Page 1

DYNAPAR brand

VEEDER-ROOT brand

VEEDER-ROOT brand

Predetermining Counters

Electronic Predetermining Counters

Electronic Predetermining Counters

R

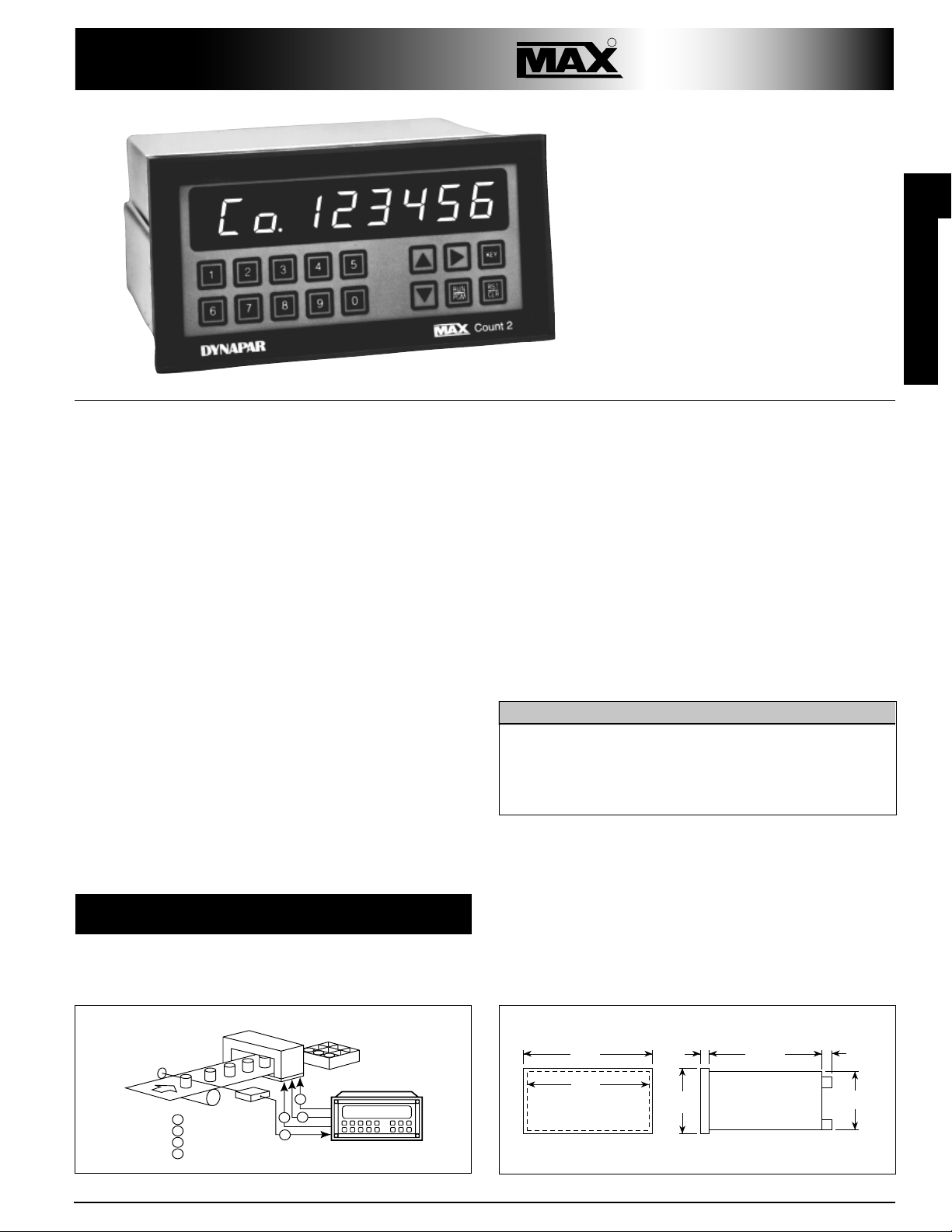

Count 2

Three Counters in one

. . . a powerful three

preset counter with

batch control and

production totalizer

2

P

T

R

E

O

E

L

T

D

E

E

A

C

T

T

L

E

R

I

R

O

M

Z

N

I

I

I

N

N

C

I

G

N

G

MAX Count 2 can handle your most demanding positioning, winding,

sequencing and other count/control tasks with its programmable 3-limit

predetermining counter. Preset batch counter and units totalizer features

allow it to automatically direct a batching operation and totalize

production quantity.

■ 6-decade display for all three counters

■ Calibration constant for display scaling

■ Bidirectional and unidirectional count modes

■ Three transistor outputs—optional relays

■ Flexible programming for custom application

■ RS-422/485 data port with selectable baud rate

■ Bright, 0.6" high LED display

■ Sealed NEMA 4 front panel

■ DIN-size panel mounting

■ Non-volatile memory during power loss

MAX Count 2 can accept bidirectional or unidirectional count input from

a variety of encoders, sensing devices, pulse, and contact closure

sources, at speeds to 40 kHz. An RS-422/485 communications port will

support your present needs or future plans for system use.

An easy-to-use display prompted setup mode enables MAX Count 2 to

be cusomized as required for a specific application. Programmable

features include: input correction constant, output hold times and logic,

and decimal point position. The program is retained in non-volatile

memory and can be secured from unauthorized change.

A full numeric keypad with display prompting allows equipment

operators to make quick and accurate changes to preset limit values.

Access to preset limits can be restricted if desired.

SPECIFICATIONS

Input Power: Selectable, 100 to 130 VAC or 200 to 260 VAC, 50/60 Hz, 20

VA (12 VDC @ 0.3 A optional).

Accessory Power: 12 VDC @ 175 mA, short circuit protected.

Main Counter and Totalizer: Programmable x1, x2, or x4 logic; Maximum

Input Frequency: 40 kHz x1, 20 kHz x2, 10 kHz x4.

Calibration Constant: 0.0001 to 9.9999 programmable range.

Program Security: System Lock and User Lock.

Signal Input: Contact closure or 3.5 to 15 VDC square wave @ 3.25 mA

source.

Outputs: 3 solid state, 100 mA sink, 28 VDC max.; 3 SPDT, 5 amp, relays

optional.

Serial Communications: RS-485/422 Differential, ASCII.

Operating Temperature: 32° to 122°F (0° to 50°C)

Model No. Description

MC200S00 MAX Count 2 w/Solid State Outputs, A-B, A+B

MC201S00 MAX Count 2 w/Solid State and Relay Outputs, A-B, A+B

MC210S00 MAX Count 2 w/Solid State Outputs, A-B, A+B, Quad

MC211S00 MAX Count 2 w/Solid State and Relay Outputs, A-B, A+B,

Quad

For 12 VDC operation, change the sixth digit in the model no. from S to D.

For more presets, see MAX Count 6

For position indication, see MAX Position 1

Typical Application:

Reflector

Packaging

Machinery

1

2

3

4

Batch Control

Row Control

Column Control

Add A Input

Automatic Packaging Machinery

Photocell

1

2

3

4

Row

Column

Batch

MAX

Count 2

Dimensions:

5.67"

144 mm

5.35"

136 mm

FRONT SIDE

Panel Dims: Cutout: 2.68" x 5.43". Thickness: 1/16" to 1/4". Depth: 5.68" min.

.39"

10 mm

74 mm

2.91"

5.20"

132 mm

VEEDER-ROOT • EAGLE SIGNAL • DYNAPAR

.50"

13 mm

2.60"

66 mm

2.11

Loading...

Loading...