Page 1

Transit Time Ultrasonic Flow Meters

TFX-5000 Meter

DESCRIPTION

The TFX-5000 transit time ultrasonic flow meter measures

volumetric flow and heating/cooling energy rates in clean liquids as

well as those with small amounts of suspended solids or aeration,

such as surface water or raw sewage.

TFX-5000 flow and energy meters clamp onto the outside of pipes

and do not contact the internal liquid.

BENEFITS

By clamping onto the outside of pipes, the meters have inherent

advantages over other flow meter technologies, including:

• Reduced installation time and cost

• Non-invasive, non-contact measurement

• Continued operation during installation—no need to shut down

the process

• No pressure head loss

• No moving parts to maintain or replace

FEATURES

• Large, bi-directional flow measuring range

• Data log up to 8 records

• Modbus® RTU or BACnet® MS/TP over EIA-485; BACnet/IP,

EtherNet/IP, or Modbus TCP/IP; AquaCUE®/BEACON® connectivity

• Configure and troubleshoot over USB with SoloCUE

• Reynolds, ultrasonic speed and temperature compensation

• Large, easy-to-read graphical display

• Rugged, aluminum enclosure for a long service life in

harsh environments

OPERATION

Transit time flow meters measure the time difference between

the travel time of an ultrasound wave going with the fluid flow

and against the fluid flow. The time difference is used to calculate

the velocity of the fluid traveling in a closed-pipe system. The

transducers used in transit time measurements operate alternately

as transmitters and receivers. Transit time measurements are

bi-directional and are most effective for fluids that have low

concentrations of suspended solids and are sonically conductive.

APPLICATIONS

The TFX-5000 meter is available in a variety of configurations that

permit the user to select a meter with features suitable to meet

particular application requirements.

The TFX-5000 meter is available in two versions:

• A flow meter for water delivery, sewage, cooling water,

water-glycol mixtures, alcohols and chemicals

• A heating/cooling energy flow meter used in conjunction with

dual clamp-on RTDs for temperature measurement—ideal for

hydronic process and HVAC applications

TTM-DS-02221-EN-01 (August 2019)

An ultrasonic meter equipped with heat flow capabilities measures

the rate and quantity of heat delivered or removed from devices

such as heat exchangers. By measuring the volumetric flow rate of

the heat exchanger liquid, the temperature at the inlet pipe and

the temperature at the outlet pipe, the energy usage can

be calculated.

Product Data Sheet

Page 2

Transit Time Ultrasonic Flow Meters, TFX-5000 Meter

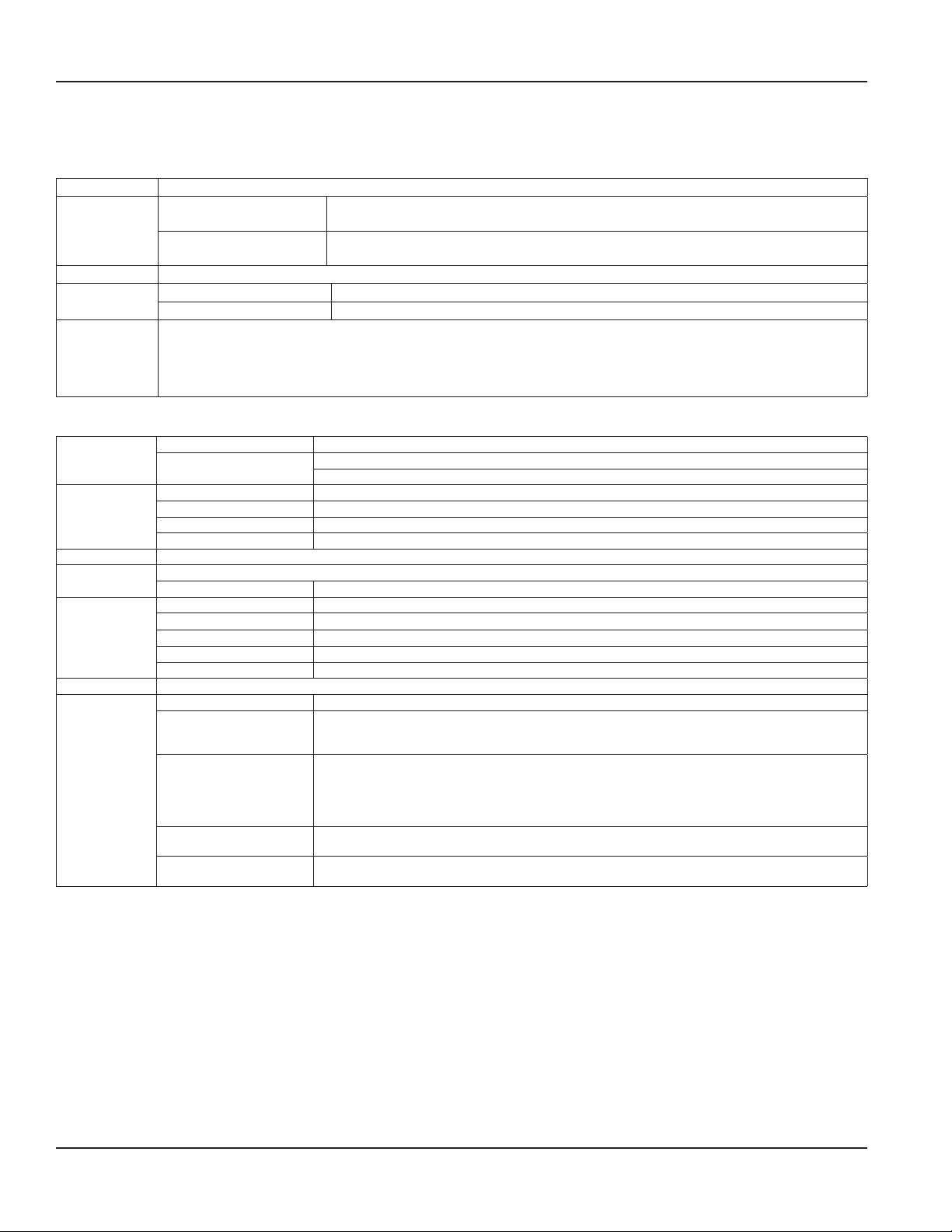

SPECIFICATIONS

System

Liquid Types Most clean liquids or liquids containing small amounts of suspended solids or gas bubbles

Medium and Large Pipes (RZ,

Flow Accuracy

Repeatability 0.2% above 1.5 ft/s

Velocity

Certification and

Compliance

NZ, WZ, HZ, LZ, YZ, JZ, KZ)

Small Pipes (CA-CT, UZ)

Medium and Large Pipes Up to 40 ft/s, depending on pipe and fluid

Small Pipes Up to 20 ft/s, depending on pipe and fluid

General Safety (all models): cCSAus, CE, Pollution Degree 2, CE compliance to Low Voltage Directive, 2014/35/EU

Hazardous Location transmitter and transducers:

CSA-c-us Class I Division 2 Groups ABCD T4

Requires flexible conduit

Not available with UZ, HZ or JZ and KZ (Easy Rail) transducers, Auxiliary Dry Contact card or units with AquaCUE/BEACON endpoints

Transmitter

24V DC/AC 9…28V DC @ 8 W max. or 20…26 AC 47…63 Hz @ 0.5 A max., 2 Amp slow-blow fuse, not eld replaceable

Power Options

Display

Enclosure NEMA Type 4, IP67

Construction

Environmental

Ratings

Conguration Via optional keypad or SoloCUE conguration software; SoloCUE available on DVD

Units

(FieldSelectable)

Mains AC

Options Display with keypad or no display/keypad

Keypad 4-button navigation, keypad with tactile feedback; polyester lm

Display 128 × 64 pixel LED backlit graphical display; adjustable brightness and timeout; polycarbonate window

Flow rate/total 8-digit

Aluminum construction; painted; wall, panel or pipe mounting; stainless steel fasteners and mounting hardware; EPDM gasket

Conduit Holes (4) 1/2 in. NPT, M20 × 1.5 or 1/2 BSPP; cable glands available for NPT and M20

Pollution Degree 2

Altitude Restriction Up to 2000 m (6561 ft)

Ambient Temperature Range –4…140° F (–20…60° C)

Storage Temperature Range –40…176° F (–40…80° C)

Humidity 0…85%, non-condensing

Velocity feet/second, meters/second

Volumetric total

Flow rate

Energy total

(energy meters)

Heat/cooling rate

(energy meters)

± 0.5% ± 0 0.049 ft/s (0.015 m/s)

1 in. (25 mm) and larger = ±1% ± 0.03 ft/s (0.009 m/s)

3/4 in. (19 mm) and smaller = ±1% of full scale

85…264V AC 47…63 Hz @ 24VA max. 1 Amp slow-blow fuse, manually eld replaceable

Over-Voltage Rating Category II (CAT II)

US Gallons, Million Gallons, Imperial Gallons, Million Imperial Gallons, Acre-Feet, Liters, Hectoliters,

Cubic Meters, Cubic Feet, Oil Barrels (42 gallons), Fluid Barrels (31.5 gallons), Imperial Fluid Barrels

(36 imperial gallons), Pounds (Kilograms) and custom units

Acre Feet/Day, Liters/Second, Liters/Minute, Liters/Hour, Cubic Meters/Second, Cubic Meters/Minute,

Cubic Meters/Hour, Cubic Feet/Minute, Cubic Feet/Minute, Cubic Feet/Hour, Gallons/Second,

Gallons/Minute, Gallons/Hour, Million Gallons/Day, Imperial Gallons/Second, Imperial Gallons/Minute,

Imperial Gallons/Hour, Million Imperial Gallons/Day, Oil Barrels/Day, Fluid Barrels/Day,

Imperial Fluid Barrels/Day and custom units

British Thermal Unit (Btu), Thousand Btu, Millions Btu, Kilocalories, Mega calories, Kilowatt-hour,

Megawatt hour, Kilojoules, Mega joules, Ton-hour (Refrigeration)

Btu/hour, Thousand Btu/hour, Millions Btu/hour, Ton (Refrigeration), Watts, Kilowatts, Megawatts,

Kilojoules/hour, Mega joules/hour, Kilocalories/hour, Mega calories/hour

Page 2 August 2019

TTM-DS-02221-EN-01

Page 3

Flow Meter Energy Meter

0/4…20 mA output

One 16-bit, isolated, max 800 Ohms, internal or

external power

Two 16-bit, isolated, max 800 Ohms, internal or

external power

Digital input One 5…30V DC, isolated, externally or internally sourced, reset totalizer or alarm output

Inputs and

Outputs

Digital output

Two selectable pulse, alarm, ow direction, sink isolated

open collector, 5…30V DC, max. 50 mA externally or

internally sourced

Frequency output: 50% duty cycle, 63…10k Hz maximum frequency

Three selectable pulse, frequency, alarm, ow direction,

isolated open collector, 5…30V DC, externally or

internally sourced

Pulse (totalizer) output: 5 kHz max. output, open collector, pulse width 5…500 ms programmable

Optional: Two dry contact output for alarm or ow direction 30V DC max., 5A max.

(Ethernet not available with this option)

RTD (energy only) None

Two 2-wire, 3-wire or 4-wire Pt100/Pt1000 RTD inputs;

Range of –40…200° C; Clamp-on resistor kits available

Programming USB 2.0 mini B connector for connection to a device with SoloCUE conguration software

Ports

EIA-485

Modbus RTU command set or BACnet MS/TP; Baud rates 9600, 14400,19200, 38400, 57600, 76800, 115k;

terminating resistor selectable

Ethernet Optional 10/100 Base T RJ45, communication via Modbus TCP/IP, EtherNet/IP, or BACnet/IP with webserver

AquaCUE/BEACON Connectivity to AquaCUE/BEACON endpoint (LTE cellular)

Up to 8 parameters per record. Selectable 1 second to 1 day

Transfer logs via memory card

Data Logging

Number of points

Real Time Clock Backed up with a super capacitor, minimum of 32 days of data retention without power; Requires no servicing

MicroSD card slot 8 GB card, included with transmitter

Alarms Records 150 previous alarms, warnings or errors

Languages English

Security Four levels: Read-only, Operator, Service and Admin; 6-digit passcode number; selectable auto logout

Product Data Sheet

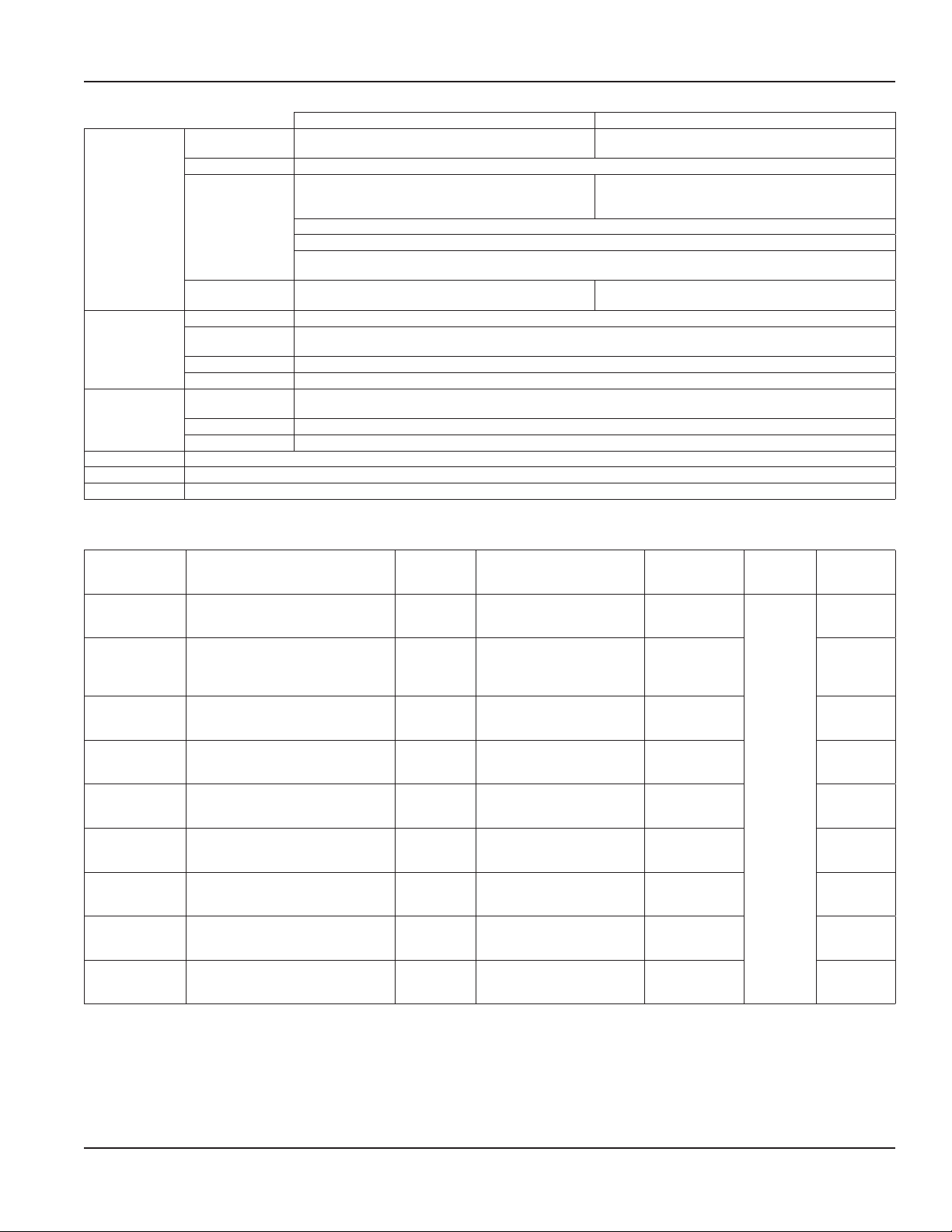

Transducers

Model Construction

CA-CT

fixed small pipe

UZ

adjustable

small pipe

NZ

standard pipe

RZ

standard pipe

JZ, KZ

standard pipe,

integrated rail

WZ

standard pipe,

submersible

HZ

high temperature

LZ

large pipe

YZ

large pipe,

submersible

Recommendations based on unlined, new pipes with water. Recommended pipe or tubing sizes vary with pipe conditions and uid.

PVC, CPVC, HDPE, PTFE, PDVF, stainless steel, ductile iron, aluminum, brass naval, carbon steel copper.

Large pipe transducers are recommended for 8…12 in. pipes if normal velocity is expected to be greater than 12 ft/s (3.6 m/s).

Consult factory for larger pipe sizes.

CPVC, Ultem®, Nylon cord grip

Polyethylene cable jacket;

–40…194° F (–40…90° C)

CPVC, Ultem, and anodized

aluminum track system; Nickel-plated

brass connector with Teflon insulation;

–40…194° F (–40…90° C)

PVC, Ultem®, Nylon cord grip

Polyethylene cable jacket;

–40…194° F (–40…90° C)

PBT glass filled, Ultem®,

Nylon cord grip; PVC cable jacket;

–40…250° F (–40…121° C)

PBT glass filled, Ultem,

Nylon cord grip; PVC cable jacket;

–40…250° F (–40…121° C)

CPVC, Ultem, Nylon cord grip

Polyethylene cable jacket;

–40…194° F (–40…90° C)

PTFE, Vespel, Nickel-plated

brass cord grip; PFA cable jacket;

–40…350° F (–40…176° C)

CPVC, Ultem, Nylon cord grip

Polyethylene cable jacket;

–40…194° F (–40…90° C)

CPVC, Ultem, Nylon cord grip

Polyethylene cable jacket;

–40…194° F (–40…90° C)

Cable Length

Max.

Pipe/Tubing Sizes

100 ft (30 m) 0.5…2 in. (12…50 mm) 190 (720)

100 ft (30 m) 0.5…2 in. (12…50 mm) 190 (720) NEMA 12

300 ft (90 m) 2.5…12 in. (DN65…DN300) 4000 (15,000) NEMA 6/IP67

300 ft (90 m) 2.5…12 in. (DN65…DN300) 4000 (15,000) NEMA 6/IP67

300 ft (90 m)

2.5…6 in. (DN65…DN150)

2.5…12 in. (DN65…DN300)

300 ft (90 m) 2.5…12 in. (DN65…DN300) 4000 (15,000)

300 ft (90 m) 2.5…12 in. (DN65…DN300) 4000 (15,000) NEMA 6/IP67

300 ft (90 m) 8…48 in. (DN200…DN1200)

300 ft (90 m) 8…48 in. (DN200…DN1200)

Flow Rate

Max. GPM (LPM)

4000 (15,000) NEMA 6/IP67

3, 4

33,000 (125,000) NEMA 6/IP67

3, 4

33,000 (125,000) NEMA 6/IP68

Pipe/

Tubing

Materials

See 2

Protection

NEMA 6/IP67

NEMA 6P/

IP68

TTM-DS-02221-EN-01

Page 3 August 2019

Page 4

Transit Time Ultrasonic Flow Meters, TFX-5000 Meter

RTD Kits

Part Number Description Installation RTD Type Construction Temperature Range

68996-001 RTD matched pair; 15 ft (4.5 m) cable

68996-002 RTD matched pair; 50 ft (15 m) cable

68996-003 RTD matched pair; 100 ft (30 m) cable

Pipe clamp,

surface mount, IP54

Pt 1000, Class A

Aluminum body,

silicone cable jacket

-58…356° F

(14.4…180° C)

Data Logging Storage

Part Number Description

69032-001 MicroSD card, industrial grade, 8 GB

SoloCUE Flow Device Manager Software

The flow meter may be programmed through the keypad or with SoloCUE software. If the meter is ordered without a display/keypad, the

flow meter must be programmed with SoloCUE software. The software is used to configure, calibrate and communicate with TFX-5000

meters. Additionally, it has numerous troubleshooting tools to make diagnosing and correcting installation problems easier.

SoloCUE Used to configure, calibrate and troubleshoot flow meters and control valves; Software is compatible with Windows 7, 8, 10

USB Cable RC820648 USB 2.0 mini B connector to A connector, shielded

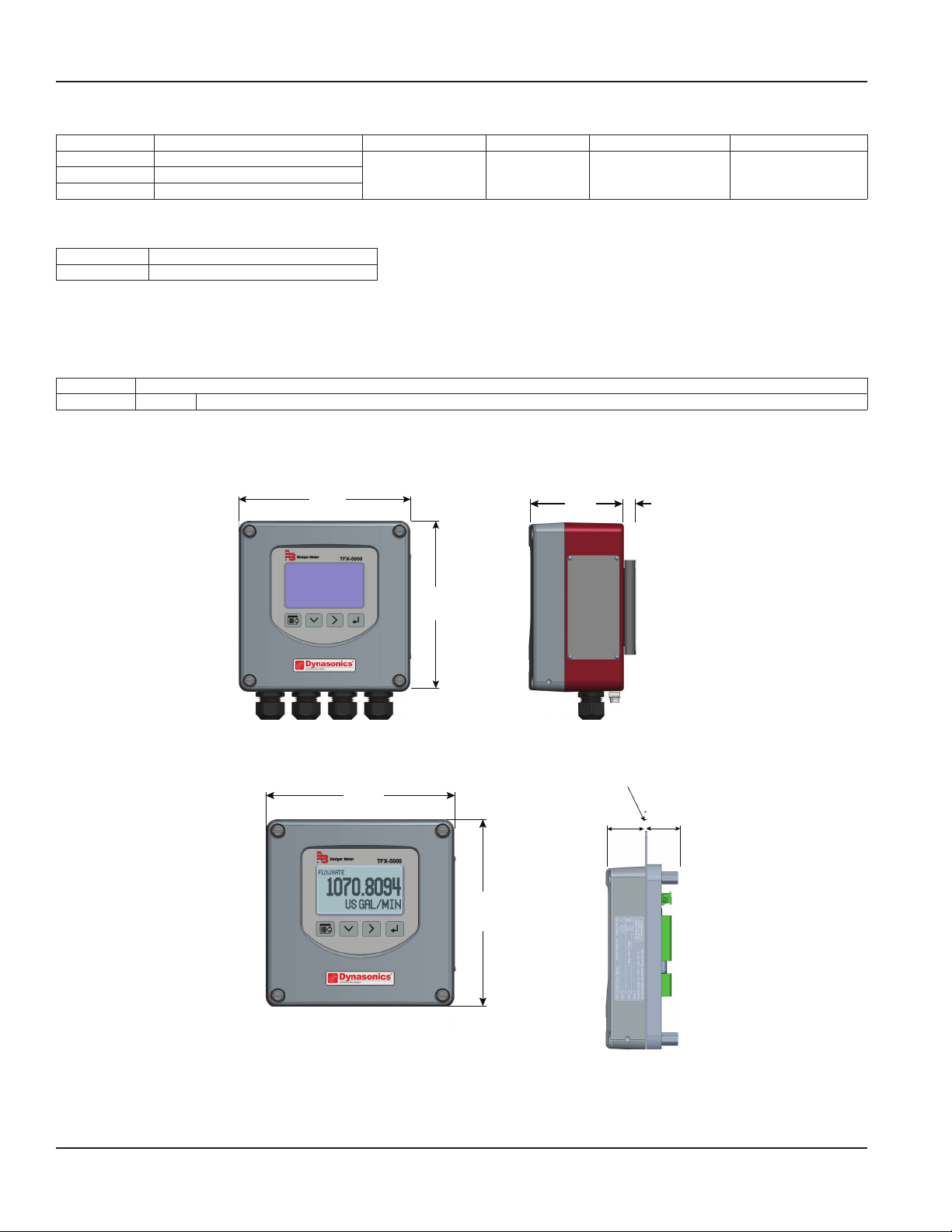

DIMENSIONS

Remote System Enclosure

6.50 in.

(165.10 mm)

3.63 in.

(92.20)

0.50 in.

(12.70 mm)

Panel Mount Enclosure

Torque the

cover screws

to 45 in-lb.

6.50 in.

(165.10 mm)

6.50 in.

(165.10 mm)

6.50 in.

(165.10 mm)

Customer-supplied panel

1.38 in.

(35.05 mm)

1.25 in.

(31.75 mm)

Consult factory for part number selection.

Page 4 August 2019

TTM-DS-02221-EN-01

Page 5

Product Data Sheet

B

A

D

C

B

D

A

C

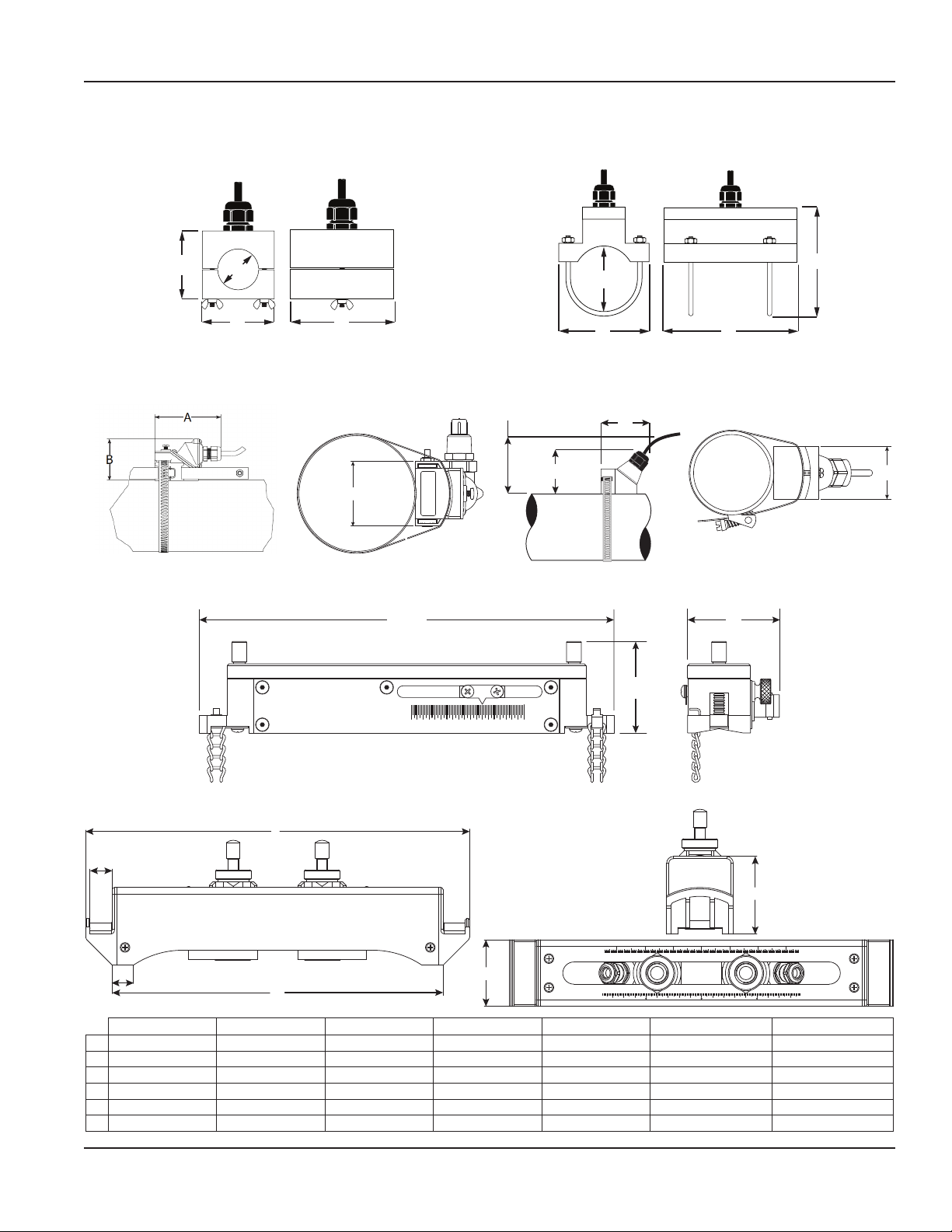

Transducers

Pipes and Tubing 1/2…2 in. (12…50 mm)

Fixed Small Pipe

RZ

Pipes Larger than 2 in. (50 mm)

D

TOP VIEW

OF PIPE

Fixed Small Pipe U-Bolt Connections CF, CL

(Min Clearance)

C

B

TOP VIEW

OF PIPE

ANSI/DN and Copper 2 in. (50 mm) Models

NZ, WZ, HZ, LZ, YZ

Pipes Larger than 2 in. (50 mm)

A

D

Adjustable Small Pipe

UZ

A B

C

0.3 1.51.0 2.0

Easy Rail (JZ, KZ)

A

D

E

inch

C

B

RZ NZ, WZ HZ LZ, YZ UZ JZ KZ

A 3.75 in. (95 mm) 2.95 in. (74.9 mm) 2.95 in. (74.9 mm) 3.40 in. (86.4 mm) 7 in. (178 mm) 13.62 in. (345.95 mm) 19.92 in. (505.97 mm)

B 2.35 in. (60 mm) 2.75 in. (69.8 mm) 2.75 in. (69.8 mm) 2.94 in. (74.7 mm) 1.6 in. (42 mm) 11.73 in. (297.94 mm) 18.03 in. (457.96 mm)

C — 3.00 in. (76.2 mm) 3.00 in. (76.2 mm) 3.20 in. (81.3 mm) 1.5 in. (39 mm) 0.75 in. (19.05 mm) 0.75 in. (19.05 mm)

D 2.19 in. (56 mm) 1.70 in. (43.2 mm) 1.71 in. (43.4 mm) 2.50 in. (63.5 mm) — 0.79 in. (20.06 mm) 0.79 in. (20.06 mm)

E — — — — — 2.76 in. (70.10 mm) 2.76 in. (70.10 mm)

F — — — — — 2.36 in. (59.94 mm) 2.36 in. (59.94 mm)

F

mm

TTM-DS-02221-EN-01

Page 5 August 2019

Page 6

Transit Time Ultrasonic Flow Meters, TFX-5000 Meter

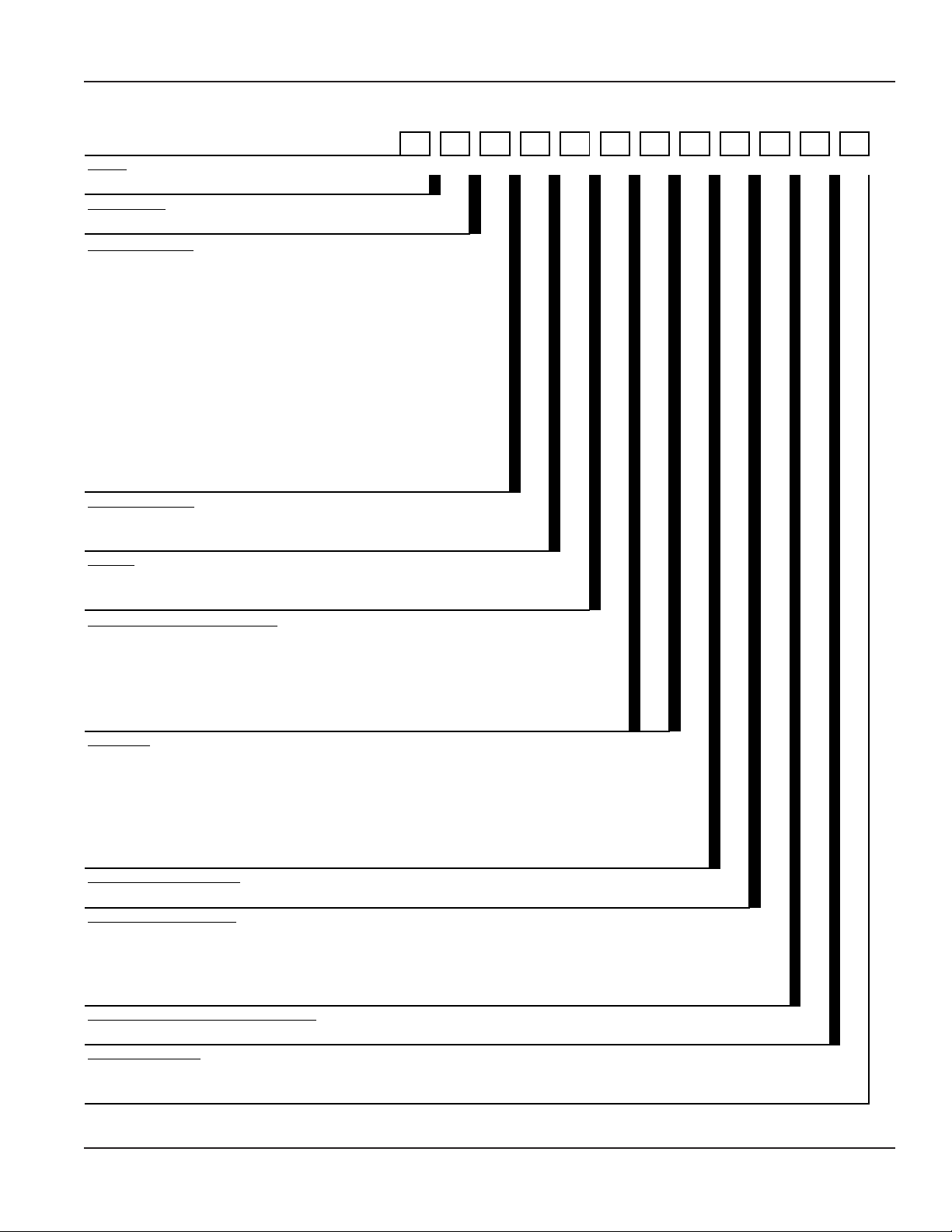

Model

TFX-5000 Ultrasonic Clamp-On Meter DQ

Certification

General Area US/Canada, CE G

1

1/2 inch ANSI Pipe CA

3/4 inch ANSI Pipe CB

1 inch ANSI Pipe CC

1-1/4 inch ANSI Pipe CD

1-1/2 inch ANSI Pipe CE

2 inch ANSI Pipe CF

1/2 inch Copper Tube CG

3/4 inch Copper Tube CH

1 inch Copper Tube CT

1-1/4 inch Copper Tube CJ

1-1/2 inch Copper Tube CK

2 inch Copper Tube CL

Small pipe, universal (not available with conduit) UZ

Transmitter Type

110/220V AC Remote Mounted R

24V DC/AC Remote Mounted B

Display

Display and Keypad S

No Display/Keypad W

Remote Cable Length

15 feet (4.5 m) AC

30 feet (9 m) AF

50 feet (15 m) AK

75 feet (23 m) AR

100 feet (30 m) BW

Conduit Type and Length (Conduit length is less than or equal to cable length)

None WW

5 feet (1.5 m) AA

15 feet (4.5 m) AC

30 feet (9 m) AF

50 feet (15 m) AK

75 feet (23 m) AR

100 feet (30 m) BW

Hardware

1/2 in. NPT Threads, Poly cable glands S

1/2 in. NPT Threads, Nickel Plated Brass cable glands T

1/2 in. NPT Threads, no cable glands N

M20 Threads, Poly cable glands C

M20 Threads, Nickel Plated Brass cable glands D

M20 Threads, no cable glands A

Endpoint Wiring Method

None XX

Communication/Output

Standard Output (Modbus RTU or BACnet MS/TP field selectable) S

Standard Output plus Modbus TCP Ethernet T

Standard Output plus EtherNet/IP U

Standard Output plus BACnet/IP Ethernet V

Standard Output plus Aux Output 9

Units of Measure Totalizer/Flow Rate

Gallons/gallons per minute (field selectable, additional options available) G

Testing & Tagging

Factory Calibrated

F

Factory Calibrated/Stainless Steel Tag

S

1

Stainless steel tube 1/2…2 in. options are available.

PART NUMBER CONSTRUCTION

Part Number Construction for TFX-5000 Flow Meters for Pipes 2 in. and Smaller

Transducer Type

DQ-G

- - - - - - -

XX

- - -

Page 6 August 2019

TTM-DS-02221-EN-01

Page 7

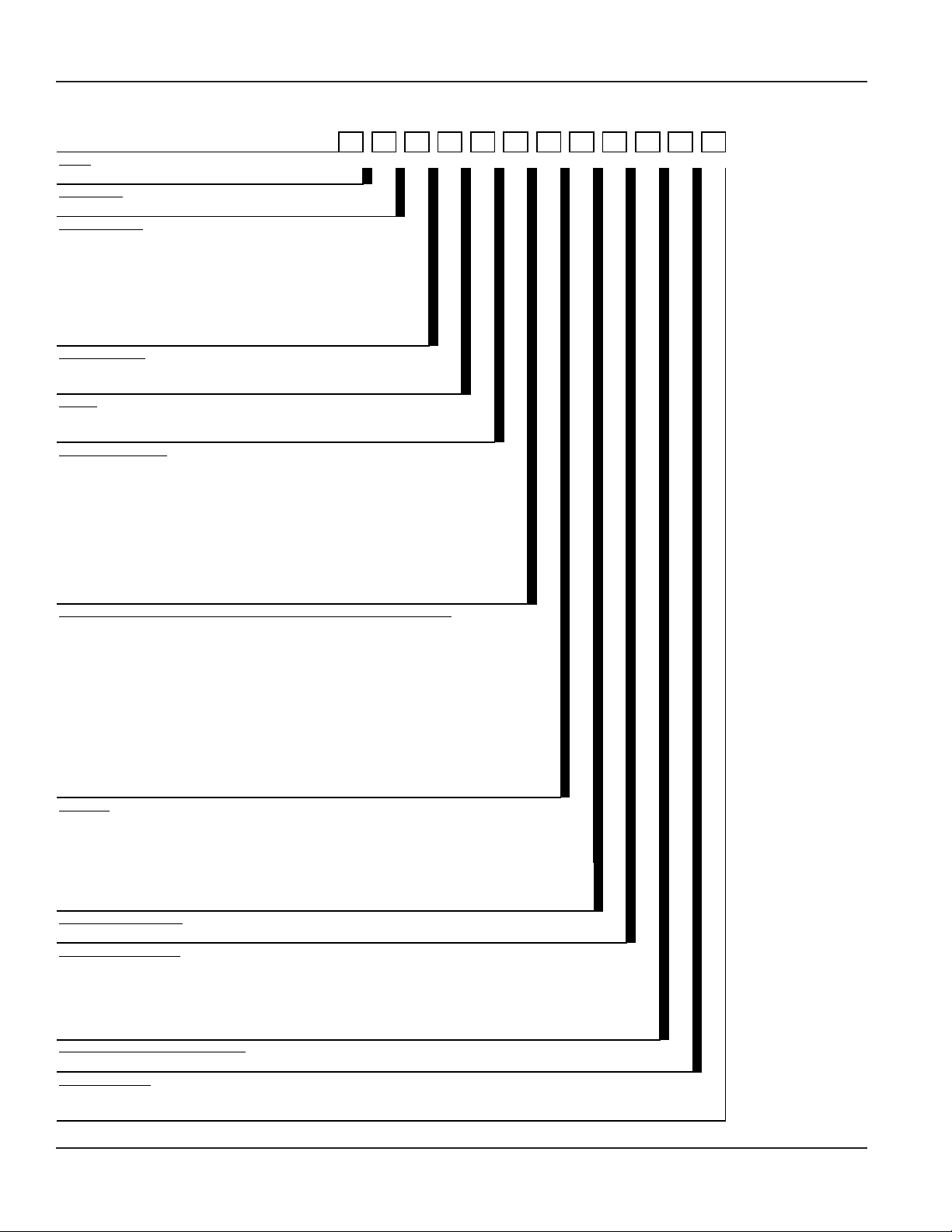

Part Number Construction for TFX-5000 Flow Meters for Pipes 2 in. and Smaller for Hazardous Locations

Model

TFX-5000 Ultrasonic Clamp-On Meter DQ

Certification

Hazardous Location, Class I, Division 2 B

1

1/2 inch ANSI Pipe CA

3/4 inch ANSI Pipe CB

1 inch ANSI Pipe CC

1-1/4 inch ANSI Pipe CD

1-1/2 inch ANSI Pipe CE

2 inch ANSI Pipe CF

1/2 inch Copper Tube CG

3/4 inch Copper Tube CH

1 inch Copper Tube CT

1-1/4 inch Copper Tube CJ

1-1/2 inch Copper Tube CK

2 inch Copper Tube CL

Transmitter Type

110/220V AC Remote Mounted R

24V DC/AC Remote Mounted B

Display

Display and Keypad S

No Display/Keypad W

2

15 feet (4.5 m) AC AC

30 feet (9 m) AF AF

50 feet (15 m) AK AK

75 feet (23 m) AR AR

100 feet (30 m) BW BW

Hardware

1/2 in. NPT Threads, Poly cable glands S

1/2 in. NPT Threads, Nickel Plated Brass cable glands T

1/2 in. NPT Threads, no cable glands N

M20 Threads, Poly cable glands C

M20 Threads, Nickel Plated Brass cable glands D

M20 Threads, no cable glands A

Endpoint Wiring Method

None XX

Communication/Output

Standard Output (Modbus RTU or BACnet MS/TP field selectable) S

Standard Output plus Modbus TCP Ethernet T

Standard Output plus EtherNet/IP U

Standard Output plus BACnet/IP Ethernet V

Units of Measure Totalizer/Flow Rate

Gallons/gallons per minute (field selectable, additional options available) G

Testing & Tagging

Factory Calibrated

F

Factory Calibrated/Stainless Steel Tag

S

1

2

For hazardous location units, Remote Cable and Conduit Length codes must match.

Transducer Type

DQ-B

- - - - - -

XX

- - -

Product Data Sheet

Remote Cable/Conduit Length

Stainless steel tube 1/2…2 in. options are available.

TTM-DS-02221-EN-01

Page 7 August 2019

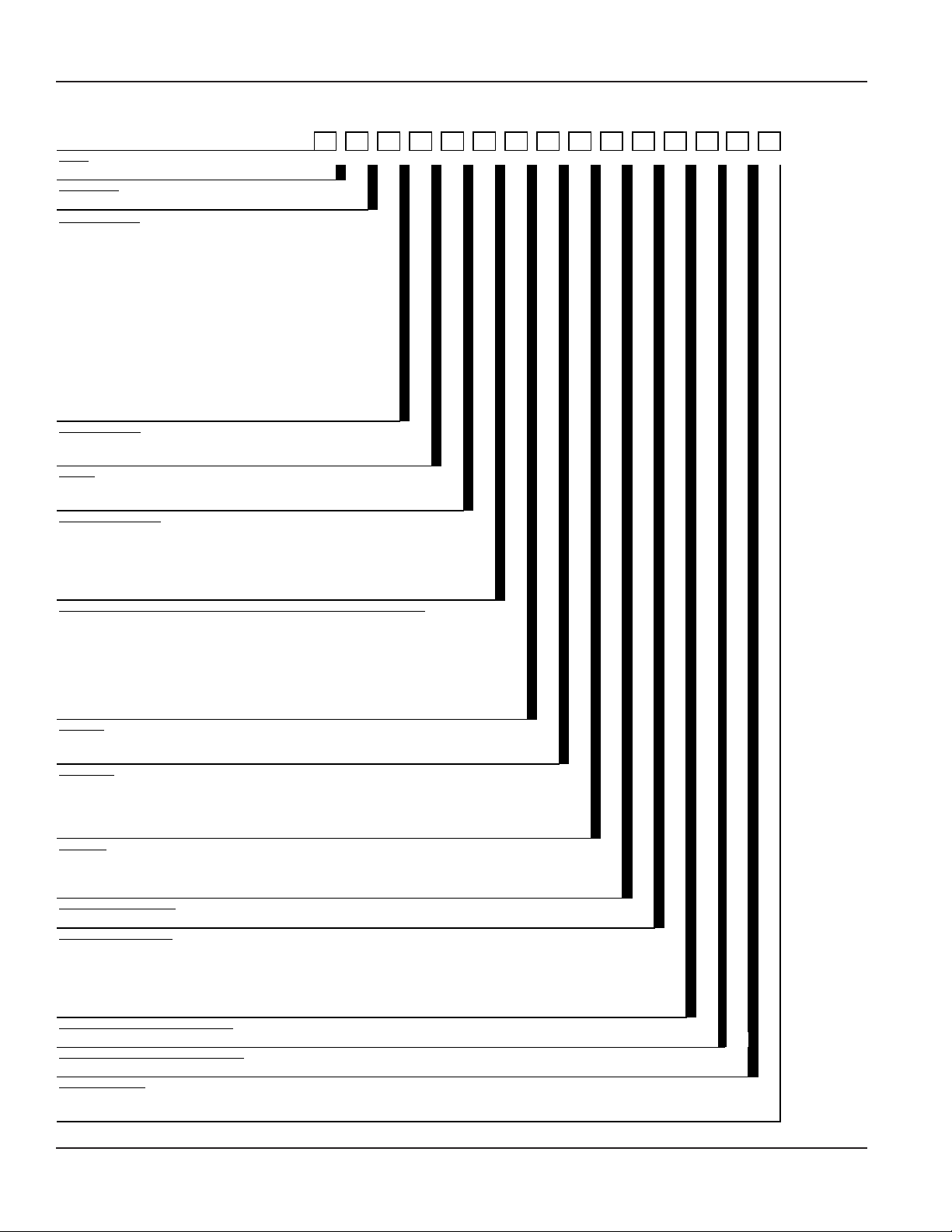

Page 8

Transit Time Ultrasonic Flow Meters, TFX-5000 Meter

Model

Certification

Transducer Type

Medium pipe, submersible, 2.5 in. (65 mm) or larger

1

WZ

Medium pipe, high temperature (not available with conduit)

Large pipe, submersible, 8 in. (200 mm) or larger

1

YZ

Transmitter Type

Display

Remote Cable Length

Conduit Type and Length (Conduit length is less than or equal to cable length.)

Hardware

Endpoint Wiring Method

Communication/Output

Units of Measure Totalizer/Flow Rate

Gallons/gallons per minute (field selectable, additional options available) G

Testing & Tagging

1

Part Number Construction for TFX-5000 Flow Meters for Pipes Larger than 2 in.

DQ-G

TFX-5000 Ultrasonic Clamp-On Meter DQ

General Area US/Canada, CE G

Medium pipe, 2.5 in. (65 mm) or larger RZ

2.5…6 inches (65…150 mm) Easy Rail (not available with conduit) JZ

2.5…12 inches (65…300 mm) Easy Rail (not available with conduit) KZ

Large pipe, 8 in. (200 mm) or larger LZ

110/220V AC Remote Mounted R

24V DC/AC Remote Mounted B

Display and Keypad S

No Display/Keypad W

15 feet (4.5 m) AC

30 feet (9 m) AF

50 feet (15 m) AK

75 feet (23 m) AR

100 feet (30 m) BW

150 feet (46 m) BK

200 feet (61 m) DW

250 feet (76 m) DK

300 feet (90 m) EW

- - - - - - -XX- - -

HZ

None WW

5 feet (1.5 m) AA

15 feet (4.5 m) AC

30 feet (9 m) AF

50 feet (15 m) AK

75 feet (23 m) AR

100 feet (30 m) BW

150 feet (46 m) BK

200 feet (61 m) DW

250 feet (76 m) DK

300 feet (90 m) EW

1/2 in. NPT Threads, Poly cable glands S

1/2 in. NPT Threads, Nickel Plated Brass cable glands T

1/2 in. NPT Threads, no cable glands N

M20 Threads, Poly cable glands C

M20 Threads, Nickel Plated Brass cable glands D

M20 Threads, no cable glands A

None XX

Standard Output (Modbus RTU or BACnet MS/TP field selectable) S

Standard Output plus Modbus TCP Ethernet T

Standard Output plus EtherNet/IP U

Standard Output plus BACnet/IP Ethernet V

Standard Output plus Aux Output 9

Factory Calibrated F

Factory Calibrated/Stainless Steel Tag S

Submersible transducer cables use two conduit openings.

Page 8 August 2019

TTM-DS-02221-EN-01

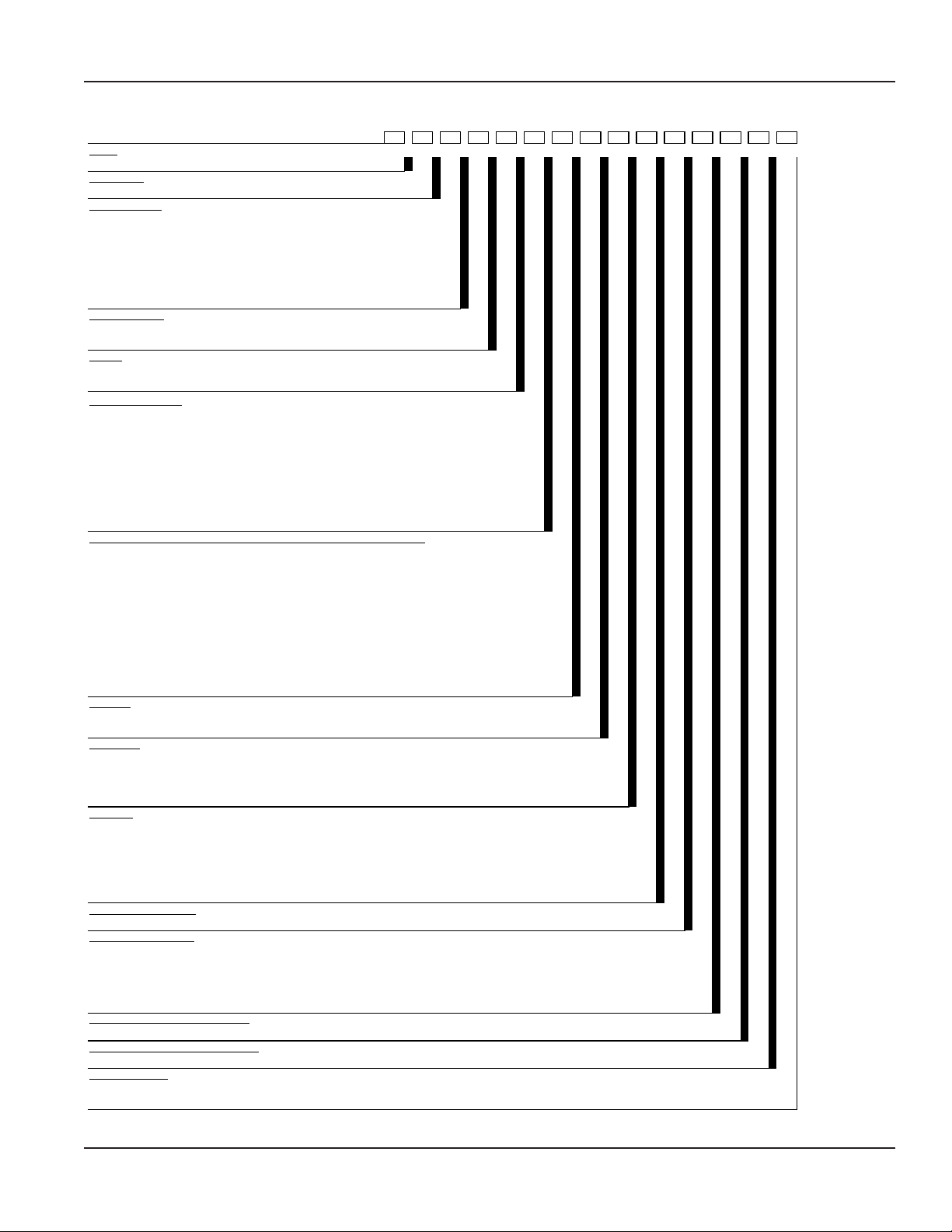

Page 9

Part Number Construction for TFX-5000 Flow Meters for Pipes Larger than 2 in. for Hazardous Locations

DQ-B

- - - - - - -

XX

- -

Model

Certification

Hazardous Location, Class I, Division 2

B

Transducer Type

Medium pipe, submersible, 2.5 in. (65 mm) or larger

1

WZ

Large pipe, submersible, 8 in. (200 mm) or larger

1

YZ

Transmitter Type

Display

2

Hardware

Endpoint Wiring Method

Communication/Output

Units of Measure Totalizer/Flow Rate

Gallons/gallons per minute (field selectable, additional options available) G

Testing & Tagging

Factory Calibrated/Stainless Steel Tag

S

2

TFX-5000 Ultrasonic Clamp-On Meter DQ

Medium pipe, 2.5 in. (65 mm) or larger RZ

Large pipe, 8 in. (200 mm) or larger LZ

110/220V AC Remote Mounted R

24V DC/AC Remote Mounted B

Standard S

No Display/Keypad W

Remote Cable/Conduit Length

15 feet (4.5 m) AC AC

30 feet (9 m) AF AF

50 feet (15 m) AK AK

75 feet (23 m) AR AR

100 feet (30 m) BW BW

150 feet (46 m) BK BK

200 feet (61 m) DW DW

250 feet (76 m) DK DK

300 feet (90 m) EW EW

Product Data Sheet

1/2 in. NPT Threads, Poly cable glands S

1/2 in. NPT Threads, Nickel Plated Brass cable glands T

1/2 in. NPT Threads, no cable glands N

M20 Threads, Poly cable glands C

M20 Threads, Nickel Plated Brass cable glands D

M20 Threads, no cable glands A

None XX

Standard Output (Modbus RTU or BACnet MS/TP field selectable) S

Standard Output plus Modbus TCP Ethernet T

Standard Output plus EtherNet/IP U

Standard Output plus BACnet/IP Ethernet V

Factory Calibrated

1

Submersible transducer cables use two conduit openings.

For hazardous location units, Remote Cable and Conduit Length codes must match.

F

TTM-DS-02221-EN-01

Page 9 August 2019

Page 10

Transit Time Ultrasonic Flow Meters, TFX-5000 Meter

Model

TFX-5000 Ultrasonic Clamp-On Meter DR

Certification

General Area US/Canada, CE G

Transducer Type

1

1/2 inch ANSI Pipe CA

3/4 inch ANSI Pipe CB

1 inch ANSI Pipe CC

1-1/4 inch ANSI Pipe CD

1-1/2 inch ANSI Pipe CE

2 inch ANSI Pipe CF

1/2 inch Copper Tube CG

3/4 inch Copper Tube CH

1 inch Copper Tube CT

1-1/4 inch Copper Tube CJ

1-1/2 inch Copper Tube CK

2 inch Copper Tube CL

Small pipe, universal, DTTSU (not available with conduit) UZ

Transmitter Type

110/220V AC Remote Mounted R

24V DC/AC Remote Mounted B

Display

Display and Keybad S

No Display/Keypad W

Remote Cable Length

15 feet (4.5 m) AC

30 feet (9 m) AF

50 feet (15 m) AK

75 feet (23 m) AR

100 feet (30 m) BW

Conduit Type and Length (Conduit length is less than or equal to cable length)

None WW

5 feet (1.5 m) AA

15 feet (4.5 m) AC

30 feet (9 m) AF

50 feet (15 m) AK

75 feet (23 m) AR

100 feet (30 m) BW

RTD Type

Surface, Commercial C

None (user provided) X

RTD Length

15 feet AC

50 feet AK

100 feet BW

None (user provided) WW

Hardware

1/2 in. NPT Threads, Poly cable glands S

1/2 in. NPT Threads, Nickel Plated Brass cable glands T

1/2 in. NPT Threads, no cable glands N

Endpoint Wiring Method

None XX

Communication/Output

Standard Output (Modbus RTU or BACnet MS/TP field selectable) S

Standard Output plus Modbus TCP Ethernet T

Standard Output plus EtherNet/IP U

Standard Output plus BACnet/IP Ethernet V

Standard Output plus Auxilliary Dry Contact Output 9

Units of Measure Totalizer/Flow Rate

Gallons/gallons per minute (field selectable, additional options available) G

Units of Measure Energy Totalizer/Rate

Kilowatt-hour/Watt (field selectable, additional options available)

R

Testing & Tagging

Factory Calibrated

F

Factory Calibrated/Stainless Steel Tag

S

Part Number Construction for TFX-5000 Energy Meters for Pipes 2 in. and Smaller

DR-G

- - - - - - - - -XX- - - -

1

Stainless steel tube 1/2…2 in. options are available.

Page 10 August 2019

TTM-DS-02221-EN-01

Page 11

Part Number Construction for TFX-5000 Energy Meters for Pipes Larger than 2 in.

DR-G

- - - - - - - - -XX- - - -

Model

Certification

Transducer Type

Medium pipe, submersible, 2.5 in. (65 mm) or larger

1

WZ

Large pipe, submersible, 8 in. (200 mm) or larger

1

YZ

Transmitter Type

Display

Conduit Type and Length (Conduit length is less than or equal to cable length)

RTD Type

RTD Length

Hardware

Endpoint Wiring Method

Communication/Output

Units of Measure Totalizer/Flow Rate

Gallons/gallons per minute (field selectable, additional options available) G

Units of Measure Energy Totalizer/Rate

Testing & Taggin g

TFX-5000 Ultrasonic Clamp-On Meter DR

General Area US/Canada, CE G

Medium pipe, 2.5 in. (65 mm) or larger RZ

2.5…6 inches (65…150 mm) Easy Rail (not available with conduit) JZ

2.5…12 inches (65…300 mm) Easy Rail (not available with conduit) KZ

Medium pipe, high temperature (not available with conduit) HZ

Large pipe, 8 in. (200 mm) or larger LZ

110/220V AC Remote Mounted R

24V DC/AC Remote Mounted B

Standard S

No Display/Keypad W

Remote Cable Length

15 feet (4.5 m) AC

30 feet (9 m) AF

50 feet (15 m) AK

75 feet (23 m) AR

100 feet (30 m) BW

150 feet (46 m) BK

200 feet (61 m) DW

250 feet (76 m) DK

300 feet (90 m) EW

Product Data Sheet

None WW

5 feet (1.5 m) AA

15 feet (4.5 m) AC

30 feet (9 m) AF

50 feet (15 m) AK

75 feet (23 m) AR

100 feet (30 m) BW

150 feet (46 m) BK

200 feet (61 m) DW

250 feet (76 m) DK

300 feet (90 m) EW

Surface, Commercial C

None (user provided) X

15 feet (4.5 m) AC

50 feet (15 m) AK

100 feet (30 m) BW

None (user provided) WW

1/2 in. NPT Threads, Poly cable glands S

1/2 in. NPT Threads, Nickel Plated Brass cable glands T

1/2 in. NPT Threads, no cable glands N

M20 Threads, Poly cable glands C

M20 Threads, Nickel Plated Brass cable glands D

M20 Threads, no cable glands A

None XX

Standard Output (Modbus RTU or BACnet MS/TP field selectable) S

Standard Output plus Modbus TCP Ethernet T

Standard Output plus EtherNet/IP U

Standard Output plus BACnet/IP Ethernet V

Standard Output plus Aux Output 9

Kilowatt-hour/Kilowatt (field selectable, additional options available) R

Factory Calibrated F

Factory Calibrated/Stainless Steel Tag S

1

Submersible transducer cables use two conduit openings.

TTM-DS-02221-EN-01

Page 11 August 2019

Page 12

Transit Time Ultrasonic Flow Meters, TFX-5000 Meter

Control. Manage. Optimize.

Dynasonics, AquaCUE and SoloCUE are registered trademarks of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities. Due

to continuous research, product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the extent

an outstanding contractual obligation exists. © 2019 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Eastern Europe Branch Oce (for Poland, Latvia, Lithuania, Estonia, Ukraine, Belarus) | Badger Meter Europe | ul. Korfantego 6 | 44-193 Knurów | Poland | +48-32-236-8787

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 19-07 Parkway Parade | Singapore 449269 | +65-63464836

Switzerland | Badger Meter Swiss AG | Mittelholzerstrasse 8 | 3006 Bern | Switzerland | +41-31-932 01 11

Loading...

Loading...