Page 1

Doppler Ultrasonic Flow Meters

Series DFX

DPP-UM-00256-EN-03 (August 2019)

User Manual

Page 2

Doppler Ultrasonic Flow Meters, Series DFX

Page 2 August 2019DPP-UM-00256-EN-03

Page 3

User Manual

CONTENTS

Scope of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Terminology and Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Quick-Start Operating Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Transducer Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Pipe Preparation and Transducer Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Transducer Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Application Versatility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

User Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Data Integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Product Identication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Transducer Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Unpacking and Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Mounting Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pipe Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

DT9 Clamp-On Transducer Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

DP7 Probe Transducer Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Transmitter Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Unpacking and Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Mounting Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Transducer Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Power Supply Wiring Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

AC Power Supply Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

DC Power Supply Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Multiple Meter Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

ISO Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4…20 mA Output Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Internal Power Conguration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

External Power Conguration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Page 3 August 2019 DPP-UM-00256-EN-03

Page 4

Doppler Ultrasonic Flow Meters, Series DFX

Control Relay Output Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Rate Pulse Output Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Instrument Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Keypad Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Totalizer Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Menu Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Hierarchy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Menu Maps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Setup Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Module Conguration Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Advanced Conguration Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Startup and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Specications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

North American Pipe Schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Part Number Construction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Page 4 August 2019DPP-UM-00256-EN-03

Page 5

Scope of This Manual

SCOPE OF THIS MANUAL

This manual is divided into two main sections:

• “Quick-Start Operating Overview” on page6 is intended to help you get the DFX flow meter up and running quickly.

Refer to the detailed instructions if you require additional information.

• The remaining chapters provide a detailed description of all software settings and hardware installation guidance.

MPORTANTI

Read this manual carefully before attempting any installation or operation. Keep the manual accessible for future reference.

UNPACKING AND INSPECTION

Upon opening the shipping container, visually inspect the product and applicable accessories for any physical damage such

as scratches, loose or broken parts, or any other sign of damage that may have occurred during shipment.

OTE:N If damage is found, request an inspection by the carrier’s agent within 48 hours of delivery and file a claim with the

carrier. A claim for equipment damage in transit is the sole responsibility of the purchaser.

SAFETY

Terminology and Symbols

Indicates a hazardous situation, which, if not avoided, is estimated to be capable of causing death or serious

personal injury.

Indicates a hazardous situation, which, if not avoided, could result in severe personal injury or death.

Indicates a hazardous situation, which, if not avoided, is estimated to be capable of causing minor or moderate

personal injury or damage to property.

Page 5 August 2019 DPP-UM-00256-EN-03

Page 6

Quick-Start Operating Overview

QUICKSTART OPERATING OVERVIEW

This manual contains detailed operating instructions for all aspects of the DFX flow instrument. The following condensed

instructions are provided to help you get the instrument up and running as quickly as possible. This pertains to basic

operation of the clamp-on transducer only. If specific instrument features, a hazardous area installation or an alternate

transducer style are to be used—or if you are unfamiliar with this type of instrument—see the appropriate section in the

manual for complete details.

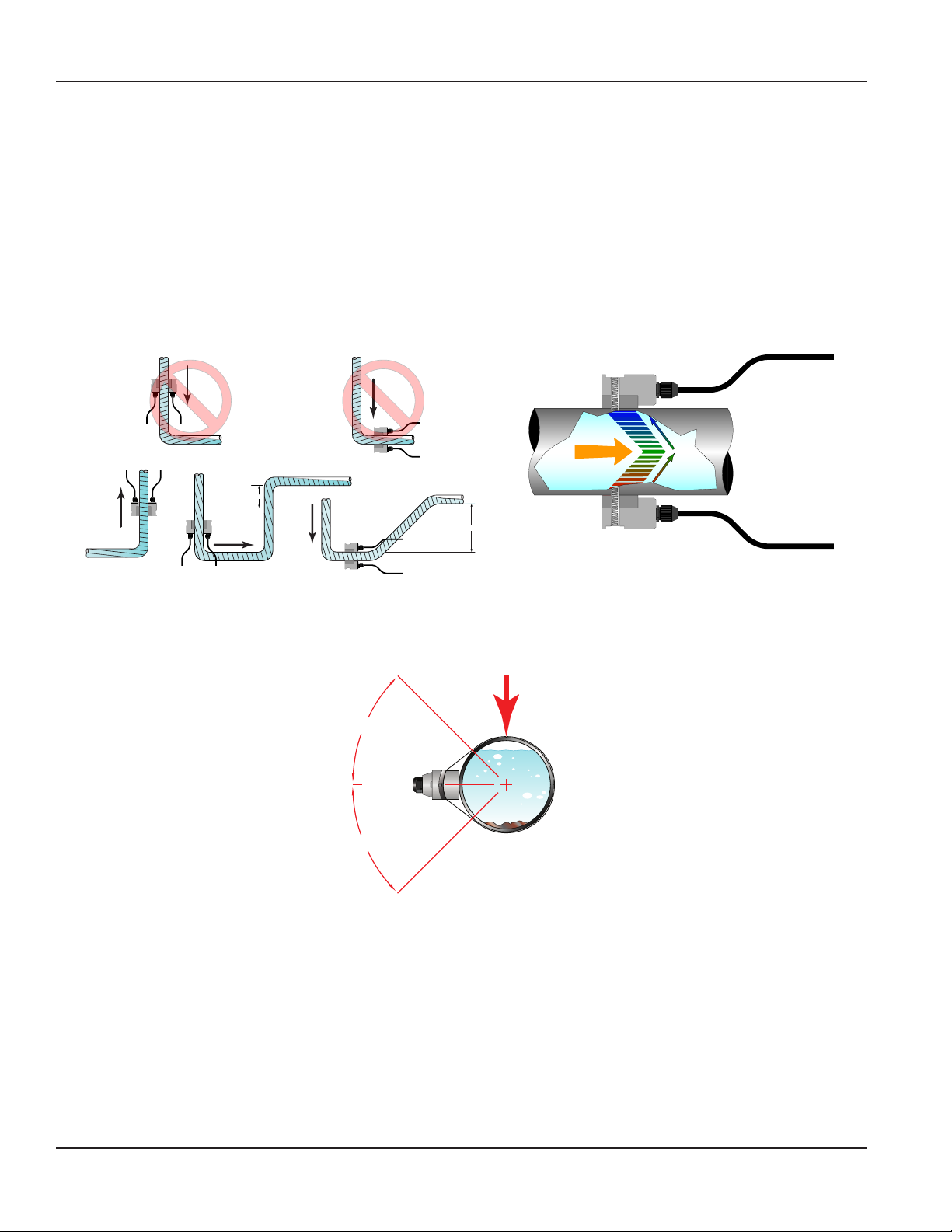

Transducer Location

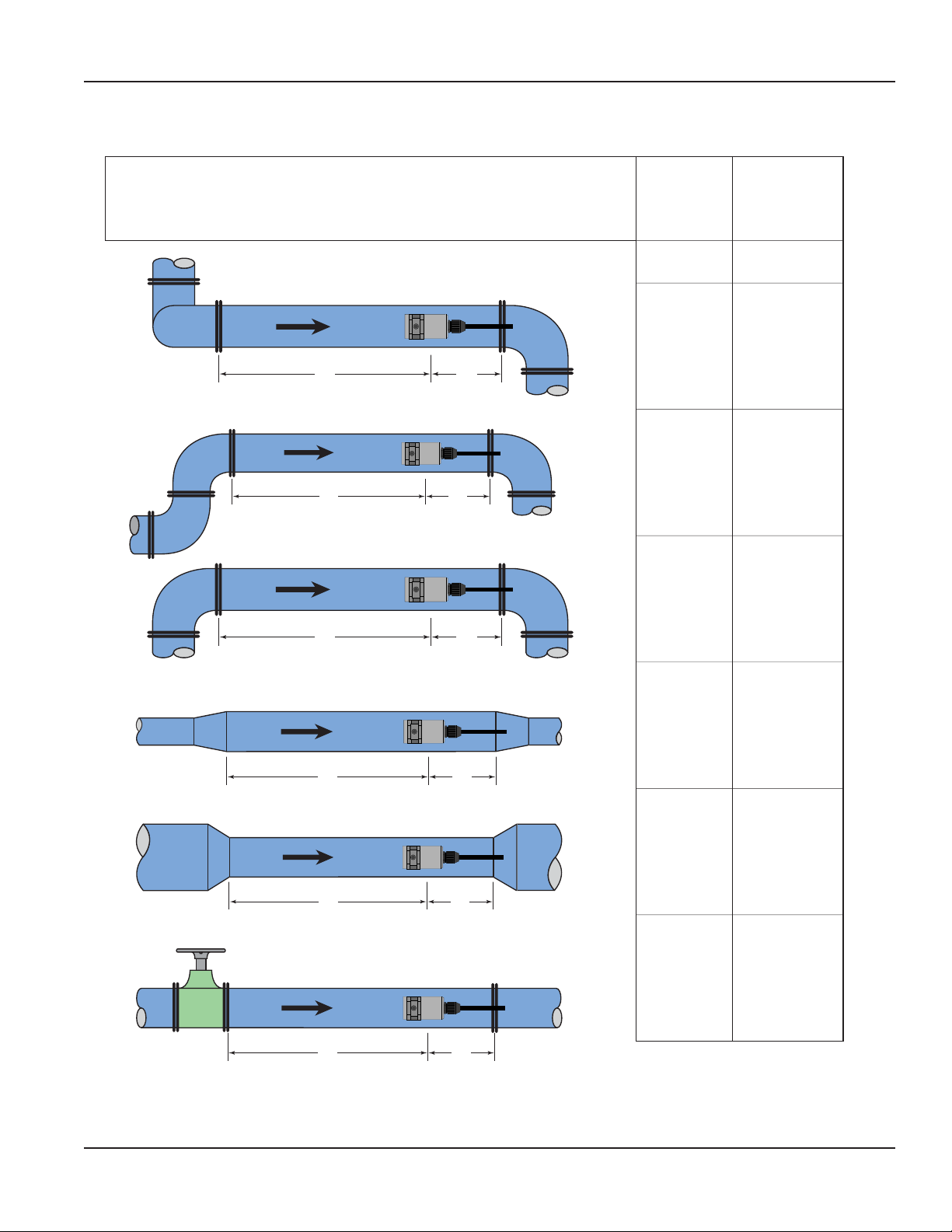

Determine the appropriate mounting location for the transducers. (See Figure 1.) Pipe must be filled with liquid for

proper operation.

FLOW

h

Figure 1: Transducer locations

45°

YES

45°

Figure 2: Transducer mounting configuration

Pipe Preparation and Transducer Mounting

h

Top View of Pipe

Top of

Pipe

W and V Mount

1. The piping surface, where the transducers mount, needs to be clean and dry. Remove loose scale, rust and paint for

satisfactory acoustical bonds.

2. Connect the mounting straps around the pipe. Leave the strap loose enough to slip the transducers underneath.

3. Apply a liberal amount of couplant grease onto the transducer faces.

4. Place each transducer under the mounting strap, 180° apart on the pipe. Verify that the transducer cables are facing the

same direction on the downstream side of the ow. See Figure 3.

5. Route the transducer cable back to the monitor, avoiding conduits that contain high voltage AC supply wires.

Page 6 August 2019DPP-UM-00256-EN-03

Page 7

Quick-Start Operating Overview

FLOW

Figure 3: Transducer direction

Top View

of Pipe

Transducer Connections

1. Mount the monitor within the length of the transducer cables.

2. Route the transducer cables through the center conduit hole in the bottom of the enclosure and connect to terminal block

J4. The terminal blocks are a removable and can be disconnected to simplify wiring access. See the wiring diagram inside

the door for reference.

Startup

Initial Settings and Powerup

1. Verify that the power supply jumper settings are properly congured for the power supply. See “Power Supply Wiring

Connections” on page 21 or the wiring and jumper selection diagram is located inside the door.

OTE:N Power supply selection is specified during order placement and appropriate jumpers are placed at the factory.

If power is changed from AC to DC or vice versa, the fuse requirement changes. Fuse ratings are listed on the

transmitter’s door.

2. Route power connections through the conduit hole farthest to the left and in the enclosure. Then connect power to the J2

terminal block. See Figure 11 on page 17.

3. Apply power. On initial power-up, the DFX ow meter conducts a series of self-diagnostic tests and buering operations

that take approximately 30 seconds.

4. Enter pipe internal diameter (Pipe ID), measuring units and output conguration.

Page 7 August 2019 DPP-UM-00256-EN-03

Page 8

Introduction

INTRODUCTION

General

The DFX ultrasonic flow meter is designed to measure volumetric flow of solids-bearing or aerated liquid within a closed

conduit. Transducers are available as non-contacting (DT9) or insertion probe (DP7) types. DT9 non-contacting transducers

are strapped to the outside of a pipe and are suitable for most installations where the pipe material supports the transmission

of ultrasound. Some pipe materials, such as concrete pressure pipe and some plastic lined pipes do not allow ultrasound to

penetrate to the liquid inside. For these applications, use the DP7 insertion probe.

The flow meter operates by transmitting an ultrasonic sound from a transmitting transducer through the pipe wall or from

the probe tip into the moving liquid. The sound is reflected by sonic reflectors suspended in the liquid and recorded by the

receiving transducer. If the sonic reflectors are moving within the sound transmission path, sound waves are reflected at a

frequency shifted (Doppler frequency) from the transmitted frequency. The shift in frequency is directly related to the speed

of the moving particle or bubble. This shift in frequency is interpreted by the instrument and converted to various user

defined measuring units.

The criteria for a good Doppler reflector are:

• The scattering material must have a sonic impedance (sound speed difference) at least 10% different from the fluid.

• There must be some particles large enough to cause longitudinal reflection—particles larger than 35 micron.

• For a given pipe size, the longitudinal reflection must have sufficient energy to overcome the Rayleigh (energy wasting)

scattering caused by smaller particles.

• The reflecting material must travel at the same velocity as the fluid for good accuracy.

Application Versatility

The DFX flow meter can be successfully applied on a wide range of metering applications. The easy-to-program transmitter

allows the standard product to be used on pipe sizes ranging from 1…120 in. (25…3050 mm) pipe ID. With the small pipe

transducer option, the pipe size range is 0.25…1 in. (6…25 mm). A variety of liquid applications can be accommodated:

• Sewage

• River water

• Plant effluent

• Mining slurries

• Sludge

• Others

Because the transducers are non-contacting and have no moving parts, the flow meter is not affected by system pressure,

fouling or wear. Standard transducers are rated to a pipe surface temperature of 250° F (121° C).

Page 8 August 2019DPP-UM-00256-EN-03

Page 9

Introduction

User Safety

The DFX flow meter employs modular construction and provides electrical safety for the operator. The enclosure is

constructed from rugged polycarbonate plastic with UV inhibitors. The enclosure does not contain any conductive materials

that can become energized while the door is closed. The keypad is made of polycarbonate and is designed for outdoor use.

The AC power transformer provides 4000 Volts of isolation from the power supply mains. The display face contains voltages

no greater than 24V DC. Output modules are optically isolated from external power supplies and provide a great degree of

immunity to ground loops.

CAUTION

IF THE DFX FLOW METER IS USED IN A MANNER NOT SPECIFIED BY THE MANUFACTURER, THE PROTECTION PROVIDED

BY THE EQUIPMENT MAY BE IMPAIRED.

Data Integrity

The DFX flow meter retains all user configuration data and totalizer accumulations in non-volatile FLASH memory indefinitely.

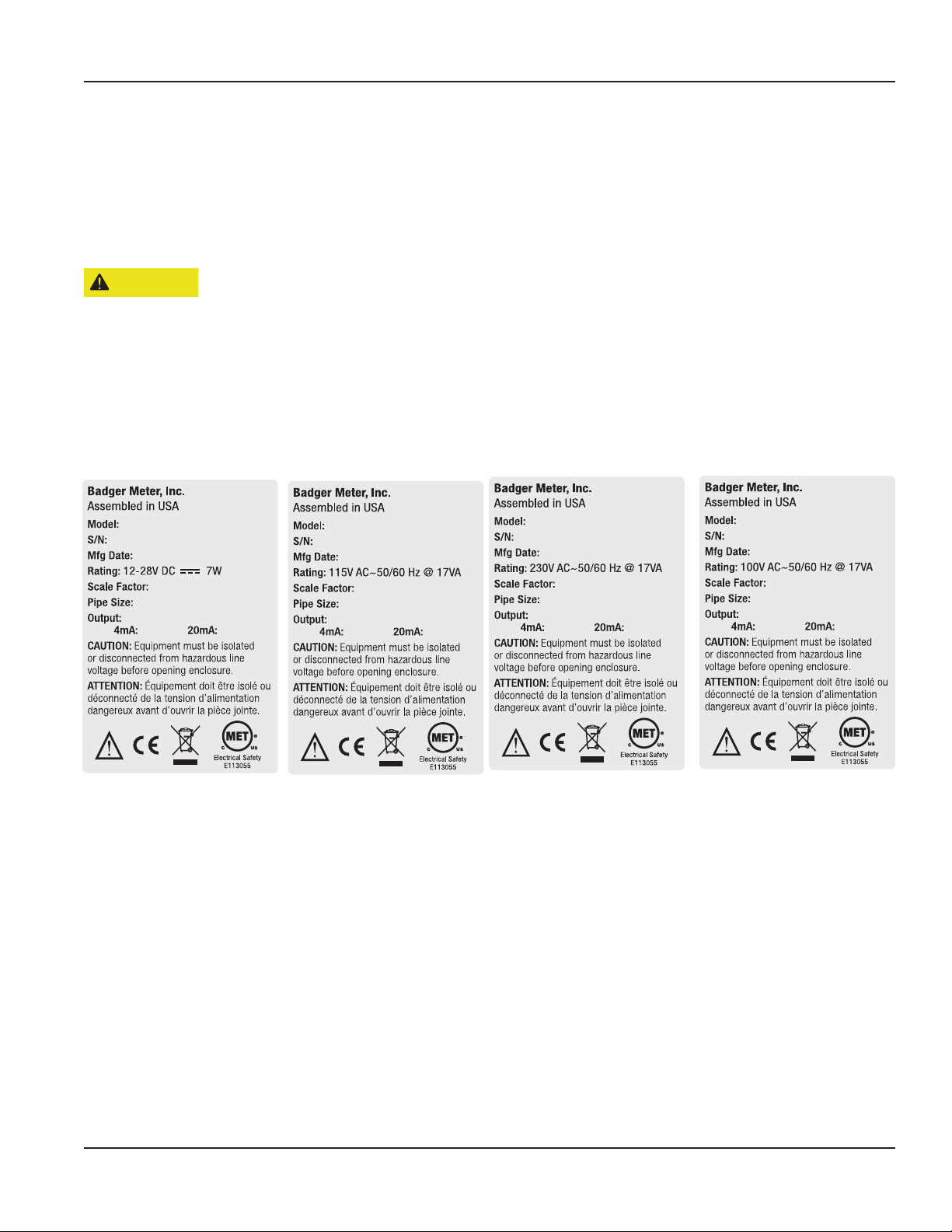

Product Identication

The serial number and complete model number of the transmitter are on the side of the monitor enclosure.

Figure 4: Product labels

Page 9 August 2019 DPP-UM-00256-EN-03

Page 10

Transducer Installation

TRANSDUCER INSTALLATION

Unpacking and Inspection

Upon opening the shipping container, visually inspect the product and applicable accessories for any physical damage such

as scratches, loose or broken parts, or any other sign of damage that may have occurred during shipment.

OTE:N If damage is found, request an inspection by the carrier’s agent within 48 hours of delivery and file a claim with the

carrier. A claim for equipment damage in transit is the sole responsibility of the purchaser.

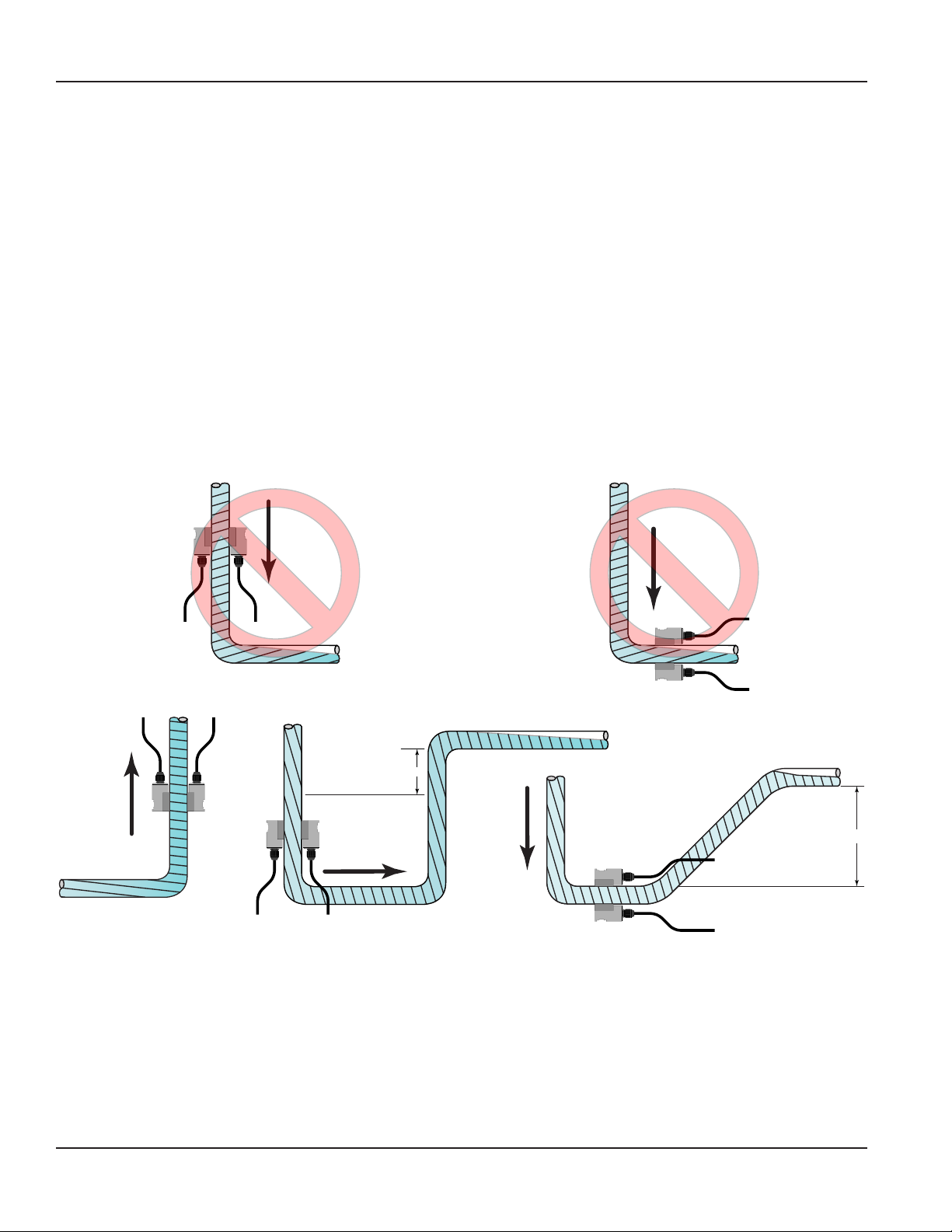

Mounting Locations

The transducers contain piezoelectric crystals for transmitting and receiving ultrasonic sound energy through the pipe wall

(DT9) and from the probe tip (DP7). Placement of the ultrasonic transducer is the most critical step in achieving an accurate

and reliable flow reading. All flow meters of this type rely on a full-pipe of fluid that is flowing symmetrically (evenly) in

the pipe. Flow in partially filled pipes and immediately downstream of elbows, valves and pumps is unstable and leads to

unstable readings and non-linearity.

The DFX flow meter has software algorithms that assume a full pipe of liquid. Install only in locations where the pipe is filled

at all times when flow measurements are required. Avoid partially filled pipes that can lead to very large flow measurement

errors. See Figure 5 for possible pipe configurations.

h

Figure 5: Pipe configurations and installation recommendations

Page 10 August 2019DPP-UM-00256-EN-03

h

Page 11

Transducer Installation

Select a transducer mounting location with adequate straight runs of pipe, both upstream and downstream, to achieve stable

readings1. See Figure 6 for examples of minimum upstream and downstream requirements.

Piping Conguration

and Transducer Positioning

Flow

*

Flow

*

Flow

**

**

Upstream

Pipe

Diameters

Downstream

Diameters

* **

24

14

10

Pipe

5

5

5

**

**

**

**

10

10

24

5

5

5

*

Flow

*

Flow

*

Flow

*

Figure 6: Upstream/Downstream Pipe Requirements

1

The DFX system provides repeatable measurements on piping systems that do not meet these requirements, but the

accuracy may be affected.

Page 11 August 2019 DPP-UM-00256-EN-03

Page 12

Transducer Installation

Pipe Preparation

Before the transducer heads are mounted to the pipe surface, an area slightly larger than the flat surface of the transducer

face must be prepared. If pipe insulation is present, it must be peeled back to expose the pipe surface. Use a wire brush to

remove loose paint, rust, scale or dirt. Paint, if bonded well to the pipe surface, does not need to be removed. Any bumps

present on ductile iron pipe do not need to be removed. Thoroughly dry the mounting surfaces so that the couplant grease

bonds to the surface.

OTE:N Small pits in the piping surface typically do not significantly impact ultrasonic transmission or signal reception.

Couplant

Use a coupling compound to create an acoustically conductive path between the transducer and the prepared pipe surface.

Clamp-on ultrasonic meters do not operate without coupling compound mounted between the pipe wall and the transducer

face. Enclosed with the DFX system is a tube of coupling compound that is adequate for general purpose applications. Use

a silicone-based valve grease or RTV (Room Temperature Vulcanizing) products or grease for Doppler installations as they

operate over a very wide temperature range. In some installations, such as automotive, silicone is not permitted. Alternate

petroleum-based products can be used, but verify that the grease is rated not to flow at the maximum surface temperature

anticipated on the pipe.

In general, use the following couplants with these transducers:

Transducer Couplant

DT90, DT91, DT94, DT95 Dow 732 or Dow 111 (or equivalent)

DT92, DT93, DT96, DT97 Krytox® LVP

DP7 Not applicable

Table 1: Transducer couplants

DT9 Clamp-On Transducer Mounting

Clamp-on transducers should be mounted on the pipe 180° apart and facing each other on the pipe, with the cables on the

downstream side of the transducers. If the pipe is horizontal, the preferred mounting orientation is 3 and 9 o’clock, with

12 o’clock being the top of the pipe. See Figure 7. Orientation on vertical pipes does not matter.

FLOW

Figure 7: Transducer Placement

Large pipe installations use stainless steel straps to secure the transducers to the outside of the pipe. The DFX system is

shipped with four 36 in. (900 mm) straps, which are suitable for pipes up to 39 in. (1000 mm) diameter.

1. Select the proper number of transducer straps to allow a complete strap to go around the circumference of the pipe. If a

pipe is larger than 39 in. (1000 mm), use a single strap/buckle arrangement to reduce the number of strap connections.

The straps can be connected together to make a continuous length. Small pipe installations use an integral clamping

mechanism built into the transducer.

Pipe Size Straps Required

1…9 in. (25…225 mm) 1

10…19 in. (250…480 mm) 2

20…29 in. (500…740 mm) 3

30…39 in. (760…1000 mm) 4

Table 2: Straps required vs. pipe size

Top View

of Pipe

Page 12 August 2019DPP-UM-00256-EN-03

Page 13

Transducer Installation

2. Wrap the strap around the pipe where the transducers mount. Leave the strap loose enough to allow the transducers to

be placed underneath. If multiple straps are being used, wrap electrical tape around all but one strap connection to secure

the strap worm screws in place.

3. Spread an even layer of coupling compound, approximately 1/8 in. (3 mm) thick, to the prepared transducer mounting

areas of the pipe.

4. Spread an even layer of coupling compound, approximately 1/8 in. (3 mm) thick, to the at face of the two transducers.

5. Place each transducer under the strap with the at face—amber plastic window—positioned towards the pipe. The notch

on the back of the transducer provides a mounting surface for the strap. The transducer cables must be facing in the same

direction and downstream of the transducers for proper operation.

OTE:N Large pipes may require two people for this procedure.

6. Tighten the strap enough to hold the transducers in place, but not so tight that all of the couplant squeezes out of the gap

between the transducer face and pipe. Make sure that the transducers are squarely aligned on the pipe and 180° apart. If

RTV is used, avoid moving the transducers during the curing time (typically 24 hours) as bubbles may form between the

transducer and pipe that can reduce ultrasonic signal transmission to unsatisfactory levels.

7. Route the transducer cables back to the area where the transmitter mounts, avoiding high voltage cable trays and

conduits. While transducer cable extension is not generally recommended, if additional transducer cable length is

required, use cable and connectors of the correct type and impedance. In many cases, especially if a splice my be exposed

to water or other liquids, it may be more eective to replace the entire cable. Transducers use RG59, 75 Ohm coaxial cable

or Twinax (Belden #9463) or (Belden # 9463DB) 78 Ohm two conductor cable.

8. If the transducers are permanently mounted using Dow 732, the RTV must be completely cured before proceeding to

Instrument Startup. Make sure that no relative motion between the transducer and pipe occurs during the 24 hour curing

process. If Dow 111 grease was used for temporary operation of the DFX system, proceed with the Startup procedures.

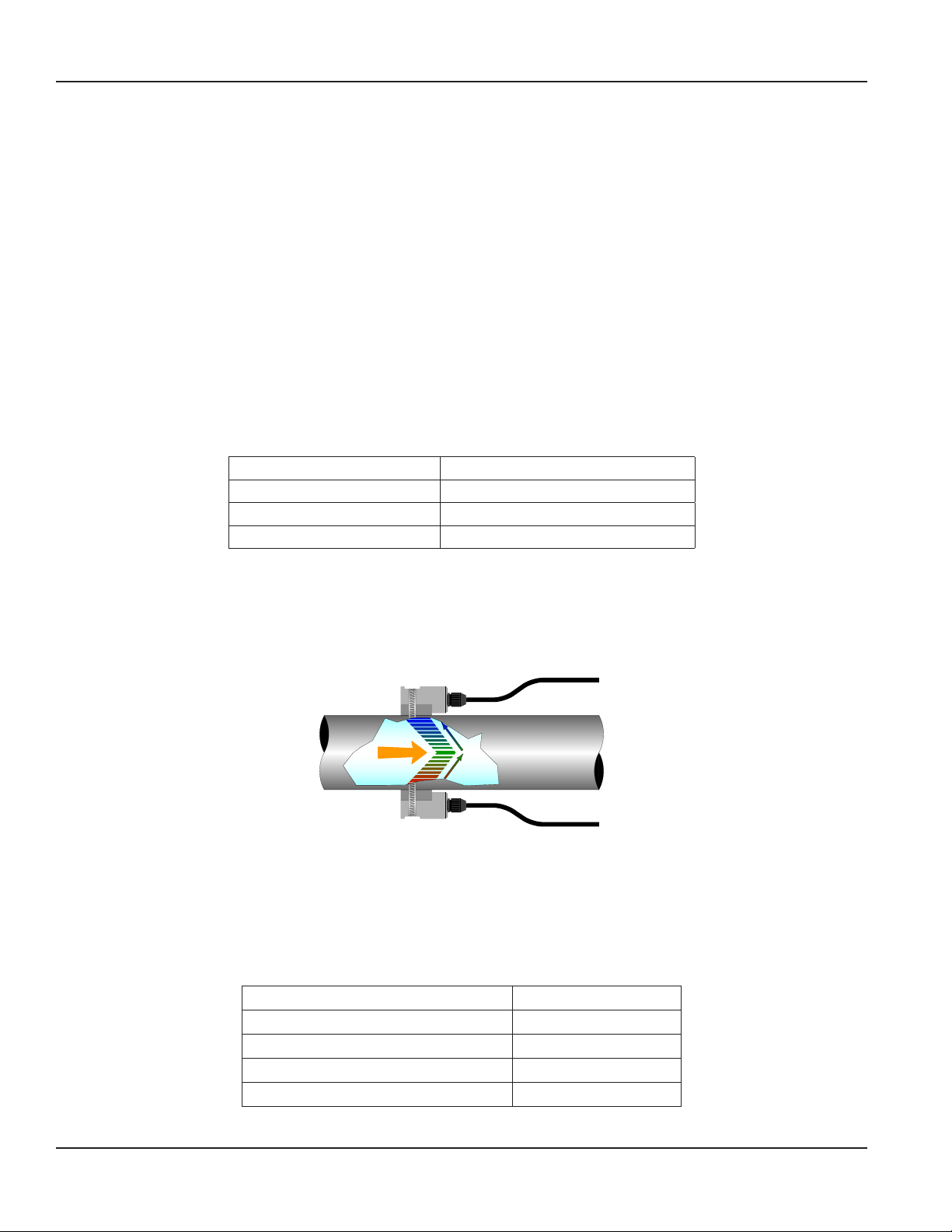

DP7 Probe Transducer Mounting

The DP7 insertion transducer that is used by the DFX flow meter contains piezoelectric crystals for transmitting and receiving

ultrasonic sound energy. The black Ultem® plastic tip of the DP7 transducer contains these crystals, which are designed to be

inserted just into the path of the flowing liquid.

Select a transducer mounting location that is completely filled with liquid when flow measurements are made (see

Figure 5) and with adequate straight runs (without disturbances) of pipe, both upstream and downstream, to achieve stable

and accurate readings. Examples of minimum upstream and downstream requirements are included in Figure 5 on page 10.

Figure 8: Installation locations

When installing the DP7 transducer in a horizontal pipe, the preferred orientation is at least 20 degrees from the top or

bottom of the pipe. Verify that the mounting location allows for adequate clearance to install and retract the probe fully from

the pipe.

The following instructions cover hot tapping applications where the installation or removal of the transducer probe must

be done without shutting down the process pressure. If the product is being installed without an isolation valve, ignore

the steps that pertain to its installation. Figure 9 illustrates an exploded view of an isolation valve assembly and names the

various components.

Page 13 August 2019 DPP-UM-00256-EN-03

Page 14

Transducer Installation

Seal

Fitting

Full Port

Ball Valve

Close

Nipple

Weld

Coupling

Figure 9: Hot tap installation

The Bronze Hot Tap Kit (p.n. D030-1006-001) and the Stainless Steel Hot Tap Kit (p.n. D030-1006-002) include an isolation valve

assembly and are designed for installation in pipes under pressure, up to 700 psi (48 bar) at 70° F (21° C).

All items required for installation are provided with the kit, except for the 1-1/2 in. NPT weld coupling or service saddle and

the drilling and welding equipment. These instructions call for the use of a drilling machine designed for operations under

pressure (for example, Mueller Co., Water Products Division).

1. Verify that the pipe’s line pressure is within the rated limits of the pressure drilling machine being used.

2. Grind o paint or other coatings from the pipe in the DP7 probe mounting area.

3. Tack weld a 1-1/2 in. NPT weld coupling to the pipe or install a service saddle according to the supplier’s instructions. The

coupling or saddle must be aligned perpendicular to the pipe axis and square to its plane.

4. Complete welding. A water tight, 0.25 in. minimum weld bead is recommended.

5. Install the close nipple (supplied with assembly) into the weld coupling. Use appropriate pipe sealants.

6. Install the isolating ball valve on the close nipple. Verify that the valve is in the fully open position.

7. Install drill bit and adapter into the pressure drilling machine. Then attach the machine to the isolation valve.

8. Drill through the pipe wall in accordance with the instructions supplied with the drilling machine.

9. Withdraw the drill bit through the isolating valve.

10. Close the valve and remove the drilling machine.

11. Check for leakage at valve and connections.

12. Place pipe sealant on the 1-1/2 in. NPT threads of the insertion tting assembly.

13. Screw the assembly into the isolation valve and tighten with a 2-1/2 in. pump wrench.

Page 14 August 2019DPP-UM-00256-EN-03

Page 15

Transducer Installation

Probe Cables

Before inserting the probe into the pipe, the sensor cables should be routed to the transmitter location. Verify that the

supplied cable length is sufficient to meet the installation requirements. While transducer cable extension is not generally

recommended, if additional transducer cable length is required, use cable and connectors of the correct type and

impedance. In many cases, especially if a splice my be exposed to water or other liquids, it may be more effective to replace

the entire cable. Transducers use RG59, 75 Ohm coaxial cable, Twinax (Belden #9463) or (Belden # 9463DB) 78 Ohm

two-conductor cable.

CAUTION

THE PROBE CABLES ARE DESIGNED TO CARRY LOW LEVEL SIGNALS THAT ARE DEVELOPED BY THE SENSOR. CARE

SHOULD BE TAKEN IN ROUTING THE CABLES. AVOID RUNNING CABLES NEAR SOURCES OF HIGH VOLTAGE OR EMI/RFI.

ALSO AVOID ROUTING THE CABLES IN CABLE TRAY CONFIGURATIONS, UNLESS THE TRAYS ARE SPECIFICALLY USED

FOR OTHER LOW VOLTAGE, LOW LEVEL SIGNAL CABLES.

CAUTION

THE INTERNAL DP7 PROBE WIRING IS EPOXY ENCAPSULATED TO SEAL IT FROM MOISTURE. THE DP7 PROBE IS

PROVIDED WITH TWO COAXIAL CABLES TO SHIELD THE LOW LEVEL SIGNALS AND MUST BE CONTINUOUS TO THE DP7

PROBE TRANSMITTER. EXCESS WIRE MAY BE CUTOFF OR SIMPLY COILED NEAR THE DFX FLOW METER.

Probe Retraction Procedure

1. Retract the probe by loosening the upper jam nuts counterclockwise as viewed from the top of the probe using the proper

size wrench. If the pipe is under pressure, the nuts must be turned alternately about two turns at a time to prevent binding

as a result of non-equal seal loading. In many cases, the line pressure causes the probe to retract. Should the probe bind,

use the retraction nuts on the lower side of the probe ange to assist in the probe retraction. Continue this procedure until

the probe is fully retracted into the isolation valve.

CAUTION

DO NOT RUN THE DRIVE NUTS OFF THE RODS UNTIL THE ISOLATION VALVE IS FULLY CLOSED.

2. After the probe is retracted past the “ball” in the isolation valve, the isolation valve may be closed to isolate the probe from

the line so the probe can be removed entirely.

CAUTION

IF THE INSERTION PROBE IS NOT ABOVE THE “BALL” OF THE ISOLATION VALVE, THE VALVE CANNOT BE CLOSED. IF

THE VALVE WILL NOT CLOSE SMOOTHLY, THE BODY OR TIP OF THE PROBE IS MOST LIKELY NOT ABOVE THE “BALL”.

ATTEMPTING TO FORCE THE VALVE INTO THE CLOSED POSITION MAY RESULT IN DAMAGE TO THE PROBE.

Page 15 August 2019 DPP-UM-00256-EN-03

Page 16

Transducer Installation

Probe Insertion

Before inserting the DP7 probe into the piping system, calculate the probe insertion depth. Refer to the paragraphs that

follow and Figure 10 on page 17 for information regarding this process. The variables required are:

• The overall probe length

• Pipe internal diameter (ID)

• Pipe wall thickness

• The length of the valve stack

• Amount of straight pipe diameters in the system

To Calculate Insertion Depth

Using this information and referring to Figure 10, proper insertion depth can be determined.

• Measurement A — The typical depth that the DP7 probe tip is inserted into the piping system is 1/8 (12.5%) of the pipe

internal diameter.

• Measurement B — Pipe wall thickness. This information can be obtained from standard pipe wall charts (see

“Specifications” on page40) or ideally can be measured using an ultrasonic wall thickness gauge.

• Measurement C — Measure the distance that is going to be taken up by the pipe tap, nipple, full-flow ball valve and the

insertion fitting. DP7 probes use 1-1/2 in. NPT hardware and the insertion fitting is approximately 2-1/2 in. in height.

• Measurement D — The length of DP7 probe that protrudes from the insertion fitting after it is inserted to the proper

depth in the fluid stream.

• Measurement E — This is the overall length of the probe measured from the black measurement tip to the top flange on

the probe.

Measure and record the following linear dimensions.

A = 0.125 x Pipe OD =

B = Pipe Wall Thickness =

C = Seal Fitting to Pipe Wall =

D = E - C - B - A

D =

E = Probe Length =

Page 16 August 2019DPP-UM-00256-EN-03

Page 17

Transducer Installation

Full Port

Ball Valve

Seal

Fitting

DP7 Probe

Pipe WallB

E

A

1/8 Pipe

Diameter

DP7

Length

Insertion

Measurement

D

Valve and

Seal Stack

C

Internal

Diameter

OTE:N For some low pressure/low temperature applications less than 30 psi (2.1 bar) and less than 100° F (38° C), the probe

may be pushed in by hand to decrease the insertion time.

Figure 10: Installation measurements

Flow Direction

Arrow

Figure 11: Flow direction arrow

1. Lubricate the O-rings located within the DP7 probe seal tting so that the seals are not damaged during probe insertion.

2. Run the lower jam nuts down to a point that approximates the nal insertion position or at least far enough to allow

insertion into the insertion tting.

3. Using the threaded rods as a guide, position the probe in the insertion tting. Continue to insert the probe into the

isolation assembly until the probe tip comes in contact with the closed “ball” in the isolation valve.

CAUTION

DO NOT FORCE THE PROBE TIP AGAINST THE “BALL”, AS DAMAGE TO THE PROBE TIP MAY RESULT.

4. Replace the upper jam nuts (2 on each rod) and the cotter pins. The nuts should be run down to the top side of the

retaining collar and the cotter pins replaced.

5. Orient the probe in the direction of ow as indicated by the ow direction arrow located on the top of the probe ange.

6. Lock the probe in position with the enclosed Allen wrench.

CAUTION

THE NUTS ON BOTH ENDS OF THE RETAINING RODS MUST ALWAYS BE IN PLACE AS A SAFETY MEASURE TO PREVENT

POSSIBLE PROBE BLOW OUT. INSERTING COTTER PINS IS A FURTHER SAFETY MEASURE.

7. Slowly open the isolation valve. When the valve is fully open, use the proper size wrench on the insertion nuts, alternately

tightening each nut about two complete turns to avoid uneven seal loading.

Page 17 August 2019 DPP-UM-00256-EN-03

Page 18

Transmitter Installation

TRANSMITTER INSTALLATION

Unpacking and Inspection

Upon opening the shipping container, visually inspect the product and applicable accessories for any physical damage such

as scratches, loose or broken parts, or any other sign of damage that may have occurred during shipment.

OTE:N If damage is found, request an inspection by the carrier’s agent within 48 hours of delivery and file a claim with the

carrier. A claim for equipment damage in transit is the sole responsibility of the purchaser.

Mounting Location

The enclosure should be mounted in an area that is convenient for servicing, calibration and for observation of the

LCD readout.

1. Locate the transmitter within the length of transducer cable that was supplied with the DFX system. If this is not possible,

exchange the cable for one that is of proper length. While transducer cable extension is not generally recommended,

if additional transducer cable length is required, use cable and connectors of the correct type and impedance. In many

cases, especially if a splice my be exposed to water or other liquids, it may be more eective to replace the entire cable.

Transducers use RG59,75 Ohm coaxial cable or Twinax (Belden #9463) or

(Belden # 9463DB) 78 Ohm two-conductor cable.

2. Mount the DFX ow meter in a location that is:

• Free of vibration

• Protected from falling corrosive fluids

• Within ambient temperature limits – 40…185° F (– 40…85° C)

• Out of direct sunlight. Direct sunlight may increase transmitter temperature to above the maximum limit

3. See Figure 12 for enclosure and mounting dimension details. Make sure there is enough room for door swing, maintenance

and conduit entrances. Secure the enclosure to a at surface with four appropriate fasteners.

4. Use conduit hubs where cables enter the enclosure. Seal unused holes with plugs.

OTE:N Use NEMA 4 (IP-65) rated fittings/plugs to maintain the watertight integrity of the enclosure. Generally, the left

conduit hole (viewed from front) is used for line power, the center conduit hole for transducer connections and the

right hole is used for ISO-MOD I/O wiring.

5. If additional holes are required, drill the appropriate size hole in the enclosure’s bottom. Use extreme care not to run the

drill bit into the wiring or circuit cards.

Page 18 August 2019DPP-UM-00256-EN-03

Page 19

Dimensions

7.00"

(177.8)

RUN PROGRAM

RELAY 1 RELAY 2

5.75"

(146.1)

Transmitter Installation

4.25"

(108.0)

3.93"

(99.8)

Power

Connection

Transducer

Connection

PANEL MOUNT (OPTION)

0.07”(1.8)

Maximum

Radius

5.19"

(131.8)

PANEL CUT-OUT

Panel Thickness: 0.5” (12) Max

Input/Output

Connection

WALL MOUNT (OPTION)

6.25”

(158.8)

Figure 12: DFX transmitter installation dimensions

(3) ½” (m20) Conduit

Holes

1.99”

(50.5)

3.31

(84.1)

1.70”

(43.2)

6.08"

(154.4)

6.65"

(169.0)

Page 19 August 2019 DPP-UM-00256-EN-03

Page 20

Transmitter Installation

Transducer Wiring Connections

To access terminal strips for electronic connectors, loosen the two screws in the enclosure door and open the door.

1. Guide the transducer connectors through the middle conduit hole located of the transmitter enclosure. Secure the

transducer cable with the supplied conduit nut (See Figure 13).

JP1

J3

J4

J2

Figure 13: Transducer cable installation

The terminals within the DFX flow meter are removable. They can be unplugged, wired and then plugged back in.

2. Connect the wires to J4 at the corresponding screw terminals in the transmitter. See Figure 14 or the Wiring Diagram

located inside the door of the transmitter.

OTE:N The transducer cable carries low level, high frequency signals. While transducer cable extension is not generally

recommended, if additional transducer cable length is required, use cable and connectors of the correct type and

impedance. In many cases, especially if a splice my be exposed to water or other liquids, it may be more effective to

replace the entire cable. Transducers use RG59, 75 Ohm coaxial cable or Twinax (Belden #9463) or (Belden # 9463DB)

78 Ohm two conductor cable. Cable lengths up to 990 feet (300 meters) are available.

+

C3

Transducer

Connections

JP3

1

7

241

VPP12-800

3

9

CLASS B

3

R

®

4

10

6

12

VDE

JP2

JP1

J3

J4

J2

+

C3

Grounding

Wire

Lock Nut

Figure 14: Transducer connections

Page 20 August 2019DPP-UM-00256-EN-03

Page 21

Transmitter Installation

Power Supply Wiring Connections

Connect power to the screw terminal block marked J2 through the conduit hole on the left side of the enclosure. See Figure 15

for AC power supplies and Figure 16 for DC power supplies. Use wiring practices that conform to local and national codes (for

example, The National Electric Code Handbook in the U.S.).

CAUTION

ANY OTHER WIRING METHOD MAY BE UNSAFE OR CAUSE IMPROPER OPERATION OF THE INSTRUMENT.

TO AVOID SERIOUS INJURY OR DAMAGE, DISCONNECT ELECTRICAL POWER BEFORE SERVICING THIS METER.

OTE:N This instrument requires clean electrical line power. Do not operate this unit on circuits with noisy components (such

as fluorescent lights, relays, compressors or variable frequency drives). Do not run line power with other signal wires

within the same wiring tray or conduit.

WIRING DIAGRAM

CAUTION! To avoid serious injury or damage,

disconnect electrical power before servicing this meter

JP3

Connections

2 1

115 VAC

4 3

2 1

230 VAC

4 3

2 1

9-28 VDC

4 3

JP1/JP2

Connections

AC

DC

2

2 1

2 1

2 1

L1

+V

115/230

VAC

9-28 VDC

JP3

2 1

4 3

2

1

JP2

2 1

J4

J2

Fuse (5x20mm)

AC: 0.25 A/250V Delay

DC: 1.0 A/250V Delay

1

L2

GND

JP1

J3

EARTH

EARTH

SYNC SELECT

INT

MODULE #2

MODULE #1

RED BLK

BLU CLR

Receive Transmit

REDBLK

BLUCLR

GND

EXT SYNC

EXT

Figure 15: DFX flow meter wiring diagram

Page 21 August 2019 DPP-UM-00256-EN-03

Page 22

Transmitter Installation

AC Power Supply Connections

LINE VOLTAGES MAY BE PRESENT WITHIN THE ENCLOSURE. THERE IS A RISK OF SHOCK, SPARKS AND DEATH IF THIS

PRODUCT IS HANDLED IN AN UNSAFE WAY. SERVICE SHOULD ONLY BE DONE BY QUALIFIED PERSONNEL.

1. Verify that the jumpers at JP3 are properly oriented for the power supply. See Figure 15.

2. Verify that the jumpers at JP1 and JP2 are not present.

3. Connect L1, L2 and EARTH to the terminals referenced in Figure 15. Phase and neutral connections to L1 and L2 are not

polarized. Do not operate without an earth ground connection.

4. See Figure 16 for AC connection schematic. Wire gauges up to 14 AWG can be accommodated in the DFX ow meter’s

terminal blocks.

OTE:N A switch or circuit breaker is required in the installation. The switch or circuit breaker must be in close proximity

of the DFX flow meter and within easy reach of the operator. The switch or circuit breaker must be marked as the

disconnect device for the DFX flow meter.

JP1

J3

J4

J2

AC Power

Connections

Figure 16: DFX flow meter AC power connection

50/60 Hz

17 Watts Maximum

DC Power Supply Connections

The DFX flow meter may be operated from a 12…28V DC source, as long as the source is capable of supplying 7 Watts.

• 12V DC Supply @ 600 mA minimum

• 24V DC Supply @ 300 mA minimum

1. Verify that the jumpers are properly placed. See the wiring diagram inside the door of the DFX ow meter enclosure or see

Figure 15. The jumpers at JP3 should not be present and the jumpers at JP1 and JP2 should be in place.

2. Connect the DC power source as illustrated in the schematic in Figure 17 on page 23. Wire up to 14 AWG can be

accommodated in the DFX ow meter terminal blocks.

OTE:N A switch or circuit breaker is required in the installation. The switch or circuit breaker must be in close proximity

of the DFX flow meter and within easy reach of the operator. The switch or circuit breaker must be marked as the

disconnect device for the DFX flow meter.

Page 22 August 2019DPP-UM-00256-EN-03

Page 23

Transmitter Installation

JP1

J3

J4

J2

DC Power

Connections

12 to 28 VDC

7 Watts Maximum

Figure 17: DC power connection

Multiple Meter Installations

The DFX flow meter contains a provision for synchronizing multiple DFX flow meters together. Synchronization is required

when more than one DFX flow meter is mounted on a common pipe or header system. If the meters are not synchronized, a

phenomena called “cross-talk” can occur between meters, which can lead to erroneous readings or no readings at all.

Cross-talk results from the small differences in transmitted frequency generated from two or more different ultrasonic

flow meters. By synchronizing the transmitted ultrasonic energy, cross-talk caused by differences in transmitted frequency

is eliminated.

The DFX flow meter synchronization circuit is designed to interconnect up to four DFX flow meters over a cable length of 100

feet (30 meters). Use 20-22 AWG twisted-pair shielded interconnection wire for this purpose. See Figure 18.

4 3

1

2

2 1

2 1

2 1

L2

L1

GND

+V

SYNC SELECT

J3

EARTH

EARTH

2 1

J4

INT

EXT

J2

Fuse (5x20mm)

AC: 0.25 A/250V Delay

DC: 1.0 A/250V Delay

RED BLK

BLU CLR

Receive Transmit

EXT SYNC

REDBLK

BLUCLR

GND

9-28 VDC

JP1/JP2

Connections

115/230

VAC

9-28 VDC

AC

DC

Synchronization

Selection

(Connect one end only to earth ground)

Twisted Pair

Shield

Figure 18: Meter synchronization detail

To Synchronize Multiple Meters

1. Remove power from the DFX ow meters.

2. Daisy-chain connect the EXTernal SYNChronization and GND terminal blocks together between the meters to be

synchronized, using the twisted-pair cable described previously. The terminal block is located on the circuit board that is

mounted on the door of the meter’s monitor. See Figure 15 on page 21 or the Wiring Diagram inside the door of the

DFX monitor.

3. At a single point, connect the shield drain wire from the interconnection cable to earth ground.

4. Congure the SYNC SELECT jumpers on the DFX ow meters. One DFX ow meter should be congured for INT and the

remaining units congured for EXT (see Figure 19).

5. Apply power to the DFX system.

Page 23 August 2019 DPP-UM-00256-EN-03

Page 24

Transmitter Installation

MODULE #2

MODULE #1

JP1/JP2

Connections

115/230

VAC

JP2

JP1

JP3

J4

J3

J2

9-28 VDC

9-28 VDC

2 1

4 3

2 1

4 3

2 1

4 3

2 1

4 3

2

1

2 1

2

1

2 1

2 1

2 1

Fuse (5x20mm)

AC: 0.25 A/250V Delay

DC: 1.0 A/250V Delay

Receive Transmit

RED BLK

BLU CLR

REDBLK

BLUCLR

EXT SYNC

SYNC SELECT

INT

EXT

GND

ACDCEARTH

EARTH

GND

L1

L2

+V

230 VAC

115 VAC

Connections

JP3

WIRING DIAGRAM

CAUTION! To avoid serious injury or damage,

disconnect electrical power before servicing this meter

Master Meter Slave Meter Slave Meter

WIRING DIAGRAM

CAUTION! To avoid serious injury or damage,

disconnect electrical power before servicing this meter

JP3

JP3

Connections

2 1

2 1

115 VAC

4 3

2 1

230 VAC

4 3

2 1

9-28 VDC

4 3

JP1/JP2

Connections

1

2

115/230

VAC

2 1

2 1

9-28 VDC

2 1

ACDCEARTH

L1

+V

4 3

JP1

2 1

J3

L2

EARTH

GND

SYNC SELECT

INT

EXT

1

2

JP2

J4

J2

Fuse (5x20mm)

AC: 0.25 A/250V Delay

DC: 1.0 A/250V Delay

MODULE #2

MODULE #1

RED BLK

BLU CLR

Receive Transmit

EXT SYNC

REDBLK

BLUCLR

GND

WIRING DIAGRAM

CAUTION! To avoid serious injury or damage,

disconnect electrical power before servicing this meter

JP3

JP3

Connections

2 1

2 1

115 VAC

4 3

2 1

230 VAC

4 3

2 1

9-28 VDC

4 3

JP1/JP2

Connections

1

2

115/230

VAC

2 1

2 1

9-28 VDC

2 1

ACDCEARTH

L1

+V

4 3

JP1

2 1

J3

L2

EARTH

GND

SYNC SELECT

INT

EXT

1

2

JP2

J4

J2

Fuse (5x20mm)

AC: 0.25 A/250V Delay

DC: 1.0 A/250V Delay

MODULE #2

MODULE #1

RED BLK

BLU CLR

Receive Transmit

EXT SYNC

REDBLK

BLUCLR

GND

Twisted Pair

Master Meter

Set to Internal

Synchronization

Shield

(Connect one end

only to earth ground)

Slave Meters

Set to External

Synchronization

Twisted Pair

Wire

Slave Meters

Set to External

Synchronization

Figure 19: DFX flow meter synchronization connections

ISO Modules

The DFX flow meter uses ISO-MODs for input and output functions. ISO-MODs are epoxy encapsulated electronic input/

output modules that are simple to install and replace in the field. See Figure 20. All modules are 2500 V optically isolated from

the DFX flow meter’s power and earth grounds. This eliminates the potential for ground loops and reduces the chance of

severe damage in the event of an electrical surge.

Three ISO-MOD options are available: 4…20 mA, dual-relay and rate pulse. The DFX flow meter supports any two ISO-MOD

input/output modules. All modules are field-configurable by using the keyboard interface. Field wiring connections to

ISO-MODs are quick and easy using removable wiring terminals. Configuration and connection of the various ISO-MODs are

described on the following pages.

ISO Module Replacement

To remove an ISO-MOD, remove the two machine screws that secure the module in place and pull the module straight out of

the enclosure. A 10-pin connection is on the bottom of the module that mates with the circuit board underneath. To install

and ISO-MOD, push the module into the 10-pin connector and tighten the two machine screws. Re-calibrate the parameters if

the 4…20 mA modules are replaced. See “Module Configuration Parameters” on page 35 for instructions.

WIRING DIAGRAM

CAUTION! To avoid serious injury or damage,

disconnect electrical power before servicing this meter

JP3

JP3

Connections

2 1

2 1

115 VAC

4 3

4 3

2 1

230 VAC

JP1

4 3

2 1

9-28 VDC

4 3

JP1/JP2

Connections

1

2

115/230

VAC

2 1

2 1

9-28 VDC

2 1

Page 24 August 2019DPP-UM-00256-EN-03

ACDCEARTH

L2

L1

EARTH

GND

+V

SYNC SELECT

MODULE #2

1

2

JP2

2 1

MODULE #1

J4

J3

J2

Fuse (5x20mm)

AC: 0.25 A/250V Delay

DC: 1.0 A/250V Delay

RED BLK

REDBLK

BLU CLR

BLUCLR

Receive Transmit

GND

EXT SYNC

INT

EXT

Figure 20: Two ISO-MOD I/O modules installed

JP3

1

241

7

VPP12-800

3

9

CLASS B

3

R

®

4

10

6

12

VDE

JP2

JP1

J3

J4

J2

OUT (-)

IN (+)

JP2

JP1

b NO

b CM

b NC

a NO

a CM

a NC

INT PWR EXT PWR

I/O: RELAY

P.N. D020-1045-102

+

I/O: 4-20 mA

C3

P.N. D020-1045-100

ISO-MOD

ISO-MOD

Page 25

Transmitter Installation

4…20 mA Output Module

The 4…20 mA Output Module interfaces with most recording and logging systems by transmitting an analog current signal

that is proportional to system flow rate. Configure the 4…20 mA ISO-MOD via jumper selections for an internally powered

(Figure 22) or externally powered (Figure 23) module. Do not exceed the maximum load for a particular supply voltage.

See Figure 21.

Supply Voltage - 7 VDC

1100

1000

900

800

700

600

500

400

Loop Load (Ohms)

300

200

100

12 14 16 18 20 22 24 26 28

0.02

Supply Voltage (VDC)

Figure 21: Maximum 4…20 mA loads

= Maximum Loop Resistance

Operate in the

Shaded Regions

Internal Power Conguration

Verify that jumpers are in place at JP1 and JP2 on the module. See Figure 22 . In this configuration, the 4…20 mA output

is driven from a +24V DC source located within the DFX flow meter. The 24V DC source is isolated from the DC ground

and earth ground connections within the DFX flow meter. The module can accommodate loop loads up to 800 Ohms in

this configuration.

OTE:N The +24V internal supply, if configured to power the 4…20 mA output, shares a common ground with another

ISO-MOD (if installed). If another module is connected to earth ground, a ground loop may occur. The solution to this

problem is to configure the 4…20 mA module for external power and use an external isolated supply to power the

4…20 mA loop.

4-20 mA IN (+)

4-20 mA OUT (-)

RTU/PLC

MONITOR

Figure 22: Internally powered 4…20 mA

OUT (-)

IN (+)

INT PWR EXT PWR

JP2

JP1

Use Both

Jumpers

I/O: 4-20 mA

P.N. D020-1045-100

ISO-MOD

Page 25 August 2019 DPP-UM-00256-EN-03

Page 26

Transmitter Installation

External Power Conguration

Remove the two jumpers located at JP1 and JP2 on the module. See Figure 23. In this configuration, the 4…20 mA module

requires power from an external DC power supply. The voltage of the external power source must be sufficient to power the

module and drive the loop load. The loop loss attributed to the ISO-MOD is 7V DC, so the minimum voltage required to power

a loop can be calculated using the following formula: Loop voltage (min) = (loop load Ohms × 0.02) + 7

I/O: 4-20 mA

OUT (-)

IN (+)

INT PWR EXT PWR

JP2

JP1

Jumpers

P.N. D020-1045-100

ISO-MOD

Remove

4-20 mA IN (+)

4-20 mA OUT (-)

RTU/PLC

MONITOR

Figure 23: Externally powered 4…20 mA

Page 26 August 2019DPP-UM-00256-EN-03

Page 27

Transmitter Installation

Control Relay Output Module

Two independent SPDT (single-pole, double-throw, Form C) relays are contained in this module. The relay operations are user

configured via the front panel to act in either a flow rate alarm, error alarm or totalizing pulse. The relays are rated for 200V AC

maximum and have a current rating of 0.5 A resistive load (175V DC @ 0.25 A resistive). Use a secondary relay whenever the

Control Relay ISO-MOD is used to control inductive loads such as solenoids and motors.

Typical relay connections are illustrated in Figure 24. The reed relays located within the relay module can interface directly

with small pilot lights, PLCs, electronic counters and SCADA systems.

Figure 25 shows the connection of an external power relay to the Relay ISO-MOD. Use external power relays whenever the

load to be switched exceeds the switch rating of the reed relays, or if the load is inductive in nature.

FLOW OK

LOW F LOW

P

EXTERNAL

TOTALIZER/SAMPLER

Figure 24: Typical relay connections

INTERNAL

CURCUIT

b NO

b CM

b NC

a NO

a CM

a NC

I/O: RE L A Y

P.N. D020-1045-102

ISO-MOD

POWER

RELAY

b NO

b CM

b NC

a NO

a CM

a NC

POWER

SOURCE

Figure 25: External relay connections

I/O: RELAY

P.N. D020-1045-102

ISO-MOD

Page 27 August 2019 DPP-UM-00256-EN-03

Page 28

Instrument Programming

Rate Pulse Output Module

The Rate Pulse Output Module is used to transmit information to external counters and PID systems via a frequency output

that is proportional to system flow rate. The frequency output range of the Rate Pulse Module is 0…2500 Hz. This module has

two types of outputs: one simulates the output of the coil of a turbine flow meter and the other is an open-collector type that

does not source voltage at its output. Both outputs may be connected simultaneously.

The turbine meter output creates a 500 mV peak-to-peak saw-tooth waveform that is not referenced to ground. This output

can be run to electronic monitors that are compatible with variable reluctance outputs from coils, such as those found in

turbine and paddle-wheel flow meters. The input impedance of the receiving device should not be smaller than 2000 Ohms.

The standard pulse output does not output a voltage, but acts as an open-collector output requiring an external power

source and pull-up resistor. See Figure 26. The MOSFET in the Rate Pulse Module can support loads of 100V @ 1 A. Resistor

selection is based on the input impedance of the receiving device. Select a resistor that is a maximum of 10% of the input

impedance of the receiving device, but does not exceed 10k Ohms.

500 mV

+V

p-p

TURBINE IN

TURBINE IN

RTU/PLC

MONITOR

+V EXT SENSOR

RTU/PLC

MONITOR

0

0

500 mVpp

R

PULSE IN

GND

Figure 26: Rate pulse module

+V

I/O: 0-2.5KHz

P.N. D020-1045-207

TURBINE - B

TURBINE - A

OUT (-)

IN (+)

ISO-MOD

0

TIME

Page 28 August 2019DPP-UM-00256-EN-03

Page 29

Instrument Programming

INSTRUMENT PROGRAMMING

General

The DFX flow meter is configured through the keypad interface. All entries are saved in non-volatile FLASH memory that is

retained indefinitely in the event of power loss.

Keypad Operation

The DFX flow meter contains a four-key tactile feedback keypad interface that lets you view and change configuration

parameters used by the meter’s operating system.

Figure 27: Keypad layout

The DFX flow meter has two basic sets of programming procedures: list item selection and numeric value entry.

OTE:N While in RUN mode, simultaneously press the UP and DOWN keys to display the current firmware version.

List Item Selection Procedure

OTE:N If you are in PROGRAM mode and the selection to be viewed or changed is displayed, proceed to step 3 below. If

you are in PROGRAM mode and the selection to be viewed or changed is not displayed, press UP or DOWN until the

selection appears. Proceed to step 3.

1. Press MENU. PROGRAM appears in the lower left-hand corner and ID UNITS appears on the lower line of the display.

2. Press DOWN to move to the selection.

3. Press ENTER to view the current selection.

4. If the current selection is correct, press ENTER to conrm. The unit automatically advances to the next selection.

5. To change the current selection, press UP to scroll through the available choices. Press ENTER to conrm your selection.

The unit automatically advances to the next selection.

6. To exit the programming mode, press MENU. Depending on your position in the programming mode, up to three MENU

presses may be required to exit. The display changes to RUN mode.

OTE:N While in RUN mode, simultaneously press the UP and DOWN keys to display the current firmware version.

Numeric Value Entry Procedure

OTE:N If you are in PROGRAM mode and the selection to be viewed or changed is displayed, proceed to step 3 below. If

you are in PROGRAM mode and the selection to be viewed or changed is not displayed, press UP or DOWN until the

selection appears. Proceed to step 3.

1. Press MENU. PROGRAM displays in the lower left corner and ID UNITS displays on the lower line.

2. Press DOWN until the correct selection displays. The current numeric value for this selection displays on the upper line.

3. If the current value is correct, press ENTER. The left-most programmable number ashes. Press ENTER again to conrm

and keep the current numeric value. The unit automatically advances to the next menu selection.

4. To change the current selection, press ENTER. The left-most programmable number ashes. Press UP to scroll through the

digits 0…9. Press DOWN to move the active digit to the right. Continue until all digits are selected.

5. Press ENTER to conrm your selection. The unit automatically advances to the next selection.

6. To exit the programming mode, press MENU. Depending on your position in the programming mode, up to three MENU

presses may be required to exit. The display changes to RUN mode.

Totalizer Reset

Press ENTER and MENU simultaneously when in the RUN mode to reset the totalizer. The message TOTAL RST displays for a

few seconds to indicate that the totalizer had been cleared. If a password has been set, you must enter the password to clear

the totalizer.

Page 29 August 2019 DPP-UM-00256-EN-03

Page 30

Menu Structure

MENU STRUCTURE

Hierarchy

The DFX flow meter has a hierarchical menu structure. See “Menu Maps” on page31 for a visual path to the configuration

parameters. Use the table below as a quick reference guide to the pages with detailed information on each parameter.

Setup

Parameters

ID UNIT → INCH 33 AD SETUP → YES 36 CFG MOD1 → YES 34

DISPLAY → RAT E 33 HIGH 36 NO 35

RATE UNT → GALLONS 33 LOW 36 RELAY 27, 35

RATE INT → SEC 33 FLOW 0HZ → (numeric entry) 35

TOTL UNT → GALLONS 33

TOTL MUL → X PT 01 33

SP GRAV → (numeric entry) 33

FL C OFF → (numeric entry) 33

SCALE F → (numeric entry) 34

DAMPING → (numeric entry) 34

PASSWORD → (numeric entry) 34

Options

MM 33 NO 36 NO 34

ID → (numeric entry) 33 AGC MODE → NORMAL 36 CFG MOD2 → YES 35

TOTAL 33 MANUAL 36 MOD TYPE → NONE 35

BOTH 33 GAIN POT → (numeric entry) 36 4-20MA 25, 35

DIA 33 FILTER → NONE 36 R ATE 28, 35

LITERS 33 MEDIUM 36 FLOW 4MA → (numeric entry) 35

MGAL 33 HIGH 36 FLOW 20MA → (numeric entry) 35

CUBIC FT 33 XDCR TYP → DT90 36 4-20 CAL? → YES 35

M CU FT 33 PROBE 36 NO 35

CUBIC ME 33 C FACTOR → (numeric entry) 36 4MA OUT → (numeric entry) 35

MEG LTRS 33 LINEAR → YES 36 20MA OUT → (numeric entry) 35

ACRE FT 33 NO 36 4-20TEST → (numeric entry) 35

OIL BARR 33 NUM PTS → (numeric entry) 36 RATE → NONE 35

LIQ BARR 33 FREQ n → (numeric entry) 36 TOTA L 35

LBS 33 COEFF n → (numeric entry) 36 FLOW 35

KGS 33 ERRORS 35

VEL FT 33 n OFF → (numeric entry) 35

VEL MTRS 33 n ON → (numeric entry) 35

MIN 33 FLOW MAXHZ → (numeric entry) 35

HOUR 33 RATE TST → (numeric entry) 35

DAY 33 RATE PCT → (numeric entry) 35

LITERS 33

MGAL 33

CUBIC FT 33

M CU FT 33

CUBIC ME 33

MEG LTRS 33

ACRE FT 33

OIL BARR 33

LIQ BARR 33

LBS 33

KGS 33

VEL FT 33

VEL MTRS 33

X PT 1 33

X 1 33

X 10 33

X 100 33

X 1000 33

X 10000 33

X 100000 33

X 10000000 33

For Details,

see page

Advanced

Setup

Parameters

Options

For Details,

see page

Module

Configuration

Parameter

Options

For Details,

see page

Page 30 August 2019DPP-UM-00256-EN-03

Page 31

Menu Maps

Menu Structure

To Module Conguration

NUM PTS

Number of Linearization Points

Numeric Entry (0 to 10)

AGC MODE

Automatic Gain Control

NORMAL

FL C-OFF

Low Flow Cuto

Numeric Entry

HIGH

FREQ n

MANUAL

SCALE F

COEFF n

Frequency of Point (n)

Numeric Entry

depending on the number

May require up to 10 cycles

of linear points chosen.

Coecient of Point (n)

Numeric Entry

From Module Conguration

Numeric Entry

DAMPING

Damping Percentage

Numeric Entry

FILTER

Hardware Filter

NONE

CFG MOD 1

Congure Module 1

LOW

MEDIUM

YES

NO

HIGH

XDCR TYP

Transducer Type

CFG MOD 2

Congure Module 2

YES

GAIN POT

4 mA Flow Value

Scale Factor

Numeric Entry

DT90

NO

PROBE

C FACTOR

Correction Factor

PASSWORD

LINEAR

Linearization?

YES

AD SETUP

Advanced Setup

NO

YES

NO

Numeric Entry

Password Entry

Numeric Entry

RATE INT

START

V1.16

SETUP MENU

Rate Inter val

SEC

MIN

I D UNIT

Pipe Measurement Units

HOUR

DAY

INCH (Inches)

MM (Millimeters)

TOTL UNT

Totalizer Units

ID

Pipe Inside Diameter

GALLONS

LITERS

NUMERIC ENTRY

MGAL

CUBIC FT

M CU FT

CUBIC ME

DISPLAY

Display Choices

(42 Gal)

MEGL TRS

ACRE FT

OIL BARR

LIQ BARR (31.5 Gal)

LBS

KGS

RATE UNT

BOTH

DIAGNOSTICS

RAT E

TOTA L

Figure 28: Menu Map 1

VEL FEET

Flow Rate Units

VEL MTRS

GALLONS

LITERS

MGAL

TOTL MUL

Totalizer Multiplier

X PT 01(÷100)

CUBIC FT

M CU FT

X PT 1 (÷10)

X 1 (X1)

CUBIC ME

MEGL LTRS

ACRE FT

X 10 (X10)

X 100 (X1,00)

(42 Gal)

OIL BARR

LIQ BARR (31.5 Gal)

X 1000 (X1,000)

LBS

X 10000 (X10,000)

X 100000 (X100,000)

KGS

X 1000000 (X1,000,000)

VEL FEET

VEL MTRS

SP GRAV

Specic Gravity

Numeric Entry

Specic Gravity only appears

when LBS or KGS are selected

in either Rate Unit or Total Unit

Page 31 August 2019 DPP-UM-00256-EN-03

Page 32

Menu Structure

MOD TYPE

Numeric Entry

RATE TST

n OFF <

Relay (n) O

Select Rate Test Function

FLOW 0HZ

Flow Rate at 0 Hz

RELAY n

Relay Functions

Numeric Entry

TOTAL

NONE

FLOW

FL MAXHZ

Flow Rate at 2500 Hz

ERRORS

Numeric Entry

Module Type

4-20 MA

NONE

RATE

RELAY

For Test Press Enter

n ON >

Relay (n) On

RATE PCT

10% Increments

Numeric Entry

Numeric Entry

1 & 2 are in

n = the relay

number 1, 2, 3 ,4

module 1.

3 & 4 are in

module 2.

To Password

4MA OUT

FLOW 4MA

4 mA Flow Value

FLOW 20MA

20 mA Flow Value

Numeric Entry

4-20 CAL?

4-20 Calibration?

YES

Numeric Entry

NO

From Module Conguration

Figure 29: Menu map 2

Page 32 August 2019DPP-UM-00256-EN-03

4 mA DAC Value

20MA OUT

20 mA DAC Value

Numeric Entry

4-20TEST

4-20 mA Output Test

Numeric Entry

Numeric Entry

Page 33

PARAMETERS

The following tables list and explain the parameters. The tables are divided into three main sections:

• Setup parameters

• Module configuration parameters

• Advanced setup parameters

Setup Parameters

The setup menu contains all of the configuration parameters necessary to make the transmitter operational.

Parameter Function Options Description

ID UNITS

ID

DISPLAY Display mode

RATE UNT

RATE INT

TOTL UNT Totalizer units

TOTL MUL

SP GRAV

FL COFF Low flow cutoff (Enter a numeric value)

Measurement

standard

Pipe inside

diameter

Engineering units

for flow rate

Time interval for

flow rate

Flow totalizer

multiplier value

Fluid specific

gravity

ENGLSH (Inches)

METRIC (Millimeters)

(Enter a numeric value)

RAT E

TOTAL

BOTH

DIA

Select an engineering unit for flow rate measurements. When Pounds (LBS) or Kilograms (KGS) is selected, the specific

gravity for the fluid type must be entered for the SP GRAV setup parameter.

Measurement Selection Measurement Selection

Pounds LBS Cubic Meters CUBIC ME

Kilograms KGS Millions of Metric Liters MEGLTRS

Gallons GALLONS Acre Feet ACRE FT

Liters LITERS Oil Barrels (42 Gallons) OIL BARR

Millions of Gallons MGAL Liquor Barrels (31.5 Gallons) LIQ BARR

Cubic Feet CUBIC FT Velocity in Linear Feet VEL FEET

Millions of Cubic Feet M CU FT Velocity in Linear Meters VEL MTRS

SEC Seconds

MIN Minutes

HOUR Hours

DAY Days

Select an engineering unit for flow totalizer measurements. When Pounds (LBS) or Kilograms (KGS) is selected, the specific

gravity for the fluid type must be entered for the SP GRAV setup parameter.

Measurement Selection Measurement Selection

Pounds LBS Cubic Meters CUBIC ME

Kilograms KGS Millions of Metric Liters MEGLTRS

Gallons GALLONS Acre Feet ACRE FT

Liters LITERS Oil Barrels (42 Gallons) OIL BARR

Millions of Gallons MGAL Liquor Barrels (31.5 Gallons) LIQ BARR

Cubic Feet CUBIC FT Velocity in Linear Feet VEL FEET

Millions of Cubic Feet M CU FT Velocity in Linear Meters VEL MTRS

0.01…1,000,000

(Enter a numeric value)

Selects the unit of measure for pipe ID entry.

Enter the pipe inside diameter in inches if ENGLSH was selected as UNITS; in millimeters if METRIC

was selected.

To display only the Flow Rate, select R ATE . To display only the Flow Total, select TOTAL . To

alternately display the Flow Rate and the Total, select BOTH. By selecting BOTH, the display

switches between RATE and TOTAL every 7 seconds.

The DIA selection places the display in the diagnostics mode. When selected, the display shows

the measured frequency, the gain setting and the signal strength.

Select a time interval for flow rate measurements.

Used for setting the flow totalizer exponent. This feature is useful for accommodating a very

large accumulated flow. The exponent is a ×10n multiplier, where “n” can be from -2 (×0.01) to +6

(×1,000,000). Reference the table below for valid entries and their influence on the DFX meter

display.

Exponent Display Multiplier

× PT 01 2 × 0.01

× PT 1 1 × 0.1

×1 0 × 1

×10 1 × 10

×100 2 × 100

×1000 3 × 1000

×10000 4 × 10,000

×100000 5 × 100,000

×1000000 6 × 1,000,000

Allows adjustments to be made to the specific gravity (density relative to water) of the liquid.

If Pounds (LBS) or Kilograms (KGS) is selected for either the RATE UNT or the TOTL UNT, a specific

gravity must be entered for the correct mass flow to be calculated. A list of fluids and their

associated specific gravities is located in “Specifications” on page40.

A Low Flow Cutoff entry is provided to allow very low flow rates (that can be present when

pumps are off and valves are closed) to be displayed as Zero flow. The value entered is in actual

rate units.

Parameters

Page 33 August 2019 DPP-UM-00256-EN-03

Page 34

Parameters

Parameter Function Options Description

The SCALE F function applies a correction factor/multiplier to the readings and outputs so

the DFX system can agree with a different or reference flow meter, or to compensate for an

installation where there is inadequate straight pipe to obtain a laminar flow profile. A factory

SCALE F Scale factor value (Enter a numeric value)

DAMPING

CFG MOD1

CFG MOD2

System damping

percentage

Configure I/O

Module

Configure I/O

Module

(Enter a numeric value

0…99%)

YES or NO

YES or NO

calibrated system should be set to 1.000. The range of settings for this entry is 0.5000…5.000. The

following example describes using the SCALE F entry.

The DFX meter is indicating a flow rate that is 4% higher than another flow meter located in the

same pipe line. To have the meter indicate the same flow rate as the other meter, enter a SCALE F

of 0.960, to lower the readings by 4%.

Flow Filter Damping establishes a maximum adaptive filter value. Under stable flow conditions

(flow varies less than 10% of reading), this adaptive filter increases the number of successive flow

readings that are averaged together up to this maximum value. If flow changes outside of the

10% window, the Flow Filter adapts by decreasing and allows the meter to react faster. Increasing

this value tends to provide smoother steady-state flow readings and outputs.

This prompt lets you access the setup parameters associated with installation of the optional

ISO-MOD interface modules. If NO is selected, the unit skips ahead to CFG MOD2. If YES is

selected, configuration and calibration of the module installed in the first position is accessible.

If NO was selected at CFG MOD1, CFG MOD2 becomes active. This prompt lets you access the

setup parameters associated with installation of the optional ISO-MOD interface modules. If NO

is selected, the unit skips ahead to PASSWORD. If YES is selected, configuration and calibration of

the module installed in the second position is accessible.

Page 34 August 2019DPP-UM-00256-EN-03

Page 35

Module Conguration Parameters

When YES is selected at CFG MOD1 or CFG MOD2, these MOD TYPE parameters become available:

• NONE

• 4…20 mA

• RATE

• RELAY

Once the module is configured, the menu moves to the PASSWORD parameter.

MOD TYPE Function Options Description

NONE

420MA

RAT E

RELAY

No module is

installed

4…20 mA type

module

Rate pulse output

module

Relay 1 and Relay

2 configuration

NONE Select NONE (no module installed) to move to the PASSWORD parameter.

FLOW 4MA Enter the flow rate that corresponds to 4 mA. The units are equal to the units set in RATE UNT.

FLOW 20MA Enter the flow rate that corresponds to 20 mA. The units are equal to the units set in RATE UNT.

Select NO to move to the PASSWORD parameter.

Select YES to adjust the “zero” and span of the 4…20 mA output.

To adjust either the 4 mA or 20 mA output, connect a milliammeter or reliable

4MA OUT

4-20 CAL?

20MA OUT

4-20TEST

FLOW 0Hz Enter the flow rate that corresponds to 0 Hz. The units are equal to the units set in RATE UNT.

FL MAXHZ Enter the flow rate that corresponds to 2500 Hz. The units are equal to the units set in RATE UNT.

RATE TST Simulate a pulse output. Moves to RATE PCT entry.

Allows a simulated value to be output from the rate pulse output. By incrementing this value,

the rate pulse output transmits the indicated frequency in terms of percentage of the maximum

RATE PCT

NONE Select NONE (no Relay 1 installed) to move to the Relay 2 parameter.

TOTAL

FLOW

ERRORS

output frequency.

For example, if the maximum output frequency is 2500 Hz, increment the displayed value to 50 to

output a test frequency of 1250 Hz.

TOTAL mode configures the relay to output a 50 m/s pulse (contact changeover) each time the

display totalizer increments. Select TOTAL to configure the relay for Totalizer Relay and move to

the PASSWORD menu.

Flow Rate Relay configuration permits relay changeover at two separate flow rates allowing

operation with an adjustable switch deadband. Figure 30 on page 37 illustrates how the setting

of the two set points influences Rate Alarm operation.

A single-point flow rate alarm would place the ON> setting slightly higher than the OFF<

setting—allowing a switch deadband to be established. If a deadband is not established, switch

chatter (rapid switching) may result if the flow rate is very close to the switch point.

When a relay is set to ERROR mode, the relay activates when any error occurs in the flow meter

that has caused the meter to stop measuring reliably. See “Startup and Troubleshooting” on

page38 for a list of potential errors.

reference to the output.

1. Disconnect one side of the current loop and connect the milliammeter

in series (disconnect either wire at the terminals labeled +/– on the ISOMOD 4…20 mA module).

2. Using the arrow keys, increase the numerical value to increase the

current in the loop to the output. Decrease the value to decrease the

current in the loop to output. The value range for 4MA OUT is 40…80

counts. The value range for 20MA OUT is 3700…3900 counts.

3. Re-connect the 4…20 mA output circuitry as required.

Outputs a simulated value from the 4…20 mA output. By incrementing this

value, the 4…20 mA output transmits the indicated current value.

Parameters