Dynapar Series H25 Technical Bulletin

~

Dynapar

Technical

The Dynapar brand Series H25

reliable and economical encoder for industrial

motion applications. Models with resolutions

of t

024 or less are available with

able metal code disk that meets the demands

of the most severe shock and vibration

generating processes; and a long life

(352 N.) bearing that keeps tough

disrupting internal alignment, avoiding failure

due to the disk "crashes"

competitive encoders. Protection against

installation problems such as wiring errors

prevents the encoder from damage, while

immunity

signals intact. A NEMA4

protects against damage from contamination.

Packaged

enclosure, the Series H25 offers a variety of

mechanical options: servo or face mounting,

1/4" or

and

include: resolutions from 1 to

revolution; bidirectional operation with optional

index; single ended open collector or push-pull

outputs, or differential line drivers; and a

connector

The Series H25 utilizes the latest technology

optical emitters and sensors, surface mount

assembly and preCisely fabricated metal

components to deliver a high reliability and

performance

package.

brand

so

to.

eJe.ctric<l!

noise keeps the encoder

I IP66 sealing option

in

an

industry standard 2.5"

3/S"

shafts. Electrical options

or

cable exit terminations.

in

a compact and economical

Encoder

Bulletin

is

a rugged.

an

unbreak-

SO

pound

loads from

typical

in

2540 pulsesl

Mechanical/Environmental

Features

Unbreakable, metal code disk and long

life

SO#

bearing available

Extended temperature range available

Industry Standard, Size 25 Form Factor

NEMA4 I IP66 washdown rating option

Electrical Features

Noise Immune to ESD,

transients

High current outputs

Over-Voltage protection

Reverse Voltage protection

Output Short-Circuit Protection

RFI

and electrical

Series

H25

SPECIFICATIONS

Electrical

Code: Incremental

Pulses

per

Revolution: HR_25: 1

HA_25: 1 to 2540; consult factory for other

available PPRs

Output

Signal: Two channel quadrature with

optional zero reference

Phasing Sense: A leads B for CCW or CW

rotation as viewed from the shaft end of the

encoder - see ordering information

Quadrature Phasing: 90° ± 22.5°

Symmetry:

Zero Reference:

Input:

Outputs:

Frequency Response:

Electrical

Noise

Connector: 7 pin, style MS3102E-16S-1P

Cable: PVC jacket,

Mating Connector:

Mechanical

Shaft

Starting

Shaft Runout: 0.001" max. TIR

Moment

Shaft Speed: HR_25: 10,000

180"

l:18"

1S0° ± 1So

Differential Line Driver and Push-Pull:

5 to 26 VDC at

Open

plus load

VDC max.; Push-Pull and Differential Line

Driver: 40mA sink/source

voltage and short-circuit protected

Immunity:

Electro

Interference and

10

pin, style MS3102E-1S-1P

shield; 3 twisted pairs 26 AWG plus 2 twisted

pairs

7 pin, style MS3106A-16S-1S

(Dynapar No. MCN-N5);

10 pin, style MS3106A-1S-1S

(Dynapar

Loading:

40 pounds axial and 35 pounds radial at

0.25" from face

seal: 1.0 oz-in; wi shaft seal: 2.5 oz-in

HA_25:

SOmA

Collector: 5

Open Collector: 40mA sink at 0.5

Protection:

Tested to

Static Discharge, Radio Frequency

24

AWG

No.

HR_25:

Torque: (max. at

of

Inertia: 3.0 x 104 oz-in-sec'

5,000

RPM

(Gated with

max. plus load;

to

26VDC at 135mA max.

100kHz Data, Index

Over-voltage, reverse

IECS01

Electrical Fast Transients

105°C

rated, overall foil

MCN-N6)

SO

pounds; HA_25:

25°C)

RPM

max.

CE:

Bulletin Number: 701950-0000

Revision Level: A

Date:

April

23,

1997

Manufactured by:

Danaher Controls

1675 Delany Road

Gurnee,

Phone: 847.662.2666

Application Assistance 1.800.234.8731

to

1024;

B)

level 3 for

wlo shaft

max.;

IL 60031-1282

Fax: 847.662.6633

Environmental

Operating Temperature: Standard:

+70

°C;

Extended:

Storage Temperature Range: -40° to +90°C

Shock:

50

Vibration: 5 to 2000

Humidity:

to

Enclosure Rating:

Series H_525: NEMA12/1P54

Series H_625: NEMA4 I IP66

-40

G's for

11

milliseconds duration

Hz @ 20

9S%

without condensation

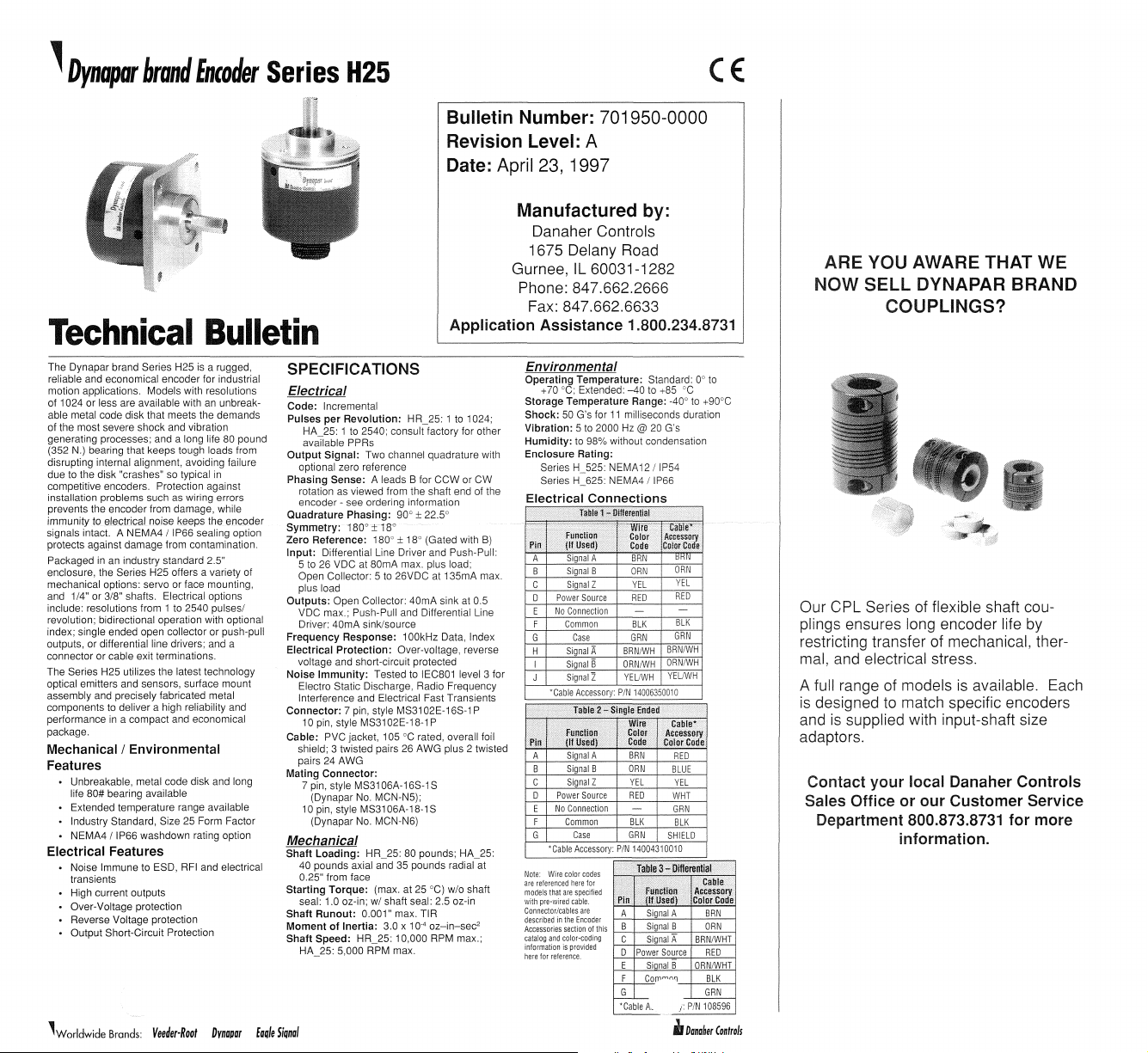

Electrical Connections

Note:

Wire

color

are

models

withpre-wiredcab!e.

Connector/cablesare

described

:~~~~~o;~e:

information

here

codes

referenced

here

for

that

are

specified

in

the

Encoder

:~,~t:~cno~i~~iS

I u I

is

provided

for

reference.

0°

+S5

G's

to

°c

__

~::~~

to

ARE YOU AWARE THAT

WE

NOW SELL DYNAPAR BRAND

COUPLINGS?

-~

'" "'''''I":

".~

-

Our CPL Series of flexible shaft couplings ensures long encoder life by

restricting transfer of

mal, and electrical stress.

full range of models is available. Each

A

is designed to match specific encoders

supplied with input-shaft size

and is

adaptors.

Contact your local Danaher Controls

Sales Office

Department

..

_I

mechanical, ther-

or

our

Customer Service

800.873.8731

information.

for

more

~Worldwide

Brands:

Veeder-Root

Dvnaaar

EaQle

Sil/nal

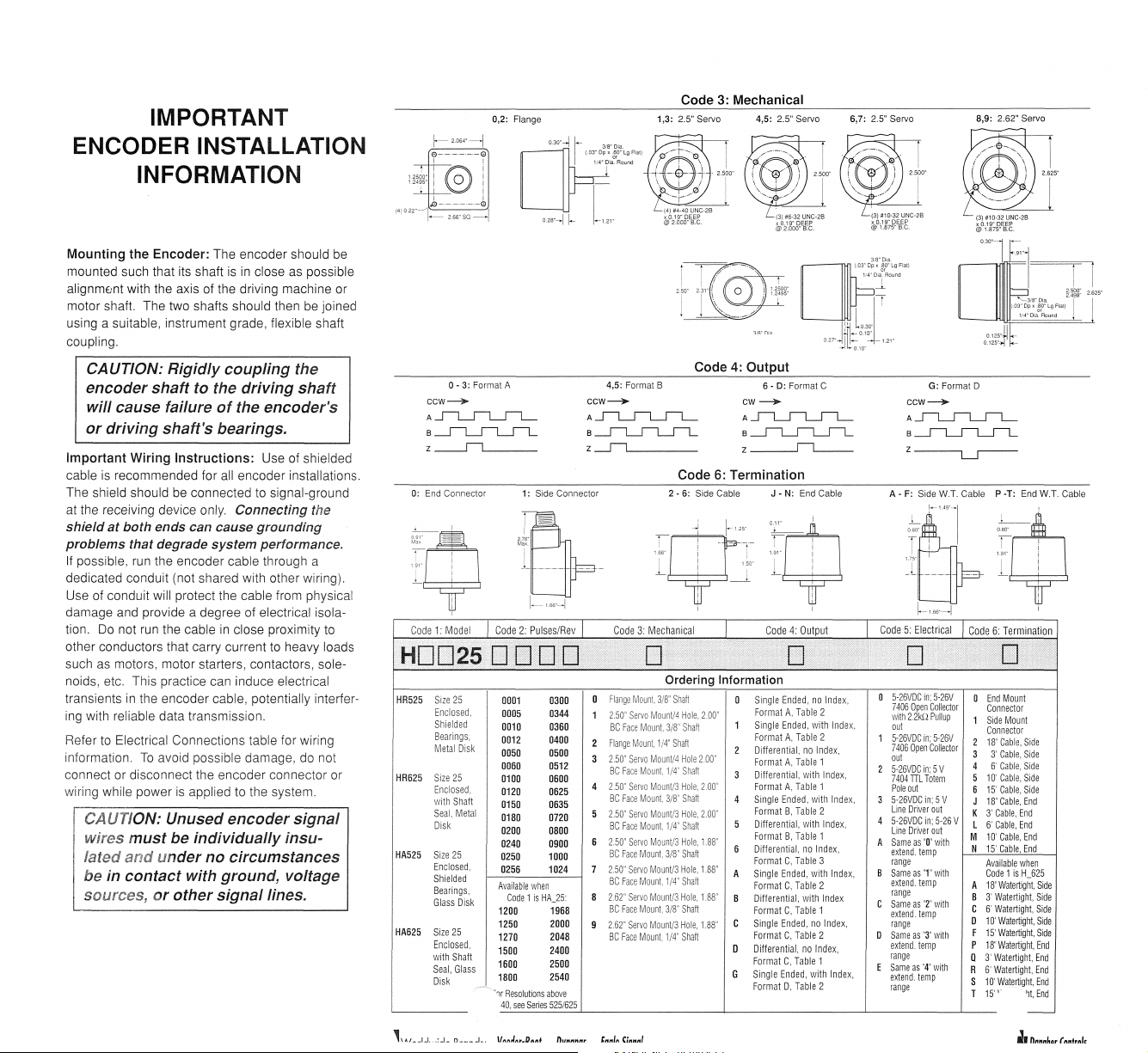

IMPORTANT

ENCODER INSTALLATION

INFORMATION

(41

022

"---F

r--''''''-I

,---.

-------1

266"

sa

0,2:

Flange

O.30·--.j I

JlS"Dia

(oa"Opx-:o"LgFTat)

114"

Dia. Round

Code

3: Mechanical

1,3:

2.5"

Servo 4,5: 2.5" Servo

6,7:

2.5"

Servo

8,9: 2.62" Servo

Mounting

mounted such that its shaft is

alignmElnt

motor shaft. The two shafts

using a

the

Encoder:

The encoder should be

in

close

as

possible

with the axis of the driving machine or

should then

be

joined

suitable, instrument grade, flexible shaft

coupling.

CAUTION: Rigidly coupling the

encoder shaft to the driving shaft

will

cause failure

or

driving shaft's bearings.

Important

cable

The

at the receiving device

shield

Wiring

is recommended for all encoder installations.

shield should

at

both ends can cause grounding

of

the encoder's

Instructions:

be

connected to signal-ground

Use of shielded

only. Connecting the

problems that degrade system performance.

If

possible, run the encoder cable through a

dedicated conduit (not shared with other wiring).

Use of conduit

will protect the cable from physical

damage and provide a degree of electrical isolation.

Do

not run the cable

other conductors that carry current to heavy

in

close proximity to

loads

such as motors, motor starters, contactors, solenoids, etc. This practice can induce electrical

transients

ing with

Refer

information.

in

the encoder cable, potentially interfer-

reliable data transmission.

to

Electrical Connections table for wiring

To

avoid possible damage, do not

connect or disconnect the encoder connector or

wiring while power is

CAUTION: Unused encoder

wires

must

lated

and

applied to the system.

signal

be individually insu-

under no circumstances

be in contact with ground, voltage

sources,

or

other

signal

lines.

o

~

3: Format A

CCW_

A~

B~

Z--'L-

0: End Connector

M"

.-

,

I ,

~~!

•.

I :

i

,

HR525

Size

25

Disk

25

Shaft

Metal

25

Disk

25

Shaft

Glass

0001

0005

0010

0012

0050

0060 0512

0100 0600

0120

0150 0635

0180

0200

0240

0250

0256

Available

CDde 1 is

1200 1968

1250

1270

1500

1600

1800

Resolutions

0,

see

HR625

HA625

EnclDsed,

Shielded

Bearings,

Metal

Size

EnclDsed,

with

Seal,

Disk

Size

EnclDsed,

Shielded

Bearings,

Glass

Size

Enclosed,

with

Seal,

Disk

CCW_

A~

B~

z-"'--

1: Side Connector

"".'

M"

1____

__

£}

1.-'00'--1

0300

0344

0360

0400

0500

0625

0720

0800

0900

1000

1024

when

HA_25:

2000

2048

2400

2500

2540

above

Series

525/625

4,5: Format B

___

Code

2·6:

Iq1it"l-

1 i

Flange

Moun!.

3/8"

Servo

Face

Servo

Face

Servo

Face

Servo

face

Servo

Face

Servo

Face

Servo

face

Servo

Face

MounV4

MDunt,

Moun!,

MounV4

Mount,

MounV3

MDun!,

MDunV3

MDun!.

MounV3

Moun!,

MounV3

Moun!,

MDunV3

MDunl,

MounV3

Mount.

1/4"

ShaH

3/8"

ShaH

1/4"

3/8"

1/4"

3/8"

1/4"

3/8"

1/4"

2.50"

BC

Flange

2.50"

Be

2.50"

BC

2.50'

BC

2.50"

Be

2.50"

BC

2.62"

Be

2.62"

BC

_

Hole,

ShaH

Hole

Shaft

Hole,

ShaH

Hole,

ShaH

Hole,

Shaft

Hole,

ShaH

Hole,

ShaH

HDle,

ShaH

Code

Side

•

i

i

2.00"

2.00"

2.00"

2.00"

1.88"

1.88"

1.88"

1.88"

6:

Cable

4:

Output

6 -

0:

Format C

CW_

A~

B~

Z-",-----

Termination

J •

N:

-'

-

O'''"q:J'

1.50'

f i

_I

Single

Ended,

FDrmat

A,

Single

Ended,

FDrmat

A,

Differential,

FDrmat

A,

Differential,

FDrmat

A,

Single

Ended,

FDrmat

B,

Differential,

Format

B,

Differential,

FDrmat

C,

Single

Ended,

A

FDrmat

C,

Differential,

FDrmat

C,

Single

Ended,

format

C,

Differential,

0

FDrmat

C,

Single

Ended,

G

FDrmat

D,

I 0_10.

i'

~

O.27"-iJ

End

Cable

i

nD

Index,

Table

2

with

Index,

Table

2

nD

Index,

Table

1

with

Index,

Table

1

with

Index,

Table

2

with

Index,

Table

1

nD

Index,

Table

3

with

Index,

Table

2

with

Index

Table

1

nD

Index,

Table

2

no

Index,

Table

1

with

Index,

Table

2

3/B"Dia

(,03'Dpx~rLgFlall

'W~"'""d

l"J.

0.10'

1.21"

G:

ccw---.

A~

B~

Z~

A·

F:

Side

'-""l

' ,

I

1.75" 1.91" i

~~'

_L

_____

!--1.56"---l

5·26VDC

in;

5·26V

7406

Open

CDllectDr

with

2.2kn

Pullup

Dut

5-26VDC

In;

5·26V

7406

Open

CDllector

Dut

5·26VDC

in;

5 V

7404

TTL

TDtem

PDleDut

5·26VDC

in;

5 V

Une

Driver

out

5·26VDC

in;

5·26

Line

DriverDut

Same

as

"0"

with

extend.

temp

range

Same

as

"1"

with

extend.

temp

range

Same

as

"2"

with

extend,

temp

range

Same

as'3'

with

extend.

temp

range

Same

as

"4"

with

extend.

temp

range

:::18~

I

'.500'

2.498"

Format D

W.T.

Cable

P ·T:

End

W.T.

Cable

'

:----1""'¢'

1 :

i

End

MDunt

ConnectDr

SldeMDunt

CDnnectDr

18"

Cable,

Side

2

3'

Cable,

Side

3

6'

Cable,

Side

4

5

10'

Cable,

Side

15'

Cable,

Side

6

18"

Cable,

End

J

K

3'

Cable,

L

M

N

A

B

C

0

f

P

Q

R

S

T

6'

Cable,

10'

Cable,

15'

Cable,

Available

CDde 1 is

18"

Watertiglrt,

3'

Watertight.

6'

Watertight.

10'

Watertight,

15'

Watertight,

18"

Watertight,

3'

Watertight,

6'

Watertight,

10'

Watertight,

15'"

End

End

End

End

when

H_625

End

End

1t,

Side

Side

Side

Side

Side

End

End

End

V

.

'"''

~\A/

__

U ... :..l_ 0

___

-1

••

V","I"p.DA"f

nu

•••••

r

••

I.

(1

•••

1

an,.a"J..:.rr".',IIlr

Loading...

Loading...