Page 1

Series 902/903

Portable Doppler Ultrasonic Flow Meter

Operations & Maintenance

Manual

REV 10/08

Page 2

Page 3

BEFORE OPERATING THE D902/3

Important Notice!

The D902/3 flow meter is equipped with a Lead Acid Gel

Cell battery. This battery will require charging before initial

operation.

Apply AC power, utilizing the enclosed line power cord, to

the D902/3 for a period of 16-24 hours prior to using the

product for the first time. The line cord connects to the

socket connection located on the side of the enclosure.

Do not allow the battery to completely discharge.

(Discharging the battery to the point where the LOW

BATTERY indicator illuminates will not damage the

battery. Allowing the battery to stay discharged for long

periods of time can degrade the storage capacity of the

battery.) When not in use, continually charge the battery

by keeping it plugged into line power. The D902/3 has an

integral charging circuit that prevents overcharging. The

instrument can be permanently connected to AC line power

without damaging the flow meter or the battery.

Rev. 10/08 - 1 - D902/3

Page 4

TABLE OF CONTENTS

Part 1 - Introduction

Part 2 - Installation

Quick-Start Operating Instructions 4-5

Introduction

General 6

Applications 6

Model Matrix 7

Product Specifications 8

Bench Test Procedure 9

Installation

Transducer Mounting Locations 11-12

Pages

Pipe Preparation 13

Transducer Mounting 13-15

Electrical Connections 16-17

Battery Charging and Maintenance 18-19

Part 3 - Startup and

Configuration

Rev. 10/08 - 2 - D902/3

Instrument Startup and Configuration

Initial Settings 20

Modes of Operation 21

Pipe I.D. Input 22

Full Scale Input 23

Totalizer Exponent Input 24

Engineering Units Input 25

Page 5

TABLE OF CONTENTS

Part 4 - Troubleshooting

Instrument Startup and Configuration

CAL. Constant Input 25

Display Damping 26

TEST Diagnostic Key 26

System and Totalizer RESET 27

Totalizer Reset 27

FLOW ANALYZER Indicator 27

Troubleshooting Guide 28-29

Appendices 31+

Spare Parts Listing

Mechanical Drawing

Pages

Fluid Sound Speed Conversion Chart

Clean Liquid Installation Guide

Pipe Dimension Chart: Cast Iron

Pipe Dimension Chart: ST, SS, PVC

Velocity to Volumetric Conversion

Statement of Warranty

Customer Service

Rev. 10/08 - 3 - D902/3

Page 6

Location

QUICK-START OPERATING INSTRUCTIONS

This manual contains detailed operating instructions for all

aspects of the D902/3 instrument. The following condensed

instructions are provided to assist the operator in getting

the instrument started up and running as quickly as

possible. This pertains to basic operation only. If specific

instrument features are to be used or if the installer is

unfamiliar with this type of instrument, refer to the

appropriate section in the manual for complete details.

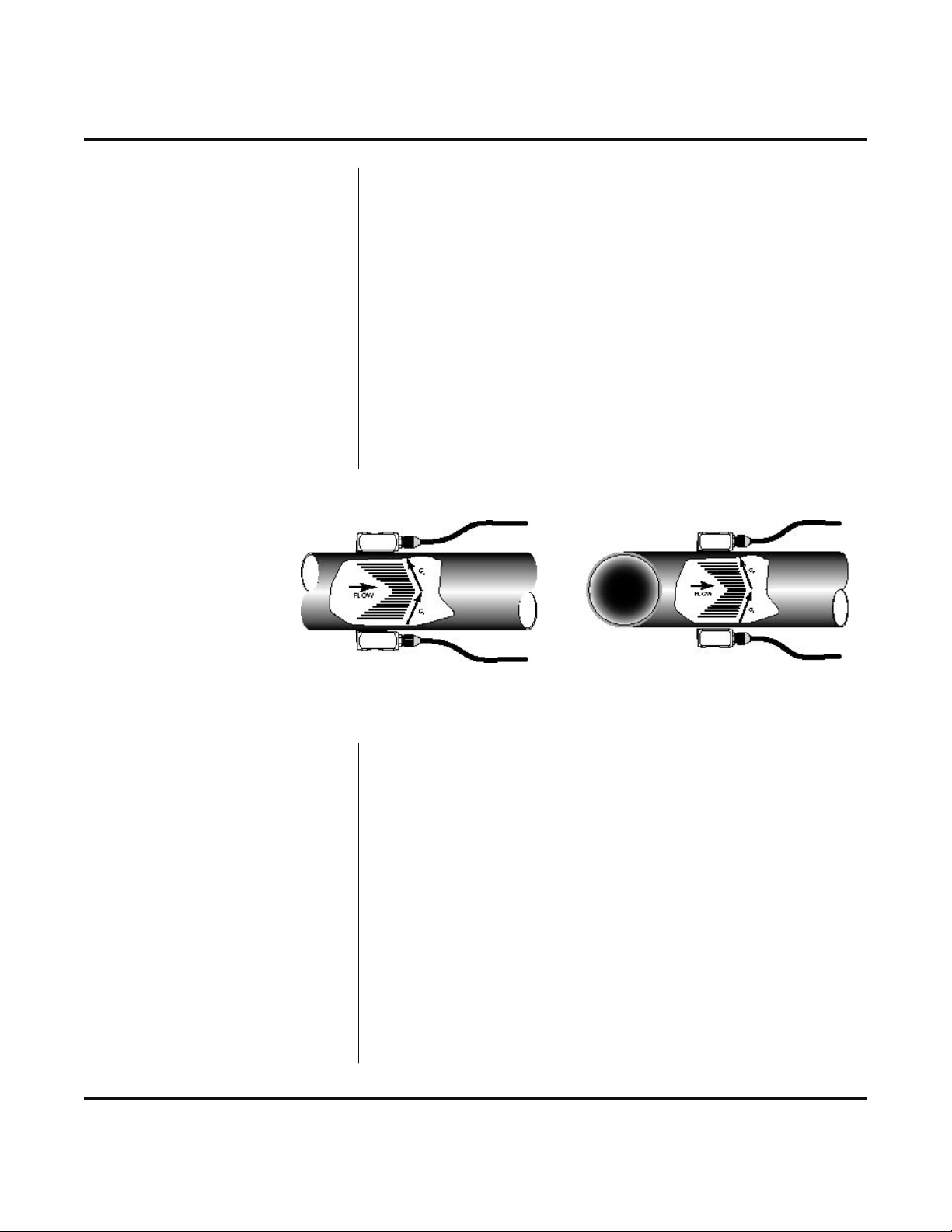

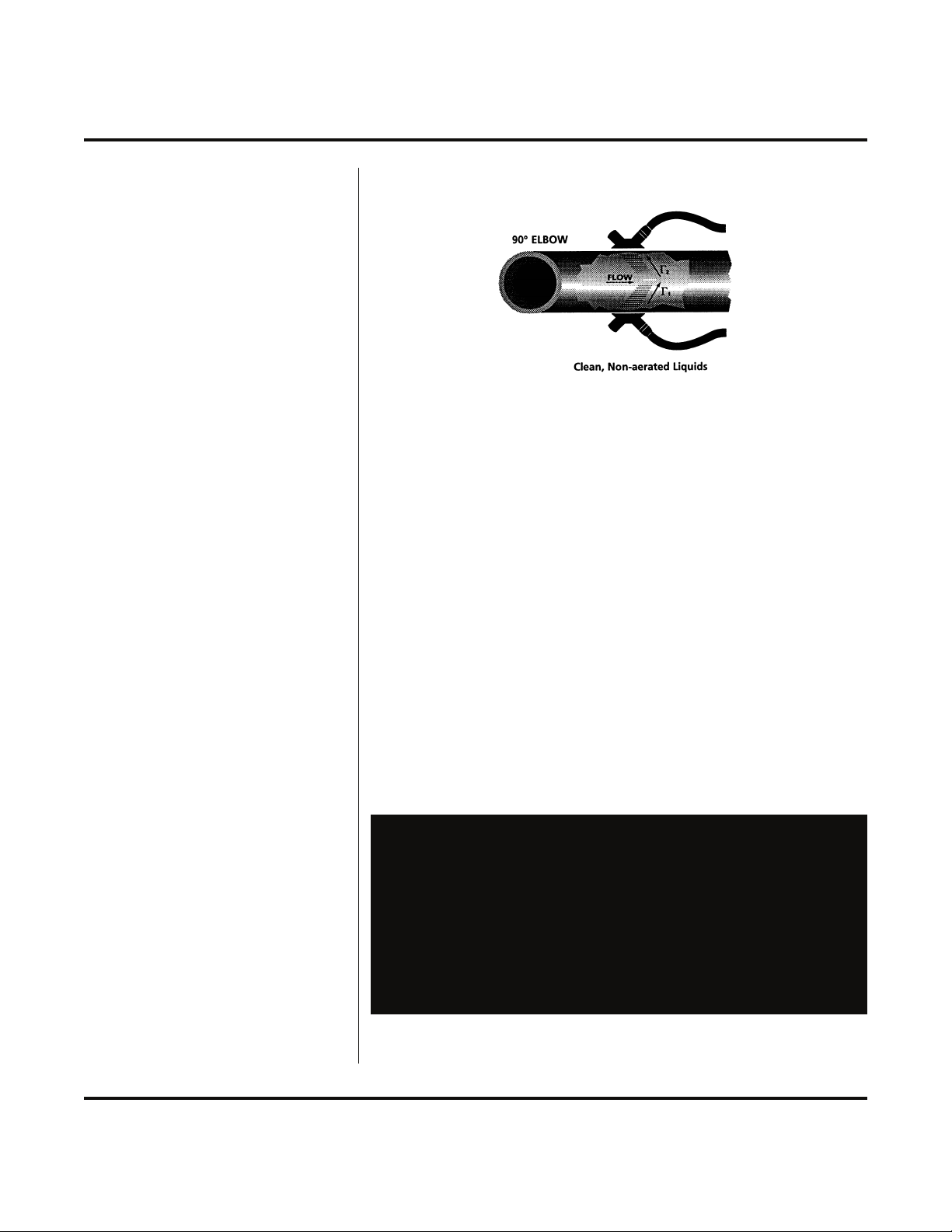

1. TRANSDUCER LOCATION

A. Determine the appropriate mounting location for the

transducers by referring to Figure 1.

TOP VIEW OF PIPE

Pipe Preparation

and Mounting

RECEIVING

TRANSDUCER

TRANSMITTING

TRANSDUCER

90° ELBOW

Fluid Velocity ∝ Г - Г2

Clean, Non-aerated Liquids Liquids with Suspended Solids or Aeration

Figure 1 Transducer Locations

2. PIPE PREPARATION AND TRANSDUCER

MOUNTING

A. The piping surface, where the transducers are to be

mounted, needs to be clean and dry. Remove

loose scale, rust and paint to ensure satisfactory

acoustical bonds.

B. Connect the elastic mounting strap around the pipe.

Leave the strap just loose enough to slip the

transducers underneath.

C. Apply a liberal amount of silicone grease (enclosed)

onto the transducer faces and the prepared areas of

the pipe.

Rev. 10/08 - 4 - D902/3

Page 7

QUICK-START OPERATING INSTRUCTIONS

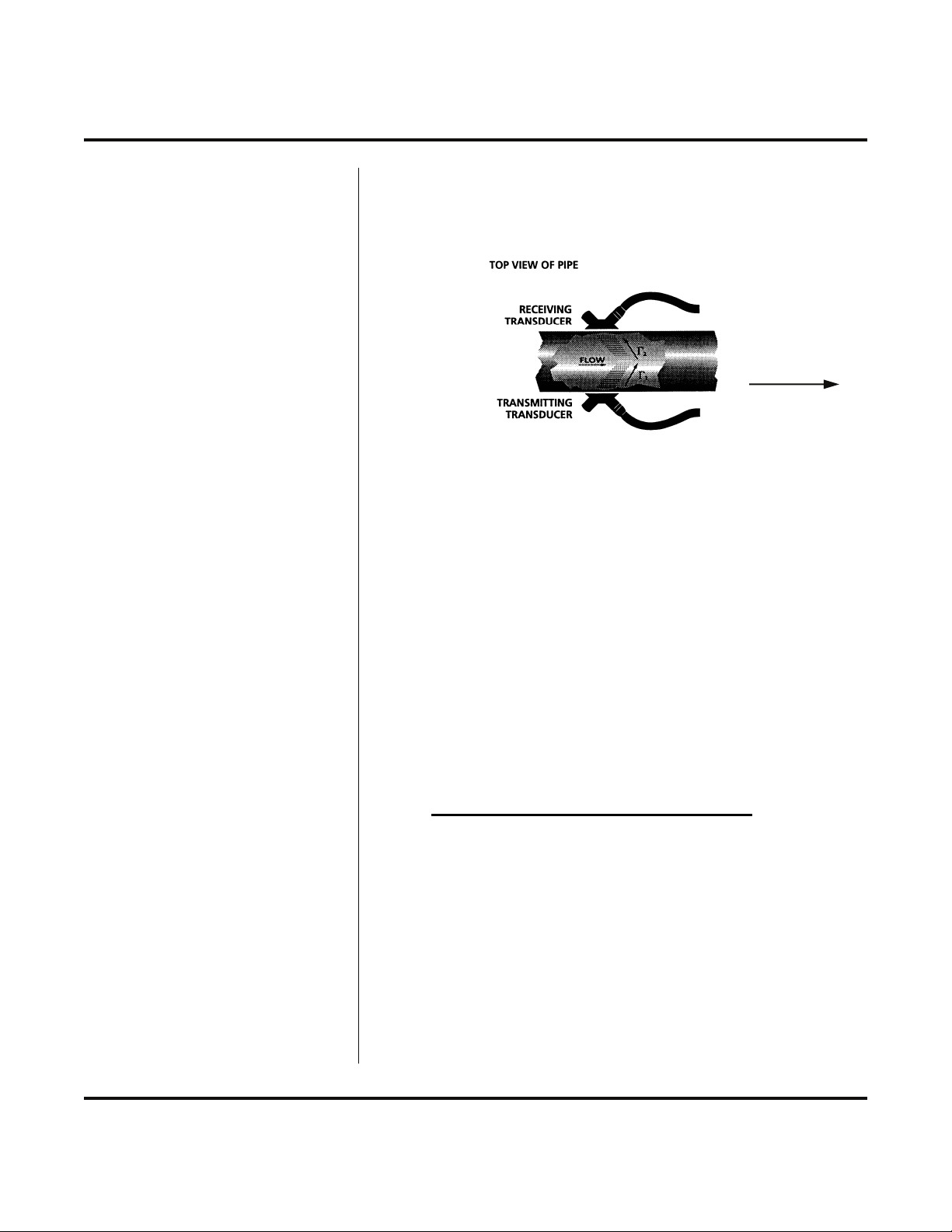

D. Place each transducer under the mounting strap, 180°

apart on the pipe. Ensure that the transducer cables

are facing the same direction. See Figure 2.

FLOW

DIRECTION

Figure 2 Transducer Cable Direction

E. Route the transducer cable back to the transmitter,

avoiding locations near high voltage supply wires.

Connections

Startup

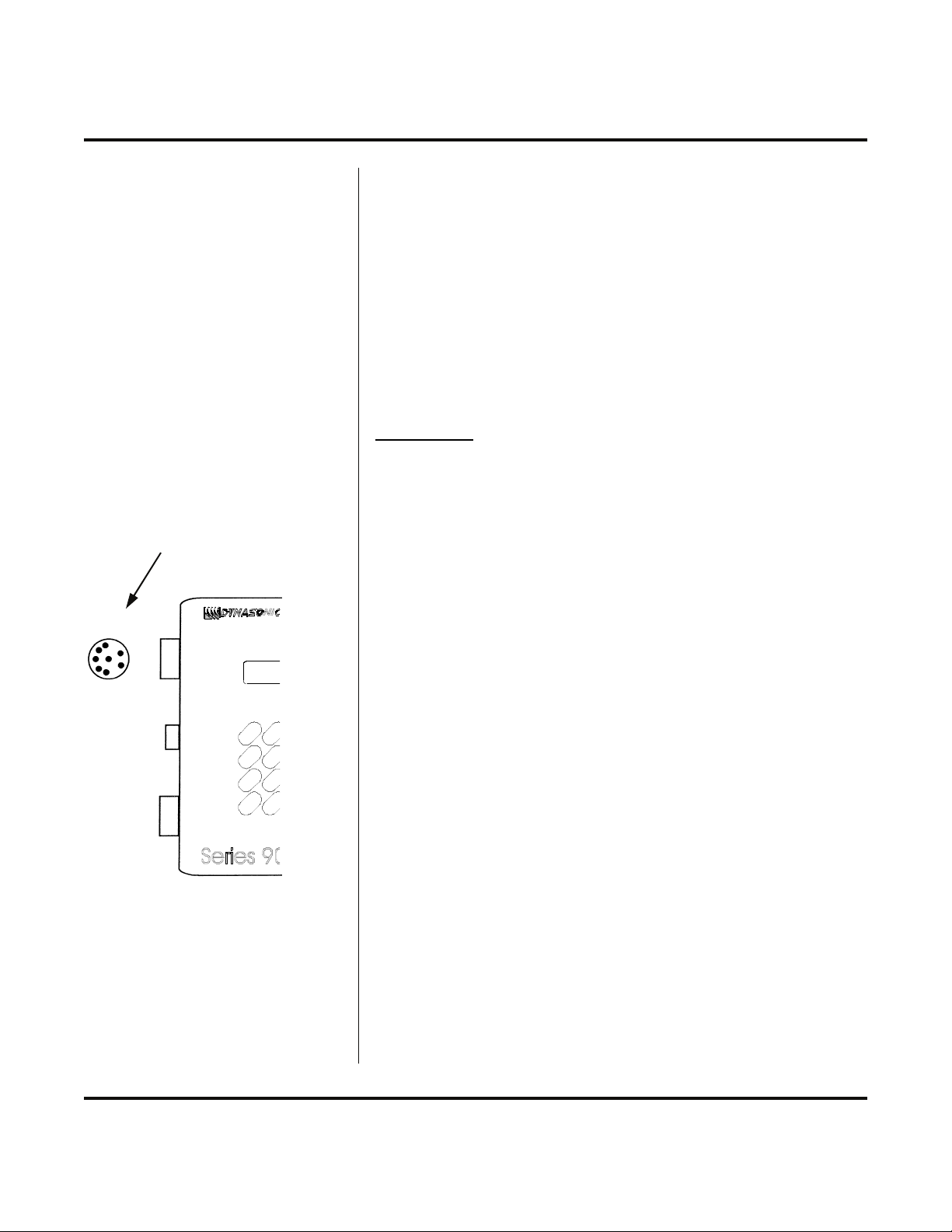

3. TRANSDUCER CONNECTION

A. Connect the transducer plug to the appropriate mating

socket on the side the D902/3 enclosure.

4. INITIAL SETTINGS AND POWER UP

A. Set the SENSITIVITY control to -2.

B. Press the POWER button. The POWER indicator will

illuminate.

C. If the pipe is full of a flowing liquid

STRENGTH meter will indicate and the READ

indicator will illuminate.

D. Adjust the SENSITIVITY control so that the right-most

green LED just comes ON.

E. The default display indicates fluid velocity as either

FPS or MPS. Refer to the appropriate place in this

manual for specific features and options.

, the SIGNAL

Rev. 10/08 - 5 - D902/3

Page 8

PART 1 - INTRODUCTION

General

Application Versatility

The D902/3 ultrasonic flow meter is designed to measure

the fluid velocity of liquid within closed conduit. The

transducers are a non-contacting, clamp-on type, which

will provide benefits of non-fouling operation and ease of

installation.

The flow meter operates by transmitting an ultrasonic

sound from its transmitting transducer through the pipe

wall into the flowing liquid. The sound will be reflected by

suspended particles or bubbles within the liquid and

recorded by the receiving transducer. A frequency shift

(Doppler effect) will occur that is directly related to the

speed of the moving particle or bubble. This shift in

frequency is interpreted by the instrument and converted to

various user defined measuring units.

A unique feature of this product is that it employs a

proprietary digital filtering system and recognition circuit.

This feature allows the instrument to measure fluid

velocities of clean liquids if the transducers are mounted

downstream from a 90° elbow. The non-symmetrical

hydraulic turbulence which occurs downstream of an elbow

is captured, linearized and can be displayed as liquid

velocity and volume. This capability is not available in

conventional Doppler technology.

The D902/3 flow meter can be successfully applied on a

wide range of metering applications. The simple to program

transmitter allows the standard product to be used on pipe

sizes ranging from 1 - 120 inch (25 - 3048 mm) pipe I.D.

With the small pipe transducer option, the pipe size range

is 0.25 - 1 inch (6 - 25 mm). A variety of liquid applications

can be accommodated: raw sewage, reclaimed water,

cooling water, river water, plant effluent, mining slurries,

sludge, etc. Because the transducers are non-contacting

and have no moving parts, the flow meter is not affected

by system pressure, fouling or wear. Standard transducers

are rated to 250 °F (121 °C). Optional high temperature

transducers are rated to operate to 400 °F (204 °C).

Rev. 10/08 - 6 - D902/3

Page 9

PART 1 - INTRODUCTION

User Safety

Battery Backup

Product Identification

The D902/3 employs modular construction and provides

electrical safety for the operator. The display face contains

voltages no greater than 9 Vdc and the metal work is

electrically connected to earth ground. All user connections

are made through sealed, bulk-head plugs located on the

side of the D902/3 enclosure.

A rechargeable nickel-cadmium battery on the back of the

display board retains all user-entered configuration values

in memory for several years (at 25 °C), even if power is

lost or turned off. The ten year battery is continually trickle

charged whenever line power is applied. A completely

discharged battery recharges fully after 48 hours of

instrument operation.

The serial number and complete model number of the

D902/3 are located on the inside of the transmitter cover.

Should technical assistance be required, please provide

the Dynasonics Customer Service Department with this

information.

Product Matrix

D 9

Measuring Units/

Transducer Type

02) U.S.

03) Metric

12) U.S. (High Temp)

13) Metric (High Temp)

22) U.S. (Small Pipe)

23) Metric (Small Pipe)

32) U.S. (High Temp &

Small Pipe)

33) Metric (High Temp &

Small Pipe)

* High Temp (+400 °F)

Small Pipe (1/4" - 1")

*

Power Supply

A) 115 VAC

B) 230 VAC

C) 100 VAC

D) 200 VAC

E) 12 VDC

1 N A

Output 2

N) None

Output 1

1) 4-20 mA

Totalizer

A) Six digit

resettable

NOTE: The Series D902 is shipped with one set of

standard transducers, acoustic couplant, two mounting

straps, power cord and a 4-20 mA cable.

Rev. 10/08 - 7 - D902/3

N

Approvals

N) None

Options

N) U.S. Power Cord

E) U.K. Power Cord

G) Euro Power Cord

Page 10

PART 1 - SPECIFICATIONS

TRANSMITTER

DESCRIPTION SPECIFICATION

Power Requirements

Flow Range

Outputs

Indicators

Display

Units

Rate U.S. (Metric) FPS, GPM, MGD (MPS, LPM, M

Totalizer U.S. (Metric) Gallons (liters, M3)

Ambient Conditions

Enclosure

Internal Lead Acid Gel Cell battery provides 8 hours of continuous operation. AC charging:

(Std) 115/230 VAC 50/60 Hz ±10%. (Opt) 100/200 VAC 50/60 Hz ±10%. (Opt) 12 VDC.

0.5 to 20 FPS (0.15 to 6 MPS)

4-20 mA, 600 Ohms max. isolated

Power, Signal Strength, Flow Analyzer, Read Fault, Overrange, Charging and Low Battery

2 line × 20 character alphanumeric LCD (backlit).

Digit height 0.2 inches (5 mm), 6 digit rate, 6 digit totalizer (resettable)

User configured

-20 to +160 °F (-30 to +70 °C), 0-95% relative humidity, non-condensing

NEMA 4, (IP-65) ABS with SS hardware. 11W × 17L × 8D inches (279W × 432L × 203D mm)

3

/hr)

Accuracy

Sensitivity

Repeatability

Response Time

±2% Full Scale

0.4% of Full Scale

±0.4% of Full Scale

5-50 seconds, user configured, to 90% of value, step change in flow

TRANSDUCERS

DESCRIPTION SPECIFICATION

Liquid Requirements

Transducer Cable

Pipe Sizes

Housing Material

25 ppm of 30 micron size suspended solids or entrained gases.

(Std) 20 feet (6 m), retractable cord.

(Std) 1 inch (25 mm) and above

(Small pipe) 1/4 to 1 inch (6 to 25 mm)

Standard Clamp-On: NEMA 6P (IP-68) - 40 °F to +210 °F (- 40 °C to +100 °C)

CPVC, Ultem

High Temp Clamp-On: NEMA 4 (IP-65) - 40 °F to +400 °F (- 40 °C to +200 °C)

Vespel

®

, Nylon, PVC (Cable Jacket), Aluminum (small pipe)

®

, Anodized Aluminum, Nickel-plated brass, Teflon® (Cable Jacket)

Rev. 10/08 - 8 - D902/3

Page 11

PART 2 - PRE-INSTALLATION CHECKOUT

Unpacking

Functional Test

Transducer Connection

After unpacking, it is recommended to save the shipping

carton and packing materials in case the instrument is

stored or re-shipped. Inspect the equipment and carton for

damage. If there is evidence of shipping damage, notify

the carrier immediately.

The D902/3 flow meter can be checked for basic

functionality using the following Bench Test procedure. It

is recommended that this operation be performed before

each day of operation.

Procedure:

1. Open the D902/3 transmitter cover.

2. Connect the transducer cable connector plug to the

corresponding connector socket located on the side of

the D902/3 enclosure. See Figure 3.

3. Set the transmitter SENSITIVITY control (located on

the front panel) to -2.

4. Apply power.

5. Hold the transducers, the flat sides facing each other,

approximately 6 - 8 inches (150 - 200 mm) apart.

6. Move the transducers towards and away from each other

1 inch (25 mm) for several cycles at approximately 1

second intervals.

7. If unit is functioning properly, the READ LED will

illuminate and the rate display will indicate flow

readings.

Bench Test is Complete

Figure 3

Rev. 10/08 - 9 - D902/3

Page 12

PART 2 - TRANSDUCER INSTALLATION

Transducer Mounting

Considerations

Step A -

Mounting

Locations

CASE 1:

Figure 4

The transducers that are utilized by the D902/3 contain

piezoelectric crystals for transmitting and receiving

ultrasonic sound energy through the pipe wall.

The transducers can be mounted in three different

configurations. The selection of the proper configuration is

dependent on the characteristics of the liquid to be

measured.

The three liquid characteristics, which will affect mounting

location and orientation, are as follows:

CASE 1: Liquid that contains 25 to 10,000 PPM (1%) of

30 micron or larger suspended solids or aeration.

CASE 2: Liquid that contains greater than 10,000 PPM

(1%) of 30 micron or larger suspended solids or aeration.

CASE 3: Liquid that contains fewer than 25 PPM of 30

micron or larger suspended solids or aeration and

suspended solids and aeration content which is smaller

than 30 microns.

Liquid that contains 25 to 10,000 PPM (1%) of 30

micron or larger suspended solids or aeration.

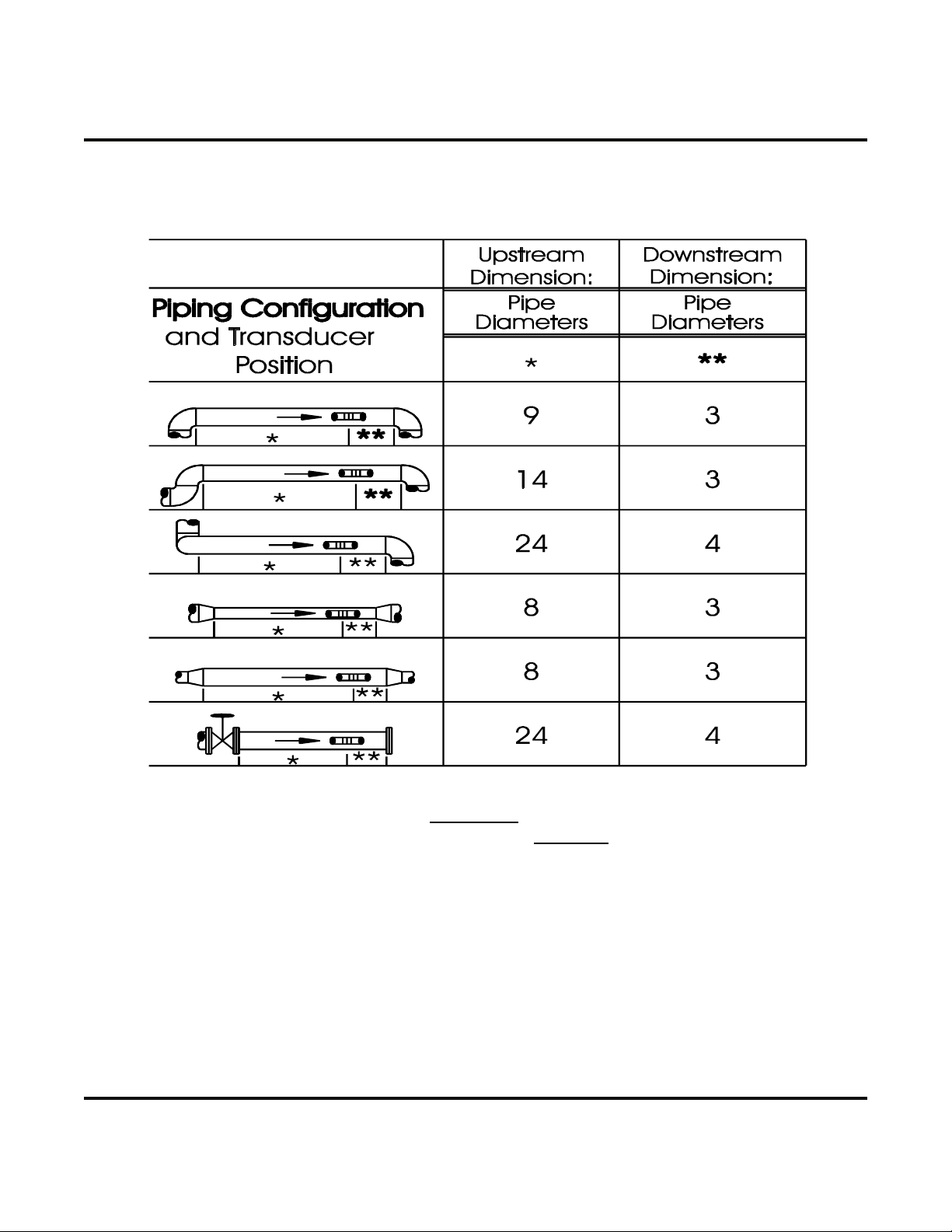

Select a transducer mounting location with adequate

straight runs of pipe, both upstream and downstream, to

achieve stable readings. Examples of minimum upstream

and downstream requirements are included in Table 1.

Mount the transducers 180° apart and facing each other on

the pipe. If the pipe is horizontal, the preferred mounting

orientation is 3 and 9 o’clock, with 12 o’clock being the top

of the pipe. Orientation on vertical pipes does not matter.

See Figure 4.

Rev. 10/08 - 10 - D902/3

Page 13

PART 2 - TRANSDUCER INSTALLATION

Table 1

1

1

The D902/3 system will provide repeatable measurements on piping systems

that do not meet these requirements, but the accuracy of these readings may

be influenced to various degrees.

Rev. 10/08 - 11 - D902/3

Page 14

PART 2 - TRANSDUCER INSTALLATION

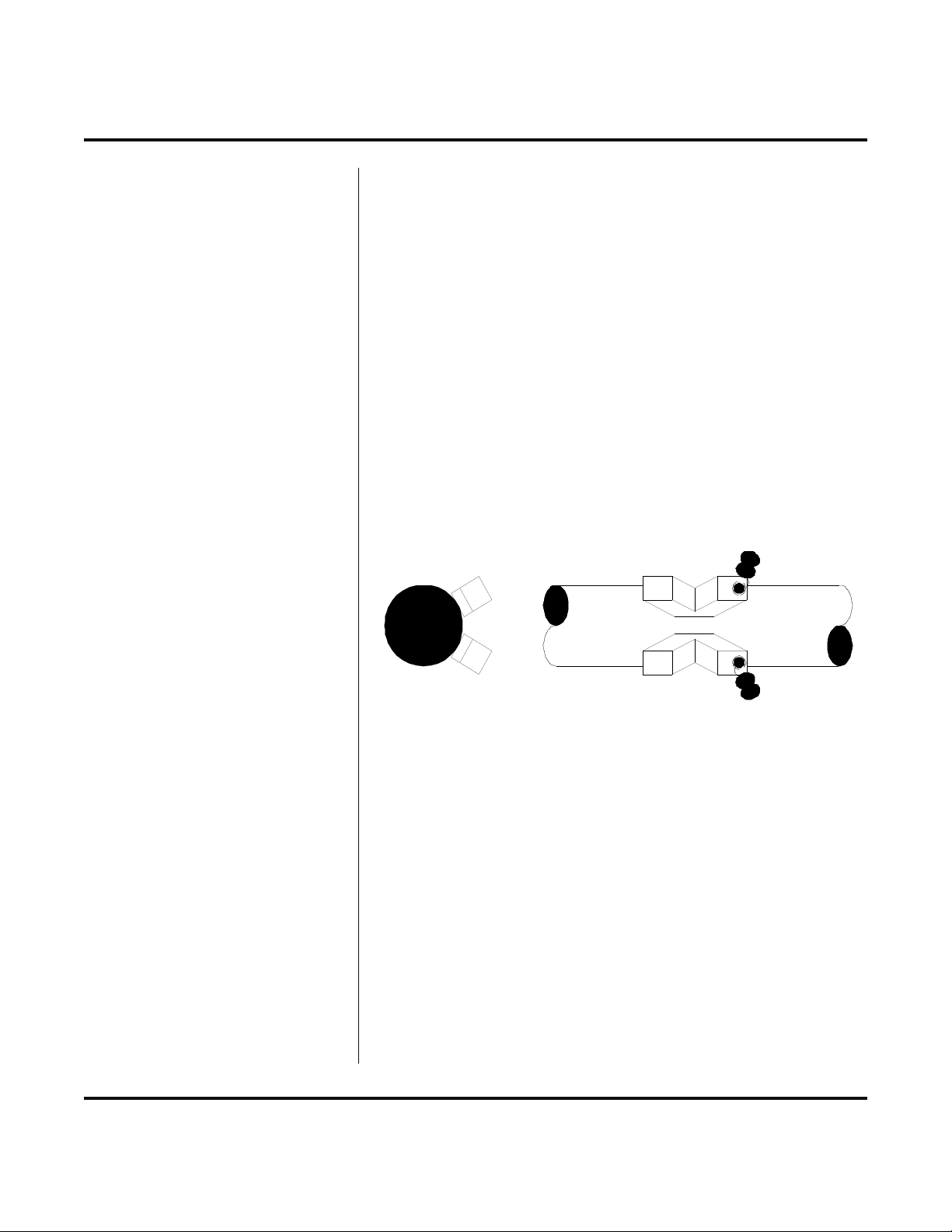

CASE 2:

Liquid that contains greater than 10,000 PPM (1%) of

30 micron or greater suspended solids or aeration.

The mounting location and straight pipe requirements for

CASE 2 liquid characteristics are the same as those

described in CASE 1. The difference will be in the location

of the transducers on the pipe. As the discontinuities

(suspended solids or aeration) reach a level of

approximately 1% or 10,000 PPM, sound can no longer be

reliably transmitted through the liquid as it has a tendency

to scatter and absorb into the high concentration of

discontinuity. To compensate for this, the D902/3

transducers can be located on the same region of the pipe.

In a horizontal pipe, mount the transducers at 2 o’clock

and 4 o’clock positions. (Assuming 12 o’clock as the top of

the pipe.) See Figure 5.

Figure 5

CASE 3:

Rev. 10/08 - 12 - D902/3

Liquid that contains fewer than 25 PPM of 30 micron or

larger suspended solids or aeration. Or, liquid that

contains solids or aeration which is smaller than 30

microns.

The transducers will be mounted 1 to 3 pipe diameters

downstream from a 90° elbow. The orientation of the

transducers on the pipe will be 180° apart and facing each

other and 90° out of the plane of the elbow. See Figure 6

on page 13.

Page 15

PART 2 - TRANSDUCER INSTALLATION

Step B -

Pipe Surface

Preparation

Step C -

Transducer

Mounting

Figure 6

Before the transducer heads are bonded to the pipe

surface, an area slightly larger than the flat surface of the

transducer must be cleaned to bare metal on the pipe.

(Plastic pipes do not require preparation beyond removal

of paint.) Remove all scale, rust and paint. Thoroughly

dry and degrease the mounting surfaces.

NOTE: Small pits in the piping surface typically do not

significantly impact ultrasonic transmission or signal

reception.

After selecting the applicable mounting location and

preparing the piping surface as detailed in Steps A and B,

the transducer can be mounted to the pipe.

NOTE: High Temperature transducer installations require

specialized mounting hardware and instructions. For

drawings detailing installation of this option, contact

the factory.

Steps A and B, Mounting Locations and Pipe Preparation

sections of this manual apply to the High Temperature

option. Reference these sections as required.

Rev. 10/08 - 13 - D902/3

Page 16

PART 2 - TRANSDUCER INSTALLATION

To assure an acoustically conductive path between the

transducer face and the prepared piping surface, a

coupling compound is employed. Enclosed with the

D902/3 system is a tube of Dow Corning 111, silicone

grease. This couplant is satisfactory for temporarily

mounting the transducers to the pipe. If the installation is

long-term (more than a few days), Dynasonics

recommends utilizing a silicone-based RTV such as Dow

Corning RTV-732. If alternate couplants are utilized, the

grease chosen must be rated to not flow at the

temperature of the pipe.

1. Wrap the elastic strap (enclosed) around the pipe in the

area where the transducers are to be mounted. Mount

the strap snuggly, but leave the strap just loose enough

to allow the transducers to be placed underneath.

2. Spread an even layer of coupling compound,

approximately 1/8 inch (3 mm) thick, to the prepared

transducer mounting areas of the pipe. Utilize Dow 111

for temporary mounting or Dow 732 for permanent

mounting.

3. Spread an even layer of the coupling compound,

approximately 1/8 inch (3 mm) thick, to the flat face of

the two transducers.

FLOW

DIRECTION

Figure 7

Rev. 10/08 - 14 - D902/3

4. Place each transducer under the strap with the flat face

positioned towards the pipe. The notch on the back of

the transducer will provide a mounting surface for the

strap. The transducer cables must be facing in the

same direction for proper operation. See Figure 7.

NOTE: Large pipes may require two people for this

procedure.

5. Tighten the strap tight enough to hold the transducers

in place, but not so tight that all of the couplant

squeezes out of the gap between the transducer face

and pipe. Ensure that the transducers are squarely

aligned on the pipe.

Page 17

PART 2 - TRANSDUCER INSTALLATION

6. Route the transducer cable back to the transmitter

mounting area avoiding high voltage cable trays and

conduits. Do not attempt to add additional cable to the

factory supplied transducer cable. The D902/3

processes very small signals, so the cable shield must

be continuous.

7. If the transducers are to be permanently mounted using

Dow 732, the RTV must be completely cured

proceeding to Instrument Startup. Ensure that no

relative motion between the transducer and pipe occurs

during the 24 hour curing process. If Dow 111 grease

was used for temporary operation of the D902/3

system, proceed with the Instrument Startup procedures.

Transducer Installation is complete.

before

Rev. 10/08 - 15 - D902/3

Page 18

PART 2 - ELECTRICAL CONNECTIONS

Transmitter Location

Transducer Connection

Figure 8

The D902/3 enclosure should be located in an area that is

convenient for observation of the LCD readout and keypad

operations. To prolong the life of the keypad and controls,

the enclosure cover should be left closed when the unit is

unattended.

Place the D902/3 transmitter in a location that is:

♦ Where little vibration exists.

♦ Protected from falling corrosive fluids.

♦ Within ambient temperature limits -22 to +160 °F (+30

to +70 °C)

♦ Out of direct sunlight. Direct sunlight may increase

temperatures within the transmitter to above maximum

limit.

Connect the transducer plug to the socket connection

located on the side of the D902/3 enclosure. Refer to

Figure 8. Ensure that tension on the retractable cables

has not pulled either of the transducers out of position on

the pipe. The transducers must be squarely mounted to

achieve greatest accuracy.

NOTE: The transducer cable carries low level signals. Do

not attempt to add additional cable to the factory supplied

transducer cable.

Rev. 10/08 - 16 - D902/3

Page 19

PART 2 - ELECTRICAL CONNECTIONS

4-20 mA Output

Battery Charging and

AC Power Operation

4-20 mA Output

Figure 9

AC Power

Connection

Figure 10

The 4-20 mA output is proportional to the flow rate

measuring scale and can drive a load of up to 600 Ohms.

The output is isolated from earth ground and circuit low.

Connect the load to the 4-20 mA connection socket

located on the side of the D902/3 enclosure, matching

polarity as indicated. See Figure 9. A mating plug for the

connection socket has been included.

To recharge the internal battery of the D902/3 or to

operate the meter for periods of time greater than 8 hours,

connect the meter to AC line power. Line power is

connected by plugging the enclosed line cord into the

appropriate connector socket located on the side of the

D902/3 enclosure. See Figure 10. Use wiring practices

that conform to local codes (National Electric Code

Handbook in the USA). Use only the standard three wire

connection. The ground terminal grounds the instrument,

which is mandatory for safe operation.

CAUTION: Any other wiring method may be unsafe or

cause improper operation of the instrument.

It is recommended not to run line power with other signal

wires within the same wiring tray or conduit.

NOTE: This instrument requires clean electrical line

power. Do not operate this unit on circuits with noisy

components (i.e. Fluorescent lights, relays, compressors,

variable frequency drives, etc.).

®

Rev. 10/08 - 17 - D902/3

Page 20

PART 2 - SERVICE AND MAINTENANCE

Battery Care and

Maintenance

The D902/3 flow meter is equipped with a Lead Acid Gel

Cell battery. This battery will require charging before initial

operation. Apply AC power, utilizing the enclosed line

power cord, to the D902/3 for a period of 16-24 hours prior

to using the product for the first time. The line cord

connects to the socket connection located on the side of

the enclosure.

The D902/3’s integral battery provides continuous

operation for up to 8 hours on a full-charge. The battery is

“maintenance free”, but it still requires a certain amount of

attention to prolong its useful life. To obtain the greatest

capacity and longevity from the battery, the following

practices are recommended:

• Do not allow the battery to completely discharge.

(Discharging the battery to the point where the LOW

BATTERY indicator illuminates will not damage the

battery. Allowing the battery to stay discharged for long

periods of time can degrade the storage capacity of the

battery.) When not in use, continually charge the

battery by keeping it plugged into line power. The

D902/3 battery management circuitry will not allow the

battery to become “over-charged”.

NOTE: The D902/3 will automatically enter a low power

consumption mode approximately 1-1/2 minutes after the

LOW BATTERY indicator illuminates. This circuit prevents

excessive discharge of the internal battery.

• If the D902/3 is stored for prolonged periods of time,

monthly charging is recommended.

• If the D902/3 is stored for prolonged periods of time,

store at a temperature below 70 ºF (21 ºC).

The CHARGING indicator will always be illuminated when

the D902/3 is connected to line power and the flow meter

is turned ON. If the D902/3 is turned OFF and line power

is connected, the CHARGING indicator will illuminate only

when the internal circuit is charging the battery. During

storage, the CHARGING indicator will cycle as necessary.

Rev. 10/08 - 18 - D902/3

Page 21

PART 2 - SERVICE AND MAINTENANCE

Desiccant Cartridge

The D902/3 is equipped with a DESICCANT CARTRIDGE,

which is located in the face plate of the meter. The

purpose of the cartridge is to absorb the humidity that was

present inside of the enclosure when the product was

manufactured and to absorb moisture that may seep into

the enclosure during field operation. Observing the color

indicator of the DESICCANT CARTRIDGE and replacing it

when it turns PINK will decrease the chance of corrosion

and resulting failure of the internal components of the

D902/3.

Procedure:

1. Obtain a new DESICCANT CARTRIDGE from

Dynasonics (Dynasonics P.N. D005-9909-001).

2. Replace the cartridge in a temperature and humidity

controlled environment. Allow the meter to reach the

same ambient temperature as the area in which the

cartridge will be replaced. (Do not attempt to change

the cartridge if the meter is below the Dew Point

Temperature.)

3. Remove the old cartridge with a 1-3/8" open-end

wrench or appropriate adjustable wrench.

4. Insert the new cartridge and tighten with the wrench.

5. Discard the used cartridge.

Rev. 10/08 - 19 - D902/3

Page 22

PART 3 - STARTUP AND CONFIGURATION

Before Starting the

Instrument

Instrument Startup

Important!

NOTE: The D902/3 flow meter system requires a full

pipe of flowing liquid before a successful startup can be

completed. Do not attempt to make adjustments or

change configurations until both a full pipe and liquid flow

are verified.

NOTE: If Dow 732 RTV was utilized to couple the

transducers to the pipe, the adhesive must fully cure

before power is applied to the instrument. Dow 732

requires 24 hours to cure satisfactorily. If Dow 111 silicone

grease was utilized as a couplant, the curing time is not

required.

Procedure:

1. Verify that all wiring is properly connected and routed.

2. Set the SENSITIVITY Control to -2. This control is

located on the D902/3 front panel.

3. Apply power. The POWER indicator will illuminate.

4. Adjust the SENSITIVITY control so that the right-most

LED on the SIGNAL STRENGTH bar meter just

illuminates or SIGNAL STRENGTH is at least in the

yellow/green region.

NOTE: It is undesirable to adjust the SENSITIVITY control

to a position higher than necessary, as ambient noise can

also be amplified. This noise can cause false readings to

occur.

5. If the pipe is full of a flowing liquid, the READ indicator

will illuminate and the display will begin reading fluid

velocity as FPS (Feet per Second) or MPS (Meters per

Second). It is normal to have low SIGNAL STRENGTH

and FAULT indication at ZERO flow.

6. If a SIGNAL STRENGTH reading in the green portion

of the bar meter or a FLOW ANALYZER indication

could not be obtained, refer to the troubleshooting

section of this manual.

Rev. 10/08 - 20 - D902/3

Page 23

PART 3 - STARTUP AND CONFIGURATION

Keypad

Configurations

Modes of Operation

Default Configuration

After a successful flow meter installation and startup

(covered in the previous sections of this manual) the

D902/3 can be keypad configured to provide select

engineering unit readings of flow and a scaled 4-20 mA

output. Configuration inputs are made via the keypad and

are stored by the microprocessor. The entries are retained

by the flow meter’s backup battery in the event of power

failure. If fluid velocity readings in FPS or MPS are the

only required measurement, keypad configuration is not

required.

The RUN/ENT key toggles the flow meter between the two

modes of operation.

RUN Mode: This is the primary operating mode of the

flow meter. The meter is in RUN mode when the readout

is displaying flow as velocity (FPS, MPS) or volume (GPM,

LPM, LPS). In RUN mode the outputs are active and

transmitting signals proportional to flow rate.

ENTRY Mode: This mode is used to view or change the

configuration of the flow meter. When the D902/3 ships

from the Dynasonics factory, it contains the following

Default configuration:

PARAMETER U.S. METRIC

ID

UNITS

DAMP

Volume/PLS

FULL SCALE

CAL

Each of these parameters may be viewed and/or modified

in the ENTRY Mode. Changes are processed when the

RUN/ENT is pressed and the meter returns to RUN

MODE. In ENTRY Mode flow totalization is suspended

and process outputs are frozen at the last value recorded.

Rev. 10/08 - 21 - D902/3

1 Inch 25 mm

1 (FPS) 1 (MPS)

1 Sec 1 Sec

φ φ

20 FPS 6.08 MPS

100% 100%

Page 24

PART 3 - STARTUP AND CONFIGURATION

Pipe I.D. Input

The ID key allows the entry of a pipe’s Internal Diameter.

The D902/3 utilizes the I.D. constant to process volumetric

flow rates such as GPM (Gallons per Minute) or LPM

(Liters per Minute). The entry is made as either inches or

mm, dependent on whether the unit is configured as U.S.

units or Metric units.

Press the I.D. key from the ENTRY MODE. The display

will show

This is the present I.D. constant. Enter a new I.D. based

on information obtained from the pipe manufacturer, a

physical measurement or a pipe chart. Some common

pipe sizes and dimensions are located on a series of

charts located in the Appendix of this manual. The

acceptable input range for the I.D. constant is shown in

Table 3.

I.D. U.S. METRIC

Max

Min *

* Pipe sizes less than 1 inch (25 mm) require a Small Pipe

Transducer. Dynasonics P.N. D070-1004-003.

INSIDE DIAMETER

Table 3

120 Inches 3050 mm

0.25 Inches 6 mm

NOTE: If a decimal value of less than 1 is to be entered,

enter 0

NOTE: If an entered value is out of the acceptable range

of the instrument, an UNDER! or OVER! indication will be

displayed. The meter will not allow any other entries to be

made until a legitimate value is entered.

Rev. 10/08 - 22 - D902/3

. X X. The zero must precede the decimal value.

Page 25

PART 3 - STARTUP AND CONFIGURATION

Full Scale Input

Important!

The FULL SCALE key allows the entry of the highest

anticipated fluid velocity. The entry is made as either FPS

(Feet per Second) or MPS (Meters per Second) dependent

on whether the unit is configured as U.S. units or Metric

units. The FULL SCALE input is used by the D902/3

microprocessor to scale the 4-20 mA output and adjust the

resolution of the flow rate display.

Acceptable input range for the FULL SCALE constant is

shown in Table 4.

Table 4

I.D. U.S. METRIC

Max

Min *

* NOTE: FULL SCALE values below 1.5 FPS (0.5 MPS)

are not recommended.

NOTE: If an entered value is out of the acceptable range

of the instrument, a RANGE! indication will be displayed.

The meter will not allow any additional entries to be made

until a legitimate value is entered.

20 FPS 8 MPS

n/a n/a

NOTE: If a decimal value is to be entered, enter 0 . X X.

The zero must precede the decimal value (if less than 1)

and only two numbers should be entered after the

decimal value.

Volume to Velocity

Conversion

Rev. 10/08 - 23 - D902/3

Two useful equations which relate volumetric flow in round

pipes to flow velocity are as follows:

FPS = U.S. GPM × 0.409

ID

MPS = LPM × 21.23

ID

2

(inches)

2

(mm)

Page 26

PART 3 - STARTUP AND CONFIGURATION

Totalizer Exponent

Input

The VOL. PULSE key allows the entry of a totalizer

exponent. This feature is useful for accommodating a very

large accumulated flow. The exponent is a “×10” multiplier,

which can be from 0 (no multiplier) to 2 (×100). For

example, to totalize in GAL × 100, a VOL. PULSE value of

2 would be used (10² or 100).

Acceptable input range for the VOL. PULSE constant is

shown in Table 5.

I.D. U.S. METRIC

Max

Min *

* NOTE: If an entry greater than 2 is attempted, the meter

will display OVER!. If a non-whole number value is attempted,

the meter will display RANGE!. A legitimate value will need to

be entered.

After a VOL. PULSE value is entered, the display will

reflect the unit as 0=10º=×1, 1=10¹=×10 and 2=10²=×100.

Table 6 illustrates various codes and their display results.

Table 5

2 2

0 0

Table 6

VOL. PULSE

CODE

0

1

2

Rev. 10/08 - 24 - D902/3

ENG. NOTATION

10E0 999,999

10E1 999,999

10E2 999,999

DISPLAY

MAXIMUM

Page 27

PART 3 - STARTUP AND CONFIGURATION

Engineering Units

Input

Altering the

CALibration of the

D902/3

The UNITS key allows the selection of measuring units.

Table 7 shows applicable codes for the engineering units

available.

UNITS CODE U.S. METRIC

1

2

3

Attempting to enter values other than 1, 2 or 3 will result in

an UNDER! or OVER! to be displayed. Non-whole number

values will result in a RANGE! display. A legitimate value

must be entered.

A few factors can influence the readings of the D902/3

flow meter. The CAL entry allows the user to compensate

for flow discrepancies without affecting the factory

calibration. Examples of situations that can cause reading

discrepancies are:

• Operation on liquids with sonic velocity carrying

properties that are different than water. Please refer to

the Fluid Sound Speed correction chart located in the

Appendix of this manual.

Table 7

FPS MPS

GPM LPM

MGD LPS

• Transducers mounted in non-recommended locations.

• Operation on fluids with a large amount of suspended

solids.

By applying a CAL value other than 100%, the factory

calibrated readings will be altered by the percentage

entered. This CAL value will not

output.

For example, if a reading of 175 GPM is displayed and the

known flow rate is 160 GPM, a CAL value of

160 GPM

175 GPM

Rev. 10/08 - 25 - D902/3

× 100 = 91.4%

be reflected in the 4-20 mA

Page 28

PART 3 - STARTUP AND CONFIGURATION

Display Damping

The TEST Diagnostic

Key

The D902/3 will not allow decimal values to be entered as

a CAL constant, so round to the nearest whole number. In

this case 91%.

Acceptable input ranges for the CAL constant are shown in

Table 8. Values outside of this range will result in an

OVER! or UNDER! display. Non-whole number entries will

result in a RANGE! display. Enter an appropriate value.

I.D. U.S. METRIC

Max

Min

The DAMP key allows the selection of time duration

between display updates. The value selected and entered

will result in display updates of

n × 2 = seconds between updates

Acceptable input ranges for the DAMP constant are shown

in Table 9. Values outside of this range will result in an

OVER! or UNDER! display. Entry of an appropriate value

is required.

I.D. U.S. METRIC

Max

Min

The TEST key is used for diagnostic purposes. It displays

the operand presently available at the analog to digital

converter. This value will always be in the range of 0 to

255.

Table 8

200% 200%

3% 3%

Table 9

5 5

0.5 0.5

Rev. 10/08 - 26 - D902/3

Page 29

PART 3 - STARTUP AND CONFIGURATION

System and Totalizer

RESET

Reset the Flow

Totalizer

FLOW ANALYZER

The RESET key is used for generating a system reset or

to reset the accumulated flow. Press the RESET button

from the ENTER Mode. A choice is then made to:

RESET Reset the system

VOL. MULT Press VOL. PULSE to

reset the totalizer to

zero

If the RESET key is pressed again, all configuration

constants will return to default values.

If the VOL. PULSE key is pressed, the accumulated flow

will be erased and the display will return to zero.

In RUN Mode, pressing the decimal point once will

suspend totalizer accumulation. Pressing the decimal

point again will clear the total. Pressing it a third time will

restart the accumulation from zero.

NOTE: In RUN mode, the key presses are processed

and displayed at the interval defined by the DAMP

constant setting. (i.e. If the DAMP constant is set to

10, the key presses will be acknowledged only every

20 seconds.)

The FLOW ANALYZER bar meter indicates the relative

condition of the Doppler signal that is being processed by

the D902/3. When the instrument is utilized on liquids with

suspended solids or aeration, the FLOW ANALYZER will

indicate within the two right segments — an ideal Doppler

condition. When the D902/3 is used to measure cleaner

liquids, the FLOW ANALYZER bar meter will search its

discrete filter banks and adjust to match the particular

liquid parameters that are present. The bar meter will

indicate these changes when they occur. If no segments

are illuminated on the FLOW ANALYZER, the level of

liquid discontinuity or hydraulic turbulence is inadequate

and the transducers will have to be relocated. Typically,

moving the transducers closer to a 90º elbow will provide

adequate liquid conditions.

Rev. 10/08 - 27 - D902/3

Page 30

PART 4 - TROUBLESHOOTING

CONDITION

Unit does not turn “ON” when power is

applied

These procedures require the

face plate to be removed from

the enclosure.

OVERRANGE light is ON

FAULT light is ON; low SIGNAL

STRENGTH indication

POSSIBLE CAUSE

• Verify that the battery is charged. Plug

into an AC power source.

• Test the fuse.

• Ensure the terminal block located in the

upper left corner of the main PCB is

secure.

• Verify that ribbon cables between PCBs

are connected.

• Increase the value of the FULL SCALE

constant.

• Verify that fluid velocity is not greater than

20 FPS (6.08 MPS).

• Ensure that the transducers are properly

mounted to the pipe.

• Verify that transducer connections are

correct.

• Ensure that the pipe is full of moving

liquid.

• Increase SENSITIVITY so that right-most

SIGNAL STRENGTH light just comes ON.

• On cleaner liquids, move the transducers

o

closer to a 90

pipe elbow.

• On dirtier liquids, mount the transducers

as described in CASE 3 in Part 2 of this

manual.

• If the pipe has a polyethylene liner, move

the transducers to another area. The liner

may contain an air void at this location.

(continued)

Rev. 10/08 - 28 - D902/3

Page 31

PART 4 - TROUBLESHOOTING

FAULT light is ON; low SIGNAL

STRENGTH indication (continued)

Stability of flow readings are

unsatisfactory

This procedure requires the

face plate to be removed

from the enclosure.

Erroneous Reading

• If GND connection and pipe are at different

potentials, ground D902/3 to pipe potential.

• If Variable Frequency Drives are being

utilized, verify that the D902/3 obtains a

READ light when the pump is turned OFF.

If possible, increase the carrier frequency

of the drive.

• Increase the DAMP constant from keypad.

• Increase the system time constant by

turning R17 (DAMP) clockwise till readings

are satisfactory.

• Move transducers to a location further from

piping tees, elbows, valves, filters, etc.

• Transducers mounted incorrectly.

• Another local ultrasonic instrument is

operating at about the same frequency

(consult the Dynasonics factory).

The D902/3 display indicates flow, when

true fluid velocity is zero

• Presence of large amounts of suspended

solids or aeration. Use CAL constant to

compensate.

• Sources of radiated interference are

present. Apply appropriate shielding.

• An electrically noisy power supply is

powering the D902/3. Power the meter

with a circuit that does not power motors,

ballasts or switching supplies.

• Verify that residual leakage and flow are

not present (i.e. leaking check valves).

• Verify that SENSITIVITY is not adjusted

too high. With nominal flow running

through the pipe, adjust SENSITIVITY

control till the right-most bar meter light just

comes ON.

Rev. 10/08 - 29 - D902/3

Page 32

NOTES

Rev. 10/08 - 30 - D902/3

Page 33

PART 5 - APPENDICES

Appendices

Spare Parts List

Mechanical Drawing

Fluid Sound Speed Conversion Chart

Clean Liquid Installation Guide

Pipe Dimension Chart: Cast Iron

Pipe Dimension Chart: Steel, SS, PVC

Velocity to Volumetric Conversion Chart

Statement of Warranty

Customer Service

Rev. 10/08 - 31 - D902/3

Page 34

SPARE PARTS - D902/3

PART NUMBER

D070-1004-001 Series D902 Std. Temp./Std. Pipe Transducer

D040-0402-001 Series D902 High Temp./Std. Pipe Transducer

D070-1004-003 Series D902 Std. Temp./Small Pipe Transducer

D902 O&M Series D902 Installation and Operations Manual

D005-1003-100 Two conductor, 20 AWG, unshielded cable

D003-0825-001 Stainless Steel Identification Tag

D005-9909-001 Series 902 Desiccant Cartridge

DESCRIPTION

D005-1201-001 Series 902 Gel Cell Battery

D002-2011-002 Couplant, RTV (for permanent mounting)

D002-2011-001 Couplant, Silicone (for temporary mounting)

D005-2109-002 Series 902 U.S. Line Cord (Two spades and ground)

D005-2109-011 Series 902 U.K. Line Cord (Three rectangular spades)

D005-2109-021 Series 902 German Line Cord (Two round spades)

D010-0200-100 Series 902 Transducer Extension Cable, 20 ft. (6 m)

D005-1301-002 Fuse, 0.125A Slow Blow, 250V

D005-1301-004 Fuse, 0.75A Slow Blow, 250V

D002-2009-046 Elastic Pipe Strap, 46" (1100 mm)

D002-2009-076 Elastic Pipe Strap, 76" (2000 mm)

D005-0904-001 4-20 mA MIL Connector

Rev. 10/08 - 32 - D902/3

Page 35

MECHANICAL DRAWING - D902/3

Rev. 10/08 - 33 - D902/3

Page 36

Fluid Properties

Original Date: 7/30/1999

Revision: A

Revision Date: 9/10/2003

File: I:/dynasonics/dyna_code/tables/fluid_ss.xls

Fluid Specific Gravity Sound Speed delta-v/degree C Kinematic Viscosity Absolute Viscosity

20 degrees C m/s ft/s m/s/degree C Centistokes Centipoise

Acetate, Butyl 1270 4163.9

Acetate, Ethyl 0.901 1085 3559.7 4.4 0.489 0.441

Acetate, Methyl 0.934 1211 3973.1 0.407 0.380

Acetate, Propyl 1280 4196.7

Acetone 0.79 1174 3851.7 4.5 0.399 0.316

Alcohol 0.79 1207 3960.0 4.0 1.396 1.101

Alcohol, Butyl 0.83 1270 4163.9 3.3 3.239 2.688

Alcohol, Ethyl 0.83 1180 3868.9 4 1.396 1.159

Alcohol, Methyl 0.791 1120 3672.1 2.92 0.695 0.550

Alcohol, Propyl 1170 3836.1

Alcohol, Propyl 0.78 1222 4009.2 2.549 1.988

Ammonia 0.77 1729 5672.6 6.7 0.292 0.225

Anlline 1.02 1639 5377.3 4.0 3.630 3.710

Benzene 0.88 1306 4284.8 4.7 0.711 0.625

Benzol, Ethyl 0.867 1338 4389.8 0.797 0.691

Bromine 2.93 889 2916.7 3.0 0.323 0.946

n-Butane 0.60 1085 3559.7 5.8

Butyrate, Ethyl 1170 3836.1

Carbon dioxide 1.10 839 2752.6 7.7 0.137 0.151

Carbon tetrachloride 1.60 926 3038.1 2.5 0.607 0.968

Chloro-benezene 1.11 1273 4176.5 3.6 0.722 0.799

Chloroform 1.49 979 3211.9 3.4 0.550 0.819

Diethyl ether 0.71 985 3231.6 4.9 0.311 0.222

Diethyl Ketone 1310 4295.1

Diethylene glycol 1.12 1586 5203.4 2.4

Ethanol 0.79 1207 3960.0 4.0 1.390 1.097

Ethyl alcohol 0.79 1207 3960.0 4.0 1.396 1.101

Ether 0.71 985 3231.6 4.9 0.311 0.222

Ethyl ether 0.71 985 3231.6 4.9 0.311 0.222

Ethylene glycol 1.11 1658 5439.6 2.1 17.208 19.153

Freon R12 774.2 2540

Gasoline 0.7 1250 4098.4

Glycerin 1.26 1904 6246.7 2.2 757.100 953.946

Glycol 1.11 1658 5439.6 2.1

Isobutanol 0.81 1212 3976.4

Iso-Butane 1219.8 4002

Isopentane 0.62 980 3215.2 4.8 0.340 0.211

Isopropanol 0.79 1170 3838.6 2.718 2.134

Isopropyl alcohol 0.79 1170 3838.6 2.718 2.134

Kerosene 0.81 1324 4343.8 3.6

Linalool 1400 4590.2

Linseed Oil .925-.939 1770 5803.3

Methanol 0.79 1076 3530.2 2.92 0.695 0.550

Methyl alcohol 0.79 1076 3530.2 2.92 0.695 0.550

Methylene chloride 1.33 1070 3510.5 3.94 0.310 0.411

Methylethyl Ketone 1210 3967.2

Motor Oil (SAE 20/30) .88-.935 1487 4875.4

Octane 0.70 1172 3845.1 4.14 0.730 0.513

Page 37

Oil, Castor 0.97 1477 4845.8 3.6 0.670 0.649

Oil, Diesel 0.80 1250 4101

Oil (Lubricating X200) 1530 5019.9

Oil (Olive) 0.91 1431 4694.9 2.75 100.000 91.200

Oil (Peanut) 0.94 1458 4783.5

Paraffin Oil 1420 4655.7

Pentane 0.626 1020 3346.5 0.363 0.227

Petroleum 0.876 1290 4229.5

1-Propanol 0.78 1222 4009.2

Refrigerant 11 1.49 828.3 2717.5 3.56

Refrigerant 12 1.52 774.1 2539.7 4.24

Refrigerant 14 1.75 875.24 2871.5 6.61

Refrigerant 21 1.43 891 2923.2 3.97

Refrigerant 22 1.49 893.9 2932.7 4.79

Refrigerant 113 1.56 783.7 2571.2 3.44

Refrigerant 114 1.46 665.3 2182.7 3.73

Refrigerant 115 656.4 2153.5 4.42

Refrigerant C318 1.62 574 1883.2 3.88

Silicone (30 cp) 0.99 990 3248 30.000 29.790

Toluene 0.87 1328 4357 4.27 0.644 0.558

Transformer Oil 1390 4557.4

Trichlorethylene 1050 3442.6

1,1,1-Trichloro-ethane 1.33 985 3231.6 0.902 1.200

Turpentine 0.88 1255 4117.5 1.400 1.232

Water, distilled 0.996 1498 4914.7 -2.4 1.000 0.996

Water, heavy 1 1400 4593

Water, sea 1.025 1531 5023 -2.4 1.000 1.025

Wood Alcohol 0.791 1076 3530.2 2.92 0.695 0.550

m-Xylene 0.868 1343 4406.2 0.749 0.650

o-Xylene 0.897 1331.5 4368.4 4.1 0.903 0.810

p-Xylene 1334 4376.8 0.662

Page 38

Page 39

Cast Iron Pipe

Standard Classes

CLASS B CLASS C CLASS D CLASS E CLASS F

Size

(Inches)

10 11.10 10.10 0.50 11.10 9.96 0.57 11.40 10.16 0.62 11.40 10.04 0.68 11.60 10.12 0.74 11.60 10.00 0.80 11.84 10.12 0.86 11.84 10.00 0.92

12 13.20 12.12 0.54 13.20 11.96 0.62 13.50 12.14 0.68 13.50 12.00 0.75 13.78 12.14 0.82 13.78 12.00 0.89 14.08 12.14 0.97 14.08 12.00 1.04

14 15.30 14.16 0.57 15.30 13.98 0.66 15.65 14.17 0.74 15.65 14.01 0.82 15.98 14.18 0.90 15.98 14.00 0.99 16.32 14.18 1.07 16.32 14.00 1.16

16 17.40 16.20 0.60 17.40 16.00 0.70 17.80 16.20 0.80 17.80 16.02 0.89 18.16 16.20 0.98 18.16 16.00 1.08 18.54 16.18 1.18 18.54 16.00 1.27

18 19.50 18.22 0.64 19.50 18.00 0.75 19.92 18.18 0.87 19.92 18.00 0.96 20.34 18.20 1.07 20.34 18.00 1.17 20.78 18.22 1.28 20.78 18.00 1.39

20 21.60 20.26 0.67 21.60 20.00 0.80 22.06 20.22 0.92 22.06 20.00 1.03 22.54 20.24 1.15 22.54 20.00 1.27 23.02 20.24 1.39 23.02 20.00 1.51

24 25.80 24.28 0.76 25.80 24.02 0.89 26.32 24.22 1.05 26.32 24.00 1.16 26.90 24.28 1.31 26.90 24.00 1.45 27.76 24.26 1.75 27.76 24.00 1.88

30 31.74 29.98 0.88 32.00 29.94 1.03 32.40 30.00 1.20 32.74 30.00 1.37 33.10 30.00 1.55 33.46 30.00 1.73

36 37.96 35.98 0.99 38.30 36.00 1.15 38.70 35.98 1.36 39.16 36.00 1.58 39.60 36.00 1.80 40.04 36.00 2.02

42 44.20 42.00 1.10 44.50 41.94 1.28 45.10 42.02 1.54 45.58 42.02 1.78

48 50.50 47.98 1.26 50.80 47.96 1.42 51.40 47.98 1.71 51.98 48.00 1.99

O.D.

Inch

3 3.80 3.02 0.39 3.96 3.12 0.42 3.96 3.06 0.45 3.96 3.00 0.48

4 4.80 3.96 0.42 5.00 4.10 0.45 5.00 4.04 0.48 5.00 3.96 0.52

6 6.90 6.02 0.44 7.10 6.14 0.48 7.10 6.08 0.51 7.10 6.00 0.55 7.22 6.06 0.58 7.22 6.00 0.61 7.38 6.08 0.65 7.38 6.00 0.69

8 9.05 8.13 0.46 9.05 8.03 0.51 9.30 8.18 0.56 9.30 8.10 0.60 9.42 8.10 0.66 9.42 8.10 0.66 9.60 8.10 0.75 9.60 8.00 0.8

I.D.

Inch

Wall

O.D.

Inch

I.D.

Inch

Wall

O.D.

Inch

I.D.

Inch

Wall

O.D.

Inch

I.D.

Inch

Wall

O.D.

Inch

I.D.

Inch

Wall

O.D.

Inch

I.D.

Inch

Wall

CLASS G CLASS HCLASS A

O.D.

Inch

I.D.

Inch

Wall

O.D.

Inch

I.D.

Inch

Wall

54 56.66 53.96 1.35 57.10 54.00 1.55 57.80 54.00 1.90 58.40 53.94 2.23

60 62.80 60.02 1.39 63.40 60.06 1.67 64.20 60.20 2.00 64.82 60.06 2.38

72 75.34 72.10 1.62 76.00 72.10 1.95 76.88 72.10 2.39

84 87.54 84.10 1.72 88.54 84.10 2.22

March, 2000

Page 40

Steel, Stainless Steel, P.V.C.

Standard Schedules

Nominal

Pipe Size

Inches

1.25 1.660 1.530 0.065 1.442 0.109 1.380 1.380 0.140 1.278 0.191 1.278 0.191 1.160 0.250

OUTSIDE

DIAMETER

1 1.315 1.185 0.065 1.097 0.109 1.049 1.049 0.133 0.957 0.179 0.957 0.179 0.815 0.250

1.5 1.900 1.770 0.065 1.682 0.109 1.610 1.610 0.145 1.500 0.200 1.500 0.200 1.338 0.281

2 2.375 2.245 0.065 2.157 0.109 2.067 2.067 0.154 1.939 0.218 1.939 0.218 1.687 0.344

2.5 2.875 2.709 0.083 2.635 0.120 2.469 2.469 0.203 2.323 0.276 2.323 0.276 2.125 0.375

3 3.500 3.334 0.083 3.260 0.120 3.068 3.068 0.216 2.900 0.300 2.900 0.300 2.624 0.438

3.5 4.000 3.834 0.083 3.760 0.120 3.548 3.548 0.226 3.364 0.318 3.364 0.318

4 4.500 4.334 0.083 4.260 0.120 4.026 0.237 4.026 0.237 3.826 0.337 3.826 0.337 3.624 0.438 3.624 0.438 3.438 0.531

5 5.563 5.345 0.109 5.295 0.134 5.047 0.258 5.047 0.258 4.813 0.375 4.813 0.375 4.563 0.500 4.563 0.500 4.313 0.625

6 6.625 6.407 0.109 6.357 0.134 6.065 0.280 6.065 0.280 5.761 0.432 5.761 0.432 5.501 0.562 5.501 0.562 5.187 0.719

8 8.625 8.407 0.109 8.329 0.148 8.125 0.250 8.071 0.277 7.981 0.322 7.981 0.322 7.813 0.406 7.625 0.500 7.625 0.500 7.437 0.594 7.187 0.719 7.187 0.719 6.183 1.221

10 10.750 10.482 0.134 10.42 0.165 10.25 0.250 10.13 0.310 10.02 0.365 10.020 0.365 9.750 0.500 9.750 0.500 9.562 0.594 9.312 0.719 9.062 0.844 9.062 0.844 8.500 1.125

12 12.750 12.420 0.165 12.39 0.180 12.25 0.250 12.09 0.330 12.00 0.375 11.938 0.406 11.626 0.562 11.750 0.500 11.370 0.690 11.060 0.845 10.750 1.000 10.750 1.000 10.120 1.315

14 14.000 13.50 0.250 13.37 0.315 13.25 0.375 13.25 0.375 13.124 0.438 12.814 0.593 13.000 0.500 12.500 0.750 12.310 0.845 11.810 1.095 11.810 1.095 11.180 1.410

16 16.000 15.50 0.250 15.37 0.315 15.25 0.375 15.25 0.375 15.000 0.500 14.688 0.656 15.000 0.500 14.310 0.845 13.930 1.035 13.560 1.220 13.560 1.220 12.810 1.595

18 18.000 17.50 0.250 17.37 0.315 17.12 0.440 17.25 0.375 16.876 0.562 16.564 0.718 17.000 0.500 16.120 0.940 15.680 1.160 15.250 1.375 15.250 1.375 14.430 1.785

20 20.000 19.50 0.250 19.25 0.375 19.25 0.375 19.25 0.375 18.814 0.593 18.376 0.812 19.000 0.500 17.930 1.035 17.430 1.285 17.000 1.500 17.000 1.500 16.060 1.970

24 24.000 23.50 0.250 23.25 0.375 23.25 0.375 23.25 0.375 22.626 0.687 22.126 0.937 23.000 0.500 21.560 1.220 20.930 1.535 20.930 1.535 20.930 1.535 19.310 2.345

30 30.000 29.37 0.315 29.00 0.500 29.00 0.500 29.25 0.375 29.250 0.375 29.000 0.500

36 36.000 35.37 0.315 35.00 0.500 35.00 0.500 35.25 0.375 35.250 0.375 35.000 0.500

42 42.000 41.25 0.375 41.250 0.375 41.000 0.500

48 48.000 47.25 0.375 47.250 0.375 47.000 0.500

SCH.

5

ID Wall ID Wall ID Wall ID Wall ID Wall ID Wall ID Wall ID Wall ID Wall ID Wall ID Wall ID Wall ID Wall

SCH. 10

(LTWALL)

SCH. 20 SCH. 30 STD. SCH. 40 SCH. 60

X STG. SCH. 80 SCH. 100 SCH. 120

SCH. 140 SCH. 180

March, 2000

Page 41

Ductile Iron Pipe

Standard Classes

Cement Lining

Pipe

Size

(inches)

3 3.96 3.46 0.25 3.40 0.28 3.34 0.31 3.28 0.34 3.22 0.37 3.14 0.41

4 4.80 4.28 0.26 4.22 0.29 4.16 0.32 4.10 0.35 4.04 0.38 3.93 0.44

6 6.90 6.40 0.25 6.34 0.28 6.28 0.31 6.22 0.34 6.16 0.37 6.10 0.40 6.04 0.43 .123/.250

8 9.05 8.51 0.27 8.45 0.30 8.39 0.33 8.33 0.36 8.27 0.39 8.21 0.42 8.15 0.45

10 11.10 10.32 0.39 10.46 0.32 10.40 0.35 10.34 0.38 10.28 0.41 10.22 0.44 10.16 0.47

12 13.20 12.58 0.31 12.52 0.34 12.46 0.37 12.40 0.40 12.34 0.43 12.28 0.46 12.22 0.49

14 15.30 14.64 0.33 14.58 0.36 14.52 0.39 14.46 0.42 14.40 0.45 14.34 0.48 14.28 0.51

16 17.40 16.72 0.34 16.66 0.37 16.60 0.40 16.54 0.43 16.48 0.46 16.42 0.49 16.36 0.52

18 19.50 18.80 0.35 18.74 0.38 18.68 0.41 18.62 0.44 18.56 0.47 18.50 0.50 18.44 0.53 .1875/.375

Outside

Diameter

(inches)

Class 54 Class 55 Class 56Class 50 Class 51 Class 52 Class 53

ID Wall ID Wall ID Wall ID Wall ID Wall ID Wall ID Wall

Std./Double

Thickness

20 21.60 20.88 0.36 20.82 0.39 20.76 0.42 20.70 0.45 20.64 0.48 20.58 0.51 20.52 0.54

24 25.80 25.04 0.38 24.98 0.41 24.92 0.44 24.86 0.47 24.80 0.50 24.74 0.53 24.68 0.56

30 32.00 31.22 0.39 31.14 0.43 31.06 0.47 30.98 0.51 30.90 0.55 30.82 0.59 30.74 0.63

36 38.30 37.44 0.43 37.34 0.48 37.06 0.62 37.14 0.58 37.40 0.45 36.94 0.68 36.84 0.73

42 44.50 43.56 0.47 43.44 0.53 43.32 0.59 43.20 0.65 43.08 0.71 42.96 0.77 42.84 0.83 .250/.500

48 50.80 49.78 0.51 49.64 0.58 49.50 0.65 49.36 0.72 49.22 0.79 49.08 0.86 48.94 0.93

54 57.10 55.96 0.57 55.80 0.65 55.64 0.73 55.48 0.81 55.32 0.89 55.16 0.97 55.00 1.05

March, 2000

Page 42

FPS TO GPM CROSS - REFERENCE (Schedule 40)

Nominal

Pipe

(Inches)

1 1.05 2.6989 4.0484 5.3978 6.7473 8.097 9.4462 10.796 12.145 13.490 14.844 16.190 17.540 18.890 20.240 21.590 22.941 24.290

1.25 1.38 4.6620 6.9929 9.3239 11.655 13.99 16.317 18.648 20.979 23.310 25.641 27.970 30.300 32.630 34.960 37.300 39.627 41.958

1.5 1.61 6.3454 9.5182 12.691 15.864 19.04 22.209 25.382 28.555 31.730 34.900 38.070 41.250 44.420 47.590 50.760 53.936 57.109

2 2.07 10.489 15.734 20.979 26.224 31.47 36.713 41.958 47.202 52.450 57.692 62.940 68.180 73.430 78.670 83.920 89.160 94.405

2.5 2.47 14.935 22.402 29.870 37.337 44.80 52.272 59.740 67.207 74.670 82.142 89.610 97.080 104.50 112.00 119.50 126.95 134.41

3 3.07 23.072 34.608 46.144 57.680 69.22 80.752 92.288 103.82 115.40 126.90 138.40 150.00 161.50 173.00 184.60 196.11 207.65

3.5 3.55 30.851 46.276 61.702 77.127 92.55 107.98 123.40 138.83 154.30 169.68 185.10 200.50 216.00 231.40 246.80 262.23 277.66

4 4.03 39.758 59.636 79.515 99.394 119.3 139.15 159.03 178.91 198.80 218.67 238.50 258.40 278.30 298.20 318.10 337.94 357.82

5 5.05 62.430 93.645 124.86 156.07 187.3 218.50 249.72 280.93 312.10 343.36 374.60 405.80 437.00 468.20 499.40 530.65 561.87

6 6.06 89.899 134.85 179.80 224.75 269.7 314.65 359.60 404.55 449.50 494.45 539.40 584.30 629.30 674.20 719.20 764.14 809.09

8 7.98 155.89 233.83 311.78 389.72 467.7 545.61 623.56 701.50 779.40 857.39 935.30 1013.0 1091.0 1169.0 1247.0 1325.1 1403.0

10 10.02 245.78 368.67 491.56 614.45 737.3 860.23 983.12 1106.0 1229.0 1351.8 1475.0 1598.0 1720.0 1843.0 1966.0 2089.1 2212.0

I.D.

INCH

1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9

12 11.94 348.99 523.49 697.99 872.49 1047.0 1221.5 1396.0 1570.5 1745.0 1919.5 2094.0 2268.0 2443.0 2617.0 2792.0 2966.5 3141.0

14 13.13 422.03 633.04 844.05 1055.1 1266.0 1477.1 1688.1 1899.1 2110.0 2321.1 2532.0 2743.0 2954.0 3165.0 3376.0 3587.2 3798.2

16 15.00 550.80 826.20 1101.6 1377.0 1652.0 1927.8 2203.2 2478.6 2754.0 3029.4 3305.0 3580.0 3856.0 4131.0 4406.0 4681.8 4957.2

FPS TO GPM: GPM = (PIPE ID)² X VELOCITY IN FPS X 2.45 FPS X .3048 = MPS

GPM TO FPS: FPS =

GPM

(ID)² X 2.45

GPM X .0007 = GPD

GPM X 3.7878 = LPM

Page 43

FPS TO GPM CROSS - REFERENCE (Schedule 40)

Nominal

Pipe

(Inches)

18 16.88 697.52 1046.3 1395.0 1743.8 2093.0 2441.3 2790.1 3138.8 3488.0 3836.3 4185.0 4534.0 4883.0 5231.0 5580.0 5928.9 6277.7

20 18.81 866.14 1299.0 1732.0 2165.3 2598.4 3031.5 3464.6 3897.6 4330.7 4763.8 5196.8 5629.9 6063.0 6496.0 6929.1 7362.2 7795.3

24 22.63 1253.7 1880.0 2507.0 3134.1 3761.0 4387.8 5014.6 5641.5 6268.3 6895.1 7522.0 8148.8 8775.6 9402.4 10029 10656 11283

26 25.25 1560.7 2341.0 3121.0 3901.9 4682.2 5462.6 6243.0 7023.4 7803.7 8584.1 9364.5 10145 10925 11706 12486 13266 14047

28 27.25 1817.8 2727.0 3636.0 4544.5 5453.4 6362.3 7271.2 8180.0 9088.9 9997.8 10907 11816 12725 13633 14542 15451 16360

30 29.25 2094.4 3142.0 4189.0 5236.0 6283.2 7330.4 8377.6 9424.9 10472 11519 12566 13614 14661 15708 16755 17803 18850

32 31.25 2390.6 3586.0 4781.0 5976.5 7171.9 8367.2 9562.5 10758 11953 13148 14344 15539 16734 17930 19125 20320 21516

34 33.25 2706.4 4060.0 5413.0 6766.0 8119.2 9472.4 10826 12179 13532 14885 16238 17592 18945 20298 21651 23004 24358

36 35.25 3041.8 4563.0 6084.0 7604.5 9125.4 10646 12167 13688 15209 16730 18251 19772 21292 22813 24334 25855 27376

42 41.25 4165.4 6248.0 8331.0 10414 12496 14579 16662 18744 20827 22910 24992 27075 29158 31241 33323 35406 37489

48 47.99 5637.8 8457.0 11276 14095 16913 19732 22551 25370 28189 31008 33827 36646 39465 42284 45103 47922 50740

54 53.98 7133.1 10700 14266 17833 21399 24966 28532 32099 35665 39232 42798 46365 49931 53498 57065 60631 64198

I.D.

INCH

1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9

60 60.09 8839.2 13259 17678 22098 26518 30937 35357 39777 44196 48616 53035 57455 61875 66294 70714 75134 79553

72 72.10 12726 19089 25451 31814 38177 44540 50903 57266 63628 69991 76354 82717 89080 95443 101805 108168 114531

84 84.10 17314 25971 34628 43285 51943 60600 69257 77914 86571 95228 103885 112542 121199 129856 138514 147171 155828

FPS TO GPM: GPM = (PIPE ID)² X VELOCITY IN FPS X 2.45 FPS X .3048 = MPS

GPM TO FPS: FPS =

GPM

(ID)² X 2.45

GPM X .0007 = GPD

GPM X 3.7878 = LPM

Page 44

Limited Warranty and Disclaimer

Dynasonics, division of Racine Federated Inc. warrants to the end purchaser, for a period

of one year from the date of shipment from the factory, that all new transmitters and

transducers manufactured by it are free from defects in materials and workmanship. This

warranty does not cover products that have been damaged due to misapplication, abuse,

lack of maintenance, or improper installation. Dynasonics’ obligation under this

warranty is limited to the repair or replacement of a defective product, at no charge to the

end purchaser, if the product is inspected by Dynasonics and found to be defective.

Repair or replacement is at Dynasonics’ discretion. A return goods authorization (RGA)

number must be obtained from Dynasonics before any product may be returned for

warranty repair or replacement. The product must be thoroughly cleaned and any process

chemicals removed before it will be accepted for return.

The purchaser must determine the applicability of the product for its desired use and

assumes all risks in connection therewith. Dynasonics assumes no responsibility or

liability for any omissions or errors in connection with the use of its products.

Dynasonics will under no circumstances be liable for any incidental, consequential,

contingent or special damages or loss to any person or property arising out of the failure

of any product, component or accessory.

All expressed or implied warranties, including the implied warranty of

merchantability and the implied warranty of fitness for a particular purpose or

application are expressly disclaimed and shall not apply to any products sold or

services rendered by Dynasonics.

The above warranty supersedes and is in lieu of all other warranties, either expressed or

implied and all other obligations or liabilities. No agent or representative has any

authority to alter the terms of this warranty in any way.

Page 45

GENERAL TERMS AND CONDITIONS OF SALES

1. PAYMENT – Terms of payment are effective from the actual date of invoice. If, in the Seller’s

opinion, the financial condition of the Buyer at any time – or any other circumstances – do not justify

the incurrence of production costs of shipment on the terms of payment specified, the Seller may

require partial or full payment in advance. Payment terms are net 30 days unless otherwise stated on

invoice.

2. F.O.B. – All shipments are from Racine, Wisconsin, USA, unless otherwise other stated, and title

transfers to the buyer upon leaving factory.

3. QUOTATION AND PRICES – Quoted prices are firm for 30 days unless stated in the quotation and

are subject to change without notice after expiration of this period.

4. TAXES – Any applicable sales, use, revenue, excise or other taxes not specifically stated in the

quotation are to be remitted by the Buyer directly to the appropriate regulatory agency.

5. WARRANTY – Seller’s standard published warranty in effect at the time of shipment shall apply.

This warranty is exclusive and is in lieu of all other warranties, express, implied, or statutory, including

the warranty of merchantability.

6. DELIVERY – The Seller shall not be liable for loss or damage of any kind resulting from delay or

inability to deliver on account of flood, fire, labor trouble, riots, civil disturbances, accidents, acts or

orders or regulations of civil or military authorities, shortages of material, or any other causes beyond

Seller’s control.

7. PRODUCT CHANGES – In keeping with our continuing policy of product improvement, we reserve

the right to make changes in our products at any time, without incurring an obligation to change,

replace or upgrade equipment previously shipped.

8. CANCELLATIONS – An order placed by Buyer and accepted by Seller may be cancelled only with

the Seller’s consent and upon terms that will indemnify the Seller against loss.

9. RESTOCKING CHARGE – On standard equipment, the charge is 25%, provided the equipment is

returned within 30 days in acceptable condition with a RGA number. Restocking charges for special

equipment may vary from standard equipment, and will be handled on a case-by-case basis.

No returns will be taken after one year.

Page 46

RETURN OF EQUIPMENT/SALES INFORMATION

CONTACTS AND PROCEDURES

Customer Service/Application Engineer:

If you have a question regarding order status, placing an order, reviewing applications for

future purchases, or wish to purchase a new flow meter, please contact our new National

Sales and Marketing Headquarters:

DYNASONICS

Division of Racine Federated Inc.

8635 Washington Avenue

Racine, WI 53406

PHONE: (800) 535-3569 or

(262) 639-6770

FAX: (262) 639-2267

Service/Repair Department:

If you already purchased equipment and have an operation problem, require service, or

need to schedule field service, please contact our Service Department:

DYNASONICS

Division of Racine Federated Inc.

8635 Washington Avenue

Racine, WI 53406

PHONE: (800) 535-3569 or

(262) 639-6770

FAX: (262) 639-2267

Return Goods Authorization:

When returning equipment, it is necessary for you to contact our Service Department at

(800) 535-3569 or (262) 639-6770 to obtain an RGA number for the authority and proper

tracking of your material and its prompt inspection and return. The RGA number should

be noted on the outside of the box. All returns of equipment go to the following address:

DYNASONICS

Division of Racine Federated Inc.

8635 Washington Avenue

Racine, WI 53406

Attn: RGA #

Page 47

Page 48

8635 WASHINGTON AVENUE

RACINE, WI 53406

TOLL-FREE IN NORTH AMERICA

TEL: (800) 535-3569 FAX: (800) 732-8354

TEL: (262) 639-6770 FAX: (262) 639-2267

URL: www.dynasonics.com

DYNASONICS is a registered trademark of Racine Federated Inc.

Ultem is a registered trademark of General Electric Co.

Vespel is a registered trademark of E.I. DuPont de Nemours and Company.

National Electric Code is a registered trademark of NFPA.

UL is a registered trademark of Underwriters Laboratories.

© 2008 Racine Federated Inc.

All rights reserved.

Printed in USA

D902/903 O&M REV 10/08

Loading...

Loading...