Page 1

Hybrid Ultrasonic Flow Meter

DXN Portable Ultrasonic Flow and Energy Meter

DESCRIPTION

The DXN Portable Ultrasonic Flow and Energy Meter is a true

hybrid instrument, capable of measuring liquid flow with multiple

technologies, including: Doppler, transit time and liquid thermal

(heat energy) flow. Easy to install by clamping onto the outside

of the pipe, the DXN measures flow using non-invasive ultrasonic

sensors. Compatible with a pipe wall thickness gauge, inside

pipe diameter can be verified to ensure accurate ultrasonic

measurements when piping details are unknown or unavailable.

The DXN has a number of advanced features including a

touchscreen interface, full-color graphing, wizard-based start-up

configuration, USB connectivity, and Modbus TCP/IP connectivity.

These features make it easy for technicians to obtain accurate

readings while capturing flow surges and high-speed batch

operations. The DXN captures and displays multiple user-defined

and application parameters at once and can record the data with

an easy-to-use data logging function. The ability to monitor and

record several parameters at once allows technicians to verify and

troubleshoot permanent flow installations with ease.

OPERATION

Transit time flow meters measure the time difference between

the travel time of an ultrasound wave going with the fluid flow

and then against the fluid flow. This time difference is used to

calculate the velocity of the fluid traveling in a closed-pipe system.

The transducers used in transit time measurements operate

alternately as transmitters and receivers. Transit time measurements

are bi-directional and are most effective for fluids that have low

concentrations of suspended solids.

Doppler flow meters operate by transmitting an ultrasonic wave

from a transducer through the pipe wall and into the moving

liquid. The sound wave is “reflected” by suspended particles or

bubbles moving with the liquid and ultimately gathered by the

receiving transducer. A frequency shift (Doppler effect) will occur

that is directly proportional to the speed of the moving particles or

bubbles. This shift in frequency is interpreted by the digital signal

processor (DSP) and converted to a fluid velocity measurement.

Using its built-in hybrid technology, the DXN will automatically

choose which type of flow measurement to read based on signal

quality during operation. Regardless of the method used to

determine velocity, multiplying the pipe’s cross-sectional area by

the fluid velocity produces a volumetric flow rate. The measurement

also presumes that the pipe is completely full during the

measurement cycle.

When used in conjunction with flow measurement, temperature

measurements can yield energy usage readings in the form of heat

flow. To find the net heat loss or gain, energy usage is calculated by

multiplying the flow rate of the heat transfer fluid by the change of

heat content in the fluid after it has done some kind of work

An ultrasonic meter equipped with heat flow capabilities measures

the rate and quantity of heat delivered or removed from devices

such as heat exchangers. The instrument measures the volumetric

flow rate of the heat exchanger liquid, the temperature at the inlet

pipe and the temperature at the outlet pipe.

Rate of Heat Delivery = Q * (TIn - T

Where…

Q = Volumetric ow rate

T

= Temperature at the Inlet

In

T

= Temperature at the Outlet

Out

C = Heat Capacity

ρ = Density of uid

By applying a scaling factor, this heat flow measurement can be

expressed in the units of your choosing (Btu, Watts, Joules, Kilowatts

and so on).

) * C * ρ

Out

HYB-DS-00086-EN-06 (October 2018)

Product Data Sheet

Page 2

Hybrid Ultrasonic Flow Meter, DXN Portable Ultrasonic Flow and Energy Meter

SPECIFICATIONS

Process Monitoring Inputs/Outputs

Connector 15-pin high-density DSUB

Breakout Box 0.2 in. quick disconnect screw terminal; 15-pin to adapter box; 6 ft (1.8 m) of cable (DSUB to DSUB connectors)

RTD Input

Current Output 4…20 mA active/passive 1% accuracy

Voltage Input 0…5V or 0…10V, 1% accuracy, Software scaling and control, 80 k Ohms input impedance, Data log capable

Voltage Output 0…5V or 0…10V output voltage, 1% accuracy, Software scaling and control, 100 Ohms output impedance

Sensor Supply 14V @ 50 mA max for powering current or voltage sensors

Digital Output

Digital Input Totalizer reset, external pull-up, software enabled

System

Measurement Type

Liquid Types Liquid dominant fluids, acoustically conductive

Velocity Range Transit Time: Bi-directional to 40 FPS (12 MPS) Doppler: Uni-directional to 40 FPS (12 MPS)

Flow Rate Accuracy Transit Time: ±1% of reading or ±0.01 FPS (0.003 MPS), whichever is greater. Doppler: 2% of full scale

Flow Sensitivity 0.001 FPS (0.0003 MPS)

Repeatability ±0.1% of reading

Temperature Accuracy Absolute: 0.5° F (1° C) Difference: 0.2° F (0.5° C) Resolution: 0.02° F (0.01° C)

Logging Greater than 300 sites stored in 1 GB; download to USB flash drive

Update Time 0.1…10 seconds update/filter rate. Transit time, up to 50 Hz high speed mode

Battery

Power Requirements

Power Cords

Display

Ambient Conditions Battery powered: –4…110° F (–20…45° C) Externally powered: –20…140° F (–30…60° C)

Storage Temperature Do not exceed 175° F (80° C)

Enclosure Water/dust resistant

User Menu

Compliance Safety: UL61010-1, CSA C22.2 No. 61010-1, EN61010-1 Directives: 2006/95/EC low Voltage, 2004/108/EC EMC

Energy/Temperature (2) tab type PT1000 RTDs.

Can handle various temperature ranges from –58…392º F (–50…200º C), based on RTD type

Open collector, external pull-up; Rate or total pulse user selectable

Rate pulse:

0…1000 Hz

Flow: Ultrasonic transit time and Doppler (reflection of acoustic signals); hybrid operation; liquid thermal energy

Pipe wall thickness: Ultrasonic transit time of acoustic signals

Internal 11.1V lithium ion battery, 75 W-hr. Provides 6…9 hr of continuous operation with battery and indefinitely on

external power. Complete charge at 32…104° F (0…40° C), 4 hours when powered off.

Transmitter: 10…30V DC via 3-pin connector, 40 W, minimum; 3.6 A re-settable fuse

Supplies: Wall adapter: 100…240V AC 50/60 Hz 50 W 10…18 V; Cigarette lighter adapter: 5 A fused

North American plug (2 flat & 1 round prong; NEMA 5/15P); Chinese plug (3 flat prongs; GB2099);

Euro plug (2 round prongs; CEE7/7); U.K./Singapore plug (3 rectangular prongs; BS1363A)

Japanese plug (2 flat & 1 round, JIS8303, w/ 3-2 prong adapter)

Australian plug (3 flat prongs, AS3112)

800 × 480 WVGA color outdoor readable display;

gloved-operation resistive touch screen 6 in. × 3.6 in. (152.4 mm × 41.44 mm)

Multi-language: English, Spanish, German, French, Portuguese, Japanese, Russian, Italian, Dutch, Norwegian, Swedish,

Korean, simplified Chinese, Polish

Total pulse: 33 ms duration

Transducers

Pipe Sizes 1/2 in. and larger; US standard pipe tables are built into user Interface

DTTSU: CPVC, Ultem®, and

Housing Material

Pipe Surface Temperature

Transducer Frequency

Cable Length Transit time: 20 ft (6 m) paired coaxial cable, BNC to BNC, Doppler: 20 ft (6 m) paired coaxial cable, BNC to 4-pin

Pipe Thickness

RTDs 2 × platinum TCR 0.00385, 1000 Ohm, 3-wire PVC jacketed cable standard with quick connector

anodized aluminum track

system; nickel-plated brass

connector with Teflon®

insulation

DTTSU/DTTL: –40…194° F

(–40…90° C)

DTTSU: 2 MHz DTTR/DTTH: 1 MHz DTTL: 500 kHz DT94: 625 kHz

Dual mode transducer with 6 ft (1.8 m) of cable (BNC ends), ± 0.03 in. (0.76 mm), stainless steel, carbon steel, pipe,

polypropylene, PVC pipes

Page 2 October 2018HYB-DS-00086-EN-06

DTTR: PBT glass filled, Ultem,

Nylon cord grip, PVC cable

jacket

DTTR: –40…250° F

(–40…121° C)

DTTL/DT94: CPVC, Ultem®;

nickel-plated brass connector

with Teflon® insulation

DT94: –40…194° F

(–40…90° C)

DTTH: PTFE, Vespel, Nickelplated brass cord grip PFA

cable jacket

DTTH: –40…350° F

(–40…176° C)

Page 3

Product Data Sheet

MOUNTING SYSTEM

For DTTR transducers, the rail mounting kit aids in installation and positioning of the transducers. Transducers slide on the rails, which have

measurement markings that are used for proper spacing of transducers.

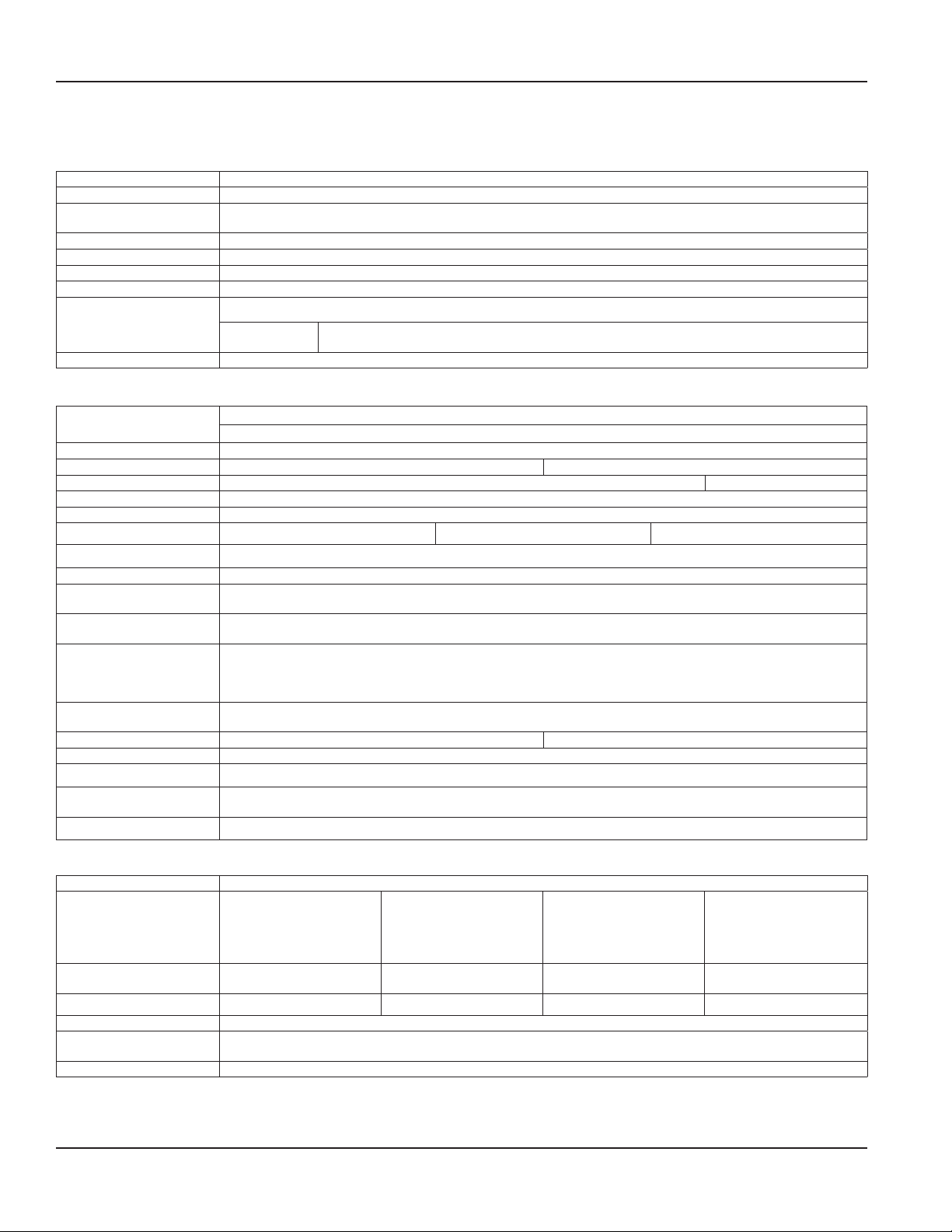

DXN CONNECTION PANEL

Doppler Transducer

Transit Time Transducer (Upstream)

Transit Time Transducer (Downstream)

Auxiliary

I/O

DIMENSIONS

DXN Transmitter

On/O Switch

A

A B C

7.8 in. (198 mm) 9.4 in. (240 mm) 3.8 in. (96 mm)

Power/Charger

B

EthernetUSB

C

Page 3 October 2018 HYB-DS-00086-EN-06

Page 4

Hybrid Ultrasonic Flow Meter, DXN Portable Ultrasonic Flow and Energy Meter

Transducers

A B

0.3 1.51.0 2.0

DTTSU Transit Time Transducer

C

A

B

C

DT94 Doppler Transducer

C

B

A

B

C

A

DTTR Transit Time Transducer

A B C D Minimum Pipe O.D. Maximum Pipe O.D.

DTTSU 7 in. (178 mm) 1.6 in. (42 mm) 1.5 in. (39 mm) — 0.5 in. (12 mm) 2.4 in. (60 mm)

DT94 1.7 in. (43 mm) 4.1 in. (105 mm) 1.9 in. (48 mm) — 1 in. (25 mm) 60 in. (1524 mm)

DTTR 4.6 in. (117mm) 2.3 in. (58 mm) 3.6 in. (91 mm) — 2 in. (50 mm) 98 in. (2500 mm)

DTTL 2.5 in. (63 mm) 4.2 in. (107 mm) 2.5 in. (63 mm) 3.9 in. (99 mm) 16 in. (400 mm) 120 in. (3050 mm)

DTTH 3.1 in. (79 mm) 2.9 in. (75 mm) 1.7 in. (43 mm) 3 in. (76 mm) 2 in. (50 mm) 98 in. (2500 mm)

DTTL/DTTH Transit Time Transducer

Page 4 October 2018HYB-DS-00086-EN-06

Page 5

PART NUMBER CONSTRUCTION

-

-

1

Product Data Sheet

Transit Time/Doppler Hybrid

DXN P

S

MODEL

Portable Ultrasonic Flow Meter P

POWER CORD (see image below for details)

North American A

Chinese C

European E

Japanese J

United Kingdom U

Australian Z

SENSOR AND HARDWARE KIT

Basic B

Transit Time T

Hybrid H

Hybrid All Sizes U

Energy E

Full F

CARRYING CASE

DXN Shoulder Strap and Outter Carrying Case S

APPROVALS

CE; General Safety, U.S., Canada and Europe N

OPTIONS

None N

1

Includes Universal AC Power Converter; 95… 264V AC 50/60 Hz; C14 Connection

N N

SENSOR AND HARDWARE KIT OPTIONS

Small pipe and standard pipe transit time transducers and 20 ft cables

Basic

Transit Time

Standard Temperature

Hybrid Basic kit, Doppler transducers and 20 ft cables for Doppler tranducers

Hybrid All Sizes Basic kit, large pipe transducers, Doppler transducers and 20 ft cables for Doppler transducers

Energy

Full

OTE:N High temperature transducers available separately.

(1) Couplant, grease; 5.3 oz; Dow 111

(1) Couplant, Ultrasound gel; 0.25 liter bottle

(4) Stainless steel straps (1/2" wide, 12-5/16" max dia., worm drive clamp)

Basic Kit and large pipe transducers

Basic kit and non-invasive RTDs

(1) Silicone Heat Sink Compound; 5 oz. syringe

(1) RTD Installation tape, 36 feet

Basic kit plus all, transit time, Doppler, RTDs and pipe wall thickness gauge

(1) Silicone Heat Sink Compound; 5 oz. syringe

RTD Installation tape, 36 feet

(2) Stainless steel straps (1/2" wide, 21-1/4" max dia., worm drive clamp)

Page 5 October 2018 HYB-DS-00086-EN-06

Page 6

Hybrid Ultrasonic Flow Meter, DXN Portable Ultrasonic Flow and Energy Meter

PARTS AND ACCESSORIES

Power Cords and Cables

Part Number Description

D005-2109-013 North American Plug (2 flat & 1 round prong; NEMA 5/15P)

D005-2109-015 UK Plug (3 rectangular prongs; BS1363A)

D005-2109-016 European Plug (2 round prongs; CEE7/7)

D005-2109-017 Japan Plug (2 flat & 1 round, JIS8303, w/ 3-2 prong adapter)

D005-2109-014 China Plug (3 flat prongs; GB2099)

D005-2109-018 Australian Power Plug (3 Flat Prongs; AS3112)

D005-2129-020 Transit Time Cables, 20 ft (6 m)

D005-2129-050 Transit Time Cables, 50 ft (15 m)

D005-2129-100 Transit Time Cables, 100 ft (30 m)

D005-2130-020 Doppler Cables, 20 ft (6 m)

D005-2130-050 Doppler Cables, 50 ft (15 m)

D005-2130-100 Doppler Cables, 100 ft (30 m)

Transducers (Heads with Case)

Part Number Description Minimum Pipe O.D. Maximum Pipe O.D.

D010-2200-002-C DTTSU Universal Small Pipe 0.5 in. (12 mm) 2.4 in. (60 mm)

D071-0107-302-C DTTR Standard Pipe 2 in. (50 mm) 98 in. (2500 mm)

D071-0110-200-C DTTL Large Pipe 16 in. (400 mm) 120 in. (3050 mm)

D071-0112-001-C DT94 Doppler Transducer 1 in. (25 mm) 60 in. (1524 mm)

DTTH-020-D000-N-C

Spare Parts

DTTH High Temperature,

Standard Pipe Kit

2 in. (50 mm) 98 in. (2500 mm)

Part Number Description

D002-2007-004 0…392° F (0…200º C) RTD Silicone stretch tape

D002-2007-001 36 in. (914 mm) SS Hose clamp / transducer strap

D002-2007-005 72 in. (1829 mm) SS Hose clamp / transducer strap

D002-2011-014 AcquaSonic 100

D002-2011-001 Acoustic couplant, grease (Dow 111), 150° F (65° C) 5.3 oz (150.2 gram) tube

D002-2011-011 Acoustic couplant, paste high temperature, 5 oz (142 gram) tube, 392° F (200° C)

D010-2102-310 DTTR rail

D040-0115-003-T Wall thickness gauge, 6 ft (1.83 m)

D010-3000-128 Industrial RTD Kit1, 1000 Ohm, 392° F (200° C); 20 ft (6 m) cable

D010-3000-130 Industrial RTD Kit1, 1000 Ohm, 392° F (200° C); 50 ft (15 m) cable

D010-3000-132 Industrial RTD Kit1, 1000 Ohm, 392° F (200° C); 100 ft (30 m) cable

1

RTD Kits include 2 RTDs, heat sink compound and installation tape.

Page 6 October 2018HYB-DS-00086-EN-06

HYB-DS-00086-EN-06

Page 7

INTENTIONAL BLANK PAGE

Product Data Sheet

Page 7 October 2018 HYB-DS-00086-EN-06HYB-DS-00086-EN-06

Page 8

Hybrid Ultrasonic Flow Meter, DXN Portable Ultrasonic Flow and Energy Meter

Control. Manage. Optimize.

DYNASONICS is a registered trademark of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities. Due to continuous research,

product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the extent an outstanding

contractual obligation exists. © 2018 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Czech Republic | Badger Meter Czech Republic s.r.o. | Maříkova 2082/26 | 621 00 Brno, Czech Republic | +420-5-41420411

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-06 Parkway Parade | Singapore 449269 | +65-63464836

Switzerland | Badger Meter Swiss AG | Mittelholzerstrasse 8 | 3006 Bern | Switzerland | +41-31-932 01 11 Legacy Document Numbers: 06-HYB-DS-00482-EN

Loading...

Loading...