Page 1

Transit Time Flow Meters

TFX Ultra

DESCRIPTION

The TFX Ultra transit time meter measures clean liquids as well as

those with small amounts of suspended solids or aeration such as

surface water or sewage.

FEATURES

• Bi-directional flow measurement system

• Totalizer options include forward, reverse and net total

• Modbus RTU or BACnet MSTP over RS485; Ethernet

connections including BACnet/IP, EtherNet/IP, and

Modbus TCP/IP protocols

• Large, easy-to-read digital display

• Rugged, aluminum enclosure ensures a long service life in

harsh environments

• Certified for hazardous area installation in North America

and Europe

APPLICATIONS

TFX Ultra ultrasonic flow and energy meters clamp onto the outside

of pipes and do not contact the internal liquid. The technology has

inherent advantages over alternate devices including: low-cost

installation, no pressure head loss, no moving parts to maintain or

replace, and a large, bi-directional measuring range that ensures

reliable readings even at very low and high flow rates. The

TFX Ultra is available in a variety of configurations that permit the

user to select a meter with features suitable to meet particular

application requirements.

The TFX Ultra is available in two versions:

• A flow meter

• An energy flow meter used in conjunction with dual

clamp-on RTDs for temperature measurement—ideal for

retrofit, hydronic process and HVAC applications

OPERATION

Transit time flow meters measure the time difference between

the travel time of an ultrasound wave going with the fluid flow

and against the fluid flow. The time difference is used to calculate

the velocity of the fluid traveling in a closed-pipe system. The

transducers used in transit time measurements operate alternately

as transmitters and receivers. Transit time measurements are

bi-directional and are most effective for fluids that have low

concentrations of suspended solids.

Temperature measurements, when used in conjunction with flow

measurement, can yield energy usage readings in the form of heat

flow. To find the net heat loss or gain, energy usage is calculated by

multiplying the flow rate of the heat transfer fluid by the change of

heat content in that fluid after it has done some kind of work.

An ultrasonic meter equipped with heat flow capabilities is

designed to measure the rate and quantity of heat delivered or

removed from devices such as heat exchangers. The instrument

measures the volumetric flow rate of the heat exchanger liquid, the

temperature at the inlet pipe and the temperature

at the outlet pipe.

Rate of Heat Delivery = Q × (Tin – T

Where

Q = Volumetric ow rate

Tin = Temperature at the inlet

T

= Temperature at the outlet

out

C = Heat capacity

ρ = Density of uid

By applying a scaling factor this heat flow measurement can be

expressed in various units: Btu, Watts, Joules, Kilowatts, and others.

) × C × ρ

out

TTM-DS-00085-EN-09 (June 2019)

Product Data Sheet

Page 2

TFX Ultra Transit Time Flow Meter

COMMON FEATURES

• Rate-Total Backlit Display

• 4…20 mA Output

• 0…1000 Hz Rate Pulse and Dual Alarm Outputs

(Flow Meter Model only)

• Auxiliary Total Pulse Output 0…16 Hz

(Energy Meter model only)

• USB Programming Port

• RS485 Modbus Network Connection

• Remote Totalizer Reset

METER WITH REMOTE FLOW TRANSDUCER

METER WITH INTEGRAL FLOW TRANSDUCER

For pipe/tubing sizes of 2 in. (50 mm) and smaller, the TFX Ultra meter

is available with a clamp-on transducer mounted and wired directly

to the flow meter display/electronics enclosure. This design provides

a convenient installation in areas where local indication is required.

Bottom View

Integral Flow Transducer

Front View

Supply

Temperature Transducers

(Energy Meter Only)

Return

RAIL MOUNTING KIT

The TFX Ultra is available with remote mounted transducers that

permit separation of up to 990 feet (300 m). This design is used

on larger pipes or when pipes are located in areas that are not

convenient for viewing, or on piping systems with severe vibration.

Remote Flow

Transducers

Supply

Temperature Transducers

(Energy Meters Only)

Return

For remote flow DTTR transducers, the rail mounting kit aids in

installation and positioning of the transducers. Transducers slide

on the rails, which have measurement markings that are viewable

through the sight opening.

Page 2 June 2019

TTM-DS-00085-EN-09

Page 3

Product Data Sheet

NETWORK OPTIONS

RS485 Network

All TFX Ultra meters come equipped with an RS485 and use a Modbus RTU command set (data can be returned in single-precision, doubleprecision, integer or oating point values) or an optional BACnet MSTP protocol. Up to 126 Ultra products can be run on a single daisy-chain

network and be individually queried for ow rate, positive ow accumulator, negative ow accumulator, supply temperature, return temperature

and signal strength. Flow accumulators can be cleared at discrete addresses or globally. The RS485 network is also compatible with EnergyLink,

direct to Excel, application. (EnergyLink is compatible with Modbus RTU only.)

Address 126Address 2Address 1

RS485

converter

3-wire + shield

4000 feet (1220 m) max. without repeaters

Ethernet 10/100 Base-T Network

If equipped with the optional Ethernet communications module, the TFX Ultra can be plugged into a LAN and queried for flow rate, positive

flow accumulator, negative flow accumulator, supply temperature, return temperature and signal strength. The module contains

Modbus TCP/IP, EtherNet/IP and BACnet/IP network compatibility.

Device N Device 3 Device 2 Device 1

LAN

RTD KITS FOR INTEGRAL AND REMOTE ENERGY MEASUREMENT METERS

D010-3000-120 RTD Kit1, clamp on, 130° C, 1000 Ohm, 20 ft D010-3000-200 Insertion RTD Kit2, 3 in., 1/4 in. O.D., 260° C, 1000 Ohm, 20 ft

D010-3000-121 RTD Kit1, clamp on, 130° C, 1000 Ohm, 50 ft D010-3000-201 Insertion RTD Kit2, 3 in., 1/4 in. O.D., 260° C, 1000 Ohm, 50 ft

D010-3000-122 RTD Kit1, clamp on, 130° C, 1000 Ohm, 100 ft D010-3000-202 Insertion RTD Kit2, 3 in., 1/4 in. O.D., 260° C, 1000 Ohm, 100 ft

1

D010-3000-123 RTD Kit1, clamp on, 200° C, 1000 Ohm, 25 ft

D010-3000-124 RTD Kit1, clamp on, 200° C, 1000 Ohm, 50 ft

RTD Kits include: 2 RTDs, heat sink compound and installation tape

2

Insertion RTD Kits include: A set of 2 RTD

D010-3000-125 RTD Kit1, clamp on, 200° C, 1000 Ohm, 100 ft

MOUNTING SYSTEM FOR DTTR TRANSDUCERS MOUNTING SYSTEM FOR DTTN TRANSDUCERS

D010-2102-310 10 in. scaled mounting rail system D010-2102-010 10 in. scaled mounting rail system

D010-2102-016 16 in. scaled mounting rail system

TTM-DS-00085-EN-09

Page 3 June 2019

Page 4

TFX Ultra Transit Time Flow Meter

SPECIFICATIONS

System

Liquid Types Most clean liquids or liquids containing small amounts of suspended solids or gas bubbles

Velocity Range Bi-directional to greater than 40 FPS (12 MPS)

DTTR/DTTN/DTTH/DTTL/

Flow Accuracy

Temperature

Accuracy

(Energy Models

Only)

Sensitivity

Repeatability 0.5% of reading

Installation

Compliance

Easy Rail (DTTJ/DTTK):

DTTS/DTTC:

DTTS/DTTC:

Option A:

Option B:

Option C:

Option D:

Flow: 0.001 FPS (0.0003 MPS)

Temperature:

Option A:

Option B:

Option C:

Option D:

General Safety (all models): UL 61010-1, CSA C22.2 No. 61010-1; (power options A and D only) EN 61010-1

Hazardous Location (power supply options A and D only): Class I Div. 2 Groups C, D, T4; Class II, Division 2, Groups F, G,

T4; Class III Division 2 for US/CAN; Standards: UL 1604, CSA 22.2 No. 213, ANSI/ISA 12.12.01 (2013)

Compliant with directives 2004/108/EC, 2006/95/EC and 94/9/EC on meter systems with integral flow transducers, transducers

constructed with twinaxial cable (all transducers with cables 100 ft (30 m) and shorter) or remote transducers with conduit

32…122° F (0…50° C)

32…212° F (0…100° C)

–40…350° F (–40…177° C)

–4…85° F (–20…30° C)

0.03° F (0.012° C)

0.05° F (0.025° C)

0.1° F (0.06° C)

0.03° F (0.012° C)

±1% of reading or ±0.01 FPS (0.003 MPS), whichever is greater

1 in. (25 mm) and larger = ±1 % above 1 FPS (0.3 MPS) and ±0.01 FPS below 1 FPS

3/4 in. (19 mm) and smaller = ±1% of full scale

Absolute: 0.22° F (0.12° C)

Absolute: 0.45° F (0.25° C)

Absolute: 1.1° F (0.6° C)

Absolute: 0.22° F (0.12° C)

Difference: 0.09° F (0.05° C)

Difference: 0.18° F (0.1° C)

Absolute: 1.1° F (0.6° C) Difference: 0.45° F (0.25° C)

Absolute: 0.22° F (0.12° C)Difference: 0.09° F (0.05° C)

Transmitter

Power

Requirements

Display

Enclosure

Temperature –40…131° F (–40…55° C) for line AC power with Ethernet option; –40…149° F (–40…65° C) for all others

Configuration

Engineering

Units

Inputs/Outputs

AC:

DC:

Protection:

Two line LCD, LED backlit:

Icons: RUN, PROGRAM, RELAY1, RELAY2

Flow rate indication: 8-digit positive, 7-digit negative max. Auto decimal, lead zero blanking

Flow accumulator (totalizer):

NEMA Type 4 (IP-65)

Construction:

Size: 6.0 in. W x 4.4 in. H x 2.2 in. D (152 mm W x 112 mm H x 56 mm D)

Conduit Holes: (2) 1/2 in. NPT female; (1) 3/4 in. NPT female; Optional Cable Gland Kit

Via optional keypad or PC running ULTRALINK software

(Note: not all configuration parameters are available from the keypad—for example flow and temperature calibration and advanced

filter settings)

Flow-Only Model:

Energy Model: Btu, mBtu, mmBtu, tons, kJ, kW, MW, kilocalorie, megacalorie

USB 2.0: For connection of a PC running ULTRALINK configuration utility

RS485: Modbus RTU command set or BACnet® MSTP; Baud rates 9600, 14400,19200, 38400, 56000, 57600, 76800

Ethernet: Optional 10/100 Base T RJ45, communication via Modbus TCP/IP, EtherNet/IP, or BACnet/IP

4-20 mA: 12-bit, internal power, can span negative to positive flow/energy rates

Input: Reset totalizer when input is connected to signal ground

Energy Model:

Flow-Only Model:

95…264 V AC 47…63 Hz @ 17 VA max. or 20…26 V AC 47…63 Hz @ 0.35 A max.

10…28 V DC @ 5 W max.

Auto resettable fuse, reverse polarity and transient suppression

Top row 0.7 inch (18 mm) height, 7-segment

Bottom row 0.35 inch (9 mm) height, 14-segment

8-digit positive, 7-digit negative max. Reset via keypad, ULTRALINK, network command or momentary

contact closure

Powder-coated aluminum, polycarbonate, stainless steel, polyurethane, nickel-plated steel mounting

brackets

Feet, gallons, cubic feet, million gallons, barrels (liquid and oil), acre-feet, pounds, meters, cubic meters,

liters, million liters, kilograms

Total Pulse: Opto isolated open collector transistor

2…28V DC, 100 mA max, 30 ms pulse width up to 16 Hz, 12-bit resolution, can span negative to positive

rates; square-wave or turbine meter simulation outputs. Cannot be used with Ethernet option

Frequency Output: Open collector, 10…28V DC, 100 mA max, 0…1000 Hz; square wave or turbine

meter simulation

Two Alarm Outputs: Open-collector, 10…28V DC, 100 mA max, congure as rate alarm, signal strength

alarm or totalizer pulse (100 ms pulse width up to 1 Hz max )

Page 4 June 2019

TTM-DS-00085-EN-09

Page 5

Transducers

?

Product Data Sheet

PBT glass filled, Ultem, Nylon cord grip,

PVC cable jacket; –40…250° F (–40…121° C)

CPVC, Ultem, Nylon cord grip,

PVC cable jacket; –40…194° F (–40…90° C)

CPVC, Ultem, Nylon cord grip,

PVC cable jacket; –40…185° F (–40…85° C)

CPVC, Ultem, Nylon cord grip

Polyethylene cable jacket; –40…194° F (–40…90° C)

PTFE, Vespel, Nickel-plated brass cord grip

PFA cable jacket; –40…350° F (–40…176° C)

PVC, Ultem, Nylon cord grip,

PVC cable jacket; –40…140° F (–40…60° C)

Construction

DTTR/Easy Rail (DTTJ/DTTK) NEMA 6*/IP67

DTTC/DTTL NEMA 6*/IP67

DTTN IS NEMA 6*/IP67

DTTN/DTTL (Submersible) NEMA 6P*/IP68

DTTH NEMA 6*/IP67

DTTS NEMA 6*/IP67

*NEMA 6 units: to a depth of 3 ft (1 m) for 30 days max. NEMA 6P units: to a depth of 100 ft (30 m) seawater equivalent

density indefinitely.

Frequency

DTTS/DTTC:

DTTR/DTTN/DTTH/ DTTJ/DTTK:

DTTL:

2 MHz

1 MHz

500 KHz

Cables RG59 Coaxial or Twinaxial (optional armored conduit)

Cable Length 990 ft (300 meter) max. in 5 ft (1.5 m) increments; Submersible Conduit limited to 100 ft (30 m)

RTDs

(Energy Models

Platinum 385, 1000 Ohm, 3-wire; PVC jacket cable

Only)

DTTN (option N) /DTTR/DTTS/DTTH/DTTC: General (see “Installation Compliance” on page4)

Installation

DTTN Transducer (option F) and IS Barrier D070-1010-002: Class I Div. 1, Groups C&D T5 Intrinsically

Safe Ex ia; CSA C22.2 No. 142 & 157; UL 913 & 916

Software Utilities

ULTRALINK

Programming Cable USB A/B cable; 10 ft (3.05 m); part number D005-2117-003

Used to configure, calibrate and troubleshoot Flow-Only and Energy models. Connection via USB A/B cable; software is

compatible with Windows® 2000, Windows XP, Windows Vista and Windows 7

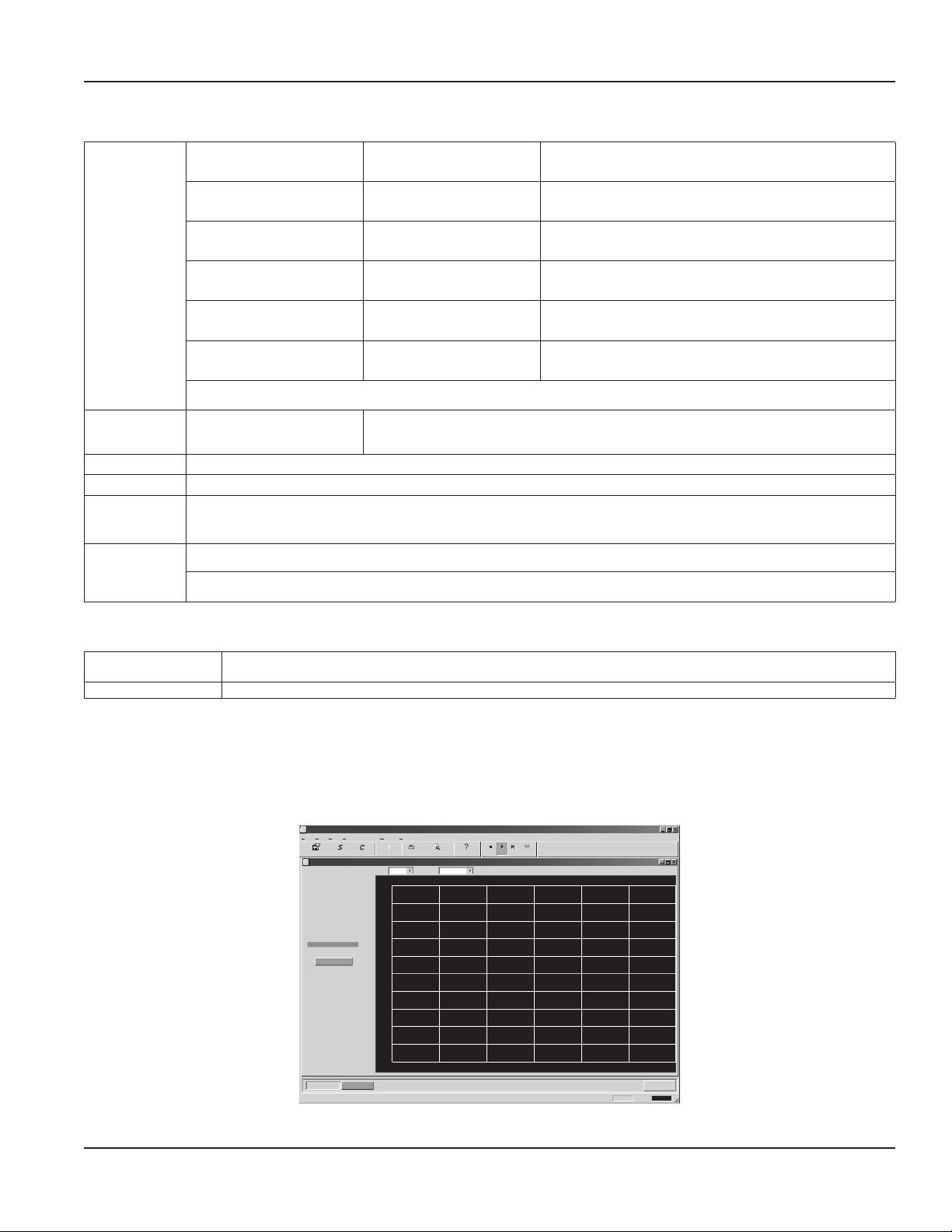

ULTRALINK SOFTWARE UTILITY

In addition to, or as a replacement for, the keypad entry programming, the flow meter can be used with the ULTRALINK software utility. The

software is used to configure, calibrate and communicate with TFX Ultra flow meters. Additionally, it has numerous troubleshooting tools to

make diagnosing and correcting installation problems easier.

A PC can be hard-wired to the TFX Ultra through a standard USB connection found on most current computers.

UltraLINK Device Addr 127

U

Conguration CalibrationStrategy

Device Addr 127

U

135 Gal/Min

Flow:

237 Gal

Totalizer Net:

Pos:

237 Gal

Neg:

0 Gal

Sig. Strength:

15.6%

Margin:

100%

Delta T:

2.50 ns

Last Update:

12:17:20

Signal Strength too Low!

Reset Totalizers

Data Display Diagnostics

HelpWindowCommunicationsViewEditFile

!

Print About

Errors

60 Min

2000

1600

1200

800

400

0

Flow Rate

-400

-800

-1200

-1600

-2000

-1.00:00

?

Stop

Step View

Go

Stop

Print Preview

2000

Scale:Time:

-50:00 -40:00 -30:00 -20:00 -10:00 -0:00

Stop

Historical Data

Time (mm:ss)

13:26:33

COMM:For Help, press F1

Exit

OK

TTM-DS-00085-EN-09

Page 5 June 2019

Page 6

TFX Ultra Transit Time Flow Meter

DIMENSIONS

Remote System Electronics Enclosure

B

A

C

Wall mount

A

Pipe mount

A

B

C

DIA Mounting

holes (2)

Enclosure Wall Mount Pipe Mount

A 6.00 in. (132.4 mm) 6.50 in. (165.1 mm) 1.38 in. (35.1 mm)

B 4.20 in. (106.7 mm) 2.30 in. (58.4 mm) 2.90 in. (73.7 mm)

C 4.32 in. (110 mm) 0.19 in. (4.8 mm) 1.20 in. (30.5 mm)

D 2.12 in. (53.8 mm)

D

B

C

Page 6 June 2019

TTM-DS-00085-EN-09

Page 7

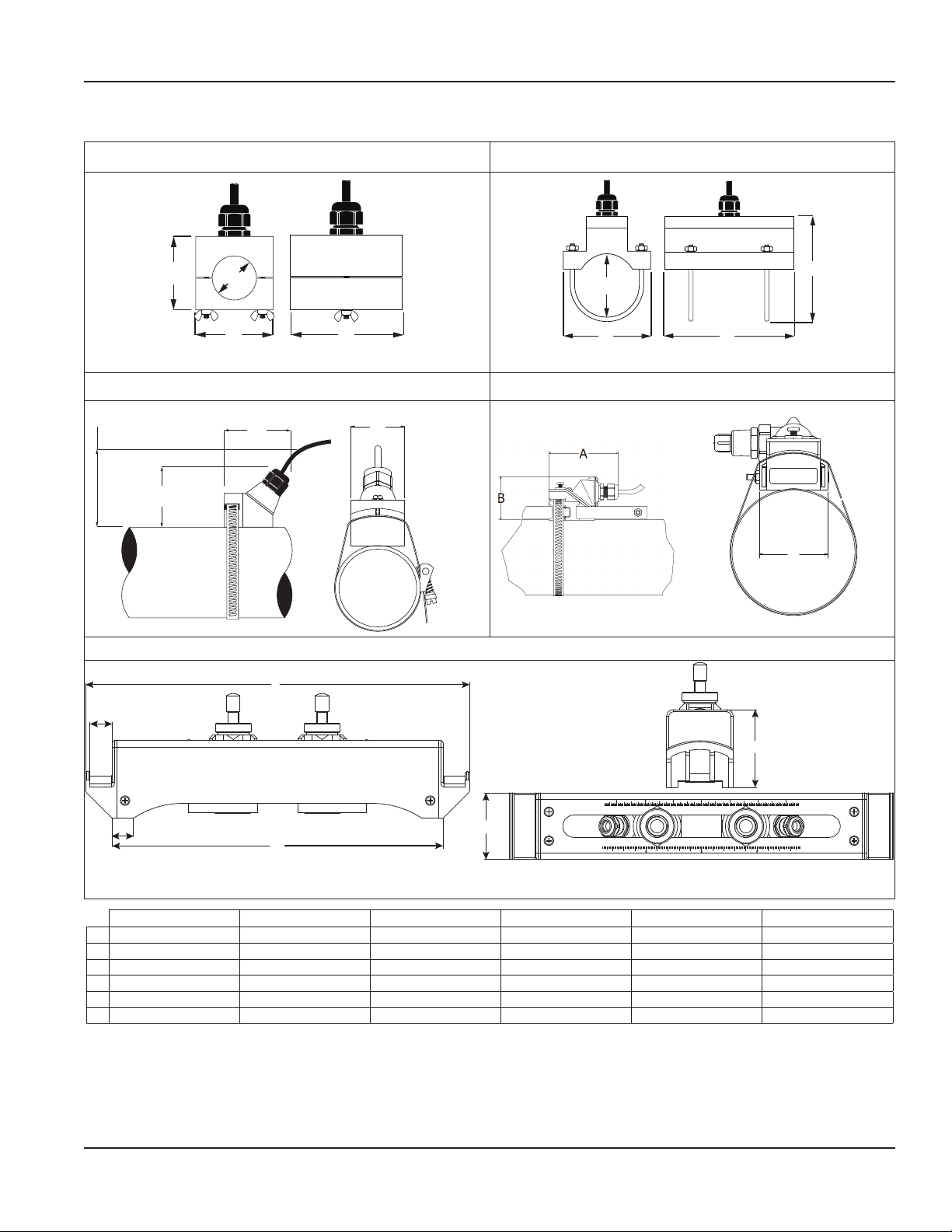

DTTR/DTTN/DTTH/DTTL/DTTJ/DTTK (EasyRail) Transducers

Product Data Sheet

(Min Clearance)

C

TOP VIEW

Pipes and Tubing 1/2…2 in. (12…50 mm)

B

DTTS/DTTC

D

A

DTTN/DTTH/DTTL

Pipes Larger than 2 in. (50 mm)

A

B

OF PIPE

DTTS/DTTC U-Bolt Connections

ANSI/DN and Copper 2 in. (50 mm) Models

B

D

C

A

C

DTTR

D

D

DTTJ/DTTK

A

D

E

inch

C

B

DTTR DTTN DTTH DTTL DTTJ DTTK

A 3.75 in. (95 mm) 2.95 in. (74.9 mm) 2.95 in. (74.9 mm) 3.40 in. (86.4 mm) 13.62 in. (345.95 mm) 19.92 in. (505.97 mm)

B 2.35 in. (60 mm) 2.75 in. (69.8 mm) 2.75 in. (69.8 mm) 2.94 in. (74.7 mm) 11.73 in. (297.94 mm) 18.03 in. (457.96 mm)

C — 3.00 in. (76.2 mm) 3.00 in. (76.2 mm) 3.20 in. (81.3 mm) 0.75 in. (19.05 mm) 0.75 in. (19.05 mm)

D 2.19 in. (56 mm) 1.70 in. (43.2 mm) 1.71 in. (43.4 mm) 2.50 in. (63.5 mm) 0.79 in. (20.06 mm) 0.79 in. (20.06 mm)

E — — — — 2.76 in. (70.10 mm) 2.76 in. (70.10 mm)

F — — — — 2.36 in. (59.94 mm) 2.36 in. (59.94 mm)

F

mm

TTM-DS-00085-EN-09

Page 7 June 2019

Page 8

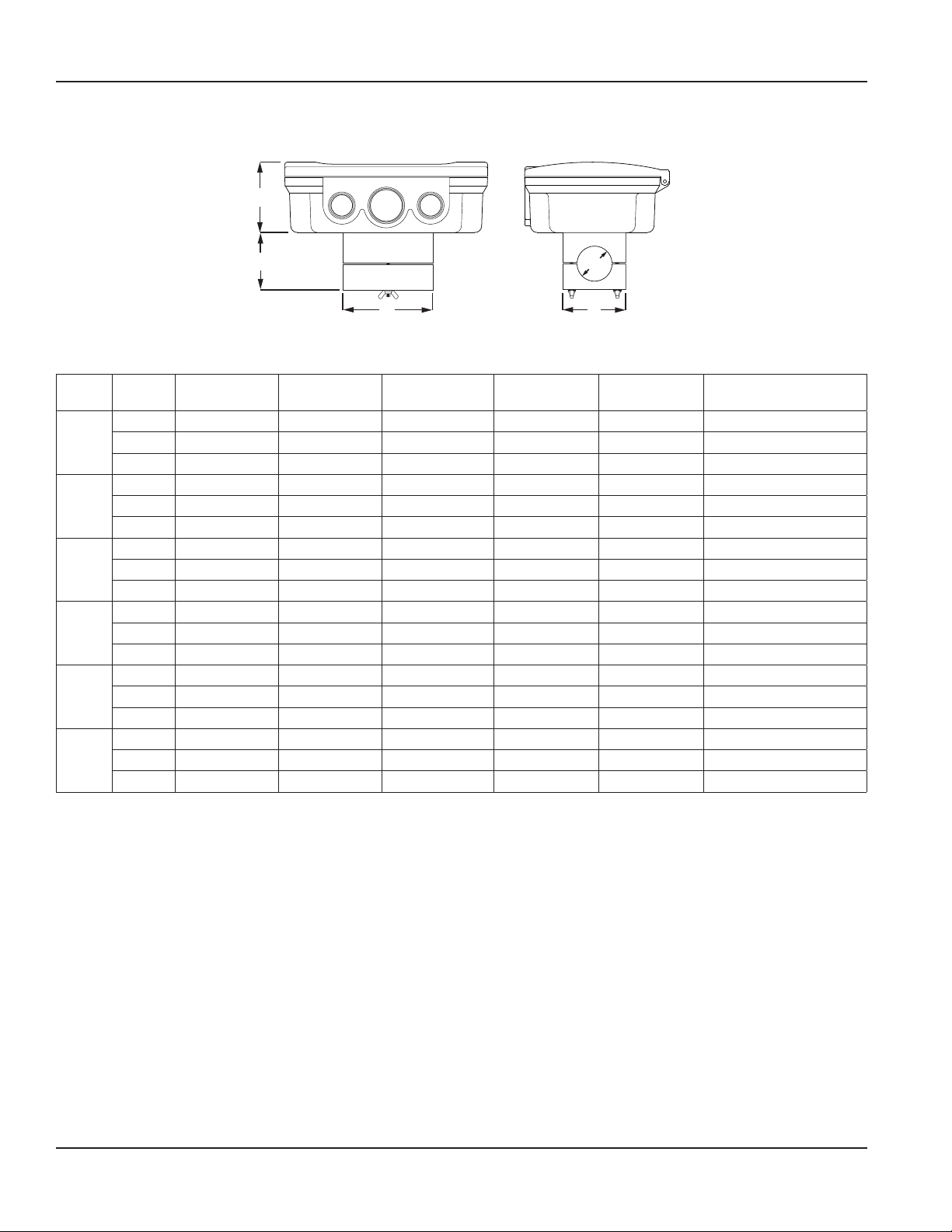

TFX Ultra Transit Time Flow Meter

C

B

E

A

D

Integral System

DTTS/DTTC Transducers

Pipe

Size

1/2 in.

3/4 in.

1 in.

1-1/4 in.

1-1/2 in.

2 in.

* Varies due to U-bolt conguration

Pipe

Material

ANSI/DN 2.46 in. (62.5 mm) 2.36 in. (59.9 mm) 2.66 in. (67.6 mm) 0.84 in. (21.3 mm) 2.12 in. (53.8 mm) 2.0…38 gpm (8…144 lpm)

Copper 2.46 in. (62.5 mm) 2.36 in. (59.9 mm) 3.33 in. (84.6 mm) 0.63 in. (15.9 mm) 2.12 in. (53.8 mm) 1.8…27 gpm (7…102 lpm)

Tubing 2.46 in. (62.5 mm) 2.28 in. (57.9 mm) 3.72 in. (94.5 mm) 0.50 in. (12.7 mm) 2.12 in. (53.8 mm) 1.5…18 gpm (6…68 lpm)

ANSI/DN 2.46 in. (62.5 mm) 2.57 in. (65.3 mm) 2.66 in. (67.6 mm) 1.05 in. (26.7 mm) 2.12 in. (53.8 mm) 2.75…66 gpm (10…250 lpm)

Copper 2.46 in. (62.5 mm) 2.50 in. (63.5 mm) 3.56 in. (90.4 mm) 0.88 in. (22.2 mm) 2.12 in. (53.8 mm) 2.5…54 gpm (10…204 lpm)

Tubing 2.46 in. (62.5 mm) 2.50 in. (63.5 mm) 3.56 in. (90.4 mm) 0.75 in. (19.0 mm) 2.12 in. (53.8 mm) 2.5…45 gpm (10…170 lpm)

ANSI/DN 2.46 in. (62.5 mm) 2.92 in. (74.2 mm) 2.86 in. (72.6 mm) 1.32 in. (33.4 mm) 2.12 in. (53.8 mm) 3.5…108 gpm (13…409 lpm)

Copper 2.46 in. (62.5 mm) 2.87 in. (72.9 mm) 3.80 in. (96.5 mm) 1.13 in. (28.6 mm) 2.12 in. (53.8 mm) 3.5…95 gpm (13…320 lpm)

Tubing 2.46 in. (62.5 mm) 2.75 in. (69.9 mm) 3.80 in. (96.5 mm) 1.00 in. (25.4 mm) 2.12 in. (53.8 mm) 3.5…85 gpm (13…320 lpm)

ANSI/DN 2.80 in. (71.0 mm) 3.18 in. (80.8 mm) 3.14 in. (79.8 mm) 1.66 in. (42.2 mm) 2.12 in. (53.8 mm) 5.0…186 gpm (19…704 lpm)

Copper 2.46 in. (62.5 mm) 3.00 in. (76.2 mm) 4.04 in. (102.6 mm) 1.38 in. (34.9 mm) 2.12 in. (53.8 mm) 4.5…152 gpm (17…575 lpm)

Tubing 2.46 in. (62.5 mm) 3.00 in. (76.2 mm) 4.04 in. (102.6 mm) 1.25 in. (31.8 mm) 2.12 in. (53.8 mm) 4.0…136 gpm (15…514 lpm)

ANSI/DN 3.02 in. (76.7 mm) 3.40 in. (86.9 mm) 3.33 in. (84.6 mm) 1.90 in. (48.3 mm) 2.12 in. (53.8 mm) 6.0…250 gpm (23…946 lpm)

Copper 2.71 in. (68.8 mm) 2.86 in. (72.6 mm) 4.28 in. (108.7 mm) 1.63 in. (41.3 mm) 2.12 in. (53.8 mm) 5.0…215 gpm (19…814 lpm)

Tubing 2.71 in. (68.8 mm) 3.31 in. (84.1 mm) 4.28 in. (108.7 mm) 1.50 in. (38.1 mm) 2.12 in. (53.8 mm) 5.0 …200 gpm (19…757 lpm)

ANSI/DN 3.70 in. (94.0 mm) 3.42 in. (86.9 mm)* 5.50 in. (139.7 mm) 2.38 in. (60.3 mm)* 2.12 in. (53.8 mm) 8.0…420 gpm (30…1590 lpm)

Copper 3.70 in. (94.0 mm) 3.38 in. (85.9 mm)* 5.50 in. (139.7 mm) 2.13 in. (54.0 mm)* 2.12 in. (53.8 mm) 8.0…375 gpm (30…1419 lpm)

Tubing 3.21 in. (81.5 mm) 3.85 in. (98.0 mm) 4.75 in. (120.7 mm) 2.00 in. (50.8 mm) 2.12 in. (53.8 mm) 8.0…365 gpm (30…1381 lpm)

A B C D E Measuring Range

Page 8 June 2019

TTM-DS-00085-EN-09

Page 9

PART NUMBER CONSTRUCTIONTFX ULTRA FLOW METERS, REMOTE MOUNT

-

- - -

MODEL

PIPE SIZE / MEASUREMENT RANGE

3

TRANSDUCER MATERIAL / TEMPERATURE

POWER

KEYPAD

ADVANCED COMMUNICATIONS

RTD TEMPERATURE RANGE

4

B

4…85° F (-20…35° C) | DTFXE Only

D

APPROVALS

OPTIONS

LANGUAGE

Product Data Sheet

1

Flow

2

Energy

Remote Mount

None N

AC (Universal) | 95…264V AC A

AC | 20…26V AC, General Safety Only C

DC | 11…28V DC D

No Keypad N

4 Button Keypad K

Modbus RTU

BACnet MS/TP

BACnet MS/TP 76800 Baud

BACnet MS/TP; 10/100 Base-T (EtherNet/IP, BACnet/IP, Modbus TCP/IP)

Modbus RTU and 10/100 Base-T (EtherNet/IP, BACnet/IP, Modbus TCP/IP)

Totalizing Pulse - Modbus RTU

Totalizing Pulse - BACnet MS/TP Q

DTFX

Z N

B

E

Z

N

B

H

C

E

P

None | Select for DTFXB

32…122° F (0…50° C) | DTFXE Only

N

A

32…212° F (0…100° C) | DTFXE Only

-40…350° F (-40…177° C) | DTFXE Only

Class I Div 2, Groups C, D T4; Class II Div 2, Groups F, G T4; Class III Div 2 |

For Power Supply Options A or D

C

F

General Safety N

None N

Cable Gland Kit A

English

French F

German G

Spanish S

1

4…20 mA Output; 0…1000 Hz Frequency Pulse Output; Dual Open Collector Outputs; communication options

2

4…20 mA output; Dual 1000 Ohm RTD Connections; communication options; order RTD kits separately

3

Transducers sold separately

4

RTDs sold separately

TTM-DS-00085-EN-09

Page 9 June 2019

Page 10

TFX Ultra Transit Time Flow Meter

- - - -

B

Energy

E

BACnet MS/TP; 10/100 Base-T (Ethernet/IP, BACnet/IP, Modbus TCP/IP)

RTD TEMPERATURE RANGE

3

N

A

32 ... 212° F (0 … 100° C) | DTFXE Only

B

-40 … 350° F (-40 … 177° C) | DTFXE Only

C

D

Class I Div 2, Groups C,D T4; Class II Div 2, Groups F,G T4; Class III Div 2 |

F

PART NUMBER CONSTRUCTIONTFX ULTRA FLOW METERS, INTEGRAL MOUNT

DTFX

MODEL

1

Flow

2

PIPE SIZE / MEASUREMENT RANGE

1/2 in. ANSI pipe A

3/4 in. ANSI pipe B

1 in. ANSI pipe C

1-1/4 in. ANSI pipe D

1-1/2 in. ANSI pipe E

2 in. ANSI pipe F

1/2 in. Copper Tube G

3/4 in. Copper Tube H

1 in. Copper Tube I

1-1/4 in. Copper Tube J

1-1/2 in. Copper Tube K

2 in. Copper Tube L

1/2 in. Stainless Steel Tube M

3/4 in. Stainless Steel Tube N

1 in. Stainless Steel Tube P

1-1/4 in. Stainless Steel Tube Q

1-1/2 in. Stainless Steel Tube R

2 in. Stainless Steel Tube S

TRANSDUCER MATERIAL / TEMPERATURE

PVC | -40 … 140° F (-40 … 60° C) P

CPVC | -40 … 194° F (-40 … 90° C) C

POWER

AC (Universal) | 95 … 264V AC A

AC | 20 ... 26V AC, General Safety Only C

DC | 11 ... 28V DC D

KEYPAD

No Keypad N

4-Button Keypad K

ADVANCED COMMUNICATIONS

Modbus RTU N

BACnet MS/TP B

BACnet MS/TP 76800 Baud H

C

Modbus RTU and 10/100 Base-T (Ethernet/IP, BACnet/IP, Modbus TCP/IP) E

Totalizing Pulse - Modbus RTU P

Totalizing Pulse - BACnet MS/TP Q

None | Select for DTFXB

32 ... 122° F (0 … 50° C) | DTFXE Only

4 … 85° F (-20 … 35° C) | DTFXE Only

APPROVALS

General Safety N

OPTIONS

None N

Cable Gland Kit A

LANGUAGE

English

French F

German G

Spanish S

1

4 … 20 mA Output; 0 … 1000 Hz Frequency Pulse Output; Dual Open Collector Outputs; communication options

2

4 … 20 mA output; Dual 1000 Ohm RTD Connections; communication options; order RTD kits separately

3

RTDs sold separately. See page 29 for avaiable options

Page 10 June 2019

For Power Supply Options A or D

TTM-DS-00085-EN-09

Page 11

Product Data Sheet

Piping Environment

No

Pipe Type

Cable Length

Conduit Type

Conduit Length

PART NUMBER CONSTRUCTIONREMOTE FLOW TRANSDUCERS, SMALL PIPES 1/2…2 IN. 15…50 MM

DTT - -

PVC -40…140° F (-40…60° C)

CPVC -40…194° F (-40…90° C)

minal Pipe Size

1/2 in.

3/4 in.

1 in.

1-1/4 in.

1-1/2 in.

2 in.

ANSI Pipe

Copper Pipe

Tubing

20 ft (6.10 m)

50 ft (15.24 m)

100 ft (30.48 m)

None (Bare Twinax Cable)

Flexible Armored (LiquidTite)

S

C

D

F

G

H

J

L

P

C

T

020

050

100

N

A

None

20 ft (6.10 m)

50 ft (15.24 m)

100 ft (30.48 m)

000

020

050

100

TTM-DS-00085-EN-09

Page 11 June 2019

Page 12

General

General Purpose, Submersible (IP68)

Hazardous Location (Class 1, Division 1, Groups C and D)

TFX Ultra Transit Time Flow Meter

PART NUMBER CONSTRUCTIONREMOTE FLOW TRANSDUCERS, PIPES LARGER THAN 2 IN. 50 MM

Purpose

DTT - - - N

Transmitter Type

Standard (1 MHz), 250° F (121° C) Max Temp.

Large Pipe (500 kHz), 194° F (90° C) Max Temp.

High Temperature (1 MHz), 350° F (176° C) Max Temp.

Easy Rail (1 MHz), 2…6 in. (50…150 mm), 250° F (121° C) Max Temp.

Easy Rail (1 MHz), 2…10 in. (50…250 mm), 250° F (121° C) Max Temp.

Cable Length

20 ft (6.10 m)

50 ft (15.24 m) 050

100 ft (30.48 m)

Conduit Type

None, Bare Twinax Cable

Flexible Armored |Not available with Easy Rail or high temperature DTTH transducer

Conduit Length

None 000

20 ft (6.10 m)

50 ft (15.24 m)

100 ft (30.48 m)

R

L

H

J

K

020

100

N

A

020

050

100

Transmitter Type

Standard: 1 MHz N

Large Pipe: 500 kHz L

Cable Length

20 ft (6.10 m)

50 ft (15.24 m)

100 ft (30.48 m)

Cable Length

20 ft (6.10 m)

50 ft (15.24 m) 050

100 ft (30.48 m)

Conduit Type

None, Bare Twinax Cable

Flexible Armored

Conduit Length

None 000

20 ft (6.10 m)

50 ft (15.24 m)

100 ft (30.48 m) 100

Control. Manage. Optimize.

Dynasonics, TFX Ultra and UltraLink are registered trademarks of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities. Due

to continuous research, product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the extent

an outstanding contractual obligation exists. © 2019 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Eastern Europe Branch Oce (for Poland, Latvia, Lithuania, Estonia, Ukraine, Belarus) | Badger Meter Europe | ul. Korfantego 6 | 44-193 Knurów | Poland | +48-32-236-8787

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 19-07 Parkway Parade | Singapore 449269 | +65-63464836

Switzerland | Badger Meter Swiss AG | Mittelholzerstrasse 8 | 3006 Bern | Switzerland | +41-31-932 01 11 Legacy Document Number: 06-TTM-DS-00431-EN

DTT - - S 000 - N

020

050

100

DTT N - - - F

020

100

N

A

020

050

Loading...

Loading...