Page 1

No. 60025, Issue 5. January 1999

TM

DX Dolphin Remote

(DX-Rem34)

Installation Manual

Order/Part Number for this Manual : GBK60025 issue 5

Important Notes

1. Read this Manual carefully before installing or operating your DX control system.

2. Due to continuous product improvement Dynamic reserves the right to update this Manual.

3. Any attempt to gain access to or in any way abuse the electronic components and

This Manual supersedes all previous issues which must not continue to be used.

associated assemblies that make up the wheelchair control system renders the

Manufacturer’s Warranty void and the Manufacturer free from liability.

Page 2

No. 60025, Issue 5. January 1999

Contents

1 Introduction ................................................. 1

2 Related Documentation ....................................... 2

3 Features .................................................... 3

4 Specifications ............................................... 5

Electrical ................................................ 5

Mechanical .............................................. 5

Environmental ............................................ 6

5 Operation ................................................... 7

On/Off and Key Lock system ................................ 7

Arming/Disarming the locking system ..................... 7

Using the system without the lock ........................ 7

Joystick OONAPU ........................................ 7

Drive Program Selection and Display .......................... 8

Profile Selection ..................................... 8

Drive Program Display ................................ 8

Drive Inhibit Display .................................. 8

Remote Status Display ................................ 8

System Status LED ................................... 8

Lighting Control .......................................... 9

Actuator Control .......................................... 9

Battery Gauge Display .................................... 10

6 Installation and Testing ...................................... 11

Attention: If replacing existing Power Wheelchair Controller ........ 11

Compatibility with Power Wheelchairs ........................ 11

DX Dolphin Mounting ..................................... 12

DX Dolphin Connection with the DX System ................... 13

Testing ................................................ 14

Powering Up Method ................................ 14

Power Up Response ................................. 14

DX Dolphin Check Sequence .......................... 14

7 Batteries and Charging ...................................... 15

Battery Type ............................................ 15

Battery Charging ......................................... 15

Battery Gauge ........................................... 16

Battery Saver ............................................ 16

Page 3

No. 60025, Issue 5. January 1999

Battery Condition Warnings ................................ 17

Battery High warning condition ......................... 17

Battery Low warning condition ......................... 17

Low Capacity warning condition ........................ 18

8 Programming ............................................... 19

Introduction ............................................. 19

Default Programs ......................................... 19

Auto Download .......................................... 20

Programming Tools ....................................... 21

Dynamic Wizard .................................... 21

HHP ............................................. 22

Wizard High Volume Programming ........................... 22

Example .......................................... 22

DX Dolphin Wizard Programming ............................ 24

Drive Program Parameters ............................. 24

Keypad and Speed Pot Parameters ...................... 28

Joystick Parameters .................................. 30

Actuator Parameters ................................. 32

Lighting Parameters .................................. 36

DX Dolphin HHP Programming ............................. 37

Initial Operation .................................... 37

Test Driving and Saving Changes ....................... 38

To View / Adjust Drive Programs ....................... 38

To Adjust Joystick Source ............................. 39

Reverse Joystick - Forward / Reverse .................... 39

To Enable Technician Mode ........................... 40

Joystick Calibration .................................. 40

Combined Lighting Actuator Module (CLAM) Enable ....... 41

Lighting Module (LM) Enable .......................... 42

9 Diagnostics and Fault Finding ................................ 43

Flash Code ............................................. 43

Limp Mode ............................................. 47

Wizard Diagnostics ....................................... 48

To View Diagnostics ................................. 48

Status Report ............................................ 48

To View Status Report ............................... 48

Chair Log .............................................. 49

To View Chair Log .................................. 49

10 Product Disclaimer .......................................... 52

11 Electromagnetic Compatibility (EMC) .......................... 53

Page 4

No. 60025, Issue 5. January 1999

12 Maintenance ............................................... 54

13 Safety and Misuse Warnings .................................. 55

14 Warranty ................................................... 57

15 Sales and Service Information ................................ 58

16 Appendix A : Abbreviations .................................. 59

17 Appendix B : Change Record ................................. 61

18 Anhang C : Deutschsprachige Warnhinweise ................... 62

Page 5

No. 60025, Issue 5. January 1999

1 Introduction

The DX Dolphin Remote is a DX compatible remote supplied by Dynamic

Controls Ltd. As well as driving, this DX Remote has switches for selecting

up to five actuators, which can then be operated under joystick control. A

battery gauge, side lights, indicator lights, hazard lights, magnetic key and horn

are also supported. Up to five individual Drive Programs or profiles are

available, and the currently selected program is displayed.

This DX Remote has two standard DXBUS connectors so that it may be

connected to the DX System.

The DX Dolphin Remote and the associated DX Power Module are fully

programmable to cater for a wide range of chair types and user needs. Correct

installation and programming are essential to ensure optimum performance and

safety.

This manual and others listed below must be read and understood. For more

information contact Dynamic Controls Ltd or an agent as listed in section14.

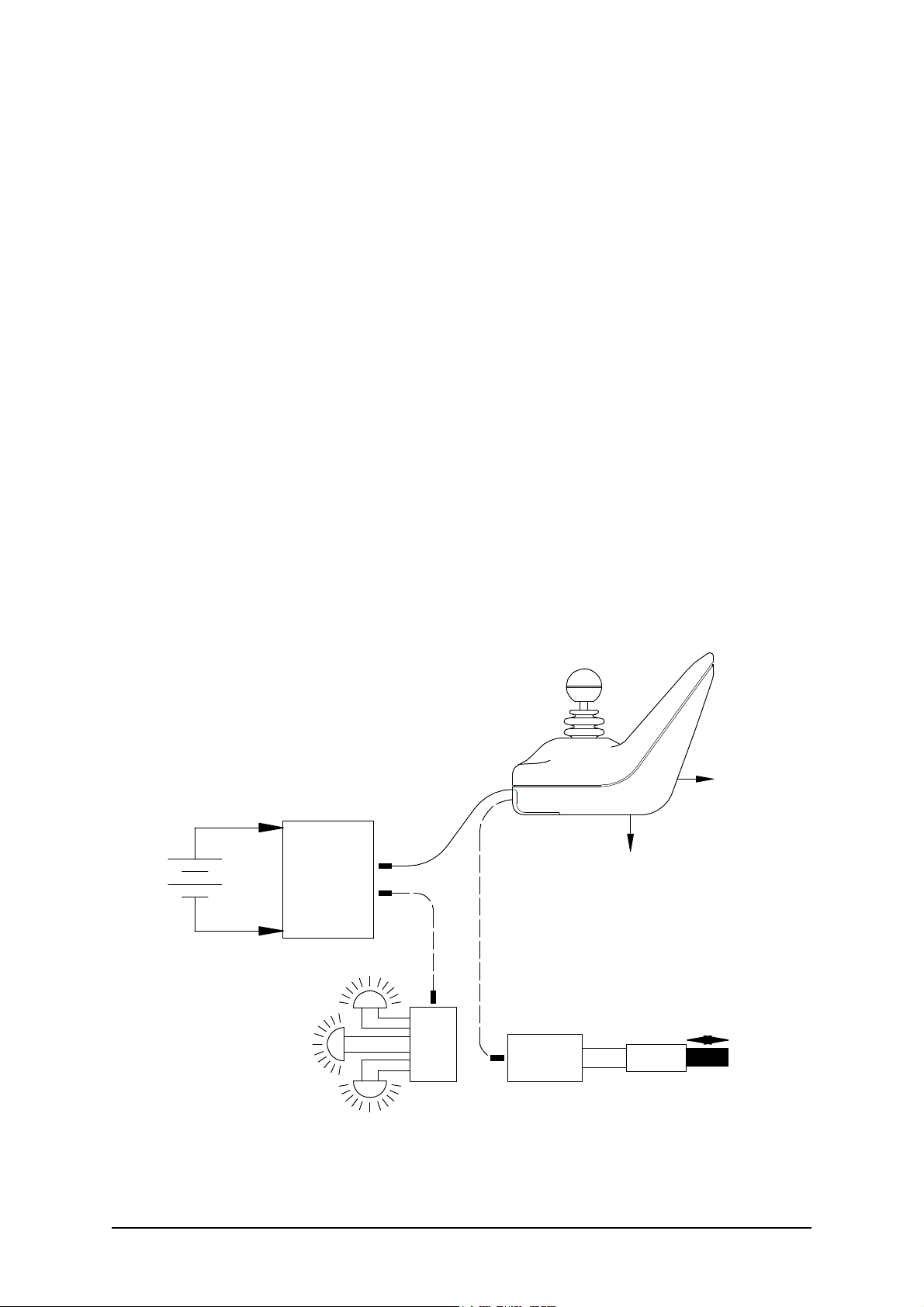

Example DX System

DX Pow er

Module

24V

Wheelchair

Battery

Right Indicator Lights

DX Dolphin

(DX-REM34)

DXBUS

Optional DXBUS

To Battery

Charg er

To HHP

or Wizard

Optional DXBUS

1 Introduction

Side Lights

Left Indicator Lights

DX-LM

Example

DX Module

Actuator

DX-TAM

Example

DX Module

1

Page 6

No. 60025, Issue 5. January 1999

2 Related Documentation

A DX based wheelchair control system may comprise between two and

sixteen DX compatible modules depending on the application. Each DX

compatible module has its own Installation Manual which describes the

installation requirements of that particular module.

This Manual describes installation of the DX Dolphin Remote only and must

therefore be read in conjunction with the :

! DX Power Module (PMB) Installation Manual

! DX Hand Held Programmer (HHP) Manual

! Dynamic Wizard Installation Sheet / Online Help

! Installation Manuals for all other DX Modules to be used in your

application.

2

Related Documentation 2

Page 7

No. 60025, Issue 5. January 1999

3 Features

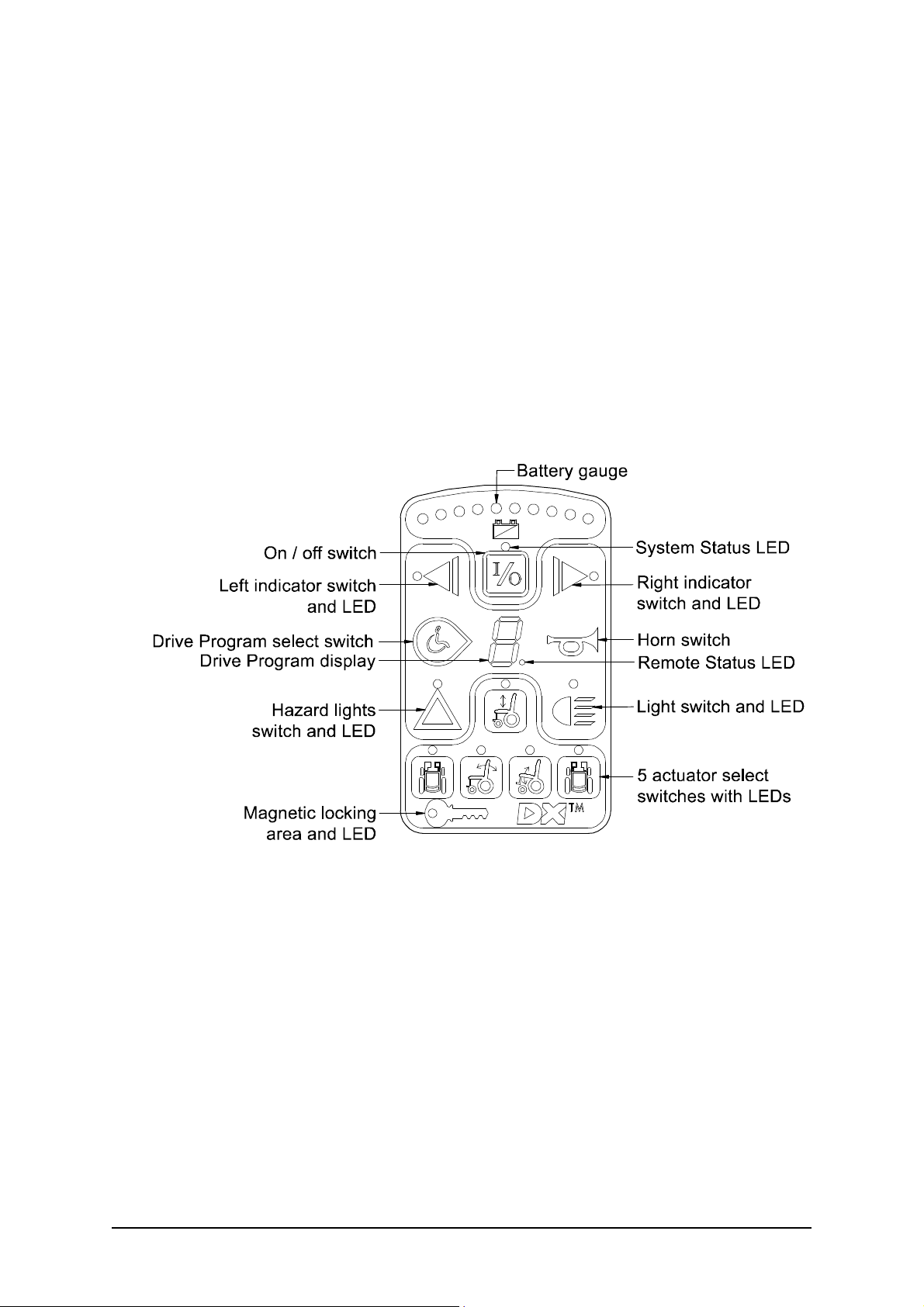

Joystick Normally used for controlling wheelchair speed and

direction. Can also be used for actuator control

when any of the 5 actuators have been selected.

On/off switch / Toggles the entire DX control system between the

On and Off modes.

System Status LED The System Status LED indicates the On/Off status

of the system. It also flashes to indicate system

faults. (Refer to Diagnostics section 9 for Fault

Codes details.)

Remote Status LED The Remote Status LED indicates the status of the

Dolphin as an individual DX Module. If it is

flashing, there is a fault within the Dolphin.

Battery gauge Battery charge level is indicated by a set of ten

LEDs. These are arranged in an arc from left to right

as three red, four orange, and three green.

Actuator select A separate switch for each set of seat raise/lower,

switches (x5) seat tilt, back tilt, left leg rest and right leg rest, each

with its own LED indicator. Once selected, actuator

operation is activated using the joystick.

Drive Program A switch is used to cycle through and select one of

select switch the five Drive Programs.

Drive Program A seven segment display for showing the currently

Display selected Drive program.

Lighting controls Separate push switches for the control of lights,

indicators, and hazard, each with its own LED.

Horn switch Activates horn while pressed if system power is on.

Magnetic key lock Magnetic key may be used to "lock" the DX System

to prevent unauthorised use (see later details).

3 Features

3

Page 8

No. 60025, Issue 5. January 1999

Programming socket A standard HHP / Wizard socket.

HHP / Wizard socket

Standard DXBUS For connecting the DX Remote, with a DXBUS

Connection (x2) cable for connection to other DX compatible

modules.

Battery charger Standard 3 pin XLR type battery charger socket.

socket

Fully functional keypad

4

Features 3

Page 9

No. 60025, Issue 5. January 1999

4 Specifications

Electrical

Compatible with standard DXBUS

Operating voltage range 18V - 32 V d.c.

Charger rating 12 A RMS continuous, limited by

DXBUS rating.

Quiescent Current <1mA Off, typically 100mA On

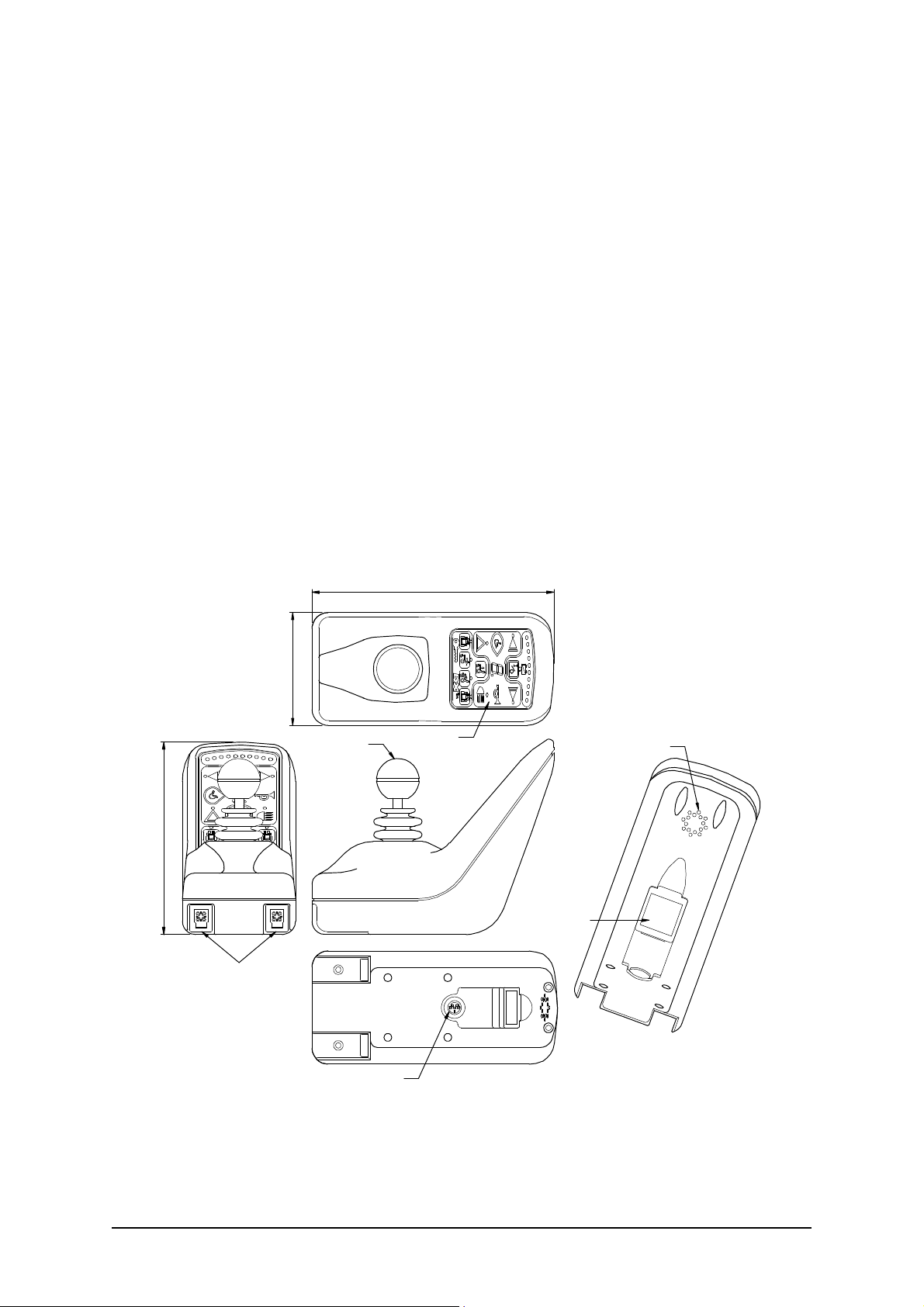

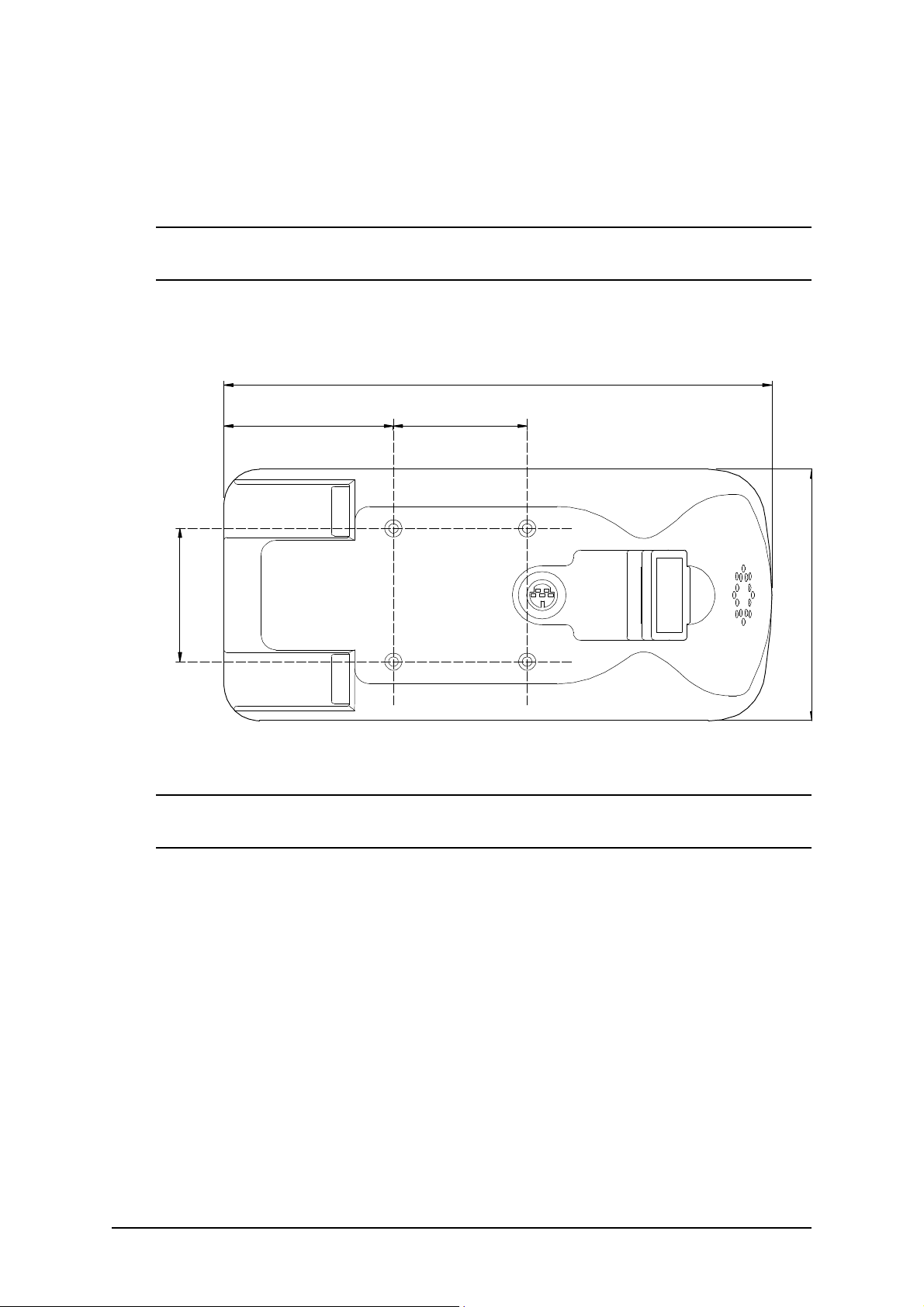

Mechanical

Weight: 0.59 Kg

Mounting: As per Installation section 6, Mounting

Case material: Injection moulded plastic, Noryl N90 flame

retardant

147mm

Two DXBUS

connectors

85mm

Joys tick

182mm

Keypa d

Horn g rill

Cove red

charger socket

4 Specifications

Programmer s ocket

5

Page 10

No. 60025, Issue 5. January 1999

Environmental

Parameter Min Max Units

Operating ambient temperature range -25 50 °C

Storage temperature range -25 70 °C

Operating and storage humidity 0 90 %RH

Environmental Rating IP54

RFI Emissions CISPR 11, Class B.

ESD ISO7176 part 21

Durability ISO7176 part 14 (pending).

Vibration Specification BS2011: part 2Fd and BS7527: section 3.5,

class 5M3.

Complies with environmental standard : prEN12184.

6

Specifications 4

Page 11

No. 60025, Issue 5. January 1999

5 Operation

On/Off and Key Lock system

The On/Off button toggles the system power on or off provided the DX

Remote is not locked.

The Key Lock system uses a magnetic key to power the wheelchair down in

such a way to prevent subsequent unauthorised power up and driving. This

function is required for TÜV approval and operates as follows :

Arming/Disarming the locking system

To arm the locking system hold the magnetic key on or near the key symbol

on the DX Remote front panel. The system will beep and automatically power

itself down and no LEDs should be lit.

To turn the chair back on press the On/Off button. This will cause the system

to power up but the chair needs to be disarmed before it can be driven - this

waiting to be disarmed state is indicated by the flashing key symbol.

To disarm the lock put the magnetic key on or near the key symbol - this will

cause the key to stop flashing and the chair may now be driven normally. If the

wheelchair is not disarmed within one minute, the Dolphin will automatically

turn itself off.

Using the system without the lock

If locking the chair is not required simply power the chair down by pressing the

On/Off button - all indicators will go out.

To turn the system back on press the On/Off button - the system is now able

to be driven without the use of the magnetic key.

Joystick OONAPU

All DX Remotes feature Out Of Neutral At Power Up (OONAPU) detection.

If the system is powered up while the joystick is not in the neutral position, or

an inhibit condition such as a battery charger is removed, the System Status

LED flashes rapidly for either as long as the condition persists or for a

maximum of 5 seconds.

If the condition persists, after 5 seconds a DX Module Fault (Flash Code 1) is

signalled on the System Status LED, and the Remote Status LED flashes. This

is a latching fault and must be cleared by powering the system down and up

again (with the joystick in neutral).

5 Operation

7

Page 12

No. 60025, Issue 5. January 1999

An OONAPU fault is also generated if the joystick source is changed. This

occurs when the Attendant / User switch on the DX-ACU is toggled or the

Drive Program is changed causing a joystick swap, while the joystick is not in

the neutral position. In these situations the fault is non-latching and the system

does not need to be powered down to clear the fault.

Drive Program Selection and Display

The Dolphin can offer up to five different Driving Programs, depending on its

configuration. (See Programming section.)

Profile Selection

Profiles can be selected using the Drive Program Select switch. Pressing this

switch will increment the Drive Program number up to the maximum

configured value. A further switch press will return the Dolphin to Profile 1.

Drive Program Display

The current Drive Program number is displayed on the 7-segment Drive

Program Display. When the ACU has control of the wheelchair, this display

is blank.

Drive Inhibit Display

A '-' is displayed on the Drive Program Display whenever the DX System is in

Drive Inhibit state, e.g. during battery charging, operation of actuators, active

Stop Switch (CLAM or TAM).

Remote Status Display

The Remote Module Status is displayed beside the 7-segment Drive Program

display. This LED will flash if there is an internal DX Remote fault, or if an

OONAPU fault has occurred.

System Status LED

The System Status LED is displayed above the On/Off switch. This LED is lit

if the system is turned on. It also flashes in groups called Flash Codes, to

indicate system faults.

8

Operation 5

Page 13

No. 60025, Issue 5. January 1999

Lighting Control

A set of four lighting control switches, with feedback LED's, are provided to

control the Lighting System. A lighting module must be installed and enabled.

Suitable modules include: DX Combined Lighting Actuator Module (CLAM);

a DX Lighting Module (LM); or a DX Servo Lighting Module (SLM).

The Light switch toggles on or off the Head/Tail/Sidelight output,

independently of any other switch (except the On / Off switch). The Light

switch LED is lit when the lights are activated.

The Left or Right Indicator switch flashes the appropriate indicator output.

These are turned off by either pressing the same Indicator switch again, or

pressing the other Indicator switch, or the Hazard switch. Each associated LED

is lit when its matching Indicator switch is active.

The Hazard switch flashes both indicator outputs concurrently. The Hazard

LED also flashes if the Hazard LED is enabled. (See Programming section.)

The Hazard Indication can only be cancelled by pressing the Hazard switch

again.

All lighting functions will only operate with the system power on. Refer to the

relevant Installation Manual (e.g. LM or CLAM) for further lighting details.

Actuator Control

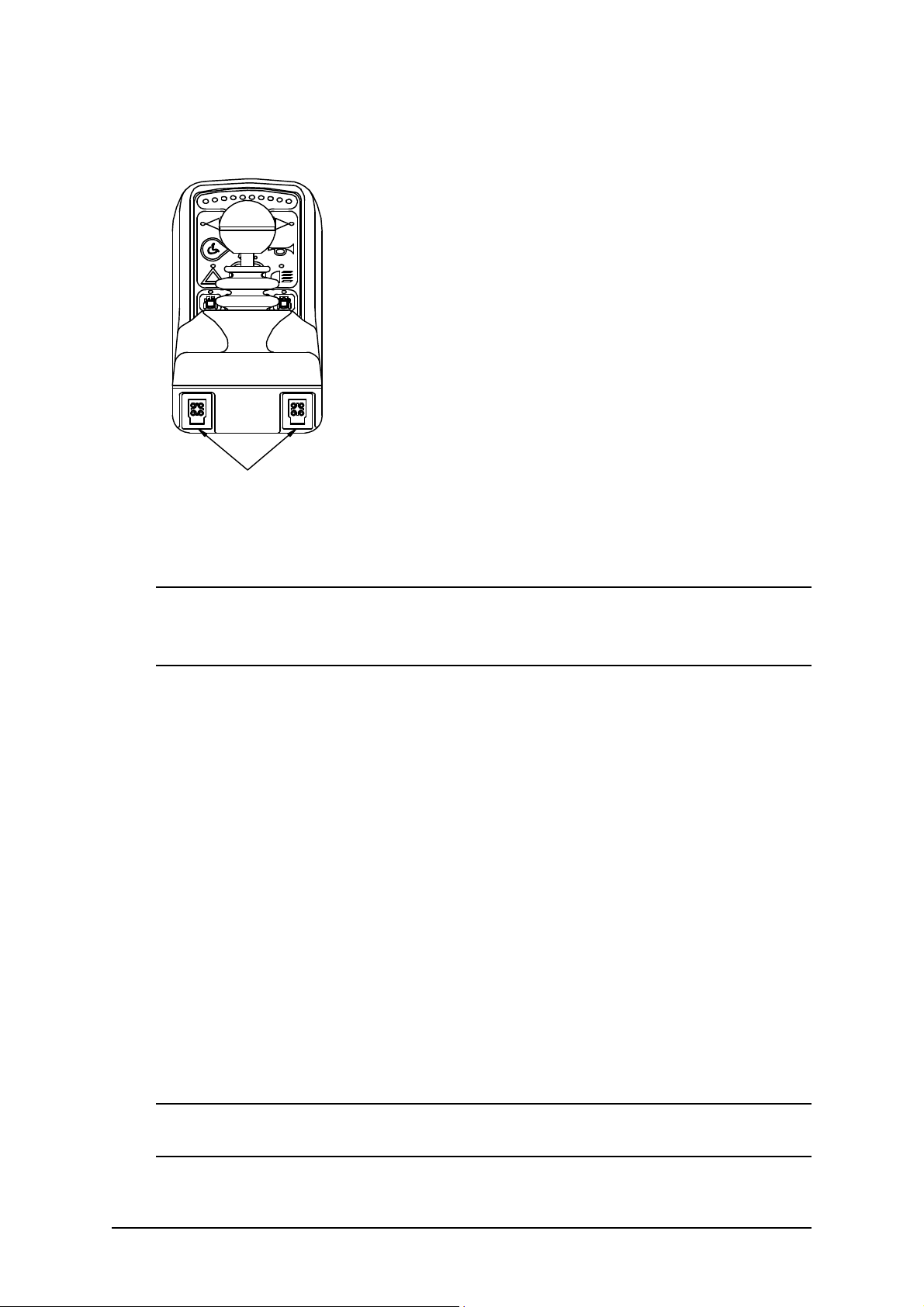

The DX Remote supports the control of up to five actuators if a correctly

configured actuator control module is present (see Programming section). For

example, a Combined Lighting Actuator Module (CLAM) can drive five

actuators or a Two Actuator Module (TAM) can drive two actuators.

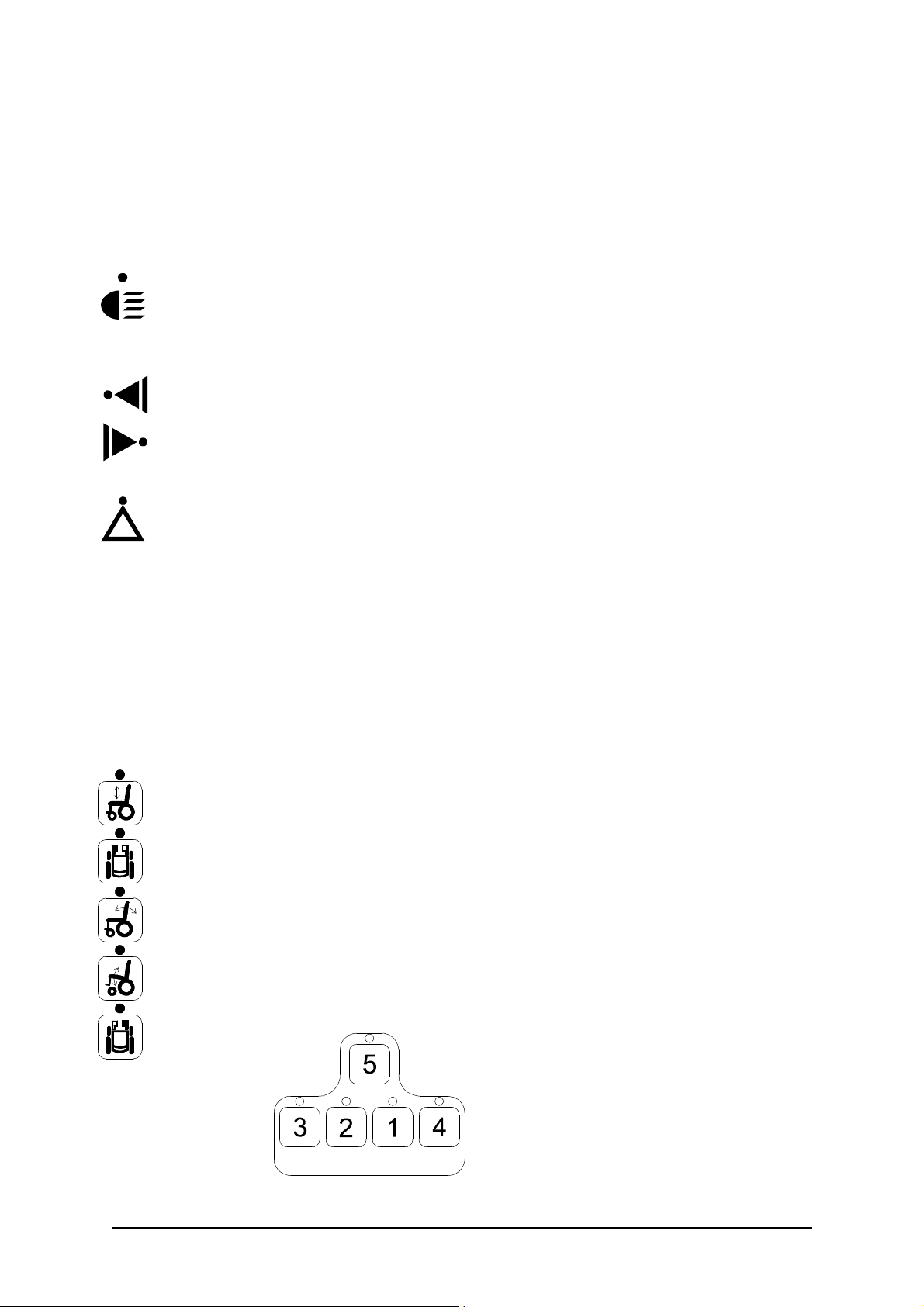

The Dolphin has a set of five Actuator Select switches. Pressing an Actuator

Select switch will inhibit driving and select the appropriate actuator output as

indicated by the adjacent LED. The actuator order assigned in the Wizard as

Actuator 1, 2, 3, 4 and 5 Enable, is arranged on the Dolphin keypad as follows:

5 Operation

9

Page 14

No. 60025, Issue 5. January 1999

The actuator may then be adjusted up or down with

the Joystick, by deflecting the Joystick beyond half

travel in the forward / reverse axis.

To resume driving, press the current Actuator Select

switch again to deselect. Alternatively another

actuator may be selected directly.

If the user attempts to change modes (e.g. from

driving to actuator mode) while the Joystick is

deflected, the current mode will be terminated and

the Joystick must be returned to neutral position

before the newly selected mode will operate.

The Joystick Actuator parameter must be set to ‘yes’ and the Actuator While

Drive parameter must be set to ‘no’ if actuators are to be controlled with the

Dolphin Joystick, (See Programming section). An Actuator Remote Control

(ARC) can be used to control the actuators. If an ARC is used to control the

actuators the Actuator Select switches on the Dolphin are disabled and the

Joystick Actuator parameter should be set to ‘no’.

The above information is for normal, intended operation of actuators by the

Dolphin. Other options for actuator operation are possible, dependant on

programming. See the TAM Installation Manual for full explanations.

Refer to the relevant DX Module Installation Manual for further actuator

details.

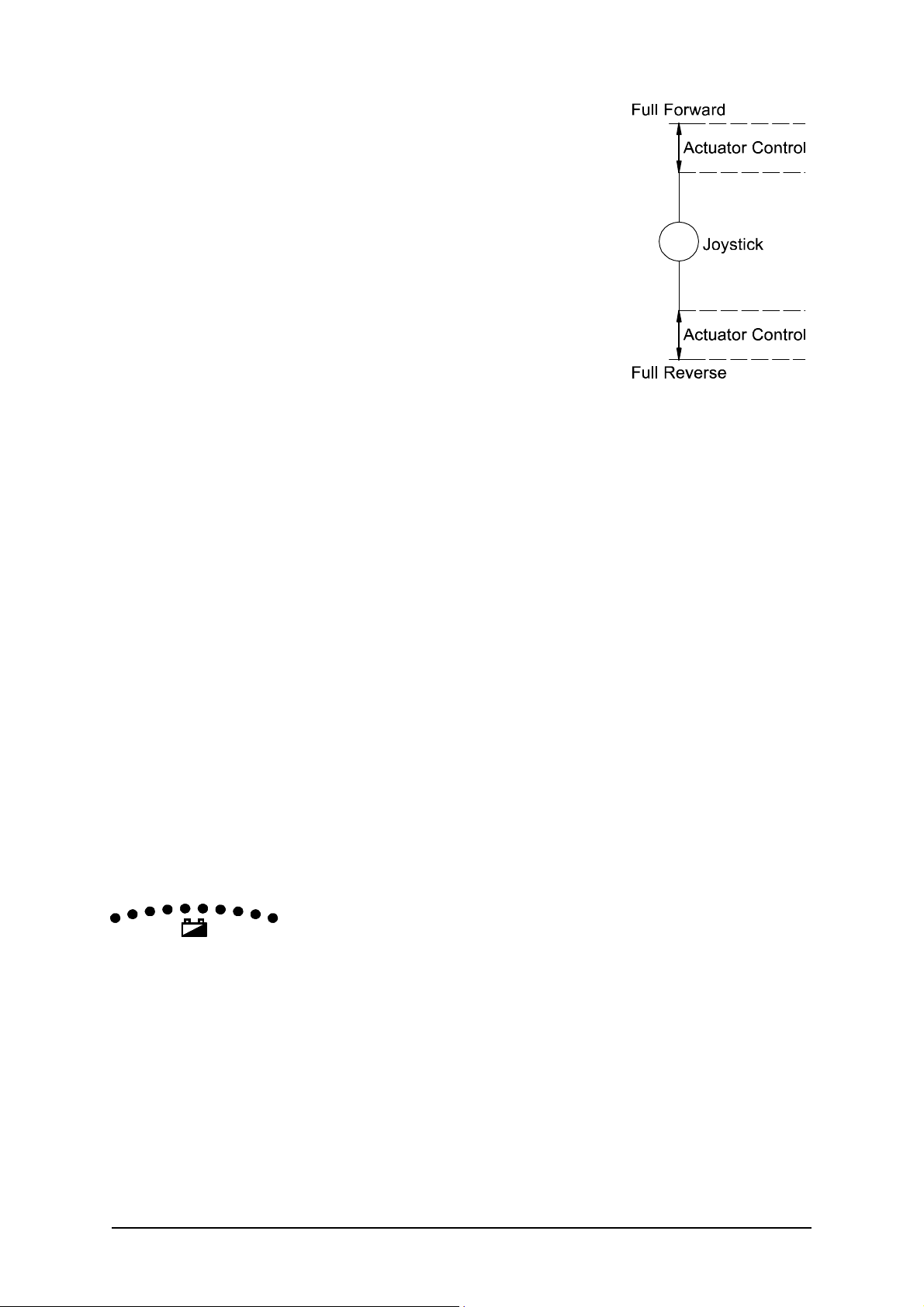

Battery Gauge Display

Battery charge level is continuously indicated by a set of ten LED's. These are

arranged in an arc from left to right as three red, four orange and three green.

The Battery Gauge provides true, useable battery capacity information, and

indicates other related battery conditions. Full battery capacity is indicated by

all ten LEDs on.

10

Operation 5

Page 15

No. 60025, Issue 5. January 1999

6 Installation and Testing

Attention: If replacing existing Power Wheelchair Controller

The model DX joystick/controller recently installed by your home care dealer,

has been designed to function and perform in the same manner as the

joystick/controller you may have already become accustomed to. If properly

installed and programmed, you should notice no difference in the manner in

which your wheelchair performs.

Should your wheelchair not perform as expected, or if you are not satisfied

with its performance, immediately contact the home health care dealer who

performed the installation, or contact Invacare Technical Services Department

at (800) 333-6900.

Compatibility with Power Wheelchairs

The model DX Series power wheelchair controller will function on those

wheelchairs equipped with the following specifications:

! Motor resistance from 0 to 0.5 ohms;

! Motor voltage from 20V to 30V;

! Batteries greater than 20Ahr lead acid;

! Motor current 60 - 80 Amp maximum;

! 12V or 24V parking brake;

(Note: 12V motors can be used if the controller is programmed to half speed)

Note : This controller is not designed for use with specialty type power

wheelchairs, such as stair climbing wheelchairs or stand up wheelchairs.

6 Installation and Testing

11

Page 16

No. 60025, Issue 5. January 1999

DX Dolphin Mounting

The DX Dolphin Remote can be mounted on either side of the wheelchair, in

an upright position, using four M4 screws.

Warning : For safe installation, select a screw length that protrudes between

4mm and 10mm into the case.

Dimensions of the mounting positions are shown below.

185mm

57mm 45mm

45mm

Note : If the programmer socket needs to be accessible when the DX

Remote is mounted, make allowance for this prior to fitting.

85mm

12

Installation and Testing 6

Page 17

No. 60025, Issue 5. January 1999

DX Dolphin Connection with the DX System

The Dolphin has two DXBUS connectors which

enables any DXBUS cable to be used to interconnect

it to the remainder of the DX system.

The Dolphin will normally be connected directly to

one of the two PM DXBUS connectors.

Two DXBUS

connectors

Note : If only one DXBUS connector is used on the Dolphin and the

remaining connector is accessible to the wheelchair user, a dummy connector

should be fitted to the unused connector. This will comply with ISO7176.

The DXBUS cables are available in the following standard lengths:

DXBUS Cable, Straight, 0.12 M Part/Order Number GSM 630012

DXBUS Cable, Straight, 0.3 M Part/Order Number GSM 63003

DXBUS Cable, Straight, 0.5 M Part/Order Number GSM 63005

DXBUS Cable, Straight, 1.0 M Part/Order Number GSM 63010

DXBUS Cable, Straight, 1.5 M Part/Order Number GSM 63015

The DXBUS is also available with a ferrite.

DXBUS Cable, Ferrite, 2.0 M Part/Order Number GSM 63020F

Other cable lengths in multiples of 0.1 m are available on request.

Warning: Any protruding screws should be either plastic or plastic coated to

prevent short circuits occurring with the DXBUS Cable pins.

6 Installation and Testing

13

Page 18

No. 60025, Issue 5. January 1999

Testing

Ensure that all DX Modules used in your DX System have been installed as

specified in their Installation Manuals. The Dolphin needs to be correctly

programmed for the appropriate wheelchair prior to testing.

A DX Remote contains the complete wheelchair system set up, from which all

DX Modules download their relevant information when the DX System is first

turned on. Refer to the later Auto Download section.

Powering Up Method

Power up the Dolphin by pressing the On/Off switch.

Power Up Response

The power up response for the Dolphin is :

! The System Status LED will come on steady.

Note : The first time the Dolphin is turned on, the System Status LED will

flash a fault. This is because the Dolphin must download its information to the

DX Power Module . Turn the Dolphin off then on to clear this fault. Refer to

the later Auto Download section.

! At least one of the LEDs on the Battery gauge will be on.

! The Mode display will indicate a number from 1 - 5.

DX Dolphin Check Sequence

Perform the following Dolphin check sequence :

1. Press the On/Off switch again and check the Power LED turns off. Press

it again to turn it on.

2. Press the Drive Program select switch a number of times. Check that the

display changes as expected.

3. Check all Lighting Buttons operate correctly.

4. Check the Key Lock system operates correctly.

5. Perform the remainder of the tests as outlined in the Testing sections of the

Installation Manuals of all other DX Modules used on the wheelchair.

14

Installation and Testing 6

Page 19

No. 60025, Issue 5. January 1999

7 Batteries and Charging

Battery Type

The DX System is designed to perform optimally with either Lead-Acid or Gel

Cell 24 V deep cycle batteries, rated at 20 - 120 Amp hours. The maximum

average discharge rate must not exceed half the rated capacity, in Amp hours.

High continuous discharge rates dramatically reduces the available battery

capacity. For example, at a discharge rate equal to the rated capacity, the

available capacity is 50 - 60 %. At a discharge rate of half the rated capacity,

the available capacity is 70 - 80 %..

A wheelchair that draws maximum average battery current of 20 A, requires

a battery of at least 40 Amp hours. A battery of only 20 Amp-hours, would

begin to suffer a drop in performance at about half of its available capacity.

The 40 Amp hour battery would have a full performance range of 4.5 times

greater than the 20 Amp hour battery; a 80 Amp hour battery would only

increase this range by 2.5 when compared to a 40 Amp hour battery.

Battery Charging

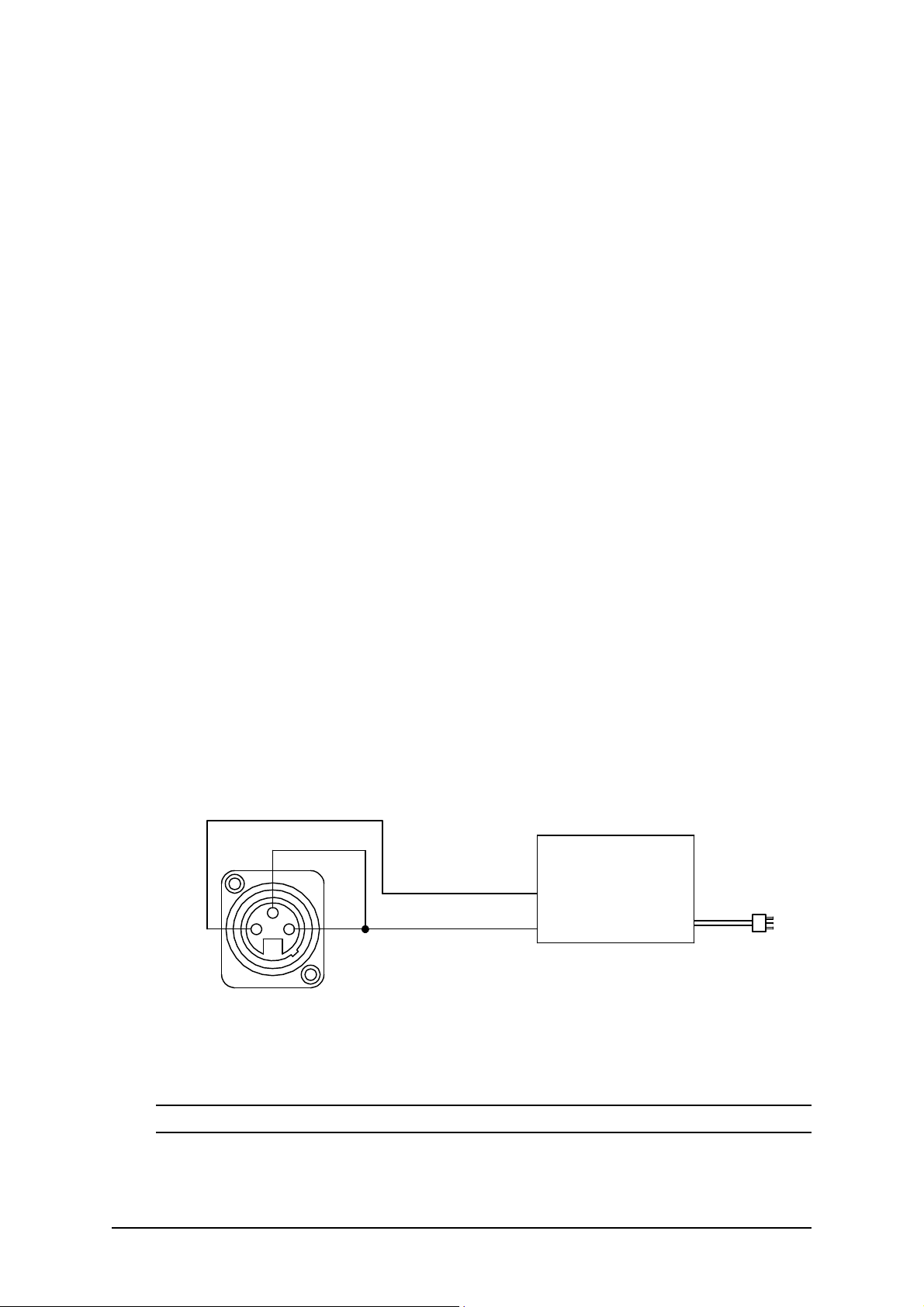

The battery charger socket is a 3 pin XLR type with pin configuration as

shown below. Ensure that the charger used is compatible with this pin out

before connection.

Inhibit

3

2

1

Battery Cha rger Plug

front view

Battery +

Battery -

Battery Ch arger

Note : The inhibit is shorted to B- on the Battery Charger plug.

7 Batteries and Charging

15

Page 20

No. 60025, Issue 5. January 1999

The wheelchair is automatically disabled from driving whenever the battery

charger is plugged in. The Drive Program will show ‘ ’ to indicate that the

wheelchair is inhibited.

Connection of the battery charger will automatically power the wheelchair, if

the wheelchair was powered down at the time of connection. This allows the

progress of battery charging to be monitored on the Dolphin battery gauge. The

wheelchair can, if required, be subsequently powered down by pressing the

On/Off switch, and charging will still proceed normally.

Battery Gauge

The Battery Gauge provides true, useable battery capacity information. A full

battery with at least 85 % of rated capacity, is represented by all ten LED’s lit.

Some new batteries can start with as little as 80 % capacity, developing higher

capacity in their early life (sometimes up to 110 %), before slowly

deteriorating over their rated life.

As the battery voltage drops, the number of LEDs lit reduces from right to left.

When only the red LEDs are lit, the available battery capacity is typically less

than 10 %. At this level and below, the Battery Gauge flashes at 1 Hz to alert

the user that the wheelchair is running on reserve capacity. The battery

capacity will reduce more rapidly in the reserve capacity range.

Battery Saver

The Battery Saver is a feature programmed into the DX Remote. When the

battery capacity is in the reserve range (below 21V), the wheelchair

performance is reduced. This is to preserve the life of the battery by

encouraging the user to recharge the battery before it becomes harmfully flat.

Operating the wheelchair with more than two LEDs of the Battery Gauge lit

will generally give normal wheelchair performance. This is provided that the

battery size and the PM program settings are matched to the wheelchair.

16

Batteries and Charging 7

Page 21

No. 60025, Issue 5. January 1999

Battery Condition Warnings

A battery warning is shown by the Battery Gauge flashing its LEDs, the

number of which depends on what it currently has lit.

Battery High warning condition

This condition occurs when the battery voltage exceeds 28V, as measured by

the PM.

The cause can be :

! The wheelchair is still on charge and the batteries are full or faulty.

! The batteries are overcharged.

! The wheelchair is travelling down a slope and the batteries are full or

faulty.

The wheelchair will drive during this fault condition which will reset

automatically when the battery voltage drops below 28V.

Battery Low warning condition

This condition occurs when the battery voltage drops below 23.3V, when the

joystick is in neutral.

The cause can be :

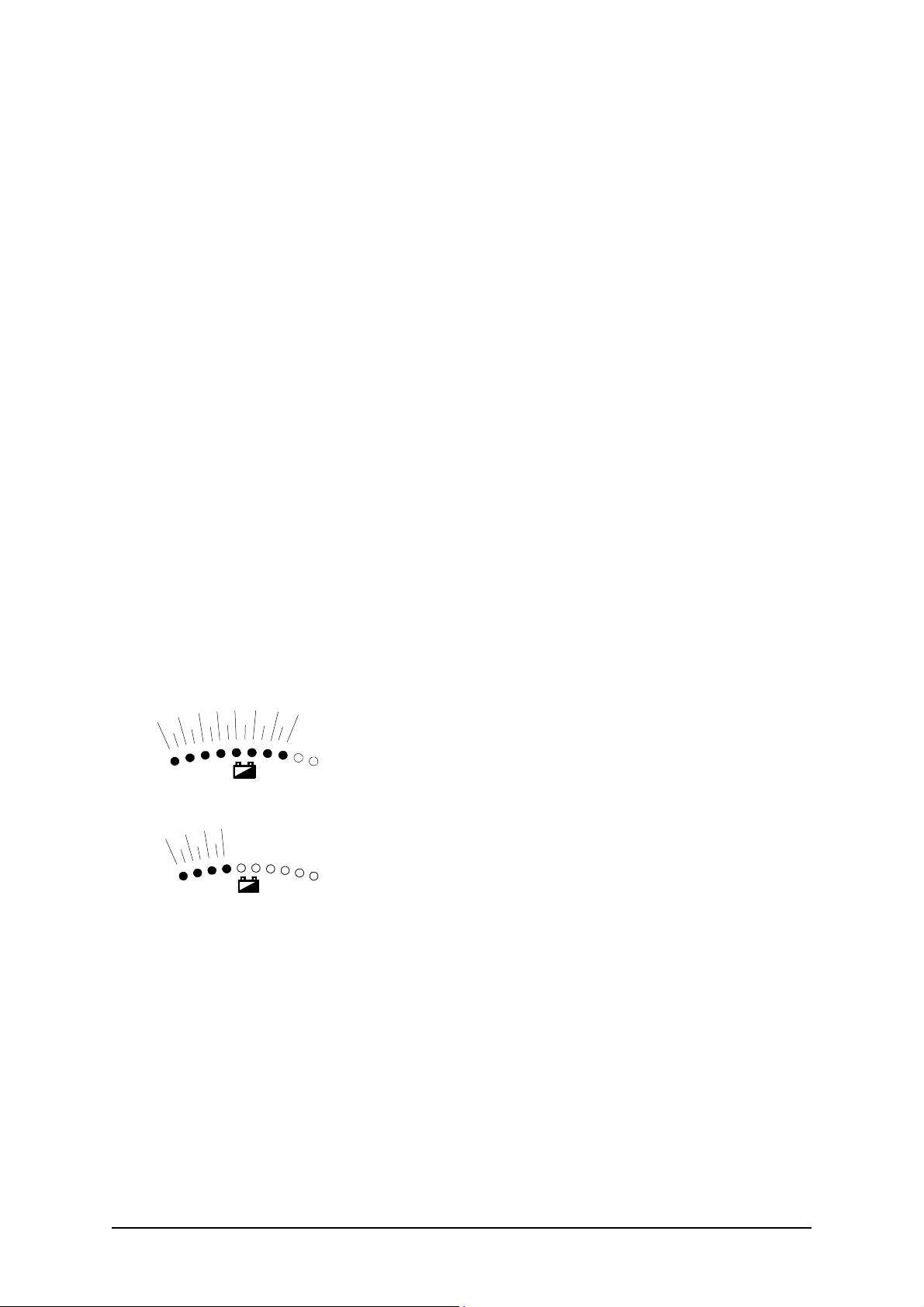

If the Battery Gauge flashes with orange or green

LEDs lit, but the cause is not due to a Battery High

warning condition, the battery or battery wiring may

be faulty.

If the Battery Gauge flashes with just the left 3 or 4

LEDs after stopping the wheelchair, the battery may

be too small for the wheelchair type, or the battery

may be old or damaged.

The wheelchair will drive during this fault condition, but the flashing will

continue until the joystick is returned to neutral again.

A Battery Low warning normally coincides with a Low Capacity warning.

7 Batteries and Charging

17

Page 22

No. 60025, Issue 5. January 1999

Low Capacity warning condition

When the calculated available battery capacity drops below 10% of full

capacity the two left most red LEDs flash.

The wheelchair will drive during this fault condition but it shows that the

battery is in the reserve capacity range and battery capacity will begin to

reduce rapidly. The Low Capacity warning will not stop until the batteries have

been recharged adequately.

18

Batteries and Charging 7

Page 23

No. 60025, Issue 5. January 1999

8 Programming

Warning !!

Incorrect or inappropriate programming of a DX System can put the wheelchair into

a dangerous state. Dynamic Controls accept no responsibility or liability for

accidents caused by incorrect programming. This Programming section, the HHP

Manual, and the Dynamic Wizard Installation Sheet/Online Help must be read and

understood before attempting to program a DX System.

Ensure that the programmed wheelchair complies with all prevailing regulatory

requirements for your country and application.

Introduction

The driving performance of the DX System is dependant on its programming.

Different features can be selected and parameters fine tuned for a particular

application, or to suit the requirements of an individual.

The DX Remote and the DX Power Module are the modules most responsible

for defining the driving performance of the DX System. Software in the DX

Remote, processes the joystick movements according to its Drive Programs,

and sends direction and speed commands to the PM.

Default Programs

The Dolphin is programmed during manufacturing with a set of factory default

settings which are incorporated into a controlled document by Dynamic. The

default settings programmed into a Dolphin will not be suitable for all DX

Systems and must be checked and reprogrammed prior to connecting with a

DX System.

The optimum settings for all programmable DX Modules are determined by the

wheelchair manufacturer (OEM). If more than one type of wheelchair is to be

used by the customer, each wheelchair type may have its own set of optimum

settings.

Warning : If a wheelchair is programmed with settings other than default,

under some very rare fault conditions default settings could be automatically

restored, thereby changing driving characteristics. This in turn could lead to a

chair moving in a direction or speed that is not intended. Programmers should

consider this risk when programming settings other than default.

8 Programming

19

Page 24

No. 60025, Issue 5. January 1999

Auto Download

The DX System has a feature called Auto Download. It is designed to

minimise the programming requirements associated with Module servicing by

down loading the correct programming to a replacement DX Module.

A DX Module with a flashing System Status LED is considered faulty and,

when serviced, is replaced by a new one. The replacement module is likely to

be programmed differently to the one that it replaces, which could leave the

wheelchair in a dangerous state. The DX System automatically detects that a

DX Module swap has occurred, and the programmed data from the old module

is transferred to the replacement module.

Auto Download is achieved by the DX Remote containing both its own

programming and also a backup copy of the programmed data for all other DX

Modules. When a module swap is detected, or a checksum error found in a

module, the DX Remote automatically down loads its backup copy to the

module. The Auto Down load occurs immediately on power up after the

Module has been replaced. This applies to all DX Modules except a DX

Remote.

Warning : When a Dolphin is replaced it will perform an Auto Down load

to all DX Modules. This may result in incorrect and dangerous programming

for a particular wheelchair system if the wheelchair program installed in the

Dolphin is not suitable for that wheelchair system.

Do not attempt to drive or test the DX System before the correct and suitable

wheelchair program has been installed in the Dolphin using the Wizard.

The Dolphin can be programmed with the Wizard using a ‘dummy’ DX

System and / or a 24V power supply, or on the wheelchair provided driving is

prevented e.g. by disengaging the drive wheels.

After replacing any DX Module, turn the DX System off, then on again, to

initiate the Auto Down load of the DX Remote backup data. When a Auto

Down load has occurred, but the system needs to be cycled on and off, a

Module Fault (Flash Code 1) is displayed on the DX Remote’s System Status

LED and also the Status LED of the offending module. When the System if

turned off then on again, the fault is cleared and the Auto Down load is

correctly terminated.

20

Programming 8

Page 25

No. 60025, Issue 5. January 1999

Programming Tools

Two programming tools are available, the Dynamic Wizard and the HHP.

Dynamic Wizard

The Wizard is a PC based tool suited to programming production runs of

identical wheelchairs or modules, or individual highly customised wheelchairs.

The Wizard is available in several versions :

OEM Generally used by the wheelchair manufacturer. Able to

program a wide range of parameters.

DEALER Similar in function to above, but with a reduced range of

programmable options. This ensures that options that the

manufacturer wishes to keep control of cannot be

disturbed. Parameters that may cause hazards or require

special expertise to be set are not available to adjust.

ENHANCED As above but with the ability to edit parameters that relate

DEALER directly to wheelchair accessories (e.g. actuators).

FACTORY Can only replace Standard or Custom Wheelchair

Programs. No editing or diagnostics available.

Warning : The Wizard is a very powerful tool and as such requires well

trained operators and a disciplined approach to usage and distribution.

It is up to the wheelchair manufacturer to determine whether they will allow

distribution of the Wizard to dealers. Refer to the Wizard Documentation for

further details.

DXBUS +DXBUS -

A Dolphin can be programmed with the

Wizard using a 24V power supply and an

optional PM. If the Dolphin is connected

directly to the 24V power supply, then a

DXBUS Cable can have one end modified to

connect to the power supply.

Dolphin DXBUS Pins

8 Programming

21

Page 26

No. 60025, Issue 5. January 1999

HHP

The DX Hand Held Programmer (HHP) is the normal programming tool used

by dealers, allowing easy adjustment of all commonly adjusted Drive Program

parameters.

Warning : The DX HHP is for use only by wheelchair manufacturers, their

authorised dealers and support personnel. It is not intended for use by the

wheelchair user.

The DX HHP Manual should be read and understood before attempting to use

it.

Wizard High Volume Programming.

Programming in the factory environment is normally done using the Wizard.

With the Wizard’s Create a new Chair Program option, you can set up the

standard parameters for the Dolphin and any other modules used for a

particular wheelchair. This Chair Program is then saved to disk under a name

such as "SuperChair, Deluxe, with lights" and can be down-loaded to a

Dolphin at the push of a button.

Example

Modify/Edit the "SuperChair, Deluxe, with Lights” Chair Program as

follows.

1. Enter the Wizard’s Main Menu screen as described in the Wizard

Installation Sheet.

2. Use the keyboard or the mouse, to select the File, Open menu option.

3. Select the “SuperChair, Deluxe” program from the dialog box.

4. Select the ‘Edit Module Parameters’ menu option.

6. Select ‘UCM Remote’ or the required group of parameters.

7. Scroll through the list of Dolphin parameters and adjust as necessary.

22

Programming 8

Page 27

No. 60025, Issue 5. January 1999

8. Press «Enter» to accept the changes, or «Esc» to exit without saving. Select

the File, Save menu option. These values will then be part of the Standard

Chair Program for the “SuperChair, Deluxe”

Down load the “SuperChair, Deluxe” to a Dolphin as follows.

1. Connect the Wizard serial communications cable to the Dolphin

programmer socket and return to the main menu of the Wizard.

2. Use the keyboard or the mouse to select the File, Open menu option.

3. Select the “SuperChair, Deluxe” program from the dialog box.

4. Select the ‘Program Wheelchair’ option.

5. Choose if the Chair Program is to be down-loaded to the ‘Total System’ (to

program a fully built up chair system) or just the ‘UCM Remote’ (to preprogram the Dolphin only).

6. Press «Enter» to write the Chair Program data.

7. Disconnect the Dolphin and repeat for as many Dolphins, or DX Systems,

as required, by repeating steps 4 through 7.

8 Programming

23

Page 28

No. 60025, Issue 5. January 1999

DX Dolphin Wizard Programming

The Wizard accesses a set of parameters that are programmed to define the

configuration desired by a wheelchair manufacturer.

Some parameters can be both read and written to (edited) by an OEM and a

Dealer. Other parameters can only be read but not edited. Some parameters

available to an OEM are not displayed by a dealer.

The DX System, with the Dolphin, supports up to five user selectable Drive

Programs. The Drive Programs govern the performance of the wheelchair, as

suitable for different environmental and user conditions. Drive Programs are

also adjustable with the HHP.

Remaining parameters are related to other system functions and DX Modules

which may, or may not, be included in your DX System. Parameters that may

be accessed by the HHP are marked with an asterisk (*).

Drive Program Parameters

The five Drive Programs (or Profiles) can be set up as, for example, an Indoors

program, an Outdoors program or a Sports program. These settings are

originally factory set to the values defined in the Chair Program used by the

Wizard during the down-loading process.

The values of the Drive Programs can be altered for a particular wheelchair

user using an HHP if necessary (except Damping Point and Sleep Timeout).

Note: As all program settings are stored in the Dolphin, replacement of the

Dolphin in the DX System may result in a change in Drive Program values that

may be substantially and dangerously different from those of the Dolphin it

replaced. The Wizard may be used to up-load and save the 'old' system settings

for later reprogramming of the replacement Dolphin.

Program (Profile) 6 is a special program that is automatically selected when an

Attendant Control Unit (ACU) is connected and in the Attendant mode. Note

that Program 6 is not programmable using the HHP on standard Dolphins.

When the ACU is disconnected, or it returns to the 'User Mode', the wheelchair

automatically reverts to the Program that was selected prior the ACU

becoming active (see ACU User Manual for more details).

24

Programming 8

Page 29

No. 60025, Issue 5. January 1999

The Wizard can be used to restrict the minimum and maximum limits for Drive

Program parameters adjustable with an HHP.

Max Forward Speed * Range : 10 - 100% Default : 100

OEM Access: Read / Write

Dealer Access: Read / Write

Sets the maximum speed obtainable for maximum forward joystick

deflection.

Forward Acceleration * Range : 10 - 70% Default : 40

OEM Access: Read / Write

Dealer Access: Read / Write

Sets the maximum output (linear) acceleration rate for large joystick

forward deflections, where 70% provides the quickest response.

Warning : Setting the Acceleration / Deceleration too low or too high can

result in an unsafe wheelchair. Test thoroughly after programming to ensure

that the wheelchair complies with regulatory requirements such as ISO7176

7176 and the GMD-TND Homologation Directive R04 for maximum allowable

braking distance.

Forward Deceleration * Range : 15 - 100% Default : 70

OEM Access: Read / Write

Dealer Access: Read / Write

Sets the maximum braking effect (linear deceleration) for large joystick

deflection back towards neutral, where 100% provides maximum braking

effect.

Max Reverse Speed * Range : 10 - 100% Default : 70

OEM Access: Read / Write

Dealer Access: Read / Write

Sets the maximum speed obtainable for maximum reverse joystick

deflection.

8 Programming

25

Page 30

No. 60025, Issue 5. January 1999

Reverse Acceleration * Range : 10 - 70% Default : 40

OEM Access: Read / Write

Dealer Access: Read / Write

Sets the maximum output (linear) acceleration rate for large joystick

backward deflections, where 70% provides the quickest response.

Reverse Deceleration * Range : 15 - 100% Default : 70

OEM Access: Read / Write

Dealer Access: Read / Write

Sets the maximum braking effect (linear deceleration) for large joystick

deflection back towards neutral, where 100% provides maximum braking

effect.

Max Turning Speed * Range : 10 - 100% Default : 50

OEM Access: Read / Write

Dealer Access: Read / Write

Sets the maximum turning speed obtainable for maximum joystick

deflection left or right.

Turning Acceleration * Range : 10 - 70% Default : 40

OEM Access: Read / Write

Dealer Access: Read / Write

Sets the maximum output (linear) acceleration rate for large joystick left

and right deflections, where 70% provides the quickest response.

Turning Deceleration * Range : 15 - 100% Default : 70

OEM Access: Read / Write

Dealer Access: Read / Write

Sets the maximum braking effect (linear deceleration) for large joystick

deflection back towards neutral, where 100% provides maximum braking

effect.

26

Programming 8

Page 31

No. 60025, Issue 5. January 1999

Damping Point * Range : 10 - 100% Default : 40

OEM Access: Read / Write

Dealer Access: Read / Write

The damping point defines the speed error size (of output speed verses

joystick demand speed) using progressive error reduction (ie acceleration

/ deceleration). Speed errors exceeding this value will be limited to the

programme maximum linear acceleration or deceleration rate. In other

words it sets the 'compromise' ratio between joystick directness /

responsiveness and chair controllability. Note: for most applications the

default value of 40% should not require adjusting. Achieving the desired

response is done by setting the appropriate acceleration / deceleration

values.

Warning : An unsuitably high or low value can make the wheelchair

unstable.

Joystick Source * State : Local / Remote Default : Local

OEM Access: Read / Write

Dealer Access: Read / Write

Selects whether the Drive Program will use the Dolphin's built in joystick

or an external RJM based input control device.

Reverse J/S - Fwd/Rev State : Normal / Reverse Default : Normal

OEM Access: Read / Write

Dealer Access: Read only

Reverses the direction of the Dolphin’s inbuilt joystick, This can be set

for each profile.

If set to ‘Normal’, forward and reverse joystick deflection causes forward

and reverse motion respectively.

If set to ‘Reverse’, forward and reverse joystick deflection causes the

opposite effect. Used if the Dolphin was to be mounted in any other than

standard orientation in order to maintain joystick sense.

8 Programming

27

Page 32

No. 60025, Issue 5. January 1999

Sleep Timeout Range : 1 - 255 min. (off) Default : 255 min (off)

OEM Access: Read / Write

Dealer Access: Read / Write

Inactivity timeout. The DX system goes to sleep after 'x' minutes of

inactivity, if enabled.

Keypad and Speed Pot Parameters

Max Profile Number Range: 1 - 5 Default: 5

OEM Access: Read / Write

Dealer Access: Read only

Sets the number of Profiles (Drive Programs) available for selection by

the user of the Dolphin. The Dolphin supports up to 5 user programs

(profiles).

Wrap Profiles State: yes / no Default: yes

OEM Access: Read / Write

Dealer Access: Read only

Allows Profile 5 to wrap around to Profile 1 (and vice-versa).

Change Prof Driving State: yes / no Default: no

OEM Access: Read / Write

Dealer Access: Read only

If set to ‘no’, the Drive Program can only be changed while the

wheelchair is stopped. If set to ‘yes’, the Drive program can be changed

while driving.

Warning : Care should be taken if set to ‘yes’ if adjacent Drive

Programs have markedly different settings (this includes the wrap-around

between Prog 1 and Prog 5).

We recommend you do not set this parameter to ‘yes’ if the DX System

contains an RJM based input device, as this would cause the wheelchair

to come to a sudden halt when changing to an RJM Drive Program, or

visa versa.

28

Programming 8

Page 33

No. 60025, Issue 5. January 1999

Allow Non Driv Prof State: yes / no Default: no

OEM Access: Read / Write

Dealer Access: Not available

If set to ‘yes’, Drive Program 0 is enabled and is displayed between

Drive Profile 5 and Drive Profile 1.

Lock Enable State: yes / no Default: yes

OEM Access: Read only

Dealer Access: Read only

Enables the Dolphin's magnetic key operated lock function.

Speed Pot Scalar Range: 20 - 100% Default: 100

OEM Access: Read / Write

Dealer Access: Read only

The Dolphin does not have a speed potentiometer, do not change default.

Sets the maximum forward and reverse speed scalar when speed pot is set

at minimum.

Sleep Mode Enable State: disable / enable Default: disable

OEM Access: Read / Write

Dealer Access: Read / Write

Set to 'Enable' if Sleep Mode is required. System goes to sleep (partial

power down) after [sleep timeout] minutes of inactivity. The system can

be woken up by activating the last selected device or any switch on the

Dolphin.

8 Programming

29

Page 34

No. 60025, Issue 5. January 1999

Joystick Parameters

Neutral Maximum Range: 10 - 49 Default: 10

OEM Access: Read / Write

Dealer Access: Read / Write

Determines the neutral window size. Affects all joysticks used in the

system. Adjust only in special cases.

Neutral to PB Delay Range: 20 - 5000 msec Default: 100

OEM Access: Read / Write

Dealer Access: Read only

The delay between zero output speed and de-energising the Park Brake.

It is dependant on the particular Park Brake mechanics and motor

characteristics. It is set so as to minimise the jerk or roll back when

parking on a slope. The jerk is also influenced by the Load Compensation

setting in the Power Module.

Reverse UCM Joystick State: normal / reverse Default: normal

OEM Access: Read / Write

Dealer Access: Read only

Reverses the direction (left / right) of the Dolphin’s inbuilt joystick.

If set to ‘Normal’, left and right joystick deflection causes a left and right

turn, respectively.

If set to ‘Reverse’, left and right joystick deflection produces the opposite

effect. Forward and reverse are not affected. Used if the Dolphin is

mounted in an other than standard orientation in order to maintain normal

joystick sense.

UCM Dual Decode State: single / dual Default: dual

OEM Access: Read only

Dealer Access: Not available

Set to 'dual' for six wire joysticks with mirror signals. Normally set to

'dual' for safety requirements (View only, not adjustable by OEM).

30

Programming 8

Page 35

No. 60025, Issue 5. January 1999

ACU Enable State: yes / no Default: yes

OEM Access: Read / Write

Dealer Access: Read / Write

Must be set to ‘yes’ for Attendant Control Unit (ACU) operation. The

Dolphin will automatically detect the presence of an ACU when the DX

System is turned on.

Reverse ACU Joystick State: normal / reverse Default: normal

OEM Access: Read / Write

Dealer Access: Read only

Reverses the direction (left / right) of the ACU joystick.

If set to ‘No’, left and right joystick deflection causes a left and right turn,

respectively.

If set to ‘Yes’, left and right joystick deflection produces the opposite

effect. Forward and reverse are not affected. Used if the ACU is mounted

in an other than standard orientation in order to maintain normal joystick

sense.

ACU Dual Decode State: single / dual Default: dual

OEM Access: Read only

Dealer Access: Not available

Set to ‘dual’ if the ACU is connected and has a six wire joystick with

mirror signals. Normally set to ‘dual’ for safety requirements. (View only,

not adjustable by OEM).

RJM Enable State: yes / no Default: yes

OEM Access: Read / Write

Dealer Access: Read / Write

Must be set to ‘yes’ for Remote Joystick Module (RJM) operation. The

Dolphin will automatically detect the presence of an RJM when the DX

System is turned on.

8 Programming

31

Page 36

No. 60025, Issue 5. January 1999

Reverse RJM Joystick State: normal / reverse Default: normal

OEM Access: Read / Write

Dealer Access: Read / Write

Reverses the direction (left / right) of the RJM joystick.

If set to 'Norm', left and right joystick deflection causes a left and right

turn, respectively

If set to ‘Yes’, left and right joystick deflection produces the opposite

effect. Forward and reverse are not affected. Used if the RJM is mounted

in an other than standard orientation in order to maintain normal joystick

sense.

RJM Dual Decode State: single / dual Default: dual

OEM Access: Read only

Dealer Access: Not available

Set to ‘dual’ if the RJM is connected and has a six wire joystick with

mirror signals. Normally set to ‘dual’ for safety requirements. (View only,

not adjustable by OEM).

Actuator Parameters

Refer to the Installation Manual for the DX Module driving the actuators,

e.g. TAM, CLAM, ARC5.

CLAM Enable * State: yes / no Default: no

OEM Access: Read / Write

Dealer Access: Read / Write

Must be set to ‘yes’ for CLAM or TAM operation.

CLAM is critical State: yes / no Default: no

OEM Access: Read / Write

Dealer Access: Read only

If set to ‘yes’, a CLAM or TAM must be present in the system and

operating normally. The loss or lack of communications between the

CLAM (or TAM) and the Dolphin will cause the wheelchair to stop, and

a Flash Code 1 to be displayed by the Remote.

32

Programming 8

Page 37

No. 60025, Issue 5. January 1999

If set to ‘no’, the wheelchair will drive normally with no CLAM (or

TAM) attached. Providing that all CLAM (or TAM) parameters have

been programmed, this is a useful factory setting. It allows a CLAM (or

TAM) to be added later to wheelchair systems that do not have one fitted,

without the HHP or Wizard.

CLAM Slowdown Range: 0 - 100% Default: 20

OEM Access: Read / Write

Dealer Access: Read only

Set to a required percentage of maximum wheelchair speed allowed when

the slow input is active. For this facility to be used, the hardware of the

wheelchair must be arranged as described in the Slow / Stop section in

the Installation Manual of the DX Module driving the actuators, e.g.

CLAM or TAM.

Actuator 1 Enable State: yes / no Default: no

OEM Access: Read / Write

Dealer Access: Read only

If set to ‘Yes’, Actuator 1 is enabled and can be selected by pressing the

Actuator 1 select switch on the Dolphin or ARC (Actuator Remote

Control) type module.

If set to ‘no’, there will be no response to the Dolphin Actuator switch.

Actuator buttons can be disabled if there are less actuators fitted to the

wheelchair than the number of actuator switches on the Remote.

Actuator 2 Enable State: yes / no Default: no

to

Actuator 5 Enable

OEM Access: Read / Write

Dealer Access: Read only

As described for Actuator 1 Enable. Refer to the Installation Manual for

the DX Module driving the actuators, e.g. TAM, CLAM, ARC5.

8 Programming

33

Page 38

No. 60025, Issue 5. January 1999

Actuator 1 I Limit Range: 3 - 12 amps Default: 6

to

Actuator 5 I Limit

OEM Access: Read / Write

Dealer Access: Read only

Sets the current trip point for each actuator between the allowable range

of 3 - 12 Amps. Refer to the Installation Manual of the Actuator Module

for details.

Actuator Timeout Range: 1 - 120 sec. Default: 30

OEM Access: Read / Write

Dealer Access: Read only

Sets the maximum time a wheelchair user can continuously operate any

actuator.

Actr Open Circ Test State: yes / no Default: no

OEM Access: Read / Write

Dealer Access: Not available

When set to ‘Yes’, an open circuit at the actuator output pins of the

Actuator Module (e.g. TAM or CLAM), will cause a Flash Code 2 to be

displayed (see Diagnostics section). The wheelchair will still drive.

ARC Enable State: yes / no Default: no

OEM Access: Read / Write

Dealer Access: Read / Write

Must be set to ‘yes’ for Actuator Remote Control (ARC) operation.

Set to ‘no’ for control of actuators by the switches on the Dolphin and

joystick.

Joystick Actuator State: yes / no Default: yes

OEM Access: Read / Write

Dealer Access: Read / Write

Set to ‘no’ if switch operation of actuators is required. This is not

recommended since the Dolphin has only one switch per actuator.

34

Programming 8

Page 39

No. 60025, Issue 5. January 1999

Set to ‘yes’ if joystick operation of actuators is required. The Actuator

Select switch will now select the actuator, if fitted, but will not cause it

to operate. If the wheelchair is driving when an actuator is selected, it will

stop driving.

Num Actuator Button State: one / two Default: two

OEM Access: Read / Write

Dealer Access: Read / Write

When set to ‘one’, pressing an Actuator Select switch, or moving the

joystick forward, will toggle between the actuator up / extend and

actuator down / retract.

Can only be set to ‘two’ for the Dolphin if the Joystick Actuator

parameter is set to ‘yes’. In this case, the joystick forward is used for

actuator up / extend, and joystick down for actuator down / retract.

Actr While Drive State: yes / no Default: no

OEM Access: Read / Write

Dealer Access: Read only

If set to ‘No’, the wheelchair will not drive while an actuator is being

operated. If the wheelchair is driving, the actuator command will be

ignored until the joystick returns to neutral.

If set to ‘yes’ and the Joystick Actuator

parameter is set to 'Yes', pressing the actuator

button will stop the wheelchair from driving and

select the actuator. The joystick can not be used

to operate the actuator until it has returned to

within the 50% window around neutral.

If the Joystick Actuator parameter is set to 'No',

actuators can be operated irrespective of the

driving state of the wheelchair.

8 Programming

35

Page 40

No. 60025, Issue 5. January 1999

Lighting Parameters

Lighting Mod Enable * State: yes / no Default: no

OEM Access: Read / Write

Dealer Access: Read / Write

Set to ‘yes’ for Lighting Module (LM) operation, ‘no’ if Combined

Lighting Actuator (CLAM) based lights are used.

CLAM Lighting Enable * State: yes / no Default: no

OEM Access: Read / Write

Dealer Access: Read / Write

Set to ‘yes’ for CLAM operation, ‘no’ in all other cases.

Side Lights Enable State: yes / no Default: yes

OEM Access: Read / Write

Dealer Access: Read only

If set to ‘yes’, Side Lights, if fitted, can be operated by the Dolphin.

If set to ‘no’, there will be no response to the Dolphin Light switch.

Indicators Enable State: yes / no Default: yes

OEM Access: Read / Write

Dealer Access: Read only

If set to ‘yes’, Indicators, if fitted, can be operated by the Dolphin.

If set to ‘no’, there will be no response to the Dolphin Indicator switches.

Hazard Enable State: yes / no Default: yes

OEM Access: Read / Write

Dealer Access: Read only

If set to ‘yes’, Hazard Lights, if fitted, can be operated by the Dolphin.

If set to ‘no’, there will be no response to the Dolphin Hazard Light

switch.

36

Programming 8

Page 41

No. 60025, Issue 5. January 1999

DX Dolphin HHP Programming

Warnings: Do not plug the HHP in while the vehicle is in motion. Plug in

the HHP while the DX System is turned on. A setting is saved once the NEXT

button is pressed. If the DX System is turned off during programming, the

current parameter being modified will not be saved and DX System will retain

the previous setting.

Initial Operation

1. Turn on the DX System and plug the HHP into the Programmer Socket on

the Dolphin. The initial screen appears for two seconds.

DX HHP V1.x

If a fault has occurred, the fault screen appears.

SYSTEM FAULT

5

L parkbrake

EXIT

The number and message displayed represents the Flash Code. See the

Diagnostics section for the list of faults that can be displayed.

Press EXIT to return to the main menu.

2. Then the main menu screen reads :

* * MAIN MENU * *

View or edit?

Program : 1 ?

NEXT YES

Pressing NEXT cycles through the Main Menu options. These are the

Drive Programs and Technician Mode enable / disable.

8 Programming

37

Page 42

No. 60025, Issue 5. January 1999

Test Driving and Saving Changes

Changes can be test driven before being permanently saved as the DX System

can be driven with the HHP plugged in. Even if the HHP is disconnected, the

changes will remain current until the DX Remote is turned off. Once turned

off, the settings will return to their original values.

Changes are saved when the NEXT button on the HHP is pressed. If the DX

Remote is turned off before the HHP is returned to the main menu, all changes

to the current parameter are lost.

To View / Adjust Drive Programs

Pressing EXIT at any point during the procedure will return you to the main

menu.

1. Press NEXT in the main menu until the appropriate Drive Program is

shown.

* * MAIN MENU * *

View or edit

Program : 1 ?

NEXT YES

2. Press YES to edit Drive Program.

3. The screen now reads :

TUNE PROG 1 RESPONSE

Max forward speed

25%

EXIT NEXT UP DOWN

Press NEXT to step through the adjustable parameters.

These are : Max. Forward Speed

Forward Acceleration

Forward Deceleration

Max. Reverse Speed

Reverse Acceleration

Reverse Deceleration

Max. Turning Speed

Turning Acceleration

Turning Deceleration

38

Programming 8

Page 43

Damping Point

Joystick Source

Reverse Joystick - Fwd/Rev

Press UP or DOWN to adjust the value (excluding Joystick Source).

To Adjust Joystick Source

The Joystick Source screen reads :

EXIT NEXT SWAP

Pressing ‘SWAP’ toggles the parameter between :

‘Remote’ if an RJM based input device is fitted, and ‘Local’ if the

joystick on the Dolphin is to be used.

No. 60025, Issue 5. January 1999

TUNE PROG 1 RESPONSE

Joystick Source

Local

This setting does not affect the ACU profile.

Reverse Joystick - Forward / Reverse

The Joystick Reverse screen reads :

TUNE PROG 1 RESPONSE

Joystick reverse

Normal

NEXT SWAP

2. Pressing ‘SWAP’ toggles the parameter between ‘Normal’ and ‘Reverse’.

This parameter reverses the forward / reverse direction of the controlling

joystick.

If set to 'Normal', forward and reverse joystick deflection causes forward

and reverse motion respectively.

If set to ‘Reverse’,forward and reverse joystick deflection causes the

opposite effect. Used if the Dolphin was to be mounted in any other than

standard orientation in order to maintain joystick sense.

8 Programming

39

Page 44

No. 60025, Issue 5. January 1999

To Enable Technician Mode

1. In the main menu, press NEXT until the Technician Mode screen appears:

* * MAIN MENU * *

Technician Mode

disabled. Enable ?

NEXT YES

Pressing YES toggles this screen between Technician Mode Enabled and

Technician Mode Disabled. If disabled, press YES to enable.

2. Press YES and a password screen will appear.

Technician Mode

Enter Password

0 0 0

EXIT D1 D2 D3

3. Press the D1, D2 and D3 buttons to cycle each digit through to the correct

password. When the password reads correctly, press the EXIT button.

4. The screen now reads :

* * MAIN MENU * *

Technician Mode

enabled. Disable ?

ì

NEXT YES

Joystick Calibration

1. Enable the Technician Mode

2. Press NEXT in the main menu until the screen reads :

* * MAIN MENU * *

View or edit Remote

Module ? (Tech Only)

NEXT YES

Press YES.

40

Programming 8

Page 45

No. 60025, Issue 5. January 1999

3. The display reads:

JOYSTICK CALIBRATION

EXIT NEXT BEGIN

Pressing EXIT at any point during the calibration procedure will return

you to screen .

ì

6. Press BEGIN.

JOYSTICK CALIBRATION

Rotate J/S

-> Neutral -> END

EXIT END

7. Move the joystick around the outer physical extremities of the restrictor

plate. Ensure that all corners are pressed into.

Return the joystick to neutral.

8. Press END to end the sequence and return to the main menu.

The calibration is saved.

Combined Lighting Actuator Module (CLAM) Enable

1. Enable the Technician Mode

2. Press NEXT in the main menu until the screen reads :

* * MAIN MENU * *

View or edit Remote

Module ? (Tech Only)

NEXT YES

Press YES.

3. The display reads:

8 Programming

CLAM

disabled. Enable ?

EXIT NEXT YES

41

Page 46

No. 60025, Issue 5. January 1999

Pressing YES toggles between CLAM enabled and CLAM disabled.

Setting this parameter to ‘Enabled’ allows the CLAM or TAM to be used

in the DX System.

Pressing EXIT will return you to screen .

ì

Lighting Module (LM) Enable

1. Enable the Technician Mode

2. Press NEXT in the main menu until the screen reads :

* * MAIN MENU * *

View or edit Remote

Module ? (Tech Only)

NEXT YES

Press YES.

3. The display reads:

LM

disabled. Enable ?

EXIT NEXT YES

Pressing YES toggles between LM enabled and LM disabled. Setting this

parameter to ‘Enabled’ allows the LM to be used in the DX System.

Pressing EXIT will return you to screen .

ì

42

Programming 8

Page 47

No. 60025, Issue 5. January 1999

9 Diagnostics and Fault Finding

DX Dolphin diagnostics can be examined from two platforms : from the Flash

Codes signalled with the System Status LED on the Dolphin (and on the HHP);

and from the Wizard which can provide more detailed information about the

fault.

Flash Code

Any fault condition on the DX system will cause the Dolphin’s System Status

LED to flash. Flashing occurs in bursts of flashes separated by a two second

pause. The number of flashes in each burst is referred to as the Flash Code and

indicates the nature of the fault. The title of the Flash Code fault is also

displayed by the HHP if connected to the faulty wheelchair.

Faults that affect the safety of the chair will cause the chair to stop while less

critical ones will be indicated but allow the chair to continue driving. Some

faults will automatically clear when the fault condition is removed, in which

case the System Status LED will become steady and the wheelchair may be

driven normally. Other faults are latched and must be cleared by turning the

DX System off, waiting for two seconds, turning it back on again.

DX System

Status LED

Flash Code

1

Likely Cause of Condition and Possible Action

DX Module Fault (see Limp Mode below)

Cause: An Auto Download has occurred.

Action < Turn the Dolphin off then on again.

Cause: The Dolphin is not correctly programmed.

Action < Try reprogramming the Dolphin.

Cause: Connection between DX Modules may be faulty,

or there may be an internal fault in a Module.

Action < Check DXBUS connections and replace where

necessary.

< If the Status LED on another Module is

flashing, replace the Module.

< An expected module may not be present (e.g.

the DX Lighting Module).

9 Diagnostics and Fault Finding

43

Page 48

No. 60025, Issue 5. January 1999

DX System

Status LED

Flash Code

2

3

Likely Cause of Condition and Possible Action

DX Accessory Fault

Cause: There is a fault in an accessory device attached to

a DX Module (excluding the PM). Examples of

faults in accessory devices may be : the clutch is,

or has been, disengaged; a light bulb is short or

open circuit; an actuator terminal is shorted to

Battery +.

Action < Check all accessory devices connected to your

DX System.

Left (M1) Motor Fault

Cause: The connection from the PM left (M1) connector

to its associated motor, or the motor itself, is

defective. The connection is either open or short

circuit.

Action < Disconnect the left motor plug and check

continuity between the motor pins on M1.

4

Right (M2) Motor Fault

Cause: The connection from the PM right (M2) connector

to its associated motor, or the motor itself, is

defective. The connection is either open or short

circuit.

Action < Disconnect the right motor plug and check

continuity between the motor pins on M2.

5

Left (M1) Park Brake Fault

Cause: The M1 plug connection to its associated Park

brake is either open or short circuit.

Action < Disconnect the M1 plug and check continuity

between the two Positronic park brake pins.

6

Right (M2) Park Brake Fault

Cause: The M2. plug connection to its associated Park

brake is either open or short circuit.

Action < Disconnect the M2. plug and check continuity

between the two Positronic park brake pins.

44

Diagnostics and Fault Finding 9

Page 49

No. 60025, Issue 5. January 1999

DX System

Status LED

Flash Code

7

8

Likely Cause of Condition and Possible Action

Low Battery Fault

Cause: The battery charge is not sufficient to allow safe

driving. It has fallen below 17V

Action < Check battery connection and terminals. The

battery voltage should be similar when the

battery is on charge, and when it isn’t.

< Check that fuses have not blown, or circuit

breakers tripped.

< Replace battery if worn out or if capacity is

insufficient for the user’s needs.

Note: The wheelchair will behave sluggishly and the

Battery Gauge will flash indicating low battery voltage

prior to the display of this fault.

Overvoltage Fault

Cause: The battery voltage has exceeded 32V.

Action < If this fault occurs during battery charging, the

battery charger is defective or incorrectly

adjusted.

< Check the battery chargers open circuit voltage

is in accordance with the battery manufacturers

limits, and is less than 32V.

Cause: The battery connector is making intermittent

contact when the wheelchair is stopped, or

travelling down a slope.

Action < Check that the battery wiring and terminating is

secure.

9

CANL Fault (see Limp Mode below)

Cause: 1. An invalid voltage has been detected on the

Action < Check the continuity of the DXBUS cable.

9 Diagnostics and Fault Finding

DXBUS CANL line.

2. Communication is not possible using the CANL

wire.

< Check for shorts between DXBUS pins. An

open or short circuit on another DX Module

can cause this fault.

45

Page 50

No. 60025, Issue 5. January 1999

DX System

Status LED

Flash Code

10

Likely Cause of Condition and Possible Action

CANH Fault (see Limp Mode below)

Cause: 1. An invalid voltage has been detected on the

DXBUS CANH line.

2. Communication is not possible using the

CANH wire, or the CANH and CANL wires

are shorted together.

3. Hazard lights were turned on when the DX

System was turned on.

4. The CANH is used to generate a Kill signal by

any DX Module which detects an unsafe

condition, or by an external device such as an

emergency stop switch.

The CANH wire is pulled to either Battery + or

Battery - and causes the DX System to shut

down.

Action < Check the continuity of the DXBUS cable.

< Check for shorts between DXBUS pins. An

open or short circuit on another DX Module

can cause this fault.

< If the Hazard Lights were already switched on

when the DX System was turned on, Flash

Code 10 and Limp Mode (slow driving) may

result.

To clear this fault, turn the Hazard Lights off,

then turn the DX System off then on again.

< If generated by a Kill signal, the cause of the

fault is severe.

46

11

Stall Timeout Fault

Cause: The motor current has been at, or close to, current

limit for longer than the Stall Timeout parameter

value.

Action < Turn the DX System off then on again.

Diagnostics and Fault Finding 9

Page 51

No. 60025, Issue 5. January 1999

DX System

Status LED

Flash Code

12

Limp Mode

Likely Cause of Condition and Possible Action

Module Mismatch

Cause: There is a compatibility problem between DX

Modules in the System. The wheelchair will be

disabled.

Action < Consult your Dynamic Service Centre.

Cause: The data held by the Dolphin for another DX

Module is corrupt or incompatible with that

module.

Action < Reprogramming the wheelchair system may

correct this problem.

If the DX System detects some faults, it will revert to Limp Mode. This is a

reduced speed mode which recognises problems, but allows the wheelchair

user to limp home, where the problem can be assessed.

9 Diagnostics and Fault Finding

47

Page 52

No. 60025, Issue 5. January 1999

Wizard Diagnostics

The Programming Configuration Diagnostic (known as the Wizard) tool is used

to provide diagnostics for the Dolphin.

To View Diagnostics

1. Enter the Wizard’s Main Menu screen as described in the Wizard

Installation Sheet / Online Help.

2. Select the ‘Diagnostics’ menu.

The menu displays the following options:

Status Report

Print Status Report

Chair Log

Print Chair Log

Erase Chair Log

Print Chair Log prints the Status Report followed by the Chair Log. These

reports should be sent along with a faulty controller to a Service Centre.

contact a Dynamic Sales and Service Centre (refer to section 14).

Status Report

The Status report gives you the current status of the wheelchair, including

faults and other warning conditions currently active. Pressing «?» Or selecting

‘Info’ will display further information about the condition. Some conditions in

the Status Report are not caused by actual faults, but are only temporary

conditions e.g. a motor lead was not connected when the DX System was

turned on and driving was attempted, producing a Motor Fault.

To View Status Report

1. Perform steps 1. and 2. above.

2. Select ‘Status Report’.

3. From the ‘Modules Attached’ menu, select ‘UCM Remote’.

48

Diagnostics and Fault Finding 9

Page 53

No. 60025, Issue 5. January 1999

Chair Log

The Chair Log displays all faults and warning conditions recorded for the

wheelchair since the Chair Log was last erased. Some conditions logged in the

Fault History are not caused by actual faults, but are only temporary conditions

e.g. a motor lead was not connected when the DX System was turned on and

driving was attempted, producing a Motor Fault. It is recommended to erase

the Chair Log once the system is fully functional as only the previous 15 fault

conditions are recorded.

To View Chair Log

1. Enter the Wizard’s Main Menu screen as described in the Wizard

Installation Sheet / Online Help.

2. Select the ‘Diagnostics’ menu.

3. Select ‘Chair Log’.

4. From the ‘Modules Attached’ menu, select ‘UCM Remote’.

Below are listed the Chair Log codes and probable causes of these faults. If the

suggested action does not remove the fault, contact a Dynamic Sales and

Service Centre (refer to section 14).

Message Probable Cause and Action

CPU / General

Fault

Cause : Internal Fault

Action: < Replace Dolphin.

< Consult an approved Dynamic Service Agent.

ADC Fault

Cause: Internal Fault

Action: < Replace Dolphin.

< Consult an approved Dynamic Service Agent.

9 Diagnostics and Fault Finding

49

Page 54

Message Fault and Possible Cause

No. 60025, Issue 5. January 1999

CAN short fault

Cause : 1. Short between CANL and CANH.

Action: < The short may be within a module or within a DX

Cable, or the exposed DXBUS contacts may be

shorted by foreign material. Ensure that all DXBUS

contacts are clean.

Warning : Open circuit breaker or disconnect from

PM before probing around DXBUS connectors.

Disconnect any optional modules and turn on the

Dolphin. Use the Wizard Status Report to check if

the CAN shorted fault is still present. If possible,

substitute the DXBUS Cable between the Dolphin

and the PM. Disconnect any unnecessary DXBUS

Cables. When the fault no longer occurs, add

cables and modules one by one until the faulty

cable or module is identified. Replace the faulty

part. If the fault remains, try replacing the Dolphin

and the PM.

CAN L fault

Wake-up Fault

JS OONAPU

occurrence