Page 1

Compact Remote Modules

DX2-RJM, DX2-RJM-LF, and DX2-ACU

Installation Manual

GBK65701 DX2 Compact Remote Modules

DX2-RJM, DX2-RJM-LF, and DX2-ACU

Installation Manual

Issue 1

December 2014

Page 2

Page 3

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

1 Welcome

Welcome to the Installation Manual for the DX2 compact remote modules: DX2-RJM, DX2-RJM-LF

and DX2-ACU.

This manual will help you understand, install, test and operate the DX2-RJM, DX2-RJM-LF and DX2ACU remote modules. Please read and understand this and all other relevant DX2 system manuals

before installing and operating.

1.1 Using this manual

This manual uses the following information boxes to convey important and useful information:

Warning

Warnings provide important information that must be followed in order to install, configure, and use the product

safely and efficiently. Not following the instructions given in a warning can potentially lead to equipment failure,

damage to surrounding property, injury or death.

Note:

Notes provide supporting information in order to install, configure, and use the product. Not following the

instructions given in notes can lead to equipment failure.

See also:

The "See also" box provides cross-references to further information with clickable links to help you navigate the

manual more easily.

:

1.2 Important information

Do not install, maintain or operate this equipment without reading, understanding and following this

manual – including the Safety and Misuse Warnings – otherwise injury or damage may result. This

manual contains integration, set up, operating environment, test and maintenance information

needed in order to ensure reliable and safe use of the product.

The term ‘programming’ used in this manual refers to adjusting parameters and configuring options

to suit an application and does not change or replace any firmware within the controller.

Programming is performed using a controlled programming tool available only to authorised

personnel.

The products described in this manual are not user-serviceable. Specialised tools are necessary for the

repair of any component. Any attempt to gain access to or in any way abuse the electronic

components and associated assemblies that make up the wheelchair controller system renders the

manufacturer’s warranty void and the manufacturer free from liability.

Due to a policy of continuous product improvement, Dynamic Controls reserves the right to update

this product and manual without notice. This issue of the manual supersedes all previous issues;

previous issues must no longer be used.

1.3 Copyright, trademarks and acknowledgements

Dynamic Controls, the Dynamic logo and the DX2 logo are trademarks of Dynamic Controls. All other

brand and product names, fonts, and company names and logos are trademarks or registered

trademarks of their respective companies.

Welcome - Page 1

Page 4

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

Dynamic Controls owns and will retain all trademark rights and Dynamic Controls or its licensors own

and will retain all copyright, trade secret and other proprietary rights, in and to the documentation.

All materials contained within this manual, in hard copy or electronic format, are protected by

copyright laws and other intellectual property laws.

1.4 Contact

The latest version of this manual can be downloaded from Dynamic Controls' website:

www.dynamiccontrols.com

1.5 Related documentation

A DX/DX2 system comprises a number of modules (power module, remote module, etc.) depending

on the application. Each DX/DX2 module has its own installation manual, which describes the

installation requirements for that particular module.

This manual (GBK65701) describes the installation of the DX2-RJM, DX2-RJM-LF and DX2-ACU Remote

Modules only, and must be read in conjunction with:

l the DX System Manual;

l all other relevant DX/DX2 system manuals, depending on modules fitted.

Page 2 - Welcome

Page 5

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

2 Contents

2.1 Contents - overview

1 Welcome 1

2 Contents 3

3 Glossary 7

4 Introduction 9

5 Specifications 13

6 Installation 15

7 Operation 21

8 Testing 37

9 Diagnostics 41

10 Appendices 45

11 Index 51

Contents - Page 3

Page 6

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

2.2 Contents - detailed

1 Welcome 1

1.1 Using this manual 1

1.2 Important information 1

1.3 Copyright, trademarks and acknowledgements 1

1.4 Contact 2

1.5 Related documentation 2

2 Contents 3

2.1 Contents - overview 3

2.2 Contents - detailed 4

2.3 Table of figures 6

3 Glossary 7

4 Introduction 9

4.1 Remote module overview 9

4.1.1 The DX2-RJM / DX2-RJM-LF 9

4.1.2 The DX2-ACU 10

4.2 Feature comparison 10

4.3 System overview 11

4.3.1 System configurations 11

4.3.2 Compatible master remote modules 12

5 Specifications 13

5.1 Mechanical specifications 13

5.2 Electrical specifications 13

6 Installation 15

6.1 Mounting 15

6.1.1 Cable routing options 15

6.1.2 Tray mount 16

6.1.3 Clamp mount 16

6.1.4 Plate mount 16

6.1.5 Tube mount 17

6.1.6 Drop-in mount 17

6.2 Positioning 18

6.2.1 DX2-RJM/-LF 18

6.2.2 DX2-ACU 18

6.3 Wiring 18

6.4 Programming 20

6.4.1 User profile options 20

6.4.2 System settings 20

7 Operation 21

7.1 DX2-RJM, DX2-RJM-LF operation 21

7.1.1 The joystick 22

7.1.2 Power button and status indicator 23

7.1.3 Emergency stop 23

7.1.4 Mode button 23

7.1.5 Information display 24

7.1.6 Battery gauge indicator 25

7.1.7 Attendant indicator 26

7.1.8 Sleep mode 26

7.1.9 Lock mode 27

7.1.10 Configuration mode 27

Page 4 - Contents

Page 7

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

7.2 DX2-ACU operation 29

7.2.1 The joystick 30

7.2.2 Power button and status indicator 30

7.2.3 Emergency stop 31

7.2.4 Mode button 31

7.2.5 Speed indicator 32

7.2.6 Battery gauge indicator 32

7.2.7 Attendant indicator 33

7.2.8 Sleep mode 34

7.2.9 Lock mode 34

7.2.10 Configuration mode 35

8 Testing 37

8.1 Before testing 37

8.2 Testing the DX2-RJM / DX2-RJM-LF 37

8.2.1 Power button 37

8.2.2 User interface 38

8.2.3 Mode button 38

8.2.4 Joystick 38

8.2.5 Emergency stop 38

8.2.6 OONAPU 38

8.2.7 Wake up from sleep mode 38

8.3 Testing the DX2-ACU 39

8.3.1 Power button 39

8.3.2 User interface 39

8.3.3 Mode button 39

8.3.4 Joystick 39

8.3.5 Emergency stop 39

8.3.6 OONAPU 39

8.3.7 Wake up from sleep mode 40

9 Diagnostics 41

9.1 OONAPU 41

9.2 Drive inhibit indication 41

9.3 Fault indication 42

9.4 Dealing with compact remote module faults 42

10 Appendices 45

10.1 Parts list 45

10.2 Intended use and regulatory statement 45

10.2.1 Intended use DX2-RJM and DX2-RJM-LF 45

10.2.2 Intended use DX2-ACU 46

10.2.3 Device classification 46

10.2.4 Compliance and conformance with standards 46

10.3 Service life 46

10.4 Maintenance 46

10.5 Warranty 47

10.6 Safety and misuse warnings 47

10.6.1 Warnings to be included in the user manual 47

10.6.2 Service and configuration warnings 48

10.7 Electromagnetic compatibility 49

10.7.1 Minimising emissions 49

10.8 Environmental statement 49

Contents - Page 5

Page 8

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

10.9 Symbols and labelling 49

10.9.1 Product label 49

10.9.2 Other symbols and labels 50

10.9.3 Serial number and date of manufacture 50

11 Index 51

2.3 Table of figures

Figure 1: DX2-RJM and DX2-RJM-LF 9

Figure 2: DX2-ACU 10

Figure 3: System diagram 11

Figure 4: Dimensions - DX2-RJM, DX2-RJM-LF and DX2-ACU 14

Figure 5: Cable routing options 15

Figure 6: Fixing centres 16

Figure 7: Clamp diameter 16

Figure 8: Clamp mount 16

Figure 9: Fixing the clamp mount 16

Figure 10: Base plate example 16

Figure 11: Fixing the base plate 16

Figure 12: Tube mount (from above) 17

Figure 13: Fixing the tube mount 17

Figure 14: Concept drawing for drop-in mount 17

Figure 15: Joystick Source example 20

Figure 16: Set RJMEnable 20

Figure 17: Set ACU Enable 20

Figure 18: The DX2-RJM, DX2-RJM-LF user interface 21

Figure 19: The joystick 22

Figure 20: The mode button 23

Figure 21: Information display 24

Figure 22: The battery gauge indicator 25

Figure 23: Battery charging sequence 26

Figure 24: Attendant indicator 26

Figure 25: Sleep mode 26

Figure 26: The DX2-ACU user interface 29

Figure 27: The joystick 30

Figure 28: The mode button 31

Figure 29: Speed indicator (showing 60% speed) 32

Figure 30: The battery gauge indicator 32

Figure 31: Battery charging sequence 33

Figure 32: Attendant indicator 33

Figure 33: Sleep mode 34

Figure 34: OONAPU sequence 41

Figure 35: Drive inhibit indication (RJM top, ACU bottom) 41

Figure 36: Location of product and other labels 49

Figure 37: Serial number example 50

Page 6 - Contents

Page 9

3 Glossary

A

ACU

Attendant Control Unit - a remote module used by a wheelchair attendant. See also RJM.

C

CAN

Controller Area Network

D

DX

Dynamic Controls' modular mobility system

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

DXBUS

The DX system communication bus, comprising CAN communication lines plus power supply

to DX modules.

H

HHP

Hand-held programmer

O

OEM

Original Equipment Manufacturer. Generally refers to the wheelchair manufacturer.

OONAPU

Out Of Neutral At Power Up. A fault condition produced if the DX system is turned on while

the joystick is not in the neutral (non-driving) position.

R

RJM

Remote Joystick Module - a remote module normally used by the wheelchair occupant. See

also ACU.

U

UCM

User Control Module. The core component of all DX remote modules.

Glossary - Page 7

Page 10

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

W

Wizard

A PC based programming, configuration and diagnostics tool used by the DX system.

Page 8 - Glossary

Page 11

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

4 Introduction

4.1 Remote module overview 9

4.1.1 The DX2-RJM / DX2-RJM-LF 9

4.1.2 The DX2-ACU 10

4.2 Feature comparison 10

4.3 System overview 11

4.3.1 System configurations 11

4.3.2 Compatible master remote modules 12

4.1 Remote module overview

This manual describes the following DX2 compact remote modules:

l DX2-RJM — DX2 Remote Joystick Module (RJM)

l DX2-RJM-LF — DX2 RJM with low force joystick

l DX2-ACU — DX2 Attendant Control Unit (ACU)

The DX2-RJM, DX2-RJM-LF and DX2-ACU are compact remote modules that share the same form, yet

have different functions. The DX2-RJM and DX2-RJM-LF remote modules are designed for use by the

wheelchair occupant, whereas the DX2-ACU has been designed for use as an attendant controller.

All of the remote modules share the same user interface, have multiple mounting capabilities and

come with a fixed, trailing lead (DXBUS) that allows for easy integration into existing DX2 systems.

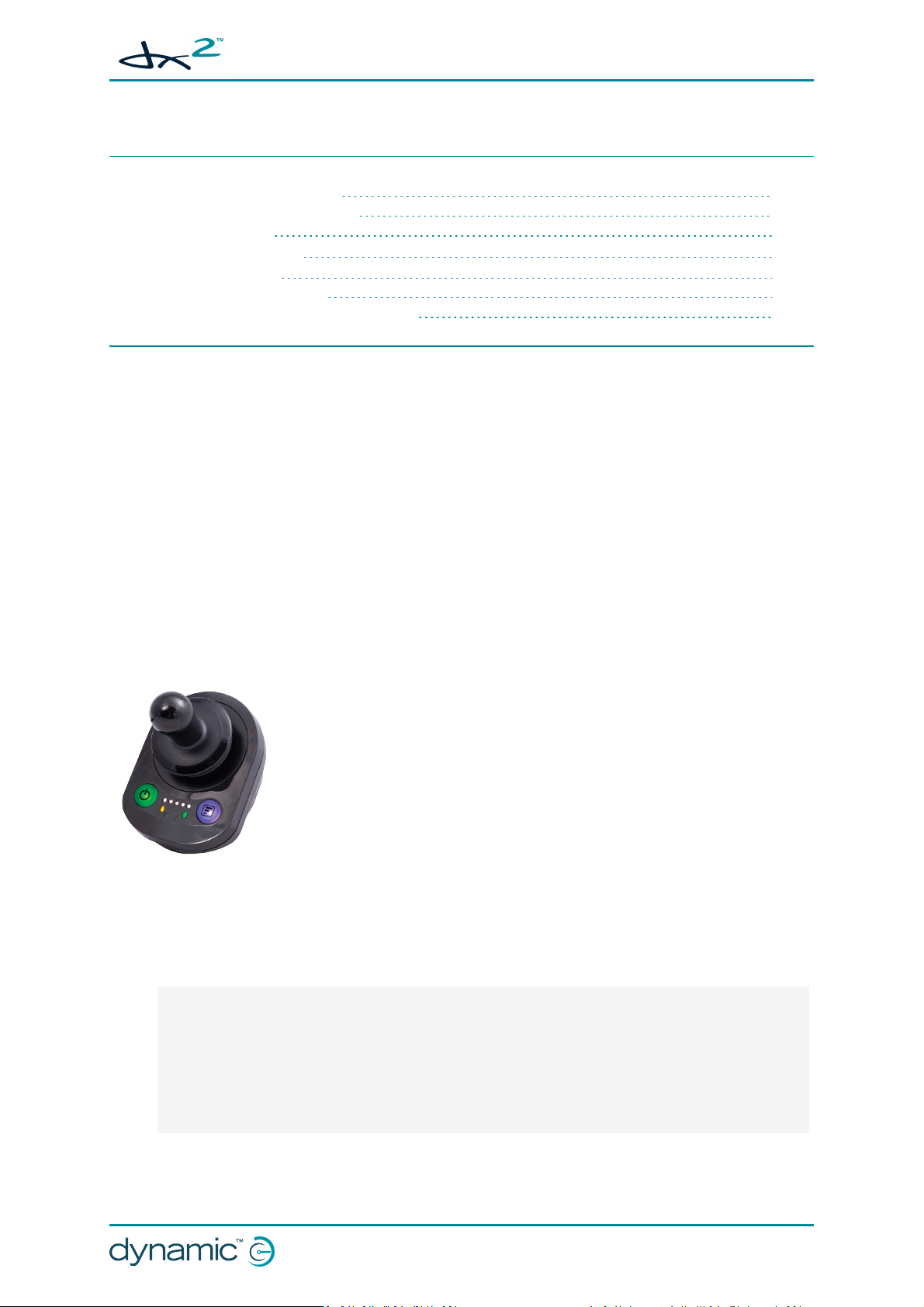

4.1.1 The DX2-RJM / DX2-RJM-LF

The DX2-RJM and DX2-RJM-LF are compact, secondary remote modules

designed to provide a simple interface for the wheelchair occupant using a

DX/DX2 system.

With a modern, low-profile design, the remote modules employ joystick

technology from the LiNX product range, and are designed to be drop-in

replacements for the DX-RJM’s. They also have several enhanced features,

including the ability to turn the system on/off and to select and operate

Figure 1: DX2-RJM and DX2RJM-LF

Low strength users will enjoy the low force joystick option with the DX2-RJM-LF, which provides

smooth control with a deflection force of just 1.1 N.

Drive and Accessory menu options.

Benefits

l Built-in power button — enables the user to easily power up or down the system

l Built-in mode button

l Simple LED indicator shows what Drive Profile is selected

l Tri-colour battery gauge

l Attendant in charge indicator

l A range of mounting orientations — standard, tray, centre-line and swing-away mounts

l Low force joystick option will improve control for those with low muscle strength

Introduction - Page 9

Page 12

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

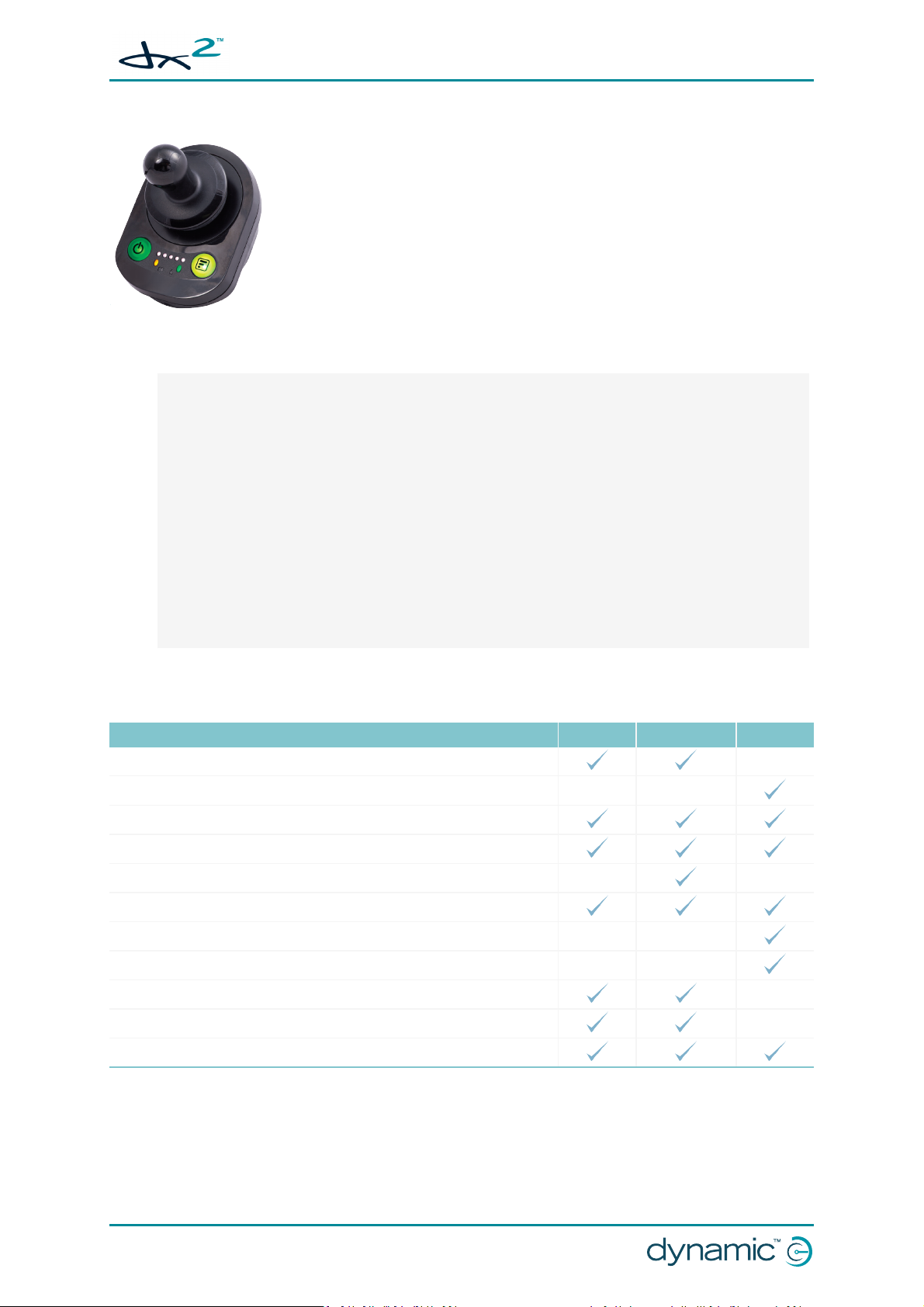

4.1.2 The DX2-ACU

The DX2-ACU, with its modern, low-profile design, is an attendant control

unit, and an ideal secondary control solution for any DX/DX2 system. It

employs joystick technology from the LiNX product range and is designed

to be a drop-in replacement for the DX-ACU’s.

The new design has several enhanced features, including a selection of

“who’s in charge” options.

Figure 2: DX2-ACU

Benefits

l Built-in power button enables the attendant to easily power up or down the system

l Mode button:

o

Short press — adjust wheelchair speed to your walking speed with digital speed control

o

Long press — easily switch control between attendant and occupant

l Range of “who’s in charge” options (first-in-first-served, attendant priority, user priority and

DX-like)

l Simple LED speed indicator showing selected speed range

l Tri-colour battery gauge

l System status and attendant in charge indication

l Control your client's comfort with the ability to select and operate actuators through the joy-

stick (with selected Master Remotes)

l Able to be mounted in a variety of orientations to suit individual chair needs

l Fully sealed case design provides improved protection against water and dust ingress

4.2 Feature comparison

Feature DX2-RJM DX2-RJM-LF DX2-ACU

Suitable for wheelchair occupants

Suitable for wheelchair attendants

Lightweight, modern design

Symmetrical design, ideal for left- and right-handed users.

Low-force joystick

Battery indicator

Speed adjustment

Speed indicator

Drive profile / accessory selection

Drive profile indicator

Attendant indicator

Page 10 - Introduction

Page 13

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

4.3 System overview

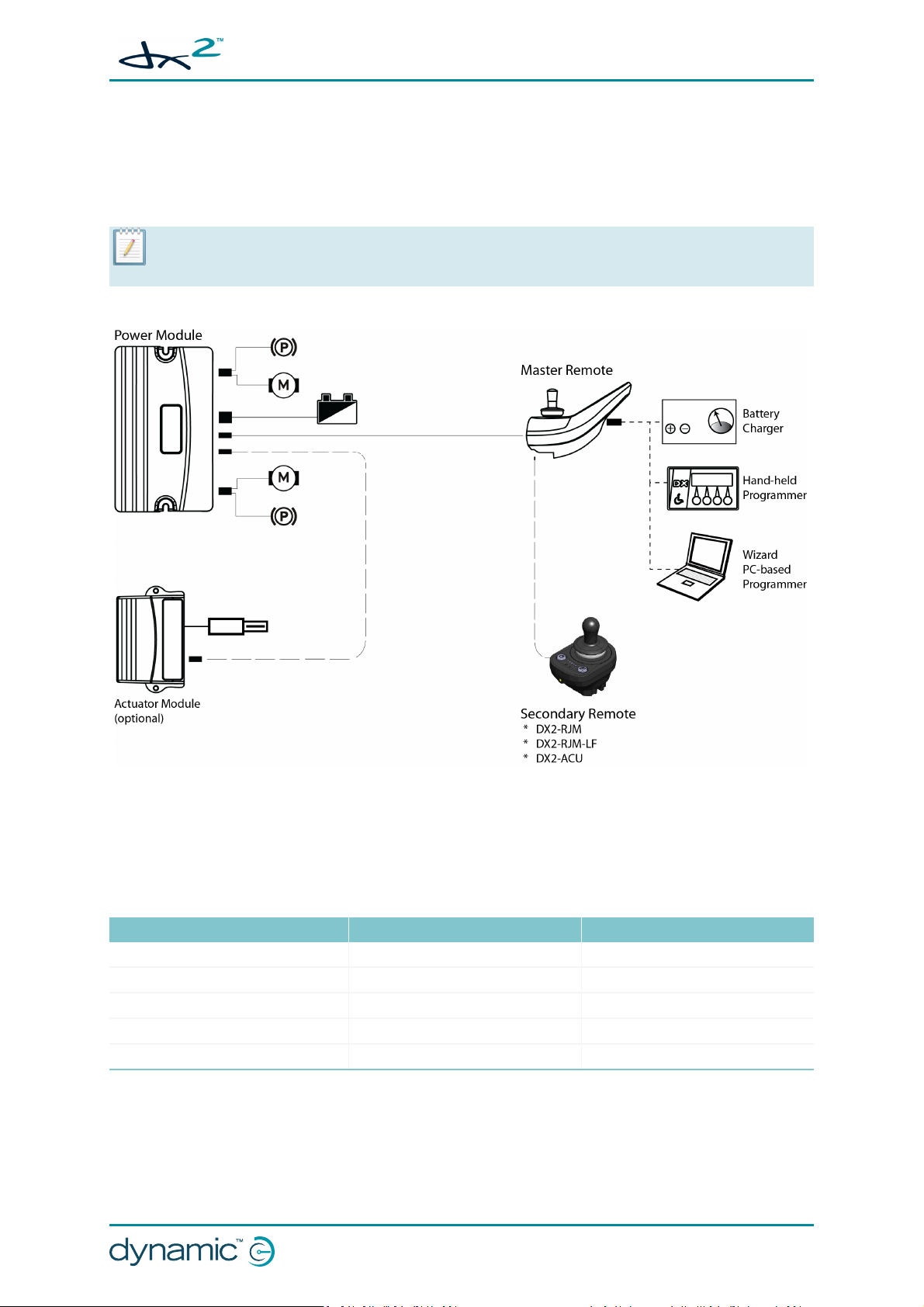

The DX2-RJM, DX2-RJM-LF and DX2-ACU operate as secondary remotes within a DX/DX2 wheelchair

control system. They connect to a master remote module via the fixed, trailing lead (DXBUS) as shown

in Figure 3: System diagram.

:

Note

Not all master remote modules are compatible with the compact remote modules - for more details, see section

4.3.2 Compatible master remote modules.

Figure 3: System diagram

4.3.1 System configurations

The DX2-RJM, DX2-RJM-LF and DX2-ACU compact remote modules can be used in the following

system configurations:

Primary Secondary Secondary

DX/DX2 Master remote DX2-ACU -

DX/DX2 Master remote DX2-RJM / DX2-RJM-LF -

DX/DX2 Master remote DX-RJM DX2-ACU

DX/DX2 Master remote DX-ACU DX2-RJM / DX2-RJM-LF

DX/DX2 Master remote DX2-ACU DX2-RJM / DX2-RJM-LF

Note that there can be only one RJM-type module in a system configuration. That is, the

configuration will support a DX2-RJM and DX2-ACU combination, or a DX2-RJM-LF and DX2-ACU

combination, but it will not support a DX2-RJM and DX2-RJM-LF combination.

Introduction - Page 11

Page 14

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

:

Note

Any accessory modules, such as the DSL-105 Proximity Head Control, or DX-SNP Sip and Puff, that appear as an RJM

in a DX/DX2 system, cannot be used in combination with another RJM-type module.

4.3.2 Compatible master remote modules

The DX2-RJM, DX2-RJM-LF and DX2-ACU compact remote modules will only operate with UCM II

based master remote modules. The following master remote modules are compatible with the DX2RJM, DX2-RJM-LF and DX2-ACU compact remote modules.

DX-REM24SD DX-REM34B

DX-REMG90/A/T DX-ACU3B

DX-REMG91/S DX2-REM420/1

DX-REM48/A

(see note below)

DX2-REMA/B-ACS2 DX-REM41D/E

DX2-REM550/1

Warning

The compact remotes described in this manual are to be used with selected UCM II based master remote modules

only - see table above. DONOT use with UCM I based master remote modules.

Note

All of the master remote modules listed in the table above, with the exception of DX-REM48/A, are UCM II based.

Depending on its age, the DX-REM48/A may be a UCM I type. If you are using a DX-REM48/A, ensure that it is a

UCM II type before using in a system. If you are unsure, consult your service centre.

:

:

Page 12 - Introduction

Page 15

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

5 Specifications

5.1 Mechanical specifications 13

5.2 Electrical specifications 13

5.1 Mechanical specifications

Parameter Value

Protection rating IPx4

Shipping weight < 400g

Min Nominal Max Units

Operating temperature range -25 - 50 °C

Storage temperature range -40 - 65 °C

Operating humidity range 0 - 90 %RH

Operating forces Min Nominal Max Units

l Joystick

o

o

l

Mode button

l

Power button

DX2-RJM / DX2-ACU

DX2-RJM-LF

-

-

- < 2.5 - N

- < 2.5 - N

1.6

1.1

-

-

N

N

5.2 Electrical specifications

Parameter Min Nominal Max Units

Operating voltage (Vbatt) 18 24 32 V

Idle current - 56 - mA@24V

Quiescent current (power off) - - 0.23 mA@24V

Specifications - Page 13

Page 16

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

Figure 4: Dimensions - DX2-RJM, DX2-RJM-LF and DX2-ACU

Page 14 - Specifications

Page 17

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

6 Installation

6.1 Mounting 15

6.1.1 Cable routing options 15

6.1.2 Tray mount 16

6.1.3 Clamp mount 16

6.1.4 Plate mount 16

6.1.5 Tube mount 17

6.1.6 Drop-in mount 17

6.2 Positioning 18

6.2.1 DX2-RJM/-LF 18

6.2.2 DX2-ACU 18

6.3 Wiring 18

6.4 Programming 20

6.4.1 User profile options 20

6.4.2 System settings 20

6.1 Mounting

There are numerous options available for mounting the compact remote module, such as:

l tray mount

l clamp mount

l base plate mount

The choice will depend on the type of compact remote (DX2-RJM/-LF or DX2-ACU) being installed and

its user (wheelchair occupant or attendant): for a wheelchair occupant, the tray, clamp and base plate

mount options may be suitable; for a wheelchair attendant, the tube or drop-in mount options may

be more suitable.

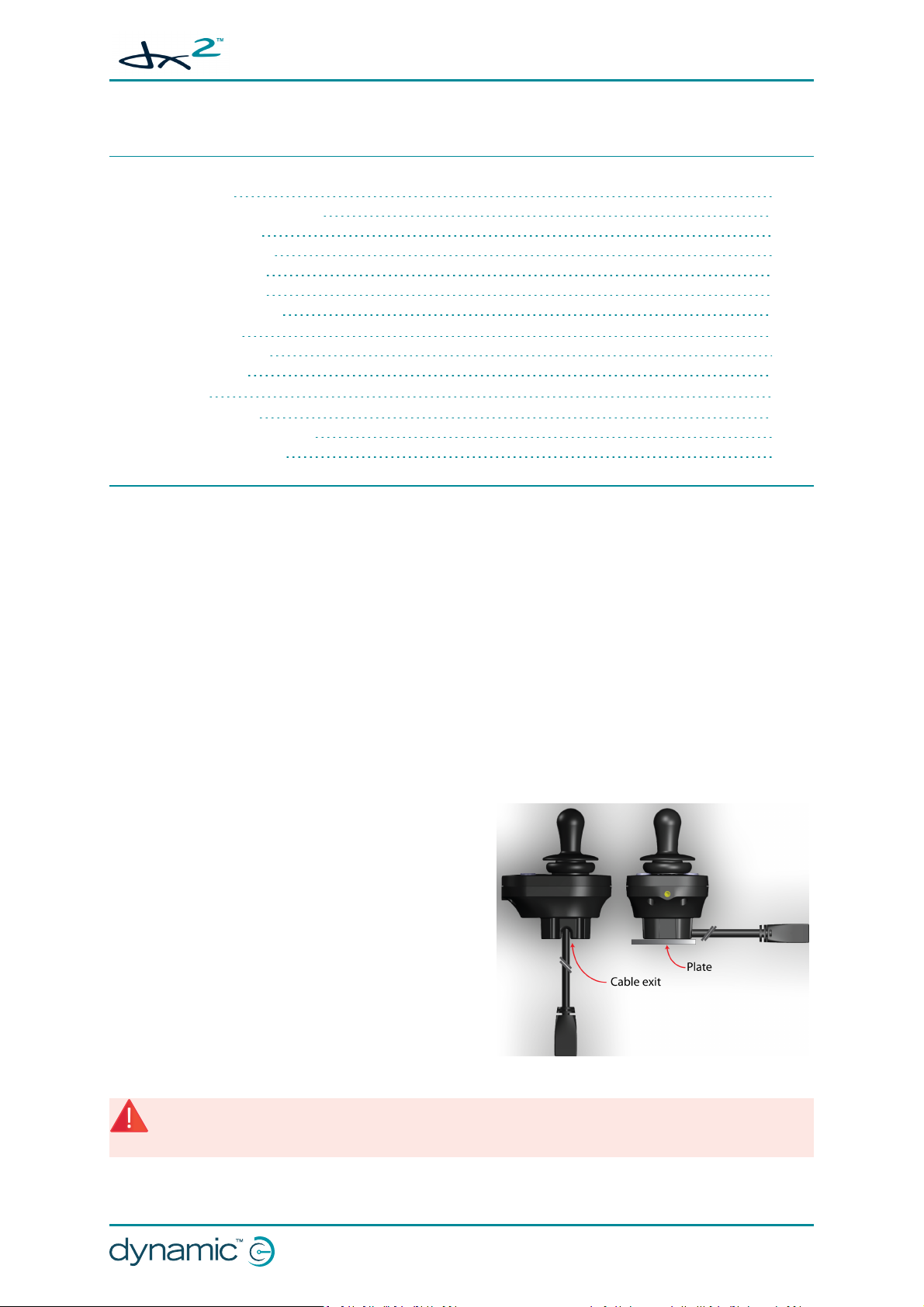

6.1.1 Cable routing options

The base of the remote module has two cable exit

recesses located on either side. These allow the bus

cable to extend from the remote at any angle between

vertical and horizontal.

For plate mounting options, this means that the cable

can be routed to the side of the remote module, and

above the plate, as shown in Figure 5.

l tube mount

l drop-in mount

Figure 5: Cable routing options

Warning

Limit to ten or fewer the number of times the compact remote module is installed on to a plate if the bus cable is

at 90° to the module; frequent flexing at this angle may damage the cable.

:

Installation - Page 15

Page 18

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

:

Note

The mounts shown in the following sections are suggestions only; Dynamic Controls does not manufacture or

supply the mounts. The OEM is responsible for the final design of the mount and its application.

6.1.2 Tray mount

The remote module can be mounted on to any suitable flat

surface, such as a tray, using the fixing holes underneath the

module and two M5 bolts. The maximum torque to fasten these

bolts is 3 Nm – do not exceed this rating as it may damage the

remote module.

This solution is ideal for wheelchair occupants that require the

remote module to be in a more central position, rather than the

standard placements of the left- or right-hand armrests.

Figure 6: Fi xing centres

6.1.3 Clamp mount

The compact remote has a cylindrical base which is suitable for attaching a cylindrical style clamp or

clip.

Figure 7: Clamp diameter Figure 8: Clamp mount Figure 9: Fi xing the clamp mount

6.1.4 Plate mount

The remote module can be mounted using a flat base plate (see Figure 10: Base plate example) and

two M5 bolts. The maximum torque to fasten these bolts is 3 Nm – do not exceed this rating as it may

damage the remote module.

Figure 10: Base plate example

Figure 11: Fixing the base plate

Page 16 - Installation

Page 19

6.1.5 Tube mount

Figure 12: Tube mount (from above)

The tube diameter will depend on the tube clamp

used, and also the fixing hole centres on the

remote module (30 mm). A tube with an outside

diameter of 15 - 22 mm would be suitable.

Use two M5 bolts to fasten the tube between the

clamp and the base. The maximum torque to

fasten these bolts is 3 Nm – do not exceed this

rating as it may damage the remote module.

Ensure that the DXBUS cable is not pinched when

tightening the tube clamp.

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

The remote module can be fixed on to a tube

using a suitable tube clamp. This solution is useful

for tubes that run perpendicular to the remote

module, as shown left.

Figure 13: Fixing the tube mount

6.1.6 Drop-in mount

The depth and shape of the base of the compact remote module allows it to be placed into a suitably

designed cradle, such as the drop-in mount shown in Figure 14.

The drop-in mount is ideal for the DX2-ACU attendant remote module, allowing an attendant to

remove and replace the module with ease, and also use the module at a comfortable, safe distance

from the wheelchair. Design the mount to prevent the remote module from falling out accidentally,

or twisting around when used in the mount. A concept drawing is shown below.

Figure 14: Concept drawing for drop-in mount

Installation - Page 17

Page 20

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

6.2 Positioning

6.2.1 DX2-RJM/-LF

Position the remote module such that a typical user's arm is in a natural, comfortable position.

:

Note

It is the responsibility of both the manufacturer and the dealer to determine the most appropriate installation

suitable for any single user. This includes, but is not limited to, the placement of the remote module for long term,

comfortable use.

For wheelchair occupants using the DX2-RJM or DX2-RJM-LF, the OEM manufacturer should consider

providing a hand guard at the front of the compact remote module to protect the user's hand against

crushing, such as when manoeuvring under a table.

Warning

If the wheelchair's remote module has not been fitted with a hand guard, the user should be made aware that

their hand will not be protected from crushing, when, for example, manoeuvring towards or under a table.

:

When positioning the compact remote, consider the position of the master remote module too. The

wheelchair occupant must be able to see the master remote display when the compact remote

module's display is switched off or when actuators are being used, since actuator feedback is only

displayed on the master remote, not the compact remote.

6.2.2 DX2-ACU

Do not install or place the compact remote module higher than 1.2 m from the ground.

To minimise the risk of snagging, Dynamic Controls recommends permanently fixing the compact

remote module to the rear of the wheelchair, when used as an attendant remote, in line with EN

12184:2009 8.6 Assistant control unit, push handles and handgrips.

For compact remote modules that are not permanently fixed to the wheelchair, limit the length of the

cable between the product and the back of the wheelchair to:

1. minimise the chance of the product hitting the floor, and being damaged if dropped;

2. minimise the chance of the joystick landing on the floor and deflecting, causing a runaway situation;

3. minimise the chance of snagging the cable on an external object.

The recommended total length of the bus cable, between the product and the back of the wheelchair,

must be no longer than the height above the ground that the product is normally placed. For an extra

margin of safety, reduce the cable length by a further 0.25 m.

:

Note

It is recommended that the low force compact remote module (DX2-RJM-LF) is not used as an attendant remote. If

the remote is dropped, the mass of the remote, relative to the joystick deflection force, makes a runaway more

likely than if the full deflection force joystick (DX2-ACU) is used.

6.3 Wiring

For safe and reliable operation, the installation of looms and cables must follow the basic principles of

power wiring.

Page 18 - Installation

Page 21

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

Cables must be secured between their connectors and any point of flexing so that flexing forces are

not transferred to the connectors.

Warning:

Route and position cables and remote modules so that they are free from physical strain, abuse or damage, such

as snagging, crushing, impacts from external objects, pinching or abrasion.

Warning

Damage to cables increases wiring impedance. A damaged cable can potentially produce localised heat, sparks or

arcing and become a source of ignition to surrounding flammable material. The installation must ensure that all

power cables, including the bus cable, are protected against damage and potential contact with flammable

materials.

:

Adequate strain relief must be provided for all cables, and the mechanical limits of the cables and

looms must not be exceeded.

Ensure that connectors and connector sockets are shielded from water splashes and water ingress.

Cables with female connectors should face horizontally or downwards. Ensure all connectors are fully

mated.

Warning

Connector pins on cables connected to the power module can still be live even when the system is off. Cables with

live pins should be connected, restrained or covered so that they are not exposed to human contact or materials

that could cause electrical shorts.

:

Make sure that the cables do not extend beyond the wheelchair to prevent them from being caught

or damaged by external objects. Take particular care on wheelchairs with movable structures such as

a seat raise.

Warning

Avoid routing the cable where it will come into continuous contact with the end user.

:

When installing the bus cable, avoid undue straining of the cable and connection points. Flexing of

the cable should be minimised wherever possible, to extend service life and minimise the risk of

accidental damage.

Warning

Use of a cable chain to support the bus cable, where the cable is subject to regular cyclic bending, is

recommended. The maximum stretch of the chain should be less than the length of the bus cable. The force

applied to flex the cable should never exceed 10 N.

Note

Appropriate life testing should be carried out to determine / confirm the expected service life and inspection and

maintenance schedule.

:

:

See also:

6.1.1 Cable routing options

Installation - Page 19

Page 22

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

6.4 Programming

Before using the compact remote modules, update the system's User Profile Options and System

Settings, as detailed below.

6.4.1 User profile options

In the User Profile Options section, set the Joystick Source

option to the type of remote

module for one of the available

profiles.

Figure 15: Joystick Source example

For example, in Figure 15, Joystick Source has been set to RJM in Profile 4.

:

Note

Dynamic Controls recommends that you do not select ACU for the Joystick Source parameter for profiles 1 - 5.

The ACU profile is automatically selected by the master remote module when the ACU takes control of a system. If

another profile, other than the ACU profile, is selected and the profile has been configured with the ACU as the

joystick source, then the Attendant indicator will not operate—the Attendant indicator only operates with the ACU

profile.

See also

7.1.7 Attendant indicator

:

6.4.2 System settings

Set RJM Enable to Yes if a DX2-RJM or DX2-RJM-LF is part

of the system.

Set ACU Enable to Yes if a DX2-ACU is part of the system.

Figure 16: Set RJ MEnable

See also

7 Operation

:

Page 20 - Installation

Figure 17: Set ACU Enable

Page 23

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

7 Operation

7.1 DX2-RJM, DX2-RJM-LF operation 21

7.1.1 The joystick 22

7.1.2 Power button and status indicator 23

7.1.3 Emergency stop 23

7.1.4 Mode button 23

7.1.5 Information display 24

7.1.6 Battery gauge indicator 25

7.1.7 Attendant indicator 26

7.1.8 Sleep mode 26

7.1.9 Lock mode 27

7.1.10 Configuration mode 27

7.2 DX2-ACU operation 29

7.2.1 The joystick 30

7.2.2 Power button and status indicator 30

7.2.3 Emergency stop 31

7.2.4 Mode button 31

7.2.5 Speed indicator 32

7.2.6 Battery gauge indicator 32

7.2.7 Attendant indicator 33

7.2.8 Sleep mode 34

7.2.9 Lock mode 34

7.2.10 Configuration mode 35

7.1 DX2-RJM, DX2-RJM-LF operation

:

Note

The following section details the operation for DX2-RJMand DX2-RJM-LF only. For a description of the DX2-ACU's

operation, see section 7.2 DX2-ACU operation .

The DX2-RJM and DX2-RJM-LF (low force joystick version)

are drop-in replacements for the DX-RJM. They are

designed to be used by the wheelchair occupant as a

secondary remote module, and connected to a DX/DX2

system via the fixed, trailing DXBUS cable.

The symmetrical design of the controller, and its trailing

lead enables the remote modules to be fitted and operated

left of the user, right of the user or anywhere in between.

The fixing holes permit a range of mounting orientations

including standard, tray, centre-line and swing-away

mounts.

Warning

Users should be aware that the surface of the remote module can potentially get hot when it is exposed to strong

sunlight for long periods.

:

Figure 18: The DX2-RJM, DX2-RJM-LF user interface

Operation - Page 21

Page 24

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

Figure 18 shows the main components of the DX2-RJM and DX2-RJM-LF. These are described below:

o

joystick - to control speed and direction

o

power button (with status LED) - to power up or power down the system, and

view the system's status

o

mode button - to select drive profile

o

information display - displays selected drive profile

o

battery indicator - displays battery status

o

attendant indicator - displays which controller (occupant's or attendant's) has

control of the wheelchair

Note

To operate, the DX2-RJM and DX2-RJM-LF must be connected to a DXsystem via the DXBUStrailing lead.

Warning

Do not use the compact remote module if it is worn or damaged. Worn or damaged modules should be serviced

immediately, especially if the DXBUS cable, joystick gaiter or keypad are ripped, torn or damaged.

:

7.1.1 The joystick

Warning

The compact remote modules may only be used with the authorised joystick knobs. Use of any other joystick knob

requires that the installer tests and confirms that the joystick returns to the neutral position whenever the joystick

is deflected. Tests with the device mounted horizontally and with a water soaked knob (foam knobs only) are

required if the installer judges these risks as significant.

Figure 19: The joystick

If the user moves the joystick back to the neutral position, the wheelchair will slow down and stop.

:

The joystick controls the direction and speed of the wheelchair.

When the joystick is deflected from the centre (neutral) position, the

wheelchair will move in the direction of the joystick movement.

The speed of the wheelchair is proportional to the joystick deflection, so that

the further the joystick is moved from the neutral position, the faster the

wheelchair will travel.

If the user releases the joystick from any position other than the neutral position, the joystick will

return to the neutral position and the wheelchair will slow down and stop.

The joystick can also be used to wake up the system when in sleep mode — see 7.1.8 Sleep mode.

Warning

It is the responsibility of the wheelchair manufacturer to inform the wheelchair user about the wheelchair's

stopping distances.

See also

9.1 OONAPU

7.1.8 Sleep mode

:

:

Page 22 - Operation

Page 25

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

7.1.2 Power button and status indicator

:

Note

In the event that the wheelchair is in a runaway situation, press the remote module's power button to perform an

EMERGENCY STOP. See section 7.1.3 Emergency stop.

The power button is on the left-hand side of the remote module, and incorporates a status indicator

that changes colour depending on the status of the system:

Off - system OFF or

sleeping

Red (flashing) - powered ON fault

Green - powered ON.

Press the power button to switch the system ON. If there is no fault with the system, the status

indicator (under the power button) will light up green.

Press the power button to switch the system OFF; the system will power down and the status

indicator will switch off.

If there is a fault with the system, the status indicator will indicate the fault with a series of red flashes

(see section 9 Diagnostics).

7.1.3 Emergency stop

If the user needs to stop the wheelchair quickly, the power button can be pressed to perform an

EMERGENCY STOP. The wheelchair will come to a halt quickly; the rate is set by the Emergency

Deceleration parameter.

Warning

Ensure that the wheelchair's settings are appropriate for both the wheelchair configuration and the user. If the

Emergency Deceleration parameter is set too high, the user can lose balance or fall out of the wheelchair when an

emergency stop is performed.

:

See also

See the DX System Manual / Master Remote manual for more information about the Emergency Deceleration

parameter.

:

7.1.4 Mode button

The mode button is on the right-hand side of the remote module and

incorporates a purple indicator that is lit continuously (except when a drive

Figure 20: The mode

button

The operation of the mode button is dependent on the type of master remote module within the

system. It can be used to:

l swap between modes (drive profile mode or accessory mode);

l step through a mode;

l step back through a mode.

The mode button reacts to two actions:

inhibit is present) while the system is powered up.

Operation - Page 23

Page 26

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

l a short press (less than ½ second)

l a long press (greater than ½ second)

The table below shows how the mode button operates with long and short presses for the

compatible master remote modules.

Master remote

module

DX-REM24SD Short Increments drive profile.

DX-REMG90/A/T Short Increments drive profile, and then, after the highest drive profile, it

DX-REMG91/S Short Behaviour depends on the input mode used. Typically a short press will

DX-REM48/A Short Increments drive profile. After the highest drive profile, it enters lighting

DX-REM34B

DX-REM41D/E

DX-ACU3B Short Increments drive profile. After the highest drive profile, it enters into

DX2-REM420/1

DX2-REMA/B-ACS2

DX2-REM550/1 Short This is configurable with the External Mode/Up Down parameter in Wiz-

Mode button

press

Long Scrolls through the available accessory modes.

enters accessory mode.

Long Decrements drive profile.

Long

Long Decrement profile.

Short Increments drive profile.

Long Decrements drive profile.

Long Decrements drive profile.

Short Increments drive profile.

Long Selects last actuator profile. Subsequent long presses increments actuator

Long This is configurable with the External Mode/Up Down parameter in Wiz-

increment a mode or profile and a long press will decrement in the same

way. Note: The RJM cannot be used in scanning input mode.

mode.

Note: The DX2-RJM cannot be used to enter/leave actuator profiles.

Note: The DX2-RJM cannot enter any accessory modes with these master

remote modules.

actuator profile (if an actuator module is connected) and the mode button

will not be responded to.

profile.

ard under User Options.

ard under User Options.

Function

7.1.5 Information display

Figure 21: Information display

Page 24 - Operation

The information display is a group of five LEDs that displays the

currently selected drive profile.

The LEDs light up one-by-one, from left to right, as the user scrolls

through the available drive profiles; the number of LEDs lit

corresponds to the selected drive profile.

Page 27

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

:

Note

Whenever a new drive profile is selected which has a different joystick source, the drive profile LEDs and the mode

button LED will flash briefly.

7.1.6 Battery gauge indicator

The battery gauge is situated below and left of the information

display. It displays the battery's state of charge if it's not being

charged or a battery charging sequence when the battery is being

charged, as described below.

Figure 22: The battery gauge indicator

:

Note

Users who find it difficult to differentiate the colours used in the battery gauge should use the master remote

module's display to determine the battery's state of charge.

7.1.6.1 Battery gauge indicator when not charging

If the battery is not being charged, the battery gauge displays the battery's state of charge with one

of three colours (green, amber and red).

The indicator is permanently lit when the battery is between full and low; when the state of charge

drops to or below the battery empty level, the indicator will flash too.

The table below shows the battery gauge indicator and the recommended actions for each state.

Indicator Battery state of charge Recommended actions

Flashing green - battery overcharged

Green - battery full. No action required.

Amber - battery half full. Consider starting return journey.

Red - battery low. Consider recharging battery soon.

Flashing red - battery empty. Recharge the battery now.

Stop charging the battery

7.1.6.2 Battery gauge indicator when charging

If the battery is being charged, the battery gauge displays the battery charging sequence. The

charging sequence, which repeats every 3.6 seconds, is a succession of:

green → amber → red → off → current state of charge → off

Each stage of the sequence is lit for 400 ms except for current state of charge, which is lit for 1.6

seconds. The current state of charge stage displays the battery level as the battery is charging: red

(empty), amber (half full) or green (full).

Operation - Page 25

Page 28

Figure 23: Battery charging sequence

7.1.7 Attendant indicator

The attendant indicator displays which controller (DX2-RJM or attendant's)

has control of the wheelchair (see note below).

If there is no attendant control module in the system, then this indicator will

Figure 24: Attendant

indicator

always be switched off.

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

If there is an attendant control module in the system, then this indicator will be switched off when

either of the occupant's remote modules has control of the wheelchair.

If there is an attendant control module in the system, then this indicator will be switched on (green)

when the attendant's remote module has control of the wheelchair.

:

Note

This indicator only operates with the ACU profile — the ACU profile is automatically selected by the master remote

module when the ACU takes control of a system. If another profile, other than the ACU profile, is selected and the

profile has been configured with the ACU as the joystick source, then this indicator will not operate.

Dynamic Controls recommends that the Joystick Source parameter for profiles 1 - 5 is not programmed for ACU.

See also

6.4.1 User profile options

:

7.1.8 Sleep mode

When the system enters into sleep mode, all indicators on the DX2-RJM and

DX2-RJM-LF are switched off. This minimises any distracting light when, for

Figure 25: Sleep mode

Waking a system from sleep depends on whether the remote module waking the system was the

active remote module before the system went to sleep.

instance, the occupant wants to sleep.

7.1.8.1 Waking from sleep mode with active remote module

If the remote module waking the system was the active remote module before the system went to

sleep, then the system can be woken by either:

l momentarily deflecting the joystick, or

l pressing the power button.

Page 26 - Operation

Page 29

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

:

Note

Set the joystick wake up parameter in Wizard to enable this functionality. The parameter name varies depending

on the remote. For example, for a DX2-REM55x, set Joystick Wake-up from Sleep parameter to Yes. Or, for a DX-

REMG91S, set the Enable Joystick Wakeup parameter to Yes.

7.1.8.2 Waking from sleep mode with inactive remote module

If the remote module waking the system was NOT the active remote module before the system went

to sleep, then the system can ONLY be woken by pressing the power button.

7.1.9 Lock mode

When a DX/DX2 system is locked, the DX2-RJM and DX2-RJM-LF user inputs and display are

deactivated. A DX/DX2 system cannot be locked or unlocked with the DX2-RJM or DX2-RJM-LF, but

the locked status can be displayed to the user when the user presses the power button. The

indication is different for DX and DX2 systems.

7.1.9.1 Locked indication in DX systems

To indicate a locked DX system, the mode button will flash (½ second on, ½ second off) when the

power button is pressed.

7.1.9.2 Locked indication in DX2 systems

To indicate a locked DX2 system, the mode button displays inhibit when the power button is pressed.

7.1.10 Configuration mode

The configuration mode is used to set the user display on or off.

The normal operation is for the user display to be on, when the system is powered up, so that the

user can see how the system is working and performing. However, there may be times, such as when

the compact remote is used as a chin control, when the user display is not required. If the display is

set to off, then nothing will be displayed on the display at any time.

The options are:

1. Display on (default setting) - all LEDs will display according to their function, when the system is

powered up.

2. Display off - all LEDs are switched offat all times.

Note:

When the display is switched off, the occupant can view wheelchair information with the master remote module.

7.1.10.1 Enter configuration mode

Configuration mode can only be entered with the following button press sequence:

[Note that the system must be powered down to begin.]

1. Press and hold the mode button.

2. Press and hold the power button until both the mode and power button indicators light up

green.

3. Release the power button as soon as the power button indicator switches off.

4. Release the mode button as soon as the mode button indicator switches off.

The battery gauge will light up with the current display setting.

Operation - Page 27

Page 30

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

7.1.10.2 Change display mode

To change the display mode, press the mode button to scroll through the options. The battery gauge

colour indicates the option:

Display on Display off

7.1.10.3 Exit configuration mode

To exit configuration mode, press the power button once. Alternatively, if there is no activity for 15

seconds, the remote module automatically exits from configuration mode.

The setting is saved automatically on exit.

Page 28 - Operation

Page 31

7.2 DX2-ACU operation

:

Note

The following section details the operation of the DX2-ACU only. For a description of the operation of the DX2-

RJM and DX2-RJM-LF, see section 7.1 DX2-RJM, DX2-RJM-LF operation .

The DX2-ACU (attendant control unit) enables an

attendant to take over control of a connected DX/DX2based wheelchair. It may be permanently mounted

onto a wheelchair (normally mounted at the rear) or

may be a general purpose, floating unit, plugged into

and used with a number of DX equipped chairs.

The DX2-ACU is connected into a DX/DX2 system via

the DXBUS trailing lead, and configured with the

Dynamic Wizard and HHP.

While in attendant mode, joystick control provided by

the DX2-ACU is enabled and joystick control from the

user remote module is disabled. Conversely, when in

user mode, only the joystick control on the user's

remote module is enabled and joystick control on the

DX2-ACU is disabled. In either case, any other controls

available on the user's remote module (lighting,

actuators, etc.) are fully functional.

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

Figure 26: The DX2-ACU user interface

Warning

When the remote module is operated while being held in the hand, be aware that it is possible for the hand to get

trapped by the trailing cable.

Warning

Users should be aware that the surface of the remote module can potentially get hot when it is exposed to strong

sunlight for long periods.

:

:

Figure 26 shows the main components of the DX2-ACU. These are described below:

o

joystick - to control speed and direction

o

power button (with status LED) - to power up or power down the system, and

view the system's status

o

mode button - to select speed, toggle who's in charge

o

speed indicator - displays selected speed

o

battery indicator - displays battery status

o

attendant indicator - displays which controller (occupant's or attendant's) has

control of the wheelchair

Note

To operate, the DX2-ACU must be connected to a DXsystem via the DXBUStrailing lead.

Warning

Do not use the compact remote module if it is worn or damaged. Worn or damaged modules should be serviced

immediately, especially if the DXBUS cable, joystick gaiter or keypad are ripped, torn or damaged.

:

Operation - Page 29

Page 32

7.2.1 The joystick

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

Warning

The compact remote modules may only be used with the authorised joystick knobs. Use of any other joystick knob

requires that the installer tests and confirms that the joystick returns to the neutral position whenever the joystick

is deflected. Tests with the device mounted horizontally and with a water soaked knob (foam knobs only) are

required if the installer judges these risks as significant.

:

The joystick controls the direction and speed of the wheelchair.

When the joystick is deflected from the centre (neutral) position, the

wheelchair will move in the direction of the joystick movement.

The speed of the wheelchair is proportional to the joystick deflection, so that

the further the joystick is moved from the neutral position, the faster the

Figure 27: The joystick

wheelchair will travel.

If the user moves the joystick back to the neutral position, the wheelchair will slow down and stop.

If the user releases the joystick from any position other than the neutral position, the joystick will

return to the neutral position and the wheelchair will slow down and stop.

The joystick can also be used to wake up the system when in sleep mode — see 7.2.8 Sleep mode.

Warning

It is the responsibility of the wheelchair manufacturer to inform the wheelchair user about the wheelchair's

stopping distances.

See also

9.1 OONAPU

7.2.8 Sleep mode

:

:

7.2.2 Power button and status indicator

:

Note

In the event that the wheelchair is in a runaway situation, press the remote module's power button to perform an

EMERGENCY STOP. See section 7.2.3 Emergency stop.

The power button is on the left-hand side of the remote module, and incorporates a status indicator

that changes colour depending on the status of the system:

Off - system OFF or

sleeping

Green - powered ON.

Red (flashing) - powered ON fault

Press the power button to switch the system ON. If there is no fault with the system, the status

indicator (under the power button) will light up green.

Press the power button to switch the system OFF; the system will power down and the status

indicator will switch off.

Page 30 - Operation

Page 33

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

If there is a fault with the system, the status indicator will indicate the fault with a series of red flashes

(see section 9 Diagnostics).

See also

7.2.10 Configuration mode

:

7.2.3 Emergency stop

If the attendant needs to stop the wheelchair quickly, the power button can be pressed to perform

an EMERGENCY STOP. The wheelchair will come to a halt quickly; the rate is set by the Emergency

Deceleration parameter.

Warning

Ensure that the wheelchair's settings are appropriate for both the wheelchair configuration and the user. If the

Emergency Deceleration parameter is set too high, the user can lose balance or fall out of the wheelchair when an

emergency stop is performed.

See also

See the DX System Manual / Master Remote manual for more information about the Emergency Deceleration

parameter.

:

:

7.2.4 Mode button

The mode button is on the right-hand side of the remote module and

incorporates a yellow indicator that is lit continuously (except when a drive

Figure 28: The mode

button

inhibit is present) while the system is powered up.

Depending on the length of time that the button is pressed (short or long), the mode button is used

to:

l change the speed setting, or

l toggle between who's in charge (occupant or attendant remote module) .

7.2.4.1 Change speed setting

A short press (less than ½ second) on the mode button changes the wheelchair's speed setting.

Each short press increments the speed by 20 %, between 20 % and 100 % of the maximum speed that

has been set for the Attendant Drive profile. After reaching 100 %, the speed setting will roll around to

20 %.

The speed is displayed on the speed indicator as shown in 7.2.5 Speed indicator.

:

Note

The speed setting is recorded when the system is powered down so that it will resume the same speed setting on

power up. If for any reason that the speed setting is not available on power up, or becomes corrupted, then the

speed setting will default to 40 % of the speed that has been set for the Attendant Drive profile.

7.2.4.2 Change who's in charge

A long press (greater than ½ second) on the mode button toggles the control between the occupant's

remote module, and the attendant's.

Operation - Page 31

Page 34

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

If the occupant's remote module has control, a long press will switch the control to the DX2-ACU, and

the Attendant indicator will light up to show that the DX2-ACU has control.

If the DX2-ACU has control, a long press will switch the control to the occupant's remote module, and

the Attendant indicator will switch off to show that the DX2-ACU does not have control.

See also

7.2.7 Attendant indicator

7.2.10 Configuration mode

:

7.2.5 Speed indicator

The speed indicator is a group of five LEDs that displays the currently

selected speed. The LEDs light up one-by-one, from left to right, as

the speed is incremented with the mode button (see 7.2.4 Mode

button).

Figure 29: Speed indicator (showing

60% speed)

:

Note

During a drive inhibit, the speed indicator is switched off.

Each LED represents 20 % of the maximum programmed speed of the Attendant Drive profile. The

LEDon the left-hand side of the indicator represents the lowest speed (20 %). The LEDon the righthand side represents the highest speed (100 %).

:

Note

The speed setting is recorded when the system is powered down so that it will resume the same speed setting on

power up. If for any reason that the speed setting is not available on power up, or becomes corrupted, then the

speed setting will default to 40 % of the speed that has been set for the Attendant Drive profile.

7.2.6 Battery gauge indicator

The battery gauge is situated below and left of the speed indicator. It displays the battery's state of charge if it's not being

charged or a battery charging sequence when the battery is being

charged, as described below.

Figure 30: The battery gauge indicator

:

Note

Users who find it difficult to differentiate the colours used in the battery gauge should use the master remote

module's display to determine the battery's state of charge.

7.2.6.1 Battery gauge indicator when not charging

If the battery is not being charged, the battery gauge displays the battery's state of charge with one

of three colours (green, amber and red).

The indicator is permanently lit when the battery is between full and low; when the state of charge

drops to or below the battery empty level, the indicator will flash too.

Page 32 - Operation

Page 35

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

The table below shows the battery gauge indicator and the recommended actions for each state.

Indicator Battery state of charge Recommended actions

Flashing green - battery overcharged

Green - battery full. No action required.

Amber - battery half full. Consider starting return journey.

Red - battery low. Consider recharging battery soon.

Flashing red - battery empty. Recharge the battery now.

Stop charging the battery

7.2.6.2 Battery gauge indicator when charging

If the battery is being charged, the battery gauge displays the battery charging sequence. The

charging sequence, which repeats every 3.6 seconds, is a succession of:

green → amber → red → off → current state of charge → off

Each stage of the sequence is lit for 400 ms except for current state of charge, which is lit for 1.6

seconds. The current state of charge stage displays the battery level as the battery is charging: red

(empty), amber (half full) or green (full).

Figure 31: Battery charging sequence

7.2.7 Attendant indicator

The attendant indicator displays which remote module (DX2-ACU or

occupant's) has control of the wheelchair.

If the occupant's remote module has control of the system, the indicator will

Figure 32: Attendant

indicator

be off. If the DX2-ACU remote module has control of the system, the

indicator will be on (green).

:

Note

This indicator only operates with the ACU profile — the ACU profile is automatically selected by the master remote

module when the ACU takes control of a system. If another profile, other than the ACU profile, is selected and the

profile has been configured with the ACU as the joystick source, then this indicator will not operate.

Dynamic Controls recommends that the Joystick Source parameter for profiles 1 - 5 is not programmed for ACU.

Operation - Page 33

Page 36

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

See also

6.4.1 User profile options

:

The system that has control is determined by the configuration mode setting and the mode button:

1. on powering up, the remote module that is initially in charge of the system is determined by

the configuration mode setting;

2. after powering up, a long press on the mode button changes which controller is in charge.

See also

7.2.4 Mode button

7.2.10 Configuration mode

:

7.2.8 Sleep mode

When the system enters into sleep mode, and if the DX2-ACU is the active

remote before entering sleep mode, all indicators on the DX2-ACU are

Figure 33: Sleep mode

Waking a system from sleep depends on whether the remote module waking the system was the

active remote module before the system went to sleep.

switched off except the battery gauge indicator. If the DX2-ACU is not the

active remote before entering sleep mode, all indicators on the DX2-ACU are

switched off, including the battery gauge indicator.

7.2.8.1 Waking from sleep mode with active remote module

If the remote module waking the system was the active remote module before the system went to

sleep, then the system can be woken by either:

l momentarily deflecting the joystick, or

l pressing the power button.

:

Note

Set the joystick wake up parameter in Wizard to enable this functionality. The parameter name varies depending

on the master remote. For example, for a DX2-REM55x, set Joystick Wake-up from Sleep parameter to Yes. Or, for

a DX-REMG91S, set the Enable Joystick Wakeup parameter to Yes.

7.2.8.2 Waking from sleep mode with inactive remote module

If the remote module waking the system was NOT the active remote module before the system went

to sleep, then the system can be woken ONLY by pressing the power button.

7.2.9 Lock mode

When a DX/DX2 system is locked, the DX2-ACU inputs and display are deactivated. A DX/DX2 system

cannot be locked or unlocked with the DX2-ACU, but the locked status can be displayed to the

attendant when the attendant presses the power button. The indication is different for DX and DX2

systems.

7.2.9.1 Locked indication in DX systems

To indicate a locked DX system, the mode button will flash (½ second on, ½ second off) when the

power button is pressed.

7.2.9.2 Locked indication in DX2 systems

To indicate a locked DX2 system, the mode button displays inhibit when the power button is pressed.

Page 34 - Operation

Page 37

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

7.2.10 Configuration mode

The configuration mode sets which remote module has the initial control of the system at power up.

The options are:

1. First in (default setting) - the remote module that powers the system up has control

2. Always user - no matter which remote module powers up the system, the wheelchair occupant will always have initial control

3. Always attendant - no matter which remote module powers up the system, the attendant will

always have initial control

4. DX-like (last out) - the remote module that has control before powering down resumes control

on power up.

:

Note

The settings in configuration mode are only used when powering up. After a system is powered up, control of a

system can be set with the mode button.

See also

7.2.4 Mode button

7.2.7 Attendant indicator

:

7.2.10.1 Enter configuration mode

Configuration mode can only be entered with the following button press sequence:

[Note that the system must be powered down to begin.]

1. Press and hold the mode button.

2. Press and hold the power button until both the the mode and power button indicators light

up green.

3. Release the power button as soon as the power button indicator switches off.

4. Release the mode button as soon as the mode button indicator switches off.

The battery gauge will light up with the current who's in charge setting.

7.2.10.2 Change who's in charge at start-up

To change who's in charge at start up, press the mode button one or more times to scroll through the

options. The battery gauge colour changes for the four options:

Amber - DX-like Red - always occupant

Blue - first in Green - always attendant

7.2.10.3 Exit configuration mode

To exit configuration mode, press the power button once. Alternatively, if there is no activity for 15

seconds, the remote module automatically exits from configuration mode.

The setting is saved automatically on exit.

Operation - Page 35

Page 38

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

Page 36

Page 39

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

8 Testing

8.1 Before testing 37

8.2 Testing the DX2-RJM / DX2-RJM-LF 37

8.2.1 Power button 37

8.2.2 User interface 38

8.2.3 Mode button 38

8.2.4 Joystick 38

8.2.5 Emergency stop 38

8.2.6 OONAPU 38

8.2.7 Wake up from sleep mode 38

8.3 Testing the DX2-ACU 39

8.3.1 Power button 39

8.3.2 User interface 39

8.3.3 Mode button 39

8.3.4 Joystick 39

8.3.5 Emergency stop 39

8.3.6 OONAPU 39

8.3.7 Wake up from sleep mode 40

The installation must be fully tested after all modules and cables have been installed. The testing

procedure is detailed in the DX System Manual (section 8 Testing), which must be read in conjunction

with this and other DX/DX2 module manuals.

Warning

Do not connect the battery positive (B+) terminal of the battery to the DX2 system until the wheelchair is lifted off

the ground. To prevent the risk of injury, Dynamic Controls recommends the use of a lifting device when lifting the

wheelchair off the ground.

:

8.1 Before testing

Check that all cables and modules in the system are connected correctly. Check especially that the

polarities of the batteries, the motors and the park brakes are connected correctly and that the

polarities are not swapped.

To prevent the wheelchair from suddenly driving away when you turn it on, put blocks under the

wheelchair frame to lift the wheels off the ground. Check that the wheels can turn freely.

Make the final connection to the battery positive (B+) terminal and close the circuit breakers.

Turn on the DX2 system with the power button on the master remote module and program the DX2

system for the appropriate wheelchair application.

Turn off the DX2 system with the power button.

8.2 Testing the DX2-RJM / DX2-RJM-LF

8.2.1 Power button

l Test that the system powers up and down correctly with the power button. For more infor-

mation on the power button, see 7.1.2 Power button and status indicator.

Test - Page 37

Page 40

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

8.2.2 User interface

l Power up the system and verify that the information display is operating correctly and that

there are no faults. For more information on the information display, see 7.1.5 Information display. For more information on fault indication, see 9 Diagnostics.

l Verify the battery gauge indicator is operating correctly. For more information on the battery

gauge indicator, see 7.1.6 Battery gauge indicator.

l Verify the attendant indicator is operating correctly - only if an ACU is part of the system. For

more information on the attendant indicator, see 7.1.7 Attendant indicator.

8.2.3 Mode button

l Press the mode button (using a combination of short and long presses) to change the drive pro-

file and access accessories (if fitted). For more information on the mode button, see 7.1.4

Mode button.

l Check that the mode is displayed correctly on the information display.

8.2.4 Joystick

l Drive the wheelchair in all directions and at all speeds. Ensure that the wheelchair responds to

the drive commands as programmed. For more information on the joystick, see 7.1.1 The joystick.

l Change the drive profile and drive the wheelchair in all directions and at all speeds. Ensure that

the wheelchair responds to the drive commands as programmed.

l If accessories are fitted, select an accessory with the mode button and operate the accessory

with the joystick.

8.2.5 Emergency stop

l Test the emergency stop feature by pressing the power button while driving the wheelchair.

For more information on the emergency stop feature, see 7.1.3 Emergency stop.

Warning

This procedure can be dangerous. Dynamic Controls recommends the use of a seatbelt to prevent the tester from

slipping out of the seat.

:

8.2.6 OONAPU

l Test the OONAPU feature by powering up the wheelchair with the joystick out of the neutral

(centre) position. An OONAPU warning will be displayed and the wheelchair will not drive.

l Continue the test with the joystick out of the neutral (centre) position for more than five sec-

onds - the OONAPU warning will change to an OONAPU fault.

:

Note

Ensure that the DX2-RJM or DX2-RJM-LF is set as the active module for this test.

Ensure that the parameter Disable OONAPUFaults is set to No.

For more information on the OONAPU feature, see 9.1 OONAPU.

8.2.7 Wake up from sleep mode

l Test the wake up feature when a system is asleep by one or both of the following:

o

momentarily deflecting the joystick. Note: this is only effective if the remote module waking the system was the active remote module before the system went to sleep, and the

Page 38 - Test

Page 41

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

system is configured to wake up from sleep with the joystick;

o

momentarily pressing the power button.

For more information on waking up from sleep, see 7.1.8 Sleep mode.

8.3 Testing the DX2-ACU

8.3.1 Power button

l Press the power button a few times to test that the system powers up and down correctly. For

more information on the power button, see 7.2.2 Power button and status indicator.

8.3.2 User interface

l Power up the system and verify that the speed indicator is operating correctly and that there

are no faults. For more information on the speed indicator, see 7.2.5 Speed indicator. For

more information on fault indication, see 9 Diagnostics.

l Verify the battery indicator is operating correctly. For more information on the battery gauge

indicator, see 7.2.6 Battery gauge indicator.

l Verify the attendant indicator is operating correctly. For more information on the attendant

indicator, see 7.2.7 Attendant indicator.

8.3.3 Mode button

l Press the mode button (using short presses) to change the driving speed.

l Check that the speed is displayed correctly on the information display.

l Press the mode button (using long presses) to toggle between who's in charge (occupant or

attendant remote module).

l Check that the attendant indicator displays correctly.

For more information on the mode button, see 7.2.4 Mode button.

8.3.4 Joystick

l Drive the wheelchair in all directions and at all speeds. Ensure that the wheelchair responds to

the drive commands as programmed.

For more information on the joystick, see 7.2.1 The joystick.

8.3.5 Emergency stop

l Test the emergency stop feature by pressing the power button while driving the wheelchair.

Warning

This procedure can be dangerous. Dynamic Controls recommends the use of a seatbelt to prevent the tester from

slipping out of the seat if the test is performed from the seat.

:

For more information on the emergency stop feature, see 7.2.3 Emergency stop.

8.3.6 OONAPU

l Test the OONAPU feature by powering up the wheelchair with the joystick out of the neutral

(centre) position. An OONAPU warning will be displayed (see OONAPU) and the wheelchair will

not drive.

Test - Page 39

Page 42

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

:

Note

Ensure that the DX2-ACU is set as the active module for this test.

For more information on OONAPU, see 9.1 OONAPU.

8.3.7 Wake up from sleep mode

l Test the wake up feature when a system is asleep by one or both of the following:

o

momentarily deflecting the joystick. Note: this is only effective if the remote module waking the system was the active remote module before the system went to sleep, and the

system is configured to wake up from sleep with the joystick;

o

momentarily pressing the power button.

For more information on waking up from sleep, see 7.2.8 Sleep mode.

Page 40 - Test

Page 43

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

9 Diagnostics

9.1 OONAPU 41

9.2 Drive inhibit indication 41

9.3 Fault indication 42

9.4 Dealing with compact remote module faults 42

9.1 OONAPU

OONAPU (“Out Of Neutral At Power Up”) is a safety feature that

prevents accidental movement of the wheelchair, either when powering

up, or when the wheelchair comes out of an inhibit state.

OONAPU warning

If the system is powered on (or comes out of an inhibit state) while the

joystick is not in the centre position, an OONAPU warning is displayed.

Figure 34: OONAPU sequence

During an OONAPU warning, the information display LEDs will flash continually (all on, followed by all

off) to alert the user, and the wheelchair will not drive. If the joystick is returned to the centre position

within five seconds, the warning will clear and the wheelchair will drive normally.

OONAPU fault

However, if the joystick remains out of neutral for longer than five seconds, an OONAPU fault will

occur (see note below); the fault is displayed by the status indicator flashing red, and the wheelchair

will not drive. To clear the fault, return the joystick to the neutral position and power the unit off and

then on again.

:

Note

An OONAPU fault will not be displayed if the Wizard parameter Disable OONAPUFaults is set to Yes.

An OONAPU fault will not occur if the active remote module is a DX2-ACU. Instead, if the DX2-ACU's joystick

remains out of neutral for longer than five seconds, the OONAPU warning will continue to be displayed.

9.2 Drive inhibit indication

When a wheelchair is in a drive inhibit state, the information display

switches off, and the mode button flashes at a rate of on for ½ second,

off for ½ second.

This sequence continues for the duration of the drive inhibit.

:

Note

Apart from the information display and mode button, the drive inhibit indication described above does not affect

any other indicators - all other indicators will continue to operate as normal.

Figure 35: Dri ve inhibit indication

(RJM top, ACU bottom)

Diagnostics - Page 41

Page 44

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

9.3 Fault indication

When a fault occurs, a flash code is displayed on both the master remote module and the compact

remote module. A flash code, which is displayed on the status indicator, is a number of flashes

separated by a 1.6 second gap; the number of flashes depends on the fault. For example, one flash

represents flash code one; two flashes represents flash code two, and so on.

:

Note

Faults that affect the safety of the wheelchair will cause the wheelchair to stop, while less critical ones will be

indicated but allow the wheelchair to continue driving. Some faults will automatically clear when the fault

condition is removed (non-latched) while others are latched and must be cleared by turning the controller off,

waiting five seconds, then turning the system on again.

Faults are categorised according to their source — that is, there are local faults (those that relate to

the compact remote module), and there are system faults (those that relate to one or more system

modules). Local faults take priority with the compact remote module and so local faults will be

displayed on the compact remote module instead of system faults if both local and system faults

occur at the same time.

When there is a local fault, the power button will flash red. All other indicators will be switched off. It is

possible that the rest of the system might not indicate a fault. All local faults (faults with the compact

remote module) are displayed as:

Flash Code 1: DX Module Fault

When there is a system fault, the power button will flash red. All other indicators will continue to

operate according to their role. The rest of the system will indicate the same fault or a related flash

code. System faults are displayed according to the flash codes described in the DX System Manual.

See also

For a full list of flash codes and more information regarding system faults, refer to the DX System Manual.

:

9.4 Dealing with compact remote module faults

1. If the compact remote module does not react to a command:

l Check that the module is not in sleep mode (see 7.1.9 Lock mode 7.1.8 Sleep mode or

7.2.8 Sleep mode).

l Check that the module is not in locked mode (see 7.1.9 Lock mode or 7.2.9 Lock mode).

2. If there is no power to the compact remote module:

l Check the DXBUS connector is mated correctly.

l Replace the DXBUS extension cable (if fitted).

l Replace the compact remote module.

3. For all flash code 1 faults:

l Check the DXBUS connector is mated correctly.

l Check the profile setting:

o

If the Joystick Source parameter (see 6.4.1 User profile options) of a pro-

grammable profile has been set up for a compact remote module (either RJM or

ACU), and the compact remote module cannot be seen by the system when operating in the profile, a flash code 1 will be displayed.

Page 42 - Diagnostics

Page 45

GBK65701 DX2 Compact Remote Modules

Installation Manual Issue 1

l Replace the DXBUS extension cable (if fitted).