Page 1

SFC332L

OPERATORS MANUAL

Flow C o m p u t e r

Liqui d V e r s i o n

11 1 0 4 W . A i r p o rt Blvd , S u i t e 1 0 8 & 1 4 8

Staf f o r d , T e x as 77 4 7 7 U S A

(2 81 ) 5 6 5 -1118

Fa x ( 2 8 1 ) 5 6 5 -11 1 9

Date: 8/1/2019

Page 2

WARRANTY

Dynamic Flow Computers warrants to the owner of the Smart Flow Computer that the

product delivered will be free from defects in material and workmanship for one (1) year

following the date of purchase.

This warranty does not cover the product if it is damaged in the process of being installed

or damaged by abuse, accident, misuse, neglect, alteration, repair, disaster, or improper

testing.

If the product is found otherwise defective, Dynamic Flow Computers will replace or

repair the product at no charge, provided that you deliver the product along with a return

material authorization (RMA) number from Dynamic Flow Computers.

Dynamic Flow Computers will not assume any shipping charge or be responsible for

product damage due to improper shipping.

THE ABOVE WARRANTY IS IN LIEU OF ANY OTHER WARRANTY EXPRESS

IMPLIED OR STATUTORY. BUT NOT LIMITED TO ANY WARRANTY OF

MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE, OR ANY

WARRANTY ARISING OUT OF ANY PROPOSAL, SPECIFICATION, OR SAMPLE.

LIMITATION OF LIABILITY:

DYNAMIC FLOW COMPUTERS SHALL HAVE NO LIABILITY FOR ANY

INDIRECT OR SPECULATIVE DAMAGES (INCLUDING, WITHOUT LIMITING

THE FOREGOING, CONSEQUENTIAL, INCIDENTAL AND SPECIAL DAMAGES)

ARISING FROM THE USE OF, OR INABILITY TO USE THIS PRODUCT.

WHETHER ARISING OUT OF CONTRACT, OR UNDER ANY WARRANTY,

IRRESPECTIVE OF WHETHER DFM HAS ADVANCED NOTICE OF THE

POSSIBILITY OF ANY SUCH DAMAGE INCLUDING, BUT NOT LIMITED TO

LOSS OF USE, BUSINESS INTERRUPTION, AND LOSS OF PROFITS.

NOTWITHSTANDING THE FOREGOING, DFM’S TOTAL LIABILITY FOR ALL

CLAIMS UNDER THIS AGREEMENT SHALL NOT EXCEED THE PRICE PAID

FOR THE PRODUCT. THESE LIMITATIONS ON POTENTIAL LIABILITY WERE

AN ESSENTIAL ELEMENT IN SETTING THE PRODUCT PRICE. DFM NEITHER

ASSUMES NOR AUTHORIZES ANYONE TO ASSUME FOR IT ANY OTHER

LIABILITIES

Date: 8/1/2019

Page 3

CHAPTER 1: QUICK START.................................................................................................................... 1-1

Introduction: ............................................................................................................................................ 1-1

Technical Data: ........................................................................................................................................ 1-2

Parts List .................................................................................................................................................. 1-3

SFC332L Flow Computer: Dimensions ................................................................................................. 1-4

Starting and Installing theWindow Software: .......................................................................................... 1-5

System Minimum Requirements ......................................................................................................... 1-5

Website - DFC Configuration Software .................................................................................................. 1-6

Getting acquainted with the flow computer wiring: ................................................................................ 1-8

Back terminal wiring: .......................................................................................................................... 1-8

Back Panel Jumper .............................................................................................................................. 1-9

Memory Jumper................................................................................................................................. 1-10

INPUT/OUTPUT: Assigning and Ranging Inputs ................................................................ ............... 1-14

Input/Output Assignment .................................................................................................................. 1-14

How to assign a transmitter to an I/O point ....................................................................................... 1-14

Ranging the Transmitter Inputs: ........................................................................................................ 1-15

WIRING: ............................................................................................................................................... 1-16

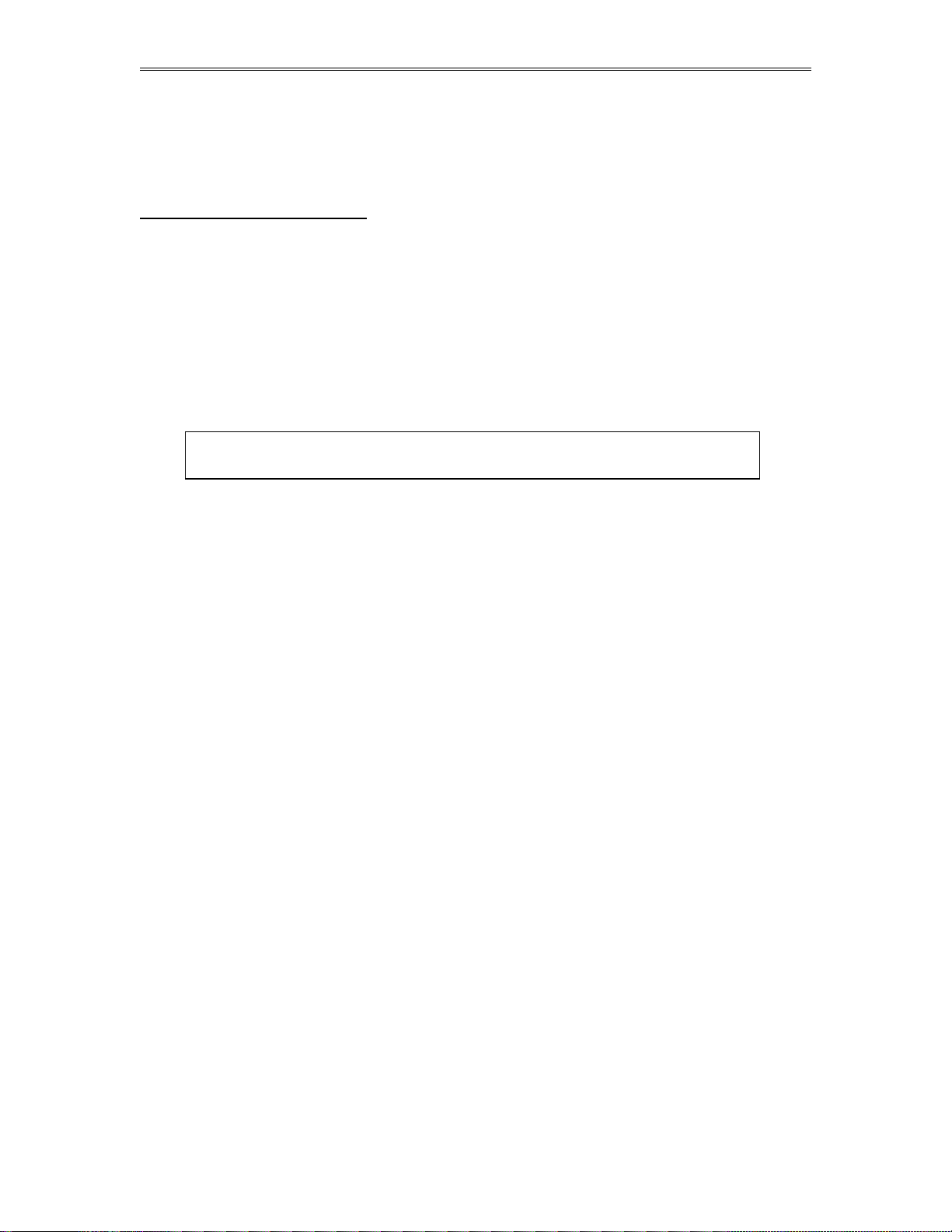

Wiring the Analog Inputs: ................................................................................................................. 1-16

Wiring the analog inputs 1-4 : ........................................................................................................... 1-17

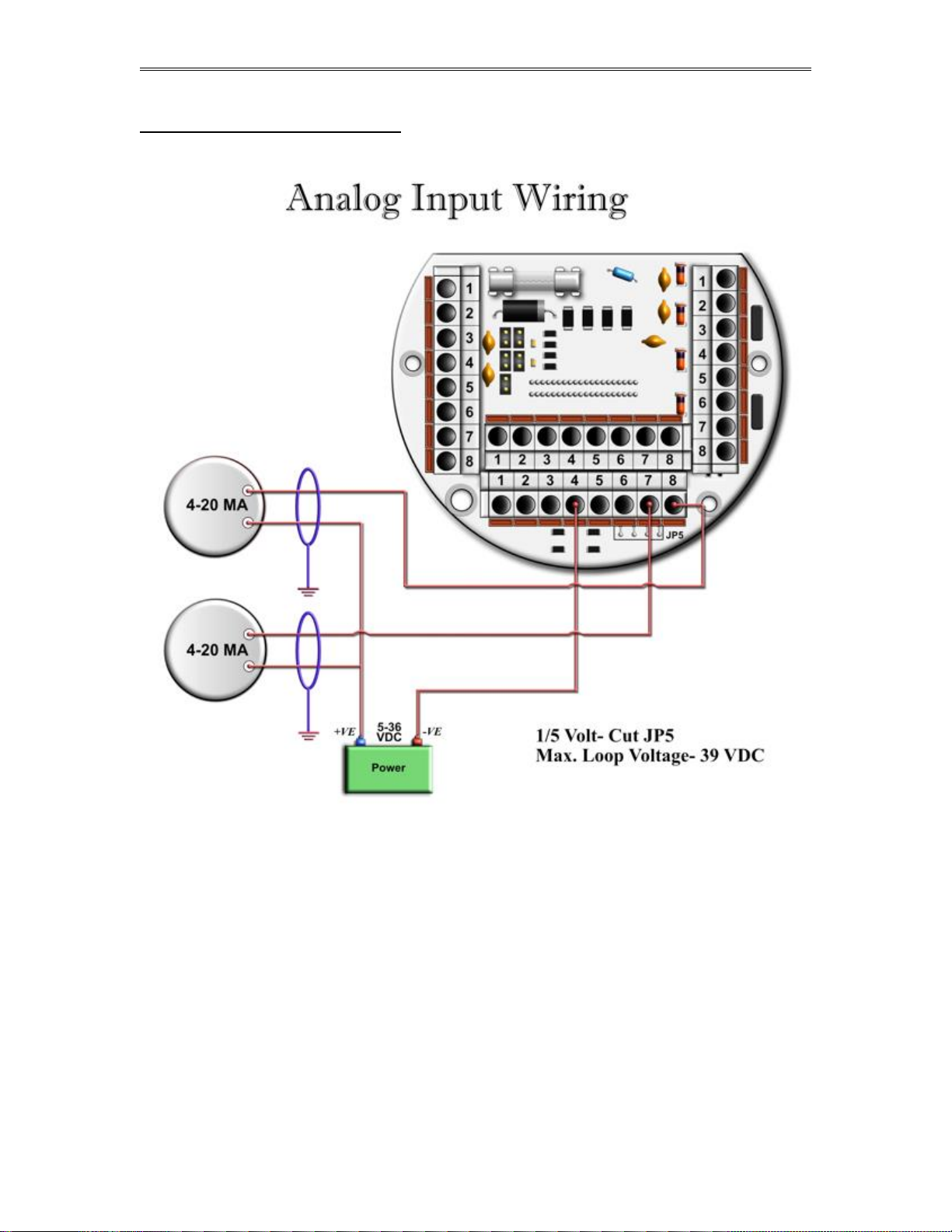

RTD ................................................................................................................................................... 1-18

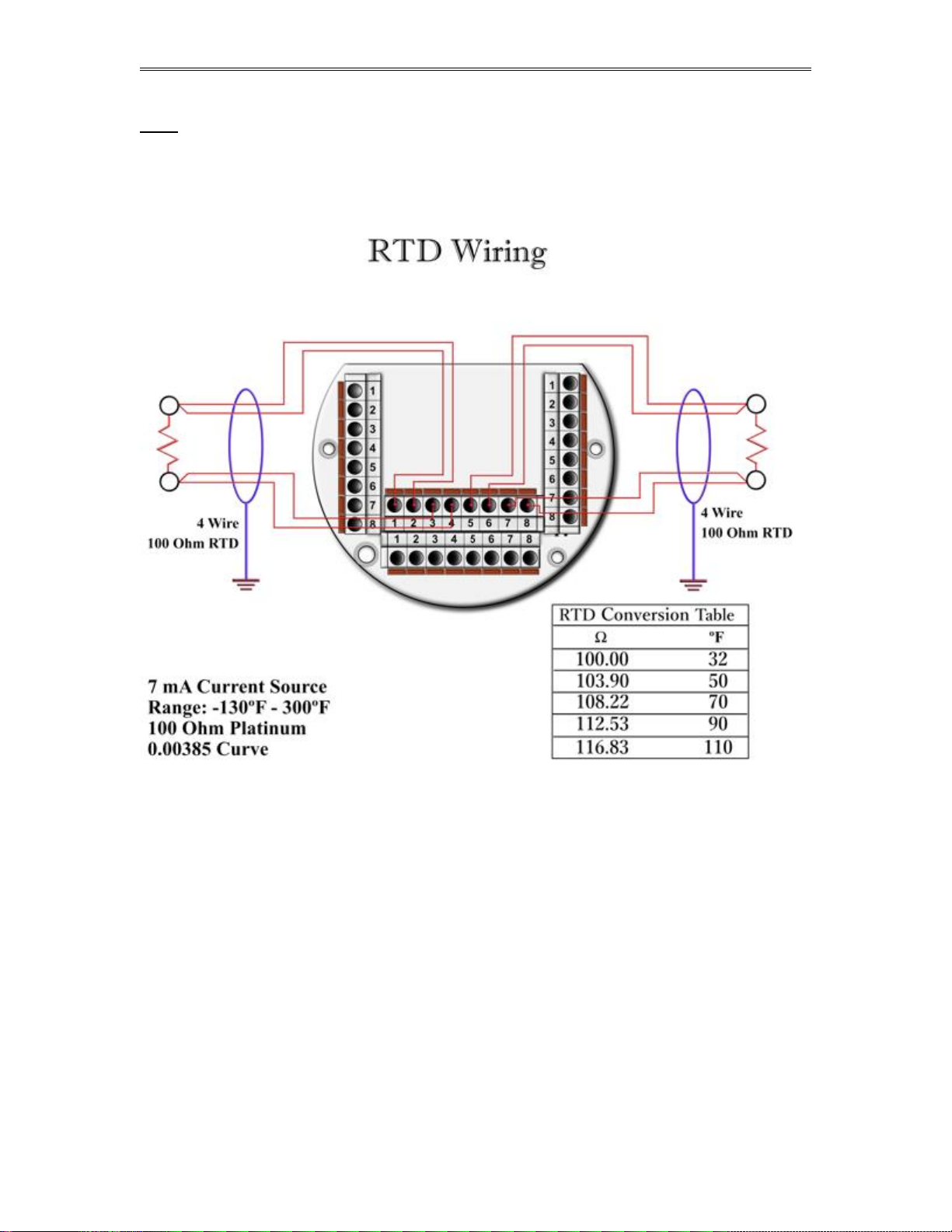

Wiring Analog Output: ................................................................ ................................ ...................... 1-19

Turbine Input Wiring ......................................................................................................................... 1-20

Turbine input wiring for passive (dry contact) pulse generators ....................................................... 1-23

Density Input Wiring: ........................................................................................................................ 1-24

RS-232 Connection: .......................................................................................................................... 1-25

RS-485: .............................................................................................................................................. 1-26

Wiring of Status Inputs: ..................................................................................................................... 1-27

Wiring of Switch/Pulse Outputs: ....................................................................................................... 1-28

I/O Expansion: ................................................................................................................................... 1-29

Prover/Expansion .............................................................................................................................. 1-31

CALIBRATION Through Window Program ........................................................................................ 1-32

Analog Input 4-20mA or 1-5 volt signal .......................................................................................... 1-32

RTD Calibration: ............................................................................................................................... 1-33

Calibration of Analog Output: ........................................................................................................... 1-34

Multi-Variable Transmitters (Model 205) – DP and Pressure ........................................................... 1-34

Multi-Variable Transmitters (Model 205) –RTD .............................................................................. 1-35

CALIBRATION Through DOS Program .............................................................................................. 1-36

Analog Input 4-20mA or 1-5 volt signal: .......................................................................................... 1-36

RTD calibration: ................................................................................................................................ 1-37

Calibration of Analog Output: ........................................................................................................... 1-38

Multi-Variable Transmitters (Model 205)- DP and Pressure ............................................................ 1-38

Multi-Variable Transmitters (Model 205)- RTD ............................................................................... 1-39

Verifying Digital Inputs and Outputs .................................................................................................... 1-40

CHAPTER 2: Data Entry ............................................................................................................................ 2-1

Introduction to the SFC332L Computer Software ................................................................................... 2-1

Configuration File through Window Program ......................................................................................... 2-1

New ..................................................................................................................................................... 2-1

Open .................................................................................................................................................... 2-1

Close .................................................................................................................................................... 2-1

Save ..................................................................................................................................................... 2-1

Save As ................................................................................................................................................ 2-1

VIEW ...................................................................................................................................................... 2-2

View Drawings .................................................................................................................................... 2-2

TOOLS .................................................................................................................................................... 2-3

Com Settings ....................................................................................................................................... 2-3

Date: 8/1/2019

Page 4

Meter Configuration ............................................................................................................................ 2-4

Security Code .................................................................................................................................... 2-33

PID OPERATING ................................................................................................................................. 2-34

CALIBRATION .................................................................................................................................... 2-34

Calibrate Mode .................................................................................................................................. 2-34

Parameter Overrides: ............................................................................................................................. 2-34

Temperature Override ....................................................................................................................... 2-34

Pressure Override .............................................................................................................................. 2-34

DP Override ....................................................................................................................................... 2-34

API/SG/Density Override .................................................................................................................. 2-34

Orifice ID Override ........................................................................................................................... 2-34

Current Batch Preset .......................................................................................................................... 2-34

Equilibrium Pressure Override .......................................................................................................... 2-35

Alpha T E-6 Override ........................................................................................................................ 2-35

Wedge Fa Override and Wedge Kd2 Override .................................................................................. 2-35

Venturi C Override ............................................................................................................................ 2-35

End Batch .......................................................................................................................................... 2-35

SYSTEM ........................................................................................................................................... 2-35

HISTORICAL DATA ........................................................................................................................... 2-36

VIEW, CAPTURE AND STORE ..................................................................................................... 2-36

Viewing previously captured reports ................................................................................................. 2-36

Exporting or Printing Reports ............................................................................................................ 2-37

SCHEDULED AUTO POLLING ..................................................................................................... 2-38

CHAPTER 3: FLOW EQUATIONS ........................................................................................................... 3-1

AGA3 ...................................................................................................................................................... 3-1

API 14.3................................................................................................................................................... 3-2

Wedge ................................................................................................................................ ...................... 3-3

Venturi ..................................................................................................................................................... 3-4

AGA7 ...................................................................................................................................................... 3-5

DENSITY EQUATIONS ........................................................................................................................ 3-6

Sarasota Density GM/CC .................................................................................................................... 3-6

UGC Density GM/CC ......................................................................................................................... 3-7

Solartron Density GM/CC ................................................................................................................... 3-8

Propylene Density ............................................................................................................................... 3-9

Ethylene Density ................................................................................................................................. 3-9

NBS 1045 ............................................................................................................................................ 3-9

NIST14 ................................................................................................................................................ 3-9

DENSITY EQUATIONS (Without Live Densitometer) ....................................................................... 3-10

CHAPTER 4: MODBUS DATA ................................................................................................................. 4-1

MODBUS PROTOCOL .......................................................................................................................... 4-1

TRANSMISSION MODE ................................................................................................................... 4-1

ASCII FRAMING ............................................................................................................................... 4-1

RTU FRAMING .................................................................................................................................. 4-1

FUNCTION CODE ............................................................................................................................. 4-2

ERROR CHECK ................................................................................................................................. 4-2

EXCEPTION RESPONSE .................................................................................................................. 4-2

BROADCAST COMMAND ............................................................................................................... 4-2

MODBUS EXAMPLES ...................................................................................................................... 4-3

FUNCTION CODE 03 (Read Single or Multiple Register Points) ..................................................... 4-3

ASCII MODE - Read Address 3076 ................................................................................................... 4-3

MODBUS ADDRESS TABLE – 16 BITS ............................................................................................. 4-5

MODBUS ADDRESS TABLE – 32 BITS ........................................................................................... 4-12

Last Batch/Daily Data Area ............................................................................................................... 4-15

Alarms and Status Codes ................................................................................................................... 4-40

Previous Audit Data Area .................................................................................................................. 4-41

CURRENT ALARM STATUS ......................................................................................................... 4-44

Date: 8/1/2019

Page 5

FLOATING POINTS ............................................................................................................................ 4-46

Historical Batch/Daily Data Area – Meter #1 ................................................................................... 4-49

Historical Hourly Data Area – Meter #1 ........................................................................................... 4-50

Current Data Area– Meter #2 ............................................................................................................ 4-51

Historical Batch/Daily Data Area – Meter #2 ................................................................................... 4-52

Historical Hourly Data Area – Meter #2 ........................................................................................... 4-53

Programmable Floating Point Variables ............................................................................................ 4-54

Date: 8/1/2019

Page 6

Dynamic Flow Computers SFC332L Manual Quick Start — 1-1

CHAPTER 1: QUICK START

Introduction:

A good flow computer must be:

User friendly

Flexible

Easy to understand and configure

Rugged

Economical to install and maintain

Accurate

The model SFC332L Smart Flow Computer incorporates all these features. We hope that your experience

with the Smart Flow Computer will be a very pleasant and friendly experience and not intimidating in any

way.

General Description: The SFC332L is a dual meter run bi-directional flow computer for the measurement

of liquid products. Using orifice plate, Venturi, turbine/PD/ultrasonic mass meter, or wedge devices, it can

meter a wide variety of products, such as crude, refined product, LPG/NGL products, products that use

table 24C, ethylene, propylene, and water. Fifty days of previous daily data, fifty previous batch data, and

fifty previous hourly data are stored in the full format type reports. The previous 100 audit trail reports and

100 alarm reports are stored. User formatted reports and user formatted ticket reports are available.

Sixteen different product files are user-configurable with easy switch feature and product scheduling for

batch operation.

Inputs/Outputs: 2 serial connections, RS-232 and RS-485, both of them Modbus ready. The RS-232 can

also be used with serial printer. Inputs: two 4 wire RTD, 4 single ended analog inputs, 4 status inputs and

1 density frequency. Outputs: 2 pulse/switch outputs; 3 switch outputs; and 2 analog outputs. Also

includes a programmable plasma display.

Date: 8/1/2019

Page 7

Dynamic Flow Computers SFC332L Manual Quick Start — 1-2

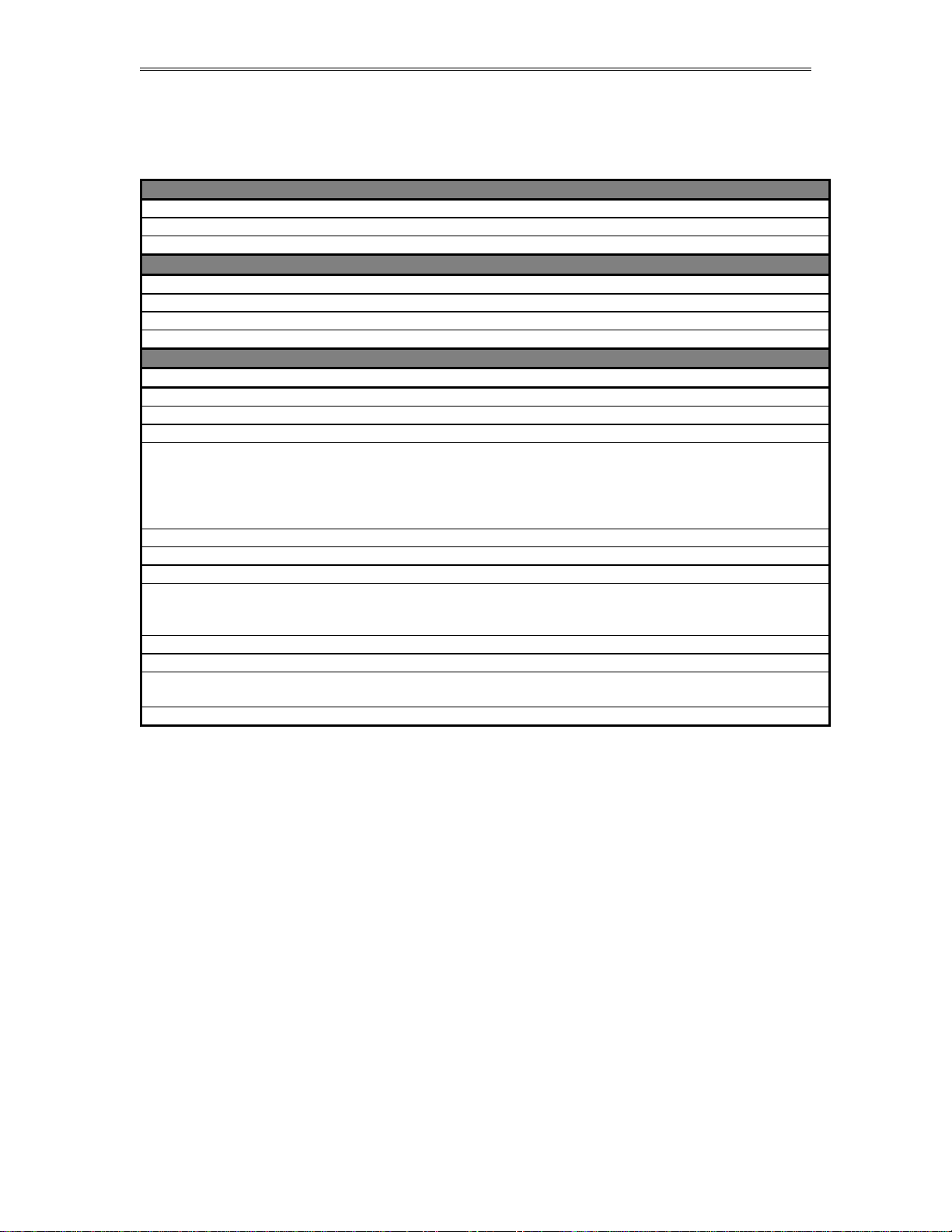

POWER

VOLTAGE RANGE

12-30 VDC

WATTAGE

4 WATT

OPERATING CONDITIONS

TEMPERATURE

- 40 TO 185 °F

HUMIDITY

100%

HOUSING

NEMA 4X CLASS 1 DIV. 1

FEATURES

DISPLAY

PLASMA 2 LINES 16 CHARACTER

PROCESSOR

32-BIT MOTOROLA 168332 @ 16.7 MHz

FLASH ROM

4 MB @ 70 NANO SECONDS

ROM

2 MB @ 30 NANO SECONDS

FREQUENCY INPUT

3 CHANNELS

0 - 5000 Hz

WITH TURBINE DIAGNOSTIC FUNCTION

>70 mV FOR SIN WAVE

> 6 VOLTS FOR SQUARE WAVE

ANALOG INPUT

FOUR 24-BIT CHANNEL

RTD INPUTS

2 CHANNELS 4 WIRES

ANALOG OUTPUT

2 CHANNELS 12 BIT SINGLE ENDED

DIGITAL OUTPUT

OUTPUTS 1 & 2 PULSE/SWITCH 0.5 AMPS RATING

OUTPUTS 3 TO 5 ARE SWITCH OUTPUTS 0.25 AMPS

RATING

STATUS INPUTS

4 ON/OFF TYPE SIGNAL

ALL INPUTS AND OUTPUTS ARE OPTICALLY ISOLATED

SERIAL

1 RS485 @ 9600 BAUDS VARIABLE

1 RS232 @ 9600 BAUDS VARIABLE

COMMUNICATION PROTOCOL

MODBUS

Technical Data:

Date: 8/1/2019

Page 8

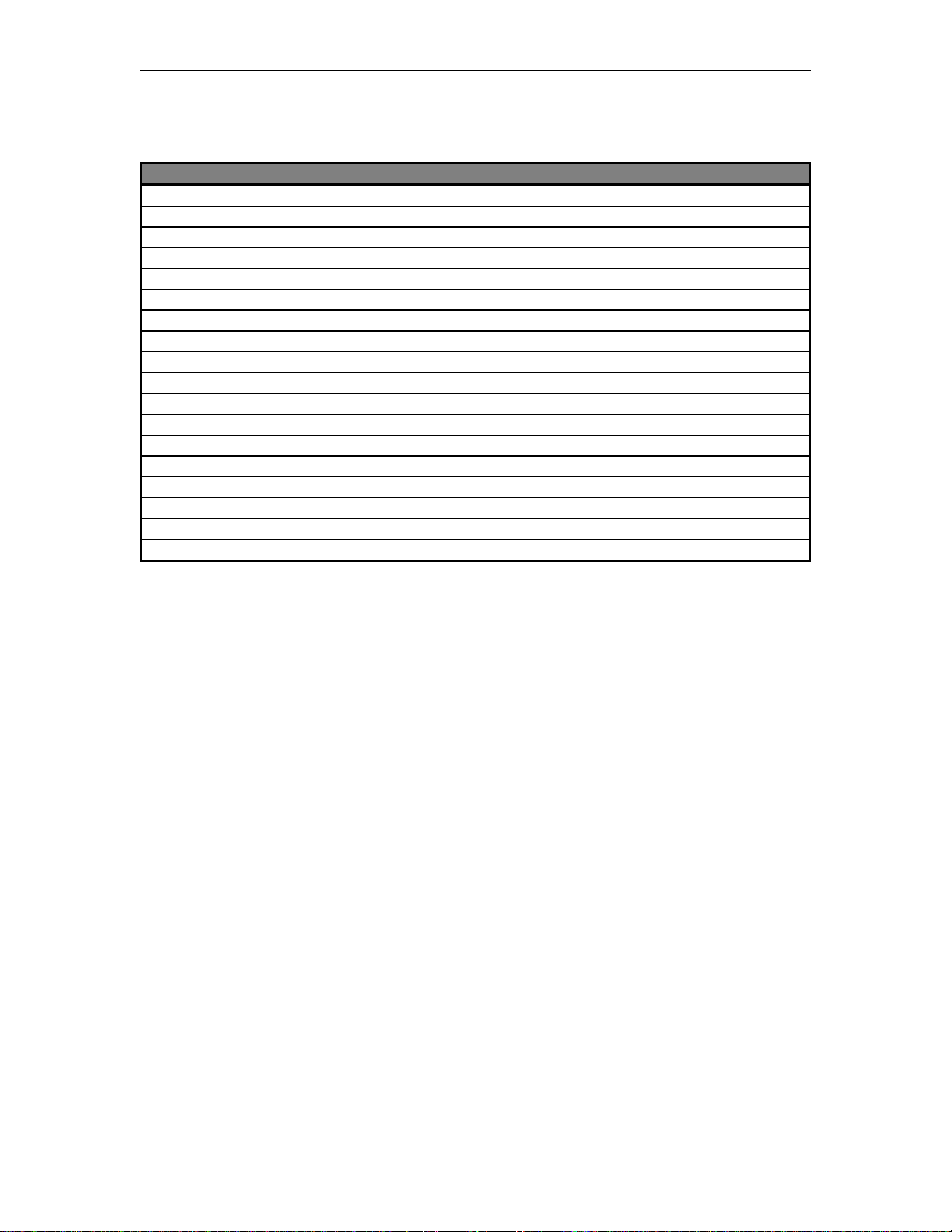

Dynamic Flow Computers SFC332L Manual Quick Start — 1-3

Part

Description

332-01P

Controller (CPU) Board for SFC332/1000 w/prover option.

332-02

Terminal (BP) Board for SFC332/1000.

332-03

Analog Board for SFC332/1000.

332-04

Display (LCD) for SFC332/1000.

332-05

Rosemount Interface Board for SFC1000.

332-06

Prover Option for SFC332/1000.

332-07

Enclosure for SFC332/1000.

332-08

Mounting Bracket w/captive screws for SFC332/1000 Boards.

332-09

Adapter between SFC1000 and Rosemount 205.

332-10

Center portion of housing for SFC332/1000 enclosure.

332-11

Glass Dome Cover for SFC332/1000 Enclosure.

332-12

Blank Dome Cover for SFC332/1000 Enclosure.

332-13

O-ring for SFC332 Enclosure.

332-14

External I/O Expansion.

332-15

Battery Replacement for SFC332/1000.

332-16

1/2 Amp 250V Fuse for SFC332/1000.

332-17

EPROM for SFC332/1000 (set of two).

RS232

External RS232 Connection for all models.

Parts List

Date: 8/1/2019

Page 9

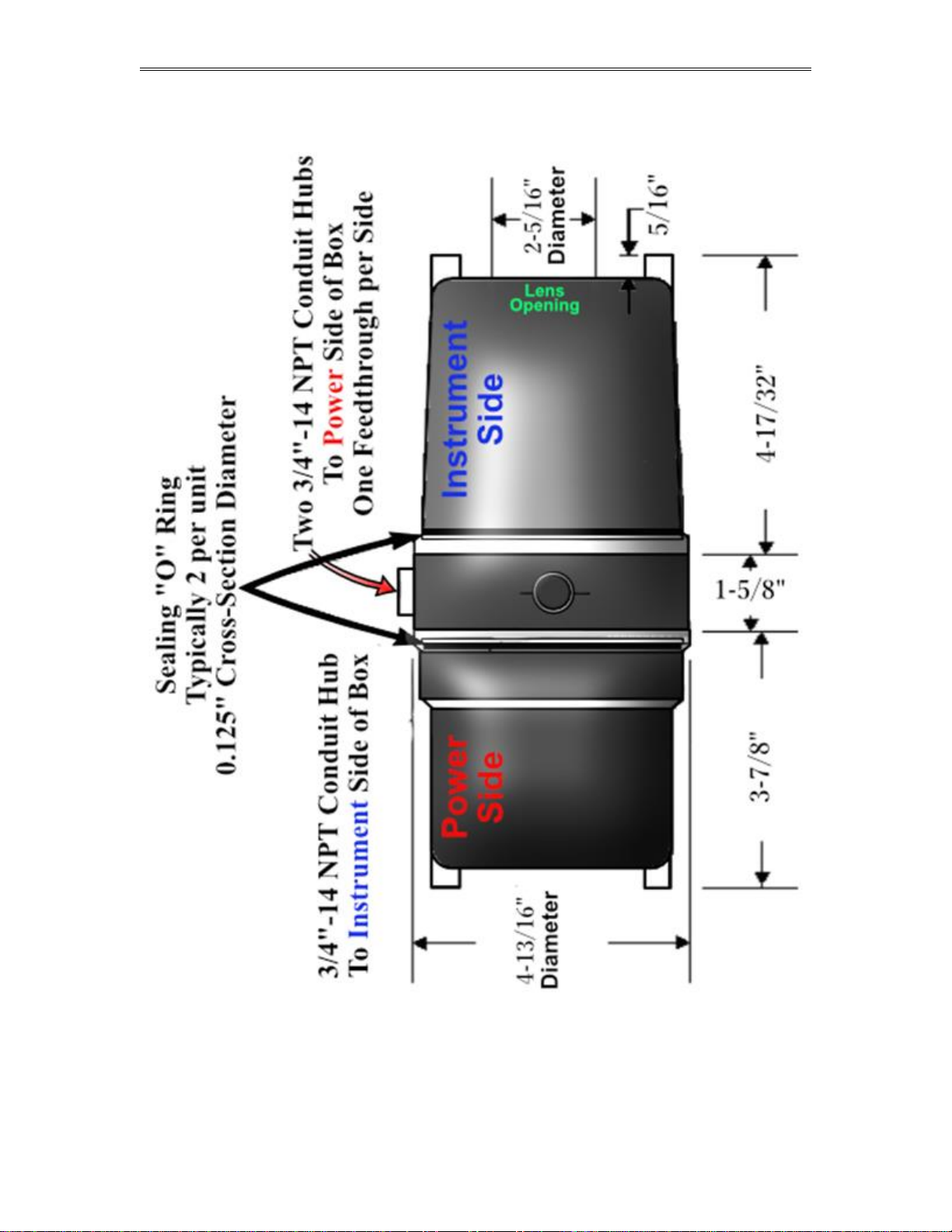

Dynamic Flow Computers SFC332L Manual Quick Start — 1-4

SFC332L Flow Computer: Dimensions

Date: 8/1/2019

Page 10

Dynamic Flow Computers SFC332L Manual Quick Start — 1-5

Starting and Installing theWindow Software:

System Minimum Requirements

In order to install this software product the following requirements must be met:

Windows Operating System (Win95, Win98, Win98SE, win2000, WinNT, WinXP, Vista,

Windows 7, Windows 8, Windows 10)

For Windows NT, 2000, XP or Vista: Administrator level access to create an ODBC system DNS.

Minimum disk space available: 16 MB.

1 Serial Communication Port

If your computer meets these requirements, you can run the setup file downloaded from our website

Date: 8/1/2019

Page 11

Dynamic Flow Computers SFC332L Manual Quick Start — 1-6

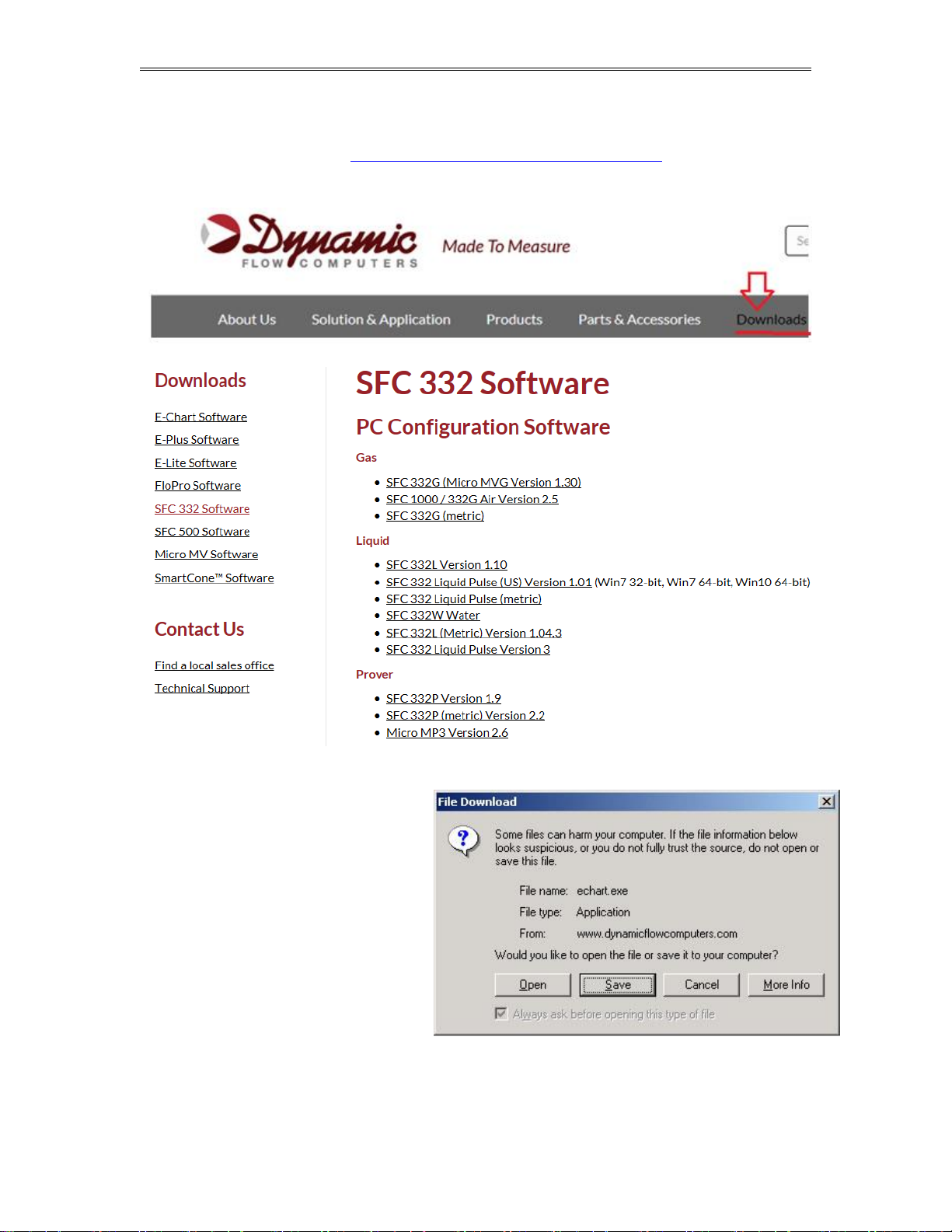

Website - DFC Configuration Software

Step 1. Go to our website WWW.DYNAMICFLOWCOMPUTERS.COM

Step 2. Click on the “Downloads”

Step 3. Select either Windows or

DOS software based on Step 2.

Step 4. On the new screen

presented to you click on the

application that you are trying to

download. Once you hit the link it

will ask you if you want to run or

save the file in your computer.

Select SAVE. (See illustration 1)

Date: 8/1/2019

Page 12

Dynamic Flow Computers SFC332L Manual Quick Start — 1-7

Step 5. The file will start to

transfer to your computer. The

download time depends on your

Internet connection speed and the

type of application that being

downloaded.

Step 6. When the download if

finish. Press the OPEN button to

start the setup process. (See

Illustration)

Step 7. Follow the steps in the

application setup.

Date: 8/1/2019

Page 13

Dynamic Flow Computers SFC332L Manual Quick Start — 1-8

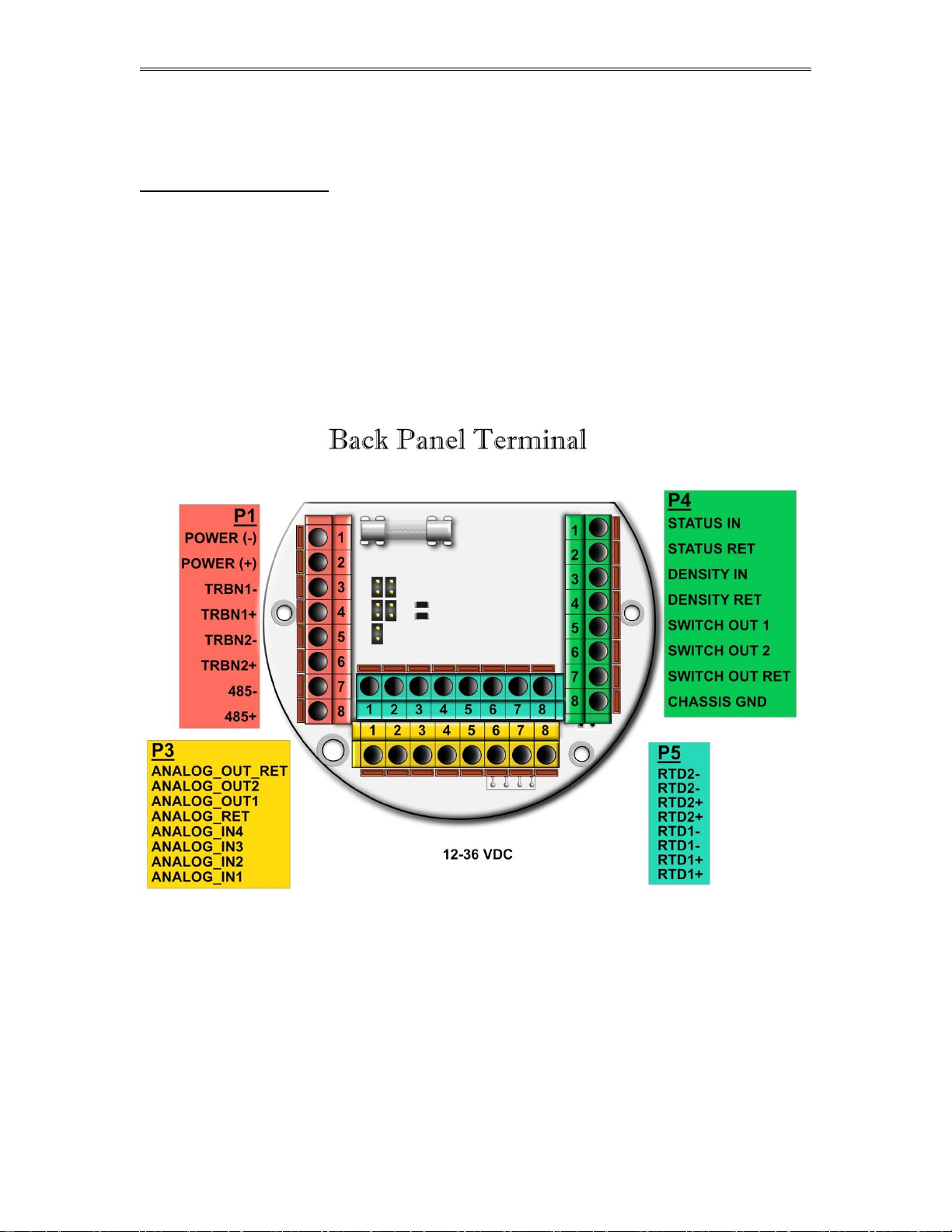

Getting acquainted with the flow computer wiring:

Back terminal wiring:

The back terminal wiring indicates the overall positions of the terminal plugs and their functions. Though

the back panel’s jumpers are also shown, refer to the next drawing, “Back Panel Jumpers”, for information

on their settings and functions.

The Smart Flow Computer receives its power via the two topmost pins on Terminal P1, on the left of the

terminal board. Also on Terminal P1 are, from top to bottom, inputs from the two turbines and the RS-485

serial connection.

To the right (P4), from top to bottom, are status input 1, density frequency input, and switch output 1 and 2.

Terminal P3, at the lower bottom, handles analog inputs and outputs. These are, in order from right to left,

analog inputs 1-4 and analog outputs 1 and 2.

Terminal P5, top middle, is the RTD terminal block, "100 platinum RTD input".

Date: 8/1/2019

Page 14

Dynamic Flow Computers SFC332L Manual Quick Start — 1-9

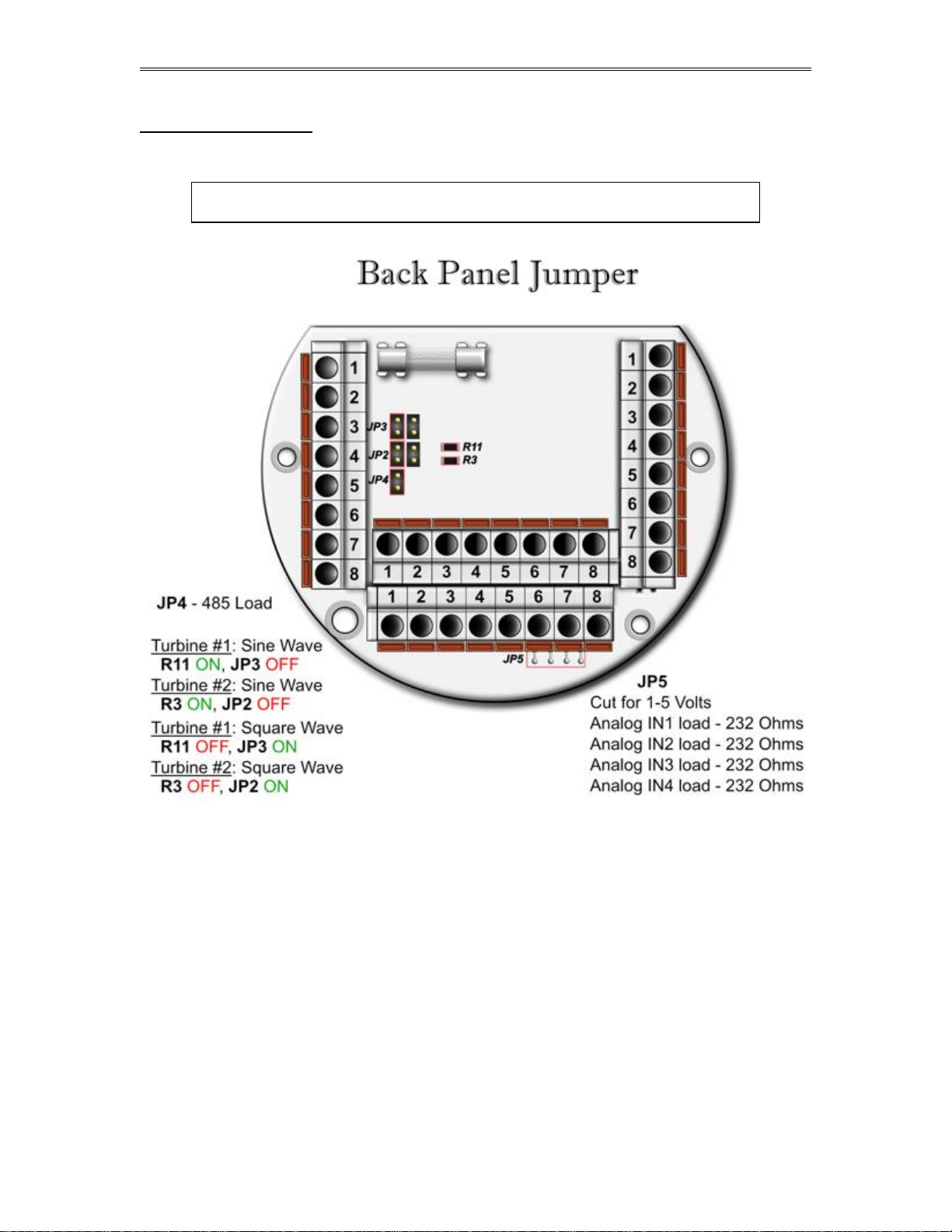

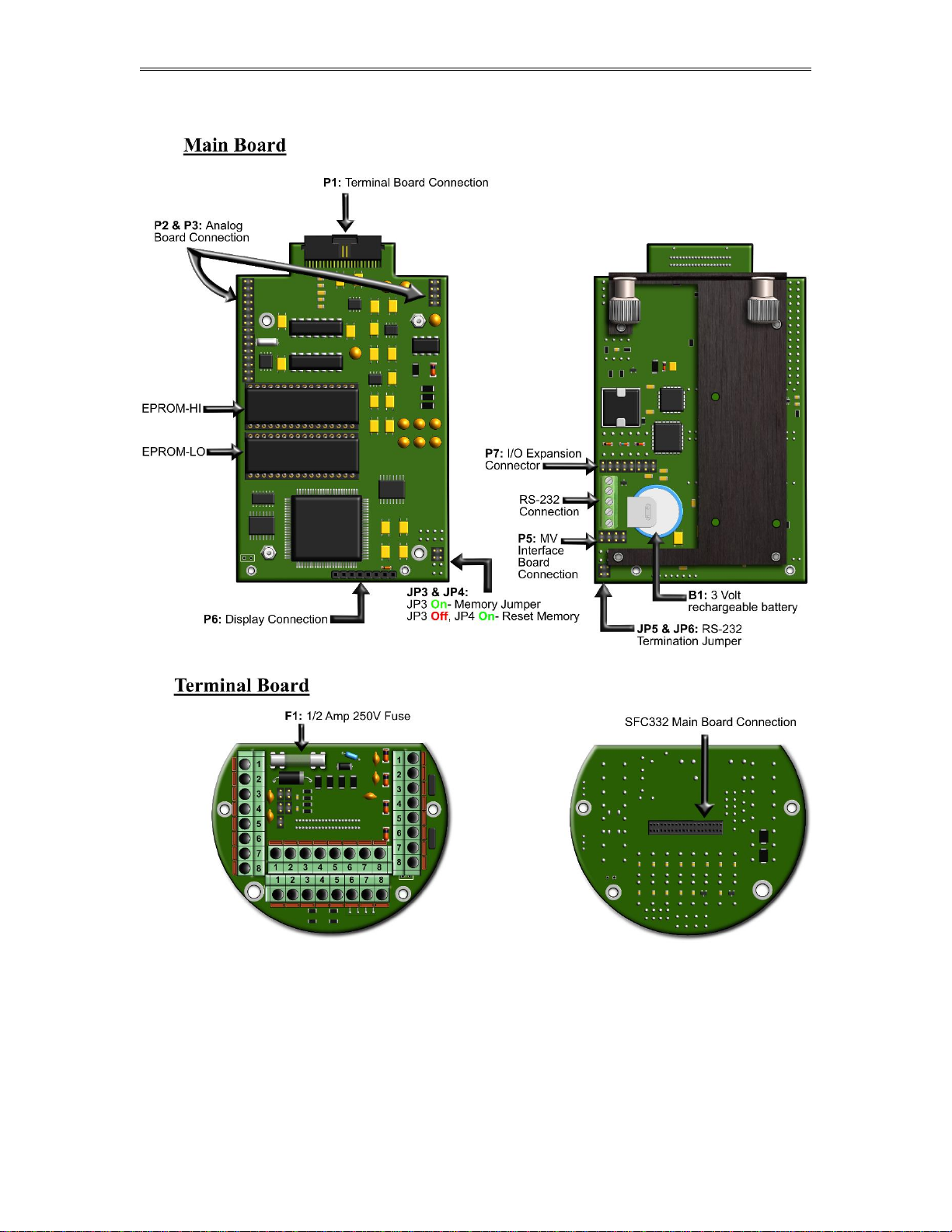

Back Panel Jumper

In this illustration, a jumper is “ON” when the jumper block is used to connect the jumper’s to wire prongs.

“OFF” means the jumper block is completely removed or attached to only one of the two wire prongs.

Note: R11 and R3 could have a vertical orientation instead of a horizontal

orientation on certain Smart Flow Computer models.

Date: 8/1/2019

Page 15

Dynamic Flow Computers SFC332L Manual Quick Start — 1-10

Memory Jumper

Date: 8/1/2019

Page 16

Dynamic Flow Computers SFC332L Manual Quick Start — 1-11

Steps to clear memory through removing the memory jumper

(1) Turn off the power, move the jumper to the next two pins, wait for 5 seconds

(2) Put the jumper back

Memory cleared and Flow Computer ID is set to 1, 9600 baud rate, RTU mode

Date: 8/1/2019

Page 17

Dynamic Flow Computers SFC332L Manual Quick Start — 1-12

Date: 8/1/2019

Page 18

Dynamic Flow Computers SFC332L Manual Quick Start — 1-13

Date: 8/1/2019

Page 19

Dynamic Flow Computers SFC332L Manual Quick Start — 1-14

INPUT/OUTPUT: Assigning and Ranging Inputs

Input/Output Assignment

We will now configure your SFC332L Flow Computer’s inputs and outputs. The flow computer allows the

user to configure the inputs and outputs. (I.e. Analog #1 is pressure for Meter #1). The flow computer will

not use the unassigned inputs.

How to assign a transmitter to an I/O point

1 Click “Configure Device”, configuration menu is prompted

2 On configuration menu, click “Input Assignment”

3 Enter assignments for DP, temperature, pressure, density and spare inputs.

4 Assignment (1-n). Assignments 1-4 are analog inputs attached

to terminal of the back panel. These inputs accept 4-20mA or 1-5

volts input and are suitable for temperature, pressure, density, or spare inputs. An assignment

5 is strictly RTD (temperature) input only for the meter, densitometer or spare. Assignment 7

indicates a density frequency input; it is assigned automatically once you choose live density

frequency input in the setup menu at density type Assignment 10 (module 1) is for

Rosemount multi-variable module only. DP, pressure, and temperature for the meter can be

assigned. When a frequency type primary element is hooked to the flow computer, the Multi

Variable pressure and temperature can be used and the DP becomes a spare input that could

be assigned for strainer differential.

Date: 8/1/2019

Page 20

Dynamic Flow Computers SFC332L Manual Quick Start — 1-15

Ranging the Transmitter Inputs:

1. Enter the range values: after assigning the inputs scroll down the transducer inputs

assignment menu to scale the 4-20mA. Enter the value at @4mA and @20mA. Enter both

values similar to the way the transmitter is ranged. 1-5 volts is equivalent to 4-20mA. Enter

the 1 volt value at the 4mA, and 5 volt value at 20mA. When the Multi Variable is used the 420 ma scale has no effect on anything and does not need to be configured for that input. The

reason is simply that the flow computer gets the data via digital communication from the

transmitter in engineering units, and therefore a scale is not needed. Normal pressure range is

0-3626, temperature –40 to 1200, DP –250 to 250, or -830 to 830 inches of water.

2. Enter the high and low limits: high limits and low limits are simply the alarm points in

which you would like the flow computer to flag as an alarm condition. Enter these values

with respect to the upper and lower range conditions. Try to avoid creating alarm log when

conditions are normal. For example: If the line condition for the pressure is between 0 to 500

PSIG, then you should program less than zero for low pressure alarm, and 500 or more for

high pressure alarm. High limits are also used in the SCALE for the Modbus variables. The

high limit is equalent to 32767 or 4095. The low limit is not used for calculating the scale.

The scale starts at zero to wherever the high limit value.

3. Set up the fail code: Maintenance and Failure Code values tell the flow computer

to use a default value in the event the transmitter fails. The default value is stored in

Maintenance. There are three outcomes: the transmitter value is always used, no matter

what (Failure Code = 0); the Maintenance value is always used, no matter what

(Failure Code = 1); and the Maintenance value is used only when the transmitter’s

value indicates that the transmitter has temporarily failed (Failure Code = 2).

RTD inputs will skip 4-20 mA assignment because RTD is a raw signal of 50 (ohms) to 156. Readings

beyond that range require a 4-20 mA signal to the flow computer or using the built in Rosemount Multi

Variable transmitter. The Rosemount Multivariable has a range of –40-1200 degrees Fahrenheit.

Density coefficients for raw frequency inputs are programmed in this menu. The menu will only show

parameters relevant to the live density selected (i.e., Solartron or UGC, etc.).

Date: 8/1/2019

Page 21

Dynamic Flow Computers SFC332L Manual Quick Start — 1-16

WIRING:

Wiring to the flow computer is very straightforward and simple. But still it is very important to get familiar

with the wiring diagram.

Wiring the Analog Inputs:

Typical wiring for analog inputs 1 and 2 are shown in the drawing. Analog inputs 3 and 4 are to the left of

analog 1 and 2. Note that the analog input has only one common return, which is the -Ve signal of power

supply powering the transmitters.

When wiring 1-5 volts, make sure to calibrate the flow computer for the 1-5 volt signal because the flow

computer calibration defaults for the 4-20mA, which is different from the 1-5 volts. JP5 must be cut for 15 volt inputs. The jumpers for analog 1-4 are in order from right to left. It is possible to cut the first two

jumpers for analog 1 & 2 in for 1-5 volts signal and have analog in 3 & 4 as 4-20mA signal. Signal line

impedance provided by our flow computer is less than 250. Therefore, when using a smart transmitter

that requires a minimum of 250 resistance in the loop, an additional resistor at the flow computer end

needs to be installed in series with the 4-20mA loop in order to allow the hand held communicator to talk to

the transmitter.

NOTE: The 4-20mA or 1-5 volt DOES NOT source power to the transmitters. You can use the DC

power feeding the flow computer to power the 4-20mA loop IF that power supply is

FILTERED.

Date: 8/1/2019

Page 22

Dynamic Flow Computers SFC332L Manual Quick Start — 1-17

Wiring the analog inputs 1-4 :

Date: 8/1/2019

Page 23

Dynamic Flow Computers SFC332L Manual Quick Start — 1-18

RTD

The flow computer shows wiring to RTD 1 and RTD 2. 100 platinum can be used; a temperature range

of -43F to +300F can be measured. RTD 1 is to the right where P5 designation is. In the figure below

notice that each side of the RTD requires two wire connections. When using less than 4 wires a jumper

must be used to make up for the missing lead. Internal excitation current source generated is approximately

7mA. .

RTD can be wired to multi-variable directly through specially provided cable. This wiring diagram

describes wiring directly into the flow computer and not into the multi-variable.

Date: 8/1/2019

Page 24

Dynamic Flow Computers SFC332L Manual Quick Start — 1-19

Wiring Analog Output:

Wiring diagram shows typical Analog output wiring. Notice that analog output will regulate 4-20 mA

current loop but DOES NOT source the power for it. External power is required.

ASSIGN ING/R ANGING THE 4-20MA AN ALOG OUT PUTS :

Go to the I/O assignment main menu and click Analog Output Assignment. A selection menu

is prompted. Select the analog output number, and then enter what the 4-mA output will indicate and the

20 mA. Make sure that the 20 mA assignment value exceeds the upper range limit of what you assigned

the Analog output for, otherwise the analog output will not update beyond 20 mA.

Date: 8/1/2019

Page 25

Dynamic Flow Computers SFC332L Manual Quick Start — 1-20

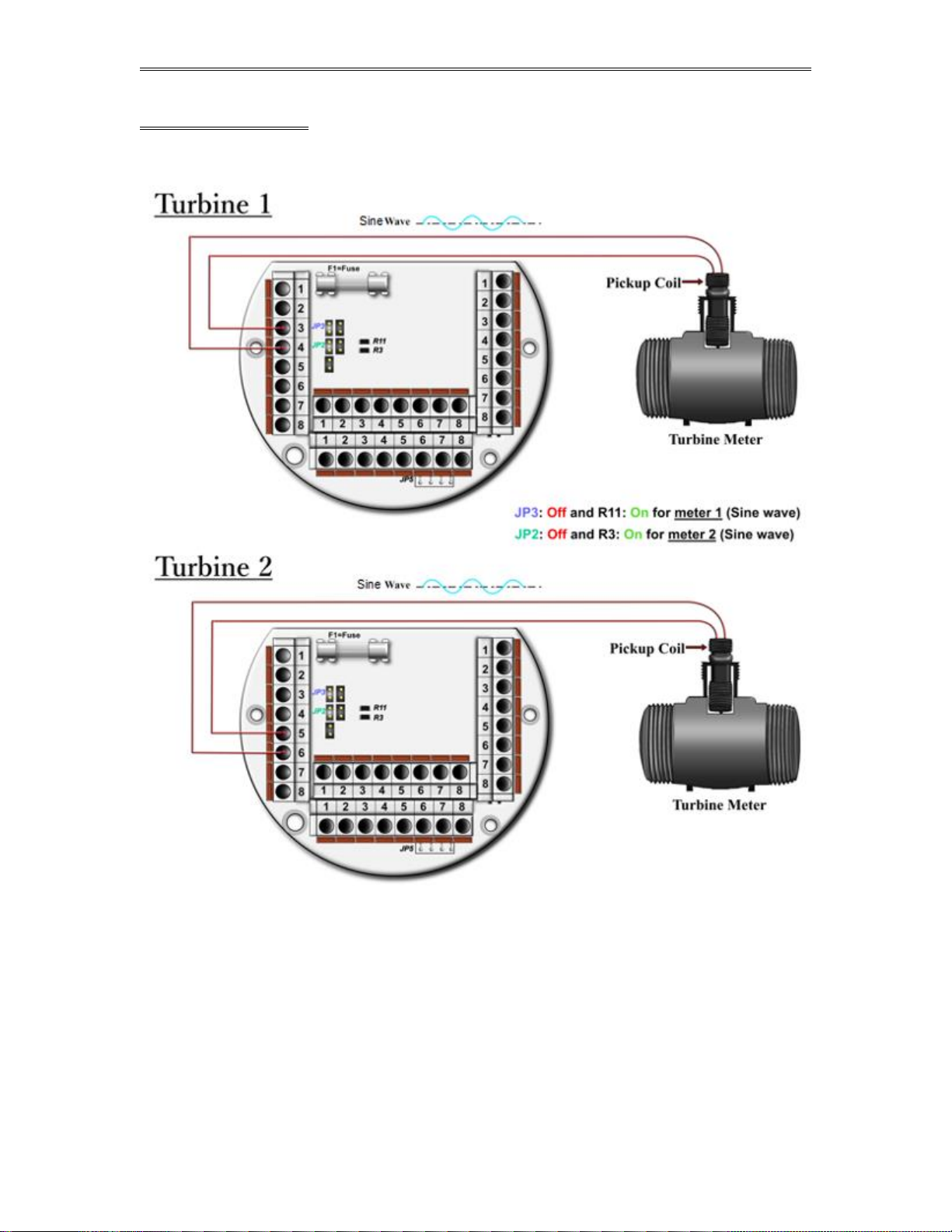

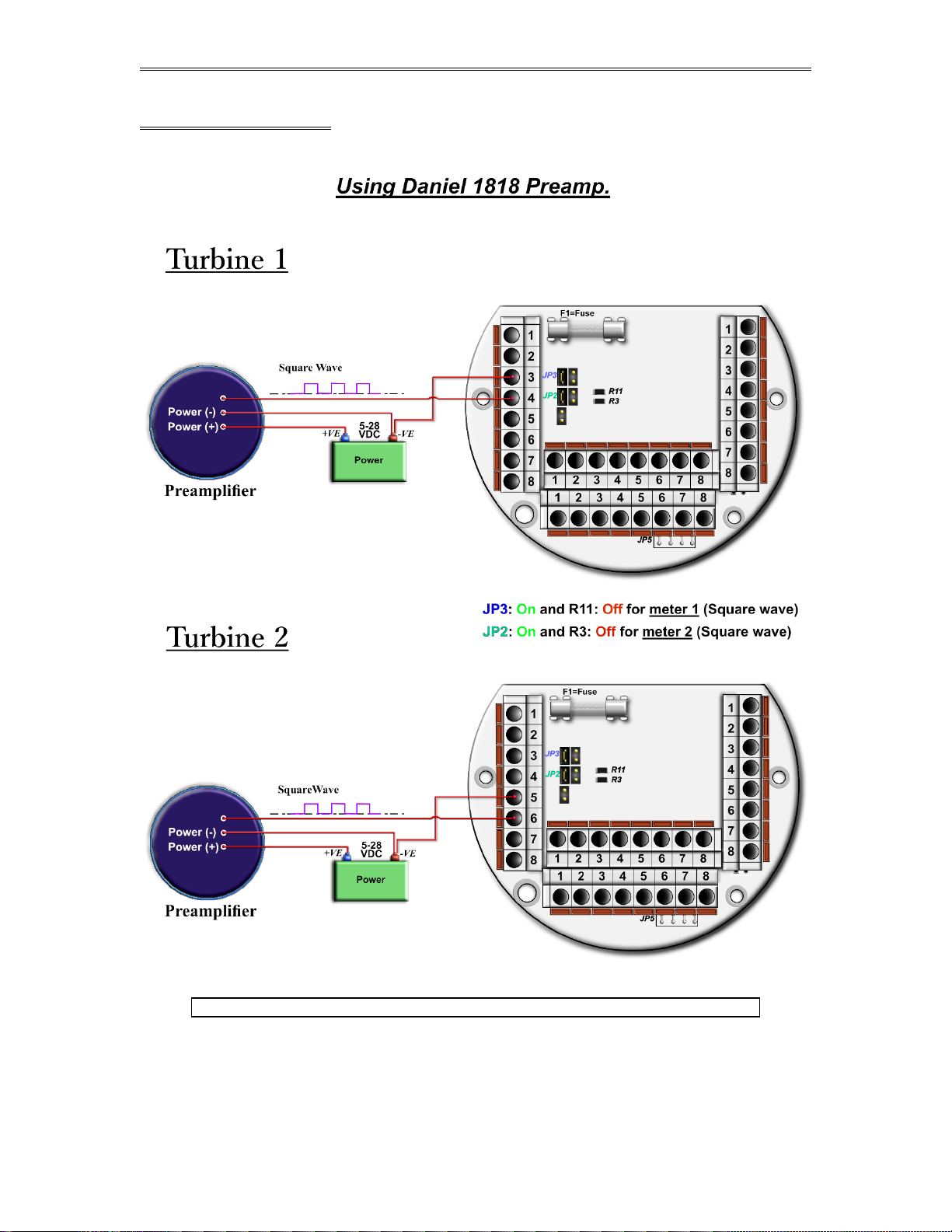

Turbine Input Wiring

Scroll to Turbine under Wiring and press ENTER. Two drawings above each other will show

typical wiring for turbine meter 1 and turbine meter 2. When dual pickups from the same turbine are

connected, use the inputs for turbine 1 for pickup 1 and turbine 2 for the second pickup coil. When

connecting sine wave directly from the pickup coil make sure the distance from the pickup coil to the flow

computer is very short--less than 50 feet with shielded cable. In the event there is presence of noise, the

distance must be shortened. When connecting sine wave signal, the R11 jumper for meter 1 must be

installed and R3 jumper for meter 2 must be installed. (JP3 and JP2 must be off when using sine wave).

On the other hand, when using square wave, the square wave signal can be sinusoidal but has to be above 5

volts peak to peak with less than 0.4 volts offset in order for the flow computer to read it. R11 and R3 must

be off and JP3 on for meter 1; JP2 must be on for meter 2.

Note: When connecting square wave input, the JP3 and JP2 connect the turbine return to the

flow computer power return. Therefore, signal polarity is very important. Reverse polarity

could result in some damage or power loss. When sine wave is used the signal polarity is

usually of no significance.

The turbine input is immediately under the power input on terminal P1. The third pin down from the top is

Turbine/PD "minus", and below it is Turbine plus. The second pulse input for Turbine/PD meter 2 or the

second pickup coil is below turbine one input on P1. The fifth pin down from the top is turbine 2 "minus"

signal and below it is Turbine/PD 2 plus signal.

Date: 8/1/2019

Page 26

Dynamic Flow Computers SFC332L Manual Quick Start — 1-21

TUR BINE- SINE WAVE

Date: 8/1/2019

Page 27

Dynamic Flow Computers SFC332L Manual Quick Start — 1-22

TUR BINE-SQUARE WAVE

Note: R11 and R3 are oriented vertically in some flow computers.

Date: 8/1/2019

Page 28

Dynamic Flow Computers SFC332L Manual Quick Start — 1-23

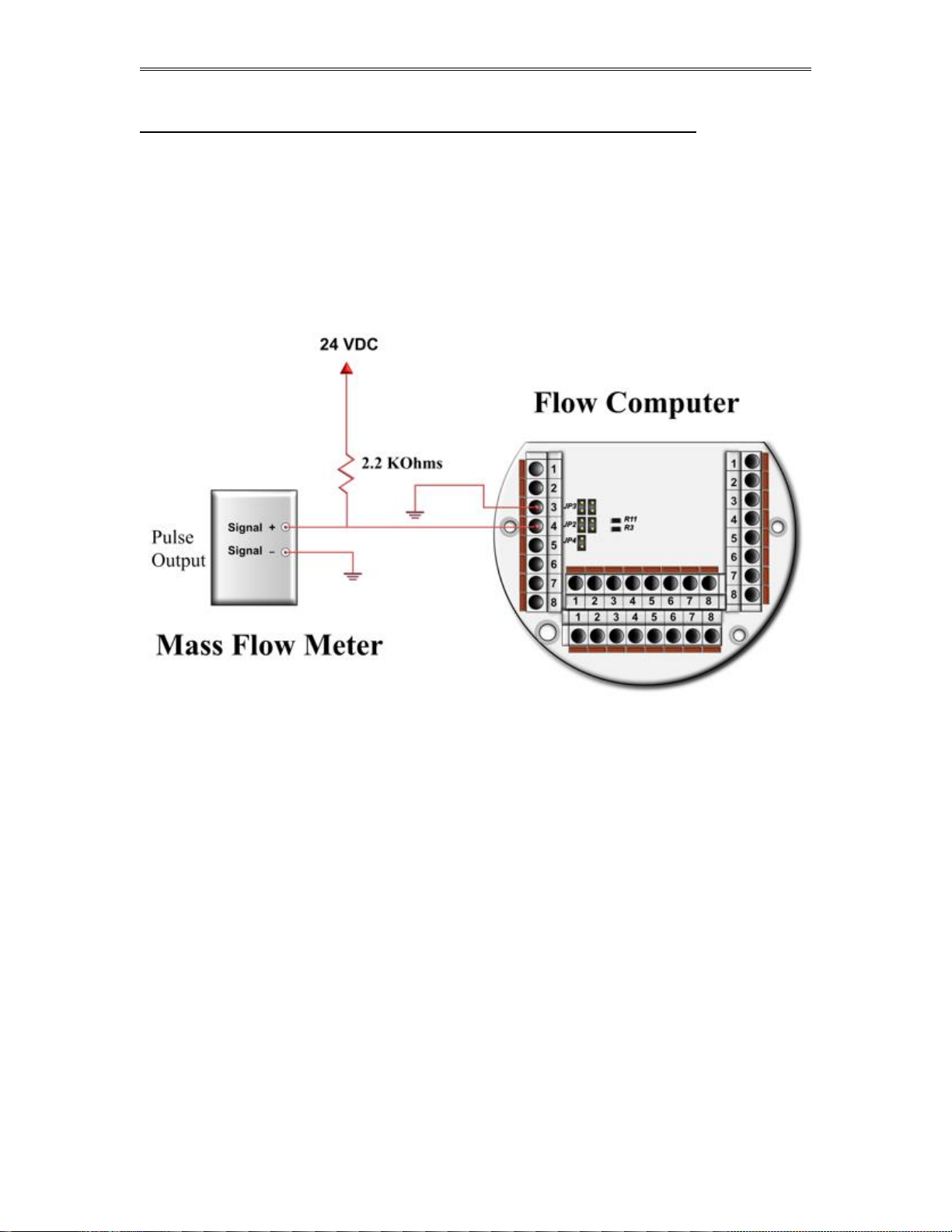

Turbine input wiring for passive (dry contact) pulse generators

Some mass flow meters have pulse outputs that do not provide power but instead require

external power, they are referred to as passive outputs, dry outputs, open collector, etc. (For

example the Krohne UFM 3030 Mass meter).

In these cases the wiring should be as shown on the below diagram. The pull up resistor can be

adjusted to limit the current sink by the Mass meter. For Turbine Input 1 JP3 must be ON and

R11 OFF and if using Turbine Input 2 then JP2 must be ON and R3 OFF.

Date: 8/1/2019

Page 29

Dynamic Flow Computers SFC332L Manual Quick Start — 1-24

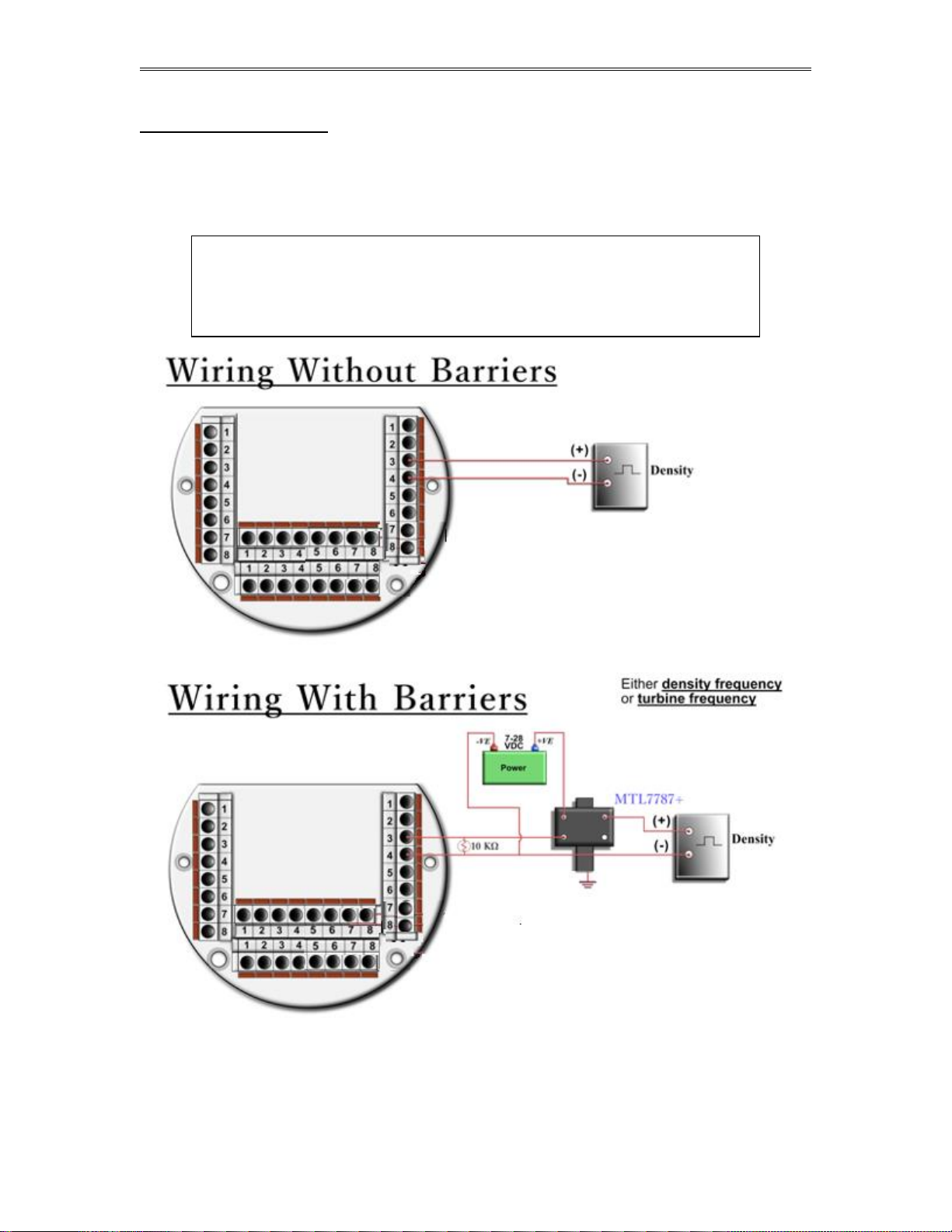

Density Input Wiring:

When using a live densitometer input with frequency signal, the signal can be brought into the Smart Flow

Computer in its raw form. The Smart Flow Computer accepts a sine wave or square with or without DC

offset. Example for density wiring can be seen in the wiring diagram. Three are two drawings, one with

barrier and the other without. Barriers are used for area classification. Notice that the RTD wiring is also

drawn to show how to hook the density RTD signal.

Note: When wiring the density input polarity is of significance and reverse polarity could

result in some damage or power loss. The density signal is on connector P4, the

third and fourth pin down from the top. The third pin down is density plus, the

fourth down is density minus. When Density input is 4-20mA it should be

connected as a regular 4-20mA signal to the analog input and not the density

frequency input.

Date: 8/1/2019

Page 30

Dynamic Flow Computers SFC332L Manual Quick Start — 1-25

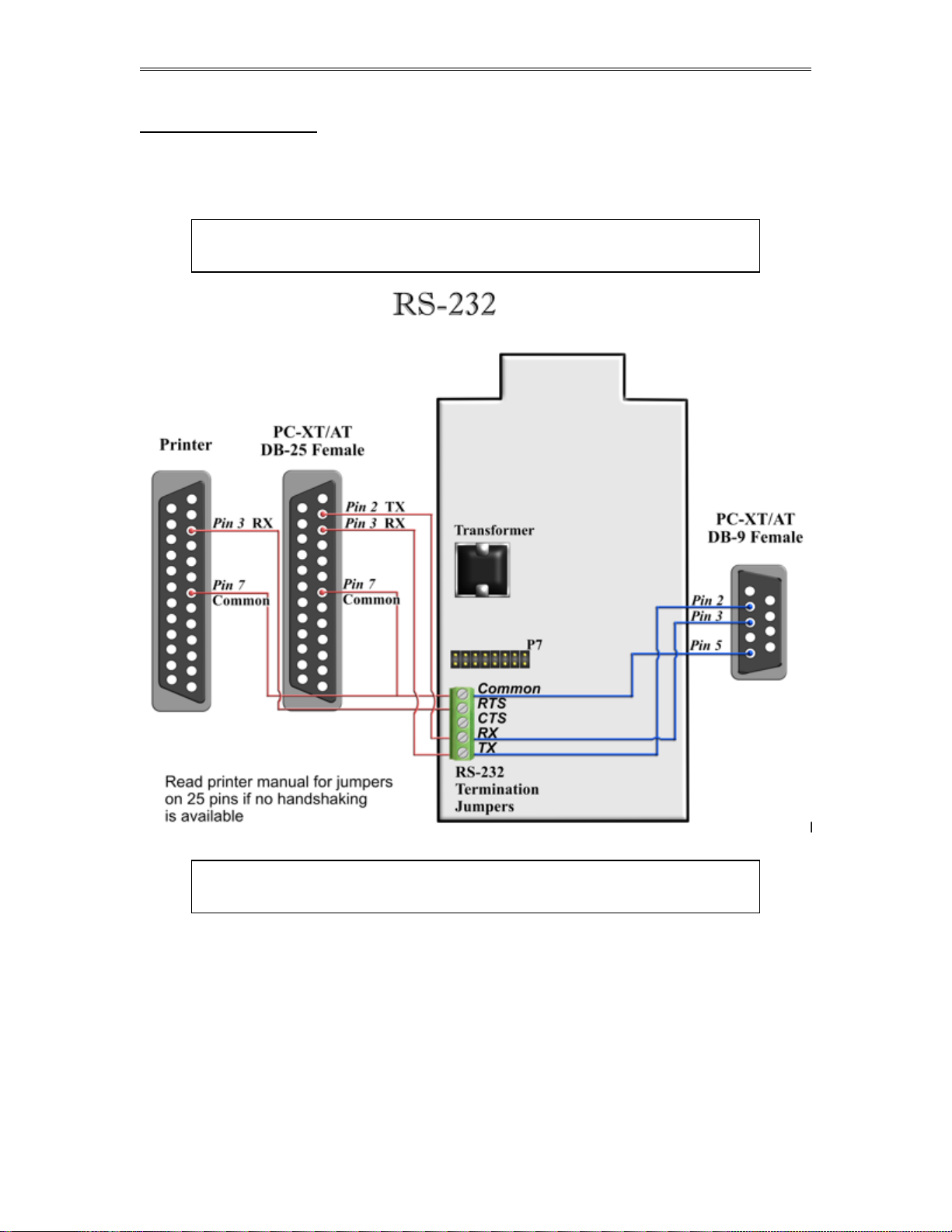

RS-232 Connection:

The RS-232 is not located on the terminal board. The RS-232 is a green 5-pin terminal block with screw

type connector located on the display side of the enclosure. Go to Wiring | RS-232. Termination

jumpers for the RS-232 are located at the top corner of the board on the same side of the RS-232 connector.

The two jumpers at the top are for terminating the transmit line and below it is the receive line.

The RS-232 port can be used for printing reports, Modbus communication, or interfacing

to the configuration program. If the port is configured as printer port in the flow

computer Note: Twisted shielded cable is required.

WARNING: When the RS-232 terminal is used with a modem, external protection on the

phone line is required. Jumper DTR to DSR, RTS to CTS, and disable software

handshake on the modem RS232 connection

Date: 8/1/2019

Page 31

Dynamic Flow Computers SFC332L Manual Quick Start — 1-26

RS-485:

RS-485 wiring is shown in the wiring diagram under RS-485. The RS-485 termination jumper is JP4

located on the back terminal. The maximum distance when 18-gauge wire is used would be 4000 feet.

Note: Twisted shielded cable is required.

WARNING: When the RS-485 terminal is used, external transient protection and optical

isolation is required, especially for long distance wiring.

Date: 8/1/2019

Page 32

Dynamic Flow Computers SFC332L Manual Quick Start — 1-27

Wiring of Status Inputs:

There is one status input standard and an optional three more on the back of the CPU board. The standard

status input is shown in the wiring diagram under Status Input. It has 4 volts of noise hysteresis,

with a trigger point of 5 volts and an off point of 1 Volt. Status inputs 2, 3, and 4 require the I/O expansion

connector and its wires be installed; refer to wiring drawing IO-Exp. Connection numbers 6, 7, and 8 are

the status in (positive) for inputs 2, 3, and 4, respectively, and 11 is the return for all three inputs.

Date: 8/1/2019

Page 33

Dynamic Flow Computers SFC332L Manual Quick Start — 1-28

Wiring of Switch/Pulse Outputs:

Go to Switch output under Wiring. The wiring diagram shows switch 1 and 2 and the return.

Please note that switches 3, 4, and 5 cannot be used for pulse output; switches 1 and 2 can be used for pulse

or switch output. See also I/O Expansion. Notice that the switch outputs are transistor type outputs (open

collector type with maximum DC rating of 350 mA continuous at 24 VDC) and require external power.

Date: 8/1/2019

Page 34

Dynamic Flow Computers SFC332L Manual Quick Start — 1-29

Connection

Purpose

Comments

1

Detector switch 1

Requires prover option CPU to operate.

Rating: 5-36 Vdc

2

Detector switch 2

3

Switch output 3

Maximum rating: 75mA @24 volts

Range: 5-36 Vdc

4

Switch output 4

5

Switch output 5

6

Status input 2

Rating: 6-36 Vdc

7

Status input 3

8

Status input 4

9

Return: detector switches

10

Return: switches 3, 4, 5

11

Return: status 2, 3, and 4

I/O Expansion:

The I/O expansion is 16-pin connector next to the RS-232 terminal. Eleven pins of the 16-pin connector

are utilized. When the flow computer is ordered with the I/O expansion feature, the wires and the plug are

provided with the flow computer. There will be 11 wires with the wire number tag at the outer end of the

wire. The tag will indicate the wire number. The following is the sequence for the wires. On the top right

edge of the connector towards the top outer side of the CPU board is pin 1, across from it is pin 9.

Date: 8/1/2019

Page 35

Dynamic Flow Computers SFC332L Manual Quick Start — 1-30

Date: 8/1/2019

Page 36

Dynamic Flow Computers SFC332L Manual Quick Start — 1-31

Connection

No.

Purpose

Comments

1

Detector switch 1

Requires prover option CPU to operate.

Rating: 5-36 Vdc

2

Detector switch 2

3

Switch output 3

Maximum rating: 75mA @24 volts

Range: 5-36 Vdc

4

Switch output 4

5

Switch output 5

6

Status input 2

Rating: 6-36 Vdc

7

Status input 3

8

Status input 4

9

Return: detector switches

10

Return: switches 3, 4, 5

11

Return: status 2, 3, and 4

12

RS232 TX

13

RS232 RX

14

RS232 RTS

15

RS232 ret

Prover/Expansion

Date: 8/1/2019

Page 37

Dynamic Flow Computers SFC332L Manual Quick Start — 1-32

CALIBRATION Through Window Program

Calibrations are performed under Calibration. Select inputs to be calibrated, and then select full,

single, offset calibration method.

Analog Input 4-20mA or 1-5 volt signal

OFF SET CALIBRATION:

For simple offset type calibration simply induce the signal into the analog input and make sure the

SFC332L is reading it. After you verify that the SFC332 recognized the analog input, enter the correct mA

reading, and then click OK. The offset type calibration is mainly used when a small offset adjustment

needs to be changed in the full-scale reading. The offset will apply to the zero and span. Offset is the

recommended method for calibrating the temperature input.

FULL CALIBRATION METHOD:

To perform full calibration be prepared to induce zero and span type signal.

1. Induce the low end signal i.e. 4mA in the analog input.

2. Click inputs to be calibrated under calibration menu, click full calibration, enter the first point

- the analog input value i.e. 4mA, and then click OK button.

3. Now be ready to enter the full-scale value. Simply induce the analog signal and then enter

the second value i.e. 20mA, and then click OK button

4. Induce live values to verify the calibration.

TO USE DEFAULT CALIBRATION

1. Select Analog Input

2. Select Reset calibration method

3. Now verify the live reading against the flow computer reading

Date: 8/1/2019

Page 38

Dynamic Flow Computers SFC332L Manual Quick Start — 1-33

RTD Calibration:

RTD Calibration is a 2-step process. The first step is a onetime procedure to verify transducer

linearity and is done at the time the meter is being setup. The second step is the routine calibration

sequence.

Step 1 – Linearity Verification

1- Use a Decade box with 0-150 °F settings.

2- Connect RTD cable to this resistive element for verification of linearity. Verify low and high

points. It must be within ½ degree.

3- Connect the actual RTD element and compare with a certified thermometer.

4- If not within ½ degree do a Full Calibration (See Full Calibration below). If problem persists

verify other elements such as RTD Probe, connections, shield, conductivity of connectors,

etc.

The purpose of the above procedure is to verify zero and span and make sure that the two points

fall within the expected tolerance.

Step 2 – Routine Calibration

Once Linearity has been verified through Step 1, the routine calibration procedure is reduced to

simply connecting the actual RTD and doing an offset point calibration (see offset calibration

below).

Calibration after that will be simple verification for the stability of the transmitter. If it drifts abnormally

then you need to verify the other parts involved.

Calibration Procedures through Windows™ Software

At the top menu, go to Calibration and Select RTD Input.

RESET TO DEFAULT CALIBRATION

1. Select Reset calibration method

2. Now verify the live reading against the flow computer reading

OFFSET CALIBRATION:

1. Select offset calibration method.

2. Induce a live value and wait for 10 seconds for the reading to stabilize. Then enter the live

value. The value entered must be in Ohm only.

3. Now verify the live reading against the flow computer reading

FULL SCALE CALIBRATION:

1. Prepare low range resistive input (i.e., 80 Ohm.) and High range resistive input (i.e., 120. Ohm).

2. Go to the calibration menu and select RTD full calibration method. Induce the low end (80

Ohm.) resistive signal and then wait 10 seconds, enter live value in ohm value, and click OK

button.

3. Induce the High range signal (120 Ohm.) and wait 10 seconds, then enter live value in Ohm

and click OK button.

4. Now verify the live reading against the flow computer reading.

Date: 8/1/2019

Page 39

Dynamic Flow Computers SFC332L Manual Quick Start — 1-34

Calibration of Analog Output:

Follow the following steps to calibrate the analog output against the end device

1. Go to the calibration menu, select analog output, and then select method. Full calibration will

cause the flow computer to output the minimum possible signal 4 mA. Enter the live output

value reading in the end device i.e. 4 mA and click OK button. Now the flow computer will

output full scale 20 mA. Enter the live output i.e. 20 then click OK button.

2. Now verify the output against the calibration device.

Multi-Variable Transmitters (Model 205) – DP and Pressure

Calibrations are performed under Calibration. . Select inputs to be calibrated, and then select full,

single, offset calibration method.

OFF SET CALIBRATION

1. Induce live value for pressure or DP.

2. Select Multivariable DP or pressure.

3. Select offset calibration method, enter offset, and click OK button.

4. Now read induce live values to verify the calibration.

FULL SCALE CALIBRATION

1. Induce live value for pressure or DP.

2. Select Multivariable DP or pressure

3. Select full calibration method

4. Induce the low range signal, enter the first point, and then click OK button.

5. Induce the high range signal, enter the second point, and then click OK button.

6. Now verify the live reading against the flow computer reading.

TO USE DEFAULT CALIBRATION

1. Select Multivariable DP or pressure

2. Select Reset calibration method

3. Now verify the live reading against the flow computer reading

While doing calibration before downloading any of the calibrated values, it is a good practice to verify that

the SFC332L close reading to the induced value.

The DP reading must be re-calibrated for the zero offset after applying line pressure.

Date: 8/1/2019

Page 40

Dynamic Flow Computers SFC332L Manual Quick Start — 1-35

Multi-Variable Transmitters (Model 205) –RTD

RTD Calibration is a 2-step process. The first step is a onetime procedure to verify transducer

linearity and is done at the time the meter is being setup. The second step is the routine calibration

sequence.

Step 1 – Linearity Verification

1. Use a Decade box with 0-150 °F settings.

2. Connect RTD cable to this resistive element for verification of linearity. Verify low and high

points. It must be within ½ degree.

3. Connect the actual RTD element and compare with a certified thermometer.

4. If not within ½ degree do a Full Calibration (See Full Calibration below). If problem persists

verify other elements such as RTD Probe, connections, shield, conductivity of connectors, etc.

The purpose of the above procedure is to verify zero and span and make sure that the two points

fall within the expected tolerance.

Step 2 – Routine Calibration

Once Linearity has been verified through Step 1, the routine calibration procedure is reduced to

simply connecting the actual RTD and doing an offset point calibration (see offset calibration

below).

Calibration after that will be simple verification for the stability of the transmitter. If it drifts abnormally

then you need to verify the other parts involved.

Calibration Procedures through Windows™ Software

At the top menu, go to Calibration and Select RTD Input.

RESET TO DEFAULT CALIBRATION

1. Select Reset calibration method

2. Now verify the live reading against the flow computer reading

OFFSET CALIBRATION:

1. Select offset calibration method.

2. Induce a live value and wait for 10 seconds for the reading to stabilize. Then enter the live

value. The value entered must be in Degrees only.

3. Now verify the live reading against the flow computer reading

FULL SCALE CALIBRATION:

1. Prepare low range resistive input (i.e., 80 Ohm.) and High range resistive input (i.e., 120.

Ohm).

2. Go to the calibration menu and select RTD full calibration method. Induce the low end (80

Ohm.) resistive signal and then wait 10 seconds, enter the equivalent temperature in degrees,

and click OK button.

3. Induce the High range signal (120 Ohm.) and wait 10 seconds, then enter the temperature

degrees equivalent to 120 Ohm and click OK button.

4. Now verify the live reading against the flow computer reading.

Date: 8/1/2019

Page 41

Dynamic Flow Computers SFC332L Manual Quick Start — 1-36

CALIBRATION Through DOS Program

Analog Input 4-20mA or 1-5 volt signal:

Calibrations are performed under I/O | Calibration. Use the arrow keys to scroll to

Calibration and press <ENTER>. After you press <ENTER> the screen should show

COMMUNICATION STATUS:OK.

OFF SET CALIBRATION:

For simple offset type calibration simply induce the signal into the analog input and make sure the flow

computer is reading it. After you verify that the flow computer recognized the analog input press <F8>.

The screen will freeze. Scroll down to the analog input you are calibrating and enter the correct mA

reading. Then press <ENTER> followed by <F3> to download. The screen will stay in the freeze mode. To

bring the live readings press <F2> and then the flow computer will display the new calibrated readings.

The offset type calibration is mainly used when a small offset adjustment needs to be changed in the fullscale reading. The offset will apply to the zero and span.

FULL CALIBRATION METHOD:

To perform full calibration be prepared to induce zero and span type signal.

1. Induce the low end signal i.e. 4mA in the analog input.

2. Press <F8> and scroll down to the reading then press <ALT><R>(alternate key and the letter

R simultaneously). Then immediately enter the analog input value i.e. 4mA. Follow that by

<ENTER> and pressing the <F3> function key to download data.

3. Now be ready to enter the full-scale value. Simply induce the analog signal and then enter

the value i.e. 20mA, and then download by pressing <ENTER> then <F3> function key.

4. Induce live values to verify the calibration.

DEF AULT CALIBRATION

Simply press <F8> and scroll to the analog Input and press <ALT><R> followed by <F3 function key.

Date: 8/1/2019

Page 42

Dynamic Flow Computers SFC332L Manual Quick Start — 1-37

RTD calibration:

For offset calibration simply go to I/O | Calibration and press <ENTER>. Once the flow computer

shows communication status OK press <F8> and scroll to RTD 1 or RTD 2. RTD Calibration is a 2-

step process. The first step is a onetime procedure to verify transducer linearity and is done at the

time the meter is being setup. The second step is the routine calibration sequence.

Step 1 – Linearity Verification

1. Use a Decade box with 0-150 °F settings.

2. Connect RTD cable to this resistive element for verification of linearity. Verify low and high points.

It must be within ½ degree.

3. Connect the actual RTD element and compare with a certified thermometer.

4. If not within ½ degree do a Full Calibration (See Full Calibration below). If problem persists verify

other elements such as RTD Probe, connections, shield, conductivity of connectors, etc.

The purpose of the above procedure is to verify zero and span and make sure that the two points

fall within the expected tolerance.

Step 2 – Routine Calibration

Once Linearity has been verified through Step 1, the routine calibration procedure is reduced to

simply connecting the actual RTD and doing an offset point calibration (see offset calibration

below).

Calibration after that will be simple verification for the stability of the transmitter. If it drifts abnormally

then you need to verify the other parts involved.

RESET TO DEFAULT CALIBRATION

To go back to the default calibration simply press <F8> and scroll to the RTD input, and press

<ALT> <R> key followed by <F3> function key.

OFFSET CALIBRATION:

For offset calibration simply go to I/O | Calibration and press < ENTER>. Once the flow

computer shows communication status OK press <F8> function key and scroll to RTD. Induce a

live value and wait for 10 seconds for the reading to stabilize. Then enter the live value followed

by <F3> function key to download the direct reading. The value entered must be in ohms only.

FULL SCALE CALIBRATION:

1. Prepare low range resistive input (i.e., 80) and High range resistive input (i.e., 120). Go to

the calibration menu and press <F8> function key. Scroll to the RTD input you are calibrating

and press <ALT> <R> (key <ALT> and the letter R at the same time). Induce the low end

(80) resistive signal and then wait 10 seconds and enter 80 followed by pressing the <F3>

function key.

2. Induce higher range signal (120) and wait 10 seconds, then enter the number 120 ohm and

press the <F3> key.

3. Now verify the live reading against the flow computer reading.

Date: 8/1/2019

Page 43

Dynamic Flow Computers SFC332L Manual Quick Start — 1-38

Calibration of Analog Output:

To calibrate the analog output against the end device follow the following steps:

1. Go to the calibration menu and press <F8>. Scroll down to analog output and press <ENTER >

and then <ALT><R>. This will cause the flow computer to output the minimum possible

signal 3.25 mA. Enter the live output value reading in the end device i.e. 3.25 mA and press

<F3> function key. Now the flow computer will output full scale 21.75 mA. Enter the live

output i.e. 21.75 then press the <F3> function key.

2. Now verify the output against the calibration device.

Multi-Variable Transmitters (Model 205)- DP and Pressure

OFF SET CALIBRATION

1. Induce live value for temperature, pressure, or DP.

2. Go to Calibration - Multi-Variable menu.

3. Press <F8>, point to the value being calibrated, enter the correct value followed by

<ENTER> key, and then press <F3> function key to download data.

4. Now read induce live values to verify the calibration.

FULL SCALE CALIBRATION

1. Press <F8>. Scroll to the parameter to be calibrated, and then press <ALT><R>.

2. Induce the low range signal, then press <ENTER> followed by <F3> function key.

3. Induce the low range signal, then press <ENTER> followed by <F3> function key.

4. Now verify the live reading against the flow computer reading.

TO USE DEFAULT CALIBRATION

1. Select Multivariable DP or pressure

2. Select Reset calibration method

3. Now verify the live reading against the flow computer reading

Date: 8/1/2019

Page 44

Dynamic Flow Computers SFC332L Manual Quick Start — 1-39

Multi-Variable Transmitters (Model 205)- RTD

Calibrations are performed under I/O | Calibration. Use the arrow keys to scroll to

Calibration-Multi-Variable and press < ENTER>. After you press < ENTER> the screen

should show COMMUNICATION STATUS : OK.

RTD Calibration is a 2-step process. The first step is a onetime procedure to verify transducer

linearity and is done at the time the meter is being setup. The second step is the routine calibration

sequence.

Step 1 – Linearity Verification

1. Use a Decade box with 0-150 °F settings.

2. Connect RTD cable to this resistive element for verification of linearity. Verify low and high points.

It must be within ½ degree.

3. Connect the actual RTD element and compare with a certified thermometer.

4. If not within ½ degree do a Full Calibration (See Full Calibration below). If problem persists verify

other elements such as RTD Probe, connections, shield, conductivity of connectors, etc.

The purpose of the above procedure is to verify zero and span and make sure that the two points

fall within the expected tolerance.

Step 2 – Routine Calibration

Once Linearity has been verified through Step 1, the routine calibration procedure is reduced to

simply connecting the actual RTD and doing an offset point calibration (see offset calibration

below).

Calibration after that will be simple verification for the stability of the transmitter. If it drifts abnormally

then you need to verify the other parts involved.

RESET TO DEFAULT CALIBRATION

To go back to the default calibration simply press <F8> and scroll to the RTD input, and press

<ALT> <R> key followed by <F3> function key.

OFFSET CALIBRATION:

For offset calibration simply go to I/O | Calibration and press < ENTER>. Once the flow

computer shows communication status OK press <F8> function key and scroll to RTD. Induce a

live value and wait for 10 seconds for the reading to stabilize. Then enter the live value followed

by <F3> function key to download the direct reading. The value entered must be in degrees only.

FULL SCALE CALIBRATION:

1. Prepare low range resistive input (i.e., 80) and High range resistive input (i.e., 120). Go to

the calibration menu and press <F8> function key. Scroll to the RTD input you are calibrating

and press <ALT> <R> (key <ALT> and the letter R at the same time). Induce the low end

(80) resistive signal and then wait 10 seconds and enter the equivalent temperature in

degrees followed by pressing the <F3> function key.

2. Induce Higher range signal (120) and wait 10 seconds, then enter the temperature degrees

equivalent to 120 followed by pressing the <F3> function key.

3. Now verify the live reading against the flow computer reading.

Date: 8/1/2019

Page 45

Dynamic Flow Computers SFC332L Manual Quick Start — 1-40

Verifying Digital Inputs and Outputs

Use the diagnostic menu. A live input and output is displayed On the top of the screen pulse inputs and

density frequency input are shown. Compare the live value against the displayed value on the screen.

Failure to read turbine input could be a result of the preamp being bad or the jumper selection for sine and

square wave input are not in the right position. Refer to wiring diagram Wiring | Turbine for

proper turbine input wiring. Density input can be sine or square wave with or without DC offset.

Minimum accepted signal has to be greater than 1.2 volt peak to peak. Status input is shown below the

frequency input to the left of the screen. When the status input is on, the live diagnostic data will show ON.

Minimum voltage to activate the status is 7 volts with negative threshold of 2 volts. Switch outputs are to

the right of the status inputs. The switch outputs are open collector and require external voltage.

Date: 8/1/2019

Page 46

Dynamic Flow Computers SFC332L Manual Data Entry — 2-1

CHAPTER 2: Data Entry

and Configuration Menus

Introduction to the SFC332L Computer Software

The SFC332L software is constructed around a menu-driven organization

Configuration File through Window Program

New

Create a new file to store all the programmed information for one SFC332L Flow Computer. After a file is

opened it becomes the currently active file, its contents can be viewed and its parameters can be edited.

Open

Use this function to open an existing configuration file. After a file is opened it becomes the currently

active file, its contents can be viewed and its parameters can be edited. When this function is chosen a list

of existing configuration files is displayed. Select the file to be opened.

Close

Close or exit configuration file.

Save

When permanent modifications are performed on a file, user must save the new changes before exiting the

program, or proceeding to open a different file.

Save As

Use Save As to save the parameters in the currently active file (that is, the parameter values currently being

edited) to a new file. The original file will remain in memory.

Date: 8/1/2019

Page 47

Dynamic Flow Computers SFC332L Manual Data Entry — 2-2

VIEW

View Drawings

Select the wiring diagram to be displayed. (See details in chapter 1)

Back Panel

Analog Input

RTD

Analog Output

Status Input

Switch Output

Turbine

Densitometer

RS 232

RS 485

Jumpers

I/O Expansion

Prover/Expansion

Dimensions

Date: 8/1/2019

Page 48

Dynamic Flow Computers SFC332L Manual Data Entry — 2-3

TOOLS

Com Settings

PORT - COMMUNICATION PORT NUMBER (1,2,3,4)

Enter the PC port used to communicate with the SFC332L Flow Computer.

Baud Rate

Note: this parameter must be set the same for both the PC and the SFC332L Flow

Computer for communication to occur.

Baud rate is defined as number of bits per second. The available selections are 1200, 2400, 4800, 9600, or

19200.

Parity

Note: this parameter must be set the same for both the PC and the SFC332L Flow

Computer for communication to occur.

RTU - NONE

ASCII - EVEN or ODD

Set the parity to match the Modbus Type.

Data Bits

Options available: 5, 6, 7, or 8. Generally used: 8 for RTU mod, 7 for ASCII mode.

Stop Bits

Options available: 1, 1.5,or28. Generally used: 1.

Modbus Type

Note: this parameter must be set the same for both the PC and the SFC332L Flow

Computer for communication to occur.

The Modbus Communication Specification is either Binary RTU or ASCII.

Unit ID Number

The Unit ID Number is used strictly for communication purposes; it can take any value from 1 to 247. Only

one master can exist in each loop.

Note: Do not duplicate the Unit ID number in a single communication loop!

This situation will lead to response collisions and inhibit communications

to units with duplicate ID numbers.

Time Out

The amount of time in seconds the program will wait for an answer from the flow computer.

Retry Times

Retry times for the program to communicate with the flow computer in case of timeout.

Auto Detect Settings

Click this button and the configuration program will attempt to communicate with a single SFC332L Flow

Computer at different baud rates and formats.

Failure to communicate can occur because of a wiring problem, wrong PC port selection, communication

parameter mismatch between PC and SFC332L Flow Computer (Modbus type, parity, baud rate, etc.) or

lack of power to the SFC332L Flow Computer. To use this feature, the user must insure that only one

SFC332L Flow Computer is connected to the PC. More than one SFC332L Flow Computer in the loop

will cause data collisions and unintelligible responses

Date: 8/1/2019

Page 49

Dynamic Flow Computers SFC332L Manual Data Entry — 2-4

Meter Configuration

METER SETTINGS

Company Name

Up to 20 characters. The company name appears in the reports.

Meter Location

Up to 20 characters. This entry appears only in the report and serves no other function.

Day Start Hour (0-23)

Day start hour is used for batch operation. If daily batch is selected, the batch will end at day start hour; all

batch totalizers and flow-weighted values are reset.

Disable Alarms

Use Disable Alarms to ignore alarms. When the alarm function is disabled alarms are not logged. Alarms

are also not logged if the DP is below the cut-off limit.

Common Parameters

This feature allows the Flow Computer to use the transmitters on meter one to substitute and compensate

for meter two.

Atmospheric Pressure

This pressure is local pressure or contracted atmospheric pressure. (I.e. 14.73 PSI).

Select Scale Value

Scale value use high limit parameters. Full-scale value can be selected using 32767 with sign bit or as

4095 analog values.

Example:

Temperature high limit is set as 150 Degree F. and current temperature reading is 80 Degree F

Scale value will read 17475 = 80/150x32767 (if 0 is selected), or 2184=80/150 x 4095 (if 1 is selected)

Meter Bank

Single or two meters run configuration per individual SFC332L Flow Computer. Enter '1', if two meters are

connected to the flow computer.

Bi-Directional

This feature allows a status input to give direction for meter one and two, just meter one, meter two, or the

flow computer phase angle feature. The phase angle require dual pickups, therefore this feature is only

available with single meter setup only. The phase angle feature relies on high precision quadrature decoder

that gives quick and precise direction detection. Bi-directional totalizers will totalize accordingly.

Stream Selection

Single stream can be single meter or bank of two meters. Dual streams allow the user to monitor

independent products on separate streams simultaneously.

Date: 8/1/2019

Page 50

Dynamic Flow Computers SFC332L Manual Data Entry — 2-5

Station Total

Station total can add meter one and two, subtract meter one from meter two, or just ignore this feature by

selecting none. Station Total does not affect, destroy or otherwise alter the data from either meter. When

Station Total is other than none, an additional data parameter, Station Total, is generated by the SFC332L

Flow Computer and appears in reports and on the live display monitor.

Select Flow Rate Display

The flow rate will be based on daily basis, hourly, or minute.

Flow Rate Average Second

The flow rate is averaged for 1-10 seconds to minimize fluctuating flow rate conditions. This number

averages the current flow rate by adding it to the previous seconds’ flow rate, and then displays an averaged

smoothed number. Only a low-resolution pulse meter requires this function.

Print Intervals in Minutes (0-1440)

When the second port (RS-232) of the SFC332L Flow Computer is configured as printer port, a snapshot

report is generated every print interval (i.e., every five minutes, every hour, or every ten hours).

GM/CC Conversion Factor

This factor is used to reference the density to density of water (i.e. .999012) to establish specific gravity.

Run Switching

Run switching is used to switch from tube one to tube two, when flow rate reaches certain limits. The

SFC332L Flow Computer has one active output that can be dedicated to this function. The time delay

allows for some delay in switching.

Note: if Run Switching is being used, then the meter should be configured for a single stream (see

Set Up under Meter).

Run Switch High Set Point

When this flow rate value is exceeded and after the delay timer expires, the switch output will activate.

This output opens normally meter run two. The SFC332L Flow Computer provides open collector type

output that requires external power.

Run Switch Low Set Point

When the flow rate drops below this value and stays below it until the delay timer expires, the output

switch will be turned off to shut meter two.

Date: 8/1/2019

Page 51

Dynamic Flow Computers SFC332L Manual Data Entry — 2-6

Daylight Saving Time (DST)

Enabling Daylight Saving Time (also called “Summer Time”) sets the Flow Computer to automatically

forward its time by one hour at 2:00 AM on a preset day (“Spring Forward”) of the year and roll back on a

second date(“Fall Back”).

If left in auto mode, the computer calculates the DST dates based on USA standards, which are, Spring

Forward the first Sunday of April and Fall Back the last Sunday of October.

For countries with other DST dates, the user can enter dates manually. For example, European Summer

Time starts the last Sunday in March and ends the last Sunday in October.

Effects of DST on Historical Data

Given the sudden time change that DST creates, the historical reports will show an hour with zero flow at

2:00 AM of Spring Forward Day and an hour with double flow at 1:00 AM of Fall Back Day, to achieve

consistent 24-Hour a day flow records.

Date: 8/1/2019

Page 52

Dynamic Flow Computers SFC332L Manual Data Entry — 2-7

0 =

AGA3 (OLD)

1 =

API 14.3 (NEW AGA3)

2 =

Wedge

3 =

Venturi

4 =

AGA7 (TURBINE or Frequency Type Input)

METER DATA

Meter ID

Up to 8 characters. This function will serve as meter tag.

Flow Equation Type (1-4)

Select the desired calculation mode. API 14.3 is the latest orifice calculations introduced in 1994 All new

installations are recommended to use API 14.3 for orifice calculations.

Flow Rate Low/High Limit

The high/low flow rate alarm is activated, when net flow rate exceeds or is below the set limit. The alarm

will be documented with time, date, and totalizer.

Flow Rate Resolution

Flow rate indication will carry the programmed decimal positions.

Volume Units

Select desired units 0=BBL, 1=GAL, 2=CF, or 3=MCF. The SFC332L Flow Computer will perform the

proper conversion routine from barrels to gallons to cubic feet.

Date: 8/1/2019

Page 53

Dynamic Flow Computers SFC332L Manual Data Entry — 2-8

Type 304 and 316 Stainless

9.25 E 6

Monel

7.95 E 6

Carbon Steel

6.20 E 6

AGA3 (OLD AGA3)

To set AGA3 flow parameters, set Flow Equation Type = 0, and click “eq. settings” button.

You will then access a submenu in which you can set the parameters below.

Pipe I.D. Inches

Pipe ID in inches is the measured inside pipe diameter to 5 decimals at reference conditions.

Orifice ID Inches

Orifice ID in inches is the measured diameter of the orifice at reference conditions.

DP Cut off

The Flow Computer suspends all calculations whenever the DP, in inches of water column, is less than this

value. This function is vital for suppressing extraneous data when the DP transmitter drifts around the zero

mark under no-flow conditions.

Y Factor (0=None,1=Upstream,2=Downstream)

Y factor is the expansion factor through the orifice. The user must enter the position of the pressure and

temperature sensors. Select y=1 if the sensors are installed upstream of the orifice plate. Select y=2 if the

sensors are down stream of the orifice plate.

Select 0=Flange Tap, 1=Pipe Tap

Tap position is where the differential transmitter is fitted. Select 0 = flange fitted or 1 = pipe fitted.

Isentropic Exponent (Specific Heat)

Ratio of specific heat is a constant associated with each product. Even though it varies slightly with

temperature and pressure, in most cases it is assumed to be a constant.

Viscosity in Centipoise

Even though viscosity will shift with temperature and pressure changes, the effect on the calculations is

negligent. Therefore using a single value is appropriate in most cases. Enter viscosity in centipoise.

Reference Temperature of Orifice

Reference temperature of orifice is the temperature at which the orifice bore internal diameter was

measured. Commonly 68 °F is used.

Orifice Thermal Expansion Coefficient E-6

Orifice thermal expansion is the linear expansion coefficient of orifice material.

Date: 8/1/2019

Page 54

Dynamic Flow Computers SFC332L Manual Data Entry — 2-9

Type 304 and 316 Stainless

9.25 E 6

Monel

7.95 E 6

Carbon Steel

6.20 E 6

Type 304 and 316 Stainless

9.25 E 6

Monel

7.95 E 6

Carbon Steel

6.20 E 6

API 14.3 DATA (NEW AGA3)

To set API 14.3 flow parameters, set Flow Equation Type = 1, and click “eq. settings” button.

You will then access a submenu in which you can set the parameters below.

Pipe I.D. Inches

Orifice ID Inches

Pipe ID in inches is the measured inside pipe diameter to 5 decimals at reference conditions. Orifice ID in

inches is the measured diameter of the orifice at reference conditions.

DP Cut off

The SFC332L Flow Computer suspends all calculations whenever the DP, in inches of water column, is

less than this value. This function is vital for suppressing extraneous data when the DP transmitter drifts

around the zero mark under no-flow conditions.

Y Factor (0=None, 1=Upstream, 2=Downstream)

Y factor is the expansion factor through the orifice. The user must enter the position of the pressure and

temperature sensors. Select y=1 if the sensors are installed upstream of the orifice plate. Select y=2 if the

sensors are down stream of the orifice plate.

Isentropic Exponent (Specific Heat)

Ratio of specific heat is a constant associated with each product. Even though it varies slightly with

temperature and pressure, in most cases it is assumed as a constant.

Viscosity in Centipoise

Viscosity is entered in centipoise even though viscosity will shift with temperature and pressure; the effect

on the calculations is negligent. Therefore using a single value is appropriate in most cases.

Reference Temperature of Orifice

Reference temperature of orifice is the temperature at which the orifice bore internal diameter was

measured. Commonly 68 °F is used.

Orifice Thermal Expansion Coefficient E-6

Orifice thermal expansion is the linear expansion coefficient of orifice material.

Reference Temperature of Pipe

Reference temperature of pipe is the temperature at which the pipe bore internal diameter was measured.

Commonly 68 °F is used.

Pipe Thermal Expansion Coefficient E-6

Pipe thermal expansion is the linear expansion coefficient of pipe material.

Date: 8/1/2019

Page 55

Dynamic Flow Computers SFC332L Manual Data Entry — 2-10

wedge oft coefficien Discharge

wedge oft coefficien Expansion

conditions flowat gravity specific liquid

d2

K

a

F

SG

DP

(GPM) Rate Flow