Dynapac Svedala Demag EB 34 Series, Svedala Demag EB34V, Svedala Demag EB34TV Operation & Maintenance Manual

OPERATION

&

MAINTENANCE

Screed

Svedala Demag

EB 34

Keep this manual for future reference

Order number for this manual: D900981487

02-0508

270.................

275.................

VALUE

QUALITY

THE ORIGINA L

Your Authorized Dynapac Dealer:

Table of conten ts

V Preface ..................................................................................... 1

1 General safety instructions ........................................................................2

1.1 Acts, directives, accident prevention regulations .......................................2

1.2 Warning instructions ..................................................................................2

1.3 Prohibitive signs ............................................. ......... .......... ......... ......... .......4

1.4 Protective gear ...................................... ......... ......... .......... ......... ......... .......5

1.5 Environmental protection ...........................................................................6

1.6 Fire prevention ...........................................................................................6

1.7 Further instructions ....................................................................................7

A Correct use and application ...................................................1

B Description of the screed .......................................................1

1 Application .................................................................................................1

2 Assemblies .................................................................................................2

3 Safety ......................................................................................................... 4

3.1 Remaining risks at the screed ....................................................................4

4 Technical data ............................................................................................6

4.1 Dimensions ................................................................................................6

4.2 Weights ...................................................................................................... 6

4.3 Adjustment/equipment featur es ........................................ .........................7

4.4 Compacting system ...................................................................................7

4.5 Gas heater system .....................................................................................8

4.6 Electric heater EB 34 (V) ...........................................................................9

4.7 Electric heater EB 34 (TV) .........................................................................9

5 Location of instruction labels and type plates ..........................................10

5.1 Screed type plate (1) ................................................................................11

5.2 Liquefied gas system type plate (2) ......................................................12

C Transporta tion ... .......... ..... ......... .......... .......... ......... .......... .......1

1 Safety regulations for transportation ..........................................................1

2 Transporting the removed screed ..............................................................2

2.1 Transportation by crane ........................ ......... ......... .......... ......... ......... .......2

2.2 Transportation by fork-lift truck ..................................................................2

EB34_GBIVZ.fm 1-4

1

D Operation ................................................................................. 1

1 Notes regarding safety ...............................................................................1

2 Operation of the screed .............................................................................2

2.1 Extend/retract screed .................................................................................2

2.2 Adjusting the tamper (o) .............................................................................3

Adjusting the vibration ...........................................................................3

Tamper/vibration frequency displays (o) (6) / (7) ...................................4

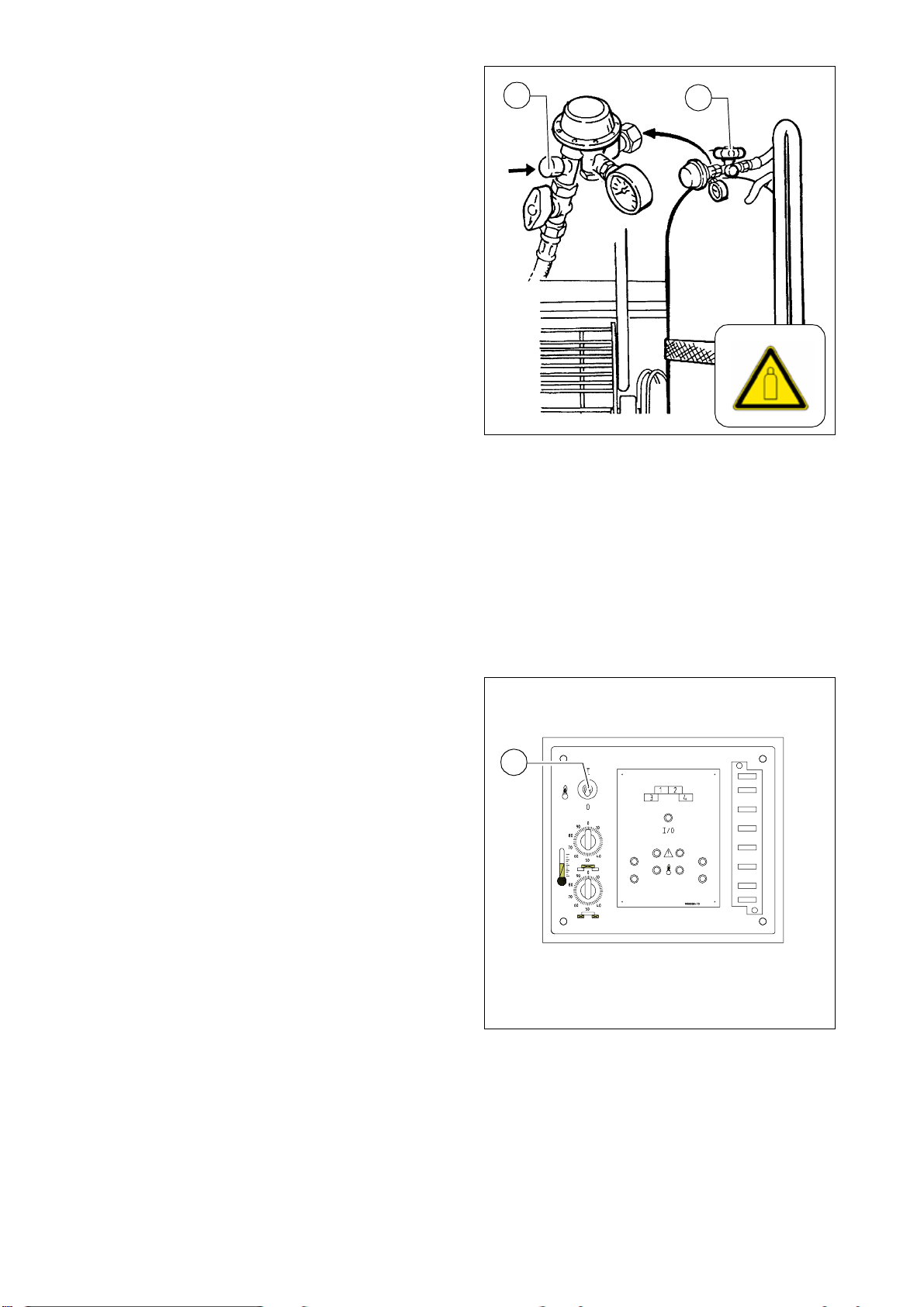

3 Operation of the gas heater system with flame monitoring ........................5

3.1 Switch cabinet for screed heating system ......................... ......... ......... .......5

3.2 Gas supply diagram ...................................................................................7

3.3 General notes on the gas heater system ...................................................8

3.4 Connection and leak test ...........................................................................9

3.5 Commissioning and checking the heating system ...................................10

Ignition process ....................... .......... ......... ......... .......... ......... ......... .....10

3.6 Function of the flame monitoring system .................................................11

3.7 Setting the temperature level ...................................................................12

3.8 Switching off the heater ...........................................................................13

3.9 Exchanging the gas bottles ......................................................................13

4 Operating the electric heater ....................................................................14

4.1 Switch cabinet for screed heating system ......................... ......... ......... .....14

4.2 General information on the heating system .............................................16

4.3 Isolation monitor .......................................................................................17

Insulation faults ....................................................................................18

4.4 Commissioning and checking the heating system ...................................19

4.5 Temperature display, setting temperature level .......................................20

4.6 Operating the control and monitoring unit ................................................20

4.7 Temperature setting .................................................................................22

4.8 Fault messages ........................................................................................22

Fault codes ..........................................................................................22

4.9 Switching off the heating system .............................................................23

5 Malfunctions .............................................................................................24

5.1 Problems during paving ..........................................................................24

5.2 Malfunctions on the screed .....................................................................26

2

EB34_GBIVZ.fm 2-4

E Set-up and modification .........................................................1

1 Notes regarding safety ...............................................................................1

2 General assembly ......................................................................................2

2.1 Fitting screed to finisher .............................................................................2

2.2 Mounting the side shields ..........................................................................3

2.3 Hydraulic connections ....................................................... ......... ......... .......4

Position and designation of the connections: .......................................4

2.4 Electrical connections ................................................................................5

3 Extending the screed ..................................... ......... ............................ .......6

3.1 Removing side shields ...............................................................................6

3.2 Preparing extension parts ..........................................................................7

3.3 Removing tamper deflector plate ...............................................................7

3.4 Assembly of tamper drive shaft ..................................................................7

3.5 Fitting tamper deflector plate .....................................................................7

3.6 Fitting extension parts ................................................................................8

3.7 Fitting side shield to extension part ............................................................8

3.8 Screed heating system gas connections ...................................................9

3.9 Screed heater system electrical connections .............................................9

4 Settings .................................................................................................... 10

4.1 Setting extendable parts ..........................................................................10

Basic setting: .......................... .......... ......... ......... .......... ......... ......... .....10

Fine adjustment, setting during installing work: ...................................10

4.2 Setting tamper height ...............................................................................11

4.3 Setting tamper deflector plate: .................................................................11

4.4 Setting side shields ..................................................................................12

4.5 Setting crowing ........................................................................................12

4.6 Setting positioning angle ..........................................................................13

4.7 Positioning angle correction

Adjustment section / central section ........................................................13

EB34_GBIVZ.fm 3-4

3

F Maintenance ............................................................................1

1 Notes regarding safety ...............................................................................1

2 Maintenance intervals - screed in general .................................................2

3 Maintenance intervals - gas system ...........................................................3

4 Maintenance intervals - electric heating system ........................................4

5 Lubrication points .......................................................................................5

5.1 Guide tubes ................................................................................................5

5.2 Other lubricating and maintenance points .................................................6

6 Checkpoints ...............................................................................................7

6.1 Guides of the extendable parts ..................................................................7

Adjustment of guide tube play ...............................................................7

6.2 Cleaning the screed .............................. ......... ............................ ......... .......8

Emptying the tamper compartment ........................................................8

Cleaning side shield ...............................................................................9

6.3 Check / adjust tamper deflector plate ......................................................10

6.4 Hydraulic hoses ................................... ......... ......... .......... ......... ......... .....10

7 Gas system ..............................................................................................11

7.1 Spark plugs ..............................................................................................11

7.2 Adjusting the flame ..................................................................................12

7.3 Injectors of the gas heater system ...........................................................12

8 Electric heating system ............................................................................13

8.1 Check insulation monitoring .....................................................................13

Insulation faults ....................................................................................14

9 Lubricants ................................................................................................15

10 Electric fuses ............................................................................................16

10.1 Equipment with gas heating system ........................................................16

Fuses in the compacting element (1) control box ................................16

Fuse board (1) .....................................................................................16

11 Test certificates .............................................. ............................ ......... .....17

11.1 Electric screed heating system ................................................................17

4

EB34_GBIVZ.fm 4-4

VPreface

Safe operation of the machine requires specific knowledge that is imparted by the

present operati ng instruction s. The information is pr ovided in a concise, cle arly structured form. The individual chapters are arranged in alphabetical order and every

chapter starts with page 1. The individual pages are identified by the chapter letter

and the page number.

Example: Page B 2 is the second page of chapter B.

These operating instructions cover various machine options. Make sure that during

operation and m aintenance w ork the description appropriate to the machin e option is

used.

Safety instructions and important notes are identified by the following pictograms:

f

m

A

Precedes safety inst ructions that must be obser ved in orde r to p revent danger t o personnel.

Precedes notes that must be observed to prevent damage to equipment.

Precedes general notes and explanations.

t Used to indicate standard equipment.

o Used to indicate optional equipment.

In the interest of continu ed development, the man ufacturer reserve s the right to make

changes to the machine ( which will not, however, change the essential features of the

type of m achine descr ibed) wi thou t up dating the pr esent oper ating i nstructi ons at the

same time.

Dynapac GmbH

Wardenburg

Ammerländer Strasse 93

D-26203 Wardenburg / Germany

Telephone:+49 / (0)4407 / 972-0

Fax: +49 / (0)4407 / 972-228

www.dynapac.com

V_01_GB.fm

V 1

1 General safety instructions

1.1 Acts, directives, accident prevention regulations

A

A

A

A

1.2 Warning instructions

The locally applicable acts, directives and accident prevention regulations shall be

obse rved, even if the attenti on is not specifically directed to these.

The operator hi mself shall be responsi ble for the observatio n and performa nce of the

related regulations and actions!

The following alerts, prohibitions and instructions refer to the risks to which people,

machinery and environment are exposed.

Ignoring these instructions, bans and commands may lead to fatal injuries!

Furthermore, the Dynapac publication "Directives for the correct and specified application of pavers" shall also be observed.

Warning pointing to hazardous place or danger!

Not observing the warning instructions may lead to injuries of life

and limb!

m

m

m

m

Warning: risk of pulling in!

In this area / with these equipment as a result of rotating or trans-

portation parts, there is a risk of pulling in!

Perform each operation only with equipment swicthed off!

Attention: electric voltage!

All maintenance and repair work on the screed's electrical system

must always be carried out by an electrician!

Attention: suspended load!

Never stand under suspended load!

Warning: risk of squeezing!

Risk of squeezing arises due to the operation of certain parts, use

of some functions and the movement of the machine.

Always make sure that no one stays in the areas exposed to risk!

V 2

V_01_GB.fm

Attention: risk of hand injury!

Attention: hot surfaces or hot liquids!

Warning, risk of falling off!

Attention: hazardous batteries!

Attention: materials harmful to health and irritating substances!

Attention: flammable materials!

Attention: gas bottles!

V_01_GB.fm

V 3

1.3 Prohibitive signs

It is prohibited to open / step on / reach into / perform / adjust

during operation or when the traction engine is running!

Do not start the engine/drive!

Maintenance and repair works can be carried out only with the Diesel engine turned off!

Do not sprinkle with water!

Do not extinguish with water!

A

Do-it-yourself maintenance is prohibited!

Maintenance can be performed by skilled professionals only!

Contact the Dynapac service!

Danger of fire: do not use open flame and no smoking!

Do not turn on!

V 4

V_01_GB.fm

1.4 Protective gear

A

The applicable local regulations may define the use of different protective gear!

Observe these specifications!

Protect your eyes with googles!

Wear appropriate head protection!

Protect your hearing with appropriate ear mufflers!

Protect your feet with safety footwear!

Always wear tight, conforming working coveralls!

Wear visibility vest for good visibility!

In case of polluted air, wear respiratory mask!

V_01_GB.fm

V 5

1.5 Environmental protection

A

The locally applicable acts, directives and waste disposal regulations shall be observed, even if the attention is not specifically directed to these.

During cl eanin g, m ainte nance and r epair op erati o n th e mater ial s p olluting water e .g.:

- lubricants (oils, grease)

- hydraulic oil

-gas oil

- coolant

- detergents

may not enter the soil or the sewer system!

These materi als shall be colle cted, stored, tran sported in the cor rect

containers until professional disposal!

Material harmful for the environment!

1.6 Fire prevention

A

The applicable local regulations may specify the mounting of appropriate fire extinguishers!

Observe these specifications!

Fire fighting device

(optional equipment)

V 6

V_01_GB.fm

1.7 Further instructions

m

A

m

m

Observe the manufacturer's and other instructions!

e.g. the maintenance instructions of the engine manufacturer

Description / figure in case of an electrically heated design!

Description / figure in case of an electrically heated design!

V_01_GB.fm

V 7

A Correct use and application

A

The “Guidelines for the Correct Use and Application of Paver finishers” compiled by

Dynapac are included in the scope of delivery for the present machine. The guidelines are part of the present operating instructions and must always be heeded. National regulations are fully applicable.

The road construction machine described in the present operating instructions is a

paver finisher that is suited for laying mixed materials, roll-down concrete or leanmixed concrete , track-layi ng ballast and unbound m ineral aggregate s for founda tions

for paving.

This machine sh all be u sed, operat ed and ma intained for the pu rpose of the intended

work as included i n the oper ation manual. A ny other u se is regarded as improper use

and can cause injury to persons or damage to the paver finisher or other equipment

or property.

Any use going beyond the range of applications described above is regarded as improper use and is expr essly forbidden! E specially in those cases wher e the paver finisher is to be operated on inclines or where it is to be used for special purposes

(construction of dump s, dams), it is absolutely necessary to contact the m anufacturer.

Duties of th e u ser : A “ user” wi thin the m eaning of the presen t ope rati ng instru cti ons

is defined as any natural or legal person who either uses the paver finisher himself,

or on whose behalf it is used. In special cases (e.g. leasing or renting), the user is

considered the person who, in accordance with existing contractual agreements between the owner and the user of the paver finisher, is charged with the observation

of the operating duties.

The user must ensure that th e paver finisher is only used in the stipu lated mann er and

that all danger to life and limb of the operator, or third parties, is avoided. In addition

to this, it must be ensured that the relevant accident pr evention regulat ions and othe r

safety-related provisions as well as the operating, servicing and maintenance guidelines are observed. The user must also ensure that all persons operating the equipment have read and understood the present operating instructions.

Mounting of attachments: The paver finisher must only be operated in conjunction

with screeds that have been approved by the manufacturer. Mounting or installation

of any attachment s that will interfere with or supple ment the functions of the paver finisher is per mitted only after w ritten a ppro val by the ma nufact urer has bee n obtain ed.

If necessary, the approval of local authorities has to be obtained.

Any approval obtained from local authorities does not, however, make the approval

by the manufacturer unnecessary.

A_01_GB.fm 1-2

A 1

B Description of the screed

1 Application

The SVEDALA D EMAG EB 34 screed is ope rated in conjuncti on with a paver finish er .

The screed is used for laying:

- bitumen materials,

- roll-down concrete or lean-mixed concrete,

- track-laying ballast or

- unbound mineral aggregates for foundations for paving.

B_EB34_DEM_05.08_GB.fm. 1-12 -01.01.07

VB340.wmf

A

The hydraulically extendable screed is intended for laying with variable operating

widths.

For the technical specifications of the screed, refer to the section ”Technical Data”.

B 1

2 Assemblies

Tamper and vibration elements: The tamper knives converging in the middle area

prevent seams in the middle.

Auxiliary vibration (option) supports the compacting process, thus improving the texture.

The tamper and the vibration elements can be individually switched on and off and

controlled with regard to speed.

Continuous speed control always ensures optimum compacting results for the different materials and layer thicknesses.

Basic scre ed an d ext endab le pa rts: The screed parts which can be hydraulically

extended from the middle section („basic screed“) extend the working width of the

screed at the push of a button.

An expensive guide system ensures high levels of stability.

The angle and the height of the extendable parts in relation to the basic screed can

be quickly and easily readjusted.

A

These adjustments, the basic adjustments of the screed in relation to the paver finisher and adjustment of the crow ning are d escri be d in chap ter E , „Set- up a nd mo di fication“.

Extensio n pa r ts : The working width can be increased through the use of extension

parts which are very simple to install.

Side shields: The side shields serve to prevent the material from overflowing to the

outside.

- Heated side shields

- Cut-off shoes

Hinged walkway plates: During installation, the hinged walkway plates should be

folded down and snapped into place.

The walkway plates may on l y be folded up for a short tim e in speci al cases ( e.g. ma terial to be laid along a wall).

B 2

B_EB34_DEM_05.08_GB.fm. 2-12 -01.01.07

Screed heater system: Two different heater systems are available as options:

Gas heater: The propane gas flame band heater features a tried-and-tested design

and is easy to handle.

The electronic te mperatur e and f lame monito ring system ensures short hea ting times

and constant temperatures.

Air guides to the tamper knives and side plates ensure efficient use of heat.

Electric h eater: The advantages of the electr ic screed he ater are its trie d-and-te sted

design, problem-free handling and maximum possible service friendliness thanks to

maintenance-free

operation.

Short heating times, con stant temperature s and efficien t heat utilisation are the refore

assured than ks to the various, separ ately m oni tored and contr ol led he ating sections.

These are designed in the form of heating strips, sensibly arranged in the bottom

plates and tamper knives of each screed section.

If extension parts are fitted to the screed, only one single, easily installed plug connection need be fitted to the supply and control cable leading to the neighbouring

screed component.

The heating system is monitored and controlled in the switch cabinet.

A

Both types of heater and their operation are described in the following chapters of

these operating instructions.

Symbols are assigned to the different descriptions and figures:

- Description / depiction when equipped with gas heater

- Description / depiction when equipped with electric heater

B_EB34_DEM_05.08_GB.fm. 3-12 -01.01.07

B 3

3 Safety

f

3.1 Remaining risks at the screed

f

f

f

The safety devices of th e paver finisher and of the screed a re described in cha pter B,

section 3 of the operating instructions for the finisher.

Danger of squeezing!

At all moving parts of the screed, there is a danger of crushing , trapping or shearing.

Keep away from these parts!

Danger of being pulled in!

A danger of catching, winding or drawing-in exists at all rotating or

circulating parts of the screed.

Keep away from these parts!

Danger of falling!

Never jump on or off the when the machine is in motion! Only use

the access boards and steps provided!

f

f

Danger of fire and explosions!

Work on the heater system involves the danger of fire and explosion.

Do not smoke! Do not use open fires!

Danger of electric voltage

Any failure to follow the safety precautions and safety regulations

when operating the electric screed heater (o) leads to the risk of

electric shock.

Danger to life!

All maintenance and repair work on the screed's electrical system

may be carried out by a specialist electrician only.

B 4

B_EB34_DEM_05.08_GB.fm. 4-12 -01.01.07

Danger of burning!

f

Heating the screed heater l eads to danger due to hot surfaces, particularly on the bottom plates and side shields.

Keep away from these parts! Or wear protective gloves!

- Always wear all protective clothing required!

Failure to wear protective clothing or wearing protective clothing in an improper

manner can be dangerous to health.

- Ensure that all protective covers and hoods are fitted and secured accordingly!

- Immediately rectify any damage which is determined! Operation must not be con-

tinued when the machine is defective!

- Always make sure during operation that no-one is endangered by the machine!

B_EB34_DEM_05.08_GB.fm. 5-12 -01.01.07

B 5

4 Technical data

4.1 Dimensions

Basic width 1,70 1,70 m

Working width:

min. width with 2 cut-off shoes

hydraulically extendable to

Depth of the bottom plates:

basic screed

extendable parts

EB34(V) EB34(TV)

1,20

3,40

310

310

1,20

3,40

270

270

m

mm

A

As regards extension of the screed, refer to the chapter entitled „Set-up and modification“.

4.2 Weights

Basic screed with extendable parts 1,35 1,35 t

plus:

side shields

350 mm per extension part

500 mm per extension part

EB34(V) EB34(TV)

68

70

105

68

84

120

kg

B 6

B_EB34_DEM_05.08_GB.fm. 6-12 -01.01.07

4.3 Adjustment/equipment features

Crowning:

- Adjustment range -2%... +4 %

- Adjusting mechanism with ratchet via chain

Height/angle adjustment of extendable parts Separate systems

Hinged walkway plate Standard

Lubrication system Individual lubrication points

4.4 Compacting system

Tamper system Vertical impact tamper

Tamper stroke max. 3,5 mm

Tamper frequency 0 ... 1500 rpm

(infinitely adjustable) (0 ... 25 Hz)

Vibration (option) 0 ... 3300 rpm

(infinitely adjustable) 0 ... 55 Hz)

Oil motors:

- for tamper (in basic screed/extendable part) 2/2

- for vibration (in basic screed/extendable part) 2/2

B_EB34_DEM_05.08_GB.fm. 7-12 -01.01.07

B 7

4.5 Gas heater system

Fuel (liquefied gas) Propane gas

Burner type Pipe burner

Heater control system

(switch cabinet on the screed)

Gas bottles (on the screed)

- Capacity per bottle

- Gross weight per bottle

Operating pressure (downstream of pressure

reducer)

Electronic ignition,

temperature monitoring,

flame monitoring

1 units

70 l

33 kg

Approx. 1.5 bar

B 8

B_EB34_DEM_05.08_GB.fm. 8-12 -01.01.07

4.6 Electric heater EB 34 (V)

Type of heater

Number of heating strips

- Per bottom plate 2

Screed heating system total output:

- Main screed - bottom plate

- Extendable part - bottom plate

- Extension part, 350 mm - bottom plate

- Extension part, 500 mm - bottom plate

4.7 Electric heater EB 34 (TV)

Type of heater

Number of heating strips

- Per bottom plate

- Per tamper knife

Electric heater with heating

strips in bottom plates

1100

1100

450

650

Electric heater with heating

strips in bottom plates and

tamper knives

2

1

Units

Watts

Units

Screed heating system total output:

Main screed - bottom plate

Main screed - tamper knife

Extendable part - bottom plate

Extendable part - tamper knife

Extension part, 350 mm - bottom plate

Extension part, 350 mm - tamper knife

Extension part, 500 mm - bottom plate

- Extension part, 500 mm - tamper knife

1100

650

1100

650

450

250

650

350

Watts

B B_EB34_DEM_05.08_GB.fm.GB 9-12 -01.01.07

B 9

5 Location of instruction labels and type plates

2 3

5

g

n

u

t

4

h

u

c

i

3

r

t

r

r

e

h

2

f

r

a

2

u

e

F

1

n

r

w

o

i

e

n

4

t

f

i

1

r

k

e

n

n

e

h

e

i

o

o

w

c

t

i

S

N

n

t

k

i

S

k

e

O

e

e

S

h

1

S

3

c

N

n

S

O

o

i

t

1

k

r

e

e

f

S

r

e

w

n

i

e

h

c

S

N

g

O

n

-

N

u

1

O

r

N

-

e

1

O

N

h

-

c

O

1

i

-

s

t

1

p

u

a

H

N

O

N

O

1

-

N

1

O

N

1

O

N

O

1

-

N

1

O

-

1

A

L

A

D

E

V

S

C

°

4

n

O

T

o

i

U

t

6

4

k

A

F

e

F

2

O

S

2

1

F

F

F

n

3

0

o

O

F

i

F

-

0

t

O

0

0

F

k

F

-

K

2

e

0

O

F

F

S

-

O

O

C

0

F

T

-

F

1

O

0

F

S

-

F

n

0

O

F

o

-

i

F

t

0

F

O

k

-

0

O

e

-

S

0

3

F

F

n

F

o

O

i

t

F

-

F

k

0

O

F

-

e

F

0

F

O

S

-

F

0

F

O

-

F

0

F

O

-

F

0

F

O

-

F

O

F

0

0

O

-

0

4

VB340.wmf

Pos. Designation

1 Screed type plate

2 Gas system type plate *

3 Bottle valve operating instructions *

4 Warning plate „Hot surfaces“

5 Safety seymbols „Danger of electrical voltage“**

1

5

(o)

B 10

6 Electric heater operating instructions**

* With „gas heater“ equipment only

** With „electric heater“ equipment only

B B_EB34_DEM_05.08_GB.fm.GB 10-12 -01.01.07

5.1 Screed type plate (1)

1

4

Typ_Bohl3.tif

Pos. Designation

1 Screed type

5

3

2

2 Maximum operating weight of the screed

3 Screed number

4 Year of manufacture

5 Manufacturer

B B_EB34_DEM_05.08_GB.fm.GB 11-12 -01.01.07

B 11

5.2 Liquefied gas system type plate (2)

GASANL3.TIF

Pos. Designation

1 Year of manufacture

2 Type of gas to be used

1

2

3

4

5

6

3 Connection overpressure in mbar

4 Average gas consumption of the installed screed, in kg/h

5 Average gas consumption of the screed extension parts, in kg/h

Maximum permissible mass flow of the installed

6

hose rupture protection in kg/h

B 12

B B_EB34_DEM_05.08_GB.fm.GB 12-12 -01.01.07

C Transportation

1 Safety regulations for transportation

m

Accidents may occur when the paver finisher and the screed are not properly prepared for transportation or when transportation is carried out improperly!

Retract the e xtension parts of the screed to the basic width and r emove all exte nsi on

parts that may have been attached.

Remove all loose and protruding parts (limiting plates, remote controls, etc.). When

transporting under a special permit, secure these parts!

Stow all par ts which are not p ermanently installed on the screed in the boxes provided

for this purpose.

Properly reattach all guards after transportation.

C 614_DYN_DEM.GB 1-2 - 01.01.07

C 1

2 Transporting the removed screed

A

f

A

2.1 Transportation by crane

m

f

The procedure required to load and transport the screed when installed on the fin-

isher is described in the operating instructions for the finisher.

The screed must be retracted to the basic width. All protruding or loose parts and the

gas bottles for the screed heating system (o) (see Chapters E and D) must be removed. Hydraulic and electrical connections must be disconnected.

Heed the capacity of the fork-lift truck / of the crane and the lifting gear (chains, cables, hooks, etc.)!

For the weights and the dimensions of the screed, refer to Chapter B, section „Technical data“.

Attach the hooks to the attachment points (1, 2) provided for this purpose.

Make sure t hat th e scre ed is in a com pl etely h orizontal position w hen attache d to the

gear; otherwise, oil and grease can leak out.

This is harmful to the environment!

Suspended load!

Never step below the suspended load!

2.2 Transportation by fork-lift truck

m

f

Always note that the centre of gravity of the screed or accessories box may be offcentre.

When a fork-lift truck i s used for transpo rtatio n, ther e is the danger that the loa d may

tip over or that parts may fall down. Keep away from the danger area!

1 2

C 2

VB340.wmf

C 614_DYN_DEM.GB 2-2 - 01.01.07

D Operation

1 Notes regarding safety

f

Improper operation of the screed or the screed heater can endanger persons.

- Ensure that all protective devices and covers are available and appropriately secured!

- Immediately rectify any damage which is determined! Operation must not be continued when the machine is defective!

- Always ensure that no person is endangered when working!

- Do not let any person ride along on the screed!

D_E34_VB340_05.08_G B.fm 1-26- 01.01.07

D 1

2 Operation of the screed

A

For all general functions of the finisher

and the screed that are not specially related to the present screed, refer to the

operating instructions of the finisher.

2.1 Extend/r etr act screed

To extend or retract the hydraulica lly adjustable extension parts,

- actuate the switch (1) on the remote

controls installed on the right-hand

and the left-hand side of the screed

(option: on the contr ol panel of the fin isher).

- The screed h azard warning system ( at

the rear lights of the finisher) starts

flashing.

m

There is a danger of squeezing while t he

extension parts are extended or retracted.

Make sure that there is no-one in the

danger area!

1

3

2

- A pointer (2) and a scale (3), from

which the extended width can be read

off, can be found on each of the extendable parts.

Remote_F6.bmp/VB340_Skala.wmf

D 2

D_E34_VB340_05.08_G B.fm 2-26 -01.01.07

2.2 Adjusting the tamper (o)

The tamper function is switched on and

off using the switch (2) on the finisher's

operating panel (see finisher operating

instructions). (o Pavers equipped with

PLC system: Button (2a))

The tamper frequency (number of

strokes a minute) is set using the speed

regulator for the tamper (4). This can be

found on the railing on th e left- hand side

of the machine (under heating switch

cabinet).

2

3

Adjustment range:

Tamperswitch.bmp/Vibrationswitch.bmp

0 – 1500 rpm =

0 – 25 strokes a second

Adjusting the vibration

The vibration fun ction i s switched on and off usi ng the switch (3) on the fini she r's op erating panel (see finisher operating instructions).

The speed regulator for vibration (5) can be found on the railings on the right-hand

side of the machine (separator fluid system holder).

Adjustment range:

0 – 3300 rpm =

0 – 55 strokes a second

4

D_E34_VB340_05.08_G B.fm 3-26- 01.01.07

5

VibDrehz340.wmf/TampRPM340.wmf

D 3

Tamper/vibration frequency displays

(o) (6) / (7)

The display can be used to optimaly adjust the tamper and vibration speed to

different paving situations.

When the igniti on is switched on , the relevant frequency is automatically displayed (range 0 to maximum).

During paving, the frequencies can be

easily checked and, if necessary, readjusted using the rotary knobs (4),(5).

6

RPMVB340.bmp

7

D 4

D_E34_VB340_05.08_G B.fm 4-26 -01.01.07

3 Operation of the gas heater system with flame monitoring

3.1 Switch cabinet for screed heating system

9

10

11

18 17 2019

12

D_E34_VB340_05.08_G B.fm 5-26- 01.01.07

15 161314

D 5

Pos. Designation

Heating system master switch ON/OFF

9

- Position 1: Heating system ON (o) and tamper/vibration speed displays ON

- Position 0: Heating system OFF (o) and speed displays OFF

10 Controller for high/low temperature pre-selection, basic screed

11 Controller for high/low temperature pre-selection, extendable parts

12 Operating display, green

13 Left middle section operating display, yellow

14 Left extendable part operating display, yellow

15 Right middle section operating display, yellow

16 Right extendable part operating display, yellow

17 Left middle section malfunction display, red

18 Left extendable part malfunction display, red

19 Right middle section malfunction display, red

20 Right extendable part malfunction display, red

D 6

D_E34_VB340_05.08_G B.fm 6-26 -01.01.07

3.2 Gas supply diagram

6

5 5

32

4

6

1

Gaslauf_EB51.bmp

Pos. Designation

1 Gas bottles

2 Bottle valves

3 Pressure reducer with pressure gauge

4 Hose rupture protection devices

5 Flame band burner

6 Solenoid valves

D_E34_VB340_05.08_G B.fm 7-26- 01.01.07

D 7

3.3 General notes on the gas heater system

The heater of the screed burns propane

gas (liquefied gas). The gas bottle

stands on the finisher.

The heater is equipped with an electron ic flame and a temperature monitoring

system.

GHeiz_340.cdr

Heed the following points before commissioning the heater system:

29

- The gas bottles must always be in the

position provided for this purpose on

the screed, and must be secured using the supplied strap retainers.

The bottles must be fixed in position

so that they cannot turn around their

longitudinal axis even while the paver

finisher is in operation.

- The liquefied gas system must not be

operated without the hose rupture protection device (29). It is also absolutely necessary that the pressure

reducing valve is installed before the

system is put into operation.

Gasflas.tif

- The gas pressure must not fall below

1.0 bar. Danger of explosion in the burner!

- All gas hoses must be checked for external damage before use, and must be immediately replaced with new hoses if any defects are found.

f

D 8

There is a danger of fire and explosions when handling gas bottles and working on

the gas heater.

Do not smoke! No naked flames!

D_E34_VB340_05.08_G B.fm 8-26 -01.01.07

3.4 Connection and leak test

The gas pipe system of the basic screed

and the extend able pa rts is permanently

installed. To connect the gas bottles:

- Unscrew the protective caps from the

bottle valves and screw onto the rear

of the bottle bracket.

- Check whether the q uick action valves

are closed.

- Check that the bottle valves (30) are

properly closed.

Install the gas h oses with the pressure

reducers and the hose rupture protection devices (29) on the bottles.

A

Note:

The gas connections always have left-handed threads!

29

Gasflas.tif

30

m

Make sure the gas pipe system has no leaks.

D_E34_VB340_05.08_G B.fm 9-26- 01.01.07

D 9

3.5 Commissioning and checking the

heating system

The gas heating system is operated with

two gas bottles.

- Check whether the battery master

switch is switched on.

- Open the bottle valves (30).

Unlock the safety valve by pressing

the hose rupture protection device

(29).

- Open the quick action valves.

A

The following sequence must be adhered to in order to guara ntee a malfunction-free ignition and heating phase:

- 1. Place screed on the ground

- 2. Fully retract the finisher's levelling cylinders

- 3. Ignite the screed and allow to heat slightly in this position

- 4. As soon as sufficient heat is available, the screed can be raised

29

Gasflas.tif

30

Ignition process

- Switch on the On/O ff switch (27) in the

switch cabinet (upwards).

- This opens the electromagnetic

non-return valves for the gas supply

to the burners;

- It activates the electronic ignition

system, causing the gas to be automatically ignited by the spark plugs

and controlled by the flame monitoring system.

27

GHeiz_340.cdr

D 10

D_E34_VB340_05.08_G B.fm 10-26 -01.01.07

3.6 Function of the flame monitoring system

32

17

16

11

18

19

35 34

33

13

12

15

14

Pos. Designation

11 Operating display, green

12 Left middle section operating display, yellow

13 Left extendable part operating display, yellow

14 Right middle section operating display, yellow

15 Right extendable part operating display, yellow

16 Left middle section malfunction display, red

17 Left extendable part malfunction display, red

18 Right middle section malfunction display, red

19 Right extendable part malfunction display, red

D_E34_VB340_05.08_G B.fm 11-26- 01.01.07

32 Switch cabinet on the screed

33 Ignition boxes on the individual screeds

34 Red indicator lamp on the ignition box in the corresponding screed

35 Yellow indicator lamp on the ignition box in the corresponding screed

D 11

Via the temperature sensor and flame monitoring system, the electronics monitor gas

heater operation. If there is no stable flame at the ignition burner within 7 seconds,

the electronics indi cate a malfun ction. Th e gas supply is interrup ted and the red indi cator lamps on the ignition box and in the switch cabinet light up.

A

m

3.7 Setting the temperature level

In the event of a malfun cti on duri ng the switch-on phase, the starting process can be

repeated up to three times. If the malfunction still occurs after three start-ups, the

cause of the malfunction has to be eliminated before starting again.

When the flame is correct, the screed is heated until the temperature sensors in the

individual screed s interrupt the heating process. Du ring the heating phase, the yellow

indicator lamps (12, 13, 14, 15) in the switch cabinet and the yellow indicator lamps

on the ignition boxes (35) indicate a correct flame at the burners.

In the event of a malfunction, the red indicator lamps (16, 17, 18, 19) in the switch

cabinet and the red indicator lamps on the ignition boxes (34) indicate that the flame

at the burners is not correct.

The indicator lamps are important for trouble-free operation of the ignition system.

Therefore, defective bulbs should be immediately replaced!

Temperature level controller for the basic screed (9)

>: Higher temperature

<: Lower temperature

A

Temperature level controller for extendable parts (10)

>: Higher temperature

<: Lower temperature

Use the high temperature to preheat the

screed and the extendable parts/extension parts before starting work; this prevents bitumen materials from sticking to

the tamper knives and to the bottom

plates on the first meters laid.

Usually, the switches can be toggled to the low temperature after a short time.

9

10

GHeiz_340.cdr

D 12

D_E34_VB340_05.08_G B.fm 12-26 -01.01.07

3.8 Switching off the heater

After work has been comp leted, or when

the heater is no longer required:

- Switch off the On/Off switch (8) in the

switch cabinet.

- Close the quick action valves and both

bottle valves (30).

m

If these valves are not closed, there is a

danger of fire and explosion due to the

possible escape of uncombusted gas!

Always close the valves during breaks

and after work has been completed!

3.9 Exchanging the gas bottles

- Check whether the q uick action valves

and both bottle valves (30 ) are closed.

- Unscrew the gas hoses.

- Screw the protective caps for the bottle valves onto the gas bottles.

- Screw pressure reducer onto the

available mounting bracket.

8

GHeiz_340.cdr

30

f

Gas bottles that are full or not compl etely

emptied are under pressure.

Therefore, make sure that bottles with

their protective valve caps removed are

protected from severe impact (particularly in the area of the valves or on the

valves themselves)!

Gasflas.tif

- Connect new gas bottles (see section 3.4, „Connection and leak test“).

D_E34_VB340_05.08_G B.fm 13-26- 01.01.07

D 13

4 Operating the electric heater

4.1 Switch cabinet for screed heating system

15

16

17

18

22

23

24

6

8

4

5

1

3

2

7

9

11

13

21

19

A

D 14

10

20

12

Schalttafel_340E.wmf

18

The arrangement of the individual elements may vary slightly!

4 x 230 V

2827 29 30

D_E34_VB340_05.08_G B.fm 14-26 -01.01.07

Item Designation

1 EMERGENCY STOP button

2

Check button for insulation monitoring and insulation error pilot lamp

3 Insulation monitoring reset button

4 Generator telltale lamp

5 Heating ON/OFF

6 Circuit breaker for heating section 1

7 Circuit breaker for heating section 2

8 Circuit breaker for heating section 3

9 Circuit breaker for heating section 4

10 Heating section 1 telltale lamp

11 Heating section 2 telltale lamp

12 Heating section 2 telltale lamp

13 Heating section 4 telltale lamp

14 Headlights On / Off (sockets 25+26)

15 Headlights On / Off (sockets 27+28)

16

17

Circuit breaker for sockets 25+26

Circuit breaker for sockets 27+28

18 Socket (heating) for main screed on left

19 Socket (heating) for main screed on right

20

Socket (heating) for extendable part on left

21 Socket (heating) for extendable part on right

22 Circuit breaker for generator telltale lamp

23 Main fuse and EMERGENCY STOP trigger

24 Control and monitoring unit STC2000

25 230 volt socket for additional headlight

26 230 volt socket for additional headlight

27 230 volt socket for additional headlight

D_E34_VB340_05.08_G B.fm 15-26- 01.01.07

28 230 volt socket for additional headlight

D 15

4.2 General information on the heating system

The electric heating system is supplied

with power by a generator on board the

paver which is controlled fully-automatically controlled in accordance with requirements.

Heating resistors in the form of heating

strips ensure direct temperature transition and even distribution of heat.

Each screed section is heated by three

heating strips. Two can be found on the

bottom plate and one on the tamper

knife.

Temperature display and temperature

control are carried out independently of

one another and in an infinitely variable

manner for: The left basic screed, right

basic screed, left extendable part and

right extendable part by means of control unit STC2000 o n the hea ting syste m

switch cabinet.

The heating system is connected to other fitted screed components via simple

plug connections.

As an option, the switch cabine t can also

be fitted with additional 230 volt sockets

for external consumers (e.g. additional

lighting).

Since fuels (gas, diesel) are not handled

and insulation monitoring takes place,

maximum possible prote cti on of person nel is offered.

Schalttafel_340E.wmf/VB340.wmf

f

f

Beware of hot surfaces! Danger of burning!

Maintenance and repair work on electrical systems with medium voltage levels, e.g.

the screed heating system, may only be carried out by specialist electricians or persons instructe d in electr ical en gineeri ng work if the ap propri ate test devices ar e used.

Always comply with rel evant tech nical elec trical prote ction precau tions. Danger to life

as a result of accidents involving medium voltage levels!

D_E34_VB340_05.08_G B.fm 16-26 -01.01.07

D 16

4.3 Isolation monitor

The function of the protective insulation

monitoring measure must be checked

every day before starting work.

A

f

This check only checks the function of

the insulation m onitor, not whether an insulation fault has occurred on the heating sections or consumers.

- Start the paver's engine.

- Switch heating system switch (1)

to ON.

- Press test button (2).

- The indicator lamp integrated into the

test button signals „insulation fault“

- Press reset button (3) for at least 3

sec. to delete the simulated fault.

- The indicator lamp goes out.

If the test is conducted successfully,

work may be undertaken with the scre ed

and external consumers may be used.

If the „insulation fault“ indicator lamp displays a fault even before the test button is

pressed or if no fault is displayed during the simula tion, work must not be underta ken

with the screed or with connected, external equipment.

Schalttafel_EB5075_neu.wmf

3

2

1

f

f

f

The screed and equ ipm en t must be ch ecke d or rep air ed by a specia list elec tr ician. Only t hen may wor k aga i n be und er tak en wit h th e scr eed and equ ipm en t.

Danger due to electrical voltage

Non-adh er ence to t he safe ty pr ecau tio ns and s afet y r egu lat ion s

when operating the electric screed heating system leads to a

risk of electric shock.

Danger to life!

All maintenance and repair work on the screed's electrical system may be carried out by a specialist electrician only.

D_E34_VB340_05.08_G B.fm 17-26- 01.01.07

D 17

Insulati on fau lts

A

f

A

A

If an insula ti on f ault o ccurs dur ing o pera ti on, and the indi cator l am p d isplays a n insu lation fault, the operator may proceed as follows:

- Switch the switches of all external equipment and the heating system to OFF and

press the reset button for at least 3 seconds to delete the fault.

- If the indicator lamp does not go out, the fault lies in the generator.

No further work may be carried out.

- If the indicator lamp goes out, the switches of the heating system and external

equipment can be switched back to ON one after another until a message again

appears and the system is shut-down.

- The equipment found to be faulty must be removed or must not be engaged, and

the reset button must be pressed for at least 3 seconds to delete the fault.

Operation may now be continued - without the faulty equipment, of course.

The generator or electrical consumer found to be faulty must be

checked or repaired by a specialist electrician. Only then may

work again be carried out with the screed and equipment.

D 18

D_E34_VB340_05.08_G B.fm 18-26 -01.01.07

4.4 Commissioning and checking the

heating system

A

In order to reach the required temperature, the heating system should be

switched on approx. 15 - 20 minutes be fore the start of paving.

- Switch on the paver's engine.

- Switch on heating system ON / OFF

switch (1).

The heating system is activated and the

heating process begins.

During the hea ting process, t he individu al screed parts' heating systems' indicator lamps (2) light up.

Once the set temperature has been

reached, the indicator lamps go out one

after another.

Once all screed parts have reached the

desired temperature, paving operation

may begin.

1

3

A

If additional heating occurs during paving operation, this is indicated by the in-

Schalttafel_340E.wmf

2

dicator lamps (2).

The heating system indicator lamp s in th e contr ol an d mon i toring unit ( 3) can also be

observed.

D_E34_VB340_05.08_G B.fm 19-26- 01.01.07

D 19

4.5 Temperature display, setting temperature level

The temp erature display and t emperatu re lev el settin g fo r the indivi dual sc reed

elements ar e car rie d out vi a t he con tr ol and monitoring unit in the screed heating system's switch cabinet.

4.6 Operating the control and monitoring unit

2 3

1

4

STC20002.bmp

6

5

6a

6b

5a

5b

8

7

7a

7b

8a

8b

D 20

D_E34_VB340_05.08_G B.fm 20-26 -01.01.07

Pos. Designation / function

1 Display. Nominal and actual temperature display. Fault code display.

Auto / OFF button

2

- Starts and stops the system. When in the „OFF“ switch position, „OFF“

is shown in the display.

Increase in nominal temperature on the selected screed section.

3

- If pressed briefly, the current tem pera ture setting for the selected screed

section is displayed.

Reduction in nominal temperature on the selected screed section.

4

- If pressed briefly, the current tem pera ture setting for the selected screed

section is displayed.

5 Selection of basic screed, left

Indicator lamp (green/red)

- Not illuminated: Screed temperature < operating temperature

- Illuminated permanently, green: Screed temperature OK (+/- 3° C of

nominal temperature)

5a

- Flashing, green: Screed temperature too high (> +3°C of nominal temperature)

- Illuminated permanently, red: Malfunction! Screed section heating system switched off, fault code shown on display.

- Flashing, red: A temperature sensor is defective. The heating system

continues to operate.

Indicator lamp (yellow)

5b

- ON: Screed section heating system in operation

- OFF: Screed section heating system off

6 Selection of extendable part, left

6a

6b

Indicator lamp (green/red)

- Refer to (5a)

Indicator lamp (yellow)

- Refer to (5b)

7 Selection of basic screed, left

7a

7b

Indicator lamp (green/red)

- Refer to (5a)

Indicator lamp (yellow)

- Refer to (5b)

8 Selection of extendable part, right

8a

8b

Indicator lamp (green/red)

- Refer to (5a)

Indicator lamp (yellow)

- Refer to (5b)

D_E34_VB340_05.08_G B.fm 21-26- 01.01.07

D 21

4.7 Temperature setting

- Select screed se cti on by p ressing bu tton.

- Depending on the desired temperature change, press button (3) or (4).

- The current nominal temperature is

shown first. Adjustment in the corresponding direction is undertaken after

1.5 seconds.

2

3

4

A

When changing the te mper atur e setting,

4 dots light up on the display.

4.8 Fault messages

When a fault occurs, the small red lamp

(5a, 6a, 7a, 8a) for the relevant screed

section lights up and the corresponding

heating system is switched off.

The fault code and faulty screed section

are shown on the display.

If several faults occur, t he last fault to occur is shown on the display; the faults

which occurred previously can be called

up on the display by pressing the relevant buttons.

To delete the fault display, the fault first

has to be rectified and then the relevant

section button pressed until the small

red lamp goes out.

STC20002.bmp

5a

6a

STC20002.bmp

7a

8a

A

D 22

Fault codes

Fault code Meaning

50 - Defective temperature sensor

Heating system remains in operation as long as at least one temperat ure sensor functions.

If the temper ature sensor of e.g. a middl e section fails, the hea ting system is switched

to the other middle section's sensor.

A similar function is provided for the extendable parts.

D_E34_VB340_05.08_G B.fm 22-26 -01.01.07

4.9 Switching off the heating system

At the end of work or when the

heating system is not required:

- Switch off ON/OFF switch (1) of heating system.

2

1

Schalttafel_340E.wmf

D_E34_VB340_05.08_G B.fm 23-26- 01.01.07

D 23

5 Malfunctions

5.1 Problems during paving

Problem Cause

- change in the material temperature, demixing

- wrong material composition

- incorrect operation of the roller

- incorrectly prepared foundation

- long standstill times between loads

- grade control reference line is not suitable

- grade control jumps to the reference line

Wavy surface

(“short waves”)

- grade control toggles between up and down

(inertia setting is too high)

- bottom plates of the screed are loose

- bottom plates of the screed are warped or not uniformly

worn

- Screed is not operated in the float position

- too much play in the mechanical screed link/suspension

- paver finisher speed is too high

- augers are overloaded

- changing material pressure against the screed

Wavy surface

(“long waves”)

Cracks in the layer (over the entire width)

- change in the material temperature

- demixing

- roller has stopped on the hot material

- roller has turned or roller speed has been changed too fast

- incorrect operation of the roller

- incorrectly prepared foundation

- truck brake is applied too tight

- long standstill times between loads

- grade control reference line is not suitable

- incorrect installation of the grade control

- limit switch is not correctly set

- screed is empty

- screed has not been switched to the floating position

- too much play in the mechanical screed link

- auger is set too deep

- auger is overloaded

- changing material pressure against the screed

- material temperature is too low

- change in the material temperature

- moisture on the foundation

- demixing

- wrong material composition

- wrong layer height for maximum grain size

- cold screed

- bottom plates of the screed are worn or warped

- paver finisher speed is too high

D 24

D_E34_VB340_05.08_G B.fm 24-26 -01.01.07

Problem Cause

- material temperature

Cracks in the layer (centre strip)

- cold screed

- bottom plates are worn or warped

- wrong crowning

- material temperature

- screed extension parts are incorrectly installed

Cracks in the layer (outer strip)

- limit switch is not correctly set

- cold screed

- bottom plates are worn or warped

- paver finisher speed is too high

- material temperature

- change in the material temperature

- moisture on the foundation

- demixing

- wrong material composition

- incorrectly prepared foundation

- wrong layer height for maximum grain size

Layer composition inconsi stent

- long standstill times between loads

- vibration is too slow

- screed extension parts are incorrectly installed

- cold screed

- bottom plates are worn or warped

- Screed is not operated in the float position

- paver finisher speed is too high

- auger is overloaded

- changing material pressure against the screed

Marks in the surface

screed does not

react as expected to corrective

measures

- truck hits too much against the finisher while aligning to the

finisher

- too much play in the mechanical screed link/suspension

- truck brake is applied

- vibration is too high while standing on a spot

- material temperature

- change in the material temperature

- wrong layer height for maximum grain size

- incorrect installation of the grade control

- vibration is too slow

- Screed is not operated in the float position

- too much play in the mechanical screed link

- paver finisher speed is too high

D_E34_VB340_05.08_G B.fm 25-26- 01.01.07

D 25

5.2 Malfunctions on the screed

Malfunction Cause Remedy

Tamper or vibration is not functioning

Screed cannot be

lifted

Tamper is obstructed by cold

bitumen

Hydraulic oil level in the tank

is too low

Pressure limiting valve is defective

Properly heat the screed

Top up the oil

Replace the valve; if necessary, repair and adjust the

valve

Seal or replace the connec-

Leak in the suctio n li ne o f the

pump

tions

Tighten or replace the hose

clamps

Oil filter is soiled

Clean the filter; if necessary,

replace the filter

Oil pressure too low Increase the oil pressure

Leaking seal Replace the collar

Screed relieving or charging

is switched on

Switch must be in the centre

position

Power supply interrupted

Check fuses and cables; re-

place if necessary

D 26

D_E34_VB340_05.08_G B.fm 26-26 -01.01.07

E Set-up and modification

1 Notes regarding safety

f

f

f

Inadvertent starting of the paver finisher can endanger persons working on the

screed.

Only carry out such work with the finisher motor at a standstill unless the instruc-

tions state the opposite!

Make sure that the paver finisher is secured against being put into operation.

When lifted, the screed can still slide downwards if the mechanical screed transport

safeguard is not inserted on the finisher.

Only carry out work when the screed is secured by mechanical means!

When connecting or di sconnecting hyd raulic h oses and whe n workin g on the h ydraulic system, hot hydraulic fluid can spurt out at a high pressure.

Switch off the engine and de-pressurise the hydraulic system! Protect your eyes!

Always install exte nsi on p arts and co nversio n par ts in the p rope r m anner ! If in dou bt,

contact the manufacturer!

Mount all protective devices before re-commissioning the paver finisher.

The walking platform must always reach over the entire width of the screed.

The hinged walkway plate (option) may only be folded up under the following conditions:

- If the machine has to be backed up very closely to a wall or another obstacle,

- During transportation on a low-bed trailer.

E_EB34_VB340__05.08_G B.fm-14 02-05.08

E 1

2 General assembly

2.1 Fitting screed to finisher

- Lower screed onto a suitable base

(square pieces of wood etc.) and driv e

the finisher in reve rse to j ust in fr ont of

the screed.

Lower crossbeams and position so

that welded-on pivot of fulcrum point

on crossbeam (1) can be guided into

the relevant hole in the screed body.

Use screw and washer to secure fulcrum point inside screed body.

To assemble further, the following steps

must be undertaken on both crossbeams:

- Fit guide bolt (2) and spacer sleeve

(2a) between crossbeam and longitudinal slot of screed guidance and use

washer (2b) and self-locking nut (2c)

to secure that this produces perfect

guidance and a good degree of freedom to move.

- Use eye of turn buckle (3a) to fit retaining bolt (3) onto crossbeam to set

screed positioning angle and fit nut

(3b) provided for this purpose.

- Fit screw (4) with indicator of screed

positioning angle (4a), with washer

(4b) and self-locking nut (4c) onto

crossbeam to provide a good level of

movement.

3

Holm_Bohle340.wmf

4

2

1

4b 4c

4a

2a 2b

Holm_Bohle340_2.wmf

3

4

2

2c

3b

3a

E 2

E_EB34_VB340__05.08_G B.fm-14 02-05.08

2.2 Mounting the side shields

The side shields are mounted after all

other mounting and adjustment work on

the screed has been completed.

- Insert swing lever shaft on side shield

through hole in extendable part or extension part.

- Use clip (1) to secure internal section

of swing lever shaft to prevent shaft

from sliding back out.

Also on outer face of side shield:

- Attach control arm of parallel guide to

pivot (2) and use folding pin (3) to secure.

- Insert height adjustment crank in clip

(4) and use cotter pin (5) to secure.

1

Schildmon_340a.wmf

2

4

Schildmon_340b.wmf

3

5

E_EB34_VB340__05.08_G B.fm-14 02-05.08

E 3

2.3 Hydraulic connections

The hydraulic connections are on the rear of the finisher.

f

m

A

When installing the hydraulic connections, hot hydraulic oil can spurt out under high

pressure.

Switch off the engine and de-pressurise the hydraulic system! Protect your eyes!

When installing the hydraulic connections, make sure the environment is absolutely

clean.

Dirt in the hydraulic oil can cause the machine to fail!

The connections present depend on the screed equipment.

Position and designation of the connections:

4 3

Rück2_F6.wmf

8 7

5126

Item Designation

1 Tamper pu mp (O)

2 Tamper return –> tank (O)

3 Vibration pump

4 Vibration return –> tank

5 Extend screed, left

6 Retract screed, left

E 4

7 Extend screed, right

8 Retract screed, right

E_EB34_VB340__05.08_G B.fm-14 02-05.08

2.4 Electrical connections

A

On the rear of the finisher:

1

- Plug connector (1) for the electrical

consumers on the screed (electromagnetic valves, remote controls,

etc.).

Under the rear console (left and right):

Rück3_F6.wmf

- Sockets (2) for remote control connection cable.

The screed settings on the finisher can only be made after the electrical conne ctions

have been established.

E_EB34_VB340__05.08_G B.fm-14 02-05.08

E 5

3 Extending the screed

A

An extension part (width of 350 mm) can be fitted on either side! This produces a

maximum operating width of 4.1m.

Before the extension parts can be fitted, the following steps must be undertaken:

3.1 Removing side shields

- Remove clip (1) for securing swing lever axis from inside of screed body.

1

Schildmon_340awmf

Also on outside of side shield:

- Remove folding pin (2) from pivot (3).

- Pull splint (4) out of clip (5).

- Take off hand-operated crank.

- Pull side shield with swing lever axis

off extendable part.

3

5

2

4

Schildmon_340b.wmf

E 6

E_EB34_VB340__05.08_G B.fm-14 02-05.08

3.2 Prepari ng extension parts

If the screed is equi pped with a ta mper, to dr ive the tamper , the tamper shaft must be

fitted before fitting the extension part. The following steps are needed for this:

3.3 Removing tamper deflector plate

- Unfasten two nuts (1) from track rod

by unscrewing them several turns.

- Remove both retaining bolts (2) from

tamper deflector plate.

- Take off tamper deflector plate (3).

2 3

3.4 Assembly of tamper drive shaft

- Insert shaft (4) in relevant recess (5) of

screed body.

- Slide both parts of driver coupling (6)

onto one another with the inserted

plastic star.

3.5 Fitting tamper deflector plate

- Insert the ra il located inside th e deflector plates (3) into the grooves (7) of the

tightening rods

- Fit both retaining bolts (2) of tamper

deflector plates.

- Tighten both nuts (1) of track rods until stop is reached. To do this, the deflector

plate is tightened before the tamper.

Leitblech_340.wmf

4

Stampferwelle_340.wmf

1

6

5

7

E_EB34_VB340__05.08_G B.fm-14 02-05.08

A

The extension part is now prepared and ready to be fitted on the extendable part.

E 7

3.6 Fitting extension parts

m

The screw-on surface must be clean and, if the screed is already being used, must

be free of any bitumen residue.

This applies in particular to the base plate joints.

- Guide extension part and extendable

part together on a level support face.

The tamper drive shaft must be secured (unable to rotate) during this

process.

- Slide the drive shaft coupling half

through the releva nt hole in the screed

body of th e extendable p art with t he inserted plastic star and place on the

1

second coupling half located there.

- Abut the extension part and extendable part against one another.

- Gently tighten retaining bolts (1).

- Set height of extension part:

- Loosen lock nut (2).

- Use adjustment screw (3) to set the

3

correct height for the extendable

part.

- Tighten lock nut (2)

- Securely tighten retaining bolts (1)

2

3.7 Fitting side shield to extension part

A

Refer to Section 2.2

Gas340.wmf/Anbau_340.jpg

E 8

E_EB34_VB340__05.08_G B.fm-14 02-05.08

3.8 Screed heating system gas connections

After the extension parts have been

mounted, the connection hoses for the

extension parts' burners must be connected to the screed's pipe system.

- All hoses must be checked for exter-

nal damage prior to use and, if a ny defects are found, must be immediately

replaced with new hoses.

- The hose connection s are established

using screw connections. (1).

f

Danger of fire and explosions!

Work on the heating system involves t he

Gas_340.wmf

danger of fire and explosion.

Do not smoke! No naked flames!

- After the exten sion p arts have been rem oved , the hose s rem ain with the exte nsi on

part to which they are screwed.

3.9 Screed heater system electrical connections

Once extension parts have been fitted,

the screed heater system's corresponding electrical connections must be connected to one another.

1

5

3

f

Each screed section contains a distributor box (1), at which the plug connections for the heating strips in the bottom

plates (2) an d (3) and the heating str ip in

the tamper knife (4) have already been

established.

4

Before being used, all cables must be

2

1

checked for externally visible damage

and, if defects are found, must be replaced immediately with new cables.

614_Elektro1.eps

The connection (5) for the supply and

control cable to the neighbouring screed section

can be found on the upper side of the distribution box.

- Open the retaining tab and protective cover, plug in cable between extension part

and neighbouring screed part and secure using the retaining tab.

E_EB34_VB340__05.08_G B.fm-14 02-05.08

E 9

4Settings

4.1 Setting extendable parts

Should you need to readjust the extendable parts, this setting can be undertaken while the screed is fitted on the

finisher.

1

A

m

A

Basic setting:

- Unfasten retaining bolts (1) and lock

nuts (3).

- Adjust adjustment screws (2) and

(3a):

Raise extendable part: turn adjustment

screws (2) to the right and turn lock nut

(3) and/or adjustment screw (3a) to the

left.

All adjustment screws must be set to the

same height! This is the only way of ensuring that no scra ping occur s duri ng installation.

The extendable parts must be set to

3mm higher than the main screed!

- After the setting process:

retighten retaining bolts (1) and lock

nuts (3).

2

1

4

4b

4a

E 10

Fine adjustment, setting during installing work:

- Unfasten fasten ing bolts (1), scre w (4 )

and nut (4a).

- Perform fi ne adjustmen t by turning t he

setting nut (4b).

- Tighten down retaining screws (1) as

well as screw (4) and nut (4a) to secure the adjusting nut.

3a

3

Einstell1_340.wmf/Einstell4_340.wmf

E_EB34_VB340__05.08_G B.fm-14 02-05.08