~Dynopor

brand

Encoder

Series

21/22

~

4It-,

o

-~

~

Technical

The Series 21/22 QUBE encoder

for operation

stable

The Series 21/22 QUBE generates digital

incremental position data proportional to shaft

rotation. Through higher mechanical and

electronic operating speeds, the Series 21/22

QUBE can boost system speeds, cycle times,

and productivity.

Its general-purpose design makes the Series

21/22 QUBE compatible with most programmable controllers, electronic counters, motion

con"Iroliers, and motor drives. The Series 21/22

QUBE is electrically and physically interchangeable with most cube-style encoders

the market. It can easily

measuring wheels, belts and pulleys,

leadscrews, rack and pinions, lineshafts, etc.

Applications

o Measuring, cut-to-Iength

metal, lumber and rubber industries

o Tracking, storage & retrieval, pick & place,

conveying, and elevating for material

handling applications

o Winding, including films, foils, wire and

extrusions

o Measuring mechanical motion for processing,

labeling, filling, mixing, batching, and

packaging

o Position control, for flexible and automatic

assembly equipment

o Speed feedback, for precise drive and

machine monitoring and control

in

industrial environments, and

in

temperatures from

0'

be

applied with

or

size for textile,

Iil

Bulletin

is

designed

to 70'C"

on

"~

Mechanical and Environmental

is

Features

o Environmentally sealed enclosure

o Large 3/8", 1/4"

steel shafts

o Durable anodized aluminum housing with

5/16" thick housing walls

o Extra-wide bearing span with heavy-duty

sealed bearings front and rear

o 6000 RPM capability

Electrical Features

o Wide selection

o Wide input voltage range eliminates the need

for multiple models

o Unidirectional

o Optional complementary (differential) outputs

SPECIFICATIONS

Mechanical

Bearings: ABEC precision bearings

Sealed Bearings: Standard

Shaft

Loading:

Starting Torque: 2.5 oz-in

Shaft

Diameters: 3/8", 1/4"

(-0.0003"/-0.0005") single or double

Moment

Weight: 14 ounces

Slew

Speed: 6000 RPM, 120 kHz max.

or

6 mm diameter stainless

of

resolutions up

or

quadrature outputs

30 Ibs. axial; 40 Ibs. radial

of

Inertia: 1.3 x

10"4

or

6 mm

oz-in

Bulletin

Number: 701820

Revision Level: B

Date: February 22, 1993

Manufactured

Danaher Controls

1675 Delany Road

Application

to

1270 PPR

sec'

max.

Gurnee,

Phone: 847.662"2666

IL

60031-1282

Fax:

847.662.6633

Assistance

1.800.234.8731

Environmental

Enclosure:

Operating Temperature Range:

Storage Temperature Range:

Electrical

Quadrature Phasing:

Symmetry:

Index:

Phase Sense: A leads B for CW rotation (as

Waveforms: Squarewaves with rise and fall

Frequency Response: 120 kHz data; 50 kHz

Power

Output

Connector:

Mating

Environmentally sealed

90'

180' ± 18' @ 10kHz

225'

±90'

viewed Irom the shaft end

"that

is farthest from the connector).

times less than 1 microsecond into a load

capacitance of 1000

with index

Requirements: current sink: 5 to 26

VDC at 100 mA max. plus load; line driver:

5 to 15 VDC at 200 mA max plus load

Current: open collector: 40 mA sink at

0.5V; line driver: 40 mA source/sink

6 pin: style MS3102E-148-6P

7 pin: style M831 02E-168-1 P

Connector:

68; 7 pin: style M83106A-168-18

6 pin: style MS3106A-148-

by:

0'

-40'

±18' @ 10kHz

rate

01

the encoder

pi

to

to

+70'C

+90'C

rate

ARE YOU AWARE THAT WE

NOW SELL DYNAPAR BRAND

COUPLINGS?

Our CPL Series of flexible shaft couplings ensure long encoder life by restricting transfer of

and electrical stress.

A full range of models is available. Each

is designed to match specific encoders,

supplied with input-shaft size

and is

adaptors.

Contact

Sales

your

Office

Department

mechanical, thermal,

local Danaher Controls

or

our

Customer Service

800.873.8731

for

more

information.

~Worldwide

Brands:

Veeder·Roof

Dynapor

Eagle

Signal

"

,.

DanaiJfr

Controls

IMPORTANT

ENCODER INSTALLATION

INFORMATION

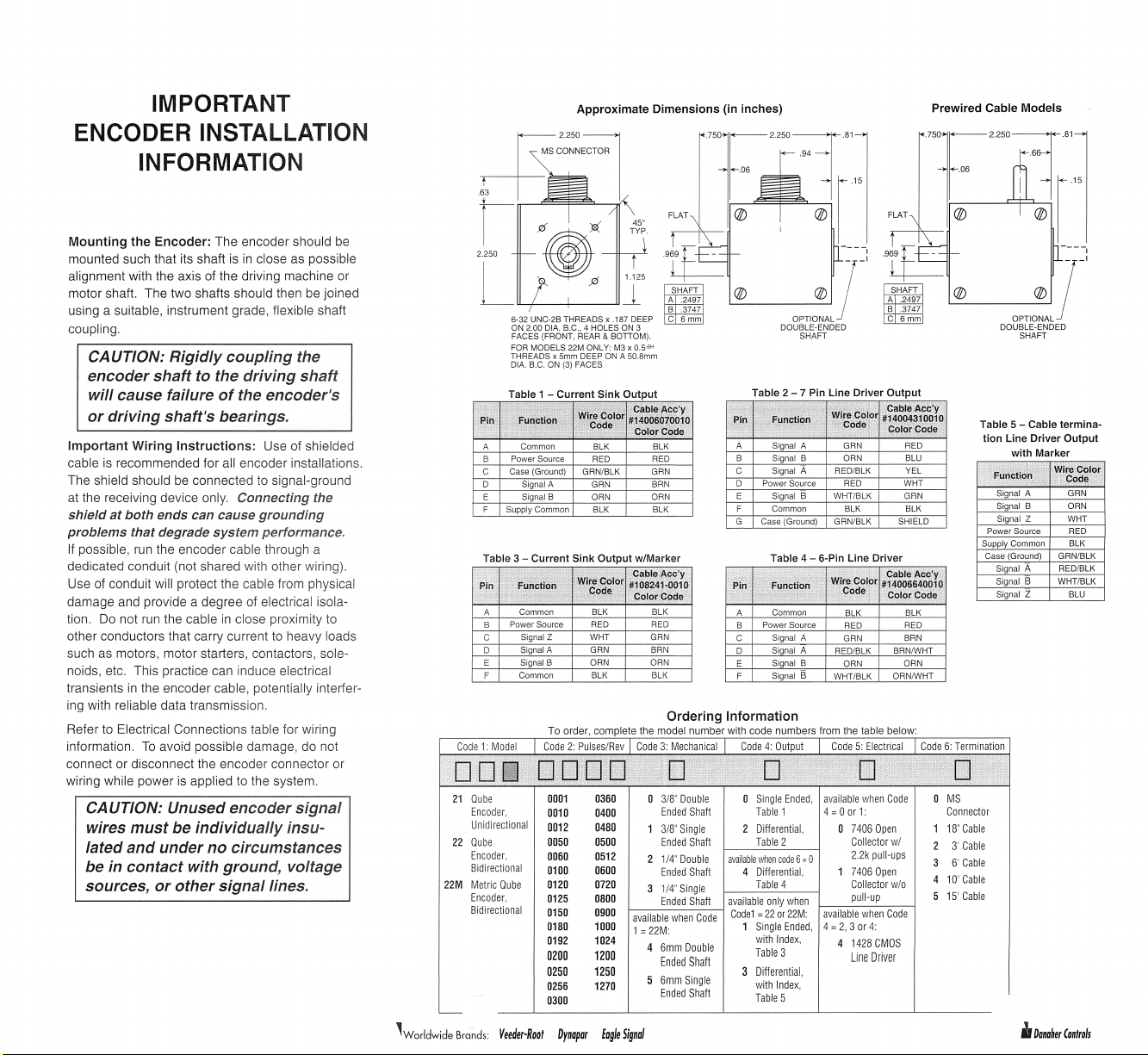

Approximate Dimensions (in inches)

Prewired Cable Models

Mounting

mounted such that its shaft is

alignment with the axis of the driving machine or

motor shaft. The two shafts should then

using a suitable, instrument grade, flexible shaft

coupling.

the

Encoder:

The encoder should

in

close as possible

be

be

joined

CAUTION: Rigidly coupling the

encoder shaft

will cause failure

or

driving shaft's bearings.

Important

cable is recommended for all encoder installations.

The shield should

at the receiving device only.

shield

problems

If possible, run the encoder cable through a

dedicated conduit (not shared with other wiring).

Use of conduit will protect the cable from physical

damage and provide a degree of electrical isolation.

other conductors that carry current to heavy loads

such as motors, motor starters, contactors, solenoids, etc. This practice can induce electrical

transients

ing with reliable data transmission.

Refer to Electrical Connections table for wiring

information.

connect or disconnect the encoder connector or

wiring while power is applied to the system.

Wiring

at

both

that

Do

not run the cable in close proximity to

in

the encoder cable, potentially interfer-

To

to the driving

of

the encoder's

Instructions:

be

connected to signal-ground

Connecting the

ends can cause

degrade system performance.

avoid possible damage, do not

shaft

Use of shielded

grounding

CAUTION: Unused encoder signal

must

wires

lated

be individually insu-

and

under no circumstances

be in contact with ground, voltage

sources,

or

other

signal

lines.

III

i

6-32 UNC-2B

ON

FACES

FOR

THREADS x 5mm

D[A.

Table 3 - Current Sink Output wIMarker

21

Qube

Encoder,

Unidirectional

22

Qube

Encoder,

Bidirectional

22M

Metric

Qube

Encoder,

Bidirectional

THREADS

2.00

D[A.

B.C., 4 HOLES

(FRONT, REAR & BOTTOM).

MODELS

22M

ONLY: M3 x

DEEP

B.C.

ON

(3)

FACES

0001

0010 0400

0012 0480

0050 0500

0060

0100 0600

0120 0720

0125 0800

0150 0900

0180

0192

0200

0250

0256

0300

1.125

!!~

x .187 DEEP

ON

3

O.5.fiH

ON

A 50.Bmm

0360

0512

available

1000

1 =

1024

1200

1250

1270

~"l~m~i'"

9rE

SHAFT

A .2497

B .3747

CI6mm

o

3/8"

Double

Ended

Shaft

1

3/8"

Single

Ended

Shaft

2

1/4"

Double

Ended

Shaft

3

1/4"

Single

Ended

Shaft

when

Code

22M:

4

6mm

Double

Ended

Shaft

5

6mm

Single

Ended

Shaft

(jJ) (jJ)

OPTIONAL C 6 mm OPT10NAL

DOUBLE·ENDED DOUBLE·ENDED

SHAFT SHAFT

Table 4 - 6-Pin Line Driver

o

Single

Ended,

Table

1 4 = 0

2

Differential,

Table

4

Code1

1

3

2

when

code

Differential,

Table

4

only

when

=220r22M:

Single

Ended,

with

Index,

Table

3

Differential,

with

Index,

Table

5

6 = 0

available

available

19

----

7-[

available

when

or

1:

o

7406

Collectorw/

2.2k

1

7406

Collector

pull·up

available

when

4 =

2, 3 or

4

1428

Line

Open

pull·ups

Open

4:

CMOS

Driver

'If'''~i',,

rE

ASH~:;7

B .3747

Code

w/o

Code

(jJ) (jJ)

Table 5 - Cable termina-

tion Line Driver Output

o

MS

Connector

1

18"

Cable

3'

Cable

2

6'

Cable

3

4

10'

Cable

5

15'

Cable

----I

7-[

with Marker

~Worldwide

Brands:

Veeder-RDIJ/

Oynapor

EagleS~nal

if

Danairer

Con/lois

Loading...

Loading...