Page 1

HEAVY DUTY

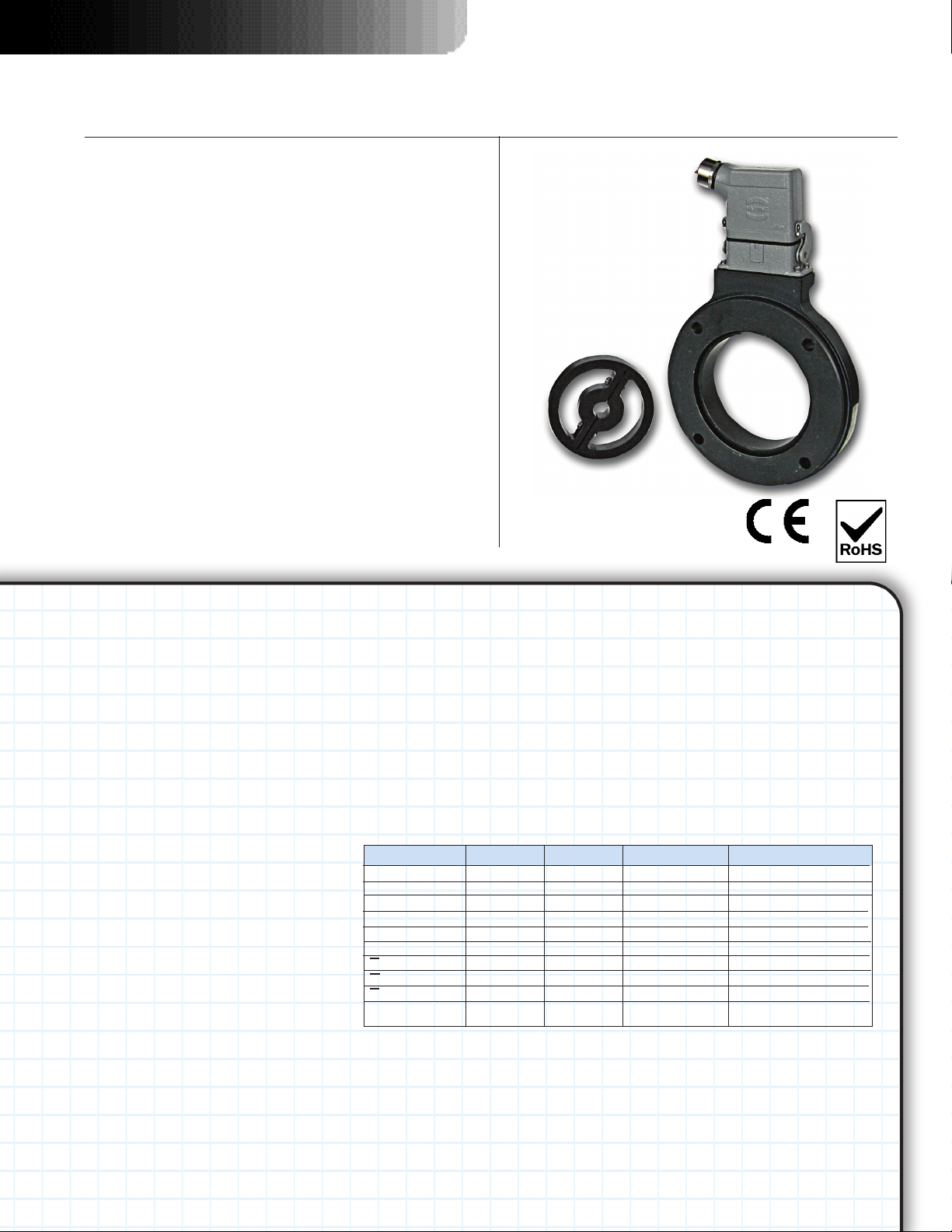

SLIM Tach ST67

Bearingless Encoder

Key Features

• RedesignedusingourRevolutionarySensorTechnologytoprovideaLargeAirGapof

0.060”

• RedesignedCircuitryforOn-BoardDiagnostics

withLEDandAlarmOutput

• BearinglessDesignMountstoReliance

6.75”Recess,56and140C-FaceMotors

• AnodizedAluminumHousingwith

Field-ServiceableConnector

NorthStar

™

brand

SPECIFICATIONS

STANDARD OPERATING CHARACTERISTICS

Code: Incremental, Magnetic

Pulses per Revolution: 64-2048 PPR

Phasing Sense: A leads B for Counter-Clockwise

rotation (CCW) viewing encoder-mounted end

Quadrature Phasing: 90° ± 45°

Symmetry: 180° ± 54°

Index: Less than phase A/B pulse width

Number of Output Modules: Single or Dual

ELECTRICAL

Input Voltage Requirement: 5-26 Volts DC

Current Requirement: 95 mA typical per sensor

module plus line driver load

Output Signals:

IC-WE Differential Line Driver: 150mA, sink or

source

Frequency Response: 0 - 180kHz Data & Index

Noise Immunity:

Electrical Immunity: Reverse polarity and short

circuit protected

Connector: 10 pin industrial duty latching, sealed

NEMA 4 &12, IP65; MS connector or pig-tail

Tested to EN61326-1

EN 61326-1

MECHANICAL

Bore Sizes: 5/8” to 2-7/8”

Mounting Configuration: 4.5” 56 C-Face or 140

C-Face Mount for NEMA MG1 Standards

Max. Shaft Speed: 7,000 RPM

Shaft Length Required: 0.7” min

Allowable Shaft End-Play: ± 0.1”

Allowable Shaft Runout: 0.005” TIR

Acceleration Rate: 3,600 rpm/sec max

Housing Material: Aluminum

Weight: 4 lbs

ELECTRICAL CONNECTIONS

Signal Connector Pin Pigtail Cable MS 3102E18-IT# Conduit Box

Common

B

A

Z *

No Connection

Vcc (5-26 VDC)

B

A

Z *

Shield

* Index (Z) optional. See Ordering Information

1

2

3

4

5

6

7

8

9

10

Black

Green

Blue

Violet

—

Red

Yellow

Gray

Orange

Braid

ENVIRONMENTAL

Operating Temperature Range:

Standard: -40°C to +100°C

Extended: -40°C to +120°C

Storage Temperature Range: -40°C to +120°C

Shock: 300 G’s Min.

Vibration: 20 G’s @ 5-2000 Hz spectrum

Humidity: Up to 98% (non-condensing)

F

B

A

C

E

D

I

H

J

G

1

5

3

7

—

2

6

4

8

—

Page 2

HEAVY DUTY

NorthStar

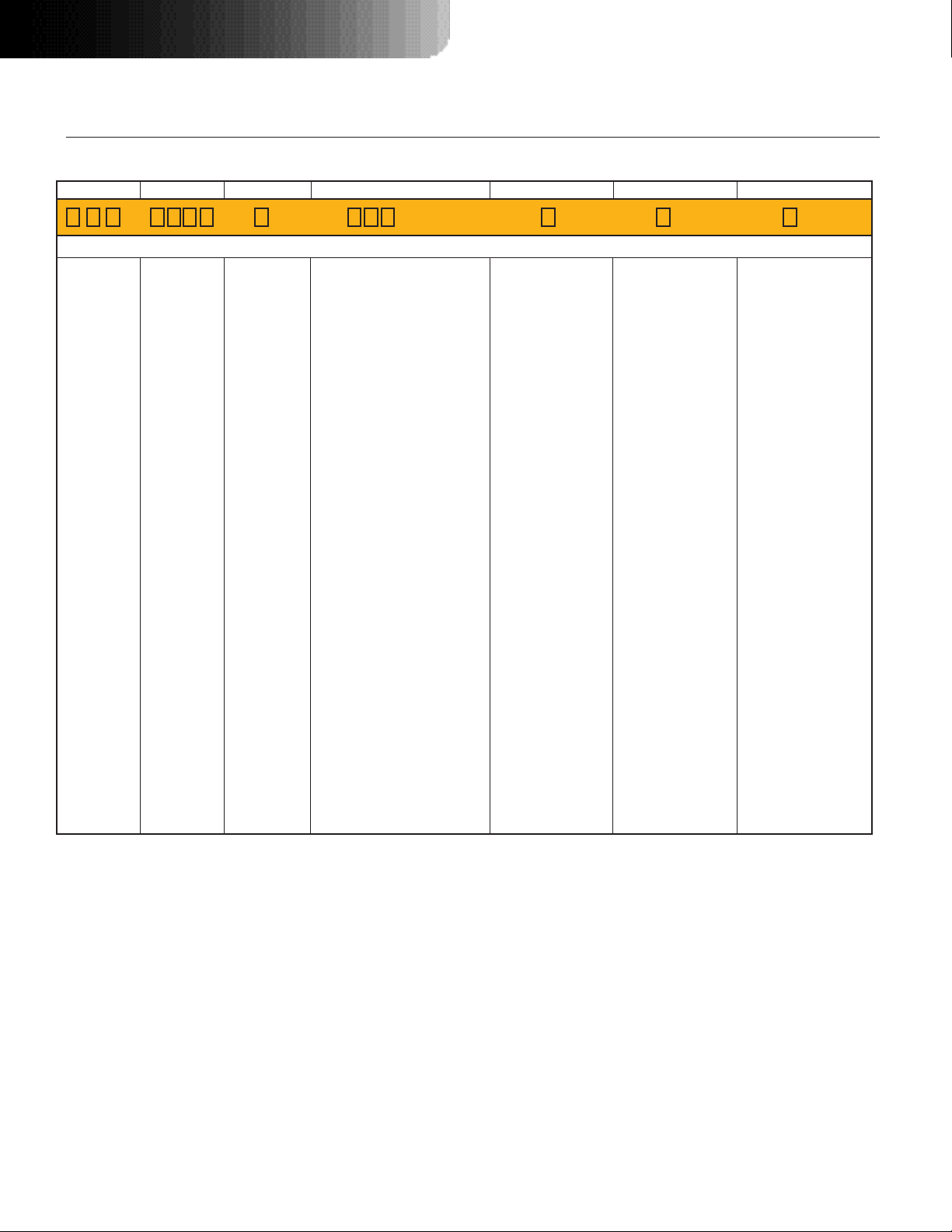

Code 1: Model

ST6 Direct

Motor

Mounting

on NEMA

56 flange

(4.5”), or

6.75” pocket.

Single output

DT6 Direct

Motor

Mounting

on NEMA 56

flange (4.5”),

or 6.75”

pocket. Dual

Output

Code 2: PPR

0064

0128

0256

0512

1024

2048

Code 3: Index

L No Index

Z Index Signal

™

brand

To order, complete the model number with code numbers from the table below:

Code 4: Wheel Bore

C04 0.625”

C05 0.875”

C06 1.000”

C07 1.125”

C08 1.250”

C09 1.375”

C10 1.500’

C11 1.625”

C12 1.750”

C13 1.875”

C14 2.000”

C15 2.125”

C16 2.250”

C17 2.375”

C18 2.500”

C20 2.625”

C19 2.875”

For additional bore sizes up

to 3.75” maximum, please

consult factory.

OrderingInformation

Ordering Information

CB4 16 mm

C36 24 mm

C29 25 mm

C31 30 mm

CA4 45 mm

C58 60 mm

C40 80 mm

SLIM Tach ST67

Code 5: Termination

B Conduit Box

C Latching Industrial

Connector with

1/2” NPT

D

1” Extended Height

Latching Industrial Connector

with 1/2” NPT

E 3” Extended Height

Latching Industrial Connector

with 1/2” NPT

F Latching Industrial

Connector without

Mating Connector

G 1” Extended Height

Latching Industrial Connector

without Mating

Connector

H 3” Extended Height

Latching Industrial Connector

without Mating

Connector

M 10 Pin MS Con-

nector

N 10 Pin MS 3112

Connector

P

18” Pigtail Cable

(25” when Code

6 = H)

Q Latching Industrial

Connector on 18”

Pigtail Cable

R Latching Indus-

trial Connector on

18” Pigtail Cable

without Mating

Connector

Code 6: Electrical

V 5-26V in, 5-26V

Line Driver (IC-WE)

out

5 5-26V in, 5V out

Line Driver (IC-WE)

Same as V but with

H

High Temperature,

Extended Operating

Range to 120°C

Code 7: Cover/Adapter

CC Flat No-Hole Cover

EE Extra Heavy Duty

Steel Cover

FF Flat Thru-Hole Cover

Note: See ACCESSORIES Section For Connectors, Spare Parts and Pulse Wheels

RL67 LEGACY MODELS

Dynapar’s legacy RL67 product line is still available for configurations not currently available in the ST67 product line.

For additional bore sizes up to 3.75” maximum, please consult the factory.

Page 3

3.26

EXPLODED VIEW

SECTION A-A

COVER

SCREWS

COVER

SPACER GASKET

WHEEL SCREWS

MAGNETIC WHEEL

ENCODER MOUNTING SCREWS

ENCODER HOUSING

MATING CONNECTOR

7.54 TYP

7.01 TYP

3.50

1.69 TYP

4.501

+.003

-.000

6.749

+.000

-.003

4.499

+.000

-.003

.56

.16

.38

1.28

SLIM Tach ST67

HEAVY DUTY

by

DIMENSIONS

inch

Worldwide Brands: NorthStar

INNOVATION - CUSTOMIZATION - DELIVERY

TM

• DynaparTM • HengstlerTM • HaroweTM

NorthStar™ brand is a trademark of DYNAPAR. All rights reserved.

Specifications subject to change without notice.

Document No. 703048-0002, Rev. C ©2016 DYNAPAR

Loading...

Loading...