Page 1

Series TFXP

Series TFXP

Series TFXPSeries TFXP

Transit Time Ultras oni c Fl ow Me t er

Operations & Maintenance

Manual

REV 4/01

Page 2

BEFORE OPERATING THE TFXP

Important Notice!

Figure 1.1

The TFXP flow meter is equipped with a Lead Acid Gel

Cell battery. This battery will require cha rging before initial operation.

Apply power, utilizing the enclosed 12 Volt DC output line

power converter or cigarette-style power cord, to the

TFXP for a period of 16-24 hours prior to using the product for the first time. The power converter connects to the

socket connection located on the side of the enclosure.

See Figure 1.1. A fully charged battery will provide up to

24 hours of contin uous op eration befo re rechargin g will b e

necessary.

When the b atte ry le vel ha s de crea sed to a po int where re charging is required, th e LOW BATTERY ind icator will illuminate on the front panel. A t that po int, the me ter will onl y

operate a short time more until it automatically turns itself

off—preventing excessive battery discharge that can damage the Gel Cell battery. The TFXP has an integral charging circuit that prevents overcharging. The instrument can

be permanently connected to AC line power without damaging the flow meter or the battery. Page 1.10 of this

manual contains additional recommendations to preserve

and maximize the power in the TFXP battery.

If the TFXP is to be used for extended periods of operation, the AC power converter or the 12 volt cigarette converter can remain connected indefinitely.

Rev. 4/01 -1.1- TFXP

Page 3

TABLE OF CONTENTS

Part 1 - Introduction

Part 1 - Connections

Part 1 - Inputs and

Outputs

Quick-Start Operating Instructions 1.4-1.5

Introduction

General 1.6

Applications 1.6

Model Matrix 1.7

Product Specifications 1.8

Transmitter Connections

Transmitter Limits and Connections 1.9-1.10

Battery Charging and Maintenance 1.10-1.12

Input/Output Connections and Options

4-20 mA Output 1.13

Datalogger 1.14

Pages

optional Dual Control Relay 1.14

optional Rate Pulse Output 1.15

optional RS232C 1.15

optional RS485 1.15

optional RTD-BTU 1.15

Part 2 - Transducer

Installation

Rev. 4/01 -1.2- TFXP

Transducer Mounting

Mounting Location 2.1-2.2

Transducer Mounting Method 2.3-2.5

Transducer Spacing - Keypad Entry 2.6-2.13

Transducer Spacing - UltraLink 2.13-2.14

Pipe Preparation 2.15

Transducer Mounting 2.15-2.21

Page 4

TABLE OF CONTENTS

Part 3 - Operation

Part 4 - Software

Programming Entries

Instrument Startup 3.1

Keypad Operation 3.2-3.3

Graphics Display Configuration 3.3

Menu Structure 3.3-3.4

Keypad Entry Detail 3.4-3.25

BASIC MENU 3.4-3.13

DATALOG OPERATION 3.14-3.16

OUT2 MENU 4-20 mA 3.17-3.19

Optional Input/Output 3.20-3.24

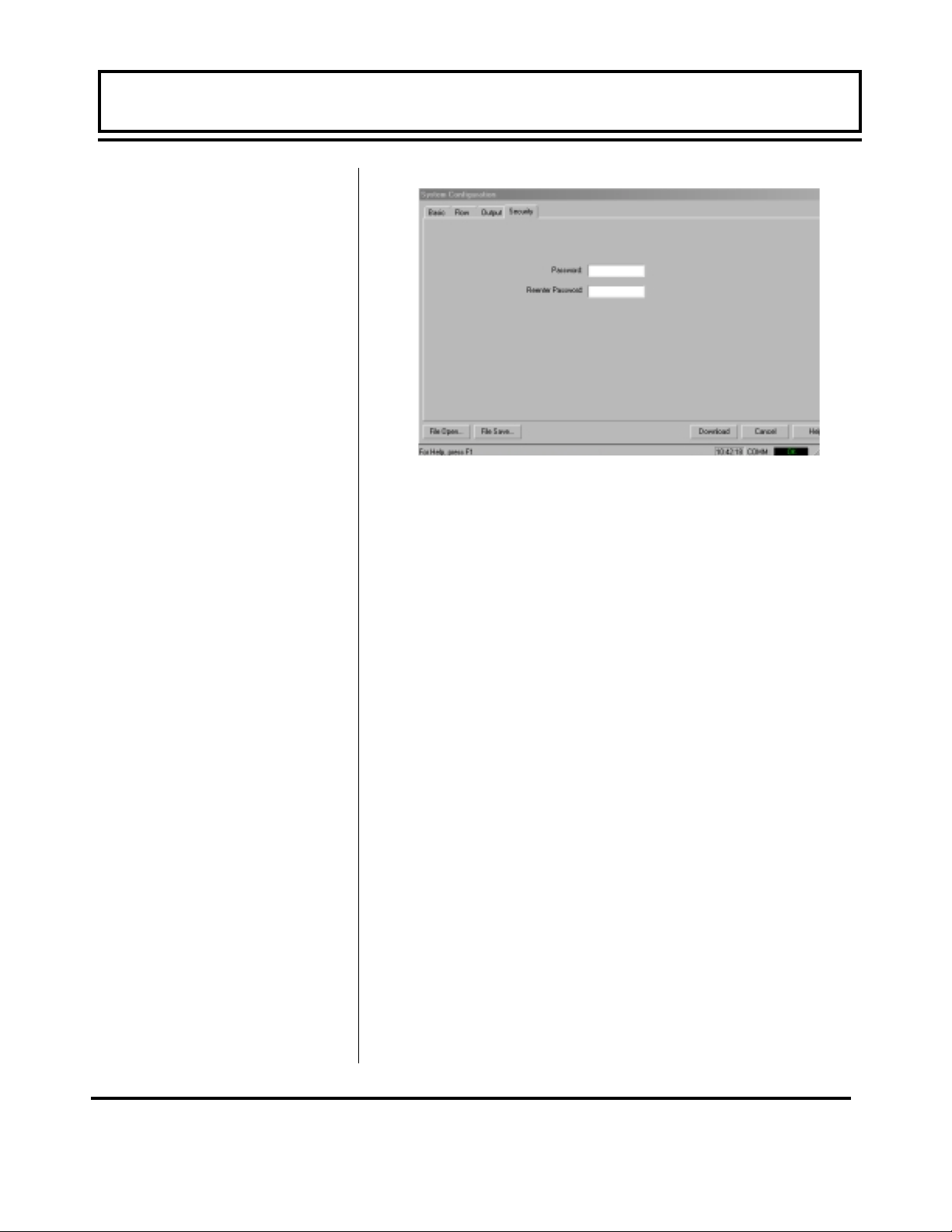

SECURITY MENU 3.25

SERVICE MENU 3.26-3.27

Signal Strength 3.26

Setting ZERO Flow 3.27

DISPLAY MENU 3.28-3.29

Software Utility Operation

UltraLink 4.1-4.9

DataLink 4.10-4.12

Appendix

Keypad Interface Map

Fluid Characteristic Table

TFX Error Codes

Modbus Protocol

Pipe Dimension Chart: Cast Iron

Pipe Dimension Chart: ST, SS, PVC

Velocity to Volumetric Conversion

RTD-BTU Option

Statement of Warranty

Customer Service

Pages

Rev. 4/01 -1.3- TFXP

Page 5

QUICK-START OPERATING INSTRUCTIONS

This manual contains detailed operating instructions for all

aspects of the TFXP instrument. The following condensed

instructions are provided to assist the operator in getting

the instrument configured and measuring as quickly as

possible. This pertains to basic operation only. If specific

instrument features are to be used or if the installer is unfamiliar with this type of instrument, refer to the app ropriate section in the manual for complete details.

Transducer Location

1. TRANSDUCER LOCATION

A. In general, select a mounting location on the piping

system with a minimum of 10 pipe diameters (10

times the pipe inside diameter) of straight pipe upstream and 5 straight diameters downsteam. See

Table 2.1 for detailed piping configurations and recommended lengths of straight pipe.

B. Select a mounting method for the transducers

based on pipe size and liquid characteristics. See

Figure 1.2. Select W-Mount for plastic pipes flowing clean, non-aerated liquids in the 1-3 inch [25-75

mm] internal diameter range. Select V-Mount for

pipes of all materials and most liquids in pipe sizes

from 1-10 inches [25-250 mm]. Select Z-Mount for

pipes larger than 10 inches.

W-Mount V-Mount

Figure 1.2

C. Enter the following data into the TFXP transmitter

via the integral keypad or UltraLink software utility.

Rev. 4/01 -1.4- TFXP

Z-Mount

Page 6

QUICK-START OPERATING INSTRUCTIONS

*Nominal values for these

parameters are included

within the TFXP operating

system. The nominal values

may be used as they appear

or may be modified if exact

system values are known.

Figure 1.3

1. Transducer mounting method

2. Pipe O.D. (Outside Diameter)

3. Pipe wall thicknes s

4. Pipe material

5. Pipe sound speed*

6. Pipe relative roughness*

7. Pipe liner thickness

8. Pipe liner material

(if present)

(if present)

9. Fluid type

10. Fluid sound speed*

11. Fluid viscosity*

12. Fluid specific gravity*

D. Record the value calculated and displayed as

Transducer Spacing/XDCR SPC.

2. PIPE PREPARATION AND TRANSDUCER MOUNTING

A. The piping surface, where the transducers are to be

mounted, needs to be clean and dry. Remove

loose scale, rust and paint to ensure satisfactory

acoustical bonds.

B. Attach the transducer mounting rail or saddles to

the pipe at the location(s) determined in Step 1.

Refer to Figure 1.1 for proper orientation.

C. Apply a liberal amount of couplant grease onto the

transducer faces. Place each transducer into the

rail/saddle ensuring proper linear and radial placement.

Connections

3. TRANSDUCER/POWER CONNECTIONS

A. Do not attempt to add additional cable to the trans-

ducers.

B. Refer to the WIRING DIAGRAM located on the in-

ner door of the TFXP transmitter and Figure 1.3 for

proper power and transducer connections.

Startup

4. INITIAL SETTINGS AND POWER UP

A. Press the ON button on the flow meter keypad.

B. From the Service Menu, verify that signal strength

is greater than 2.0%.

C. Input proper units of measure and I/O data.

Rev. 4/01 -1.5- TFXP

Page 7

PART 1 - INTRODUCTION

General

Application

Versatility

The TFXP ultrasonic flow meter is designed to measure

the fluid velocity of liquid within closed conduit (pipe). The

transducers are a non-contacting, clamp-on type, which

will provide benefits of non-fouling operation and ease of

installation.

TFXP transit time flow meters utilize two transducers

that function as both ultrasonic transmitters and receivers. The transducers

are clamped on the outside of a closed pipe at a

specific distance from

each other. The transducers can be mounted in V-mode

where the sound transverses the pipe two times, W-mode

where the sound transverses the pipe four times, or in Zmode where the transducers are mounted on opposite

sides of the pipe and the sound crosses the pipe once.

This selection is based on pipe and liquid characteristics.

The flowmeter operates by alternately transmitting and receiving a frequency modulated burst of sound energy between the two transducers and measuring the time interval

that it takes for sound to travel between the two transducers. The difference in the time interval measured is directly related to the velocity of the liquid in the pipe.

The TFXP flow meter can be successfully applied on a

wide range of metering applications. The simple to program transmitter allows the standard product to be used

on pipe sizes ranging from 1 - 100 inch [ 25 - 2540 mm ]

internal diameters. A variety of liquid applications can be

accommodated: ultrapure liquids, potable water, chemicals, raw sewage, reclaimed water, cooling water, river

water, plant effluent, etc. Because the transducers are

non-contacting and have no moving parts, the flow meter

is not affected by system pressure, fouling or wear. Standard transducers are rated to 300°F [150°C]. Higher temperatures can be accommodated. Please consult the Dynasonics factory for assistance.

Rev. 4/01 -1.6- TFXP

Page 8

PART 1 - INTRODUCTION

User Safety

Data Integrity

Product

Identification

Product Matrix

The TFXP employs modular construction and provides

electrical safety for the operator. The display face contains voltages no greater than 10 Vdc. All user connections are made through sealed bulk-head plugs located

on the side of the TFXP enclosure.

Non-volatile flash memory retains all user-entered configuration values in memory for several years, even if

power is lost or the unit is turned off. Data Logger values

are stored in flash memory in the logger. Password protection is provided as part of the Security menu and prevents inadvertent configuration changes or totalizer resets.

The serial number and complete model number of your

TFXP is located on the inside of the transmitter’s front

cover. Should technical assistance be required, please

provide the Dynasonics Customer Service Department

with this information.

TFXP - UUU

Power Supply

A) 115 VAC

B) 230 VAC

(two round terminals)

G) 230 VAC

(three rectangular

terminals)

Output 2*

1) 4-20mA

Output 1*

6) 200,000 event datalogger

Approvals

N) Class 1, Div 2 (pending)

Options

N) None

UUUA ---- UU

UUUUUU

UU

UUUU

Replacement Parts Part Number

TFXP Flow meter D040-0110-001

Data Logger, 200,000-event D020-1045-104

Padded carrying case D003-1012-002

Transducers, set of two D071-0105-000

Transducer Cable, 20 ft. [6m] D005-2112-020

Acoustic Grease, temporary mount D002-2011-001

Mounting Track, w/measuring scale D010-2102-010

Mounting Clamp, single D003-0139-002

36 inch SS hose clamp D002-2007-001

Power converter, 115V U.S. D005-2502-001

Power converter, 230V European D005-2502-002

Power converter, 230V U.K. D005-2503-003

Power cord, 12V cigarette-style D005-2116-002

4-20mA interconnect cable D005-2116-001

Infrared communicator and UltraLink D005-2115-100

Infrared communicator D005-2115-001

Manual, TFXP flow meter DTFXP O&M

Rev. 4/01 -1.7- TFXP

Page 9

Transmitter

PART 1 - SPECIFICATIONS

Transducer

Rev. 4/01 -1.8- TFXP

Page 10

PART 1 - TFXP TRANSMITTER CONNECTIONS

Transmitter Location

Considerations

After unpacking, it is recommended to save the shipping

carton and packing materials in case the instrument is

stored or re-shipped. Inspect the equipment and carton

for damage. If there is evidence of shipping damage, notify the carrier immediately.

When the TFXP is to be utilized for extend ed periods of

time in one location, the enclosure should be placed in

an area that is convenient for servicing, calibration or for

observation of the LCD readout.

1. Locate the transmitter within the length of transducer

cable that was supplied with the TFXP system. If this

is not possible, do not attempt to add additional cable

to the transducer. Contact the Dynasonics factory to

coordinate an exchange for the proper cable length.

Transducer cables that are up to 990 feet [300 meters] are available.

2. Place the TFXP transmitter in a location that is:

♦ Where little vibration exists.

♦ Protected from falling corrosive fluids.

♦ Within ambient temperature limits -40 to 185°F [-40 to

85°C]

♦ Out of direct sunlight. Direct sunlight may increase

temperatures within the transmitter to above maximum limit.

3. If the transmitter will be subjected to a wet environment, it is recommended that the cover remain closed

and the latches secured after configuration is completed. The faceplate/keypad of the TFXP is watertight, but avoid letting water collect on the keypad

area.

Rev. 4/01 -1.9- TFXP

Page 11

PART 1 - TFXP TRANSMITTER CONNECTIONS

Electrical

Connections

Figure 1.4

Battery Charging and

External Power

Sources

It is highly recommended that the internal battery in the

TFXP be fully charged before using the meter for the first

time. Details covering this procedure are located on

Page 1.1 of this manual.

1. The connectors located on the side of the TFXP consist of three 1/4 turn BNC-type and one 5.5mm power

plug. These connectors are environmentally sealed,

but it is recommended not to allow water or other liquids to collect in the electrical connections pocket.

2. Connect the appropriate wires to the corresponding

connections on the transmitter. The transducer cable

has markings of UPSTREAM and DOWNSTREAM to

assist in the installation process. The UPSTREAM

transducer is the one located closer to the direction

from which fluid flow normally comes from (The fluid

normally passes the UPSTREAM transducer before

passing the DOWNSTREAM transducer.) If the transducer wires are connected backwards, a negative flow

indication will be observed on the flow meter display.

See Figure 1.4 or the Wiring Diagram located on the

inner door of the transmitter.

NOTE: The transducer cables carry low level signals. Do

not attempt to add additional cable to the factory supplied

transducer cable. If additional cable is required, contact

the Dynasonics factory to arrange for an exchange transducer with the appropriate length of cable. Cables to 990

feet [ 300 meters ] are available.

The 12 Volt DC power converter and 12 Volt cigarettestyle power cord connect to the socket connection located

on the side of the enclosure. See Figure 1.4. A fully

charged battery will provide up to 24 hours of continuous

operation before recharging will be necessary. When the

battery level has decreased to a point where recharging is

required, the LOW BATTERY indicator will illuminate on

the front panel. At that point, the meter will only operate a

short time more until it automatically turns itself off—

preventing excessive battery discharge that can damage

Rev. 4/01 -1.10- TFXP

Page 12

PART 1 - TFXP TRANSMITTER CONNECTIONS

the Gel Cell battery.

If the TFXP is to be used for extended periods of opera-

tion, the 12 Vdc line power converter or the 12 V cigarette

converter can remain connected indefinitely.

To charge the internal Gel Cell bat tery, apply power, utilizing the enclosed 12 Vdc line power converter or cigarettestyle power cord, to the TFXP for a period of 16-24 hours.

The TFXP has an integral charging circuit that prevents

overcharging. The instrument can be permanently connected to AC line power without damaging the flow meter

or the battery.

The Gel Cell battery is “maintenance free”, but it still requires a certain amount of attention to prolong its useful

life. To obtain the greatest capacity and longevity from the

battery, the following practices are recommended:

• Do not allow the battery to completely discharge.

(Discharging the battery to the point where the LOW

BATTERY indicator illuminates will not damage the

battery. Allowing the battery to remain discharged for

long periods of time can degrade the storage capacity

of the battery.) When not in use, continually charge

the battery by keeping the 12 Vdc line power converter

plugged in and connected to the flow meter. The

TFXP battery management circuitry will not allow the

battery to be come “over-charged”.

NOTE: The TFXP will automatically enter a low power

consumption mode approximately 1-1/2 minutes after the

LOW BATTERY indicator illuminates. This circuit prevents excessive discharge of the internal battery.

• If the TFXP is stored for prolonged periods of time,

monthly charging is recommended.

• If the TFXP is stored for prolonged periods of time,

store at a temperature below 70ºF [21ºC].

Use wiring practices that conform to local codes (National

Electric Code Handbook in the USA). Use only the power

converters that have been supplied with the TFXP flow

meter. The ground terminal, if present on the converter, is

mandatory for safe operation.

Rev. 4/01 -1.11- TFXP

Page 13

PART 1 - TFXP TRANSMITTER CONNECTIONS

CAUTION: Any other wiring method may be unsafe or

cause improper operation of the instrument.

It is recommended not to run line power with other signal

wires within the same wiring tray or conduit.

NOTE: This instrument requires clean electrical line

power. Do not operate this unit on circuits with noisy components (i.e. Fluorescent lights, relays, compressors, variable frequency drives, etc.).

The TFXP can be operated from a 11-15 Vdc source, using the included cigarette-style power cord, as long as it is

capable of supplying at least 3 Watts—observe proper polarity.

Rev. 4/01 -1.12- TFXP

Page 14

PART 1 - TFXP TRANSMITTER CONNECTIONS

General Information

Regarding Input/

Output: ISO-MODs

Standard

4-20 mA Output

The TFXP flow meter contains two Isolated Input/output

Modules (ISO-MODs); one located inside of the flow meter

enclosure and one that is user accessible, located under

the access door on the keyboard. The standard configuration of these modules is to have the internal module

configured as an actively powered 4-20 mA module and

the user accessible one as a Data Logger.

ISO-MODs are epoxy encapsulated electronic input/output

modules that are simple to install and replace in the field.

All modules are 2,500 volt optically isolated from TFXP

power and Earth grounds -- eliminating the potential for

ground loops and reducing the chance of severe damage

in the event of an electrical surge.

Seven ISO-MOD options are available including: 4-20 mA,

dual-relay, rate pulse, RS232C, RS485, 200k event datalogger and RTD heat-delivered option. TFXP supports

any two ISO-MOD input/output modules. All modules are

field configurable by utilizing the keyboard or ULTRALINK

interface. Field wiring connections to ISO-MODs are

quick and easy using pluggable terminals. Features of the

various ISO-MODs are described below. See the Series

TFXH addendum for details re garding the RTD Heatflow

Module option.

The 4-20 mA Output Module interfaces with virtually all recording and logging systems by transmitting an analog

current signal that is proportional to system flow rate. Independent 4 mA and 20 mA span settings are established

in software using the FL 4MA and FL 20MA settings in the

OUTPUT2 conf iguration menu. The se entries can be set

anywhere in the –40 to +40 fps [-12 to +12 mps] measuring range of the instrument. Output resolution of the module is 12-bits (4,096 discrete points). The module can

drive more than 800 ohms of load with its internally generated 24 volt power source.

A 4-20 mA output interface cable has been included with

the TFXP package. Connect the 1/4-turn BNC connection

to the jack located on the side of the flow meter. See Fig-

Figure 1.5

Rev. 4/01 -1.13- TFXP

ure 1.5. The red clip on the cable provides the positive

Page 15

PART 1 - TFXP TRANSMITTER CONNECTIONS

leg of the output and the black clip provides the negative

side. Verify that the sum of the resistances in the loop do

not exceed 800 Ohms.

Refer to Section 3 of this manual for detailed information

regarding the configuration, calibration and testing of the

4-20 mA output.

Standard

Data Logger

Figure 1.6

A 200,000-event data logger/electronic stripchart recorder

is located within the weather-tight pocket on the face plate

of the flow meter. See Figure 1.6. Loosen the three

thumbscrews located in the corners of the pocket cover

and rotate the cover to expose the Data Logger module.

The logger stores time-stamped, high resolution (16-bit)

data at user selected intervals ranging from 1 to 30,000

(8.33 hours) seconds. Configuration of and data retrieval

from the logger can be accomplished in one of two ways:

• The module is hot-swappable -- that is, it can be in-

stalled, removed from or replaced within the flow meter

without disconnecting power. The module can be carried in a shirt pocket back to the office and plugged

into a PC serial port via the module's integral DB9 connector.

• Via the DataLink software utility and the serial DB9 in-

terface cable included with the logger. Data can be accessed by connecting the cable to the logger, which is

located in the pocket on the front faceplate of the instrument. See Figure 1.6.

Refer to Section 3 of this manual for detailed information

regarding the configuration and operation of the Data Logger Module.

Optional

Control Relay

Rev. 4/01 -1.14- TFXP

Two independent SPDT (single-pole, double-throw, Form

C) relays are contained in this module. The relay operations are user configured via software to act in either a

Page 16

PART 1 - ISO-MOD

flow rate alarm, signal strength alarm or totalizer/batching

mode. The relays are rated for 200 Vac max. and have a

current rating of 0.5 A resistive load [175 Vdc @ 0.25 A resistive]. It is highly recommended that a slave relay be

utilized whenever the Control Relay ISO-MOD is used to

control inductive loads such as solenoids and motors.

Optional

0-10 kHz Output

Optional

RS232C I/O

The Rate Pulse Output Module is utilized to transmit information to external counters and PID systems via a frequency output that is proportional to system flow rate.

This module does not source voltage at its output, it must

be connected in an “open-collector” fashion with an external power source and pull-up resistor. Independent Zero

and Span settings are established in software using the

Flow Measuring Range entries. These entries can be set

anywhere in the –40 to +40 fps [-12 to +12 mps] measuring range of the instrument. Output resolution of the module is 12-bits (4,096 discrete points) and the maximum

output frequency setting is 10,000 Hz. The MOSFET can

support loads of 100V @ 9A.

The RS232 Module can be interfaced with the serial communication ports of PCs, PLCs and SCADA systems that

are used to monitor flow rate information in piping systems. The RS232 Module may also be used to form a

hardwire connection to a PC that is running the UltraLink

software utility. Baud rates up to 19.2k are supported.

Optional

RS485 I/O

Optional

RTD-BTU

Rev. 4/01 -1.15- TFXP

The RS485 Module allows up to 126 TFXP systems to be

placed on a single three-wire cable bus. All meters are

assigned a unique one byte serial number that allows all

of the meters on the cable network to be independently

accessed. Baud rates up to 19.2k and cable lengths to

1,000 feet [300 meters] are supported .

See the Appendix of this manual for information regarding

connection and operation of the optional RTD-BTU option.

Page 17

PART 2 - TRANSDUCER POSITIONING

General

The transducers that are u tilized by the Series TFXP

contain piezoelectric crystals for transmitting and

receiving ultrasound signals through walls of liquid

piping systems. The transducers are relatively simple

and straight-forward to install, but spacing and

alignment of the transducers is critical to the system's

accuracy and performance. Extra care should be

taken to ensure that these instructions are carefully

executed.

Mounting of the clamp-on ultrasonic transit time

transducers is comprised of three steps. In general,

these steps consist of:

1. Selection of the optimum location on a piping

system.

2. Entering the pipe and liquid parameters into either

the optional software utility (UltraLink) or keying in

the parameters into the TFXP keypad. The

software embedded in UltraLink and TFXP will

calculate proper transducer spacing based on

these entries.

3. Pipe preparation and transducer mounting.

1. Mounting Location

1. Mounting Location

1. Mounting Location1. Mounting Location

The first step in the installation process is the

selection of an optimum location for the flow

measurement to be made. For this to be done

effectively, a basic knowledge of the piping system

and its plumbing are required.

An optimum location would be defined as a piping

system that is completely full of liquid when

measurements are being taken and has lengths of

straight pipe such as those described in Table 2.1.

The optimum straight pipe diameter

recommendations apply to pipes in both horizontal

and vertical orientation.

Rev. 4/01 - 2.1 - TFXP

Page 18

PART 2 - TRANSDUCER POSITIONING

Table 2.1

1

The TFXP system will provide repeatable measurements on piping systems that do not meet these

requirements, but the accuracy

of these readings may be influenced to various degrees.

1

Rev. 4/01 - 2.2 - TFXP

Page 19

PART 2 - TRANSDUCER POSITIONING

2. Transducer Spacing

2. Transducer Spacing

2. Transducer Spacing2. Transducer Spacing

TFXP transit time flowmeters utilize two transducers

that function as both ultrasonic transmitters and

receivers. The transducers are clamped on the

outside of a closed pipe at a specific distance from

each other. The transducers can be mounted in Vmode where the sound transverses the pipe two times,

W-mode where the sound transverses the pipe four

times, or in Z-mode where the transducers are

mounted on opposite sides of the pipe and the sound

crosses the pipe once. See Figures 2.1-2.3. This

selection is based on pipe and liquid characteristics.

The flowmeter operates by alternately transmitting and

receiving a frequency modulated burst of sound

energy between the two transducers and measuring

the time interval that it takes for sound to travel

between the two transducers.

IMPORTANT: Since the time interval being measured

is influenced by the transducer spacing, it is critical

that the transducer spacing be measured on the pipe

accurately to assure optimum performance from the

TFXP system.

The TFXP system calculates proper transducer

spacing by utilizing piping and liquid information

entered by the user. This information can be entered

via the keypad or the UltraLink Windows software

utility and a laptop computer.

The following information will be required before

programming the instrument:

1. Transducer mounting configuration. Use the

following guide to determine the optimum mounting

method for a particular installati o n:

Rev. 4/01 - 2.3 - TFXP

Page 20

PART 2 - TRANSDUCER POSITIONING

V-Mount

Configuration

W-Mount

Configuration

Figure 2.1 V-Mount. Reflective type (transducers

mounted on one side of the pipe) of installation used

primarily on pipe sizes in the 3-10 inch [75-250 mm]

internal diameter range.

Figure 2.1 - Transducer V-Mount

Figure 2.2 W-Mount. Reflective type (transducers

mounted on one side of the pipe) of installation used

primarily on plastic pipe sizes in the 1-3 inch [25-75

mm] internal diameter range. Metal pipes will typically

require the V-Mount for proper operation.

Figure 2.2 - Transducer W-Mount

Rev. 4/01 - 2.4 - TFXP

Page 21

PART 2 - TRANSDUCER POSITIONING

Z-Mount

Configuration

Figure 2.3 Z-Mount. Direct type (transducers

mounted on opposite sides of the pipe) of installation

used primarily on pipe sizes in the 10-100 inch [2502540 mm] internal diameter range.

Figure 2.3 - Transducer Z-Mount

In addition, the following information is required before

mounting the transducers on the pipe.

2. Pipe O.D. (Outside Diameter)

3. Pipe wall thickness

4. Pipe material

5. Pipe sound speed1

1

6. Pipe relative roughness

7. Pipe liner thickness (if present)

8. Pipe liner material (if present)

9. Fluid type

10. Fluid sound speed

1

11. Fluid viscosity1

1

12. Fluid specific gravity

1

Nominal values for these parameters are included

within the TFXP operating system. The nominal

values may be used as they appear or may be

modified if exact system values are known.

Rev. 4/01 - 2.5 - TFXP

Page 22

PART 2 - TRANSDUCER POSITIONING

Keypad Entry

The TFXP contains a tactile feedback keypad interface

that allows the user to configure parameters used by

the TFXP operating system.

Graphics Display

Soft Keys

Arrow Keys

Numeric Keys

Infrared Communications Port

The TFXP system can be configured using UltraLink

and a laptop computer. Please refer to page 2.13 for

details regarding data entry in UltraLink.

The following “Soft Key” menu items will be displayed

immediately above the two keys located in the lower

corners of the Graphics Display.

1. The (soft)MENU key is pressed from RUN mode to

enter PROGRAM mode. The (soft)EXIT key is

pressed in PROGRAM mode to exit configuration

parameters and menus. If changes to any

configuration parameters have been made, the

user will be prompted with a SAVE? (soft)YES or

(soft)NO when returning to RUN mode. If no

changes have been made, the user will not be

prompted for to SAVE.

2. The UP/DOWN ARROW keys are used to scroll

through menus and configuration parameters. The

ARROW keys can also be used to adjust

parameter numerical values. In RUN mode the

UP/DOWN ARROW keys are used to adjust the

display contrast level.

3. The Numerical Keypad is used for entering

numerical values.

Rev. 4/01 - 2.6 - TFXP

Page 23

PART 2 - TRANSDUCER POSITIONING

4. The (soft)EDIT key is used to

• access the configuration parameters in the various

menus.

• initiate changes in configuration parameters.

5. The (soft)ACCEPT key is used to

• accept configuration parameter changes.

Graphics Display

Configuration

6. The (soft)SELECT key is used to

• Configure the engineering units on the graphics

display—Press the (soft)SELECT key from RUN

mode to highlight the engineering unit presently

being displayed on the graphics display (pressing

the SELECT key multiple times will toggle the

highlighted unit from line to line). Use the UP/

DOWN ARROW keys to select display units of

• RATE

• TOTALizer

• VELocity

• SIGNAL STRength

• From Menu 7, Display Menu, the number of

graphics display lines can be toggled between two

and four lines.

Menu 1, the BASIC menu contains all of the

configuration parameters necessary to make the

transducer spacing calculation.

UNITS Entry

UNITS

ENGLSH

METRIC

Installs a global measurement standard into the

operation of the instrument. The choices are either

English or Metric measurements.

• Select ENGLSH if all configurations (pipe sizes,

etc.) are to be made in inches. Select METRIC if

the meter is to be configured in millimete rs.

• The ENGLSH/METRIC selection will also co nfigure

Rev. 4/01 - 2.7 - TFXP

Page 24

PART 2 - TRANSDUCER POSITIONING

the TFXP to display sound speeds in pipe

materials and liquids as either feet per second or

meters per second respectively.

Transducer Mount

Configuration

XDCR MNT -- Transducer Mounting Method

V

W

Z

Selects the mounting orientation for the transducers.

The selection of an appropriate mounting orientation is

based on pipe and liquid characteristics. Refer to

Figures 2.1-2.3 in this manual.

V -- Mount. A reflective type (transducers mounted on

one side of the pipe) of installation used primarily on

pipe sizes in the 3-10 inch [75-250 mm] internal

diameter range.

W -- Mount. A reflective type (transducers mounted

on one side of the pipe) of installation used primarily

on pipe sizes in the 1-3 inch [25-75 mm] internal

diameter range.

Z -- Mount. A direct type (transducers mounted on

opposite sides of the pipe) of installation used

primarily on pipe sizes in the 10-100 inch [250-2540

mm] internal diameter range.

Pipe O.D. Entry

Pipe Wall Entry

Rev. 4/01 - 2.8 - TFXP

PIPE OD -- Pipe Outside Diameter Entry

ENGLSH (Inches)

METRIC (Millimeters)

Enter the pipe outside diameter

was selected as UNITS; in millimeters if METRIC was

selected.

PIPE WT -- Pipe Wall Thickness Entry

ENGLSH (Inches)

METRIC (Millimeters)

in inches if ENGLSH

Page 25

PART 2 - TRANSDUCER POSITIONING

Pipe Material Entry

Pipe Sound Speed

Entry

Enter the pipe wall thickness in inches if ENGLSH was

selected as UNITS; in millimeters if METRIC was

selected.

PIPE MAT -- Pipe Material Selection

CARBON S - Carbon Steel

STAINLES - Stainless Steel

CAST IRO - Cast Iron

DUCTILE - Ductile Iron

COPPER - Copper

PVC - Polyvinylchloride

PVDF LOW PVDF HI - High Density Polyvinylidene Flouride

ALUMINUM - Aluminum

ASBESTOS - Asbestos Cement

FIBERGLA - Fiberglass

OTHER

This list is provided as an example. Additional

materials are being added continuously. Select the

appropriate pipe material from the list or select

OTHER if the material is not listed.

PIPE SS -- Speed of Sound in the Pipe Material

ENGLSH (Feet per Second)

METRIC (Meters per Second)

Allows adjustments to be made to the speed of sound

in the pipe wall. If the UNITS value was set to

ENGLSH, the entry is in FPS (feet per second).

METRIC entries are made in MPS (meters per

second).

Low Density Polyvinylidene Flouride

If a pipe material was chosen from the PIPE MAT list,

a nominal value for speed of sound in that material will

be automatically loaded. If the actual sound speed

rate is known for the application piping system and

that value varies from the automatically loaded value,

the value can be revised.

If OTHER was chosen as PIPE MAT, a PIPE SS will

need to be entered.

Rev. 4/01 - 2.9 - TFXP

Page 26

PART 2 - TRANSDUCER POSITIONING

Pipe Roughness

Entry

Liner Material Entry

Liner Thickness

Entry

PIPE R -- Pipe Material Relative Roughness

UNITLESS VALUE

The DTFXP provides Reynolds Number compensation

in its flow measurement calculation. The ratio of

average surface imperfection as it relates to the pipe

internal diameter is used in this comp ensation.

Linear RMS measurement of the pipe

PIPE R = internal wall surface

Internal Diameter of the pipe

If a pipe material was chosen from the PIPE MAT list,

a nominal value relative roughness in that material will

be automatically loaded. If the actual roughness is

known for the application piping system and that value

varies from the automatically loaded value, the value

can be revised.

If OTHER was chosen as PIPE MAT, a PIPE R may to

be entered.

LINER T -- Pipe Liner Thickness Entry

ENGLSH (Inches)

METRIC (Millimeters)

Enter the pipe liner thickness

inches if ENGLSH was selected as UNITS; in

millimeters if METRIC was selected.

[If a LINER Thickness was selected]

LINER MAT - Liner Material

TAR EPOXY

RUBBER

MORTAR

POLYPROPYLENE

POLYSTYROL

POLYSTYRENE

POLYESTER

. Enter this value in

Rev. 4/01 - 2.10 - TFXP

Page 27

PART 2 - TRANSDUCER POSITIONING

Liner Sound Speed

Entry

Fluid Type Entry

POLYETHYLENE

EBONITE

TEFLON

Other

This list is provided as an example. Additional

materials are being added continuously. Select the

appropriate material from the list or select OTHER if

the liner material is not listed.

LINER SS -- Speed of Sound in the Liner

ENGLSH (Feet per Second)

METRIC (Meters per Second)

Allows adjustments to be made to the speed of sound

in the liner. If the UNITS value was set to ENGLSH,

the entry is in FPS (feet per second). METRIC entries

are made in MPS (meters per second).

If a liner was chosen from the LINER MAT list, a

nominal value for speed of sound in tha t media will be

automatically loaded. If the actual sound speed rate is

known for the pipe liner and that value varies from the

automatically loaded value, the value can be revised.

FL TYPE - Fluid/Media Type

TAP WATER

SEWAGE

SEA WATE

KEROSENE

GASOLINE

FUEL OIL

CRUDE OI

PROPANE

BUTANE

OTHER

This list is provided as an example. Additional liquids

are being added continuously. Select the appropriate

liquid from the list or sele ct OTHER if the liquid is not

listed.

Rev. 4/01 - 2.11 - TFXP

Page 28

PART 2 - TRANSDUCER POSITIONING

Fluid Sound Speed

Entry

Fluid Viscosity Entry

FLUID SS -- Speed of Sound in the Fluid

ENGLSH (Feet per Second)

METRIC (Meters per Second)

Allows adjustments to be made to the speed of sound

in the liquid. If the UNITS value was set to ENGLSH,

the entry is in FPS (feet per second). METRIC entries

are made in MPS (meters per second).

If a fluid was chosen from the FL TYPE list, a nominal

value for speed of sound in that media will be

automatically loaded. If the actual sound speed rate is

known for the application fluid and that value varies

from the automatically loaded value, the value can be

revised.

If OTHER was chosen as FL TYPE, a FLUID S S will

need to be entered. A list of alternate fluids and their

associated sound speeds are located the Appendix

located at the back of this manual.

FLUID VI -- Absolute Viscosity the Fluid

cps

Allows adjustments to be made to the absolute

viscosity of the liquid.

If a fluid was chosen from the FL TYPE list, a nominal

value for viscosity in that media will be automatically

loaded. If the actual viscosity is known for the

application fluid and that value varies from the

automatically loaded value, the value can be revised.

If OTHER was chosen as FL TYPE, a FLUID VI will

need to be entered. A list of alternate fluids and their

associated viscosities are located the Appendix

located at the back of this manual.

Fluid Specific

Gravity Entr y

Rev. 4/01 - 2.12 - TFXP

SP GRVTY -- Fluid Specific Gravity Entry

unitless

Allows adjustments to be made to the specific gravity

(density) of the liquid.

Page 29

PART 2 - TRANSDUCER POSITIONING

Transducer Spacing

Calculation

If a fluid was chosen from the FL TYPE list, a nominal

value for specific gravity in that media will be

automatically loaded. If the actual specific gravity is

known for the application fluid and that value varies

from the automatically loaded value, the value can be

revised.

If OTHER was chosen as FL TYPE, a SP GRVTY may

need to be entered if mass flows are to be calculated.

A list of alternate fluids and their associated specific

gravities are located the Appendix located at the back

of this manual.

XDCR SPAC -- Transducer Spacing Calculation

ENGLSH (Inches)

METRIC (Millimeters)

This value represents the one-dimensional linear

measurement between the transducers (the upstream/

downstream measurement that runs parallel to the

pipe). This value is in inches if ENGLSH was selected

as UNITS, in millimeters if METRIC was selected.

This measurement is taken from the line which is

scribed into the side of the transducer block.

Important note for pipe sizes under 2 inches [50 mm].

If the transducer spacing that is calculated is lower

than 2.65 inches [67 mm], enter W-mount as the

transducer mount method or enter V- mou nt and pl ace

the transducers at 2.65 inches [67 mm]. See Page

2.21 for additional details .

UltraLink Entry

Rev. 4/01 - 2.13 - TFXP

UltraLink Data Entry

The UltraLink Windows®-based software utility

provides an efficient means for entering piping and

liquid parameters through the use of pop-up window/

pull-down menu structures. Data can be entered into

UltraLink, stored, later retrieved and downloaded at

Page 30

PART 2 - TRANSDUCER POSITIONING

the TFXP installation site (provided that UltraLink and

TFXP communications are not enabled at the time of

data entry) or it can be downloaded immediately to the

TFXP meter (provided that UltraLink and TFXP

communications are enabled during data entry).

To install UltraLink and establish communications with

a PC, please follow the instructions enclosed with the

UltraLink software package or in the Appendix of this

manual.

The system information required for entry into the

UltraLink package is identical to that required for

Keypad Entry covered in the previous section. See

pages 2.3-2.5.

After initializing UltraLink, click on the button labeled

Transducer

spacing

appears here.

Figure 2.4 UltraLink Windows-based software utility configuration

screen.

Rev. 4/01 - 2.14 - TFXP

Page 31

PART 2 - TRANSDUCER POSITIONING

Config. The window shown in Figure 2.4 will appear.

Enter the pipe and liquid parameters into the

appropriate data fields in the Basic window. The

correct transducer spacing will appear in the

Transducer - Spacing data field.

After all data fields have been entered Download to

the TFXP or File Save to a disk by clicking on the

appropriate button in the Config window. Download

is not possible unless communications are enabled

between the TFXP and UltraLink. Communications

are enabled when a green OK is indicated in the lower

right-hand COMM: status box. If communications are

not enabled, please review the documentation that

details the installation and initialization of UltraLink.

This document is part of Dynasonics Part Number

D005-2115-100 infrared communications adapter

package.

3. Transducer Mounting

3. Transducer Mounting

3. Transducer Mounting3. Transducer Mounting

After selecting an optimal mounting location, Step 1,

and successfully determining the proper transducer

spacing, Step 2, the transducers can now be mounted

onto the pipe.

The DTT transducers need to be properly oriented on

the pipe to provide optimum reliability and

performance. On horizontal pipes, the transducers

should be mounted 180 radial degrees from one

another and at least 45 degrees from the top-deadcenter and bottom-dead-center of the pipe. See

Figure 2.5. Figure 2.5 does not apply to vertically

oriented pipes.

Before the transducers are bonded to the pipe surface,

two areas slightly larger than the flat surface of the

transducer heads must be cleaned of all rust, scale

and moisture. Finish the surface with some emery

paper, and wipe the surface with a degreasing solvent

such as trichlorethylene. Paint and other coatings, if

Rev. 4/01 - 2.15 - TFXP

Page 32

PART 2 - TRANSDUCER POSITIONING

not flaked or bubbled, need not be removed. Plastic

pipes typically do not require surface preparation other

than soap and water cleaning.

Figure 2.5 Transducer mounting locations on

horizontal pipe.

Installations on Pipes

Smaller than 10 Inches

[250 mm] Go to Page 2.18

Mounting Transducers in Z-Mount Configuration

Installation on larger pipes requires careful

measurements to the linear and radial placement of

the DTT transducers. Failure to properly orient and

place the transducers on the pipe may lead to weak

signal strength and/or inaccurate readings. The

section below details a method for properly locating

the transducers on larger pipes. This method requires

a roll of paper such as freezer paper or wrapping

paper, masking tape and a marking device.

Wrap the paper around the pipe in the manner shown

in Figure 2.6. Align the paper ends to within 0.25

inches [6mm].

Mark the intersection of the two pieces of paper to

indicate the circumference. Remove the template and

spread it out on a flat surface. Fold the template in

half, bisecting the circumference. See Figure 2.7.

Rev. 4/01 - 2.16 - TFXP

Page 33

PART 2 - TRANSDUCER POSITIONING

Figure 2.6 Paper Template Alignment

Crease the paper at the fold line. Mark the crease.

Place a mark on the pipe where one of the

transducers will be located. See Figure 2.5 for

acceptable radial orientations. Wrap the template

back around the pipe, placing the beginning of the

paper and corner in the location of the mark. Move to

the other side of the pipe and mark the ends of the

crease. Measure from the end of the crease (directly

Figure 2.7 Bisecting the pipe circumference

Rev. 4/01 - 2.17 - TFXP

Page 34

PART 2 - TRANSDUCER POSITIONING

across the pipe from the first transducer location) the

dimension derived in Step 2, Transducer Spacing.

Mark this location on the pipe.

The two marks on the pipe are now properly aligned

and measured.

If access to the bottom of the pipe prohibits the

wrapping of the paper around the circumference, cut

a piece of paper to these dimensions and lay it over

the top of the pipe.

Length = Pipe O.D. x 1.57

Width = Spacing determined on 2.12 or 2.14

Mark opposite corners of the paper on the pipe.

Apply transducers to these two marks.

DTT1, DTT2 and

DTT3 Installation

DTT1, DTT2 and DTT3 Mounting Saddle Installation

1. Install the first mounting saddle on the pipe, with

the alignment groove placed over one of the

marks created in the previous section. The

stainless steel clamping band will be located

towards the "inside" and the thumbscrew will be

mounted towards the outside. See Figure 2.8.

2. Place a single bead of couplant, approximately

0.25 inch [6 mm] thick, on the flat face of the

transducer. See Figure 2.9. Use Dow 732 for

permanent and Dow 44 for temporary (less that

six months) installations.

3. Place the first transducer in between the saddle

and pipe near the zero point on the mounting rail

scale. Slide the transducer clamp over the

transducer. Adjust the clamp/transducer such

that the line on the transducer aligns with the

mark on the pipe. See Figure 2.8.

4. Secure with the thumb screw. (Excessive

Rev. 4/01 - 2.18 - TFXP

Page 35

PART 2 - TRANSDUCER POSITIONING

Figure 2.8 Z-Mount Alignment

pressure is not required. Apply just enough

pressure so that the couplant fills the gap

between the pipe and transducer.) If DOW 732,

or some other silicone RTV type sealant, was

used ensure that no relative movement between

the transducer and pipe takes place during the

setting time and do not apply instrument power

for at least 24 hours. If Dow 111 or an alternate

form of grease has been used as a couplant,

setting time is not necessary.

Figure 2.9 Transducer Couplant Application

5. Mount the second saddle in the same manner as

the first, but at the second mark on the pipe.

Slide the transducer clamp over the transducer

and secure with the thumb screw. Refer to

Figure 2.8 for proper ori entation.

Rev. 4/01 - 2.19 - TFXP

Page 36

PART 2 - TRANSDUCER POSITIONING

DT TA Transducer

Installation

DTTA Mounting Rail Installation

1. Install the single mounting rail on the pipe in a

orientation suggested by Figure 2.5 (using only a

single rail, not the two opposing rails pictured)

with the stainless steel bands provided.

Orientation on vertical pipe is not critical. Ensure

that the track is parallel to the pipe and that all

four mounting feet are touching the pipe.

2. Slide the two transducer clamp brackets towards

the center, 5 inch [125 mm] mark, on the

mounting rail.

3. Place a single bead of couplant, approximately

0.25 inch [6 mm] thick, on the flat face of the

transducer. See Figure 2.10. Use Dow 732 for

permanent and Dow 111 for temporary (less that

six months) installations.

Figure 2.10 Transducer Couplant Application

4. Place the first transducer in between the

mounting rails near the zero point on the

mounting rail scale. Slide the transducer clamp

over the transducer. Adjust the clamp/transducer

such that the notch in the clamp aligns with zero

on the scale. See Figure 2.11.

5. Secure with the thumb screw. Ensure that the

screw rests in the counter bore on the top of the

transducer. (Excessive pressure is not required.

Apply just enough pressure so that the couplant

Rev. 4/01 - 2.20 - TFXP

Page 37

PART 2 - TRANSDUCER POSITIONING

fills the gap between the pipe and transducer.) If

DOW 732 or some other silicone RTV type

sealant was used, ensure that no relative

movement between the transducer and pipe

takes place during the setting time and do not

apply instrument power for at least 24 hours. If

Dow 111 or an alternate form of grease has been

used as a couplant, setting time is not necessary.

Pipes Smaller than 2

inches [50 mm]

Figure 2.11 Transducer Space Measurement

6. Place the second transducer in between the

mounting rails near the dimension derived in the

Transducer Spacing section. Read the dimension

on the mounting rail scale. Slide the transducer

clamp over the transducer and secure with the

thumb screw.

Important note for pipe sizes under 2 inches [50 mm].

If the transducer spacing that is calculated is lower

than 2.65 inches [67 mm], enter W-mount as the

transducer mount method or enter V- mou nt and pl ace

the transducers as illustrated in Figure 2.12.

Rev. 4/01 - 2.21 - TFXP

Page 38

PART 2 - TRANSDUCER POSITIONING

Figure 2.12 Pipes Smaller than

2 inches [50 mm]

Rev. 4/01 - 2.22 - TFXP

Page 39

PART 3 - STARTUP AND CONFIGURATION

Before Starting the

Instrument

Instrument Startup

Note: The TFXP flow meter system requires a full

pipe of liquid before a successful startup can be

completed. Do not attempt to make adjustments or

change configurations until a full pipe is verified.

Note: If Dow 732 RTV was utilized to couple the

transducers to the pipe, the adhesive must fully cure

before power is applied to the instrument. Dow 732

requires 24 hours to cure satisfactorily. If Dow 111

silicone grease was utilized as a couplant, the curing time

is not required.

Procedure:

1. Verify that all wiring is properly connected and routed

as described previously in this manual.

2. Verify that the transducers are properly mounted as

described in Part 2 of this manual.

3. Press the ON button on the flow meter keypad. The

TFXP display backlighting will illuminate and the

software version number and Dynasonics’ logo will

appear on the display.

The display backlighting illuminates for approximately 20

seconds and automatically extinguishes to preserve

battery power. To re illuminate the display, press any key

on the keyboard. Adjustments to the backlighting duration

can be made in the Display Menu. Refer to page 3.27 for

details.

4. Confirm that Signal Strength is greater than 2%. If it

is not, verify that proper transducer mounting methods

and liquid/pipe characteristics have been entered.

The pipe must be full of liquid in order to make

this measurement.

5. Once the meter is properly operating (proper signal

strength has been achieved), refer to the later portions of this manual section for additional

programming featur es.

Rev. 4/01 -3.1- TFXP

Page 40

PART 3 - KEYPAD CONFIGURATION

General

Keypad Operation

After a installation of the transducer track or cradle

assembly and connection of appropriate power

supplies to the TFXP, keypad configuration of the

instrument can be undertaken. All entries are saved

in non-volatile FLASH memory and will be retained in

the event of power loss.

The TFXP can be configured through the keypad

interface or by using the UltraLink Windows®

software utility. Of the two methods of conf iguration,

the UltraLink software utility provides more advanced

features and offers the abililty to store and transfer

meter configurations between TFXP meters.

Graphics Display

Soft Keys

Arrow Keys

Numeric Keys

Infrared Communications Port

Figure 3.1

The following “Soft Key” menu items will be displayed

immediately above the two keys located in the lower

corners of the Graphics Display. See Figure 3.1.

1. The (soft)MENU key is pressed from RUN mode

to enter PROGRAM mode. The (soft)EXIT key is

pressed in PROGRAM mode to exit configuration

parameters and menus. If changes to any

configuration parameters have been made, the

user will be prompted with a SAVE? (soft)YES or

(soft)NO when returning to RUN mode. If no

changes have been made, the user will not be

prompted for to SAVE.

Rev. 4/01 -3.2- TFXP

Page 41

PART 3 - KEYPAD CONFIGURATION

Display Contrast

Graphics Display

Configuration

2. The UP/DOWN ARROW keys are used to scroll

through menus and configuration parameters. The

ARROW keys can also be used to adjust

parameter numerical values. In RUN mode the

UP/DOWN ARROW keys are used to adjust the

display contrast level.

3. The Numerical Keypad is used for entering

numerical values.

4. The (soft)ACCEPT key is used to

• accept configuration parameter changes.

5. The (soft)SELECT key is used to

• Conifgure the engineering units on the graphics

display—Press the (soft)SELECT key from RUN

mode to highlight the engineering unit presently

being displayed on the graphics display (pressing

the SELECT key multiple times will toggle the

highlighted unit from line to line). Use the UP/

DOWN ARROW keys to select display units of

Menu Structure

• RATE

• TOTALizer

• VELocity

• SIGNAL STRength

From Menu 8, Display Menu, the number of

graphics display lines can be toggled between two

and four lines.

• access the configuration parameters in the various

menus.

• initiate changes in configuration parameters.

The eight menus used in the structure of the TFXP are

as follows:

1. BSC MENU

BSC MENU -- BASIC operations menu. It contains all

BSC MENUBSC MENU

of the configuration parameters necessary to

program the meter to measure flow.

Rev. 4/01 -3.3- TFXP

Page 42

PART 3 - KEYPAD CONFIGURATION

2. Datalog operation

Datalog operation -- Configures the datalogging

Datalog operationDatalog operation

location, logger interval and logging duration.

3. Datalog mainte nance

Datalog maintenance -- Existing datalogger files can

Datalog maintenanceDatalog maintenance

be erased from the logger.

4. OUT2 MEN

OUT2 MEN -- Configures the type and operating

OUT2 MENOUT2 MEN

parameters of the ISO-MOD located internally in

the TFXP flow meter.

5. SEN MENU

SEN MENU -- SENSOR menu is for future use.

SEN MENUSEN MENU

6. SEC MENU

SEC MENU -- SECURITY MENU utilized for resetting

SEC MENUSEC MENU

totalizers, resetting the operating system and

revising security passwords.

7. SER MENU

SER MENU -- SERVICE MENU contains system

SER MENUSER MENU

measurements that are used by service personnel

for troubleshooting instruments installed on piping

systems. On-the-pipe “zero flow” can be captured

in this menu.

UNITS Selection

8. DSP MENU

DSP MENU -- DISPLAY MENU used to configure

DSP MENUDSP MENU

meter display functions.

1.

1. BSC MENU

BSC MENU --

1. 1.

BSC MENUBSC MENU

The following sections define the configuration

parameters located in each of the menus.

The BASIC menu contains all of the configuration

parameters necessary to make the TFX P oper ational .

UNITS

ENGLSH

METRIC

Installs a global measurement standard into the

operation of the instrument. The choices are either

English or Metric measurements.

-- BASIC MENU

BASIC M ENU

----

BASIC M ENU BASIC M ENU

• Select ENGLSH if all configurations (pipe sizes,

Rev. 4/01 -3.4- TFXP

Page 43

PART 3 - KEYPAD CONFIGURATION

etc.)are to be made in inches. Select METRIC if

the meter is to be configured in millimete rs.

• The ENGLSH/METRIC selection will also co nfigure

the TFXP to display sound speeds in pipe

materials and liquids as either feet per second or

meters per second, respectively.

Transducer Mount

XDCR MNT -- Transducer Mounting Method

V

W

Z

Selects the mounting orientation for the transducers.

The selection of an appropriate mounting orientation is

based on pipe and liquid characteristics. See PART

2 - Transducer installation in this manual.

V -- Mount. A reflective type (transducers mounted on

one side of the pipe) of installation used primarily on

pipe sizes in the 3-8 inch [75-200 mm] internal

diameter range.

W -- Mount. A reflective type (transducers mounted

on one side of the pipe) of installation used primarily

on pipe sizes in the 1-3 inch [25-75 mm] internal

diameter range.

Z -- Mount. A direct type (transducers mounted on

opposite sides of the pipe) of installation used

primarily on pipe sizes in the 8-100 inch [200-2540

mm] internal diameter range.

IMPORTANT NOTE: Charts listing popular pipe sizes

have been included in the Appendix of this manual.

Correct entries for pipe O.D. and pipe wall thickness

are critical to obtaining accurate flow measurement

readings.

Rev. 4/01 -3.5- TFXP

Page 44

PART 3 - KEYPAD CONFIGURATION

Pipe Diameter

Pipe Wall Thickness

Pipe Material

PIPE OD -- Pipe Outside Diameter Entry

ENGLSH (Inches)

METRIC (Millimeters)

Enter the pipe outside diameter in inches if ENGLSH

was selected as UNITS; in millimeters if METRIC was

selected.

IMPORTANT NOTE: Charts listing popular pipe sizes

have been included in the Appendix of this manual.

Correct entries for pipe O.D. and pipe wall thickness

are critical to obtaining accurate flow measurement

readings.

PIPE WT -- Pipe Wall Thickness Entry

ENGLSH (Inches)

METRIC (Millimeters)

Enter the pipe wall thickness in inches if ENGLSH was

selected as UNITS; in millimeters if METRIC was

selected.

PIPE MAT -- Pipe Material Selection

CARBON S - Carbon Steel

STAINLES - Stainless Steel

CAST IRO - Cast Iron

DUCTILE - Ductile Iron

COPPER - Copper

PVC - Polyvinylchloride

PVDF LOW - Low Density Polyvinylidene Flouride

PVDF HI - High Density Polyvinylidene Flouride

ALUMINUM - Aluminum

ASBESTOS - Asbestos Cement

FIBERGLA - Fiberglass

OTHER

This list is provided as an example. Additional pipe

materials are being added continuously. Select the

appropriate pipe material from the list or select

Rev. 4/01 -3.6- TFXP

Page 45

PART 3 - KEYPAD CONFIGURATION

Pipe Sound Speed

OTHER if the material is not listed.

PIPE SS -- Speed of Sound in the Pipe Material

ENGLSH (Feet per Second)

METRIC (Meters per Second)

Allows adjustments to be made to the speed of sound

in the pipe wall. If the UNITS value was set to

ENGLSH, the entry is in FPS (feet per second).

METRIC entries are made in MPS (meters per

second).

If a pipe material was chosen from the PIPE MAT list,

a nominal value for speed of sound in that material will

be automatically loaded. If the actual sound speed

rate is known for the application piping system and

that value varies from the automatically loaded value,

the value can be revised.

Pipe Roughness

If OTHER was chosen as PIPE MAT, a PIPE SS will

need to be entered.

PIPE R -- Pipe Material Relative Roughness

UNITLESS VALUE

The TFXP provides Reynolds Number compensation

in its flow measurement calculation. The ratio of

average surface imperfection as it relates to the pipe

internal diameter is used in this comp ensation.

Linear RMS measurement of the pipe

PIPE R = internal wall surface

Internal Diameter of the pipe

If a pipe material was chosen from the PIPE MAT list,

a nominal value relative roughness in that material will

be automatically loaded. If the actual roughness is

known for the application piping system and that value

Rev. 4/01 -3.7- TFXP

Page 46

PART 3 - KEYPAD CONFIGURATION

Liner Thickness

Liner Type

Liner Sound Speed

varies from the automatically loaded value, the value

can be revised.

If OTHER was chosen as PIPE MAT, a PIPE R may to

be entered.

LINER T -- Pipe Liner Thickness Entry

ENGLSH (Inches)

METRIC (Millimeters)

Enter the pipe liner thickness. Enter this value in

inches if ENGLSH was selected as UNITS; in

millimeters if METRIC was selected.

[If a LINER Thickness was selected]

LINER MAT - Liner Material

TAR EPOXY

RUBBER

MORTAR

POLYPROPYLENE

POLYSTYROL

POLYSTYRENE

POLYESTER

POLYETHYLENE

EBONITE

TEFLON

Other

This list is provided as an example. Additional

materials are being added continuously. Select the

appropriate material from the list or select OTHER if

the liner material is not listed.

LINER SS -- Speed of Sound in the Liner

ENGLSH (Feet per Second)

METRIC (Meters per Second)

Allows adjustments to be made to the speed of sound

in the liner. If the UNITS value was set to ENGLSH,

the entry is in FPS (feet per second). METRIC entries

are made in MPS (meters per second).

Rev. 4/01 -3.8- TFXP

Page 47

PART 3 - KEYPAD CONFIGURATION

Fluid Type

Fluid Sound Speed

If a liner was chosen from the LINER MAT list, a

nominal value for speed of sound in tha t media will be

automatically loaded. If the actual sound speed rate is

known for the pipe liner and that value varies from the

automatically loaded value, the value can be revised.

FL TYPE - Fluid/Media Type

WATER

SEA WATE

KEROSENE

GASOLINE

FUEL OIL

CRUDE OI

PROPANE

BUTANE

OTHER

This list is provided as an example. Additional liquids

are being added continuously. Select the appropriate

liquid from the list or sele ct OTHER if the liquid is not

listed.

FLUID SS -- Speed of Sound in the Fluid

ENGLSH (Feet per Second)

METRIC (Meters per Second)

Allows adjustments to be made to the speed of sound

in the liquid. If the UNITS value was set to ENGLSH,

the entry is in FPS (feet per second). METRIC entries

are made in MPS (meters per second).

If a fluid was chosen from the FL TYPE list, a nominal

value for speed of sound in that media will be

automatically loaded. If the actual sound speed rate is

known for the application fluid and that value varies

from the automatically loaded value, the value can be

revised.

If OTHER was chosen as FL TYPE, a FLUID S S will

need to be entered. A list of alternate fluids and their

Rev. 4/01 -3.9- TFXP

Page 48

PART 3 - KEYPAD CONFIGURATION

Fluid Viscosity

Fluid Specific Gravity

associated sound speeds are located the Appendix

located at the back of this manual.

FLUID VI -- Absolute Viscosity the Fluid

cps

Allows adjustments to be made to the absolute

viscosity of the liquid.

If a fluid was chosen from the FL TYPE list, a nominal

value for viscosity in that media will be automatically

loaded. If the actual viscosity is known for the

application fluid and that value varies from the

automatically loaded value, the value can be revised.

If OTHER was chosen as FL TYPE, a FLUID VI will

need to be entered. A list of alternate fluids and their

associated viscosities are located the Appendix

located at the back of this manual.

SP GRVTY -- Fluid Specific Gravity Entry

unitless

Allows adjustments to be made to the specific gravity

(density) of the liquid.

If a fluid was chosen from the FL TYPE list, a nominal

value for specific gravity in that media will be

automatically loaded. If the actual specific gravity is

known for the application fluid and that value varies

from the automatically loaded value, the value can be

revised.

If OTHER was chosen as FL TYPE, a SP GRVTY may

need to be entered if mass flows are to be calculated.

A list of alternate fluids and their associated specific

gravities are located the Appendix located at the back

of this manual.

Transducer Spacing

Rev. 4/01 -3.10- TFXP

XDCR SPAC -- Transducer Spacing Calculation

ENGLSH (Inches)

Page 49

PART 3 - KEYPAD CONFIGURATION

METRIC (Millimeters)

This value represents the one-dimensional linear

measurement between the transducers (the upstream/

downstream measurement that runs parallel to the

pipe). This value is in inches if ENGLSH was selected

as UNITS; in millimeters if METRIC was selected.

This measurement is taken from the line which is

scribed into the side of the transducer block.

If the transducers are being mounted using the

Figure 3.2

transducer track assembly, a measuring scale is

etched into the track. Place on transducer at 0 inches

and the other at the appropriate measurement.

NOTE: If V-mounting is used on pipes that are smaller

than 2 inches [50 mm], the transducers will be

mounted "nose-to-nose" as illustrated in Figure 3.2.

Engineering Units

RATE

Engineering Units

RATE INTERVAL

RATE UNT - Engineering Units for Flow Rate

GALLONS - U.S. Gallons

LITERS - Metric Liter

MGAL - Millions of U.S. Gallons

CUBIC FT - Cubic Feet

CUBIC ME - Cubic Meters

ACRE FT - Acre Feet

OIL BARR - Oil Barrels (42 U.S. Gallons)

LIQ BARR - Liquor Barrels (31.5 U.S. Gallons)

FEET - Linear Feet

METERS - Linear Meters

Select a desired engineering unit for flow rate

measurements.

RATE INT - Time Interval for Flow Rate

MIN - Minutes

HOUR - Hours

DAY - Days

SEC - Seconds

Rev. 4/01 -3.11- TFXP

Page 50

PART 3 - KEYPAD CONFIGURATION

Engineering Units

TOTAL

Engineering Units

TOTAL Exponent

Minimum Velocity

Select a desired engineering unit for flow rate

measurements.

TOTL UNT - Engineering Units for Flow Totalizer

GALLONS - U.S. Gallons

LITERS - Metric Liter

MGAL - Millions of U.S. Gallons

CUBIC FT - Cubic Feet

CUBIC ME - Cubic Meters

ACRE FT - Acre Feet

OIL BARR - Oil Barrels (42 U.S. Gallons)

LIQ BARR - Liquor Barrels (31.5 U.S. Gallons)

FEET - Linear Feet

METERS - Linear Meters

Select a desired engineering unit for flow accumulator

(totalizer) measurements.

TOTL E - Flow Totalizer Exponent Value

E-1 to E6

Utilized for setting the flow totalizer exponent. This

feature is useful for accommodating a very large

accumulated flow. The exponent is a "X10

where "n" can be from -1 (X 0.1) to +6 (X 1,000,000).

MIN RATE - Minimum Flow Rate Settings

Rate Unit/Rate Interval

A minimum volumetric flow rate setting is entered to

establish filter software settings.

n

" multiplier,

NOTE: The Minimum Rate may be set anywhere in

the flow measurement range of -40 to +40 FPS. For

example: If bi-directional flow needs to be logged, set

the MIN RATE a t a negative value.

Rev. 4/01 -3.12- TFXP

Page 51

PART 3 - KEYPAD CONFIGURATION

Maximum Velocity

Low Flow Cut-off

System Damping

MAX RATE - Maximum Flow Rate Settings

Rate Unit/Rate Interval

A maximum volumetric flow rate setting is entered to

establish filter software settings and as a baseline for

the FL C-OFF entry below.

NOTE: The Maximum Rate may be set anywhere in

the flow measurement range of -40 to +40 FPS. For

example: If bi-directional flow needs to be logged, set

the MIN RATE at a negative

a positive value.

FL C-OFF - Low Flow Cut-off

Percent of MAX RATE

A Low Flow Cut-off entry is provided to allow very low

flow rates (that can be present when pumps are off

and valves are closed) to be displayed as Zero flow.

Typical values that should be entered are between

1.0% and 5.0% of full-scale.

DAMP PER - System Damping

Relative Percent Entry

In installations where very turbulent or erratic flow is

encountered, increasing the Damping setting can

increase display and output stability. The DAMP PER

setting increases and decreases the response time of

the flow meter display and outputs. Set a value

between 1 and 100 percent, a setting of 1 having the

fastest response and 100 having the slowest

response.

value and MAX RATE at

Rev. 4/01 -3.13- TFXP

Page 52

PART 3 - KEYPAD CONFIGURATION

2.

2. DATALOG OPERATION MENU

DATALOG OPERATION MENU

2. 2.

DATALOG OPERATION MENUDATALOG OPERATION MENU

ISO-MOD DataLogger

Location Number 1-30,000 [16 total locations]

INTERVAL 1-30,000 seconds

DURATION 1-30,000 hours

The standard configuration for the TFXP includes a

powerful 200,000-event data logger/electronic stripchart recorde r. The logge r ca n be co nf igu red in a co uple of different ways to match user applications. The

logger stores time-stamped, high resolution (16-bit)

data at user selected intervals ranging from 1 to

30,000 (8.33 hours) seconds. Configuration of and

data retrieva l from the logger can be accomplished i n

one of two ways:

Figure 3.3

Data Logger

Configuration

• The module is hot-swappable -- that is, it can be

installed, removed from or replaced within the flow

meter without disconnecting power. The module

can be carried in a shirt pocket back to the office

and plugged into a PC serial port via the module's

integral DB9 connector. This feature eliminates the

requirement to carry a laptop computer to the flowmeter site.

• Via the DataLink software utility and the serial DB9

interface cable included with the logger. Data can

be accessed by connecting the cable to the logger,

which is located in the pocket on the front faceplate

of the instrument. See Figure 3.3

See Section 4 of this manual for details regarding operation of the DataLink and UltraLink software utilities.

There are three configuration parameters to enter for

datalogger operation:

Rev. 4/01 -3.14- TFXP

Page 53

PART 3 - KEYPAD CONFIGURATION

• FILE NUMBER/LOCATION

• INTERVAL

• DURATION

File Number or

Location

Logging Interval

The TFXP and the datalogger module can be used to

monitor and store data on up to 16 different locations.

These locations are identified by the FILE NUMBER/

LOCATION that is assigned. The datalogger will not

write over an existing file. Existing data files will need

to be uploaded and then erased from the logger before

new data can be written into the space. Uploading

and storing of datalogger files is completed using the

DataLink software utility. See Section 4 of this manual for details regarding operation of the DataLink and

UltraLink software utilities.

From the OUTPUT 1 menu, adjust the time INTERVAL

between readings. INTERVAL values between 1 and

30,000 seconds are acceptable.

For reference there are:

60 seconds in 1 minute

300 seconds in 5 minutes

1,800 seconds in 30 minutes

3,600 seconds in 1 hour

30,000 seconds in 8.33 hours

Table 3.1 describes some typical configurations of the

INTERVAL and DURATION times with what the expected data samples collected coun t will be.

Logging Duration

Rev. 4/01 -3.15- TFXP

If the TFXP is going to be left unattended, loggin g flo w

data, for extended periods of time, the DURATION

time can be configured to stop logging after the DURATION of time has passed. DURATION is configured in hours and values between 1 and 30,000 hours

are acceptable.

Page 54

PART 3 - KEYPAD CONFIGURATION

Table 3.1

Example No. INTERVAL

Seconds

1 1 24 (1 day) 86,400

2 10 168 (7 days) 60,480

3 60 (1min.) 720 (30 days) 43,200

4 300 (5 min.) 8,760 (1 yr) 105,120

5 1,800 (30

min.)

6 3,600 (1 hr.) 8,760 (1 yr) 8,760

7 18,000 (5 hr.) 26,280 (3 yr) 17,520

3.

3. DATAL OG MAINTENANCE

DATALOG MAINTENANCE

3. 3.

DATALOG MAINTENANCEDATALOG MAINTENANCE

DURATION

Hours

Operated

8,760 (1 yr) 17,520

Samples

Collected

Datalog Maintenance permits files to be deleted from

the data logger module. The Menu contains three options for deleting files: delete the last file that was

generated, delete the first file that was generated or

delete all of the files on the logger.

Rev. 4/01 -3.16- TFXP

Page 55

PART 3 - KEYPAD CONFIGURATION

4.

4. OUTPUT 2 MENU

OUTPUT 2 MENU

4. 4.

OUTPUT 2 MENUOUTPUT 2 MENU

Standard

4-20mA

4-20mA Span

ISO-MOD 4-20mA

FL 4MA

FL 20MA

CAL 4MA

CAL 20MA

4-20 TST

The 4-20 mA Output Module interfaces with virtually all

recording and logging systems by transmitting an analog current signal that is proportional to system flow

rate. Independent 4 mA and 20 mA span settings are

established in software using the Flow Measuring

Range entries. These entries can be set anywhere in

the –40 to +40 FPS [-12 to +12 MPS] measuring range