a Phillips head screw driver, remove the four

screws in the back of the plastic motor air intake

cover and slide the housing outward and off of the

motor housing.

8. Using a coin or a wide blade screw driver, remove

the plastic brush cap and carefully pull the carbon

brush out of the motor housing. Remove brushes

on both sides before attempting to pull the motor

housing off of the armature.

9. Using a Phillips head screw driver, remove the four

screws at the front of the motor housing and

carefully slide the motor housing outward and off

the armature.

10. Pull the plastic motor retaining plate out of the cutting head casting

and off the armature.

11. Grab the armature and pull the armature outward and out of the

motor housing.

If the armature does not pull out of the housing, remove the blade shaft retaining plate assembly

and use a long, wide blade screw driver and rubber mallet to tap the armature out of the cutting

head casting. Make sure to place the screw driver against the end of the armature shaft and

NOT against the radial bearing race or against the cutting head casting. Once the armature is

removed, re-insert the blade shaft retaining plate assembly into the cutting head casting. Align

the ears in the blade shaft retaining plate casting with the holes in the cutting head casting and

then insert two screws in the top ears and tighten.

NEVER ATTEMPT ANY OF THE INSTRUCTIONS WITH POWER CONNECTED TO SAW!

Loading...

Loading...