Page 1

MODEL UFX

ULTRASONIC FLOW METER

Operating Instructions

1

Page 2

2

Page 3

TABLE OF CONTENTS

• Quick Start Instructions 4-5

• Introduction 6

• Specifications 6

• Controls and Terminology 7

• Transducer Mounting Locations 8

• Mounting the Transducer 9

• Operating the UFX 10

• Velocity to Volume Conversions 11

• Battery Replacement 11

• Troubleshooting Guide 12

• Velocity Conversion Chart 13

• Warranty 14

• Spare Parts and Accessories 15

• Service Instructions 15

3

Page 4

QUICK-START INSTRUCTIONS

This manual contains detailed operating instructions for the UFX instrument.

The following condensed instructions are provided to assist an experienced

operator in basic operation of the instrument. If the operator is unfamiliar with

this type of instrument, refer to the detailed explanations located at the

corresponding letter on pages 8-11.

A. Select a transducer mounting location at least 10 pipe

diameters downstream and 5 diameters upstream of

flow disturbances (i.e. elbows, tees, valves, etc.)

STEP A

NO

B. On horizontal pipe, choose a

transducer mounting location

approximately 90 degrees from

the top of the pipe.

YES YES

C. Remove rust, scale and paint

from the transducer mounting

location. Clean to bare metal.

Plastic pipes do not require

preparation.

D. Plug the transducer plug into

the transducer jack.

4

NO

STEP B

STEP D

Page 5

E. Apply approximately ⅛ inch

[3 mm] silicone grease to

the transducer face. Place

the transducer face on the

prepared area of pipe. Hold

the transducer parallel to

the pipe with the cable

pointing downstream of the

flow direction.

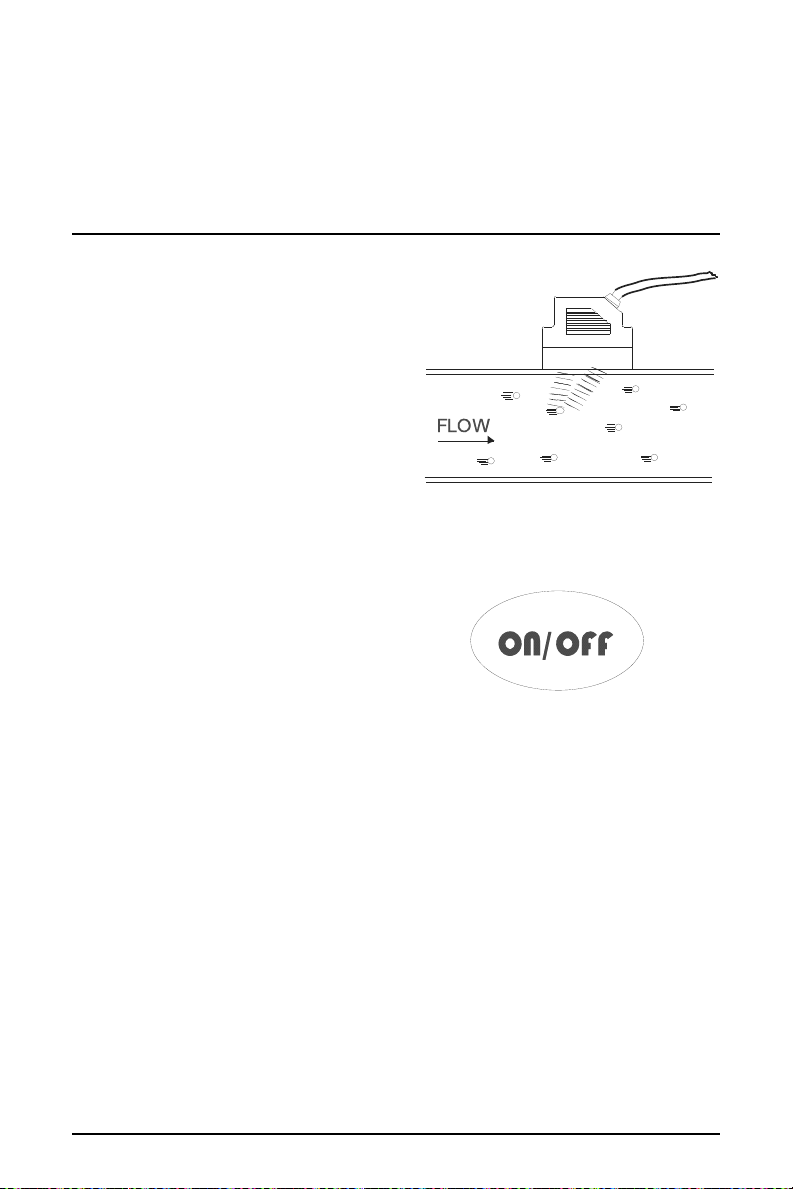

F. Press the ON/OFF key.

Wait at least 30 seconds

before recording a reading.

The UFX will automatically

turn itself off after 3

minutes.

G. Change units of measure

by pressing the FT/SEC M/SEC key.

STEP E

STEP F

5

Page 6

INTRODUCTION AND OPERATING THEORY

Series UFX Phase Shift Flow Meters feature advanced Trans-Phase

measuring technology, providing accurate and reliable flow velocity

assessments in closed piping systems. The UFX utilizes a non-invasive

transducer which is hand-held or strapped to the outside of a pipe.

Within seconds, the large 0.7 inch [18mm] LCD provides stable

readings in either FPS (Feet per Second) or MPS (Meters per Second).

This product is designed to operate on metal, plastic or rubber pipes

containing liquids with greater than 100 ppm of suspended solids or

entrained gases that act as reflectors.

Phase Shift flow meters utilize two piezoelectric crystals contained

within one transducer to transmit ultrasonic sound energy into the fluid

stream and receive reflected

Figure 1

FLOW

of oscillation will be altered with respect to the transmitted frequency.

The magnitude of frequency change is directly proportional to the

velocity of the reflector.

sound from reflectors (suspended

solids or entrained gases) within

the liquid. See Figure 1. In

accordance with the theories of

Christian Johann Doppler (circa

1842), if the liquid is moving

therefore carrying the reflectors

with it) and oscillating energy is

imposed on the moving reflector,

the reflected energy’s frequency

(and

SPECIFICATIONS

Description Specification

Power

Flow Range

Temperature

Enclosure Rating

Accuracy

Transducer Mount

6

four AA alkaline cells provide over 30 hours of

operation

0.30 to 30.00 FPS [0.10 to 9.00 MPS]

electronics: -28°F to +140°F [-20°C to +60°C]

transducer: -40°F to +180°F [-40°C to +82°C]

NEMA 12X, splash resistant

±2% full scale

Hand-held (clamp on), utilize acoustic

couplant such as DOW 111

Page 7

CONTROLS AND TERMINOLOGY

Transducer Cable

Transducer Plug

Transducer Jack

Display

Keypad

Transducer

NOTE: The UFX battery compartment

is located on the back of the enclosure.

Remove the two upper screws to gain

access to the battery compartment.

7

Page 8

A. TRANSDUCER LOCATION

Selecting the proper location for taking a flow measurement is the single

most critical step in the operational procedure. The transducer utilized

by the UFX flow meter contains two piezoelectric crystals for transmitting

and receiving ultrasonic signals through the wall of a pipe. Select a

transducer location with adequate straight runs (without flow disturbances)

of pipe, both upstream and downstream, to achieve stable and accurate

readings. Examples of common piping configurations and the

recommended minimum upstream and downstream pipe lengths are

included in Table 1.

Table 1

FLOW

FLOW

FLOW

FLOW

FLO W

FLOW

Note: If adequate straight plumbing cannot be provided the UFX will

operate repeatably

, but will most likely not achieve ideal accuracy.

8

Page 9

B. MOUNTING LOCATIONS ON THE PIPE

If the transducer is applied to

horizontal pipe, choose a

NO

mounting position at

approximately 3 o’clock or 9

o’clock, assuming 12 o’clock to

be to top of the pipe. These

YES

YES

positions typically provide

optimum acoustic penetration

into the moving liquid. As

illustrated in Figure 2,

placement at the top or bottom

of the pipe can result in poor

sound penetration due to air

NO

pockets (on the top of the pipe)

or sediment (at the bottom of

Figure 2

the pipe).

If the transducer is applied to vertical pipe, orientation does not matter.

C. PIPE PREPARATION

Before the transducer face can be coupled to a pipe surface, an area

slightly larger than the flat surface of the transducer must be cleaned to

bare metal on the pipe. Remove all scale rust and paint. Thoroughly dry

and clean the mounting surface.

NOTE: For plastic pipes, such as PVC or PVDF, pipe preparation

is typically not required.

D. CONNECTING THE TRANSDUCER

Connect the transducer plug into the transducer jack. The connection is

polarized, so alignment of the keyway is necessary.

NOTE: The splash-resistant environmental seal is provided only when

the transducer plug is secured into the transducer jack. It is advisable

to make this connection before entering an area where the UFX may be

dropped into or splashed with liquid.

E. APPLYING THE TRANSDUCER

To ensure an acoustically conductive path between the transducer face

and the prepared pipe surface, a coupling compound is employed.

Enclosed with the UFX flow meter is a tube of Dow Corning 111 silicone

based grease. This grease is adequate for the majority of installations.

If an alternate grease is utilized, the grease must be specified not to

flow at the temperature of the pipe surface or the ambient conditions.

9

Page 10

Apply an even layer of grease,

Transducer Cable

approximately ⅛" (3 mm) thick to the

flat surface of the transducer. Place

the transducer on the prepared area

of the pipe, with the cable pointing

downstream. See Figure 3. Align the

transducer with the pipe, ensuring

that it is parallel with the pipe wall.

Apply only enough pressure to hold

FLOW

the transducer in place. If no reading

is shown, perform a “rub test” by

rubbing thumb across the dry

transducer head. The zeros should

Figure 3

display a low flow reading. See

Troubleshooting Guide for further

Figure 3

recommendations.

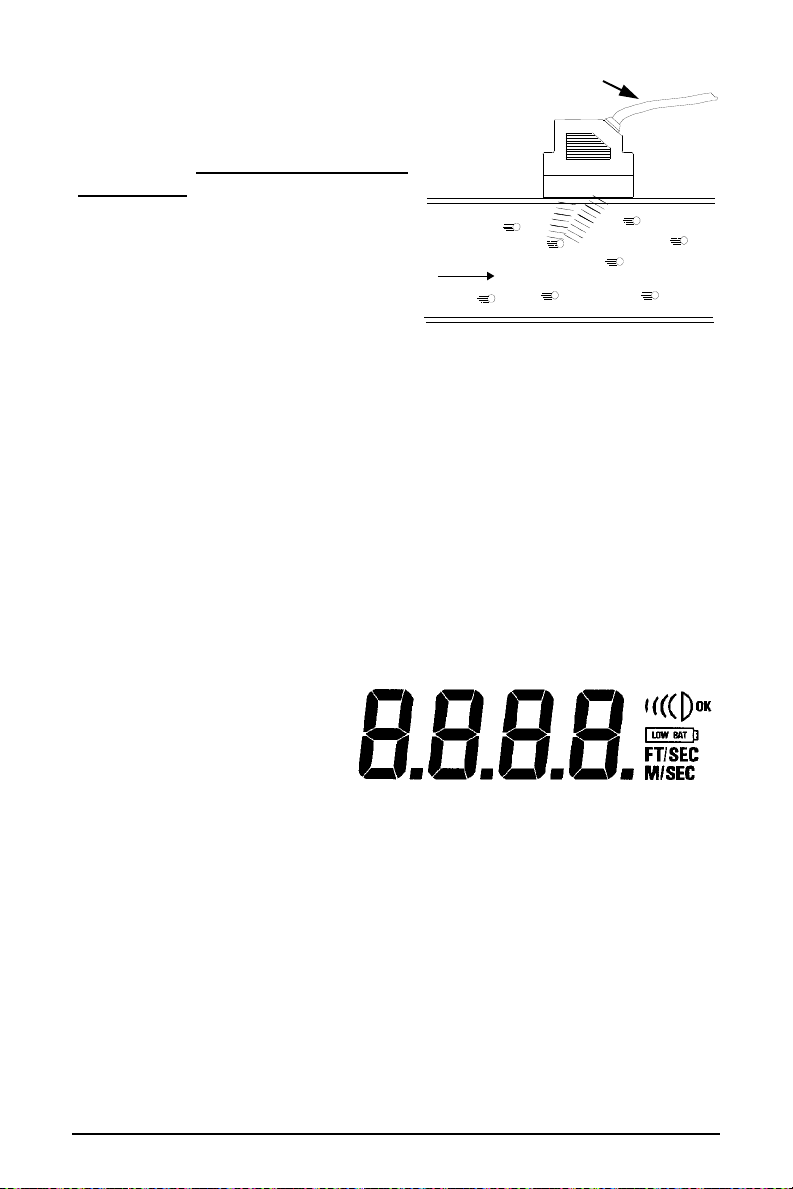

F. OBTAINING A READING

Press the ON/OFF key on the keypad. On power up, the UFX performs

internal diagnostics and starts the ultrasonic transmitter. The display will

read Hold for approximately 5 seconds during this time. If the

transducer is properly mounted to a pipe containing flowing liquid with

at least 100 ppm of 100 micron or larger particles or entrained gases,

the display will begin to indicate velocity. The default units of measure

are FPS (feet per second). The response time of the UFX is

approximately 10 seconds

to obtain a reading.

Adequate signal strength

is obtained when the OK

icon appears in the upper

right corner of the display.

See Figure 4. Readings

taken without this icon

present may be

erroneous. It is recommended that survey readings of at least 30

seconds be taken to ensure reading stability.

Figure 4

The UFX can be turned off by pressing the ON/OFF key on the keypad,

or the unit will automatically turn off after approximately 3 minutes of

operation.

G. CHANGING UNITS OF MEASURE

Toggle between FPS (feet per second) and MPS (meters per second)

by depressing the FT/SEC M/SEC key on the keypad.

10

Page 11

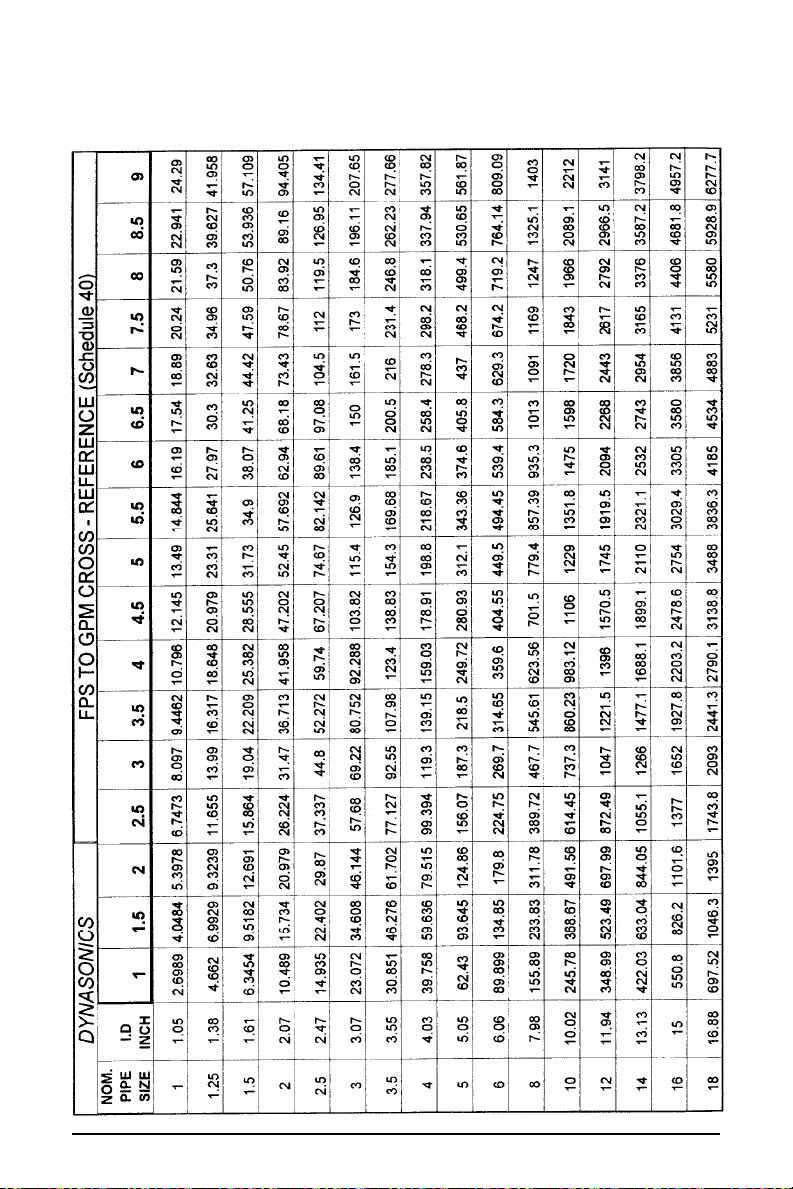

H. CONVERSION FROM VELOCITY TO VOLUME

The velocity readings taken from the UFX can be readily converted to

volumetric flow rate measurements such as GPM (gallons per minute)

or LPM (liters per minute). A chart is located on page 13 of this manual

that contains conversions for many popular schedule 40 pipe sizes. If

the pipe size is not located in this chart, use the following equations:

♦ For conversion to GPM (pipe I.D. in inches):

GPM = FT/SEC x 2.448 x I.D.

♦ For conversion to LPM (pipe I.D. in millimeters):

LPM = M/SEC x 0.047 x I.D.

2

2

I. LOW BATTERY INDICATION

When the power supply batteries become drained to a level of 4 volts,

the LOW BAT icon will illuminate on the right-hand side of the display.

Typical alkaline batteries will provide about 2 hours of operation after

the LOW BAT icon turns on. The flow meter will no longer operate when

battery voltage is less than 3.5 volts. At 3.5 volts and lower, an Err1 will

be displayed and then unit will shut off.

Replace the batteries by removing the two screws located on the upper

portion of the enclosure back. Install four fresh AA alkaline batteries

following the polarity indicated within the battery compartment and

replace the battery cover. A fresh set of alkaline batteries will provide

approximately 30 hours of service. Use of carbon-based batteries is not

recommended.

Do not allow discharged batteries to remain in the UFX during storage.

Discharged batteries can leak and may cause severe damage to the

internal circuits of the UFX. Damage caused b y leaking batteries will

not be covered under the manufacturer’s warranty.

!

J. DISPLAY TEST

The UFX contains software to verify operation of the individual LCD

segments. To run the display test, turn the UFX off. Press and hold the

FT/SEC - M/SEC key, then press the ON/OFF key. Release both keys

and verify that all segments illustrated in Figure 4 illuminate. The UFX

firmware version number (FX.XX) is displayed at the end of the test.

11

Page 12

TROUBLESHOOTING GUIDE

Unit does not turn “ON”

when ON/OFF key is

pressed

“Err1” is indicated

No display readings are

obtained and no “OK”

icon is observed

Dashes appear on display

• Verify that batteries are installed and

contain a charge.

• The batteries must be replaced.

• Poor acoustic coupling to pipe. Apply

silicone grease to transducer.

• Ensure pipe is full of a flowing liquid.

• If the pipe has a plastic liner, move the

transducer to another location. The liner

may contain an air void.

• Non-working transducer. Rub

transducer head with thumb for reading.

• Liquid contains less than 3% total

suspended solids.

• Move transducer closer to a source of

flow disturbance (i.e. an elbow, pump

outlet or control valve).

• Liquid velocity is greater than 30 FPS (9

MPS).

Readings are obtained,

but the “OK” icon does

not turn on.

Erroneous Readings

12

• Signal strength is low. Flow readings

may be erroneous. Move the transducer

closer to a source of hydraulic

disturbance.

• Transducer mounted incorrectly.

• Another local ultrasonic instrument is

operating at approximately the same

frequency as the UFX.

• Excessive pipe vibration.

• Very viscous (thick) liquids will cause

the unit to read lower than actual flow.

• The pipe is not completely full of liquid.

Page 13

LIQUID VELOCITY TO VOLUME CONVERSION CHART

13

Page 14

STATEMENT OF WARRANTY

Dynasonics, Division of Racine Federated Inc. warrants to the end

purchaser, for a period of one year from the date of shipment from the

factory, that all flow meters manufactured by it are free from defects in

materials and workmanship. This warranty does not cover products that

have been damaged due to defects caused by misapplication, abuse,

lack of maintenance, modified or improper installation. Dynasonics’

obligation under this warranty is limited to the repair or replacement of a

defective product, at no charge to the end purchase, if the product is

inspected by Dynasonics and found to be defective. Repair or

replacement is at Dynasonics’ discretion. A return goods authorization

(RGA) number must be obtained from Dynasonics before any product

may be returned for warranty repair or replacement. The product must

be thoroughly cleaned and any process chemicals removed before it

will be accepted for return.

The purchaser must determine the applicability of the product for its

desired use and assumes all risks in connection therewith. Dynasonics

assumes no responsibility or liability for any omissions or errors in

connection with the use of its products. Dynasonics will under no

circumstances be liable for any incidental, consequential, contingent or

special damages or loss to any person or property arising out of the

failure of any product, component or accessory.

All expressed or implied warranties, including the implied warranty of

merchantability and the implied warranty of fitness for a particular

purpose or application are expressly disclaimed and shall not apply

to any products sold or services rendered by Dynasonics .

The above warranty supersedes and is in lieu of all other warranties,

either expressed or implied and all other obligations or liabilities. No

agent or representative has any authority to alter the terms of this

warranty in any way.

14

Page 15

SPARE PARTS AND ACCESSORIES

PART NUMBER DESCRIPTION

D002-2007-001 SS Mounting Strap, 36 inch [900 mm]

D002-2007-002 Nylon Mounting Strap, 30 inch [750 mm]

D002-2011-002 Couplant, RTV (for permanent mounting)

D002-2011-001 Couplant, Silicone (for temporary mounting)

D003-0825-001 SS Identification tag

DTUFX-D1 Series DUFX Std. Pipe Transducer

DTUFX-B1 Series DUFX Small Pipe Transducer

DTUFX-D1-CE Series DUFX Std. Pipe Transducer - CE unit

DTUFX-B1-CE Series DUFX Small Pipe Transducer - CE unit

DUFX O&M Series DUFX Operations Manual

D003-1009-005 UFX Carrying Case

SERVICE AND REPAIR

When returning equipment, it is necessary to contact our service

department at (800) 535-3569 or (262) 639-6770 to obtain a

Return Goods Authorization (RGA) number for the authority and

tracking of your material and its proper inspection and return. All

returns of equipment must go to the following address:

Dynasonics

Attn: RGA#xxxx

8635 Washington Avenue

Racine, WI 53406

15

Page 16

8635 Washington Avenue

Racine, WI 53406

Toll-Free in U.S. and Canada:

Tel: (800) 535-3569 Fax: (800) 732-8354

Tel: (262) 639-6770 Fax: (262) 639-2267

www.dynasonics.com

DYNASONICS is a registered trademark of Racine Federated Inc.

UL is a registered trademark of Underwriters Laboratories.

16

© 2011 Racine Federated Inc.

All rights reserved.

Printed in the USA

UFX O&M REV 01/11

Loading...

Loading...