Dynarad Phantom User service manual

Phantom

Portable X-Ray System

Table of

Contents

Safety

Introduction

Installation

Installation, Operation & Service

Manual

Operation

Periodic

Maintenance

Calibration &

Adjustment

Component

Replacement

TroubleShooting

P/N 8000-Phantom

Revision: B, November 8, 2007

Electrical

Schematics

Illustrated

Parts List

Notes

Copyright 2007, Del Medical Systems. All rights reserved.

This document is the property of Del Medical Systems and contains confidential and proprietary

information owned by Del Medical Systems. Any unauthorized copying, use or disclosure of it

without the prior written permission of Del Medical Systemsis strictly prohibited.

Attention: Consult Accompanying Documents - As Applicable

Del Medical Systems Group

50B North Gary Avenue Phone:1-847-288-7000

Roselle, IL 60172 Fax:1-847-288-7011

USA Toll Free:1-800-800-6006

www.delmedical.com

Table of Contents

Chapter i — Safety Information

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i–1

Statement of Liability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i–2

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i–3

Safety Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . i–4

Warning Statements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i–4

Caution Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i–5

Equipment Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i–6

Safety and Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i–9

Radiation Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i–10

Maximum Permissible Dose (MPD) . . . . . . . . . . . . . . . . . . . . . . . i–11

Identification Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i–12

Phantom Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i–12

Radiation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i–13

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i–13

Manufacturer’s Responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i–14

Monitoring Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i–14

Radiation Protection Survey . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i–15

Hazardous Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i–16

Applicable Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i–17

Chapter ii — Record of Revisions

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii–1

Chapter 1 — Introduction

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

1.2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

1.2.1 Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

1.3 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

1.4 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

1.5 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

1.6 Accuracy Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

kVp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

mA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

Chapter 2 — Installation

2.1 Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

1

Phantom Installation, Operation and Service Manual

Chapter 3 — Operation

3.1 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–1

3.2 Operation Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–2

3.3 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–3

3.3.1 Main Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–3

3.3.2 Miscellaneous Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–4

3.3.3 Collimator Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–6

3.4 Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–7

3.5 Technique Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–12

3.6 Unfolding Phantom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–14

3.7 Folding Phantom. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–19

Chapter 4 — Periodic Maintenance

4.1 Periodic Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–1

4.2 Cleaning External Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–2

4.3 Check fasteners for tightness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–3

4.4 Check collimator tightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–4

4.5 Check interconnect cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–5

4.6 Check tube head rotation (friction lock) . . . . . . . . . . . . . . . . . . . . .4–6

Chapter 5 — Calibration and Adjustments

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–1

5.2 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–2

5.2.1 Equipment setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–3

5.2.2 Pre-Calibration (only necessary if replacing an X-ray tube)5–3

5.2.3 kVp waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–4

5.2.4 Beam current (mA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–6

5.2.5 Tube potential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–7

5.2.6 Exposure time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–8

5.2.7 X-ray to light field alignment. . . . . . . . . . . . . . . . . . . . . . . . . .5–8

5.3 Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–10

Chapter 6 — Component Replacement

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–1

6.2 Replacing Control Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–2

6.3 Interconnect Cable Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . .6–5

6.4 X-Ray Head Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–8

6.5 Locking Cylinder Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . .6–13

6.6 Release Cable Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–15

2

Phantom Installation, Operation and Service Manual

Chapter 7 — Troubleshooting

7.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

7.2 Troubleshooting Index & Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–2

7.3 Schematic Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–3

7.3.1 Main Control console Layout . . . . . . . . . . . . . . . . . . . . . . . . . 7–4

7.3.2 Generator Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–5

7.4 Technical Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–6

7.4.1 System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–6

7.4.2 Generator Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–6

7.4.3 Control assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–6

Chapter 8 — Diagrams & Electrical Schematics

8.1 Electrical Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–1

Chapter 9 — Illustrated Parts List

9.1 Ordering Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–1

9.1.1 To Order by Fax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–1

9.2 How to Use This Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–1

9.2.1 General Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–1

9.3 Commonly Ordered Parts (Collimator) . . . . . . . . . . . . . . . . . . . . . 9–2

9.4 Commonly Ordered Parts (Main Unit) . . . . . . . . . . . . . . . . . . . . . . 9–3

9.5 Overall Assembly (501031) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–4

9.6 Generator Assembly (500946). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–6

9.7 Generator Chassis Assembly (500977) . . . . . . . . . . . . . . . . . . . . . . 9–8

9.8 Portable Stand Assembly (500982). . . . . . . . . . . . . . . . . . . . . . . . . 9–10

9.9 Front Leg Assembly (500980). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–13

9.10 Tube Arm Assembly (500981). . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–14

9.11 Control Assembly (501020) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–16

9.12 Control Chassis Assembly (501203). . . . . . . . . . . . . . . . . . . . . . . 9–18

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N-1

3

Phantom Installation, Operation and Service Manual

4

Safety Information

Introduction

The policy of Del Medical Systems Group is to manufacture X-ray

equipment that meet high standards of performance and reliability. We

enforce strict quality control techniques to eliminate the potential for

defects and hazards in our products.

The intended use of this equipment is to provide an X-ray source for the

purpose of acquiring X-ray images of the desired parts of a patient’s

anatomy. Use of this equipment in any other fashion may lead to serious

personal injury.

i

The safety guidelines provided in this section of the manual are intended

to educate the operator on all safety issues in order to operate and

maintain the Phantom in a safe manner.

Introduction i-1

Phantom Installation, Operation & Service Manual

Statement of Liability

To prevent excess radiation exposure to patient and operator from either

primary or secondary radiation, this Phantom must be operated and

serviced by trained personnel who are familiar with the safety precautions

required. While this Phantom has been designed for safe operation,

improper operation or carelessness may result in serious injury or damage

to equipment. The manufacturer or its agents and representatives assume

no responsibility for the following:

1 Injury or danger to any person from x-ray exposure.

2 Overexposure due to poor technique selection.

3 Injury or danger from improper use of the Phantom function.

4 Problems or hazards resulting from failure to maintain the equipment

as specified in this manual.

5 Equipment which has been tampered with or modified. Del Medical

Systems Group is not liable for any damage or injury arising from

failure to follow the instructions and procedures provided within the

manuals or associated informational material, or from user failure to

use caution when installing, operating, adjusting, or servicing this

equipment. Del Medical Systems Group is not liable for damage or

injury arising from the use of this product for any other use than that

intended by the manufacturer.

i-2 Statement of Liability

Definitions

Phantom Installation, Operation & Service Manual

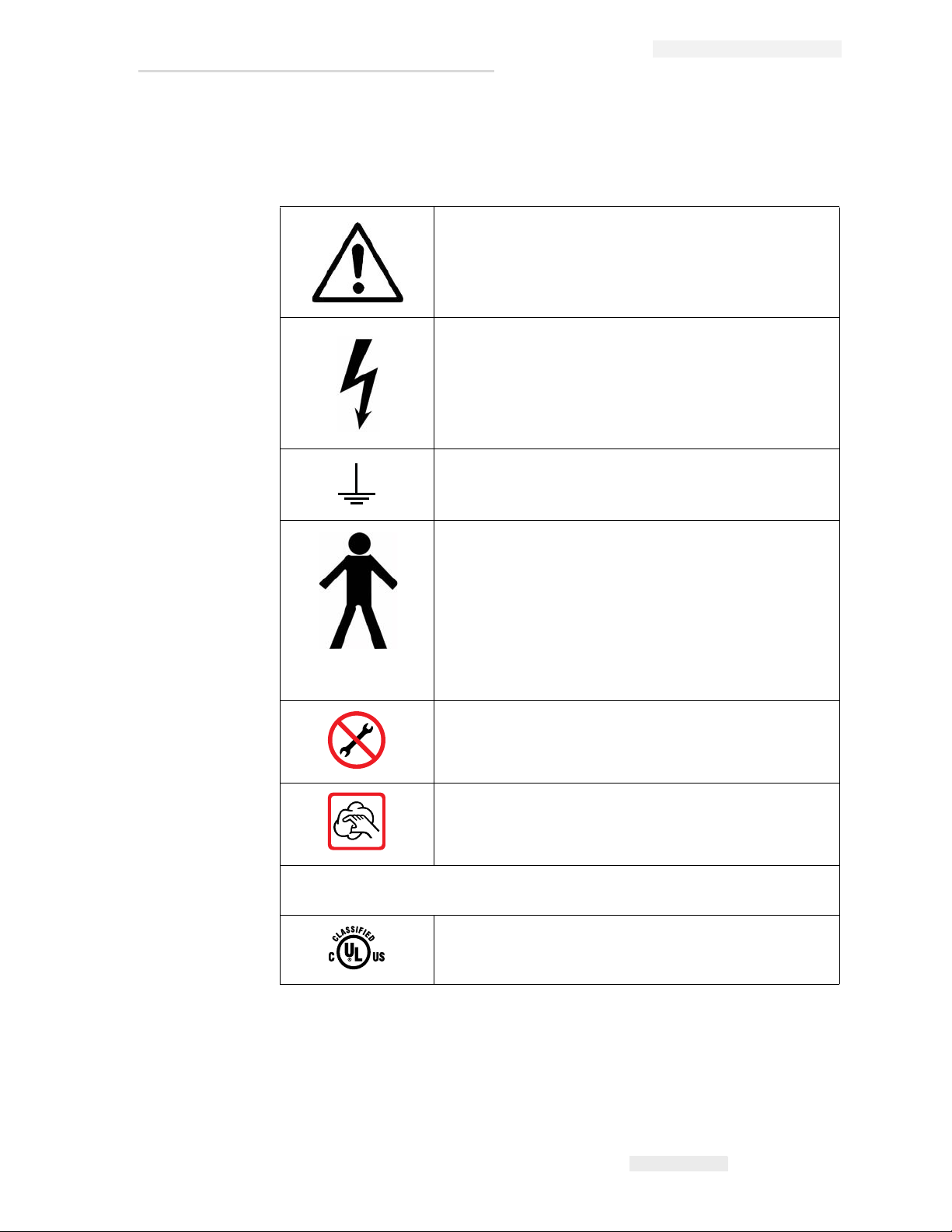

The table below defines the meaning of various symbols used on labels on

the machine.

This warning symbol is used to indicate a potential hazard to operators, service personnel or equipment. It indicates a requirement to refer to the accompanying

documentation for details.

This symbol indicates that there is accessible dangerous

voltage.

This symbol identifies a protective earth terminal.

This symbol states that this product is categorized as

Type B.

Type B is defined as:

Equipment providing a particular degree of pr ot ec tion

against electric shock, particularly regarding allowable

leakage currents and reliability of the protective earth

connection (if present).

This product contains no field serviceable part s.

Special Cleaning Instructions

One or more of the following regulatory symbols are found on the equip-

ment.

UL Classified Device

Definitions i-3

Phantom Installation, Operation & Service Manual

Warning

Safety Conventions Used in this Manual

Specific safety information is listed in this manual in the form of

WARNING and CAUTION statements. Pay close attention to these

statements - they contain important information on avoiding potential

hazards to you or the equipment.

Warning Statements

• are used to indicate hazards or unsafe practices which COULD result

in severe personal injury or death.

• appear in bold type.

• have a triangular symbol with an exclamation point above the text.

• are preceded by the word Warning.

• are always found before the step or piece of information to which they

refer to.

• look like the following example:

This text will describe special safety precautions to follow in order

to avoid unsafe practices that COULD result in severe personal

injury or death.

i-4 Safety Conventions Used in this Manual

Caution Statements

Caution

• are used to indicate hazards or unsafe practices which could result in

minor personal injury or product or property damage.

• appear in bold type.

• have a triangular symbol with an exclamation point above the text.

• are preceded by the word Caution.

• are always found before the step or piece of information to which they

refer to.

• look like the following example:

This text will describe special safety precautions to follow in order

to avoid unsafe practices that could result in personal injury or

product or property damage.

Phantom Installation, Operation & Service Manual

Safety Conventions Used in this Manual i-5

Phantom Installation, Operation & Service Manual

Warning

Warning

Equipment Safety Guidelines

The following are general safety precautions:

• Do not defeat or bypass built-in equipment safety features.

• Observe all warnings and cautions, stated or implied, in the

procedures.

• Follow all safety labels on the equipment.

The following warnings and cautions are specific to the Phantom. Read

them carefully - some of them are not obvious to typical equipment use.

Do not perform any service procedures on this device until the

power cord has been disconnected and the device has been

allowed to discharge for at least 5 minutes. You can be fatally

shocked if you do not.

Voltage as high as 100,000 volts may be present in the Phantom’s

circuitry for a few minutes after it has been turned off.

All of the movable assemblies and parts of this equipment should

be operated with care and routinely inspected in accordance with

the manufacturer’s recommendations contained in this manual.

Only properly trained and qualified personnel should be

permitted access to any internal parts. Live electrical terminals are

deadly; be sure line disconnect switches are opened and other

appropriate precautions are taken before opening access doors,

removing enclosure panels, or attaching accessories.

For all components of the equipment, protective earthing means

must be provided in compliance with the national regulations.

i-6 Equipment Safety Guidelines

Phantom Installation, Operation & Service Manual

Warning

Warning

Warning

Warning

This Phantom is intended to be used as part of a system for the

intended generation of X-rays for medical diagnosis.

X-rays generate a potential risk for both patients and operators.

For this reason, the application of X-rays for a given medical

purpose must aim at the minimization of radiation exposition to

any persons.

Those persons responsible for the application must have the

specific knowledge according to legal requirements and

regulations and must establish safe exposure procedures for this

kind of systems.

Those persons responsible for the planning and installation of this

equipment must observe the national regulations.

Federal law restricts this device for sale or use by or on order of a

physician or properly licensed practitioner.

Only qualified personnel may operate the Phantom. Operation of

the equipment by persons who have not been trained or who are

unfamiliar with the Phantom may cause serious injury to the

patient, serious injury to the operator, or equipment damage.

The Phantom includes no user serviceable parts. For service

assistance, contact Del Medical.

Equipment Safety Guidelines i-7

Phantom Installation, Operation & Service Manual

Warning

Warning

Warning

Warning

Warning

The Phantom produces ionizing radiation. Operators must meet

all state and local requirements and regulations.

The Phantom and associated cables must not be operated in the

presence of moisture.

The Phantom is rated as Class I Equipment, ensure that the earth

grounding connections between the Phantom and its power source

is maintained at all times.

The Phantom is not suitable for operation in the presence of a

flammable anesthetic mixture with air, oxygen, or nitrous oxide.

Disconnect electrical power from the Phantom before servicing.

Use care not to drop tools or other objects into the Phantom when

working on or around the unit. Electrical shock could result.

i-8 Equipment Safety Guidelines

Safety and Compliance

Exposure to ionizing radiation such as X-rays can be hazardous. United

States federal regulations establish appropriate exposure limits so that the

patient, the operator, and the general public are not unnecessarily being

exposed to such radiation. Personnel operating systems such as the

Phantom must be trained and qualified. They must be familiar with

established regulations and understand the risks associated with the

operation of a X-ray system. They must know what action to take if and

when a hazardous situation arises.

For a more complete understanding of radiological hazards and their

control, X-ray system operators are referred to publications, such as:

Medical X-ray, Electron Beam and Gamma Ray Protection for Energies up

to 50 MeV – Equipment Design, Performance and Use (Report No. 102,

National Council on Radiation Protection)

Medical X-Ray Protection up to Three Million Volts (Handbook No. 76,

National Bureau of Standards/National Institute for Standards and

Technology)

Phantom Installation, Operation & Service Manual

In addition to ionizing radiation, other safety concerns are addressed by

various U.S., Canadian, and international standards. The component parts

and subsystems used in the Phantom have all been tested for compliance

with the safety standards in effect at the time of manufacture in the United

States (UL 187) & Canada (CAN/CSA C22.2 No. 114-M90).

The results of these safety tests and inspections show that the Phantom is

safe. There are, however, certain residual hazards resulting from the

mechanical articulation of the system. Minimizing the risk of injury to the

patient and to the operator resulting from these residual hazards requires

care and alertness at the time of installation. Pinch points are labeled as

appropriate at the time of installation. These labels must not be removed.

If they become soiled or damaged, they need to be replaced.

Safety and Compliance i-9

Phantom Installation, Operation & Service Manual

Radiation Protection

Serious unfavorable health effects can result from short term exposure to

high levels of ionizing radiation (such as X-rays) as well as from long term

exposure to low levels. Personnel who operate the Phantom should

familiarize themselves with both the short term and the long term effects

of radiation exposure and take appropriate measures to minimize the

amount of radiation to which they are exposed while performing their

duties. Some effects of X-ray radiation are cumulative, and may extend

over a period of months or years. The best safety rule for X-ray operators

is to avoid exposure to the primary beam at all times.

Ionizing radiation occurs naturally in the environment. It is generated by

astronomical radiation sources such as the sun and the stars, and by the

soil under our feet. The atmosphere filters radiation from astronomical

sources. As a result, the radiation level from these sources is much lower

at sea level than on the summit of high mountains. Radiation generated in

the soil varies greatly from place to place depending on the composition of

the soil. For example, areas rich in granite rock have a higher level of

radiation than other areas.

Any materials placed in the path of the beam absorb natural as well as

man-made radiation, such as the X-rays used in the Phantom. Materials

with a high atomic number, such as tungsten, lead, and uranium, absorb

X-rays much more effectively than materials with a low atomic number

such as hydrogen, aluminum, or beryllium. Therefore, lead is used for

shielding the radiologist's workstation in most X-ray facilities, including

ones using the Phantom. If there are windows in the partition separating

the operator from the patient, these windows are typically glazed with

lead glass and provide effective protection against ionizing radiation.

To minimize dangerous exposure, use movable lead screens,

lead-impregnated gloves, and lead-impregnated aprons. These protective

devices must contain 0.25 millimeter thickness of lead or the equivalent.

Use such protective devices for all operators, observers, and/or servicing

personnel exposed to radiation fields of five or more milli-Roentgens per

hour.

The shielding provided for a typical X-ray facility's operator workstation

is generally quite effective and reduces the residual radiation from

diagnostic X-rays to a level that is comparable to or lower than natural

background radiation. If the operator abandons the protected

environment of the workstation, he or she may be exposed to a

significantly higher level of radiation. For a single exposure this may still

not lead to serious health effects, but repeated carelessness in this regard

may lead to serious consequences.

Any object in the path of the primary beam produces scattered radiation.

In the absence of proper precautions, scattered radiation can result in a

i-10 Radiation Protection

substantial radiation dose to the operator or any other personnel in the

facility. Moveable screens may be used to shield occupied areas from

scattered radiation.

The X-ray Generator/host system used to power the Phantom only

produces X-rays when high voltage is applied to the X-ray tube. When the

high voltage is removed, X-ray emission ceases without delay.

Maximum Permissible Dose (MPD)

Various studies of the effects of x-ray radiation have provided a

foundation for establishing the maximum permissible does (MPD) of xray radiation. The results of these studies have been used by the NCRP

and the ICEP to develop recommendations for MPD.

ICRP recommends that the MPD to the most critical organs (heart, lungs,

liver, kidney, brain, etc.) accumulated at any age shall not exceed five

rems multiplied by the number of years beyond 18:

Phantom Installation, Operation & Service Manual

M PD = 5 X (N - 1 8) rems where n age in years

However, in no case shall the exposure exceed three (3) rems in any period

of 13 consecutive weeks.

For hands, forearms, feet and ankles, the recommended MPD is 75 rems in

any one year.

Radiation Protection i-11

Phantom Installation, Operation & Service Manual

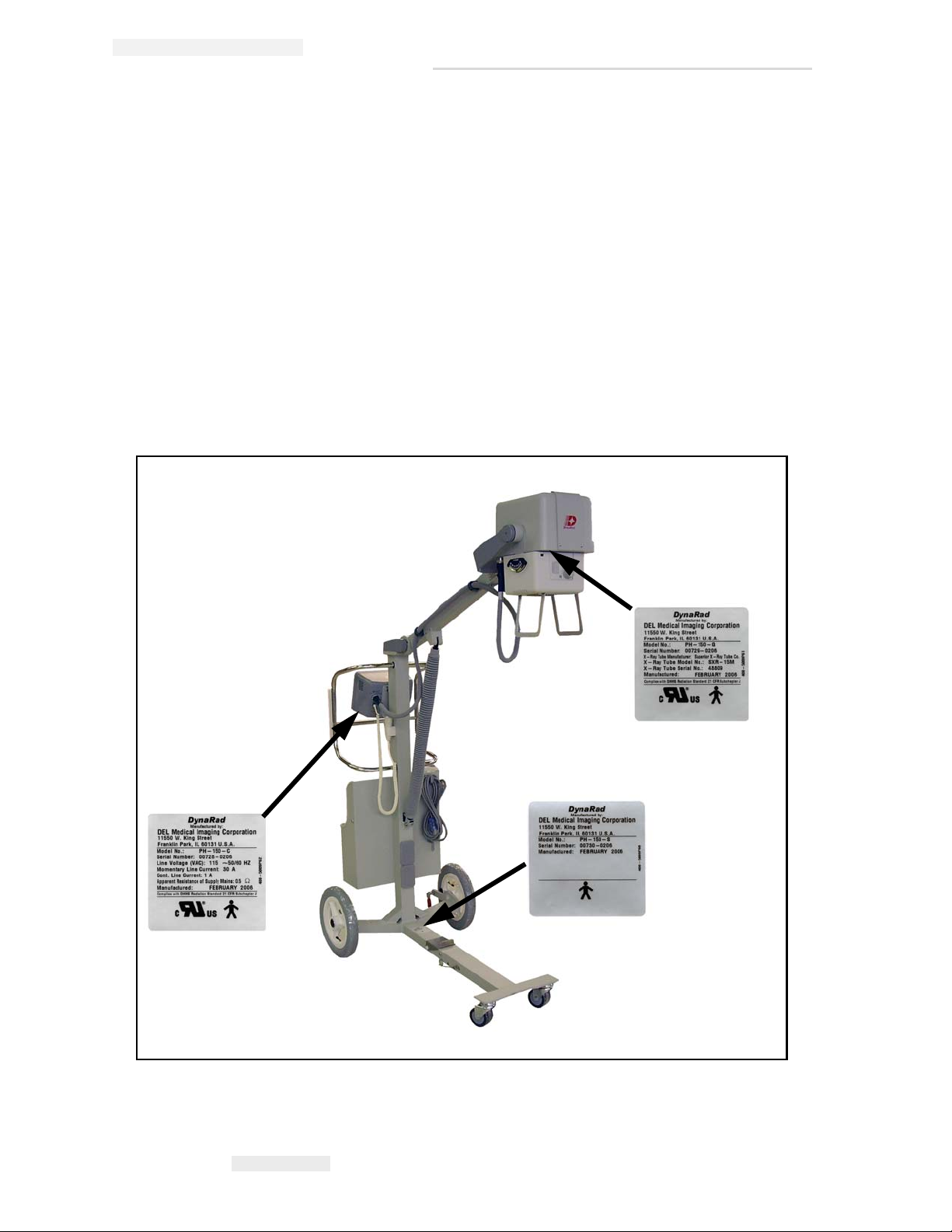

(on the bottom of the

tube head in between

the tube head and the

collimator)

(on the bottom of

the control console)

Identification Labels

The Phantom components have manufacturing and certification

information affixed. The manufacturing label contains:

• The full name and address of the manufacturer of the component

• The place, month, and year of manufacture

• The model number and serial number of the component

The certification label also states that the component complies with either

“21CFR, Subchapter J”, or the applicable DHHS standards under the

Radiation Control for Health and Safety Act of 1968 (or its equivalent).

A label may combine both manufacturing and certification information.

Phantom Labels

The location of each Phantom identification label is shown in Figure i-1.

i-12 Identification Labels

Figure i-1. Phantom Identification Labels

Radiation Safety

Warning

Caution

Safety

Everyone associated with X-ray work must be familiar with the

recommendations of the Center for Devices and Radiological Health

(CDRH), the National Institute for Standards and Technology (NIST), the

National Council on Radiation Protection (NCRP), and the International

Committee on Radiation Protection (ICRP).

Be sure that all personnel authorized to operate the X-ray system are

familiar with the established regulations of the authorities named above.

All personnel should be monitored to ensure compliance with

recommended procedures.

Current sources of information include:

• National Council on Radiation Protection Report No. 33

(“Medical X-ray and gamma ray Protection for Energies up to

10 MEV-Equipment Design and Use”).

Phantom Installation, Operation & Service Manual

• National Bureau of Standards Handbook No. 76 (“Medical X-ray

Protection up to Three Million Volts”). Refer to NCRP Report No. 33.

• Current recommendations of the International Committee on

Radiation Protection.

Although X-ray radiation is hazardous, X-ray equipment does not pose

any danger when properly used. Be certain all operating personnel are

properly educated concerning the hazards of radiation. Persons

responsible for the system must understand the safety requirements and

special warnings for X-ray operation. Review this manual and the

manuals for each component in the system to become aware of all safety

and operational requirements.

Ensure exposure parameters are properly adjusted within safety

limits.

Incorrectly positioning the X-ray tube and Collimator could cause

the X-ray field to be misaligned with the bucky, resulting in

unacceptable images.

Radiation Safety i-13

Phantom Installation, Operation & Service Manual

Manufacturer’s Responsibility

Although this equipment incorporates protection against X-ray radiation

other than the useful beam, practical design does not provide complete

protection. Equipment design does not compel the operator or assistants

to take the necessary precautions; nor does it prevent the possibility of

improper use (authorized or unauthorized persons carelessly, unwisely,

or unknowingly exposing themselves or others to direct or secondary

radiation). Allow only authorized, properly trained personnel to operate

this equipment.

Be certain that all individuals authorized to use the equipment are aware

of the danger of excessive exposure to X-ray radiation.

This equipment is sold with the understanding that the manufacturer, its

agents, and representatives, do not accept any responsibility for

overexposure of patients or personnel to X-ray radiation.

Furthermore, the manufacturer does not accept any responsibility for

overexposure of patients or personnel to X-ray radiation generated by the

equipment used in conjunction with the Phantom components as a result

of poor operating techniques or procedures.

No responsibility is assumed for any unit that has not been serviced and

maintained in accordance with the technical service manual, or which has

been modified or tampered with in any way.

Monitoring Personnel

Monitoring personnel to determine the amount of radiation to which they

have been exposed provides a valuable cross-check to determine whether

or not safety measures are adequate. This cross-check may reveal

inadequate or improper radiation protection practices and/or serious

radiation exposure situations.

The most effective method of determining whether the existing protective

measures are adequate is the use of instruments to measure the exposure

(in rads). This measurement should be taken at all locations where the

operator, or any portion of the operator’s body, may be inadequately

shielded during exposure. Exposure must never exceed the accepted

tolerable dose.

A frequently used, but less accurate, method of determining the amount of

exposure is placement of film at strategic locations. After a specified

period of time, develop the film to determine the amount of radiation.

Fluorescent screens (used in a darkened room) may also be used to detect

excessive radiation.

i-14 Manufacturer’s Responsibility

A common method of determining whether personnel have been exposed

Warning

to excessive radiation is the use of film badges. These are X-ray sensitive

film enclosed in a badge that incorporates metal filters of varying degrees

of transparency to X-ray radiation. Even though this device only measures

the radiation reaching the area of the body on which it is worn, it does

provide an indication of the amount of radiation received.

Radiation Protection Survey

A radiation protection survey must be made by a qualified expert after

every change in equipment or change in operating conditions which

might significantly increase the probability of personnel receiving more

than the maximum permissible dose equivalent.

Restrictions on Use

Phantom Installation, Operation & Service Manual

Do not install components or accessories that were not intend for

use by the system. Failure to comply could result in damage to the

equipment or injury to personnel.

The user is responsible for ensuring that the application and use of the

Phantom does not compromise the patient contact rating of any

equipment used in the vicinity of, or in conjunction with, the system.

The use of accessory equipment and/or hardware not complying with the

equivalent product safety and EMC requirements of this product may

lead to a reduced level of safety and/or EMC performance of the resulting

system. Consideration relating to the choice of accessory equipment used

with this product shall include:

• The use of the accessory in the patient vicinity

• Evidence that the safety certification of the accessory has been

performed in accordance with the appropriate IEC 60601-1 and/or

IEC 60601-1-1 Harmonized National Standards

Some components of the Phantom have been classified as to acceptable

applications of use in accordance with Information Technology

Equipment regulations such as EN60950.

Radiation Protection Survey i-15

Phantom Installation, Operation & Service Manual

Caution

Observe all safety precautions recommended by the accessory

equipment manufacturer in the user documentation provided with

the equipment.

The hardware specified for use with the Phantom has been selected,

tested, and verified by Del Medical to meet the intended applications. All

specified hardware meets applicable regulatory agency requirements for

those countries where it is offered for sale with respect to its intended

applications. Consult the user documentation included with the

equipment for specific information relating to product safety and EMC

compliance.

Hazardous Materials

The collimator used with the Phantom contains lead. Refer to the manual

provided with the collimator for additional information regarding

hazardous materials.

i-16 Hazardous Materials

Applicable Standards

This X-ray generator complies with the following regulatory requirements

and design standards:

FDA 21 CFR Subchapter J, UL187 & CAN/CSA C22.2 No. 114-M90.

Type of protection against electric shock: Class I

Degree of protection against electric shock is Type B Applied Parts.

Degree of protection against harmful ingress of water: IPXO.Ordinary

Mode of Operation: 0.5% Duty Cycle.

Equipment not suitable for use in the presence of flammable anesthetic

mixture with air, oxygen or nitrous oxide.

Degree of protection against electric shock is Type B applied part.

The equipment is intended to be used as a mobile X-ray generator in a

mobile or stationary radiographic diagnostic X-ray configuration.

Phantom Installation, Operation & Service Manual

Applicable Standards i-17

Phantom Installation, Operation & Service Manual

i-18 Applicable Standards

Record of Revisions

Revision History

REV Date Reason for Change

A 6-15-06 Original

B 10-2-07 Chapter 1: Line Volt Regulation added to Specifications

Chapter 3: Line Volt Regu lation added to Specifications, start-up

indications added

Chapter 4: items added to periodic maintenance

Chapter 5: calibration added

Chapter 6: instructions to remove control console back cover

added, X-Ray tube head replacem. procedure changed

Chapter 7: schematics removed (ref. to chapter 8)

Chapter 8: rev. level column added to table, schematics revised

Throughout the manual: uniform terminology

ii

Table ii-1. Revision History

Revision History ii-1

Phantom Installation, Operation & Service Manual

ii-2

Introduction

Collimator

Maneuvering

Control &

X-Ray Tube Head

Exposure Handswitch

Locking Cylinder

Cassette

Wheel

Storage

Display

Console

Handles

Brakes

Front Leg

Assembly

SID Tape

Measure

Lev-O-Gage

Source to Skin Distance

(Do not Use as Handles)

Tube Arm

1.1 Introduction

This manual provides installation, operation and service information for

the Phantom Portable X-Ray System. This manual also includes a spare

parts list for the system.

1

Figure 1-1. The Phantom Portable X-Ray System

Introduction 1-1

Phantom Installation, Operation & Service Manual

1.2 Description

The DynaRad Phantom is a portable and rugged x-ray system that

provides high-quality x-ray images at an affordable price.

The Phantom can retract into a small, self-contained package that can be

easily transported and set up in the most demanding environments.

And it’s easy to maneuver and operate.

1.2.1 Standard Features

• 1.25 Kilowatt X-Ray Generator

• Tape Measure for SID Distance

•Inclinometer

• Detachable, Two-Stage Handswitch

• 30-Second Timer on Collimator Lamp

• Digital Displays on Membrane Switch Control Panel

• Manually Controlled Certified Collimator

• Pneumatic Rear Tires

• Spring-Loaded Counter Weight Ram to Ease Positioning of X-Ray

Tube

1-2 Description

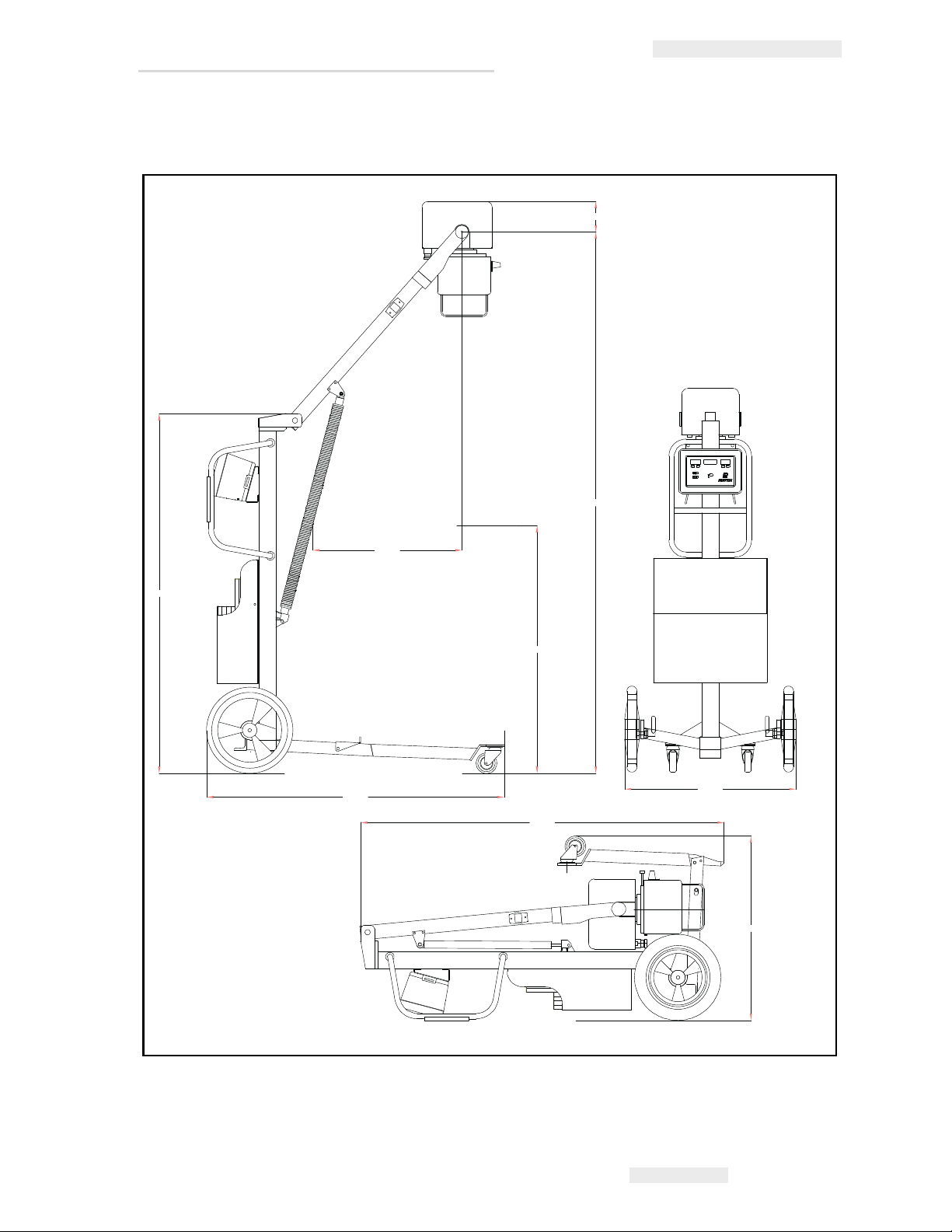

1.3 Dimensions

HIGHFREQUENCYX-RAYSYSTEM

WARNING:

SAFEEXPOSUREFACTORSANDOPERATINGINSTUCTIONS AREOBSERVED.NSTUCTIONS AREOBSERVED.

THIS X-RAYUNITMAY BEDANTMAYBEDANGEROUSTOPATIENTANDOPERATOR,UNLESS

MADE INMADE

INU.S.A.

RESET

FAULT

0.01-4.00sec.50-100kVp

TimemAskVp

12.5mA

X-RAY

READY

C.L.

4.0”

78”

43”

36”

25”

52”

21”

55”

27”

(198cm)

(91.4cm)

(140cm)

(109cm)

(53cm)

(10cm)

(69cm)

(64cm)

(132cm)

Phantom Installation, Operation & Service Manual

Figure 1-2. Dimensions

Dimensions 1-3

Phantom Installation, Operation & Service Manual

1.4 Specifications

Specifications

Voltage 104-126VAC/ 208 - 253 VAC

Line Voltage Regulation 5% maximum at maximum output

Current 30 Amps Maximum Momentary @ 115VAC

Requires 30 amp or greater dedicated breaker or line fuse.

18 Amps Maximum Momentary @ 230VAC

Requires 18 amp or greater dedicated breaker or line fuse.

Frequency 50/60 Hz Single Phase

Generator Type High frequency inverter, 1.25 kilowatt output

kVp Range 50-100 kVp continuously adjustable, with 1 kVp resolution

mA Range Fixed, 12.5 mA, constant independent of kVp or time settings

Exposure Time 0.01 to 4.0 seconds in 96 increments

X-Ray Tube Stationary Anode 100 kVp

Filtration 3.6 mm Aluminum Equivalent or More @ 100kVp

Target Material Tungsten

Anode Capacity 25,000 Heat Units

Focal Spot 1.0 mm (NEMA)

Beam Angle 15°

Collimator Certified Manual

Collimator Lamp Source 30 second timer

Duty 3.3%

Mode of Operation Momentary

Relative Humidity Limits Transit/Storage

10% to 100%

Operating

10%-80% Non-Condensing

Atmospheric Limits 14.5 inHg to 30.74 inHg

500 hPa to 1060 hPA

W eight 95 lbs (42 Kg) Total/ X-Ray Generator 39lbs (17.7 kg)/Control

Console (7 lbs (3.2kg)

Certifications:

Equipment not suitable for use in the presence of flammable anesthetic mixtures with air, oxygen or nitrous

oxide.

No user serviceable parts

Classified To UL 187. Certified To

114-M90

.

CAN/CSA C22.2 No.

1-4 Specifications

Table 1-1: Specifications

Loading...

Loading...