Page 1

PORTABLE ENHANCED

DOPPLER FLOW METER

The Series 902 Portable Enhanced Ultrasonic

Doppler Flow Meter provides accurate and

reliable readings on closed full pipe applica

containing relatively clean liquids as well as

liquids with higher concentrations of

suspended solids or aeration. Clamp-on

non-invasive transducers permit the

instrument to be installed in minutes without

interrupting the system pressure or flow,

providing a simple and cost-effective solution

to flow verification. The Series 902 transduc

function on metal or plastic pipes size ¼” (6

mm) and above. They have a NEMA 6P

(IP-68) rating, and have the ability to work

with temperatures up to +400 °F (+200 °C).

tions

ers

Series 902

The Dynasonics Series 902 is designed for

rugged field use in its NEMA 4 watertight

enclosure. The rechargeable battery housed

inside of the 902 enclosure provides a full

eight hours of continuous operation. A

complete 902 flow meter system includes

one set of transducers, one tube of acoustic

couplant, two mounting straps, a power cord

and a 4-20 mA cable.

FEATURES

Clamp-on non-invasive transducers provide simple and

cost effective flow measurement.

NEMA 6P (IP-68) rated transducers and NEMA 4

(IP-65) enclosure.

Reliable readings on closed full pipes

size ¼" (6 mm) and above.

Rechargeable battery with eight hours of continuous

operation included.

Standard 4-20 mA output.

Ability to measure relatively clean liquids as well as

liquids containing higher concentrations of suspended

solids or aeration.

Accuracy of ±2% full scale and repeatability of ±0.4%

of full scale.

Measures fluid velocities from 0.5 to 20 FPS (0.15 to 6 MPS).

For applications such as ground water, lifting stations,

wastewater sludges, and mining recirculate.

DIVISION OF RACINE FEDERATED INC.

www.dynasonics.com800.535.3569

TM

Page 2

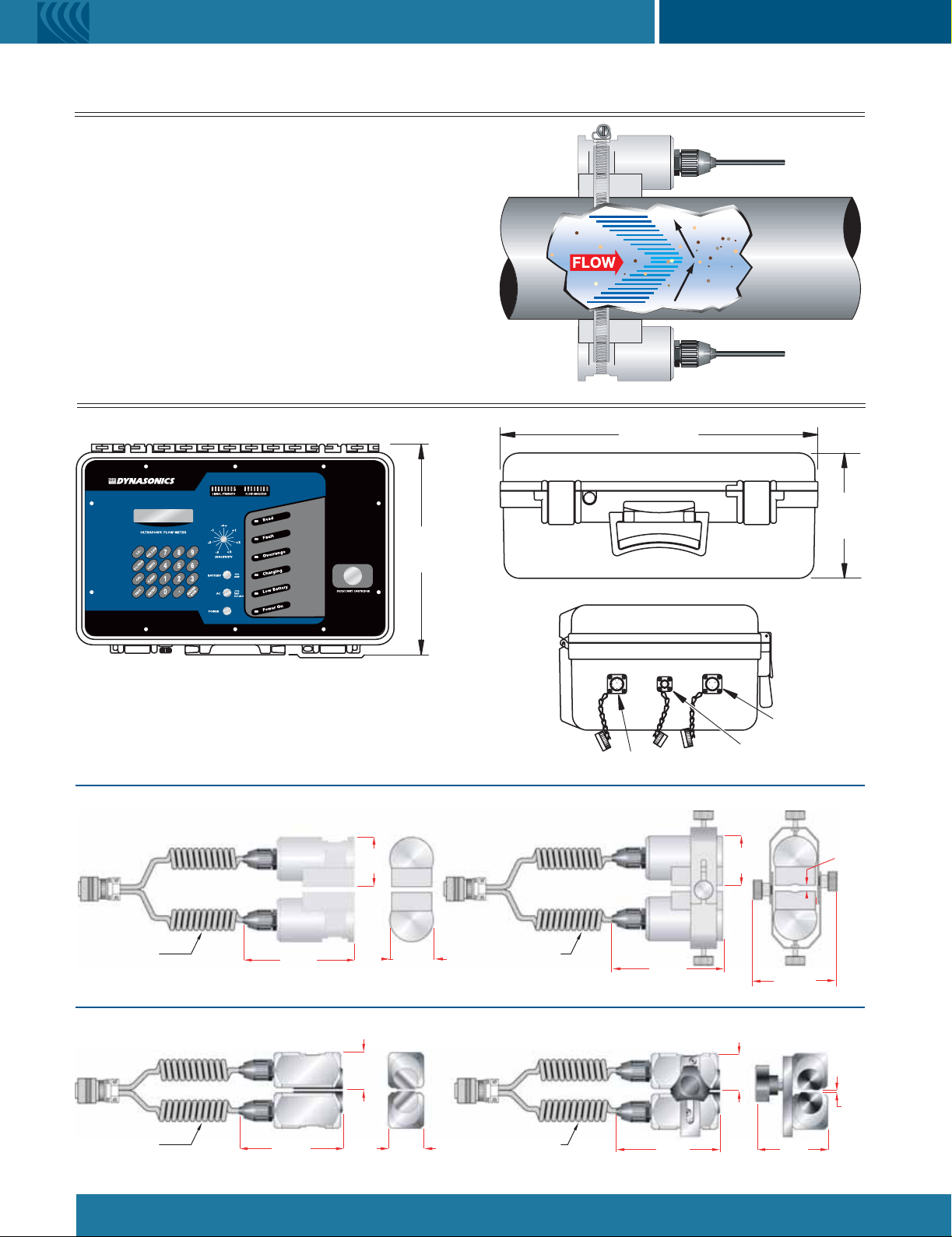

PRINCIPLE OF OPERATION / TRANSDUCER OPTIONS

Series 902 Series 902

The Series 902 flow meter operates by transmitting ultrasonic

sound from its transmitting transducer through the pipe wall

into the flowing liquid. Each transducer contains piezoelectric

crystals to transmit this signal. The sound will be reflected by

useful sonic reflectors

suspended within the liquid

recorded by the receiving transducer (see Figure 1). If the

sonic reflectors are moving within the sound transmis

and

sion path,

sound waves will be reflected at a frequency shifted (Doppler

shift) from the transmitted frequency. The difference

the reflected frequencies and transmitted frequencies is

proportional to the speed of the

sonic reflectors, resulting in a

between

directly

liquid flow rate that is converted to various user defined

measuring units.

DIMENSIONAL

S

PECIFICATIONS

MECHANICAL DIMENSIONS: INCHES (mm)

11.60

(294.64)

Figure 1

17.50

(444.50)

6.90

(175.26)

D902/D903

Two Coiled Cables

Standard Length

20 Feet (6 mm) each

D912/D913

Two Coiled Cables

Standard Length

20 Feet (6 mm) each

4.38

(111.3)

4.05

(102.9)

1.91

(48.5)

1.45

(36.8)

1.70

(43.2)

1.38

(35)

D922/D923

Two Coiled Cables

Standard Length

20 Feet (6 mm) each

D932/D933

Two Coiled Cables

Standard Length

20 Feet (6 mm) each

TRANSDUCER IN

4.38

(111.3)

4.05

(102.9)

POWER IN

4-20 mA SIGNAL IN

1.91

(48.5)

3.24

(82.3)

1.45

(36.8)

2.85

(72.4)

1.38

(35)

MAX. PIPE

DIA

1.38

(35)

MAX.

PIPE

DIA

Page 3

S

PECIFICATIONS

T

RANSMITTER

DESCRIPTION SPECIFICATION

Power Requirements Internal Lead acid Gel Cell battery provides 8 hours of continuous operation. AC charging: (Std) 115/230 VAC 50/60 Hz

±10%. (Opt) 100/200 VAC 50/60 Hz ±10%. (Opt) 12 VDC

Flow Range 0.5 to 20 FPS (0.15 to 6 MPS)

Outputs 4-20 mA, 600 Ohms max. isolated

Indicators Power, Signal Strength, Flow Analyzer, Read Fault, Overrange, Charging and Low Battery

Display 2 line × 20 character alphanumeric LCD (blacklit). Digit height 0.2 inches (5 mm), 6 digit rate, 6 digit totalizer (resettable)

Units User configured

3

Rate U.S. (Metric) FPS, GPM, MGD (MPS, LPM, M

3

Totalizer U.S. (Metric) Gallons (liters, M

Ambient Conditions -22 to +160 °F (-30 to +70 °C), 0-95% relative humidity, non-condensing.

Enclosure NEMA 4, (IP-65) ABS with SS hardware. 11W × 17L × 8D inches (279W × 432L × 203D mm)

Accuracy ±2% Full Scale

Sensitivity 0.4% of Full Scale

Repeatability ±0.4% of Full Scale

Response Time 5-50 seconds, user configured, to 90% of value, step change in flow

T

RANSDUCERS

DESCRIPTION SPECIFICATION

)

/hr)

Liquid Requirements 25 ppm of 30 micron size suspended solids or entrained gases.

Transducer Cable (Std) 20 feet (6 mm), retractable cord.

Pipe Sizes (Std) 1 inch (25 mm) and above

(Small pipe) 1/4 to 1 inch (6 to 25 mm)

Housing Material Standard Clamp-On: NEMA 6P (IP- 68) -40 °F to +210 °F (-40 °C to +100 °C) CPVC, Ultem®, Nylon,

PVC (Cable Jacket), Aluminum (small pipe)

High Temp Clamp-On: NEMA 4 (IP- 65) -40 °F to +400 °F (-40 °C to +200 °C) Vespel®, Anodized Aluminum,

Nickel-plated brass, Teflon

PART NUMBER

C

ONSTRUCTION

D9

Measuring Units/

Transducer Type*

02) US

03) Metric

12) US (High Temp)

13) Metric (High Temp)

22) US (Small Pipe)

23) Metric (Small Pipe)

32) US (High Temp &

Small Pipe)

33) Metric (High Temp &

Small Pipe)

*High Temp (+400 °F)

Small Pipe (1/4" - 1")

Power Supply

A) 115 VAC

B) 230 VAC

C) 100 VAC

D) 200 VAC

E) 12 VDC

Note: The Series D902 is shipped with one set of

standard transducers, acoustic couplant, two

mounting straps, power cord and a 4-20mA cable.

Output 1

1) 4-20mA

Totalizer

A) Six digit resettable

®

(Cable Jacket)

Output 2

N) None

NNA1

Approvals

N) None

Options

N) U.S. Power Cord

E) U.K. Power Cord

G) Euro Power Cord

SPARE PARTS AND ACCESSORIES

Description Part Number

Std Temp/Std Pipe Transducer D070-1004-001

High Temp/Std Pipe Transducer D070-1006-001

Std Temp/Small Pipe Transducer D070-1004-003

High Temp/Small Pipe Transducer D070-1004-005

Gel Cell Battery D005-1201-001

Couplant, Silicone

(for temporary mounting) D002-2011-001

U.S. Power Cord D005-2109-002

Page 4

TECHNOLOGY

S

ELECTION GUIDE

Liquid Type (in order of increasing % of suspended solids)

Ultrapure Liquids

Deionized Water

Water Filter-Bed Effluent

Hydraulic Oil

Refined Hydrocarbons

Beverages

Well Water

Reclaimed Water

Cooling Tower

Ground Water

Raw Sewage

Gray Water

Beverages - Carbonated

Waste Activated Sludge

Return Activated Sludge

Series 902

This guide provides general rules for

Transit Time

the selection of an appropriate

Dynasonics ultrasonic technology –

it is neither exhaustive nor absolute.

System factors such as

temperature, pipe materials,

suspended solid composition and

liquid velocity can influence product

selection. It is best to present

application information to a

Dynasonics Sales Representative or

to the Dynasonics factory for

evaluation.

Dynasonics offers the most

comprehensive line of ultrasonic

transit time and Doppler flow

meters in the world. These meters

are clamp-on, non-invasive flow

meters that require a good

acoustical path between the

outside of the pipe and the liquid

inside. In some instances, such as

non-saturated concrete pressure

Enhanced Doppler

pipe, ultrasonic energy will not

readily pass. For these installations,

Dynasonics offers the Series MFX

MagProbe

Please consult a Dynasonics Sales

Representative or the Dynasonics

factory to discuss the use of these

products in your flow measurement

application.

TM

.

Mining Slurries

Filter Backwash

Paper Pulp Stock

Dredging Applications

Preprocessed Crude Oil

Primary Sludge

Lime Sludge

Digested Sludge

Concrete

8635 Washington Ave.

Tel: 262.639.6770

Fax: 262.639.2267

www.dynasonics.com

Doppler

Racine, WI 53406-3738 USA

800.535.3569 North America

800.732.8354 North America

Dynasonics is a trademark of Racine Federated Inc.

Ultem is a registered trademark of General Electric Co.

Vespel and Teflon are registered trademarks of

E.I. duPont de Nemours and Company

FORM 902 6/07

Racine Flow Meter Group

Loading...

Loading...