Page 1

Transit Time Ultrasonic Flow Meters

TFX-500w Clamp-On Meter

DESCRIPTION

The TFX-500w transit time ultrasonic flow meter measures

volumetric flow of clean water in pipes 10 in. or smaller. By clamping

on the outside of the pipe, the ultrasonic meter installs without

cutting or tapping the pipe.

FEATURES

• Clamp-on, non-invasive flow meter

• Bidirectional flow measurement system

• Measures flow rate, total and velocity of water flow

• Set up the meter through keypad interface or with

SoloCUE® Flow Device Manager software

• Compact enclosure uses large, easy-to-read graphical display

• Modbus RTU or BACnet MS/TP over RS485 and

BEACON®/AquaCUE® connectivity

BENEFITS

• Reduces installation costs, especially retrofits

◊ Installs without cutting into the pipe

◊ Eliminates flanges and pipe fittings

◊ Eliminates draining and air purging

• Eliminates ingress or leak points in pipes

• No moving parts to maintain

• No pressure head loss

APPLICATION

The TFX-500w meter is well suited for building automation,

water distribution and wastewater collection in new and retrofit

applications. In addition to having lower installation costs than an

inline flow meter, the TFX-500w meter can be installed while the

system continues to operate without interruption.

The TFX-500w meter is suitable for:

• Potable water

• Reclaimed water

• Chiller water

• Boiler feed

• Make-up water

• Condenser water

• Condensate

By connecting the TFX-500w meter to Badger Meter® AquaCUE

or BEACON analytics cloud service, the meter becomes part of a

system that tracks and monitors water use for commercial buildings,

campuses and other large facilities.

OPERATION

Transit time flow meters use two transducers that function as both

ultrasonic transmitters and receivers. The flow meters operate by

alternately transmitting and receiving a frequency-modulated

burst of sound energy between the two transducers. The burst is

first transmitted in the direction of fluid flow and then against fluid

flow. Since sound energy in a moving liquid is carried faster when it

travels in the direction of fluid flow (downstream) than it does when

it travels against fluid flow (upstream), a differential in the times of

flight will occur. The sound’s time-of-flight is accurately measured in

both directions and the difference in time-of-flight calculated.

TTM-DS-02183-EN-06 (May 2019)

Product Data Sheet

Page 2

Specications

SPECIFICATIONS

System

Liquid Types Water containing small amounts of suspended solids or gas bubbles

Velocity Range 0.1…40 ft/s (0.03…12 m/s) bidirectional

Flow Accuracy

Repeatability ±0.2% of reading

Transducer Type Clamp-on ultrasonics

Certifications

DTTR/DTTN

DTTC

Easy Rail (DTTJ, DTTK)

Remote mount transmitter and

integral mount transmitter with

transducers

Transmitter

±1% of reading or ±0.01 FPS (0.003 MPS), whichever is greater

DTTC 3/4 in. and smaller are accurate to ± 1% full scale

General Safety (option): FM Class 3810:2018, ANSI/ISA 61010-1:2012, ANSI/IEC 60529:2004,

CAN/CSA-C22.2 No. 61010-1:2012, CSA C22.2 No. 60529:2005

CE: EMC Directive 2014/30/EU

Power

Requirements

Display

Enclosure IP66; polycarbonate

Ambient

Temperature

Units of

Measure

Mounting Wall or pipe remote mount or integral mount; Enclosure can be rotated in 90° increments

Inputs Digital input 5…30V DC, 3.48k Ohm impedence, externally or internally sourced; totalizer reset or alarm unlatch

Outputs

Networks

Configuration

Port

Alarms Buffer previous alarms, warnings or errors

Languages English, French, German and Spanish selectable

Security Four levels: Read-only, Operator, Service and Admin; 6-digit passcode number; selectable auto logout

DC Class II power supply is required; 9…28V DC @ 5 W maximum

Protection Reverse polarity and transient suppression

Keypad 4-button navigation, membrane keypad with domed tactile feedback

Resolution 128 × 64 pixel LED backlit graphical display; adjustable brightness and timeout

Operational ambient With display: –4…140° F (–20…60° C); without display: –40…158° F (–40…70° C)

Storage –40…176° F (–40…80° C)

Velocity feet/second, meters/second

Totals

Flow rate

Pulse / Frequency /

Digital /

Analog Output 0…20 mA and 4…20 mA drive up to 800 Ohms; minimum 16-bit resolution, isolated

EIA-485 with

selectable protocols

Endpoints Connectivity to AquaCUE or BEACON cellular endpoints

USB, Type mini-B

US Gallons, Million Gallons, Imperial Gallons, Million Imperial Gallons, Acre-Feet, Barrels, Liters, Hectoliters,

Cubic Meters, Cubic Feet

Acre Feet/Day, Liters/Second, Liters/Minute, Liters/Hour, Cubic Meters/Second, Cubic Meters/Minute, Cubic

Meters/Hour, Cubic Feet/Minute, Cubic Feet/Minute, Cubic Feet/Hour, Gallons/Second, Gallons/Minute, Gallons/

Hour, Million Gallons/Day, Imperial Gallons/Second, Imperial Gallons/Minute, Imperial Gallons/Hour, Barrel/

Minute, Million Imperial Gallons/Day, Barrel/Day

Two outputs, each selectable as frequency, pulse, forward/reverse flow or alarm output; isolated open collector,

5…30V DC, 50 mA maximum, externally or internally sourced with pullup resistor

Digital alarm output: configurable high or low

Frequency output: 63 Hz…10 kHz maximum

Pulse (totalizer) output: 100 Hz maximum output open collector, pulse width 5…500 ms programmable

Modbus RTU, baud rates 9600, 19200, 38400, 57600, 76800, 115200

BACnet MS/TP, baud rates 9600, 19200, 38400, 57600, 76800, 115200

Page 2 May 2019TTM-DS-02183-EN-06

Page 3

Transducers

Specications

Model Construction Cable Length Pipe/Tubing Sizes

DTTC

DTTR

DTTN

DTTN

Submersible

Easy Rail

(DTTJ/K)

* DTTC integral mount temperature is limited by the transmitter temperature rating

CPVC, Ultem, Nylon cord grip

Polyethylene cable jacket; –40…194° F (–40…90° C)*

PBT glass filled, Ultem®, Nylon cord grip

PVC cable jacket; –40…250° F (–40…121° C)

CPVC, Ultem, Nylon cord grip

Polyethylene cable jacket; –40…194° F (–40…90° C)

CPVC, Ultem, Nylon cord grip

Polyethylene cable jacket; –40…194° F (–40…90° C)

PBT glass filled, Ultem®, Nylon cord grip

PVC cable jacket; –40…250° F (–40…121° C)

100 ft (90 m) max. 0.5…2 in. (12…50 mm)

300 ft (90 m) max. 2.5…10 in. (DN65…DN250) NEMA 6/IP67

300 ft (90 m) max. 2.5…10 in. (DN65…DN250) NEMA 6/IP67

300 ft (90 m) max. 2.5…10 in. (DN65…DN250) NEMA 6P/IP68

100 ft (30 m) max.

2.5…6 in. (DN65…DN150)

2.5…10 in. (DN65…DN250)

Pipe/Tubing

Materials

Carbon steel,

stainless steel,

copper and

plastic

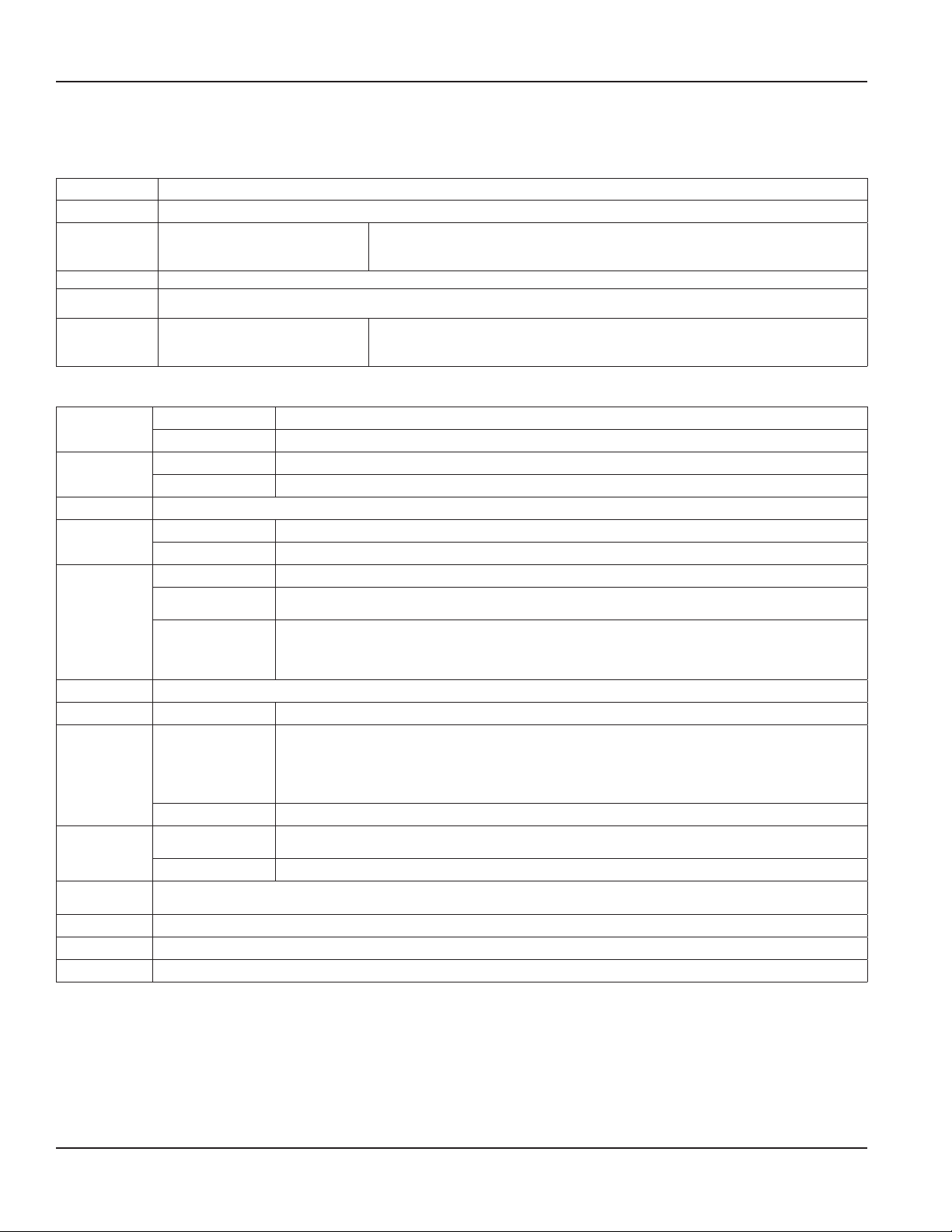

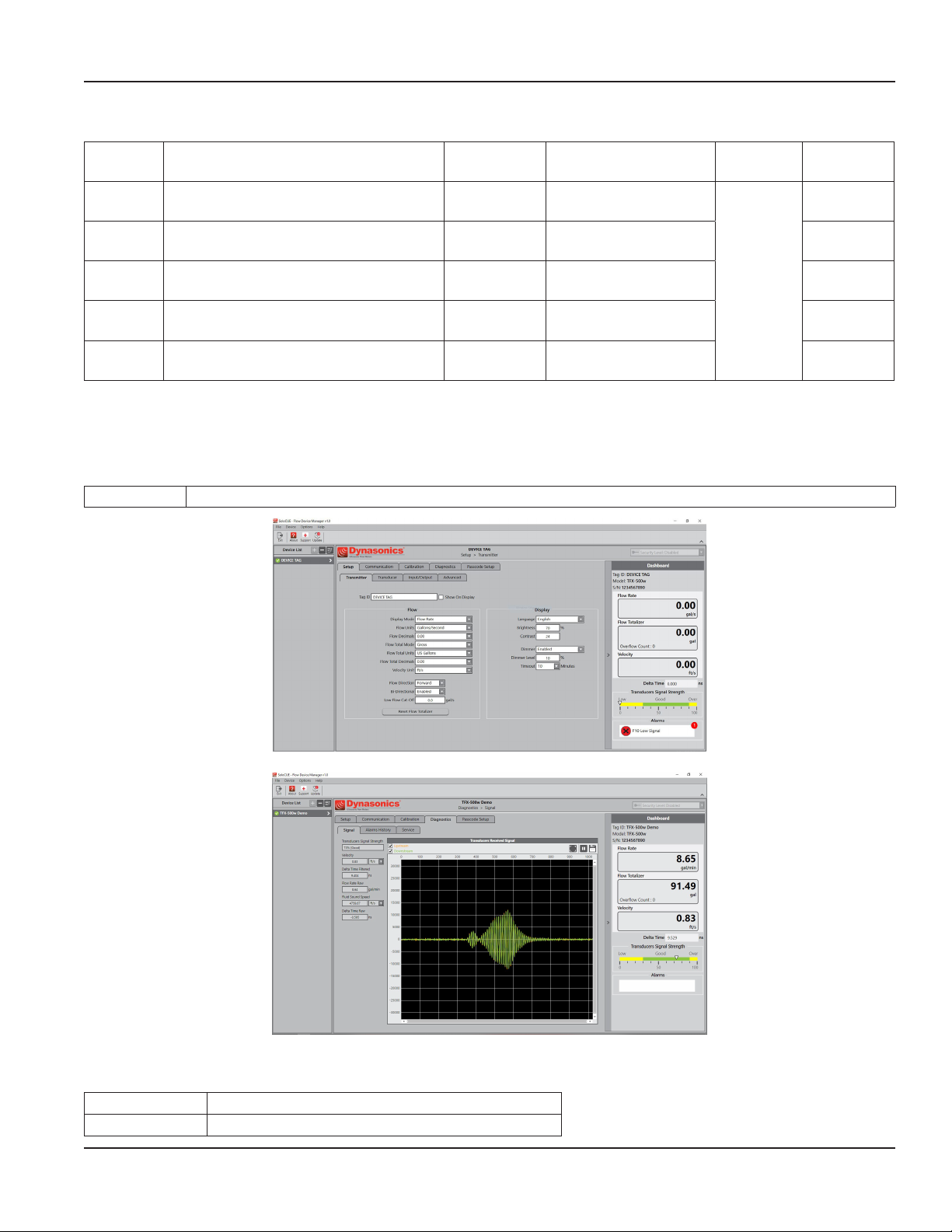

Conguration Software

The flow meter can be programmed and configured with the SoloCUE Flow Device Manager software. The software also has

troubleshooting tools for diagnosing and correcting installation problems.

SoloCUE Used to configure and troubleshoot flow meter. Software is compatible with Windows® 7 SP1 or newer

Protection

NEMA 6/IP67

NEMA 6/IP67

Figure 1: SoloCUE setup screen

Figure 2: SoloCUE diagnostics screen

Additional Parts Required for Configuration

Part Number Description

RC820648 USB Type A to mini B software cable (shielded to minimize noise)

Page 3 May 2019 TTM-DS-02183-EN-06

Page 4

Dimensions

DIMENSIONS

TFX-500w Meter

Enclosure, Integral and Remote, Front View Integral Enclosure Side View Remote Enclosure Side View

Transducers

6.00 in.

(152.40 mm)

5.55 in.

(140.97 mm)

0.65 in.

(16.51 mm)

2.68 in.

(68.07)

0.31 in.

(7.87 mm)

2.68 in.

(68.07)

0.38 in.

(9.65 mm)

Remote System with Large Pipes

DTTR/DTTN

DTTR DTTN

TOP VIEW

OF PIPE

Model A B C D

DTTR 3.75 in. (95.25 mm) 2.35 in. (59.69 mm) — 2.19 in. (55.63 mm)

DTTN 2.95 in. (74.93 mm) 2.75 in. (69.8 mm) 3.00 in. (76.2 mm) 1.70 in. (43.2 mm)

DTTJ/DTTK

D

(Min Clearance)

C

A

B

D

TOP VIEW

OF PIPE

A

E

D

inch

C

B

F

mm

Model A B C D E F

DTTJ 13.62 in. (345.95 mm) 11.73 in. (297.94 mm) 0.75 in. (19.05 mm) 0.79 in. (20.06 mm) 2.76 in. (70.10 mm) 2.36 in. (59.94 mm)

DTTK 19.92 in. (505.97 mm) 18.03 in. (457.96 mm) 0.75 in. (19.05 mm) 0.79 in. (20.06 mm) 2.76 in. (70.10 mm) 2.36 in. (59.94 mm)

Page 4 May 2019TTM-DS-02183-EN-06

Page 5

Remote System with Small Pipes

A

C

DTTC

Dimensions

DTTC

Pipes and Tubing

1/2…2 in. (12…50 mm)

B

D

A

Integral System

DTTC

DTTC U-Bolt Connections

ANSI/DS and Copper

2 in. (50 mm) Models

D

C

B

DTTC DTTC U-Bolt Connections

Pipe

Size

Pipe

Material

ANSI/DN 2.46 in. (62.48 mm) 2.36 in. (59.94 mm) 2.66 in. (67.56 mm) 0.84 in. (21.34 mm)

1/2 in.

Copper 2.46 in. (62.48 mm) 2.36 in. (59.94 mm) 3.33 in. (84.58 mm) 0.63 in. (16.00 mm)

Tubing 2.46 in. (62.48 mm) 2.28 in. (57.91 mm) 3.72 in. (94.49 mm) 0.50 in. (12.70 mm)

ANSI/DN 2.46 in. (62.48 mm) 2.57 in. (65.28 mm) 2.66 in. (67.56 mm) 1.05 in. (26.67 mm)

3/4 in.

Copper 2.46 in. (62.48 mm) 2.50 in. (63.50 mm) 3.56 in. (90.42 mm) 0.88 in. (22.35 mm)

Tubing 2.46 in. (62.48 mm) 2.50 in. (63.50 mm) 3.56 in. (90.42 mm) 0.75 in. (19.05 mm)

ANSI/DN 2.46 in. (62.48 mm) 2.92 in. (74.17 mm) 2.86 in. (72.64 mm) 1.32 in. (33.53 mm)

1 in.

Copper 2.46 in. (62.48 mm) 2.87 in. (72.90 mm) 3.80 in. (96.52 mm) 1.13 in. (28.70 mm)

Tubing 2.46 in. (62.48 mm) 2.75 in. (69.85 mm) 3.80 in. (96.52 mm) 1.00 in. (25.40 mm)

ANSI/DN 2.80 in. (71.12 mm) 3.18 in. (80.77 mm) 3.14 in. (79.76 mm) 1.66 in. (42.16 mm)

1-1/4 in.

Copper 2.46 in. (62.48 mm) 3.00 in. (76.20 mm) 4.04 in. (102.62 mm) 1.38 in. (35.05 mm)

Tubing 2.46 in. (62.48 mm) 3.00 in. (76.20 mm) 4.04 in. (102.62 mm) 1.25 in. (31.75 mm)

ANSI/DN 3.02 in. (76.71 mm) 3.40 in. (86.36 mm) 3.33 in. (84.58 mm) 1.90 in. (48.26 mm)

1-1/2 in.

Copper 2.71 in. (68.83 mm) 2.86 in. (72.64 mm) 4.28 in. (108.71 mm) 1.63 in. (41.40 mm)

Tubing 2.71 in. (68.83 mm) 3.31 in. (84.07 mm) 4.28 in. (108.71 mm) 1.50 in. (38.10 mm)

ANSI/DN 3.70 in. (93.98 mm) 3.42 in. (86.87 mm)* 5.50 in. (139.70 mm) 2.38 in. (60.45 mm)*

2 in.

Copper 3.70 in. (93.98 mm) 3.38 in. (85.85 mm)* 5.50 in. (139.70 mm) 2.13 in. (54.10 mm)*

Tubing 3.21 in. (81.53 mm) 3.85 in. (97.79 mm) 4.75 in. (120.65 mm) 2.00 in. (50.80 mm)

* Varies due to U-bolt configuration

A B C D

Page 5 May 2019 TTM-DS-02183-EN-06

Page 6

Part Number Construction

- - - - - - - -

CONDUIT TYPE AND LENGTH

1

PART NUMBER CONSTRUCTION

Transit Time: Pipes ≤ 2 in. (50 mm)

DW-G

CERTIFICATION

General Area, CE G

TRANSDUCER TYPE

1/2 in. ANSI pipe CA

3/4 in. ANSI pipe CB

1 in. ANSI pipe CC

1-1/4 in. ANSI pipe CD

1-1/2 in. ANSI pipe CE

2 in. ANSI pipe CF

1/2 in. Copper Tube CG

3/4 in. Copper Tube CH

1 in. Copper Tube CT

1-1/4 in. Copper Tube CJ

1-1/2 in. Copper Tube CK

2 in. Copper Tube CL

1/2 in. Stainless Steel Tub e CM

3/4 in. Stainless Steel Tub e CN

1 in. Stainless Steel Tube CP

1-1/4 in. Stainless Steel Tube CQ

1-1/2 in. Stainless Steel Tube CR

2 in. Stainless Steel Tube CS

TRANSMITTER TYPE

24V DC | Meter Mounted E

24V DC | Remoted Mounted

F

DISPLAY

Standard S

No display with keypad W

REMOTE CABLE LENGTH

None (Meter Mounted) WW

15 ft (4.57 m) AC

30 ft (9.14 m) AF

50 ft (15.24 m) AK

75 ft (22.86 m) AR

100 ft (30.48 m) BW

XX

None WW

15 ft (4.57 m) AC

30 ft (9.14 m) AF

50 ft (15.24 m) AK

75 ft (22.86 m) AR

100 ft (30.48 m) BW

RESERVED

Standard

XX

UNITS OF MEASURE: TOTALIZER / FLOW RATE

Gallons/gallons per minute G

Gallons/cubic feet per minute B

Cubic Meters/cubic meters per minute T

Cubic Meters/cubic meters per hour H

Cubic Feet/gallons per minute F

Cubic Feet/cubic feet per minute J

Liters/liters per second N

Liters/liters per minute P

Liters/liters per hour Q

Million Gallons/gallons per minute M

Acre Feet/gallons per minute A

TESTING & TAGGING

Factory Calibrated F

Factory Calibrated/ID Tag S

1

Conduit length must be less than or equal to cable length. Submersible Conduit limited to 100 ft (30 m).

Page 6 May 2019TTM-DS-02183-EN-06

Page 7

Part Number Construction

-

- -

- - - -

- -

CONDUIT AND CABLE LENGTH

1

DW

G

F

Transit Time: Pipes > 2 in. (50 mm)

CERTIFICATIONS

General Area, CE G

TRANSDUCER TYPE

Easy Rail | 2.5…6 in. (65…150 mm) Pipes

Easy Rail | 2.5…10 in. (65…300 mm)

Pipes DTTN | Medium Pipes

DTTN (Submersible) | Medium Pipes

DTTR | Medium Pipes

JZ

KZ

NZ

WZ

RZ

TRANSMITTER TYPE

24V DC Remote Mounted F

DISPLAY

Standard S

No display with keypad W

REMOTE CABLE LENGTH

15 ft (4.57 m) AC

30 ft (9.14 m) AF

50 ft (15.24 m) AK

75 ft (22.86 m) AR

100 ft (30.48 m) BW

150 ft (45.72 m) BK

200 ft (60.96 m) DW

250 ft (76.20 m) DK

300 ft (91.44 m) EW

XX

None WW

15 ft (4.57 m) AC

30 ft (9.14 m) AF

50 ft (15.24 m) AK

75 ft (22.86 m) AR

100 ft (30.48 m) BW

150 ft (45.72 m) BK

200 ft (60.96 m) DW

250 ft (76.20 m) DK

300 ft (91.44 m) EW

RESERVED

Standard

XX

UNITS OF MEASURE: TOTALIZER / FLOW RATE

Gallons/gallons per minute

Gallons/cubic feet per minute

Cubic Meters/cubic meters per minute

Cubic Meters/cubic meters per hour

Cubic Feet/gallons per minute

Cubic Feet/cubic feet per minute

Liters/liters per second N

Liters/liters per minute P

Liters/liters per hour Q

Million Gallons/gallons per minute M

Acre Feet/gallons per minute A

TESTING & TAGGING

Factory Calibrated

Factory Calibrated/ID Tag

1

Conduit length must be less than or equal to cable length. Submersible Conduit limited to 100 ft (30 m).

G

B

T

H

F

J

F

S

Page 7 May 2019 TTM-DS-02183-EN-06

Page 8

Transit Time Ultrasonic Flow Meters, TFX-500w Clamp-On Meter

PARTS AND ACCESSORIES

Couplant

Part Number Description

D002-2011-001 Dow Corning® Molykote® 111 Grease; 5.3 oz Tube; 150° F (65° C)

D002-2011-002 Dow Corning 732; Permanent Mount; 356° F (180° C)

Dow 111 grease is included with transducers.

Power Supplies

Part Number Description

68334-001 Wall Plug; 100…264V AC In; 24V DC Out; -20…50° C

68334-002 Module; 85…264V AC In; 24V DC Out; -30…70° C

For ordering transducers and transmitter separately, please contact factory.

Control. Manage. Optimize.

BEACON, Dynasonics, AquaCUE and SoloCUE are registered trademark of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective

entities. Due to continuous research, product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except

to the extent an outstanding contractual obligation exists. © 2019 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Eastern Europe Branch Oce (for Poland, Latvia, Lithuania, Estonia, Ukraine, Belarus) | Badger Meter Europe | ul. Korfantego 6 | 44-193 Knurów | Poland | +48-32-236-8787

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 19-07 Parkway Parade | Singapore 449269 | +65-63464836

Switzerland | Badger Meter Swiss AG | Mittelholzerstrasse 8 | 3006 Bern | Switzerland | +41-31-932 01 11

Loading...

Loading...