SERVO DUTY

SERIES F14

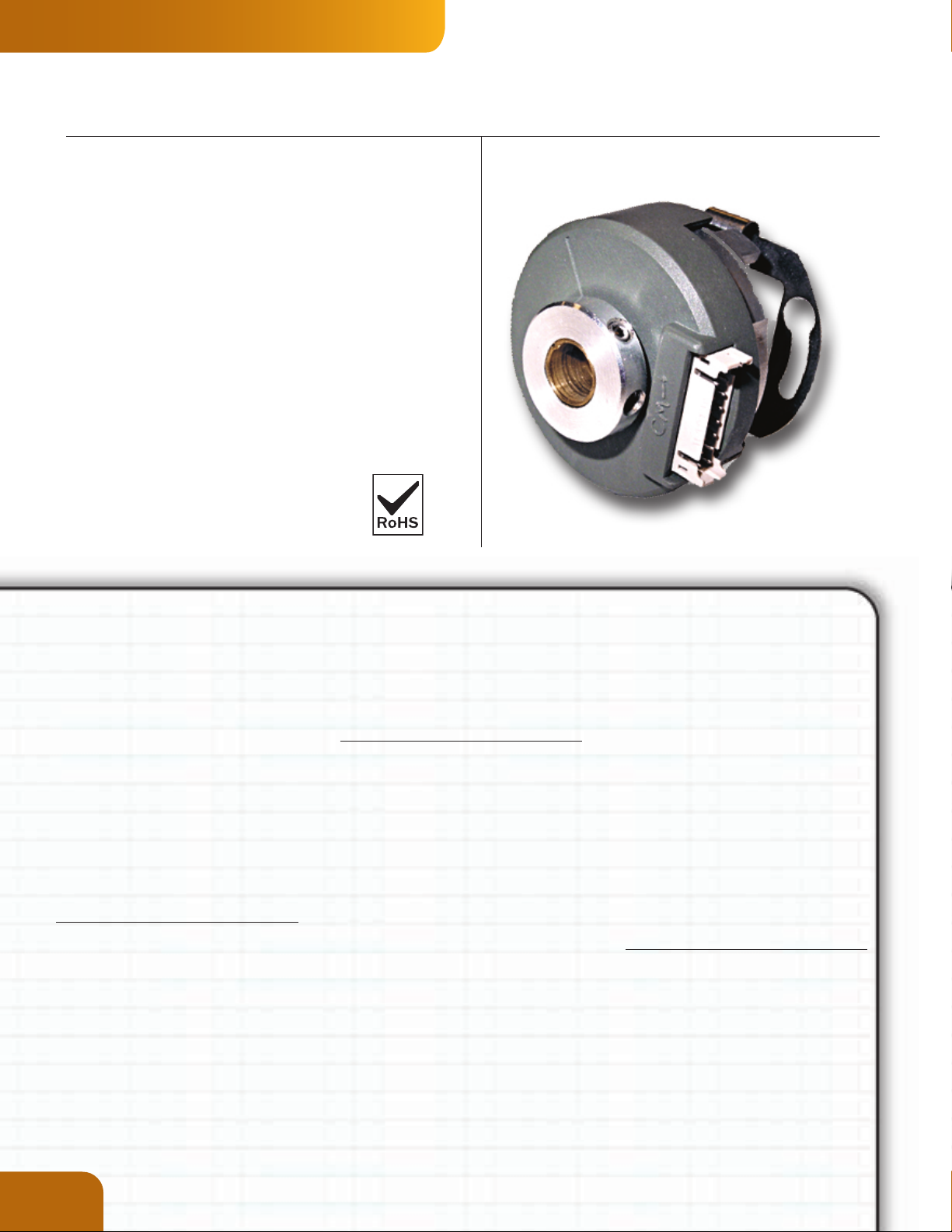

For Stepper & Small Servo Motors

Key Features

• Easy to install non-marring hollowshaft

design with flex tether

• Up to 5000PPR for smooth low-speed motor

control

• Up to 120C temperature range doesn’t limit

motor performance

Dynapar

™

brand

SPECIFICATIONS

STANDARD OPERATING CHARACTERISTICS

Code: Incremental with commutation option,

Optical

Resolution: 200, 400, 500, 1000, 1024, 2000,

2048, 2500, 4096, 5000 PPR incremental with 4, 6

and 8 pole commutation channels

Accuracy: Incremental: ±2.5 arc-mins. max.

edge to any edge; Commutation: ±6 arc-mins. max.

Phasing for CCW rotation of motor shaft (viewing

encoder cover): A leads B by 90° and U leads V

leads W by 120 °.

Minimum edge separation A to B is 45°.

Index to U channel: +/- 1 °mech. index pulse

center to U channel edge.

Index Pulse Width: 90° gated A and B high; (180°

gated B high gating options available - consult

factory)

ELECTRICAL

Input Power Requirements: 5±10% VDC at 150

mA max (incremental only); 175 mA max.

(incremental and commutation), excluding output

load

Output Signals:

Line Driver: sink / source 40 mA max.,

Open Collector Incremental ( ≤ 1024 PPR): 16 mA

sink max.

Open Collector Commutation: 30 mA sink max.

(2.0 kΩ pull-ups in encoder)

Frequency Response:

PPR ≤ 1024: 250 kHz; PPR > 1024: 500 kHz

Termination: 16 pin, fully shielded, 2mm pitch,

double row header. Accessory mating cable

assembly available: 26 AWG twisted pair, jacketed

and shielded with copper drain wire

MECHANICAL

Weight: 1.6 oz. (45gm) typ.

Dimensions: Outside Diameter with cover: 1.55"

(39.8mm), without cover 1.45" (36.8mm); Outside

collar height 1.36" (34.6mm), inside collar height

1.28" (32.4mm)

Material: Bearing housing: aluminum;

Cover: high temperature, glass filled polymer;

Hub: Brass; Disk: 0.030" thick glass

Finish: Cover: RAL 7010 (dark grey)

Moment of Inertia: 8.2X10-5 in-oz sec.2 (5.8 gm-

cm2)

Hub Diameters: 1/4", 6mm, 8mm standard

Bore Dia. Tolerance: +0.001"/-0.000" (+0.025 mm/

-0.000 mm)

Mating Shaft Length: 1.35" (34.3 mm) minimum

for outside shaft collar. 0.50 inch minimum for

inside shaft collar

Mating Shaft Runout: 0.002" (0.05 mm) max.

(Includes shaft perpendicularity to mounting

surface)

Mating Shaft Axial movement: ±0.060"

(±1.52 mm)

Mounting: Two standard configurations are

available for tethers. A choice of U.S. or Metric

screws are included. Mounting holes should be

0.01" (0.254 mm) true position to shaft for best

encoder operation.

Shaft clamp: 2 #6-32 set screws in collar

around hub shaft (will not mar shaft)

Electrical/Mechanical Alignment Range:

±15° mechanical typical (see tether options)

Acceleration: 100,000 rad/sec.2 max.

Max. Velocity: RPM= (Frequency / PPR)x 60; or

12,000 RPM, whichever is less;

Bearing Life: [(1.4 X 109) / RPM] Hours ; e.g.

230,000 hours @6,000 RPM

(

Based on bearing manufacturer's suggested

calculation for 6801ZZ with 44N equivalent

dynamic load - including preload and tether

reaction loads - at 6000 RPM continuous with

adequate lubrication

ENVIRONMENTAL

Operating Temperature: 0° to +120°C

Storage Temperature: -40° to +120°C

Shock: 100 Gs for 6 msec duration

Vibration: 2.5 Gs at 5 to 2000 Hz

Relative Humidity: 90% non-condensing

Enclosure Rating: NEMA 1 / IP40 (for models

with cover)

)

3.30

by

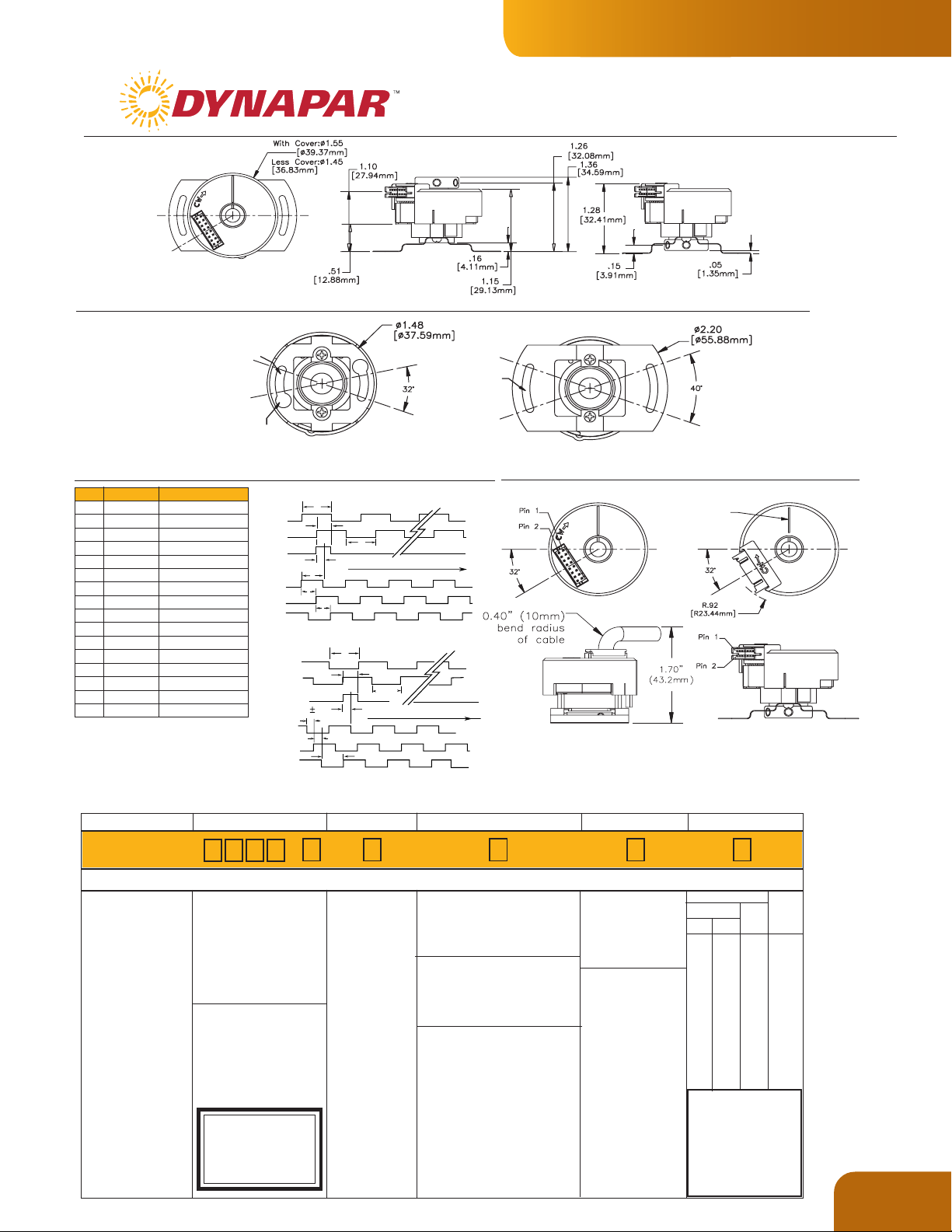

Dimensions

SERVO DUTY

SERIES F14

Code 3: Tethers

0.12

(3mm)

Electrical Connections

Pin

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Function*

NONE

NONE

VCC

U

GND

V

A

W

–

A

B

U

–

B

–

V

Z

W

–

Z

–

–

Cable Wire Color

RED

Brown

BLACK

GRAY

BLUE

WHITE

BLUE/BLACK

NONE

GREEN

BROWN/BLACK

GREEN/BLACK

GRAY/BLACK

VIOLET

WHITE/BLACK

VIOLET/BLACK

NONE

* Function availability dependant on Model

Mating Cable Assembly:

Incremental only, 111752-000x

Incremental + Comm., 111753-000x

x= length in feet

To order, complete the model number with code numbers from the table below:

Code 1: Model

Code 2: PPR, Poles

Code 5: A to F

Outside Collar

0.11

(2.8mm)

0.20

(5.1mm)

1: 1.142" (29mm)BC 3: 1.811" (46mm) BC

Output Waveforms

Signal Format A

180

e

CH. A

CH. B

CH. Z

±1

CH. U

CH. V

CH. W

m

°

°

e

°

90

180

e

°

CCW SHAFT ROTATION

180

e

°

120

e

°

120

e

°

Signal Format B

180

e

CH. A

CH. B

CH. Z

CH. U

CH. V

CH. W

°

1

m

60

°

60

°

90

180

CCW SHAFT ROTATION

e

e

°

180e°

°

e

°

e

Ordering Information

Code 3: Tether

Code 4: Electrical

0, 1, 2

Axial Connector

JST #B16B-PHDSS

Code 5: Shaft/Bore

Code 5: 0 to 5

Inside Collar

Slot on hollow shaft

alligned with molded mark

will approximately

align index

Code 6: Termination

Z, A, B

Radial Connector

JST #S16B-PHDSS

F14

F14 Size 14

Commutating

Encoder

/

Incremental channels only

0200/0

0400/0

0500/0

1000/0

1024/0

Incremental plus

Commutation channels

0500/†

1000/†

1024/†

2000/†

† Available with 4,

6 or 8 pole.

e.g. 1000/6 is

1000PPR with

6 poles

2000/0

2048/0

2500/0

4096/0

5000/0

2048/†

2500/†

4096/†

5000/†

0 No Tether

1 2 #2 on

1.181"

Diameter

3 2 #4 on

1.811"

Diameter

6 2 M2.5 on

30 mm

Diameter

8 2 M3 on

46 mm

Diameter

Ordering Information

Available when Code 2 is ≤ 1024/0

0 5V in, open collector out

incremental only - Formzat A

C 5V in, open collector out

incremental only - Format B

Available when Code 2 is XXXX/0

3 5V in, line driver out

incremental only - Format A

D 5V in, line driver out

incremental only - Format B

Available when Code 2 is XXXX/4,

XXXX/6, or XXXX/8

6 5V in, line driver out incr.; 5V

in, open collector out comm.

Format A

E 5V in, line driver out incr.; 5V

in, open collector out comm. Format B

9 5V in, line driver out incr.; 5V

in, line driver out comm.

Format A

F 5V in, line driver out incr.; 5V

in, line driver out comm. Format B

Inside Collar:

0 1/4 in.

4 6 mm

5 8 mm

Outside Collar:

A 1/4 in.

E 6 mm

F 8 mm

Code

Connector/Cable

Axial Radial

0Z

Wire

Pigtail

N/A

1AJ1 Ft.

2BK2 Ft.

3CL3 Ft.

4 DM4 Ft.

5EN5 Ft.

6FP6 Ft.

7 GQ7 Ft.

8 HR8 Ft.

CONNECTION OPTIONS

You may choose an integral

connector mounted in axial

or radial position. Available

with or without mating

connector/cable.

Alternativly, a direct-solder

pigtail cable is offered.

Length

None

3.31

Loading...

Loading...