Page 1

Doppler Ultrasonic Flow Meter

Series DFX

DESCRIPTION

The DFX ultrasonic Doppler flow meter measures flows of liquids

containing suspended particles or aerated liquids. Used with the

DT9 clamp-on, non-intrusive transducers, the meter is suitable

for sewage and mud slurries and can be used on most pipes

constructed from metal or plastic.

The DT9 transducer for the DFX meter is rated to Type 6 (IP67) and

has the ability to work with temperatures up to 194° F (90° C).

APPLICATIONS

Successful application of Doppler ultrasonic flow meters relies on

three physical constraints:

• The liquid flowing within the pipe must contain 100 ppm of

useful sonic suspended reflectors. Dissolved solids do not

generate reflections and are not relevant.

• A significant portion of the ultrasound energy generated by

the transducer must reach the sonic reflectors. The ultrasonic

transducer must be acoustically coupled to the outside of a

pipe (using grease or RTV couplant) and the pipe must permit

ultrasound to pass without significant attenuation. Most

pipes constructed of solid, homogenous materials meet this

qualification. Pipes that cause application difficulty include

concrete pressure pipes, woodstave pipes, Teflon®-lined pipes

and fiberglass reinforced pipes.

• The pipe must be completely filled with liquid when

measurements are made. The DFX microprocessor assumes that

the pipe is completely full when it calculates flow rate. Use on

partially-filled pipes may result in inaccurate readings.

BENEFITS

• Minimal installation time: the DFX may be installed and fully

operational within minutes. For most homogeneous pipe

materials, there is no need to break into pipelines.

• Minimal material costs: clamp-on sensor eliminates the need

for in-line flanges, pipe fittings, strainers or filters.

• Reduced down-time: installation may be performed on full pipes

and active systems. There is no need to shut down the process

for installation or maintenance.

• Lower maintenance costs: with no moving parts, there is nothing

on the DFX to wear down.

OPERATION

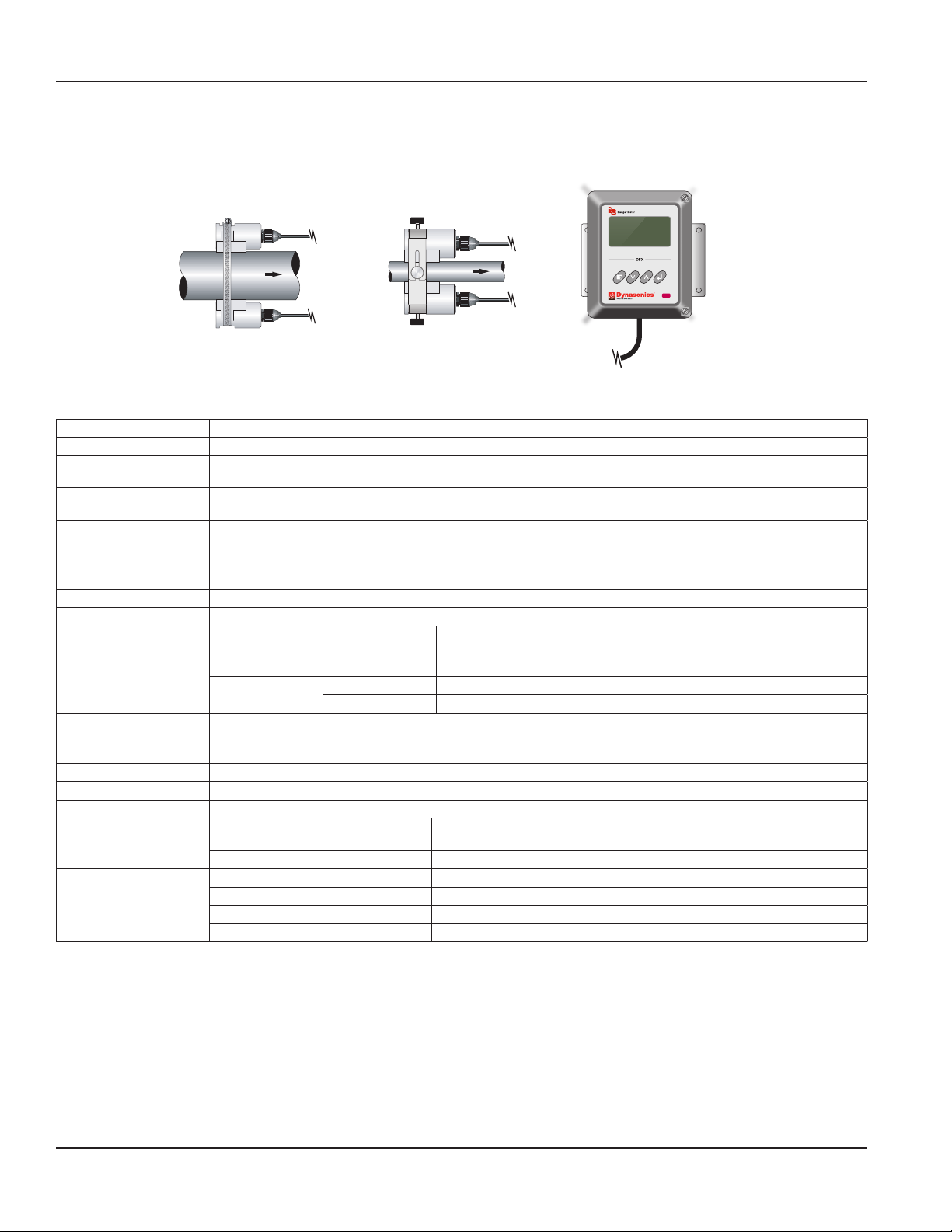

The DFX flow meter operates by transmitting ultrasonic sound from

its transmitting transducer through the pipe wall into the flowing

liquid. Each transducer contains piezoelectric crystals to transmit

this signal. The sound will be reflected by useful sonic reflectors

suspended within the liquid and recorded by the receiving

transducer (see Figure 1). If the reflectors are moving within the

sound transmission path, sound waves will be reflected at a

frequency shifted (Doppler shift) from the transmitted frequency.

The difference between the reflected frequencies and transmitted

frequencies is directly proportional to the speed of the sonic

reflectors, resulting in a liquid flow rate that is converted to various

user defined measuring units.

Figure 1: DFX operation

FEATURES

• Non-intrusive, clamp-on transducers for most pipes from

0.25 in. (6 mm) and above.

• Wide velocity range: 0.15…30 fps (0.0…9 mps).

• Flexibility: with automatic gain control and in-field linearization,

the DFX will adapt to a wide variety of applications.

DPP-DS-01296-EN-05 (August 2019)

Product Data Sheet

Page 2

Doppler Ultrasonic Flow Meter, Series DFX

CLAMPON TRANSDUCER OPTIONS

Standard temperature

Standard pipe system (DT94)

FLOW

Top view of pipe

Standard temperature

Small pipe system (DT95)

FLOW

Top view of pipe

SPECIFICATIONS

Velocity Range 0.15…30 fps (0.05…9 mps)

Accuracy ±2% full scale, over calibrated span

Liquid Types

Monitor Enclosure

Power Supply 115/100/230V AC 50/60 Hz ±15% @ 17V A max; 12…28V DC @ 7V A max

Display 2-line × 8 character LCD; LED backlighting; 8-digit rate, 8-digit total (resettable)

Units

Rate Interval Second, minute, hour, day. Totalizer exponent: E-2 to E+6 (x ¹/100 to x 1,000,000)

Response Time User selectable: 6…60 seconds

Output Options

Multiple Meters

Keypad 4-key, tactile

Ambient Conditions –40…185º F (–40…85º C); 0…95% relative humidity (non-condensing)

Approvals (Std.) General Safety US and Canada. Certified to UL 61010-1 and CSA C22.2 No. 61010-1

Transducer Type Compression-mode Ultrasonic; 625 kHz

Construction

Pipe Sizes

Liquids containing a minimum of 100 ppm of useful sonic suspended reflectors greater than 35 micron size, and at least 25%

of the overall particle volume is larger than 100 microns

NEMA 4X (IP 66), polycarbonate, stainless steel, brass,

plated-steel mounting brackets 7.00 in. H × 5.75 in. W × 3.88 in. D (178 mm × 146 mm × 99 mm)

User configured: Feet, US gallons, ft³, Mil-gal, meters, liters, Mil-ft³, m³, Mil-liters, acre-feet, oil barrels (42 US gallons),

liquid barrel (32.5 US gallons), lb, Kg

4…20 mA 800 ohms max, internal or external power supply, 12-bit resolution

Optically Isolated Dual Relay

Rate Pulse

Synchronization provision included—utilized for multiple meter, single pipe/manifold system. Up to four meters may be

interconnected, up to 100 feet (30 meters) apart

Standard Clamp-On

Optional Flexible Armored Conduit Zinc-plated steel, PVC

Standard Clamp-On Transducers 1 inch (25 mm) and above

Small Pipe Clamp-On Transducers 0.25…1 inch (6…25 mm)

Standard Lengths 20, 50 and 100 foot (6.1, 15 and 30 meter), 78 Ohm twinax cable

Optional Lengths To 990 feet (297 meters), 75 Ohm RG59 cable

500 mV AC 2500 Hz max, 12-bit resolution, 500 mV AC into 2 K Ohm minimum;

Open collector 2500 Hz max, 1 A at 100 V max

Independently configured; Form C, 200V AC @ 0.5 A resistive; rate alarm, totalizer

pulse, error

Type 6* (IP 67) –40…194º F (–40…90º C) CPVC, Ultem®, Nylon, PVC (Cable Jacket),

Aluminum (small pipe) *Depth of 1 meter for 30 minutes

Page 2 August 2019DPP-DS-01296-EN-05

Page 3

DIMENSIONS

4.25"

3.93"

(99.8 mm)

4.25"

(108.0 mm)

(3) 0.5" (m20)

Conduit Holes

WALL MOUNT (OPTION)

DDFX Digital Doppler Ultrasonic Flow

DT9 Doppler Ultrasonic

Product Data Sheet

7.00"

(177.8 mm)

Power

Connection

5.75"

(146.1 mm)

RUN PROGRAM

RELAY 1 RELAY 2

Transducer

Connection

COAXIAL CABLES

(108.0 mm)

3.93"

(99.8 mm)

Input/Output

Connection

(3) 0.5" (m20)

Conduit Holes

(169.0 mm)

DT94 DT95

1.91"

(48.5 mm)

COAXIAL CABLES

1.70

"

4.38

(111.3 mm)

"

(43.2 mm)

4.38"

(111.3 mm)

6.65"

6.08"

(154.4 mm)

(48.5 mm)

1.91"

1.99"

(50.5 mm)

3.31"

(84.1 mm)

1.70"

(43.2 mm)

3.24"

(82.3 mm)

1.38"

(35 mm)

MAX. PIPE

DIA

PART NUMBER CONSTRUCTION

D D F X D 2

Transmitter Type Power Supply Input/Output 1 Input/Output 2 Totalizer Approvals Options

2) Rate and Totalizer A) 115V AC N) None N) None A) Eight digit

D T 9

Piping Environment* Cable Length Conduit Type Conduit Length Options

4) Std temp/Std pipe 020) 20 ft (6 m) N) None 000) 0 ft (0 m) N) General safety

5) Std temp/small pipe 050) 50 ft (15 m) 020) 20 ft (6 m)

*Std Temp: Maximum (+194° F) (+90° C)

Small Pipe: 1/4…1 in. (6…25 mm)

Std. Pipe: 1 in. (25 mm) and above

Transmitter

-

B) 230V AC 1) 4

C) 100V AC 2) Dual Relay 2) Dual Relay

…28V DC 3) Rate Pulse 3) Rate Pulse

E) 9

…20 mA 1) 4…20 mA

Transducer Set

-

100) 100 ft (30 m) 050) 50 ft (15 m)

Max. length: 990 ft (297 m)

in 10 ft (3 m) increments

NOTE: All DT9 transducers include acoustic couplant. DT94 includes four (4) 36 in. (890 mm) mounting straps.

-

A

-

resettable

N N

N) General safety

to US/Canadian

standards

-

A) Flexible Armored

100) 100 ft (30 m)

Max. length: 990 ft (297 m)

in 10 ft (3 m) increments

N) None

to US/Canadian

standards

Page 3 August 2019 DPP-DS-01296-EN-05

Page 4

Doppler Ultrasonic Flow Meter, Series DFX

Control. Manage. Optimize.

Dynasonics is a registered trademark of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities. Due to continuous research,

product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the extent an outstanding

contractual obligation exists. © 2019 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Eastern Europe Branch Oce (for Poland, Latvia, Lithuania, Estonia, Ukraine, Belarus) | Badger Meter Europe | ul. Korfantego 6 | 44-193 Knurów | Poland | +48-32-236-8787

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 19-07 Parkway Parade | Singapore 449269 | +65-63464836

Switzerland | Badger Meter Swiss AG | Mittelholzerstrasse 8 | 3006 Bern | Switzerland | +41-31-932 01 11 Legacy Document Numbers: 06-DPP-BR-00011

Loading...

Loading...