Page 1

Instruction manualInstruction manual

Operating & MaintenanceOperating & Maintenance

4812159601_H.pdf4812159601_H.pdf

Vibratory rollerVibratory roller

CC224HF/324HF/384HFCC224HF/324HF/384HF

CC2200/3200/3800CC2200/3200/3800

CC3800HCC3800H

EngineEngine

Cummins QSB 3.3 (IIIA/T3)Cummins QSB 3.3 (IIIA/T3)

Deutz TCD 3.6 L04 (IIIB/T4i), (IIIB/T4f)Deutz TCD 3.6 L04 (IIIB/T4i), (IIIB/T4f)

Deutz TCD 3.6 L04 (stage V)Deutz TCD 3.6 L04 (stage V)

Serial numberSerial number

10000311xxA009344 -10000311xxA009344 10000315xxA009393 -10000315xxA009393 -

10000319xxA009520 -10000319xxA009520 10000336xxA012872 - 2571410000336xxA012872 - 25714

10000340xxA010700 - 2327210000340xxA010700 - 23272

10000344xxA012937 - 1750810000344xxA012937 - 17508

10000423xxA020964 -10000423xxA020964 -

10000427xxA021816 -10000427xxA021816 -

10000439xxA023043 -10000439xxA023043 -

10000456xxA025046 -10000456xxA025046 -

10000460xxA030824 -10000460xxA030824 -

Translation of original instructionTranslation of original instruction

Reservation for changesReservation for changes

Printed in SwedenPrinted in Sweden

Page 2

Page 3

Table of Contents

Introduction .............................................................................................................................. 1

The machine ............................................................................................... 1

Intended use ............................................................................................... 1

Signal symbols and meaning ...................................................................... 1

Safety information ....................................................................................... 1

General ....................................................................................................... 2

CE marking and Declaration of conformity.................................................. 3

Safety - General instructions.................................................................................................... 5

Safety - when operating ........................................................................................................... 7

Driving near edges ...................................................................................... 7

Work driving ................................................................................................ 8

Safety (Optional) ...................................................................................................................... 9

Air conditioning............................................................................................ 9

Edge cutter/compactor ................................................................................ 9

Working lights - Xenon .............................................................................. 10

Chip spreader............................................................................................ 11

Special instructions ................................................................................................................ 13

Standard lubricants and other recommended oils and fluids .................... 13

Higher ambient temperatures, above +40°C (104°F)................................ 13

Lower ambient temperature - Freeze risk ................................................. 13

Temperatures............................................................................................ 13

High pressure cleaning ............................................................................. 14

Fire fighting ............................................................................................... 14

Roll Over Protective Structure (ROPS), ROPS approved cab .................. 14

Battery handling ........................................................................................ 14

Jump starting (24V)................................................................................... 15

Technical specifications ......................................................................................................... 17

Vibrations - Operator station ..................................................................... 17

Noise level................................................................................................. 17

Electrical system ....................................................................................... 17

4812159601_H.pdf2021-01-14

Page 4

Slopes ....................................................................................................... 17

Dimensions, side view............................................................................... 18

Dimensions, top view ................................................................................ 19

Weights and volumes................................................................................ 20

Working capacity....................................................................................... 20

General ..................................................................................................... 22

CO2-emission............................................................................................ 22

Hydraulic system....................................................................................... 23

Air Conditioning / Automatic Climate Control (ACC) (Optional) ................ 23

Technical data, Chip Spreader (Optional)................................................. 24

Tightening torque ...................................................................................... 25

Machine description ............................................................................................................... 27

Diesel engine ............................................................................................ 27

Electrical system ....................................................................................... 27

Propulsion system..................................................................................... 27

Brake system ............................................................................................ 28

Steering system ........................................................................................ 28

Vibration system........................................................................................ 28

Cab............................................................................................................ 28

ROPS ........................................................................................................ 29

Identification ............................................................................................................ 29

Product and component plates ................................................................. 29

Product identification number on the frame .............................................. 30

Machine plate............................................................................................ 30

Explanation of 17PIN serial number.......................................................... 30

Engine plates ............................................................................................ 31

Decals...................................................................................................................... 32

Location - decals ....................................................................................... 32

Location - decals, chip spreader (Optional) .............................................. 33

Location - decals, CALIFORNIA ............................................................... 33

4812159601_H.pdf 2021-01-14

Page 5

Safety decals............................................................................................. 33

Info decals................................................................................................. 37

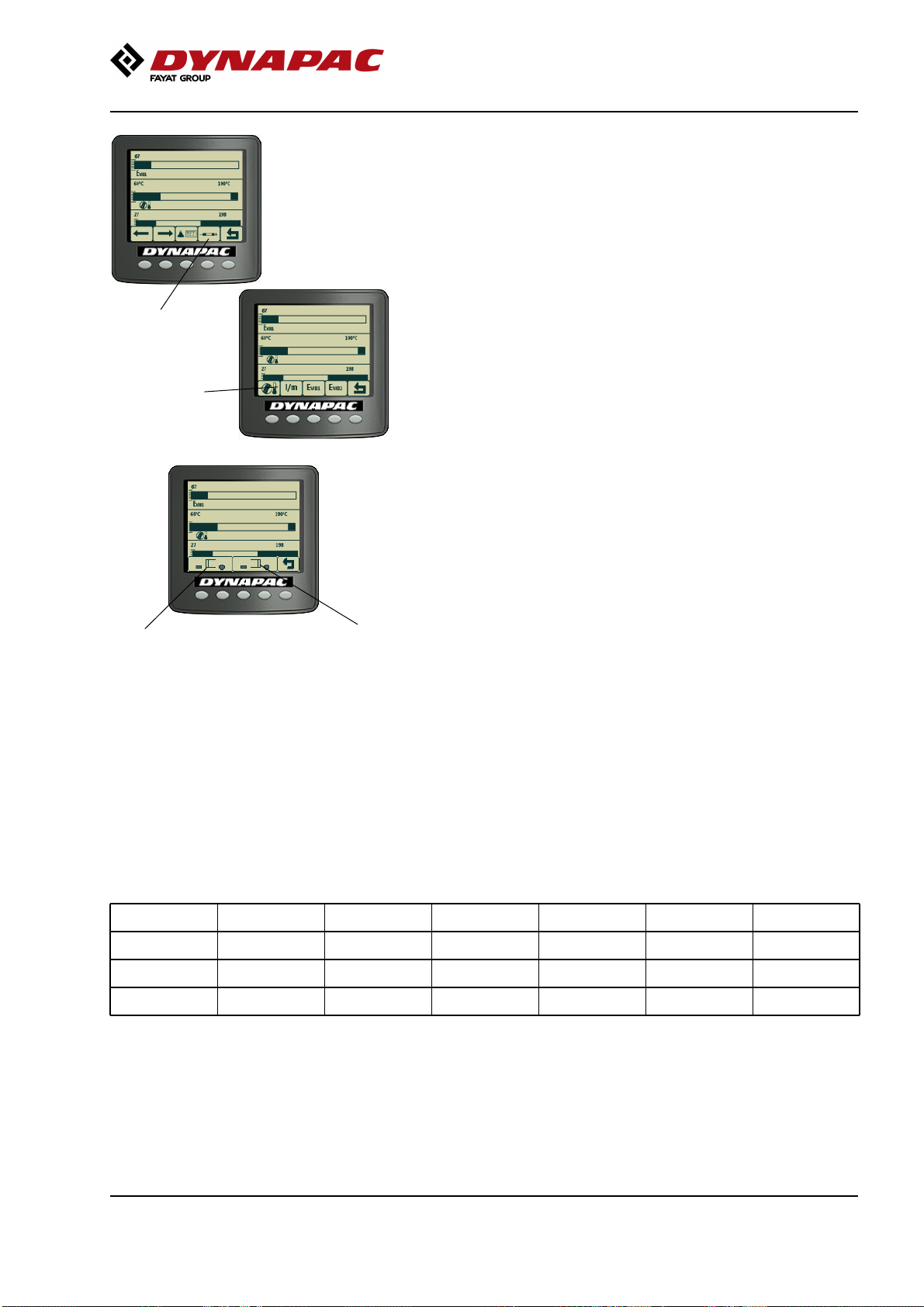

Instruments/Controls ............................................................................................... 38

Control panel and controls ........................................................................ 38

Function descriptions ................................................................................ 39

Forward & Reverse lever .......................................................................... 43

Function descriptions ................................................................................ 43

Forward & Reverse lever .......................................................................... 44

Function descriptions ................................................................................ 44

Display explanations ................................................................................. 44

Machine alarm........................................................................................... 47

"MAIN MENU" ........................................................................................... 50

"USER SETTINGS" .................................................................... 51

"MACHINE SETTINGS".............................................................. 52

Diesel engine (Stage V).............................................................. 52

"EXHAUST CLEANING"............................................................. 52

"SERVICE MENU"...................................................................... 53

"ABOUT"..................................................................................... 54

Operator help when starting...................................................................... 55

Operator help Workmode.......................................................................... 55

Instruments and controls, cab ................................................................... 56

Function description of instruments and controls in the cab ..................... 57

Using the cab controls............................................................................... 58

Defroster ..................................................................................... 58

Heat ............................................................................................ 58

AC/ACC ...................................................................................... 58

Electrical system (version 1).................................................................................... 59

Fuse boxes in main switchbox .................................................................. 59

Electrical system (version 2).................................................................................... 60

Fuse card in main switchbox..................................................................... 60

4812159601_H.pdf2021-01-14

Page 6

Power in engine compartment/battery compartment ................................ 61

Main fuse panel (Cummins) ...................................................................... 61

Fuse box at master switch (Deutz)............................................................ 62

Fuses in cab.............................................................................................. 63

Operation ............................................................................................................................... 65

Before starting ......................................................................................................... 65

Master switch - Switching on..................................................................... 65

Control panel, adjustments ....................................................................... 65

Operator's seat - Adjustment..................................................................... 66

Belt reminder............................................................................................. 66

Operator's seat, comfort - Adjustments..................................................... 67

Parking brake ............................................................................................ 67

Display - Control........................................................................................ 68

Interlock..................................................................................................... 69

Operator position....................................................................................... 70

View .......................................................................................................... 70

Starting .................................................................................................................... 71

Starting the engine .................................................................................... 71

Display when activating choice via the button set..................................... 72

Alarm descriptions..................................................................................... 73

Driving ..................................................................................................................... 73

Operating the roller ................................................................................... 73

Interlock/Emergency stop/Parking brake - Check ..................................... 75

Pivotal steering (Optional)......................................................................... 76

Burnout of DPF-filter (Regeneration) - (stage V)....................................... 77

DPF displays ............................................................................................. 77

Edge cutting (Optional) ............................................................................. 79

Chip spreader (optional)............................................................................ 80

Adjusting the feed volume......................................................................... 80

Preparations before dismantling/assembly. .............................................. 83

4812159601_H.pdf 2021-01-14

Page 7

Vibration .................................................................................................................. 84

Manual/Automatic vibration....................................................................... 84

Manual vibration - Switching on ................................................................ 85

Amplitude/frequency - Changeover........................................................... 85

Braking .................................................................................................................... 85

Normal braking.......................................................................................... 85

Emergency braking ................................................................................... 86

Switching off.............................................................................................. 86

Parking .................................................................................................................... 87

Chocking the drums .................................................................................. 87

Master switch ............................................................................................ 87

Long-term parking.................................................................................................................. 89

Engine ....................................................................................................... 89

Battery....................................................................................................... 89

Air cleaner, exhaust pipe........................................................................... 89

Watering system ....................................................................................... 89

Fuel tank ................................................................................................... 89

Hydraulic reservoir .................................................................................... 89

Hoods, tarpaulin ........................................................................................ 90

Steering cylinder, hinges, etc. ................................................................... 90

Miscellaneous ........................................................................................................................ 91

Lifting ....................................................................................................................... 91

Locking the articulation ............................................................................. 91

Lifting the roller.......................................................................................... 92

Lifting the roller with jack:.......................................................................... 92

Unlocking the articulation .......................................................................... 93

Towing/Recovering.................................................................................................. 93

Short distance towing with the engine running.......................................... 94

Short distance towing when the engine is inoperative. ............................. 95

Towing the roller........................................................................................ 95

4812159601_H.pdf2021-01-14

Page 8

Trailer eye ................................................................................................. 96

Transport ................................................................................................................. 96

Loading CC224-624, CC2200-6200, CO2200 .......................................... 97

Operating instructions - Summary ......................................................................................... 99

Preventive maintenance ...................................................................................................... 101

Acceptance and delivery inspection........................................................ 101

Warranty.................................................................................................. 101

Maintenance - Lubricants and symbols ............................................................................... 103

Maintenance symbols ............................................................................. 104

Maintenance - Maintenance schedule ................................................................................. 105

Service and maintenance points ............................................................. 105

General ................................................................................................... 105

Every 10 hours of operation (Daily)......................................................... 106

After the FIRST 50 hours of operation .................................................... 106

Every 50 hours of operation (Weekly)..................................................... 107

Every 250 hours of operation (Monthly) .................................................. 107

Every 500/1500 hours of operation ......................................................... 108

Every 1000 hours of operation (Every six months) ................................. 108

Every 2000 hours of operation ................................................................ 109

Maintenance, 10h ................................................................................................................ 111

Diesel engine - Check oil level ................................................................ 111

Coolant level - Check .............................................................................. 112

Fuel tank - Refueling ............................................................................... 112

Water tank, Std - Filling........................................................................... 113

Hydraulic reservoir - Check fluid level..................................................... 113

Sprinkler system/Drum

Check ...................................................................................................... 114

Cleaning the coarse filter ........................................................................ 114

Sprinkler system/Drum

Cleaning of sprinkler nozzle .................................................................... 115

4812159601_H.pdf 2021-01-14

Page 9

Emergency watering (Accessory) - Extra pump in pump system............ 116

Scrapers, spring-action

Check ...................................................................................................... 116

Scrapers

Setting - Adjustment................................................................................ 117

Maintenance - 50h ............................................................................................................... 119

Fuel filter - Draining................................................................................. 119

Drum gear - Checking the oil level .......................................................... 120

Maintenance - 250h ............................................................................................................. 121

Diesel engine

Oil change ............................................................................................... 121

Engine

Replacing oil filter.................................................................................... 122

Hydraulic fluid cooler

Checking - Cleaning................................................................................ 122

Battery

- Check condition .................................................................................... 123

Air conditioning (Optional)

- Inspection.............................................................................................. 123

Air conditioning (Optional)

Drying filter - Inspection .......................................................................... 124

Edge cutter (Optional)

- Lubrication ............................................................................................ 124

Maintenance - 500h ............................................................................................................. 125

Diesel engine

Oil change ............................................................................................... 125

Engine

Replacing oil filter.................................................................................... 126

The engine fuel filter - replacement/cleaning .......................................... 126

Hydraulic fluid cooler

Checking - Cleaning................................................................................ 127

Battery

- Check condition .................................................................................... 127

Air cleaner

Checking - Change the main air filter...................................................... 128

4812159601_H.pdf2021-01-14

Page 10

Backup filter - Change............................................................................. 128

Air cleaner

- Cleaning................................................................................................ 129

Drum - oil level

Inspection - filling .................................................................................... 129

Rubber elements and attachment screws

Check ...................................................................................................... 130

Seat bearing - Lubrication ....................................................................... 130

Pivot bearing (Optional) - Lubrication...................................................... 131

Hydraulic reservoir cap - Check .............................................................. 131

Air conditioning (Optional)

- Inspection.............................................................................................. 132

Air conditioning (Optional)

Drying filter - Inspection .......................................................................... 132

Edge cutter (Optional)

- Lubrication ............................................................................................ 133

Maintenance - 1000h ........................................................................................................... 135

Diesel engine

Oil change ............................................................................................... 135

Engine

Replacing oil filter.................................................................................... 136

The engine fuel filter - replacement/cleaning .......................................... 136

Hydraulic fluid cooler

Checking - Cleaning................................................................................ 137

Battery

- Check condition .................................................................................... 137

Air cleaner

Checking - Change the main air filter...................................................... 138

Backup filter - Change............................................................................. 138

Air cleaner

- Cleaning................................................................................................ 139

Hydraulic filter

Change.................................................................................................... 140

Drum - Oil change ................................................................................... 141

Drum gear - Oil change........................................................................... 141

4812159601_H.pdf 2021-01-14

Page 11

Drum gear - Checking the oil level .......................................................... 142

Rubber elements and attachment screws

Check ...................................................................................................... 142

Seat bearing - Lubrication ....................................................................... 143

Pivot bearing (Optional) - Lubrication...................................................... 143

Hydraulic reservoir cap - Check .............................................................. 144

Steering hitch - Tightening ...................................................................... 144

Cab

Fresh air filter - Replacing ....................................................................... 145

Air conditioning (Optional)

- Overhaul ............................................................................................... 145

Air conditioning (Optional)

Drying filter - Inspection .......................................................................... 146

Edge cutter (Optional)

- Lubrication ............................................................................................ 146

Maintenance - 2000h ........................................................................................................... 147

Diesel engine

Oil change ............................................................................................... 147

Engine

Replacing oil filter.................................................................................... 148

The engine fuel filter - replacement/cleaning .......................................... 148

Hydraulic fluid cooler

Checking - Cleaning................................................................................ 149

Battery

- Check condition .................................................................................... 149

Air cleaner

Checking - Change the main air filter...................................................... 150

Backup filter - Change............................................................................. 150

Air cleaner

- Cleaning................................................................................................ 151

Hydraulic filter

Change.................................................................................................... 152

Drum - Oil change ................................................................................... 153

Drum gear - Oil change........................................................................... 153

4812159601_H.pdf2021-01-14

Page 12

Drum gear - Checking the oil level .......................................................... 154

Rubber elements and attachment screws

Check ...................................................................................................... 154

Seat bearing - Lubrication ....................................................................... 155

Pivot bearing (Optional) - Lubrication...................................................... 155

Hydraulic reservoir cap - Check .............................................................. 156

Hydraulic reservoir

Fluid change............................................................................................ 156

Fuel tank

- Cleaning............................................................................................... 157

Watering system

- Draining................................................................................................ 157

Water tank - Cleaning ............................................................................. 158

Steering joint - Check.............................................................................. 158

Steering hitch - Tightening ...................................................................... 159

Cab

Fresh air filter - Replacing ....................................................................... 159

Air conditioning (Optional)

- Overhaul ............................................................................................... 160

Air conditioning (Optional)

Drying filter - Inspection .......................................................................... 160

Edge cutter (Optional)

- Lubrication ............................................................................................ 161

4812159601_H.pdf 2021-01-14

Page 13

Introduction

Introduction

The machine

Dynapac CC224HF/324HF/384HF,

CC2200/3200/3800 are models of vibratory tandem

rollers in 8/8/9.5 metric tonnes class featuring

1500/1730/1730 mm (59/68/68 in) wide drums. The

machines are equipped with drive, brakes, vibration

and timer for water sprinkler on both drums.

CC224HF/324HF, CC2200/3200 is also available as

Combi with four rubber wheels at rear replacing the

steel drum.

A variety of different engine power settings, operator

platforms, control possibilities and options makes the

machine available in a lot of different configurations.

Intended use

The machine is mainly designed to be used for thin

and thick asphalt layers with regards to dual vibration

amplitudes that are optimized for this purpose. It is

also possible to compact granular soil material, such

as sand and gravel.

Signal symbols and meaning

WARNING ! Indicates potential hazardous

WARNING ! Indicates potential hazardous

situation/procedure which, if not avoided, could

situation/procedure which, if not avoided, could

result in death or serious injury.

result in death or serious injury.

CAUTION ! Indicates potential hazardous

CAUTION ! Indicates potential hazardous

situation/procedure which, if not avoided, could

situation/procedure which, if not avoided, could

result in minor or moderate injury, damage to

result in minor or moderate injury, damage to

the machine or property.

the machine or property.

Safety information

It is recommended to at least train operators in

It is recommended to at least train operators in

handling and daily maintenance of the machine

handling and daily maintenance of the machine

in accordance with the instruction manual.

in accordance with the instruction manual.

Passengers are not allowed on the machine, and

Passengers are not allowed on the machine, and

you must sit in the seat when operating the

you must sit in the seat when operating the

machine.

machine.

The safety manual supplied with the machine

The safety manual supplied with the machine

must be read by all roller operators. Always

must be read by all roller operators. Always

follow the safety instructions. Do not remove

follow the safety instructions. Do not remove

the manual from the machine.

the manual from the machine.

4812159601_H.pdf2021-01-14

1

Page 14

Introduction

We recommend that the operator reads the

We recommend that the operator reads the

safety instructions in this manual carefully.

safety instructions in this manual carefully.

Always follow the safety instructions. Ensure

Always follow the safety instructions. Ensure

that this manual is always easily accessible.

that this manual is always easily accessible.

Read the entire manual before starting the

Read the entire manual before starting the

machine and before carrying out any

machine and before carrying out any

maintenance.

maintenance.

Replace immediately the instruction manuals if

Replace immediately the instruction manuals if

lost, damaged or unreadable.

lost, damaged or unreadable.

Ensure good ventilation (extraction of air by fan)

Ensure good ventilation (extraction of air by fan)

where the engine is run indoors.

where the engine is run indoors.

CALIFORNIA

Proposition 65

Decal and location of decal shown in section

Machine description.

General

This manual contains instructions for machine

operation and maintenance.

The machine must be correctly maintained for

maximal performance.

The machine should be kept clean so that any

leakages, loose bolts and loose connections are

discovered at as early a point in time as possible.

4812159601_H.pdf 2021-01-14

2

Page 15

Introduction

Inspect the machine every day, before starting.

Inspect the entire machine so that any leakages or

other faults are detected.

Check the ground under the machine. Leakages are

more easily detected on the ground than on the

machine itself.

If faults or suspected damage are detected on the

roller, contact the responsible supervisor for any action.

THINK ENVIRONMENT ! Do not release oil,

THINK ENVIRONMENT ! Do not release oil,

fuel and other environmentally hazardous

fuel and other environmentally hazardous

substances into the environment. Always send

substances into the environment. Always send

used filters, drain oil and fuel remnants to

used filters, drain oil and fuel remnants to

environmentally correct disposal.

environmentally correct disposal.

This manual contains instructions for periodic

maintenance, where maintenance after every 10 and

50 hours of operation can be performed by the

machine operator. Other maintenance intervals must

be carried out by accredited (Dynapac) service

personnel.

Additional instructions for the engine can be

Additional instructions for the engine can be

found in the manufacturer's engine manual.

found in the manufacturer's engine manual.

Specific maintenance and checks on diesel

Specific maintenance and checks on diesel

engines must be performed by engine supplier

engines must be performed by engine supplier

authorized personnel.

authorized personnel.

CE marking and Declaration of conformity

(Applies to machines marketed in EU/EEC)

This machine is CE marked. This shows that on

delivery it complies with the basic health and safety

directives applicable for the machine in accordance

with machinery directive 2006/42/EC and that it also

complies with other regulations and directives

applicable for this machine.

A "Declaration of conformity" is supplied with this

machine, which specifies the applicable regulations

and directives with supplements, as well as the

harmonized standards and other regulations that are

applied and according to the regulations must be

declared in writing.

4812159601_H.pdf2021-01-14

3

Page 16

Introduction

4

4812159601_H.pdf 2021-01-14

Page 17

Safety - General instructions

Safety - General instructions

(Also read the safety manual)

•

•

The operator must be familiar with the contents of the OPERATION section

The operator must be familiar with the contents of the OPERATION section

before starting the roller.

before starting the roller.

•

•

Ensure that all instructions in the MAINTENANCE section are followed.

Ensure that all instructions in the MAINTENANCE section are followed.

•

•

Only the operator is allowed to be on the roller. Remain seated at all times

Only the operator is allowed to be on the roller. Remain seated at all times

when operating the roller.

when operating the roller.

•

•

Never use the roller if it is in need of adjustment or repair.

Never use the roller if it is in need of adjustment or repair.

•

•

Only ascend and descend the roller when it is stationary. Use the intended

Only ascend and descend the roller when it is stationary. Use the intended

footsteps, grips and rails. Always use the three-point grip (both feet and one

footsteps, grips and rails. Always use the three-point grip (both feet and one

hand, or one foot and both hands) when ascending or descending the

hand, or one foot and both hands) when ascending or descending the

machine. Never jump down from the machine.

machine. Never jump down from the machine.

•

•

Dynapac always recommends mounted ROPS (Roll Over Protective

Dynapac always recommends mounted ROPS (Roll Over Protective

Structure), or a ROPS-approved cab and seat belt usage.

Structure), or a ROPS-approved cab and seat belt usage.

•

•

Drive slowly in sharp bends.

Drive slowly in sharp bends.

•

•

Avoid driving across slopes. Drive straight up or straight down the slope.

Avoid driving across slopes. Drive straight up or straight down the slope.

•

•

Never operate with the drum outside the edge, the substrate might not have

Never operate with the drum outside the edge, the substrate might not have

full bearing strength or the edge is close to a slope. Avoid operating close to

full bearing strength or the edge is close to a slope. Avoid operating close to

edges and ditches and the like as well as on poor ground conditions that

edges and ditches and the like as well as on poor ground conditions that

jeopardizes the bearing strength and capacity to support the roller.

jeopardizes the bearing strength and capacity to support the roller.

•

•

Make sure that there are no obstacles in the direction of travel, on the

Make sure that there are no obstacles in the direction of travel, on the

ground, in front of or behind the roller, or overhead.

ground, in front of or behind the roller, or overhead.

•

•

Drive particularly carefully on uneven ground.

Drive particularly carefully on uneven ground.

•

•

Keep the roller clean. Clean any dirt or grease that accumulates on the

Keep the roller clean. Clean any dirt or grease that accumulates on the

footsteps or operator platform to avoid slipping risk. Keep all signs and

footsteps or operator platform to avoid slipping risk. Keep all signs and

decals clean and legible.

decals clean and legible.

•

•

Safety measures before refueling:

Safety measures before refueling:

- Stop the engine

- Stop the engine

- Do not smoke.

- Do not smoke.

- No naked flames in the vicinity of the roller.

- No naked flames in the vicinity of the roller.

- Earth the filling equipment nozzle by keeping it in contact to the tank

- Earth the filling equipment nozzle by keeping it in contact to the tank

opening to avoid sparks.

opening to avoid sparks.

•

•

Before repairs or service:

Before repairs or service:

- Chock the drums/wheels.

- Chock the drums/wheels.

- Lock the articulation if necessary.

- Lock the articulation if necessary.

- Place blocks under overhanging equipment, such as strike-off blade, edge

- Place blocks under overhanging equipment, such as strike-off blade, edge

cutter/compactor and chip spreader.

cutter/compactor and chip spreader.

4812159601_H.pdf2021-01-14

5

Page 18

Safety - General instructions

•

•

Hearing protection is recommended if the noise level exceeds 80 dB(A). The

Hearing protection is recommended if the noise level exceeds 80 dB(A). The

noise level can vary depending on the equipment on the machine and the

noise level can vary depending on the equipment on the machine and the

surface the machine is being used on.

surface the machine is being used on.

•

•

Modifications to the roller, including the use of any attachment/equipment,

Modifications to the roller, including the use of any attachment/equipment,

not approved by Dynapac that might compromise safety (including visibility)

not approved by Dynapac that might compromise safety (including visibility)

are not allowed. Any modifications are only to be made after written approval

are not allowed. Any modifications are only to be made after written approval

has been given by Dynapac.

has been given by Dynapac.

•

•

Avoid using the roller before the hydraulic fluid has reached its normal

Avoid using the roller before the hydraulic fluid has reached its normal

working temperature. Braking distances can be longer than normal when the

working temperature. Braking distances can be longer than normal when the

fluid is cold.

fluid is cold.

•

•

For your own protection always wear:

For your own protection always wear:

- working boots with steel toecaps

- working boots with steel toecaps

- ear protectors

- ear protectors

- reflecting clothing/high visibility jacket

- reflecting clothing/high visibility jacket

Also wear:

Also wear:

- helmet if no cab or FOPS, or if required by worksite management

- helmet if no cab or FOPS, or if required by worksite management

- working gloves if no cab and for work outside operator´s platform.

- working gloves if no cab and for work outside operator´s platform.

•

•

If the machine seems to be responding abnormally during travel, stop and

If the machine seems to be responding abnormally during travel, stop and

check it.

check it.

6

4812159601_H.pdf 2021-01-14

Page 19

Safety - when operating

Safety - when operating

Prevent persons from entering or remaining in

Prevent persons from entering or remaining in

the risk zone, i.e. a distance of at least 7 m (23

the risk zone, i.e. a distance of at least 7 m (23

ft) in all directions from operating machines.

ft) in all directions from operating machines.

The operator may allow a person to remain in

The operator may allow a person to remain in

the risk zone, however he/she must be attentive

the risk zone, however he/she must be attentive

and operate the machine only when the person

and operate the machine only when the person

is fully visible or has given a clear indication of

is fully visible or has given a clear indication of

where he or she is.

where he or she is.

Avoid driving across a slope. Drive straight up

Avoid driving across a slope. Drive straight up

and down sloping ground.

and down sloping ground.

Driving near edges

Never operate with the drum outside the edge, the

Never operate with the drum outside the edge, the

substrate might not have full bearing strength or

substrate might not have full bearing strength or

the edge is close to a slope.

the edge is close to a slope.

Keep in mind that the machine's center of gravity

Keep in mind that the machine's center of gravity

moves outwards when steering. For example, the

moves outwards when steering. For example, the

center of gravity moves to the right when you steer

center of gravity moves to the right when you steer

to the left.

to the left.

4812159601_H.pdf2021-01-14

7

Page 20

Safety - when operating

Work driving

To exit the cab in an emergency, release the

To exit the cab in an emergency, release the

hammer on the rear right post and break the rear

hammer on the rear right post and break the rear

window.

window.

Dynapac always recommends mounted ROPS

Dynapac always recommends mounted ROPS

(Roll Over Protective Structure), or a

(Roll Over Protective Structure), or a

ROPS-approved cab and seat belt usage.

ROPS-approved cab and seat belt usage.

Avoid operating close to edges and ditches and the

like as well as on poor ground conditions that

jeopardizes the bearing strength and capacity to

support the roller. Pay attention to potential obstacles

above the machine, such as overhead cables and the

branches of trees etc.

Pay particular attention to the stability of the substrate

when compacting close to edges and holes. Do not

compact with a large overlap from the previous track in

order to maintain roller stability. Consider other

compaction methods such as remote-control or a

walk-behind roller close to steep slopes or where the

bearing strength of the substrate is unknown.

8

4812159601_H.pdf 2021-01-14

Page 21

Safety (Optional)

Air conditioning

The system contains pressurized refrigerant. It is

The system contains pressurized refrigerant. It is

forbidden to release refrigerants into the

forbidden to release refrigerants into the

atmosphere.

atmosphere.

Work on the refrigerant circuit is only to be carried

Work on the refrigerant circuit is only to be carried

out by authorized companies.

out by authorized companies.

The cooling system is pressurized. Incorrect

The cooling system is pressurized. Incorrect

handling can result in serious personal injury. Do

handling can result in serious personal injury. Do

not disconnect or undo the hose couplings.

not disconnect or undo the hose couplings.

Safety (Optional)

Fig. Air conditioning (ACC)

3

1

2

Fig. Edge cutter/compactor

1. Transport position

2. Operating position

3. Holder for cutter/compactor wheel.

The system must be re-filled with an approved

The system must be re-filled with an approved

refrigerant by authorized personnel when

refrigerant by authorized personnel when

necessary. See decal on or in the vicinity of the

necessary. See decal on or in the vicinity of the

installation.

installation.

Edge cutter/compactor

The operator must make sure that nobody is in the

The operator must make sure that nobody is in the

area of operation while the machine is in use.

area of operation while the machine is in use.

The edge cutter consists of rotating components

The edge cutter consists of rotating components

and there is a risk of being crushed.

and there is a risk of being crushed.

The tool must be returned to the transport

The tool must be returned to the transport

position (raised position) (1) every time it has

position (raised position) (1) every time it has

been used.

been used.

If the edge cutter and its parts are dismantled,

If the edge cutter and its parts are dismantled,

make sure that it is set in a relieved position and

make sure that it is set in a relieved position and

resting on the ground.

resting on the ground.

4812159601_H.pdf2021-01-14

9

Page 22

Figure. Xenon lighting on cab

Safety (Optional)

Working lights - Xenon

Warning, high voltage!Warning, high voltage!

The working lights of the Xenon type have a

secondary high-voltage source.

Work on the lighting should only be conducted by an

authorized electrician and with the primary voltage

disconnected.

Contact a Dynapac dealer!

Warning, environmentally hazardous waste!Warning, environmentally hazardous waste!

Working lights of the Xenon type include a discharge

lamp that contains mercury (Hg).

A defective lamp is to be considered as hazardous

waste and shall be disposed off as per local directives.

10

4812159601_H.pdf 2021-01-14

Page 23

Fig. Chip spreader

Chip spreader

The machine must not be transported with chip in

The machine must not be transported with chip in

the chip spreader. The weight for the chip

the chip spreader. The weight for the chip

spreader is noted on the sign plate of the unit. This

spreader is noted on the sign plate of the unit. This

weight is not included in the machine weight noted

weight is not included in the machine weight noted

on the lift plate.

on the lift plate.

The operator must make sure that nobody is in

The operator must make sure that nobody is in

the area of operation while the machine is in

the area of operation while the machine is in

use.

use.

Risk of crushing and pinch injuries. The chip

Risk of crushing and pinch injuries. The chip

spreader has rotating parts.

spreader has rotating parts.

The chip spreader must be reset in transport

The chip spreader must be reset in transport

mode after it has been used.

mode after it has been used.

Safety (Optional)

Fitting the chip spreader changes the total length

Fitting the chip spreader changes the total length

of the machine.

of the machine.

4812159601_H.pdf2021-01-14

11

Page 24

Safety (Optional)

12

4812159601_H.pdf 2021-01-14

Page 25

Special instructions

Special instructions

Standard lubricants and other recommended

oils and fluids

Before leaving the factory, the systems and

components are filled with the oils and fluids specified

in the lubricant specification. These are suitable for

ambient temperatures in the range -15°C to +40°C

(5°F - 105°F).

The maximum ambient temperature for

The maximum ambient temperature for

biological hydraulic fluid is +35°C (95°F).

biological hydraulic fluid is +35°C (95°F).

Higher ambient temperatures, above +40°C

(104°F)

For operation of the machine at higher ambient

temperatures, however maximum +50°C (122°F), the

following recommendations apply:

The diesel engine can be run at this temperature using

normal oil. However, the following fluids must be used

for other components:

Hydraulic system - mineral oil Shell Tellus S2V100 or

similar.

Lower ambient temperature - Freeze risk

Make sure that the watering system is empty/drained

of water (sprinkler, hoses, tank/s) or that anti-freeze

has been added, to prevent the system freezing.

The outlet hose from the central tank can be

disconnected and the end placed in a container with

antifreeze to run this through the pump/filter.

Temperatures

The temperature limits apply to standard versions of

rollers.

Rollers equipped with additional equipment, such as

noise suppression, may need to be more carefully

monitored in the higher temperature ranges.

4812159601_H.pdf2021-01-14

13

Page 26

Special instructions

High pressure cleaning

Do not spray directly onto electrical components.

Do not use high pressure cleaning for

Do not use high pressure cleaning for

dashboard/display.

dashboard/display.

The Electrical Drive Control and the computer

The Electrical Drive Control and the computer

box may not be washed with high pressure

box may not be washed with high pressure

cleaning and not at all with water. Clean them

cleaning and not at all with water. Clean them

with a dry wiper.

with a dry wiper.

Detergent that can destroy electrical parts, or

Detergent that can destroy electrical parts, or

which is conductive, must not be used.

which is conductive, must not be used.

Place a plastic bag over the fuel filler cap and secure

with a rubber band. This is to avoid high pressure

water entering the vent hole in the filler cap. This could

cause malfunctions, such as the blocking of filters.

Never aim the water jet directly at the fuel tank

Never aim the water jet directly at the fuel tank

cap, or into exhaust pipe. This is particularly

cap, or into exhaust pipe. This is particularly

important when using a high-pressure cleaner.

important when using a high-pressure cleaner.

Fire fighting

If the machine catches fire, use an ABC-class powder

fire extinguisher.

A BE-class carbon dioxide fire extinguisher can also

be used.

Roll Over Protective Structure (ROPS), ROPS

approved cab

If the machine is fitted with a Roll Over

If the machine is fitted with a Roll Over

Protective Structure (ROPS, or ROPS approved

Protective Structure (ROPS, or ROPS approved

cab) never carry out any welding or drilling in

cab) never carry out any welding or drilling in

the structure or cab.

the structure or cab.

Never attempt to repair a damaged ROPS

Never attempt to repair a damaged ROPS

structure or ROPS structure in cab. These must

structure or ROPS structure in cab. These must

be replaced with new ROPS structure or new

be replaced with new ROPS structure or new

cab.

cab.

14

Battery handling

When removing batteries, always disconnect the

When removing batteries, always disconnect the

negative cable first.

negative cable first.

4812159601_H.pdf 2021-01-14

Page 27

When fitting batteries, always connect the

When fitting batteries, always connect the

positive cable first.

positive cable first.

Dispose of old batteries in an environmentally

Dispose of old batteries in an environmentally

friendly way. Batteries contain toxic lead.

friendly way. Batteries contain toxic lead.

Do not use a quick-charger for charging the

Do not use a quick-charger for charging the

battery. This may shorten battery life.

battery. This may shorten battery life.

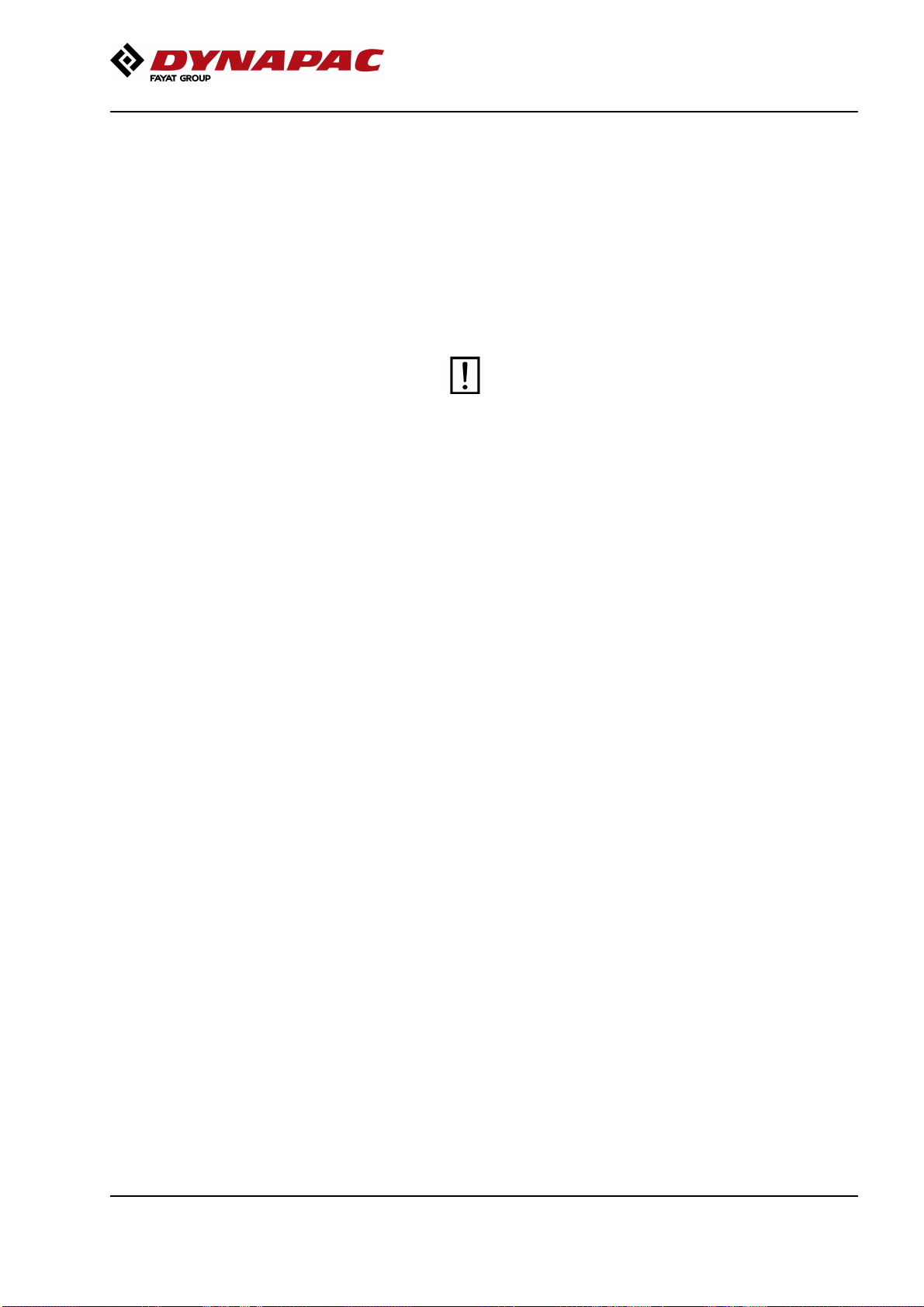

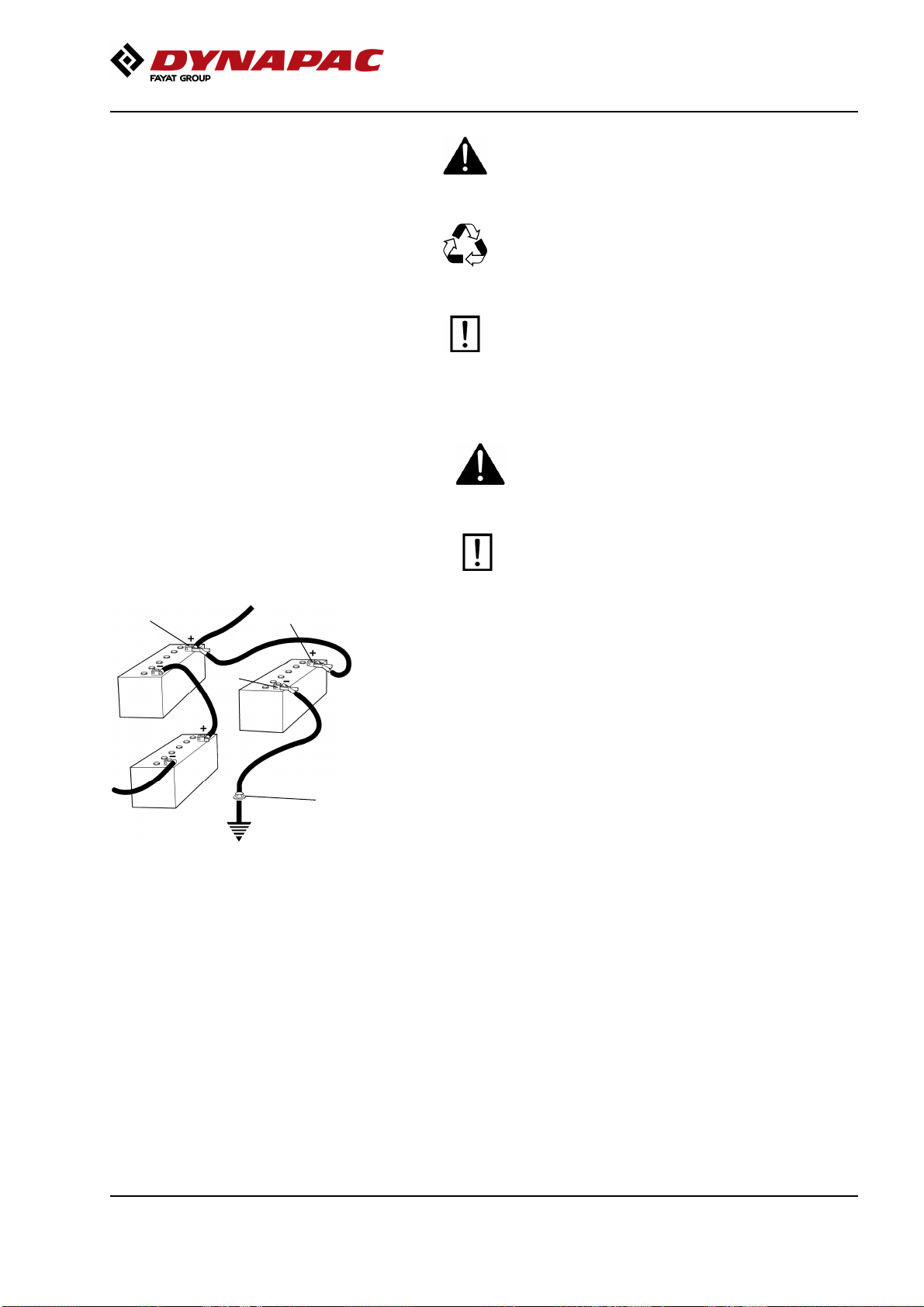

Jump starting (24V)

Do not connect the negative cable to the

Do not connect the negative cable to the

negative terminal on the dead battery. A spark

negative terminal on the dead battery. A spark

can ignite the oxy-hydrogen gas formed

can ignite the oxy-hydrogen gas formed

around the battery.

around the battery.

Check that the battery used for jump starting

Check that the battery used for jump starting

has the same voltage as the dead battery.

has the same voltage as the dead battery.

Special instructions

2

12V

12V

Fig. Jump starting

1

Turn the ignition and all power consuming equipment

off. Switch off the engine on the machine which is

providing jump start power.

3

24V

Jump leads must have 24V.

First connect the jump start battery's positive terminal

(1) to the flat battery's positive terminal (2).Then

connect the jump start battery's negative terminal (3)

to, for example, a bolt (4) or the lifjting eye on the

machine with the flat battery.

4

Start the engine on the power providing machine. Let it

run for a while. Now try to start the other machine.

Disconnect the cables in the reverse order.

4812159601_H.pdf2021-01-14

15

Page 28

Special instructions

16

4812159601_H.pdf 2021-01-14

Page 29

Technical specifications

Technical specifications

Vibrations - Operator station

(ISO 2631)

The vibration levels are measured in accordance with the operational cycle described in

The vibration levels are measured in accordance with the operational cycle described in

EU directive 2000/14/EC on machines equipped for the EU market, with vibration switched

EU directive 2000/14/EC on machines equipped for the EU market, with vibration switched

on, on soft polymer material and with the operator’s seat in the transport position.

on, on soft polymer material and with the operator’s seat in the transport position.

Measured whole-body vibrations are below the action value of 0.5 m/s² as specified in Directive

Measured whole-body vibrations are below the action value of 0.5 m/s² as specified in Directive

2002/44/EC. (Limit is 1.15 m/s²)

2002/44/EC. (Limit is 1.15 m/s²)

Measured hand/arm vibrations also were below the action level of 2.5 m/s² specified in the same

Measured hand/arm vibrations also were below the action level of 2.5 m/s² specified in the same

directive. (Limit is 5 m/s²)

directive. (Limit is 5 m/s²)

Noise level

The noise level is measured in accordance with the operational cycle described in

The noise level is measured in accordance with the operational cycle described in

EU directive 2000/14/EC on machines equipped for the EU market, on soft polymer

EU directive 2000/14/EC on machines equipped for the EU market, on soft polymer

material with vibration switched on and the operator's seat in the transport position.

material with vibration switched on and the operator's seat in the transport position.

Guaranteed sound power level, L

wA

wA

55/60kW 106 dB (A)Guaranteed sound power level, L

55/60kW 106 dB (A)

74/75kW 107 dB (A)74/75kW 107 dB (A)

Sound pressure level at the operator's ear (platform), L

Sound pressure level at the operator's ear (cab), L

During operation the above values may differ because of the actual operational

During operation the above values may differ because of the actual operational

conditions.

conditions.

pA

pA

pA

pA

Electrical system

Machines are EMC tested in accordance with EN

13309:2000 'Construction machinery'

Slopes

91 ±3 dB (A)Sound pressure level at the operator's ear (platform), L

91 ±3 dB (A)

85 ±3 dB (A)Sound pressure level at the operator's ear (cab), L

85 ±3 dB (A)

Max 20° or 36%Max 20° or 36%

The recommended max slope angle is for a machine

that runs straight on hard, flat surface.

Unstable ground, vibration on, speed and steering the

machine can all cause the machine to topple at

smaller angles than specified here.

4812159601_H.pdf2021-01-14

17

Page 30

Technical specifications

Dimensions, side view

Dimensions mm inDimensions mm in

A Wheel base 3340 131A Wheel base 3340 131

D Diameter, drum 1150 45D Diameter, drum 1150 45

H1 Height, with ROPS/cab 2990 118H1 Height, with ROPS/cab 2990 118

H2 Height, without ROPS/cab 2275 90H2 Height, without ROPS/cab 2275 90

K Ground clearance 310 12K Ground clearance 310 12

L Length, standard variant 4490 177L Length, standard variant 4490 177

S Thickness, drum amplitude, Nominal 18 0.7S Thickness, drum amplitude, Nominal 18 0.7

18

4812159601_H.pdf 2021-01-14

Page 31

Dimensions mm inDimensions mm in

B1 Machine width, standardB1 Machine width, standard

Technical specifications

Dimensions, top view

CC224HF, CC2200 1640 64.5CC224HF, CC2200 1640 64.5

CC324HF/384HF, CC3200/3800 1870 74CC324HF/384HF, CC3200/3800 1870 74

CC3800H 2020 79.5CC3800H 2020 79.5

B2 Machine width, asymmetricalB2 Machine width, asymmetrical

CC224HF, CC2200 1900 75CC224HF, CC2200 1900 75

CC324HF, CC3200 2010 79CC324HF, CC3200 2010 79

CC384HF, CC3800 2045 80.5CC384HF, CC3800 2045 80.5

CC3800H 2085 82CC3800H 2085 82

R1 Turning radius, outerR1 Turning radius, outer

CC224HF, CC2200 6570 / 5190* 259 / 204*CC224HF, CC2200 6570 / 5190* 259 / 204*

CC324HF, CC3200 6685 / 5305* 263 / 209*CC324HF, CC3200 6685 / 5305* 263 / 209*

CC384HF, CC3800 6685 263CC384HF, CC3800 6685 263

R2 Turning radius, innerR2 Turning radius, inner

CC224HF, CC2200 5570 / 3225* 219 / 127*CC224HF, CC2200 5570 / 3225* 219 / 127*

CC324HF, CC3200 - -CC324HF, CC3200 - -

CC384HF, CC3800 - -CC384HF, CC3800 - -

W Drum widthW Drum width

CC224HF, CC2200 1500 59CC224HF, CC2200 1500 59

CC324HF/384HF, CC3200/3800 1730 68CC324HF/384HF, CC3200/3800 1730 68

*) with offset*) with offset

4812159601_H.pdf2021-01-14

19

Page 32

Technical specifications

Weights and volumes

WeightsWeights

Service weight ROPS

(EN500)

(EN500)

CC224HF, CC2200 STD (kg) 7 600 7 800CC224HF, CC2200 STD (kg) 7 600 7 800

(lbs) 16 760 17 200(lbs) 16 760 17 200

OFFSET (kg) 8 100 8 300OFFSET (kg) 8 100 8 300

(lbs) 17 860 18 300(lbs) 17 860 18 300

CC324HF, CC3200 STD (kg) 8 100 8 300CC324HF, CC3200 STD (kg) 8 100 8 300

(lbs) 17 860 18 300(lbs) 17 860 18 300

OFFSET (kg) 8 600 8 900OFFSET (kg) 8 600 8 900

(lbs) 18 960 19 630(lbs) 18 960 19 630

CC384HF, CC3800 STD (kg) 9 400 9 600CC384HF, CC3800 STD (kg) 9 400 9 600

(lbs) 20 730 21 170(lbs) 20 730 21 170

CC3800H STD (kg) 9 800 10 000CC3800H STD (kg) 9 800 10 000

(lbs) 21 600 22 050(lbs) 21 600 22 050

CabService weight ROPS

Cab

Fluid volumesFluid volumes

Fuel tank 130 liters 34 galFuel tank 130 liters 34 gal

Water tank 750 liters 198 galWater tank 750 liters 198 gal

Working capacity

Compaction dataCompaction data

Static linear load (Front) (Rear)Static linear load (Front) (Rear)

CC224HF, CC2200 25,7 25,7 (kg/cm)CC224HF, CC2200 25,7 25,7 (kg/cm)

144 144 (pli)144 144 (pli)

CC324HF, CC3200 23,6 23,6 (kg/cm)CC324HF, CC3200 23,6 23,6 (kg/cm)

132 132 (pli)132 132 (pli)

CC384HF, CC3800 27,2 27,2 (kg/cm)CC384HF, CC3800 27,2 27,2 (kg/cm)

152 152 (pli)152 152 (pli)

CC3800H 28,9 28,9 (kg/cm)CC3800H 28,9 28,9 (kg/cm)

162 162 (pli)162 162 (pli)

20

4812159601_H.pdf 2021-01-14

Page 33

Technical specifications

Amplitude High Low Low(CE-2006)Amplitude High Low Low(CE-2006)

CC224HF-384HF,

CC2200-3800

CC2200-3800

CC3800H 0,6 0,3 (mm)CC3800H 0,6 0,3 (mm)

0,7 0,3 0,2 (mm)CC224HF-384HF,

0,7 0,3 0,2 (mm)

0.028 0.012 0.008 (in)0.028 0.012 0.008 (in)

0.024 0.012 (in)0.024 0.012 (in)

Vibration frequency High

Vibration frequency High

amplitude

amplitude

48 48 67 61 (Hz)48 48 67 61 (Hz)

2 850 2 850 4 020 3 660 (vpm)2 850 2 850 4 020 3 660 (vpm)

Centrifugal force High

Centrifugal force High

amplitude

amplitude

CC224HF, CC2200 78 72 67 38 (kN)CC224HF, CC2200 78 72 67 38 (kN)

17 550 16 200 15 075 8 550 (lb)17 550 16 200 15 075 8 550 (lb)

CC324HF/384HF,

CC3200/3800

CC3200/3800

90 77 75 43 (kN)CC324HF/384HF,

90 77 75 43 (kN)

20 250 17 325 16 875 9 675 (lb)20 250 17 325 16 875 9 675 (lb)

High

High

amplitude

amplitude

(CE-2006)

(CE-2006)

High

High

amplitude

amplitude

(CE-2006)

(CE-2006)

Low

Low

amplitude

amplitude

Low

Low

amplitude

amplitude

Low

Low

amplitude

amplitude

(CE-2006)

(CE-2006)

Low

Low

amplitude

amplitude

(CE-2006)

(CE-2006)

PropulsionPropulsion

Speed range 0-12 km/h 0-7.5 mphSpeed range 0-12 km/h 0-7.5 mph

Climbing capacity (theoretical)Climbing capacity (theoretical)

CC224HF, CC2200 42 %CC224HF, CC2200 42 %

CC324HF/384HF,

CC3200/3800

CC3200/3800

CC3800H 31 %CC3800H 31 %

37 %CC324HF/384HF,

37 %

4812159601_H.pdf2021-01-14

21

Page 34

Technical specifications

General

EngineEngine

Manufacturer/Model Cummins QSB 3.3 (IIIA/T3)Manufacturer/Model Cummins QSB 3.3 (IIIA/T3)

Deutz TCD 3.6 L04 (IIIB/T4i), (IIIB/T4f)Deutz TCD 3.6 L04 (IIIB/T4i), (IIIB/T4f)

Deutz TCD 3.6 L04 (stage V)Deutz TCD 3.6 L04 (stage V)

Power output (SAE J1995), 2200 rpm 60kW (IIIA/T3) 80hpPower output (SAE J1995), 2200 rpm 60kW (IIIA/T3) 80hp

74kW (IIIA/T3) 99hp74kW (IIIA/T3) 99hp

75kW (IIIB/T4i) 100hp75kW (IIIB/T4i) 100hp

55kW (IIIB/T4f) 74hp55kW (IIIB/T4f) 74hp

55kW (stage V) 74hp55kW (stage V) 74hp

Engine speedEngine speed

- idling 900 rpm- idling 900 rpm

- loading/unloading 1600 rpm- loading/unloading 1600 rpm

- work/transport 2 200 rpm- work/transport 2 200 rpm

Tier4i / T4f / Stage IIIB / Stage V engines require the use of Ultra Low Sulphur Diesel

Tier4i / T4f / Stage IIIB / Stage V engines require the use of Ultra Low Sulphur Diesel

(ULSD) fuel, which has a sulphur content of 15 ppm (parts per million) or less. A

(ULSD) fuel, which has a sulphur content of 15 ppm (parts per million) or less. A

higher sulphur content will cause operating problems and put the useful life of

higher sulphur content will cause operating problems and put the useful life of

components at risk, which can lead to engine trouble.

components at risk, which can lead to engine trouble.

CO2-emission

CO2-emissions measured according to applicable test

cycle in Regulation (EU) 2016/1628.

Manufacturer/Model Test-cycle CO2-emission

Manufacturer/Model Test-cycle CO2-emission

(g/kWh)

(g/kWh)

Deutz TCD 3.6 L04 Stage V NRTC 838,6Deutz TCD 3.6 L04 Stage V NRTC 838,6

NRTC: Non-road transient test cycles.NRTC: Non-road transient test cycles.

Electrical systemElectrical system

Battery 24V (2x12V 74Ah)Battery 24V (2x12V 74Ah)

Alternator 24V 60AAlternator 24V 60A

Fuses See the Electrical system section - fusesFuses See the Electrical system section - fuses

22

4812159601_H.pdf 2021-01-14

Page 35

Technical specifications

Bulbs (if mounted) Watt SocketBulbs (if mounted) Watt Socket

Drive lights, front 75/70 P43t (H4)Drive lights, front 75/70 P43t (H4)

Direction lights, front 2 BA9sDirection lights, front 2 BA9s

Side lights 5 SV8,5Side lights 5 SV8,5

Brake-Position lights 21/5 BAY15dBrake-Position lights 21/5 BAY15d

Direction lights, rear 21 BA15sDirection lights, rear 21 BA15s

License plate light 5 SV8,5License plate light 5 SV8,5

Working lights 70 PK22s (H3)Working lights 70 PK22s (H3)

35 Xenon35 Xenon

Cab lights 10 SV8,5Cab lights 10 SV8,5

Hydraulic system

Opening pressure MPa PsiOpening pressure MPa Psi

Drive system 35 5 080Drive system 35 5 080

Supply system 2.5 365Supply system 2.5 365

Vibration system 19 2 760Vibration system 19 2 760

Control systems 20 2 900Control systems 20 2 900

Brake release 1.8 260Brake release 1.8 260

Air Conditioning / Automatic Climate Control

(ACC) (Optional)

The system described in this manual is an AC/ACC

type (Automatic Climate Control). ACC is a system

that maintains the set temperature in the cab, provided

windows and doors are kept closed.

The system contains fluorinated greenhouse gases.

Coolant designation: HFC-134a

Coolant weight when full: 1.350 kg

CO2-equivalent: 1.930 ton

GWP: 1430

4812159601_H.pdf2021-01-14

23

Page 36

Technical specifications

Technical data, Chip Spreader (Optional)

CC224HF/CC234HF

CC2200/CC2300

CC2200/CC2300

CO2200

CO2200

Weight of container

(empty)

(empty)

Max total extra

weight (full)

weight (full)

Max permitted load

volume

volume

Spreading width 1500 mm (59 in) 1800 mm (71 in) 1500 mm (59 in)Spreading width 1500 mm (59 in) 1800 mm (71 in) 1500 mm (59 in)

Length of spreader 1200 mm (47 in) 1200 mm (47 in) 1200 mm (47 in)Length of spreader 1200 mm (47 in) 1200 mm (47 in) 1200 mm (47 in)

Total length of

machine (spreader

machine (spreader

fitted)

fitted)

340 kg (750 lb) 410 kg (904 lb) 340 kg (750 lb)Weight of container

340 kg (750 lb) 410 kg (904 lb) 340 kg (750 lb)

1390 kg (3065 lb) 1700 kg (3748 lb) 1390 kg (3065 lb)Max total extra

1390 kg (3065 lb) 1700 kg (3748 lb) 1390 kg (3065 lb)

700 l (185 gal) 850 l (224 gal) 700 l (185 gal)Max permitted load

700 l (185 gal) 850 l (224 gal) 700 l (185 gal)

5685 mm (224 in) 5685 mm (224 in) 5190 mm (204 in)Total length of

5685 mm (224 in) 5685 mm (224 in) 5190 mm (204 in)

If to mount a chip spreader, check in the spare part

catalogue for correct Dynapac P/N of the chip

spreader for the machine and follow the mounting

instructions.

CC324HF/CC334HF

CC324HF/CC334HF

CC3200/CC3300

CC3200/CC3300

CG2300CC224HF/CC234HF

CG2300

24

4812159601_H.pdf 2021-01-14

Page 37

Tightening torque

Tightening torque in Nm for oiled or dry bolts tightened

with a torque wrench.

Metric coarse screw thread, bright galvanized (fzb):

STRENGTH CLASS:

Technical specifications

M thread

thread

M6 8,4 9,4 12 13,4 14,6 16,3M6 8,4 9,4 12 13,4 14,6 16,3

M8 21 23 28 32 34 38M8 21 23 28 32 34 38

M10 40 45 56 62 68 76M10 40 45 56 62 68 76

M12 70 78 98 110 117 131M12 70 78 98 110 117 131

M14 110 123 156 174 187 208M14 110 123 156 174 187 208

M16 169 190 240 270 290 320M16 169 190 240 270 290 320

M20 330 370 470 520 560 620M20 330 370 470 520 560 620

M22 446 497 626 699 752 839M22 446 497 626 699 752 839

M24 570 640 800 900 960 1080M24 570 640 800 900 960 1080

M30 1130 1260 1580 1770 1900 2100M30 1130 1260 1580 1770 1900 2100

Metric coarse thread, zinc-treated

(Dacromet/GEOMET):

8.8, Oiled 8.8, Dry 10.9, Oiled 10.9, Dry 12.9, Oiled 12.9, DryM -

8.8, Oiled 8.8, Dry 10.9, Oiled 10.9, Dry 12.9, Oiled 12.9, Dry

STRENGTH CLASS:

M - thread 10.9, Oiled 10.9, Dry 12.9, Oiled 12.9, Dry M - thread 10.9, Oiled 10.9, Dry 12.9, Oiled 12.9, Dry

M6 12,0 15,0 14,6 18,3M6 12,0 15,0 14,6 18,3

M8 28 36 34 43M8 28 36 34 43

M10 56 70 68 86M10 56 70 68 86

M12 98 124 117 147M12 98 124 117 147

M14 156 196 187 234M14 156 196 187 234

M16 240 304 290 360M16 240 304 290 360

M20 470 585 560 698M20 470 585 560 698

M22 626 786 752 944M22 626 786 752 944

M24 800 1010 960 1215M24 800 1010 960 1215

M30 1580 1990 1900 2360M30 1580 1990 1900 2360

4812159601_H.pdf2021-01-14

25

Page 38

Technical specifications

26

4812159601_H.pdf 2021-01-14

Page 39

Machine description

Machine description

Diesel engine

The machine is equipped with a completely

electronically controlled water-cooled four-cylinder,

turbocharged (WGT) diesel engine with direct injection

(HPCR) and intercooler.

WGT - Waste Gate Turbo

HPCR - High Pressure Common Rail fuel injection

(IIIB/T4i/T4f)

The engine is also equipped with cooled exhaust gas

recirculation (ceGR) and a diesel oxidation catalysator

(DOC) system for exhaust after-treatment.

The engine has also an electronically controlled

variable flow turbo (VFT) and closed crankcase

ventilation.

ceEGR - External Cooled EGR-electronically controlled

DOC - Diesel Oxidation Catalyst

VFT - Variable Flow turbocharger-el. controlled

(stage V)

The engine is also equipped with cooled exhaust gas

recirculation (ceEGR) and a diesel particle filter (DPF)

system for exhaust after-treatment.

The engine has also an electronically controlled

variable flow turbo (VFT) and closed crankcase

ventilation.

ceEGR - External Cooled EGR-electronically controlled

DPF - Diesel particle filter

VFT - Variable Flow turbocharger-el. controlled

Electrical system

The machine has the following control units (ECU,

Electronic Control Unit) and electronic units.

• Main ECU (for the machine)

• Diesel engine control unit (ECM)

• I/O board (Control board)

• Display

Propulsion system

The propulsion system is a hydrostatic system

A drive unit (propulsion motor + gear) drives each

drum or wheel pair.

Machines with split drum/s has a drive unit per drum

half and an anti-spin system.

All propulsion motors are connected in parallel, a

4812159601_H.pdf2021-01-14

27

Page 40

Machine description

hydraulic pump supplies all motors with hydraulic oil.

The speed of the machine is proportional to the angle

of the control lever (the deflection of the

forward/reverse lever regulates the speed). A speed

selector is available as option.

Brake system

The brake system comprises a service brake,

secondary brake and parking brake. The service brake

system produces retardation of the propulsion system,

i.e. hydrostatic braking.

Secondary/Parking brake

The secondary and parking brake system comprises

sprung disc brakes to each drum, drum half

respectively wheel pair.The disc brakes are

disengaged by hydraulic pressure.

Steering system

The steering system is a hydrostatic system. The

steering wheel is connected to a steering valve that

distributes the flow to the steering cylinders at the

articulated joint. A hydraulic pump supplies the

steering valve with oil.

The steering angle is proportional to the amount the

steering wheel is turned.

In some markets, the machine is also equipped with

an emergency steering system, either manually or

electro-hydraulically.

Vibration system

The vibration system is a hydrostatic system in which

a hydraulic motor drives the eccentric shaft, which

generates the drum's vibrations.

An eccentric shaft in the front-resp. rear drum

generates the the drum's vibrations.

Each eccentric shaft is driven by a hydraulic motor. A

hydraulic pump supplies each hydraulic motor with oil.

High amplitude/low frequency or low amplitude/high

frequency is controlled by the direction of rotation of

the hydraulic motor.

Cab

The cab has a heating and ventilation system, with

defrosters for all windows. The cab can be equipped

with air conditioning (ACC).

28

Emergency exit

The cab has two emergency exits: the door and the

4812159601_H.pdf 2021-01-14

Page 41

Machine description

rear cab window, which can be broken with the

emergency hammer located in the cab.

ROPS

ROPS is the abbreviation for "Roll Over Protective

Structure".

The cab is approved as a protective cab in accordance

with the ROPS standard.

If any part of the cab's or the ROPS structure's

protective construction displays plastic deformation or

cracks, the cab or the ROPS structure must be

replaced immediately.

Never perform any modifications on the cab or ROPS

structure without first having discussed the

modification with Dynapac's production unit. Dynapac