Encoders

Series 7143 Magnetic Sensors

• High output gear tooth sensor

• Requires no power Supply

• For low RPM measurement

Dynapar™ brand

APPLICATION/INDUSTRY

For monitoring the speed of any shaft when

mated with a magnetic-input tachometer and

positioned in alignment with the teeth of a

ferrous material gear.

DESCRIPTION

Typically, 60-tooth, 16-pitch gears provide the

optimum characteristics for RPM measurement, but other gear types can serve special

application needs. They are well suited for

industrial machinery as well as test stand and

laboratory installations. Series 7143 is available

in a plastic tube model, supplied with mounting

bracket, or in threaded stainless-steel model.

Both include a 10-foot shielded cable with

mating connector.

Series 7143 features an extra strength

permanent magnet pole-piece and high

inductance coil. Gear teeth supply the motion

within the magnetic field, so that the sensor/

gear combination acts as an AC generator.

Voltage output is directly proportional to

velocity and closeness of the air gap.

FEATURES AND BENEFITS

• High output design for superior low

velocity performance

• Two-wire, self generating output

requires no power connection

• Economy plastic, or heavy-duty

noncorrosive stainless steel models

• Supplied with all necessary mounting

hardware and cable

SPECIFICATIONS

STANDARD OPERATING CHARACTERISTICS

Output Voltage: 25 VDC minimum peak to peak

(into 100 kΩ load) with 16-pitch gear, 1000 RPM,

0.01" gap

DC Resistance: 1200Ω maximum

Inductance: 400 mH maximum

Temperature Range: -100° to +225°F (-73° to

+107°C)

Materials: Model Number 714300-001: Plastic

shell, stainless steel pole piece; Model Number

714300-002: Stainless steel shell and pole piece

Mounting: Model Number 714300-001: Aluminum

bracket (supplied); Model Number 714300-002:

Threaded body with locknuts (supplied)

Connections: 10' cable assembly (supplied)

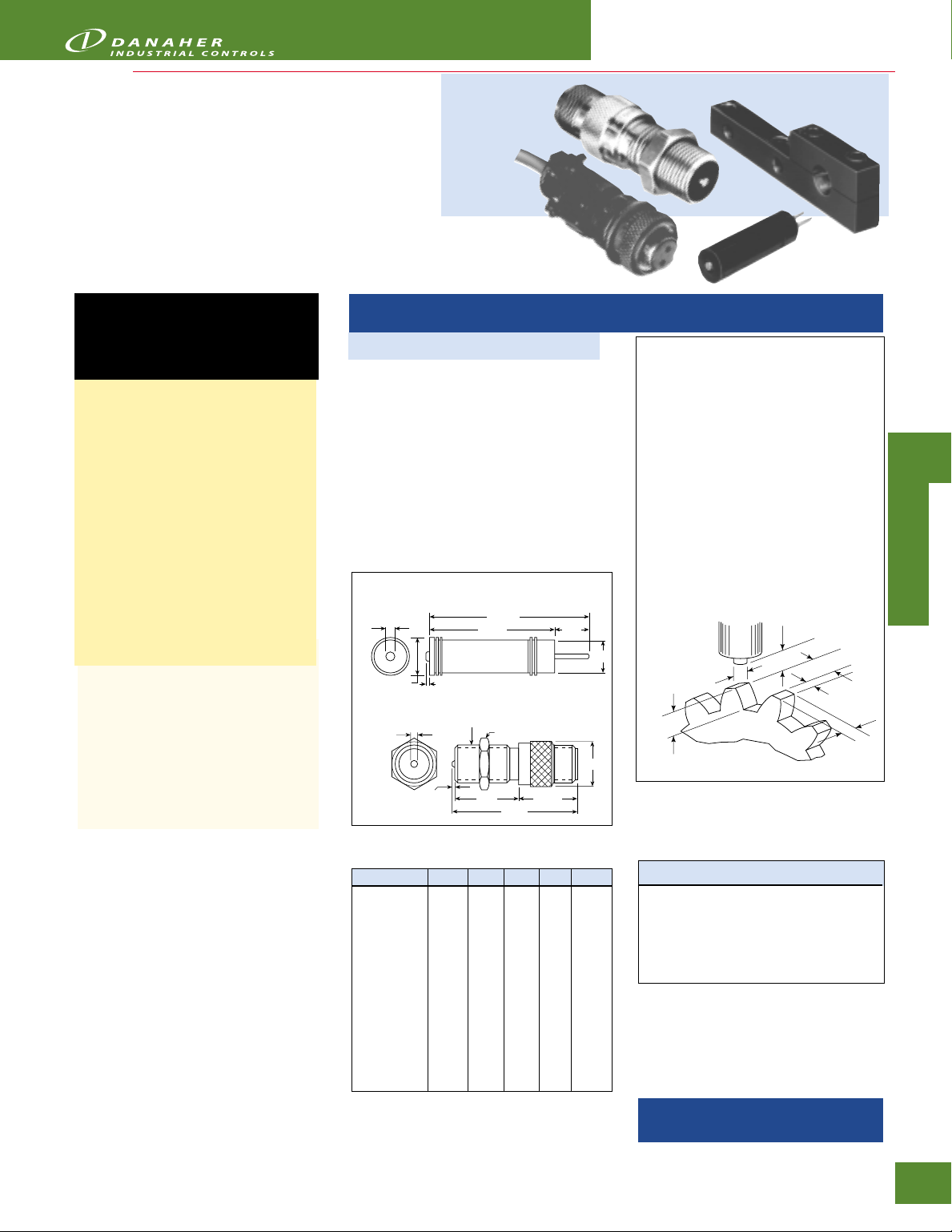

Dimensions:

714300-001

.106"

2.69 mm

12.83 mm

714300-002

2.69 mm ± .13 mm

.505"

.106" ±.005"

.020"

.51 mm

.010"/0.25 mm

.030"/0.76 mm

2.208"

56.08 mm

1.691"

42.95 mm

.625"/15.88 mm – 18 UNF 2A Thread

Locknut

2.250"

57.15 mm

1.093" Ref.

27.6 mm

1.125"

28.58 mm

.517"

13.13 mm

19.05 mm

12.52 mm

.750"

SELECTING THE PROPER GEAR

It is vital when using the Series 7143 for revolutions per minute

applications that a 60-tooth, ferrous gear be properly selected.

Optimum results relative to the sensing of low rpm, as well as

high speeds will be achieved with gears having a pitch of 16 or

less, and a gear-to-sensor gap of 0.01" or less. Sixty-tooth gears

with up to 20 pitch and/or gear-to-sensor gaps of up to 0.05",

will produce excellent results provided that operation below

approximately 600 rpm is not required.

The following figure suggests typical requirements for gear

configuration. Ideal dimensions may not be available in stock

gears, but the figure serves as a guide for selection of the best

stock gear available.

A. Dimension of tooth top, equal to or greater than D.

B. Height of tooth, equal to or greater than D.

C. Space between teeth, equal to or greater than D.

D. Diameter of pole piece, typically 0.106" (2.69 mm).

E. Clearance, as

close as possible,

typically 0.01"

(0.25 mm) or less.

F. Gear thickness,

equal to or greater

.493"

than 2 times D.

B

E

D

P

S

I

E

C

N

K

S

U

O

P

R

S

S

A

N

D

C

A

F

Recommended Gears

Gear Dia. Bore Pitch PPR 7143

16002070083 3-7/8" 1/2" 16 60 X

16002070216 5-1/2" 1-1/8" 11 60 X

16002070217 5-1/2" 1-3/8" 11 60 X

16002070218 5-1/2" 1-5/8" 11 60 X

16002600314 5-1/2" 1-7/8" 11 60 X

16002600315 5-1/2" 2" 11 60 X

16002600316 5-1/2" 2-1/8" 11 60 X

16002600317 5-1/2" 2-1/4" 11 60 X

16002600318 5-1/2" 2-3/8" 11 60 X

16002600319 5-1/2" 2-1/2" 11 60 X

16002600320 5-1/2" 2-7/8" 11 60 X

Model No. Description

714300-001 1/2" diameter x 1-3/4"

plastic probe, bracket, cable

assembly

714300-002 5/8" diameter x 2-1/4"

stainless steel probe, cable

assembly

For zero speed sensors, see

51Z, 53Z Pickups

2.

115

Loading...

Loading...