Page 1

Transit Time Ultrasonic Flow Meters

TFX-5000 Meter

TTM-UM-02222-EN-10 (July 2020)

User Manual

Page 2

Transit Time Ultrasonic Flow Meters, TFX-5000 Meter

CONTENTS

Scope of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Typographic Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Terminology and Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Remote Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Wall Mount Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Panel Mount Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Keypad Operation on the Home Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Keypad Operation in the Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Selecting an Option in a Parameter Selection List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Entering a Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Installation Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installing the Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installing a Meter with a Remote Transmitter and Fixed Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installing a Meter with a Remote Transmitter and Adjustable Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installing a Panel-Mount Meter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Wiring the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Electrical Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connection Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Rated Conditions of Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Wiring the Transducer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

9…28V DC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

20…26V AC Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Mains Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4…20 mA Output Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Digital Outputs Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Digital Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

AquaCUE/BEACON Endpoint Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Page ii July 2020TTM-UM-02222-EN-10

Page 3

User Manual

RTD Interface Wiring (Energy Models Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

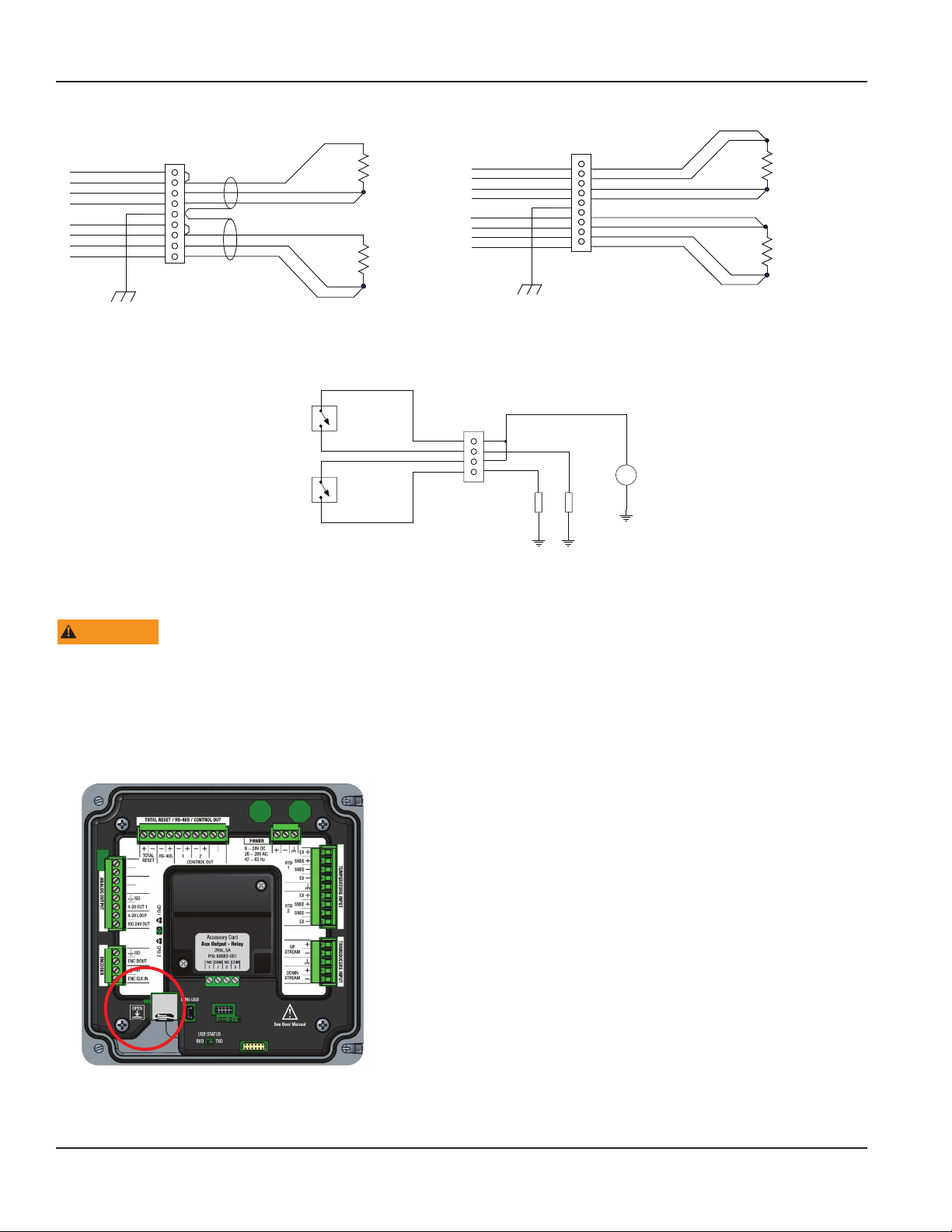

Auxiliary Output Card Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installing the MicroSD Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Connecting the USB Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Initial Meter Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Menu Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Parameter Descriptions by Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Main Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Setup > Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Setup > Meter > Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Setup > Meter > Fluid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Setup > Meter > Spacing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Setup > Meter > Flow Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Setup > Meter > Advanced . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Setup > Meter > Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Setup > Input/Output > Current #1 (or Current #2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Setup > Inputs/Output > Output #1 (or Output #2 or Output #3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Setup > Inputs/Output > Aux Output #1 (or Aux Output #2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Setup > Inputs/Output > Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Setup > Inputs/Output > RTD (Energy Models Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Setup > Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Setup > Data Logging (Service Level Access) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Setup > Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Setup > Passcode Setup > Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Setup > Passcode Setup > Passcode Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Display Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Information Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Diagnostics Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Reset Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Out of Specication Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Check Function Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Warning and Alarm Message Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Replacing an AC Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Replacing the Communication or Dry Contact Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Replacing the Main Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Firmware Update. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Page iii July 2020 TTM-UM-02222-EN-10

Page 4

Transit Time Ultrasonic Flow Meters, TFX-5000 Meter

Specications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

RTD Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

SoloCUE Flow Device Manager Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Part Number Construction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

TFX-5000 Flow Meters for Pipes 2 in. and Smaller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

TFX-5000 Flow Meters for Pipes 2 in. and Smaller for Class I, Div 2 Hazardous Locations. . . . . . . . . . . . . . . . . . . . . .56

TFX-5000 Flow Meters for Pipes 2.5 in. and Larger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

TFX-5000 Flow Meters for Pipes 2.5 in. and Larger for U.S./Canada Hazardous Locations . . . . . . . . . . . . . . . . . . . . . 58

TFX-5000 Flow Meters for Pipes Larger than 2 in. for ATEX/EICEx Hazardous Locations . . . . . . . . . . . . . . . . . . . . . . 59

TFX-5000 Energy Meters for Pipes 2 in. and Smaller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

TFX-5000 Energy Meters for Pipes 2.5 in. and Larger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

North American Pipe Schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Page iv July 2020TTM-UM-02222-EN-10

Page 5

Scope of This Manual

SCOPE OF THIS MANUAL

This manual is intended to help you get the TFX-5000 meter up and running quickly.

Read this manual carefully before attempting any installation or operation. Keep the manual accessible for future reference.

Typographic Conventions

• In step-by-step instructions, bold text indicates items on the screen you need to select or act upon.

Example: Click the Setup menu.

• Names of parameters, options, boxes, columns and fields are italicized.

Example: The value displays in the Status field.

• Messages and special markings are shown in quotation marks.

Example: “Error” displays in the title bar.

• In most cases, software screen text appears in the manual as it does on the screen. For example, if a word is capitalized on

the screen, it is capitalized when referred to in the manual.

UNPACKING AND INSPECTION

Upon opening the shipping container, visually inspect the product and applicable accessories for any physical damage such

as scratches, loose or broken parts, or any other sign of damage that may have occurred during shipment.

OTE: N If damage is found, request an inspection by the carrier’s agent within 48 hours of delivery and file a claim with the

carrier. A claim for equipment damage in transit is the sole responsibility of the purchaser.

SAFETY

Terminology and Symbols

Indicates a hazardous situation, which, if not avoided, will result in death or serious personal injury.

WARNING

Considerations

• The installation of the TFX-5000 meter must comply with all applicable federal, state, and local rules, regulations,

and codes.

• Do not use sharp objects when operating the device (such as using a pen to press buttons on the keypad).

• When the TFX-5000 meter is a part of a system, it is configured in a fail-safe operation so that if the transmitter signal is

compromised, the TFX-5000 meter will not cause harm to the system.

MPORTANTI

Not following instructions properly may impair safety of equipment and/or personnel.

WARNING

AFTER DEENERGIZING, DELAY 5 MINUTES BEFORE OPENING.

Indicates a hazardous situation, which, if not avoided, could result in death or serious personal injury.

Indicates a hazardous situation, which, if not avoided, could result in minor or moderate personal injury or

damage to property.

Page 5 July 2020 TTM-UM-02222-EN-10

Page 6

Introduction

INTRODUCTION

WARNING

THIS EQUIPMENT INCLUDES SOME EXTERNAL NONMETALLIC PARTS. THE USER SHALL THEREFORE ENSURE THAT

THE EQUIPMENT IS NOT INSTALLED IN A LOCATION WHERE IT MAY BE SUBJECTED TO EXTERNAL CONDITIONS SUCH

AS HIGHPRESSURE STEAM WHICH MIGHT CAUSE A BUILDUP OF ELECTROSTATIC CHARGES ON NONCONDUCTING

SURFACES. ADDITIONALLY, CLEANING OF THE EQUIPMENT SHOULD BE DONE ONLY WITH A DAMP CLOTH.

The TFX-5000 transit time meter measures volumetric flow and heating/cooling energy rates in clean liquids as well as those

with small amounts of suspended solids or aeration, such as surface water or sewage. TFX-5000 ultrasonic flow and energy

meters clamp onto the outside of pipes and do not contact the internal liquid.

The TFX-5000 meter is available in two versions:

• A flow meter for water delivery, sewage, cooling water, alcohols, chemical

• A heating/cooling energy flow meter used in conjunction with dual clamp-on RTDs for temperature measurement—ideal

for hydronic process and HVAC applications

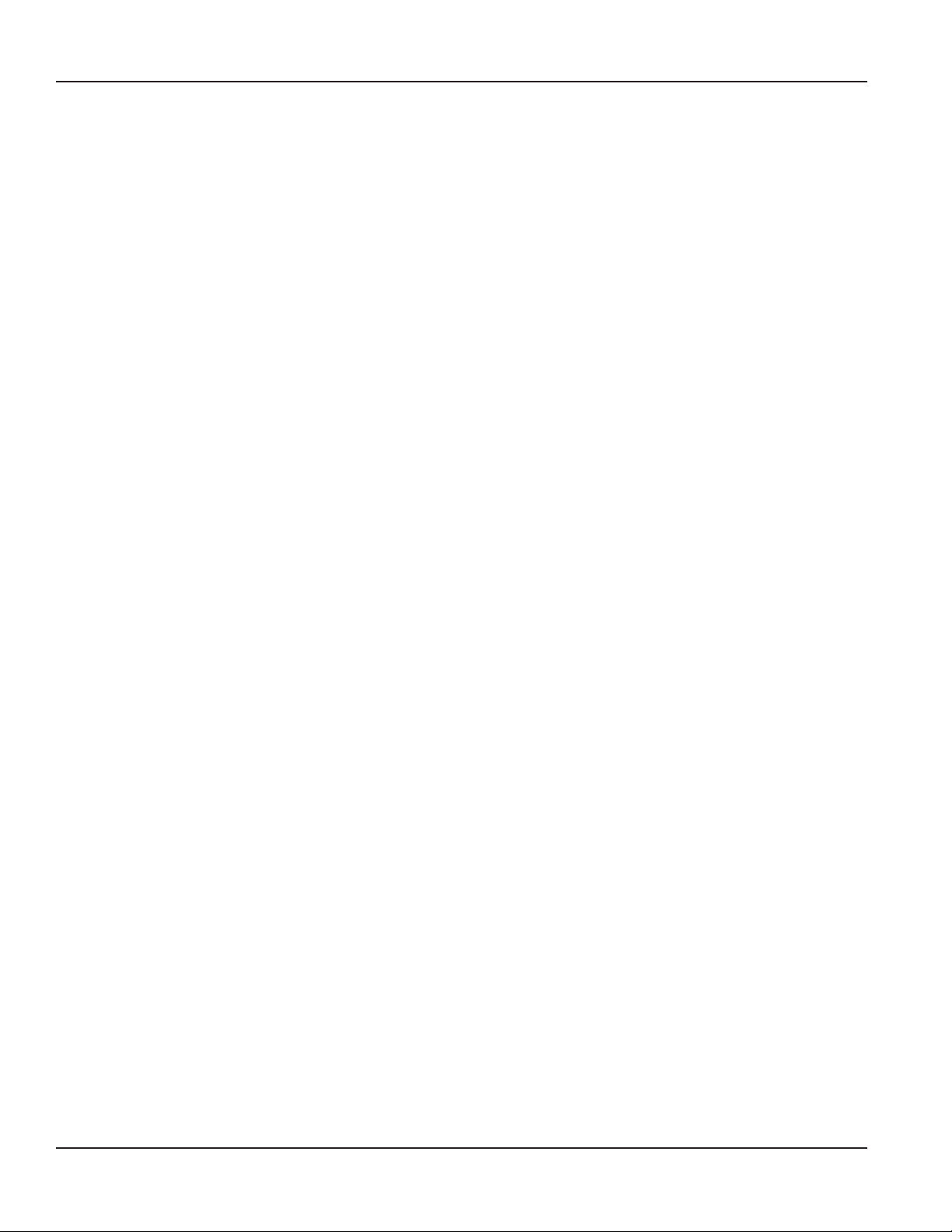

Transit time flow meters measure the time difference between the travel time of an ultrasound wave going with the fluid

flow and against the fluid flow. The time difference is used to calculate the velocity of the fluid traveling in a closed-pipe

system. The transducers used in transit time measurements operate alternately as transmitters and receivers. Transit time

measurements are bi-directional and are most effective for fluids that have low concentrations of suspended solids and are

sonically conductive.

Figure 1: Meter operation

An ultrasonic meter equipped with heat flow capabilities measures the rate and quantity of heat delivered or removed from

devices such as heat exchangers. By measuring the volumetric flow rate of the heat exchanger liquid, the temperature at the

inlet pipe and the temperature at the outlet pipe, the energy usage can be calculated.

By applying a scaling factor, this heat flow measurement can be expressed in various units (Btu, Watts, Joules, Kilowatts

and others).

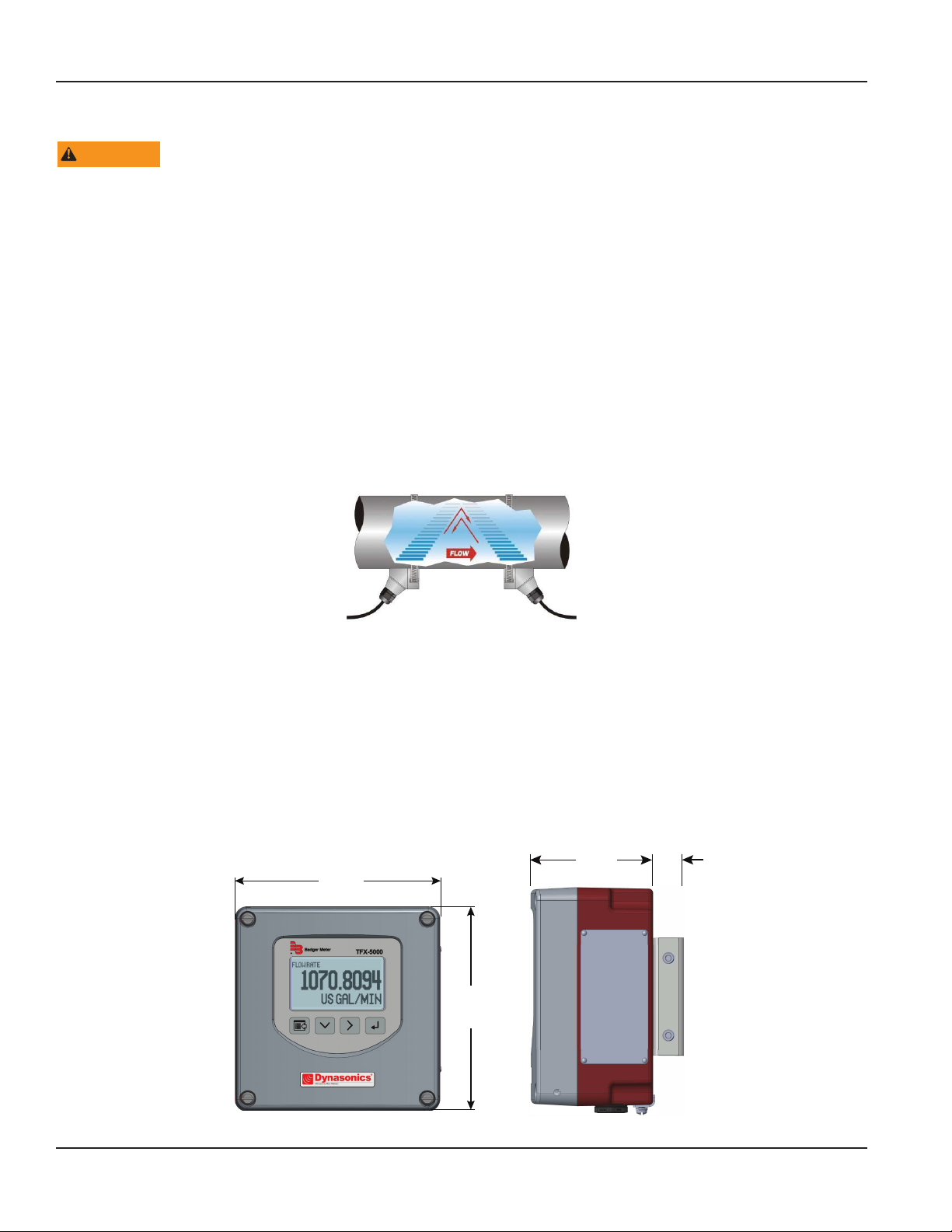

DIMENSIONS

OTE: N Installation instructions begin on page 10.

Remote Enclosure

Torque the

cover screws

to 45 in-lb.

6.50 in.

(165.10 mm)

3.63 in.

(92.20)

6.50 in.

(165.10 mm)

0.90 in.

(22.86 mm)

Figure 2: Remote mount enclosure dimensions

Page 6 July 2020TTM-UM-02222-EN-10

Page 7

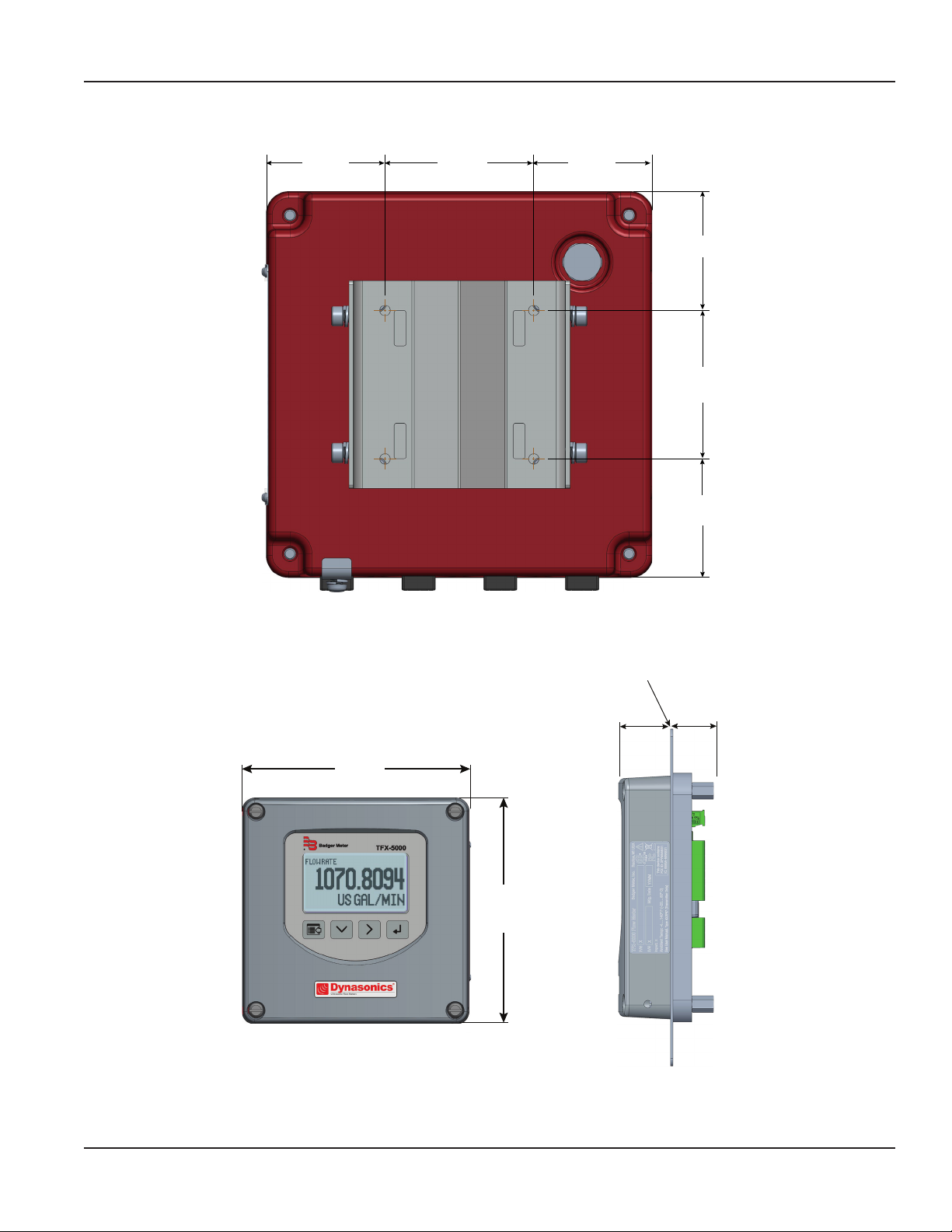

Wall Mount Bracket

Dimensions

2.00 in.

(50.80 mm)

2.50 in.

(63.50 mm)

2.00 in.

(50.80 mm)

Figure 3: Wall mount enclosure dimensions

2.00 in.

(50.80 mm)

2.50 in.

(63.50 mm)

2.00 in.

(50.80 mm)

Panel Mount Enclosure

Torque the

cover screws

to 45 in-lb.

6.50 in.

(165.10 mm)

Figure 4: Panel mount enclosure dimensions

6.50 in.

(165.10 mm)

1.38 in.

(35.05 mm)

Customer-supplied panel

1.25 in.

(31.75 mm)

Page 7 July 2020 TTM-UM-02222-EN-10

Page 8

Operation

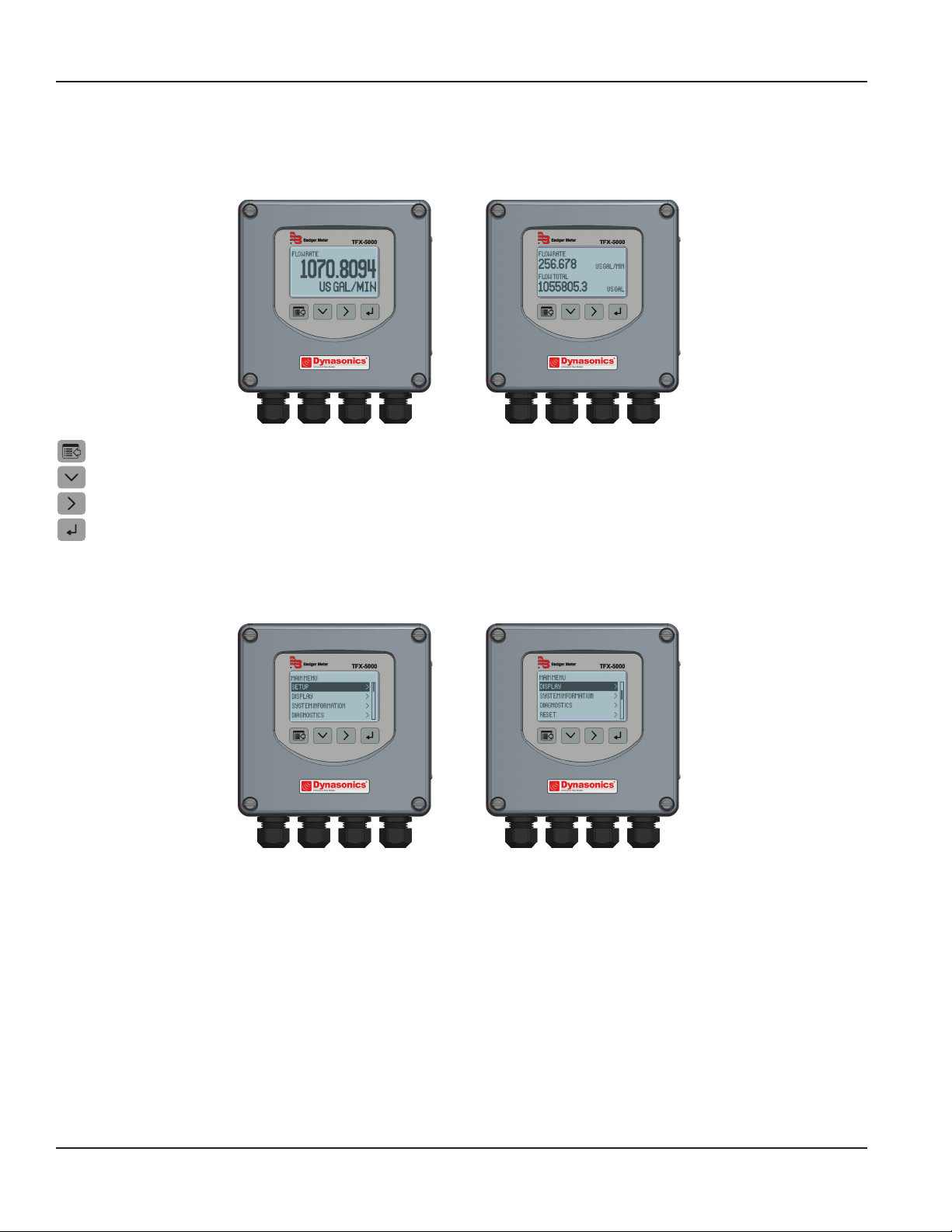

OPERATION

Keypad Operation on the Home Screen

The MENU/BACK key enters menu structure.

The DOWN ARROW key toggles between flow rate, flow total, velocity and flow rate with flow total.

The RIGHT ARROW key has no function.

The ENTER key has no function.

Keypad Operation in the Menu Structure

The cursor bar highlights the submenu or parameter that will be viewed or edited. The scroll bar on the right indicates the

relative position the cursor bar is at on the list when there are more than 4 items.

• MENU/BACK returns to parent menu (up a level). If at the Main (top level) menu, returns to the Home Screen.

• DOWN ARROW scrolls the list.

• RIGHT ARROW and ENTER have the same function in the menu structure and advance to the submenu or to

read/edit a parameter.

Page 8 July 2020TTM-UM-02222-EN-10

Page 9

Operation

Selecting an Option in a Parameter Selection List

The active option in the parameter list has a filled-in box on the left side. The scroll bar on the right indicates the relative

position the cursor bar is at on the list when there are more than 4 items.

• DOWN ARROW scrolls the list.

• ENTER selects the option and the box on the left side fills in to show the item is selected.

• MENU/BACK exits parameter editing and returns to the parent menu (up a level).

Entering a Number

The parameter name and current value is displayed in the top portion of the screen. Edit the number on the bottom right of

the screen.

• MENU/BACK exits parameter editing and returns to parent menu (up a level). The parameter remains at the value displayed

in the top portion of the screen.

• DOWN ARROW cycles through the numbers and other options.

• RIGHT ARROW moves the cursor to the right. Once it reaches the rightmost digit or a space, the cursor moves to the

leftmost digit.

• ENTER accepts the value.

Page 9 July 2020 TTM-UM-02222-EN-10

Page 10

Installation

INSTALLATION

Overview

Each of the installation steps that follow is explained in detail on page 11 through page 12 . The actual installation

procedures differ slightly, depending on whether the transducers are fixed or adjustable.

If the transducers are fixed, you will:

1. Install the transducers.

2. Install the transmitter.

3. Wire the transmitter.

4. Program the meter.

If the transducers are adjustable, you will:

1. Install the transmitter.

2. Wire the transmitter.

3. Set up the meter (select the optimum transmission mode, enter the site information, and enter the uid and

pipe properties).

4. Install the transducers.

5. Complete the meter programming.

Installation Considerations

Mount the transmitter in a location:

• Where little vibration exists.

• That is protected from corrosive fluids.

• That is within the transmitters ambient temperature limits:

–4…140° F (–20…60° C); relative humidity 0…85%, non-condensing; altitude 2000 m max.

• That is out of direct sunlight. Direct sunlight may increase transmitter temperature above the maximum limit.

• That protects the oleophobic vent from materials that may plug or seal the vent.

Equipment Required

• Screwdrivers, wide blade and tiny blade (for securing wires to the terminal blocks)

• User manual for the transducers

• Four #8 or M4 screws, if mounting the transmitter on a wall

• Stainless steel banding straps, if mounting the transmitter on a pipe

Installing the Transducers

See the user manual for your particular transducer for installation instructions.

Page 10 July 2020TTM-UM-02222-EN-10

Page 11

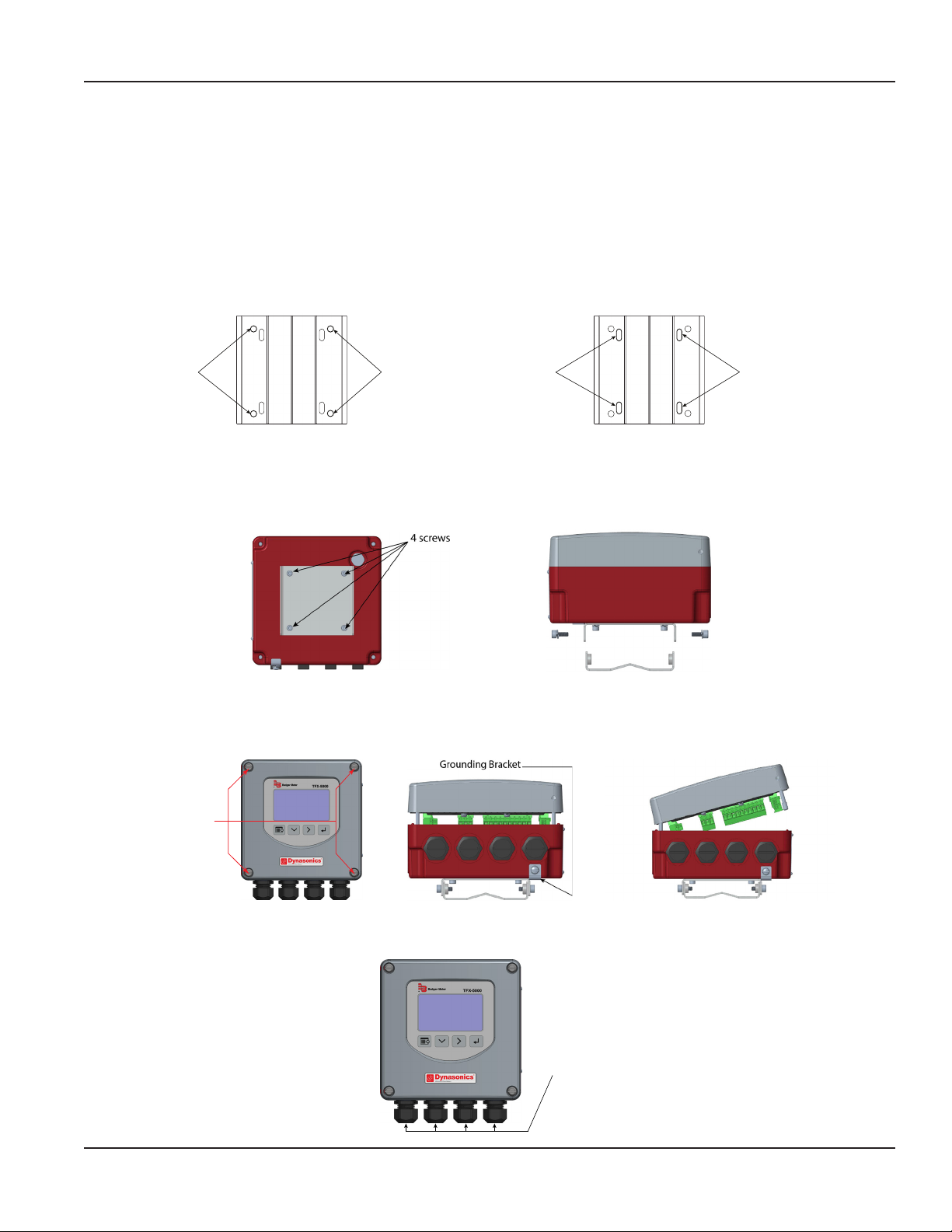

Wall Mounting

Wall Mounting

Installation

Installing a Meter with a Remote Transmitter and Fixed Transducers

• Locate the transmitter within the length of the transducer cables supplied or exchange the cable for one of proper length.

• See Figure 2 on page 6 for enclosure and mounting dimension details. Allow enough room for door swing, maintenance

and conduit entrances.

MPORTANTI

When routing wires to the transmitter, make sure the cables are not twisted, pinched or hanging loosely.

1. Install the xed transducers according to instructions in the transducer user manual.

2. Attach the mounting bracket to a wall (with 4 customer-supplied #8 or M4 screws, see “Wall Mount Bracket” on page7

for dimensions) or to a pipe (with mounting straps).

Holes for

Screws for

Figure 5: Wall mount Figure 6: Pipe Mount

Holes for

Screws for

Slots for

Straps for

Pipe Mounting

Slots for

Straps for

Pipe Mounting

3. Align the transmitter's bracket with the mounted bracket. Use a 4 mm hex tool to secure the 4 provided screws from the

sides through the mating holes. See Figure 8.

4. If necessary, you can rotate the mounting bracket in 90° increments to accommodate the nal orientation of the

transmitter. From inside the enclosure, remove the 4 screws holding the bracket. Rotate the bracket and replace the

screws. See Figure 7.

Figure 7: Rotatable adapter plate Figure 8: Secure the bracket

5. Insert a wire for earth ground under the grounding bracket (see Figure 10) and screw it down tight.

6. Partially loosen the 2 enclosure captive screws on the left side of the transmitter cover. Completely loosen the 2 screws on

the right side. Grasp and lift the cover and open it to the left. The cover remains attached and the left screws act as a hinge.

Unscrew

Captive Screws

Figure 9: Captive cover screws Figure 10: Lift cover from base Figure 11: Open cover to the left

7. Use conduit holes where cables enter the enclosure from the bottom. Use suitably certied plugs to seal any holes that are

not used for cable entry. A cable gland kit is included for inserting the transducer and power cables.

1/2 in. NPT,

1/2 in. BSPP, or

M20 Threads

Figure 12: Conduit holes

Page 11 July 2020 TTM-UM-02222-EN-10

Page 12

Wall Mounting

Wall Mounting

Installation

OTE: N Use suitably certied fittings/plugs to maintain the watertight integrity of the enclosure. Generally, the right conduit

hole (viewed from front) is used for power, the left conduit hole for transducer connections, and the center holes are

used for I/O wiring.

8. Install the wires through the gland nuts and connect the wires to the removable terminal blocks. See “Wiring the

Transmitter” on page14.

9. Wire the transducers to the transmitter.

10. Plug the wired terminal blocks into the main board.

11. Reassemble the cover. Torque the cover screws to 45 in-lb.

12. Set up the meter. See “Initial Meter Setup” on page21 for instructions.

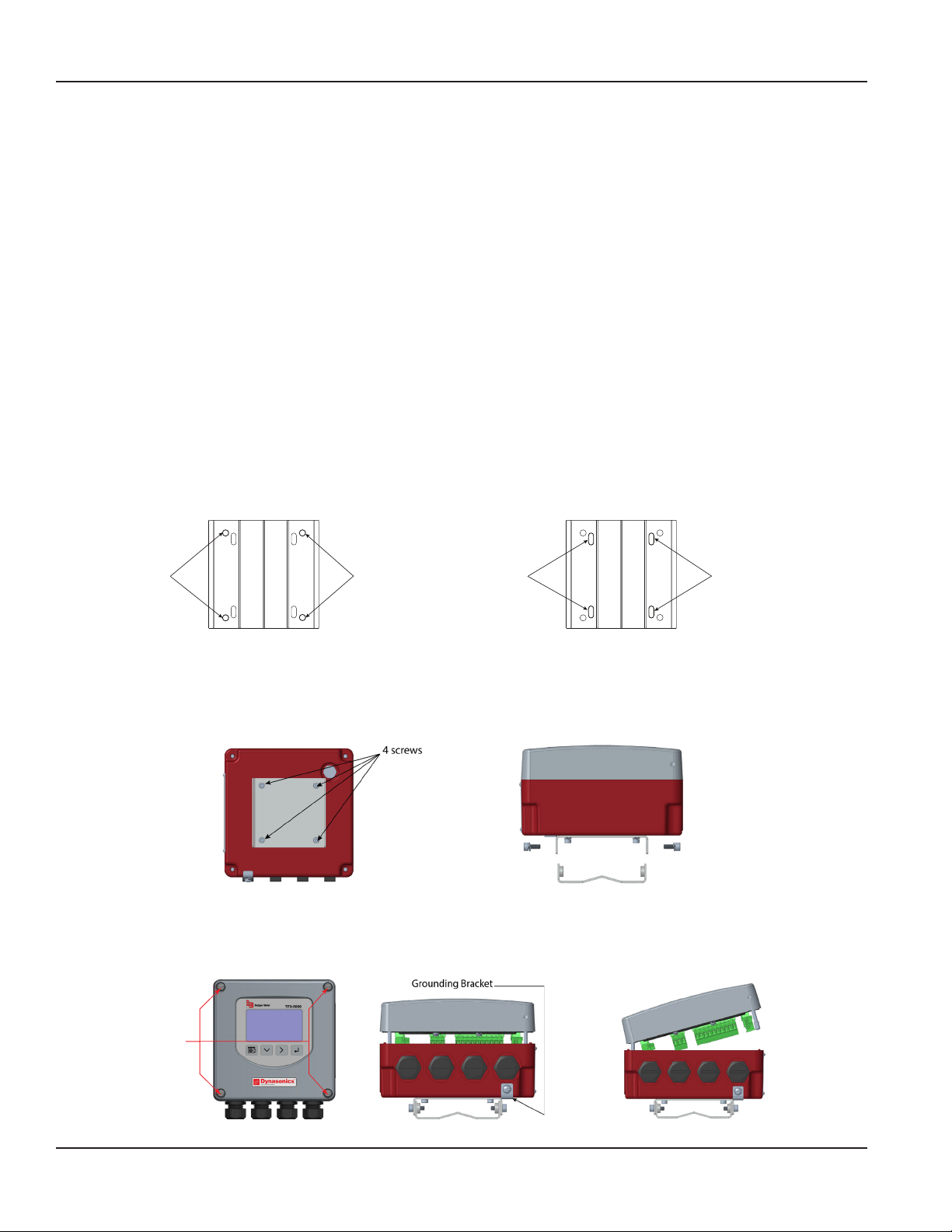

Installing a Meter with a Remote Transmitter and Adjustable Transducers

• Locate the transmitter within the length of the transducer cables supplied or exchange the cable for one of proper length.

• Install the transducers after entering the pipe settings into the transmitter and determining the spacing and

mounting method.

• See Figure 2 on page 6 for enclosure and mounting dimension details. Allow enough room for door swing, maintenance

and conduit entrances.

MPORTANTI

When routing wires to the transmitter, make sure the cables are not twisted, pinched or hanging loosely.

1. Attach the mounting bracket to a wall (with 4 customer-supplied #8 or M4 screws, see “Wall Mount Bracket” on page7

for dimensions) or to a pipe (with mounting straps).

Holes for

Screws for

Figure 13: Wall mount Figure 14: Pipe Mount

Holes for

Screws for

Slots for

Straps for

Pipe Mounting

Slots for

Straps for

Pipe Mounting

2. Align the transmitter's bracket with the mounted bracket. Use a 4 mm hex tool to secure the 4 provided screws from the

sides through the mating holes. See Figure 16.

3. If necessary, you can rotate the mounting bracket in 90° increments to accommodate the nal orientation of the

transmitter. From inside the enclosure, remove the 4 screws holding the bracket. Rotate the bracket and replace the

screws. See Figure 15.

Figure 15: Rotatable adapter plate Figure 16: Secure the bracket

4. Insert a wire for earth ground under the grounding bracket (see Figure 18) and screw it down tight.

5. Partially loosen the 2 enclosure captive screws on the left side of the transmitter cover. Completely loosen the 2 screws on

the right side. Grasp and lift the cover and open it to the left. The cover remains attached and the left screws act as a hinge.

Page 12 July 2020TTM-UM-02222-EN-10

Unscrew

Captive Screws

Figure 17: Captive cover screws Figure 18: Lift cover from base Figure 19: Open cover to the left

Page 13

Installation

6. Use conduit holes where cables enter the enclosure from the bottom. Use suitably certied plugs to seal any holes that are

not used for cable entry. A cable gland kit is included for inserting the transducer and power cables.

1/2 in. NPT,

1/2 in. BSPP, or

M20 Threads

Figure 20: Conduit holes

OTE: N Use suitably certied fittings/plugs to maintain the watertight integrity of the enclosure. Generally, the right conduit

hole (viewed from front) is used for power, the left conduit hole for transducer connections, and the center holes are

used for I/O wiring.

7. Install the wires through the gland nuts and connect the wires to the removable terminal blocks. See “Wiring the

Transmitter” on page14.

8. Set up the meter. See “Initial Meter Setup” on page21 for instructions.

9. Install the adjustable transducers according to instructions in the transducer user manual.

10. Wire the transducers to the transmitter.

11. Plug the wired terminal blocks into the main board.

12. Reassemble the cover. Torque the cover screws to 45 in-lb.

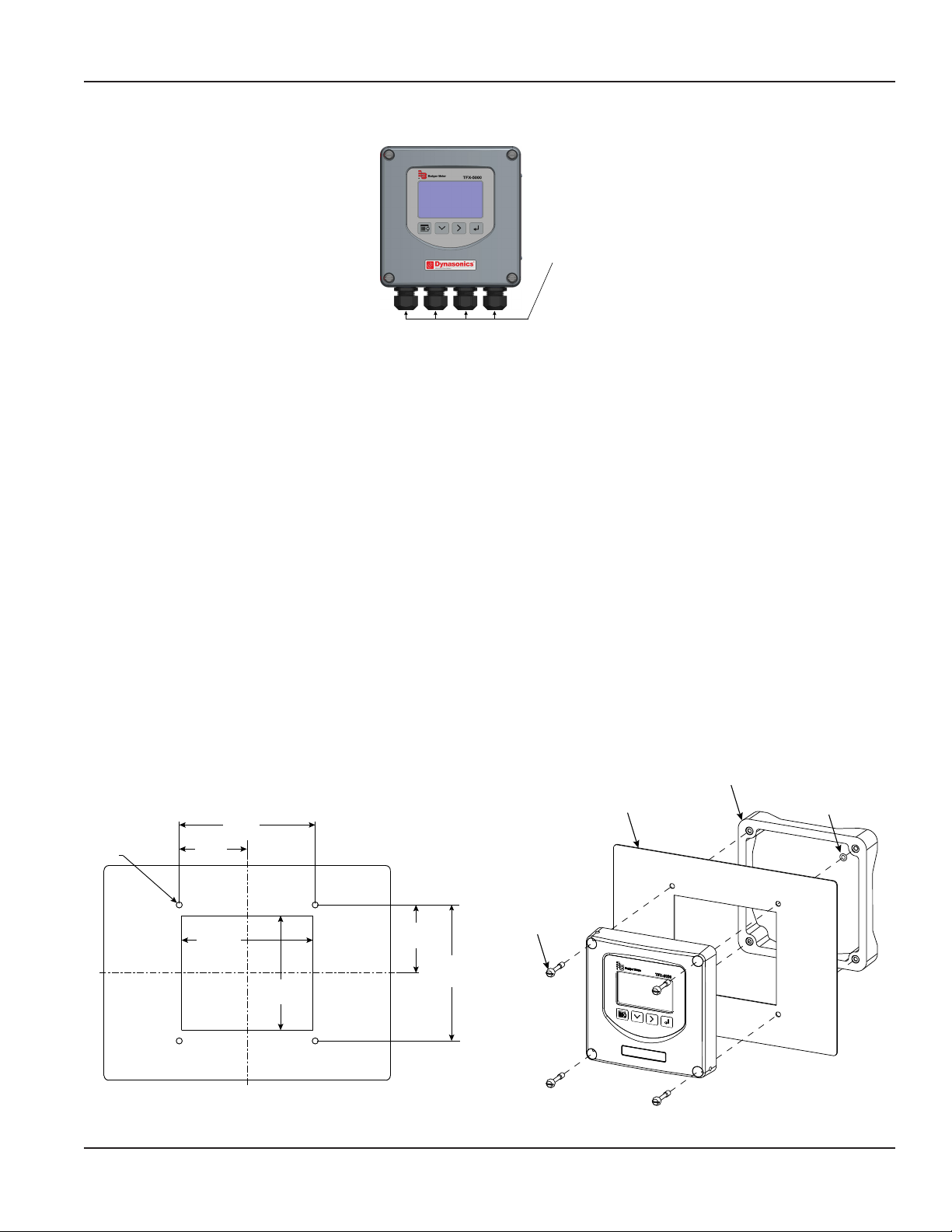

Installing a Panel-Mount Meter

1. Measure and cut a mounting hole into the customer-supplied panel to the dimensions shown in Figure 21.

2. Remove the 4 screws and 4 O-rings holding the front of the unit to the frame.

3. Verify that the gasket is secure in the mounting bezel.

4. Guide the front of the unit through the panel cutout.

5. Insert the 4 screws through the front of the unit and the panel.

6. Apply one O-ring to each screw from the back of the panel.

7. Align the front of the unit to the frame.

8. Tighten the 4 screws and torque them to 45 in-lb.

Frame

Customer-supplied panel

Ø 0.252 in. thru

typ.

(144.78 mm)

2.85 in.

(72.93 mm)

5.50 in.

(139.70 mm)

5.70 in.

4.80 in.

(121.92 mm)

2.85 in.

(72.39 mm)

(144.78 mm)

Screws (×4)

5.70 in.

O-rings (×4)

Figure 21: Panel cutout dimensions and installation exploded view

Page 13 July 2020 TTM-UM-02222-EN-10

Page 14

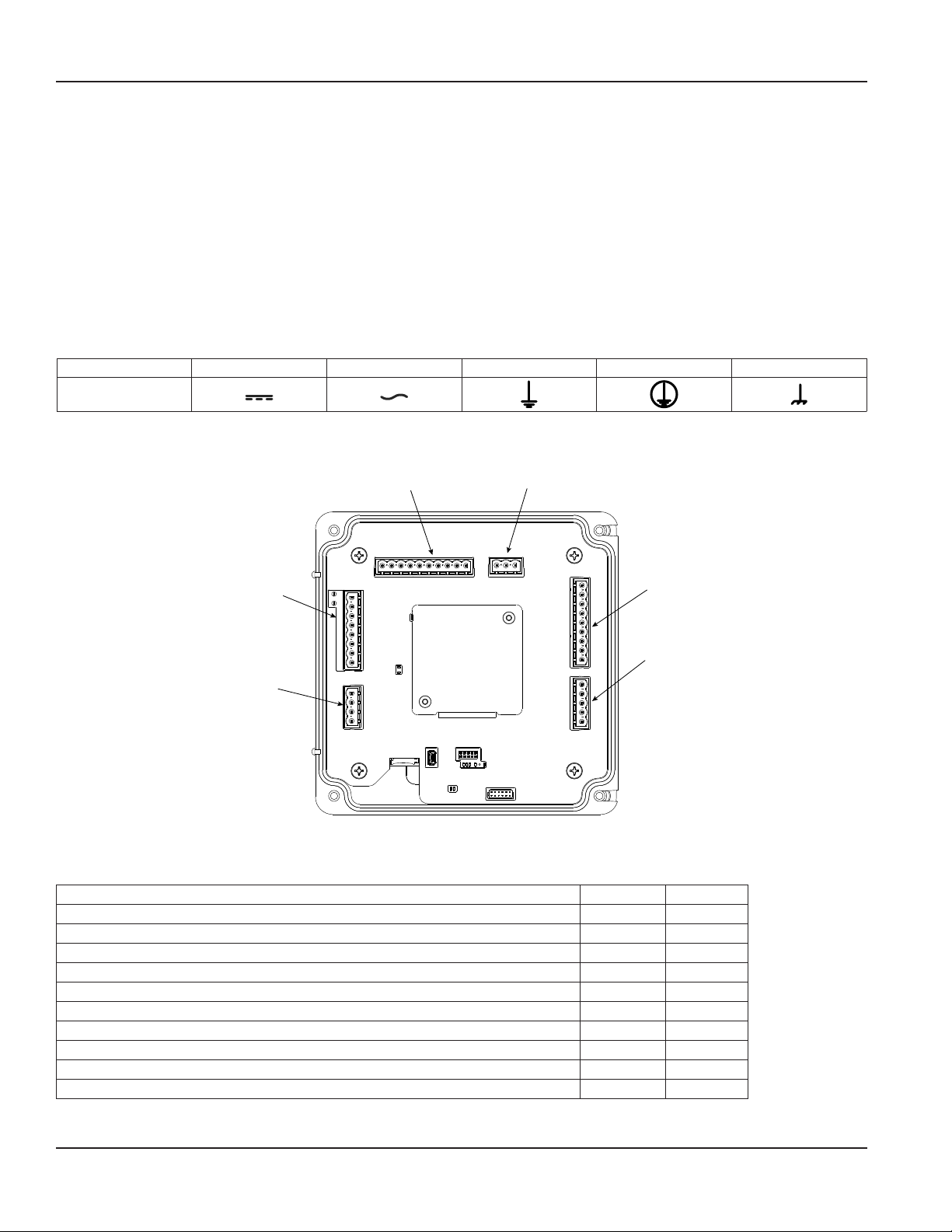

TB400

Wiring the Transmitter

WIRING THE TRANSMITTER

IMPORTANT: Select field wiring means rated for 5° C above the maximum area temperature when it is possible that the

temperature will exceed 55° C.

To access terminal strips for wiring, loosen the 4 enclosure captive screws. Grasp and lift the cover and open it to the left. The

cover remains attached and the left screws act as a hinge.

Torque Requirements

The tightening torque requirements for the screw connections of the plug-in terminals are 4.4 lb-in. (0.5 Nm) minimum to

5.3 lb-in. (0.6 Nm) maximum.

Electrical Symbols

Function Direct Current Alternating Current Earth (Ground) Protective Ground Chassis Ground

Symbol

Figure 22: Electrical symbols

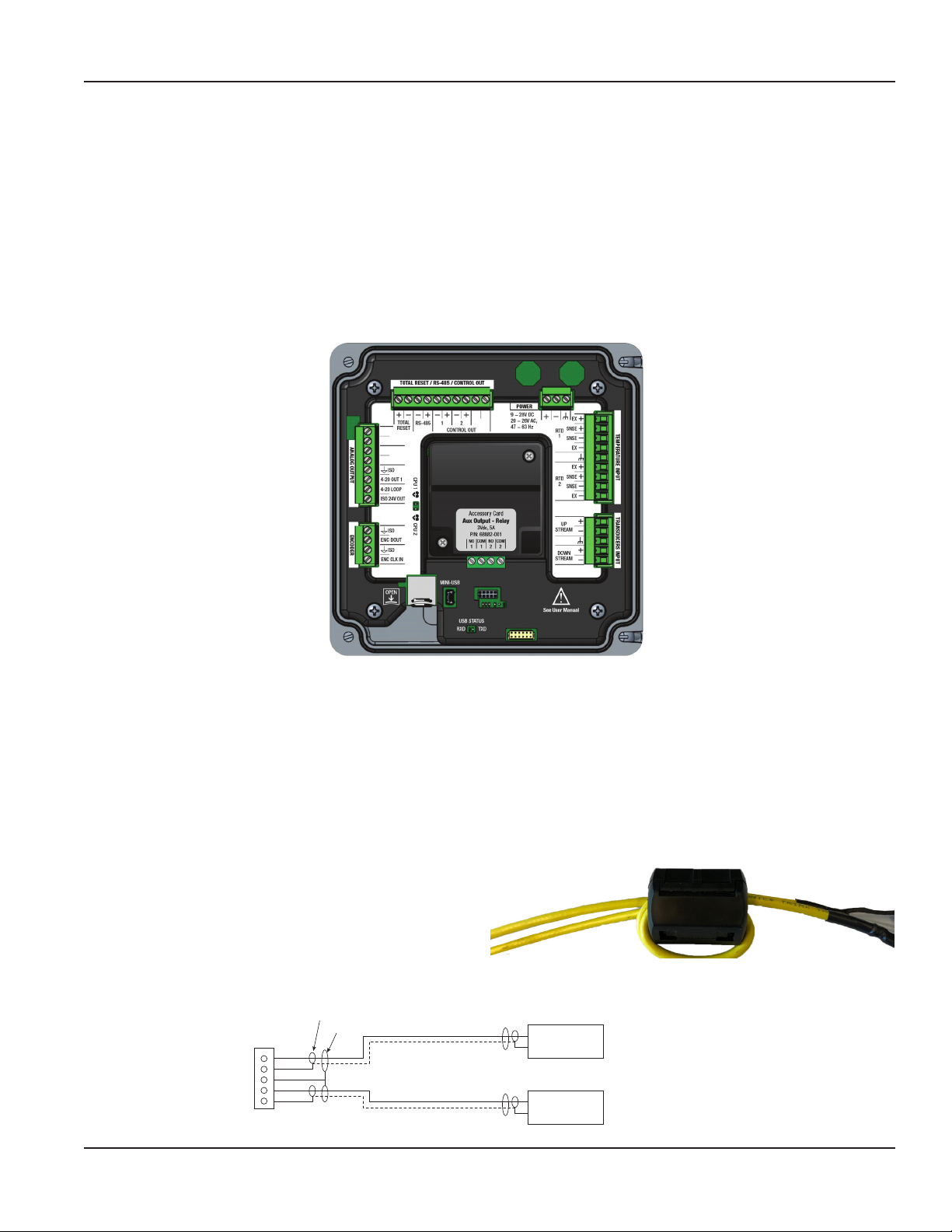

TB600

Analog

Output

Connector

TB500

BEACON/

AquaCUE

Endpoint

TB700

Digital I/O

Connector

CPU

LEDs

MicroSD

Card Holder

Figure 23: Wiring connectors

USB Mini B

Connector

Accessory

Card

Power

Connector

TB900

RTD

Connector

TB300

Transducer

Connection Data

Description Minimum Maximum

Conductor cross section solid 0.2 mm² 2.5 mm²

Conductor cross section flexible 0.2 mm² 2.5 mm²

Conductor cross section flexible, with ferrule without plastic sleeve 0.25 mm² 2.5 mm²

Conductor cross section flexible, with ferrule with plastic sleeve 0.25 mm² 2.5 mm²

Conductor cross section AWG 24 12

2 conductors with same cross section, solid 0.2 mm² 1 mm²

2 conductors with same cross section, stranded 0.2 mm² 1.5 mm²

2 conductors with same cross section, stranded, ferrules without plastic sleeve 0.25 mm² 1 mm²

2 conductors with same cross section, stranded, TWIN ferrules with plastic sleeve 0.5 mm² 1.5 mm²

AWG according to UL/CUL 30 12

Page 14 July 2020TTM-UM-02222-EN-10

Page 15

Rated Conditions of Terminals

• Mains AC 85…264V AC

Wire 18…12 AWG UL AWM 1007 Type 1007

• 9…28V DC, 20…26V AC

Wire 20 AWG UL AWM 1007 Type 1007

• Transducer Cables

Badger Meter supplied cable

• Digital Outputs/Inputs, Current Output, RS485, RTD or Encoder Interface

• Wire 28…12 AWG UL AWM 1007 Type 1007

Wiring the Transducer

Wiring the Transmitter

Figure 24: Wiring connections

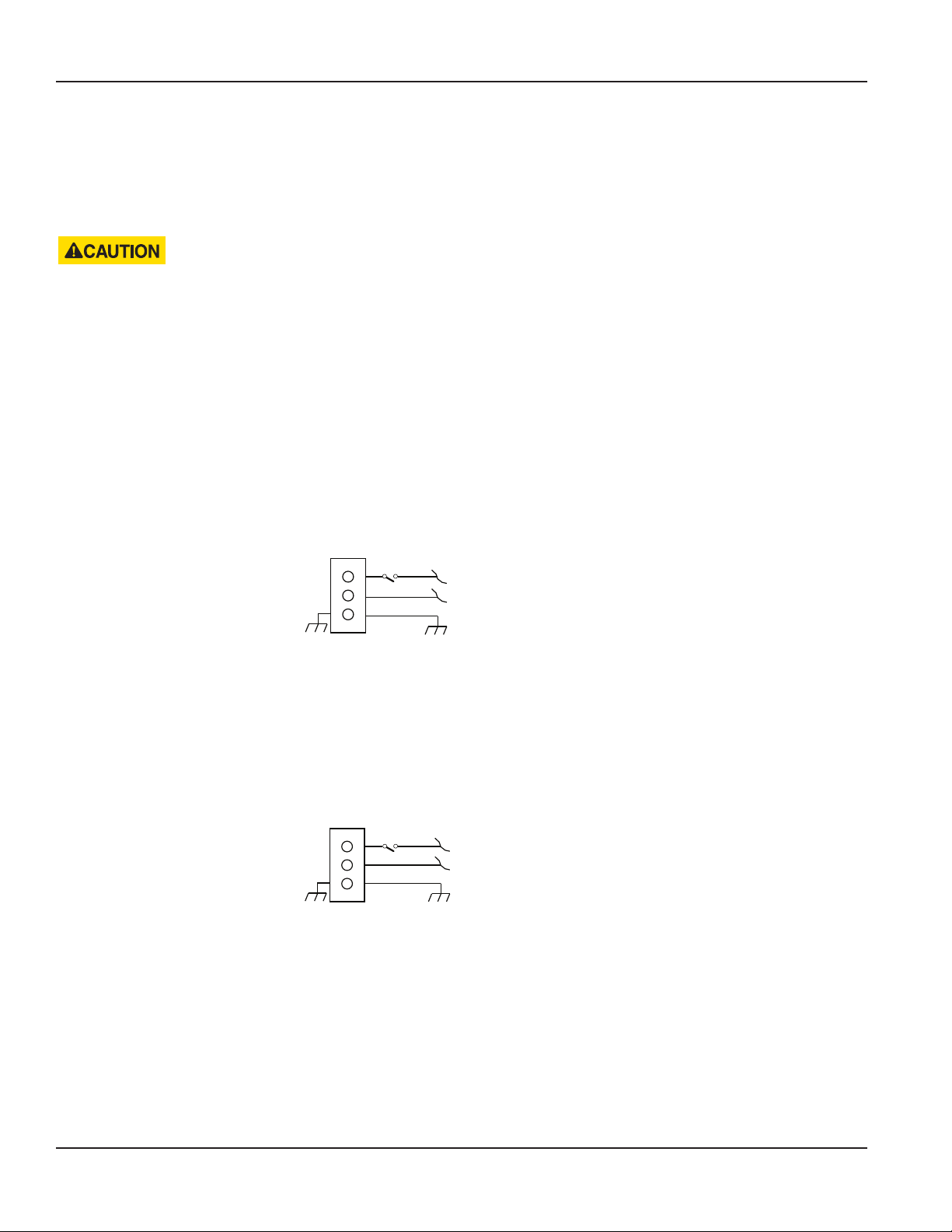

OTE: N Submersible transducer cables are larger diameter. Each cable requires a separate conduit hole. The standard yellow

cable and high temperature cables are small enough to use a single cable gland with a 2-hole grommet.

OTE: N Transducer cables have two wire-color combinations. For the blue and white combination, the blue wire is positive

(+) and the white wire is negative (–). For the red and black combination, the red wire is positive (+) and the black

wire is negative (–). The transducer wires are labeled to indicate which pair is upstream or downstream.

1. Guide the transducer terminations through a conduit hole in the bottom of the enclosure.

2. Secure the transducer cable with the supplied conduit nut (if exible conduit was ordered with the transducer).

3. Install the ferrite to the cable:

a. To open the ferrite, pull the fastener away from the

body of the ferrite.

b. Wrap the cable tightly around half of the ferrite and

place the cable into the groove.

c. Snap the ferrite shut.

4. The terminals within the transmitter are screw-down barrier terminals. Connect the wires at the corresponding screw

terminals in the transmitter. Observe upstream and downstream orientation and wire polarity. See Figure 25.

TB300

Red

Black

Green (2)

Red

Black

Inner Shield

Outer Shield

Upstream+

Upstream-

69039, Triax Cable

Downstream+

Downstream-

Transducer

Figure 25: Upstream/downstream transducer

Page 15 July 2020 TTM-UM-02222-EN-10

Page 16

Wiring the Transmitter

Power

Connect power to the screw terminal block in the transmitter.

• Low voltage power can use any available conduit hole in the enclosure.

• Line voltage AC power must use the right conduit hole, which is aligned with the terminal block on the AC power board.

• Use wiring practices that conform to local and national codes such as The National Electrical Code Handbook in the U.S.

ANY OTHER WIRING METHOD MAY BE UNSAFE OR CAUSE IMPROPER OPERATION OF THE TRANSMITTER.

OTE: N This transmitter requires clean electrical line power. Do not operate this transmitter on circuits with noisy

components (such as fluorescent lights, relays, compressors, or variable frequency drives). Do not use step-down

transformers from high voltage, high amperage sources. Do not to run signal wires with line power within the same

wiring tray or conduit.

9…28V DC Power

The transmitter may be operated from a 9…28V DC source, as long as the source supplies a maximum of 8 Watts of power.

Connect the DC power to 9…28V DC In, power return, and chassis ground, as in Figure 26.

OTE: N DC-powered transmitters are protected from major catastrophe with an internal 2.0 Amp slow-blow fuse. If this fuse

is blown, replace the transmitter or return it to the factory for repair.

IMPORTANT: A Class II DC power supply is required.

TB400

+

-

Switch

or

Circuit

Breaker

Chassis Ground

Figure 26: Power supply 9…28V DC

External Equipment

Power Supply (9 . . . 28V DC)

Power Supply (Return)

(Acceptable wire sizes: 28…12 AWG)

20…26V AC Power

The transmitter may be operated from a 20…26V AC source, as long as the source supplies a maximum of 8 Watts of power.

Connect the AC power to 20…26V AC In, power return, and chassis ground, as in Figure 27.

OTE: N 24V AC powered transmitters are protected from major catastrophe with an internal 2.0 Amp slow-blow fuse. If this

fuse is blown, replace the transmitter or return it to the factory for repair.

TB400 External Equipment

+

-

Switch

or

Circuit

Breaker

Chassis Ground

Figure 27: Power supply 20…28V AC

Power Supply (20 . . . 26V AC)

Power Supply (Return)

(Acceptable wire sizes: 28…12 AWG)

Page 16 July 2020TTM-UM-02222-EN-10

Page 17

Wiring the Transmitter

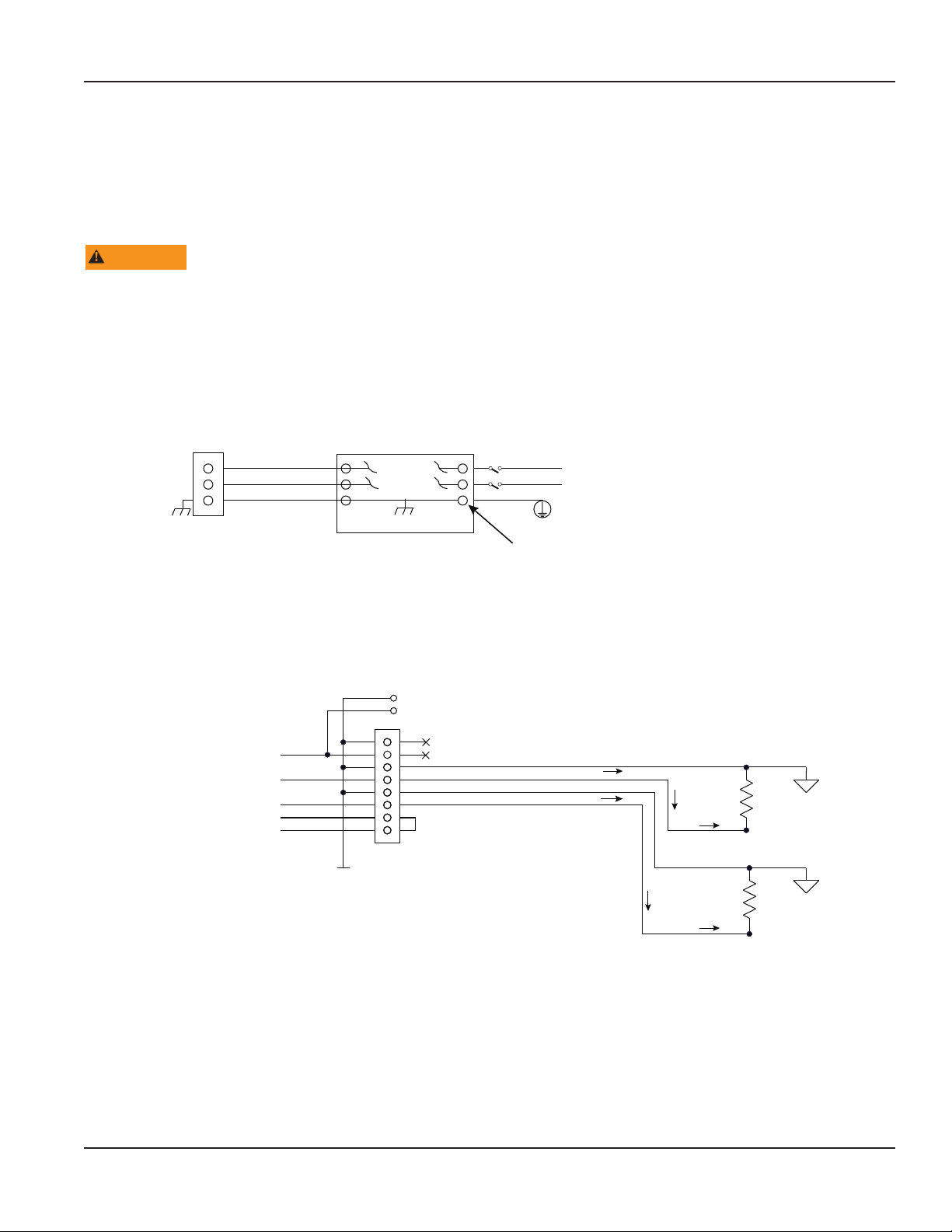

Mains Power

IMPORTANT: The measuring device does not have an internal circuit breaker. For compliance with IEC 61010-1, a switch in close

proximity to the transmitter is required so that the power supply line can be easily disconnected from the mains.

The transmitter may be operated from 90…250V AC, 47…63 Hz, 24VA maximum power source.

OTE: N Mains AC-powered transmitters are protected with 1A, 250V AC, 5×20 mm, slow-blow, field-replaceable fuse.

WARNING

TO PREVENT SHORTING OUT THE MAINS AC POWER, YOU MUST REPLACE THE TERMINAL BLOCK COVER ON THE AC

MODULE AFTER WIRING THE POWER.

Remove the terminal block covers before wiring and replace them after wiring:

1. Grasp the sides of the cover and gently pull it up.

2. Insert wires into the slots on the cover and screw them down to secure.

3. Align the cover in its original orientation over the terminal block and push down to connect.

TB400 External 85…264V

+

-

Factory Wired

AC-DC Power Module

(24VA max.)

Red

Black

Green

24V DC

0V DC

Chassis Ground

AC-L

AC-N

.

Connect protective earth conductor to terminal 3.

TB100

1

2

3

Switch

or

Circuit

Breaker

85 . . . 264V AC

Return

(Main power wiring must be of material

VW-1 or better.)

(Acceptable wire sizes: 18…12 AWG)

Protective

Ground

Figure 28: AC/DC power connections

4…20 mA Output Wiring

The 4…20 mA output transmits an analog current signal that is proportional to system flow rate. The 4…20 mA output can be

internally or externally powered and can span negative to positive flow rates.

Both current loops are ISOLATED from DC GND or Power.

ISO_GND

TP605

TP604

TB600

Black

Red

8

7

6

5

4

3

2

1

No Connect

No Connect

4…20 OUT 2 Current #2 Output

4…20 OUT 1 Current #1 Output

(Acceptable wire sizes: 28…12 AWG)

External Equipment

800 Ohms max.

Power Supply

Common

800 Ohms max.

NOTE: 4…20 OUT 2 available

with Energy model only.

Figure 29: Typical 4 . . . 20 mA interface using internal isolated 24V DC source

Page 17 July 2020 TTM-UM-02222-EN-10

Page 18

Wiring the Transmitter

NOTE: 4…20 OUT 2 available

with Energy model only.

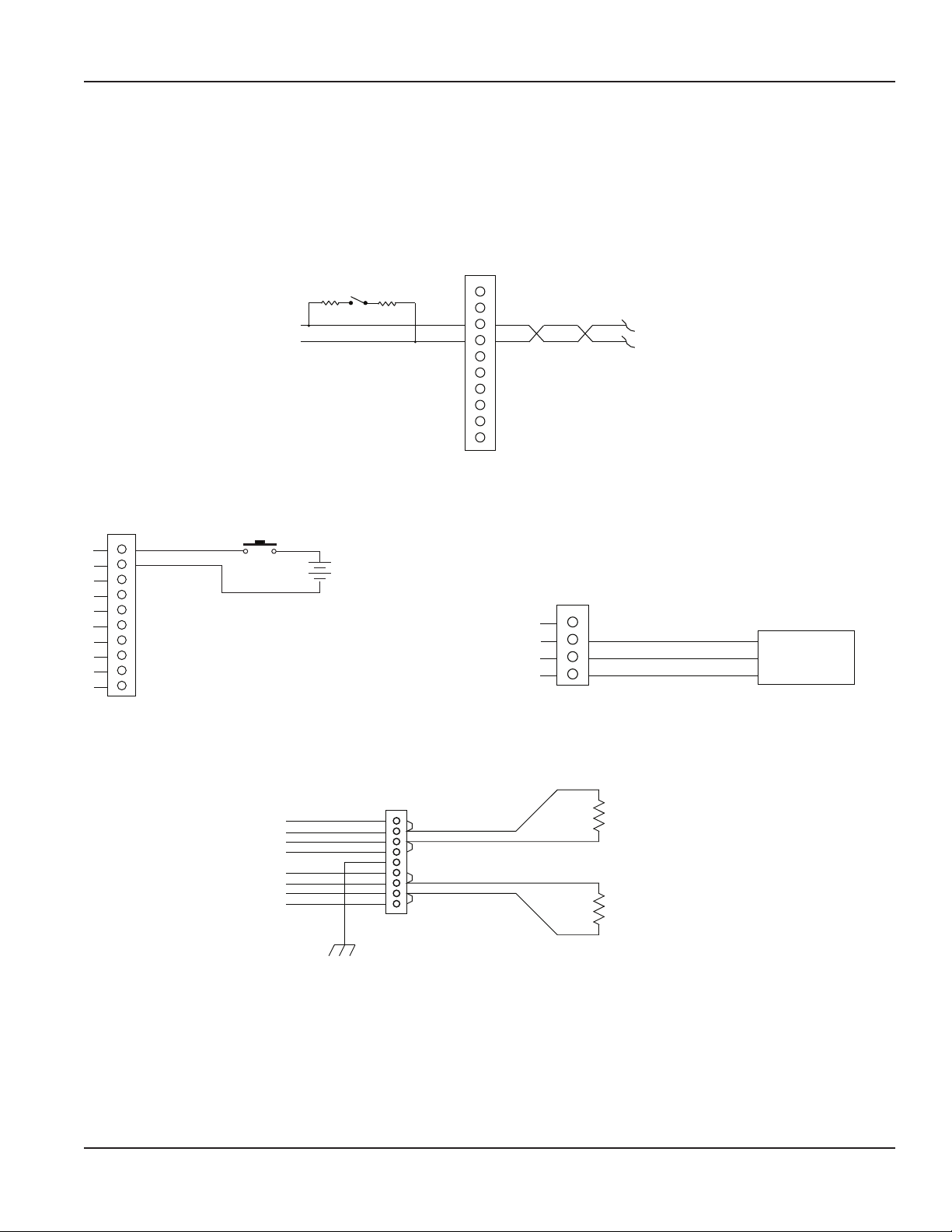

Digital Outputs Wiring

NOTE: Control Output 3

available with Energy

model only.

TP605

Black

TP604

Red

8

No Connect

7

No Connect

TB600

6

5

4

3

2

1

4…20 OUT 2 Current #2 Output

4…20 OUT 1 Current #1 Output

+24V DC Source In

No Connect

(Acceptable wire sizes: 28…12 AWG)

ISO_GND

Figure 30: Typical 4 . . . 20 mA interface using external isolated 24V DC source

ISO 24V

10k

TB700

External Equipment

800 Ohms max.

Power Supply

Common

800 Ohms max.

Power

TYP 24V DC

ISO_GND

NOTE: Control Output 3

available with Energy

model only.

10 Ohms

50 mA max. Sink

ISO_GND

10 Ohms

R12

R12

(Acceptable wire sizes: 28…12 AWG)

Figure 31: Typical control out 1, 2 and 3 interface with internal pullups active

Control Output #1

Control Output #2

Control Output #3

ISO_GND

(Acceptable wire sizes: 28…12 AWG)

Figure 32: Typical control out 1, 2 and 3 interface with external pullups passive

Control Output #1

Control Output #2

Control Output #3

ISO_GND

ISO_GND

TB700

5

6

7

8

9

10

5

6

7

8

9

10

IF REQUIRED

IF REQUIRED

IF REQUIRED

IF REQUIRED

External Equipment

External Equipment

V DC (5 . . . 30V DC)

R-Pullup

R-Pullup

R-Pullup

Control Output #1

Control Output #2

Control Output #3

Control Output #1

Control Output #2

Control Output #3

Page 18 July 2020TTM-UM-02222-EN-10

Page 19

Wiring the Transmitter

RS485 Output

The RS485 feature allows up to 126 transmitters to be placed on a single three-wire cable up to 4000 feet. All transmitters are

assigned a unique numeric address that allows all of the transmitters on the cable network to be independently accessed.

Either Modbus RTU or BACnet MS/TP protocol is used to interrogate the transmitters.

Flow rate and total can be monitored over the digital communications bus.

When a USB programming cable is connected, the RS485 and frequency outputs are disabled.

Terminator Resistors

(Enabled through Parameter Setting)

60.4 Ohms

60.4 Ohms

A B

TB700

3

4

External Equipment

RS485 +

RS485 −

Figure 33: Typical RS485 interface

Digital Input Wiring AquaCUE/BEACON Endpoint Wiring

1

2

3

4

5

6

7

8

9

10

TB700

Reset Total +

Reset Total -

Push-button

5…30V DC

TB500

4

3

2

1

NOTE: Non-isolated

Endpoint Data Pulse Out (Green Wire)

DGND (Black Wire)

Endpoint VccClk In (Red Wire)

(Acceptable wire sizes: 28…12 AWG)

AquaCUE/BEACON

Endpoint

Figure 34: Digital input—reset totalizer Figure 35: AquaCUE/BEACON wiring

RTD Interface Wiring (Energy Models Only)

TB900

RTD1 Ex +

RTD1 Sense +

RTD1 Sense RTD1 Ex -

RTD2 Ex +

RTD2 Sense +

RTD2 Sense RTD2 Ex -

Chassis_GND

1

2

3

4

5

6

7

8

9

(Acceptable wire sizes: 28…12 AWG)

Figure 36: Two-wire RTD interface

External Equipment

Temp #1

PT100 or PT1000 RTDs

Temp #2

Page 19 July 2020 TTM-UM-02222-EN-10

Page 20

Wiring the Transmitter

(NOTE: Italicized wire colors

TB900

apply to Badger Meter PN 68996.)

RTD1 Ex +

RTD1 Sense +

RTD1 Sense RTD1 Ex -

RTD2 Ex +

RTD2 Sense +

RTD2 Sense RTD2 Ex -

Chassis_GND

1

2

3

4

5

(Black)

6

7

8

9

(Acceptable wire sizes: 28…12 AWG)

Figure 30: Three-wire RTD interface Figure 37: Four-wire RTD interface

Auxiliary Output Card Wiring

AUX2 OUT

AUX1 OUT

External Equipment

(White)

(Red/Blue)

(Red)

(White)

(Red/Blue)

(Red)

44 33

Temp #1

PT100 or PT1000 RTDs

Temp #2

RTD1 Ex +

RTD1 Sense +

RTD1 Sense RTD1 Ex -

RTD2 Ex +

RTD2 Sense +

RTD2 Sense RTD2 Ex -

Chassis_GND

+V DC (30V DC, 5A max., each output)

TB100

4

3

2

1

Load 1 Load 2

Figure 38: Auxiliary output interface

TB900

1

2

3

4

5

6

7

8

9

(Acceptable wire sizes: 28…12 AWG)

Power

+

Supply

-

External Equipment

Temp #1

PT100 or PT1000 RTDs

Temp #2

Installing the MicroSD Card

WARNING

IN A HAZARDOUS LOCATION WHERE EXPLOSIVE GAS OR DUST IS PRESENT, DISCONNECT THE POWER BEFORE

OPENING THE ENCLOSURE AND INSERTING OR REMOVING THE MICROSD CARD. AFTER THE CARD IS INSERTED OR

REMOVED, CLOSE THE ENCLOSURE BEFORE REAPPLYING POWER.

1. In all locations, turn o power to the unit.

2. Remove the enclosure cover.

3. Put your nger in the groove of the tray and slide the tray downward. The tray springs open.

5. Insert the MicroSD card.

6. Slide the cover up to close.

7. Replace the enclosure cover.

Page 20 July 2020TTM-UM-02222-EN-10

Page 21

Wiring the Transmitter

Connecting the USB Cable

Use a USB cable when connecting a TFX-5000 meter to a computer with SoloCUE® Flow Device Manager software.

WARNING

DO NOT USE THE MINI USB PORT IN A HAZARDOUS LOCATION WHERE EXPLOSIVE GAS OR DUST IS PRESENT.

DO NOT OPEN THE TRANSMITTER WHILE POWERED IF WATER OR SPRAY COULD CONTACT ELECTRONICS OR INTERIOR.

1. Open the enclosure cover.

2. Connect the USB cable to the mini USB port, aligning the pins in the cable with the holes in the port.

3. Program the transmitter.

4. Remove the USB cable and close the enclosure cover.

Initial Meter Setup

You can set up the meter using the TFX-5000 keypad or the SoloCUE Flow Device Manager software. This document addresses

procedures using the TFX-5000 keypad. To use SoloCUE, see the "SoloCUE Flow Device Manager Installation Guide" available at

www.badgermeter.com.

For in-depth parameter programming, see “Parameter Descriptions by Menu” on page23.

1. Program the meter settings:

When using the keypad to set up the TFX-5000 meter to measure ow, press MENU/BACK to enter the main menu.

In the SETUP > METER menu:

a. Enter the pipe characteristics, transducer, mounting and fluid.

b. Record the calculated spacing as needed.

c. Install transducer. See the transducer user manual for instructions.

2. Check calibration:

In the SETUP > METER > CALIBRATION menu, select Field for the Factor Mode if firmware version is prior to 02.02.480. Enter

the calibration and sensor factors from the transducers into the scale factor and sensor factor value.

3. Zero the meter:

Due to different pipe characteristics, the meter must be zeroed in order to maintain accuracy. The recommended method

is to stop flow and make sure there is no flow before zeroing the meter. In situations in which that is not feasible, you may

zero the meter while the flow is steady or enter the zero manually. Based on ZERO MODE, the SET ZERO option

will be selectable.

d. If ZERO MODE is set to NO FLOW:

Check that the pipe is full of liquid and not flowing. Flow must be absolutely zero.

Securely close any valves and allow time for settling to occur.

Select SET ZERO-NO FLOW and click OK to set the new zero.

e. If ZERO MODE is set to STEADY FLOW:

Check that the pipe is full of liquid and flowing at a steady rate.

Select SET ZERO-FLOW and click OK to set the new zero.

4. Select temperature sensor (energy models only):

In the SETUP > INPUTS/OUTPUT > RTD menu, select the temperature sensor type, range and order for positive and negative

energy calculations.

5. Select units:

In the SETUP > UNITS menu, select the units and format of flow rate, total and velocity, and for energy meters the energy

rate, energy total and temperature.

6. Set up the flow settings:

In the SETUP > METER > FLOW SETUP menu, select flow direction, low and maximum flow cutoff, and minimum and

maximum signal strength.

Page 21 July 2020 TTM-UM-02222-EN-10

Page 22

Menu Map

MENU MAP

Passcode levels for write access to each menu are as follows:

NOTE:

(O) = Operator, Service or Admin

(S) = Service or Admin

(A) = Admin

If no passcode is entered, all parameters can still be read.

Press

to select

a main

menu

option.

MAIN MENU

HOME SCREEN

Flow Rate

Flow Total

Velocity

Flow Rate / Flow Total

*Energy Rate

Press

to access

this menu.

*Energy Total

*Temp #1 / Temp #2

*Energy Rate / Delta Temp

*Energy Rate / Energy Total

Time / Date

Press

to toggle

the options.

Setup Display Information

(O)

Language

Decimal

Display Tag I.D.

Brightness

Contrast

Dimmer

Dimmer Level

Timeout

Set Time

Set Date

Display Time

Display Date

Vendor

Model

P.N.

S.N.

FW Version

Cal. Date

Date Code

Tag ID

Units Meter Input/Output

(O)

Flow Units

Flow Decimals

Flow Total Mode

Flow Total Units

Flow Total Decimals

Velocity Units

Energy Rate Units

Energy Rate Decimal

Energy Total Mode

Energy Total Units

Energy Total Decimal

Temperature Units

Display Mode

Energy units only.

(S)

Transducer

Mounting

Cx Type

Pipe

Fluid

Spacing

Flow Setup

Advanced

Calibration

Aux Output #1

Aux Output #2

Optional card installed.

Readings

Signal Strength

History

Delta Time Filtered

Flow Rate Raw

Fluid Sound Speed

Delta Time Raw

Reynolds Number

Reynolds Factor

Temperature #1

Temperature #2

Delta Temperature

Total Overow Count

Energy Overow

(S)

Current #1

Current #2

Output #1

Output #2

Output #3

Input

RTD

Diagnostics

Input/Output

Status

Current #1 Output

Current #2 Output

Output #1 Status

Output #2 Status

Output #3 Status

Aux Output #1 Status

Aux Output #2 Status

Input Status

Communications

(S)

EIA-485 Type

Modbus RTU Settings

BACnet MS/TP Settings

Endpoint

BACnet/IP

Modbus TCP/IP

EtherNet/IP

Based on selected option.

Reset

(O)

Reset Flow Total

Unlatch Alarms

Hardware

Options

Card Hardware

MAC Address

Link Status

Data Logging

(S)

Log Mode

Time Interval

Parameter 1…8

Threshold

Min. Threshold

Max. Threshold

Delete Log

Available when security is enabled.

Options

(S)

Card Type

Logout

(If security is enabled

and someone is

logged in.)

System

(S)

Time

Date

Power On Time

Simulation Mode

Passcode Level

Clear History

Factory Reset

Reboot

Passcode

Setup

(A)

Security

Set Admin

Set Service

Set Operation

Logout Timeout

Passcode Recovery

Page 22 July 2020TTM-UM-02222-EN-10

Page 23

Parameter Descriptions by Menu

PARAMETER DESCRIPTIONS BY MENU

Main Menu Structure

The transmitter’s firmware has a hierarchical menu structure. See "Menu Map" on page22 for a visual path to the parameters.

The five Main Menus used in the transmitter firmware are as follows:

Menu Function

SETUP Contains all of the configuration parameters for initially programming the transmitter to measure flow

DISPLAY Configures transmitter display functions

INFORMATION Displays system information, such as the model number and firmware version

DIAGNOSTICS Displays system status and allows you to clear the history, reset to factory defaults and reboot the system

RESET Resets the flow total or unlatches alarms

The following pages define the configuration parameters located in each of the menus.

Setup > Units

Use SETUP > UNITS to define the measurement standards for the transmitter. Contains all of the configuration parameters for

setting the units and decimals for the readings and the totalizer mode. Requires operator level passcode or higher if security

is enabled.

An asterisk (*) indicates the parameter default.

Units Submenus Options/Descriptions

Select the flow rate units/interval displayed on the Home Screen. FLOW UNITS are automatically converted into

the selected option.

Option Units/Interval Option Units/Interval

Fluid BBL/D Fluid Barrels/Day (31.5 Gal) GAL/S US Gallons/Second

IBBL/D Imperial Fluid Barrels/Day (36 IG) GAL/MIN US Gallons/Minute

L/S Liters/Second GAL/H US Gallons/Hour

L/MIN Liters/Minute MG/D Million US Gallons/Day

FLOW UNITS

FLOW DECIMALS This is a numeric entry for the number of decimal places to display. Default is 2. Options are 0…7

FLOW TOTAL MODE

L/H Liters/Hour IG/S Imperial Gallons/Second

M/S Cubic Meters/Second IG/MIN Imperial Gallons/Minute

M/MIN Cubic Meters/Minute IG/H Imperial Gallons/Hour

M/H Cubic Meters/Hour MIG/D Million Imperial Gallons/Day

FT/S Cubic Feet/Minute OIL BBL/D Oil Barrels/Day (42 Gal)

FT/MIN Cubic Feet/Minute AC-FT/D Acre Feet/Day

FT/H Cubic Feet/Hour

Custom

*GROSS FLOW

FORWARD FLOW

REVERSE FLOW

NET FLOW

This selection in only available if Custom Units is enabled through SoloCUE Flow Device

Manager. Use SoloCUE to change the Custom Units.

Any ow in forward and reverse direction.

Forward ow minus reverse ow. A negative total results when reverse ow is greater than

forward ow.

Page 23 July 2020 TTM-UM-02222-EN-10

Page 24

Parameter Descriptions by Menu

Units Submenus Options/Descriptions

Select the units for the flow total displayed on the Home Screen. FLOW TOTAL UNITS are automatically converted

into the selected option:

Option Units Option Units

GAL US Gallons Fluid BBL Fluid Barrel (31.5 Gal)

MGAL Million US Gallons L Liter

FLOW TOTAL UNITS

FLOW TOTAL DECIMALS This is a numeric entry for the number of decimal places to display. Default is 0. Options are 0…7.

VELOCITY UNITS

ENERGY RATE UNITS

(Energy Units Only)

ENERGY RATE DECIMAL

(Energy Units Only)

ENERGY TOTAL MODE

(Energy Units Only)

IGAL Imperial Gallons HL Hectoliter

AC-FT Acre Foot M Cubic Meters

MIGAL Million Imperial Gallons FT Cubic Feet

Oil BBL Oil Barrels (42 Gal)

Custom

Select the units for the velocity displayed on the Home Screen.

*FT/S Feet/Second

M/S Meters/Second

Select the units for the energy rate displayed on the Home Screen. ENERGY RATE UNITS are automatically

converted into the selected option:

Option Units Option Units

BTU/H Btu/hour kJ/H Kilojoules/hour

kBTU/H Thousand Btu/hour MJ/H Mega joules/hour

MMBTU/H Million Btu/hour kCAL/H Kilocalories/hour

W Watts MCAL/H Mega calories/hour

*kW Kilowatts

MW Megawatts

This is a numeric entry for the number of decimal places to display. Default is 2. Options are 0…7.

FORWARD FLOW

REVERSE FLOW

NET FLOW Forward flow minus reverse flow. A negative total results when reverse flow is greater than

the forward flow.

*GROSS FLOW Any flow in forward and reverse direction.

Select the units for the energy total displayed on the Home Screen. ENERGY TOTAL UNITS are automatically

converted into the selected option:

This selection in only available if Custom Units is enabled through SoloCUE Flow Device

Manager. Use SoloCUE to change the Custom Units.

TON (RT)

Ton (Refrigeration)

1 Ton = 12,000 Btu/h

Option Units Option Units

ENERGY TOTAL UNITS

(Energy Units Only)

ENERGY TOTAL DECIMALS

(Energy Units Only)

TEMPERATURE UNITS

(Energy Units Only)

DISPLAY MODE

Page 24 July 2020TTM-UM-02222-EN-10

BTU British Thermal Unit kWH Kilowatt Hour

kBTU Thousand Btu MWh Megawatt Hour

MMBTU Million Btu kJ Kilo Joules

KCAL Kilo Calories MJ Mega Joules

MCAL Mega Calories TON-H Ton-hour (Refrigeration)

This is a numeric entry for the number of decimal places to display. Default is 2. Options are 0…7.

°F

°C

K

Select the parameters to display on the Home Screen. Alternatively, you can change the display from the

Home Screen by pressing the DOWN button.

*FLOW RATE ENERGY TOTAL

FLOW TOTAL TEMP #1 / TEMP #2

VELOCITY ENERGY RATE / DELTA TEMPERATURE

RATE/TOTAL ENERGY RATE / ENERGY TOTAL

ENERGY RATE TIME / DATE

Page 25

Parameter Descriptions by Menu

Setup > Meter

Contains all of the configuration parameters for setting the meter. Requires service level passcode or higher if security is

enabled. An asterisk (*) indicates the parameter default.

Meter Submenus Options/Descriptions

Select the transducer type:

UZ 2 MHZ Option UZ when ordered with the TFX-5000 meter; universal small pipe

transducers integrated in a rail

CX 2 MHZ Options CA…CT when ordered with the TFX-5000 meter; fixed size small pipe

transducers

JZ / KZ 1 MHZ Options JZ and KZ when ordered with the TFX-5000 meter; medium size pipe

TRANSDUCER

MOUNTING

Cx TYPE

NZ / RZ / WZ 1 MHZ Options NZ, WZ and RZ when ordered with the TFX-5000 meter; medium size

HZ 1 MHZ Option HZ when ordered with the TFX-5000 meter; high temperature medium

LZ / YZ 0.5 MHZ Option LZ and YZ when ordered with the TFX-5000 meter; large pipe transducers,

For mounting options, see the transducer user manual.

Z PATH

*V PATH

W PATH

DTTC TYPE is substituted for MOUNTING when TRANSDUCER DTTC is selected as the transducer type.

CA: 1/2 IN ANSI CJ: 1-1/4 IN COPPER

CB: 3/4 IN ANSI CK: 1-1/2 IN COPPER

CC: 1 IN ANSI CL: 2 IN COPPER

CD: 1-1/4 IN ANSI CM: 1/2 IN SS TUBE

CE: 1-1/2 IN ANSI CN: 3/4 IN SS TUBE

CF: 2 IN ANSI CP: 1 IN SS TUBE

CG: 1/2 IN COPPER CQ: 1-1/4 IN SS TUBE

CH: 3/4 IN COPPER CR: 1-1/2 IN SS TUBE

CT: 1 IN COPPER CS: 2 SS IN TUBE

transducers integrated in a rail

pipe transducers, including submersible

pipe transducers

including submersible

Page 25 July 2020 TTM-UM-02222-EN-10

Page 26

Parameter Descriptions by Menu

Setup > Meter > Pipe

An asterisk (*) indicates the parameter default.

Pipe Submenus Options/Descriptions

STAINLESS 302/303 STAINLESS 430 IRON - DUCTILE POLYPROPYLENE

STAINLESS 304 ALUMINUM HD POLYETHYLENE

PIPE MATERIAL

PIPE TYPE

PIPE SIZE Available only when PIPE TYPE is MANUAL; Numeric entry; min. 0.5 in (15 mm), max. 300 in (7500 mm)

PIPE SIZE NOMINAL

WALL THICKNESS

LINER MATERIAL

LINER THICKNESS Numeric entry; min. 0.00, max. 5 in. (125 mm)

I.D. SIZE Numeric display in inches or millimeters, based on PIPE TYPE

STAINLESS 304L BRASS NAVAL LD POLYETHYLENE

*STAINLESS 316 CARBON STEEL PFA TEFLON

STAINLESS 347 COPPER PVC CPVC

STAINLESS 410 IRON - CAST PVDF

For the best accuracy, measure the outer diameter and wall thickness with a gauge and select MANUAL INCHES

or MANUAL MM.

If you do not have a gauge, you can select an ASME/ANSI or ASTM definition. Schedule, copper tubing and cast

iron class are filtered based on pipe material selection.

If stainless steel pipe, carbon steel, cvc, pcvc material is selected, the following pipe schedules are also available

as applicable:

SCHEDULE STD SCHEDULE 80

SCHEDULE 5 SCHEDULE 100

*SCHEDULE 10 SCHEDULE 120

SCHEDULE 20 SCHEDULE 140

SCHEDULE 30 SCHEDULE 160

SCHEDULE 40 SCHEDULE 180

SCHEDULE 60 SCHEDULE STG

If copper material is selected, the following types are also available:

TYPE K TYPE M

TYPE L PIPE SIZE

If cast iron pipe material is selected, the following classes are also available:

CLASS A CLASS E

CLASS B CLASS F

CLASS C CLASS G

CLASS D CLASS H

If ductile iron pipe material is selected, the following classes are also available:

CLASS 50 CLASS 54

CLASS 51 CLASS 55

CLASS 52 CLASS 56

CLASS 53

If aluminum or brass naval material is selected, the following is also available:

PIPE SIZE (in inches)

PIPE SIZE NOMINAL is substituted for PIPE SIZE when a schedule/tubing/class is selected.

Enumeration based on schedule; min. 0.5 in. (15 mm), max. 24 in. (610 mm)

1/2, 3/4, 1, 1-1/4, 1-1/2, 2, 2-1/2, 3, 3-1/2, 4, 6, 8, 10, 12, 14, 16, 18, 20, 24

Numeric entry; *min. 0.00, max. 5 in. (125 mm);

WALL THICKNESS is only useful for MANUAL METRIC and MANUAL INCHES; It can be skipped for pipe schedule,

tubing and classes

NONE HD POLYETHYLENE TAR EPOXY

ACRYLIC LD POLYETHYLENE PFE TEFLON

ASBESTOS CEMENT POLYPROPYLENE GLASS PYREX

EBONITE POLYSTYRENE FIBERGLASS EPOXY

MORTAR RUBBER

Page 26 July 2020TTM-UM-02222-EN-10

Page 27

Setup > Meter > Fluid

Fluid Submenus Options/Descriptions

Water - Tap Acetone Ethylene Glycol 30% Kerosene Propylene Glycol 30%

Raw Sewage Ammonia Gasoline Methanol Stoddard Solvent

FLUID

CUSTOM FLUID

Water - Distilled Benzene Glycerin Oil Diesel #1 Sulfuric Acid 96%

Water - Sea 3.5% Ethanol Isopropanol Oil Diesel #2 Hydrochloric Acid 36%

Brine - 3.5% Ethylene Glycol 100% Jet Fuel A1/JP8 Propylene Glycol 100% Hyrdrofluoric Acid 49%

Brine - 10% Ethylene Glycol 50% Jet Fuel B/JP4 Propylene Glycol 50% Custom

SOUND SPEED Numeric entry; Units ft/s or m/s based on velocity units.

SPEED UNITS Ft/s or m/s

Numeric entry; Specific gravity (density relative to water), pipe size and viscosity are used

SPECIFIC GRAVITY

VISCOSITY Numeric entry; Units centipoise (cP) or mPa-s. Dynamic viscosity of the fluid.

VISCOSITY UNITS Units centipoise (cP) or mPa-s

REFERENCE TEMP Numeric entry, F or C. Default 15° C. Reference temperature of viscosity and specific gravity.

REF TEMP UNITS F or C

SPECIFIC HEAT

to calculate the Reynolds number. The Reynolds number indicates whether the fluid is in

turbulent, transition or laminar flow and the flow profile.

Numeric entry; Units: joule/gram °C; min. 0.01, max. 65.0; Specific heat capacity is the heat

capacity per unit mass of a material.

Setup > Meter > Spacing

An asterisk (*) indicates the parameter default.

Parameter Descriptions by Menu

Spacing Submenus Options/Descriptions

*Numeric display 0…300 units in inches or millimeters, based PIPE settings.

CALIBRATED SPACING

The spacing required between two transducers based on the pipe parameters. Take this measurement

between the lines scribed into the side of the transducers or use the scale on the rails, if used. See the

transducer user manual. For Cx transducers with fixed spacing, the parameter will not be shown.

Setup > Meter > Flow Setup

An asterisk (*) indicates the parameter default.

Flow Setup Submenus Options/Descriptions

DIRECTION

BIDIRECTIONAL

LOW FLOW CUTOFF Numeric entry. Units and decimals are based on FLOW RATE UNITS. Zero and positive values. *0.0

SIGNAL CUTOFF

SIGNAL HIGH

MINIMUM FLOW -10000 (default); min. -2,000,000. Number of decimals points depends on Home Screen settings.

MAXIMUM FLOW 10000 (default); max. 2,000,000

*FORWARD

REVERSE

*ENABLED

DISABLED

*30 The low threshold when the meter will stop reading flow and display a F10 Low Signal message

(see “Troubleshooting” on page46 for causes of a low signal).

*90% The high threshold when the meter will stop reading flow and display a F11 High Signal message (see

“Troubleshooting” on page46 for causes of a high signal).

Page 27 July 2020 TTM-UM-02222-EN-10

Page 28

Parameter Descriptions by Menu

Setup > Meter > Advanced

An asterisk (*) indicates the parameter default.

Dynasonics Calculation

EN1434 TYPE

Rate of Heat Delivery = Q × (Tin – Tout) × C × ρ

Where

HEAT CALCULATION

(Energy meter only)

DAMPING *40 seconds

SENSITIVITY *60%

HYSTERESIS *5%

BAD DATA REJECTION *3

FILTER METHOD *Adaptive

WAVE

TEMP COMPENSATION

MANUAL REF TEMP Numeric entry -40…350° F (–40…176° C)

REF TEMP UNITS

REYNOLDS

Filter Parameters

Q = Volumetric flow rate

Tin = Temperature at the inlet

Tout = Temperature at the outlet

C = Heat capacity

ρ = Density of fluid

For detailed information on these parameters,

see the paragraphs following this table.

• *AUTO automatically selects waveform based on flow speed and signal quality.

• SIN CARROT TOP is best for low speed flow.

• BEST BARKER is best for high speed flow.

*MANUAL

TEMP #1

TEMP #2

° F

° C

K

*ENABLED

DISABLED

Selection is only available for Energy meter. For the Flow meter,

manual temperature compensation is always on. Temperature

compensation adjusts the viscosity of the fluid used in Reynolds

number compensation and the fluid speed of sound.

Select the units for the manual reference temperature.

Flow rate compensation based on fluid Reynolds number as the

fluid changes from laminar to transitional to turbulent flow.

Filter Method (Default: Adaptive)

The TFX-5000 flow meter offers three levels of signal filtering:

• None imposes no filtering on the signal from the transducers.

• Simple with Rejection uses Damping and Bad Data Rejection to filter the flow data.

• *Adaptive filtering allows the meter’s software routines to alter the filtering, depending on the variability of the

transducer’s signal. The Adaptive filter uses a combination of Damping, Bad Data Rejection, Sensitivity and Hysteresis to

modify the flow input data.

Damping (Range 0…100 Seconds; Default: 40 Seconds)

Damping is the approximate amount of time the filtering routines use to attain a 99% stable rate value. Generally, the higher

the damping value, the more stable the rate readings are—but at the expense of response time.

Sensitivity (Range 0…100%; Default: 60%)

Sensitivity determines how fast the adaptive ltering responds to a change in rate. Increasing the sensitivity decreases the

ltering, which allows the display to respond to rate changes more rapidly.

Hysteresis (Range 0…25%; Default: 5%)

Hysteresis creates a window around the average flow measurement reading, defining the limits at which the automatic

damping increases occur. If the rate varies within the hysteresis window, greater damping occurs up to the maximum values

set by the flow filter Damping entry. The filter also establishes a flow rate window where measurements outside of the

window are captured by the Bad Data Rejection window. Enter the value as a percentage of actual flow rate.

For instance, a Hysteresis setting of 5% allows the flow to vary ± 5% from the currently established flow rate without

automatically decreasing the value of the Damping.

Page 28 July 2020TTM-UM-02222-EN-10

Page 29

Parameter Descriptions by Menu

For example, if the average flow rate is 100 gpm and the Hysteresis is set to 10%, a filter window of 90…110 gpm is

established. Successive flow measurements that reside within that window are recorded and averaged in accordance with

the Damping setting. Flow readings outside of the window are rejected or accepted in accordance with the

Bad Data Rejection setting.

Filter settings for this example:

Filter Method Adaptive

Damping 40 seconds

Sensitivity 60%

Hysteresis 10%

Bad Data Rejection 3

150

Flow Within

Hysteresis Limit

110

100

90

±10% Hysteresis

Limit

50

Flow

0

Figure 39: Hysteresis window

Bad Data Rejection (Range 0…10 Samples; Default: 3)

The Bad Data Rejection setting is related to the number of successive readings that must be measured outside of a the

Hysteresis value before the flow meter considers the new flow value valid. In this example, a Hysteresis setting of 10% produces

a ± 10% band centered on the current valid flow rate of 100 gpm.

The Bad Data Rejection setting is the number of successive samples that must be outside of the Hysteresis window before

the flow meter considers the change in flow as real. Larger values are entered into the Bad Data Rejection window when

measuring liquids that contain gas bubbles, as the gas bubbles tend to disturb the ultrasonic signals and cause more

extraneous flow readings to occur. Larger Bad Data Rejection values tend to make the flow meter less responsive to rapid

changes in actual flow rate.

In Figure 41 on page 30, flow data falls outside the flow Hysteresis window but does not reach the minimum time specified in

the Bad Data Rejection window. When data appears that is outside the Hysteresis band and shorter than the Bad Data Rejection

window time, the data is rejected.

Page 29 July 2020 TTM-UM-02222-EN-10

Page 30

Parameter Descriptions by Menu

150

3 Samples Outside

Hysteresis Limit

110

1 2 3

Flow Outside

Hysteresis Limit

100

90

Sample

Limits

Bad Data Rejection

Window

±10% Hysteresis

Limit

50

Flow

0

Figure 40: Bad data (rejection)

The flow rate is again outside the original ±10% Hysteresis window, but the data exists for a time period greater than the

Bad Data Rejection window. In this instance, the meter interprets the data as a new valid flow rate and moves the Hysteresis

window to correspond with the new established flow rate.

150

Old

±10% Hysteresis

Limit

110

4 Samples Outside

Hysteresis Limit

Flow Outside Original

Hysteresis Limit

100

90

1 2 3 4

50

Bad Data

Rejection Window

New

±10% Hysteresis

Limit

Flow

0

Figure 41: New valid flow data

Page 30 July 2020TTM-UM-02222-EN-10

Page 31

Parameter Descriptions by Menu

Setup > Meter > Calibration

An asterisk (*) indicates the parameter default.

Calibration Submenus Options/Descriptions

FACTOR MODE

FACTORY SETTINGS

ZERO MODE

SET ZERO - NO FLOW

SET ZERO - FLOW

MANUAL ZERO Numeric entry ## ### ns Allows for manual entry of the zero value when ZERO MODE is MANUAL.

ZERO VALUE Numeric display ## ### ns

SENSOR FACTOR Numeric entry ## ### ns

SCALE FACTOR Numeric entry

FAC TORY

*FIELD

ZERO

CAL FACTOR

SENSOR FACTOR

MANUAL

*NO FLOW

STEADY FLOW

SET ZERO AT NO FLOW in

process and confirmation

screen

SET ZERO AT FLOW in

process and confirmation

screen

Select FIELD to set the zero and use the sensor and scale factors of the transducers.

The zero offset entered during factory calibration. ZERO is for reference only and

most likely the ZERO VALUE for your installation will be different from the factory

ZERO. Numeric display; *0.000 ns

One of two calibration factors unique to each transducer pair if the transmitter was

used during factory calibration. Numeric display #.###

One of two calibration factors unique to each transducer pair if the transmitter was

used during factory calibration. Numeric display #.###

Due to different pipe characteristics, the meter must be zeroed in order to maintain

accuracy. The recommended method is to stop flow and make sure there is no flow

before zeroing the meter. In situations in which that is not feasible, you may zero the

meter while the flow is steady or enter the zero manually.

Select the method to zero the meter.

Check that the pipe is full of liquid and not flowing. Flow must be absolutely zero.

Securely close any valves and allow time for settling to occur.

Stabilize the flow to a steady level before zeroing the meter. In situations where it is

not possible to stop flow, use this method to zero the meter.

When selected, the meter will calculate the zero typically in 5…10 seconds and will

indicate if the meter was successful or not in determining the flow.

The zero offset used to calculate the flow rate If the meter is not zeroed after

installation, this value will match the factory ZERO setting.

The value used in calculating the zero value when zeroing the meter at steady flow.

This value can be found on the transducer label.

The factor used for linearizing the flow rate calculation when FIELD is selected for

FACTOR MODE. Enter the CAL FACTOR from the transducer.

Factory Calibrated Procedure

Each transducer pair has a CAL FACTOR and SENSOR FACTOR on the label. Verify FACTOR MODE is set to FIELD and enter the

factors from the transducer into the CAL FACTOR and SENSOR FACTOR settings.

Zero the meter after entering the CAL FACTOR and SENSOR FACTOR.

Field Calibration Procedure

To calibrate the TFX-5000 flow meter, use a master meter or gravimetric test stand.

1. (Skip this step if rmware is 02.02.480 or higher. ) Verify that FACTOR MODE is set to FIELD and the transducer sensor factor

is entered into the SENSOR FACTOR setting.

2. Set SCALE FACTOR set to 1.

3. Run calibration test.

4. Calculate the SCALE FACTOR.

SCALE FACTOR = (actual flow)/(meter flow rate) or (actual total)/(meter total)

5. Enter the SCALE FACTOR.

Page 31 July 2020 TTM-UM-02222-EN-10

Page 32

Parameter Descriptions by Menu

Setup > Input/Output > Current #1 (or Current #2)

Requires service level passcode or higher if security is enabled. The current output, reset input and frequency/pulse/status

output can be set up through the SETUP > INPUT/OUTPUT menus.

An asterisk (*) indicates the parameter default.

Current #1 Submenus Options/Descriptions

*FLOW RATE

TEMPERATURE #1

TEMPERATURE #2

OUTPUT SOURCE

RANGE

MIN VALUE

MAX VALUE

FAILURE MODE

FIXED VALUE

TEST CURRENT

TRIM 4 mA

TRIM 20 mA

ENERGY FLOW

VELOCITY

SIGNAL STRENGTH

TEST MODE

DISABLED

*4-20 mA

4-20 mA NAMUR Current range is NAMUR 43 compliant with lower measuring limit at 3.8 mA and upper

limit at 20.5 mA and minimum alarm 3.5 mA and maximum alarm 22.6 mA.

0-20 mA

Enter the value of the reading at 4 mA. Can also be the setting for the 0 mA setpoint when 4-20 mA RANGE is

selected. Units and decimal places based on parameter selected. Negative numbers accepted.

Enter the value of the reading at 20 mA. Units and decimal places based on parameter selected. Negative

numbers accepted.

*MIN CURRENT

MAX CURRENT

LAST VALUE

TEST CURRENT

Enter the value for the current output when there is a failure mode. This parameter is only displayed with

FAILURE MODE is set to FIXED VALUE.

Available only when OUTPUT SOURCE is in TEST MODE. Default 12.00 mA. To check the wiring to the control

system or gauge, you can override the current output with a fixed current. Numeric entry mA. 0…22 mA.

Available only when OUTPUT SOURCE is in TEST MODE. Set the test current to 4 mA or 0 mA, depending on

the current range selected. Adjusts output until PLC/ DCS/BAS reads the desired value.

Available only when OUTPUT SOURCE is in TEST MODE. Set the test current to 20 mA. Adjusts output until

PLC/DCS/BAS reads 20 mA.

Select the reading to be assigned to the 4…20 mA output.

Temperature and energy options only available with energy meter.

When an Fxx error occurs, such as low signal strength, the transmitter will set

the current output the selected value.

Page 32 July 2020TTM-UM-02222-EN-10

Page 33

Parameter Descriptions by Menu

Setup > Inputs/Output > Output #1 (or Output #2 or Output #3)

Output #1, Output #2 or Output #3 can operate independently as a frequency, totalizer pulse, direction status or alarm

status output. In the SETUP > INPUT/OUTPUTS > OUTPUT #1 (OR OUTPUT #2 OR OUTPUT #3) > MODE menu, select the MODE of

operation. Then go to the PARAMETERS menu to set up the operation for that MODE.