Page 1

Model 122A21

Helium Bleed, ICP® Dynamic Pressure Sensor

Installation and Operating Manual

For assistance with the operation of this product , contact the Pressure

Division of PCB Piezotronics, Inc.

Division toll-free 888-684-0015

24-hour SensorLineSM 716-684-0001

Fax 716-686-9129

E-mail pressure@pcb.com

Page 2

Warranty, Service, Repair, and

Return Policies and Instructions

The informati on contained in this document supersedes all similar i nformation th at

may be found elsewhere in this manual.

Total Customer Satisfaction – PCB

Piezotronics guarantees Total Customer

Satisfaction. If, at any time, for any

reason, you are not completely satisfied

with any PCB product, PCB will repair,

replace, or exchange it at no charge. You

may also choose to have your purchase

price refunded in lieu of the repair,

replacement, or exchange of the product.

Service – Due to the sophisticated nature

of the sensors and associated

instrumentation provided by PCB

Piezotronics, user servicing or repair is

not recommended and, if attempted, may

void the factory warranty. Routine

maintenance, such as the cleaning of

electrical connectors, housings, and

mounting surfaces with solutions and

techniques that will not harm the

physical material of construction, is

acceptable. Caution should be observed

to insure that liquids are not permitted to

migrate into devices that are not

hermetically sealed. Such devices should

only be wiped with a dampened cloth

and never submerged or have liquids

poured upon them.

Repair – In the event that equipment

becomes damaged or ceases to operate,

arrangements should be made to return

the equipment to PCB Piezotronics for

repair. User servicing or repair is not

recommended and, if attempted, may

void the factory warranty.

Calibration – Routine calibration of

sensors and associated instrumentation is

recommended as this helps build

confidence in measurement accuracy and

acquired data. Equipment calibration

cycles are typically established by the

users own quality regimen. When in

doubt about a calibration cycle, a good

“rule of thumb” is to recalibrate on an

annual basis. It is also good practice to

recalibrate after exposure to any severe

temperature extreme, shock, load, or

other environmental influence, or prior

to any critical test.

PCB Piezotronics maintains an ISO9001 certified metrology laboratory and

offers calibration services, which are

accredited by A2LA to ISO/IEC 17025,

with full traceablility to N.I.S.T. In

addition to the normally supplied

calibration, special testing is also

available, such as: sensitivity at elevated

or cryogenic temperatures, phase

response, extended high or low

frequency response, extended range, leak

testing, hydrostatic pressure testing, and

others. For information on standard

recalibration services or special testing,

contact your local PCB Piezotronics

distributor, sales representative, or

factory customer service representative.

Returning Equipment – Following

these procedures will insure that your

returned materials are handled in the

most expedient manner. Before returning

any equipment to PCB Piezotronics,

contact your local distributor, sales

representative, or factory customer

service representative to obtain a Return

Page 3

Materials Authorization (RMA)

Number. This RMA number should be

clearly marked on the outside of all

package(s) and on the packing list(s)

accompanying the shipment. A detailed

account of the nature of the problem(s)

being experienced with the equipment

should also be included inside the

package(s) containing any returned

materials.

A Purchase Order, included with the

returned materials, will expedite the

turn-around of serviced equipment. It is

recommended to include authorization

on the Purchase Order for PCB to

proceed with any repairs, as long as they

do not exceed 50% of the replacement

cost of the returned item(s). PCB will

provide a price quotation or replacement

recommendation for any item whose

repair costs would exceed 50% of

replacement cost, or any item that i s not

economically feasible to repair. For

routine calibration services, the Purchase

Order should include authorization to

proceed and return at current pricing,

which can be obtained from a factory

customer service representative.

Warranty – All equipment and repair

services provided by PCB Piezotronics,

Inc. are covered by a limited warranty

against defective material and

workmanship for a period of one year

from date of original purchase. Contact

DOCUMENT NUMBER: 21354

DOCUMENT REVISION: B

ECN: 17900

PCB for a complete statement of our

warranty. Expendable items, such as

batteries and mounting hardware, are not

covered by warranty. Mechanical

damage to equipment due to improper

use is not covered by warranty.

Electronic circuitry failure caused by the

introduction of unregulated or improper

excitation power or electrostatic

discharge is not covered by warranty.

Contact Information – International

customers should direct all inquiries to

their local distributor or sales office. A

complete list of distributors and offices

can be found at www.pcb.com.

Customers within the United States may

contact their local sales representative or

a factory customer service

representative. A complete list of sales

representatives can be found at

www.pcb.com. Toll-free telephone

numbers for a factory customer service

representative, in the division

responsible for this product, can be

found on the title page at the front of this

manual. Our ship to address and general

contact numbers are:

PCB Piezotronics, I nc.

3425 Walden Ave.

Depew, NY 14043 USA

Toll-free: (800) 828-8840

24-hour SensorLine

SM

: (716) 684-0001

Website: www.pcb.com

E-mail: info@pcb.com

Page 4

OPERATION MANUAL FOR

MODELS 122A, 122A21, 122A22, and 122A24

HELIUM BLEED PRESSURE SENSOR

1.0 INTRODUCTION

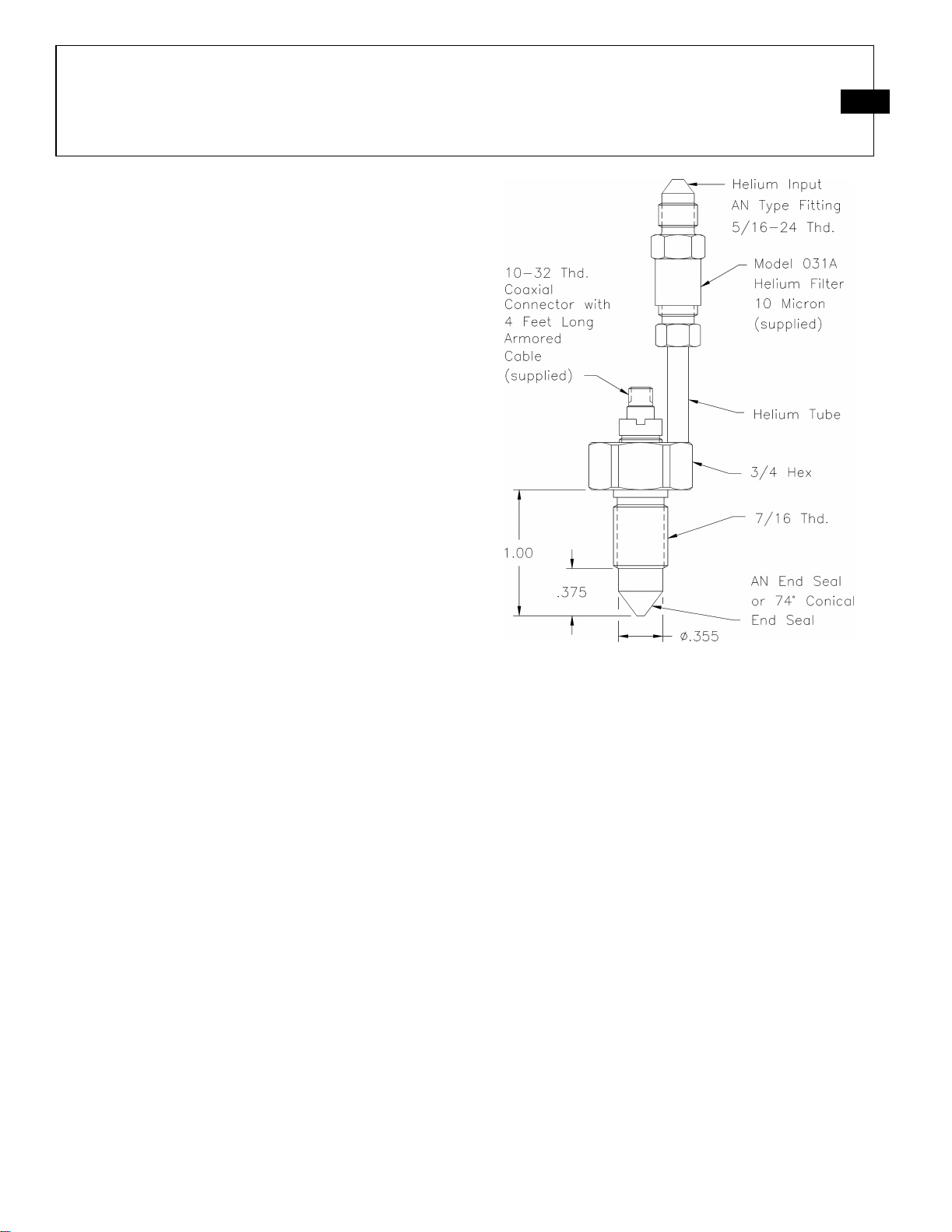

The series of sensors described in this guide is

designed to measure dynamic pressure in intense

thermal environments typified by rocket engine

combustion chambers.

These sensors feature acceleration-compensated

piezoelectric pressure probes, mounted in a conical

end seal helium bleed adaptor.

The helium gas, applied from a 1500 psi source, is

metered by a built-in orifice and flows around the

probe body and out the passage of the adaptor ahead

of the probe diaphragm. The helium gas flowing out

the passage protects the sensor diaphragm from the

hot gasses as well as increasing the natural frequency

of the passage by a factor of approximately three to

one.

2.0 DESCRIPTION

The model 122A contains a one pC/psi pressure

probe (sensor) and is designed to be used with

electrostatic charge amplifiers such as the PCB

Model 462A.

The Models 122A21, A22, and A24 contain built-in

impedance converter electronics circuits which

convert the high-impedance voltage from the quartz

crystal to a low-impedance voltage signal that can be

fed directly into most common indicating or

recording instruments.

The 122A series sensors contain a 10 micron helium

filter contained in a fitting threaded onto the helium

input tube. The purpose of this filter is to prevent

particles in the helium supply from plugging the

metering orifice.

The outer body of this series is 17-4 PH hardened

stainless steel and features a conical tip for sealing

without seal rings or washers. This feature also

allows the sensor sensing passage to be placed closer

to the chamber without a long passage that could

cause resonance problems, severely limiting highfrequency response.

Series 122A: Helium Bleed Rocket Motor, ICP

and Charge Sensors

NOTE: The sensor probe in this series is factory

installed at a precise depth in the outer body. Do not

attempt removal of this probe. Contact the factory

should any questions or problems arise concerning

the sensor probe.

The Models 122A21, A22, and A23 Sensors use low

output-impedance probes (ICP) and will not require

the insulation resistance cautions described for Model

122A.

Connect the sensor cable to the appropriate ICP

power unit and check the front panel monitor meter to

check cable connections and internal amplifier.

Consult Guide G-0001B, "General Guide to ICP

Instrumentation" for installation and usage hints for

ICP instruments.

1

®

Drawing number: 21089

Revision: NR

Page 5

OPERATION MANUAL FOR

MODELS 122A, 122A21, 122A22, and 122A24

2

HELIUM BLEED PRESSURE SENSOR

3.0 INSTALLATION

Prepare mounting port in accordance with

instructions on installation drawing 122-1010-90.

Inspect the mounting port for burrs and tool marks at

the conical seal surface.

NOTE: A 75 end-cutting reamer, Model 040A02, is

available from PCB. Contact the factory for price

and delivery information.

Use recommended mounting torque when installing

sensors. Do not overtorque as damage to seal surface

could result.

NOTE: When attaching helium supply hose, do not

torque hose fitting through helium tube on sensor.

Back up fitting with wrench on 3/8 hex on helium

hose fitting. (Refer to note 3 on installation drawing.)

In the presence of high vibration, support helium

supply tube by clamping to rigid surfaces with

adequate strain relief loop to avoid stressing helium

tube on sensor.

For charge output Model 122A, connect 4 ft. cable to

charge amplifier and switch to "long" time constant

position and check for drift.

Clean offending cable connections with

Trichloroethylene or equivalent solvent to restore

insulation resistance.

It is good practice to depress ground button (or place

switch in GND" position) on the charge amplifier

while attaching input cables to the amplifier. This

will prevent spurious charges which may accumulate

on sensors and cables from blowing out the input

circuitry of the charge amplifier.

Since the charge output sensors are susceptible to

decreased insulation resistance, use care to keep cable

connections clean by use of shrink tubing wherever

possible.

4.0 OPERATION

4.1 CHARGE OUTPUT MODEL

122A

For the 122A Charge Output Model, it is only

necessary to select the proper range on the charge

amplifier and proceed with the measurement.

The probe sensitivity is approximately 1.0 pC/psi.

(The exact sensitivity is given on the calibration

certificate supplied with each instrument.)

EXAMPLE: The dynamic pressure expected is

500 psi and the desired output voltage for this

pressure is 1 volt.

Simply set the range switch of the charge amplifier to

500 units per volt and dial the standardization pot to

the exact sensor sensitivity at 500 psi (from

calibration graph). The system will then yield exactly

1 volt for 500 psi of input pressure.

4.2 TIME CONSTANT

During in-place calibration, static methods (dead

weight tester) may be used in a drift-free system by

placing the charge amplifier in "LONG TC" position.

However, during actual use, the TC mode switch

should be in "SHORT" position for two reasons.

Often times, the dynamic pressure being measured

exists superimposed upon a higher static level. The

short TC position will allow the effect of this static

level to zero out quickly without effect on the

dynamic level indicated.

Also, the influx of large amounts of thermal energy,

as in rocket combustion measurements, can cause the

sensor to generate spurious transient outputs of

considerable magnitude. Using the charge amplifier

on SHORT TC alleviates this problem by shunting

these longer term charge outputs to ground while

measuring the faster dynamic pressure pulses.

Drawing number: 21089

Revision: NR

Page 6

OPERATION MANUAL FOR

MODELS 122A, 122A21, 122A22, and 122A24

3

HELIUM BLEED PRESSURE SENSOR

4.3 OPERATION - ICP MODELS

122A21, A22, and A24

Consult Guide G-0001B for a complete description of

the low-impedance concept in instrumentation.

All PCB power units designed for ICP use contain

built-in fault monitor meters to aid in locating circuit

faults (shorts or opens) and to identify normal

operation of the miniature impedance converting

amplifier built into the sensor.

Do not attempt to apply voltage directly to the input

pin of the sensor from any other power source. The

input current must be limited to 20 mA maximum and

the input voltage must not be higher than 35 VDC.

Consult the factory if it is desired to build a power

unit rather than to use one of those available from

PCB.

The Models 122A21, 122A22 and 122A24 are

identical except for sensitivity.

The Model 122A21 has a sensitivity of 20mV/psi

which gives a full-scale range (for +5 V out) of 250

psi.

The Model 122A22 has a sensitivity of 1.0 mV/psi

and a full-scale range of 5000 psi.

The Model 122A24 has a sensitivity of 5.0 mV/psi

and a full-scale range of 1000 psi.

NOTE: Full-scale range is limited by the helium

source pressure. The helium source pressure must be

at least twice the peak combustion pressure (static

plus dynamic) to be measured, but not more than

about ten times the lowest pressure.

This is true for all models, charge or ICP.

5.0 CALIBRATION

5.1 CHARGE MODEL 122A

To calibrate this model, install in pressure port of

dead weight tester and apply various static pressures

recording corresponding outputs at each pressure of

interest.

Discharge the charge amplifier before each reading

and return pressure to zero before each new pressure

input.

Use the charge amplifier on "LONG" time constant

and keep cables and connections clean to avoid drift.

A D.C. digital voltmeter is ideal for readout during

calibration.

NOTE: The helium tube must be plugged with a

pressure-tight seal before attempting to calibrate to

avoid losing pressure through the helium tube.

If a hydraulic calibration system is used, be sure to

remove all traces of oil from the diaphragm passage.

5.2 ICP MODELS 122A21, 122A22

and 122A24

Because of the shorter time constants built into these

models, static calibration methods are much more

difficult to use.

Pressures must be applied rapidly and readout must

be made with fast recording devices such as light

storage oscilloscopes or similar types of data

acquisition hardware.

A pneumatic (compressed air or hydrogen) system

with quick opening valve and reference gage is an

excellent method of calibrating these sensors.

To take full advantage of the time constant built into

the sensor, use a DC-coupled power unit such as the

PCB Model 484B06.

Drawing number: 21089

Revision: NR

Page 7

OPERATION MANUAL FOR

MODELS 122A, 122A21, 122A22, and 122A24

HELIUM BLEED PRESSURE SENSOR

6.0 GROUND ISOLATION

All sensor probes in this series are mounted in an

"OFF GROUND" configuration. That is, the probe

body is electrically insulated from the sensor outer

body to avoid ground loops.

7.0 MAINTENANCE AND REPAIR

The sealed construction and miniature size of these

sensors make field repair impractical.

The helium filter element should be cleaned should

the flow rate decrease. Remove the element and

ultrasonically agitate in solvent for 15 minutes, then

dry.

Should the orifice become plugged, back pressure the

orifice by applying air pressure to diaphragm end of

sensor with filter off and helium tube vented to

atmosphere.

The only maintenance possible on the probe is

maintaining of insulation resistance of the Model

122A probe/cable assembly. Clean connectors with

suitable solvent and dry.

Contact factory for assistance should problems

arise.

ICP is a registered trademark of PCB Piezotronics

4

Drawing number: 21089

Revision: NR

Page 8

Page 9

Page 10

OPERATION MANUAL FOR

MODELS 122A, 122A21, 122A22, and 122A24

HELIUM BLEED PRESSURE SENSOR

Test Report

Helium Flow Test and Burst Test

Sensor Model ________________________ S/N __________________________

Initial Calibration:

Input (PSI) 500 1000 1500 2000 2500 3000

System Output (V)

Burst Test to 5000 PSI - Failed

Final Calibration:

Input (PSI) 500 1000 1500 2000 2500 3000

System Output (V)

Helium Flow Test:

Input Pressure _________ PSIG

Flow Rate _________ SCFH

Date: _____________________

By: _____________________

7

Drawing number: 21089

Revision: NR

Page 11

Page 12

Loading...

Loading...