Page 1

Series MFX

HOT-TAPPED INSERTION MAGNETIC PROBE

Series MFX Insertion MagProbe™ Flow Meters feature the world’s

most advanced magnetic flow measurement technology. The Series

MFX is a cost-effective solution for accurate measurement of

conductive liquid in closed conduit, pressurized-pipes without

process shutdown. The "flat tip" design will reduce fouling in

applications where suspended solids are present.

The MFX reliably measures most conductive fluids including water,

sewage, wastewater, clarified water, RAS, WAS, primary sludge and

cooling tower water, as long as adequate lengths of straight pipe are

available where the sensor is installed.

The MFX system consists of a hot-tappable insertion-type sensor that

mounts through a 1-1/2” ball valve pipe-tap into the flowing liquid,

and a remote digital display enclosure. The digital display is utilized to

FEATURES

Absolute (bi-directional) measurements from 0.1 to 30 FPS

(0.03 to 9 MPS).

Integrated sensor pre-amplifier permits separation of up to 990 feet

(297 m) between the sensor probe and MFX electronic analyzer.

Optional, optically isolated, field replaceable input/output modules

include: 4-20mA, dual-relay, rate pulse, RS232 and RS485.

Hot-tap sensor can be installed and retracted from process piping

without draining or depressurizing the system.

program engineering units, view flow rate/totalizer values and provide

process outputs. Velocity and pipe diameter information are entered by

the user via the display keypad or UltraLink™ software and used to

calculate volumetric flow, over wide flow ranges, with a high degree

of accuracy.

The Series MFX is more versatile and convenient than most

conventional full-pipe magnetic meters. MFX meters can be universally applied to a large range of pipe sizes without hardware changes,

compared to the specific internal pipe dimension design of conventional magnetic meters. In addition, cost differences are minimal when

moving to larger pipe sizes.

MagProbe sensors are available in

limited access mounting configura

diameters 4 to 120 inches (102 to 3048 mm).

High impedance input circuits minimize the influence of

electrode coating.

Industrial-grade sensor design: NEMA 6 (IP 67) submersible,

temperature to +225 °F (+105 °C), pressure to 700 PSIG (48 bar), titanium,

316SS, Viton

UltraLink PC utility permits configuration and intelligent diagnostics

to be performed.

®

and PVDF wetted materials.

various lengths to accommodate

tions and installation in pipe internal

DIVISION OF RACINE FEDERATED INC.

www.dynasonics.com800.535.3569

TM

Page 2

PRINCIPLES OF OPERATION

Series MFX Series MFX Series MFX

™

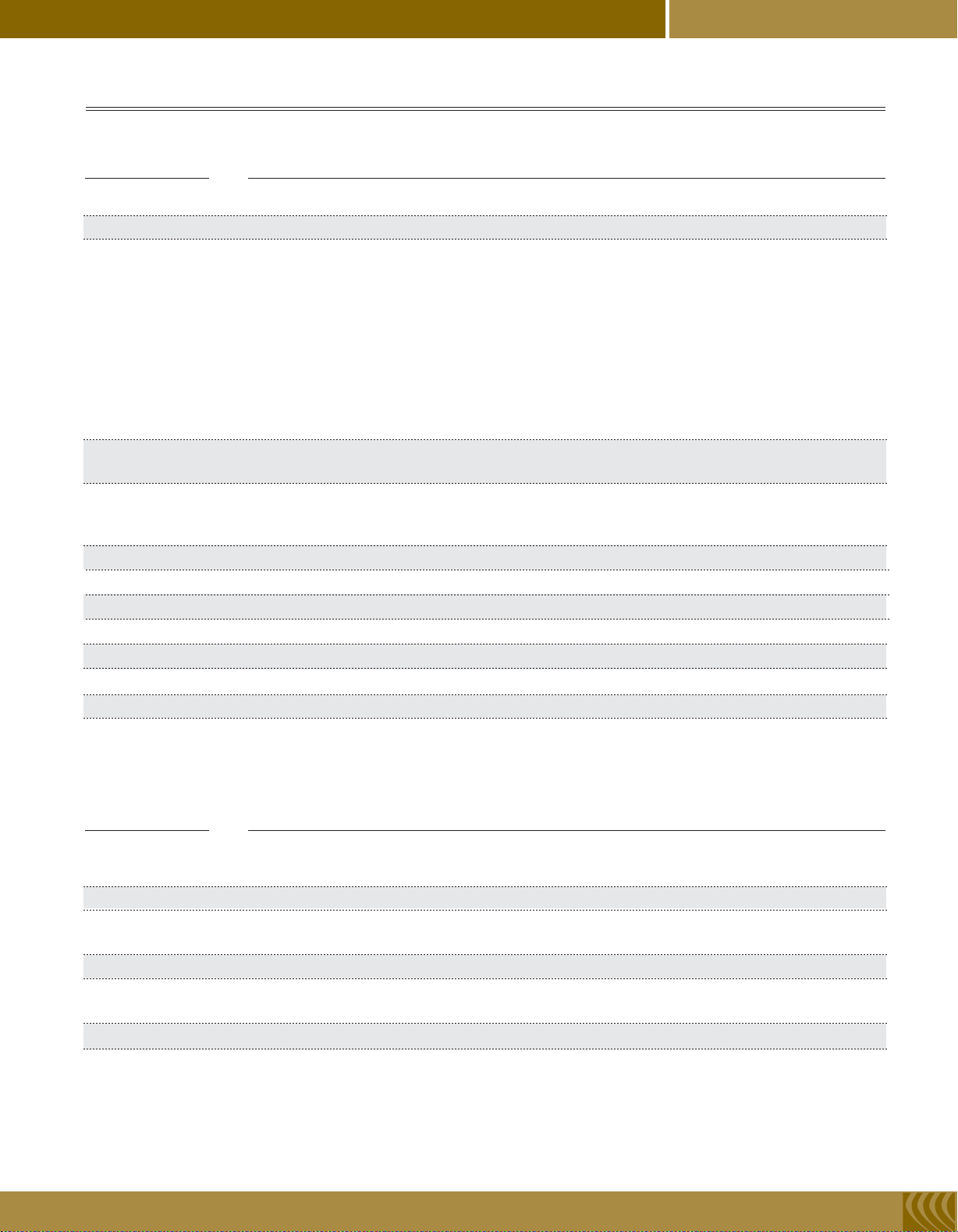

The MagProbe

used for measuring electrically conductive liquids, such

as water and water-based fluids, in closed piping

systems. The unit operates utilizing Faraday’s principle

of magnetic conduction, whereby a moving conductor

(the liquid) has a voltage imposed on it that is directly

proportional to two variables – the strength of a local

magnetic field and the velocity of the moving conductor.

Imposed voltage α Magnetic field × Fluid velocity

If the strength of the magnetic field is held constant,

then the magnitude of the voltage will be proportional to

the velocity of the moving conductor. The equation then

simplifies to Imposed voltage α Fluid velocity. The

MFX applies tri-stated, alternating polarity DC pulses to

an integral electromagnet (See Figure 1). Voltage

measurements are made with the magnet off, to

measure ambient background noise, and then with the

magnet on in both polarities. The magnitude difference

in voltage measured is proportional to flow. Once fluid

velocity is measured, then various volumetric flow

measurements will be obtained if the pipe internal

diameter (I.D.) is known.

Point-velocity flow meters measure the fluid velocity at a

specified depth into the fluid stream, typically 1/8 of the

pipe I.D., which has been proven to be the nominal

velocity point when symmetrical flow profiles are

present. This assumption requires the probe to be

downstream of any piping condition (elbows, valves,

thermo-wells, tees, etc.) that can cause flow

Typically, a minimum of 15 pipe diameters of straight

pipe is required to develop a symmetrical flow profile.

is a point-velocity measuring device

abnormalities.

The MFX is the perfect alternative to clamp-on and inline style

flow meters where pipe construction and site accessibility may

present an installation problem. Dynasonics’ “hot-tap” design

makes installation of the MagProbe sensor possible without

having to plumb in or drain a line.

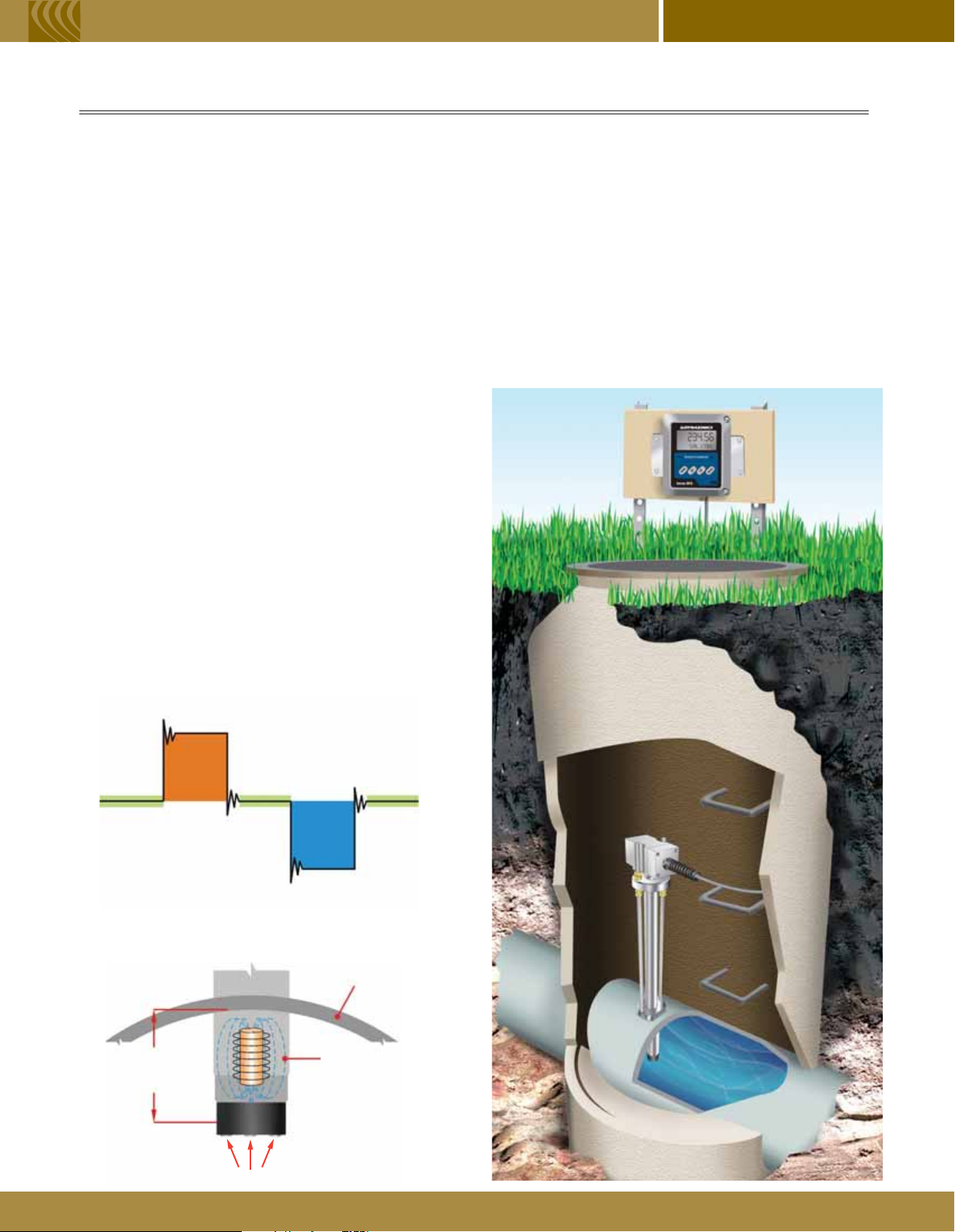

A typical application would find the MagProbe installed on a pipe

inside a vault or manhole (See Figure 3), measuring the flow of

water or wastewater. The NEMA 4X enclosure rating of the MFX

transmitter gives the added flexibility of indoor or outdoor usage.

The MFX is best suited for measuring clean liquids on large

pipes with large amounts of straight run.

Figure 3 – Typical MagProbe Water Application

Figure 1 – Magnet Excitation

Magnet On

+ Polarity

Magnet

Off

Figure 2 – MagProbe Design

1/8 of Pipe

Diameter

Magnet

Off

Magnet

Off

Magnet On

- Polarity

Pipe Wall

Pulsed

Magnetic

Field

Electrodes

Page 3

S

PECIFICATIONS

T

RANSMITTER

DESCRIPTION SPECIFICATION

Power Requirements 115/230 VAC 50/60 Hz ± 15% @ 5 VA max.; 9-28 VDC @ 3 VA max.

Velocity Range -30 to +30 FPS (-9 to +9 MPS); minimum flow 0.1 FPS (0.03 MPS)

Inputs/Outputs All modules are optically isolated from earth and system grounds.

Only one module may be installed.

Optional 4-20 mA Output 800 Ohms max.; 12-bit resolution; internal or external power; can be spanned anywhere

in the velocity range

Relay two separate Form C relays, 200 VAC @ 0.5 A resistive max.

Rate Pulse 0-2,500 Hz; 0.21 Ohm resistance; 1 A max.; can be spanned anywhere in the velocity range

RS232C data rate to 57.6K

RS485 supports up to 126 drops on three wires; 57.6K max. baud; Communications protocol

Data Logger 200,000 point, 16-bit resolution; integral DB-9 connector for plugging into PC;

can be removed and installed without disconnecting system power

Display 2-line x 8-character LCD, back lit. Top row: 7-segment digit height 0.7 inches (18 mm),

Bottom row: 14-segment digit height 0.35 inches (9 mm); 8-digit rate, 8-digit totalizer (resettable)

Units:

Engineering units Feet, gallons, cubic feet, mil-gal, barrels, acre-feet, lbs., meters, cubic meters, mil-liters, kg

Rate time intervals Seconds, minutes, hours and days

Temperature Range -40 ° to +185 °F (-40 ° to +85 °C), 0-95% relative humidity, non-condensing

Enclosure NEMA 4X (IP-65), polycarbonate, SS, brass and plated steel. 7.00H × 5.75W × 3.88D inches (178H × 146W × 99D mm)

Accuracy Flow Rate ±2% of full scale

Sensitivity ±0.005 FPS (±0.0017 MPS)

Response Time 3-300 seconds, user configured, to 100% of value, step change in flow.

Security Keypad lockout, access code enable

Approvals (Std) Ordinary area

User configured

P

ROBE

DESCRIPTION SPECIFICATION

Pipe Sizes Internal diameters 4 to 120 inches (102 to 3048 mm); requires 11/2" NPT port

Liquid Requirements Liquids with conductivity > 1 micro-Siemen/cm; liquids with solids that will not coat or wrap around the probe tip

Transmitter to Up to 990 feet (297 meters)

Probe Distance

Environment

Materials of Construction 316 Stainless Steel, PVDF, Viton

Electrodes: Titanium

Operating Pressure

-40 ° to +225 °F (-40 ° to +105 °C), NEMA 6 (IP67) submersible

®

, PVC jacketed cable rated for outdoor and direct-burial use

Up to 700 PSIG (48 bar) max. @ +75 °F (+25 °C)

Page 4

MAGPROBE

Seal Fitting

1-1/2" Full Flow

Ball Valve

1-1/2" NPT

Thread-O-Let

™

SELECTION

MagProbe

Diameter

Seal Fitting

Valve Stack

Pipe Wall

1/8 of Pipe

Diameter

Probe Length Selection Procedure

Before purchasing a MagProbe insertion flow

meter, it is necessary to calculate the probe length

required for a particular piping system. In order to

complete this calculation, some knowledge of the

piping system must be known. The variables

required are:

Pipe internal diameter

Pipe wall thickness

The length of the valve stack

Amount of straight pipe diameters in the system

Using this information and referring to the picture

to the left, a minimum probe length can be

determined.

Measurement A – The typical depth that the

MagProbe tip is inserted into the piping system is

1/8 of the pipe internal diameter. Assume 1/8 of the

pipe internal diameter unless a system piping

configuration does not have at least 15 pipe

diameters of straight pipe in the installation area.

In that case, assume 1/2 of the pipe internal

diameter – this will allow for flow profiling to

be performed.

Measurement B – Pipe wall thickness. This

information can be obtained from standard pipe

wall charts or, ideally, can be measured using an

ultrasonic wall thickness gauge.

Measurement C – Estimate the height that is

going to be taken up by the pipe tap, nipple and

full-flow ball valve. DMP2 through DMP5 probes

1

utilize 1

Measurement D – The insertion fitting for DMP2

through DMP5 probes is 2.5 inches.

Minimum Probe Length Required = A+B+C+D

/2" NPT hardware.

TRANSMITTER PART NUMBER MATR I X

D M F X N

Transmitter Type

2) Rate and Totalizer

Power Supply

A) 115 VAC

B) 230 VAC

C) 100 VAC

E) 9-28 VDC

Input/Output 1

N) None

1) 4-20 mA Output

2) Relay

3) Rate Pulse

4) RS232C

5) RS485

6) Data Logger

2

Input/Output 2

N) Reserved

Totalizer

A) Eight Digit Resettable

A

NN

Options

N) None

Approvals

N) Ordinary Area

MAGPROBE PART NUMBER MATR I X

D M P

Probe Length

2) 18 inches (457 mm)

3) 28 inches (711 mm)

4) 38 inches (965 mm)

5) 48 inches (1220 mm)

*Consult Factory for Longer Lengths

Cable Length

020) 20 feet (6 m)

050) 50 feet (15 m)

100) 100 feet (30 m)

Maximum Length: 990 feet (297 m)

in 10 ft. (3 m) increments

Conduit Type**

N) None

Conduit Length**

000) 0 feet (0 m)

**Consult the Dynasonics factory for

conduit availability and part numbers.

Options

N) None

B) 1.5 inch

150# RF

flange

connection

316SS

Page 5

ISO-MOD INPUT/OUTPUT MODULES DIMENSIONAL

General

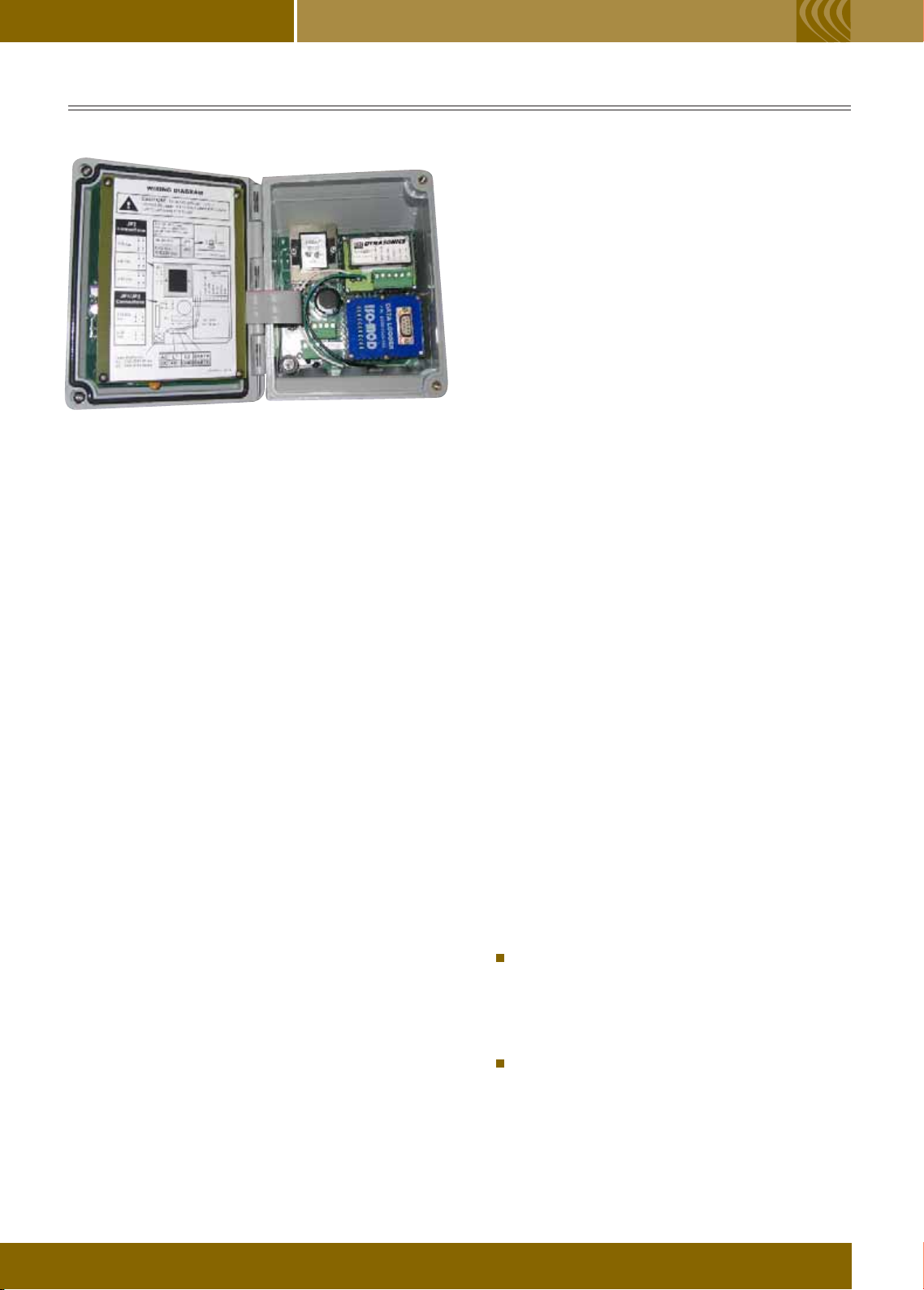

ISO-MODs are epoxy-encapsulated electronic output

modules that are simple to install and replace in the field.

All modules are 2500 V optically isolated from MFX

power and earth grounds – eliminating the potential for

ground loops and reducing the chance of severe

damage in the event of an electrical surge. Six ISO-MOD

options are available including: 4-20 mA output,

dual-relay, rate pulse, RS232C, RS485 and 200K-point

data logger. All modules are field-configurable by utilizing

the front keypad. Field wiring connections to ISO-MODs

are quick and easy using pluggable terminals. Features

of the various ISO-MODs are described below.

4-20 mA Output Module

Easily configured via jumper selections into either an

internally-powered or externally-powered mode, the

4-20 mA Output Module interfaces with virtually all

recording and logging systems by transmitting an

analog current signal that is proportional to system flow

rate. Independent 4 mA and 20 mA span settings are

established in software. These settings can span

negative and positive flow directions to output

bi-directional flow data. These entries can be set

anywhere in the -30 to +30 FPS (-9 to +9 MPS)

measuring range of the instrument. Output resolution of

the module is 12-bits (4096 discrete points) and

because of its low insertion loss characteristics (less

than 5 V typical), the module can drive up to 800 ohms

of load with a 24 V power source.

Rate Pulse Output Module

The Rate Pulse Output Module is utilized to transmit

information to external counters and PID systems via

a frequency output that is proportional to system

flow rate. Independent Zero and Span settings are

established in software. These entries can be set

anywhere in the -30 to +30 FPS (-9 to +9 MPS)

measuring range of the instrument. Output resolution

of the module is 12-bits (4096 discrete points) and the

maximum output frequency setting is 2500 Hz.

RS485 Input/Output Module

The RS485 Module allows up to 126 MFX systems to be

placed on a single three-wire cable network. All meters

are assigned a unique serial number that allows all of

the meters on the cable network to be accessed

independently. Baud rates up to 57.6K and cable

lengths to 5,000 feet (1,500 meters) are supported.

Control Relay Module

Two independent SPDT (single-pole, double-throw,

Form C) relays are contained in this module. The relay

operations are user configured via software to act in

either a flow rate alarm, system diagnostic alarm or

totalizer/batching mode. The relays are rated for 200

VAC max. and have a current rating of 0.5A resistive

load (175 VDC @ 0.25 A resistive). It is highly

recommended that a secondary relay be utilized

whenever the Control Relay ISO-MOD is used to control

inductive loads such as solenoids and motors.

Data Logger Module

This powerful 200,000-point data logger/electronic

stripchart recorder configures to match user

The logger stores time-stamped, high resolution (16-bit)

data at user-selected intervals ranging from 1 to 1,000

seconds. Configuration of and data retrieval from the

logger can be accomplished in one of two ways:

applications.

Two electronic outputs are integrated into the module –

an open-drain MOSFET and a turbine meter simulated

type. The MOSFET has an ON resistance of 0.21 Ohms

and is rated at 1 A and 100 V. The turbine simulation

permits the instrument to transmit information to

devices configured for magnetic turbine and

paddle-wheel flow meter pickups.

RS232C Input/Output Module

The RS232C Module can be interfaced with serial

communication ports of PCs, PLCs and SCADA

systems, running a Modbus protocol, that are used to

monitor flow rate information in piping systems. Baud

rates up to 57.6K are supported.

The module can be carried back to the office and

plugged into a serial port on a PC via the module’s

integral DB9 connector. This feature eliminates the

need to carry a laptop computer to the flow

meter site.

A hardwire connection can be made to the data

logger module which allows direct interface to the

serial communication port of a PC, PLC or SCADA

system. Historical data can be uploaded via the

supplied Windows® software utility.

Page 6

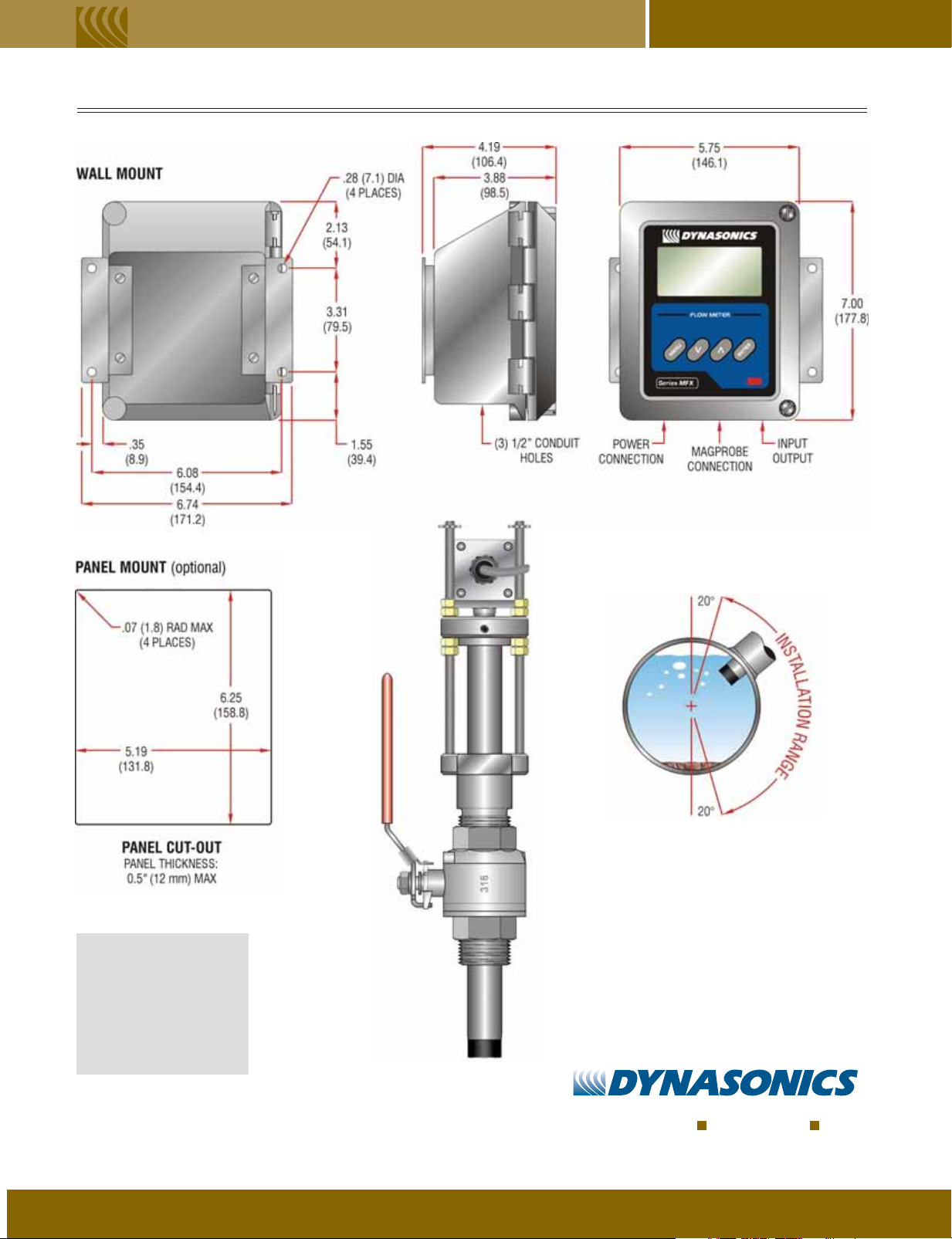

S

PECIFICATIONS

MECHANICAL DIMENSIONS: INCHES (mm)

Series MFXSeries MFX

MODEL LENGTH (L)

DMP 2

DMP 3

DMP 4

DMP 5

28.82 (732)

38.82 (986)

48.82 (1240)

58.82 (1494)

HEAD-ON VIEW

OF PIPE

INSTALL MAGPROBE

BETWEEN 1 0’CLOCK

AND 5 0’CLOCK ON THE PIPE

TM

Dynasonics, MagProbe and UltraLink are trademarks of Racine Federated Inc.

Viton is a registered trademark of DuPont Dow Elastomers

Windows is a registered trademark of Microsoft Corp.

FORM MFX 3/07

DIVISION OF RACINE FEDERATED INC.

8635 Washington Ave. Racine, WI 53406 USA

Tel: 262.639.6770

Fax: 262.639.2267

www.dynasonics.com

800.535.3569 North America

800.732.8354 North America

Loading...

Loading...