Page 1

SFC3

OPERATORS MANUAL

Smart F l o w C o m p uter

Liqui d P u l s e V e r s i on

11 1 0 4 W . A i r p o rt Blvd , S u i t e 1 0 8 & 1 4 8

Staf f o r d , T e x as 77 4 7 7 U S A

(2 81 ) 5 6 5 -1118

Fa x ( 2 8 1 ) 5 6 5 -11 1 9

Date: 8/1/2019

Page 2

WARRANTY

Dynamic Fluid Measurement warrants to the owner of the Flow Computer that the

product delivered will be free from defects in material and workmanship for one (1) year

following the date of purchase.

This warranty does not cover the product if it is damaged in the process of being installed

or damaged by abuse, accident, misuse, neglect, alteration, repair, disaster, or improper

testing.

If the product is found otherwise defective, Dynamic Fluid Measurement will replace or

repair the product at no charge, provided that you deliver the product along with a return

material authorization (RMA) number from Dynamic Fluid Measurement.

Dynamic Fluid Measurement will not assume any shipping charge or be responsible for

product damage due to improper shipping.

THE ABOVE WARRANTY IS IN LIEU OF ANY OTHER WARRANTY EXPRESS

IMPLIED OR STATUTORY. BUT NOT LIMITED TO ANY WARRANTY OF

MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE, OR ANY

WARRANTY ARISING OUT OF ANY PROPOSAL, SPECIFICATION, OR SAMPLE.

LIMITATION OF LIABILITY:

DYNAMIC FLUID MEASUREMENT SHALL HAVE NO LIABILITY FOR ANY

INDIRECT OR SPECULATIVE DAMAGES (INCLUDING, WITHOUT LIMITING

THE FOREGOING, CONSEQUENTIAL, INCIDENTAL AND SPECIAL DAMAGES)

ARISING FROM THE USE OF, OR INABILITY TO USE THIS PRODUCT.

WHETHER ARISING OUT OF CONTRACT, OR UNDER ANY WARRANTY,

IRRESPECTIVE OF WHETHER DFM HAS ADVANCED NOTICE OF THE

POSSIBILITY OF ANY SUCH DAMAGE INCLUDING, BUT NOT LIMITED TO

LOSS OF USE, BUSINESS INTERRUPTION, AND LOSS OF PROFITS.

NOTWITHSTANDING THE FOREGOING, DFM’S TOTAL LIABILITY FOR ALL

CLAIMS UNDER THIS AGREEMENT SHALL NOT EXCEED THE PRICE PAID

FOR THE PRODUCT. THESE LIMITATIONS ON POTENTIAL LIABILITY WERE

AN ESSENTIAL ELEMENT IN SETTING THE PRODUCT PRICE. DFM NEITHER

ASSUMES NOR AUTHORIZES ANYONE TO ASSUME FOR IT ANY OTHER

LIABILITIES

Date: 8/1/2019

Page 3

CHAPTER 1: QUICK START.................................................................................................................... 1-1

Introduction: ............................................................................................................................................ 1-1

Technical Data ......................................................................................................................................... 1-2

Parts List .................................................................................................................................................. 1-3

Smart Flow Computer : Dimensions ....................................................................................................... 1-4

Starting and Installing the Software: ....................................................................................................... 1-5

System Minimum Requirements ......................................................................................................... 1-5

Website - DFC Configuration Software .................................................................................................. 1-6

Getting acquainted with the flow computer wiring: ................................................................................ 1-8

Back terminal wiring: .......................................................................................................................... 1-8

Back Panel Jumper .............................................................................................................................. 1-9

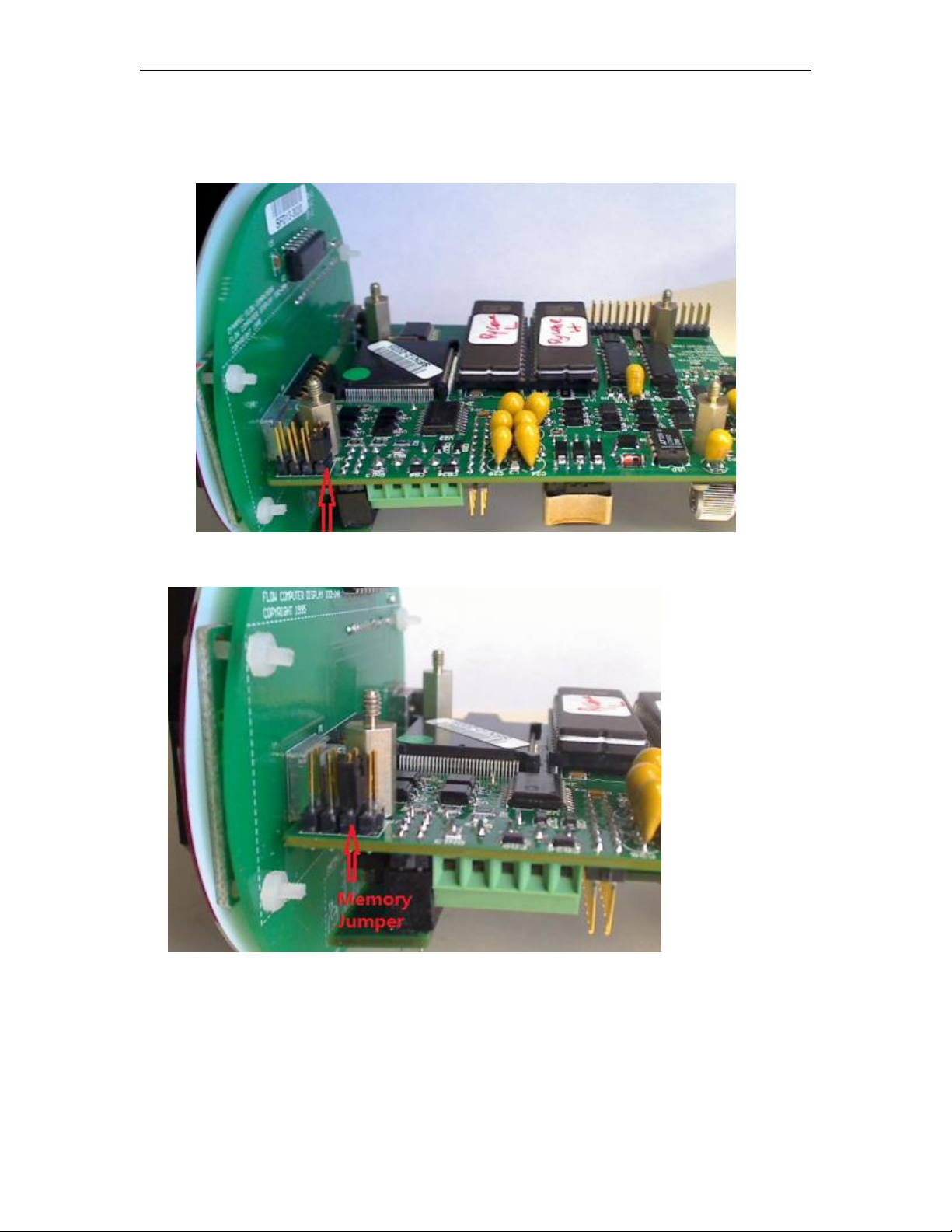

Memory Jumper................................................................................................................................. 1-10

INPUT/OUTPUT: Assignment, Ranging, Wiring, and Calibration ................................................. 1-14

Input/Output Assignment .................................................................................................................. 1-14

How to assign a transmitter to an I/O point: ...................................................................................... 1-14

Ranging the Transmitter Inputs: ........................................................................................................ 1-14

WIRING: ............................................................................................................................................... 1-16

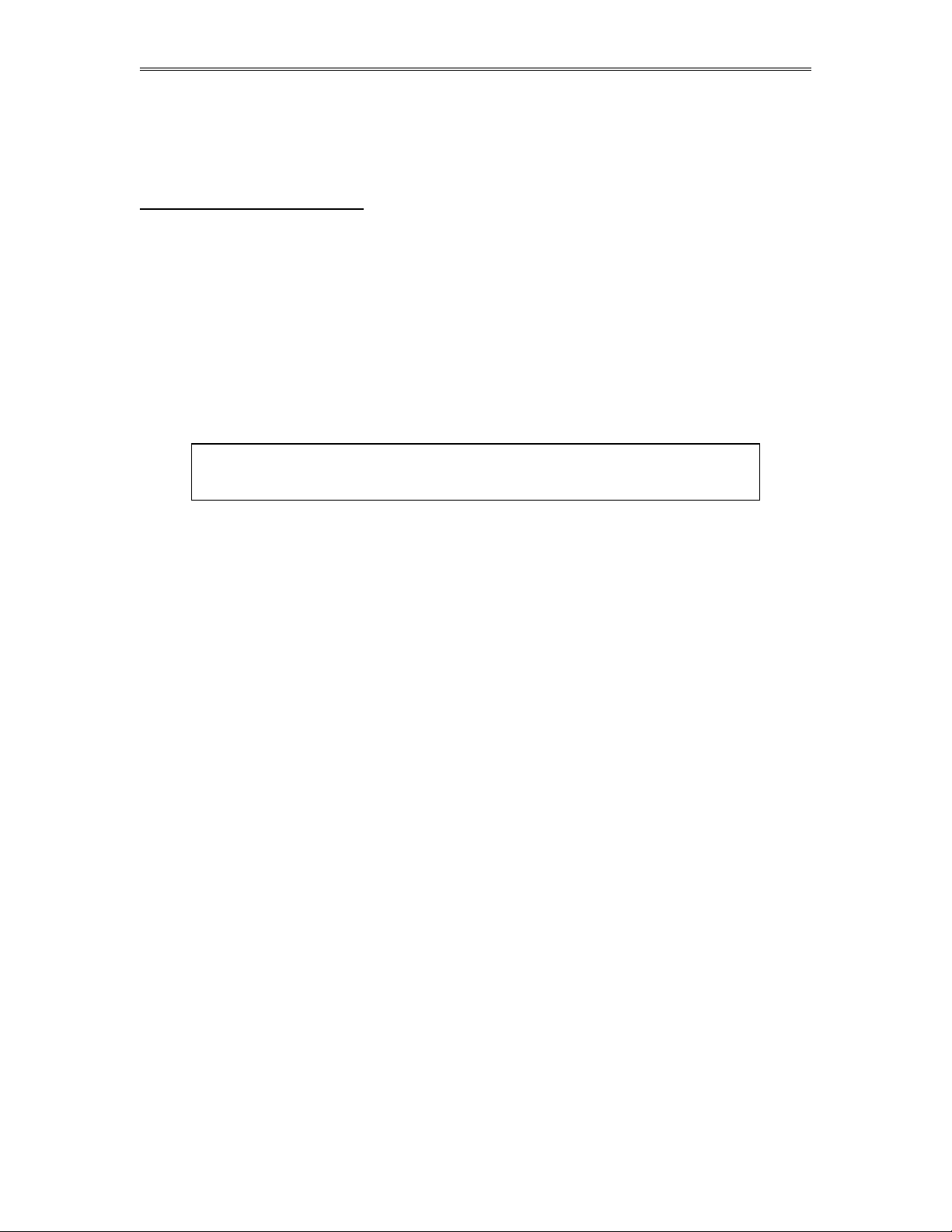

Wiring the analog inputs: .................................................................................................................. 1-16

Wiring the Analog Inputs 1-4 : .......................................................................................................... 1-17

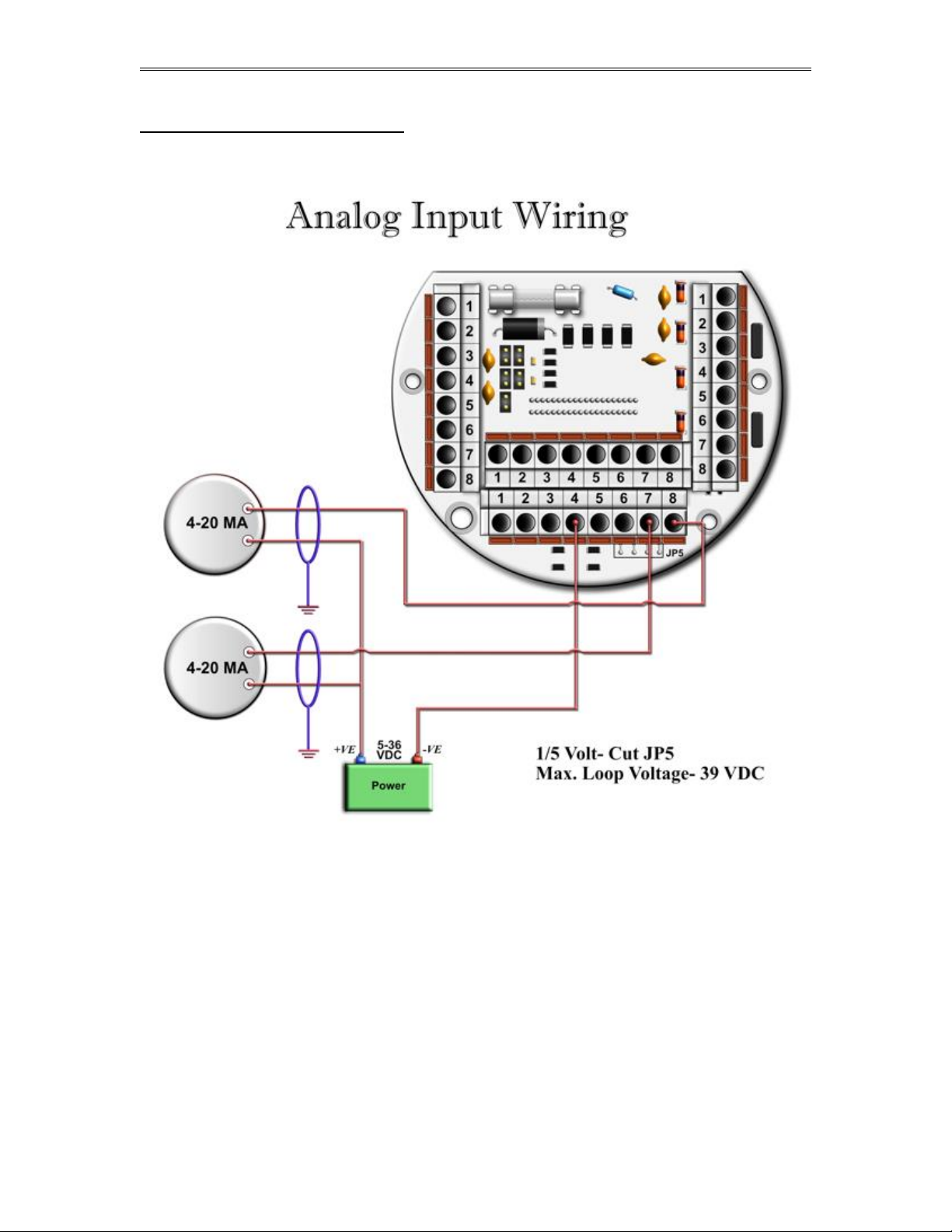

RTD Wiring ....................................................................................................................................... 1-18

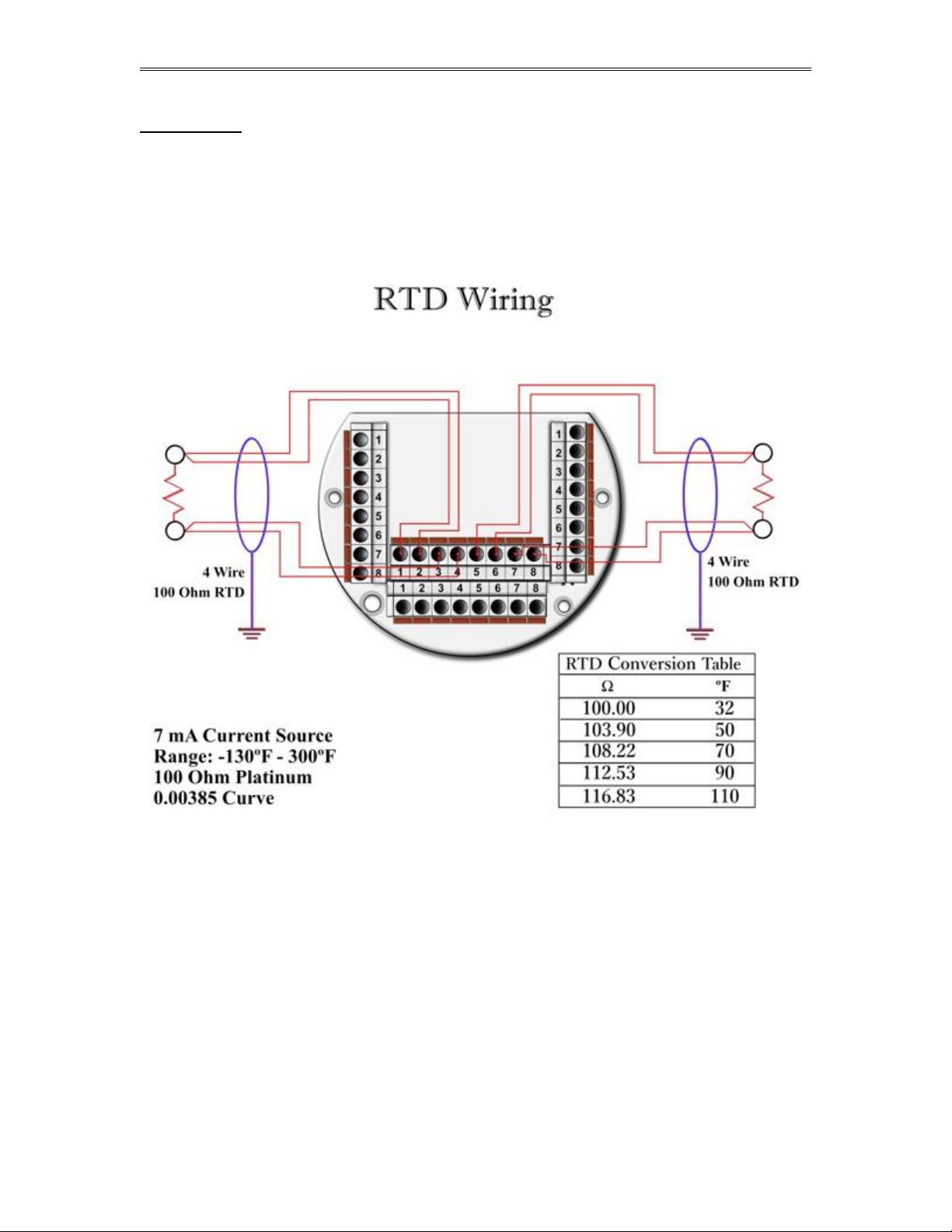

Wiring Analog Output: ...................................................................................................................... 1-19

Turbine input wiring .......................................................................................................................... 1-20

Turbine input wiring for passive (dry contact) pulse generators ....................................................... 1-23

Density input wiring: ......................................................................................................................... 1-24

RS-232 Connection ........................................................................................................................... 1-25

RS-485 Connection ........................................................................................................................... 1-26

Wiring of Status Inputs: ..................................................................................................................... 1-27

Wiring of Switch/Pulse Outputs: ....................................................................................................... 1-28

I/O Expansion: ................................................................................................................................... 1-29

Wiring of Brooks Prover ................................................................................................................... 1-32

Wiring of Calibron Prover ................................................................................................................. 1-33

CALIBRATION ................................................................ ................................................................ .... 1-34

Analog Input 4-20mA or 1-5 volt signal: .......................................................................................... 1-34

RTD calibration: ................................................................................................................................ 1-35

Calibration of analog output: ............................................................................................................. 1-36

Multi-Variable Transmitters (Model 205)- DP and Pressure ............................................................ 1-36

Multi-Variable Transmitters (Model 205)- RTD ............................................................................... 1-37

Verifying Digital Inputs and Outputs .................................................................................................... 1-38

Pulse Interpolation: ................................................................................................................................ 1-39

Double Chronometry: ................................................................................................ ............................ 1-39

Calculations and Terminology: ............................................................................................................. 1-40

Liquid pulse units .............................................................................................................................. 1-40

Terms ................................................................................................................................................. 1-40

CHAPTER 2: Data Entry ............................................................................................................................ 2-1

Introduction to the Smart Flow Computer Software................................................................................ 2-1

Introduction to the Flow Computer Software ......................................................................................... 2-1

ABOUT ................................................................................................................................................... 2-1

FILE ........................................................................................................................................................ 2-2

Open a File .......................................................................................................................................... 2-2

Open a New File .................................................................................................................................. 2-2

Delete a File ......................................................................................................................................... 2-2

Load File.............................................................................................................................................. 2-3

View File ............................................................................................................................................. 2-3

Save As ................................................................................................................................................ 2-3

Save ..................................................................................................................................................... 2-4

Date: 8/1/2019

Page 4

Save and Exit ....................................................................................................................................... 2-4

Exit ...................................................................................................................................................... 2-4

PORT ....................................................................................................................................................... 2-5

PC Communication Set Up.................................................................................................................. 2-5

Flow Computer Communication Set Up ............................................................................................. 2-6

Dial ...................................................................................................................................................... 2-7

Phone Book ......................................................................................................................................... 2-8

Modem Setup ...................................................................................................................................... 2-8

Hang-up Phone .................................................................................................................................... 2-8

DIAG ....................................................................................................................................................... 2-9

Read Single Flow Computer Communication Setup ........................................................................... 2-9

Diagnostic Data ................................................................................................................................... 2-9

PROVER ............................................................................................................................................... 2-10

Prove Request .................................................................................................................................... 2-10

Prover Temperature Override ............................................................................................................ 2-10

Prover Pressure Override ................................................................................................................... 2-10

Prover Gravity Override .................................................................................................................... 2-10

Prover Shaft Temperature Override ................................................................................................... 2-10

CTL or CPL Override ........................................................................................................................ 2-10

Prove Data ......................................................................................................................................... 2-10

Prover Diagram ................................................................................................................................. 2-14

Previous Prove Report ................................................................ ................................ ....................... 2-14

Single Prove Report ........................................................................................................................... 2-14

Prove Abort Report ............................................................................................................................ 2-14

METER ................................................................................................................................................. 2-15

Batch and Stream Data ...................................................................................................................... 2-15

METER DATA ................................................................................................................................. 2-16

PRODUCT DATA ............................................................................................................................ 2-19

OTHER PARAMETERS ...................................................................................................................... 2-20

Day Start Hour (0-23) ........................................................................................................................ 2-20

Company Name ................................................................................................................................ . 2-20

Flow Rate Average Second ............................................................................................................... 2-20

Old Table Gravity Unit ...................................................................................................................... 2-20

Disable Alarms .................................................................................................................................. 2-20

Print Intervals in Minutes .................................................................................................................. 2-20

GM/CC Conversion Factor ................................................................................................................ 2-20

Weight of H2O in Vac @60 Deg.F ................................................................................................... 2-20

Atmospheric Pressure ................................................................................................ ........................ 2-20

Pulse Output Width ........................................................................................................................... 2-20

Date and Time ................................................................................................................................... 2-20

End Batch .......................................................................................................................................... 2-20

Overrides: .......................................................................................................................................... 2-20

Security Code .................................................................................................................................... 2-21

INPUT/OUTPUT .................................................................................................................................. 2-22

Transducer Input Assignment ............................................................................................................ 2-22

Transducer Override .......................................................................................................................... 2-22

Calibration ................................................................ ................................................................ ......... 2-22

Status Input Assignment .................................................................................................................... 2-23

Switch Output Assignment ................................................................................................................ 2-26

Pulse Output and Pulse Output Width ............................................................................................... 2-26

Analog Output Assignment ............................................................................................................... 2-30

Flow Computer Display Assignment ................................................................................................. 2-32

Modbus Shift ..................................................................................................................................... 2-34

REPORTS ............................................................................................................................................. 2-35

Current Data - Snapshot Totalizer Updates ....................................................................................... 2-35

Previous Batch Data .......................................................................................................................... 2-35

Date: 8/1/2019

Page 5

Previous Hourly Data ........................................................................................................................ 2-35

Previous Daily Data ........................................................................................................................... 2-35

Previous Alarm Data ......................................................................................................................... 2-35

Audit Trail Report ............................................................................................................................. 2-36

Build User Report .............................................................................................................................. 2-36

View User Report .............................................................................................................................. 2-36

Formatted Ticket Report .................................................................................................................... 2-36

Auto Data Retrieval ........................................................................................................................... 2-36

WIRING ................................................................................................................................................ 2-37

PRINT ................................................................................................................................................... 2-38

Print "Help" File ................................................................................................................................ 2-38

Print Modbus Registers ..................................................................................................................... 2-38

Print Schematic .................................................................................................................................. 2-38

Print Calibration Data ........................................................................................................................ 2-38

Print Files .......................................................................................................................................... 2-38

CHAPTER 3: Flow Equations ..................................................................................................................... 3-1

FLOWRATES ......................................................................................................................................... 3-1

Mass Flowrate (MASS) ....................................................................................................................... 3-1

PROVE EQUATION .............................................................................................................................. 3-3

DENSITY EQUATIONS ........................................................................................................................ 3-6

Sarasota Density GM/CC .................................................................................................................... 3-6

UGC Density GM/CC ......................................................................................................................... 3-7

Solartron Density GM/CC ................................................................................................................... 3-8

CHAPTER 4: MODBUS DATA ................................................................................................................. 4-1

MODBUS PROTOCOL .......................................................................................................................... 4-1

TRANSMISSION MODE ................................................................................................................... 4-1

ASCII FRAMING ............................................................................................................................... 4-1

RTU FRAMING .................................................................................................................................. 4-1

FUNCTION CODE ............................................................................................................................. 4-2

ERROR CHECK ................................................................................................................................. 4-2

EXCEPTION RESPONSE .................................................................................................................. 4-2

BROADCAST COMMAND ............................................................................................................... 4-2

MODBUS EXAMPLES ...................................................................................................................... 4-3

FUNCTION CODE 03 (Read Single or Multiple Register Points) ..................................................... 4-3

Scaled Data Area (N: 1-meter1, 2-meter2, … 6-meter6) ................................................................... 4-13

Stream Data Area (N=: 1=Stream #1, 2=Stream#2, 3=Stream#3) .................................................... 4-14

Last Batch/Daily/Hourly Data Area .................................................................................................. 4-21

Stream Data Area - Last Batch/Daily/Hourly Data Area ................................................................... 4-22

Stream Data Area (N=: 1=Stream #1, 2=Stream#2, 3=Stream#3) .................................................... 4-24

Last Prove Data Area ......................................................................................................................... 4-27

Current Prove Data Area ................................................................................................................... 4-32

Last Single Prove Report Data Area .................................................................................................. 4-33

Last Abort Prove Report Data Area................................ ................................................................ ... 4-34

Alarms and Status Codes ................................................................................................................... 4-37

Previous Audit Data Area: ................................................................................................................. 4-39

CURRENT ALARM STATUS ......................................................................................................... 4-43

FLOATING POINT DATA AREA................................................................................................ ... 4-46

Date: 8/1/2019

Page 6

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-1

CHAPTER 1: QUICK START

Introduction:

A good flow computer must be:

User friendly

Flexible

Easy to understand and configure

Rugged

Economical to install and maintain

Accurate

The model SFC332 Smart Flow Computer incorporates all these features. We hope that your experience

with the Smart Flow Computer will be a very pleasant and friendly experience and not intimidating in any

way.

General Description: The SFC332 is a dual meter run bi-directional flow computer for the measurement

of liquid products. Twelve days of previous daily data, twelve previous batch data, and twelve previous

hourly data are stored in the full format type reports. The previous 50 audit trail reports and 50 alarm

reports are stored. User formatted reports and user formatted ticket reports are available. Sixteen different

product files are user-configurable with easy switch feature and product scheduling for batch operation.

Inputs/Outputs: 2 serial connections, RS-232 and RS-485, both of them Modbus ready. The RS-232 can

also be used with serial printer. Inputs: two 4 wire RTD; 4 single ended analog inputs; , 4 status inputs;

and density frequency. Outputs: 2 pulse/switch outputs; 3 switch outputs; and 2 analog outputs.

Programmable plasma display.

Date: 8/1/2019

Page 7

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-2

POWER

VOLTAGE RANGE

12-30 VDC

WATTAGE

4 WATT

OPERATING CONDITIONS

TEMPERATURE

- 40 TO 185 °F

HUMIDITY

100%

HOUSING

NEMA 4X CLASS 1 DIV. 1

FEATURES

DISPLAY

PLASMA 2 LINES 16 CHARACTER

PROCESSOR

32-BIT MOTOROLA 168332 @ 16.7 MHz

FLASH ROM

4 MB @ 70 NANO SECONDS

ROM

2 MB @ 30 NANO SECONDS

FREQUENCY INPUT

3 CHANNELS

0 - 5000 Hz

>70 mV FOR SIN WAVE

> 6 VOLTS FOR SQUARE WAVE

ANALOG INPUT

FOUR 24-BIT CHANNEL

RTD INPUTS

2 CHANNELS 4 WIRES

ANALOG OUTPUT

2 CHANNELS 12 BIT SINGLE ENDED

DIGITAL OUTPUT

OUTPUTS 1 & 2 PULSE/SWITCH 0.5 AMPS RATING

OUTPUTS 3 TO 5 ARE SWITCH OUTPUTS 0.25 AMPS

RATING

STATUS INPUTS

4 ON/OFF TYPE SIGNAL

ALL INPUTS AND OUTPUTS ARE OPTICALLY ISOLATED

SERIAL

1 RS485 @ 9600 BAUDS VARIABLE

1 RS232 @ 9600 BAUDS VARIABLE

COMMUNICATION PROTOCOL

MODBUS

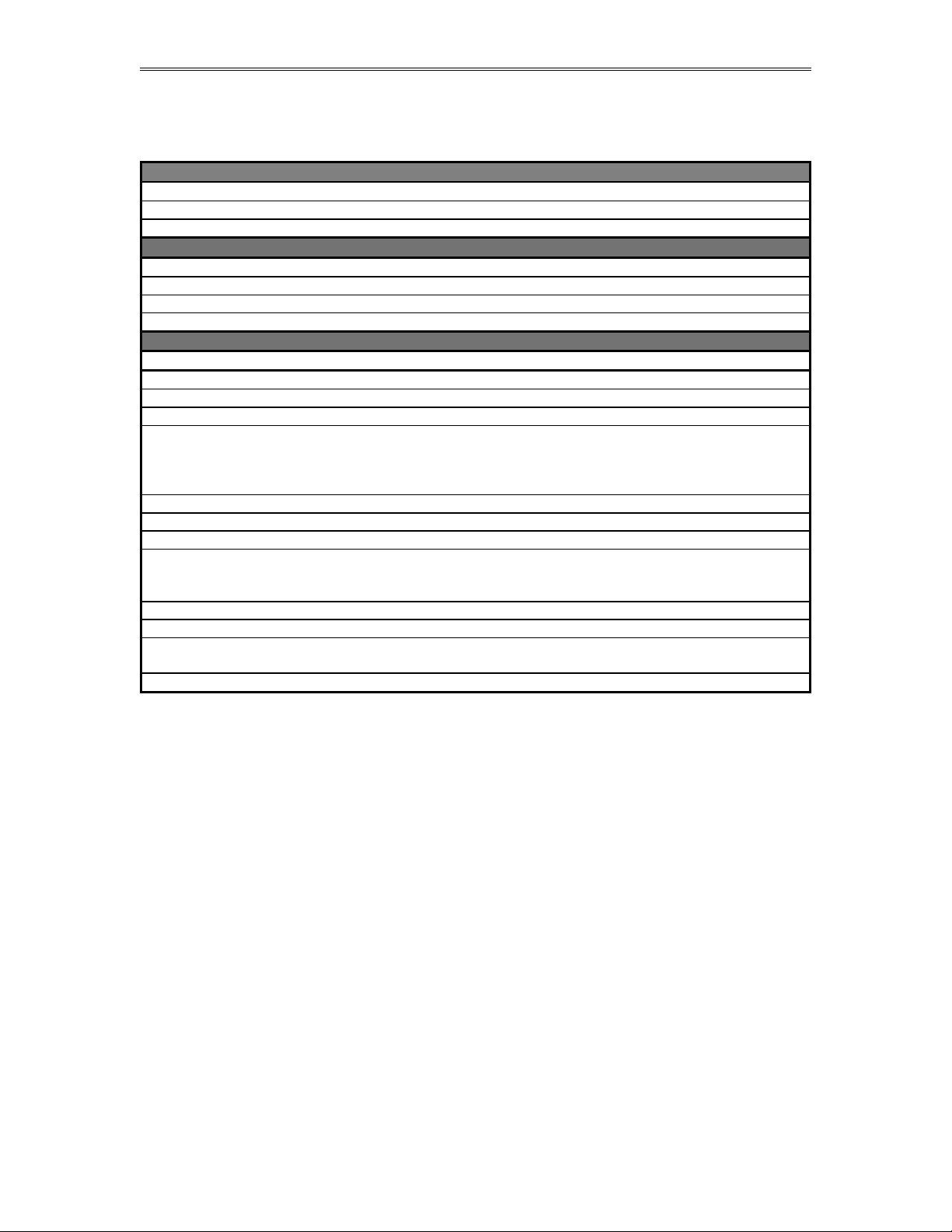

Technical Data

Date: 8/1/2019

Page 8

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-3

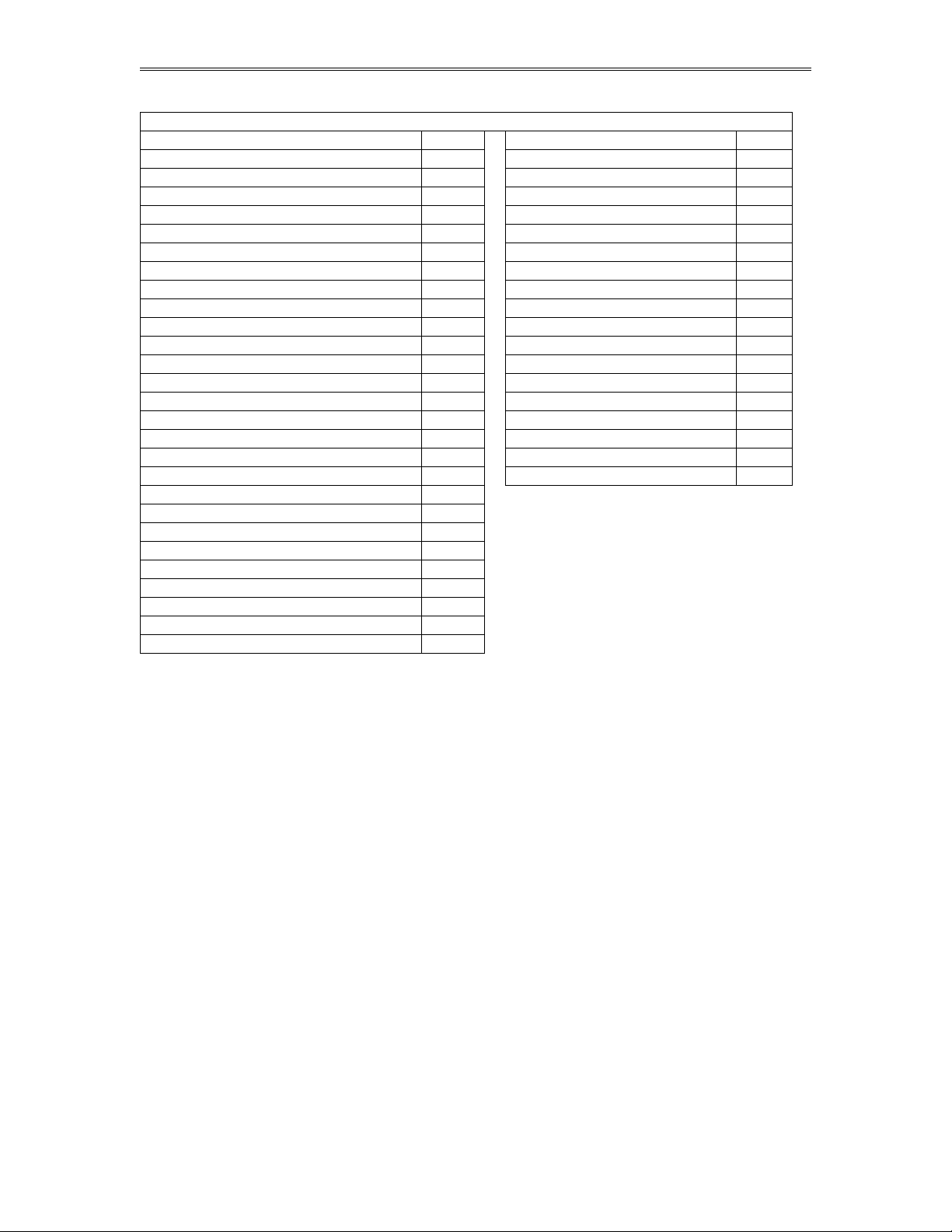

Part

Description

332-01P

Controller (CPU) Board for SFC332/1000 w/prover option.

332-02

Terminal (BP) Board for SFC332/1000.

332-03

Analog Board for SFC332/1000.

332-04

Display (LCD) for SFC332/1000.

332-05

Rosemount Interface Board for SFC1000.

332-06

Prover Option for SFC332/1000.

332-07

Enclosure for SFC332/1000.

332-08

Mounting Bracket w/captive screws for SFC332/1000 Boards.

332-09

Adapter between SFC1000 and Rosemount 205.

332-10

Center portion of housing for SFC332/1000 enclosure.

332-11

Glass Dome Cover for SFC332/1000 Enclosure.

332-12

Blank Dome Cover for SFC332/1000 Enclosure.

332-13

O'ring for SFC332 Enclosure.

332-14

External I/O Expansion.

332-15

Battery Replacement for SFC332/1000.

332-16

1/2 Amp 250V Fuse for SFC332/1000.

332-17

EPROM for SFC332/1000 (set of two).

RS232

External RS232 Connection for all models.

Parts List

Date: 8/1/2019

Page 9

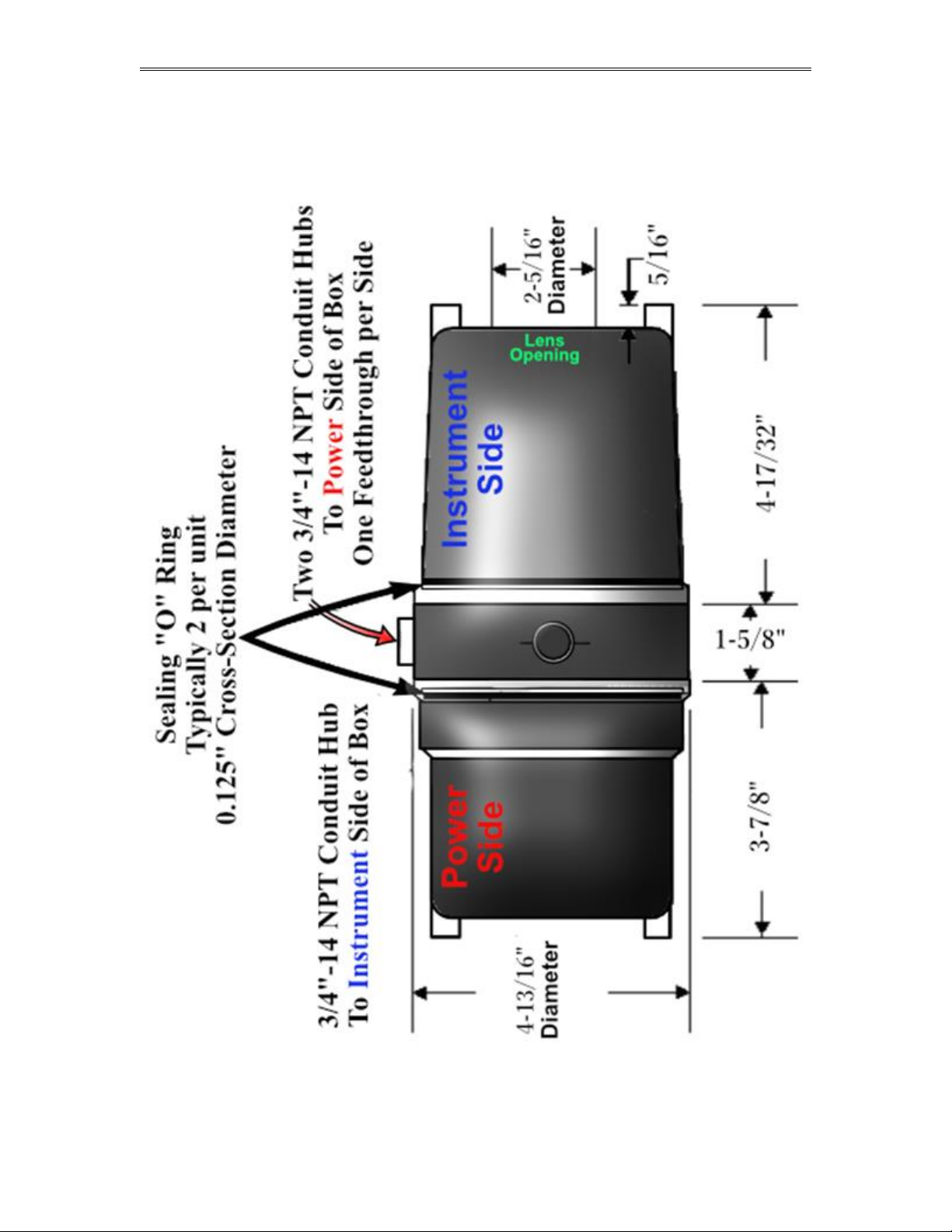

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-4

Smart Flow Computer : Dimensions

Date: 8/1/2019

Page 10

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-5

Starting and Installing the Software:

First make sure your computer has the minimum requirements to install Dynamic’s Dynacom software.

System Minimum Requirements

In order to install this software product the following requirements must be met:

Windows Operating System (Win95, Win98, Win98SE, win2000, WinNT, WinXP, Vista,

Windows 7, Windows 8, Windows 10)

For Windows NT, 2000, XP or Vista: Administrator level access to create an ODBC system DNS.

Minimum disk space available: 16 MB.

1 Serial Communication Port

If your computer meets these requirements, you can run the setup file downloaded from our website

Date: 8/1/2019

Page 11

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-6

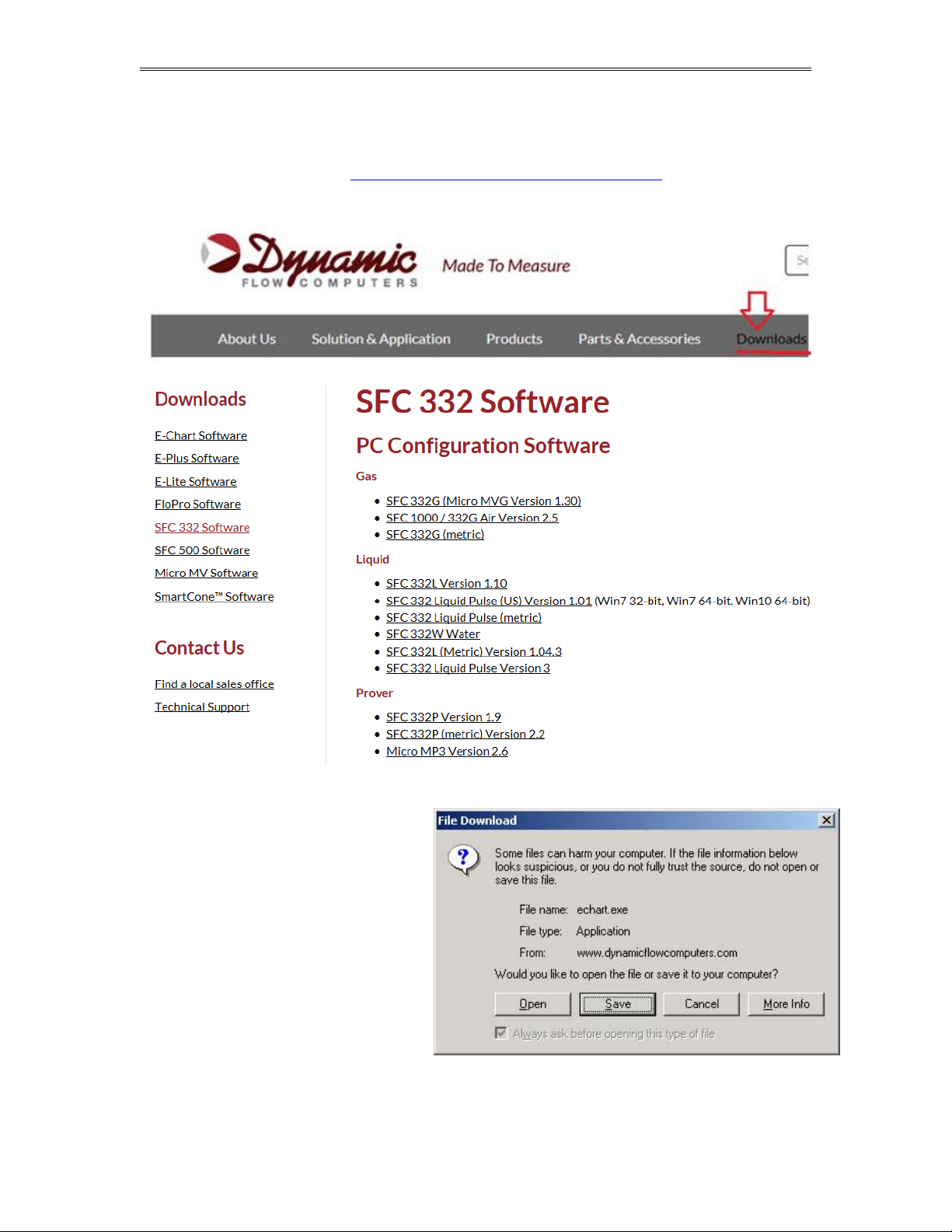

Website - DFC Configuration Software

Step 1. Go to our website WWW.DYNAMICFLOWCOMPUTERS.COM

Step 2. Click on the “Downloads”

Step 3. Select either Windows or

DOS software based on Step 2.

Step 4. On the new screen

presented to you click on the

application that you are trying to

download. Once you hit the link it

will ask you if you want to run or

save the file in your computer.

Select SAVE. (See illustration 1)

Date: 8/1/2019

Page 12

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-7

Step 5. The file will start to

transfer to your computer. The

download time depends on your

Internet connection speed and the

type of application that being

downloaded.

Step 6. When the download if

finish. Press the OPEN button to

start the setup process. (See

Illustration)

Step 7. Follow the steps in the

application setup.

Date: 8/1/2019

Page 13

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-8

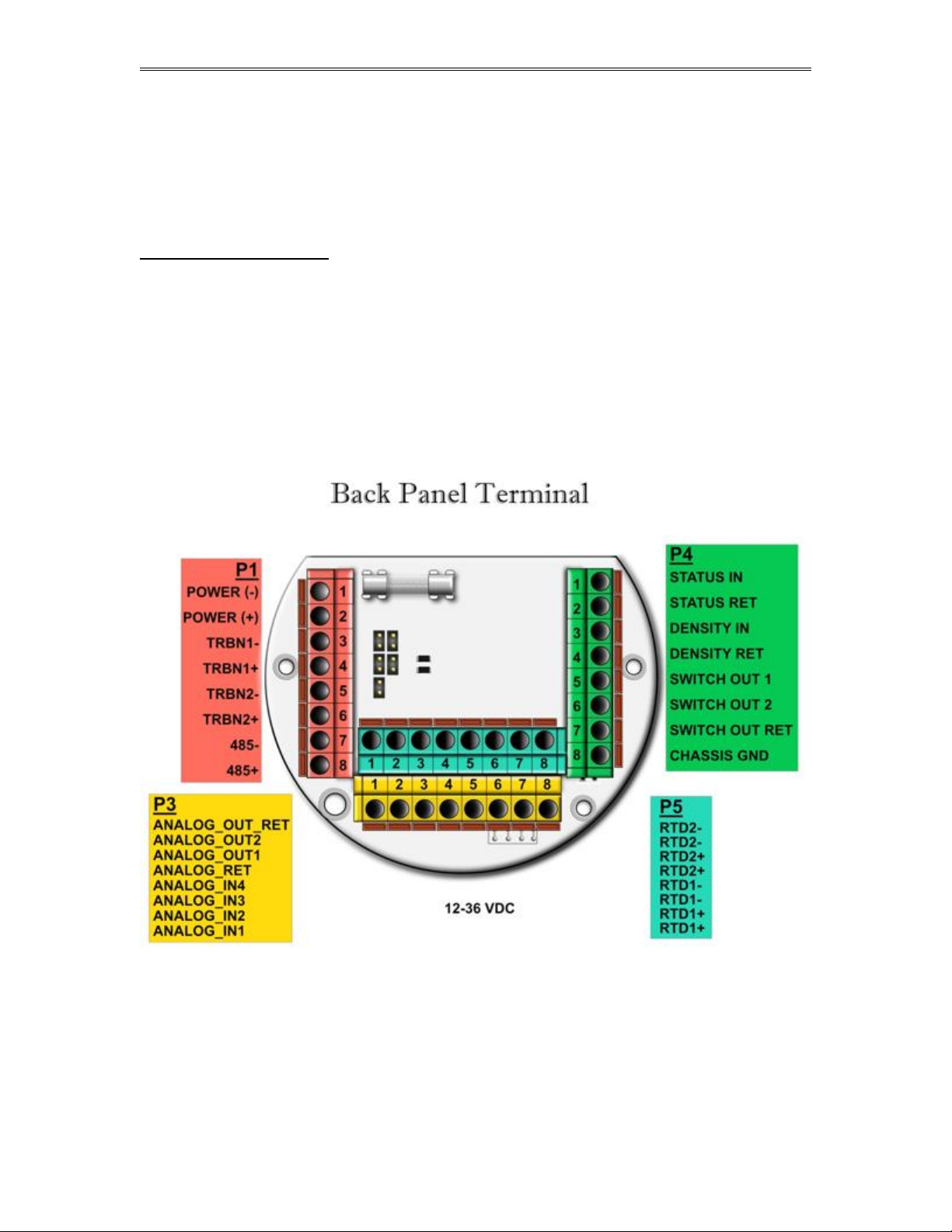

Getting acquainted with the flow computer

wiring:

To wire the flow computer, get familiar with the drawings provided in the software’s Wiring menu. Use

the arrow left and right keys to move to and select Wiring, then press ENTER.

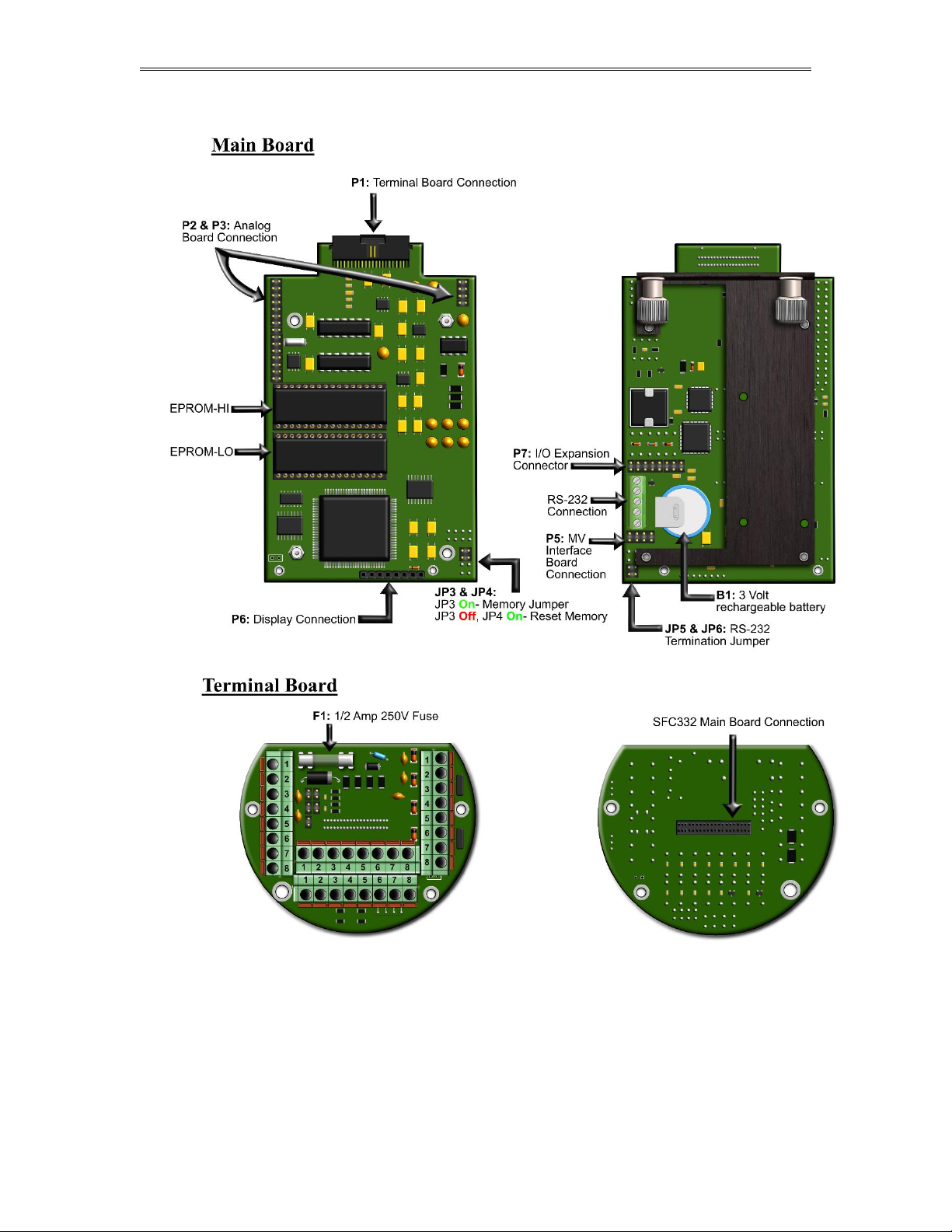

Back terminal wiring:

The back terminal wiring indicates the overall positions of the terminal plugs and their functions. Though

the back panel’s jumpers are also shown, refer to the next drawing, “Back Panel Jumpers”, for information

on their settings and functions.

The Smart Flow Computer receives its power via the two topmost pins on Terminal P1, on the left of the

terminal board. Also on Terminal P1 are, from top to bottom, inputs from the two turbines and the RS-485

serial connection.

To the right (P4), from top to bottom, is status input 1, density frequency input, and switch output 1 and 2.

Terminal P3, at the lower bottom, handles analog inputs and outputs. These are, in order from right to left,

analog inputs 1-4 and analog outputs 1 and 2.

Terminal P5, top middle, is the RTD terminal block, "100 platinum RTD input".

Date: 8/1/2019

Page 14

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-9

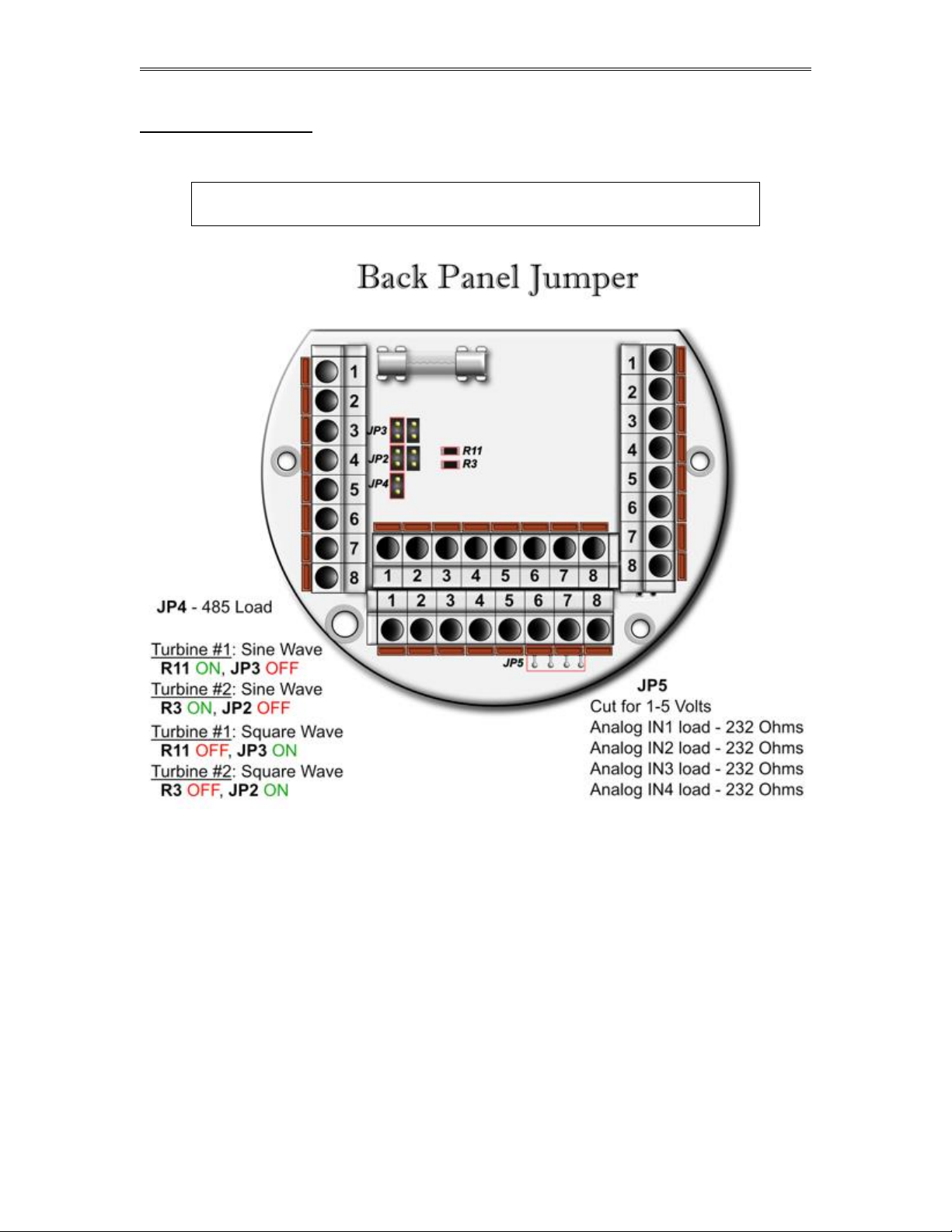

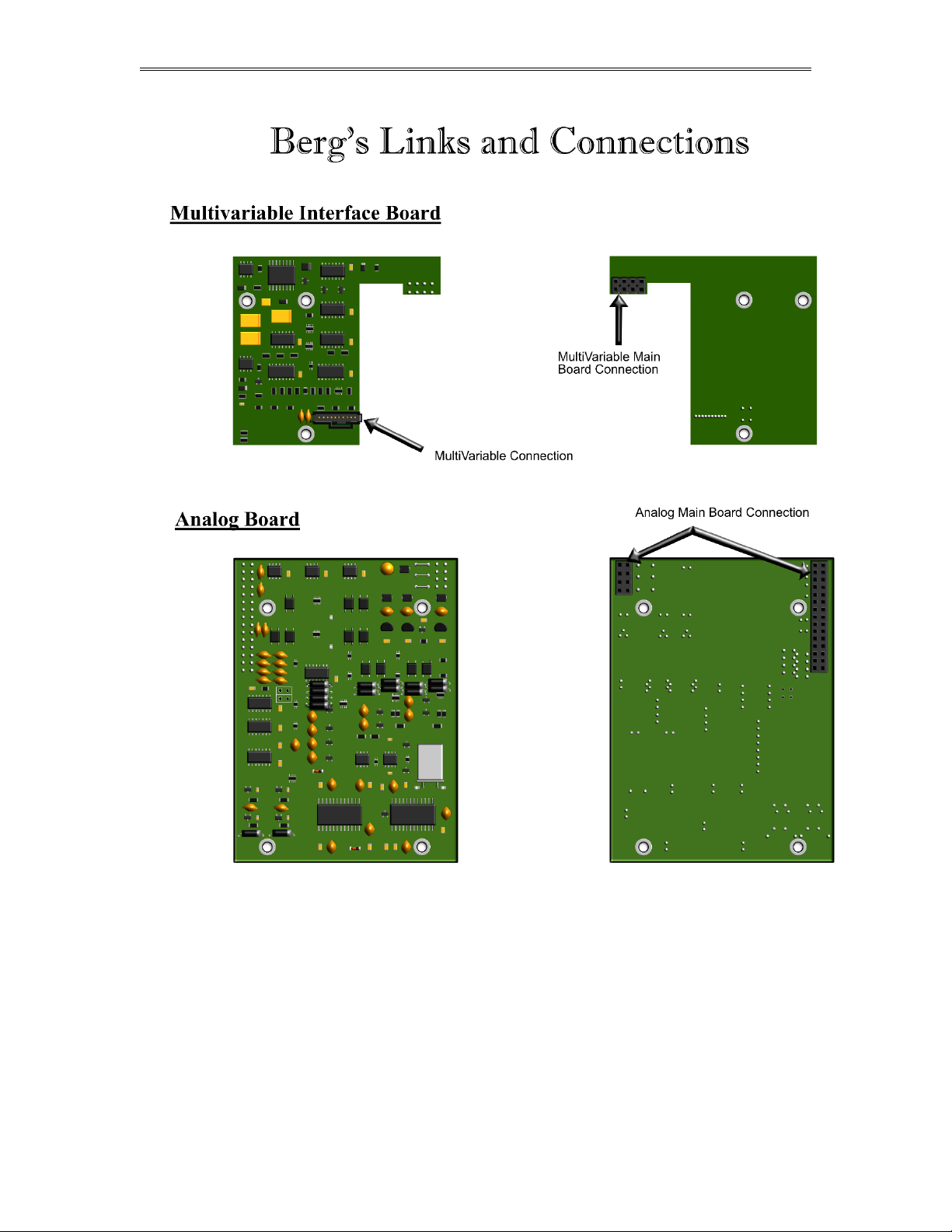

Back Panel Jumper

In this illustration, a jumper is “ON” when the jumper block is used to connect the jumper’s to wire prongs.

“OFF” means the jumper block is completely removed or attached to only one of the two wire prongs.

Note: R11 and R3 could have a vertical orientation instead of a

horizontal orientation on certain Smart Flow Computer models.

Date: 8/1/2019

Page 15

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-10

Memory Jumper

Date: 8/1/2019

Page 16

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-11

Steps to clear memory through removing the memory jumper

(1) Turn off the power, move the jumper to the next two pins, wait for 5 seconds

(2) Put the jumper back

Memory cleared and Flow Computer ID is set to 1, 9600 baud rate, RTU mode

Date: 8/1/2019

Page 17

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-12

Date: 8/1/2019

Page 18

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-13

Date: 8/1/2019

Page 19

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-14

INPUT/OUTPUT: Assignment, Ranging, Wiring, and Calibration

Input/Output Assignment

We will now configure your Smart Flow Computer’s inputs and outputs. The flow computer allows the

user to configure the inputs and outputs. i.e. Analog #1 is pressure for Meter #1. Unassigned inputs are not

used by the flow computer.

How to assign a transmitter to an I/O point:

Before beginning the procedure of assigning inputs and outputs, it is advisable to set up the meter (Meter

| Set Up). This is because certain parameters on the Transducer Input Assignment page

change (or may not appear, etc.) based on Meter | Set Up.

1 Use your arrow keys to scroll to menu item I/O (between Meter and Report). Its first

entry is Transducer Input Assignment. Press <ENTER>.

2. Use the down/up arrow key to scroll through this menu. The first four parameters are used to

set the number of decimals you would like to see in your live inputs (these numbers do not

affect the precision of your calculated data). Spare inputs are inputs that the flow computer

will read and display in the diagnostic data but are not used in the calculations. Spare inputs

high and low limit alarms are documented in the historical alarm report.

3. After the parameters used for setting the number of decimals come a series of parameters

ending with the words Assignment (1-n). Assignments 1-4 are analog

inputs attached to terminal P3 of the back panel. These

inputs accept 4-20mA or 1-5 volts input and are suitable for temperature, pressure,

density, BS&W, or spare inputs. Assignments 5 and 6 are strictly RTD (temperature) inputs

only for the meter, prover, densitometer or spare; temperatures are inputted via terminal P5

on the back panel. Assignment 7 indicates a density frequency input; it is assigned

automatically once you choose live density frequency input in the setup menu at density type

selection (and it can only be assigned via Meter | Set Up | Density #n, where n = 1 to

4). Assignment 10 (module 1) and assignment 11 (module 2) are used for Rosemount multivariable module only. DP, pressure, and temperature for the meter can be assigned.

Ranging the Transmitter Inputs:

1. Enter the range values: after assigning the inputs scroll down the transducer inputs

assignment menu to scale the 4-20mA. Enter the value at …@4mA and …@20mA. Enter both

values similar to the way the transmitter is ranged. 1-5 volts is equivalent to 4-20mA. Enter

the 1 volt value at the 4mA, and 5 volt value at 20mA.

2. Enter the high and low limits: high limits and low limits are simply the alarm points in

which you would like the flow computer to flag as an alarm condition. Enter these values

with respect to the upper and lower range conditions. Try to avoid creating alarm log when

conditions are normal. For example: If the line condition for the pressure is between 0 to 500

PSIG. then you should program less than zero for low pressure alarm, and 500 or more for

high pressure alarm. High and low limits are also used in the scale for the Modbus variables.

3. Set up the fail code: Maintenance and Failure Code values tell the flow computer

to use a default value in the event the transmitter fails. The default value is stored in

Maintenance. There are three outcomes: the transmitter value is always used, no matter

what (Failure Code = 0); the Maintenance value is always used, no matter what

(Failure Code = 1); and the Maintenance value is used only when the transmitter’s

value indicates that the transmitter has temporarily failed (Failure Code = 2).

Date: 8/1/2019

Page 20

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-15

RTD inputs will skip 4-20mA assignments because RTD is a raw signal of 50 (ohms) to 156. Readings

beyond that range require a 4-20mA signal to the flow computer.

Density coefficients for raw frequency inputs are programmed in this menu. The menu will only show

parameters relevant to the live density selected (i.e., Solartron or UGC, etc.).

NOTE: Solartron density input requires values in US units, i.e. PSI, and

F. Request a calibration sheet in US units from the densitometer

manufacturer.

Date: 8/1/2019

Page 21

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-16

WIRING:

Wiring to the flow computer is very straightforward and simple. But still it is very important to get familiar

with the wiring diagram.

Wiring the analog inputs:

Use your arrow keys to move the cursor to the menu item Wiring and then use up/down arrow keys to

select Analog Wiring. Press <ENTER>. Typical wiring for analog inputs 1 and 2 are shown in the

drawing. Analog inputs 3 and 4 are to the left of analog 1 and 2. Note that the analog input has only one

common return, which is the -ve signal of power supply powering the transmitters.

When wiring 1-5 volts, make sure to calibrate the flow computer for the 1-5 volt signal because the flow

computer calibration defaults for the 4-20mA, which is different from the 1-5 volts. JP5 must be cut for 15 volt inputs. The jumpers for analog 1-4 are in order from right to left. It is possible to cut the first two

jumpers for analog 1 & 2 in for 1-5 volts signal and have analog in 3 & 4 as 4-20mA signal. Signal line

impedance provided by our flow computer is less than 250. Therefore, when using a smart transmitter

that requires a minimum of 250 resistance in the loop, an additional resistor at the flow computer end

needs to be installed in series with the 4-20mA loop in order to allow the hand held communicator to talk to

the transmitter.

NOTE: The 4-20mA or 1-5 volt DOES NOT source power to the transmitters. You can use

the DC power feeding the flow computer to power the 4-20mA loop IF that power

supply is FILTERED.

Date: 8/1/2019

Page 22

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-17

Wiring the Analog Inputs 1-4 :

Date: 8/1/2019

Page 23

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-18

RTD Wiring

When ‘Flow Computer’ is configured as 4 analog inputs and 2 RTD inputs, go to the wiring menu where it

says RTD and press <ENTER>. The flow computer shows wiring to RTD 1 and RTD 2. 100 platinum

can be used; a temperature range of -43F to +300F can be measured. RTD 1 is to the right where P5

designation is. In the figure below notice that each side of the RTD requires two wire connections. When

using less than 4 wires a jumper must be used to make up for the missing lead. Internal excitation current

source generated is approximately 7mA. .

Date: 8/1/2019

Page 24

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-19

Wiring Analog Output:

The analog outputs are located on the left side of P3 connector. Go to the wiring diagram and scroll down

to Analog Output and press <ENTER>. Wiring diagram shows typical Analog output wiring. Notice

that analog output will regulate 4-20mA current loop but DOES NOT source the power for it. External

power is required.

ASS IGNING/RANGING THE 4-20MA AN ALOG OUT PUTS :

Go to the I/O assignment main menu and scroll to Analog Output Assignment. Press

<ENTER>. A selection menu is prompted. Select the analog output number and then enter what the 4mA

output will indicate and the 20mA. Make sure that the 20mA assignment value exceeds the upper range

limit of what you assigned the Analog output for, otherwise the analog output will not update beyond

20mA.

Date: 8/1/2019

Page 25

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-20

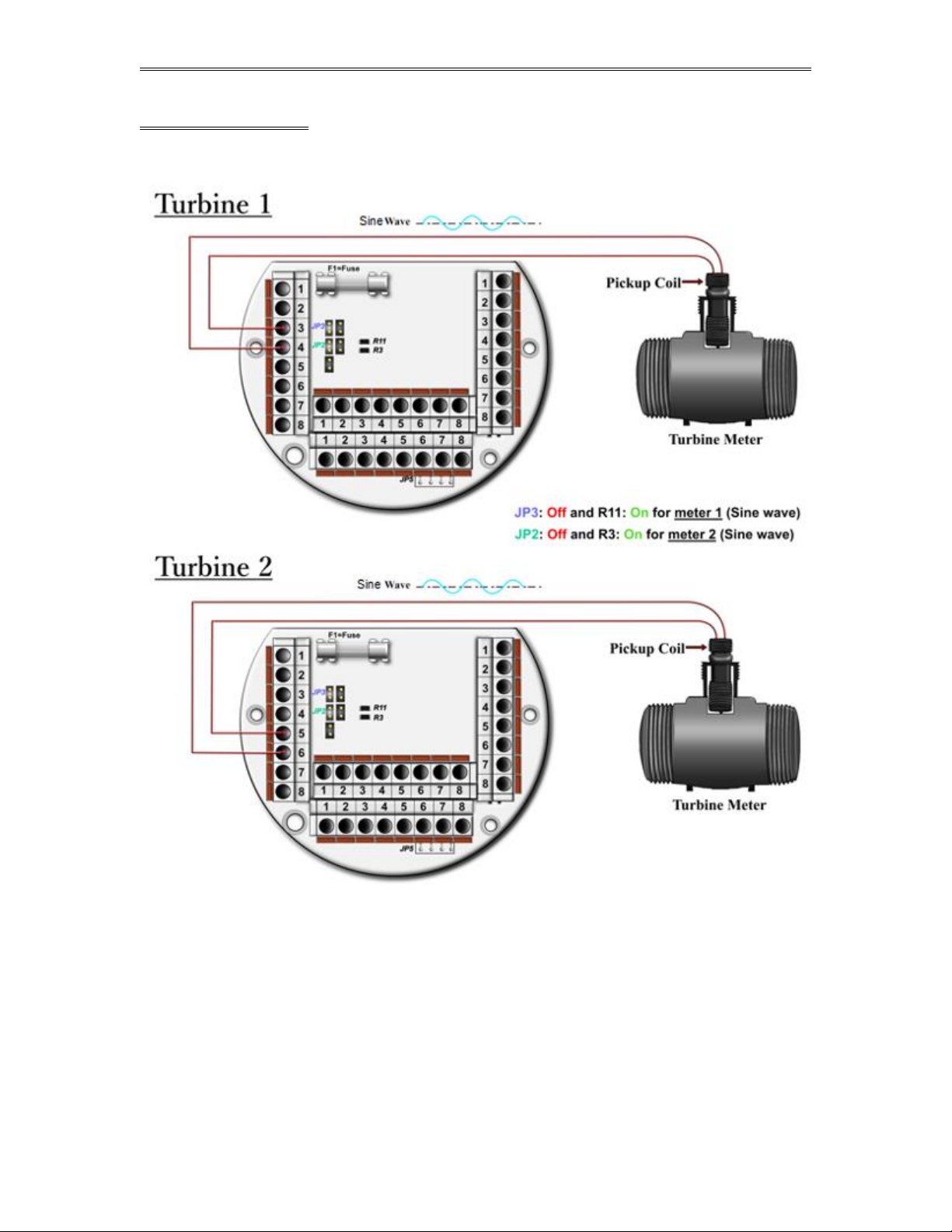

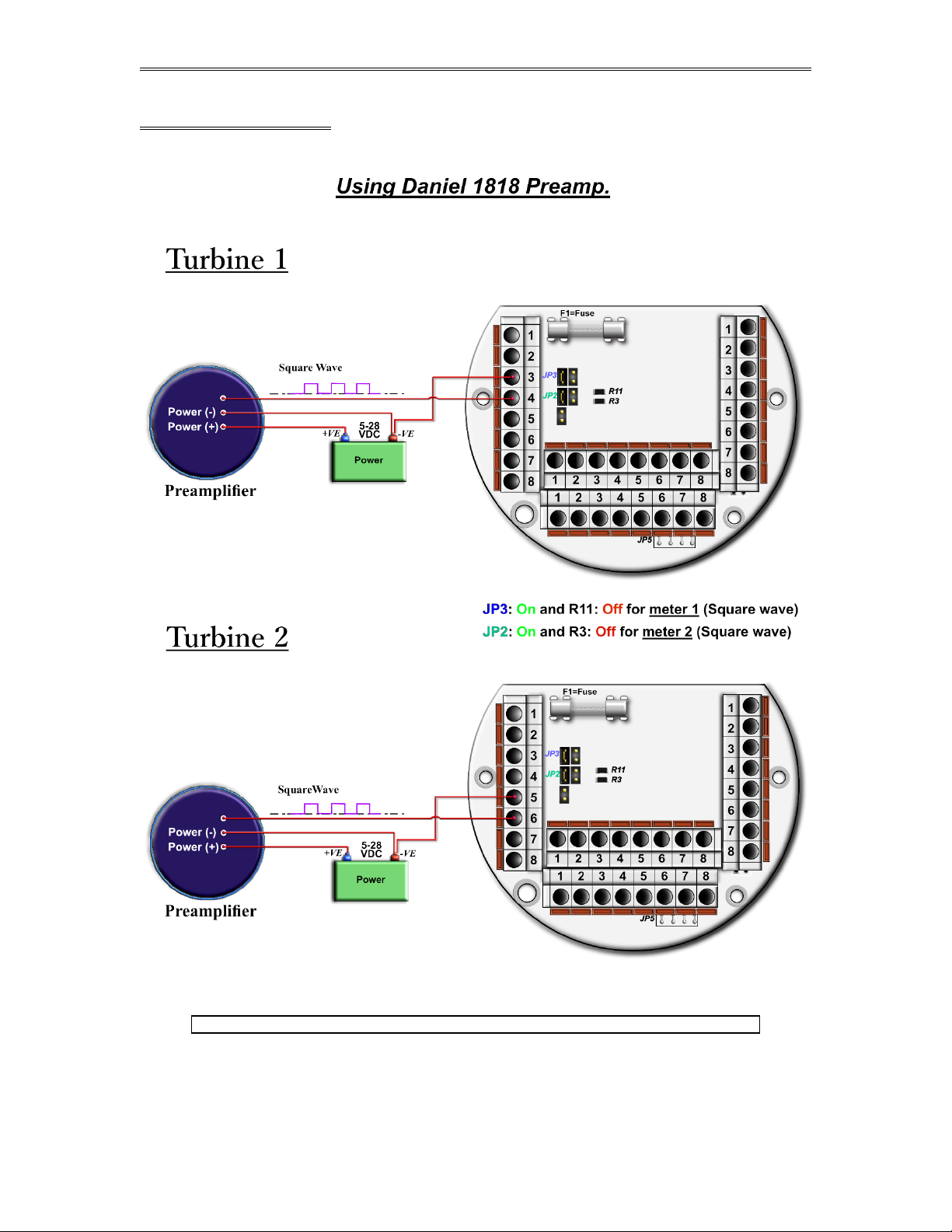

Turbine input wiring

Scroll to Turbine under Wiring and press <ENTER>. Two drawings above each other will show

typical wiring for turbine meter 1 and turbine meter 2. When dual pick ups from the same turbine are

connected, use the inputs for turbine 1 for pickup 1 and turbine 2 for the second pickup coil. When

connecting sine wave directly from the pickup coil make sure the distance from the pickup coil to the flow

computer is very short--less than 50 feet with shielded cable. In the event there is presence of noise, the

distance must be shortened. When connecting sine wave signal, the R11 jumper for meter 1 must be

installed and R3 jumper for meter 2 must be installed. (JP3 and JP2 must be off when using sine wave).

On the other hand, when using square wave, the square wave signal can be sinusoidal but has to be above 5

volts peak to peak with less than 0.4 volts offset in order for the flow computer to read it. R11 and R3 must

be off and JP3 on for meter 1; JP2 must be on for meter 2.

Note: When connecting square wave input, the JP3 and JP2 connect the turbine return to the

flow computer power return. Therefore, signal polarity is very important. Reverse polarity

could result in some damage or power loss. When sine wave is used the signal polarity is

usually of no significance.

The turbine input is immediately under the power input on terminal P1. The third pin down from the top is

Turbine/PD "minus", and below it is Turbine plus. The second pulse input for Turbine/PD meter 2 or the

second pickup coil is below turbine one input on P1. The fifth pin down from the top is turbine 2 "minus"

signal and below it is Turbine/PD 2 plus signal.

Date: 8/1/2019

Page 26

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-21

TUR BINE- SINE WAVE

Date: 8/1/2019

Page 27

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-22

TUR BINE-SQUARE WAVE

Note: R11 and R3 are oriented vertically in some flow computers.

Date: 8/1/2019

Page 28

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-23

Turbine input wiring for passive (dry contact) pulse generators

Some mass flow meters have pulse outputs that do not provide power but instead require

external power, they are referred to as passive outputs, dry outputs, open collector, etc. (For

example the Krohne UFM 3030 Mass meter).

In these cases the wiring should be as shown on the below diagram. The pull up resistor can be

adjusted to limit the current sink by the Mass meter. For Turbine Input 1 JP3 must be ON and

R11 OFF and if using Turbine Input 2 then JP2 must be ON and R3 OFF.

Date: 8/1/2019

Page 29

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-24

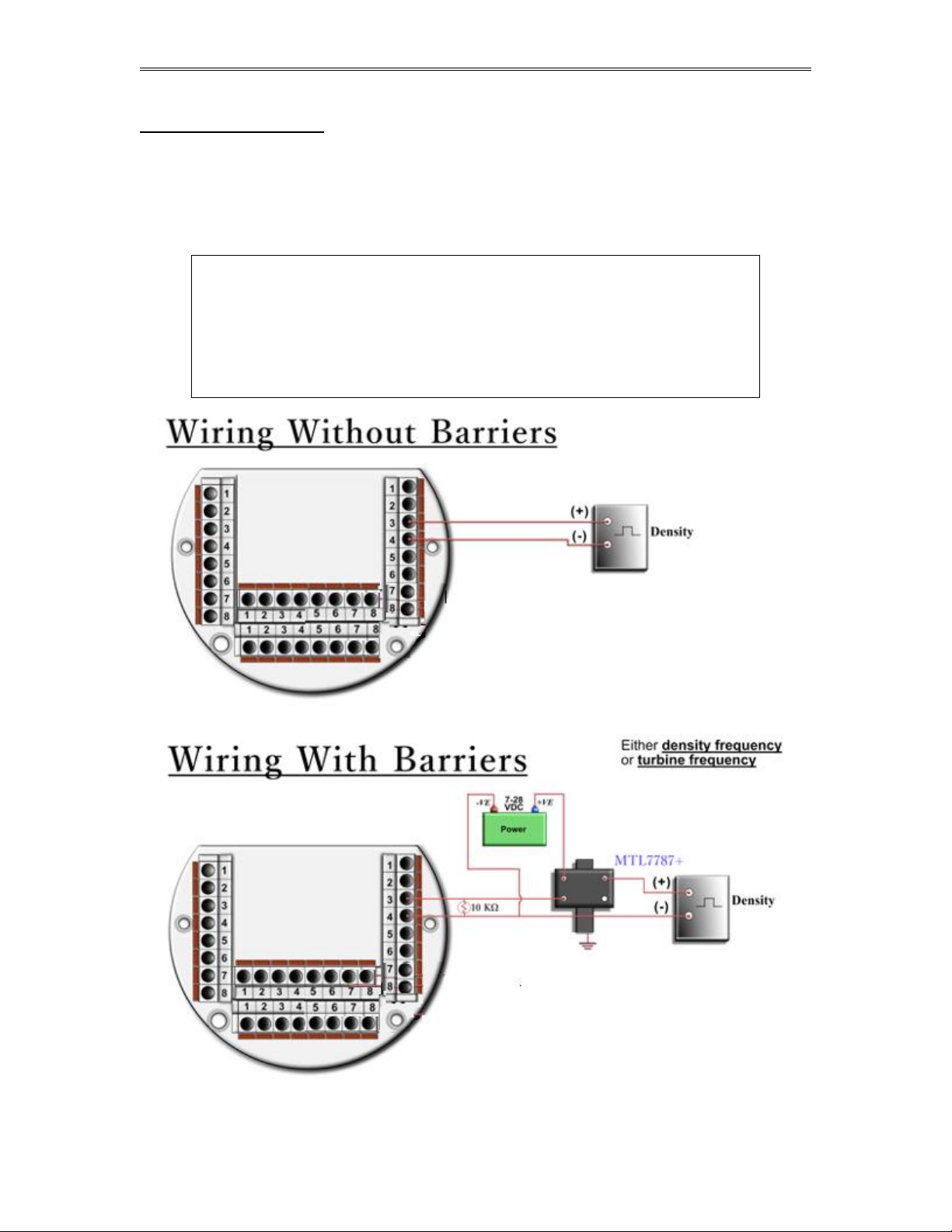

Density input wiring:

When using a live densitometer input with frequency signal, the signal can be brought into the Smart Flow

Computer in its raw form. The Smart Flow Computer accepts a sine wave or square with or without DC

offset. Example for density wiring can be seen in the wiring diagram. Use the arrow keys to get to

Wiring | Density and press ENTER. Find two drawings, one with barrier and the other without.

Barriers are used for area classification. Notice that the RTD wiring is also drawn to show how to hook the

density RTD signal.

Note: When wiring the density input polarity is of significance and

reverse polarity could result in some damage or power loss. The

density signal is on connector P4, the third and fourth pin down

from the top. The third pin down is density plus, the fourth down is

density minus. When Density input is 4-20mA it should be

connected as a regular 4-20mA signal to the analog input and not

the density frequency input.

Date: 8/1/2019

Page 30

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-25

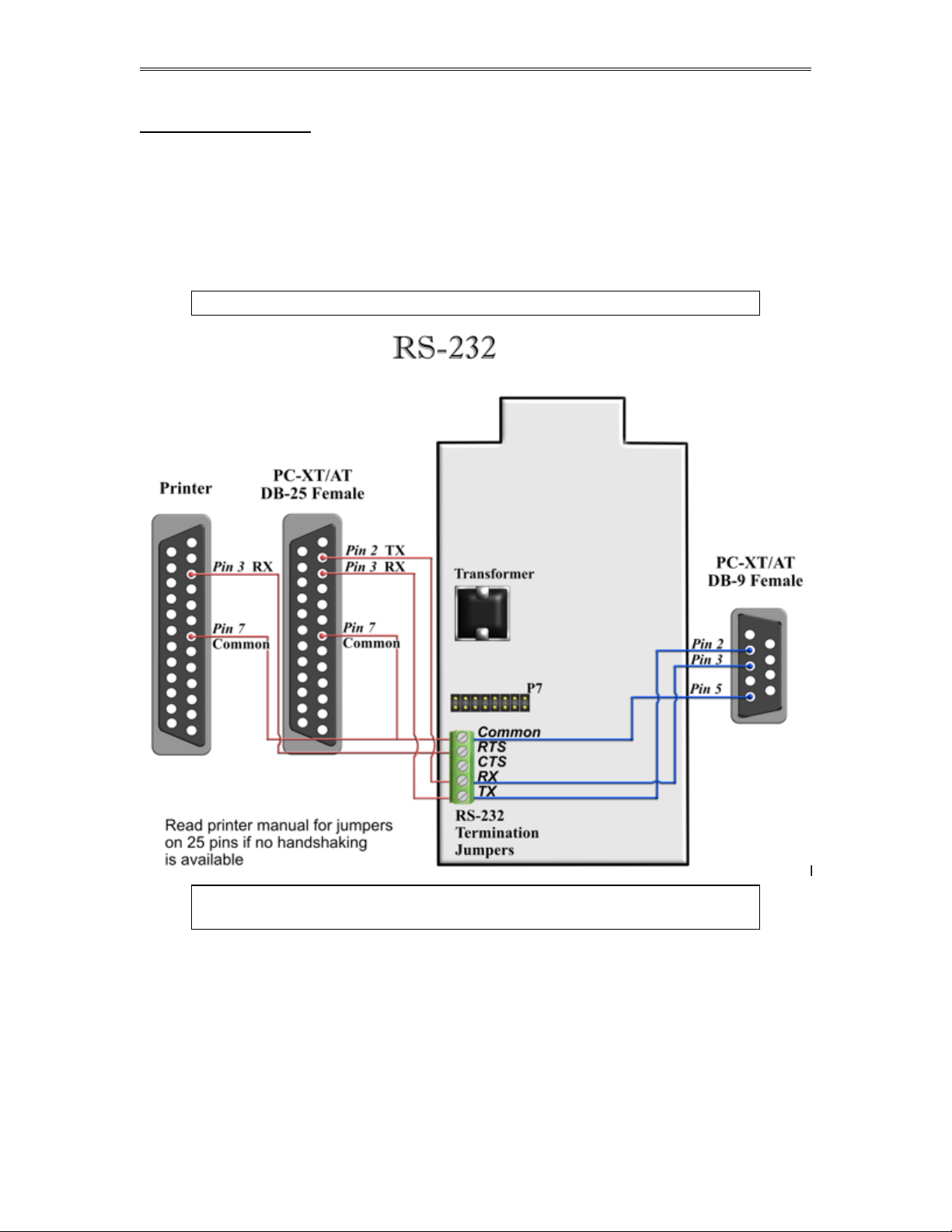

RS-232 Connection

The RS-232 is not located on the terminal board. The RS-232 is a green 5 pin terminal block with screw

type connector located on the display side of the enclosure. Scroll to Wiring | New RS-232 and press

ENTER. Termination jumpers for the RS-232 are located at the top corner of the board on the same side of

the RS-232 connector. The two jumpers at the top are for terminating the transmit line and below it is the

receive line.

The RS-232 port can be used for printing reports, Modbus communication, or interfacing to the

configuration program. If the port is configured as printer port in the flow computer communication setup,

then reports get printed (i.e. interval and daily reports).

Note: Twisted shielded cable is required.

WARNING: When the RS-232 terminal is used with a modem, external

protection on the phone line is required.

Date: 8/1/2019

Page 31

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-26

RS-485 Connection

RS-485 wiring is shown in the wiring diagram under RS-485. The RS-485 termination jumper is JP4

located on the back terminal. The maximum distance when 18 gauge wire is used would be 4000 feet.

Note: Twisted shielded cable is required.

WARNING: When the RS-485 terminal is used, external transient

protection and optical isolation is required, especially for long

distance wiring.

Date: 8/1/2019

Page 32

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-27

Wiring of Status Inputs:

There is one status input standard and an optional three more on the back of the CPU board. The standard

status input is shown in the wiring diagram under Status Input. It has 4 volts of noise hysteresis,

with a trigger point of 5 volts and an off point of 1 Volt. Status inputs 2, 3, and 4 require the I/O expansion

connector and its wires be installed; refer to wiring drawing IO-Exp. Connection numbers 6, 7, and 8 are

the status in (positive) for inputs 2, 3, and 4, respectively, and 11 is the return for all three inputs.

Date: 8/1/2019

Page 33

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-28

Wiring of Switch/Pulse Outputs:

Scroll to Switch output under Wiring and press <ENTER>. The wiring diagram shows switch 1

and 2 and the return. Please note that switches 3, 4, and 5 cannot be used for pulse output; switches 1 and 2

can be used for pulse or switch output. See also I/O Expansion. Notice that the switch outputs are

transistor type outputs (open collector type with maximum DC rating of 350 mA continuous at 24 VDC)

and require external power.

Date: 8/1/2019

Page 34

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-29

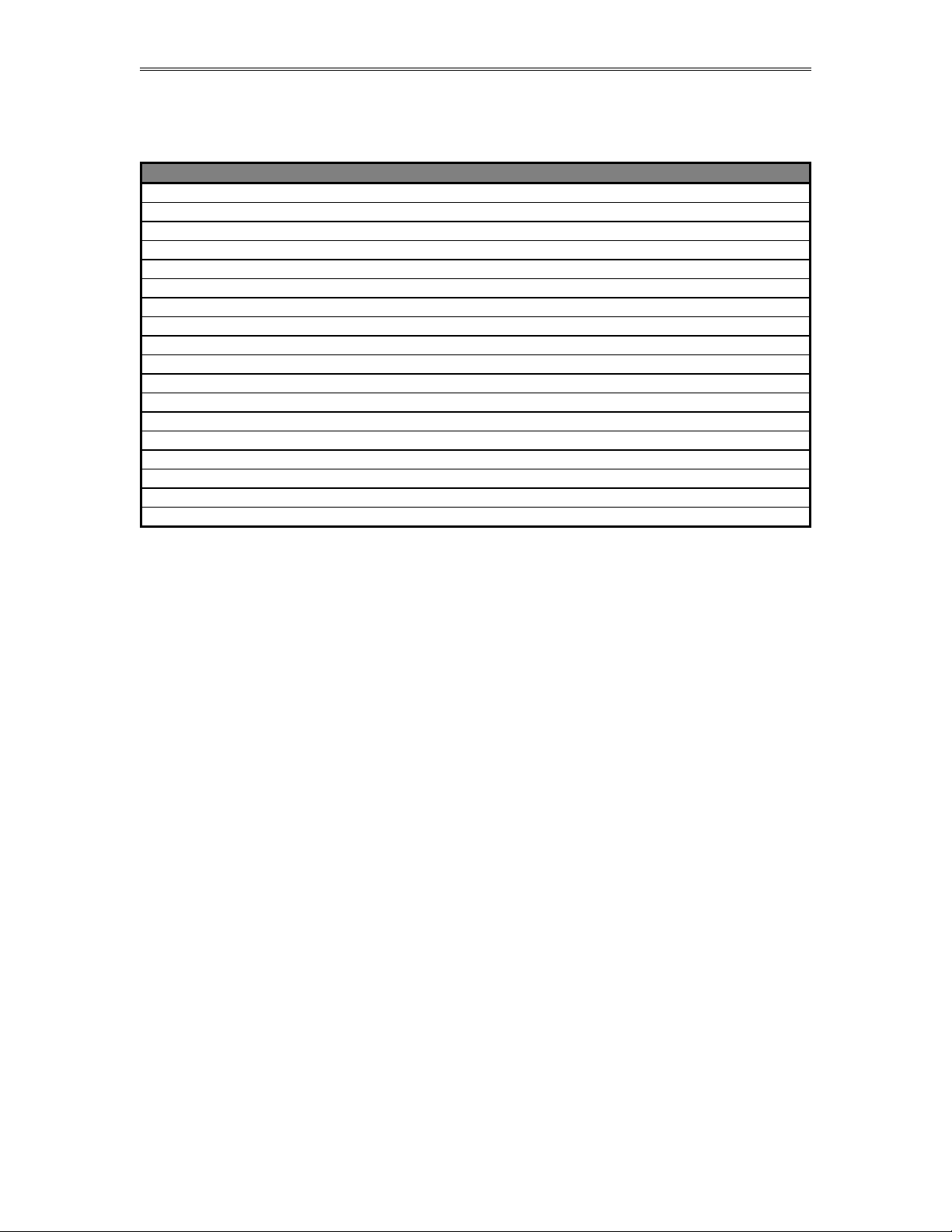

Connection

Purpose

Comments

1

detector switch 1

Requires prover option CPU to operate.

Rating: 5-36 Vdc

2

detector switch 2

3

switch output 3

Maximum rating: 75mA @24 volts

Range: 5-36 Vdc

4

switch output 4

5

switch output 5

6

status input 2

Rating: 6-36 Vdc

7

status input 3

8

status input 4

9

Return: detector switches

10

Return: switches 3, 4, 5

11

Return: status 2, 3, and 4

I/O Expansion:

The I/O expansion is 16-pin connector next to the RS-232 terminal. Eleven pins of the 16-pin connector

are utilized. When the flow computer is ordered with the I/O expansion feature, the wires and the plug are

provided with the flow computer. There will be 11 wires with the wire number tag at the outer end of the

wire. The tag will indicate the wire number. The following is the sequence for the wires. On the top right

edge of the connector towards the top outer side of the CPU board is pin 1, across from it is pin 9.

Date: 8/1/2019

Page 35

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-30

Date: 8/1/2019

Page 36

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-31

Connection No.

Purpose

Comments

1

detector switch 1

Requires prover option CPU to operate.

Rating: 5-36 Vdc

2

detector switch 2

3

switch output 3

Maximum rating: 75mA @24 volts

Range: 5-36 Vdc

4

switch output 4

5

switch output 5

6

status input 2

Rating: 6-36 Vdc

7

status input 3

8

status input 4

9

Return: detector switches

10

Return: switches 3, 4, 5

11

Return: status 2, 3, and 4

12

RS232 TX

13

RS232 RX

14

RS232 RTS

15

RS232 ret

Prover/Expansion

Date: 8/1/2019

Page 37

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-32

Wiring of Brooks Prover

Date: 8/1/2019

Page 38

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-33

Wiring of Calibron Prover

Date: 8/1/2019

Page 39

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-34

CALIBRATION

Analog Input 4-20mA or 1-5 volt signal:

Calibrations are performed under I/O | Calibration. Use the arrow keys to scroll to

Calibration and press <ENTER>. After you press <ENTER> the screen should show

COMMUNICATION STATUS : OK.

OFF SET CALIBRATION:

For simple offset type calibration simply induce the signal into the analog input and make sure the flow

computer is reading it. After you verify that the flow computer recognized the analog input press <F8>.

The screen will freeze. Scroll down to the analog input you are calibrating and enter the correct mA

reading. Then press <ENTER> followed by pressing F3 function key to download. The screen will stay in

the freeze mode. To bring the live readings press <F2> key , and then the flow computer will display the

new calibrated readings. The offset type calibration is mainly used when a small offset adjustment needs to

be changed in the full-scale reading. The offset will apply to the zero and span.

FULL CALIBRATION METHOD:

To perform full calibration be prepared to induce zero and span type signal.

1. Induce the low end signal i.e. 4mA in the analog input.

2. Press <F8> and scroll down to the reading then press <ALT><R> (alternate key and the letter

R simultaneously). Then immediately enter the analog input value i.e. 4mA. Follow that by

< ENTER> and then press <F3> function key to download data.

3. Now be ready to enter the full-scale value. Simply induce the analog signal and then enter

the value i.e. 20mA, and then download by pressing <ENTER>, then press <F3> function key.

4. Induce live values to verify the calibration.

DEF AULT CALIBRATION

Simply press <F8> and scroll to the analog Input and press <ALT><R> followed by <F3 function key.

Date: 8/1/2019

Page 40

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-35

RTD calibration:

RTD Calibration is a 2-step process. The first step is a one time procedure to verify transducer

linearity and is done at the time the meter is being setup. The second step is the routine calibration

sequence.

Step 1 – Linearity Verification

1. Use a Decade box with 0-150 °F settings.

2. Connect RTD cable to this resistive element for verification of linearity. Verify low and high points.

It must be within ½ degree.

3. Connect the actual RTD element and compare with a certified thermometer.

4. If not within ½ degree do a Full Calibration (See Full Calibration below). If problem persists verify

other elements such as RTD Probe, connections, shield, conductivity of connectors, etc.

The purpose of the above procedure is to verify zero and span and make sure that the two points

fall within the expected tolerance.

Step 2 – Routine Calibration

Once Linearity has been verified through Step 1, the routine calibration procedure is reduced to

simply connecting the actual RTD and doing an offset point calibration (see offset calibration

below).

Calibration after that will be simple verification for the stability of the transmitter. If it drifts abnormally

then you need to verify the other parts involved.

RESET TO DEFAULT CALIBRATION

To go back to the default calibration simply press <F8> and scroll to the RTD input, and press

<ALT> <R> key followed by <F3> function key.

OFFSET CALIBRATION:

For offset calibration simply go to I/O | Calibration and press < ENTER>. Once the flow

computer shows communication status OK press <F8> function key and scroll to RTD. Induce a

live value and wait for 10 seconds for the reading to stabilize. Then enter the live value followed

by <F3> function key to download the direct reading. The value entered must be in ohms only.

FULL SCALE CALIBRATION:

1. Prepare low range resistive input (i.e., 80) and High range resistive input (i.e., 120). Go to

the calibration menu and press <F8> function key. Scroll to the RTD input you are calibrating

and press <ALT> <R> (key <ALT> and the letter R at the same time). Induce the low end

(80) resistive signal and then wait 10 seconds and enter 80 followed by pressing the <F3>

function key.

2. Induce higher range signal (120) and wait 10 seconds, then enter the number 120 ohm and

press the <F3> key.

3. Now verify the live reading against the flow computer reading.

Date: 8/1/2019

Page 41

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-36

Calibration of analog output:

To calibrate the analog output against the end device follow the following steps:

1. Go to the calibration menu and press <F8>. Scroll down to analog output and press <ENTER>

and then <ALT><R>. This will cause the flow computer to output the minimum possible

signal 3.25 mA. Enter the live output value reading in the end device i.e. 3.25 mA and press

<F3> function key. Now the flow computer will output full scale 21.75 mA. Enter the live

output i.e. 21.75 then press the <F3> key.

2. Now verify the output against the calibration device.

Multi-Variable Transmitters (Model 205)- DP and Pressure

OFF SET CALIBRATION

1. Induce live value for temperature, pressure, or DP.

2. Go to Calibration - Multi-Variable menu.

3. Press <F8>, point to the value being calibrated, enter the correct value followed by

<ENTER>, and then press <F3> to download data.

4. Now read induce live values to verify the calibration.

FULL SCALE CALIBRATION

1. Press <F8>. Scroll to the parameter to be calibrated, and then press <ALT><R>

2. Induce the low range signal, then press <ENTER> followed by <F3>.

3. Induce the high range signal, then press <ENTER> followed by <F3>.

4. Now verify the live reading against the flow computer reading.

TO USE DEFAULT CALIBRATION

1. Select Multivariable DP or pressure

2. Select Reset calibration method

3. Now verify the live reading against the flow computer reading

Date: 8/1/2019

Page 42

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-37

Multi-Variable Transmitters (Model 205)- RTD

Calibrations are performed under I/O | Calibration. Use the arrow keys to scroll to

Calibration-Multi-Variable and press < ENTER>. After you press < ENTER> the screen

should show COMMUNICATION STATUS : OK.

RTD Calibration is a 2-step process. The first step is a one time procedure to verify transducer

linearity and is done at the time the meter is being setup. The second step is the routine calibration

sequence.

Step 1 – Linearity Verification

1. Use a Decade box with 0-150 °F settings.

2. Connect RTD cable to this resistive element for verification of linearity. Verify low and high points.

It must be within ½ degree.

3. Connect the actual RTD element and compare with a certified thermometer.

4. If not within ½ degree do a Full Calibration (See Full Calibration below). If problem persists verify

other elements such as RTD Probe, connections, shield, conductivity of connectors, etc.

The purpose of the above procedure is to verify zero and span and make sure that the two points

fall within the expected tolerance.

Step 2 – Routine Calibration

Once Linearity has been verified through Step 1, the routine calibration procedure is reduced to

simply connecting the actual RTD and doing an offset point calibration (see offset calibration

below).

Calibration after that will be simple verification for the stability of the transmitter. If it drifts abnormally

then you need to verify the other parts involved.

RESET TO DEFAULT CALIBRATION

To go back to the default calibration simply press <F8> and scroll to the RTD input, and press

<ALT> <R> key followed by <F3> function key.

OFFSET CALIBRATION:

For offset calibration simply go to I/O | Calibration and press < ENTER>. Once the flow

computer shows communication status OK press <F8> function key and scroll to RTD. Induce a

live value and wait for 10 seconds for the reading to stabilize. Then enter the live value followed

by <F3> function key to download the direct reading. The value entered must be in degrees only.

FULL SCALE CALIBRATION:

1. Prepare low range resistive input (i.e., 80) and High range resistive input (i.e., 120). Go to

the calibration menu and press <F8> function key. Scroll to the RTD input you are calibrating

and press <ALT> <R> (key <ALT> and the letter R at the same time). Induce the low end

(80) resistive signal and then wait 10 seconds and enter the equivalent temperature in

degrees followed by pressing the <F3> function key.

2. Induce Higher range signal (120) and wait 10 seconds, then enter the temperature degrees

equivalent to 120 followed by pressing the <F3> function key.

3. Now verify the live reading against the flow computer reading.

Date: 8/1/2019

Page 43

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-38

Verifying Digital Inputs and Outputs

Use the diagnostic menu. Scroll down by using the arrow keys to Diag | Diagnostic Data and

press <ENTER>. A live input and output is displayed. On the top of the screen pulse inputs and density

frequency input are shown. Compare the live value against the displayed value on the screen. Failure to

read turbine input could be a result of a bad preamplifier or the jumper selection for sine and square wave

input are not in the right position. Refer to wiring diagram Wiring | Turbine for proper turbine

input wiring. Density input can be sine or square wave with or without DC offset. Minimum accepted

signal has to be greater than 1.2 volt peak to peak. Status input is shown below the frequency input to the

left of the screen. When the status input is on, the live diagnostic data will show ON. Minimum voltage to

activate the status is 7 volts with negative threshold of 2 volts. Switch outputs are to the right of the status

inputs. Press <F8> in the diagnostic menu to manually activate the switch outputs to the on and off

position. After the screen freeze the cursor will point to switch output one. Use the space bar to toggle the

switch on/off and the <ENTER> key to advance to the next switch. Press <ESC> to exit diagnostic screen.

The switch outputs are open collector and require external voltage.

Date: 8/1/2019

Page 44

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-39

D

C

BTime

ATime

K

_

_

Pulse Interpolation:

When interfacing with Small Volume Provers (SVP), Dynamic uses Dual chronometry as the pulse

interpolation method which is required for provers providing less then 10,000 unaltered pulses.

Pulse interpolation is a pulse counting technique used to calculate the total number of meter pulses between

two detectors, including fractional pulses. A conventional pipe prover requires a minimum of 10,000

unaltered pulses to ensure an accurate test. This minimum is based upon the assumption there is a potential

error of 1 pulse each time a detector is passed, which equates to a 2-pulse error per run. The value of 2 pulses

per 10,000 equates to a potential 0.02 % error. SVPs require less than 10,000 pulses, which would equate to

a potential error greater than 0.02 %.

To enhance the meter's pulse output, Small Volume Provers use pulse interpolation for fractional meter pulse

counting. To interpolate fractional meter pulses or to mathematically interpolate partial pulses, Dynamic uses

the double chronometry method for this purpose since it is the method most widely used.

Double Chronometry:

Double chronometry pulse interpolation increments time precisely every millisecond. A high frequency

master oscillator operates two time counters referred to as Time A and Time B. Time A starts when the first

detector switch is tripped, and Time B starts with the leading edge of the first flow meter pulse after Time A

has started. Time A is stopped when the final detector is tripped and Time B is stopped with the leading edge

of the first flow meter pulse after Time A has stopped (see figure below). Using the ratio of Time A and Time

B allows for counting of a fraction of the flow meter pulse.

K = K Factor, or counts per unit Volume, from the flow meter.

A = Time for displaced volume.

B = Time for whole meter pulses.

C = Total number of whole meter pulses.

D = Displaced Volume

Double Chronometry Figure

Date: 8/1/2019

Page 45

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Quick Start — 1-40

)%1(

3600

BSWLMFCPLCTLIV

LMFCPLCTLIV

CPLCTLIV

L)(Pulses/BBFactor K Nominal

es/sec)Total(Puls

NSV VolumeStandard Net

GSV VolumeStandard Gross

ISV VolumeStandard Indicated

IV VolumeIndicated

Correction Rate Flow Linearized Factor Meter

WaterWeight of

SG-BSW)%(LMFCPLCTL IV

WaterWeight of

.

Density

-BSW)%(LMF IV

LMF

density) live (without

MASS

applied) is density live (if

MASS

1000

1

10009990120

1

Calculations and Terminology:

Liquid pulse units

Crude refined products use API 2540 equation 5, 6 A & B, 23, 4 A & B, 11-2-1, and 11-2-2. Table 24 C is

used when thermal expansion coefficient is known. Old tables 23 and 24 with GPA16 and 11-2-2 are used

for NGL or light hydrocarbon mixes. API 2565 is used for propylene, and ethylene. In addition, NBS

1045 can be selected for ethylene calculations. ASTM 1550 can be used for butadiene.

Terms

Date: 8/1/2019

Page 46

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Data Entry 2-1

CHAPTER 2: Data Entry

and Configuration Menus

Introduction to the Smart Flow Computer Software

Introduction to the Flow Computer Software

Your SFC3 software is constructed around a menu-driven organization. Begin your software and, across

the top of your screen, you see a bar like this:

This is called the menu bar. It consists primarily of series of topics–Port, Diag, and so forth. When

you move the cursor to a topic you will see a list–we will call it a menu list– of topics related to the main

topic on the menu bar.

At the bottom of the screen is the prompt bar. It informs you of appropriate actions that you can perform

while your cursor is at its present location. In this example:

you are informed that your valid choices are the four arrow (, , , and )keys, the ENTER key,

and the key.

Another important area of the screen is the filename area. This is the rightmost section of the menu bar; it

informs you what configuration file you are presently viewing and editing. In the example above, you are

editing the file mainunits. When you first begin the SFC sotware, however, it will display

because no file has yet been chosen. Until you choose a file to edit or view, by opening either an existing

file or a new one, you will not be able to move from the File menu item.

The center portion of the screen is simply called the viewing area. Here you view either various menu lists

or the prompt window associated with an item in a menu list after it is selected (that is, after you press

ENTER). When you are in a prompt window the message appears in the filename area.

Under certain conditions you will have a screen where the viewing area takes up the whole screen and the

menu and/or prompt bars disappear. Examples of these are: the wiring diagrams, the calibration windows,

and the Diag windows.

ABOUT

Displays the version number of EPROM and PC configuration menu. Press <Esc> to Exit.

Date: 8/1/2019

Page 47

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Data Entry 2-2

FILE

Open a File

Use this function to open an existing configuration file. After a file is opened it becomes the currently

active file; its contents can be viewed and its parameters can be edited.

Open a New File

Create a new file to store all the programmed information for one Flow Computer. You are prompted for

the new file’s name of eight characters or less. If you enter the name of a pre-existing file, the software

informs you of this and prompts you for your file’s name again. After a file is opened it becomes the

currently active file; its contents can be viewed and its parameters can be edited.

Delete a File

Delete a file when that file is no longer needed.

When this function is chosen a list of existing configuration files is displayed. Use the arrow keys to move

the cursor to your selection, then press to delete the file.

Date: 8/1/2019

Page 48

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Data Entry 2-3

Load File

Use this function to exchange parameter values between the PC and the Flow Computer. After this action

is performed all parameter values in the Flow Computer and the currently active file in the PC are identical.

To read all current parameters from the Flow Computer to the currently active file in the PC, press the

function key; this is called “uploading”.

To write all current parameters from the currently active file in the PC to the Flow Computer press the

function key; this is called “downloading”.

View File

Unlike every other file function, View File does not act upon configuration files. Instead, View File allows

the user to view files that were previously captured in a report. For capturing data in a report, look for

these items under the Report menu header:

Prev. Hourly Data

Prev. Daily Data

Alarm Data

Audit Trail Report

TicKet Report

Auto Data Retrieval

Current Data

When viewing a file use PageUp and PageDown to browse through it.

Save As

Use Save As to save the parameters in the currently active file (that is, the parameter values currently being

edited) to a new file. You are prompted for the new file’s name of eight characters or less. If you enter the

name of a pre-existing file, the software informs you of this and prompts you for your file’s name again.

The original file will remain in memory.

Date: 8/1/2019

Page 49

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Data Entry 2-4

Save

When permanent modifications are performed on a file, user must save the new changes before exiting the

program, or proceeding to open a different file.

Save and Exit

Exit the program and save the parameters that were changed.

Exit

Exit without saving new modified parameters.

Date: 8/1/2019

Page 50

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Data Entry 2-5

PORT

PC Communication Set Up

Communication Port Number (1,2,3,4)

Enter the PC port used to communicate with the Flow Computer.

Flow Computer Port Number

There are two available ports in the Flow Computer. Port 1 is the RS-485 Modbus port. Port 2 is the RS232 Modbus port. The PC set up must match the Flow Computer port set up.

Unit ID Number

The Unit ID Number is used strictly for communication purposes; it can take any value from 1 to 247. Only

one master can exist in each loop.

Note: Do not duplicate the Unit ID number in a single communication loop!

This situation will lead to response collisions and inhibit communications

to units with duplicate ID numbers.

Modbus Type

Note: this parameter must be set the same for both the PC and the Flow

Computer for communication to occur.

The Modbus Communication Specification is either Binary RTU or ASCII.

Parity

Note: this parameter must be set the same for both the PC and the Flow

Computer for communication to occur.

RTU - NONE

ASCII - EVEN or ODD

Set the parity to match the Modbus Type.

Baud Rate

Note: this parameter must be set the same for both the PC and the

Flow Computer for communication to occur.

Date: 8/1/2019

Page 51

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Data Entry 2-6

Baud rate is defined as number of bits per second. The available selections are 1200, 2400, 4800, or 9600.

Transmit Delay

This Delay in milliseconds is used to allow hand shaking between the PC and the Flow Computer. The PC

will hold the RTS line high for the specified Transmit Delay time. After that time expires the data stream

will begin transmitting. Transmit Delay is applicable regardless of the type of communication with the

Flow Computer (RS-232 or RS-485).

This function can be very useful, especially when using a half-duplex RS-485 port; it allows the RS-485

port to turn off. A delay of 50 milliseconds is normally sufficient.

RTS can also be used as transmit line to printer. (RTS to Pin2, Common to Pin7)

Flow Computer Communication Set Up

Unit ID Number

The Unit ID Number is used strictly for communication purposes; it can take any value from 1 to 247.

Note: Do not duplicate the Unit ID number in a single communication

loop! This situation will lead to response collisions and inhibit

communications to units with duplicate ID numbers.

Only one master can exist in each loop.

Port #1 Modbus Type

Note: this parameter must be set the same for both the PC and the

Flow Computer for communication to occur.

The Modbus Communication Specification is either Binary RTU or ASCII.

Date: 8/1/2019

Page 52

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Data Entry 2-7

Port #1 Parity

Note: this parameter must be set the same for both the PC and the

Flow Computer for communication to occur.

RTU - NONE

ASCII - EVEN or ODD

Set the parity to match the Modbus Type.

Port #1 Baud Rate

Note: this parameter must be set the same for both the PC and the

Flow Computer for communication to occur.

Baudrate is defined as number of bits per second. The available selections are 1200, 2400, 4800, or 9600.

Port #1 RTS Delay

This function allows for a modem or radio delay time before transmission. The Flow Computer will turn

the RTS line high before transmission for the entered time delay period.

Port #2 Modbus Type

Note: This parameter must be set the same for both the PC and the

Flow Computer for communication to occur.

The Modbus Communication Specification is either Binary RTU or ASCII.

Port #2 Parity

RTU - NONE

ASCII - EVEN or ODD

Set the parity to match the Modbus Type.

Port #2 Baud Rate

Baud rate is defined as number of bits per second. The available selections are 1200, 2400, 4800, or 9600.

Select 0=RTS,1=Printer

RTS line has dual function selection; either RTS for driving request to send or transmit to serial printer.

To use serial printer interface for printing reports, ie.batch, daily, interval and proving. Connect the serial

printer pin2 to RTS and common return to pin7 and select 1 for printer.

Port #2 Number of Nulls

This function is used because no hand shaking with the printer is available and data can become garbled as

the printer’s buffer is filled. The Flow Computer will send nulls at the end of each line to allow time for

the carriage to return. Printers with large buffers do not require additional nulls. If data is still being

garbled, try reducing the baud rate to 1200.

Dial

Use the cursor arrow

keys to move the cursor to the desired phone number and press ENTER. Dial’s display indicates the

owner of each phone number according to the Phone Book.

Dial cannot add new phone numbers; it can only dial numbers that have previously been entered in the

Phone Book.

Example: T,9,1281-530-5539 instructs the dialer to use tone dialing, pause, dial 9 for an outside line,

pause, then dial the number. See Phone Book for more information.

Date: 8/1/2019

Page 53

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Data Entry 2-8

Phone Book

Phone Book lists all the phone numbers with the phone’s owner new numbers can be added to the list.

<Arrow Keys> Select Number to Modify or Delete.

Add new entry to phonebook.

+ Delete selected entry.

or ENTER Modify selected entry.

<Esc> Exit and save changes.

Phone Book Edit

Type name, press , and type phone number. Press ENTER to save, <Esc> to leave entry unchanged.

In the phone number the following codes may be used:

<0-9> Dial digit

<P> Change to pulse dialing

<T> Change to tone dialing

<Comma> Pause

Example: T,9,1281-530-5539 instructs the dialer to use tone dialing, pause, dial 9 for an outside line,

pause, then dial the number.

Modem Setup

<Modem Dial Prefix> Enter the string sent to the modem before the phone number.

Normally either "ATDT" (dial tone) or "ATDP" (dial pulse)

<Modem Dial Suffix> Enter the string sent to the modem after the phone number.

Normally just "^M" (CR)

<Modem Hangup String> Enter the string sent to the modem to hang-up the phone.

See your modem manual for other characters.

Hang-up Phone

Press ENTER to send the Modem Hang-up string (Defined in Modem Setup) to the modem.

Note : Hand shake and error checking should be turned off. Commands

to turn off the hand shake vary between modems. Check your

modem manual. Typical command - AT&K0, AT&Y0.

Date: 8/1/2019

Page 54

Dynamic Fluid Measurement SFC3 Liquid Pulse Manual Data Entry 2-9

DIAG

Read Single Flow Computer Communication Setup

Press and the configuration program will attempt to communicate with a single Flow Computer at

different baud rates and formats.

Failure to communicate can occur because of a communication wiring problem, wrong PC port selection,

communication parameter mismatch between PC and Flow Computer (Modbus type, parity, baud rate,

etc.) or lack of power to the Flow Computer. To use this feature, the user must insure that only one Flow

Computer is connected to the PC. More than one Flow Computer in the loop will cause data collisions and

unintelligible responses.

Diagnostic Data

Diagnostic Data shows real-time, live data. Use it to monitor switch outputs, status inputs, analog

inputs and outputs, analog frequency, failure codes and so forth. To control the switch outputs manually