Page 1

Series MFX

Insertion MagProbe™ Flow Meter

Operations & Maintenance

Manual

REV 01/11

Page 2

Page 3

TABLE OF CONTENTS

Part 1 -

Introduction

Part 1 -

Installation

Quick-Start Operating Instructions

Introduction

General

Applications

Model Matrix

Product Specifications

Installation

Transmitter Installation

MagProbe Connection

Pages

1.3 - 1.4

1.5

1.6

1.7 - 1.8

1.9

1.10 - 1.11

1.12

Part 1 -

ISO-MOD

Part 2 -

Probe

Installation

Transmitter Power Connections

ISO-MOD Wiring and Configuration

4-20mA Output

Dual Control Relay

Rate Pulse Output

RS232C

RS485

DATALOGGER

Instrument Startup

MagProbe Installation

MagProbe Insertion/Retraction

1.12 - 1.15

1.17

1.18

1.19

1.20

1.21

1.22

1.23

2.1 - 2.9

2.9

Rev. 01/11 -1.1- MFX

Page 4

TABLE OF CONTENTS

Pages

Part 3 -

Keypad

Configuration

Part 4 -

Software

Utilities

Programming Entries

Keypad Operation

BASIC MENU

OUTPUT MENU

SECURITY MENU

SERVICE MENU

DISPLAY MENU

Installation

Initialization

Configuration

Pipe & Liquid

Flow Units

Outputs

3.1 - 3.2

3.3 - 3.7

3.8 - 3.15

3.15

3.15 - 3.17

3.17 - 3.18

4.1

4.2

4.3

4.4

4.6 - 4.12

Setting Zero

Signal Quality

Data Logger Software

Appendix

Keypad Interface Map

Digital Communications Protocol

Pipe Dimension Chart: ST, SS, PVC

Pipe Dimension Chart: Ductile Iron

Pipe Dimension Chart: Cast Iron

Velocity to Volumetric Conversion

Statement of Warranty

Customer Service

4.17 - 4.19

4.13

4.15

Rev. 01/11 -1.2- MFX

Page 5

QUICK-START OPERATING INSTRUCTIONS

This manual contains detailed operating instructions for all aspects of

the MFX instrument. The following condensed instructions are

provided to assist the operator in getting the instrument started up

and running as quickly as possible. This pertains to basic operation

only. If specific instrument features are to be used or if the installer is

unfamiliar with this type of instrument, refer to the appropriate section

in the manual for complete details.

MagProbe

Location

1. SELECT THE MAGPROBE LOCATION

A. In general, select a mounting location

on the piping system with a minimum

of 10 pipe diameters (10 the pipe

inside diameter) of straight pipe

upstream and 5 straight diameters

downstream. See Table 2.1 for

additional configurations.

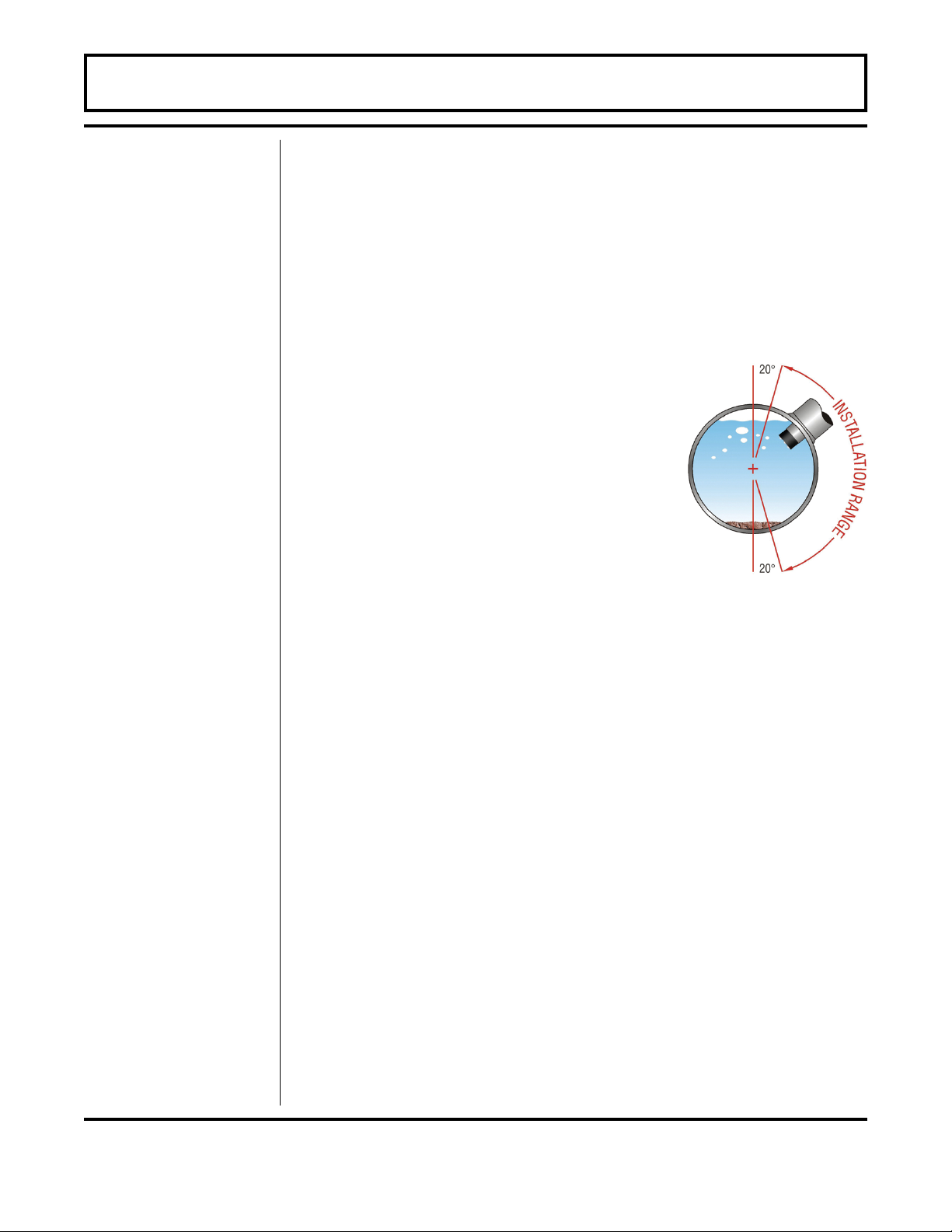

B. When the probe is installed on

a horizontal pipe, the preferred

orientation for the probe is between 1

and 5 o’clock as shown in Figure 1.1.

Ensure that the probe is installed

square and centered on the pipe.

2. HOT TAP CONFIGURATION

A. Verify that all components being permanently installed or used

during the installation procedure are rated for operation at the

greatest system pressure anticipated.

B. Mount the pipe saddle or weld fitting at the location

determined in step 1. Install the close nipple and ball valve.

Drill a hole in the pipe that is at least " (3 mm) larger than the

MagProbe tip. Close the ball valve.

Horizontal Installation

Top of Pipe

Figure 1.1

C. Install the MagProbe insertion fitting.

Inserting

MagProbe

Rev. 01/11 -1.3- MFX

3. INSERT THE MAGPROBE INTO THE PIPE

A. To obtain greatest accuracy, the measuring tip of the

MagProbe must be inserted a proper distance into the pipe.

For long, straight runs of pipe, this is 12.5% of the pipe

internal diameter.

B. Before inserting the MagProbe into the insertion fitting, it is

best to make all of the necessary measurements on the probe

and installation fittings and place a insertion depth mark on the

probe.

Page 6

QUICK-START OPERATING INSTRUCTIONS

Connections

C. Measure the full length of the probe (E), calculate 12.5% of

the pipe I.D. (A), obtain the pipe wall thickness (B) and

measure the distance between the outer pipe wall and the top

of the insertion fitting (C).

D. Place a mark on the probe this is the proper distance from the

top of the probe (D):

D = E - A - B - C

E. Insert the MagProbe into the insertion fitting and secure with

the brass lock nuts—Series DMP2 - DMP6.

F. Open the ball valve and insert the probe to the distance

marked in step D. Secure with the brass nuts.

G. Rotate the probe in the pipe so that the FLOW DIRECTION

arrow points in the nominal forward flow direction (the MFX

system will read flow in both directions) and to within ±2° of

parallel to the pipe length.

4. ELECTRICAL CONNECTIONS

Run the MagProbe cables back to

the MFX transmitter mounting

location. Connect the MagProbe and

power to the appropriate terminal

connections within the MFX

enclosure. See Figure 1.2.

Startup

A. Do not run the probe cable

adjacent to electrically noisy

wiring.

B. Verify that the MFX is

configured for the power

supply that will be utilized in

the installation. Run power

through the left hand conduit

hole and secure to the proper

terminals.

C. Connect a 12 AWG (minimum)

ground wire between the

ground lug on the MagProbe

seal fitting and earth ground.

5. INITIAL SETTINGS AND POWER UP

A. Apply power to the instrument.

B. Verify that fluid velocity is indicated on the top line of the MFX

display.

C. Input proper units of measure and I/O data.

Electrical Connections

Figure 1.2

Rev. 01/11 -1.4- MFX

Page 7

PART 1 - INTRODUCTION

General

The MagProbe is a point-velocity measuring device used primarily

for measuring electrically conductive liquids, such as water and

water-based liquids, in closed piping systems. The unit operates

utilizing Faraday’s principle of magnetic conduction, whereby a

moving conductor (the liquid) has a voltage imposed on it that is

directly proportional to two variables—the strength of a local

magnetic field and the velocity of the moving conductor.

Imposed voltage Magnetic field X Fluid velocity

If the strength of the magnetic field is held constant, then the

magnitude of the voltage will be proportional to the velocity of the

moving conductor. The equation then simplifies to Imposed voltage

Fluid velocity. Most modern magnetic meters, including the MFX,

apply tri-stated, alternating polarity DC pulses to an integral

electromagnet. See Figure 1.3. Voltage measurements are made

with the magnet off, to measure ambient background noise, and

then with the magnet on

in both polarities. The

magnitude difference in

voltage measured is

proportional to flow. Once

fluid velocity is measured,

then various volumetric

flow measurements can

be obtained if the pipe

internal diameter (I.D.) is

known.

Point-velocity flow meters measure the fluid velocity at a specified

depth into the fluid stream, typically of the pipe I.D., which has

been proven to be the nominal velocity point when symmetrical flow

profiles are present. This assumption requires the probe to be

certain numbers of pipe diameter downstream of any piping

condition (elbows, valves, thermo-wells, tees, etc.) that can cause

flow abnormalities. Typically, a minimum of 15 pipe diameters of

straight pipe is required to develop a symmetrical flow profile.

Systems where symmetrical flow profiles are not present can still be

measured accurately, but flow profiling must be performed to

determine proper probe insertion depth. A diagram of the MagProbe

tip is illustrated in Figure 1.4.

Figure 1.3 - Magnet Excitation

Rev. 01/11 -1.5- MFX

Page 8

PART 1 - INTRODUCTION

The MFX MagProbe flow meter can be successfully applied on a

wide range of metering applications. The simple to program

transmitter allows the standard product to be used on pipe sizes

ranging from 4 - 120 inch (100 - 3048 mm) pipe. A variety of liquid

applications can be accommodated: potable water, chemicals, raw

sewage, reclaimed water, cooling water, river water, plant effluent,

etc. The MFX product will not operate on fluids with very high

impedance such as DI water, distilled water, petroleum-based

liquids or glycol-based liquids.

Figure 1.4 - MagProbe Design

Rev. 01/11 -1.6- MFX

Page 9

PART 1 - INTRODUCTION

User Safety

Data Integrity

Product

Identification

The MFX employs modular construction and provides electrical

safety for the operator. The display face contains voltages no

greater than 10 Vdc. The display face swings open to allow access

to user connections. As a general precaution, always disconnect

electrical power before opening the instrument enclosure.

Non-volatile memory retains all user-entered configuration values in

memory even if power is lost or turned off. Password protection is

provided as part of the Security menu and prevents inadvertent

configuration changes or totalizer resets.

The serial number and complete model number of your MFX and

the DMP probe that was shipped with the MFX is located on the

inside of the transmitter’s front cover. Should technical assistance

be required, please provide the Dynasonics Customer Service

Department with this information.

Product Matrix

Transmitter

Rev. 01/11 -1.7- MFX

Page 10

MagProbe Insertion Probe

PART 1 - INTRODUCTION

Rev. 01/11 -1.8- MFX

Page 11

Transmitter MagProbe

PART 1 - SPECIFICATIONS

Rev. 01/11 -1.9- MFX

Page 12

PART 1 - TRANSMITTER INSTALLATION

Transmitter

Installation

After unpacking, it is recommended to save the shipping carton and

packing materials in case the instrument is stored or re-shipped.

Inspect the equipment and carton for damage. If there is evidence of

shipping damage, notify the carrier immediately.

The enclosure should be mounted in an area that is convenient for

servicing, calibration or for observation of the LCD readout.

1. Locate the transmitter within the length of MagProbe cable that

was supplied with the MFX system. If this is not possible, replace

the entire length of interconnect cable with Belden

9536, Dynasonics part number D005-1003-003 or equivalent. Do

not splice the cable as shield integrity will be compromised and

poor performance can result.

2. Mount the MFX transmitter in a location that is:

i Where little vibration exists.

i Protected from falling corrosive fluids.

i Within ambient temperature limits -40 to +185°F (-40 to +85°C)

i Out of direct sunlight. Direct sunlight may increase temperatures

within the transmitter to above maximum limit.

3. Mounting: Refer to Figure 1.5 for enclosure and mounting

dimension details. Ensure that enough room is available to allow

for door swing, maintenance and conduit entrances. Secure the

enclosure to a flat surface with four appropriate fasteners.

4. Conduit holes. Conduit hubs should be used where cables enter

the enclosure. Holes not used for cable entry should be sealed

with plugs.

NOTE: Use NEMA 4X (IP66) rated fittings/plugs to maintain the

water tight integrity of the enclosure. Generally, the left conduit hole

(viewed from front) is used for line power; the center conduit hole for

transducer connections and the right hole is utilized for ISO-MOD

I/O wiring.

5. If additional holes are required, drill the appropriate size hole in

the enclosure’s bottom or side. Use extreme care not to run the

drill bit into the wiring or circuits cards.

®

part number

Rev. 01/11 -1.10- MFX

Page 13

PART 1 - TRANSMITTER INSTALLATION

Figure 1.5 - MFX Transmitter Installation Dimensions

Rev. 01/11 -1.11- MFX

Page 14

PART 1 - TRANSMITTER INSTALLATION

MagProbe

Connections

Transmitter AC

Power

Connections

To access terminal strips for electronic connectors, loosen the two

screws in the enclosure door and open the door.

1. Guide the MagProbe terminations through the transmitter

conduit hole located in the bottom-center of the enclosure.

Secure the MagProbe conduit with the supplied conduit nut if

flexible conduit was ordered with the transducer. If conduit was

not purchased with the MagProbe sensor, an appropriate sealed

strain relief bulkhead fitting should be utilized.

2. The terminals within MFX are a pluggable type—they can be

removed wired and then plugged back in. Connect the

appropriate MagProbe wires to P1 (Sensor) at the corresponding

screw terminals on the

MagProbe module. Observe

proper wire colors and

shield connections. See

Figure 1.6 or the Wiring

Diagram located on the

inner door of the transmitter.

NOTE: The MagProbe cable

carries low level signals. Locate

the transmitter within the length

of MagProbe cable that was

supplied with the MFX system.

If this is not possible, replace

the entire length of interconnect

cable with Belden

9536, Dynasonics part number

D005-1003-003 or equivalent.

Do not splice the cable as

shield integrity will be

compromised and poor

performance can result.

Connect line power to the screw terminals marked L1, L2 and Earth

in the transmitter. See Figure 1.7 and Figure 1.8. Utilize the

conduit hole on the left side of the enclosure for this purpose. Use

wiring practices that conform to local codes (National Electrical

®

Code

the instrument, which is mandatory for safe operation and optimum

flow meter performance.

Handbook in the USA). The earth ground terminal grounds

®

part number

Electrical Connections

Figure 1.6

Rev. 01/11 -1.12- MFX

Page 15

PART 1 - TRANSMITTER INSTALLATION

!

CAUTION: Any other wiring method may be unsafe or cause

improper operation of the instrument.

Do not run line power with other signal wires within the same wiring

tray or conduit.

NOTE: This instrument requires clean electrical line power. Do not

operate this unit on circuits with noisy components (i.e. fluorescent

lights, relays, compressors, variable frequency drives, etc.)

WIRING DIAGRAM

CAUTION! To avoid serious injury or

JP3

Connections

115 Vac

230 Vac

9-28 Vdc

JP1/JP2

Connections

115/230

Vac

9-28 Vdc

product damage, disconnect electrical power

before servicing this meter.

12 or 24 Vdc jumper

selection located on the

circuit board below this

decal.

1 2

16-28 Vdc JP1

9-16 Vdc

3 4

115/230 Vac

1 2

JP3

3 4

1 2

3 4

1 2

1

2

1 2

1

2

J3

1 2

3 4

JP2

JP1

2

J4

J2

JP2

1 2

1

No Connections

JP2

JP1

Bottom of circuit board

GREEN/SHIELD

L1

L2

EARTH

Optional

I/O Module

R41

MagProbe

Interface Module

BROWN

BLACK

Y1

BLUE

WHITE

RED

Fuse (5x20mm):

AC: 0.1A/250V Delay

DC: 0.5A/250V Delay

AC L1 L2 EARTH

DC +V GND EARTH

D003-0905-301 REV. B

Figure 1.7

MFX Power Supply Configuration

Rev. 01/11 -1.13- MFX

Page 16

PART 1 - TRANSMITTER INSTALLATION

AC POWER CONNECTIONS

1. Verify that the jumpers at JP3 are properly oriented for the power

supply. Verify that the jumpers at JP1 and JP2 are not present.

2. Connect L1, L2 and earth to the terminals referenced in Figure

1.7 on page 1.13. Phase and neutral connections to L1 and L2 are

not polarized. Do not operate without an earth ground

connection.

3. See Figure 1.8 for AC connection schematic. Wire gauges up to

14 AWG can be accommodated in the MFX terminal blocks.

Figure 1.8

AC Power Connection

Rev. 01/11 -1.14- MFX

Page 17

PART 1 - TRANSMITTER INSTALLATION

DC Power

Supply

DC POWER CONNECTIONS

The MFX may be operated from a 9-28 Vdc source, as long as the

source is capable of supplying a minimum of 3 Watts.

1. Verify that the jumpers are properly placed. See the wiring

diagram located on the inside door of the MFX enclosure or see

Figure 1.7 on page 1.13. The jumpers at JP3 should not be

present and the jumpers at JP1 and JP2 will be in place. The

jumper located beneath the microprocessor protection shield—

the panel with the wiring diagram label mounted on it—should be

positioned at JP2 for 9-16 Vdc input power and in JP1 position

for 16-28 Vdc input power.

2. Connect the DC power source as illustrated in the schematic in

Figure 1.9. Wire up to 14 AWG can be accommodated in the

MFX terminal blocks.

Figure 1.9

DC Power Connection

Rev. 01/11 -1.15- MFX

Page 18

PART 1 - IS O-MO D

General

The MFX utilizes ISO-MODs for input and output functions. ISOMODs are epoxy encapsulated electronic input/output modules that

are simple to install and replace in the field. See Figure 1.10. All

modules are 2,500 V optically isolated from MFX power and earth

grounds. This eliminates the potential for ground loops and reduces the

chance of severe damage in the event of an electrical surge.

Figure 1.10

Two ISO-MOD I/O Modules Installed

Six ISO-MOD options are available, including: 4-20 mA, dual-relay,

rate pulse, RS232C, RS485, and 200k point data logger. The MFX

supports any of the six ISO-MOD input/output modules. All modules

are field configurable by utilizing the keyboard or ULTRALINK™

interface. Field wiring connections to ISO-MODs are quick and easy

using removable plug-in terminals. Configuration and connection of

the various ISO-MODs are described on the following pages.

To remove an ISO-MOD, remove the two machine screws that

secure the module in place and pull the module straight out of the

enclosure. A 10-pin connection is on the bottom of the module that

mates with the circuit board underneath. Installation of a module is

simply the reverse operation of removal. 4-20 mA modules will

require calibration parameters to be entered if the module is

replaced. See Part 3 of this manual for instructions on entry of

calibration parameters.

Rev. 01/11 -1.16- MFX

Page 19

PART 1 - IS O-MO D

4-20 mA Output

The 4-20 mA Output Module interfaces with most recording and

logging systems by transmitting an analog current signal that is

proportional to system flow rate. The 4-20 mA ISO-MOD may be

configured via jumper selections for either an internally powered

mode (current sourcing) Figure 1.11A or externally powered mode

(current sinking) Figure 1.11B.

Internal Power Configuration: Ensure that jumpers are in place at

JP1 and JP2 on the module. See Figure 1.11A. In this

configuration the 4-20 mA output is driven from a +24 Vdc source

located within the MFX flow meter. The 24 Vdc source is isolated

from DC ground and earth ground connections within the MFX

instrument. The module can accommodate loop loads up to 800

Ohms in this configuration.

External Power Configuration: Remove the two jumpers located at

JP1 and JP2 on the module. See Figure 1.7B. In this

configuration the 4-20 mA module requires power from an external

DC power supply. The voltage of the external power source must be

sufficient to power the module and drive the loop load. The loop loss

attributed to the ISO-MOD is 7 Vdc, so the minimum voltage

required to power a loop can be calculated using the following formula:

Loop voltage (min) = (loop load Ohms x 0.02) + 7

Figure 1.11A

Internally Powered

4-20mA

Figure 1.11B

Externally Powered

4-20mA

Rev. 01/11 -1.17- MFX

Page 20

PART 1 - IS O-MO D

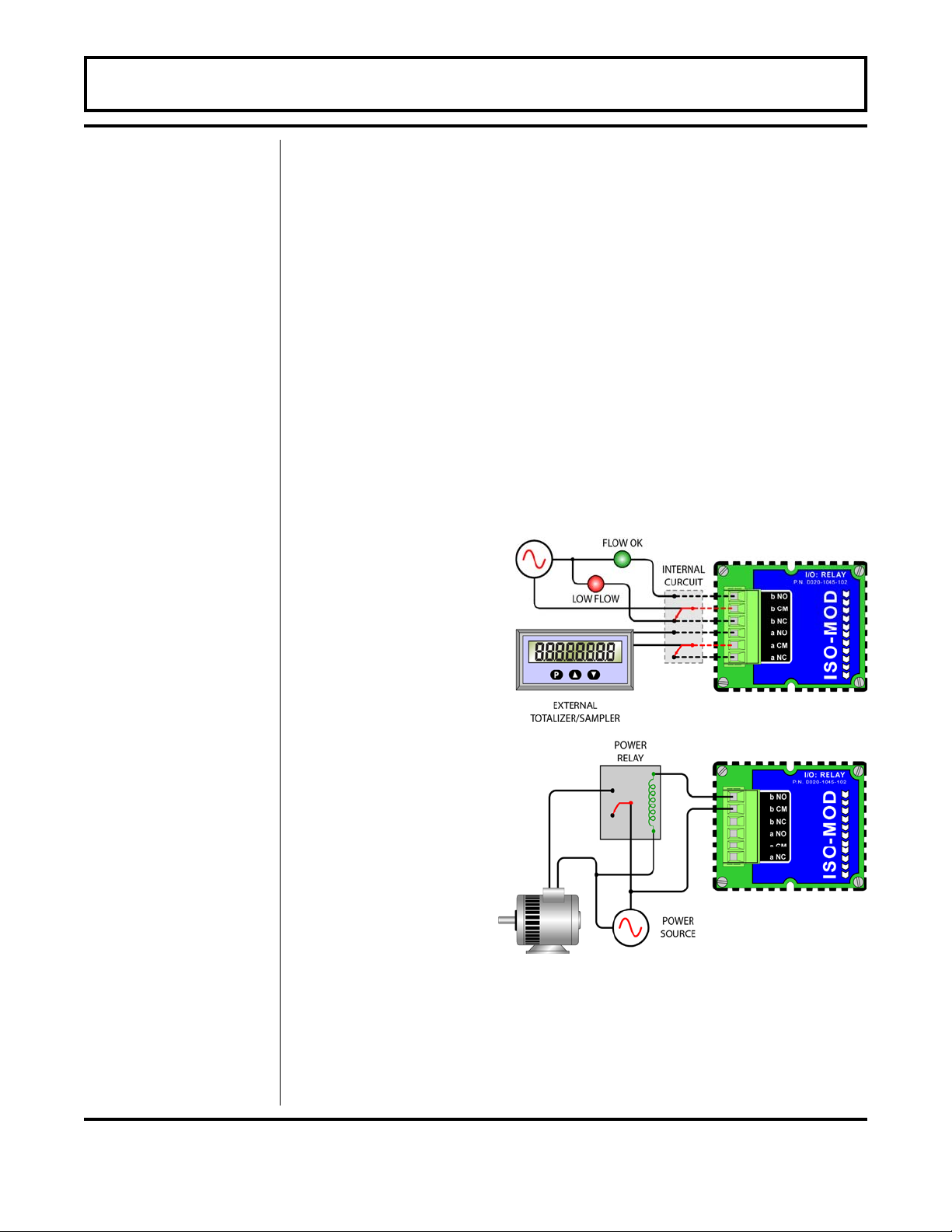

Control Relay

Two independent SPDT (single-pole, double-throw) Form C relays

are contained in this module. The relay operations are user

configured via software to act in either a flow rate alarm, signal

strength alarm or totalizer/batching mode. The relays are rated for

200 Vac maximum and have a current rating of 0.5 A resistive load

(175 Vdc @ 0.25 A resistive). It is highly recommended that a

secondary relay be utilized whenever the Control Relay ISO-MOD is

used to control inductive loads such as solenoids and motors.

Typical relay connections are illustrated in Figure 1.12A. The reed

relays located within the relay module can interface directly with

small pilot lights, PLCs, electronic counters and SCADA systems.

Figure 1.12B describes the connection of an external power relay to

the Relay ISO-MOD. It is recommended that external power relays

are utilized whenever the load to be switched exceeds the switch

rating of the reed relays, or if the load is inductive in nature.

POWER

SOURCE

Figure 1.12A

Typical Relay

Connections

Figure 1.12B

Slave Relay

Connections

Rev. 01/11 -1.18- MFX

Page 21

PART 1 - IS O-MO D

Rate Pulse

The Rate Pulse Output Module is utilized to transmit information to

external counters and PID systems via a frequency output that is

proportional to system flow rate. The frequency output range of the

Rate Pulse Module is 0–2,500 Hz. This module has two types of

outputs: one simulates the output of the coil of a turbine flow meter,

and the other is an open-collector type that does not source voltage

at its output. Both outputs may be connected simultaneously.

The turbine meter output creates a 500 mV peak-to-peak saw-tooth

waveform that is not referenced to ground. This output can be run to

electronic monitors that are compatible with variable reluctance

outputs from coils, such as those found in turbine and paddle-wheel

flow meters. The input impedance of the receiving device should not

be smaller than 2,000 Ohms.

The standard pulse output does not output a voltage, but acts as an

“open-collector” output requiring an external power source and pullup resistor. See Figure 1.13. The MOSFET in the Rate Pulse

Module can support loads of 100 V @ 1A. Resistor selection is

based on the input impedance of the receiving device. Select a

resistor that is a maximum of 10% of the input impedance of the

receiving device, but do not exceed 10k Ohms.

Figure 1.13

Rate Pulse Module

Rev. 01/11 -1.19- MFX

Page 22

PART 1 - IS O-MO D

RS232C

The RS232C Module will interface with the serial communication

ports of PCs, PLCs and SCADA systems that are used to monitor

flow rate information in piping systems. A proprietary digital

communications protocol is used for this communication. An

explanation of the command structure is detailed in the Appendix of

this manual. Flow rate, total, signal strength and temperature (if so

equipped) can be monitored over the digital communications module.

The RS232C Module may also be used to form a hardwire

connection to a PC that is running the ULTRALINK™ software

utility. Baud rates up to 19.2k are supported. Figure 1.14 illustrates

typical connections.

Figure 1.14

RS232 Connections

Rev. 01/11 -1.20- MFX

Page 23

PART 1 - IS O-MO D

RS485

The RS485 Module allows up to 128 MFX systems to be placed on

a single three-wire cable bus. All meters are assigned a unique one

byte serial number that allows all meters on the cable network to be

independently accessed. A proprietary digital communications

protocol is used for this communication. An explanation of the

command structure is detailed in the Appendix of this manual. Flow

rate, total, signal strength and temperature (if so equipped) can be

monitored over the digital communications bus. Baud rates up to

9600 and cable lengths to 5,000 feet (1,500 meters) are supported

without repeaters or “end of line” resistors. ULTRALINK™ is also

compatible with a multiple MFX network, allowing individual meters

to be accessed, programmed, diagnosed and calibrated.

To interconnect meters, utilize three-wire shielded cable such as

Belden

®

9939 or equal. In noisy environments the shield should be

connected on one end to a good earth ground connection. An

RS232 to RS485 scond, such as B&B electronics p/n 485SD9TB

(illustrated in Figure 1.15) is required to interconnect the RS485

network to a communication port on a PC. If more than 128 meters

must be monitored, an additional scond and communication port is

required.

Figure 1.15

RS485 Network

Connections

Rev. 01/11 -1.21- MFX

Page 24

PART 1 - IS O-MO D

Data Logger

The 200,000 event data logger/electronic stripchart recorder can be

configured to match most user applications. The logger stores timestamped, high resolution (16-bit) data at user selected intervals

ranging from 1 to 1,000 seconds. Configuration of and data retrieval

from the logger are detailed in Sections 3 and 4 of this manual.

The module can be carried in a shirt pocket back to the office and

plugged into a PC serial port via the module’s integral DB-9

connector. See Figure 1.16. This eliminates the requirement to

carry a computer to the flow meter site. The data in the logger can

also be accessed without removing the module from the flow meter.

Open the door of the flow meter and interconnect the 9-pin cable

between the data logger and the PC serial communications port.

The logger is capable of storing up to 200,000 measurements. The

measurements are broken into 16 blocks or pages with a maximum

number of data points per block of 30,000.

If each block(page) is filled to the maximum, 6-2/3 blocks would be

used:

If all 16 blocks are to be used, each block could hold 12,500 data

points:

NOTE: The data logger is not accessible using the MFX’s infrared

adapter. Communications between the data logger and computer

must be accomplished using a directly connected RS232C or

RS485 connection.

200,000 Points

30,000 Points

200,000 Points

16 Pages

= 6-2/3 Pages

= 12,500 Points per page

Figure 1.16

Rev. 01/11 -1.22- MFX

Data Logger Connection

Page 25

PART 1 - INSTRUMENT STARTUP

Before Starting

the

Instrument

Instrument

Startup

NOTE: The MFX flow meter system requires a full pipe of liquid

before a successful startup can be completed. Do not attempt to

make adjustments or change configurations until a full pipe is

verified.

Procedure:

1. Verify that all wiring is properly connected and routed as

described in Part 1 of this manual.

2. Verify that the MagProbe sensor is properly mounted as

described in Part 2 of this manual.

3. Apply power. The display of a MFXD2 will display a software

version number and then all of the segments will illuminate in

succession. The meter will then enter run mode.

4. Verify that the following parameters have been entered into the

MFX Flow Meter in the BASIC MENU (See Section 3 of this

manual):

x UNITS—either ENGLISH or METRIC

x K-FACTOR (as it appears on the MagProbe sensor)

x PIPE Outside Diameter

x PIPE Wall Thickness

x PIPE Liner Thickness

x RATE unit selected

x RATE interval selected

5. Once these parameters have been entered and saved, the flow

meter will begin to measure and display flow rate. Section 3 of

this manual describes in greater detail the configuration and

programming of the MFX instrument.

Rev. 01/11 -1.23- MFX

Page 26

PART 2 - MAGPROBE INSTALLATION

MagProbe

Mounting

Considerations

Step A -

Mounting

Locations

After unpacking, it is recommended to save the shipping carton and

packing materials in case the instrument is stored or re-shipped.

Inspect the equipment and carton for damage. If there is evidence of

shipping damage, notify the carrier immediately.

The DMP insertion probe that is utilized by the MFX flow meter

system contains an electromagnet, electrodes and amplification

circuitry. Three electrodes, two measurement and one ground, are

located in the black Ultem

to be inserted to the average fluid velocity point within a pipe. Not all

liquid within a pipe is flowing at a uniform fluid velocity, but a long

straight run of pipe, full of flowing liquid, contains a predictable liquid

velocity profile. By selecting proper upstream and downstream

lengths of straight pipe from the probe installation point and by

making precise insertion depths into the pipe, very accurate and

reliable volumetric flow rates and totals can be obtained.

Select a probe mounting location with adequate straight runs

(without disturbances) of pipe, both upstream and downstream, to

achieve stable and accurate readings. Examples of minimum

upstream and downstream requirements are included in Table 2.1.

Note that if adequate straight plumbing cannot be provided, the

MFX system will operate repeatably

specified accuracy

When installing the DMP probe in a

horizontal pipe, the preferred

orientation is between 1 and 5 o’clock

on the pipe—assuming 12 o’clock as

the top. See Figure 2.1. Ensure that

the mounting location allows for

adequate clearance to install and

retract the probe fully from the pipe.

and will likely provide less stable readings.

®

plastic tip of the probe and are designed

, but will probably not achieve

Top View of Pipe

Figure 2.1

Horizontal Installation

Rev. 01/11 -2.1- MFX

Page 27

PART 2 - MAGPROBE INSTALLATION

Table 2.1 - Straight Pipe Recommendations

1

The MFX system will provide repeatable measurements on piping systems that do not

1

meet these requirements, but the accuracy of these readings may be influenced to various

degrees.

Rev. 01/11 -2.2- MFX

Page 28

PART 2 - MAGPROBE INSTALLATION

Step B -

Hot-Tapped

Installation

The installation instructions cover hot-tapped installations

(installations where it is required to install or remove the MagProbe

without shutting down the process pressure). If the product is being

installed without an isolation valve, ignore the steps that pertain to

its installation. Figure 2.2 illustrates an exploded view of an

isolation valve assembly and names the various components.

Hot-tapped installation will require the installation of either a welded

pipe coupling or installation of a pipe saddle. The ball valve and

close nipple can be purchased as a kit from Dynasonics or can be

procured at most hydraulic or plumbing supply shops. The two

critical factors that must be considered with the components are

pressure rating and internal sizes. The DMP2 through DMP6 1-½"

MagProbes are designed to operate with pipe pressures up to 700

psi (48 Bar). Verify that the internal port of the opened valve is at

least 1-½ inches (38 mm) to permit free passage of the probe

without interference. Attempts to force a MagProbe through an

opening smaller that stated will damage the probe tip and void the

warranty.

Figure 2.2

Isolation Valve Assembly

Rev. 01/11 -2.3- MFX

Page 29

PART 2 - MAGPROBE INSTALLATION

Step C -

Component

Assembly

These instructions call for the use of a drilling machine designed for

drilling holes in pipes that are under pressure (for example, Muller

Co., Decatur, Illinois manufactures products for this purpose).

Procedures are as follows:

1. Verify that the line pressure within the pipe is within the rated

limits of the pressure drilling machine, welded coupling or pipe

saddle, valve and MagProbe to be used.

2. Grind off paint or other coatings from the pipe in the area where

the DMP MagProbe Assembly is to be installed. Recommended

minimum straight pipe lengths for best accuracy are 10

diameters upstream and 5 downstream. See Table 2.1.

3. Tack weld a 1-½" NPT female weld-coupling to the pipe or

install a pipe saddle according to the suppliers instructions. The

coupling or saddle must be aligned perpendicular to the

pipe axis and square to its plane.

4. Complete welding. A watertight, 0.25" minimum weld bead is

recommended.

5. Install the close nipple into the weld coupling. Use appropriate

pipe sealants.

6. Install the isolating ball valve on the close nipple. Verify that the

valve is in fully open position.

7. Install drill bit and adapter into the pressure drilling machine.

Then attach the machine to the isolation valve.

8. Drill through the pipe wall in accordance with the instructions

supplied with the drilling machine.

9. Withdraw the drill bit through the isolating valve. Close the valve

and remove the drilling machine. Check for leakage at valve and

connections.

Rev. 01/11 -2.4- MFX

Page 30

PART 2 - MAGPROBE INSTALLATION

Step D -

Probe Insertion

Distances

PROBE INSERTION

Before inserting the MagProbe into the piping system, it is

necessary to calculate the probe insertion depth that will place the

measuring electrodes at the proper position in the pipe. In order to

complete this calculation, some knowledge of the piping system

must be known. Refer to the paragraphs that follow and Figure 2.3

for information regarding this process. The variables required are:

x The overall probe length

x Pipe internal diameter

x Pipe wall thickness (including liners)

x The length of the valve stack

x Amount of straight pipe diameters in the system

Using this information and referring to Figure 2.3 proper insertion

depth can be determined.

Measurement A — the typical depth that the MagProbe tip is

inserted into the piping system is (12.5%) of the pipe internal

diameter. Assume of the pipe internal diameter unless a system

piping configuration does not have

straight pipe in the installation area.

at least 15 pipe diameters of

Measurement B — Pipe wall thickness. This information can be

obtained from standard pipe wall charts (see the Appendix of this

manual) or ideally can be measured using an ultrasonic wall

thickness gauge. If the pipe is lined, include the liner thickness in

this measurement.

Measurement C — Measure the distance that is going to be taken

up by the pipe tap, nipple, full-flow ball valve and the insertion fitting.

NOTE: DMP1 through DMP6 probes utilize 1-½" NPT hardware.

The insertion fitting for the DMP1 through DMP6 probes is

approximately 2.5 inches long once completely torqued into

position.

Measurement E — This is the overall length of the probe measured

from the black measurement tip to the top flange on the probe.

Measurement D — This is the length of MagProbe that will be

protruding from the insertion fitting after it is inserted to the proper

depth in the fluid stream.

Rev. 01/11 -2.5- MFX

Page 31

PART 2 - MAGPROBE INSTALLATION

TO CALCULATE INSERTION DEPTH

Measure and record the following linear

distances:

E = PROBE LENGTH = _______

C = INSERTION FITTING to PIPE WALL

= _______

B = PIPE WALL THICKNESS

= _______

A = 0.125 x PIPE ID = _______

D = INSERTION DEPTH = _______

D = E - C - B - A

Installation Measurements: DMP2 through

DMP6 MagProbes

Figure 2.3

Installation

Measurements

Rev. 01/11 -2.6- MFX

Page 32

PART 2 - MAGPROBE INSTALLATION

Step E -

Cable Routing

PROBE CABLE

Before inserting the MagProbe into the pipe, the sensor cables

should be routed to the transmitter location. Locate the transmitter

within the length of MagProbe cable that was supplied with the MFX

system. If this is not possible, replace the entire length of

interconnect cable with Belden

number D005-1003-003 or equivalent. Do not splice the cable as

shield integrity will be compromised and poor performance can

result. Cable lengths up to 1000 feet (300 meters) can be utilized.

The wiring inside of the MagProbe conduit box is pictured in

Figures 2.5.

®

part number 9536, Dynasonics part

Figure 2.5

MagProbe Interface Enclosure

IMPORTANT

NOTE!

Rev. 01/11 -2.7- MFX

CAUTION: Both power and digital signals are carried through the

MagProbe cable. These signals are robust, but care should be

taken in routing the cables. Avoid running cables near sources of

high voltage equipment or sources of extreme electrical noise—high

EMI/RFI. Also avoid routing the cables in cable tray configurations,

unless the trays are specifically used for other low voltage, low level,

signal cables.

PROBE GROUND CONNECTION

Attach a wire of 12 AWG or larger between the #10-32 ground lug

on the insertion fitting and earth ground.

Page 33

PART 2 - MAGPROBE INSTALLATION

Step F -

MagProbe

Insertion DMP2

through DMP6

MAGPROBE INSERTION DMP2 through DMP6

1. Apply sealant to the 1-½" NPT threads of the insertion fitting

assembly. Screw the assembly into the isolation valve and

tighten with a 2-½" pump wrench. Final orientation of the two

threaded rods on the MagProbe insertion fitting should be

approximately perpendicular to the pipe’s axis.

2. Run the lower Jam Nuts down to a point that approximates the

final insertion position or at least far enough to allow insertion of

the MagProbe into the insertion Fitting. Using the threaded rods

as a guide and with the flow direction arrow pointing in the

correct direction, position the MagProbe in the insertion fitting.

Continue to insert the MagProbe as far into the isolation

assembly as possible. The MagProbe tip will come in contact

with the closed “ball” in the isolation valve.

CAUTION: Do Not Force the MagProbe Tip Against the “Ball”, as

damage to the MagProbe tip may result.

3. Replace the upper Jam Nuts (2 on each rod) and the cotter pins.

The nuts should be run down to the top side of the retaining

collar and the cotter pins replaced. Orient the MagProbe in the

direction of flow as indicated on by the FLOW direction arrow

located on the top of the MagProbe amplifier enclosure. See

Figure 2.6.

Figure 2.6

Flow Direction

CAUTION: The nuts on both ends of the retaining rods must

always be in place as a safety measure to prevent possible

MagProbe blow out. Inserting cotter pins is a further safety

measure.

Rev. 01/11 -2.8- MFX

Page 34

PART 2 - MAGPROBE INSTALLATION

Retracting DMP2

through DMP6

Probes

4. Slowly open the isolation valve. When the valve is fully open,

use a 9/16" wrench on the insertion nuts, alternately tightening

each nut about two complete turns to avoid uneven seal

loading—two 9/16" ratcheting wrenches can expedite this

process. Repeat until the length of probe remaining above the

seal fitting equals the “D” length calculated in step D.

NOTE: For some low pressure/low temperature [less than 30 psi (2

Bar) and less than 100 °F (38 °C)], the MagProbe may be pushed in

by hand to decrease the insertion time. Dynasonics also offers

insertion cranking tools for these probes.

PROBE RETRACTION PROCEDURE

1. Retract the MagProbe by loosening the Upper Jam Nuts

counterclockwise—as viewed from the top of the MagProbe—

using a 9/16" wrench. If the pipe is under pressure, the nuts

must be turned alternately about two turns at a time to prevent

binding as a result of non-equal seal loading—two 9/16"

ratcheting wrenches can expedite this process. In many cases,

the line pressure will cause the MagProbe to retract. Should the

MagProbe bind or if system pressure is very low, use the

retraction nuts on the lower side of the MagProbe flange to

assist in the MagProbe retraction. Continue this procedure until

the MagProbe is fully retracted into the insertion fitting.

CAUTION: Do not run the drive nuts off the rods until the isolation

valve is fully closed.

2. After the MagProbe is retracted past the “ball” in the isolation

valve, the Isolation Valve may be closed to isolate the MagProbe

from the line and the MagProbe can be removed entirely.

CAUTION: If the probe tip is not above the “ball” of the isolation

valve, the valve cannot be closed. If the valve will not close

smoothly, the body or tip of the MagProbe is most likely not above

the “ball”. Attempting to force the valve into the closed position may

result in damage to the probe.

Rev. 01/11 -2.9- MFX

Page 35

PART 3 - KEYPAD CONFIGURATION

General

Keypad

Operation

After installation of the MagProbe sensor and connection of

appropriate power supplies to the MFX, keypad configuration of the

instrument can be undertaken. All entries are saved in non-volatile

FLASH memory and will be retained in the event of power loss.

The DMFXD2 is configured through the keypad interface and the

DMFXD1 is configured through a software utility at the Dynasonics

factory.

The MFX contains a four-key tactile feedback keypad interface that

allows the user to view and change configuration parameters used

by the MFX operating system.

1. The MENU key is pressed from RUN mode to enter PROGRAM

mode. The MENU key is pressed in PROGRAM mode to exit

configuration parameters and menus. If changes to any

configuration parameters have been made, the user will be

prompted with a SAVE?YES when returning to RUN mode.

2. The ARROW keys are used to scroll through menus and

configuration parameters. The ARROW keys are also used to

adjust parameter numerical values.

Rev. 01/11 -3.1- MFX

Page 36

Menu

Structure

PART 3 - KEYPAD CONFIGURATION

3. The ENTER key is pressed from the RUN mode to view the

current software version operating in the instrument.

x Used to access the configuration parameters in the various

menus.

x Used to initiate changes in configuration parameters.

x Used to accept configuration parameter changes.

The MFX software is structured using menus. A Map of the user

interface has been included in the Appendix of this manual. The

Map provides a visual path to the configuration parameters that

users need to access. This tool should be employed each time

configuration parameters are accessed or revised.

The five menus used in the structure of the MFX are as follows:

1. BSC MENU -- BASIC operations menu. It contains all of the

configuration parameters necessary to program the meter to

measure flow.

2. OUT1 MEN -- Configures the type and operating parameters of

the ISO-MOD located in Module #1 position.

3. SEC MENU -- SECURITY MENU utilized for resetting totalizers,

resetting the operating system and revising security passwords.

4. SER MENU -- SERVICE MENU contains system measurements

that are used by service personnel for troubleshooting

instruments installed on piping systems.

5. DSP MENU -- DISPLAY MENU used to configure meter display

functions.

Rev. 01/11 -3.2- MFX

Page 37

PART 3 - KEYPAD CONFIGURATION

The following sections define the configuration parameters located

in each of the menus.

1. BASIC MENU

The BASIC menu contains all of the configuration parameters

necessary to make the MFX operational.

UNITS

Selection

IMPORTANT!

K-factor Entry

UNITS

ENGLSH

METRIC

Installs a global measurement standard into the operation of the

instrument. The choices are either English or Metric measurements.

x Select ENGLSH if all configurations (pipe sizes, etc.) are to be

made in inches. Select METRIC if the meter is to be configured

in millimeters.

NOTE: If the UNITS entry has been changed from ENGLSH to

METRIC or from METRIC to ENGLSH, the entry must be saved

and the instrument reset (power cycled or System Reset entered)

in order for the MFX to initiate the change in operating units.

Failure to save and reset the instrument may result in meter not

measuring properly.

K FACTOR -- MagProbe K-Factor Entry

0.1 - 100.00

Each MagProbe has a unique K-factor that is factory set and

recorded on the information tag located on the MagProbe flow

sensor. To enter the MagProbe K-factor into the MFX, press the

ENTER key, then use the up/down arrow keys to adjust displayed

value to equal the unique K-factor value. When the value is proper,

press the ENTER key to record the value. This procedure must be

followed if a replacement MagProbe is procured from the

Dynasonics factory.

Rev. 01/11 -3.3- MFX

Page 38

PART 3 - KEYPAD CONFIGURATION

Pipe Diameter

Pipe Wall

Thickness

PIPE OD -- Pipe Outside Diameter Entry

ENGLSH (Inches)

METRIC (Millimeters)

Enter the pipe outside diameter

as UNITS; in millimeters if METRIC was selected.

IMPORTANT NOTE: Charts listing popular pipe sizes have been

included in the Appendix of this manual. Correct entries for pipe

O.D. and pipe wall thickness are critical to obtaining accurate flow

measurement readings.

PIPE WT -- Pipe Wall Thickness Entry

ENGLSH (Inches)

METRIC (Millimeters)

Enter the pipe wall thickness

UNITS; in millimeters if METRIC was selected.

in inches if ENGLSH was selected

in inches if ENGLSH was selected as

Liner

Thickness

Insertion

Depth

IMPORTANT NOTE: Charts listing popular pipe sizes have been

included in the Appendix of this manual. Correct entries for pipe

O.D. and pipe wall thickness are critical to obtaining accurate flow

measurement readings.

LINER T -- Pipe Liner Thickness Entry

ENGLSH (Inches)

METRIC (Millimeters)

Enter the pipe liner thickness

was selected as UNITS; in millimeters if METRIC was selected.

INS DEPTH -- Insertion Depth Entry

ENGLSH (Inches)

METRIC (Millimeters)

Data defaulted to .125 pipe I.D. No manual entry is necessary.

. Enter this value in inches if ENGLSH

Rev. 01/11 -3.4- MFX

Page 39

PART 3 - KEYPAD CONFIGURATION

Engineering

Units—RATE

Engineering

Units—RATE

INTERVAL

Engineering

Units—TOTAL

RATE UNT -- Engineering Units for Flow Rate

GALLONS - U.S. Gallons

LITERS - Metric Liter

MGAL - Millions of U.S. Gallons

CUBIC FT - Cubic Feet

CUBIC ME - Cubic Meters

ACRE FT - Acre Feet

OIL BARR - Oil Barrels (42 U.S. Gallons)

LIQ BARR - Liquor Barrels (31.5 U.S. Gallons)

FEET - Linear Feet

METERS - Linear Meters

Select a desired engineering unit for flow rate measurements.

RATE INT -- Time Interval for Flow Rate

MIN - Minutes

HOUR - Hours

DAY - Days

SEC - Seconds

Select a desired engineering unit for flow rate measurements.

TOTL UNT -- Engineering Units for Flow Totalizer

GALLONS - U.S. Gallons

LITERS - Metric Liter

MGAL - Millions of U.S. Gallons

CUBIC FT - Cubic Feet

CUBIC ME - Cubic Meters

ACRE FT - Acre Feet

OIL BARR - Oil Barrels (42 U.S. Gallons)

LIQ BARR - Liquor Barrels (31.5 U.S. Gallons)

FEET - Linear Feet

METERS - Linear Meters

Select a desired engineering unit for flow accumulator (totalizer)

measurements.

Rev. 01/11 -3.5- MFX

Page 40

PART 3 - KEYPAD CONFIGURATION

Engineering

Units—TOTAL

Exponent

TOTL E -- Flow Totalizer Exponent Value

E-1 to E6

Utilized for setting the flow totalizer exponent. This feature is useful

for accommodating a very large accumulated flow. The exponent

is a “10

(1,000,000).Table 3.5 should be referenced for valid entries

and their influence on the DMFX display.

Exponent Display Multiplier

E-1 0.1 (÷10)

E0 1 (no multiplier)

E1 10

E2 100

E3 1,000

E4 10,000

n

” multiplier, where “n” can be from -1 (0.1) to +6

Table 3.5 - Totalizer Exponent Values

Minimum Flow

Rate

Maximum Flow

Rate

E5 100,000

E6 1,000,000

MIN RATE -- Minimum Flow Rate Settings (Value)

Rate Unit/Rate Interval

A minimum volumetric flow rate setting is entered to establish filter

software settings. Volumetric entries will be in the Engineering Rate

Units and Interval selected on pages 3.9 and 3.10 of this manual.

For unidirectional measurements, set MIN RATE to zero. For bidirectional measurements, set MIN RATE to the highest negative

(reverse) flow rate expected in the piping system.

MAX RATE -- Maximum Flow Rate Settings (Value)

Rate Unit/Rate Interval

A maximum volumetric flow rate setting is entered to establish filter

software settings. Volumetric entries will be in the Engineering Rate

Units and Interval selected on pages 3.9 and 3.10 of this manual.

Set MAX RATE to the highest (positive) flow rate expected in the

piping system.

Rev. 01/11 -3.6- MFX

Page 41

PART 3 - KEYPAD CONFIGURATION

Low Flow

Cut-off

System

Damping

FL C-OFF -- Low Flow Cut-off

Percent of MAX RATE

A Low Flow Cut-off entry is provided to allow very low flow rates

(that can be present when pumps are off and valves are closed) to

be displayed as Zero flow. Typical values that should be entered are

between 1.0% and 5.0% of full-scale.

DAMP PER -- System Damping

Relative Percent Entry

DAMP PER establishes a maximum

stable flow conditions (flow that varies less than ±5%) this adaptive

filter will increase the number of successive flow readings that are

averaged together up to this maximum value. If flow changes

outside of the ±5% window, the Flow Filter adapts by decreasing

and allows the meter to react faster. A minimum

established with the MIN DAMP setting described below. DAMP

PER is usually set to a value that is equal to or greater than MIN

DAMP. Increasing this value tends to provide smoother steady-state

flow readings and outputs.

adaptive filter value. Under

filter setting is

Minimum

System

Damping

MIN DAMP -- System Damping

Relative Percent Entry

In installations where very turbulent or erratic flow is encountered,

increasing the MIN DAMP setting can increase display and output

stability by forcing more averaging of flow readings. This filter is not

adaptive, so increasing this setting will decrease the response time

of the instrument to all changes in flow rate. MIN DAMP is usually

set to a value that is equal to or less than DAMP PER.

Rev. 01/11 -3.7- MFX

Page 42

PART 3 - KEYPAD CONFIGURATION

2. OUTPUT #1 MENU

4-20mA

4-20mA Span

ISO-MOD 4-20mA

FL 4MA

FL 20MA

CAL 4MA

CAL 20MA

4-20 TST

Configured via jumper selections into either a passive or active

transmission mode (see Section 2 for details), the 4-20 mA Output

Module interfaces with virtually all recording and logging systems by

transmitting an analog current signal that is proportional to system

flow rate. Independent 4 mA and 20 mA span settings are

established in software using the Flow Measuring Range entries.

These entries can be set anywhere in the –30 to +30 FPS (-9 to +9

MPS) measuring range of the instrument. Output resolution of the

module is 12-bits (4096 discrete points) and the module can drive

up to 800 Ohms of load with its internal 24V isolated power source.

The FL 4MA and FL 20MA entries are used to set the span of the 4

-20 mA analog output. These entries are volumetric rate units that

are equal to the volumetric units configured as Engineering Rate

Units and Engineering Units Time Interval entered on page 3.10.

These entries may be entered anywhere in the flow measurement

range of the instrument [velocity range of –30 to +30 FPS (-9 to +9

MPS)].

NOTE: The Minimum Rate may be set anywhere in the flow

measurement range of –30 to +30 FPS (-9 to +9 MPS). For

example: if bi-directional flow needs to be logged, set the MIN

RATE at a negative

For example, to span the 4-20mA output from –100 GPM to +100

GPM, with 12mA being 0 GPM, set the FL 4MA and FL 20MA

inputs as follows:

FL 4MA = -100.0

FL 20MA = 100.0

Rev. 01/11 -3.8- MFX

value.

Page 43

PART 3 - KEYPAD CONFIGURATION

4-20mA

Calibration

For example, to span the 4-20mA output from 0 GPM to +100 GPM,

with 12mA being 50 GPM, set the FL 4MA and FL 20MA inputs as

follows:

FL 4MA = 0.0

FL 20MA = 100.0

The 4-20mA ISO-MOD is factory calibrated and should not require

adjustment unless it is replaced.

The CAL4MA entry allows fine adjustments to be made to the “zero”

of the 4-20mA output. To adjust the 4mA output, an ammeter or

reliable reference connection to the 4-20mA output must be present.

NOTE: The CAL 4MA and CAL 20MA entries should not be used

in a attempt to set the 4-20mA range. Utilize FL 4MA and FL

20MA, detailed above, for this purpose.

Procedure:

1. Disconnect one side of the current loop and connect the

ammeter in series (disconnect either wire at the terminals

labeled +/- on the ISO-MOD 4-20mA module).

2. Using the arrow keys, increase the numerical value to increase

the current in the loop to 4mA. Decrease the value to decrease

the current in the loop to 4mA. Typical values range between 4080 counts.

Re connect the 4-20mA output circuitry as required.

Calibration of the 20mA setting is conducted much the same way as

the 4mA adjustments.

Procedure:

1. Disconnect one side of the current loop and connect the

ammeter in series (disconnect either wire at the terminals

labeled +/- on the ISO-MOD 4-20mA module).

2. Using the arrow keys, increase the numerical value to increase

the current in the loop to 20mA. Decrease the value to decrease

the current in the loop to 20mA. Typical values range between

3700-3900 counts.

Re connect the 4-20mA output circuitry as required.

Rev. 01/11 -3.9- MFX

Page 44

PART 3 - KEYPAD CONFIGURATION

4-20mA Test

Rate Pulse/

Freq

4-20 TST - 4-20mA Output Test

4-20

Allows a simulated value to be output on from the 4-20mA output.

By incrementing this value, the 4-20mA output will transmit the

indicated current value. This feature can be utilized to confirm

connectivity with chart recorders, data acquisition systems or other

monitoring equipment.

ISO-MOD RATE PULSE (Value)

Flow at 0 Hz (FL 0H)

Flow at 2.5k Hz (FL 2.5KH)

NOTE: The Maximum Rate may be set anywhere in the flow

measurement range of -30 to +30 FPS (-9 to +9 MPS). For

example: If bi-directional flow needs to be logged, set the MIN

RATE at a negative value and MAX RATE at a positive value.

The Rate Pulse Output Module is utilized to transmit information to

external counters and PID systems via a frequency output that is

proportional to system flow rate. Independent Zero and Span

settings are established in software using the Flow Measuring

Range entries. Output resolution of the module is 12-bits (4096

discrete points) and the maximum output frequency setting is

2,500

simulation and “open collector”. The turbine meter simulation

sources a non-ground referenced saw-tooth waveform with a

maximum amplitude of approximately 500 mV p-p. The open

collector output utilizes a 0.21 Ohm FET output that is rated to

operate at 100 V and 1 A maximum. If the open collector output is

utilized, an external voltage source and limit resistor must be

present. See Part 1 of this manual for connection information.

Hz. The module has two output modes, turbine meter

Rate Pulse

Span

Rev. 01/11 -3.10- MFX

The FL 0H and FL 25KH entries are used to set the span of the

0 to

units that are equal to the volumetric units configured as

Engineering Rate Units and Engineering Units Time Interval entered

on pages 3.11 and 3.12 of this manual.

2.5k Hz frequency output. These entries are volumetric rate

Page 45

PART 3 - KEYPAD CONFIGURATION

Dual Relay

For example, in a bi-directional system, to span the 0 to 2.5k Hz

output from –100 GPM to +100 GPM, with 1.25k Hz being 0 GPM,

set the FL 100H and FL 10KH inputs as follows:

FL 0H = –100.0

FL 25KH = 100.0

For example, to span the 0 to 2.5k Hz output from 0 GPM to +100

GPM, with 1.25k Hz being 50 GPM, set the FL 0H and FL 25KH

inputs as follows:

FL 0H = 0.0

FL 25KH = 100.0

ISO-MOD Dual Relay

RELAY 1 AND RELAY 2

Batch/Totalizer

Relay

NONE

TOTALIZE

TOT MULT

FLOW

ON

OFF

SIG STR

ERRORS

Two independent SPDT (single-pole, double-throw, Form C) relays

are contained in this module. The relay operations are user

configured via software to act in either a flow rate alarm, signal

strength alarm, error alarm or totalizer/batching mode. The relays

are rated for 200 VAC max. and a have current rating of 0.5A

resistive load (175 VDC @ 0.25A resistive). It is highly

recommended that a slave relay be utilized whenever the Control

Relay ISO-MOD is used to control inductive loads such as solenoids

and motors.

TOTALIZE mode configures the relay to output a 50 mSec pulse

(contact changeover) each time the display totalizer increments—

divided by the TOT MULT. The TOT MULT value must be a whole,

positive, numerical value.

Rev. 01/11 -3.11- MFX

Page 46

PART 3 - KEYPAD CONFIGURATION

Flow Rate

Relay

Error Alarm

Relay

For example, if the Totalizer Exponent is set to E0 (1) and the

Relay Multiplier is set to 1, then the relay will pulse each time the

totalizer increments one count, or each single, whole measurement

unit totalized.

If the Totalizer Exponent is set to E2 (100) and the Relay

Multiplier is set to 1, then the relay will pulse each time the display

totalizer increments or once per 100 measurement units totalized.

If the Totalizer Exponent is set to E0 (1) and the Relay Multiplier

is set to 2, the relay will pulse once for every two counts that the

totalizer increments.

Flow Rate Relay configuration permits relay changeover at two

separate flow rates allowing operation with an adjustable switch

deadband. Figure 3.1 illustrates how the setting of the two set

points influences rate alarm operation.

A single-point flow rate alarm would place the ON> setting slightly

higher than the OFF< setting—allowing a switch deadband to be

established. If a deadband is not established, switch chatter (rapid

switching) may result if the flow rate is very close to the switch point.

When a relay is set to ERROR mode, the relay will activate when

any error occurs in the flow meter that has caused the meter to stop

measuring reliably. See the Appendix of this manual for a list of

potential error codes.

Figure 3.1

Single Point Alarm Operation

Rev. 01/11 -3.12- MFX

Page 47

PART 3 - KEYPAD CONFIGURATION

RS232C

Module

RS-485 I/O

ISO-MOD RS232C

Baud Rate (RS232 BA)

1200 Baud (1200)

2400 Baud (2400)

9600 Baud (9600)

19,200 Baud (19200)

The RS232C Module can be interfaced with serial communication

ports of PCs, PLCs and SCADA systems. This module runs a

proprietary digital protocol, detailed in the Appendix of this manual,

that is used to monitor flow rate information in piping systems. The

RS232C Module may also be used to form a hardwire connection to

a PC that is running the ULTRALINK™ software utility. Baud rates

up to 19.2k are supported.

ISO-MOD RS485 (Choices and Values)

RS485 Mode (RS485 MO)

Slave (SLAVE)

Master (MASTER)

Baud Rate (RS485 BA)

1200 Baud (1200)

2400 Baud (2400)

9600 Baud (9600)

19,200 Baud (19200)

Device Address (1-127)

The RS485 Module allows up to 126 MFX systems to be daisychained on a single three-wire cable network. Communications are

through a proprietary digital protocol, detailed in the Appendix of this

manual. All meters are assigned a unique one byte serial number

that allows all of the meters on the cable network to be accessed

independently. Baud rates up to 19.2k and cable lengths to 5,000

feet (1,500 meters) are supported without the need for repeaters.

RS485 MO

Select SLAVE for all of the MFX meters connected to the unit

designated as MASTER.

RS485 BA

Select a Baud rate that is compatible with the operating system.

Rev. 01/11 -3.13- MFX

Page 48

PART 3 - KEYPAD CONFIGURATION

ADDRESS

Each MFX connected on the communications bus must have an

unique address number assigned. Address 127 is a universal

address that will result in all MFX instruments on the network

responding simultaneously—regardless of address—resulting in

CRC errors. Only select address location 127 if one meter is on the

network.

Data Logger

Option

ISO-MOD DATALOGGER (Value)

LOGGING INTERVAL

From the OUTPUT 1 menu, select the time INTERVAL between

readings. INTERVAL values between 1 and 30,000 seconds are

acceptable.

For reference there are:

60 seconds in 1 minute

300 seconds in 5 minutes

1,800 seconds in 30 minutes

3,600 seconds in 1 hour

30,000 seconds in 8.33 hours

Table 3.6 describes some typical configurations of the INTERVAL

and DURATION times with what the expected data samples

collected count will be.

Example No. INTERVAL

Table 3.6 - Interval and Duration Times

DURATION

Seconds

1 1 24 (1 day) 86,400

2 10 168 (7 days) 60,480

Hours

Operated

Samples

Collected

3 60 (1min) 720 (30 days) 43,200

4 300 (5 min) 8,760 (1 yr) 105,120

5 1,800 (30 min) 8,760 (1 yr) 17,520

6 3,600 (1 hr) 8,760 (1 yr) 8,760

7 18,000 (5 hr) 26,280 (3 yr) 17,520

Rev. 01/11 -3.14- MFX

Page 49

PART 3 - KEYPAD CONFIGURATION

3. SECURITY MENU

The SEC MENU allows the user to make password revisions, reset

the flow totalizer and reset the transmitter microprocessor.

Totalizer

RESET

System RESET

Change

Password

TOT RES

NO

YES

Select YES to reset the Positive, Negative and Net flow totalizer/

accumulator to Zero.

SYS RSET

NO

YES

Select YES to initiate a microprocessor reset. All system

configurations and totalizer values will be maintained.

CH PSWD? -- Change the Security Password

0-9999

By changing the Security Password from 0 to some other value (any

value between 1-9999), configuration parameters will not be

accessible without first entering that value when prompted. If the

value is left at 0, no security is invoked and unauthorized changes

could be made.

4. SERVICE MENU

Signal

Strength

Signal

SIG STR -- Signal Strength

This feature is not activated on the MFX flow meter product.

SIG C-OF -- Signal Strength Cutoff

Strength

Cutoff

This feature is not activated on the MFX flow meter product.

Rev. 01/11 -3.15- MFX

Page 50

PART 3 - KEYPAD CONFIGURATION

Substitute

Flow Entry

SUB FLOW - Substitute Flow

Substitute Flow or SUB FLOW is a value that the analog outputs

and the flow rate display will be driven at when an error condition in

the flow meter occurs. The typical setting for this entry is a value

that will make the instrument display zero flow during an error

condition. TABLE 3.2 below lists some typical settings to achieve

“Zero” with respect to MIN and MAX FLOW settings.

TABLE 3.2

Substitute Flow Entry

MIN RATE

SETTING

0.0 1,000.0 0.0 0.000

-500.0 500.00 50.0 0.000

-100.0 200.0 33.3 0.000

0.0 1,000.0 -5.0* -50.00

*ULTRALINK is required to set values outside of 0.0-100.0.

MAX RATE

SETTING

SUB FLOW

SETTING

DISPLAY READING

DURING ERRORS

Setting/

Calibrating

Zero Flow

SET ZERO -- Calibrating Zero Flow

The MFX flow meter has been calibrated at the Dynasonics factory;

this calibration procedure includes calibration of “zero” flow. Field

calibration of “zero” is typically not required and other

troubleshooting methods should typically be reviewed to ensure that

the flow meter “zero” requires recalibration.

To zero the meter:

1. The pipe must be full of liquid.

2. Flow must be absolute zero—verify by closing a valve securely.

Allow time for any settling to occur.

3. Press ENTER, use the arrow keys to make the display read

YES.

4. Press ENTER.

5. The procedure is complete.

An alternative method for verifying and calibrating zero flow

when flow cannot be turned off

manual.

is covered in Section 4 of this

Rev. 01/11 -3.16- MFX

Page 51

PART 3 - KEYPAD CONFIGURATION

Factory

Default Zero

Calibration

Correction

Factor

D-FLT 0 -- Reverting to Factory Default Zero

If the flow in a piping system cannot be shutoff, allowing the SET

ZERO procedure described above to be performed, the factory

default zero should be utilized. To utilize the D-FLT 0 function,

simply press ENTER, then press an ARROW key to display YES on

the display and then press ENTER. This function can also be

utilized to correct an inadvertently entered or erroneous SET ZERO

entry.

COR FTR -- Universal Correction Factor

This function can be used to make the MFX system agree with a

different or reference flow meter, by applying a correction factor/

multiplier to the readings and outputs. A factory calibrated system

should be set to 1.000. The range of settings for this entry is 0.500

to 1.500. The following examples describe two uses for the COR

FTR entry.

x The MFX meter is indicating a flow rate that is 4% higher than

another flow meter located in the same pipe line. To make the

MFX indicate the same flow rate as the other meter, enter a

COR FTR of 0.960, to lower the readings by 4%.

5. DISPLAY MENU

T/R SCAN -- Totalizer and Rate Display Scan

Flow Display

Mode

Rev. 01/11 -3.17- MFX

FLOW

TOTAL

BOTH

The MFX will only display FLOW RATE

FLOW—it will not display the TOTAL FLOW. MFX will only display

FLOW TOTAL

the FLOW RATE. By selecting BOTH, the display will scan between

RATE and TOTAL at the interval selected in SCN DWL.

with the T/R SCAN set to TOTAL—it will not display

with the T/R SCAN set to

Page 52

PART 3 - KEYPAD CONFIGURATION

Totalizer

Display Mode

Rate/Total

Scan Time

TOTAL -- Totalizer Mode

NET

POS

NEG

BATCH

Select NET to display the net difference between the positive

direction and negative direction totalizers. Select POS to only view

the positive direction totalizer. Select NEG to only view the negative

direction totalizer. Select the BATCH totalizer to configure the

totalizer to count up to a value that is entered as BTCH MUL

(described on the following page). After reaching the BTCH MUL

value, the display will return to zero and will repeat counting to the

BTCH MUL value.

SCN DWL -- Display Scan Dwell Time

1-10 Seconds

Adjustment of SCN DWL sets the time interval that the display will

dwell at RATE and then alternately TOTAL values. This adjustment

range is from 1 second to 10 seconds.

Displaying

Batch

Total

BTCH MUL -- Totalizer Batch Quantity

If BATCH was chosen for the TOTALIZER DISPLAY MODE, a value

for batch accumulation must be entered. This is the value that the

totalizer will accumulate to before resetting to zero and repeating

the accumulation. This value includes any exponents that were

entered in the BASIC menu as TOTAL E. For example:

x If BTCH MUL is set to 1,000, RATE UNT to LITERS and TOTL E

to E0 (liters 1); the BATCH totalizer will accumulate to 1,000

liters, return to zero and repeat indefinitely. The totalizer will

increment 1 count for every 1 liter that has passed.

x If BTCH MUL is set to 1,000, RATE UNT to LITERS and TOTL E

to E2 (liters 100); the BATCH totalizer will accumulate to

100,000 liters, return to zero and repeat indefinitely. The totalizer

will only increment 1 count for every 100 liters that has passed.

Rev. 01/11 -3.18- MFX

Page 53

PART 4 - SOFTWARE UTILITIES

The MFX flow meter is supported by a troubleshooting software

utility called ULTRALINK™. While ULTRALINK™ was developed to

be utilized with Dynasonics Series TFX ultrasonic flow meters, the

utility does have features that can assist MFX users in

troubleshooting, configuration and calibration of the insertion

magnetic flow meter system.

A PC running ULTRALINK™ can be hardwired to an MFX flow

meter through an RS232 or RS485 module or, more commonly, the

communications link is through an infrared communicator. The

infrared communicator is available from Dynasonics as part

number D005-2115-001. If the infrared communicator is to interface

with a USB port on a PC, a USB-to-DB-9 interface adapter is required

(Dynasonics part number D005-2116-004).

System Requirements

PC-type computer, running Windows 95, Windows 98, Windows 2000,

Windows XP or Windows Vista

®

operating system, a communications

port (USB ports require a USB-to-DB-9 adapter, Dynasonics p/n

D005-2116-004).

Installation

1. ULTRALINK™ can be found on the Dynasonics website

(www.dynasonics.com) for no cost or a CD can be purchased by

contacting Dynasonics sales.

2. Backup/Copy all files from the website link to a folder on the

computer hard disk.

3. From the “Start” command, RUN UlSetup.exe from the hard disk

folder.

4. During the installation of ULTRALINK™, the installer will be

queried as to which product the software is primarily going to be

used with; select TFXD.

5. UlSetup will automatically extract and install on the hard disk

and place a short-cut icon on the desktop.

Rev. 01/11 -4.1- MFX

Page 54

PART 4 - SOFTWARE UTILITIES

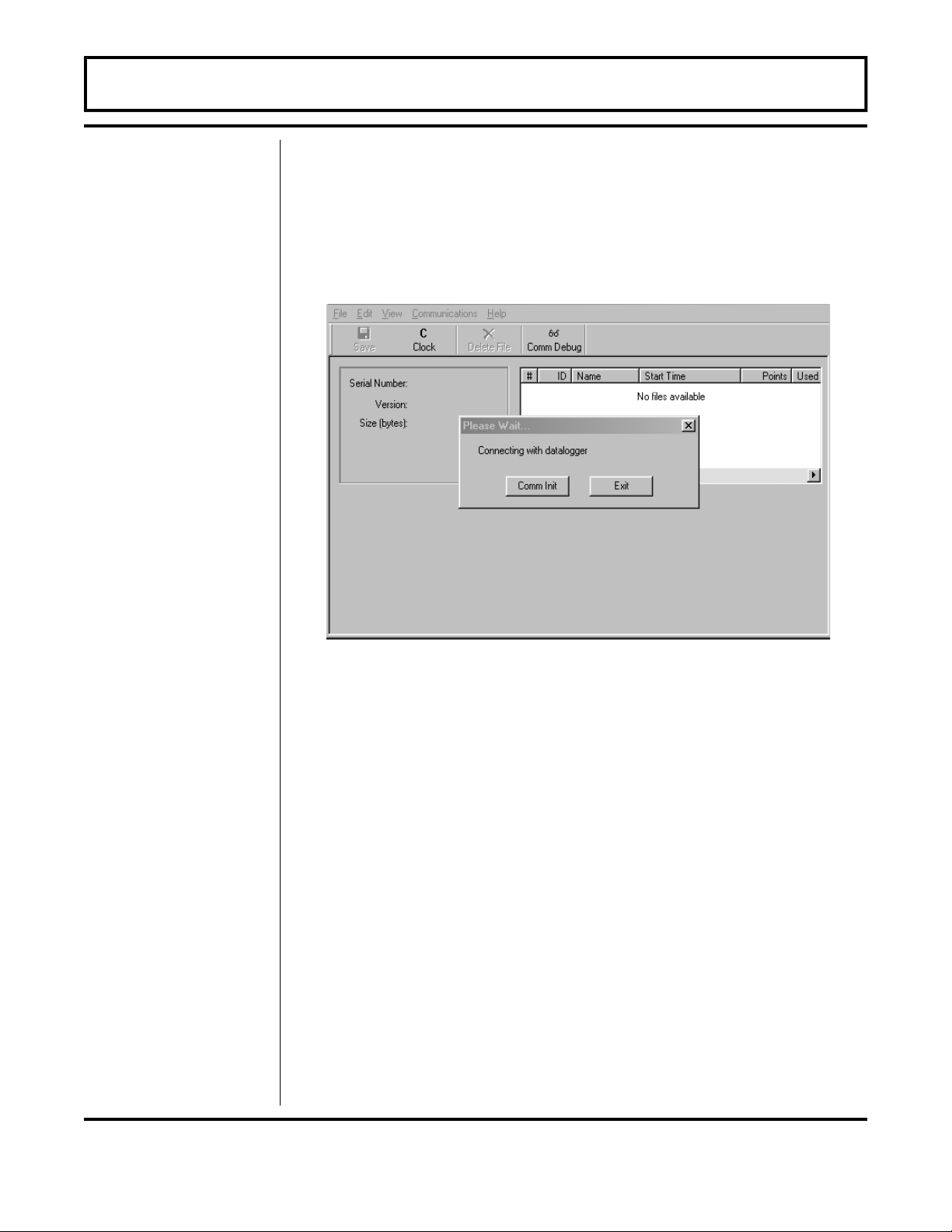

Initialization

1. Connect communications cable, Dynasonics p/n D005-2115-001,

to a PC communication port and point the communicator at the

MFX infrared window, located in the lower right-hand corner of

the meter front panel. Alternately, connect the PC communications

port directly to an optionally installed RS232C or RS485 module

located within the MFX flow meter.

2. Double-click on the ULTRALINK™ icon. The first screen is the

“RUN-mode” screen (see Figure 4.1), which contains realtime information regarding flow rate, totalizer accumulation,

system signal strength, diagnostic data and the flow meter’s

serial number. The indicator in the lower right-hand corner will

indicate communications status. If a red ERROR is indicated,

click on the Communications button on the top bar. Click on

Communications/Initialize. Choose the appropriate COM port

and interface type. Proper communications are established when

a green OK is indicated in the lower right-hand corner of the PC

display.

Data Trend Minutes Data Trend Flow Rate

Figure 4.1

ULTRALINK™ Data Screen

Rev. 01/11 -4.2- MFX

Page 55

PART 4 - SOFTWARE UTILITIES

Pipe and

Liquid

Configuration

Click on the button labeled Configuration for updating flow range,

liquid, pipe and I/O operating information. The first screen that

appears after clicking the Configuration button is the BASIC tab.

See Figure 4.2.

Figure 4.2

Basic Tab

1. BASIC TAB - see Figure 4.2

x General Units allows selection of either English (U.S.) or Metric

units of measure. If measurements of the pipe are to be entered

in inches, select English. If pipe measurements are to be entered

in millimeters, select Metric. If the General Units are altered from

those at instrument startup, then click on the Download button

on the lower right-hand portion of the screen and recycle power

to the MFX.

x Transducer Type does not pertain to the MFX product.

x Transducer Mount does not pertain to the MFX product.

x Transducer Spacing does not pertain to the MFX product.

x Pipe Material does not pertain to the MFX product.

x Pipe O.D. and Wall Thickness are based on the physical

dimensions of the pipe in which the probe will be inserted. Enter

this value in inches for English units or millimeters for Metric units.

x Liner Material is selected from the pull-down list.

Rev. 01/11 -4.3- MFX

Page 56

Flow Units

Configuration

PART 4 - SOFTWARE UTILITIES

x Liner Thickness (entry becomes available when a Liner

Material is selected) enter this value in inches for English units or

millimeters for Metric units.

x Fluid Type does not pertain to the MFX product.

2. FLOW TAB - see Figure 4.3

x Flow Rate Units are selected from the pull-down lists. Select an

appropriate rate unit and time from the two lists.

x Totalizer Units are selected from pull-down lists. Select an

appropriate totalizer unit and totalizer exponent. The totalizer

exponents are in Scientific Notation and permit the eight digit

totalizer to accumulate very large values before the totalizer

“rolls over” and starts again at zero. Table 4.1 on page 4.5

illustrates the Scientific Notation values and their respective

decimal equivalents.

x MIN Flow is used by the MFX to establish filter settings in its

operating system. Enter a flow rate that is the minimum flow rate

anticipated within the system. For unidirectional systems, this

value is typically zero. For bi-directional systems this value is set

to a negative number that is equal to the maximum negative flow

rate that is anticipated within the system.

Figure 4.3

Flow Tab

Rev. 01/11 -4.4- MFX

Page 57

PART 4 - SOFTWARE UTILITIES

Exponent Display Multiplier

E-1 0.1 (decimal is moved on display)

E0 1 (no multiplier)

E1 10

E2 100

E3 1,000

E4 10,000

E5 100,000

E6 1,000,000

TABLE 4.1