Page 1

TFXL Clamp-On Ultrasonic Flow

Meter for Liquids

06-TTM-UM-00158 (August 2012)

Installation & Operation Manual

Page 2

2 06-TTM-UM-00158 8/2012

Page 3

TABLE OF CONTENTS

QUICKSTART OPERATING INSTRUCTIONS ......5

Q1 - Transducer Location

Q2 - Pipe Preparation and Transducer Mounting

(Integral DTTS and DTTC Transducers)

(DTTN and DTTH Transducers)

Q3 - Electrical Connections ...............................................................6

POWER CONNECTIONS

TRANSDUCER CONNECTIONS

Q4 - Startup...........................................................................................7

INITIAL SETTINGS AND POWER UP

INTR ODUCTI ON ................................................... 7

General

Application Versatility

Product Identi cation .........................................................................8

PART 1 TRANSMITTER INSTALLATION ........... 8

General...................................................................................................9

Transducer Co nnectio ns

DC Power Connections ..................................................................... 10

PART 2 TRANSDUCER INSTALLATION .......... 10

General

Step 1 - Mounting Location

Step 2 - Transducer Spacing ............................................................11

Step 3 - Entering Pipe and Liquid Data .........................................12

Step 4 - Transducer Mounting

Pipe Preparation

V-Mount and W-Mount Installation ............................................. 13

Application of Couplant

Transducer Positio ning

DTTS/DTTC Small Pipe Transducer Installation ..........................14

Mounting Transducers in Z-Mount Con guration ..................... 15

Mounting Track Installation ............................................................16

PART 3 INPUTS/OUTPUTS .............................. 16

General

4-20 mA Output

Totalizer Outputs Option for TFXL .................................................17

Frequency Output

PART 4 ULTRALINK UTILITY ...........................18

Introduction

System Requirements

Installation

Initialization

Basic Tab ..............................................................................................19

General

Tra ns du cer

Flow Tab...............................................................................................20

Filtering Tab ........................................................................................21

Output Tab ..........................................................................................22

Channel 1 - 4-20 mA Con guration/ Pulse

Setting Zero and Calibration ..........................................................23

Target Dbg Data Screen - De nitions ...........................................24

Saving Meter Con guration on a PC

Printing a Flow Meter Con guration Report

APPENDIX .......................................................... 25

Speci cations .....................................................................................26

Product Matrix ...................................................................................27

TFXL Error Codes ................................................................................28

Control Drawings ..............................................................................29

Brad Harrison® Connector Option ................................................. 31

K-Factors Explained .......................................................................... 32

Fluid Properties ..................................................................................34

Symbol Explanations ........................................................................36

Pipe Charts .......................................................................................... 37

06-TTM-UM-00158 8/2012 3

Page 4

FIGURES

TABLES

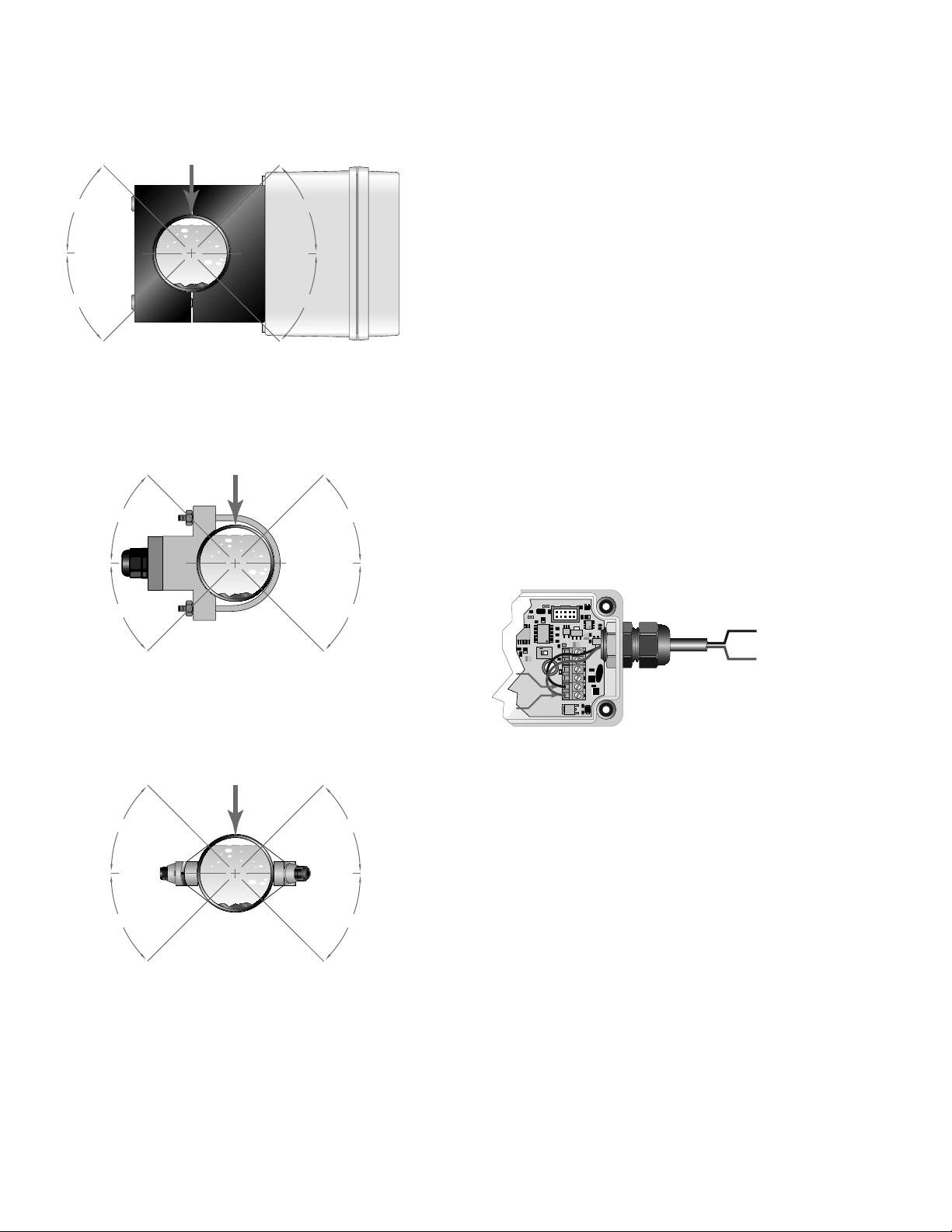

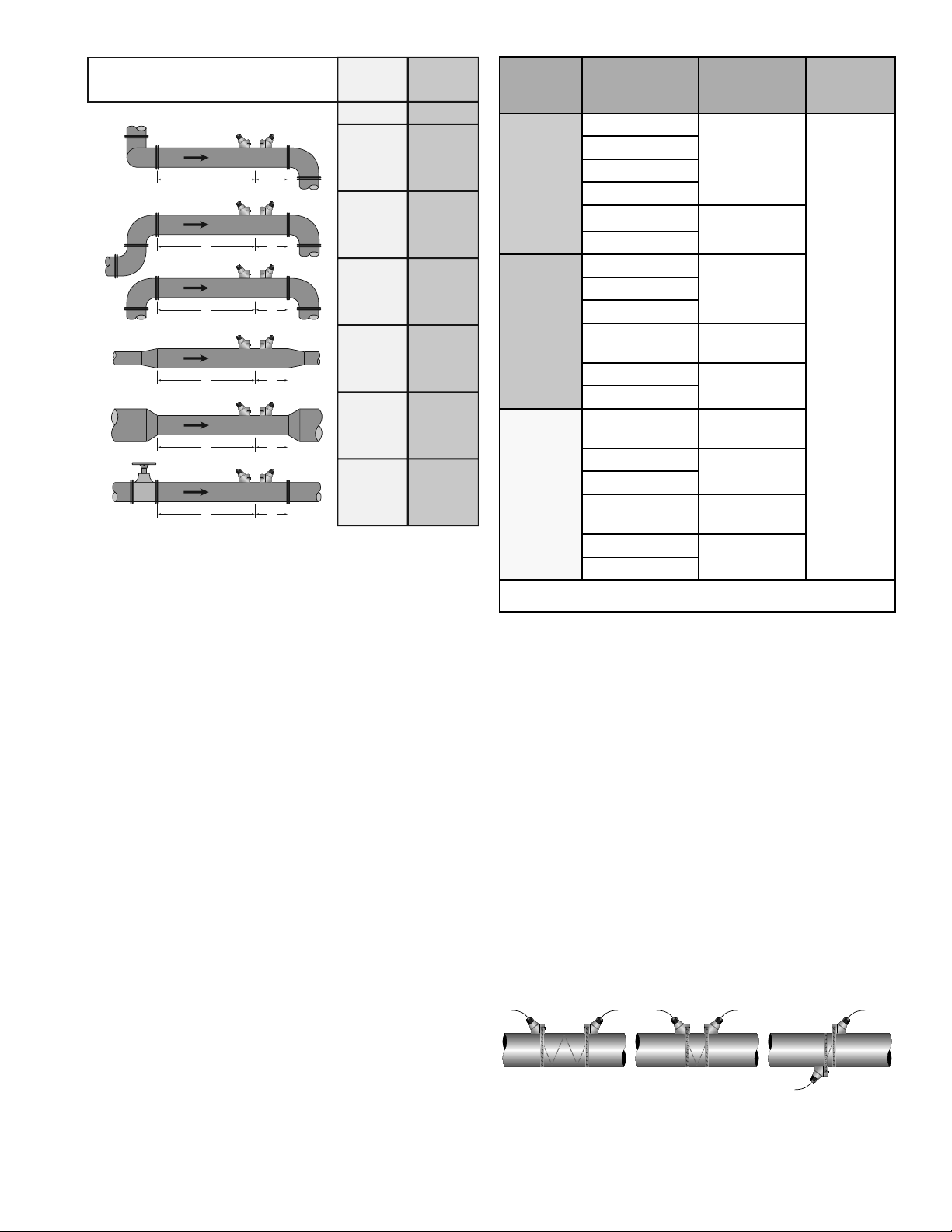

Figure Q.1 - Transducer Mounting Con gurations ...................... 5

Figure Q.2 - Transducer orientation ................................................6

Figure Q.3 - Power Connections

Figure Q.4 - Remote Mount Connections .......................................7

Figure 1.1 - Ultrasound Transmission .............................................. 7

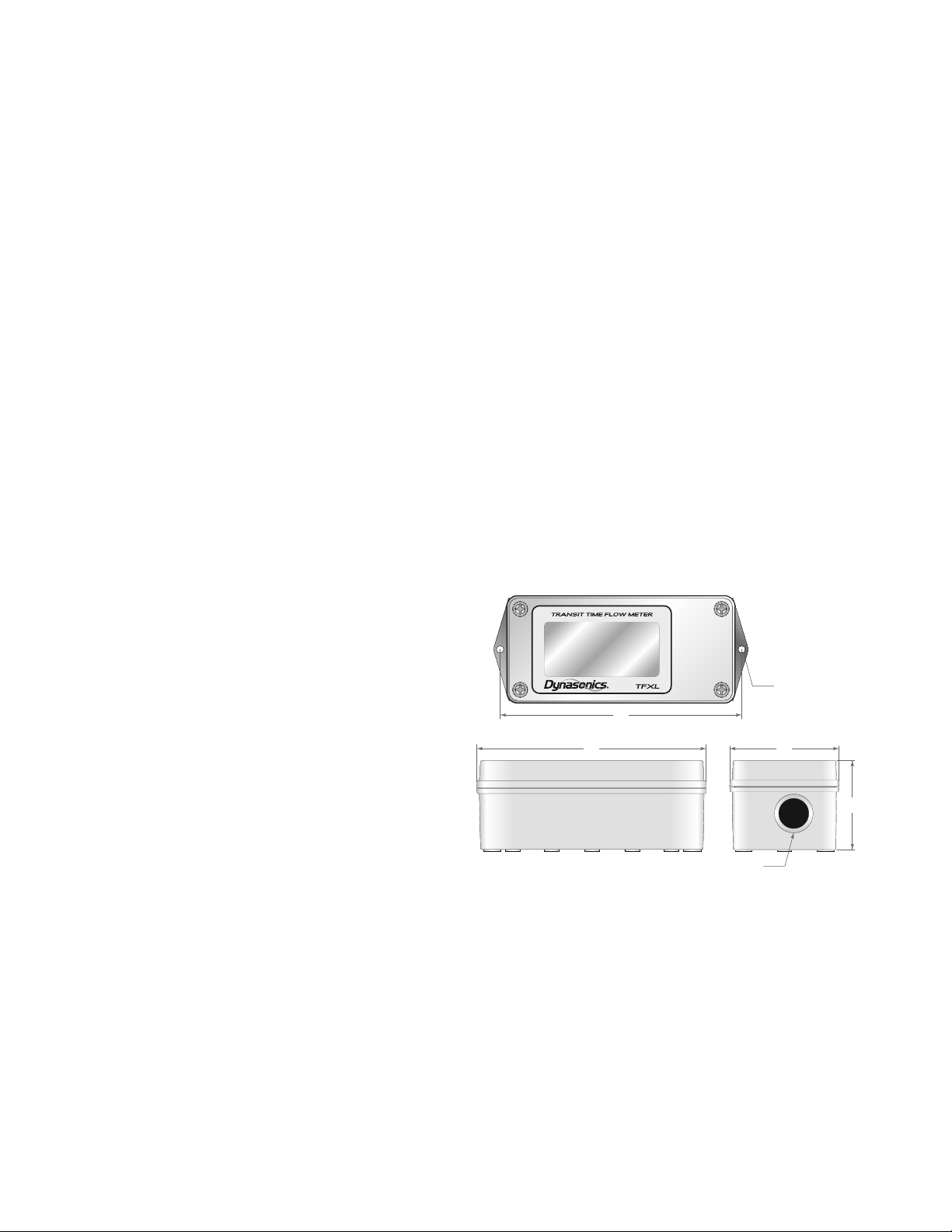

Figure 1.2 - Enclosure Dimensions ................................................... 8

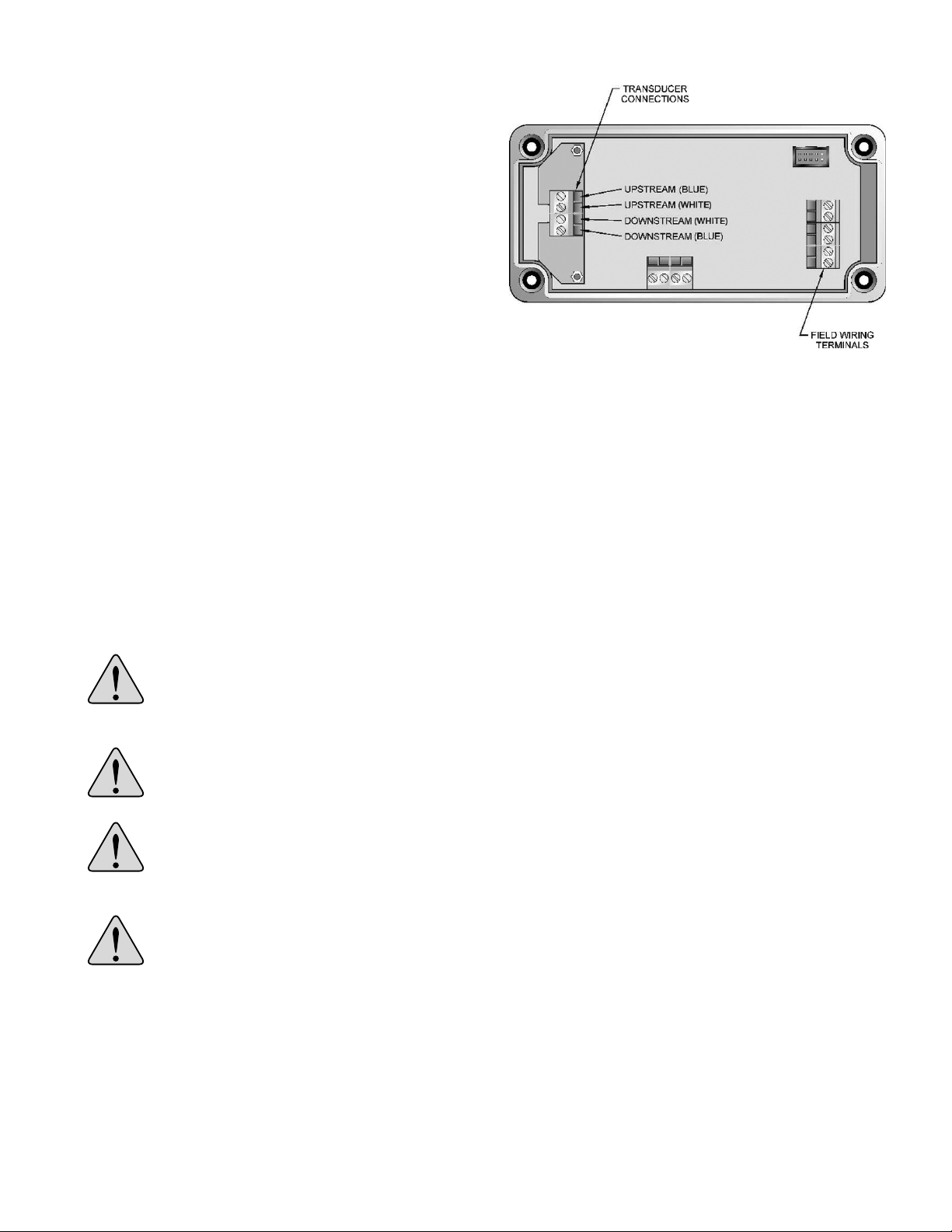

Figure 1.3 - Transducer Connections ............................................... 9

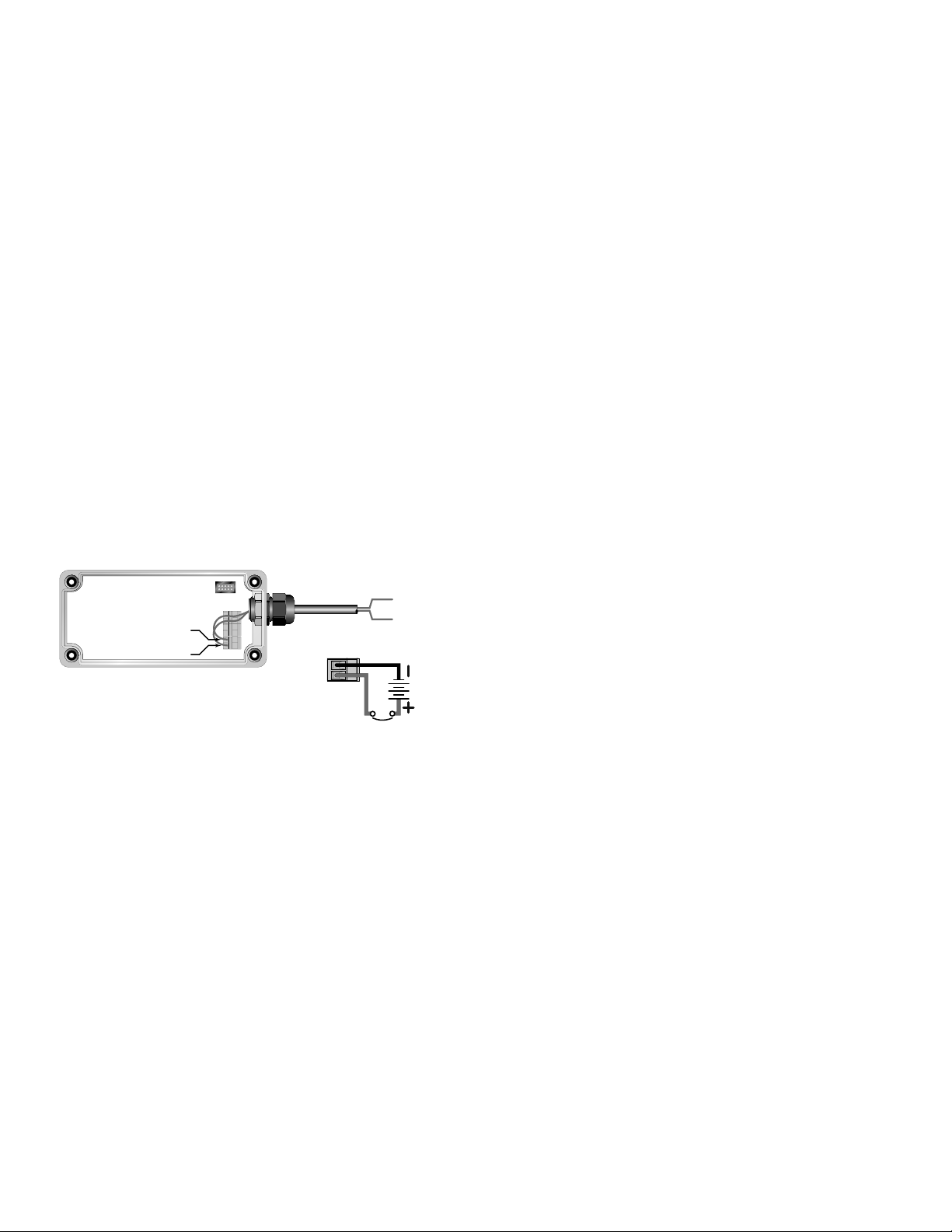

Figure 1.4 - DC Power Connections ...............................................10

Figure 2.1 -

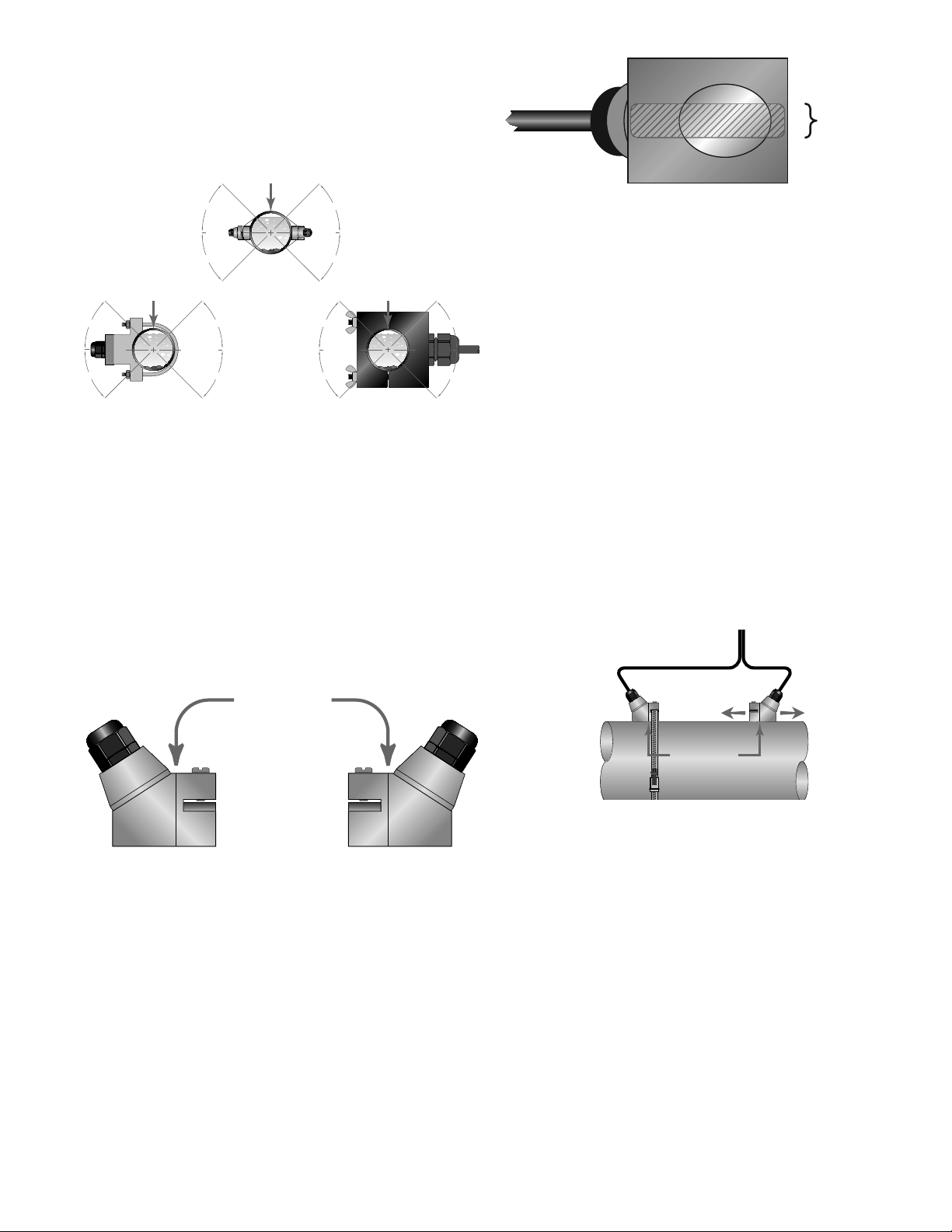

Figure 2.2 - Transducer Orientation - Horizontal Pipes ............. 13

Figure 2.3 - Transducer Alignment Marks

Figure 2.4 - Application of Couplant

Figure 2.5 - Transducer Positioning

Figure 2.6 - Application of Acoustic Couplant -

Figure 2.7 - Data Display Screen

Figure 2.8 - Calibration Page 3 of 3

Figure 2.9 - Calibration Points Editor

Figure 2.10 - Edit Calibration Points ..............................................15

Figure 2.11 - Paper Template Alignment

Figure 2.12 - Bisecting the Pipe Circumference

Figure 2.13 - Z-Mount Transducer Placement ..............................16

Figure 2.14 - Mounting Track Installation

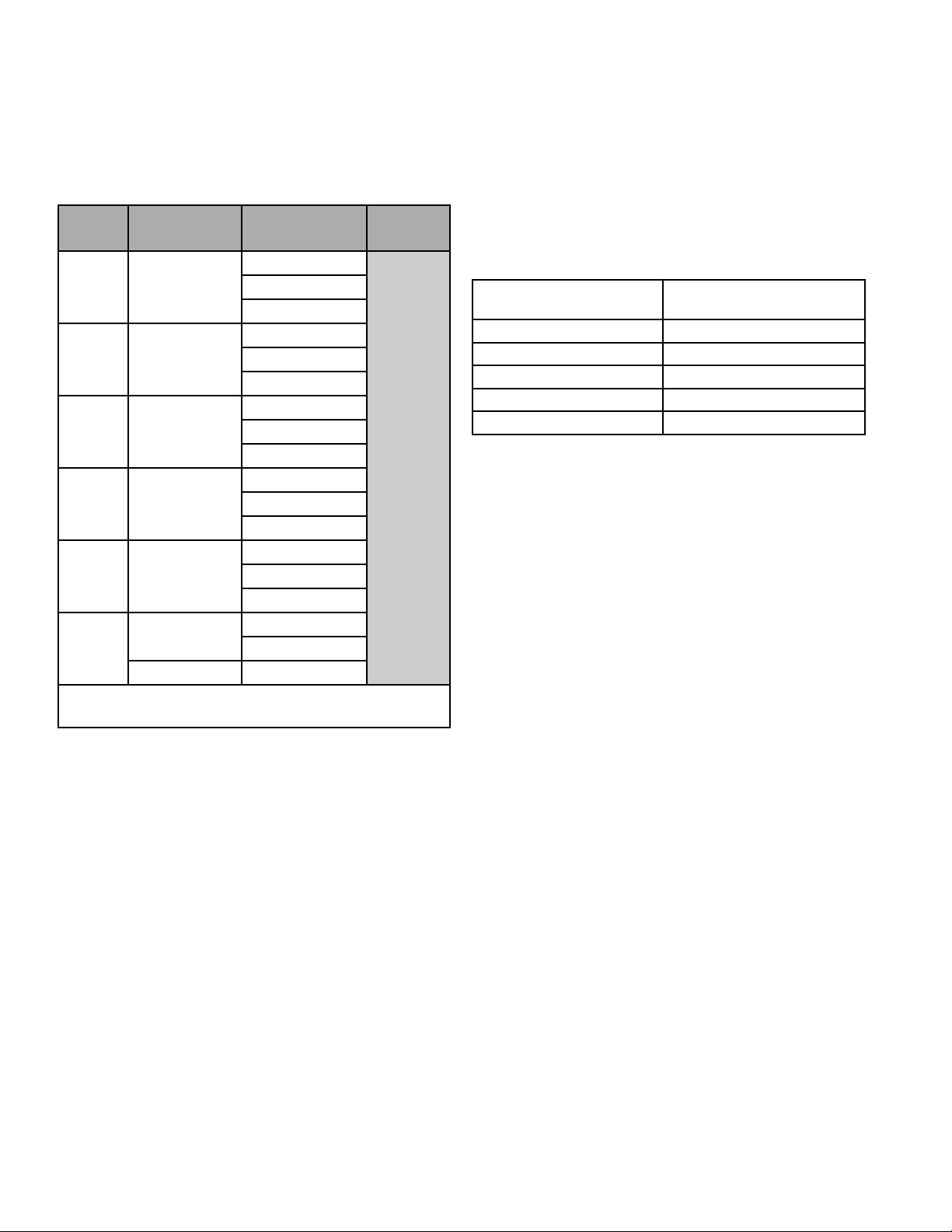

Transducer Mounting Modes - DTTN & DTTH

DTTS/DTTC Transducers ............................................. 14

.............. 11

Table 2.1 - Piping Con guration and Transducer Positioning

Table 2.2 - Transducer Mounting Modes - DTTN and DTTH

Table 2.3 - Transducer Mounting Modes - DTTS / DTTC ........... 12

Table 4.1 - Transducer Frequencies ................................................20

Table 4.2 - Exponent Values

Table A-5.1 - DTFX Ultra Error Codes .............................................28

Table A-8.1 - Fluid Properties ..........................................................34

Table A-10.1 - ANSI Pipe Data ..........................................................37

Table A-10.2 - ANSI Pipe Data .........................................................38

Table A-10.3 - Copper Tube Data ...................................................39

Table A-10.4 - Ductile Iron Pipe Data ............................................40

Table A-10.5 - Cast Iron Pipe Data .................................................41

...... 11

Figure 3.1 - Allowable Loop Resistance.........................................17

Figure 3.2 - 4-20 mA Output

Figure 3.3 - TFXL Totalizer Output Option

Figure 3.4 - Frequency Output Switch Settings

Figure 3.5 Figure 3.6 - Frequency Output Waveform (Square Wave)

Figure 4.1 - PC Connection .............................................................. 18

Figure 4.2 - Data Display Screen .................................................... 19

Figure 4.3 - Basic Tab

Figure 4.4 - Flow Tab .........................................................................20

Figure 4.5 - Filtering Tab ...................................................................21

Figure 4.6 - Output Tab ....................................................................22

Figure 4.7 - Calibration Page 1 of 3 ...............................................23

Figure 4.8 - Calibration Page 2 of 3

Figure 4.9 - Calibration Page 3 of 3 ...............................................24

Figure A-6.1 - Control Drawing I.S. Barrier DTT Transducers ........

Figure A-6.2 - Control Drawing I.S. Barrier DTT Transducers

Figure A-7.1 - Brad Harrison® Connections ................................... 31

Frequency Output Waveform (Simulated Turbine)

Flexible Conduit........................................................30

...18

29

4 06-TTM-UM-00158 8/2012

Page 5

QUICKSTART OPERATING

INSTRUCTIONS

This manual contains detailed operating instructions for all

aspects of the TFXL instrument. The following condensed

instructions are provided to assist the operator in getting the

instrument started up and running as quickly as possible.

This pertains to basic operation only. If speci c instrument

features are to be used or if the installer is unfamiliar with this

type of instrument, refer to the appropriate section in the

manual for complete details.

* NOMINAL VALUES FOR THESE PARAMETERS ARE

INCLUDED WITHIN THE TFXL OPERATING SYSTEM. THE

NOMINAL VALUES MAY BE USED AS THEY APPEAR OR

MAY BE MODIFIED IF THE EXACT SYSTEM VALUES ARE

KNOWN.

4) Record the value calculated and displayed as Transducer Spacing.

Q2 PIPE PREPARATION AND TRANSDUCER

MOUNTING

NOTE: The following steps require information supplied by

the TFXL meter itself so it will be necessary to supply power

to the unit, at least temporarily, and connect to a computer

using ULTRALINK to obtain setup information.

Q1 TRANSDUCER LOCATION

1) In general, select a mounting location on the piping

system with a minimum of 10 pipe diameters (10 × the

pipe inside diameter) of straight pipe upstream and 5

straight diameters downstream. See Table 2.1 for addi-

tional con gurations.

2) If the application requires DTTN or DTTH transducers

select a mounting method for the transducers based on

pipe size and liquid characteristics. See Table 2.2. Trans-

ducer con gurations are illustrated in Figure Q.1 below.

NOTE: All DTTS and DTTC transducers use V-Mount

con guration.

3) Enter the following data into the TFXL transmitter via

the ULTRALINK™ software utility:

1. Transducer mounting method

2. Pipe O.D. (Outside Diameter)

3. Pipe wall thickness

4. Pipe material

5. Pipe sound speed*

6. Pipe relative roughness*

7. Pipe liner thickness

8. Pipe liner material

9. Fluid type

10. Fluid sound speed*

11. Fluid viscosity*

12. Fluid speci c gravity*

INTEGRAL & REMOTE DTTS AND DTTC

TRANSDUCERS

1) Refer to the signal strength values available on the Data

Display screen in the ULTRALINK software utility.

2) The pipe surface, where the transducers are to be

mounted, must be clean and dry. Remove scale, rust or

loose paint to ensure satisfactory acoustic conduction.

Wire brushing the rough surfaces of pipes to smooth

bare metal may also be useful. Plastic pipes do not

require preparation other than cleaning.

On horizontal pipe, choose a ow meter mounting

location within approximately 45-degrees of the side of

the pipe. See Figure Q.2. Locate the ow meter so that

the pipe will be completely full of liquid when ow is

occurring in the pipe. Avoid mounting on vertical pipes

where the ow is moving in a downward direction.

3) Apply a single ½” (12 mm) bead of acoustic couplant

grease to the top half of the transducer and secure it to

the pipe with bottom half or U-bolts.

4) Tighten the nuts so that the acoustic coupling grease

begins to ow out from the edges of the transducer

and from the gap between the transducer and the pipe.

Finger tighten only. Do not over tighten.

DTTN AND DTTH TRANSDUCERS

1) Place the ow meter in signal strength measuring

mode. This value is available in the data display of the

software utility.

2) The pipe surface, where the transducers are to be

mounted, must be clean and dry. Remove scale, rust or

loose paint to ensure satisfactory acoustic conduction.

Wire brushing the rough surfaces of pipes to smooth

bare metal may also be useful. Plastic pipes do not

require preparation other than cleaning. On horizontal

TOP VIEW

OF PIPE

TOP VIEW

OF PIPE

TOP VIEW

OF PIPE

W-Mount V-Mount Z-Mount

FIGURE Q.1 TRANSDUCER MOUNTING CONFIGURATIONS

06-TTM-UM-00158 8/2012 5

Page 6

pipe, choose a ow meter mounting location within approximately 45-degrees of the side of the pipe. See Figure Q.2. Locate

the ow meter so that the pipe will be completely full of liquid

when ow is occurring in the pipe. Avoid mounting on vertical

TOP OF

PIPE

pipes where the ow is moving in a downward direction.

3) Apply a single ½” (12 mm) bead of acoustic couplant grease

to the upstream transducer and secure it to the pipe with a

45°

45°

mounting strap.

4) Apply acoustic couplant grease to the downstream transducer

and press it onto the pipe using hand pressure at the lineal

YES

YES

distance calculated by the ULTRALINK software utility.

5) Space the transducers according to the recommended values

from the ULTRALINK software utility. Secure the transducers with

45°

45°

the mounting straps at these locations.

FLOW METER

MOUNTING ORIENTATION

DTTS and DTTC TRANSDUCERS

(Integral mount shown)

TOP OF

PIPE

45°

YES

45°

FLOW METER

MOUNTING ORIENTATION

2” DTTS and DTTC TRANSDUCERS

(Remote mount shown)

TOP OF

PIPE

45°

YES

Q3 ELECTRICAL CONNECTIONS

POWER CONNECTIONS

1) Power for the TFXL ow meter is obtained from a direct current

(DC) power source. The power source should be capable of

supplying between 11 and 28 VDC at a minimum of 250 milliamps. With the power from the DC power source disabled or

disconnected, connect the positive supply wire and ground to

45°

the appropriate eld wiring terminals in the ow meter. See

Figure Q.3. A wiring diagram decal is located on the inner cover

of the ow meter enclosure for reference.

45°

PIC16F628

O

N

1

DC Ground

11 - 28 VDC

DC Ground

11 - 28 VDC

FIGURE Q.3 POWER CONNECTIONS

TRANSDUCER CONNECTIONS

45°

YES

YES

1) Guide the transducer terminations through the transmitter

(Remote Mount Transducers)

45°

45°

conduit hole located in the bottom-left of the enclosure using

a sealed cord grip or NEMA 4 conduit connection. Secure the

transducer cable with the supplied conduit nut (if exible con-

FLOW METER

MOUNTING ORIENTATION

DTTN and DTTH TRANSDUCERS

duit was ordered with the transducer).

2) The remote mount transducers use an add-in connection board

on the left had side of the meter below the LCD (TFXL 2 version).

The terminals within TFXL are of a screw-down barrier terminal

type. Connect the appropriate wires at the corresponding screw

FIGURE Q.2 TRANSDUCER ORIENTATION

terminals in the transmitter. Observe upstream and downstream

orientation and wire polarity. See Figure Q.4.

6 06-TTM-UM-00158 8/2012

Page 7

Upstream

Transducer

Up Blue/Red

Up White/Black

the sound crosses the pipe once. The selection of how

transducers are mounted on opposite sides of the pipe and

method is based on pipe and liquid characteristics which

both have an e ect on how much signal is generated. The

ow meter operates by alternately transmitting and receiving

a frequency modulated burst of sound energy between the

two transducers and measuring the time interval that it takes

for sound to travel between the two transducers. The di erence in the time interval measured is directly related to the

velocity of the liquid in the pipe.

Down White/Black

Down Blue/Red

Downstream

Transducer

FIGURE Q.4 REMOTE MOUNT CONNECTIONS

Q4 STARTUP

INITIAL SETTINGS AND POWER UP

1) Apply power to the transmitter.

2) Verify that the signal strength is greater than 5.0.

3) Input proper units of measure and I/O data.

INTRODUCTION

GENERAL

The TFXL ultrasonic ow meter is designed to measure

the uid velocity of liquid within a closed conduit. The

transducers are a non-contacting, clamp-on type or clamparound, which will provide bene ts of non-fouling operation

and ease of installation.

APPLICATION VERSATILITY

The TFXL ow meter can be successfully applied on a wide

range of metering applications. The simple-to-program transmitter allows the standard product to be used on pipe sizes

ranging from ½ inch to 100 inches (12 mm to 2540 mm). A

variety of liquid applications can be accommodated:

ultrapure liquids sewage cooling water

potable water reclaimed water river water

chemicals plant e uent others

Because the transducers are non-contacting and have no

moving parts, the ow meter is not a ected by system pressure, fouling or wear.

The DTTN transducer set is rated to a pipe surface temperature of 250° F (121° C). High temperature DTTH transducers

can operate to a pipe surface temperature of 350° F (177° C).

The DTTS series of small pipe transducers can be used to a

pipe surface temperature of 185° F (85° C) and the DTTC high

temperature small pipe transducers are rated for 250° F

(121° C).

The TFXL uses a low voltage DC power source that provides

electrical safety for the user. Removing the cover allows access to all the meter connections and the computer interface

connection.

Non-volatile ash memory retains all user-entered con guration values in memory inde nitely, even if power is lost or

turned o .

The TFXL family of transit time ow meters utilize two

transducers that function as both ultrasonic transmitters

and receivers. The transducers are clamped on the outside

of a closed pipe at a speci c distance from each other. The

transducers can be mounted in V-Mount where the sound

transverses the pipe two times, W-Mount where the sound

transverses the pipe four times, or in Z-Mount where the

The enclosure should be mounted in an area that is convenient for servicing, calibration or for observation of the LCD

readout.

Mount the TFXL transmitter in a location that is:

~ Where little vibration exists.

~ That is protected from corrosive uids.

~ That is within the transmitters ambient temperature

limits.

TOP VIEW

OF PIPE

TOP VIEW

OF PIPE

TOP VIEW

OF PIPE

~ That is out of direct sunlight. Direct sunlight may

increase transmitter temperature to above the

W-Mount V-Mount Z-Mount

maximum limit.

FIGURE 1.1 ULTRASOUND TRANSMISSION

06-TTM-UM-00158 8/2012 7

Page 8

Locate the transmitter within the length of transducer cable

that was supplied with the TFXL system. If this is not possible,

it is recommended that the cable be exchanged for one that

is of proper length. Both transducer cables must be of the

same length.

NOTE: The transducer cable carries low level, high frequency

signals. In general, it is not recommended to add additional

cable to the cable supplied with the DTTN, DTTH, DTTS or

DTTC transducers. If additional cable is required, contact the

factory to arrange an exchange for a transducer with the

appropriate length of cable. Cables to 990 feet (300 meters)

are available. To add cable length to a transducer, the cable

must be the same type as utilized on the transducer. Twinaxial

cables can be lengthened with like cable to a maximum

overall length of 100 feet (30 meters). Coaxial cables can be

lengthened with RG59 75 Ohm cable and BNC connectors to

990 feet (300 meters).

If the transmitter will be subjected to a wet environment, it is

recommended that the cover remain closed after con guration is completed. The faceplate of the TFXL is watertight, but

avoid letting water collect on it. A sealed cord grip or NEMA

4 conduit connection should be used where cables enter the

enclosure. Holes not used for cable entry should be sealed

with plugs.

To access terminal strips for electronic connectors, loosen

the four screws in the display lid and remove the cover. The

terminals where the transducers connect are located underneath the display. To connect transducers, remove the four

screws that secure the display and carefully move it out of

the way. Do not over stress the ribbon cable located between

the display and the microprocessor circuit boards.

PRODUCT IDENTIFICATION

The serial number and complete model number of each

TFXL are located on the side of the instrument enclosure.

Should technical assistance be required, please provide the

Customer Service Department with this information.

of proper length. To add cable length to a transducer,

the cable must be the same type as utilized on the

transducer. Twinaxial cables can be lengthened with

like cable to a maximum overall length of 100 feet (30

meters). Coaxial cables can be lengthened with RG59

75 Ohm cable and BNC connectors to 990 feet (300

meters).

2) Mount the TFXL transmitter in a location:

~ Where little vibration exists.

~ That is protected from corrosive uids.

~ That is within the transmitters ambient temperature

limits -40 to +185° F (-40 to +85° C).

~ That is out of direct sunlight. Direct sunlight may

increase transmitter temperature to above the

maximum limit.

3) Mounting - Refer to Figure 1.2 for enclosure and

mounting dimension details. Ensure that enough room

is available to allow for door swing, maintenance and

conduit entrances. Secure the enclosure to a at surface

with two appropriate fasteners.

4) Conduit Holes - Conduit holes should be used where

cables enter the enclosure. Holes not used for cable

entry should be sealed with plugs.

NOTE: Use NEMA 4 [IP-65] rated ttings/plugs to maintain the

watertight integrity of the enclosure. Generally, the right side

conduit hole (viewed from front) is used for power, the bottom

conduit hole(s) for transducer connections.

0.21(5.3) DIA

2 Mounting Holes

7.01

(178)

6.66

(169.2)

(80.5)

3.17

2.57

(65.3)

PART 1 TRANSMITTER

INSTALLATION

After unpacking, it is recommended to save the shipping

FIGURE 1.2 ENCLOSURE DIMENSIONS

GENERAL

0.875 (22.2) DIA

Conduit Hole

carton and packing materials in case the instrument is stored

or re-shipped. Inspect the equipment and carton for damage.

If there is evidence of shipping damage, notify the carrier

immediately.

The remote mount TFXL is equipped with three conduit holes

located in the ow meter enclosure that should be suitable

for most installations. A sealed cord grip or NEMA 4 conduit

connection should be utilized to retain the NEMA 3 integrity

The enclosure should be mounted in an area that is convenient for servicing, calibration or for observation of the LCD

of the ow meter enclosure. Failure to do so will void the

manufacturer’s warranty and can lead to product failure.

readout (if equipped).

The TFXL is housed in an insulating plastic enclosure that

1) Locate the transmitter within the length of transducer

cables supplied. If this is not possible, it is recommended that the cable be exchanged for one that is

does not provide continuity of bonding between eld wiring

conduit and the TFXL chassis or other conduits connected to

the enclosure.

8 06-TTM-UM-00158 8/2012

Page 9

Wiring methods and practices are to be made in accordance

with the NEC - National Electrical Code® - and/or other local

ordinances that may be in e ect. Consult the local electrical

inspector for information regarding wiring regulations.

When making connections to the eld wiring terminals

inside the ow meter, strip back the wire insulation approximately 0.25 inch (6 mm). Stripping back too little may cause

the terminals to clamp on the insulation and not make good

contact. Stripping back too much insulation may lead to a

situation where the wires could short together between adjacent terminals. Wires should be secured in the eld wiring

terminals using a screw torque of between 0.5 and 0.6 Nm.

If the DC ground terminal is to be utilized as a protective conductor terminal, the protective conductor shall be

applied rst and secured independently of other connections. The protective conductor shall be connected in

such a way that it is unlikely to be removed by servicing

not involving the protective conductor or there shall be a

warning marking requiring the replacement of the protective

conductor after removal.

Power the TFXL ow meter with a Class 2 direct current

(DC) power source. The power source should be capable of

supplying between 11 and 28 VDC at a minimum of 250 milliamps. With the power from the DC power source disabled or

disconnected, connect the positive supply wire and ground

to the appropriate eld wiring terminals in the ow meter.

See Figure 1.5. A wiring diagram decal is located on the inner

cover of the ow meter enclosure for reference.

IMPORTANT NOTE:

Not following instructions properly may impair

safety of equipment and/or personnel.

IMPORTANT NOTE:

Must be operated by a power supply suitable for

the location.

IMPORTANT NOTE:

Do not connect or disconnect either power

or outputs unless the area is known to be

nonhazardous

TRANSDUCER CONNECTIONS

FIGURE 1.3 TRANSDUCER CONNECTIONS

To access terminal strips for wiring, rst loosen the four

screws holding the top of the case to the bottom.

NOTE: The four screws are “captive” screws and cannot be

removed from the top of the case.

If the unit has a display remove the four Phillips head screws

that hold the display to the main circuit board and carefully

move it out of the way. Do not over stress the ribbon cable

located between the display and the microprocessor circuit

boards.

Guide the transducer terminations through the transmitter

conduit hole located in the bottom-left of the enclosure.

Secure the transducer cable with the supplied conduit nut (if

exible conduit was ordered with the transducer).

NOTE: TFXL models with integral transducers have the transducers connected at the factory and the transducer connections

section can be skipped.

The terminals within TFXL are of a screw-down barrier

terminal type. Depending on the type of transducers being

used there are two terminal strip arrangements possible.

Remote mount small pipe transducers are connected to the

terminals found on the main circuit board.

IMPORTANT NOTE:

Do not connect the interface cable between a

TFXL ow meter and a personal computer unless

the area is known to be non-hazardous.

06-TTM-UM-00158 8/2012 9

Remote mount transducers are connected to a “daughter”

board found on the left hand side of the meter.

Connect the appropriate wires at the corresponding screw

terminals in the transmitter. Observe upstream and downstream orientation and wire polarity. See Figure 1.3.

NOTE: High temperature transducer cables come with red and

black wire colors. For the red and black combination, the red

wire is positive (+) and the black wire is negative (-).

Page 10

NOTE: The transducer cable carries low level, high frequency

signals. In general, it is not recommended to add additional

length to the cable supplied with the transducers. If additional

cable is required, contact the factory to arrange an exchange

for a transducer with the appropriate length of cable. Cables

100 to 990 feet (30 to 300 meters) are available with RG59 75

Ohm coaxial cable. If additional cable is added, ensure that it is

the same type as utilized on the transducer. Twinaxial (blue and

white conductor) cables can be lengthened with like cable to

a maximum overall length of 100 feet (30 meters). Coaxial

cables can be lengthened with RG59 75 Ohm cable and BNC

connectors to 990 feet (300 meters).

DC POWER CONNECTIONS

The TFXL should be operated from an 11 to 28 VDC Class 2

power source capable of supplying a minimum of 250 mA

of current.

PART 2 TRANSDUCER

INSTALLATION

GENERAL

The transducers that are utilized by the TFXL contain piezoelectric crystals for transmitting and receiving ultrasonic

signals through walls of liquid piping systems. DTTN and

DTTH transducers are relatively simple and straightforward

to install, but spacing and alignment of the transducers is

critical to the system’s accuracy and performance. Extra care

should be taken to ensure that these instructions are carefully executed. DTTS and DTTC, small pipe transducers, have

integrated transmitter and receiver elements that eliminate

the requirement for spacing measurement and alignment.

Mounting of the DTTN and DTTH clamp-on ultrasonic transit

time transducers is comprised of three steps:

Connect power to the screw terminal block in the TFXL transmitter. See Figure 1.4. Utilize the conduit hole on the right

side of the enclosure for this purpose. Use wiring practices

that conform to local and national codes (e.g., The National

Electrical Code® Handbook in the U.S.)

Connect the DC power to 11 to 28 VDC In, and DC Gnd., as

in Figure 1.4.

DC Ground

11 - 28 VDC

DC Ground

11 - 28 VDC

FIGURE 1.4 DC POWER CONNECTIONS

1) Connect an 11-28 VDC Class 2 power source as illustrated in the schematic in Figure 1.4. Wire up to 14

AWG can be accommodated in the TFXL terminal blocks

a) A switch or circuit breaker is required in the

installation.

b) The switch or circuit breaker must be in close

proximity of the TFXL and within easy reach of

the operator.

c) The switch or circuit breaker must be marked as

the disconnect device for the TFXL.

1) Selection of the optimum location on a piping system.

2) Entering the pipe and liquid parameters into the software utility. The software utility will calculate proper

transducer spacing based on these entries.

3) Pipe preparation and transducer mounting.

STEP 1 MOUNTING LOCATION

The rst step in the installation process is the selection of an

optimum location for the ow measurement to be made. For

this to be done e ectively, a basic knowledge of the piping

system and its plumbing are required.

An optimum location is de ned as:

~ A piping system that is completely full of liquid when

measurements are being taken. The pipe may become

completely empty during a process cycle – which will

result in the error code 0010 (Low Signal Strength)

being displayed on the ow meter while the pipe is

empty. This error code will clear automatically once the

pipe re lls with liquid. It is not recommended to mount

the transducers in an area where the pipe may become

partially lled. Partially lled pipes will cause erroneous

and unpredictable operation of the meter.

~ A piping system that contains lengths of straight pipe

such as those described in Table 2.1. The optimum

straight pipe diameter recommendations apply to pipes

in both horizontal and vertical orientation. The straight

runs in Table 2.1 apply to liquid velocities that are

nominally 7 FPS (2.2 MPS). As liquid velocity increases

above this nominal rate, the requirement for straight

pipe increases proportionally.

10 06-TTM-UM-00158 8/2012

Page 11

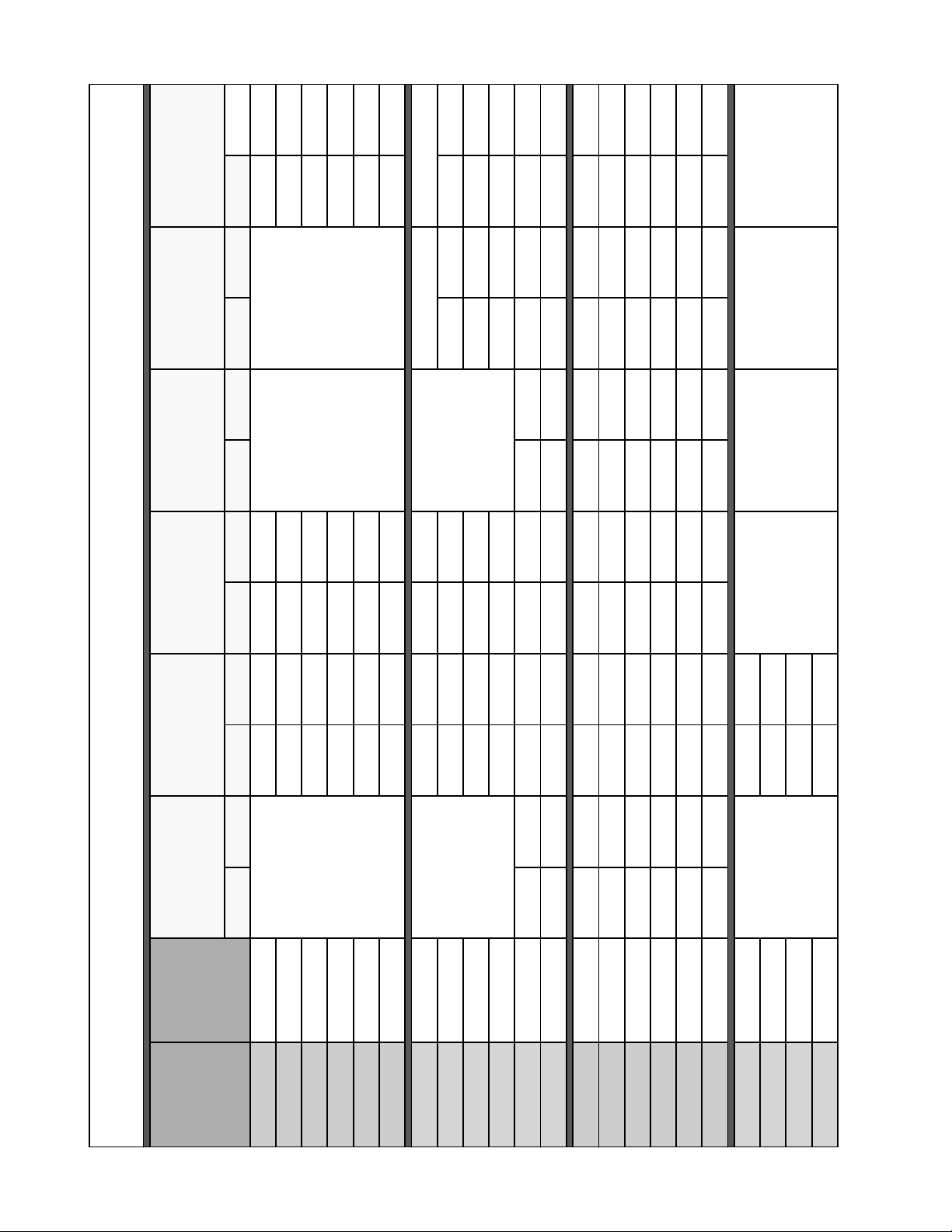

Piping Configuration

and Transducer Positioning

Flow

*

Flow

*

Flow

*

Flow

*

Flow

*

Flow

*

**

**

**

**

**

**

TABLE 2.1 PIPING CONFIGURATION AND

TRANSDUCER POSITIONING

Upstream

Pipe

Diameters

Downstream

Pipe

Diameters

***

24

14

10

10

10

24

5

5

5

5

5

5

Transducer

Mount

Mode

W-Mount

V-Mount

Z-Mount

Pipe Material Pipe Size

Plastic (all types)

Carbon Steel

Stainless Steel

Copper

Ductile Iron

Cast Iron

Plastic (all types)

Carbon Steel

Stainless Steel

Copper

Ductile Iron

Cast Iron

Plastic (all types)

Carbon Steel

Stainless Steel

Copper

Ductile Iron

Cast Iron

2-4 in.

(50-100 mm)

recommended

4-12 in.

(100-300 mm)

4-30 in.

(100-750 mm)

2-12 in.

(50-300 mm)

> 30 in.

(> 750 mm)

> 12 in.

(> 300 mm)

> 30 in.

(> 750 mm)

> 12 in.

(> 300 mm)

Liquid

Composition

Not

Low TSS;

non-aerated

~ Mount the transducers in an area where they will not

be inadvertently bumped or disturbed during normal

operation.

~ Avoid installations on downward owing pipes unless

adequate downstream head pressure is present to overcome partial lling of or cavitation in the pipe.

The ow meter system will provide repeatable measurements on piping systems that do not meet these requirements, but accuracy of these readings may be in uenced to

various degrees.

STEP 2 TRANSDUCER SPACING

TFXL remote mount transit time ow meters can be used

with four di erent transducer types: DTTN, DTTH, DTTS

and DTTC. Meters that utilize the DTTN or DTTH transducer

sets consist of two separate sensors that function as both

ultrasonic transmitters and receivers. DTTS and DTTC transducers integrate both the transmitter and receiver into one

assembly that xes the separation of the piezoelectric crystals. DTTN and DTTH transducers are clamped on the outside

of a closed pipe at a speci c distance from each other.

TSS = Total Suspended Solids

TABLE 2.2 TRANSDUCER MOUNTING MODES

DTTN AND DTTH

The DTTN and DTTH transducers can be mounted in:

W-Mount where the sound traverses the pipe four

times. This mounting method produces the best relative

travel time values but the weakest signal strength.

V-Mount where the sound traverses the pipe twice.

V-Mount is a compromise between travel time and

signal strength.

Z-Mount where the transducers are mounted on opposite sides of the pipe and the sound crosses the pipe

once. Z-Mount will yield the best signal strength but

the smallest relative travel time.

For further details, reference Figure 2.1. The appropriate

mounting con guration is based on pipe and liquid characteristics. Selection of the proper transducer mounting

method is not entirely predictable and many times is an

TOP VIEW

OF PIPE

TOP VIEW

OF PIPE

TOP VIEW

OF PIPE

W-Mount V-Mount Z-Mount

FIGURE 2.1 TRANSDUCER MOUNTING MODES

DTTN AND DTTH

06-TTM-UM-00158 8/2012 11

Page 12

iterative process. Table 2.2 contains recommended mounting

con gurations for common applications. These recommended con gurations may need to be modi ed for speci c

applications if such things as aeration, suspended solids, out

of round piping or poor piping conditions are present. Use of

the TFXL diagnostics in determining the optimum transducer

mounting is covered later in this section.

Size

Frequency

Setting

Transducer

Mounting

Mode

DTTSnP

½ 2 MHz

DTTSnC

DTTSnT

DTTSnP

¾ 2 MHz

DTTSnC

DTTSnT

DTTSnP

1 2 MHz

1¼ 2 MHz

DTTSnC

DTTSnT

DTTSnP

DTTSnC

V

DTTSnT

DTTSnP

1½ 2 MHz

DTTSnC

DTTSnT

2

1 MHz

DTTSnP

DTTSnC

2 MHz DTTSnT

NOTE: DTTS transducer designation refers to both DTTS

and DTTC transducer types.

TABLE 2.3 TRANSDUCER MOUNTING

MODES DTTS / DTTC

mize signal strength is to con gure the display to show signal

strength, x one transducer on the pipe and then starting

at the calculated spacing, move the remaining transducer

small distances forward and back to nd the maximum signal

strength point.

Important! Enter all of the data on this list, save the data and

reset the TFXL before mounting transducers.

The following information is required before programming

the instrument:

Transducer mounting

con guration

Pipe wall thickness Pipe material

Pipe sound speed

Pipe liner thickness (if present) Pipe liner material (if present)

Fluid type Fluid sound speed

Fluid viscosity

1

1

Pipe O.D. (outside diameter)

Pipe relative roughness

Fluid speci c gravity

1

1

1

NOTE: Much of the data relating to material sound speed,

viscosity and speci c gravity is pre-programmed into the TFXL

ow meter. This data only needs to be modi ed if it is known

that a particular application’s data varies from the reference

values. Refer to Part 4 of this manual for instructions on

entering con guration data into the TFXL ow meter via the

software.

1

NOMINAL VALUES FOR THESE PARAMETERS ARE INCLUDED

WITHIN THE TFXL OPERATING SYSTEM. THE NOMINAL

VALUES MAY BE USED AS THEY APPEAR OR MAY BE MODI

FIED IF EXACT SYSTEM VALUES ARE KNOWN.

After entering the data listed above, the TFXL will calculate

proper transducer spacing for the particular data set. This

distance will be in inches if the TFXL is con gured in English

units, or millimeters if con gured in metric units.

STEP 3 ENTERING PIPE AND LIQUID DATA

The TFXL system calculates proper transducer spacing by

STEP 4 TRANSDUCER MOUNTING

PIPE PREPARATION

utilizing piping and liquid information entered by the user.

This information can be entered on a TFXL via the software

utility.

After selecting an optimal mounting location (Step 1) and

successfully determining the proper transducer spacing

(Step 2 & 3), the transducers may now be mounted onto the

The best accuracy is achieved when transducer spacing is

pipe (Step 4).

exactly what the TFXL calculates, so the calculated spacing

should be used if signal strength is satisfactory. If the pipe

is not round, the wall thickness not correct or the actual

liquid being measured has a di erent sound speed than the

liquid programmed into the transmitter, the spacing can vary

from the calculated value. If that is the case, the transducers

should be placed at the highest signal level observed by

moving the transducers slowly around the mount area.

Before the transducers are mounted onto the pipe surface,

an area slightly larger than the at surface of each transducer

must be cleaned of all rust, scale and moisture. For pipes with

rough surfaces, such as ductile iron pipe, it is recommended

that the pipe surface be wire brushed to a shiny nish. Paint

and other coatings, if not aked or bubbled, need not be

removed. Plastic pipes typically do not require surface preparation other than soap and water cleaning.

NOTE: Transducer spacing is calculated on “ideal” pipe.

Ideal pipe is almost never found so the transducer spacing

distances may need to be altered. An e ective way to maxi-

The DTTN and DTTH transducers must be properly oriented

and spaced on the pipe to provide optimum reliability and

performance. On horizontal pipes, when Z-Mount is required,

12 06-TTM-UM-00158 8/2012

Page 13

the transducers should be mounted 180 radial degrees from

one another and at least 45 degrees from the top-deadcenter and bottom-dead-center of the pipe. See Figure 2.2.

Also see

Z-Mount Transducer Installation. On vertical pipes

the orientation is not critical.

TOP OF

PIPE

½”

(12 mm)

TOP OF

PIPE

45°

YES

45°

FLOW METER

MOUNTING ORIENTATION

2” DTTS and DTTC TRANSDUCERS

45°

YES

45°

MOUNTING ORIENTATION

DTTN and DTTH TRANSDUCERS

45°

YES

45°

FLOW METER

45°

YES

45°

45°

YES

45°

FLOW METER

MOUNTING ORIENTATION

DTTS and DTTC TRANSDUCERS

TOP OF

PIPE

45°

YES

45°

FIGURE 2.2 TRANSDUCER ORIENTATION

HORIZONTAL PIPES

The spacing between the transducers is measured between

the two spacing marks on the sides of the transducers. These

marks are approximately 0.75” (19 mm) back from the nose of

the DTTN and DTTH transducers. See Figure 2.3.

DTTS and DTTC transducers should be mounted with the

cable exiting within ±45 degrees of the side of a horizontal

pipe. See Figure 2.2. On vertical pipes the orientation does

not apply.

FIGURE 2.4 APPLICATION OF COUPLANT

TRANSDUCER POSITIONING

1) Place the upstream transducer in position and secure

with a mounting strap. Straps should be placed in the

arched groove on the end of the transducer. A screw

is provided to help hold the transducer onto the strap.

Verify that the transducer is true to the pipe and adjust

as necessary. Tighten the transducer strap securely.

2) Place the downstream transducer on the pipe at the

calculated transducer spacing. See Figure 2.5. Apply

rm hand pressure. If signal strength is greater than

5, secure the transducer at this location. If the signal

strength is not 5 or greater, using rm hand pressure

slowly move the transducer both towards and away

from the upstream transducer while observing signal

strength.

NOTE: Signal strength readings update only every few

seconds, so it is advisable to move the transducer ⁄”, wait, see

if signal is increasing or decreasing and then repeat until the

highest level is achieved.

Alignment

Marks

Transducer

Spacing

FIGURE 2.5 TRANSDUCER POSITIONING

FIGURE 2.3 TRANSDUCER ALIGNMENT MARKS

VMOUNT AND WMOUNT INSTALLATION

APPLICATION OF COUPLANT

For DTTN and DTTH transducers, place a single bead of

couplant, approximately ½ inch (12 mm) thick, on the at

face of the transducer. See Figure 2.4. Generally, a siliconebased grease is used as an acoustic couplant, but any greaselike substance that is rated not to “ ow” at the temperature

that the pipe may operate at will be acceptable. For pipe

surface temperature over 150° F (65° C), acoustic couplant

(P.N. D002-2011-011) is recommended.

06-TTM-UM-00158 8/2012 13

Signal strength is displayed on the main data screen in

the software utility. See Part 4 of this manual for details

regarding the software utility. Clamp the transducer

at the position where the highest signal strength is

observed. The factory default signal strength cuto

setting is 5, however there are many application speci c

conditions that may prevent the signal strength from

attaining this level. For the TFXL, signal levels much

less than 5 will probably not be acceptable for reliable

readings.

3) If after adjustment of the transducers the signal

strength does not rise to above 5, then an alternate

transducer mounting method should be selected. If the

mounting method was W-Mount, then re-con gure the

transmitter for V-Mount, move the downstream transducer to the new spacing distance and repeat Step 4.

Page 14

NOTE: Mounting of high temperature transducers is similar to

30.00 ns 2000.00 Gal/Min 1.000

mounting the DTTN transducers. High temperature installations require acoustic couplant that is rated not to “ ow” at

the temperature that will be present on the pipe surface.

DTTS/DTTC SMALL PIPE TRANSDUCER AND

INTEGRAL MOUNT INSTALLATION

The small pipe transducers are designed for speci c pipe

outside diameters. Do not attempt to mount a DTTS/DTTC or

integral mount transducer onto a pipe that is either too large

or too small for the transducer. Contact the manufacturer to

arrange for a replacement transducer that is the correct size.

DTTS/DTTC and integral installation consists of the

following steps:

1) Apply a thin coating of acoustic coupling grease to both

halves of the transducer housing where the housing

will contact the pipe. See Figure 2.6.

2) On horizontal pipes, mount the transducer in an orientation such that the cable exits at ±45 degrees from the

side of the pipe. Do not mount with the cable exiting on

either the top or bottom of the pipe. On vertical pipes

the orientation does not matter. See Figure 2.2.

3) Tighten the wing nuts or “U” bolts so that the acoustic

coupling grease begins to ow out from the edges of

the transducer or from the gap between the transducer

halves. Do not over tighten.

4) If signal strength is less than 5, remount the transducer

at another location on the piping system.

5) If calibration point is displayed in Calibration Points Editor screen, record the information, highlight and click

Remove. See Figure 2.9.

6) Click ADD...

7) Enter Delta T, Un-calibrated Flow, and Calibrated Flow

values from the DTTS/DTTC calibration label, the click

OK. See Figure 2.10.

8) Click OK in the Edit Calibration Points screen.

9) Process will return to Page 3 of 3. Click Finish. See

Figure 2.8.

10) After “Writing Con guration File” is complete, turn

power o . Turn on again to activate new settings.

UltraLINK Device Addr 127

U

HelpWindowCommunicationsViewEditFile

Configuration CalibrationStrategy

Device Addr 127

U

1350 Gal/Min

Flow:

Pos:

Neg:

0 OB

0 OB

0 OB

15.6%

100%

-2.50 ns

09:53:39

Totalizer Net:

Sig. Strength:

Margin:

Delta T:

Last Update:

!

Errors

2000

1600

1200

Print PreviePrint

Scale:60 MinTime:

FIGURE 2.7 DATA DISPLAY SCREEN

Calibration (Page 3 of 3) - Linearization

28.2

Gal/M

1) Please establish a

reference flow rate.

1FPS / 0.3MPS Minimum.

2) Enter the reference flow

rate below. (Do not enter 0)

3) Wait for flow to stabilize.

4) Press the Set button.

Flow:

Set

200

FIGURE 2.6 APPLICATION OF ACOUSTIC COUPLANT

DTTS/DTTC AND INTEGRAL TRANSDUCERS

NOTE: If a DTTS/DTTC small pipe transducer was purchased

separately from the TFXL meter, the following con guration

procedure is required.

DTTS/DTTC Small Pipe Transducer Con guration

Procedure

1) Establish communications with the transit time meter.

See Part 4 - Software Utility.

2) From the Tool Bar select Calibration. See Figure 2.7.

3) On the pop-up screen, click Next button twice to get to

Page 3 of 3. See Figure 2.8.

4) Click Edit.

14 06-TTM-UM-00158 8/2012

⁄” (1.5 mm)

Acoustic Couplant

Grease

Delta Time

FIGURE 2.8 CALIBRATION PAGE 3 OF 3

Calibration Points Editor

Select point(s) to edit or remove:

30.00 ns 2000.00 Gal/Min 1.000

OK

Cancel

FIGURE 2.9 CALIBRATION POINTS EDITOR

Edit

Export...

Add...

Edit...

Remove

Select All

Select All

Select None

Select None

Page 15

Model: DTTSJP-050-N000-N

S/N: 39647 Delta-T: 391.53nS

Uncal. Flow: 81.682 GPM

Cal. Flow: 80 GPM

Edit Calibration Points

Delta T:

Uncalibrated Flow:

Calibrated Flow:

391.53

81.682

80.000

ns

Gal/Min.

Gal/Min.

tion of the mark. Move to the other side of the pipe and

mark the pipe at the ends of the crease. Measure from

the end of the crease (directly across the pipe from the

rst transducer location) the dimension derived in Step

2, Transducer Spacing. Mark this location on the pipe.

OK

Cancel

FIGURE 2.10 EDIT CALIBRATION POINTS

MOUNTING TRANSDUCERS IN ZMOUNT

CONFIGURATION

Installation on larger pipes requires careful measurements

of the linear and radial placement of the DTTN and DTTH

transducers. Failure to properly orient and place the transducers on the pipe may lead to weak signal strength and/or

inaccurate readings. This section details a method for properly locating the transducers on larger pipes. This method

requires a roll of paper such as freezer paper or wrapping

paper, masking tape and a marking device.

1) Wrap the paper around the pipe in the manner shown

in Figure 2.11. Align the paper ends to within ¼ inch

(6 mm).

2) Mark the intersection of the two ends of the paper to

indicate the circumference. Remove the template and

spread it out on a at surface. Fold the template in half,

bisecting the circumference. See Figure 2.12.

Edge of

Paper

Line Marking

Circumference

Fold

Pipe Circumference

Transducer

Spacing

Crease

(Center of Pipe)

FIGURE 2.12 BISECTING THE PIPE CIRCUMFERENCE

4) The two marks on the pipe are now properly aligned

and measured. If access to the bottom of the pipe

prohibits the wrapping of the paper around the circumference, cut a piece of paper ½ the circumference of the

pipe and lay it over the top of the pipe. The length of ½

the circumference can be found by:

½ Circumference = Pipe O.D. × 1.57

The transducer spacing is the same as found in the

Transducer Positioning section. Mark opposite corners

of the paper on the pipe. Apply transducers to these

two marks.

5) For DTTN and DTTH transducers, place a single bead of

couplant, approximately ½ inch (12 mm) thick, on the

at face of the transducer. See Figure 2.4. Generally, a

silicone-based grease is used as an acoustic couplant,

but any good quality grease-like substance that is rated

to not “ ow” at the temperature that the pipe may

operate at will be acceptable.

LESS THAN ¼” (6 mm)

FIGURE 2.11 PAPER TEMPLATE ALIGNMENT

6) Place the upstream transducer in position and secure

with a stainless steel strap or other fastening device.

Straps should be placed in the arched groove on the

end of the transducer. A screw is provided to help hold

3) Crease the paper at the fold line. Mark the crease. Place

a mark on the pipe where one of the transducers will

be located. See Figure 2.2 for acceptable radial orientations. Wrap the template back around the pipe, placing

the beginning of the paper and one corner in the loca-

the transducer onto the strap. Verify that the transducer

is true to the pipe, adjust as necessary. Tighten transducer strap securely. Larger pipes may require more

than one strap to reach the circumference of the pipe.

7) Place the downstream transducer on the pipe at the

06-TTM-UM-00158 8/2012 15

Page 16

calculated transducer spacing. See Figure 2.13. Using

rm hand pressure, slowly move the transducer both

towards and away from the upstream transducer while

observing signal strength. Clamp the transducer at the

position where the highest signal strength is observed.

Signal strength of between 5 and 98 is acceptable. The

factory default signal strength setting is 5, however

there are many application speci c conditions that may

prevent the signal strength from attaining this level.

A minimum signal strength of 5 is acceptable as long as

this signal level is maintained under all ow conditions.

On certain pipes, a slight twist to the transducer may

cause signal strength to rise to acceptable levels.

8) Certain pipe and liquid characteristics may cause signal

strength to rise to greater than 98. The problem with

ating a TFXL with very high signal strength is

oper

that the signals may saturate the input ampli ers

and cause erratic readings. Strategies for lowering

signal strength would be changing the transducer

mounting method to the next longest transmission path. For example, if there is excessive signal

strength and the transducers are mounted in a

Z-Mount, try changing to V-Mount or W-Mount.

Finally you can also move one transducer slightly

o line with the other transducer to lower signal

strength.

9)

Secure the transducer with a stainless steel strap

or other fastener.

TOP VIEW

OF PIPE

vertical pipe is not critical. Ensure that the track is

parallel to the pipe and that all four mounting feet are

touching the pipe.

3) Slide the two transducer clamp brackets towards the

center mark on the mounting rail.

4) Place a single bead of couplant, approximately ½ inch

(12 mm) thick, on the at face of the transducer. See

Figure 2.4.

5) Place the rst transducer in between the mounting rails

near the zero point on the scale. Slide the clamp over

the transducer. Adjust the clamp/transducer such that

the notch in the clamp aligns with zero on the scale. See

Figure 2.14.

Top View

of Pipe

FIGURE 2.14 MOUNTING TRACK INSTALLATION

6) Secure with the thumb screw. Ensure that the screw

rests in the counter bore on the top of the transducer.

(Excessive pressure is not required. Apply just enough

pressure so that the couplant lls the gap between the

pipe and transducer.)

7) Place the second transducer in between the mounting

rails near the dimension derived in the transducer

spacing section. Read the dimension on the mounting

rail scale. Slide the transducer clamp over the transducer and secure with the thumb screw.

PART 3 INPUTS/OUTPUTS

GENERAL

FIGURE 2.13 ZMOUNT TRANSDUCER PLACEMENT

MOUNTING TRACK INSTALLATION

1) A convenient transducer mounting track can be used

for pipes that have outside diameters between 2 and

10 inches (50 and 250 mm). If the pipe is outside of that

range, select a V-Mount or Z-Mount mounting method.

2) Install the single mounting rail on the side of the pipe

with the stainless steel bands provided. Do not mount it

on the top or bottom of the pipe. Orientation on

16 06-TTM-UM-00158 8/2012

The TFXL is available in two general con gurations. There is

the standard TFXL ow model that is equipped with a 4-20

mA output and a rate frequency output.

The TFXL is also available with a totalizing pulse output.

420 mA OUTPUT

The 4-20 mA output interfaces with most recording and

logging systems by transmitting an analog current signal

that is proportional to system ow rate. The 4-20 mA output

is internally powered (current sourcing) and can span negative to positive ow/energy rates.

Page 17

Supply Voltage - 7 VDC

1100

1000

900

800

700

600

500

400

Loop Load (Ohms)

300

200

100

10 12 14 16 18 20 22 24 26 28

0.02

Supply Voltage (VDC)

= Maximum Loop Resistance

Operate in the

Shaded Regions

FIGURE 3.1 ALLOWABLE LOOP RESISTANCE

OPTIONAL TOTALIZING PULSE SPECIFICATIONS

OPTIONAL TFXL TOTALIZING PULSE OUTPUT

Signal

Operation

Pulse

Duration

Source/

sink

Logic

1 pulse for each increment of the totalizers least

signi cant digit.

Normal state - high; pulses low with display total

increments

30mSec minute

2 mA maximum

5 VDC

Wiring and con guration of this option is similar to the totalizing pulse output for the TFXL variation. This option must

use an external current limiting resistor.

4-20 mA Ground

4-20 mA Output

4-20 mA Return (-)

4-20 mA Output (+)

FIGURE 3.2 420 MA OUTPUT

The 4-20 mA output signal is available between the 4-20 mA

Out and Signal Gnd terminals as shown in Figure 3.2.

BATCH/TOTALIZER OUTPUT FOR TFXL

Totalizer mode con gures the output to send a 33 mSec

pulse each time the display totalizer increments divided by

the TOT MULT. The TOT MULT value must be a whole, posi-

tive, numerical value.

For example, if the totalizer exponent (TOTL E) is set to E0

(×1) and the totalizer multiplier (TOT MULT) is set to 1, then

the output will pulse each time the totalizer increments one

count, or each single, whole measurement unit totalized.

If the totalizer exponent (TOTL E) is set to E2 (×100) and the

totalizer multiplier (TOT MULT) is set to 1, then the control

output will pulse each time the display totalizer increments

or once per 100 measurement units totalized.

If the totalizer exponent (TOTL E) is set to E0 (×1) and

the totalizer multiplier (TOT MULT) is set to 2, the control

output will pulse once for every two counts that the totalizer

increments.

TTL Pluse (+)

TTL Pluse (-)

TTL Pluse (+)

TTL Pluse (-)

O

N

1

FIGURE 3.3 TFXL TOTALIZER OUTPUT OPTION

FREQUENCY OUTPUT

The frequency output is a TTL circuit that outputs a pulse

waveform that varies proportionally with ow rate. This type

of frequency output is also know as a “Rate Pulse” output. The

output spans from 0 Hz, normally at zero ow rate to 1,000

Hz at full ow rate (con guration of the MAX RATE parameter is described in detail in the ow meter con guration

section of this manual).

Turbine Output

Turbine Output

1

Turbine Simulation

O

N

FIGURE 3.4 FREQUENCY OUTPUT SWITCH SETTINGS

The frequency output is proportional to the maximum ow

rate entered into the meter. The maximum output frequency

is 1,000 Hz.

If, for example, the MAX RATE parameter was set to 400 GPM

then an output frequency of 500 Hz (half of the full scale

frequency of 1,000 Hz) would represent 200 GPM.

TOTALIZER OUTPUT OPTION FOR TFXL

TFXL units can be ordered with a totalizer pulse output option. This option is installed in the position where the rate

pulse would normally be installed.

In addition to the control outputs, the frequency output can

be used to provide total information by use of a “K-factor”.

A K-factor simply relates the number of pulses from the

frequency output to the number of accumulated pulses that

equates to a speci c volume.

06-TTM-UM-00158 8/2012 17

Page 18

For the TFXL this relationship is described by the following

equation. The 60,000 relates to measurement units in

volume/min. Measurement units in seconds, hours or days

would require a di erent numerator.

K factor

60,000

Full Scale Units

EQUATION 3.1 KFACTOR CALCULATION

PART 4 ULTRALINK UTILITY

INTRODUCTION

The ULTRALINK utility is used for con guring, calibrating

and communicating with the TFXL family of ow meters.

Additionally, it has numerous troubleshooting tools to make

diagnosing and correcting installation problems easier.

A practical example would be if the MAX RATE for the appli-

cation were 400 GPM, the K-factor (representing the number

of pulses accumulated needed to equal 1 Gallon) would be:

K factor Pulses Per Gallon

60,000

400

GPM

150

If the frequency output is to be used as a totalizing output,

the TFXL and the receiving instrument must have identical

K-factor values programmed into them to ensure that accurate readings are being recorded by the receiving instrument.

Unlike standard mechanical ow meters such as turbines,

gear or nutating disk meters, the K-factor can be changed by

modifying the MAX RATE ow rate value.

NOTE: For a full treatment of K-factors please see the

Appendix of this manual.

There are two frequency output types available:

Turbine meter simulation - This option is utilized

when a receiving instrument is capable of interfacing

directly with a turbine ow meter’s magnetic pickup.

The output is a relatively low voltage AC signal whose

amplitude swings above and below the signal ground

reference. The minimum AC amplitude is approximately

500 mV peak-to-peak. To activate the turbine output

circuit, turn SW1 OFF.

500 mV

0

p-p

This software has been designed to provide the TFXL user

with a powerful and convenient way to con gure calibrate

and troubleshoot all TFXL family ow meters.

SYSTEM REQUIREMENTS

ULTRALINK requires a PC-type computer, running Windows

98, Windows ME, Windows 2000, Windows NT, Windows XP,

Windows Vista® or Windows® 7 operating systems and an

RS-232 9-pin communications port. (Part # D010-0204-001)

INSTALLATION

1) From the Windows “Start” button, choose the Run

command. From the “Run” dialog box, use the Browse

button to navigate to the ULTRALINK_Setup.exe le and

double-click.

2) The ULTRALINK Setup will automatically extract and

install on the hard disk. The ULTRALINK icon can then be

copied to the desktop, if desired.

NOTE: If a previous version of this software is installed, it

must be un-installed before a new version of the software

can be installed. Newer versions will “ask” to remove the old

version and perform the task automatically. Older versions

must be removed using the Microsoft Windows® Add/Remove

Programs applet.

NOTE: Most PCs will require a restart after a successful

installation.

FIGURE 3.5 FREQUENCY OUTPUT WAVEFORM

SIMULATED TURBINE

Square-wave frequency - This option is utilized when

a receiving instrument requires that the pulse voltage

INITIALIZATION

1) Connect the 9-pin serial end to an available port on the

PC. Connect the other end to the TFXL.

level be either of a higher potential and/or referenced

to DC ground. The output is a TTL square-wave (5V).

5V

0

FIGURE 3.6 FREQUENCY OUTPUT WAVEFORM

PC INTERFACE

CABLE

PC INTERFACE

PC INTERFACE

FLOW METER MOUNTING ORIENTATION

10 D

ULTRALINK

CABLE

TM

SQUARE WAVE

FIGURE 4.1 PC CONNECTIONS

NOTE: It is advisable to have the TFXL meter powered up prior

to running this software.

18 06-TTM-UM-00158 8/2012

Page 19

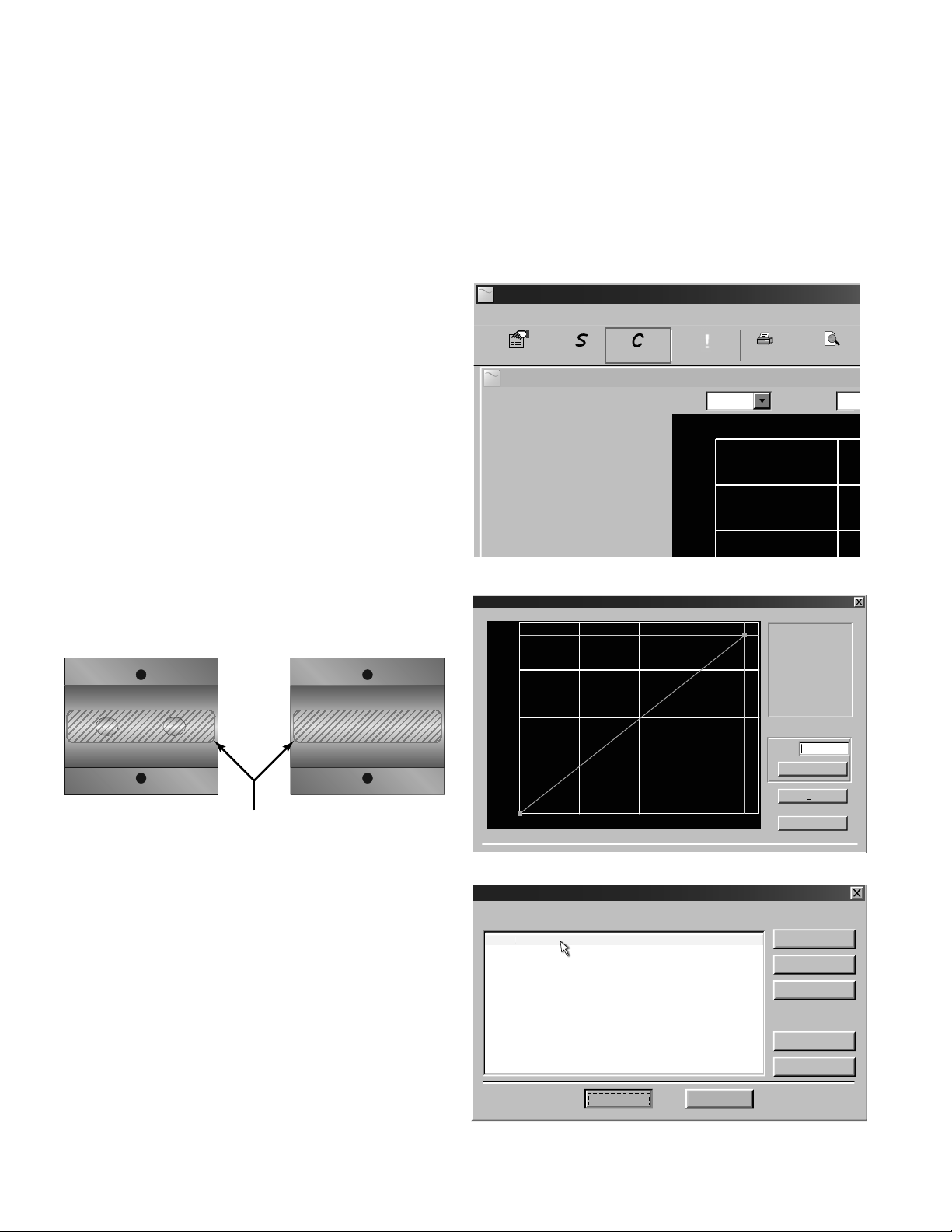

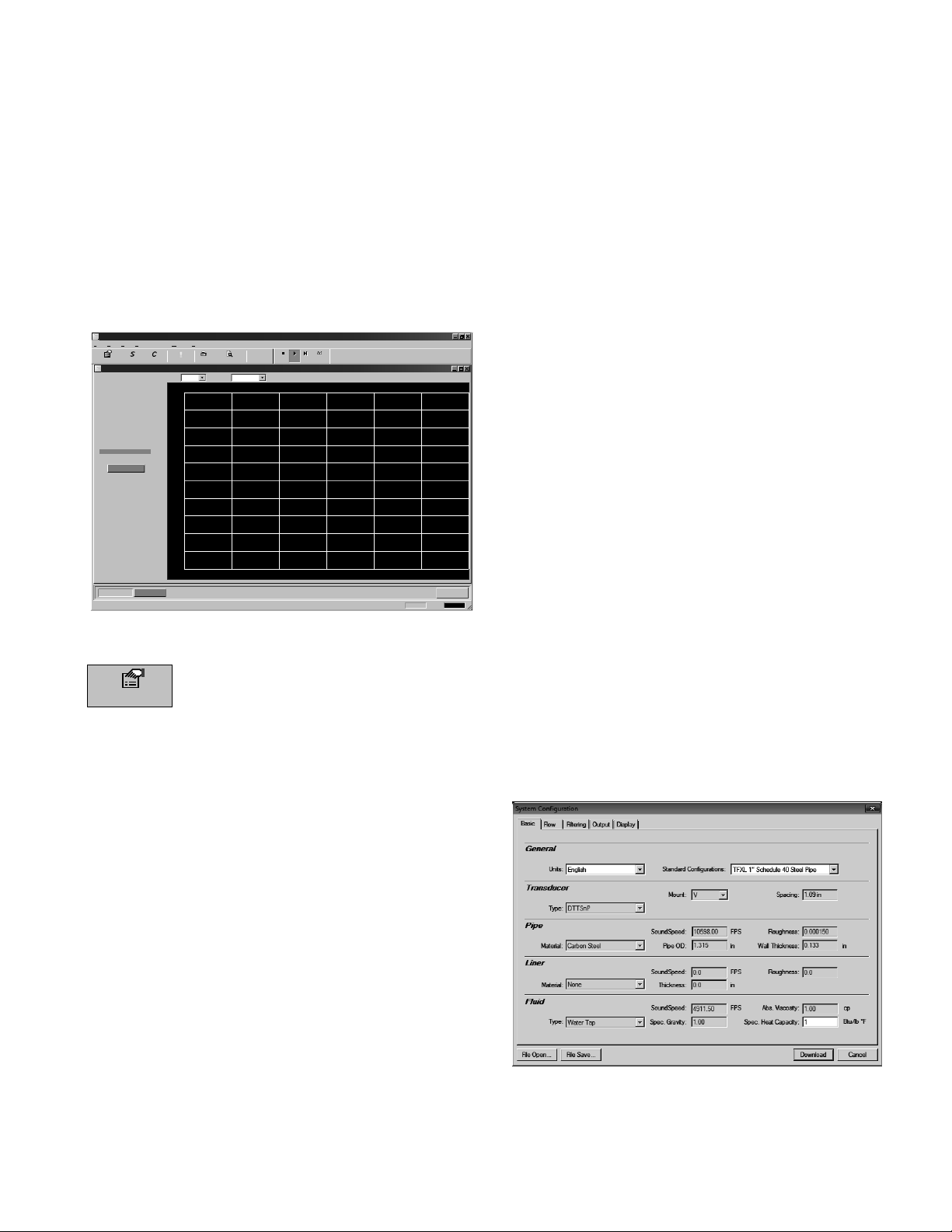

2) Double-click on the ULTRALINK icon. The rst screen is

the “RUN” mode screen (see Figure 4.2), which contains

real-time information regarding ow rate, totals, signal

strength, communications status, and the ow meter’s

serial number. The COMM indicator in the lower righthand corner indicates that the serial connection is

active. If the COMM box contains a red ERROR, click

on the Communications button on the Menu bar and

select Initialize. Choose the appropriate COM port and

the RS232 / USB Com Port Type. Proper communica-

tion is veri ed when a green OK is indicated in the

lower right-hand corner of the PC display and the “Last

Update” indicator in the text area on the left side of the

screen changes from red to an active clock indication.

UltraLINK Device Addr 127

U

Conguration CalibrationStrategy

Device Addr 127

U

135 Gal/Min

Flow:

237 Gal

Totalizer Net:

Pos:

237 Gal

Neg:

0 Gal

Sig. Strength:

15.6%

Margin:

100%

Delta T:

2.50 ns

Last Update:

12:17:20

Signal Strength too Low!

Reset Totalizers

Data Display Diagnostics

HelpWindowCommunicationsViewEditFile

!

Print About

Errors

60 Mi

n

2000

1600

1200

800

400

0

Flow Rate

-400

-800

-1200

-1600

-2000

-1.00:00

?

Go

Stop

Step View

Stop

Print Preview

2000

Scale:Time:

-50:00 -40:00 -30:00 -20:00 -10:00 -0:00

Stop

Historical Data

Time (mm:ss)

13:26:33

COMM:For Help, press F1

FIGURE 4.2 DATA DISPLAY SCREEN

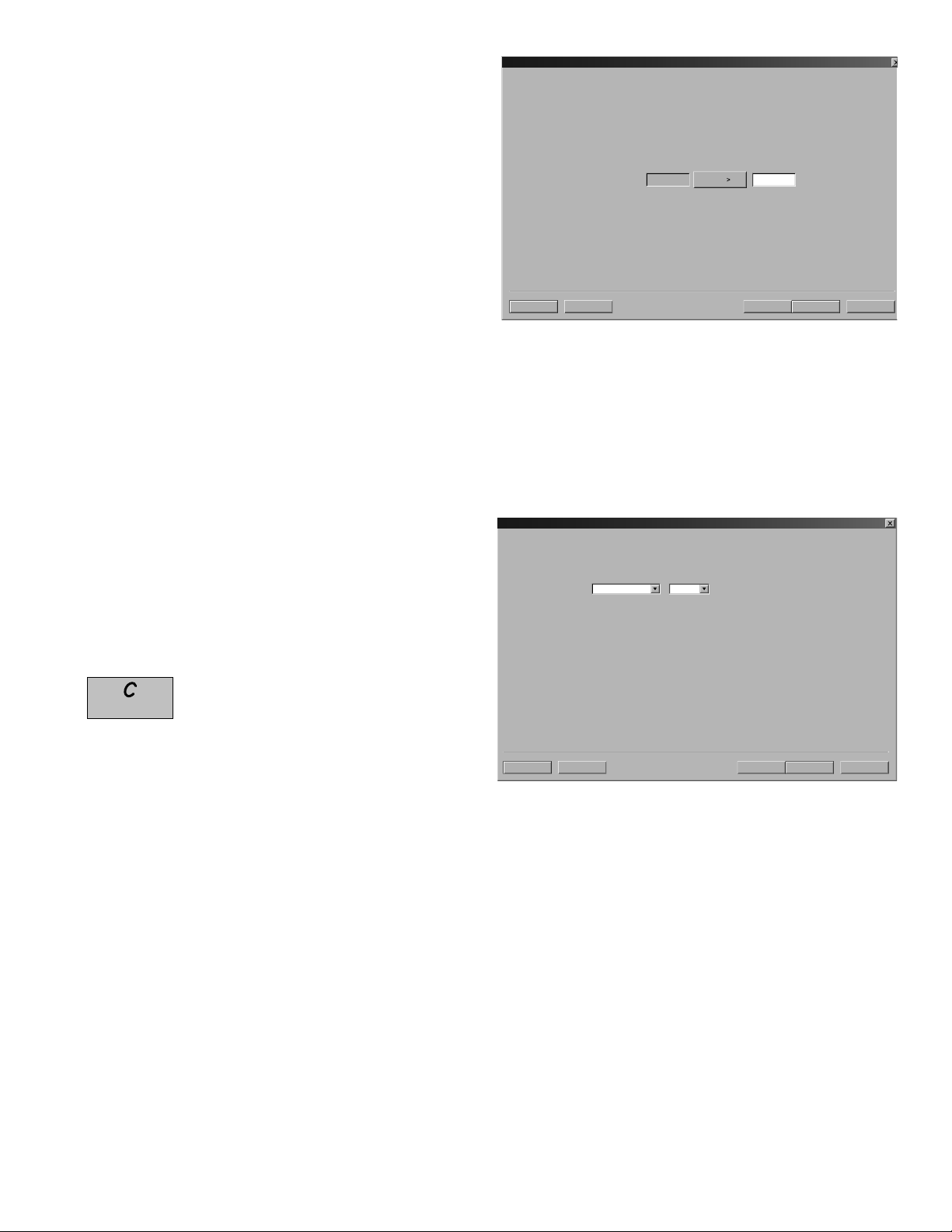

The Con guration drop-down houses six

Configuration

screens used to control how the TFXL is set up

and responds to varying ow conditions. The

rst screen that appears after clicking the Con guration

button is the Basic screen. See Figure 4.3.

1) Select the transducer type and pipe size for the transducer to be used. The rmware will automatically enter

the appropriate values for that pipe size and type. Every

entry parameter except for Units, Standard Con gura-

tions, and Speci c Heat Capacity will be unavailable

behind a “grayed out” entry box.

2) Go back to the Standard Con gurations drop-down

menu and select Custom. As soon as Custom is chosen,

the previously grayed out selections will become available for editing.

3) Make any changes to the Basic con guration deemed

necessary and press Download.

4) To ensure that the con guration changes take e ect,

turn the power o and then back on again to the

transmitter.

TRANSDUCER

Transducer Typ e selects the transducer that will be

connected to the TFXL ow meter. Select the appropriate

transducer type from the drop-down list. This selection

in uences transducer spacing and ow meter performance,

so it must be correct. If you are unsure about the type of

transducer to which the TFXL will be connected, consult the

shipment packing list or call the manufacturer for assistance.

NOTE: A change of Transducer Type will cause a System

Con guration Error (1002: Sys Con g Changed) to occur. This

Exit

OK

error will clear when the microprocessor is reset or power is

cycled on the ow meter.

Transducer Mount selects the orientation of the transducers

on the piping system. See Part 2 of this manual and Table

2.2 for detailed information regarding transducer mounting

modes for particular pipe and liquid characteristics. Whenever Transducer Mount is changed, a download command

and subsequent microprocessor reset or ow meter power

cycle must be conducted.

BASIC TAB

GENERAL

The general heading allows users to select the measurement

system for meter setup, either English or Metric and choose

from a number of pre-programmed small pipe con gurations in the Standard Con gurations drop-down. If pipe

measurements are to be entered in inches, select English. If

pipe measurements are to be entered in millimeters, select

Metric. If the General entries are altered from those at instrument start-up, then click on the Download button in the

lower right-hand portion of the screen and cycle power to

the TFXL.

When using the Standard Con gurations drop-down menu

alternate, menu choices can be made by using the following

guidelines:

06-TTM-UM-00158 8/2012 19

FIGURE 4.3 BASIC TAB

Page 20

Frequency Transducers

All ½” thru 1½”

2 MHz

1 MHz

Transducer Spacing is a value calculated by the TFXL

rmware that takes into account pipe, liquid, transducer

and mounting information. This spacing will adapt as these

parameters are modi ed. The spacing is given in inches

for English units selection and millimeters for Metric. This

value is the lineal distance that must be between the transducer alignment marks. Selection of the proper transducer

mounting method is not entirely predictable and many times

is an iterative process.

NOTE: This setting only applies to DTTN, and DTTH

transducers.

Transducer Flow Direction allows the change of the

direction the meter assumes is forward. When mounting

TFXL meters with integral transducers, this feature allows

upstream and downstream transducers to be “electronically”

reversed, making upside down mounting of the display

unnecessary.

Pipe Material is selected from the pull-down list. If the pipe

material utilized is not found in the list, select Other and

enter the actual pipe material Sound Speed and Roughness

(much of this information is available at web sites such as

www.ondacorp.com/tecref_acoustictable.shtml for pipe

relative roughness calculations.

Small Pipe and

Tube

2” Tubing

2” ANSI Pipe and

Copper Tube

Standard and

High Temp

TABLE 4.1 TRANSDUCER FREQUENCIES

Transmission

Modes

Selected by

Firmware

Selected by

Firmware

W, V, and Z 2” and Greater

Pipe Size

and Type

Speci c to

Transducer

Speci c to

Transducer

Speed and Absolute Viscosity into the appropriate boxes.

The liquid’s Speci c Gravity is required if mass measure-

ments are to be made.

FLOW TAB

Flow Rate Units are selected from the drop-down lists.

Select an appropriate rate unit and time from the two lists.

This entry also includes the selection of Flow Rate Interval

after the / sign.

Totalizer Units are selected from drop-down lists. Select

an appropriate totalizer unit and totalizer exponent. The

totalizer exponents are in scienti c notation and permit the

eight digit totalizer to accumulate very large values before

the totalizer “rolls over” and starts again at zero. Table 4.2

illustrates the scienti c notation values and their respective

decimal equivalents.

Exponent Display Multiplier

E-1 × 0.1 (÷10)

E0 × 1 (no multiplier)

E1 × 10

E2 × 100

E3 × 1,000

E4 × 10,000

E5 × 100,000

E6 × 1,000,000

TABLE 4.2 EXPONENT VALUES

Pipe O.D. and Wall Thickness are based on the physical

dimensions of the pipe on which the transducers will be

mounted. Enter this value in inches for English units or milli-

meters for Metric units.

NOTE: Charts listing popular pipe sizes have been included

in the

Appendix of this manual. Correct entries for pipe O.D.

and pipe wall thickness are critical to obtaining accurate ow

measurement readings.

Liner Material is selected from the pull-down list. If the pipe

liner material utilized is not included in the list, select Other

and enter liner material Sound Speed and Roughness

(much of this information is available at web sites such as

www.ondacorp.com/tecref_acoustictable.shtml. See

Page 40 for pipe liner relative roughness calculations.

Fluid Type is selected from a pull-down list. If the liquid is

not found in the list, select Other and enter the liquid Sound

20 06-TTM-UM-00158 8/2012

Min Flow is the minimum volumetric ow rate setting

entered to establish ltering parameters. Volumetric entries

will be in the Flow Rate Units. For unidirectional measurements, set Min Flow to zero. For bidirectional measurements,

set Min Flow to the highest negative (reverse) ow rate

expected in the piping system.

Max Flow is the maximum volumetric ow rate setting

entered to establish ltering parameters. Volumetric entries

FIGURE 4.4 FLOW TAB

Page 21

will be in the Flow Rate Units. For unidirectional measurements, set Max Flow to the highest (positive) ow rate

expected in the piping system. For bidirectional measurements, set Max Flow to the highest (positive) ow rate

expected in the piping system.

Low Flow Cuto is provided to allow very low ow rates

(that can be present when pumps are o and valves are

closed) to be displayed as zero ow. Typical values that

should be entered are between 1.0% and 5.0% of the ow

range between Min Flow and Max Flow.

Low Signal Cuto is used to drive the ow meter and its

outputs to the value speci ed in the Substitute Flow eld

when conditions occur that cause low signal strength. A

signal strength indication below 5 is generally inadequate for

measuring ow reliably, so generally the minimum setting

for Low Signal Cuto is 5. A good practice is to set the Low

Signal Cuto at approximately 60-70% of actual measured

maximum signal strength.

NOTE: The factory default “Low Signal Cuto ” is 5.

If the measured signal strength is lower than the Low Signal

Cuto setting, a “Signal Strength too Low” highlighted in

red will become visible in the text area to the left in the Data

Display screen until the measured signal strength becomes

greater than the cuto value.

Signal strength indication below 2 is considered to be no

signal at all. Verify that the pipe is full of liquid, the pipe size

and liquid parameters are entered correctly, and that the

transducers have been mounted accurately. Highly aerated

liquids will also cause low signal strength conditions.

Substitute Flow is a value that the analog outputs and the

ow rate display will indicate when an error condition in the

ow meter occurs. The typical setting for this entry is a value

that will make the instrument display zero ow during an

error condition.

Substitute Flow is set as a percentage between Min Flow and

Max Flow. In a unidirectional system, this value is typically

set to zero to indicate zero ow while in an error condition.

In a bidirectional system, the percentage can be set such that

zero is displayed in an error condition. To calculate where

to set the Substitute Flow value in a bidirectional system,

perform the following operation:

100

u

SubstituteFlow

100

-

Maximum Flow Minimum Flow

Maximum Flow

-

FILTERING TAB

The Filtering tab contains several lter settings for the TFXL

ow meter. These lters can be adjusted to match response

times and data “smoothing” performance to a particular

application.

System Configuration

Filtering

Advanced Filter Settings:

File Open... File Save...

Output Security

Time Domain Filter:

Time Domain Filter (range 1-256) adjusts the number

of raw data sets (the wave forms viewed on the software

Diagnostics Screen) that are averaged together. Increasing

this value will provide greater damping of the data and slow

the response time of the ow meter. Conversely, lowering

this value will decrease the response time of the meter to

changes in ow/energy rate. This lter is not adaptive, it is

operational to the value set at all times.

NOTE: The TFXL completes a measurement in approximately

350-400 mS. The exact time is pipe size dependent.

Flow Filter (Damping) establishes a maximum adaptive

lter value. Under stable ow conditions ( ow that varies less

than the Flow Filter Hysteresis entry), this adaptive lter

will increase the number of successive ow readings that are

averaged together up to this maximum value. If ow changes

outside of the Flow Filter Hysteresis window, the lter

adapts by decreasing the number of averaged readings and

allows the meter to react faster.

The damping value is increased to increase stability of the

ow rate readings. Damping values are decreased to allow

the ow meter to react faster to changing ow rates. The

factory settings are suitable for most installations. Increasing

this value tends to provide smoother steady-state ow readings and outputs.

DisplayBasic Flow

8

Flow Filter (Damping): %

Flow Filter Hystersis:

Flow Filter Sensitivity:

Bad Data Rejection:

80

5

303

3

3

FIGURE 4.5 FILTERING TAB

%

psecFlow Filter Min Hystersis:

Factory Defaults

Download Cancel

Entry of data in the Basic and Flow tabs is all that is required

to provide ow measurement functions to the ow meter.

If the user is not going to utilize input/output functions,

click on the Download button to transfer the con guration

to the TFXL instrument. When the con guration has been

completely downloaded, turn the power to the meter o and

then on again to guarantee the changes take e ect.

Flow Filter Hysteresis creates a window around the average

ow measurement reading allowing small variations in

ow without changing the damping value. If the ow varies