Page 1

THE PROFESSIONAL ACCESS DRAWERS

Use and Care and Installation Guide

MODELS:

ADR148 ADR130

ADR136 ADR124

Page 2

Page 3

A MESSAgE TO OUR CUSTOMERS

• Closing drawers may cause injury to

your hands or fingers.

• Always close or open drawers using

their handles.

• Be sure to keep hands away from

drawer edges when opening or

closing drawers.

WARNING

Thank you for selecting these DCS by Fisher & Paykel Professional Access Drawers. Because of this product’s unique features

we have developed this Installation Guide. It contains valuable information on how to properly install and maintain your

new Professional Access Drawers for years of safe and enjoyable use.

To help serve you better, please fill out and submit your Product Registration by visiting our website at www.dcsappliances.

com and selecting “Customer Care” on the home page and then select “Product Registration”. In addition, keep this guide

handy, as it will help answer questions that may arise as you use your new Access Drawers.

For your convenience, product questions can be answered by a DCS by Fisher & Paykel Customer Care Representative at

1-888-936-7872, or email: customer.care@fisherpaykel.com.

Note: Please write the model, code, and serial numbers on this page for reference (located on the sticker on the rear brace in

the tank side - see Fig. 04).

Model number Code Serial number

NOTE: Inspect the product to verify that there is no shipping damage. If any damage is detected, call the shipper and initiate

a damage claim. DCS by Fisher & Paykel is not responsible for shipping damage.

DO NOT discard any packing material (box, pallet, straps) until the unit has been inspected.

WARNINg

Do Not store or use gasoline or other flammable vapors and liquids inside or in the vicinity of this or any other 1.

appliance.

An LP cylinder not connected for use shall not be stored inside or in the vicinity of this unit.2.

FOR YOUR SAFETY

Do not allow children or pets to play in or around the Access Drawers.1.

Clean the Access Drawers regularly using a mild dish washing liquid and water.2.

To maintain the exterior appearance, apply a stainless steel polish to the outside surfaces on a regular basis.3.

Sanitize the Access Drawers surfaces each season as necessary.4.

To prevent the formation of mold or mildew, do not store cloth napkins or tablecloths in the Access Drawers for long 5.

periods.

Cooking utensils that are stored in the Access Drawers should be stored in 6.

sealable plastic bags and/or washed each time before re-use.

To prevent personal injury or damage to the drawers, do not overload them. 7.

The maximum rating per drawer is 75 pounds.

1

Page 4

TAblE OF CONTENTS

SAFETY PRACTICES & PRECAUTIONS 2

MODEL IDENTIFICATION & DIMENSIONS 3

SHIPPING INSPECTION 3

CABINET PREPARATION 4

INSTALLATION

Make Cutout and Installing Support Structure 5

Removing Drawers 6

Slide in Access Drawers and Mount to Support Structure 6

Re-installing Drawers 7-8

CARE & MAINTENANCE 9

SERVICE 10

WARRANTY 1112

SAFETY PRACTICES AND PRECAUTIONS

Begin by insuring proper installation and servicing. 1.

Follow the installation instructions in this manual.2.

To extend the service life of your product, be sure to follow the use and care guidelines in this manual.3.

WARNINg:

Do not store items of interest to children above or on the inside of any appliance. Children could be seriously

injured if they should climb onto or into the appliance to reach these items.

PlEASE RETAIN ThIS MANUAl FOR FUTURE REFERENCE

2

Page 5

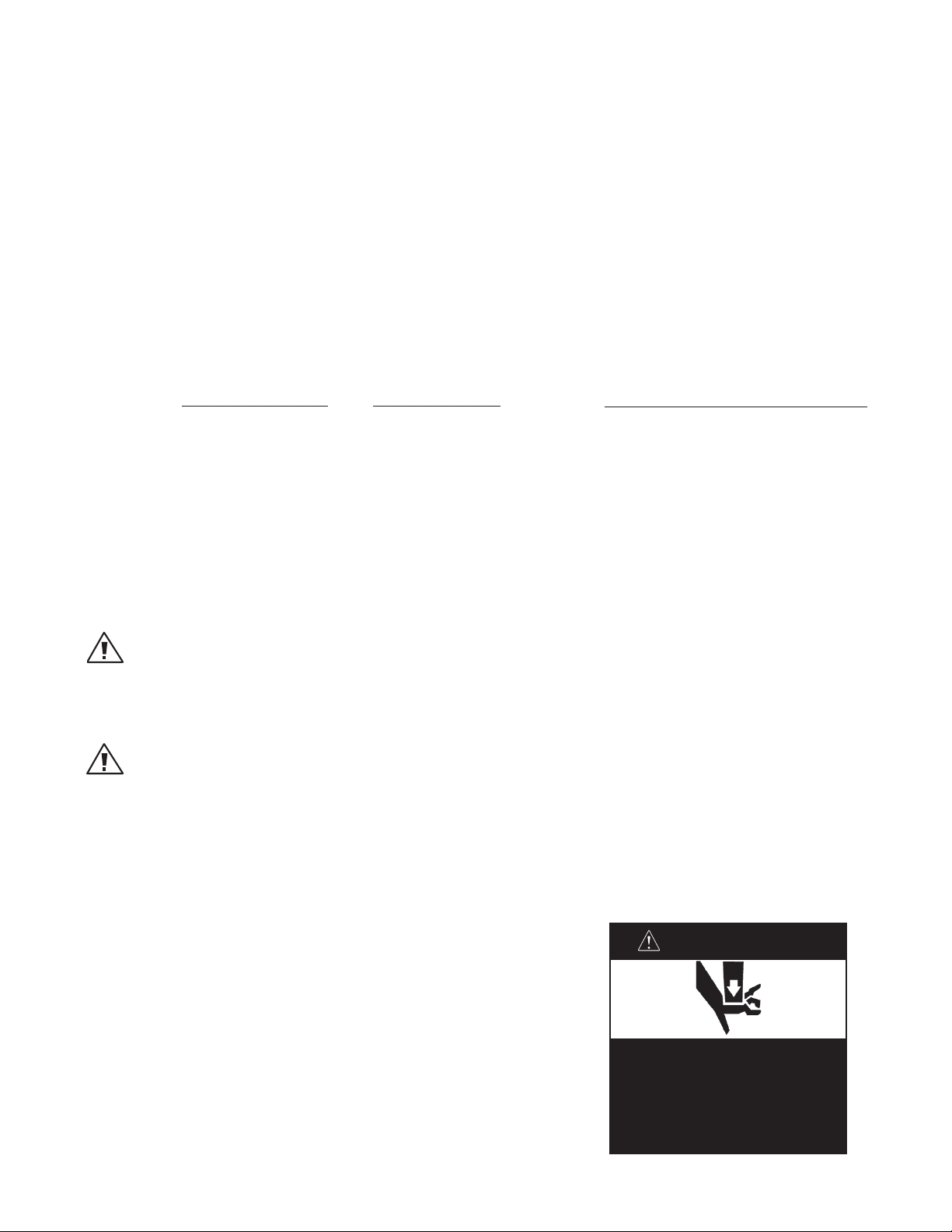

MODEl IDENTIFICATION & DIMENSIONS

ADR148

D

H

ADR136

W

F

ADR130 ADR124

Fig. 1

ShIPPINg INSPECTION

Inspect the Access Drawers to verify that there is no 1.

shipping damage.

If any damage is detected, call the shipper and 2.

initiate a damage claim. DCS by Fisher & Paykel is not

responsible for shipping damage.

DIMENSIONS

Model

ADR148 231/2” 48” 217/8” 2”

ADR136 231/2” 36” 217/8” 2”

ADR130 231/2” 30” 217/8” 2”

ADR124 231/2” 24” 217/8” 2”

D W H F

Fig. 1a

NOTE: Do not discard any packing material (box, pallet,

straps) until the unit has been inspected.

Operate the drawers to be sure they glide smoothly. ■

Examine the drawer fronts to be sure there are no dents or ■

scratches or discoloring.

Fig. 2

3

Page 6

CAbINET PREPARATION

Cabinet face should be clean and flat. ■

All angles must be at 90 ■

Support structure must be resistant to moisture damage. ■

All gas lines and plumbing must be done before installing access drawers. ■

Do not use any harsh products (acid, solvent, sealers) around this unit. ■

Any cabinet and/or ground preparations must be completed prior to installation. ■

º

and plumb.

4

Page 7

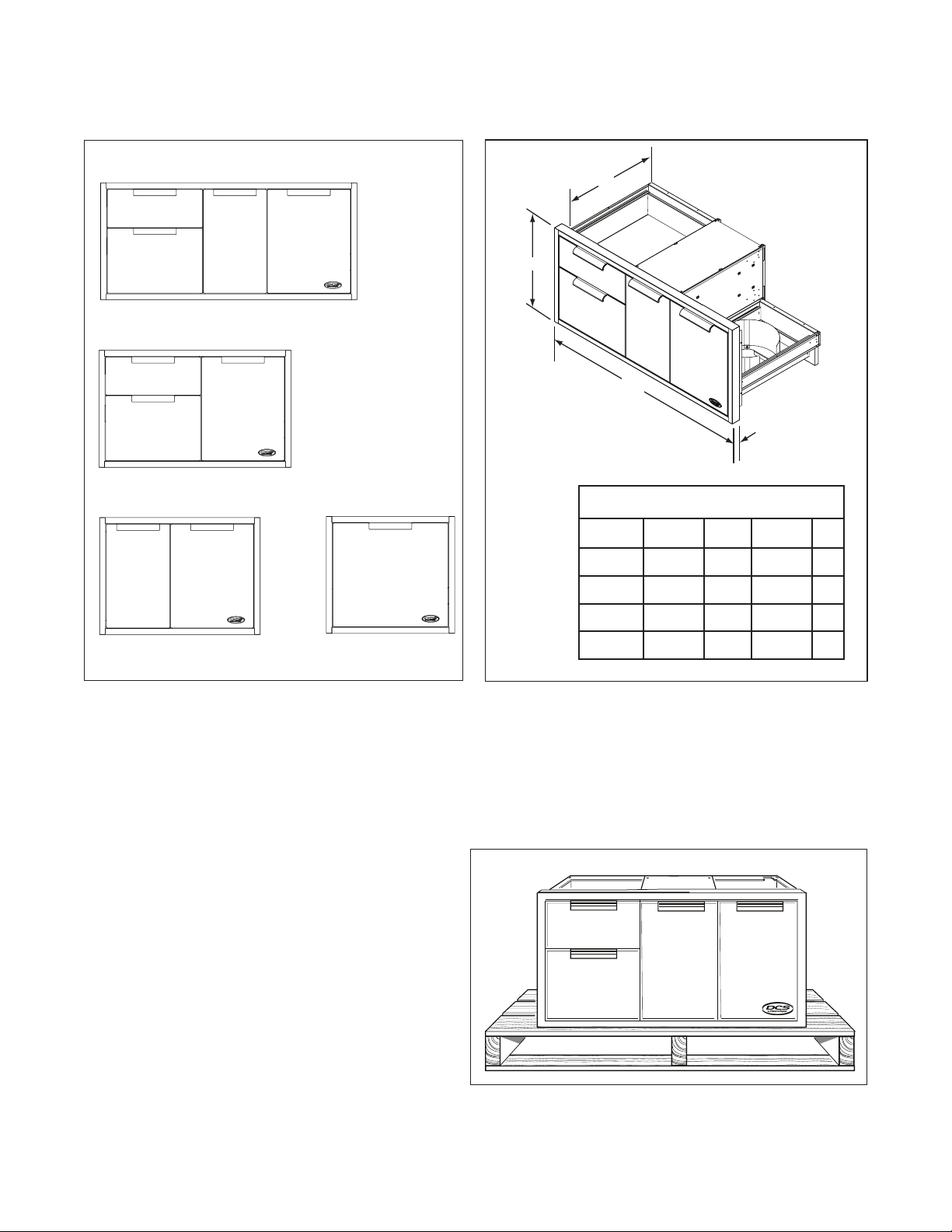

INSTAllATION

island cutout

1/2" Bottom of center divider to

C

B

A

A

B

E

D

Sticker location of

Model, Serial, Code Number

*

A

90º

B

Vent*

Vent*

Vent*

C

D

MAkE CUTOUT AND INSTAll SUPPORT STRUCTURE

Make a cut-out in your cabinet or island with the following dimensions (Fig. 3): 1.

NOTE: Each corner of the cutout should be 90º for the Access Drawers to fit properly.

CUTOUT DIMENSIONS

* Island installation to use minimum of 3 vents

providing 10 sq. in. per vent (typical).

Fig. 3

Place 2 X 4s to provide support for the Access Drawers structure in the locations indicated in the figure below (Fig. 4).2.

Board lengths are provided in the table below (Fig. 5).3.

To ensure proper drawer operation, be sure

your support boards are flat & level.

Model

A

0,+1/8”B0,+1/8”

C D

ADR148 46” 20” 1.0” min. 1.0” min.

ADR136 34” 20” 1.0” min. 1.0” min.

ADR130 28” 20” 1.0” min. 1.0” min.

ADR124 22” 20” 1.0” min. 1.0” min.

SUPPORT BOARD DIMENSIONS

Model A B C D E

48” 2 X 20” 11/2”* 31/2” min. 14 12

36” 20” 11/2”* 31/2” min. 14

30” 2 X 20” 11/2”* 31/2” min. 14 12

24” 20” 11/2”* 31/2” min. 14

When installing your support boards, be 4.

sure they are level.

Ensure that the bottom of the center 5.

divider rests on top of the support

boards as shown (Fig. 4).

Fig. 4

FRONT VIEW TYPICAL

Support Board (typical)

5

Fig. 5

*Dependent on application. Top of 2x4’s

must be 1/2” above the bottom edge of

the cutout.

END VIEW TYPICAL

For proper

support & drawer

operation, insure

that support

boards are level

front to back &

side to side.

Support Boards

(typical)

Fig. 6

Page 8

INSTAllATION

11-3/4"

4-1/8"

1-3/8"

(

Ø

1/4" )

Anchor hole

15/16"

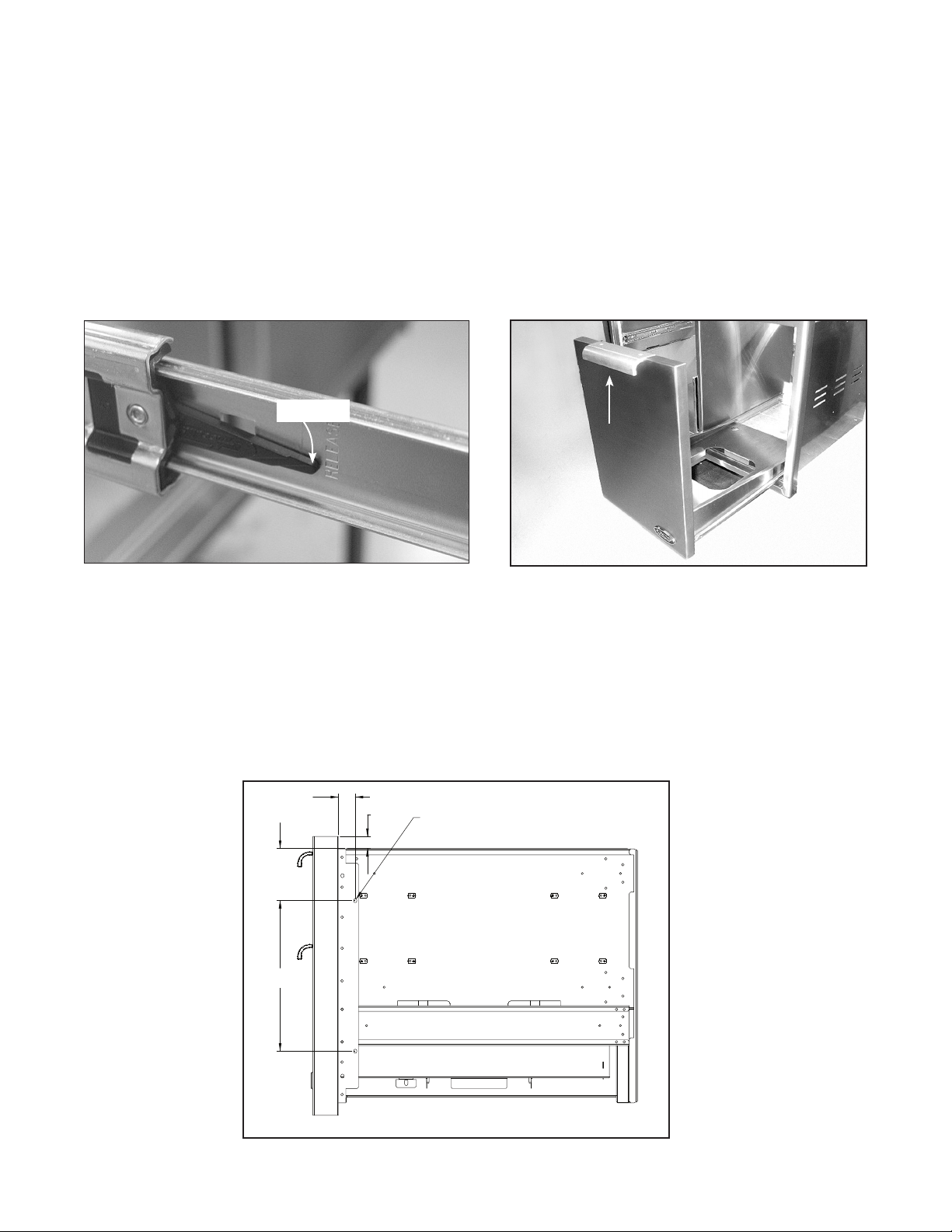

REMOvINg DRAWERS

Once the unit has been inspected, remove the drawers by pulling them out until their slider latch is visible. Carefully push the 1.

latch down on the left side while pulling up on the right side and pull the drawers completely out of the frame (Fig. 7).

To prevent damage to surfaces, place the drawers on a stable surface on a protective towel or table cloth. 2.

TO REMOVE THE ADR124 DRAWER, pull the drawer out and lift the end by the handle to disengage the rollers (Fig. 8).

Slider latch

LIFT

Fig. 7

Fig. 8

SlIDE IN FRAME AND MOUNT TO SUPPORT STRUCTURE

With the help of an assistant, lift the unit and slide it into the cabinet cutout. Adjust for level and fit.1.

Locate mounting holes on the frame (Fig. 9 and views). Secure the unit using screws suited for the type of cabinet material.2.

NOTE: Depending on the wall thickness and location of mounting holes, an additional board may be required to properly

receive the screws.

Fig. 9

6

Page 9

INSTAllATION

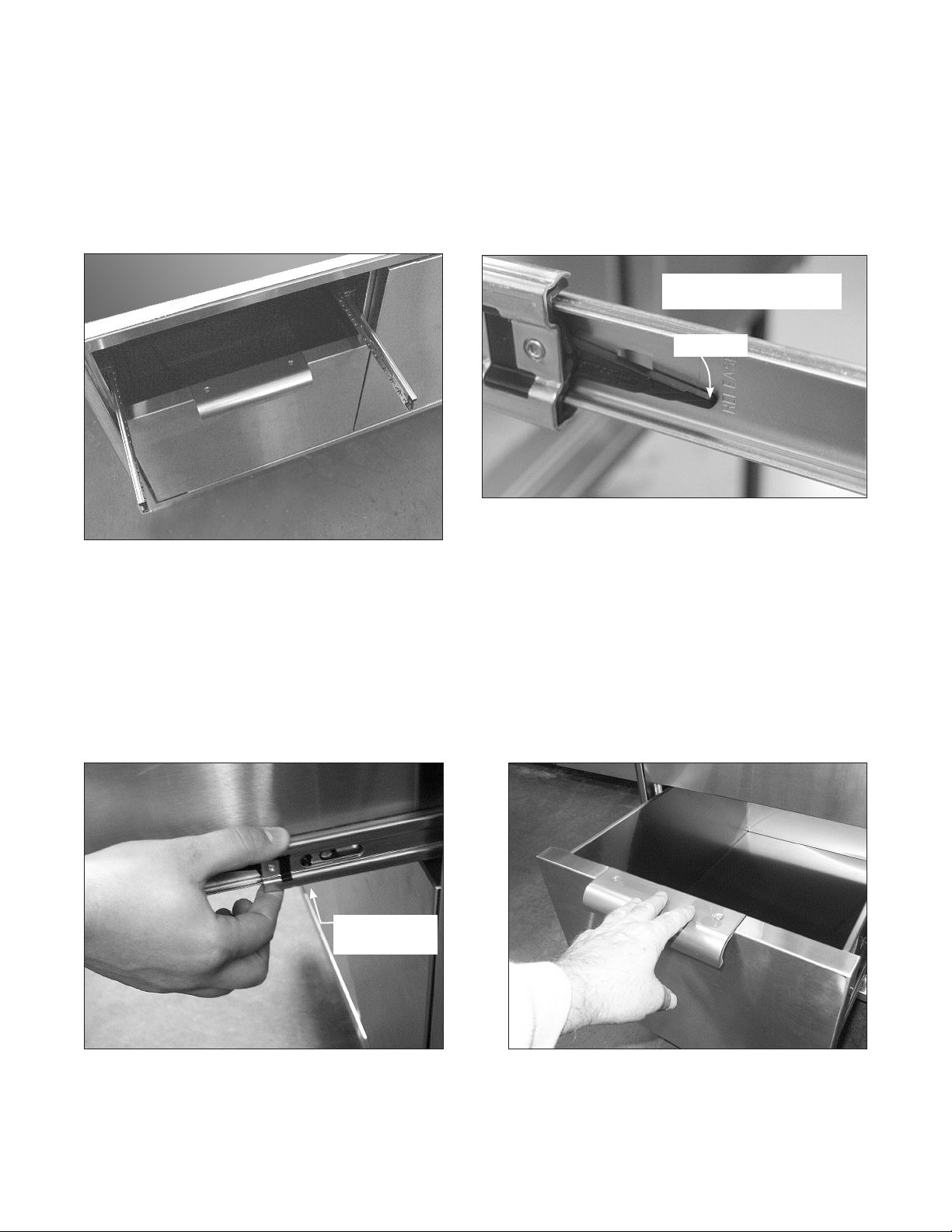

RE-INSTAllINg DRAWERS

Re-install the drawers by extending their guides as shown in Fig. 10.1.

While holding the drawer parallel to the cabinet, carefully align & engage the ends of the glides. 2.

Slide the drawer in about an inch so that the glides are supporting the back of the drawer (Fig. 11).

Drawer Glide properly

Engaged.

Slider latch

Fig. 11

Fig. 10

While holding the drawer up by the handle, pull the glides from the drawer cavity out over the 3.

drawer glide until they click (Fig. 12).

As you push the drawers in, you will encounter moderate resistance. Continue to push the drawer all the way in to complete 4.

the engagement process. The drawer will now glide smoothly in & out with light effort (Fig. 13).

D r a w e r C a v i t y

Glide

Fig. 12

Fig. 13

7

Page 10

INSTAllATION

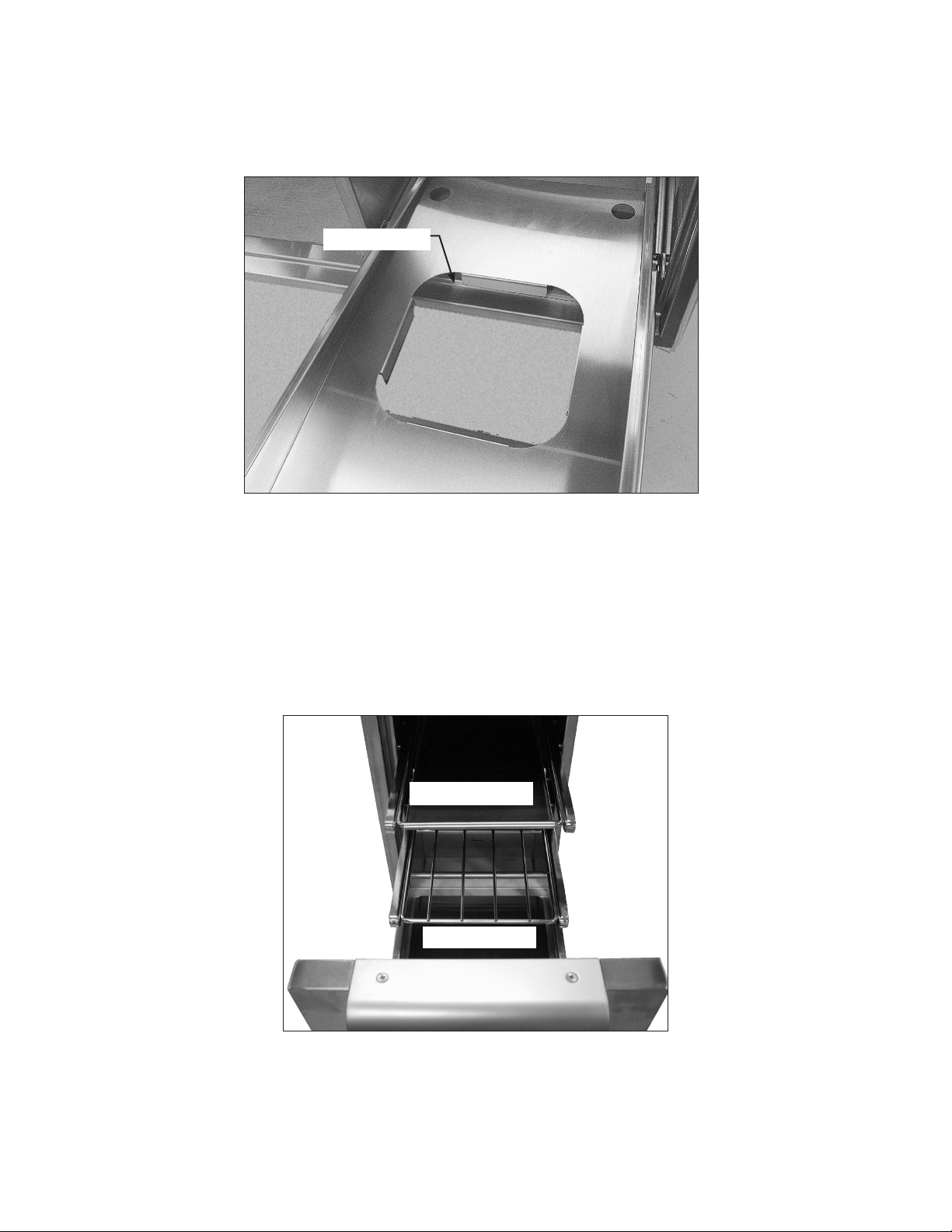

Your LP tank will be installed in the recess provided in the bottom of the right compartment (Fig. 14).5.

Tank Receptacle

Fig. 14

When connecting the LP tank to your grill be certain that all connections are tight. Once gas connections are made, test for 6.

gas leaks.

On models so equipped, install the two (2) racks provided into the opening by sliding them onto the rollers on the sidewalls 7.

of the center cavity (Fig. 15).

Rack & Rack Cover

Drain drawer

Fig. 15

8

Page 11

CARE & MAINTENANCE

The Access Drawers are made from corrosion-resistant and non-magnetic stainless steel. All parts of the Access Drawers

can be cleaned with hot soapy water, rinsed, dried and buffed to a shine with a soft, heavy cloth. Always try this first, as it is

the mildest cleaning procedure. There are many different stainless steel cleaners available. Always use the mildest cleaning

procedure first, scrubbing in the direction of the grain to avoid marring the surface The cleaner will be more effective when

used in the direction of the grain (polish lines).

Some brands of cleaners of the same type are harsher than others, read their directions. A scent or a propellant can make 1. a

difference in the product, read the ingredients. Try on a small area first.

To touch up noticeable scratches in the stainless steel, sand very lightly with wet 100 grit emery paper in the direction of the 2.

grain.

Specks of grease can gather on the surfaces of the stainless steel and bake on to 3.

the surface and give the appearance of rust. For removal use an abrasive pad

(Scotch Brite is good) in conjunction with a stainless steel cleaner. Always rub in

the direction of the grain.

Use only clean sponges, soft cloths, paper towels, plastic non-metal soap pads for 4.

cleaning or scouring as recommended in this section. (Use only soap pads with

soap still in them. An empty pad can scratch.)

Be sure to rinse all parts thoroughly and to wipe dry to avoid water marks.5.

NOTE: Stainless steel tends to corrode in presence of chlorides and

sulfides especially in coastal areas. To ensure corrosion prevention, wash

all stainless steel surfaces every 3-4 weeks with fresh water and stainless

cleaner.

Lubrication

points

(Use

silicone

spray

annually)

Fig. 16

bRAND NAME ClEANERS

In this section on cleaning, the use of name brands is intended only to indicate a type of cleaner. This does not constitute

an endorsement. The omission of any name brand cleaner does not imply its adequacy or inadequacy. Many products are

regional in distribution and can be found in local markets and department stores.

MAINTENANCE

After cleaning, use a stainless steel polish, such as Stainless Steel Magic® applied to the drawer and handle surfaces.

To maintain the smooth operation of the drawers, spray the bearing areas with silicone spray lubricant annually (Fig. 16).

ACCESSORIES

Freezer Pack (optional, Kit #70696A)(Fig. 17)1.

Waste Basket Holder (optional, Kit #70906)(Fig. 18)2.

Bottom Cover (optional, Kit #70907)(Fig. 19)3.

NOTE: To order these accessories, please contact Fisher &

Paykel Customer Care at 1-888-936-7872.

Fig. 17 - Freezer Pack (optional)

Fig. 18 - Waste Basket Holder (optional)

9

Fig. 19 - Bottom Cover

(optional)

Page 12

SERvICE

For warranty service, please contact your local service provider or DCS Customer Care Representative at (888) 936-7872 or go

to our website at www.dcsappliances.com and choose “Customer Care” to find your nearest Authorized Service Center. Before

you call, please have the following information ready:

Model Number (located on the sticker on the rear brace in the tank side - see Fig. 04). ■

Serial Number (located on the sticker on the rear brace in the tank side - see Fig. 04). ■

Code Number (located on the sticker on the rear brace in the tank side - see Fig. 04). ■

Date of installation ■

A brief description of the problem ■

Your satisfaction is of the utmost importance to us. If a problem cannot be resolved to your satisfaction, please write or email

us at:

Write:

Fisher & Paykel Appliances, Inc.

Attention: DCS Customer Care

5900 Skylab Road

Huntington Beach, CA 92647

email: customer.care@fisherpaykel.com

10

Page 13

WARRANTY

lIMITED WARRANTY

When you purchase a new DCS by Fisher & Paykel Professional Access Drawers, you automatically receive a One Year Limited

Warranty covering parts and labor for the entire product, and a Five Year Limited Warranty on all stainless steel assemblies

(parts only) for servicing within the 48 mainland United States, Hawaii, Washington D.C. and Canada. In Alaska, the Limited

Warranty is the same except that you must pay to ship the Product to the service shop or for the service technician’s travel to

your home. Products for use in Canada must be purchased through the Canadian distribution channel to ensure regulatory

compliance. Surface corrosion and discoloration is not covered under warranty.

FIShER & PAYkEl UNDERTAkES TO:

Repair without cost to the owner either for material or labor any part of the Product, the serial number of which appears on

the Product, which is found to be defective. In Alaska, you must pay to ship the Product to the service shop or for the service

technician’s travel to your home.

If we are unable to repair a defective part of the Product after a reasonable number of attempts, at our option we may

replace the part or the Product, or we may provide you a full refund of the purchase price of the Product (not including

installation or other charges).

This warranty extends to the original purchaser and any succeeding owner of the Product for products purchased for

ordinary single-family home use. All service under this Limited Warranty shall be provided by Fisher & Paykel Appliances Inc.

or its Authorized Service Agent during normal business hours.

hOW lONg DOES ThIS lIMITED WARRANTY lAST?

Our liability under this Limited Warranty for the entire product expires One Year from the date of purchase of the Product by

the first consumer.

Our liability under any implied warranties, including the implied warranty of merchantability (an unwritten warranty that the

Product is fit for ordinary use) also expires One Year (or such longer period as required by applicable law) from the date of

purchase of the Product by the first consumer. Some states do not allow limitations on how long an implied warranty lasts,

so this limit on implied warranties may not apply to you.

ThIS WARRANTY DOES NOT COvER:

Service calls that are not related to any defect in the Product. The cost of a service call will be charged if the problem is not A.

found to be a defect of the Product. For example:

Correct faulty installation of the Product.1.

Instruct you how to use the Product.2.

Correct fault(s) caused by the user.3.

Change the set-up of the Product.4.

Unauthorized modifications of the Product.5.

Correcting damage caused by pests, for example, rats, cockroaches etc.6.

Discoloration or rust stains.7.

B. Defects caused by factors other than:

Normal domestic use or1.

Use in accordance with the Product’s User Guide.2.

The cost of repairs carried out by non-authorized repairers or the cost of correcting such unauthorized repairs.C.

Travel Fees and associated charges incurred when the product is installed in a location with limited or restricted access (i.e. D.

airplane flights, ferry charges, isolated geographic areas).

Normal recommended maintenance as set forth in the Product’s Care & User Guide.E.

Defects to the Product caused by accident, neglect, misuse, fire, flood or Act of God.F.

11

Page 14

WARRANTY (continued)

If you have an installation problem contact your dealer or installer. You are responsible for providing adequate electrical,

exhausting and other connection facilities. We are not responsible for consequential or incidental damages (the cost of

repairing or replacing other property damaged if the Product is defective or any of your expenses caused if the Product is

defective). Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

hOW TO gET SERvICE

Please read your Care & User Guide. If you then have any questions about operating the Product, need the name of your

local DCS Authorized Service Agent, or believe the Product is defective and wish service under this Limited Warranty, please

contact your dealer or call us at:

TOLL FREE 1-888-936-7872 or contact us through our web site: www.dcsappliances.com.

You may be required to provide reasonable proof of the date of purchase of the Product before the Product will be serviced

under this Limited Warranty.

COMMERCIAl USE

This warranty applies to appliances used in residential applications; it does not cover their use in commercial situations.

NO OThER WARRANTIES

This Limited Warranty is the complete and exclusive agreement between you and Fisher & Paykel Appliances Inc. regarding

any defect in the Product. None of our employees (or our Authorized Service Agents) are authorized to make any addition or

modification to this Limited Warranty.

Warrantor: Fisher & Paykel Appliances, Inc.

If you need further help concerning this Limited Warranty, please call us at the above number, or write to:

Fisher & Paykel Appliances, Inc.

Attention: DCS Customer Care

5900 Skylab Road, Huntington Beach, CA 92647

This Limited Warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Fisher & Paykel Appliances Inc. is a leading manufacturer of premium quality cooking and specialty appliances under the

Fisher & Paykel and DCS by Fisher & Paykel brands.

12

Page 15

LES TIROIRS PROFESSIONNELS

Manuel d’utilisation, d’entretien et d’installation

MODÈLES :

ADR148 ADR130

ADR136 ADR124

Page 16

A l’INTENTION DE NOS ClIENTS

• Closing drawers may cause injury to

your hands or fingers.

• Always close or open drawers using

their handles.

• Be sure to keep hands away from

drawer edges when opening or

closing drawers.

WARNING

Nous vous remercions d’avoir choisi ces tiroirs professionnels DCS by Fisher & Paykel. Nous avons conçu ce Manuel

d’utilisation et d’entretien pour expliquer les fonctions uniques de ces appareils. Ce manuel contient des informations

extrêmement utiles sur la façon correcte de les installer, les faire fonctionner et en faire l’entretien. Vous pourrez ainsi en

profiter pendant des années en toute sécurité.

Aidez-nous à mieux vous servir en remplissant l’enregistrement de produit et en nous le soumettant depuis notre site Web à

www.dcsappliances.com. Sélectionnez « Customer Care » sur la page d’accueil puis « Product Registration ». De plus, gardez

ce manuel à portée de main afin de rapidement trouver réponse à vos questions durant l’utilisation de votre nouvel appareil.

Si vous avez des questions au sujet de notre produit, communiquez avec un représentant du centre de service à la clientèle

DCS par téléphone :1-888-936-7872, ou par courriel : customer.care@fisherpaykel.com.

REMARQUE : Veuillez noter les numéros de modèle, code, et de série sur cette page pour information (situé sur l’autocollant

sur la contrefiche arrière du côté réservoir - voir Fig. 04)

NUMÉRO DE MODÈLE CODE NUMÉRO DE SÉRIE

REMARQUE : Inspecter le produit pour vérifier qu’il n’a pas été endommagé pendant l’expédition. En cas de dommages,

contacter le transporteur et entamer une déclaration pour dommage. DCS by Fisher & Paykel n’est en aucun cas responsable

des dommages pendant l’expédition.

Ne pas jeter le matériau d’emballage (boîte, palette, sangles) avant d’avoir inspecté l’unité.

AvERTISSEMENT

1. Évitez de stocker ou d’utiliser de l’essence ou tout autre liquide et vapeur inflammable à l’intérieur ou à proximité de

cet appareil ou de tout autre.

2. Évitez de ranger une bouteille de gaz propane (qui n’est pas connectée car non utilisée) à l’intérieur ou à proximité

de cet appareil ou de tout autre.

POUR vOTRE SÉCURITÉ

1. Ne laissez pas des enfants ou des animaux de compagnie jouer à l’intérieur ou autour des tiroirs.

2. Nettoyez les tiroirs périodiquement avec un détergent liquide pour

vaisselle doux et de l’eau.

3. Pour préserver l’aspect extérieur, appliquez un produit à polir pour acier

inoxydable sur les surfaces extérieures sur une base régulière.

4. Désinfectez les surfaces des tiroirs à chaque saison au besoin.

5. Pour éviter la formation de moisissure, évitez de ranger des serviettes

de table en tissu ou des nappes dans les tiroirs pendant des périodes

prolongées.

6. Les ustensiles de cuisson rangés dans les tiroirs doivent être placés dans

des sacs en plastique scellables ou lavés chaque fois avant d’être réutilisés.

7. Pour éviter des blessures corporelles ou ne pas endommager les tiroirs,

évitez de les surcharger. Le poids maximum par tiroir est de 34 kg (75 lb).

1

Page 17

TAblE DES MATIERES

MESURES DE SECURITE ET DE PRECAUTION 2

IDENTIFICATION DU MODELE ET DIMENSIONS 3

INSPECTION APRES LIVRAISON 3

PRÉPARATION DE L’ÉLÉMENT 4

INSTALLATION

Effectuer la découpe et installer la structure de support 5

Retrait des tiroirs 6

Enfoncer les tiroirs et les monter sur la structure de support 6

Réinstallation des tiroirs 7-8

ENTRETIEN ET MAINTENANCE 9

ACCESSOIRES 10

SERVICE 11

GARANTIE 1213

MESURES DE SECURITE ET DE PRECAUTION

Commencez par vous assurer que l’installation et l’entretien sont effectués correctement. 1.

Suivez les instructions d’installation du manuel.2.

Pour prolonger la durée de vie utile du produit, suivez les consignes d’utilisation et d’entretien de ce manuel.3.

AvERTISSEMENT :

Évitez de ranger au-dessus ou à l’intérieur d’un quelconque appareil des articles pouvant attirer les enfants.

Ceux-ci peuvent se blesser sérieusement s’ils grimpent sur ou à l’intérieur de l’appareil pour atteindre l’objet en

question.

2

Page 18

IDENTIFICATION DU MODElE ET DIMENSIONS

ADR148

ADR136

ADR130 ADR124

H

D

W

F

DIMENSIONS/COTES

MODELE D W H F

ADR148 59,7 cm 121,9cm 55,6 cm 5,1 cm

ADR136 59,7 cm 91,4 cm 55,6 cm 5,1 cm

ADR130 59,7 cm 76,2 cm 55,6 cm 5,1 cm

F

Fig. 1

INSPECTION APRES lIvRAISON

Inspectez les tiroirs pour vous assurer qu’ils n’ont subi aucun 1.

dommage durant le transport.

Le cas échéant, appelez le transporteur et soumettez une 2.

réclamation pour dommages. DCS by Fisher & Paykel n’est

pas responsable des dommages subis durant le transport.

REMARQUE : Ne jetez aucun matériel d’emballage (boîte,

palette, sangles) avant d’avoir inspecté l’appareil.

Faites fonctionner les tiroirs pour vous assurer qu’ils glissent ■

correctement.

Examinez le devant des tiroirs pour vous assurer qu’il n’y a ■

aucune bosse ou égratignure.

ADR124 59,7 cm 61 cm 55,6 cm 5,1 cm

Fig. 1a

Fig. 2

3

Page 19

PRÉPARATION DE l’ÉlÉMENT

La face de l’élément doit être propre et plate. ■

Tous les angles doivent être de 90º et d’équerre. ■

La structure de support doit être résistante aux dommages de l’humidité. ■

Toutes les conduites de gaz et tuyauteries doivent être effectuées avant d’installer les tiroirs d’accès. ■

Ne pas utiliser de produits abrasifs (acide, solvant, produit d’étanchéité) autour de cette unité. ■

Toutes les préparations d’élément et/ou de sol doivent être terminées avant l’installation. ■

4

Page 20

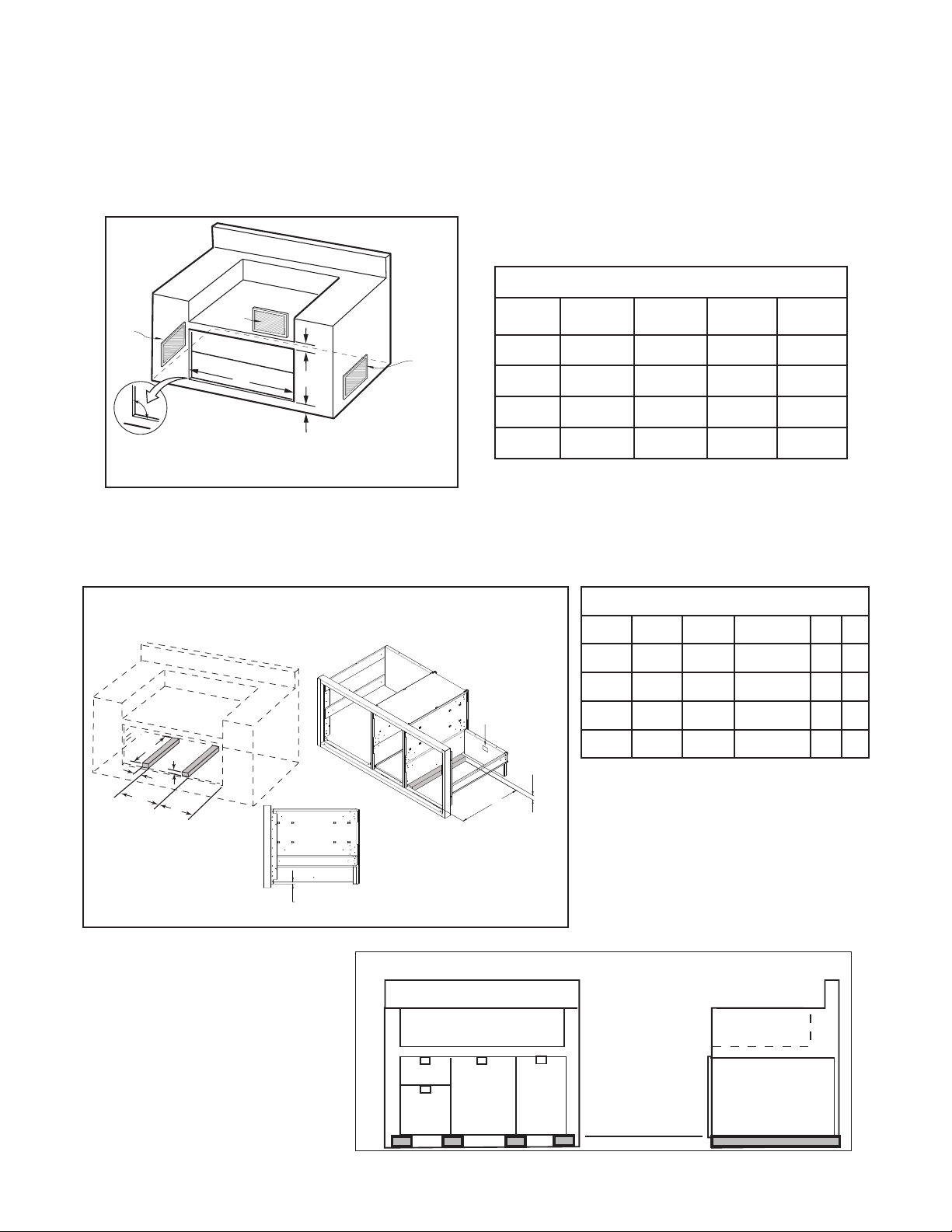

INSTAllATION

A

90º

B

Vent*

Vent*

Vent*

C

D

Le fond du séparateur central à la

découpe de l'îlot est de 1/2 po

C

B

A

A

B

E

D

Emplacement de

l'autocollant des

numéros de modèle,

code et série.

*

EFFECTUER lA DECOUPE ET INSTAllER lA STRUCTURE DE SUPPORT

Effectuez une découpe dans votre armoire ou îlot avec les dimensions suivantes (Fig. 3) : 1.

REMARQUE : Chaque coin de découpe doit être de 90º pour que les tiroirs d’accès entrent correctement.

DIMENSIONS DES DECOUPES

MODELE

ADR148 116,8 cm 50,8 cm 2,54 cm min. 2,54 cm min.

A

0,+0,3cmB0,+0,3cm

C D

ADR136 86,4 cm 50,8 cm

ADR130 71,2 cm 50,8 cm

* Prévoir pour l’installation en îlot 3

évents minimum à raison de 64 cm2 (10

po2) par évent (installation typique).

ADR124 56 cm 50,8 cm

Fig. 3

Placez des pièces 2 x 4 pour fournir un support à la structure des tiroirs aux emplacement indiqués sur la figure ci-dessous 2.

(Fig. 4).

La longueur des planches est indiquée dans le tableau ci-dessous (Fig. 5).3.

Afin d’assurer le bon fonctionnement des tiroirs, assurez-vous que les

planches de support sont plates et de niveau.

2,54 cm min. 2,54 cm min.

2,54 cm min. 2,54 cm min.

2,54 cm min. 2,54 cm min.

DIMENSIONS DES PLANCHES DE SUPPORT

A B C D E

2 X 5,1

48 po

3,8 cm* 8,9 cm min. 35,6 cm 30,5 cm

cm

36 po 5,1 cm 3,8 cm* 8,9 cm min. 35,6 cm

30 po 5,1 cm 3,8 cm* 8,9 cm min. 35,6 cm 30,5 cm

24 po 5,1 cm 3,8 cm* 8,9 cm min. 35,6 cm

Fig. 5

Lors de l’installation des planches de 4.

support, assurez-vous qu’elles sont de

niveau.

S’assurer que le fond du séparateur 5.

central repose sur les planches de

support comme il l’est illustré (Fig. 4).

Fig. 4

*En fonction de l’application. Dessus des 2 x 4

doit être à 1/2” au-dessus du chant inférieur

de la découpe.

Vue de face (typique)

Planche de support

(typique)

Pour permettre

un support et un

fonctionnement

adéquat des tiroirs,

assurez-vous que

les planches de

support sont de

niveau de l’avant

à l’arrière et d’un

côté à l’autre.

Vue de l’extrémité (typique)

Planches de

support (typique)

Fig. 6

5

Page 21

INSTAllATION

29,8 cm

(11-3/4 po)

10,5 cm

(4-1/8 po)

3,5 cm (1-3/8 po)

(Ø

6,35 mm [1/4 po])

TROU D’ANCRAGE

2,4 cm (15/16 po)

RETRAIT DES TIROIRS

Une fois l’appareil inspecté, retirez les tiroirs en tirant jusqu’à ce que le verrou de glissière soit visible. Enfoncez soigneuse-1.

ment le verrou du côté gauche tout en soulevant du côté droit, et tirez les tiroirs pour les sortir complètement du châssis

(Fig. 7).

Pour éviter d’endommager les surfaces, placez les tiroirs sur une surface stable sur une serviette ou une nappe de protection.2.

Pour retirer le tiroir ADR124, tirez le tiroir et soulevez l’extrémité par la poignée pour dégager les roulettes (Fig. 8).

Verrou de glissière

Soulevez

Fig. 7

Fig. 8

ENFONCER DANS lE CADRE ET MONTER SUR lA STRUCTURE DE SUPPORT

Avec l’aide d’un assistant, Soulever l’unité et la glisser dans la découpe de l’élément. Effectuez l’ajustement nécessaire.1.

Repérer les trous de montage sur le cadre (Fig. 9 et illustrations). Fixez l’appareil à l’aide de vis appropriées pour le type de 2.

matériau des armoires.

REMARQUE : Selon l’épaisseur du mur et l’emplacement des trous de montage, ajoutez au besoin une planche supplémentaire pour permettre une bonne prise des vis.

Fig. 9

6

Page 22

INSTAllATION

REINSTAllATION DES TIROIRS

Réinstallez les tiroirs en étirant leurs guides tel qu’indiqué à la Fig. 10.1.

Tout en gardant le tiroir parallèle à l’armoire, alignez soigneusement puis enfoncez les extrémités des glissières. Glissez le 2.

tiroir de 2,5 cm (1 po) environ de sorte que les glissières puissent soutenir l’arrière du tiroir (Fig. 11).

Glissière de tiroir enfoncée correctement.

Verrou de glissière

Fig. 10 Fig. 11

Tout en retenant le tiroir par la poignée, tirez les glissières de la cavité du tiroir par dessus les glissières du tiroir jusqu’à ce 3.

qu’elles cliquent (Fig. 12).

Vous sentirez une faible résistance lorsque vous enfoncez les tiroirs. Continuez à enfoncer le tiroir complètement pour 4.

achever la procédure. Le tiroir devrait à présent glisser en douceur, dans un sens comme dans l’autre, sans effort (Fig. 13).

Glissière de la

cavité du tiroir

Fig. 12

Fig. 13

7

Page 23

INSTAllATION

Votre réservoir de propane sera installé dans le renfoncement situé dans le bas du compartiment droit (Fig. 14).5.

Réceptacle du réservoir

Fig. 14

Lors de la connexion à une bouteille de propane au grill, s’assurer que toutes les connexions sont serrées. Une fois les connex-6.

ions de gaz effectuées, tester pour présence éventuelle de fuites de gaz.

Dans les modèles ainsi équipés, installez les deux (2) grilles fournies dans l’ouverture en les glissant sur les roulettes des 7.

parois latérales de la cavité centrale (Fig. 15).

Grille et couvercle de grille

Tiroir de propreté

Fig. 15

8

Page 24

ENTRETIEN ET MAINTENANCE

Les tiroirs d’accès sont fabriqués en acier inoxydable résistant à la corrosion et non magnétique. Toutes les pièces des tiroirs

d’accès peuvent être nettoyées à l’eau chaude savonneuse, rincées, séchées et lustrées pour être brillantes avec un chiffon

épais et doux. Toujours essayer cette méthode en premier car c’est la procédure de nettoyage la plus douce. On trouve

toute sorte de nettoyants pour acier inoxydable sur le marché. Toujours utiliser la procédure de nettoyage la plus douce en

premier, en frottant dans le sens du grain pour éviter de rayer la surface. Le nettoyant sera plus efficace quand il est utilisé

dans le sens du grain (lignes de poli).

Certaines 1. marques de nettoyants du même type sont plus durs que d’autres, lire leurs mode d’emploi. Un parfum ou

un agent propulseur peut faire une différence dans le produit, lire les ingrédients. Essayer sur une petite surface pour

commencer.

Pour réparer des égratignures visibles à l’œil nu, frotter très légèrement avec du papier de verre 100, dans le sens du grain. 2.

Des taches de graisse peuvent s’accumuler et s’incruster sur les surfaces en acier inoxydable sous l’effet de la cuisson, ce qui 3.

peut ressembler à de la rouille. Pour les enlever, utiliser un tampon abrasif (Scotch Brite par exemple) conjointement avec un

nettoyant pour acier inoxydable. Toujours frotter dans le sens du grain.

3. Pour nettoyer ou récurer, utilisez uniquement des éponges propres, des tissus doux, des essuie-tout, des tampons

à récurer savonneux en plastique sans métal. (Utilisez uniquement des tampons contenant encore du savon car

un tampon sec peut égratigner la surface.)

4. Rincez soigneusement et séchez en essuyant pour éviter de laisser des marques d’eau.

REMARQUE : L’acier inoxydable a tendance à se corroder en présence de chlorures et de sulfures, spécialement

dans les régions côtières. Pour prévenir les risques de corrosion, laver toutes les surfaces en acier inoxydable

toutes les 3 à 4 semaines à l’aide d’eau douce et d’un nettoyant pour acier inoxydable.

MARQUES DE NETTOYANTS

La référence à des noms de marques dans cette section est donnée à titre indicatif et ne saurait constituer un acte de

promotion. L’omission d’une marque de nettoyant particulière ne signifie pas qu’elle est adéquate ou non. De nombreux

produits sont distribués dans certaines régions seulement et sont disponibles dans des marchés et grands magasins locaux.

MAINTENANCE

Après le nettoyage, utilisez un produit à polir pour acier inoxydable, tel que Stainless Steel Magic®, sur les surfaces des

tiroirs et des poignées. Pour préserver le fonctionnement doux des tiroirs, vaporisez les pièces de roulement avec du

lubrifiant au silicone une fois l’an. (Fig. 16).

Points de

lubrification

(Vaporisez

du lubrifiant

au silicone

une fois

l’an)

Fig. 16

9

Page 25

ACCESSOIRES

ACCESSOIRES

Freezer Pack (option, Kit n° 70696A)(Fig. 17)1.

Porte-panier de déchets (option, Kit n° 70906)(Fig. 18)2.

Couvercle inférieur (option, Kit n° 70907)(Fig. 19)3.

REMARQUE: Pour commander les accessoires ci-dessous,

veuillez contacter le centre de service a la clientele Fisher &

Paykel au numero 1-888-936-7872.

Fig. 17 F

reezer Pack (option)

Fig. 18

Porte-panier de déchets

(option)

Fig. 19

Couvercle inférieur

(option)

10

Page 26

SERvICE

Pour le service sous garantie, veuillez contacter votre distributeur ou contactez le centre DCS agréé le plus proche au

(888) 936-7872 ou consulter notre site Web www.dcsappliances.com et choisir « Customer Care » pour trouver le Centre de

service le plus proche. Avant d’appeler, veuillez avoir les informations suivantes à portée de main :

Numéro de modèle (situé sur l’autocollant sur la contrefiche arrière du côté réservoir - voir Fig. 04) ■

Numéro de série (situé sur l’autocollant sur la contrefiche arrière du côté réservoir - voir Fig. 04) ■

Code (situé sur l’autocollant sur la contrefiche arrière du côté réservoir - voir Fig. 04) ■

Date d’installation ■

Brève description du problème ■

Votre satisfaction revêt la plus haute importance pour nous. Si un problème n’est pas résolu à votre entière satisfaction,

veuillez communiquer avec nous :

Écrivez-nous à l’adresse suivante :

Fisher & Paykel Appliances, Inc.

Attention : DCS Customer Care

5900 Skylab Road

Huntington Beach, CA 92647

ou email : customer.care@fisherpaykel.com

11

Page 27

gARANTIE

gARANTIE lIMITEE

Lors de l’achat de tiroirs professionnels neufs DCS by Fisher & Paykel, vous bénéficiez automatiquement d’une garantie

limitée d’un an couvrant les pièces et la main d’œuvre pour l’intégralité du produit, et d’une garantie limitée de cinq ans

sur toutes les ensembles en acier inoxydable (pièces seulement) valide dans les 48 états continentaux des États-Unis,

ainsi que Hawaï, Washington D.C. et le Canada. La garantie limitée est la même en Alaska sauf que vous devez payer les

frais d’expédition du produit à un centre de service ou les frais de déplacement d’un technicien dans le cas d’une visite à

domicile. Les produits destinés à une utilisation au Canada doivent être achetés auprès d’un distributeur canadien afin de

respecter la réglementation en vigueur.Les phénomènes de décoloration ou de corrosion en surface ne sont pas couverts

par la garantie.

FIShER & PAYkEl S’ENgAgE À :

entreprendre à ses frais (pièces et main-d’oeuvre) toutes réparations du produit (sur lequel figure le numéro de série) jugé

défectueux. En Alaska, vous devez payer les frais d’expédition du produit à un centre de service ou les frais de déplacement

d’un technicien dans le cas d’une visite à domicile.

Si nous sommes dans l’incapacité de réparer une pièce défectueuse du produit après un nombre raisonnable de tentatives,

nous pourrons, à notre choix, remplacer la pièce ou le produit, ou vous rembourser entièrement le prix d’achat du produit (à

l’exclusion des frais d’installation ou autres frais.)

Cette garantie s’applique à l’acheteur initial et à tous les propriétaires successifs du produit dans la mesure où il s’agit d’un

produit acheté pour une utilisation à domicile normale. Tout service couvert par cette garantie limitée sera assuré par Fisher

& Paykel Appliances Inc. ou son agent de service DCS agréé durant les heures d’ouverture normales.

QUEllE EST lA DURÉE DE CETTE gARANTIE lIMITÉE?

Notre responsabilité en vertu de cette garantie limitée concernant l’intégralité du produit expire UN AN à partir de la date

d’achat du produit par le premier acheteur.

Notre responsabilité en vertu de toute garantie implicite, y compris la garantie implicite de qualité marchande (la garantie

tacite selon laquelle le produit est approprié pour un usage normal) expire également UN AN (ou une période plus longue

si requis par la loi) à partir de la date d’achat du produit par le premier acheteur. Certaines juridictions ne permettent pas la

limitation de la garantie implicite, il est donc possible que la limitation ci-dessus sur les garanties implicites ne s’applique pas

à vous.

NE SONT PAS COUvERTS PAR lA gARANTIE :

Les appels de service n’ayant aucun rapport avec un défaut éventuel du produit. Le coût de l’appel de service sera facturé s’il A.

se trouve que le problème n’est pas dû à un défaut du produit. Par exemple :

1. Corriger une mauvaise installation du produit.

2. Montrer comment utiliser le produit.

3. Corriger des anomalies causées par l’utilisateur.

4. Changer la configuration du produit.

5. Modifications non autorisées du produit

6. Décoloration ou taches de rouille.

7. Corriger des dommages causés par des animaux nuisibles, par exemple des rats, des coquerelles, etc.

Défauts causés par des facteurs autres que :B.

1. Utilisation domestique normale ou

2. Utilisation conformément au manuel d’utilisation et d’entretien du produit.

Défauts du produit pour cause d’accident, négligence, mauvaise utilisation, incendie, inondation ou calamité naturelle.C.

Les coûts des réparations effectuées par des techniciens non autorisés ou le coût de correction de ces réparations non D.

autorisées.

Les frais de voyage et les frais connexes encourus lorsque le produit est installé dans un lieu à accès illimité ou restreint E.

(déplacement par avion ou par bateau, régions géographiques isolées, etc).

Entretien normal recommandé par le manuel d’utilisation et d’entretien du produit.F.

12

Page 28

gARANTIE (suite)

Nous ne sommes pas responsables des dommages indirects ou accessoires (coût de réparation ou de remplacement d’autres

biens endommagés parce que le produit était défectueux ou tout autre coût que vous auriez encouru parce que le produit

était défectueux). Certaines juridictions interdisent l’exclusion ou la restriction de la responsabilité des dommages indirects

ou accessoires; l’exclusion ou la restriction indiquée ci-dessus peut donc ne pas s’appliquer à votre cas particulier.

POUR ObTENIR DES RÉPARATIONS

Veuillez consulter le manuel d’utilisation et d’entretien. Si vous avez des questions concernant l’utilisation du produit, que

vous cherchez le nom de l’agent de service DCS agréé local ou que pensez que le produit est défectueux et désirez le faire

réparer dans le cadre de cette garantie limitée, veuillez contacter votre distributeur ou nous appeler au numéro suivant :

(NUMÉRO SANS FRAIS) 1-888-936-7872 ou contactez-nous par l’intermédiaire de notre site Web :

www.dcsappliances.com

Vous devrez peut-être présenter une preuve raisonnable de la date d’achat du produit avant de pouvoir bénéficier d’une

réparation dans le cadre de cette garantie limitée.

UTIlISATION COMMERCIAlE

Cette garantie s’applique à des appareils électroménagers utilisés à domicile; elle ne couvre pas les cas d’utilisation commerciale.

AUCUNE AUTRE gARANTIE

Cette garantie limitée constitue l’accord entier et exclusif entre vous et Fisher & Paykel Appliances Inc. en ce qui concerne

tout défaut du produit. Aucun de nos employés (ou agents de service agréés) n’est autorisé à apporter des ajouts ou des

modifications à cette garantie limitée.

Garant : Fisher & Paykel Appliances, Inc.

Si vous avez besoin d’aide au sujet de cette garantie limitée, veuillez nous appeler au numéro ci-dessus ou nous écrire à

l’adresse suivante :

Fisher & Paykel Appliances, Inc.

Attention: DCS Customer Care

5900 Skylab Road, Huntington Beach, CA 92647 États-Unis

Cette garantie limitée vous donne des droits juridiques spécifiques et vous pouvez bénéficier d’autres droits qui varient

d’une juridiction à l’autre.

Fisher & Paykel Appliances inc. est un fabricant de pointe d’appareils de cuisson et d’appareils spécialisés, sous les marques

Fisher & Paykel et DCS by Fisher & Paykel.

13

Page 29

REMARQUE

14

Page 30

REMARQUE

15

Page 31

Page 32

Fisher & Paykel Appliances, Inc.

5900 Skylab Road, Huntington Beach, CA 92647

Customer Care: 888.936.7872

Fax: 714.372.7003

www.dcsappliances.com

As product improvement is an ongoing process at DCS by

As product improvement is an ongoing process, we reserve

the right to change specifications or design without notice.

Nous améliorons constamment ses produits et se réserve le

droit de modifier les spécifications ou la conception de ses

produits sans aucun préavis.

P/N 243444 Rev. C

Litho in USA 01/2010

Loading...

Loading...