Page 1

THE PROFESSIONAL RGT SERIES

GAS RANGE

Installation Guide

MODELS:

RGT-305

RGT-366

RGT-364GL

-364GD

RGT

-484GG

RGT

RGT-486GL

RGT-486GD

RGT-485GD

Page 2

Page 3

A MESSAGE TO OUR CUSTOMERS

Thank you for selecting this professional gas Range. Because of this appliance’s unique features we have

developed this Installation Guide. It contains valuable information on how to properly install your new appliance

for years of safe and enjoyable cooking.

For your convenience, product questions can be answered by a DCS Customer Care Representative by phone:

1-888-936-7872, or email:

NOTE: Please write the Model and Serial Numbers on this page for references (located on the label above the kick

panel on the right)

MODEL NUMBER SERIAL NUMBER

NOTE: Inspect the product to verify that there is no shipping damage. If any damage is detected, call the shipper

and initiate a damage claim. DCS by Fisher & Paykel is not responsible for shipping damage.

DO NOT discard any packing material (box, pallet, straps) until the unit has been inspected.

customer.care@fisherpaykel.com

.

WARNING

Improper installation, adjustment alteration, service or maintenance can cause property damage, injury or death.

Read the installation, operating and maintenance instructions thoroughly before use, installing or servicing this

equipment.

WARNING

If the information in this manual is not followed exactly, a fire or explosion may result causing property damage,

personal injury or death.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

DANGER

If You Smell Gas:

1. Do not try to light any appliance.

2. Do not touch any electrical switch; do not use any phone in your building.

3. Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

4. If you cannot reach your gas supplier, call the fire department.

5. Installation and service must be performed by a qualified installer, service agency or the gas supplier.

WARNING

To reduce the risk of injury to persons in the event of a rangetop grease fire, observe the following: Turn burner off

ookie sheet, metal tray, baking soda or use a dry chemical or foam-type

. Smother flames with a close

first

fire extinguisher. Be careful to prevent burns. If the flames do not go out immediately, evacuate and call the fire

department. Never pick up a flaming pan - You may be burned. DO NOT USE WATER ON GREASE FIRES, including

wels - a violent steam explosion will result. Use an extinguisher ONLY if:

et dishcloths or t

w

1. You know you ha

2. The fire is small and contained in the area where it started.

3. The fire department is being called.

4. You can fight the fir

o

e a Class ABC extinguisher, and you already know how to operate it.

v

e with y

-fitting lid

our back t

, c

o an exit.

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE.

1

Page 4

TABLE OF CONTENTS

INTRODUCTION 3

SAFETY PRACTICES AND PRECAUTIONS 4-6

MODELS 7

PLANNING THE INSTALLATION 8-9

UNPACKING AND HANDLING 9-11

VENTILATION REQUIREMENTS 12

INSTALLING ANTI-TIP DEVICE 13

CABINET PREPARATION 14-16

BACKGUARD INSTALLATION 17

ELECTRICAL CONNECTIONS 17-18

GAS HOOK-UP 18-19

TEST AND ADJUSTMENTS 19-20

CLEANING EXTERIOR SURFACES 20

INSTALLER FINAL CHECKLIST 21

HOW TO OBTAIN SERVICE 22

WARRANTY 23-24

2

Page 5

INTRODUCTION

The DCS RGT series ranges are designed with a large number of features available in a multitude of different

ombinations. Patented Dual Flow Burners

c

output of 17,500 Btu/hr, with two burners at 12,500 Btu/hr. Also available on the ranges are an 18,000 Btu/hr

riddle and/or grill.

g

The large capacity gas convection ovens, 30,00 Btu/hr, of the RGT series are equipped with an in-oven gas

infrared broiler, 19,000 Btu/hr. The smaller gas oven, 18,000 Btu/hr, found on the 48” RGT series is ideal for

baking smaller dishes. All range models require the installation of one of the two offered Backguards if installed

with less than 12” to combustible material. See pages 8 and 17.

M

T

llow for consistently lower simmer temperatures and have a high

a

IMPORTANT INSTALLATION INFORMATION

The RGT series ranges are tested in accordance with ANSI Z21.1 Standard for Household Cooking Gas Appliances.

These ranges must be installed in conjunction with a suitable overhead vent hood (see ventilation requirements).

Due to the professional high heat capacity of this unit, particular attention should be paid to the hood and duct

ork installation to ensure it meets local building codes. To eliminate risk of burns or fire by reaching over

w

ted surface units, cabinet storage located above the surface units should be avoided.

hea

Check local building codes for the proper method of range installation. Local codes vary. Installation, electrical

connections, and grounding must comply with all applicable codes. In the absence of local codes, the range

should be installed accordance with the National Fuel Gas Code ANSI Z223-1 and National Electrical Code

ANSI/NFPA 70. Be sure that the unit being installed is set up for the kind of gas being used. The gas ranges are

shipped from the factory set and adjusted for natural gas or LP (propane), depending on the specific model

ordered.

further. Return range to dealer if unit is not set for site gas supply.

Verify that the range is compatible with gas supply at the installation site before proceeding

3

Page 6

SAFETY PRACTICES AND PRECAUTIONS

When properly cared for, your new DCS Appliance has been designed to be a safe, reliable cooking appliance.

When using this restaurant caliber appliance, use it with extreme care, as this type appliance provides intense

heat and can increase the accident potential. Basic safety precautions must be followed when using kitchen

ppliances, including the following:

a

■

Read the Use and Care Manual, which came with this appliance, thoroughly before using your new appliance.

This will help to reduce the risk of fire, electric shock, or injury to persons.

■

Begin by insuring proper installation and servicing. Follow the installation instructions in this manual. Be sure to

have a qualified technician install and ground this appliance before using.

■

Have the installer show you where the gas supply shut-off valve is located so you will know how and where to

turn off the gas to the appliance.

■

If you smell gas, the installer has not done a proper job of checking for leaks. You can have a small leak and

therefore a faint gas smell if the connections are not completely tight. Finding a gas leak is not a “do-it-yourself”

procedure. Some leaks can only be found with the burner control in the “ON” position and for your protection it

must be done by a qualified service technician.

■

If by some chance a burner goes out and gas escapes, open a window or a door to let the room air out. Do not

attempt to use the appliance until the gas has had time to dissipate. Follow the instructions on page 1, “For your

safety – if you smell gas”.

■

This appliance has been factory assembled for natural or LP gas. It should be correctly adjusted from the factory

for the type of gas that is used.

■

Do not repair or replace any part of this appliance unless it is specifically recommended in this manual. All other

servicing should be referred to a qualified technician.

■

Children should not be left alone or unattended in an area where appliances are in use. They should never be

allowed to turn knobs, push buttons, sit or stand on, and/or touch any part of an appliance while in operation.

■

Children in walkers, or children crawling can be attracted to the round oven door handle and may grab and open

the oven door. This can result in injury from the door being pulled open on a child, or severe burns if the oven is

in use and hot.

WARNING:

e items of interest to children above or at the back of any appliance. Children could be seriously injured

er st

or

ything in the o

e an

or

er on grease fires. Turn all burners “OFF”, then smother fire with baking soda or use a dry

t

a

v

ch on fire.

t

en or on the c

ooktop. Flammable materials can catch fire, plastic items may melt

Do not st

if they should climb onto the appliance to reach these items.

■

Nev

or ignite and other types of items could be ruined.

■

Do not hang articles from any part of the appliance or place anything against the oven. Some fabrics are quite

flammable and may ca

■

If the appliance is near a window be certain the curtains do not blow over or near the cooktop burners; they

could catch on fire.

o not use w

■

D

chemical or foam-type fire extinguisher.

■

Never let clothing, pot holders, or other flammable materials come in contact with, or too close to, any burner or

ner grate until it has cooled. Fabric may ignite and result in personal injury.

bur

■

Be certain to use only dry pot holders: moist or damp pot holders on hot surfaces may cause burns from steam.

el or other bulky cloth in place of pot holders. Do not let pot holders touch hot burners, or

w

Do not use a t

burner grates

4

o

.

Page 7

SAFETY PRACTICES AND PRECAUTIONS

■

For personal safety, wear proper apparel. Loose fitting garments or hanging sleeves should never be worn while

sing this appliance. Some synthetic fabrics are highly flammable and should not be worn while cooking.

u

■ Do not use aluminum foil to line any part of the oven or cooktop. This will cause heat to be trapped underneath

it. This trapped heat can upset the cooking performance and can damage the finish of the oven or the cooktop

parts.

WARNING! NEVER cover any slots, holes or passages in the oven bottom or cover an

entire rack with materials such as aluminum foil. Doing so blocks airflow through the oven and may

cause carbon monoxide poisoning. Aluminum foil linings may also trap heat, causing a fire hazard.

■ This appliance is for cooking. Never use the oven or cooktop to warm or heat a room. This could damage the

cooktop or oven parts.

WARNING! NEVER use this appliance as a space heater to heat or warm the room.

Doing so may result in carbon monoxide poisoning and overheating of the oven.

■

When using the cooktop: Do not touch the burner grates or the immediate surrounding area. Areas adjacent to

the burners may become hot enough to cause burns.

■

When using the oven: Do not touch the interior surfaces of the oven, the exterior area immediately surrounding

the door or the back trim. The surfaces directly above the oven door may be hot if the oven has been operated

with the door open, or if something has prevented the door from sealing. Always use caution when pulling out

the drip trays (GD & GL models only) when the oven has been on, or is currently on. The drip trays get hot when

the oven is on. Do not remove drip trays until they are cool.

■

Never leave the cooktop unattended when using high flame settings. When cooking with high flame settings,

boil overs may cause smoking and greasy spill overs may ignite. More importantly, if the burner flames are

smothered by a severe boil over which effects the igniter, unburned gas will escape into the room.

■

Only certain types of glass, heat-proof glass-ceramic, ceramic, earthen ware, or other glazes utensils are suitable

for cooktop use. This type of utensil may break with sudden temperature changes. Use only on low or medium

flames settings according to the manufacturer’s directions. The use of professional utensils is recommended.

o not hea

■

D

■

During cooking, set the burner control so that the flame heats only the bottom of the pan and does not extend

beyond the bottom of the pan. This could heat and/or melt the handles, and may increase cooking time.

■

Always use utensils that have flat bottoms large enough to cover the burner. The use of undersized utensils will

expose a portion of the flame to direct contact and may result in ignition of clothing.

■

To minimize burns, ignition of flammable materials and unintentional spill overs, position handles of utensils

ar

w

in

■

Hold the handle of the pan to prevent movement of the utensil when stirring or turning food.

ease is flammable

■

Gr

ound the c

ar

t unopened food containers; a build up of pressure may cause the container to burst.

d so they do not extend over adjacent work areas, cooking areas, or the edge of the cooktop.

. Let hot grease cool before attempting to handle it. Avoid letting grease deposits collect

ooktop burners. Clean af

ter each use or boil over.

■

For proper lighting and performance of the cooktop burners, keep the burner ports clean. It may be necessary to

clean these when there is a boil over or when the burner does not light, even though the electronic igniters

click.

■

Do not use the grill for cooking excessively fatty meats or products which promote flare-ups. Do not use

cooking utensils on the grill.

5

Page 8

SAFETY PRACTICES AND PRECAUTIONS

Installer supplied shut-off valve

must be easily accessible inside

cabinetry.

Gas Supply

■

Clean the cooktop with caution. Avoid steam burns; do not use a wet sponge or cloth to clean the cooktop

while it is hot. Some cleaners produce noxious fumes if applied to a hot surface. Follow directions provided by

the cleaner manufacturer.

■

Be sure all the range and/or cooktop controls are turned off and the appliance is cool before using any type of

aerosol cleaner on or around the appliance. The chemical that produces the spraying action could, in the

presence of heat, ignite or cause metal parts to corrode.

■

Place oven racks in desired position while the oven is cool. If a rack must be moved while the oven is hot, do not

let the pot holders contact the hot interior of the oven.

■

Use care when opening the oven door; let hot air or steam escape before removing or replacing foods.

■

Do not rub, damage, move or remove the door gasket. It is essential for a good seal during baking. Wash the

gasket with hot water only.

■

Clean the ventilator hood and filters above the range or cooktop frequently so grease from cooking vapors does

not accumulate on them. The filters can be cleaned in a dishwasher or DishDrawer. Follow directions provided

by ventilation manufacturer for cleaning.

■

Turn the ventilator “OFF” in case of fire or when intentionally “flaming” liquor or other spirits on the cooktop.

The blower, if in operation, could unsafely spread the flames.

■

DO NOT obstruct the flow of combustion or ventilation air to the appliance. Be sure a fresh air supply is

available.

■

For safety reasons and to avoid damage to the appliance never sit, stand, or lean on the oven door or cooking

surface.

■

Service should only be done by authorized technicians. Technicians must disconnect the power supply before

servicing this appliance.

WARNING:

California Proposition 65 - The burning of gas cooking fuel generates some by-products which are known by the

State of California to cause cancer or reproductive harm. California law requires businesses to warn customers of

potential exposure to such substances. To minimize exposure to these substances, always operate this unit

according to the instructions contained in this booklet and provide good ventilation to the room when cooking with

.

gas

RECOMMENDATIONS ON HOOK-UP TO GAS SUPPLY:

A manual valve must be installed external to the appliance, in an accessible location from the front for the

purpose of shutting off the gas supply. The supply line must not protrude beyond the back of the unit. Make

e the gas supply is tur

sur

The gas supply connections should be made by a qualified technician and in accordance with local codes or

dinances. In the absence of a local code, the installation must conform to the latest edition of National Fuel

or

ode ANSI Z223.1.

as C

G

NOTE:

This product must be installed by a licensed plumber or gas fitter

when installed within the C

ned off at the wall valve before connecting the appliance.

ommon

wealth of Massachusetts.

NOTE:

y for the Stat

(mandat

Alternate method of supplying gas must be installed into the unit.

6

or

e of Massach

usetts)

Page 9

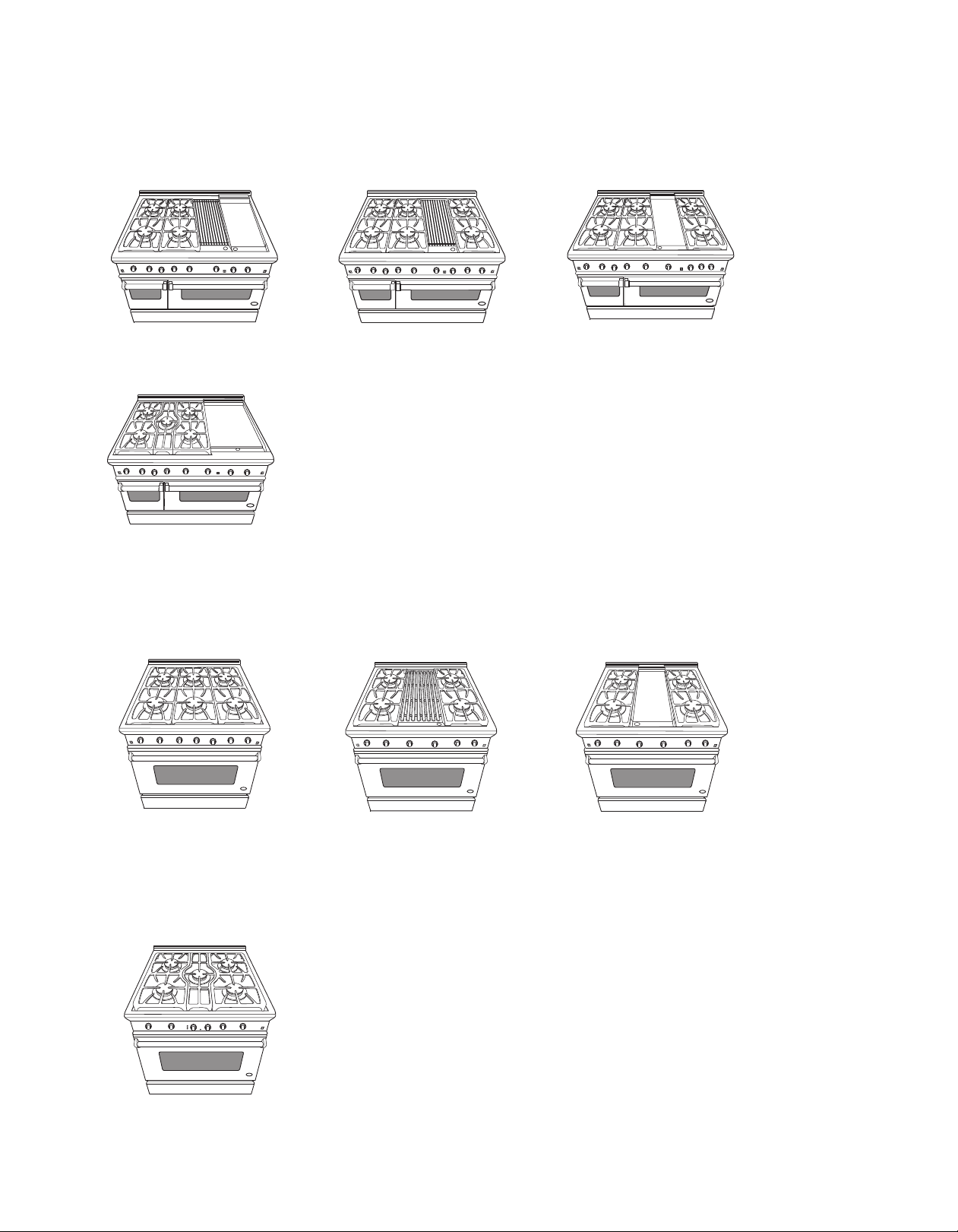

MODELS

OVENON

H

EATING

D

OOR LOCKED

H

EATING

48” RGT RANGE MODELS

RGT-484GG

RGT-485GD

36” RGT RANGE MODELS

RGT-486GL RGT-486GD

RGT-366

30” RGT RANGE MODELS

-305

RGT

RGT-364GL RGT-364GD

7

Page 10

PLANNING THE INSTALLATION

IMPORTANT INSTALLATION INFORMATION

he RGT is tested in accordance with ANSI Z21.1 Standard for Household Cooking Gas Appliances.

T

The range must be installed in conjunction with a suitable overhead vent hood. (See ventilation requirements,

age 12). Due to the professional high heat capacity of this unit, particular attention should be paid to the hood

p

and duct work installation to ensure it meets local building codes. To eliminate risk of burns or fire by reaching

over heated surface units, cabinet storage located above the surface units should be avoided.

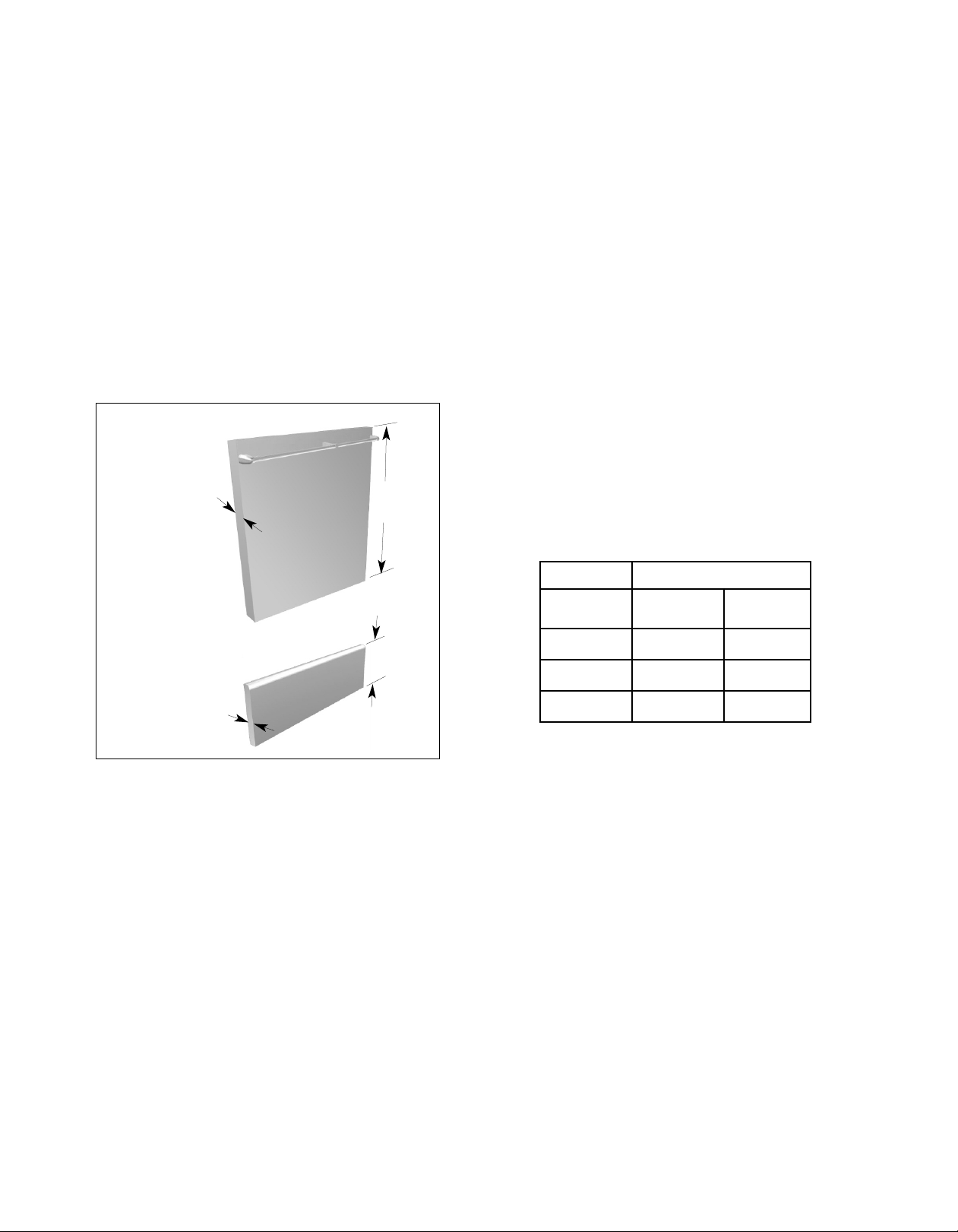

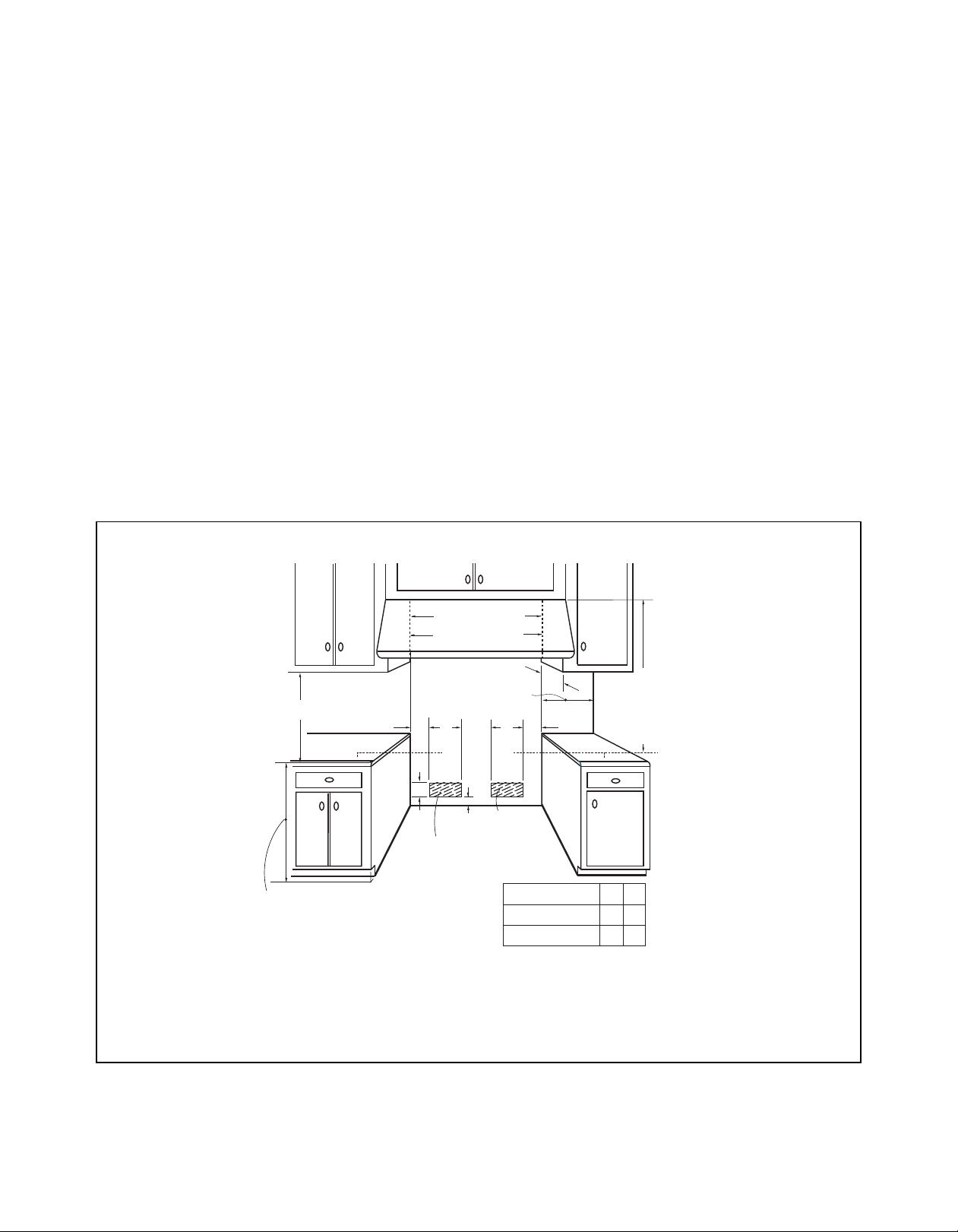

All range models with less than a 12” clearance between combustible material and the back edge of the range,

require the installation of one of the two offered Wall Mount Backguards – see page 17.

Wall Mount Full

Backguard

1-5/16”

28-1/8”

Model Number

Low

Backguard

Wall Mount

Low Backguard

1-5/16”

FIG. 1

Check local building c

connections, and grounding must comply with all applicable codes. In the absence of local codes, the range /

cooktop should be installed in accordance with the latest edition of National Fuel Gas Code ANSI Z223.1 and

National Electrical Code ANSI / NFPA 70.

Be sure that the unit being installed is set up for the kind of gas being used. The gas range is shipped from the

tory set and adjusted for Natural Gas or LP (propane), depending on the specific model ordered.

fac

the range is c

dealer if the unit is not set for site gas supply.

ompa

odes for the proper method of range installation. Local codes vary. Installation, electrical

tible with the gas a

10-1/8”

t the installa

tion site before proceeding further.

48” Range BGS-1248 BGS-3048

36” Range BGS-1236 BGS-3036

30” Range

All Ranges are shipped with a standard 2”

integral island trim.

BGS-1230 BGS-3030

Full

Backguard

erify that

V

ange t

n r

etur

R

o

8

Page 11

PLANNING THE INSTALLATION

RECOMMENDED INSTALLATION INSTRUCTION

Install components in the following order:

A. Vent Hood

B. Backguard System (sold separately)

. Range

C

1. Locate and level range according to range installation instructions.

2. Measure distance from floor to top of island trim on range, adding 1/8” for backguard clearance.

3. Transfer this measurement to the wall. This will mark the bottom of your backguard.

4. From this line measure 28” up wall to mark the top of a 30” backguard. This is the minimum height that the

bottom of your vent hood can be installed.

5. Follow vent hood manufacturer’s installation instructions to install vent hood.

6. Follow backguard installation instructions to install backguard.

7. Connect gas and electric connections and slide range into position.

NOTE:

A manual gas supply valve must be installed. See page 15.

UNPACKING AND HANDLING

CAUTION:

Proper equipment and adequate manpower must be used in moving the range to avoid damage to the unit or the

floor. The unit is heavy and rests on adjustable steel legs.

WARNING:

ange by the oven door handles or drip pan handle!!

t r

T lif

DO NO

WARNING:

DO NOT remove the grill or griddle assemblies!!

MOVING AND PLACING THE RANGE

The ranges have shipping weights varying from 420 lbs. to 630 lbs less approx. 50lbs. after removal of packing

material. It is recommended that the door(s), grates, and front kick panel be removed to facilitate handling. This

will reduce the weight for ease of handling.

It may be necessary to remove the oven doors and knobs to pass through some doorways. With the doors and

nobs removed, a 29-1/16” (RGT-36/48) 29-3/8” (RGT-305) wide opening is required. Without removing the door,

k

a 31-1/2” (RGT-36/48) or 30” (RGT-305) wide opening is required. Remove the outer carton and packing material

from the shipping base.

9

Page 12

UNPACKING AND HANDLING

Left Rear Shipping

Screws

22"

Leveling Legs

Range Must

be Uniformly

Supported

on Braces

Kick Panel

MOVING AND PLACING THE RANGE (cont.)

lectric and gas connections should be made before the

E

range is slid into the cabinet opening (see pages 14~18). If

installing a full backguard with the range, it should also be

installed before the range is placed in its final position (refer

to pages 8 & 17). For proper performance, the professional

range should be level. To achieve a flush fit of the range to

adjoining countertops, it will be necessary to have level

cabinets (front to back, and left to right across opening of the

range). After checking the countertops for level and before

sliding the range into place, measure the distance from the

floor to the top of the counter work surface in the rear left

and right corners. Adjust the corresponding rear corner of the

range to an equal height of the counter, as the rear leveling

legs are not accessible once the range is pushed into place.

Once the range is in place, the front leg levelers can be

accessed to level the front of the range. Replace the kick

panel and oven doors by reversing the procedure described

previously. It is important that the two screws retaining the

kick panel are secure to prevent accidental access to live

electrical components and wires (fig. 2).

Kick Panel

Fig. 2

eft Rear

L

hipping Screws

S

Anti-tip device should be installed (see page 13 for

instructions). The professional range should be transported by

a dolly close to its final location. The range can be tipped

back and supported on the rear legs while the dolly is

removed. The floor under the legs should be protected (wood

strips, carpet, paneling, etc.) before pushing the unit back into

position.

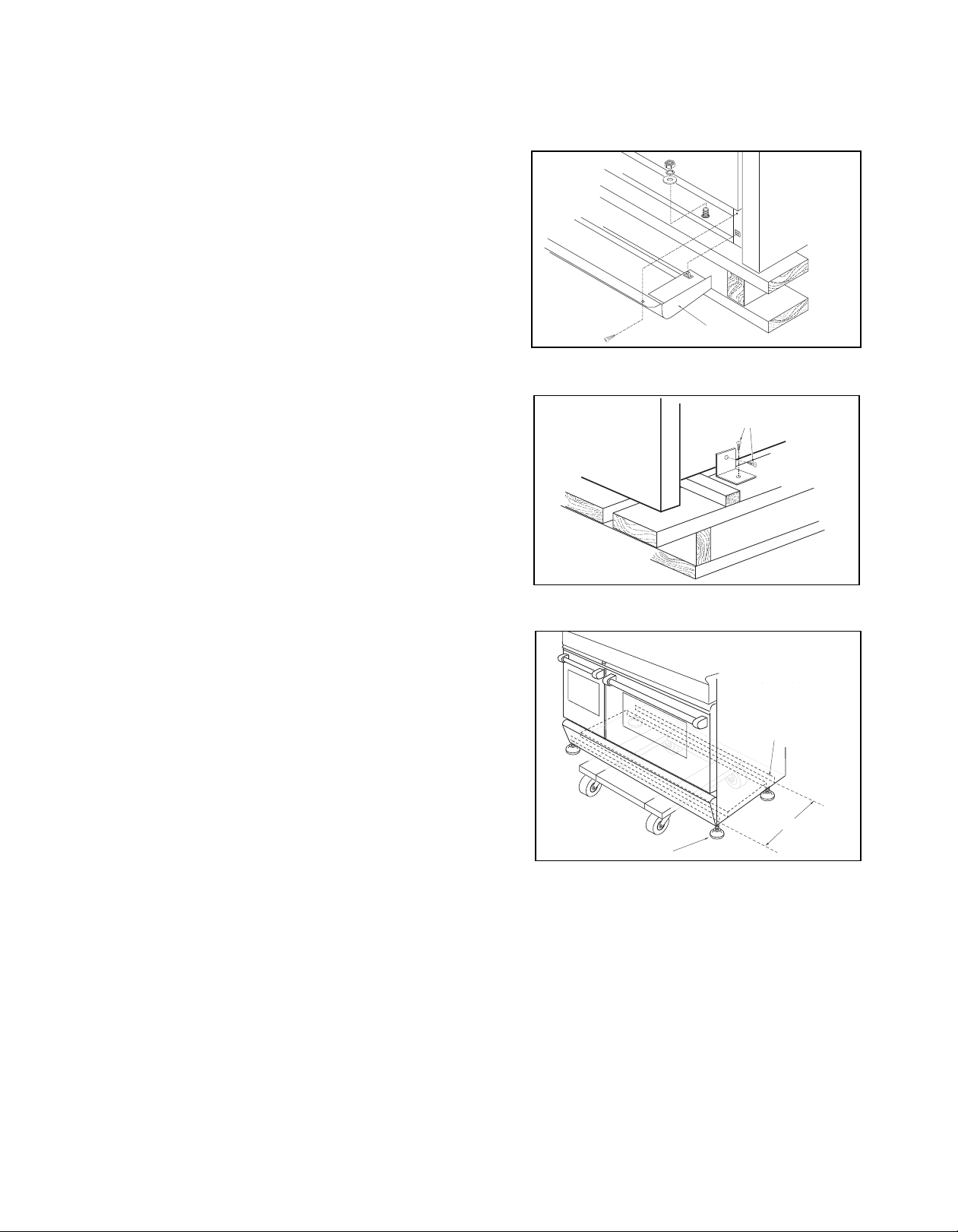

To remove the kick panel:

Removing two screws at the top and pulling forward. The

ange is held t

r

o the skid by two bolts in the front, behind the

kick panel, (fig. 2) and two L-brackets located on the bottom

flange of the range back (fig. 3). After removing the bolts and

brackets, the range must be lifted and removed from the skid.

Due to the weight, a dolly with soft wheels should be used to

move this unit. The weight must be supported uniformly

oss the bottom (fig. 4).

acr

Leveling Legs

Fig. 3

ig

F

Range Must be

Uniformly

Supported on

Braces

. 4

10

Page 13

UNPACKING AND HANDLING

To remove door:

WARNING!

Do not lift oven door by the handle - this will cause damage! Be sure

the oven and door are cool before you begin to remove the door!

1. Open the door all the way open (Fig. 5a).

2. Unlock the door hinges by rotating the lock forward (Fig. 5b).

3. Once both hinges are unlocked, gently close the door until

approximately halfway closed. Grabbing the sides of the door

and gently lifting up and slightly forward, the door will unlatch

from the hinge.

4. Continue to lift and pull the door away from the range.

To re-install door:

1. Position the door in approximately halfway open position.

2. Simply place the hinge tongue into the hinge slots (See Fig. 6a).

3. Push the door into the slots until you feel them fall into the

latches.

4. Open the door completely and rotate the locks into the closed

position (Fig. 6b).

5. Close the oven door.

Fig. 5a Oven hinge assembly

Fig. 5b Hinge retainer clip in unlocked position

hinge t

ongue

hinge t

ongue

hinge slot

hinge slot

Fig. 6a Hinge assembly

GRIDDLE AND GRILL LEVEL ADJUSTMENTS

The grill and griddle sections (if equipped) are fastened

in place at the front with screws. They are designed to

be stationary and not meant to be removed for cleaning.

The griddle has two leveling screws beneath the rear flue

over which can be used to adjust the griddle to the

c

desired slope. To access the leveling adjustment screws,

remove the griddle flue cover by lifting upwards. The

center screw is for shipping and should be removed

(Fig. 7).

ig. 6b Hinge retainer clip in locked position

F

iddle F

Gr

Cover

Shipping Screw

lue

ig

F

e)

v

emo

(r

Outer Leveling

Screws (2)

. 7

11

Page 14

VENTILATION REQUIREMENTS

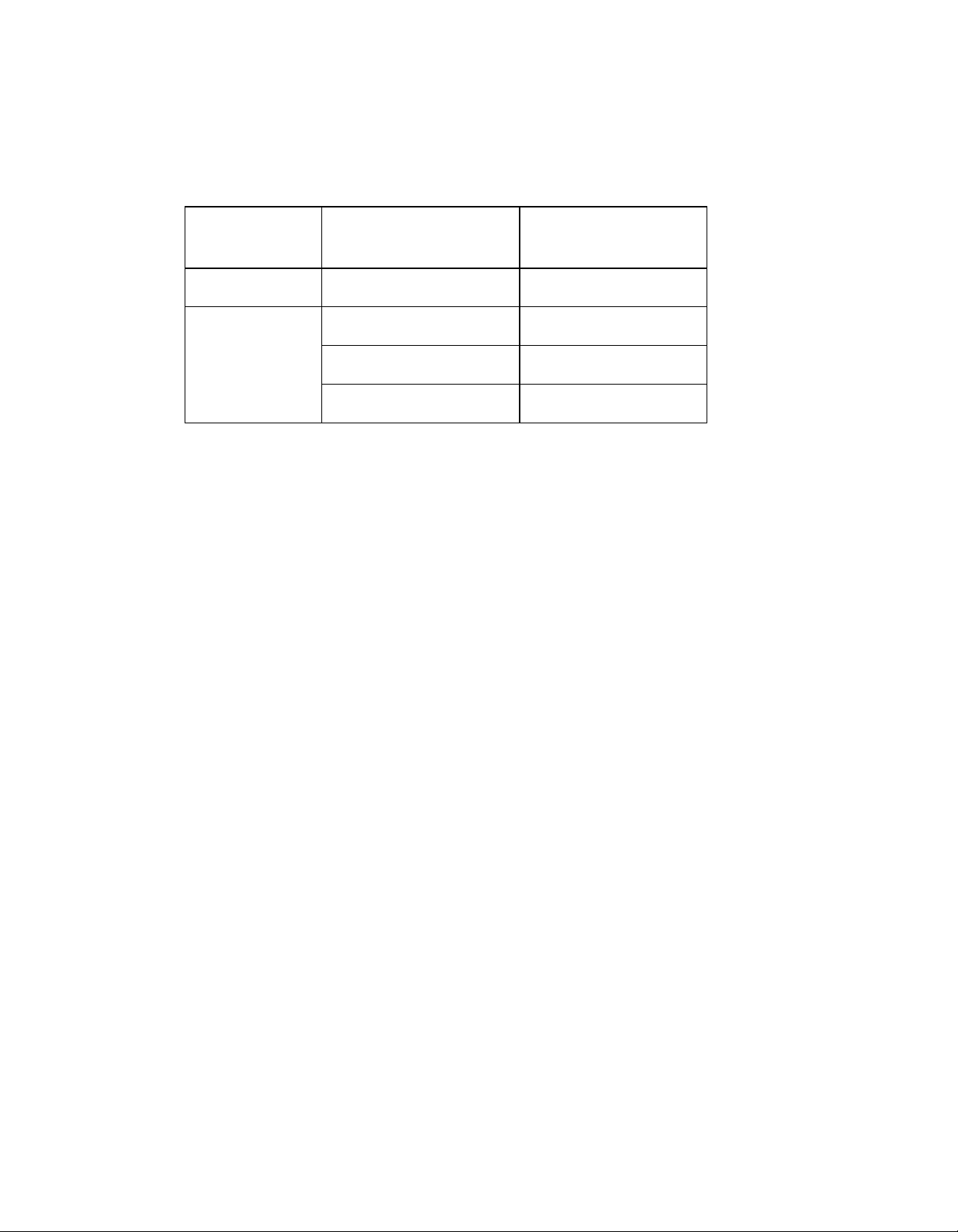

A suitable exhaust hood must be installed above the range. The following chart indicates the minimum blower

capacity recommended for hood ventilation.

Standard Counter

Ventilation Unit

Installation

Recommendatons

HOOD 24" Deep x Unit Width 30" Deep x 36" at Bottom

48” Range

1200 CFM

BLOWER

* When installing a unit featuring a grill, GL models, requires a 1200 CFM ventilation unit

*36” Range

600-1200 CFM

30” Range

600 CF

M

Island Installation

Recommendatons

1200 CFM

600-1200 CFM

600 CFM

CAUTION:

Ventilation hoods and blowers are designed for use with single wall ducting. However, some local building codes or

inspectors may require double wall ducting and/or damper. Consult local building codes and/or local agencies,

before starting, to ensure that hood and duct installation will meet local requirements.

Hood blower speeds should be variable to reduce noise and loss of heated or air conditioned household air

when maximum ventilation is not required. Normally, the maximum blower speed is only required when using

the grill.

For best smoke elimination, the lower edge of the hood should be installed a minimum of 30" to a maximum of

36" above the range cooking surface, (page 14 & 15). If the hood contains any combustible materials (i.e. a

wood covering) it must be a minimum of 36" above the cooking surface.

Due to a high volume of ventilation air, a source of make-up air (outside replacement air) is recommended. This

is particularly important for tightly sealed and insulated homes. A reputable heating and ventilating contractor

should be consulted.

12

Page 15

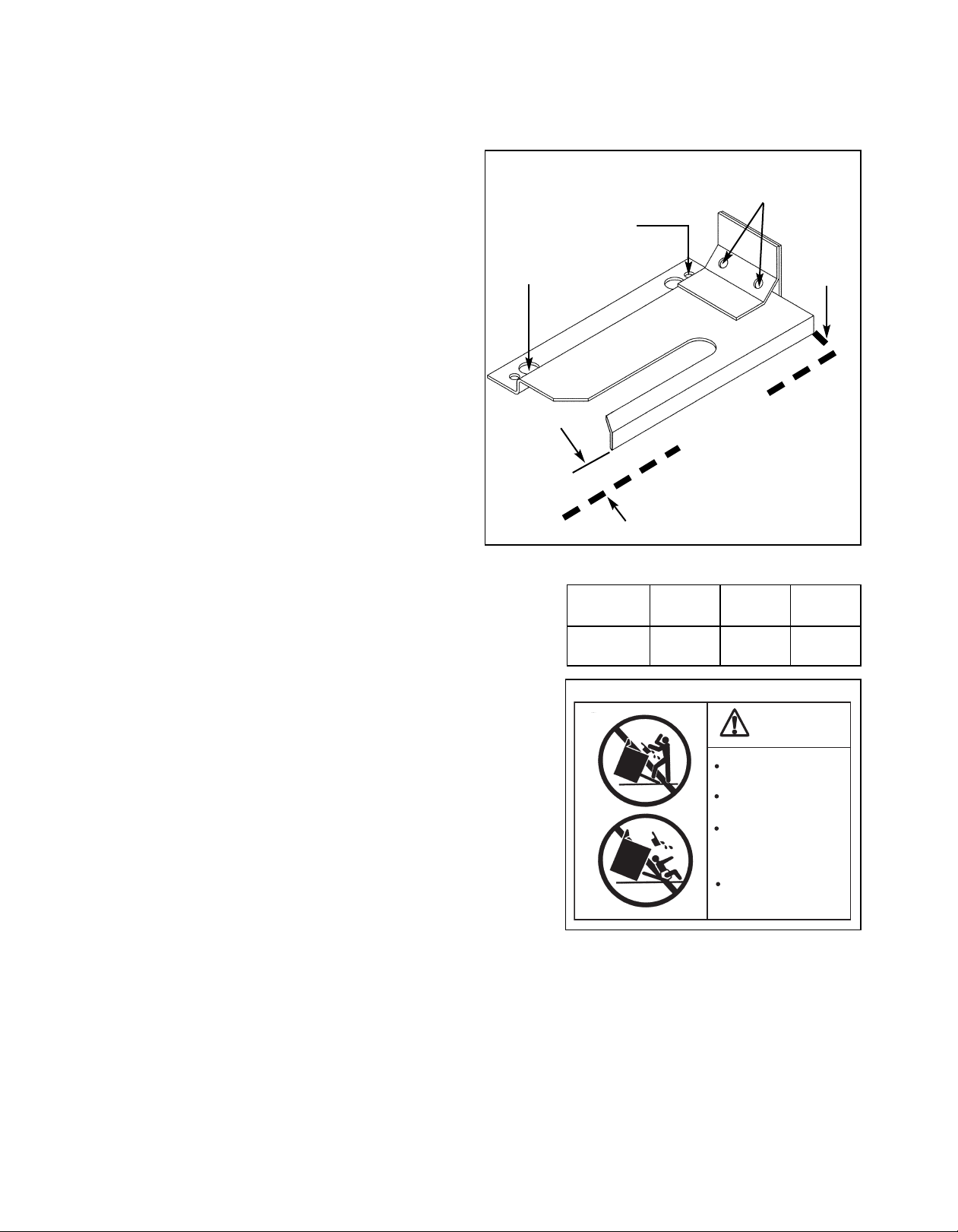

INSTALLING ANTI-TIP DEVICE

WARNING

ALL RANGES CAN TIP

INJURY COULD RESULT

INSTALL ANTI-TIP

BRACKET PACKED

INSIDE OVEN

SEE INSTRUCTIONS

All ranges must have an anti-tip device correctly

installed as per the following instructions. If you pull

the range out from the wall for any reason, make sure

hat the device is properly engaged when you push

t

(2) Small Holes for Wood

the range back against the wall. If it is not, there is a

ossible risk of the range tipping over and causing

p

injury if you or a child stand, sit or lean on an open

(2) Large Holes for Concrete

oven door.

INCLUDED PARTS:

(4) #10 x 2” wood screws,

(1) Anti-tip bracket, and (1) Installation Instructions.

INSTALLING THE KIT:

Instructions are provided for wood and cement floors.

Any other type of construction may require special

installation techniques as deemed necessary to

provide adequate fastening of the Anti-tip bracket to

the floor and wall. The use of this bracket does not

preclude tipping of the range when not properly

installed.

WOOD CONSTRUCTION:

Place the bracket against the back wall, into the right

rear corner where the range is to be located. Leave a

gap between the wall (or side of range) and the bracket

(see fig. 8). Drill (2) 1/8” diameter pilot holes in the center of the

small holes. A nail or awl may be used if a drill is not available.

Fasten the bracket securely to the floor and wall.

Installations

Installations

A

Model

Series

A

(2) Wood Screws into Back

Wall (ALL Installations)

RIGHT SIDE OF

WALL OR RANGE

Fig. 8

-48 RGT

RGT

1/2” 5/8” 7/8”

-36 RGT

BACK

WALL

-305

CONCRETE OR CEMENT CONSTRUCTION:

Hardware Required:

(2) sleeve anchors, lag bolts, and washers (not provided).

Locate the bracket as described above. Drill the recommended

size holes for the hardware. Install the sleeve anchors into the

holes and then install the lag bolts through the bracket. The

bolts must be pr

operly tightened as recommended for the

hardware. Fasten the bracket securely to the floor and wall.

ONCE INSTALLED:

Complete the range installation per the instructions provided

with the produc

ti-tip devic

An

t. Check f

y g

e b

attempt to tilt the range forward.

or proper installation of the range and

asping the back of the unit and car

r

efully

. 9

ig

F

13

Page 16

CABINET PREPARATION

min. 36" wide hood

CAUTION:

36" min. to

combustible

material #,

from cooking

surface

electrical

supply

gas supply

35-3/8" max. for level counter,

36-3/4" max. with range

leveling legs fully extended

12" min. to combustible

material #, each side

cooking surface

12"

B

A

A

min. 48" wide hood

3-1/4 "

3-1/2 "

18" Min.

13 "

Max

#

Asdefined in the “National Fuel Gas Code”

ANSI Z223.1, lastest edition).

The horizontal surfaces of the range top (cooktop)

trim must not be below countertop level.

Models

RGT-48

RGT-36

A B

8" 16"

4" 12"

. The range is a free standing unit. If the unit is to be placed adjacent to cabinets, the clearances shown in fig. 10

1

(RGT-36 & 48) & fig. 11 (RGT-305) are required. The same clearances apply to island installations.

2. The range can be placed in various positions with respect to the cabinet front, with the front frame either flush

or projecting, depending on the countertop depth.

3. The gas and electrical supply should be within the zones shown figures 10 & 11.

4. The maximum depth of over head cabinets installed on either side of the hood is 13”.

5. Any openings in the wall behind the range and in the floor under the range must be sealed.

6. When there is less than a 12” clearance between combustible material and the back edge of the range, (above

the cooking surface) a DCS Low backguard or Full backguard must be installed (fig. 13, standard installation).

When clearance to combustible material is over 12” no backguard is necessary (fig. 13, island installation). These

parts must be ordered separately (page 8). Fig. 13 indicates the space required for each type of backguard.

7. Always keep the appliance area clear and free from combustible materials, gasoline and other flammable vapors

and liquids.

8. Do not obstruct the flow of combustion and ventilation air to the unit.

14

. 10 RGT 48”

ig

F

& 36” Models Only

Page 17

CABINET PREPARATION

CAUTION:

36" min. to

combustible

material #,

from cooking

surface

35-3/8" max. for level counter,

36-3/4" max. with range

leveling legs fullyextended

1

2" min. to combustible

material #, each side

cooking surface

min. 30" wide hood

18" Min.

13"

Max

#

As defi ned inthe “National Fuel Gas Code”

(ANSI Z223.1, lastestedition).

The horizontal surfaces ofthe range top (cooktop)

trim must not bebelow countertop level.

B

A

4

"

electrical and

gas supply

Model

RGT-305

A B

2" 16"

2" Maximum

Protrusion from Wall

for Gas Supply

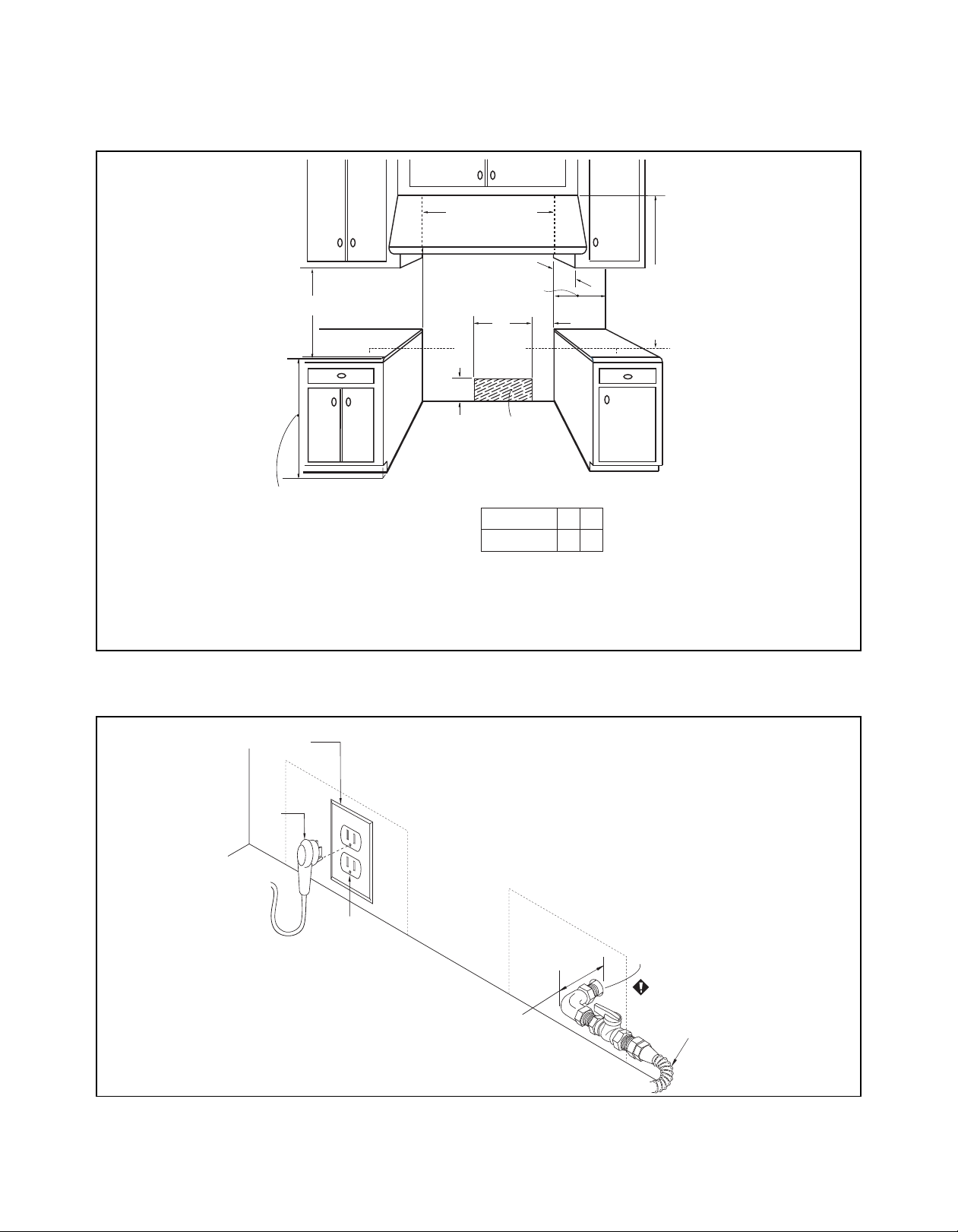

Gas Supply

Flex Line to Range

Manual Shut-Off

Valve must be

Easily Accessible

Receptacle Box

Cover Plate

Three Prong

Receptacle

Three

Prong

Plug

Fig. 11 RGT-305 Model Only

Fig. 12 All RGT Models

15

Page 18

0” Clearance

C

J

I

0” Clearance

B

A

F

C

H

E

D

G

36" Min. to

Combustibles #

12" Min. to

Combustibles #

without backguard

#

As defined in the “National Fuel Gas Code”

(ANSI Z223.1, Latest Edition).

The horizontal surfaces of the range top

(cooktop) trim must not be below

countertop level.

CABINET PREPARATION

K

K

K

Standard Installation:

Island Installation:

M

RGT-48 Models

-36 M

RGT

RGT-305 Models

16

odels

odels

-48 models

RGT

ABC D E F G H I J K

28-1/8” 10-1/8” 2” 35-3/4” min.–37”max. 30-1/4” 44-1/2” 28-1/4” 1-5/16” 25” 27-3/8” 47-7/8”

28-1/8” 10-1/8” 2” 35-3/4”

28-1/8” 10-1/8” 2” 35-3/4” min.–37”max. 30” 44” 27-1/2” 1-5/16” 24-1/4” 26-3/4” 29-7/8”

. 13 RGT 48”

ig

F

RGT

min.–37”

, 36”

odels

-36 M

max.

30-1/4 ” 44-1/2 ” 28-1/4 ” 1-5/16” 25” 27-3/8 ” 35-7/8”

nstallation Clearance

and 305 M

odels I

RGT

-305 M

odel

Page 19

Receptacle Box

Cover Plate

Three Prong

Receptacle

Three

Prong

Plug

BACKGUARD INSTALLATION

28-1/8"

10-1/8"

2"

1-5/16"

he backguard is located as shown in Fig. 14. Secure

T

the backguard to the wall behind the range. Specific

instructions for installation of the full backguard or low

backguard can be found packaged with the backguard.

See also page 8, “Planning The Installation” section. A

ackguard must be installed when there is less than a

b

12” clearance between combustibles and the back of

the range (above the cooking surface). See fig. 13.

DCS backguards are sold separately.

all Mount

W

Full Backguard

Model #’s BGS-3030,

(

GS-3036, BGS-3048)

B

Wall Mount

Low Backguard

(Model #’s BGS-1230,

GS-1236, BGS-1248)

B

Fig. 14

ELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

Power Requirements Range:

■

120 VAC, 60 Hz., single phase

■

RGT-305: 4 Amp. Max.

■

RGT-36: 7 Amp. Max.

■

RGT-48: 13 Amp. Max.

Always disconnect electric supply cord from the wall outlet or service

disc

onnec

t before servicing this appliance. Observe all governing codes

and ordinances when grounding, in absence of which, observe National

Electrical Code ANSI / NFPA No. 70.

RECOMMENDED GROUNDING METHOD

his applianc

T

-pr

ee

thr

plugged into a mating grounding, type receptacle, connected to a

orrectly polarized 120 volt circuit. If the circuit does not have a grounding type receptacle, it is the responsi-

c

y and obliga

bilit

polarized receptacle in accordance with all applicable local codes and ordinances by a qualified electrician. In

the absenc

trical Code

Elec

e is factory equipped with a power supply cord with a

ounding plug (with polarized parallel blades). It must be

r

ong g

tion of the installer t

e of local codes and ordinances, the receptacle replacement shall be in accordance with the National

.

use 15 Amp. circuit

}

e the existing receptacle changed to a properly grounded and

v

o ha

. 15

ig

F

Note:

The third prong should not, under ANY circumstances, be cut or removed.

17

Page 20

Metal Flex Gas Line

Hard Pipe

1/2" NPT

Manual Shut-Off

Valve must be

Easily Accessible

WALL

Hard Pipe

Connection

GAS HOOK-UP

GAS REQUIREMENTS

Verify the type of gas supplied to the location. The range is shipped from the factory set up and adjusted for

Natural Gas or LP (propane), depending on the specific model ordered.

gas supply at the installation site before proceeding further.

Return the range to the dealer if the unit is not set

for the gas supplied at the site.

NATURAL GAS

■ Connection: 1/2” NPT Minimum 5/8” dia. flex line. ■ Supply Pressure: 6” to 9” W.C.

LP GAS

■ Connection: 1/2” NPT Minimum 5/8 dia. flex line. ■ Supply Pressure: 11” to 14”W.C.

A regulator is required at the LP source to provide a maximum of 14” W.C. to the range regulator.

HOOK-UP TO GAS SUPPLY

A manual valve must be installed external to the appliance, in an accessible location from the front for the

purpose of shutting off the gas supply. The supply line must not protrude beyond the back of the unit. Make

sure the gas supply is turned off at the wall valve before connecting the appliance.

The gas supply connections should be made by a qualified technician and in accordance with local codes or

ordinances. In the absence of a local code, the installation must conform to the National Fuel Gas Code ANSI

Z223.1, latest edition.

Verify that the range is compatible with

CAUTION:

The appliance must be isolated from the building’s gas supply piping system by closing its individual manual shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psig

(3.5kPa.). The appliance and its individual shut-off valve must be disconnec

during any pressure testing of the sy

stem at the test pressures in excess of 1/2 psig (3.5kPa.). When checking the

manifold gas pressure, the inlet pressure to the regulator should be at least 7.0”W.C. for natural gas or 12.0”for LP.

NOTE:

The flex line for the gas supply must be metal and be

approved by an approved certifying agency (AGA, CGA, or

UL). Never use a hose made of rubber or other synthetic

material, as the heat may cause the hose to melt and

develop leaks.

hen hook

W

pipe to wall hard pipe, installation length of flex line

between range/wall hard piping must accommodate

ange being pulled from wall for cleaning or servicing

r

purposes. When range is pulled from wall, no strain

should occur at range or wall hard pipe connections

. 16).

(fig

ing up the gas supply from range rear hard

ted from the gas supply piping system

18

ig. 16

F

Page 21

TEST AND ADJUSTMENTS

1-1/2"

WARNING :

F

or warranty coverage, DCS requires that burner adjustments be made by a

qualified technician at the time of installation. Extreme care should be used

when adjustments are made after installation. IMPROPER OR LACK OF

ADJUSTMENT WILL VOID YOUR WARRANTY.

COOKTOP BURNERS

The cooktop burners are not adjustable. Proper operation is achieved when

the correct orifices for gas supply are installed at the factory, based on

model ordered.

When installing the burner port ring, be sure that the two locating pins in

the bottom side of the brass port ring are properly aligned with the locating

notch and center holes on the top side of the simmer ring. Incorrect

alignment will produce a potentially dangerous flame and poor burner

formance.

per

Note:

No air shutter adjustment is possible on the cooktop burners. Burner flames

should be blue and stable with no yellow-tipping (some yellow-tipping is normal

with LP gas), excessive noise, or lifting of flame from the burner (Fig. 17).

COOKTOP BURNER LIGHTING NOTE

The cooktop burners have an infinite number of heat settings and there are no fixed positions on the control

knobs between HI and LO. To turn the cooktop burner on, push in on the control knob and turn it counterclockwise to the “LITE” position. An audible clicking sound will be heard. When the gas has been ignited by the

electronic spark igniter, turn the knob to the desired setting (Fig. 18).

COOKTOP BURNER

SIM

LO

FIG. 17

FF

O

FIG. 18

LITE

HI

Note:

The igniter will continue to click until a flame is present. If the cooktop burner does not ignite, check the spark igniter by

listening for a clicking sound. If you do not hear the igniter click, turn off the burner. Check for a tripped circuit breaker,

blown fuse, or poor wire connection to the igniter.

WARNING:

When turning on any cooktop burner, be sure to stop at the “LITE” position before turning the burner to a flame

setting f

will be a burst of flame when the burner does ligh

countertop.

or cooking. If the burner is not lit and it is turned beyond the “LITE” position, to HI, MEDIUM, or LO, there

ould cause burns or damage to the surrounding

his c

T

.

t

19

Page 22

TEST AND ADJUSTMENTS

1-1/2" ~ 2"

Typical Section of Proper Flame

3/8" ~ 5/8"

(Grill)

(Griddle)

THIS ADJUSTMENT SECTION APPLIES TO THE GRIDDLE,

GRILL AND OVEN BURNERS.

Check for the proper burner flame characteristics and adjust air shutters

if necessary (fig. 19). Each valve and air shutter is individually tested and

djusted prior to shipment. Normally adjustment is not required,

a

however, vibration during transit, gas conversion or variations in the

local gas supply may make minor adjustments necessary. Burner flames

should be blue and stable with no yellow tips, excessive noise or lifting

of the flame from the burner. If any of these conditions exist, check that

the air shutter or burner ports are not blocked. If this condition persists,

adjust the air shutter as required. If the flame is too yellow, indicating

insufficient air, adjust the shutter counterclockwise to increase air inlet.

If the flame is noisy or tends to lift away from the burner, indicating too

much air, turn the shutter clockwise to reduce air. The griddle and oven

flames should be 1-1/2" to 2". The grill burner flames should be 3/8” to

5/8” (fig. 20).

INFRARED BROIL BURNER

CAUTION:

The oven infrared broiler burner has no air shutter and is not

adjustable. The oven bake burner has an air shutter and is

adjustable . It is necessary to operate the oven broiler for 20~30

minutes to eliminate the harsh odor of the insulation binder.

This must be done before using the range for the first time and

with proper ventilation.

Fig. 19

Typical Section of Proper Flame

Griddle and oven

-1/2” – 2”

1

Fig. 20

INFRARED BROIL BURNER

air shutter

Grill

/8” – 5/8”

3

The infrared broil burner flames should be approximately 1/8”

high over the entire burner screen (Fig. 21).

CLEANING EXTERIOR SURFACES

The stainless steel surfaces may be cleaned by wiping with a damp soapy cloth or sponge. Any liquid soap (like

Dawn or Stainless Steel Magic) will remove fingerprints and smears. Do not use steel wool as it will scratch this

.

e

fac

sur

BLUE FLAME

Fig. 21

20

Page 23

INSTALLER FINAL CHECKLIST

GENERAL

lacement of unit.

❑

P

❑

Specified clearance maintained to cabinet surfaces.

❑

Unit Level - front to back, side to side.

❑

All packaging material and tie straps removed, drip pans clean and empty.

❑

Backguard attached if there is less than 12" clearance above the cooking surface to combustibles behind unit.

❑

Radiant tray placed in grill unit (if equipped). The two grill racks in place.

ELECTRICAL

❑

Receptacle with 15 ampere over-current protection is provided for service cord connection.

❑

Adequate ground connection.

❑

Front kick panel in place and two (2) screws secure.

GAS SUPPLY

❑

Connection: 1/2 NPT with a minimum 5/8" diameter flex line. Site gas supply is compatible with range model,

and sufficient pressure is available (see gas requirements pg. 18).

❑

The pressure regulator which is connected to the manifold is set for 5.0” W.C. for natural gas or 10.0” W.C. for LP.

❑

Manual gas shut-off valve installed in an accessible location.

❑

Unit tested and free of gas leaks.

OPERATION

❑

All internal packing materials removed. Check below grate, pans and drip drawers.

❑

If used on LP gas, verify that pressure regulator, orifice hoods, air shutters, and valve jets have been set for use

with LP gas.

ill compartment seated and does not rock (if equipped).

❑

Gr

els centered on burner knobs and knobs turn freely.

ez

❑

B

❑

Each burner lights satisfactorily, both individually and with other burners operating at the same time.

❑

Flame adjustment for 3/8” soft blue cone made on ports of each top burner, low flame adjustment verified.

lame adjustment made on air shutter of each oven, griddle, or grill burner.

❑

F

❑

Griddle is level and does not rock (if equipped).

ays are properly in place and pull out freely (if equipped).

ip tr

❑

Dr

en door hinges seated and door opens and closes properly.

v

❑

O

❑

Burner grates correctly positioned, level, and do not rock.

❑

Griddle flame (see page 20).

ill flame (see page 20).

❑

Gr

❑

Cooktop burner flame (see page 19).

21

Page 24

HOW TO OBTAIN SERVICE

For warranty service, please contact DCS Customer Care Representative at (888) 936-7872. Before you call,

please have the following information ready:

■

Model Number (located on the label above the kick panel on the right)

■

Serial Number (located on the label above the kick panel on the right)

ate of installation

■

D

■

A brief description of the problem

Your satisfaction is of the utmost importance to us. If a problem cannot be resolved to your satisfaction, please

write to Customer Care or email:

rite:

W

Fisher & Paykel Appliances, Inc.

Attention: DCS Customer Care

5900 Skylab Road

Huntington Beach, CA 92647

BEFORE YOU CALL FOR SERVICE:

customer.care@fisherpaykel.com

1. Is the circuit breaker tripped or the fuse blown?

2. Is there a power outage in the area?

22

Page 25

WARRANTY

LIMITED WARRANTY

When you purchase a new DCS Range you automatically receive a One Year Limited Warranty covering parts and

abor for the entire product, a Five Year Limited Warranty on surface burners, griddle burners, grill burner and

l

oven burners (parts only), and a Two Year Limited Warranty on the porcelain oven liner and porcelain inner door

panel (parts only) for servicing within the 48 mainland United States, Hawaii, Washington D.C. and Canada. In

Alaska the Limited Warranty is the same except that you must pay to ship the Product to the service shop or the

service technician’s travel to your home. Products for use in Canada must be purchased through the Canadian

distribution channel to ensure regulatory compliance.

FISHER & PAYKEL UNDERTAKES TO:

Repair without cost to the owner either for material or labor any part of the Product, the serial number of which

appears on the Product, which is found to be defective. In Alaska, you must pay to ship the Product to the

service shop or for the service technician’s travel to your home.

If we are unable to repair a defective part of the Product after a reasonable number of attempts, at our option

we may replace the part or the Product, or we may provide you a full refund of the purchase price of the Product

(not including installation or other charges).

This warranty extends to the original purchaser and any succeeding owner of the Product for products purchased

for ordinary single-family home use. All service under this Limited Warranty shall be provided by Fisher & Paykel

Appliances, Inc. or its Authorized DCS Service Agent during normal business hours.

HOW LONG DOES THIS LIMITED WARRANTY LAST?

Our liability under this Limited Warranty for the entire product expires One Year from the date of purchase of the

Product by the first consumer. Our liability under this Limited Warranty for surface burners, griddle burners, grill

burner and oven burners (parts only) expires Five Years from the date of the purchase of the Product by the first

customer. Our liability under this Limited Warranty for the porcelain oven liner and porcelain inner door panel

(parts only) expires Two Years from the date of the purchase of the Product by the first customer.

Our liability under any implied warranties, including the implied warranty of merchantability (an unwritten

warranty that the Product is fit for ordinary use) also expires One Year (or such longer period as required by

applicable law) from the date of purchase of the Product by the first consumer. Some states do not allow

limitations on ho

w long an implied warranty lasts, so this limit on implied warranties may not apply to you.

THIS WARRANTY DOES NOT COVER:

A. Service calls that are not related to any defect in the Product. The cost of a service call will be charged if the

problem is not found to be a defect of the Product. For example:

1. Correct faulty installation of the Product.

2. Instruct you how to use the Product.

3. Replace house fuses, reset circuit breakers, correct house wiring or plumbing, or replace light bulbs.

4. Correct fault(s) caused by the user.

5. Change the set-up of the Product.

6. Unauthorized modifications of the Product.

7. Noise or vibration that is considered normal, for example, drain/fan sounds, regeneration noises or user

warning beeps.

8. Correcting damage caused by pests, for example, rats, cockroaches etc.

23

Page 26

WARRANTY

B. Defects caused by factors other than:

. Normal domestic use or

1

2. Use in accordance with the Product’s Use & Care Guide.

C. Defects to the Product caused by accident, neglect, misuse, fire, flood or Act of God.

D. The cost of repairs carried out by non-authorized repairers or the cost of correcting such unauthorized repairs.

E. Travel Fees and associated charges incurred when the product is installed in a location with limited or restricted

access. (i.e. airplane flights, ferry charges, isolated geographic areas).

F. Normal recommended maintenance as set forth in the Product’s Use & Care Guide.

If you have an installation problem contact your dealer or installer. You are responsible for providing adequate

electrical, exhausting and other connection facilities.

We are not responsible for consequential or incidental damages (the cost of repairing or replacing other

property damaged if the Product is defective or any of your expenses caused if the Product is defective). Some

states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

HOW TO GET SERVICE

Please read your Use & Care Guide. If you then have any questions about operating the Product, need the name

of your local DCS Authorized Service Agent, or believe the Product is defective and wish service under this

Limited Warranty, please contact your dealer or call us at:

TOLL FREE 1-888-936-7872 or contact us through our web site: www.dcsappliances.com

You may be required to provide reasonable proof of the date of purchase of the Product before the Product will

be serviced under this Limited Warranty.

COMMERCIAL USE

This warranty applies to appliances used in residential applications; it does not cover their use in commercial

situations.

NO OTHER WARRANTIES

This Limited Warranty is the complete and exclusive agreement between you and Fisher & Paykel Appliances Inc.

egarding any defect in the Product. None of our employees (or our Authorized Service Agents) are authorized to

r

make any addition or modification to this Limited Warranty.

Warrantor: Fisher & Paykel Appliances, Inc.

If you need further help concerning this Limited Warranty, please call us at the above number, or write to:

Fisher & Paykel Appliances, Inc.

5900 Skylab Road, Huntington Beach, CA 92647

his Limited Warranty gives you specific legal rights, and you may also have other rights which vary from state to

T

state.

isher & P

F

under the F

aykel Appliances Inc. is a leading manufacturer of premium quality cooking and specialty appliances

isher & Pa

ykel and DCS brands

.

24

Page 27

LA CUISINIÈRE À GAZ PROFESSIONNELLE RGT

Guide d'installation

MODÈLES :

RGT-305

RGT-366

RGT-364GL

RGT-364GD

RGT-484GG

-486GL

RGT

RGT-486GD

RGT-485GD

Page 28

À L'INTENTION DE NOS CLIENTS

Nous vous remercions d'avoir choisi cette cuisinière à gaz professionnelle DCS. Nous avons conçu ce Manuel

d'installation pour expliquer ses fonctions uniques. Il contient des informations extrêmement utiles sur la façon

d'installer correctement votre nouvel appareil. Vous pourrez ainsi en profiter pendant des années en toute

écurité.

s

Si vous avez des questions au sujet de notre produit, communiquez avec un représentant du centre de service à

la clientèle DCS par téléphone :1-888-936-7872, ou par courriel :

REMARQUE : Veuillez noter les numéros de modèle et de série sur cette page pour information (situé sur la

plaque signalétique, sur le panneau arrière et également sur le cadre avant, coin inférieur droit entre le panneau

de seuil de porte et la porte du four).

NUMÉRO DE MODÈLE NUMÉRO DE SÉRIE

REMARQUE : Inspecter le produit pour vérifier qu’il n’a pas été endommagé pendant l’expédition. En cas de

dommages, contacter le transporteur et entamer une déclaration pour dommage. DCS by Fisher & Paykel n’est en

aucun cas responsable des dommages pendant l’expédition.

Ne pas jeter le matériau d’emballage (boîte, palette, sangles) avant d’avoir inspecté l’unité.

AVERTISSEMENT!

Toute installation, ajustement, altération ou entretien incorrect peut causer des dommages matériels, des blessures

ou la mort. Veuillez lire soigneusement ces instructions d'installation, d'utilisation et d'entretien avant d'installer,

utiliser ou effectuer l'entretien de cet appareil.

customer.care@fisherpaykel.com

.

AVERTISSEMENT!

Si les informations de ce manuel ne sont pas suivies à la lettre, un incendie ou une explosion peuvent se produire et

causer des dommages matériels, des blessures ou la mort.

Évitez de stocker ou d'utiliser de l'essence ou tout autre liquide et vapeur inflammable à proximité de cet appareil

oménager ou de tout autre.

électr

DANGER

Si vous sentez une odeur de gaz :

essayez pas d'allumer aucun appareil électroménager.

N'

1.

2. Ne touchez aucun interrupteur électrique; n'utilisez aucun téléphone dans l'édifice.

3. Appelez immédiatement votre fournisseur de gaz de chez un voisin. Suivez les instructions du fournisseur

de gaz.

4. Si vous n'arrivez pas à joindre votre fournisseur de gaz, appelez les pompiers.

5. Toute installation ou service doit être confié à un installateur qualifié, un organisme de service ou le

nisseur de gaz.

our

f

AVERTISSEMENT!

Pour réduire les risques de blessures en cas de feu de graisse sur la table de cuisson, respectez les consignes

suivantes : Éteignez d'abord le brûleur. Étouffez les flammes à l'aide d'un couvercle hermétique, d'une plaque à

biscuits d'un plateau métallique, de bicarbonate de soude ou à l'aide d'un extincteur à poudre ou à mousse.

Attention à ne pas vous brûler. Si les flammes ne s'éteignent pas immédiatement, évacuez les lieux et appelez les

pompiers. Ne prenez jamais en main une poêle ou une casserole qui a pris feu; vous pourriez vous brûler. N'UTILISEZ

PAS D'EAU SUR UN FEU DE GRAISSE, y compris des serviettes mouillées; une explosion de vapeur violente pourrait

en résulter. Utilisez un extincteur SEULEMENT si :

1. Vous êtes sûr qu'il s'agit d'un extincteur de classe ABC et savez comment le faire fonctionner.

2. L'incendie est limité et se limite à l'endroit où il s'est déclenché.

3. Vous êtes en train d'avertir les pompiers.

4. Vous pouvez combattre l'incendie le dos tourné vers une sortie.

VEUILLEZ CONSERVER CE MANUEL À TITRE DE RÉFÉRENCE.

1

Page 29

TABLE DES MATIÈRES

INTRODUCTION 3

MESURES DE SÉCURITÉ ET DE PRÉCAUTION 4-6

MODÈLES 7

PLANIFICATION DE L'INSTALLATION 8-9

DÉBALLAGE ET MANIPULATION 9-11

EXIGENCES EN MATIÈRE DE VENTILATION 12

INSTALLATION DU DISPOSITIF ANTIBASCULEMENT 13

PRÉPARATION DES ARMOIRES 14-16

INSTALLATION DU DOSSERET 17

CONNEXIONS ÉLECTRIQUES 17-18

BRANCHEMENT DU GAZ 18-19

ESSAI ET RÉGLAGES 19-21

NETTOYAGE DES SURFACES EXTÉRIEURES 21

LISTE DE CONTRÔLE FINALE DE L'INSTALLATEUR 22

POUR L'OBTENTION DE SERVICE 23

GARANTIE 24-25

2

Page 30

INTRODUCTION

Les cuisinières de série RGT DCS sont dotées de nombreuses fonctions offertes dans une multitude de

ombinaisons variées. Les brûleurs à double débit (Dual Flow BurnersTM) brevetés permettent des températures

c

de mijotage constamment plus basses et dégagent une puissance de 17 500 BTUH, incluant deux brûleurs de 12

00 BTUH. Également disponibles sur les cuisinières : plaque chauffante et/ou gril de 18 000 BTU.

5

Les fours à convection à gaz à grande capacité des cuisinières RGT sont équipés d'un gril infrarouge à gaz dans le

four. Le petit four à gaz de la série RGT 48 po est idéal pour la cuisson de petit plats. Vous devez installer l'un des

deux dosserets muraux fournis si le dégagement entre les matériaux combustibles et l'appareil est inférieur à

30,5 cm/12 po. Voir pages 9 et 18.

INFORMATIONS IMPORTANTES CONCERNANT L'INSTALLATION

Les cuisinières de série RGT ont été testées conformément à la norme ANSI Z21.1 pour les appareils électroménagers domestiques de cuisson à gaz. Ces cuisinières doivent être installées avec une hotte de ventilation

suspendue (voir les exigences en matière de ventilation). Étant donnée la puissance de feu professionnelle

élevée de cet appareil, faites particulièrement attention à l'installation de la hotte et de ses conduites de

manièr

peuvent se produire lorsqu'on s'étire au-dessus d'appareils aux surfaces chauffantes, évitez de placer des

ar

Consultez les codes du bâtiment en vigueur concernant la méthode à suivre pour installer la cuisinière. Les codes

peuvent varier d'une région à l'autre. L'installation, les connexions électriques et la mise à la terre doivent être

conformes à tous les codes en vigueur. En l'absence de tels codes, l'appareil doit être installé conformément à la

norme ANSI Z223.1 du National Fuel Gas Code et la norme 70 ANSI/NFPA du National Electrical Code (Code

national de l'électricité). Assurez-vous que l'appareil installé est réglé selon le type de gaz utilisé. Les cuisinières

à gaz sont réglées en usine pour fonctionner au gaz naturel ou propane selon le modèle spécifique commandé.

Avant d'aller plus loin, vérifiez que la cuisinière est compatible avec l'alimentation en gaz du site où elle

doit être installée. Renvoyez la cuisinière au distributeur si elle n'est pas réglée pour fonctionner avec l'alimen-

tation en gaz du site.

e à respecter les codes du bâtiment en vigueur. Afin d'éliminer les risques de brûlures ou d'incendie qui

moires de cuisine au-dessus de l'appareil.

3

Page 31

MESURES DE SÉCURITÉ ET DE PRÉCAUTION

Votre nouvel appareil DCS fonctionnera de manière sûre et fiable pendant des années si vous en prenez bien

soin. Faites extrêmement attention quand vous utilisez cet appareil de niveau professionnel, car il dégage une

chaleur intense et peut augmenter les risques d'accidents. Vous devez respecter des consignes de sécurité

lémentaires durant l'utilisation d'appareils de cuisine, dont celles-ci :

é

■ Veuillez lire attentivement ce manuel d'utilisation et d'entretien avant d'utiliser votre nouvel appareil. Ceci vous

permettra de réduire les risques d'incendie, de choc électrique ou de blessures.

■ Commencez par vous assurer que l'installation et l'entretien sont effectués correctement. Suivez les instructions

d'installation fournies avec cet appareil. Avant d'utiliser l'appareil, confiez son installation et sa mise à la terre à

un technicien qualifié.

■ Demandez-lui de vous montrer l'emplacement du robinet d'arrêt de l'alimentation de gaz afin de savoir comment

couper l'arrivée de gaz.

■ Si vous sentez une odeur de gaz, cela signifie que l'installateur n'a pas vérifié correctement s'il y avait des fuites.

Si les connexions ne sont pas complètement étanches, une petite fuite pourrait se produire et laisser s'échapper

une faible odeur de gaz. La détection des fuites n'est pas une procédure à faire soi-même. Certaines fuites ne

peuvent être détectées que si la commande du brûleur est sur ON. Dans l'intérêt de votre sécurité, confiez cette

procédure à un technicien qualifié.

■ Si jamais un brûleur s'éteint et laisse s'échapper du gaz, ouvrez la fenêtre ou la porte pour évacuer l'air. N'essayez

pas d'utiliser l'appareil avant que le gaz ne se soit complètement dissipé. Suivez les instructions de la page 1, «

Pour votre sécurité - Si vous sentez une odeur de gaz ».

■ Cet appareil électroménager a été monté en usine pour être utilisé avec du gaz naturel ou propane. Il doit être

réglé correctement en usine selon le type de gaz utilisé.

■ Ne réparez pas ni ne remplacez aucune pièce de cet appareil, sauf indication contraire du manuel. Tout autre

travail d'entretien doit être confié à un technicien qualifié.

■ Les enfants ne doivent pas être laissés seuls ou sans surveillance dans un endroit où l'on utilise des appareils

électroménagers. Il ne faut jamais les laisser tourner ou enfoncer des boutons, ni s'asseoir ou se tenir debout sur

ces appareil ou les toucher lorsqu'ils sont en marche.

■ Des enfants en marchette ou à quatre pattes peuvent être attirés par la poignée ronde de la porte et la saisir

pour ouvrir la porte du four. Ils pourraient alors se blesser si la porte est ouverte ou se brûler sérieusement si le

four fonctionne et qu'il est chaud.

AVERTISSEMENT!

anger sur les appar

ez de r

évit

blessés sérieusement s'ils grimpent sur l'appareil pour atteindre ces articles.

■ Ne rangez jamais rien dans le four ni sur la table de cuisson. Des matériaux inflammables pourraient prendre feu,

des éléments en plastique pourraient fondre ou s'enflammer et d'autres types d'objets pourraient être détruits.

■ Ne suspendez aucun article sur l'appareil et ne placez aucun objet contre le four. Certains matériaux sont très

inflammables et pourraient prendre feu.

■ Si l'appareil se trouve près d'une fenêtre, assurez-vous que les rideaux sont suffisamment éloignés des brûleurs

de la table de cuisson; ils pour

eils ou à l'arrière des articles pouvant attirer les enfants. Les enfants peuvent être

raient prendre feu sinon.

■ Ne v

■ Ne laissez jamais des v

ersez pas d'eau sur les feux de graisse. ÉTEIGNEZ tous les brûleurs, puis étouffez le feu avec du bicarbonate

de soude ou à l'aide d'un extincteur à poudre ou à mousse.

, gants ou autres matériaux inflammables en contact ou à proximité d'un brûleur

ts

emen

êt

on

ou d'une grille de brûleur tan

blessures.

t que c

es der

niers n

'

t pas refroidi. Les tissus peuvent s'enflammer et causer des

4

Page 32

MESURES DE SÉCURITÉ ET DE PRÉCAUTION

■ Utilisez seulement des gants isolants secs : les gants humides sur des surfaces chaudes peuvent provoquer des

rûlures causées par la vapeur. N'utilisez pas de serviette ou de linge épais à la place de gants isolants. Ne

b

laissez pas les gants isolants toucher les brûleurs ou leurs grilles.

■ Pour assurer votre propre sécurité, habillez-vous de façon appropriée. Ne portez jamais de vêtements ou de

manches lâches lorsque vous utilisez l'appareil. Certains tissus synthétiques sont extrêmement inflammables et

ne doivent pas être portés pendant la cuisson.

■ Ne recouvrez aucune partie du four ou de la table de cuisson avec du papier aluminium. C'est un isolant

thermique qui peut emprisonner la chaleur, laquelle peut alors affecter la performance de la table de cuisson et

endommager la finition du four ou des pièces de la table de cuisson.

AVERTISSEMENT! Ne recouvrez JAMAIS les fentes, trous ou passages

situés au bas du four et évitez de recouvrir entièrement une grille avec des matériaux tel

que le papier d'aluminium. Cela a pour effet de bloquer la circulation d'air à l'intérieur du

four et peut causer un empoisonnement à l'oxyde de carbone. Le papier d'aluminium peut

également emprisonner la chaleur et causer ainsi un risque d'incendi

■ Cet appareil électroménager est destiné à la cuisson. N’utilisez jamais le four ou la table de cuisson pour

réchauffer ou chauffer une pièce. Une telle utilisation peut endommager les pièces de la table de cuisson ou du

four.

AVERTISSEMENT! N’utilisez JAMAIS cet appareil comme appareil de

chauffage pour chauffer la pièce. Cela pourrait entraîner un empoisonnement à l'oxyde de

carbone et une surchauffe du four.

■ Durant l'utilisation de la table de cuisson : ne touchez pas les grilles des brûleurs ou les surfaces adjacentes. Ces

surfaces peuvent devenir suffisamment chaudes pour provoquer des brûlures.

■ Durant l'utilisation du four, évitez de toucher les surfaces intérieures du four, la surface extérieure autour de la

porte et la garniture arrière. Les surfaces situées directement au-dessus de la porte du four peuvent être

chaudes si le four a fonctionné avec la porte ouverte ou si quelque chose a empêché la porte de se fermer.

■ Ne laissez jamais la table de cuisson sans surveillance lorsque vous cuisinez à flamme haute. Un débordement

par bouillonnement pourrait produire de la fumée et un déversement graisseux qui pourrait prendre feu. Et, ce

qui est plus grave, si les flammes des brûleurs sont étouffées par un débordement important affectant

l'allumeur, le gaz non brûlé s'échappera dans la pièce.

■ Seuls certains types d'ustensiles en verre, vitrocéramique calorifugée, céramique, poterie ou émaillés sont

opriés pour être utilisés sur la table de cuisson. Ce genre d'ustensile peut se briser à la suite de

appr

empéra

changemen

fabricant. Il est recommandé d'utiliser des ustensiles de cuisine professionnels.

■ Ne chauffez pas de contenant de nourriture fermé car la pression pourrait s'accumuler et le faire exploser.

■ Durant la cuisson, réglez la commande du brûleur de sorte que la flamme ne chauffe que le fond du récipient et

ne le dépasse jamais. Cela pourrait sinon chauffer ou faire fondre les poignées.

■ Servez-vous toujours d'ustensiles à fond plat suffisamment larges pour couvrir les brûleurs. L'utilisation

d'ust

ts de t

ensiles tr

op petits r

ture soudains. Utilisez-les seulement à feu doux ou moyen selon les instructions du

isque d'offrir un contact direct à la flamme et de mettre le feu aux vêtements.

■ Afin de réduire le risque de brûlures, d'allumage de matériaux inflammables et de déversement involontaire,

tournez les poignées des ustensiles vers l'intérieur afin qu'elles ne surplombent pas les surfaces de travail

adjacentes, les zones de cuisson et le bord extérieur de la table de cuisson.

■ Tenez la poig

la nourriture.

5

née du r

écipien

t afin d'

empêcher t

out mouv

emen

t de l'ust

ensile lorsque v

ous retournez ou remuez

Page 33

MESURES DE SÉCURITÉ ET DE PRÉCAUTION

■ La graisse est inflammable. Laissez toute graisse chaude refroidir avant d'essayer de la manipuler. Évitez de

laisser la graisse s'accumuler autour des brûleurs de la table de cuisson. Nettoyez après chaque utilisation ou

déversement.

■ Pour assurer un bon allumage et une bonne performance des brûleurs de la table de cuisson, gardez leurs ports

dans un état propre. Il peut s'avérer nécessaire de nettoyer ceux-ci en cas de débordement ou lorsque le brûleur

ne s'allume pas, même si les allumeurs électroniques cliquent.

■ N'utilisez pas le gril pour cuire des viandes ou des produits très gras pouvant alimenter les flammes. N'utilisez

pas d'ustensiles de cuisson dans le gril.

■ Nettoyez la table de cuisson avec précaution. Évitez de vous brûler à la vapeur : n'utilisez pas d'éponge ou de

linge mouillé pour nettoyer l'appareil alors qu'il est encore chaud. Certains produits de nettoyage dégagent des

vapeurs nocives au contact d'une surface chaude. Respectez le mode d'emploi du fabricant du produit de

nettoyage.

■ Assurez-vous que les boutons de la cuisinière ou de la table de cuisson sont fermés et que l'appareil est froid

avant d'utiliser des nettoyants aérosol sur l'appareil ou à proximité. L'élément chimique qui produit le jet de

vaporisation peut, en présence de chaleur, s'enflammer ou provoquer la corrosion des parties métalliques.

■ Placez les grilles de four à la position voulue quand le four est froid. Si vous devez déplacer une grille alors que

le four est encore chaud, ne laissez pas les gants isolants toucher l'intérieur chaud du four.

■ Faites attention lorsque vous ouvrez la porte du four; laissez s'échapper l'air chaud ou la vapeur avant de retirer

ou remplacer les aliments.

■ Évitez de frotter, endommager, déplacer ou enlever le joint de la porte, car il est essentiel à l'obtention d'une

bonne cuisson. Lavez le joint avec de l'eau chaude seulement.

■ Nettoyez fréquemment la hotte et les filtres de ventilation surplombant la cuisinière ou table de cuisson afin

d'empêcher toute accumulation de graisse provenant des vapeurs de cuisson. Le filtre peut être nettoyé dans un

lave-vaisselle ou un dishdrawer. Respectez le mode d'emploi du fabricant du produit de ventilation en ce qui a

trait au nettoyage.

■ ÉTEIGNEZ le ventilateur en cas d'incendie ou si vous flambez intentionnellement des liqueurs ou des spiritueux

sur la table de cuisson. Si le ventilateur est en marche, il pourrait en effet répandre les flammes.

■ ÉVITEZ de bloquer la circulation de l'air de combustion ou de ventilation. Assurez toujours un apport d'air frais.

■ Pour des raisons de sécurité et pour ne pas endommager l'appareil, évitez de vous asseoir, de vous tenir debout

ou de vous appuyer contre la porte du four ou la surface de cuisson.

■ Les réparations doivent être effectuées par des techniciens agréés uniquement. Ceux-ci doivent débrancher le

bloc d'alimentation avant de travailler sur l'appareil.

AVERTISSEMENT!

Proposition 65 de la Californie - L'incinération de gaz de cuisson génère des sous-produits considérés par l'État de

alifornie comme pouvant causer le cancer ou des malformations congénitales. Les lois de Californie exigent que les

C

tissent leurs clients qu'ils risquent d'être exposés à de telles substances. Pour minimiser l'exposition

er

eprises a

tr

en

es substanc

à c

ez une bonne ventilation lorsque vous cuisinez au gaz.

assur

v

onformément aux instructions contenues dans ce manuel et

es

, fait

oujours f

es t

tionner l'appar

onc

eil c

6

Page 34

MESURES DE SÉCURITÉ ET DE PRÉCAUTION

Le robinet d'arrêt fourni

par l'installateur doit

être facilement accessible de

l'intérieur du boîtier.

A

limentation

en gaz

Comptoir

RECOMMANDATIONS CONCERNANT LE BRANCHEMENT DU GAZ :

n robinet manuel doit être installé à l'extérieur de l'appareil, sur le devant, dans un endroit accessible, afin de

U

permettre de couper le gaz. La conduite d'alimentation ne doit pas dépasser l'arrière de l'appareil. Avant de

brancher l'appareil, prenez soin de couper le gaz par le robinet mural.

Toutes les connexions d'alimentation en gaz doivent être effectuées par un technicien qualifié conformément

aux codes et règlements en vigueur. En l'absence d'une réglementation locale, l'installation doit être conforme à

la dernière édition du National Fuel Gas Code ANSI Z223.1.

REMARQUE :

Ce produit doit être installé par un plombier ou ajusteur

d'appareils à gaz agréé si l'installation a lieu au sein du

Commonwealth du Massachusetts.

REMARQUE :

(obligatoire dans l'état du Massachusetts)

Une méthode alternative d'alimentation en gaz doit être

installée dans l'appareil.

7

Page 35

IDENTIFICATION DU MODÈLE

OVENON

H

EATING

D

OOR LOCKED

H

EATING

MODÈLES DE CUISINIÈRES 48 PO RGT

RGT-484GG

RGT-486GL RGT-486GD

RGT-485GD

MODÈLES DE CUISINIÈRES 36 PO RGT

RGT-366

MODÈLES DE CUISINIÈRES 30 PO RGT

-305

RGT

RGT-364GL RGT-364GD

8

Page 36

PLANIFICATION DE L'INSTALLATION

INFORMATIONS IMPORTANTES CONCERNANT L'INSTALLATION

e modèle RGT a été testé conformément à la norme ANSI Z21.1 pour les appareils électroménagers domestiques

L

de cuisson à gaz.

a cuisinière doit être installée avec une hotte de ventilation suspendue appropriée. (Voir les exigences en

L

matière de ventilation, page 12.) Étant donnée la puissance de feu professionnelle élevée de cet appareil, faites

particulièrement attention à l'installation de la hotte et de ses conduites de manière à respecter les codes du

bâtiment en vigueur. Afin d'éliminer les risques de brûlures ou d'incendie qui peuvent se produire lorsqu'on

s'étire au-dessus d'appareils aux surfaces chauffantes, évitez de placer des armoires de cuisine au-dessus de

l'appareil.

Vous devez installer l'un des deux dosserets muraux disponibles si le dégagement entre les matériaux

combustibles et le bord arrière de la cuisinière (au-dessus de la surface de cuisson) est inférieur à 30,5 cm/12 po

(voir page 18).

Dosseret mural

intégral

1-5/16”

(3.3 cm)

28-1/8”

71,4 cm