Page 1

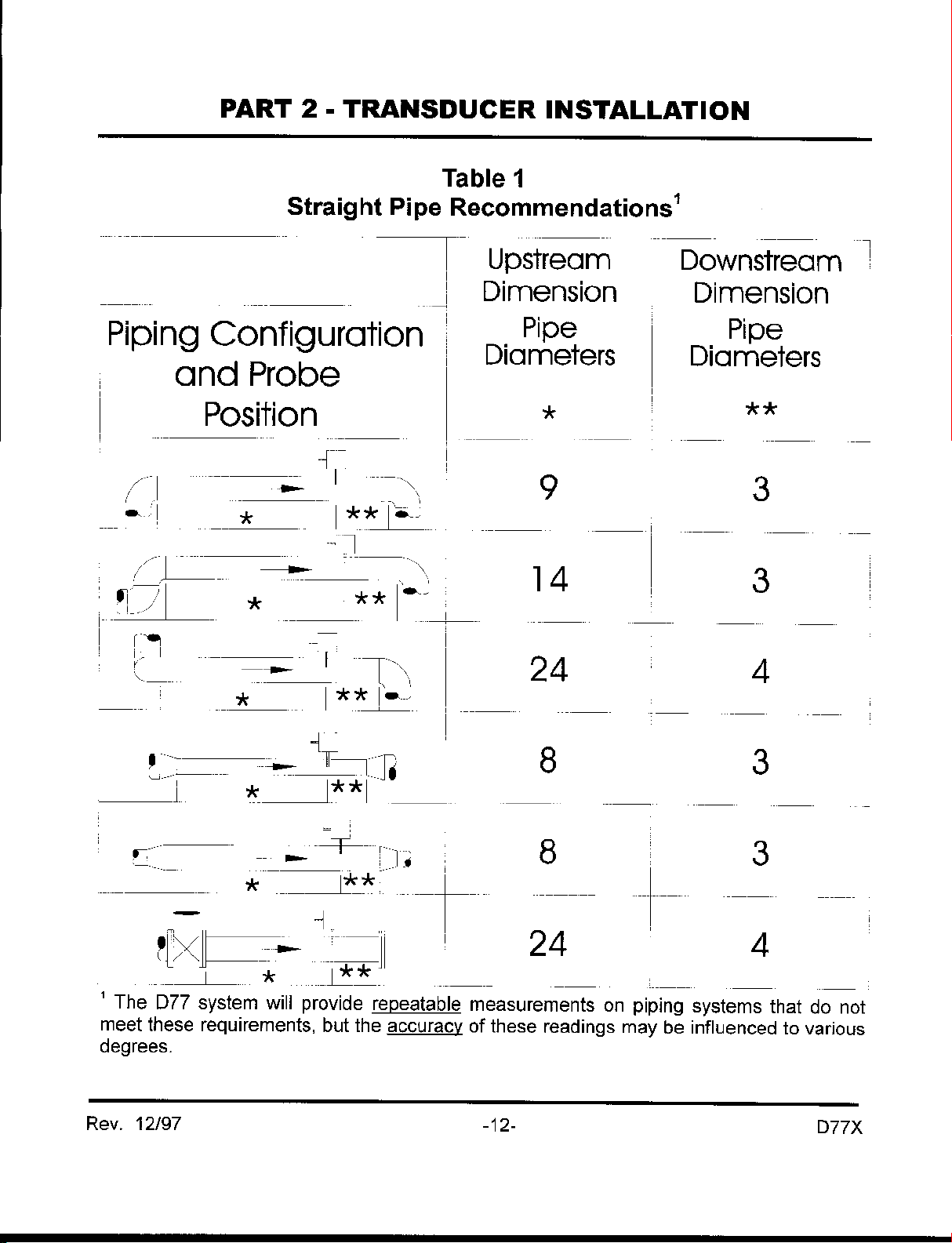

Series

Series D7700

Series Series

Insertion Doppler Ultrasonic Flow Meter

Operations & Maintenance

D7700

D7700D7700

Manual

REV 2/00

Page 2

Location

QUICK-START OPE R ATING INSTRUCTIONS

This manual contains detailed operating instructions for

all aspects of the D77X instrument. The following

condensed instructions are provided to assist the

operator in getting the instrument started up and running

as quickly as possible. This pertains to basic operation

only. If specific instrument features are to be used or if

the installer is unfamiliar with this type of instrument,

refer to the appropriate section in the manual for

complete details.

1. TRANSDUCER LOCATION AND PIPE

PREPARATION

A. Select an appropriate mounting location for the

DT7 transducer probe.

B. The probe should be located on a straight piece of

pipe with a minimum of 10 unobstructed pipe

diameters upstream from the installation point and

a minimum of 5 unobstructed diameters

downstream of the installation point.

Pipe Preparation

and Mounting

C. A 1-1/2” NPT female threaded connection on the

pipe is required for the probe assembly to be

mounted. This connection is typically made by

welding a threaded coupling to the pipe wall or

installing a pipe saddle. The connection should

be mounted perpendicular to the pipe at a radial

location 20-160 degrees from the top of the pipe.

2. TRANSDUCER INSTALLATION

DO NOT remove the cotter pins located at the ends

of the threaded rods. They prevent the probe from

being completely extracted from the insertion fitting

and causing a potentially dangerous condition.

A. Insert the DT7 Transducer Probe tip to the 1/8

pipe I.D. location. The velocity measurement is

made 0.67 inches [17 mm] from the very tip of the

probe. Total insertion depth can be calculated at:

Rev. 12/97 -1- D77X

Page 3

QUICK-START OPE R ATING INSTRUCTIONS

Insertion Depth =

(pipe I.D. inches) X 0.125 + 0.67 inches

or

(pipe I.D. mm) X 0.125 + 17 mm

B. Secure the probe insertion distance using the upper

and lower brass jam nuts located on the threaded

rods.

C. Loosen the set screw located in the probe retaining

collar with the enclosed allen wrench.

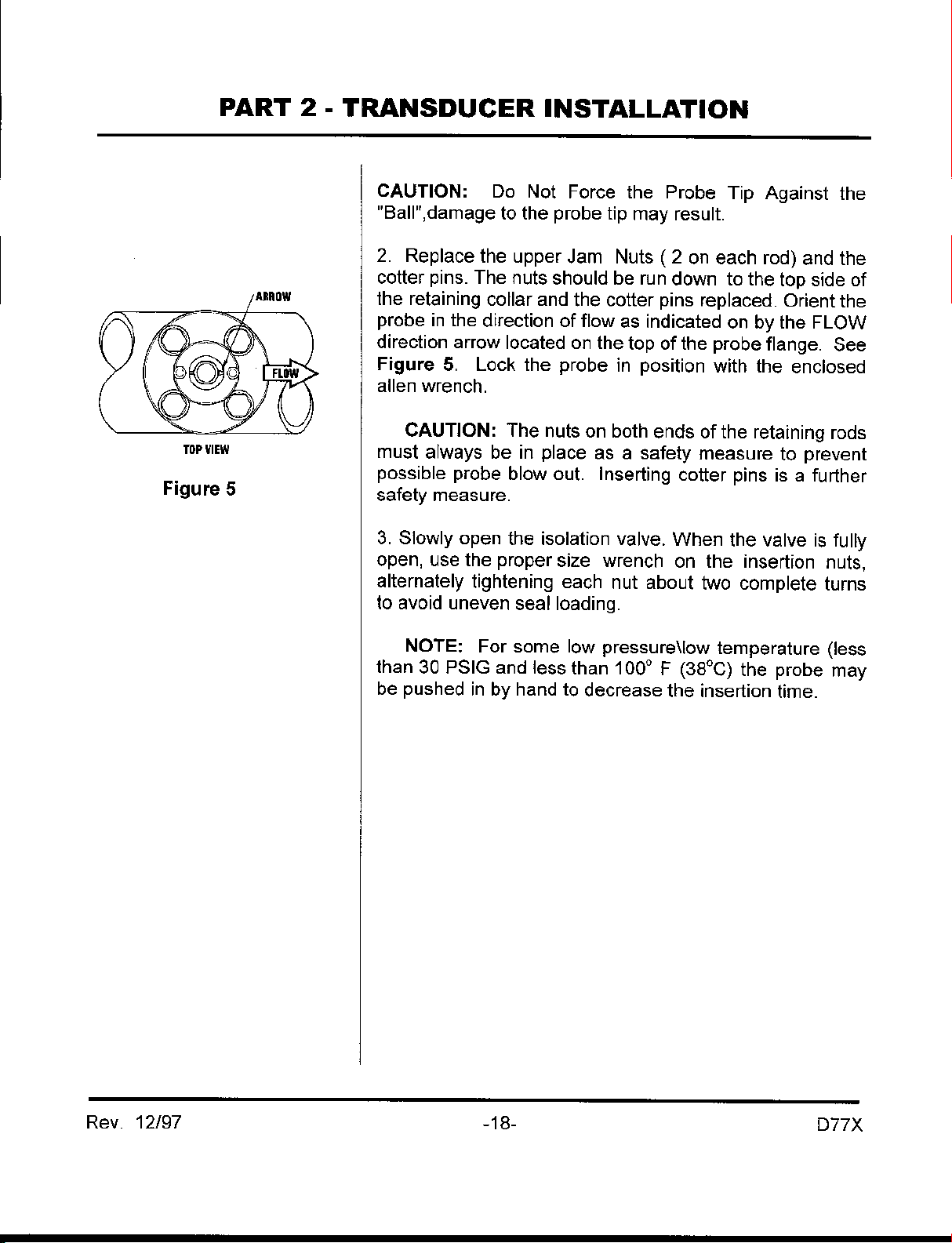

D. Rotate the probe body till the arrowhead, located

on the top of the probe, is parallel with the pipe and

points down stream in the direction of flow.

E. Lock the probe rotation with the set screw in the

retaining collar.

F. Route the transducer cable back to the transmitter,

avoiding locations near high voltage supply wires.

Transducer connections are made through the left

conduit hole in the bottom of the transmitter.

Connections

Startup

3. TRANSDUCER CONNECTION

A. DO NOT attempt to connect additional cable to the

factory supplied transducers.

B. Connect the transducer spade terminals to the

XDCR terminal block located on the lower left

corner of the main PCB.

4. INITIAL SETTINGS AND POWER UP

A. Route a stable, grounded power supply to the

transmitter. Power wiring is made through the right

conduit hole.

B. Connect Power to the upper right terminal block as

appropriate. Apply power.

C. If the D77 system is installed in a pipe full of flowing

liquid, the LED indicator D21 will begin to flash

steadily. If it does not, adjust R10 (GAIN) CW until

the LED just begins to flash.

Rev. 12/97 -2- D77X

Page 4

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

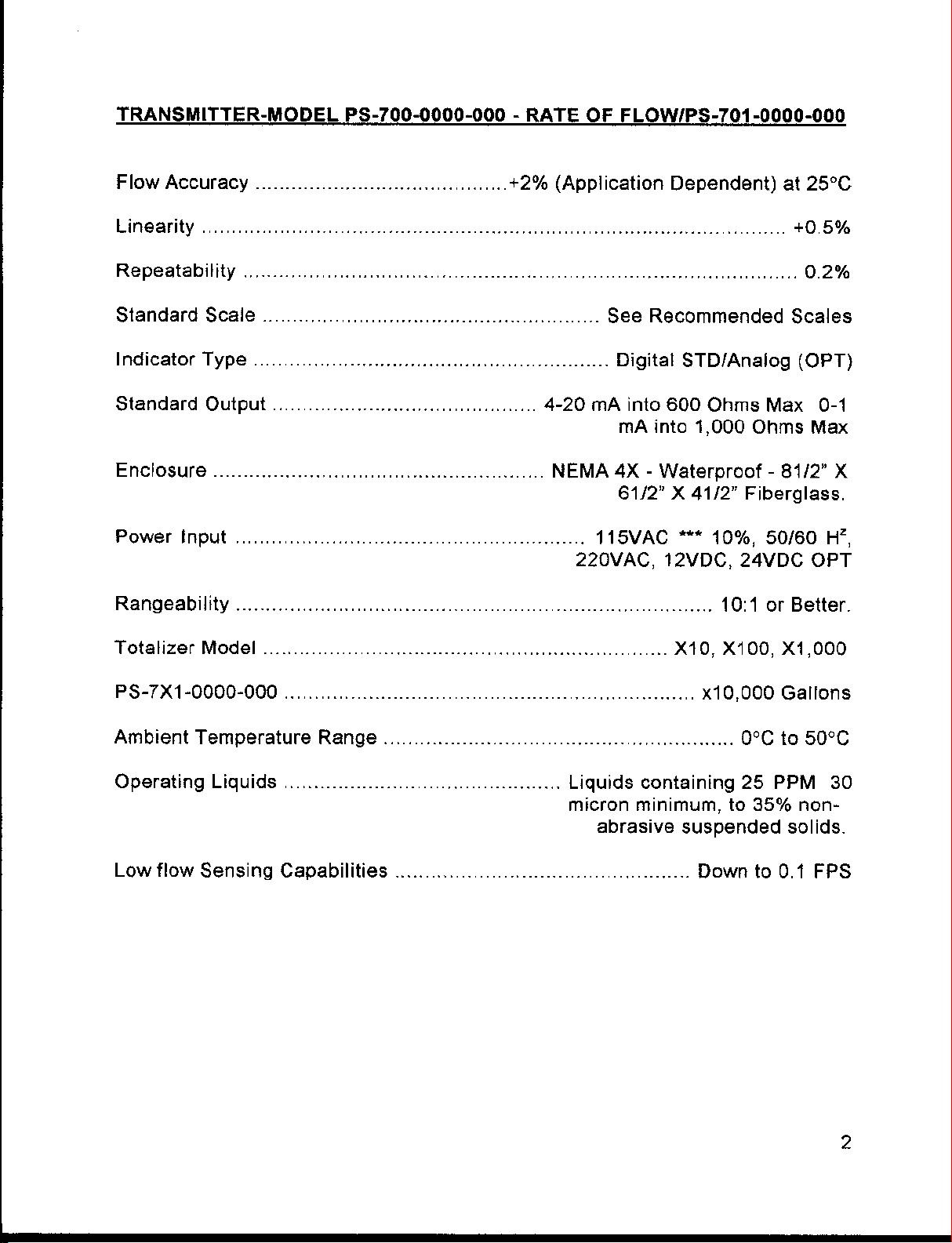

PART 3 - TRANSMITTER INSTALLATION

Installation of

Transmitter Box

The enclosure should be mounted in an area that is

convenient for servicing, calibration or for observation

of the LCD readout.

1. Locate the transmitter within the length of

transducer cable that was supplied with the D7700

system. If this is not possible, do not attempt to

add additional cable to the transducer. Contact

the Dynasonics factory to coordinate an exchange

for the proper cable length. Transducer cables

that are up to 300 feet [90 meters] are available.

2. Mount the D7700 transmitter in a location that is:

♦ Where little vibration exist.

♦ Protected from falling corrosive fluids.

♦ Within ambient temperature limits - 22 to 122°F

[30 to 50°C]

♦ Out of direct sunlight. Direct sunlight may

increase temperatures within the transmitter to

above maximum limit.

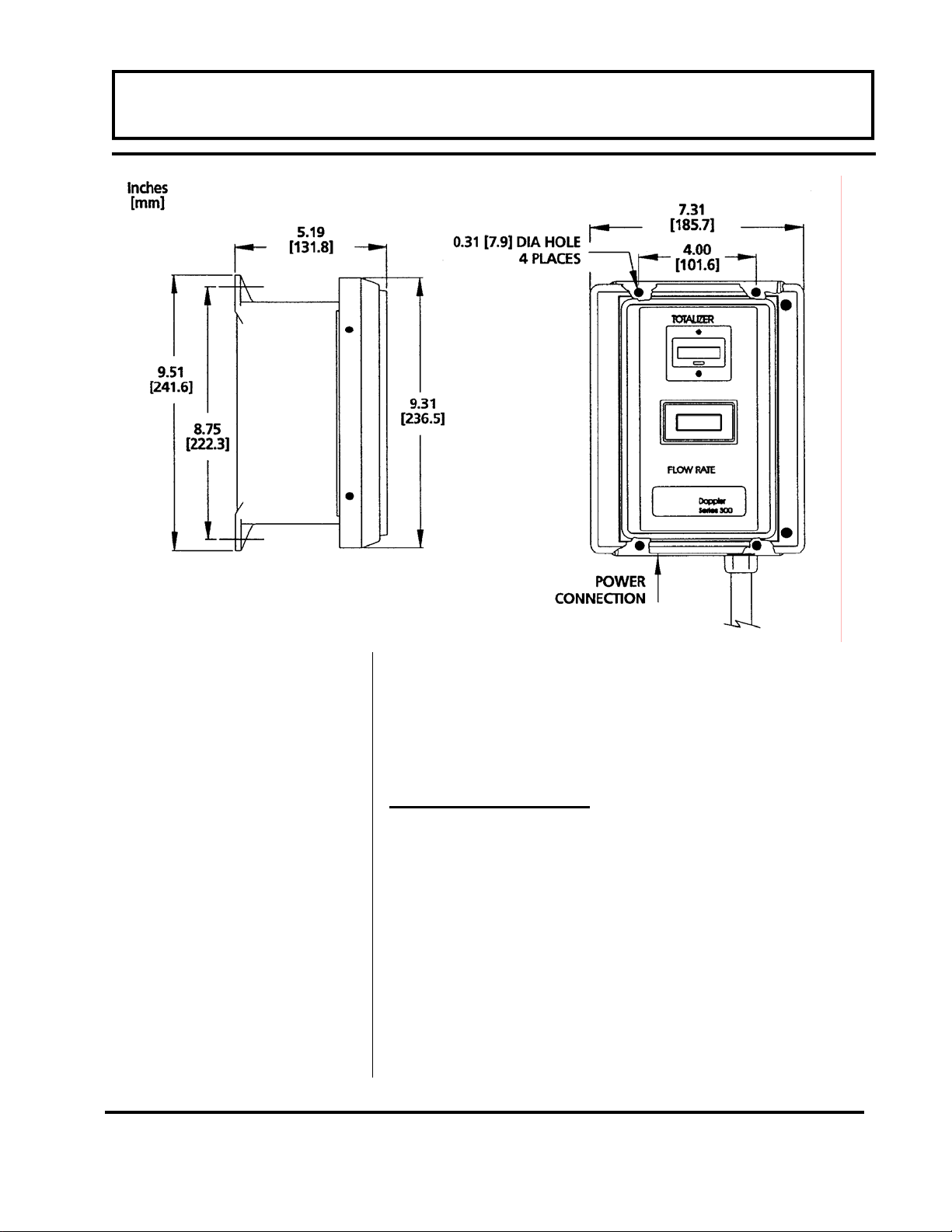

3. Mounting: Refer to Figure 3.1 for enclosure and

mounting dimension details. Ensure that enough

room is available to allow for door swing,

maintenance and conduit entrances. Secure the

enclosure to a flat surface with four appropriate

fasteners.

4. Conduit holes. Conduit hubs should be used

where cables enter the enclosure. Holes not used

for cable entry should be sealed with plugs.

NOTE: Use NEMA 4 [ IP65 ] rated fittings plugs to

maintain the water tight integrity of the enclosure.

Generally, the left conduit hole (viewed from front) is

used for line power; the right conduit hole for

transducer connections.

Rev. 2/00 -3.1- 77X

Page 20

PART 3 - TRANSMITTER INSTALLATION

Figure 3.1

5. If additional holes are required, (analog outputs,

etc.) drill the appropriate size hole in the

enclosure’s bottom. Use extreme care not to run

the drill bit into the wiring or circuits cards.

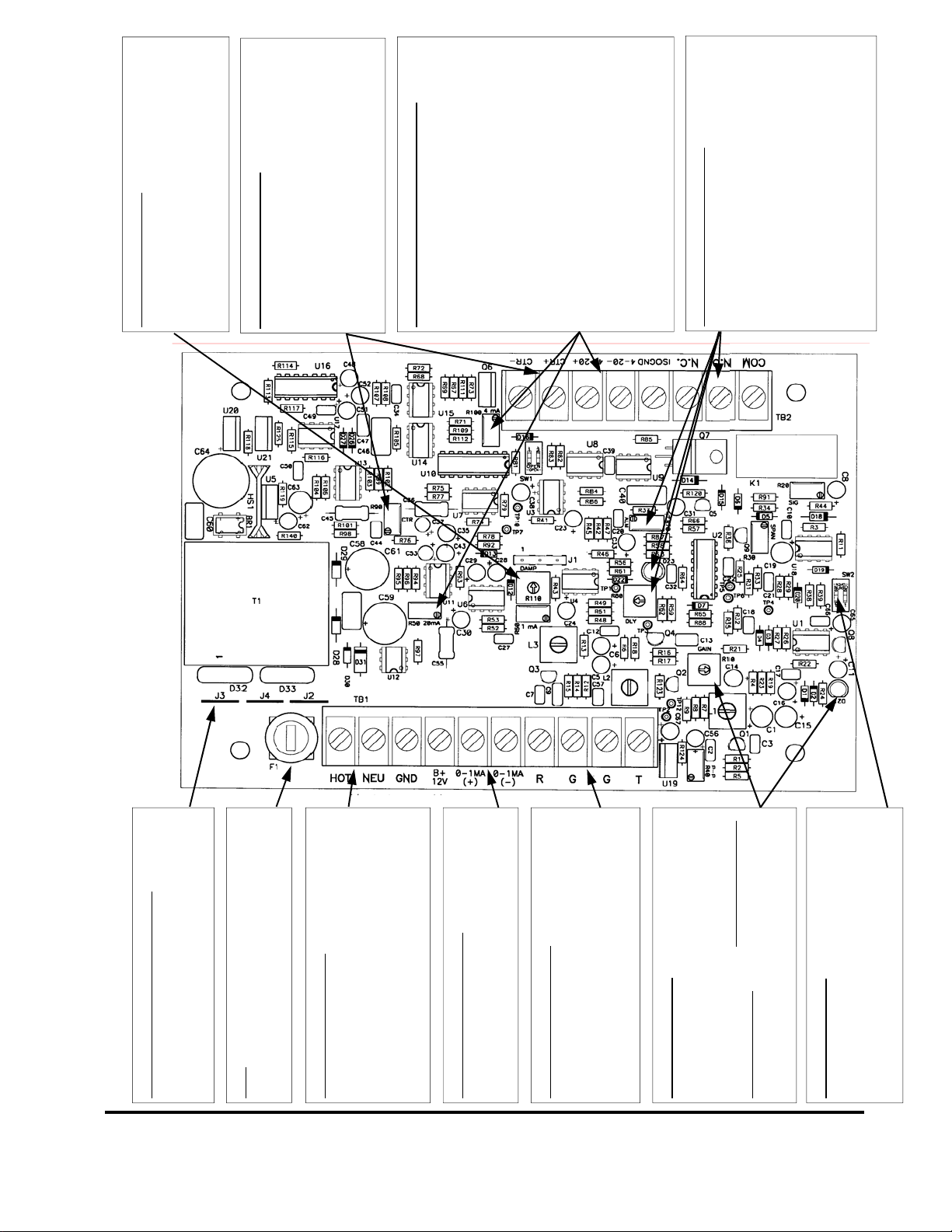

Electrical Connections

1. To access terminal strips for electronic

connections, loosen the two screws in the

enclosure door and open the door.

2. Guide the transducer terminations through the

transmitter conduit hole located on the right side

of the enclosure. Secure the transducer cable

with the supplied conduit nut.

3. The terminals on the transducer cable are coded

with wire markings. Connect the appropriate wires

to the corresponding screw terminals in the

Rev. 2/00 -3.2- 77X

Page 21

PART 3 - TRANSMITTER INSTALLATION

transmitter. See the electrical connections detail in

Figure 3.2 and 3.3.

NOTE: The transducer cable carries low level

signals. Do not attempt to add additional cable to the

factory supplied transducer cable. If additional cable

is required, contact the Dynasonics factory to arrange

for an exchange transducer with the appropriate

length of cable. Cables to 300 feet [ 90 meters ] are

available.

Rev. 2/00 -3.3- 77X

Page 22

power sources, 24 Vdc of isolated power

is available at the 4-20mA+ terminal. Sim-

ply connecting the target’s (chart recorder,

data logger, ADC) 4-20mA+ and 4-20mA–

inputs to these two output terminals will

drive 4-20mA through 1000 ohms.

utilized to power the 4-20mA loop, Con-

nect the ISOGND terminal to the target’s

ground and the target’s 4-20mA input to

the 4-20mA– terminal.

The D300/D301 is equipped with a flow rate

control relay. The relay is designed to control

loads to 250 Vac and 10A. The relay activates

when the flow rate is less than the set point.

Activation is indicated by D23 [LED]. The relay

setpoint is controlled by adjusting R70 [ALM]

there is also a alarm delay feature that requires

the alarm condition to be present for a period of

time before relay activation. The delay can be

Adjust R110 [DAMP] to stabilize flow rate and

R110 [DAMP] Control

output readings. Adjust CCW to increase the

response of the instrument; adjust CW to de-

crease response time (smooth the display

readings and outputs).

CTR Output Connections

The CTR output is designed to operate both

electronic and electromechanical totalizers.

The output can drive loads as low as 90

There are two methods to connect this output:

ohms. Control R90 [CTR] adjusts the span of

this output. Switch set SW1 controls the CTR

output by factors of X10. See details in the

manual describing CTR adjustment.

Isolated 4-20mA Output Connections

• When the D300/D301 is powered from AC

• If the target’s internal DC power source is

Control R100 [4mA] is used to adjust 4mA

offset and R50 [20mA] to adjust 20mA span.

Flow Rate Relay Connections

increased by adjusting R80 [DELAY] CW.

115/230 Vac 50/60 Hz clean AC power re-

quired. Do not connect in parallel with circuits

operating florescent lighting, valves, control

relays, VFDs, etc. GND connection is op-

tional. If GND is connected, verify that it is at

Figure 2.2 D7700 Operated with 115/230 VAC Power Supply 02/02/2000

Power Supply Jumper Placement

115 Vac J2 and J3 only

230 Vac J4 only

12-24 Vdc Does not matter

Fuse

115/230 Vac 1/16A 3AG

Delay Action

AC Power Connections

the same potential as the piping system.

This output is designed to drive loads up to

0-1 mA Output Connection

1500 ohms. Use R60 [1mA] control to adjust

span.

Transducer Connections

Connect the four wires from the two coaxial

cables to the respective terminals. Wire

markers on the coaxial cables identify the “R”

and the “T” pair. Do not run these cables

R10 [GAIN] Control

adjacent to AC power cables.

After all electrical and transducer connections

have been made, the GAIN control is set to

of a flowing liquid. Start with the control fully

match liquid and pipe parameters. To prop-

CCW [counter clockwise]. Adjust CW until

erly set the R10 [GAIN], the pipe must be full

Rev. 2/00 -3.4- 77X

D21 [the LED] just begins to flash steadily.

For measuring fluid velocities up to 20 FPS [6

MPS] set the two switches at SW2 to OPEN.

LOW Velocity Filter

If continuous flow rate will not exceed 2 FPS

[0.6 MPS] turn the two switches ON.

Page 23

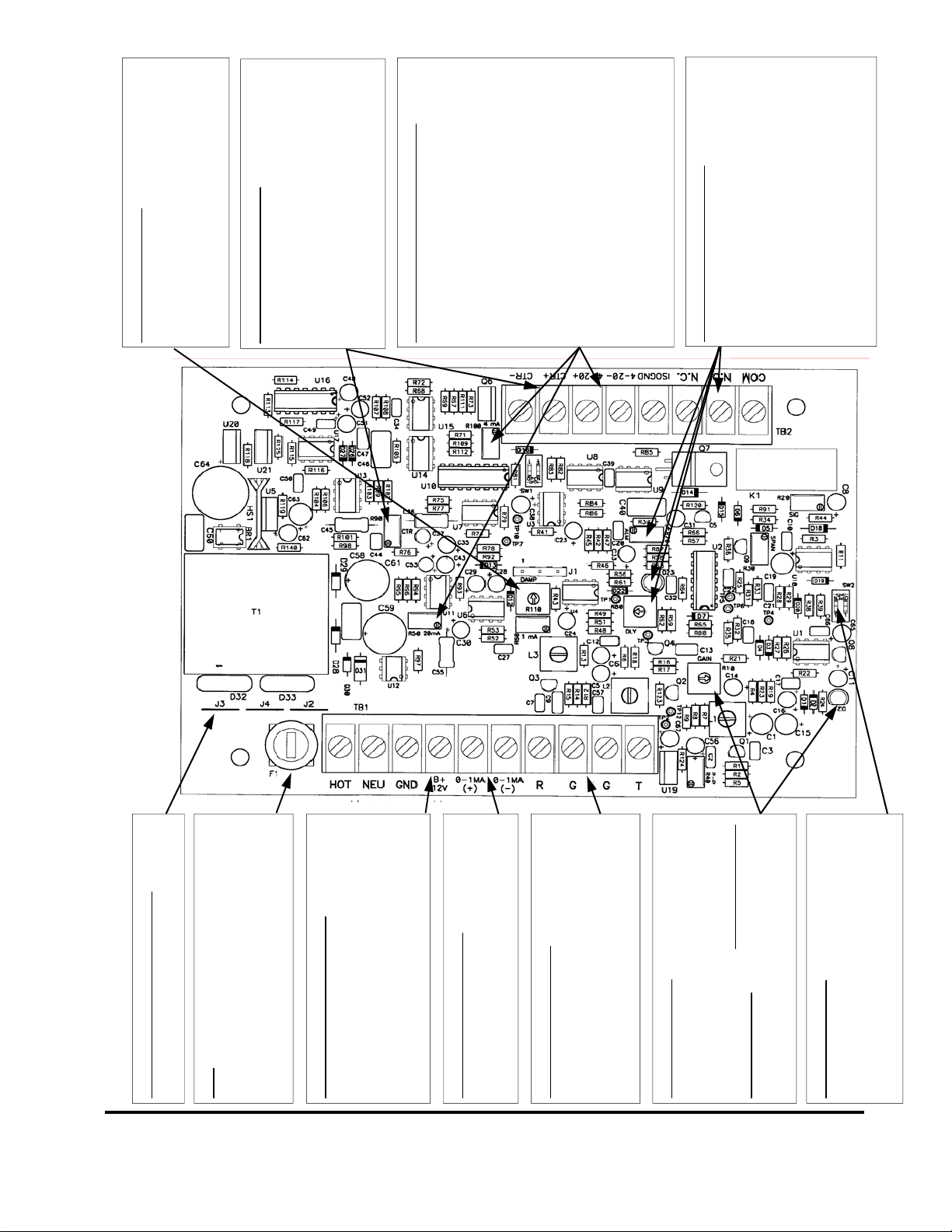

same DC supply operating the flow meter,

connect jumper wires from +B/12V to 4-

20+ and from GND to ISOGND. Connect

the 4-20mA loop load between 4-20+ and

4-20-.

etc.) internal DC power source is utilized

to power the 4-20mA loop, Connect the

ISOGND terminal to the target’s ground,

the target’s +DC output to 4-20+ terminal

and the target’s 4-20mA input to the 4-

20mA– terminal.

Flow Rate Relay Connections

The D300/D301 is equipped with a flow rate

control relay. The relay is designed to control

loads to 250 Vac and 10A. The relay activates

when the flow rate is less than the set point.

Activation is indicated by D23 [LED]. The relay

setpoint is controlled by adjusting R70 [ALM]

there is also a alarm delay feature that requires

the alarm condition to be present for a period

of time before relay activation. The delay can

R110 [DAMP] Control

Adjust R110 [DAMP] to stabilize flow rate

and output readings. Adjust CCW to in-

crease the response of the instrument; adjust

CW to decrease response time (smooth the

display readings and outputs).

CTR Output Connections

The CTR output is designed to operate both

electronic and electromechanical totalizers.

The output can drive loads as low as 90

ohms. Control R90 [CTR] adjusts the span

of this output. Switch set SW1 controls the

CTR output by factors of X10. See details in

Isolated 4-20mA Output Connections

There are two methods to connect this output:

the manual describing CTR adjustment.

• To operate the 4-20mA loop from the

• If the target’s (chart recorder, datalogger,

Control R100 [4mA] is used to adjust 4mA

offset and R50 [20mA] to adjust 20mA span.

be increased by adjusting R80 [DELAY] CW.

Figure 2.3 D7700 Operated with 12-24 Vdc Power Supply 02/02/2000

Power Supply Jumper Placement

12-24 Vdc Does not matter

The fuse provides protection for AC powered

units only. DC power sources should be

connected with a 0.25A current limiter [fuse]

Fuse

in the positive supply line.

12-24 Vdc Power Connections

Connect a DC power source capable of sourc-

ing 0.2A to the terminals marked +B/12V and

GND. The DC power source will operate all

functions of the D300/D301 except the iso-

lated 4-20mA output. See the box describing

Isolated 4-20mA Output for connection details.

This output is designed to drive loads up to

0-1 mA Output Connection

1500 ohms. Use R60 [1mA] control to adjust

span.

Transducer Connections

Connect the four wires from the two coaxial

cables to the respective terminals. Wire

markers on the coaxial cables identify the “R”

and the “T” pair. Do not run these cables

adjacent to AC power cables.

R10 [GAIN] Control

After all electrical and transducer connections

have been made, the GAIN control is set to

CCW [counter clockwise]. Adjust CW until

of a flowing liquid. Start with the control fully

match liquid and pipe parameters. To prop-

erly set the R10 [GAIN], the pipe must be full

Rev. 2/00 -3.5- 77X

For measuring fluid velocities up to 20 FPS [6

MPS] set the two switches at SW2 to OPEN.

If continuous flow rate will not exceed 2 FPS

D21 [the LED] just begins to flash steadily.

LOW Velocity Filter

[0.6 MPS] turn the two switches ON.

Page 24

PART 4 - CONFIGURATION AND OPERATION

Power Up and GAIN

Adjustment

After power has been applied to the flowmeter and if

the pipe is full of a flowing liquid, the LED located on

the bottom of the main circuit card [D21] should begin

flashing. If the LED does not flash, gradually turn the

GAIN control [R10] clockwise until the LED just

begins to flash steadily. (Do not over adjust this

setting as ambient noise can influence readings.)

If possible, turn off the flow to the pipe. Verify that the

LED [D21] ceases to flash. If the LED continues to

flash when flow rate is zero, the GAIN control [R10] is

set too far clockwise and ambient noise is influencing

the readings. Turn the control counter-clockwise until

the flashing ceases. The indicated flow will take

several seconds to achieve the desired reading

because of the built-in electronic damping circuits.

The flow rate meter is factory calibrated to the pipe

size and flow range indicated on the label located on

the inside front cover of the flow meter.

Totalizer - Series D7701 only

Each digit will be in a volumetric unit x 10, x 100, x

1000 or x10,000 as set by SW 1. The totalizer

multiplier that was set at the factory will be indicated

on the label adjacent to the totalizer display. By

changing this switch setting, the totalizer label,

located by the totalizer indicator on the front cover of

the flow meter, will need to be adjusted accordingly.

SW 1—Totalizer Multiplier

SW1-1 SW1-2 MULTIPLIER

OFF OFF X 10

ON OFF X 100

OFF ON X 1000

ON ON X 10000

Rev. 2/00 -4.1- 77X

Page 25

PART 4 - CONFIGURATION AND OPERATION

FIELD CALIBRATION PROCEDURES

After the Equipment is properly installed and

operating, there may be a need to field calibrate the

flowmeter. This could be caused by a number of

reasons:

1. Using a size pipe other than the one specified

when factory configured.

2. When used to measure a liquid with a sound

speed that is different than the one specified when

factory configured.

3. When proper lengths of straight pipe are not

available.

4. Percent of solids are greater than 2%.

5. Operating off turbulence or non-linear suspended

solids.

Field Calibration

Procedure

Field Calibration is as follows:

A. To calibrate the flow rate indicators (meter)

against a known flow:

1. With an established flow, the digital readout and/

or current outputs on D7700 can be adjusted in

accordance with a verified flow measurement, by

adjusting pot R30 (SPAN) adjustment. Turning

the pot C.C.W. decreases the reading. This is a

20 turn, stop-less potentiometer. (Note: Pot R60

will adjust the 0-1 mA output only).

2. It is desired to adjust 4-20 mA to other than

factory calibration, pot R50 can be used to adjust

the 20 mA span.

3. Adjust damping pot R110 for desired flow

response. CW rotation increases flow damping.

The total flow damping range can be varied from

about 5 seconds to 50 seconds. This setting is

usually used to smooth out chart recorder

readings.

Rev. 2/00 -4.2- 77X

Page 26

PART 4 - CONFIGURATION AND OPERATION

B. Totalizer Calibration — Series D7701

1. If an oscilloscope or signal counter is available, a

signal from test point TP10 will show the totalizer

count rate at a particular flow. Refer to the drawing in

the Appendix titled 091-1048-102 Series 300

Waveforms. The pulse rate at TP10 can be x 10, x

100, x 1000 or x10,000 of totalizer count rate, at the

CTR output on terminal strip. For example, if the

pulse rate is 200 milliseconds (multiplier switch SW 1

programmed for 100), then the counter rate at CTR

terminals will be scaled to provide a count every 20

seconds. The total counter output (CTR) range can

be adjusted from approximately 0.5 to 5 seconds with

a full scale flow indication.

Totalizer Adjustment:

(CTR CAL) - (pot R90 and DIP SW 1). The multiplier

DIP switch SW 1 may be programmed as follows:

SW 1 Position

SW1-1 SW1-2 MULTIPLIER

OFF OFF X 10

ON OFF X 100

OFF ON X 1000

ON ON X 10000

If an oscilloscope or signal counter is not available,

then use the following procedure. The Pot R90 has a

range of 0.5 to 5 seconds. SW1 is then used to

increase this rate all the way up to 50 minutes.

2. Stopwatch Procedure - with a known flow rate

established on the flow meter digital display, time the

count rate on the totalizer by a stopwatch, measuring

the time between totalizer counts. If the totalizer is

reading lower than desired, turn CTR, CAL pot R90

Rev. 2/00 -4.3- 77X

Page 27

PART 4 - CONFIGURATION AND OPERATION

C.W. Time the new rate and adjust as required. For

example, if the flow indicator reads 1,000 GPM and a

totalizer count rate of 1 count every 60 seconds

should be displayed. If the actual count rate is one

count every 50 seconds, then turn the adjustment

R90 slightly (with SW 1 Position x 1,000) C.C.W. to

decrease the count rate until there is one count on

the totalizer every 60 seconds when the flow rate

indicator is reading 1,000 GPM. As noted above, 20

full turns on R90 will produce a variation in count rate

of at least x 10, or from approximately 50 to 500

seconds when the indicator is reading full scale. To

determine count rate:

60 (TM)

Count rate = ---------------- GPM

Where,

TM = totalizer multiplier or gallons x totalizer counts

GPM = flow at time of calibration

Electronic Calibration

The flowmeter is electronically calibrated at the

factory by calculating the fluid velocity in Feet per

Second (FPS) that corresponds to the pipe size and

volumetric flow rate that was customer supplied at the

time of the order. The following equations were used

to determine the “calibration frequency” that is

required to properly span the flow meter.

FPS = GPM

(PIPE I.D.)2 X 2.45

Where

PIPE I.D. is inches

A DP7 transducer generates 120 Hz / 1 FPS of

frequency shift when operated on room temperature

water. Alternate fluids can influence this factor. See

Rev. 2/00 -4.4- 77X

Page 28

PART 4 - CONFIGURATION AND OPERATION

the Fluid Sound Speed Compensation chart located

in the Appendix of this manual.

Once a new calibration frequency has been

determined, the frequency is input as a 1 Vpp sinewave into TP3 on the main circuit card. This input will

simulate full scale flow in the circuit. With the function

generator inputting the calibration frequency the

SPAN, 1mA, 20mA and CTR inputs can be

configured. A 10% and 50% of SPAN frequency can

be input and flow meter linearity can be verified.

Noise and Gain Adjust

If meter indicates a reading with no flow, turn R10

(GAIN) C.C.W. just enough to eliminate. Since this

reduces sensitivity, do not turn past point of proper

operation. If indicator will not read flow, turn R10

(GAIN) C.W.

Relay Adjustment

1. Turn R80 (DLY) fully CCW for minimum delay (2

sec.) before proceeding with alarm trip

adjustments.

2. For a point of reference, turn R70 (ALM) also fully

CCW.

3. At the desired flow dropout (which can be

simulated by the procedure covered in the

Electronic Calibration Procedure on Page 4.4),

slowly (due to time delay) adjust alarm R70 (ALM)

CW until relay is deactivated. Do not overturn.

NOTE: About 10% flow hysteresis is built-in into

the flow switch system at 1 FPS.

4. After a desired alarm trip point is established,

adjust R80 (DLY) CW for a desired time delay (20

sec. Max. On flow dropouts).

Rev. 2/00 -4.5- 77X

Page 29

PART 4 - CONFIGURATION AND OPERATION

HOW TO CALIBRATE FOR A DIFFERENT SCALE

& PIPE

This procedure is an outline of how to re-scale the

series D7700 flow meter.

1. The first step is to determine the full scale velocity

setting. To determine this you would need the full

scale setting (i.e. GPM, MGD etc) and the pipe inside

diameter (refer to the charts in the Appendix).

Example calculation: Full scale 500 GPM. Pipe size:

4.026 inches I.D.

Feet per Second = 500 GPM

(4.026)2 x 2.45

2. Multiply the Full Scale in FPS by 120 Hertz.

12.755 * 120 = 1530 Hertz.

3. As described in the Electronic Calibration section

on page 4.4 of this operations manual, input a 1Vpp

sine-wave at 1530 Hz into TP3 to simulate full scale

flow.

4. Adjust R30 (SPAN) for 5.0 VDC at TP7. On A

D301 meter adjust the digital indicator located on the

door of the instrument. The adjustments for the

scaling on the digital indicator are also labeled SPAN.

The fine adjustment on the digital indicator is labeled

CAL. Use both of these adjustments to correctly set

the indicator.

5. On a D301 equipped with a totalizer the new count

rate would be determined by the following example:

60/500 = 0.12 sec per count. In this example it has

been determined that 1 count at .12 sec per count is

equal to 1 gallon. Since 0.12 seconds is too fast for

the electronic circuit design (i.e. 0.5 sec minimum

setting), the decimal place is moved over one and

= 12.755 FPS

Rev. 2/00 -4.6- 77X

Page 30

PART 4 - CONFIGURATION AND OPERATION

the new count rate is 1.2 seconds per count at 10

gallons per count.

A digital counter is placed on the output of the circuit

card to measure the period between pulses so that at

a full scale of 500 GPM the CTR adjustment is set to

correspond to a 1.2 second period interval. The SW1

switch is only used if the customer wishes to set the

gallons per count rate higher (i.e. x 10, x 100, x

1000).

Rev. 2/00 -4.7- 77X

Page 31

A P P E N D I X

Page 32

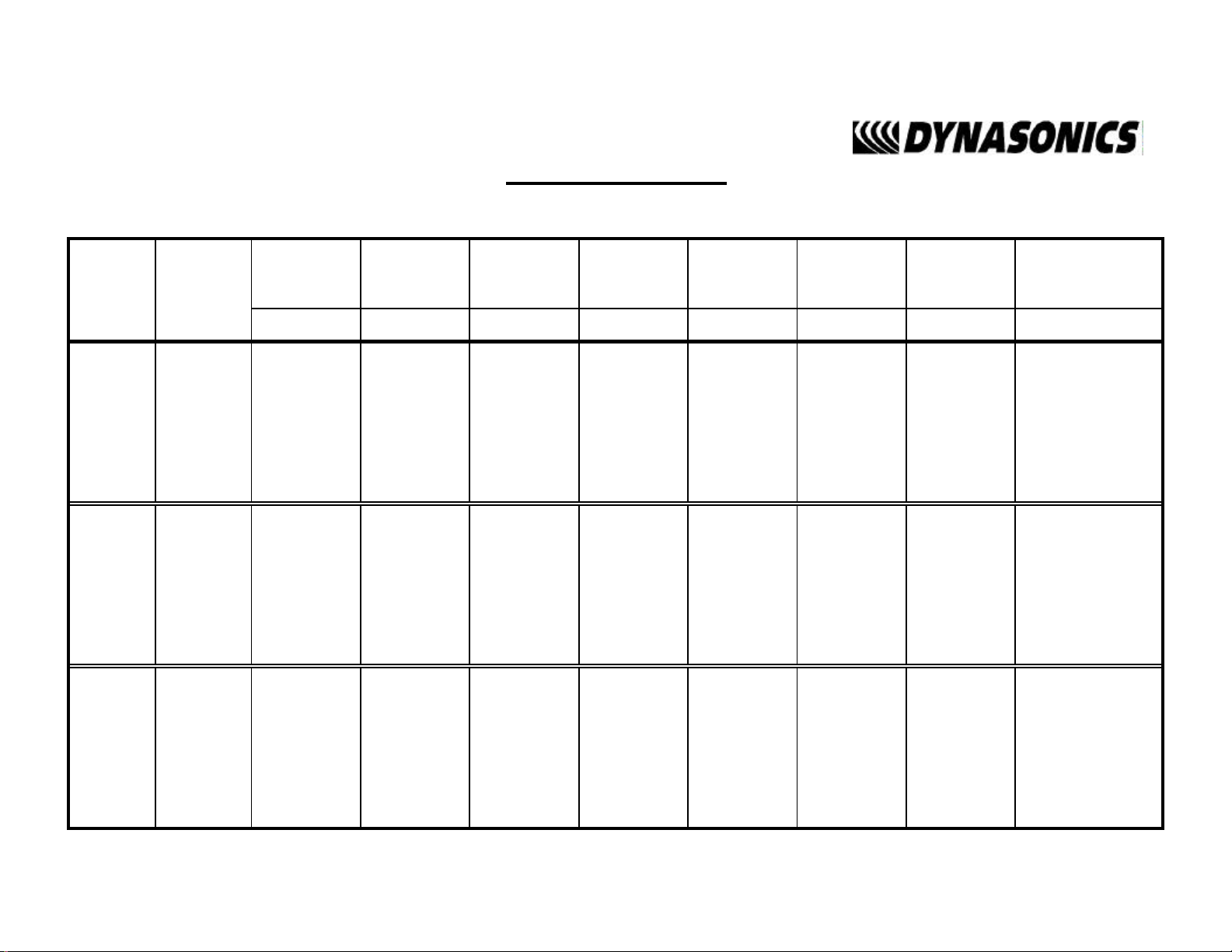

Fluid Sound Speeds

g

Original Date: 10/19/99

Revision: none

Revision Date: none

File: I:/dynasonics/dyna_code/tables/doppler ss conversions.xls

120.0176921

Doppler

Fluid Specific Gravity Sound Speed Calibration Entry

20 de

Acetate, Butyl (n) 1270 4163.9 85

Acetate, Ethyl 0.901 1085 3559.7 72

Acetate, Methyl 0.934 1211 3973.1 81

Acetate, Propyl 1280 4196.7 85

Acetone 0.79 1174 3851.7 78

Alcohol 0.79 1207 3960.0 81

Alcohol, Butyl (n) 0.83 1270 4163.9 85

Alcohol, Ethyl 0.83 1180 3868.9 79

Alcohol, Methyl 0.791 1120 3672.1 75

Alcohol, Propyl (I) 1170 3836.1 78

Alcohol, Propyl (n) 0.78 1222 4009.2 82

Ammonia (35) 0.77 1729 5672.6 115

Anlline (41) 1.02 1639 5377.3 109

Benzene (29,40,41) 0.88 1306 4284.8 87

Benzol, Ethyl 0.867 1338 4389.8 89

Bromine (21) 2.93 889 2916.7 59

n-Butane (2) 0.60 1085 3559.7 72

Butyrate, Ethyl 1170 3836.1 78

Carbon dioxide (26) 1.10 839 2752.6 56

Carbon tetrachloride 1.60 926 3038.1 62

Chloro-benezene 1.11 1273 4176.5 85

Chloroform (47) 1.49 979 3211.9 65

Diethyl ether 0.71 985 3231.6 66

Diethyl Ketone 1310 4295.1 87

Diethylene glycol 1.12 1586 5203.4 106

Ethanol 0.79 1207 3960.0 81

Ethyl alcohol 0.79 1207 3960.0 81

Ether 0.71 985 3231.6 66

Ethyl ether 0.71 985 3231.6 66

Ethylene glycol 1.11 1658 5439.6 111

Freon R12 774.2 2540 52

Gasoline 0.7 1250 4098.4 83

Glycerin 1.26 1904 6246.7 127

Glycol 1.11 1658 5439.6 111

Isobutanol 0.81 1212 3976.4 81

Iso-Butane 1219.8 4002 81

Isopentane (36) 0.62 980 3215.2 65

Isopropanol (46) 0.79 1170 3838.6 78

Isopropyl alcohol (46) 0.79 1170 3838.6 78

Kerosene 0.81 1324 4343.8 88

Linalool 1400 4590.2 93

rees C m/s ft/s relative to 25C water

Page 33

Linseed Oil .925-.939 1770 5803.3 118

(

)

Methanol (40,41) 0.79 1076 3530.2 72

Methyl alcohol (40,44) 0.79 1076 3530.2 72

Methylene chloride (3) 1.33 1070 3510.5 71

Methylethyl Ketone 1210 3967.2 81

Motor Oil (SAE 20/30) .88-.935 1487 4875.4 99

Octane (23) 0.70 1172 3845.1 78

Oil, Castor 0.97 1477 4845.8 99

Oil, Diesel 0.80 1250 4101 83

Oil (Lubricating X200) 1530 5019.9 102

Oil (Olive) 0.91 1431 4694.9 96

Oil (Peanut) 0.94 1458 4783.5 97

Paraffin Oil 1420 4655.7 95

Pentane 0.626 1020 3346.5 68

Petroleum 0.876 1290 4229.5 86

1-Propanol (46) 0.78 1222 4009.2 82

Refrigerant 11 (3,4) 1.49 828.3 2717.5 55

Refrigerant 12 (3) 1.52 774.1 2539.7 52

Refrigerant 14 (14) 1.75 875.24 2871.5 58

Refrigerant 21 (3) 1.43 891 2923.2 59

Refrigerant 22 (3) 1.49 893.9 2932.7 60

Refrigerant 113 (3) 1.56 783.7 2571.2 52

Refrigerant 114 (3) 1.46 665.3 2182.7 44

Refrigerant 115 (3) 656.4 2153.5 44

Refrigerant C318 (3) 1.62 574 1883.2 38

Silicone (30 cp) 0.99 990 3248 66

Toluene (16,52) 0.87 1328 4357 89

Transformer Oil 1390 4557.4 93

Trichlorethylene 1050 3442.6 70

1,1,1-Trichloro-ethane 1.33 985 3231.6 66

Turpentine 0.88 1255 4117.5 84

Water, distilled

Water 0 degrees C 1402 4596.7 94

Water 20 degrees C 1482 4859.0 99

Water 40 degrees C 1529 5013.1 102

Water 60 degrees C 1551 5085.2 103

Water 80 degrees C 1554 5095.1 104

Water 100 degrees C 1543 5059.0 103

Water 120 degrees C 1519 4980.3 101

Water 140 degrees C 1485 4868.9 99

Water 160 degrees C 1440 4721.3 96

Water 180 degrees C 1390 4557.4 93

Water 200 degrees C 1333 4370.5 89

Water, heavy 1 1400 4593 93

Water, sea 1.025 1531 5023 102

Wood Alcohol (40,41) 0.791 1076 3530.2 72

m-Xylene (46) 0.868 1343 4406.2 90

o-Xylene (29,46) 0.897 1331.5 4368.4 89

p-Xylene (46) 1334 4376.8 89

49,50

0.996 1498 4914.7 100

Page 34

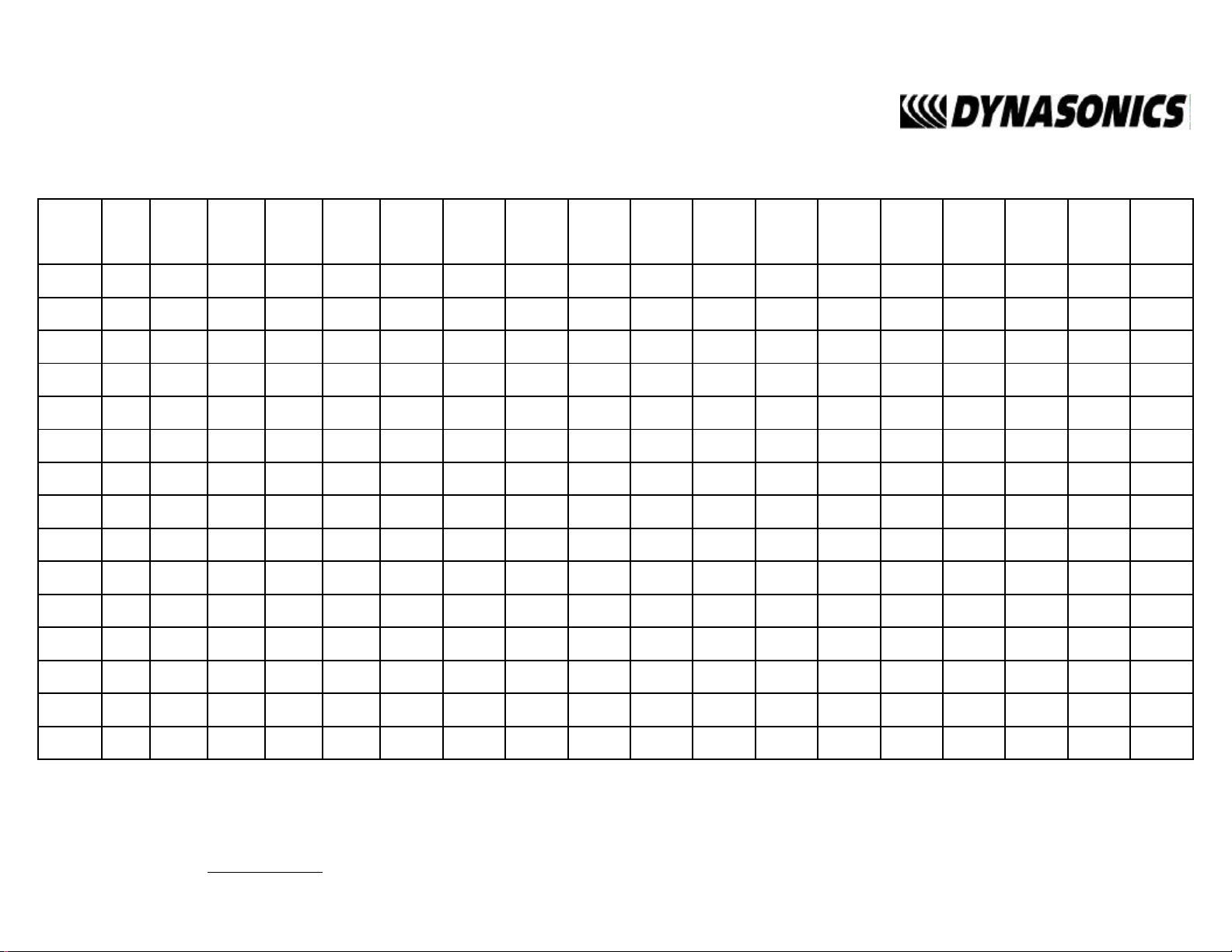

Cement Lining

Ductile Iron Pipe

Standard Classes

Pipe

Size

(inches)

3 3.96 3.46 0.25 3.40 0.28 3.34 0.31 3.28 0.34 3.22 0.37 3.14 0.41

4 4.80 4.28 0.26 4.22 0.29 4.16 0.32 4.10 0.35 4.04 0.38 3.93 0.44

6 6.90 6.40 0.25 6.34 0.28 6.28 0.31 6.22 0.34 6.16 0.37 6.10 0.40 6.04 0.43 .123/.250

8 9.05 8.51 0.27 8.45 0.30 8.39 0.33 8.33 0.36 8.27 0.39 8.21 0.42 8.15 0.45

10 11.10 10.32 0.39 10.46 0.32 10.40 0.35 10.34 0.38 10.28 0.41 10.22 0.44 10.16 0.47

12 13.20 12.58 0.31 12.52 0.34 12.46 0.37 12.40 0.40 12.34 0.43 12.28 0.46 12.22 0.49

14 15.30 14.64 0.33 14.58 0.36 14.52 0.39 14.46 0.42 14.40 0.45 14.34 0.48 14.28 0.51

16 17.40 16.72 0.34 16.66 0.37 16.60 0.40 16.54 0.43 16.48 0.46 16.42 0.49 16.36 0.52

18 19.50 18.80 0.35 18.74 0.38 18.68 0.41 18.62 0.44 18.56 0.47 18.50 0.50 18.44 0.53 .1875/.375

20 21.60 20.88 0.36 20.82 0.39 20.76 0.42 20.70 0.45 20.64 0.48 20.58 0.51 20.52 0.54

24 25.80 25.04 0.38 24.98 0.41 24.92 0.44 24.86 0.47 24.80 0.50 24.74 0.53 24.68 0.56

30 32.00 31.22 0.39 31.14 0.43 31.06 0.47 30.98 0.51 30.90 0.55 30.82 0.59 30.74 0.63

Outside

Diameter

(inches)

Class 53

ID Wall ID Wall ID Wall ID Wall ID Wall ID Wall ID Wall

Class 54 Class 55 Class 56Class 50 Class 51 Class 52

Std./Double

Thickness

36 38.30 37.44 0.43 37.34 0.48 37.06 0.62 37.14 0.58 37.40 0.45 36.94 0.68 36.84 0.73

42 44.50 43.56 0.47 43.44 0.53 43.32 0.59 43.20 0.65 43.08 0.71 42.96 0.77 42.84 0.83 .250/.500

48 50.80 49.78 0.51 49.64 0.58 49.50 0.65 49.36 0.72 49.22 0.79 49.08 0.86 48.94 0.93

54 57.10 55.96 0.57 55.80 0.65 55.64 0.73 55.48 0.81 55.32 0.89 55.16 0.97 55.00 1.05

March, 2000

Page 35

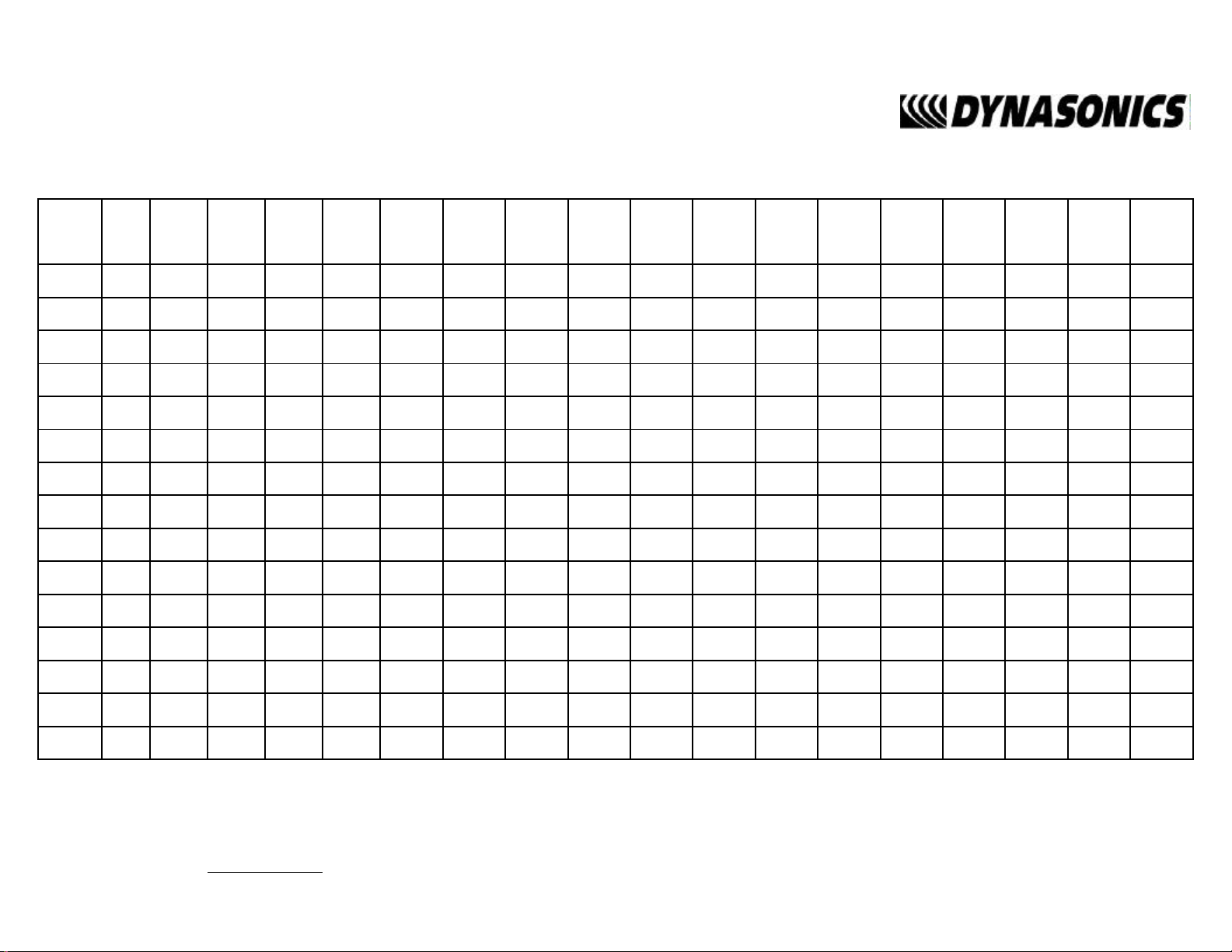

Cast Iron Pipe

Standard Classes

CLASS B CLASS C CLASS D CLASS E CLASS F CLASS G CLASS HCLASS A

Size

(Inches)

10 11.10 10.10 0.50 11.10 9.96 0.57 11.40 10.16 0.62 11.40 10.04 0.68 11.60 10.12 0.74 11.60 10.00 0.80 11.84 10.12 0.86 11.84 10.00 0.92

12 13.20 12.12 0.54 13.20 11.96 0.62 13.50 12.14 0.68 13.50 12.00 0.75 13.78 12.14 0.82 13.78 12.00 0.89 14.08 12.14 0.97 14.08 12.00 1.04

14 15.30 14.16 0.57 15.30 13.98 0.66 15.65 14.17 0.74 15.65 14.01 0.82 15.98 14.18 0.90 15.98 14.00 0.99 16.32 14.18 1.07 16.32 14.00 1.16

16 17.40 16.20 0.60 17.40 16.00 0.70 17.80 16.20 0.80 17.80 16.02 0.89 18.16 16.20 0.98 18.16 16.00 1.08 18.54 16.18 1.18 18.54 16.00 1.27

18 19.50 18.22 0.64 19.50 18.00 0.75 19.92 18.18 0.87 19.92 18.00 0.96 20.34 18.20 1.07 20.34 18.00 1.17 20.78 18.22 1.28 20.78 18.00 1.39

20 21.60 20.26 0.67 21.60 20.00 0.80 22.06 20.22 0.92 22.06 20.00 1.03 22.54 20.24 1.15 22.54 20.00 1.27 23.02 20.24 1.39 23.02 20.00 1.51

24 25.80 24.28 0.76 25.80 24.02 0.89 26.32 24.22 1.05 26.32 24.00 1.16 26.90 24.28 1.31 26.90 24.00 1.45 27.76 24.26 1.75 27.76 24.00 1.88

30 31.74 29.98 0.88 32.00 29.94 1.03 32.40 30.00 1.20 32.74 30.00 1.37 33.10 30.00 1.55 33.46 30.00 1.73

36 37.96 35.98 0.99 38.30 36.00 1.15 38.70 35.98 1.36 39.16 36.00 1.58 39.60 36.00 1.80 40.04 36.00 2.02

42 44.20 42.00 1.10 44.50 41.94 1.28 45.10 42.02 1.54 45.58 42.02 1.78

48 50.50 47.98 1.26 50.80 47.96 1.42 51.40 47.98 1.71 51.98 48.00 1.99

O.D.

Inch

3 3.80 3.02 0.39 3.96 3.12 0.42 3.96 3.06 0.45 3.96 3.00 0.48

4 4.80 3.96 0.42 5.00 4.10 0.45 5.00 4.04 0.48 5.00 3.96 0.52

6 6.90 6.02 0.44 7.10 6.14 0.48 7.10 6.08 0.51 7.10 6.00 0.55 7.22 6.06 0.58 7.22 6.00 0.61 7.38 6.08 0.65 7.38 6.00 0.69

8 9.05 8.13 0.46 9.05 8.03 0.51 9.30 8.18 0.56 9.30 8.10 0.60 9.42 8.10 0.66 9.42 8.10 0.66 9.60 8.10 0.75 9.60 8.00 0.8

I.D.

Inch

Wall

O.D.

Inch

I.D.

Inch

Wall

O.D.

Inch

I.D.

Inch

Wall

O.D.

Inch

I.D.

Inch

Wall

O.D.

Inch

I.D.

Inch

Wall

O.D.

Inch

I.D.

Inch

Wall

O.D.

Inch

I.D.

Inch

Wall

O.D.

Inch

I.D.

Inch

Wall

54 56.66 53.96 1.35 57.10 54.00 1.55 57.80 54.00 1.90 58.40 53.94 2.23

60 62.80 60.02 1.39 63.40 60.06 1.67 64.20 60.20 2.00 64.82 60.06 2.38

72 75.34 72.10 1.62 76.00 72.10 1.95 76.88 72.10 2.39

84 87.54 84.10 1.72 88.54 84.10 2.22

March, 2000

Page 36

Steel, Stainless Steel, P.V.C.

Standard Schedules

Nominal

Pipe Size

Inches

OUTSIDE

DIAMETER

1 1.315 1.185 0.065 1.097 0.109 1.049 1.049 0.133 0.957 0.179 0.957 0.179 0.815 0.250

1.25 1.660 1.530 0.065 1.442 0.109 1.380 1.380 0.140 1.278 0.191 1.278 0.191 1.160 0.250

1.5 1.900 1.770 0.065 1.682 0.109 1.610 1.610 0.145 1.500 0.200 1.500 0.200 1.338 0.281

2 2.375 2.245 0.065 2.157 0.109 2.067 2.067 0.154 1.939 0.218 1.939 0.218 1.687 0.344

2.5 2.875 2.709 0.083 2.635 0.120 2.469 2.469 0.203 2.323 0.276 2.323 0.276 2.125 0.375

3 3.500 3.334 0.083 3.260 0.120 3.068 3.068 0.216 2.900 0.300 2.900 0.300 2.624 0.438

3.5 4.000 3.834 0.083 3.760 0.120 3.548 3.548 0.226 3.364 0.318 3.364 0.318

4 4.500 4.334 0.083 4.260 0.120 4.026 0.237 4.026 0.237 3.826 0.337 3.826 0.337 3.624 0.438 3.624 0.438 3.438 0.531

5 5.563 5.345 0.109 5.295 0.134 5.047 0.258 5.047 0.258 4.813 0.375 4.813 0.375 4.563 0.500 4.563 0.500 4.313 0.625

6 6.625 6.407 0.109 6.357 0.134 6.065 0.280 6.065 0.280 5.761 0.432 5.761 0.432 5.501 0.562 5.501 0.562 5.187 0.719

8 8.625 8.407 0.109 8.329 0.148 8.125 0.250 8.071 0.277 7.981 0.322 7.981 0.322 7.813 0.406 7.625 0.500 7.625 0.500 7.437 0.594 7.187 0.719 7.187 0.719 6.183 1.221

10 10.750 10.482 0.134 10.42 0.165 10.25 0.250 10.13 0.310 10.02 0.365 10.020 0.365 9.750 0.500 9.750 0.500 9.562 0.594 9.312 0.719 9.062 0.844 9.062 0.844 8.500 1.125

12 12.750 12.420 0.165 12.39 0.180 12.25 0.250 12.09 0.330 12.00 0.375 11.938 0.406 11.626 0.562 11.750 0.500 11.370 0.690 11.060 0.845 10.750 1.000 10.750 1.000 10.120 1.315

14 14.000 13.50 0.250 13.37 0.315 13.25 0.375 13.25 0.375 13.124 0.438 12.814 0.593 13.000 0.500 12.500 0.750 12.310 0.845 11.810 1.095 11.810 1.095 11.180 1.410

16 16.000 15.50 0.250 15.37 0.315 15.25 0.375 15.25 0.375 15.000 0.500 14.688 0.656 15.000 0.500 14.310 0.845 13.930 1.035 13.560 1.220 13.560 1.220 12.810 1.595

18 18.000 17.50 0.250 17.37 0.315 17.12 0.440 17.25 0.375 16.876 0.562 16.564 0.718 17.000 0.500 16.120 0.940 15.680 1.160 15.250 1.375 15.250 1.375 14.430 1.785

20 20.000 19.50 0.250 19.25 0.375 19.25 0.375 19.25 0.375 18.814 0.593 18.376 0.812 19.000 0.500 17.930 1.035 17.430 1.285 17.000 1.500 17.000 1.500 16.060 1.970

24 24.000 23.50 0.250 23.25 0.375 23.25 0.375 23.25 0.375 22.626 0.687 22.126 0.937 23.000 0.500 21.560 1.220 20.930 1.535 20.930 1.535 20.930 1.535 19.310 2.345

30 30.000 29.37 0.315 29.00 0.500 29.00 0.500 29.25 0.375 29.250 0.375 29.000 0.500

36 36.000 35.37 0.315 35.00 0.500 35.00 0.500 35.25 0.375 35.250 0.375 35.000 0.500

42 42.000 41.25 0.375 41.250 0.375 41.000 0.500

48 48.000 47.25 0.375 47.250 0.375 47.000 0.500

SCH.

5

ID Wall ID Wall ID Wall ID Wall ID Wall ID Wall ID Wall ID Wall ID Wall ID Wall ID Wall ID Wall ID Wall

SCH. 10

(LTWALL)

SCH. 20 SCH. 30 STD. SCH. 40 SCH. 60 SCH. 140 SCH. 180

X STG. SCH. 80 SCH. 100 SCH. 120

March, 2000

Page 37

FPS TO GPM CROSS - REFERENCE (Schedule 40)

Nominal

Pipe

(Inches)

1 1.05 2.6989 4.0484 5.3978 6.7473 8.097 9.4462 10.796 12.145 13.490 14.844 16.190 17.540 18.890 20.240 21.590 22.941 24.290

1.25 1.38 4.6620 6.9929 9.3239 11.655 13.99 16.317 18.648 20.979 23.310 25.641 27.970 30.300 32.630 34.960 37.300 39.627 41.958

1.5 1.61 6.3454 9.5182 12.691 15.864 19.04 22.209 25.382 28.555 31.730 34.900 38.070 41.250 44.420 47.590 50.760 53.936 57.109

2 2.07 10.489 15.734 20.979 26.224 31.47 36.713 41.958 47.202 52.450 57.692 62.940 68.180 73.430 78.670 83.920 89.160 94.405

2.5 2.47 14.935 22.402 29.870 37.337 44.80 52.272 59.740 67.207 74.670 82.142 89.610 97.080 104.50 112.00 119.50 126.95 134.41

3 3.07 23.072 34.608 46.144 57.680 69.22 80.752 92.288 103.82 115.40 126.90 138.40 150.00 161.50 173.00 184.60 196.11 207.65

3.5 3.55 30.851 46.276 61.702 77.127 92.55 107.98 123.40 138.83 154.30 169.68 185.10 200.50 216.00 231.40 246.80 262.23 277.66

4 4.03 39.758 59.636 79.515 99.394 119.3 139.15 159.03 178.91 198.80 218.67 238.50 258.40 278.30 298.20 318.10 337.94 357.82

5 5.05 62.430 93.645 124.86 156.07 187.3 218.50 249.72 280.93 312.10 343.36 374.60 405.80 437.00 468.20 499.40 530.65 561.87

6 6.06 89.899 134.85 179.80 224.75 269.7 314.65 359.60 404.55 449.50 494.45 539.40 584.30 629.30 674.20 719.20 764.14 809.09

8 7.98 155.89 233.83 311.78 389.72 467.7 545.61 623.56 701.50 779.40 857.39 935.30 1013.0 1091.0 1169.0 1247.0 1325.1 1403.0

10 10.02 245.78 368.67 491.56 614.45 737.3 860.23 983.12 1106.0 1229.0 1351.8 1475.0 1598.0 1720.0 1843.0 1966.0 2089.1 2212.0

I.D.

INCH

1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9

12 11.94 348.99 523.49 697.99 872.49 1047.0 1221.5 1396.0 1570.5 1745.0 1919.5 2094.0 2268.0 2443.0 2617.0 2792.0 2966.5 3141.0

14 13.13 422.03 633.04 844.05 1055.1 1266.0 1477.1 1688.1 1899.1 2110.0 2321.1 2532.0 2743.0 2954.0 3165.0 3376.0 3587.2 3798.2

16 15.00 550.80 826.20 1101.6 1377.0 1652.0 1927.8 2203.2 2478.6 2754.0 3029.4 3305.0 3580.0 3856.0 4131.0 4406.0 4681.8 4957.2

FPS TO GPM: GPM = (PIPE ID)² X VELOCITY IN FPS X 2.45 FPS X .3048 = MPS

GPM TO FPS: FPS =

GPM

(ID)² X 2.45

GPM X .0007 = GPD

GPM X 3.7878 = LPM

Page 38

FPS TO GPM CROSS - REFERENCE (Schedule 40)

Nominal

Pipe

(Inches)

18 16.88 697.52 1046.3 1395.0 1743.8 2093.0 2441.3 2790.1 3138.8 3488.0 3836.3 4185.0 4534.0 4883.0 5231.0 5580.0 5928.9 6277.7

20 18.81 866.14 1299.0 1732.0 2165.3 2598.4 3031.5 3464.6 3897.6 4330.7 4763.8 5196.8 5629.9 6063.0 6496.0 6929.1 7362.2 7795.3

24 22.63 1253.7 1880.0 2507.0 3134.1 3761.0 4387.8 5014.6 5641.5 6268.3 6895.1 7522.0 8148.8 8775.6 9402.4 10029 10656 11283

26 25.25 1560.7 2341.0 3121.0 3901.9 4682.2 5462.6 6243.0 7023.4 7803.7 8584.1 9364.5 10145 10925 11706 12486 13266 14047

28 27.25 1817.8 2727.0 3636.0 4544.5 5453.4 6362.3 7271.2 8180.0 9088.9 9997.8 10907 11816 12725 13633 14542 15451 16360

30 29.25 2094.4 3142.0 4189.0 5236.0 6283.2 7330.4 8377.6 9424.9 10472 11519 12566 13614 14661 15708 16755 17803 18850

32 31.25 2390.6 3586.0 4781.0 5976.5 7171.9 8367.2 9562.5 10758 11953 13148 14344 15539 16734 17930 19125 20320 21516

34 33.25 2706.4 4060.0 5413.0 6766.0 8119.2 9472.4 10826 12179 13532 14885 16238 17592 18945 20298 21651 23004 24358

36 35.25 3041.8 4563.0 6084.0 7604.5 9125.4 10646 12167 13688 15209 16730 18251 19772 21292 22813 24334 25855 27376

42 41.25 4165.4 6248.0 8331.0 10414 12496 14579 16662 18744 20827 22910 24992 27075 29158 31241 33323 35406 37489

48 47.99 5637.8 8457.0 11276 14095 16913 19732 22551 25370 28189 31008 33827 36646 39465 42284 45103 47922 50740

54 53.98 7133.1 10700 14266 17833 21399 24966 28532 32099 35665 39232 42798 46365 49931 53498 57065 60631 64198

I.D.

INCH

1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9

60 60.09 8839.2 13259 17678 22098 26518 30937 35357 39777 44196 48616 53035 57455 61875 66294 70714 75134 79553

72 72.10 12726 19089 25451 31814 38177 44540 50903 57266 63628 69991 76354 82717 89080 95443 101805 108168 114531

84 84.10 17314 25971 34628 43285 51943 60600 69257 77914 86571 95228 103885 112542 121199 129856 138514 147171 155828

FPS TO GPM: GPM = (PIPE ID)² X VELOCITY IN FPS X 2.45 FPS X .3048 = MPS

GPM TO FPS: FPS =

GPM

(ID)² X 2.45

GPM X .0007 = GPD

GPM X 3.7878 = LPM

Page 39

GENERAL TERMS AND CONDITIONS OF SALES

1. PAYMENT – Terms of payment are effective from the actual date of invoice. If, in the Seller’s

opinion, the financial condition of the Buyer at any time – or any other circumstances – do not justify

the incurrence of production costs of shipment on the terms of payment specified, the Seller may

require partial or full payment in advance. Payment terms are net 30 days unless otherwise stated on

invoice.

2. F.O.B. – All shipments are from Racine, Wisconsin, USA, unless otherwise other stated, and title

transfers to the buyer upon leaving factory.

3. QUOTATION AND PRICES – Quoted prices are firm for 30 days unless stated in the quotati on and

are subject to change without notice after expiration of this period.

4. TAXES – Any applicable sales, use, revenue, excise or other taxes not specifically stated in the

quotation are to be remitted by the Buyer directly to the appropriate regulatory agency.

5. WARRANTY – Seller’s standard published warranty in effect at the time of shipment shall apply.

This warranty is exclusive and is in lieu of all other warranties, express, implied, or statutory, including

the warranty of merchantability.

6. DELIVERY – The Seller shall not be liable for loss or damage of any kind resulting from delay or

inability to deliver on account of flood, fire, labor trouble, riots, civil disturbances, accidents, acts or

orders or regulations of civil or military authorities, sh ortages of material, or any other causes beyond

Seller’s control.

7. PRODUCT CHANG ES – In keeping with our continuing policy of product improvement, we reserve

the right to make changes in our products at any time, without incurring an obligation to change,

replace or upgrade equipment previously shipped.

8. CANCELLATIONS – An order placed by Buyer and accepted by Seller may be cancelled only with

the Seller’s consent and upon terms that will indemnify the Seller against loss.

9. RESTOCKING CHARGE – On standard equipment, the charge is 25%, provided the equipment is

returned within 30 days in acceptable condition with a RGA number. Restocking charges for special

equipment may vary from standard equipment, and will be handled on a case-by-case basis. No

returns will be taken after one year.

Page 40

Limited Warranty and Disclaimer

Dynasonics, div. of Racine Federated Inc. warrants to the end purchaser, for a period of

one year from the date of shipment from our factory, that all new transmitters and

transducers manufactured by it are free from defects in materials and workmanship.

This warranty does not cover products that have been damaged due to normal use,

misapplication, abuse, lack of maintenance, or improper installation. Dynasonics’

obligation under this warranty is limited to the repair or replacement of a defective

product, at no charge to the end purchaser, if the product is inspected by Dynasonics

and found to be defective. Repair or replacement is at Dynasonics’ discretion. An

authorization number must be obtained from Dynasonics before any product may be

returned for warranty repair or replacement. The product must be thoroughly cleaned

and any process chemicals removed before it will be accepted for return.

The purchaser must determine the applicability of the product for its desired use and

assumes all risks in connection therewith. Dynasonics assumes no responsibility or

liability for any omissions or errors in connection with the use of its products.

Dynasonics will under no circumstances be liable for any incidental, consequential,

contingent or special damages or loss to any person or property arising out of the failure

of any product, component or accessory.

All expressed or implied warranties, including the implied warranty of

merchantability and the implied warranty of fitness for a particular purpose or

application are expressly disclaimed and shall not apply to any products sold or

services rendered by Dynasonics.

The above warranty supersedes and is in lieu of all other warranties, either expressed or

implied and all other obligations or liabilities. No agent or representative has any

authority to alter the terms of this warranty in any way.

Page 41

RETURN OF EQUIPMENT/SALES INFORMATION

CONTACTS AND PROCEDURES

Customer Service/Application Engineer:

If you have a question regarding order status, placing an order, reviewing applications for

future purchases, or wish to purchase a new flowmeter, please contact our new National

Sales and Marketing Headquarters:

DYNASONICS

Division of Racine Federated, Inc.

8635 Washington Avenue

Racine, WI 53406

PHONE: (800)535-3569 or

(262)639-6770

FAX: (262)639-2267

Service/Repair Department:

If you already purchased equipment and have an operation problem, require service, or

need to schedule field service, please contact our Service Department:

DYNASONICS

Division of Racine Federated, Inc.

8635 Washington Avenue

Racine, WI 53406

PHONE: (800)535-3569 or

(262)639-6770

FAX: (262)639-2267

Return Goods Authorization:

When returning equipment, it is necessary for you to contact our Service Department at

(800)535-3569 or (262)639-6770 to obtain an RGA number for the authority and proper

tracking of your material and its prompt inspection and return. The RGA number should

be noted on the outside of the box. All returns of equipment go to the following address:

DYNASONICS

Division of Racine Federated, Inc.

8635 Washington Avenue

Racine, WI 53406

Attn: RGA #

Page 42

8635 WASHINGTON AVENUE

RACINE, WI 53406

TOLL-FREE IN NORTH AMERICA.:

TEL: (800) 535-3569 FAX: (800) 732-8354

TEL: (262) 639-6770 FAX: (262) 639-2267

URL: www.dynasonics.com

Loading...

Loading...